Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

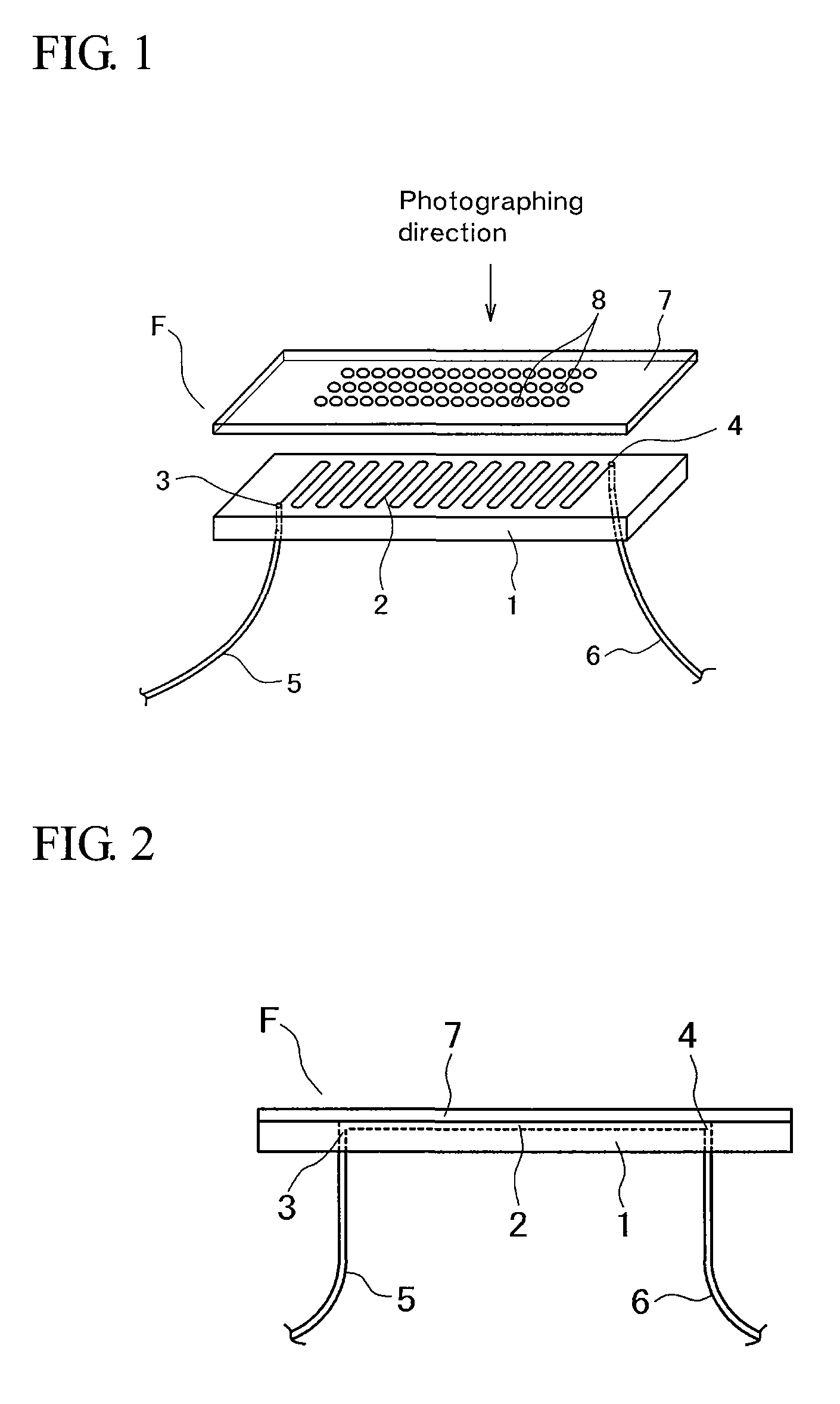

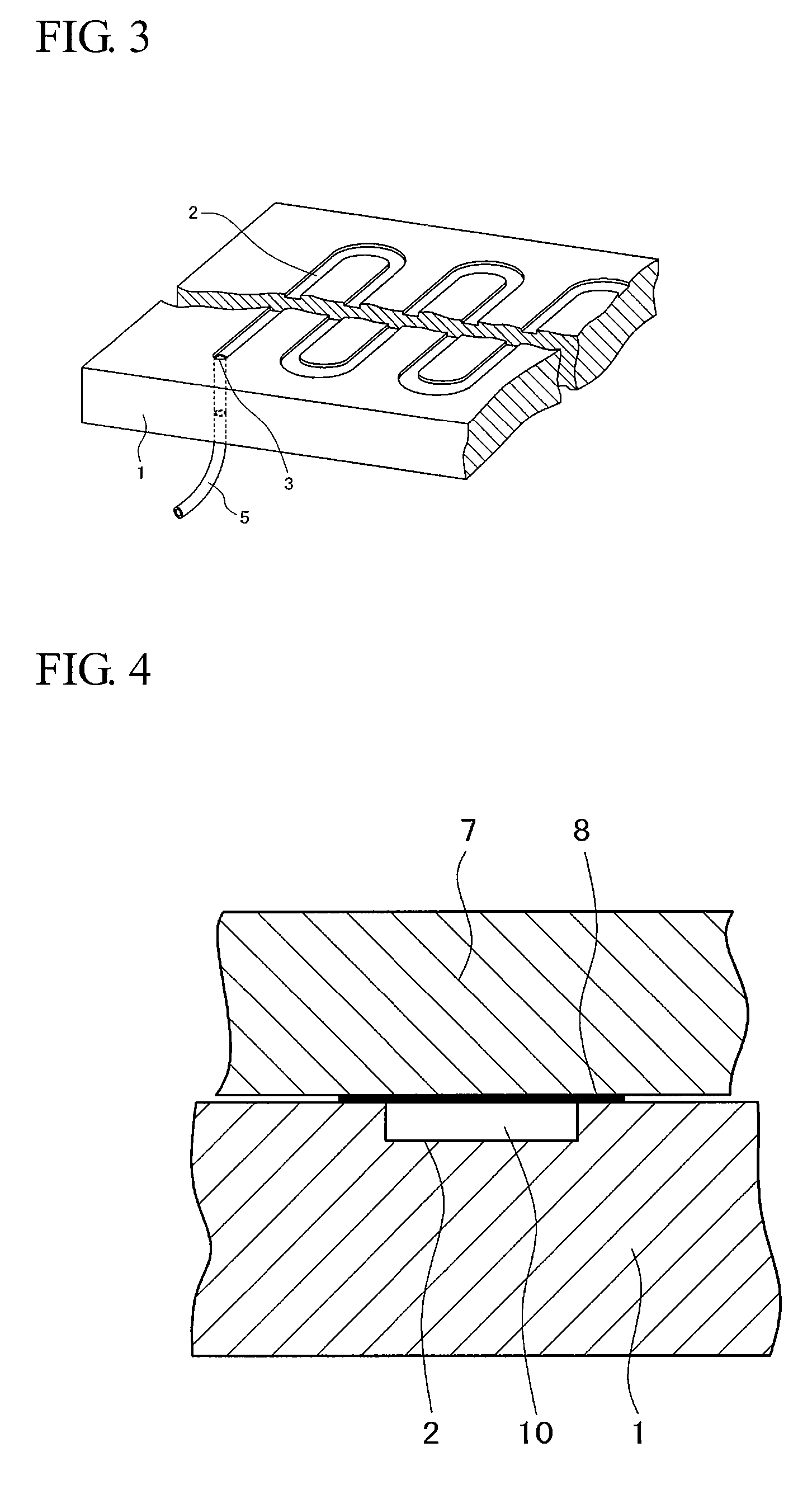

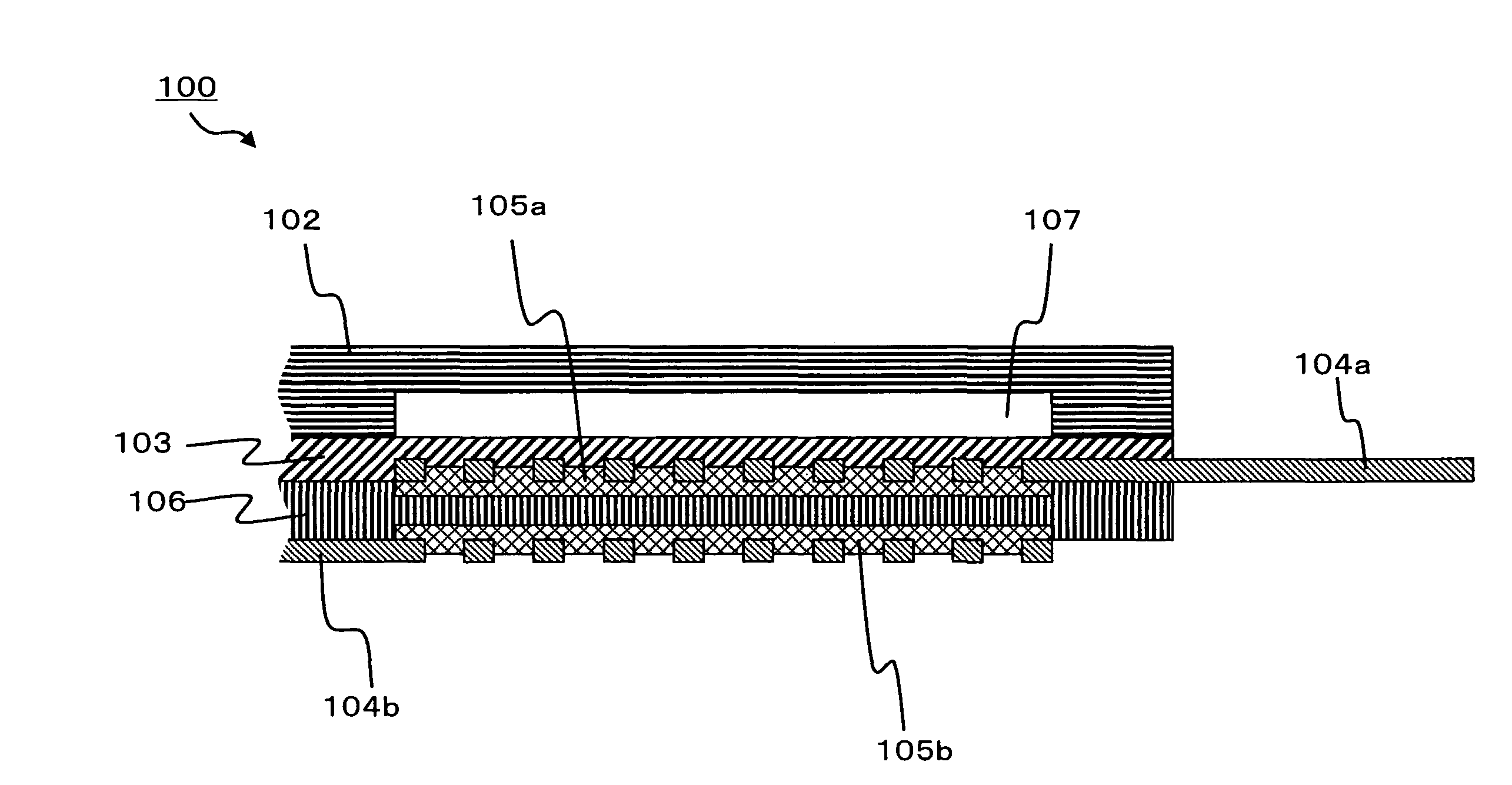

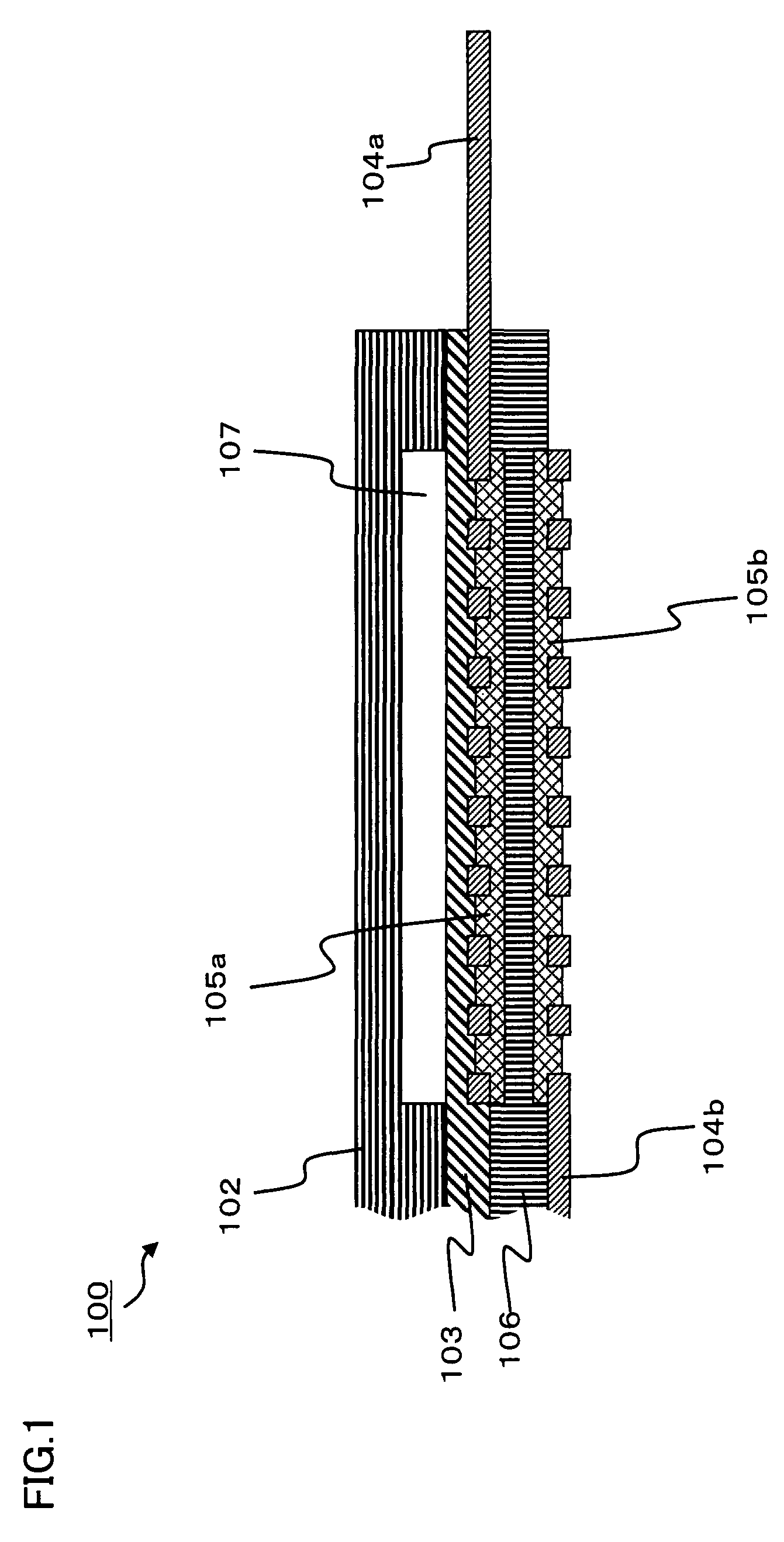

Fuel cell, fuel cell system and electronic device

InactiveUS20080107949A1Stable and good power generation characteristicImprove securityReactant parameters controlActive material electrodesIn planeFuel cells

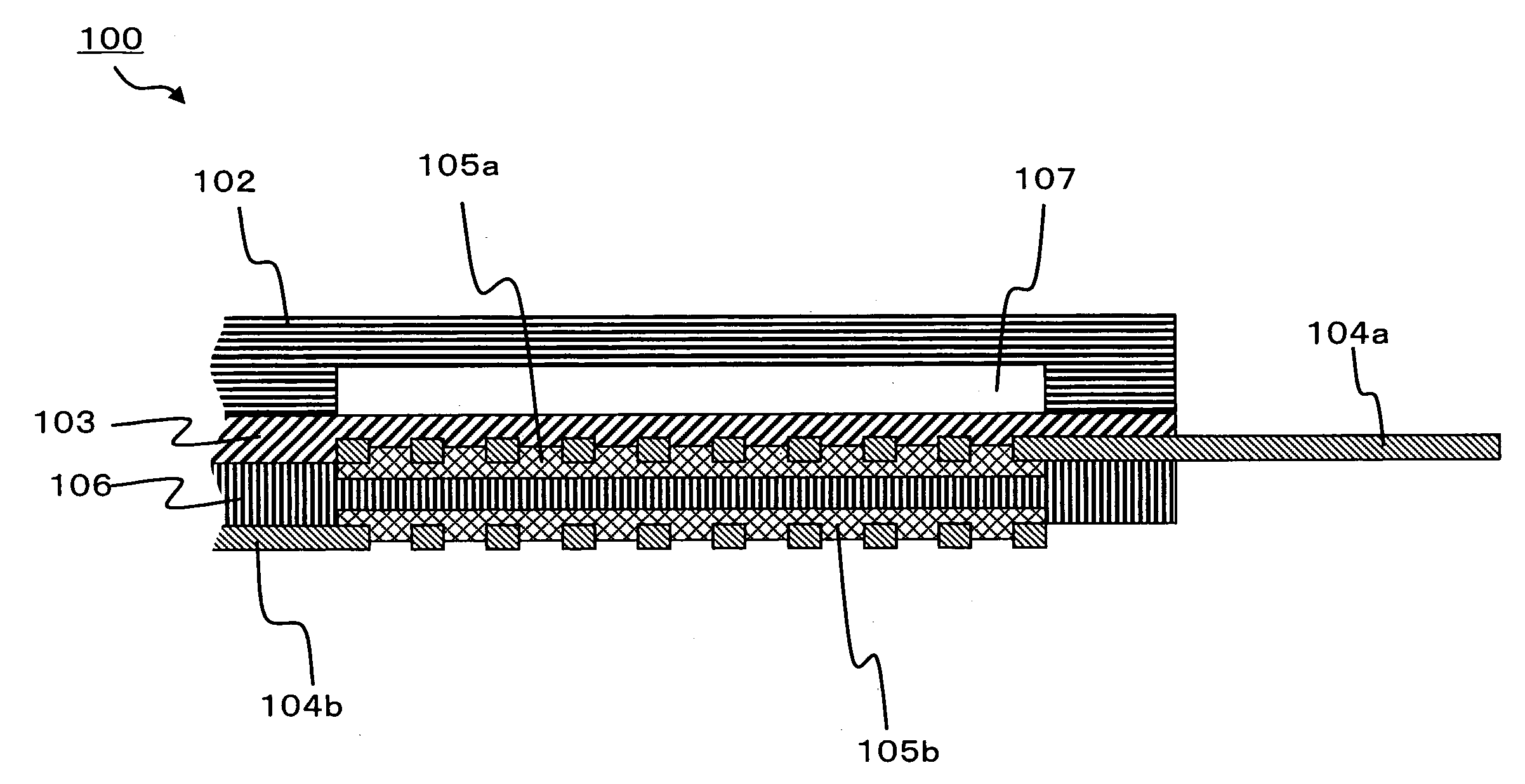

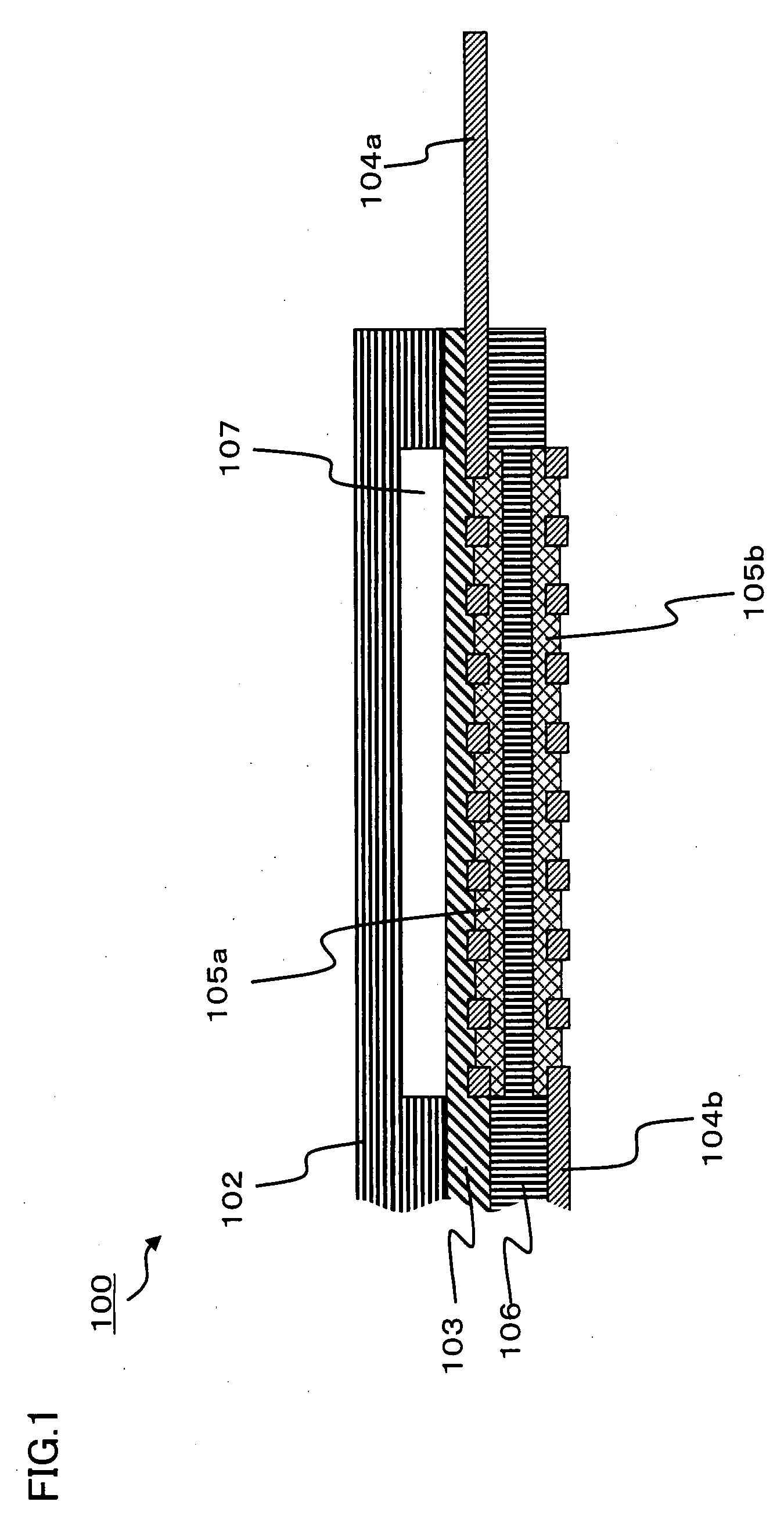

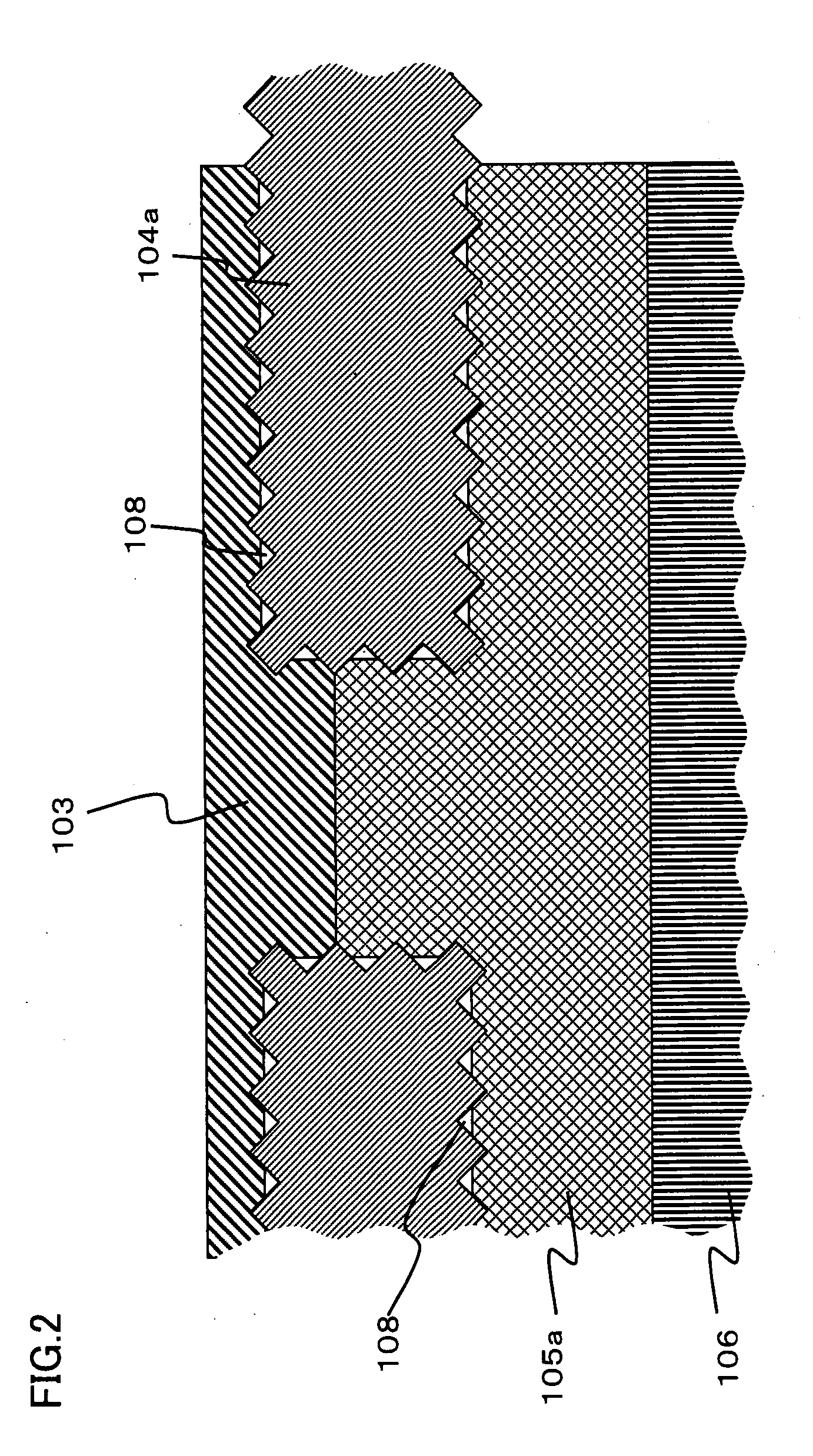

There are provided a fuel cell having stable and good power generation characteristics and good safety, a fuel cell system including the fuel cell and an electronic device equipped with the fuel cell. The fuel cell includes at least an electrolyte membrane, an anode formed on one surface of the electrolyte membrane, a cathode formed on the other surface of the electrolyte membrane, a liquid fuel chamber for supplying a liquid fuel to the anode, and a separating layer formed between the anode and the liquid fuel chamber. The separating layer and / or the anode has an exhaust passage that is continuously formed in an in-plane direction to discharge exhaust gas generated at the anode. The separating layer allows the liquid fuel to pass from the liquid fuel chamber to the anode and blocks the movement of gas from the anode to the liquid fuel chamber.

Owner:SHARP KK

Flow cell and a reactor for reactions between fixed reacting substances and liquid reacting substances, and a method for operating the reactor

InactiveUS20060240545A1Low costSave spaceBioreactor/fermenter combinationsBiological substance pretreatmentsFlow cellEngineering

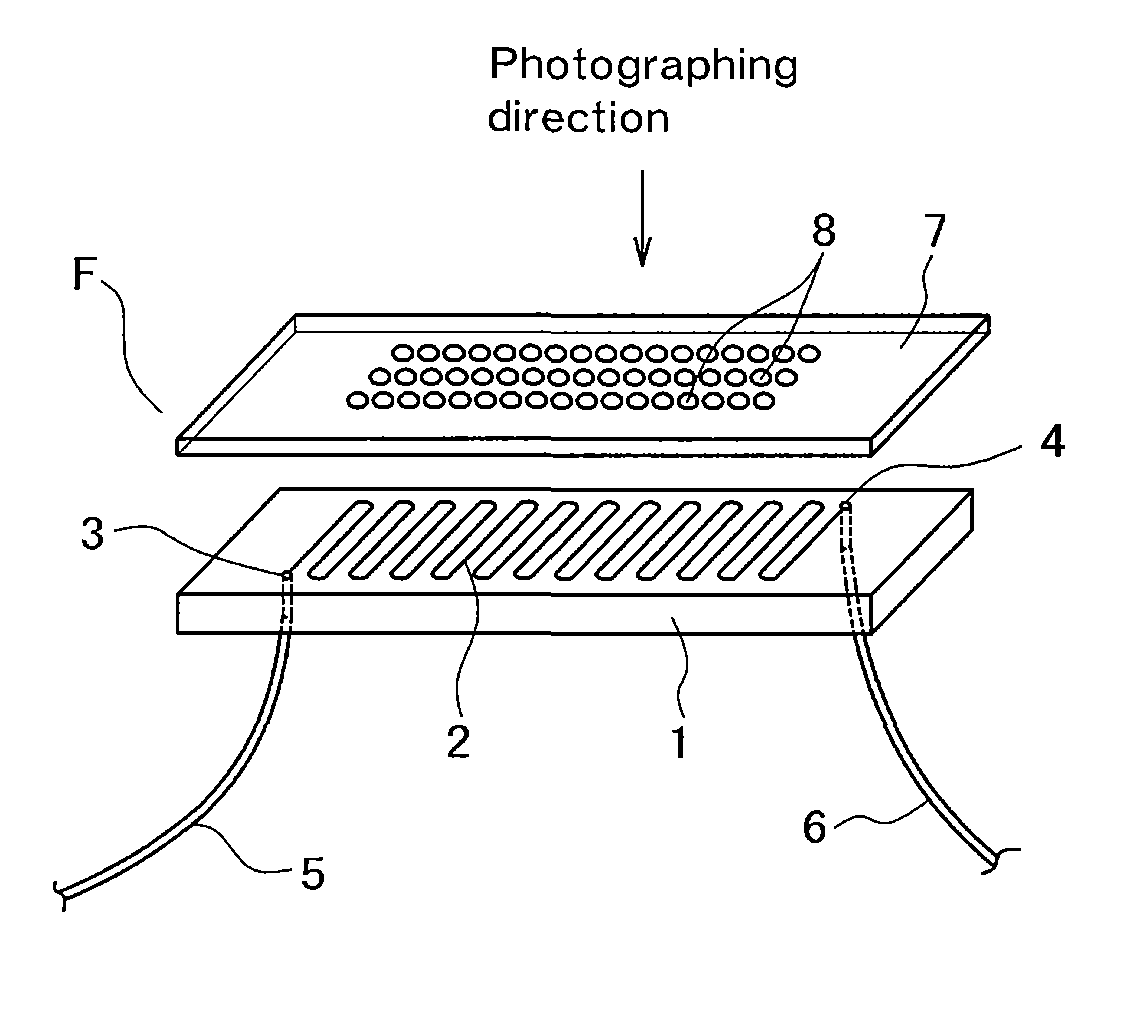

A flow cell having a first plate having a continuous groove formed as a passage on one surface of the plate and having gas / liquid inlet / outlet portions at both the ends of the continuous groove, and a second plate to be kept in contact with said one surface of the first plate, wherein at least either of the first and second plates allows light transmission; fixable reacting substances are fixed on the surface of the second plate, to be kept in contact with the first plate, at plural places corresponding to the continuous groove; and the first and second plates are kept in contact with each other to support each other, for establishing the passage of any one of liquid reacting substances common to the plural fixed reacting substances.

Owner:MORITEX CORP

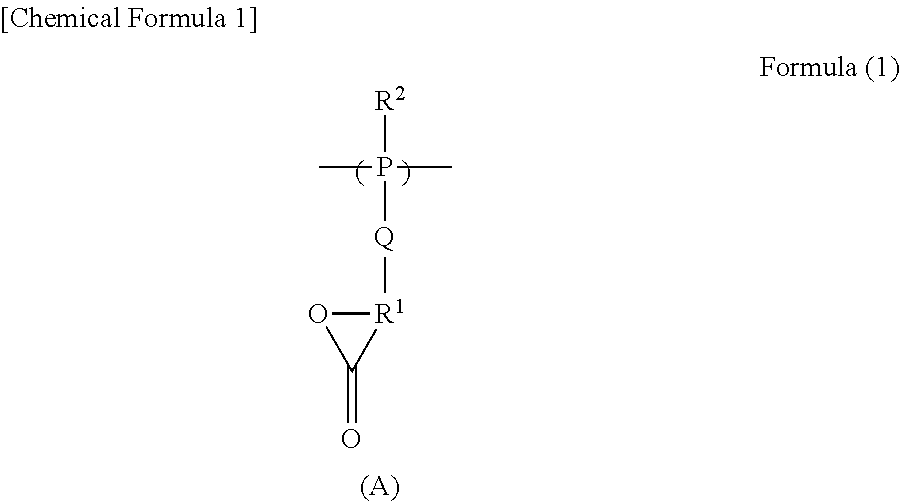

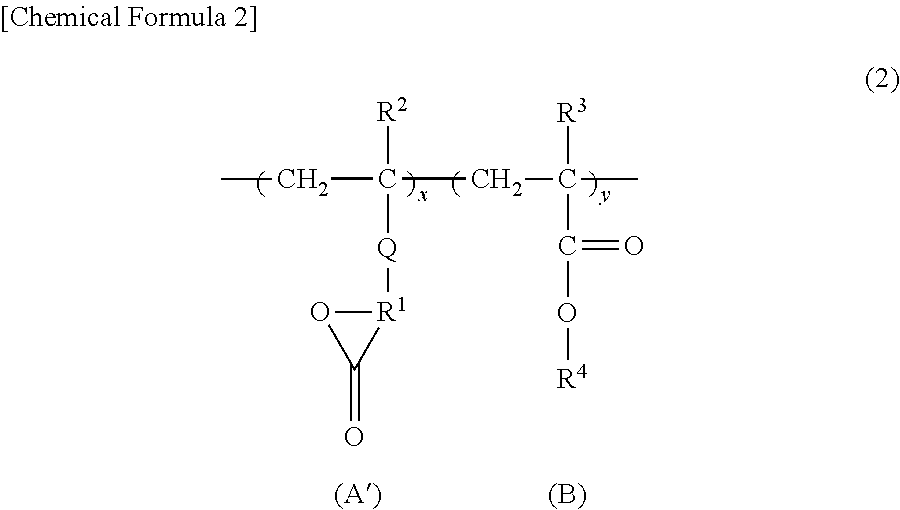

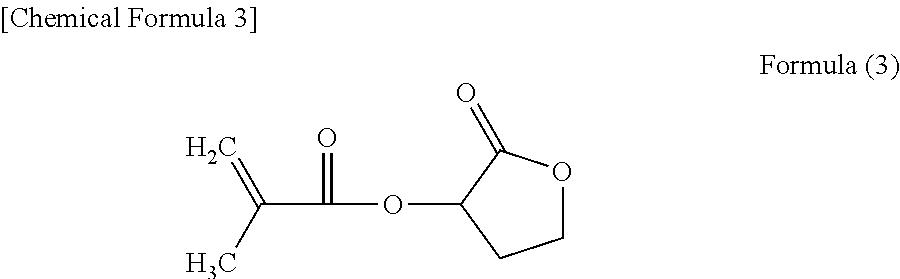

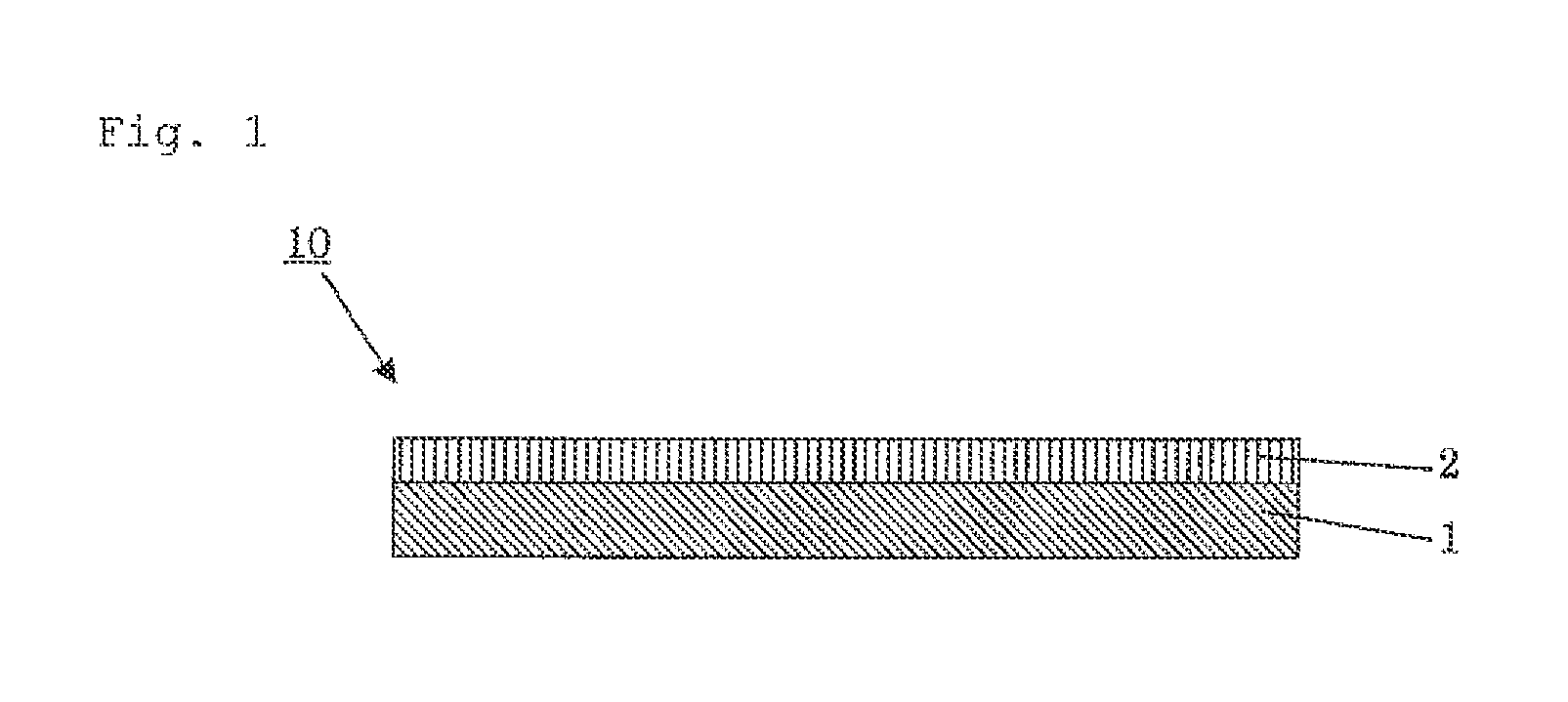

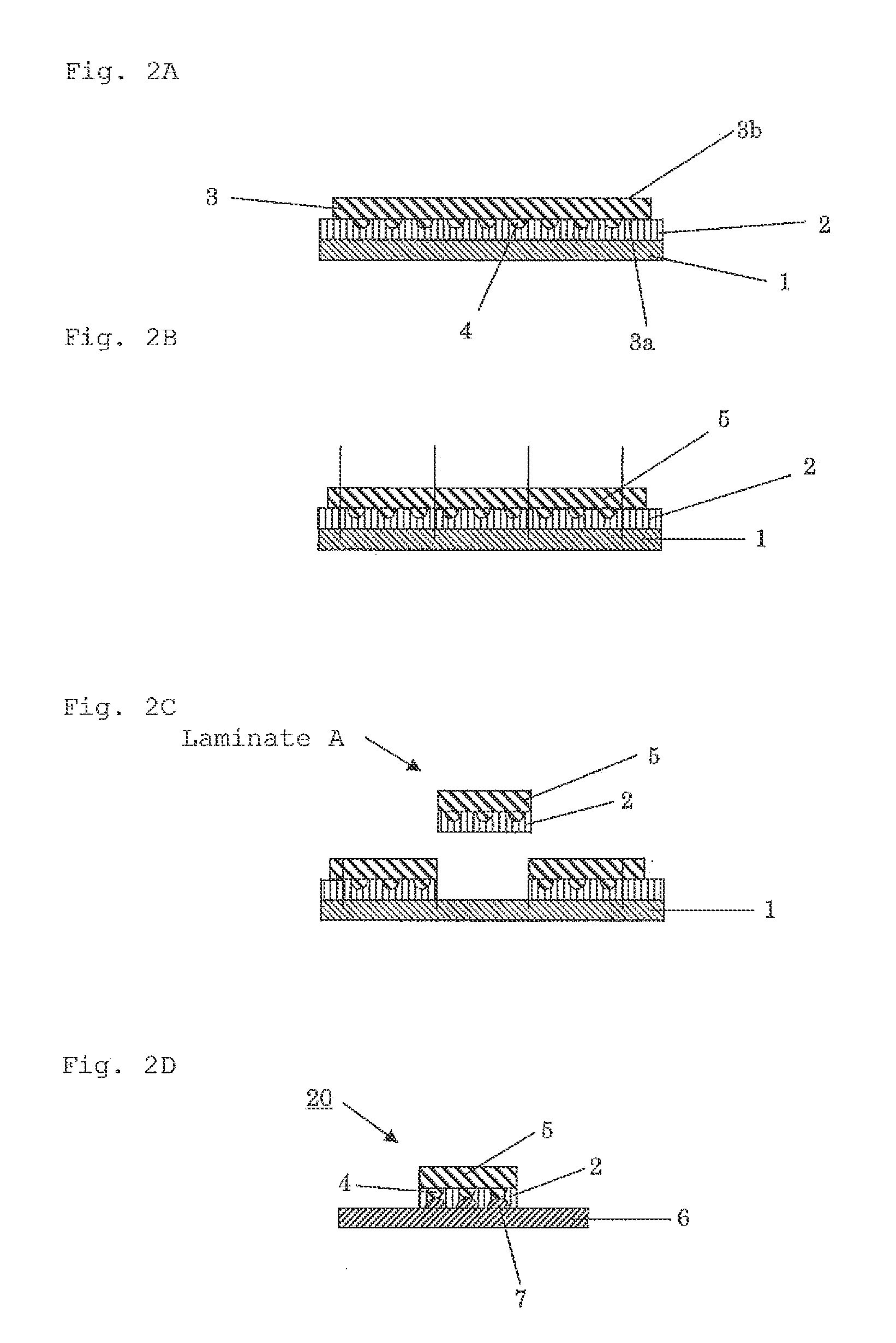

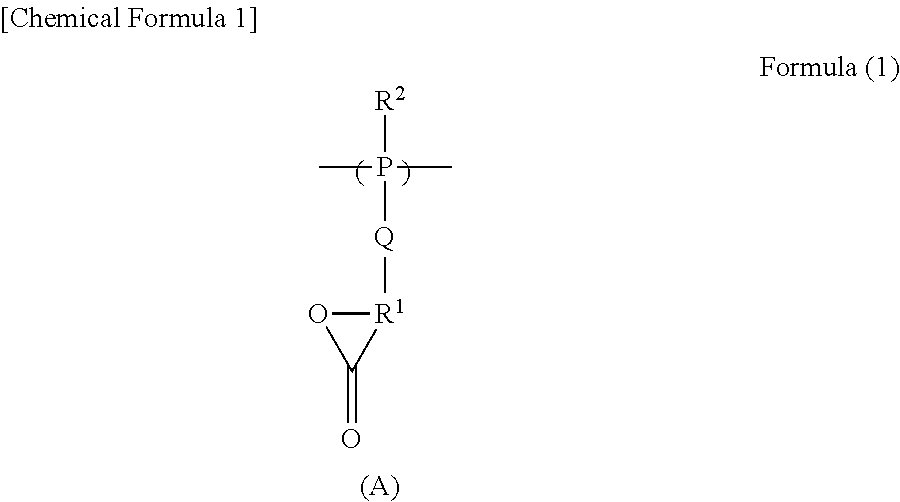

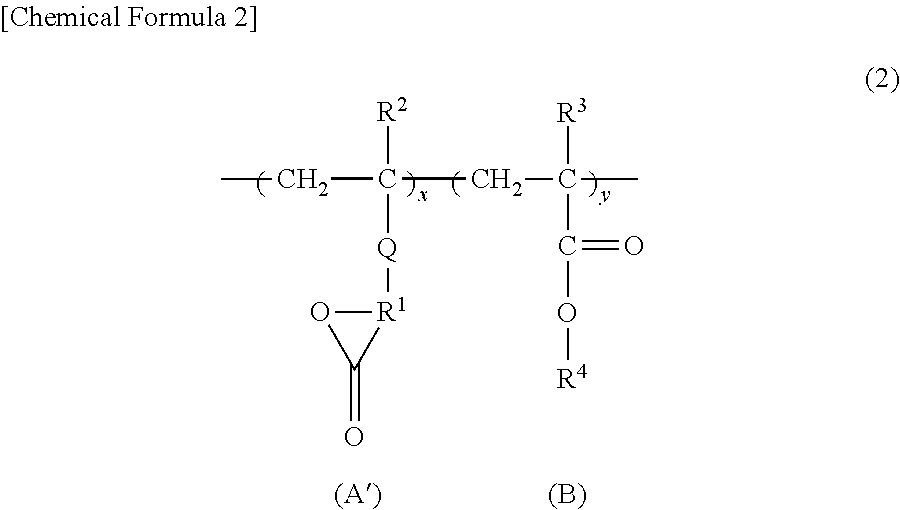

Method of producing semiconductor device using resist underlayer film by photo-crosslinking curing

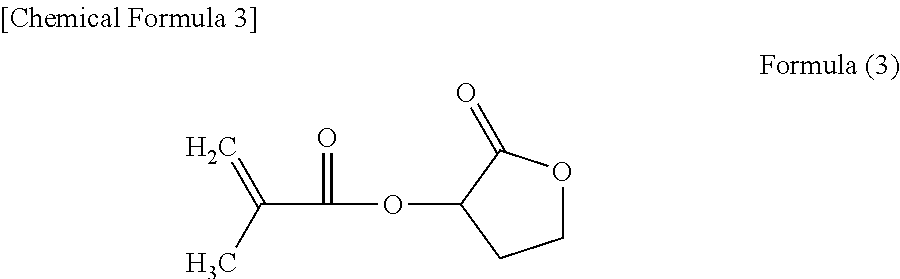

ActiveUS20100022092A1Improve homogeneityEasy to fillPhotosensitive materialsRadiation applicationsLithography processSide chain

There is provided a resist underlayer film forming composition used in a lithography process for producing semiconductor devices. A method of producing a semiconductor device comprising: forming a coating film by applying a resist underlayer film forming composition containing a polymer, a crosslinker and a photoacid generator on a semiconductor substrate; forming an underlayer film by irradiating light to the coating film; and forming a photoresist by applying a photoresist composition on the underlayer film and heating the resultant layer. The polymer polymer is a polymer having a benzene ring or a hetero ring in a main chain or a side chain bonded to the main chain, and the content rate of a benzene ring in the polymer is 30 to 70% by mass. The polymer may be a polymer containing a lactone structure.

Owner:NISSAN CHEM IND LTD

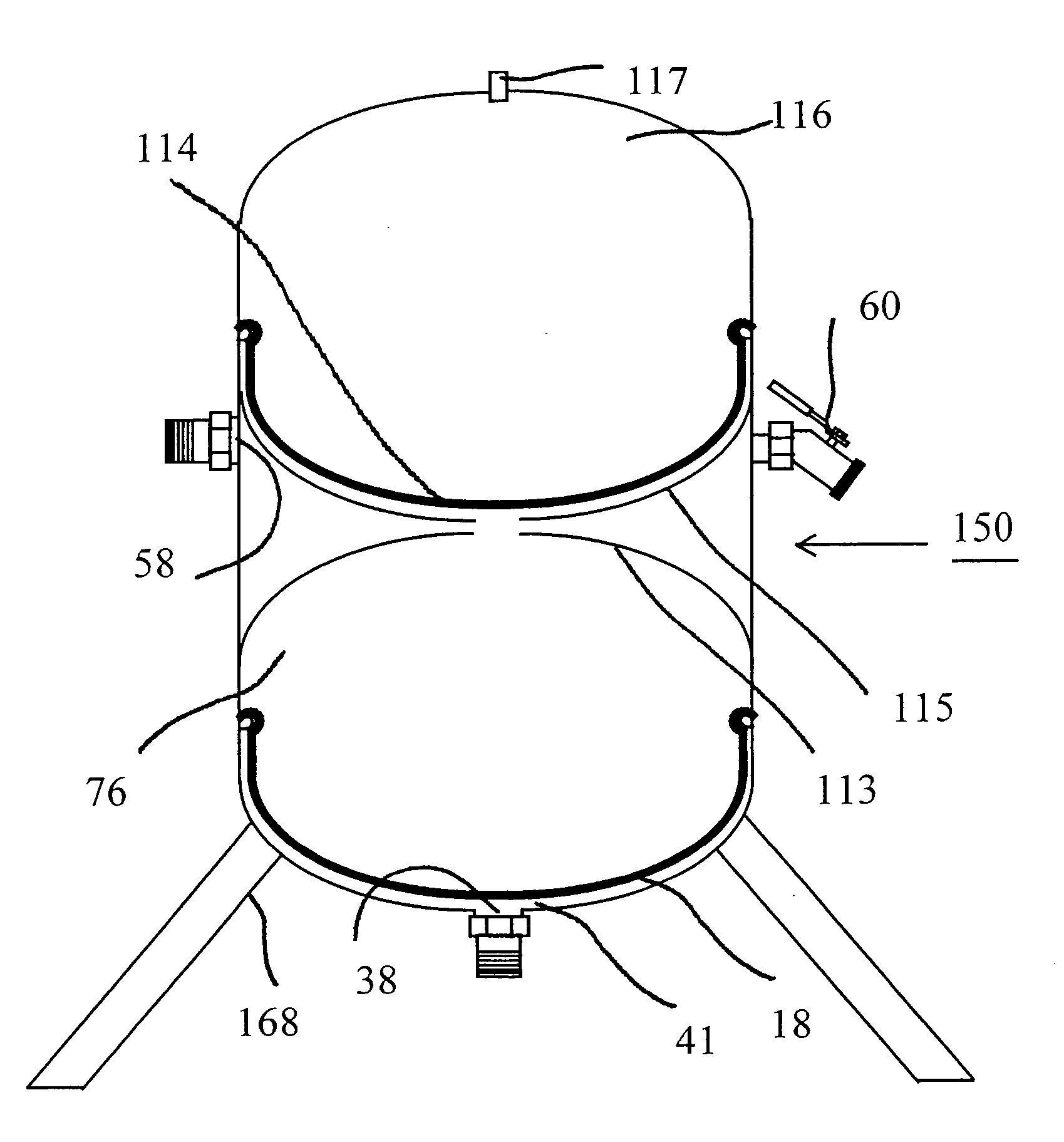

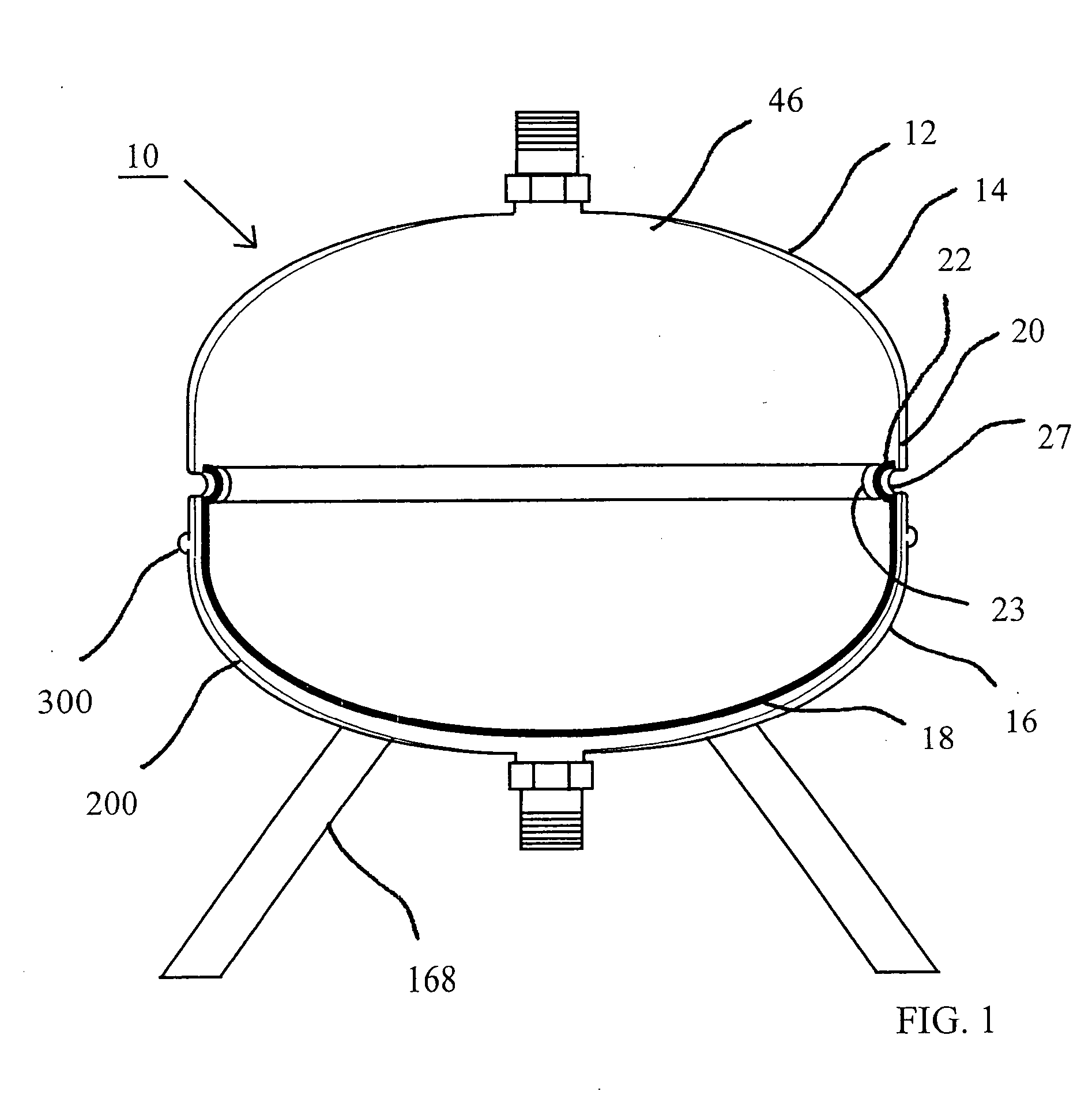

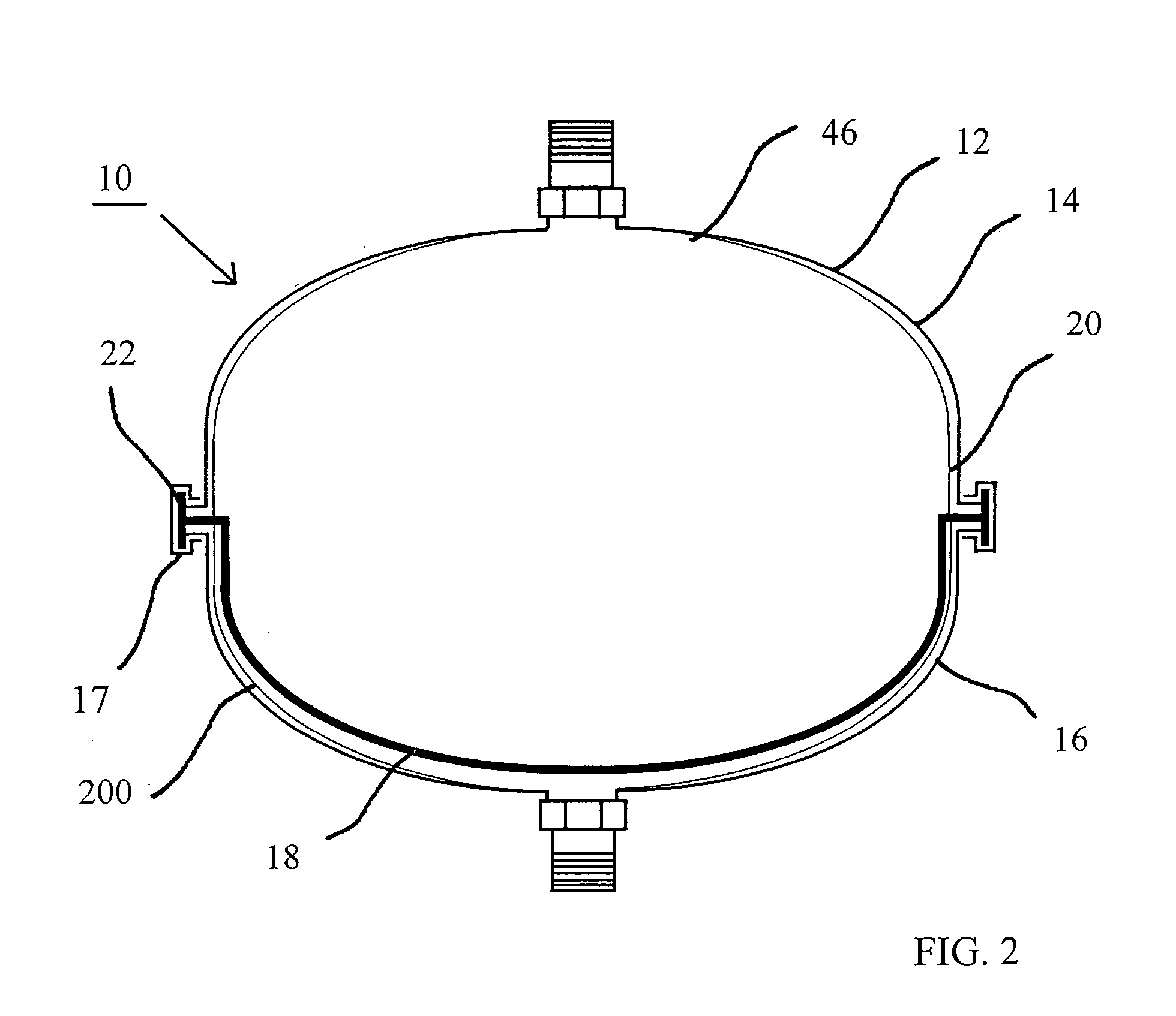

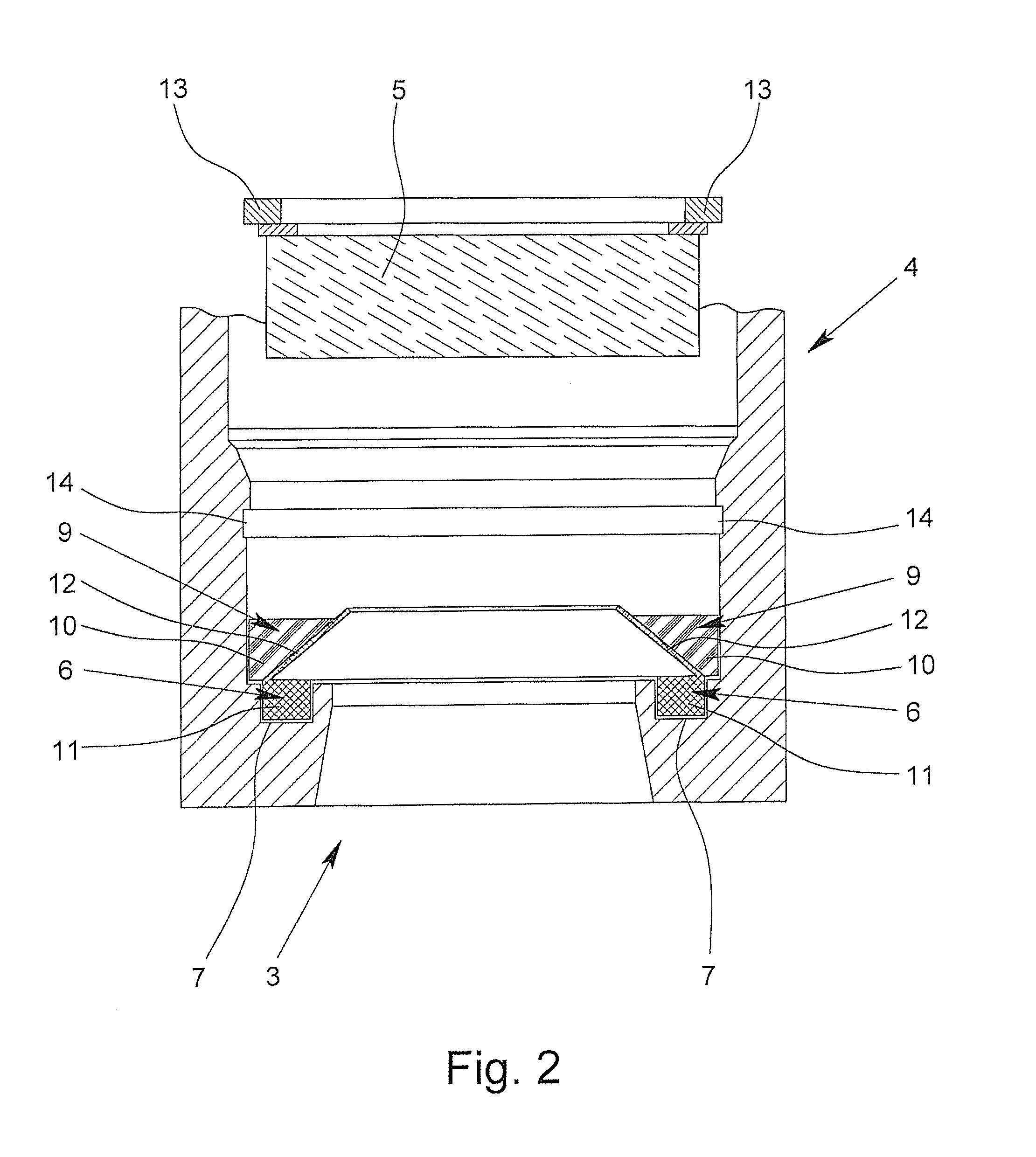

Pressure control isolation and flood preventative tank for a hot water based heating system

The present invention provides a pressure control isolation tank for a closed loop heating system. A diaphragm within the tank separates heating system fluid from non-system fluid. The heating system fluid is provided under constant pressure, typically 12 PSI. Usually the non-system fluid is service water or clean water flowing through a pressure reducing valve. As the heating system loses system fluid through tiny leaks, and also loses air through vents, the non-system fluid causes the diaphragm to displace the volume lost by the leaked heating system fluid and leaked air. Thus, the heating system fluid is maintained at a constant pressure.

Owner:POLKHOUSKIY NIKOLAY

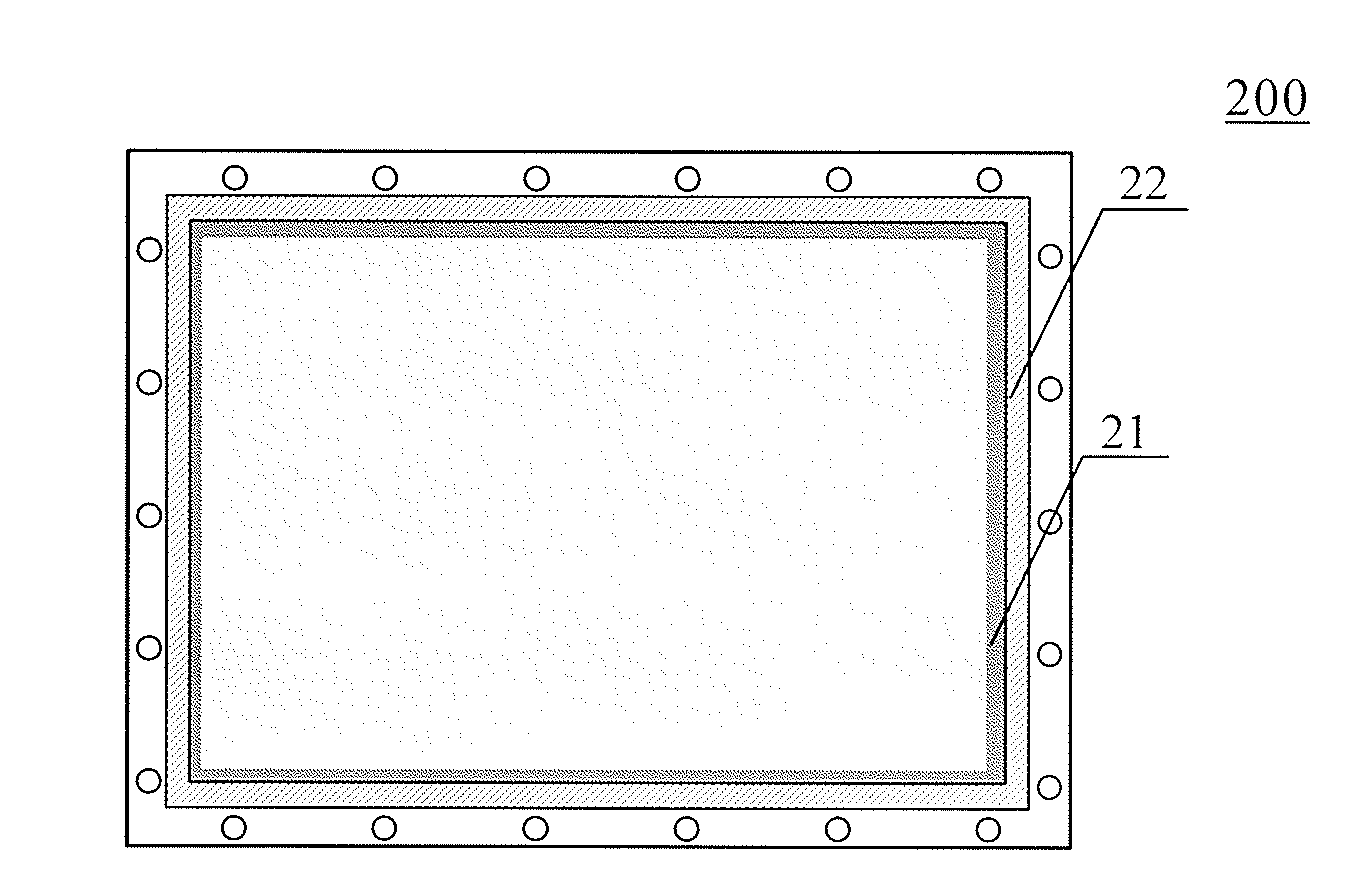

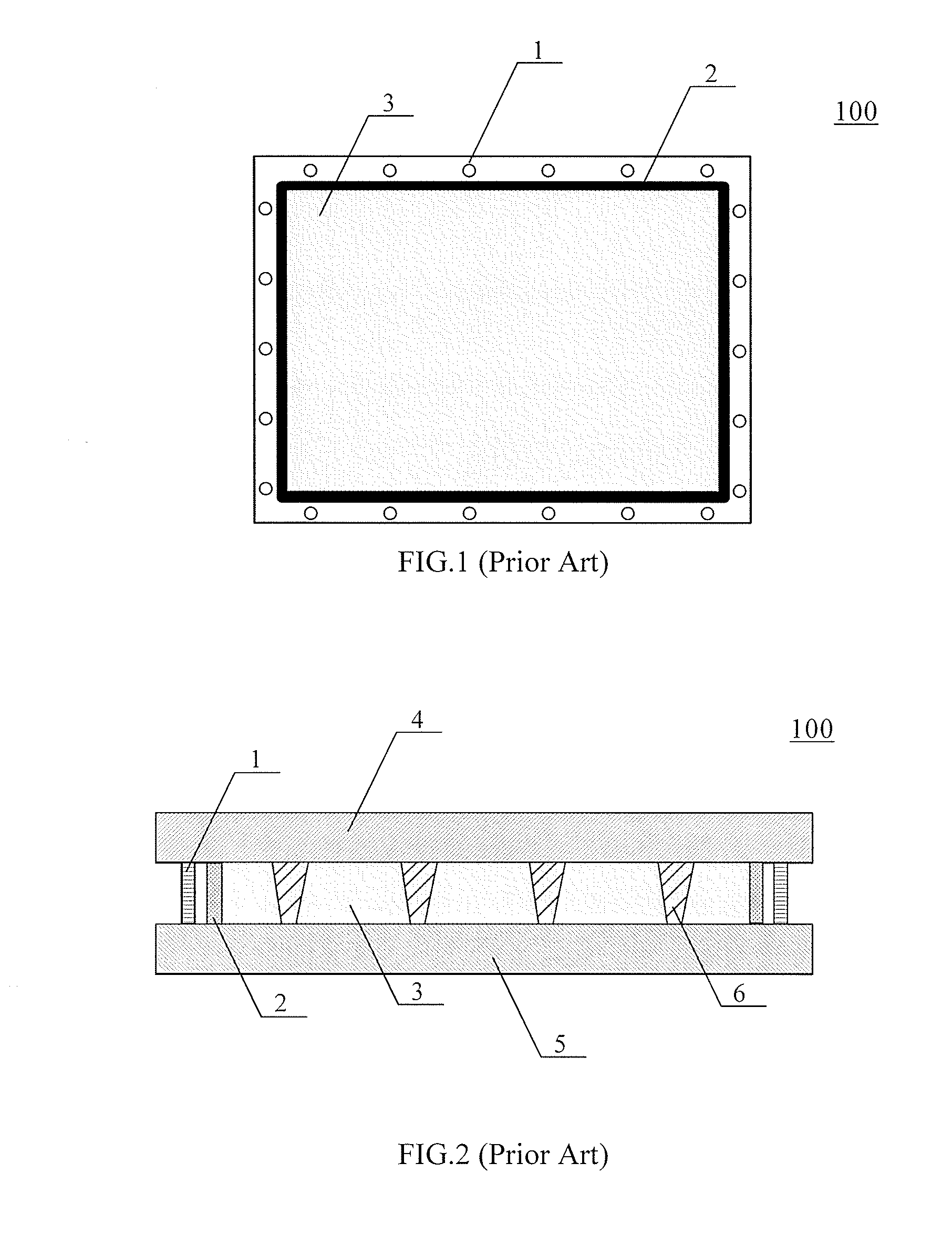

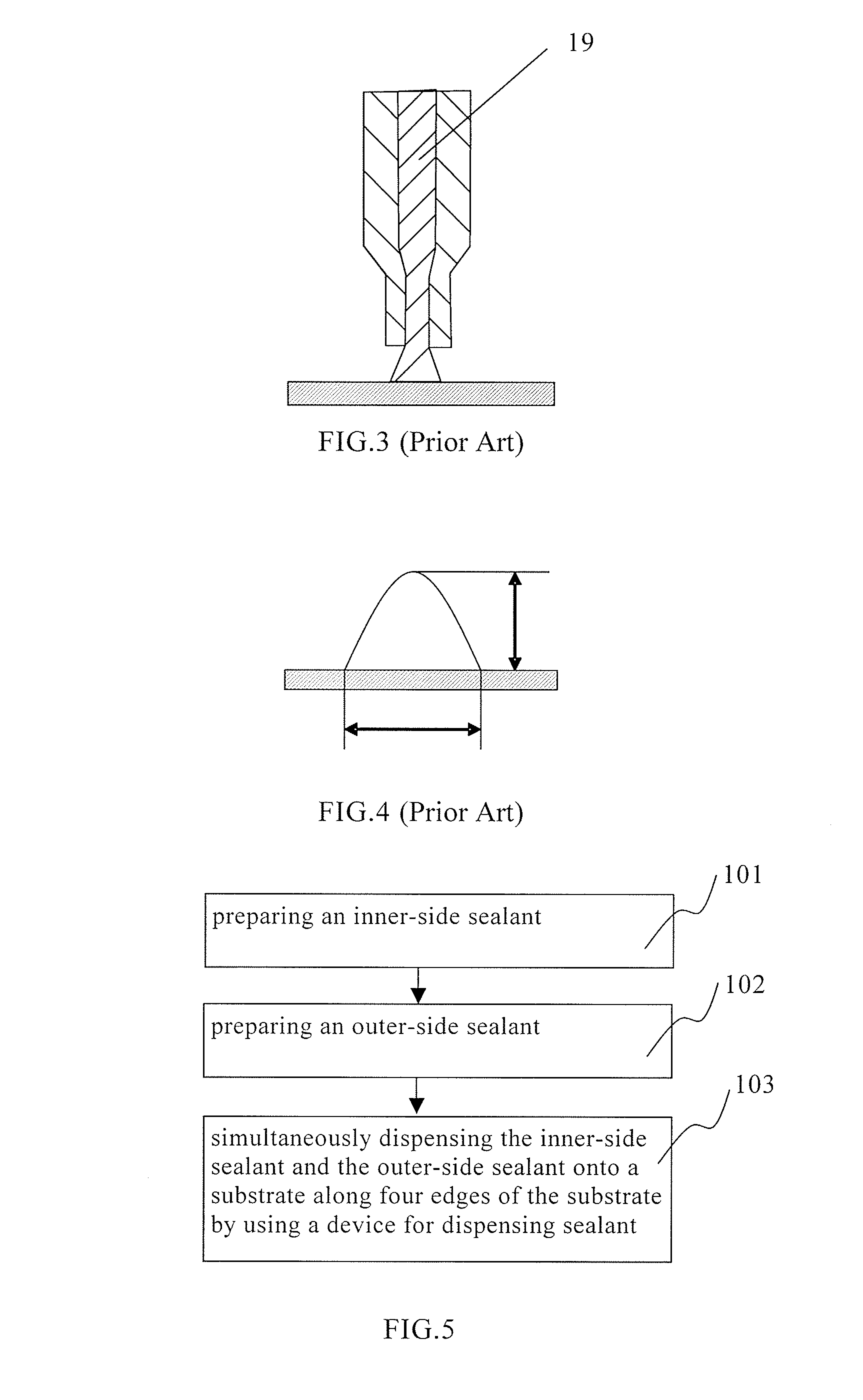

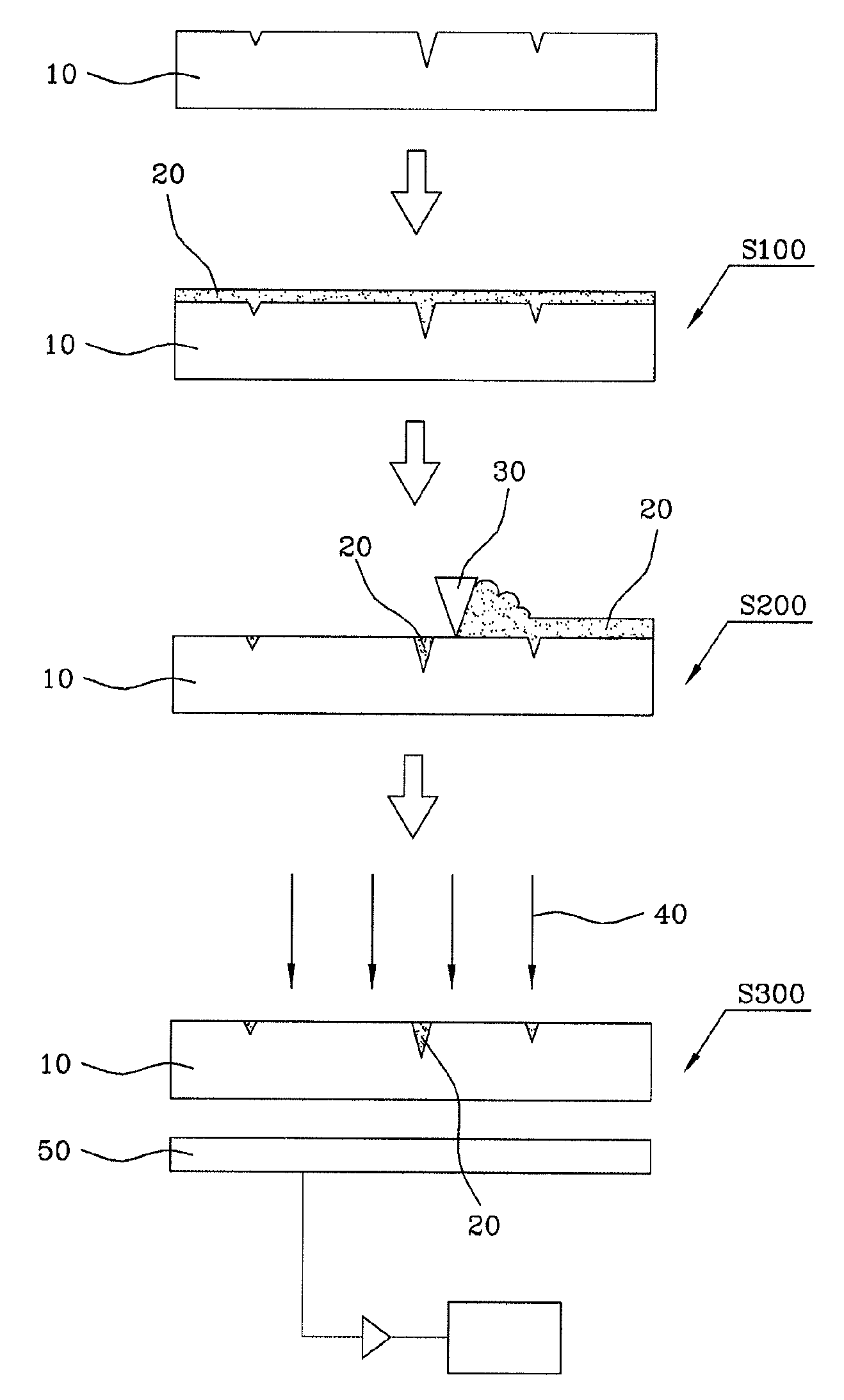

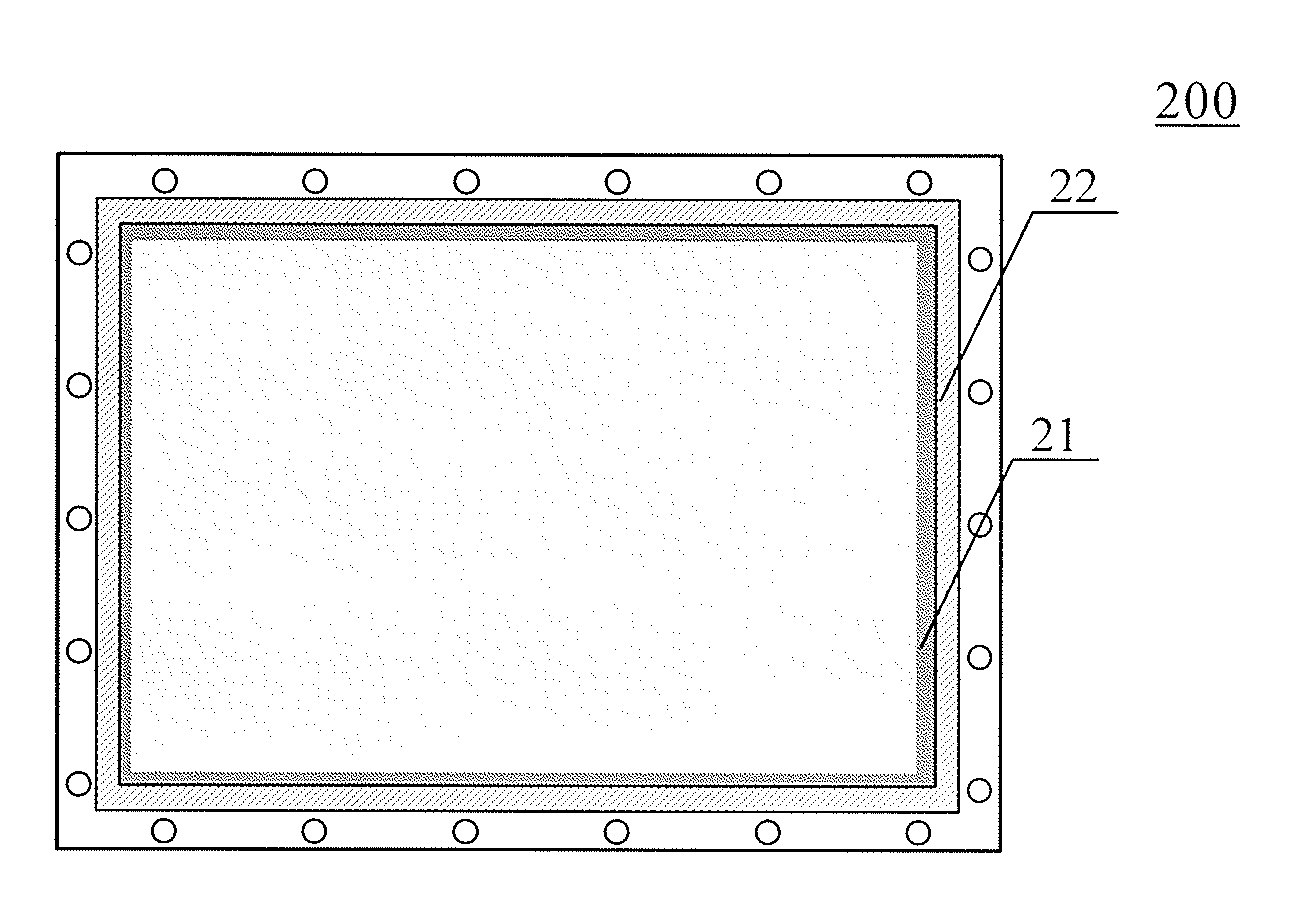

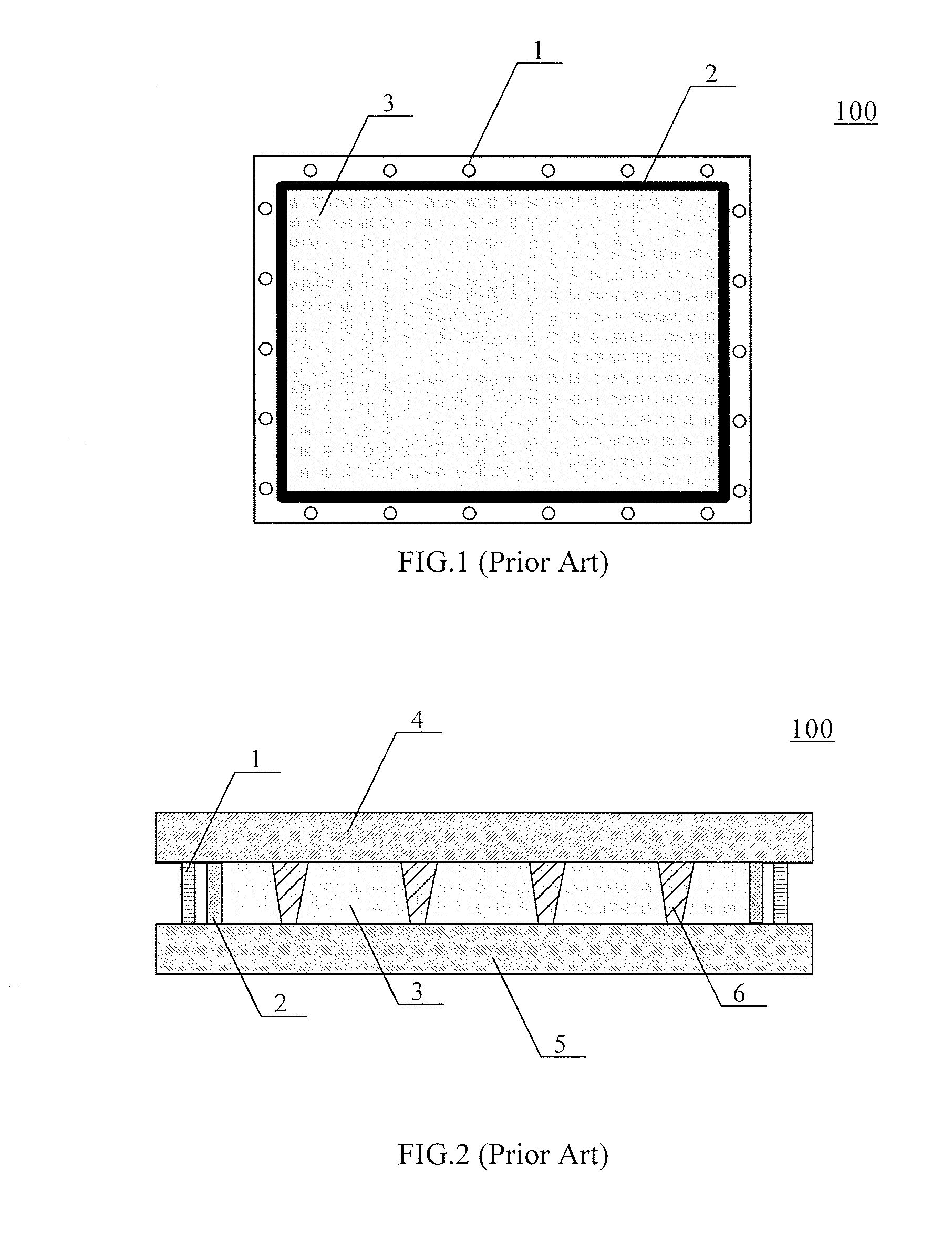

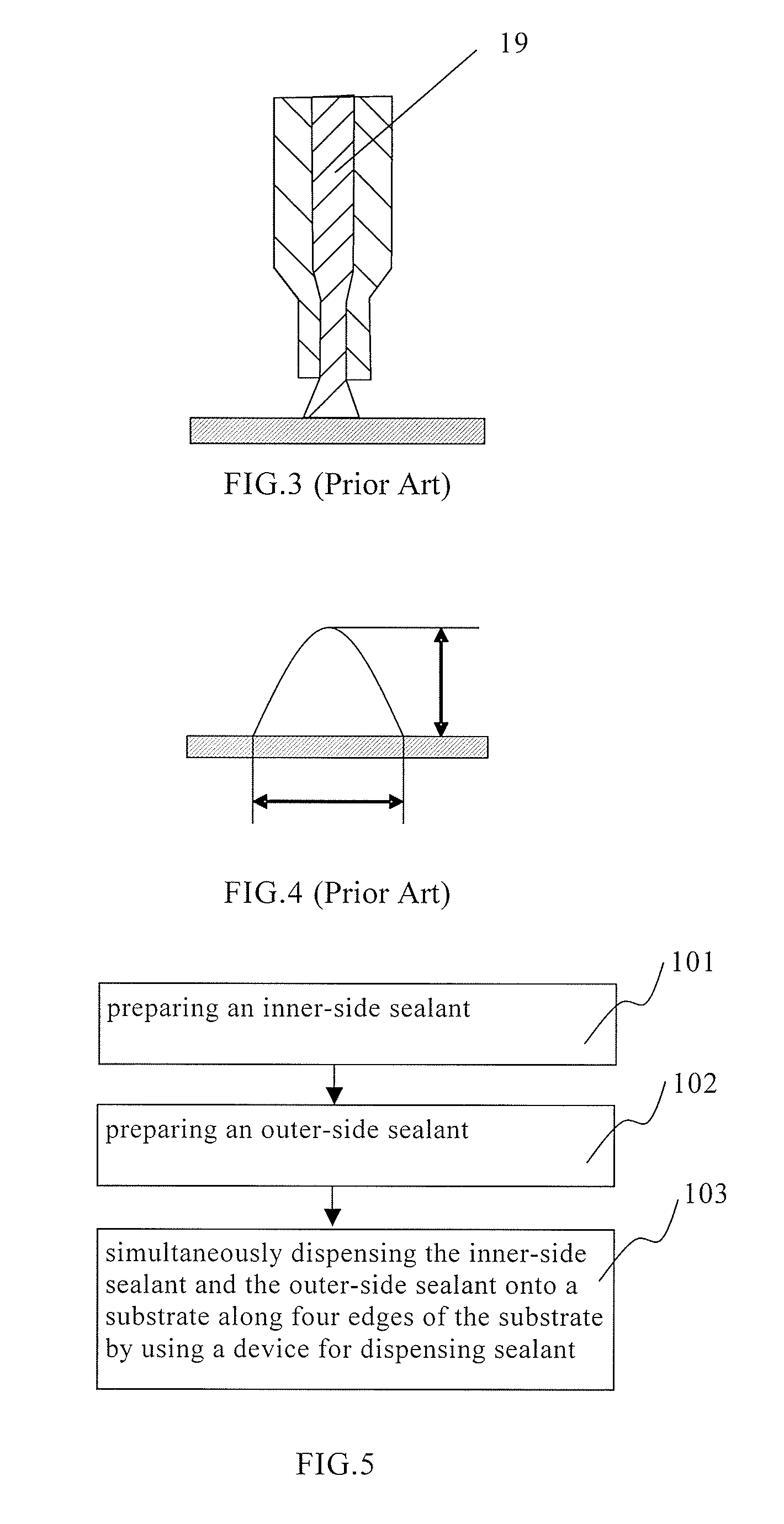

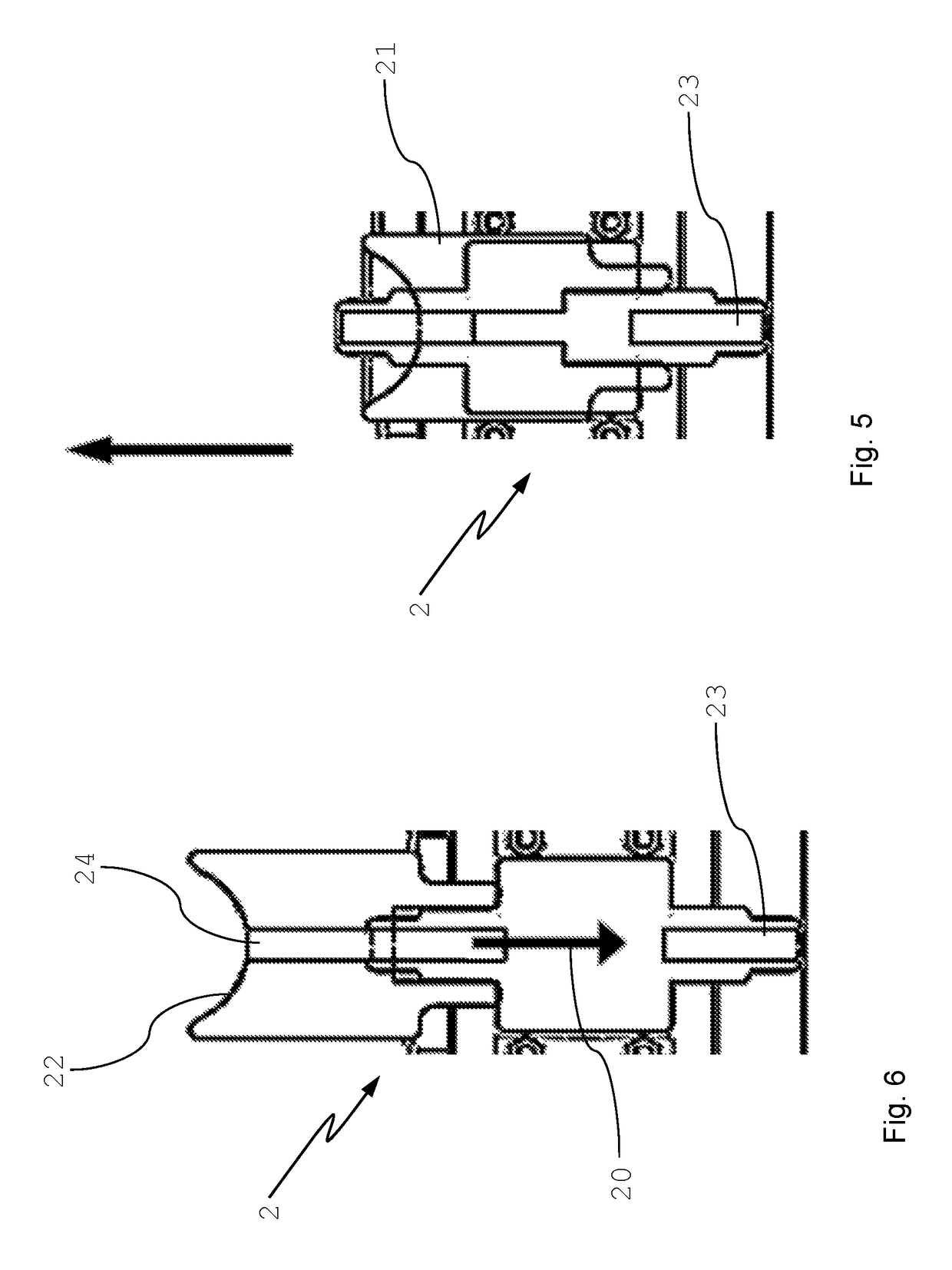

Method and device for dispensing sealant and LCD panel

ActiveUS20100039605A1Satisfactory adhesive strengthShorten the curing timeOpening closed containersBottle/container closureSealantLiquid crystal

The method for dispensing sealant comprises: preparing an inner-side sealant that comprises a light curing sealant or a first mixture of a light curing sealant and a thermal curing sealant in which the content of the light curing sealant is more than that of the thermal curing sealant; preparing an outer-side sealant that comprises a thermal curing sealant or a second mixture of a light curing sealant and a thermal curing sealant in which the composition of the light curing sealant is less than or equal to that of the thermal curing sealant; simultaneously dispensing the inner-side sealant and the outer-side sealant onto a substrate along four edges of the substrate by using a device for dispensing sealant so that one side of the inner-side sealant abuts the sealed liquid crystal materials and the other side thereof integrates with the outer-side sealant.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

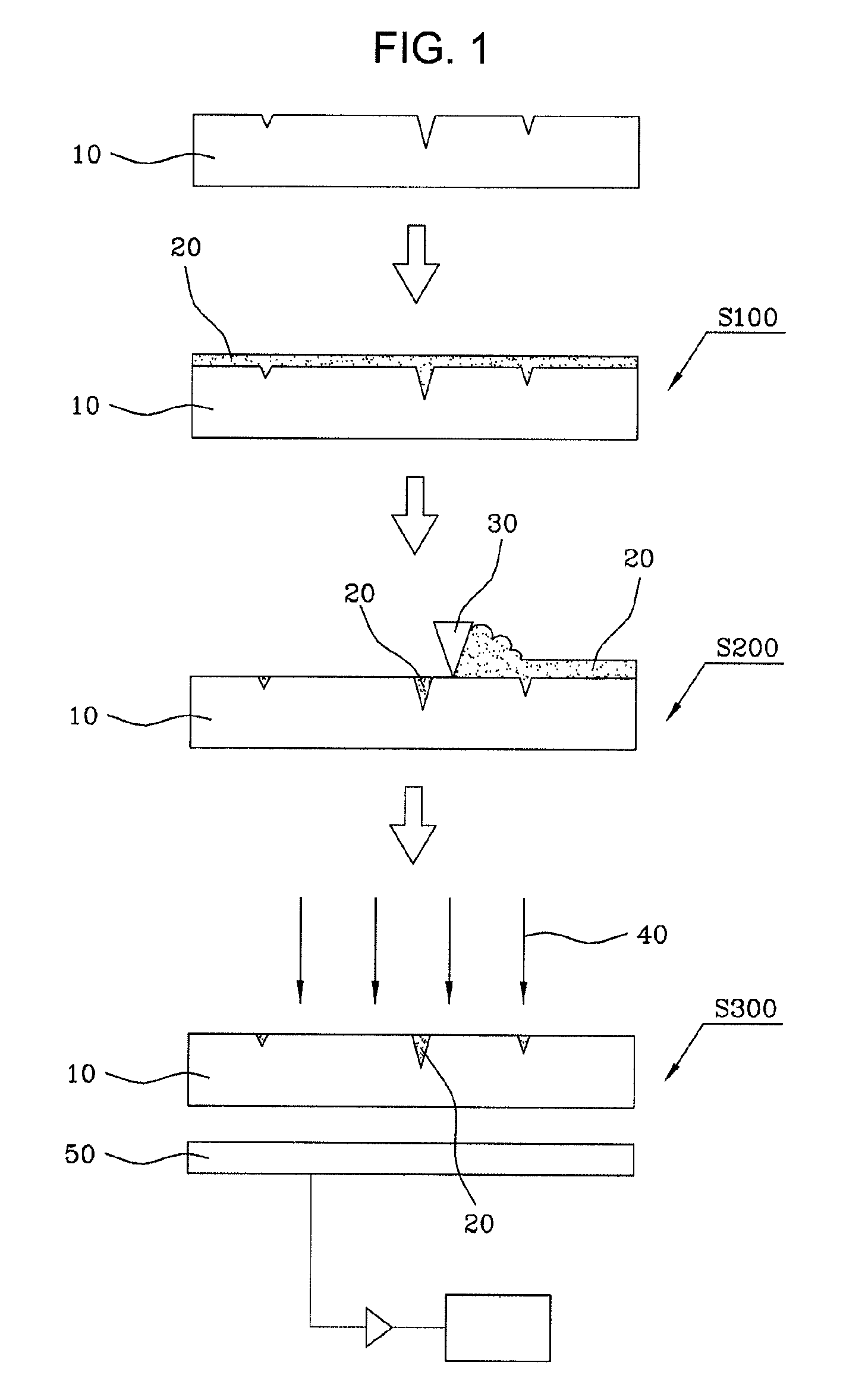

Method of detecting fine surface defects

InactiveUS20090180587A1Improve inspection efficiencyOvercome problemsMaterial nanotechnologyMaterial analysis using wave/particle radiationPhosphorSubject matter

Disclosed herein is a method of detecting fine surface defects, including: applying nano phosphor paste on a surface of a subject; squeegeeing the surface of the subject such that the nano phosphor paste remains only in defects in the subject; and detecting the fine defects in the subject by placing the subject over a light detection plate, irradiating the subject with a light source, and then determining that light-emitting portions detected using the light detection plate are defects in the subject. The method of detecting fine surface defects is advantageous in that the problems with the conventional methods, such as surface contamination, the difficulty in realizing uniform application of a penetrant on a subject, the limitations on the dwelling time of the penetrant and the testing temperature (surface temperature of the subject: 16˜50° C.) thereof, and the contamination of the penetrant, can be overcome, and in that the incidence of inspection errors is decreased, and the time and cost of inspection are reduced, thus improving the production yield of the subject.

Owner:NAM SANG HEE +5

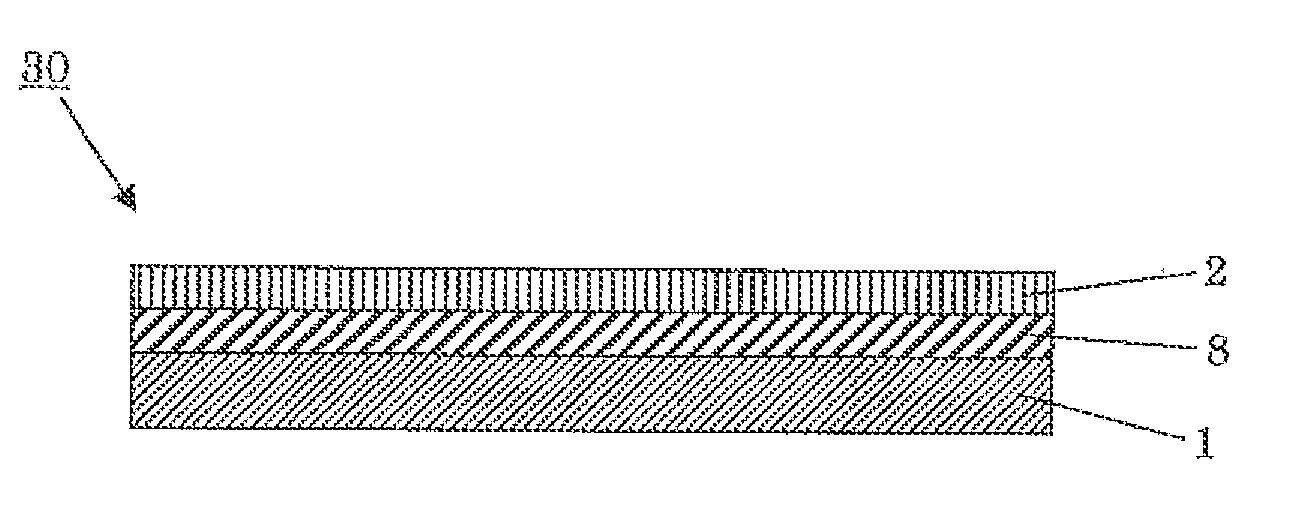

Method for producing semiconductor device

InactiveUS20130137219A1Avoid contaminationImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesFilling materialsEngineering

There is provided a method for producing a semiconductor device, which is capable of suppressing voids during mounting of a semiconductor element to produce a semiconductor device with high reliability. A method for producing a semiconductor device of the present invention includes the steps of: providing a sealing sheet having a base material and an under-fill material laminated on the base material; bonding the sealing sheet to a surface of a semiconductor wafer on which a connection member is formed; dicing the semiconductor wafer to form a semiconductor element with the under-fill material; retaining the semiconductor element with the under-fill material at 100 to 200° C. for 1 second or more; and electrically connecting the semiconductor element and the adherend through the connection member while filling a space between the adherend and the semiconductor element with the under-fill material.

Owner:NITTO DENKO CORP

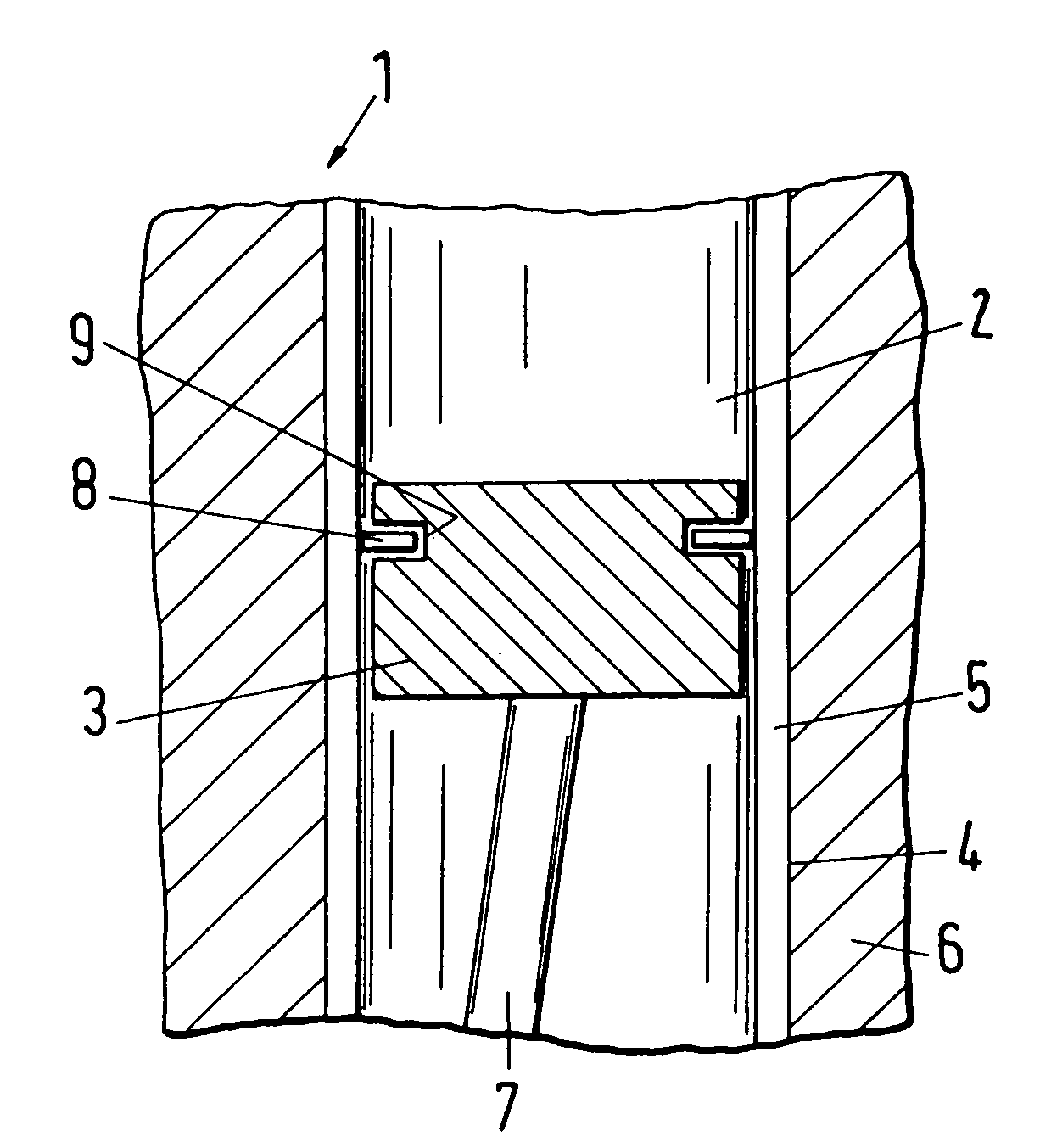

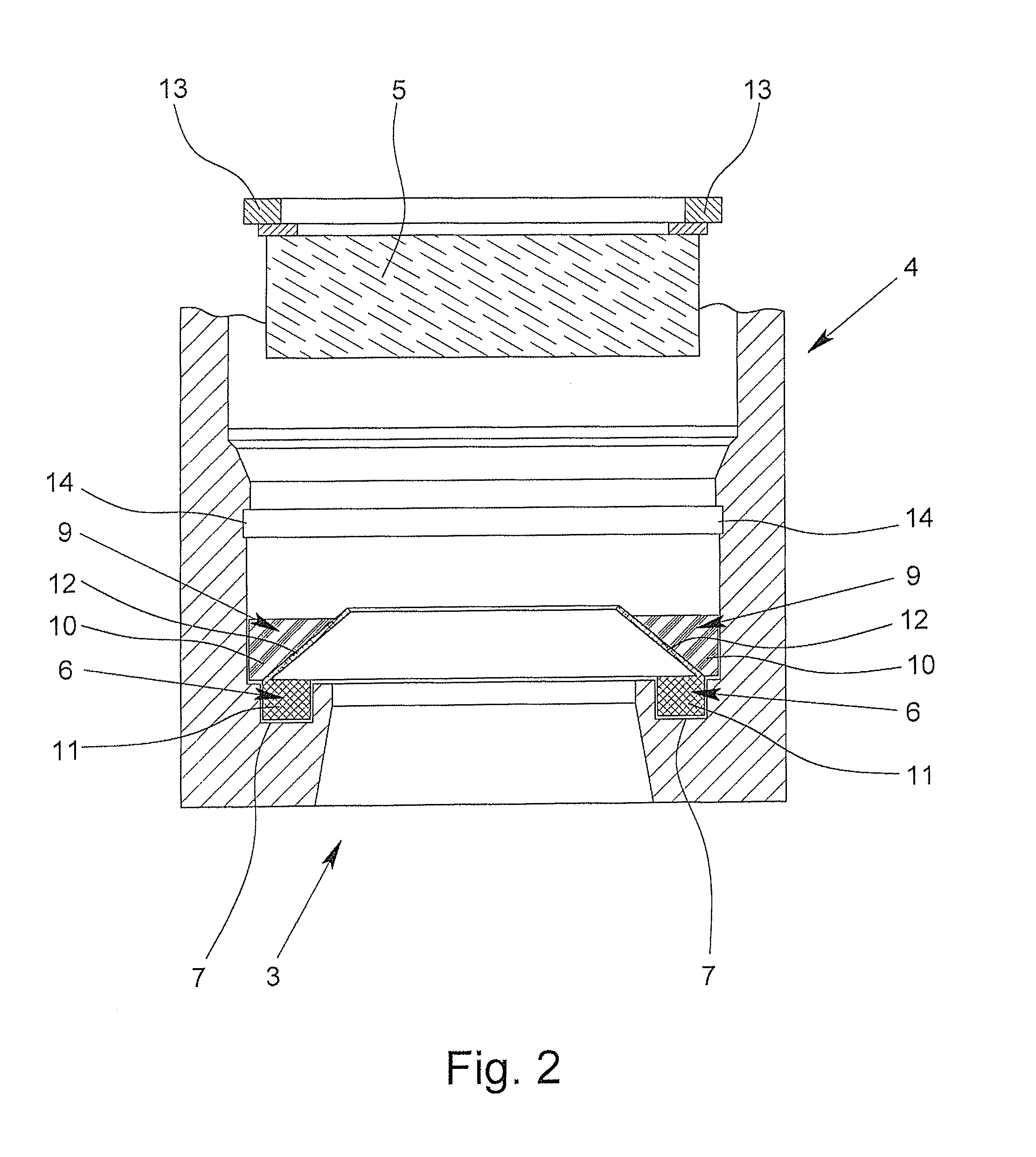

Material and process for thermal coating, surface layer and also compressor with a surface layer of the material

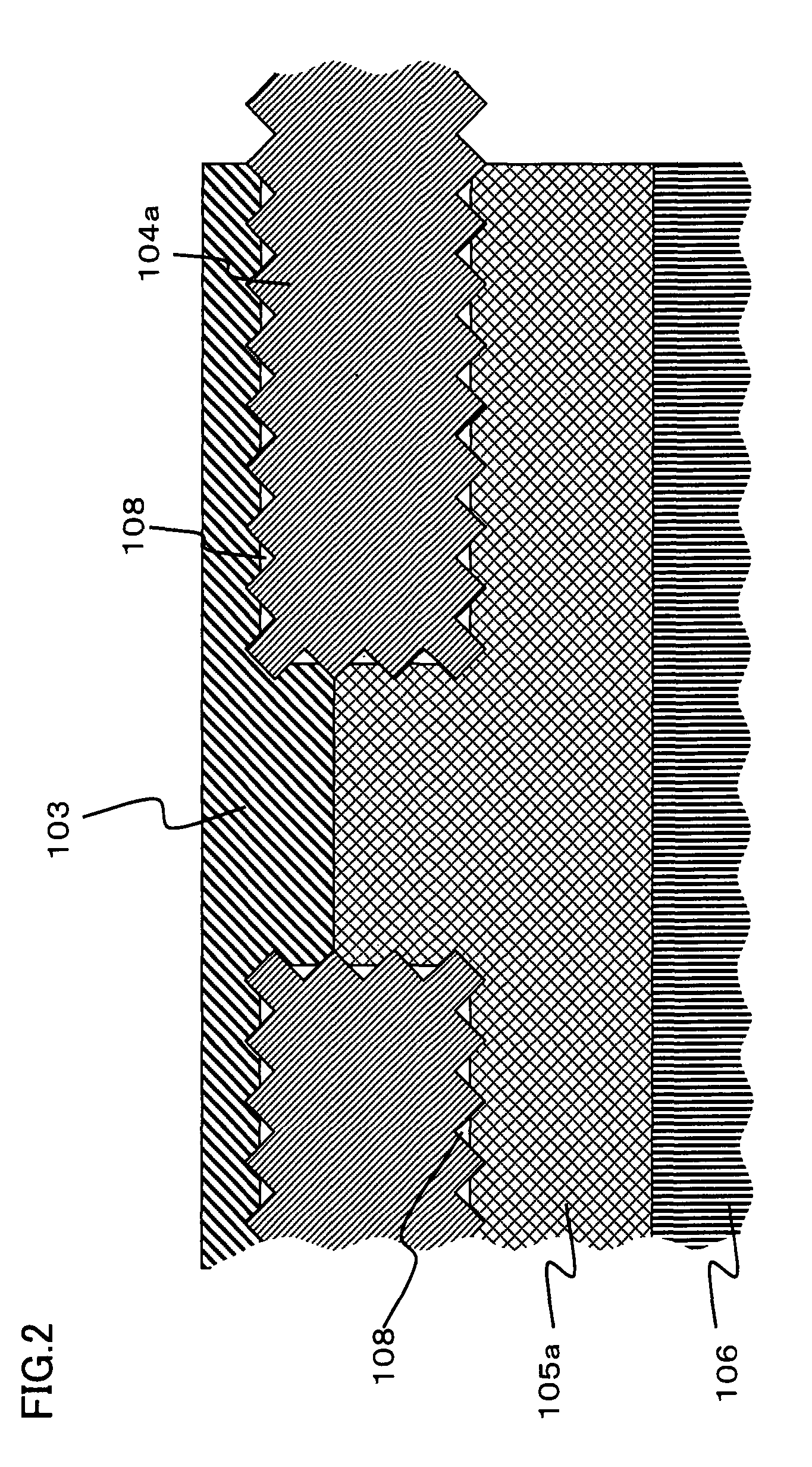

ActiveUS7357068B2Improve toughnessHigh hardnessMolten spray coatingPositive displacement pump componentsOxide ceramicSurface layer

The invention relates to a material based on an oxide ceramic for the manufacture of a surface layer (5) by means of a thermal coating process including aluminum oxide and zirconium oxide, with the material additionally containing chromium oxide for the simultaneous optimization of the hardness and toughness of the surface layer (5).

Owner:SULZER METRO AG

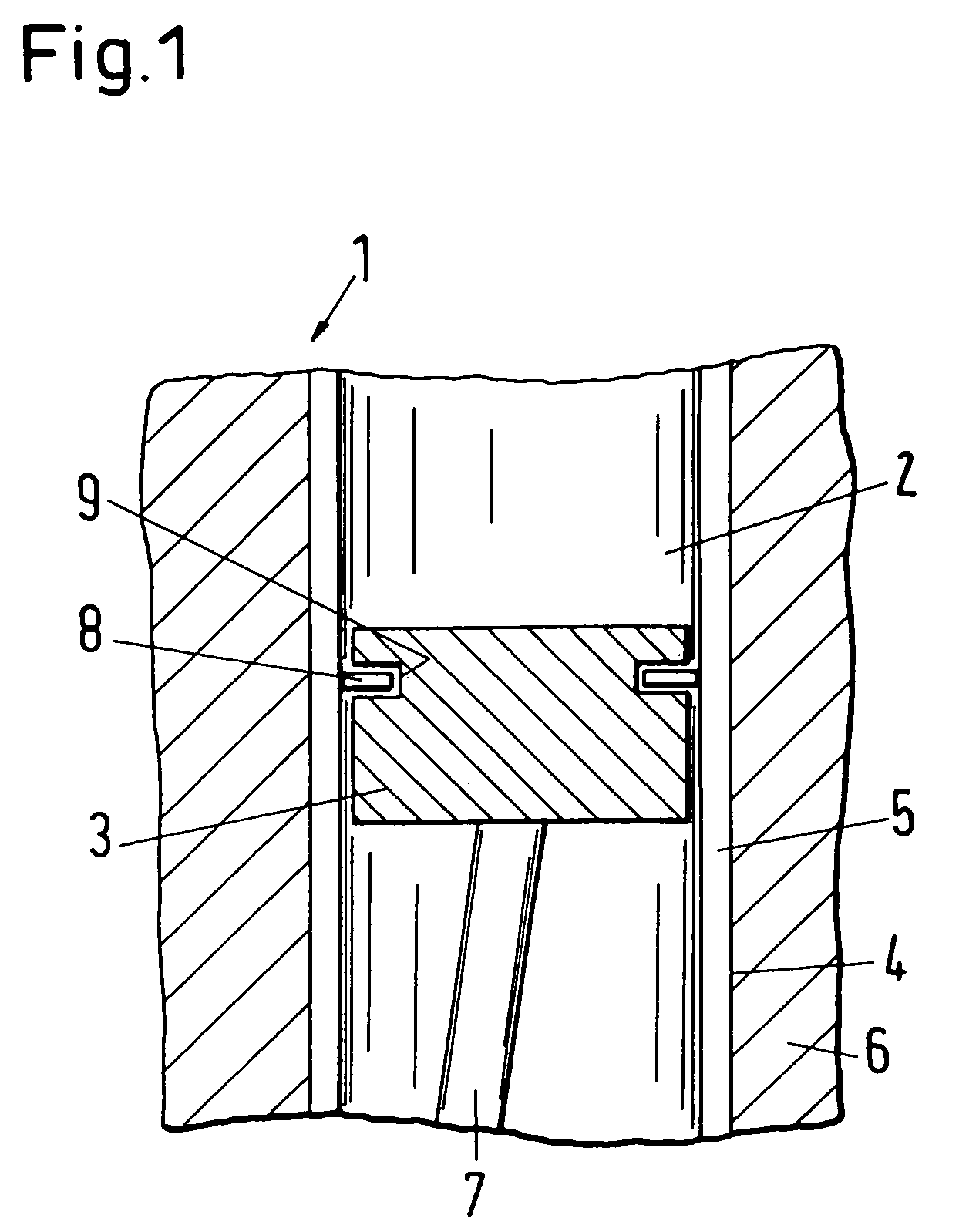

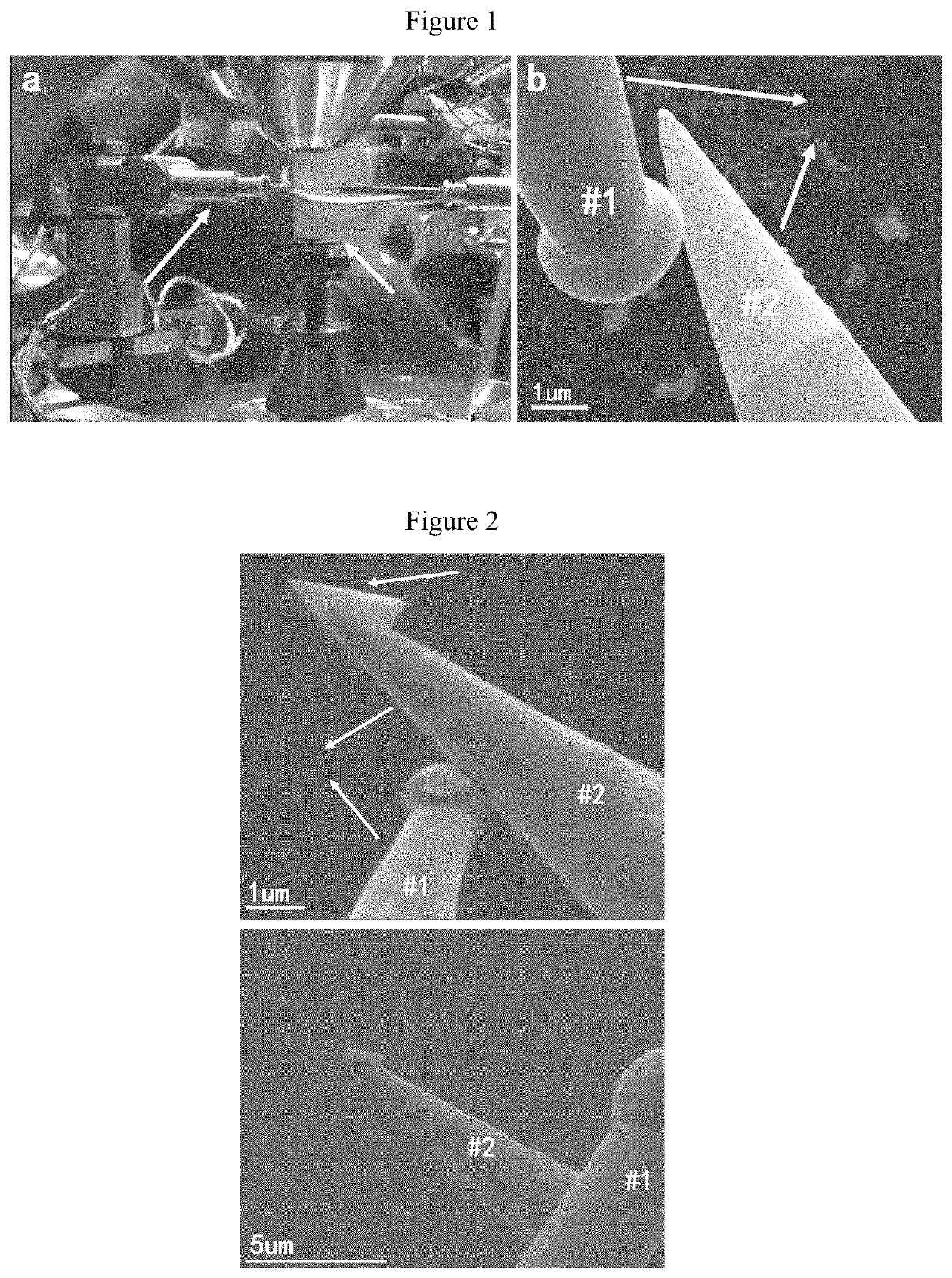

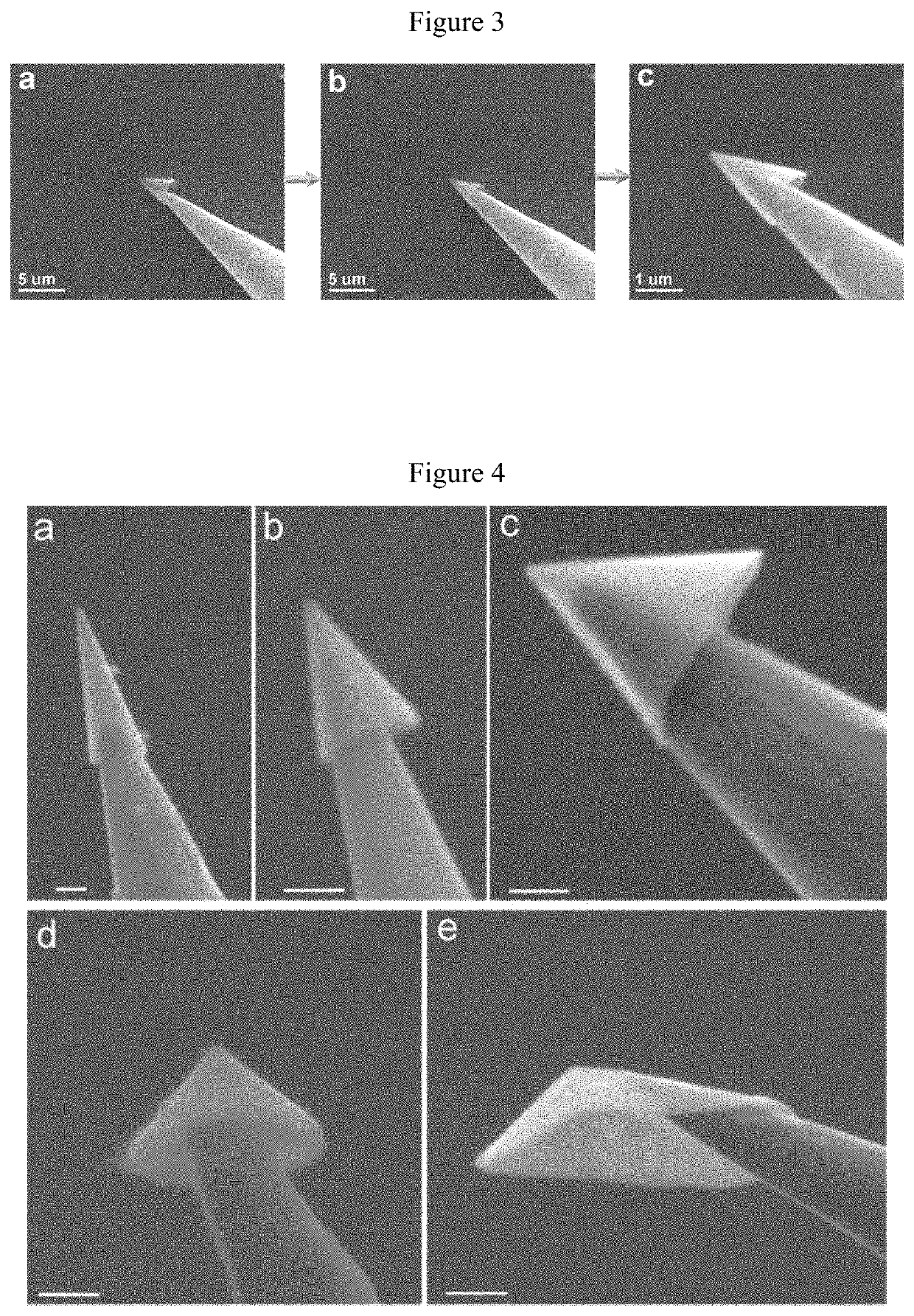

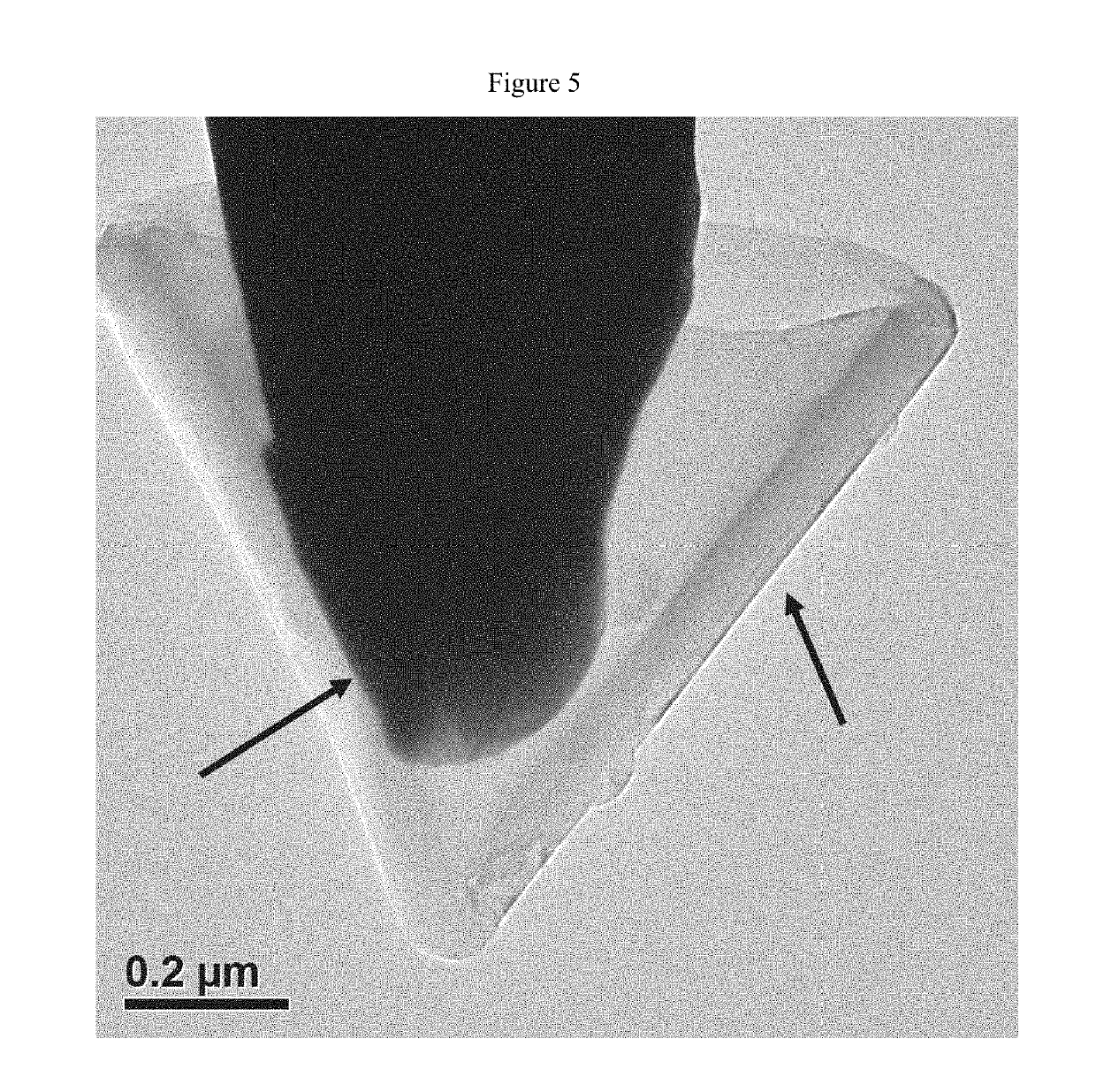

Conical nano-carbon material functionalized needle tip and preparation method therefor

ActiveUS10823758B2Improve conductivityHigh mechanical strengthMaterial nanotechnologyFixed microstructural devicesPlatinumCarbide

Provided is a conical nano-carbon material functionalized needle tip, formed by assembling a nano-carbon material with a material of a needle tip by means of a covalent bond; and the material of the needle tip is a metal selected from one or more of tungsten, iron, cobalt, nickel and titanium. Further provided is a method for preparing the conical nano-carbon material functionalized needle tip. The conical nano-material functionalized needle tip has an outstanding interface formed by metal-carbide covalent bonds, and the orientation of the conical nano-material is matched with the axial direction of the metal needle tip (illustrated in FIG. 6). The proposed preparation method affords a robust interface and avoids the potential pollution to the nano-material caused during the deposition of fixing materials, such as carbon or platinum or the like, in other preparation methods.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Tapered nano-carbon material functionalized needle tip and preparation method therefor

ActiveUS20190107556A1Improve conductivityHigh mechanical strengthMaterial nanotechnologyFixed microstructural devicesPlatinumCarbide

Provided is a conical nano-carbon material functionalized needle tip, formed by assembling a nano-carbon material with a material of a needle tip by means of a covalent bond; and the material of the needle tip is a metal selected from one or more of tungsten, iron, cobalt, nickel and titanium. Further provided is a method for preparing the conical nano-carbon material functionalized needle tip. The conical nano-material functionalized needle tip has an outstanding interface formed by metal-carbide covalent bonds, and the orientation of the conical nano-material is matched with the axial direction of the metal needle tip (illustrated in FIG. 6). The proposed preparation method affords a robust interface and avoids the potential pollution to the nano-material caused during the deposition of fixing materials, such as carbon or platinum or the like, in other preparation methods.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

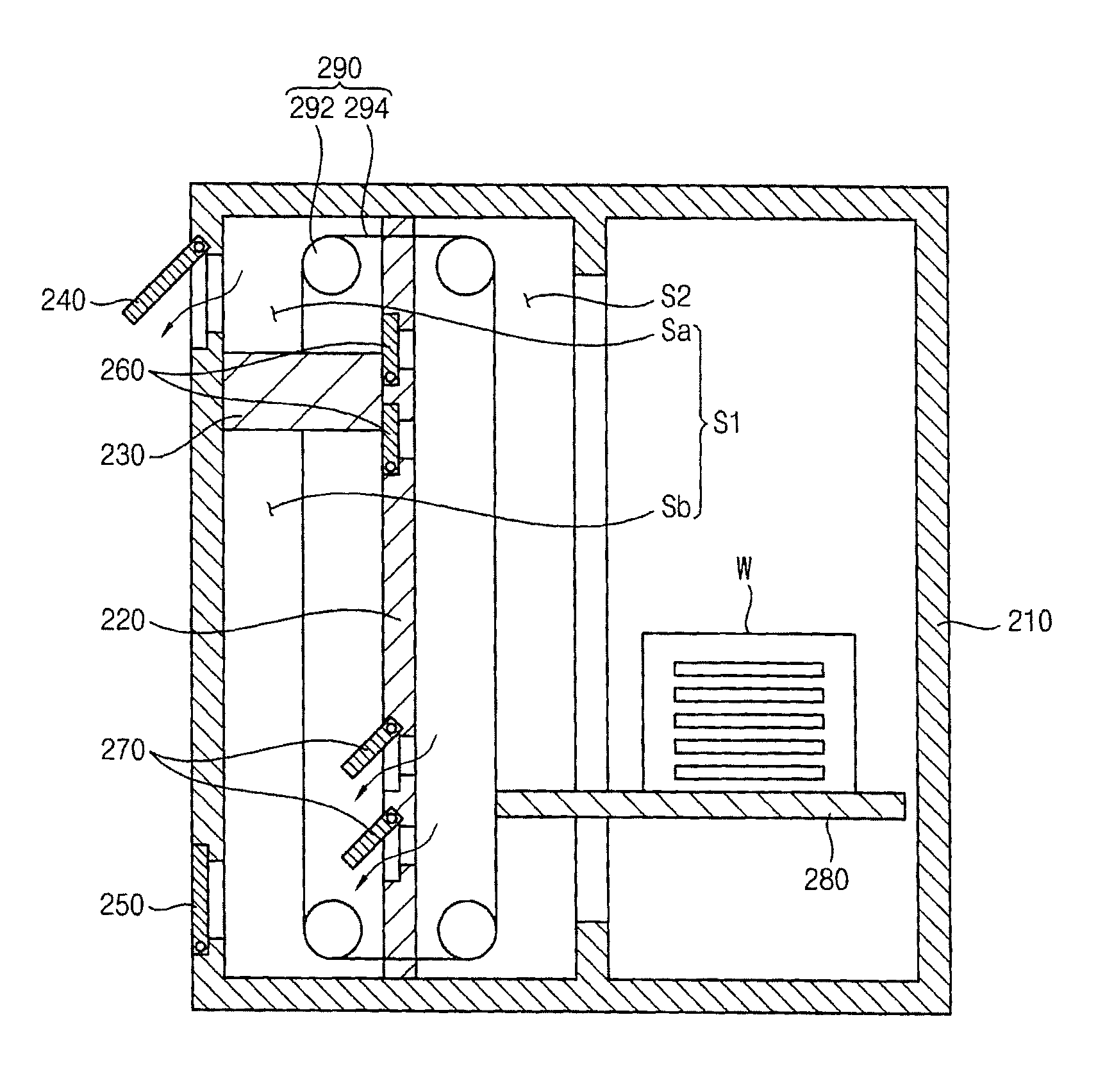

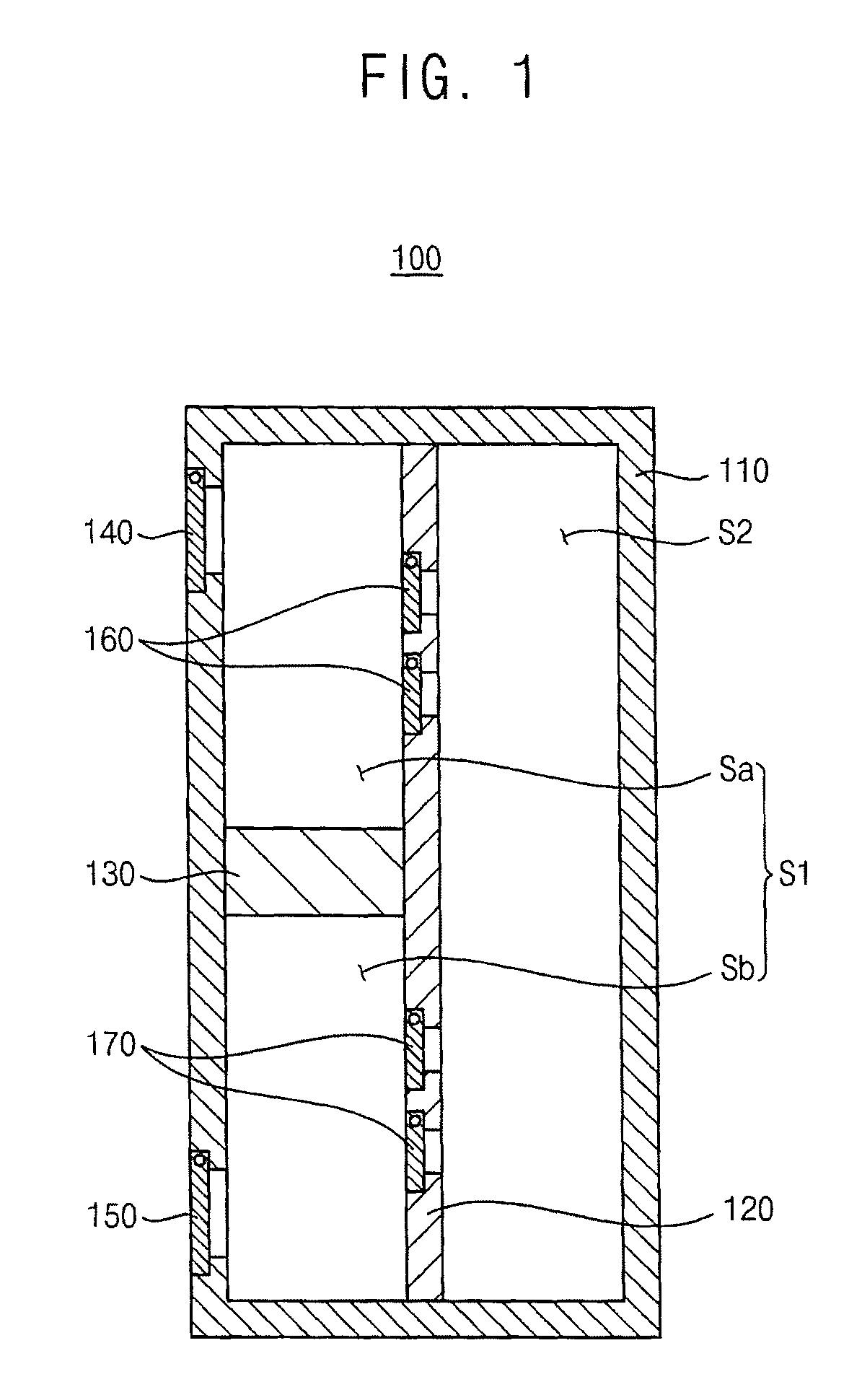

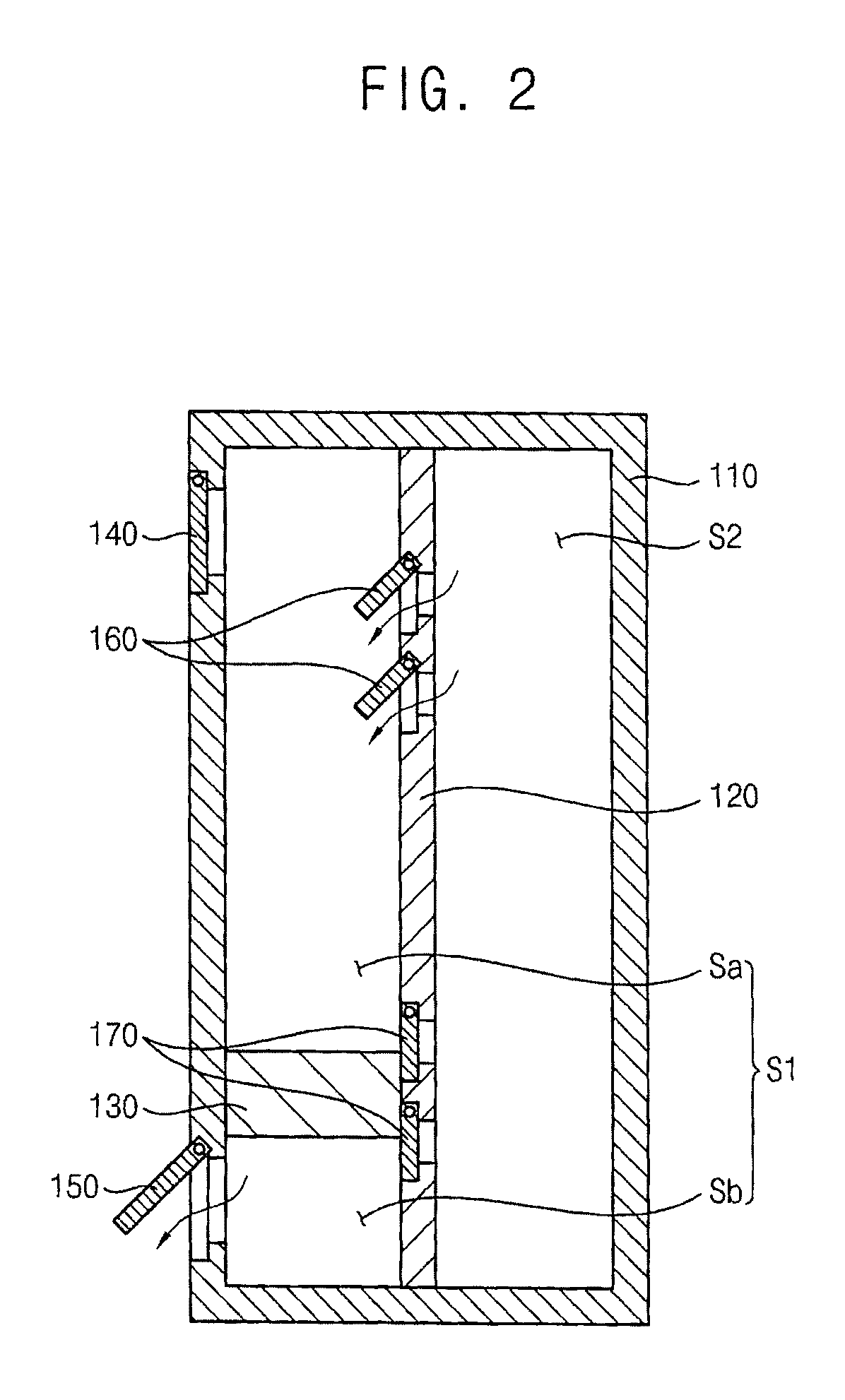

Unit for eliminating particles and apparatus for transferring a substrate having the same

ActiveUS7918910B2ContaminationReduce pollutionCombination devicesLiquid degasificationInterior spacePositive pressure

In an apparatus for transferring a substrate, a partition wall is disposed in a vertical direction in a housing to divide an interior space of the housing into a first space and a second space. A pressure generating member divides the first space into an upper space and a lower space and moves in a vertical direction in the first space such that a positive pressure and a negative pressure are alternately generated in the upper space and the lower space. A substrate supporting member is movably disposed in the second space to support and to transfer the substrate. A plurality of gates is disposed on a side wall of the housing and the partition wall, and is opened and closed by the positive pressure and the negative pressure such that the particles are eliminated from the second space to an exterior space via the first space.

Owner:SEMES CO LTD

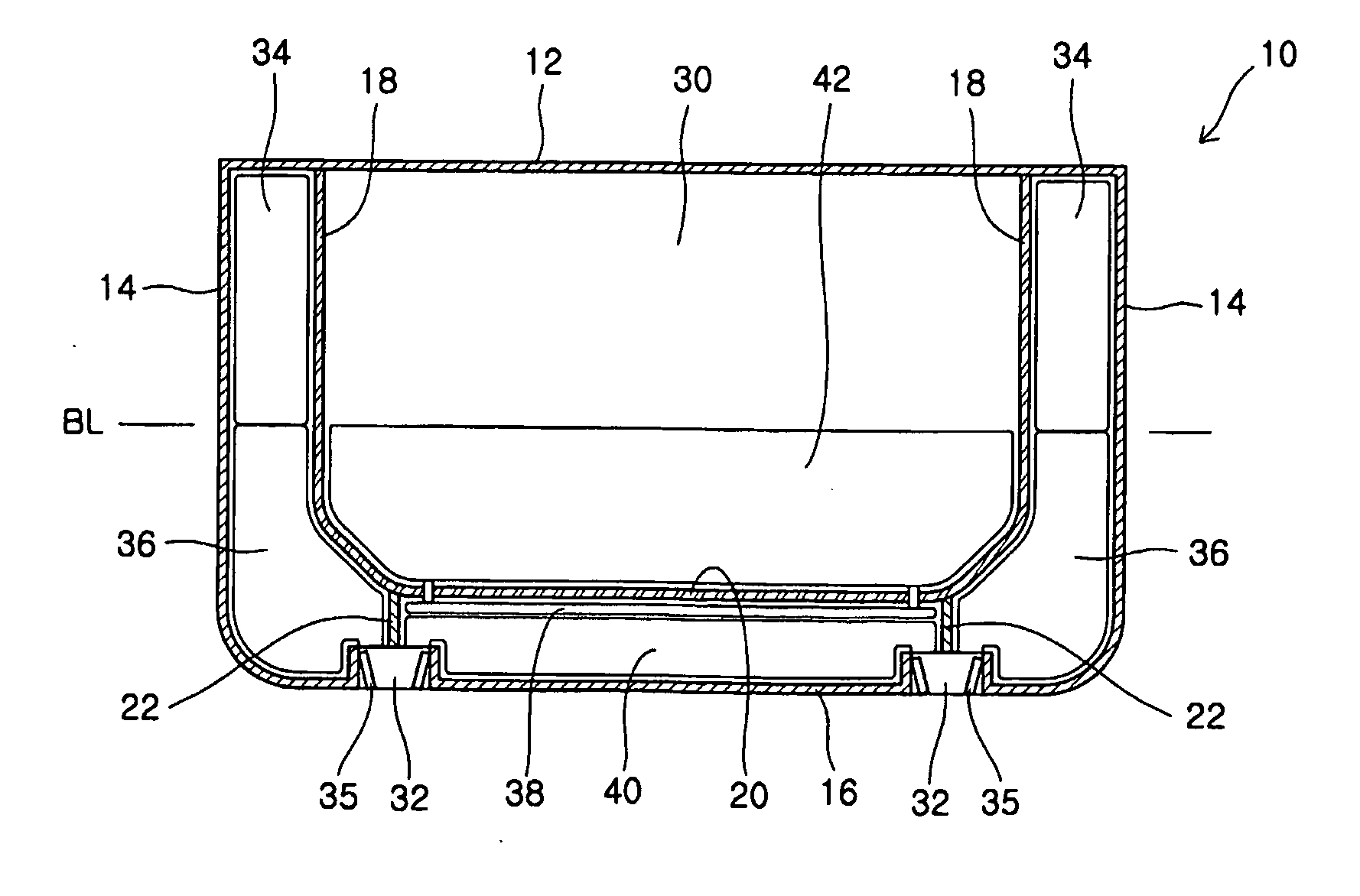

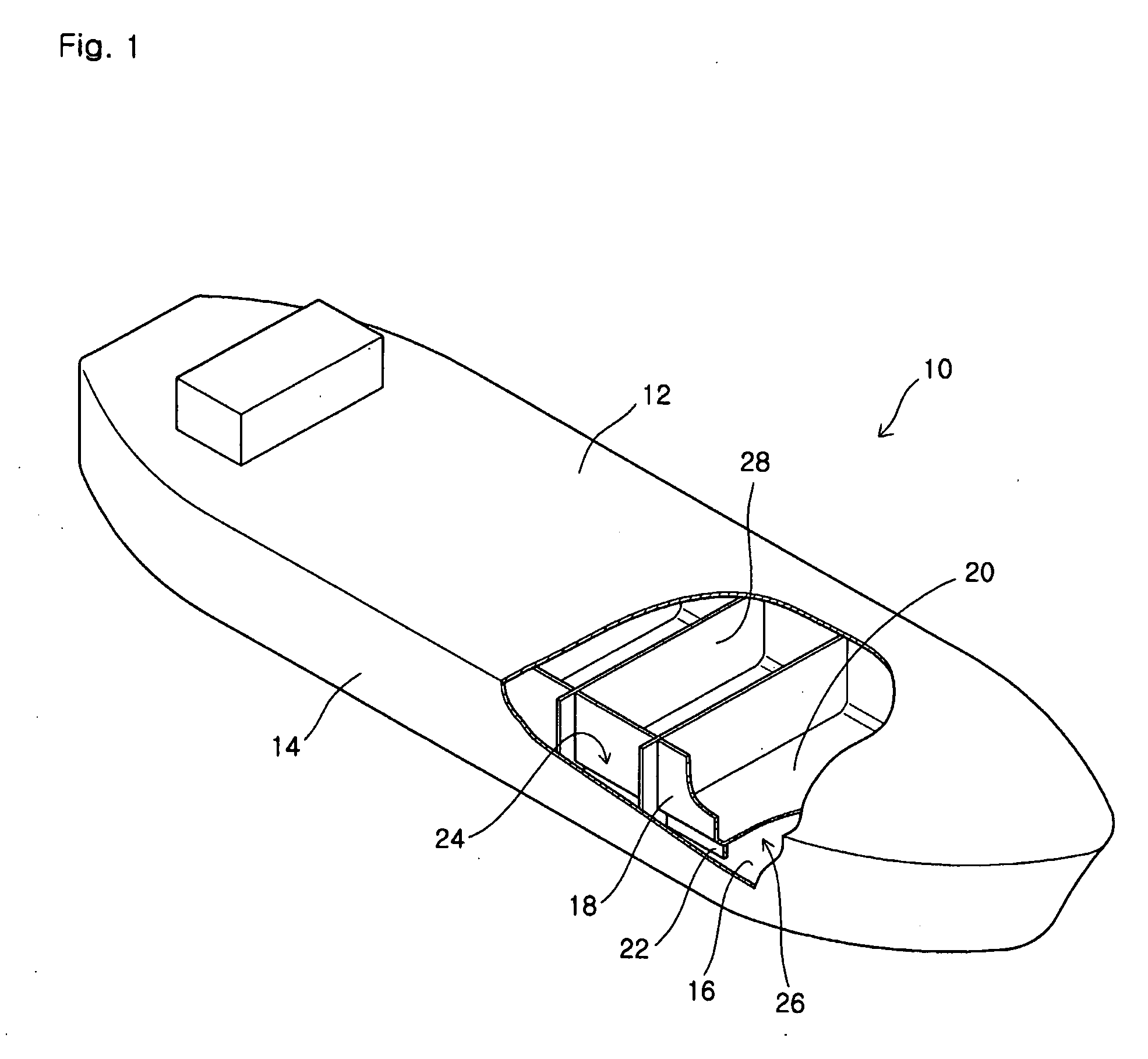

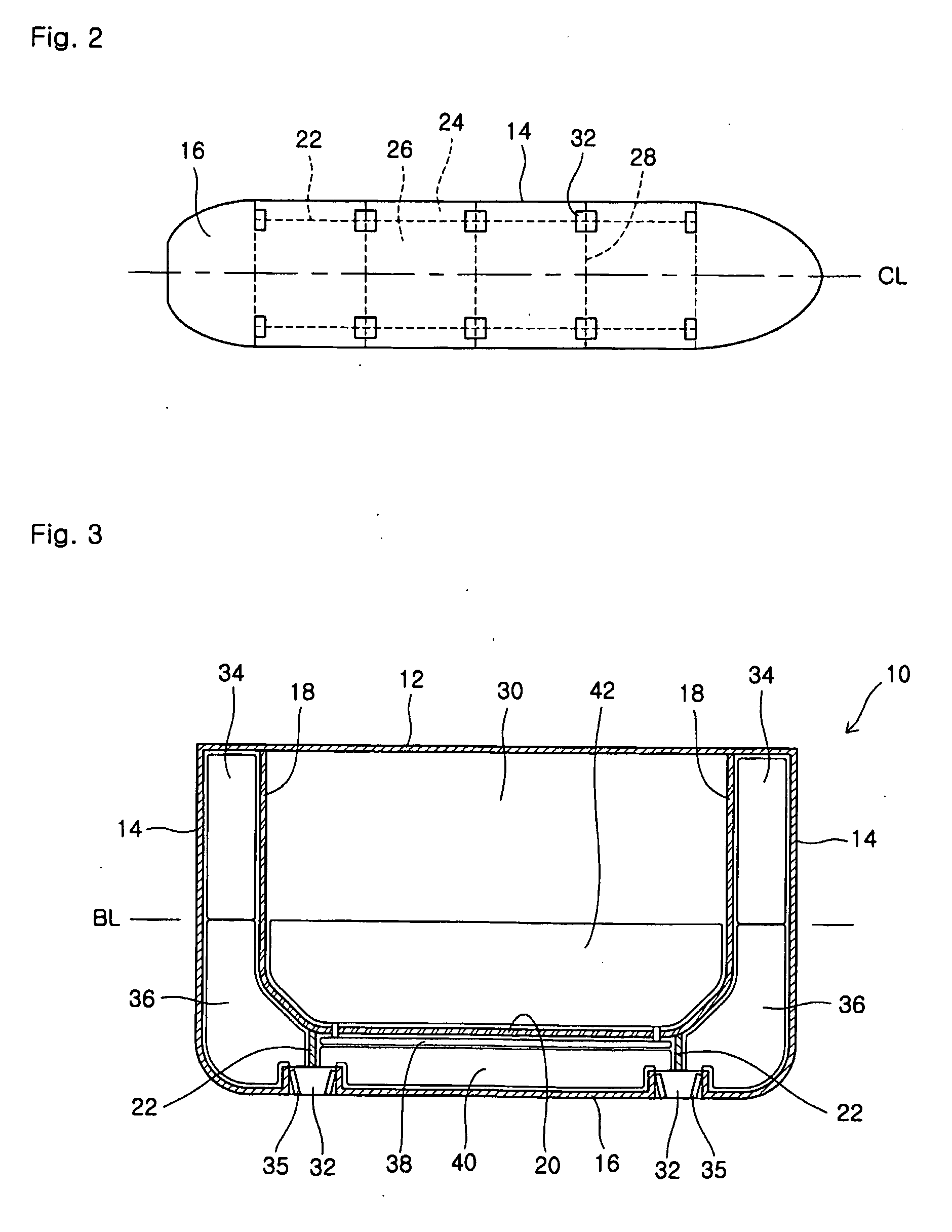

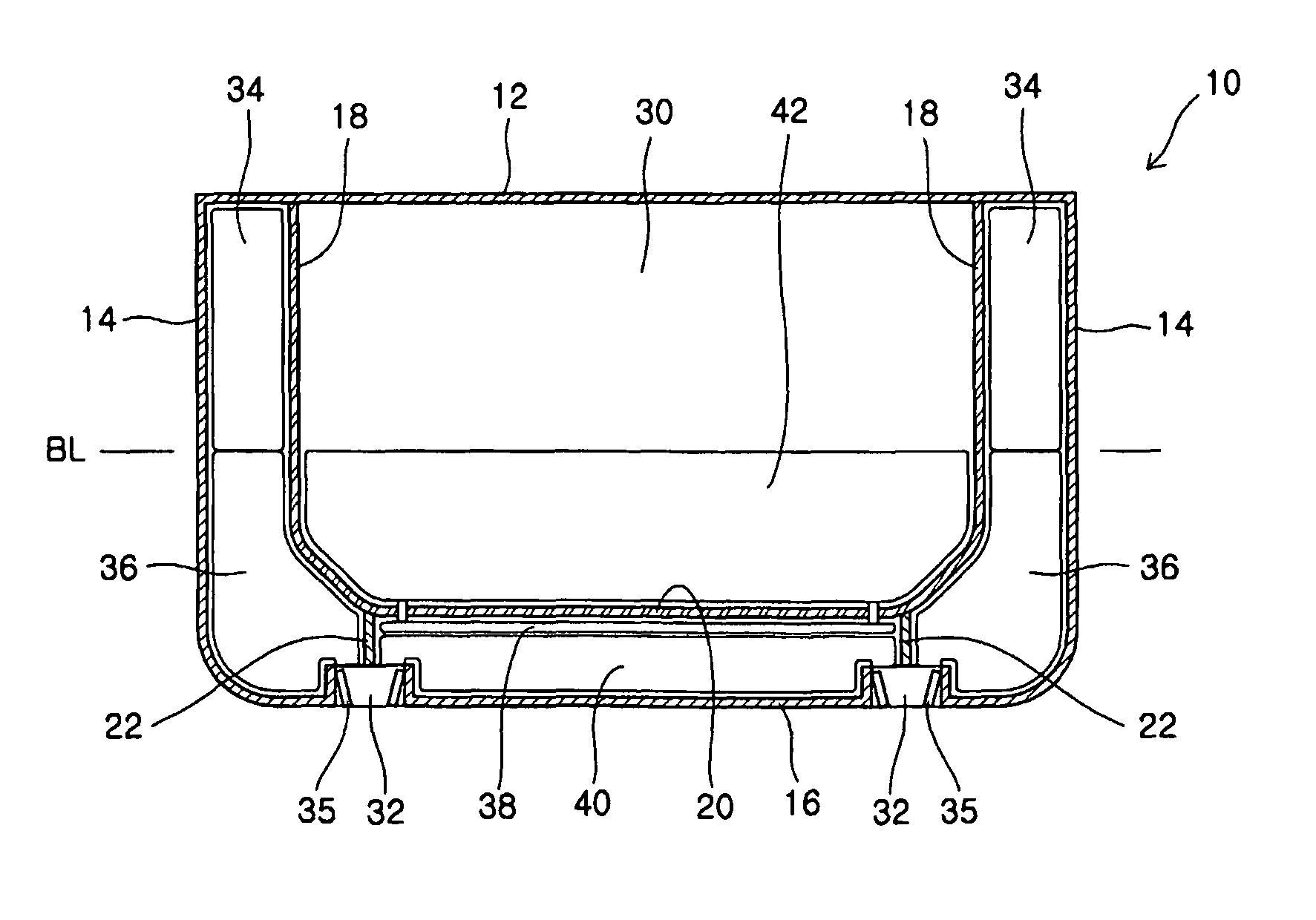

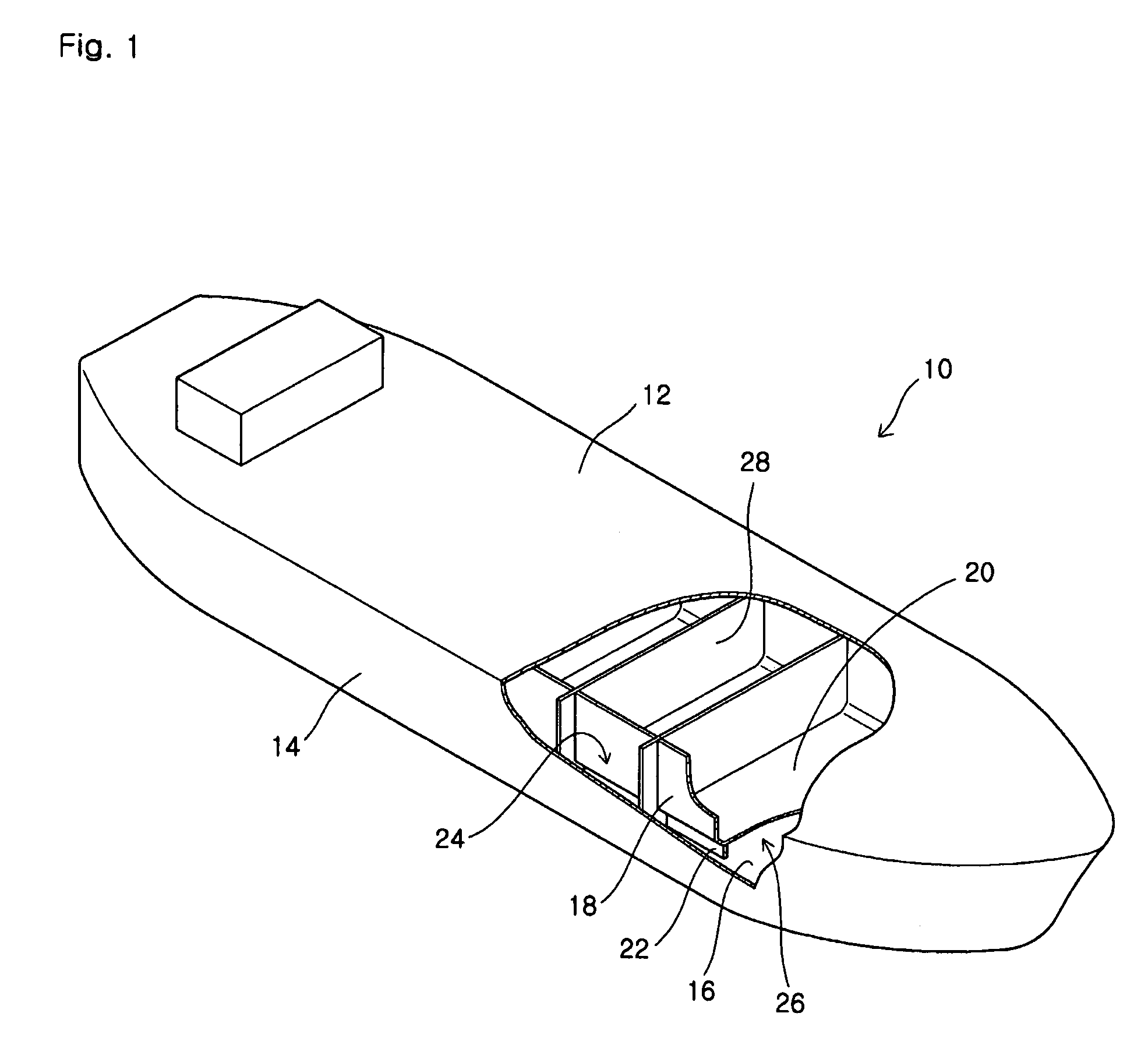

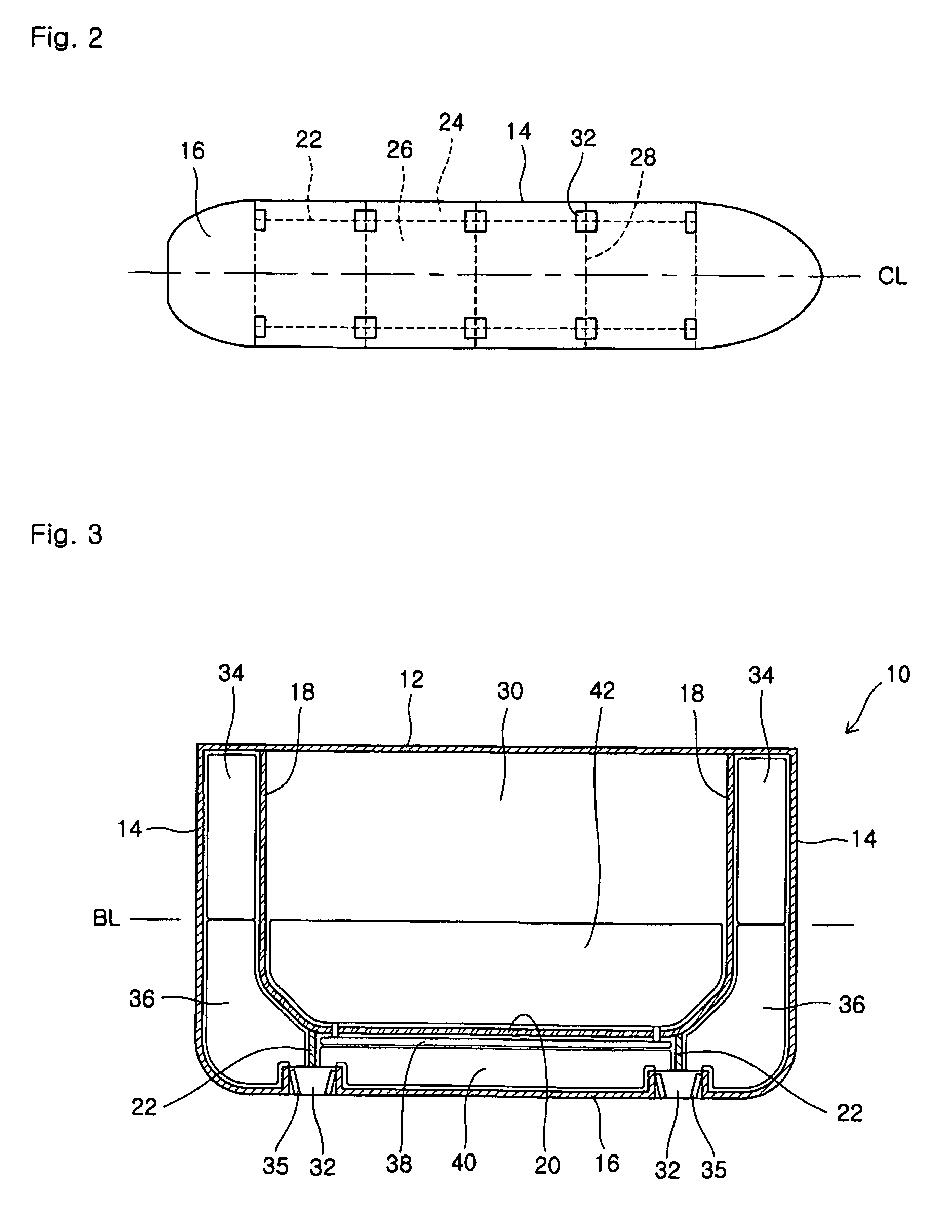

Vessel Including Automatic Ballast System Using Tubes

InactiveUS20090194011A1ContaminationLow costHull interior subdivisionAuxillariesMarine engineeringSeawater

A double-hulled vessel has a ballast draft line previously set at an empty state thereof. The double-hulled vessel of the present invention comprises an outer shell formed on bottom and side portions of the vessel; an inner shell formed on bottom and side portions of the vessel within the outer shell; an air tube positioned between the inner and outer shells; and a seawater tube positioned between the inner and outer shells, wherein seawater holes are formed in the outer shell to be connected to the seawater tube, the seawater tube is capable of containing seawater to substantially fill a space between the inner and outer shells extending from the bottom portion of the vessel up to the ballast draft line of the side portion of the vessel when the vessel is not loaded with cargo, and the air tube is capable of containing air to substantially fill the space between the inner and outer shells of the bottom and side portions of the vessel when the vessel is loaded with cargo.

Owner:KIM YONG KYUNG

Method of producing semiconductor device using resist underlayer film by photo-crosslinking curing

ActiveUS8227172B2Improve homogeneityContaminationPhotosensitive materialsRadiation applicationsLithography processSide chain

There is provided a resist underlayer film forming composition used in a lithography process for producing semiconductor devices. A method of producing a semiconductor device comprising: forming a coating film by applying a resist underlayer film forming composition containing a polymer, a crosslinker and a photoacid generator on a semiconductor substrate; forming an underlayer film by irradiating light to the coating film; and forming a photoresist by applying a photoresist composition on the underlayer film and heating the resultant layer. The polymer polymer is a polymer having a benzene ring or a hetero ring in a main chain or a side chain bonded to the main chain, and the content rate of a benzene ring in the polymer is 30 to 70% by mass. The polymer may be a polymer containing a lactone structure.

Owner:NISSAN CHEM CORP

Method and device for dispensing sealant and LCD panel

ActiveUS8223308B2Satisfactory adhesive strengthShorten the curing timeOpening closed containersBottle/container closureSealantLiquid crystal

The method for dispensing sealant comprises: preparing an inner-side sealant that comprises a light curing sealant or a first mixture of a light curing sealant and a thermal curing sealant in which the content of the light curing sealant is more than that of the thermal curing sealant; preparing an outer-side sealant that comprises a thermal curing sealant or a second mixture of a light curing sealant and a thermal curing sealant in which the composition of the light curing sealant is less than or equal to that of the thermal curing sealant; simultaneously dispensing the inner-side sealant and the outer-side sealant onto a substrate along four edges of the substrate by using a device for dispensing sealant so that one side of the inner-side sealant abuts the sealed liquid crystal materials and the other side thereof integrates with the outer-side sealant.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

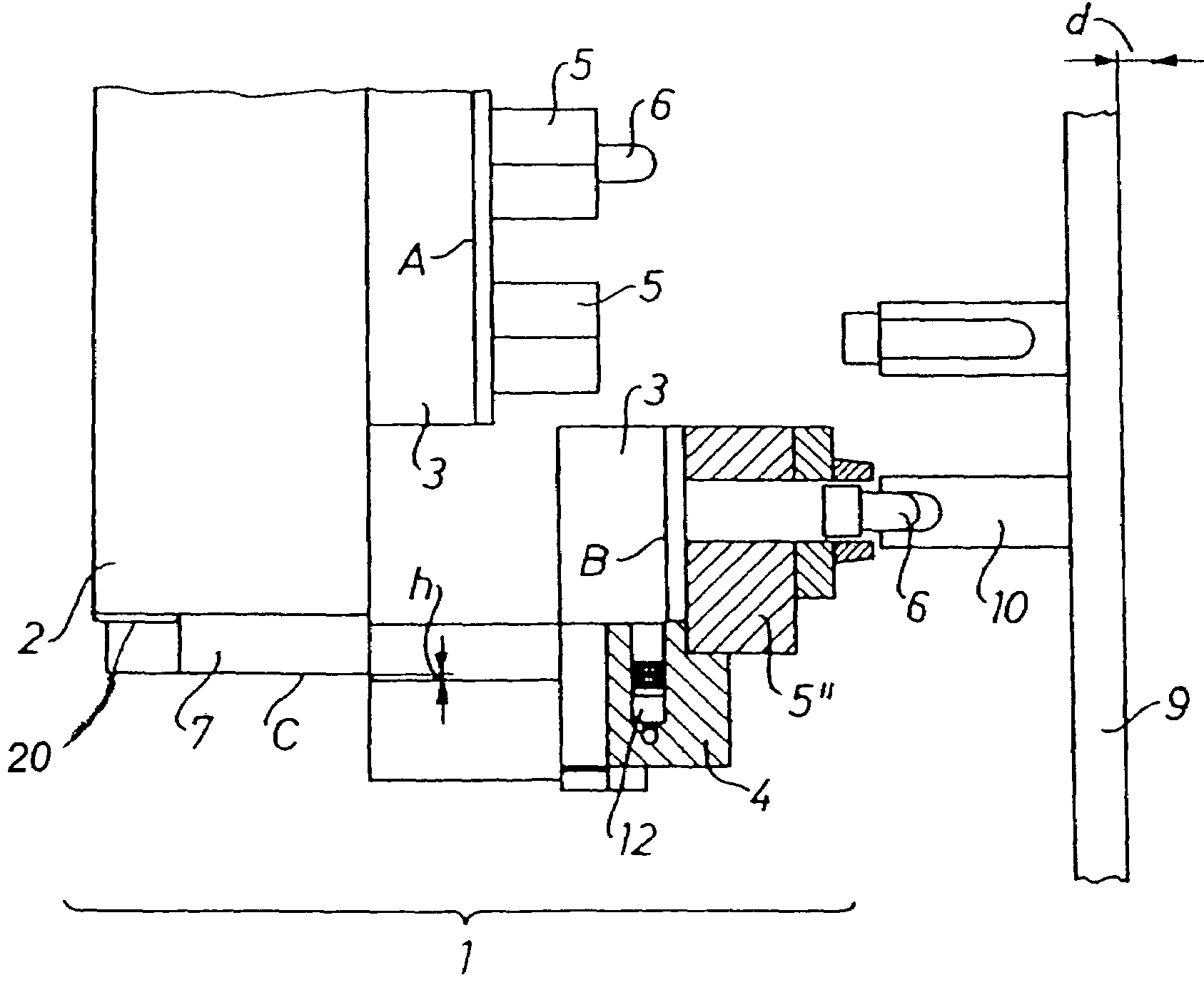

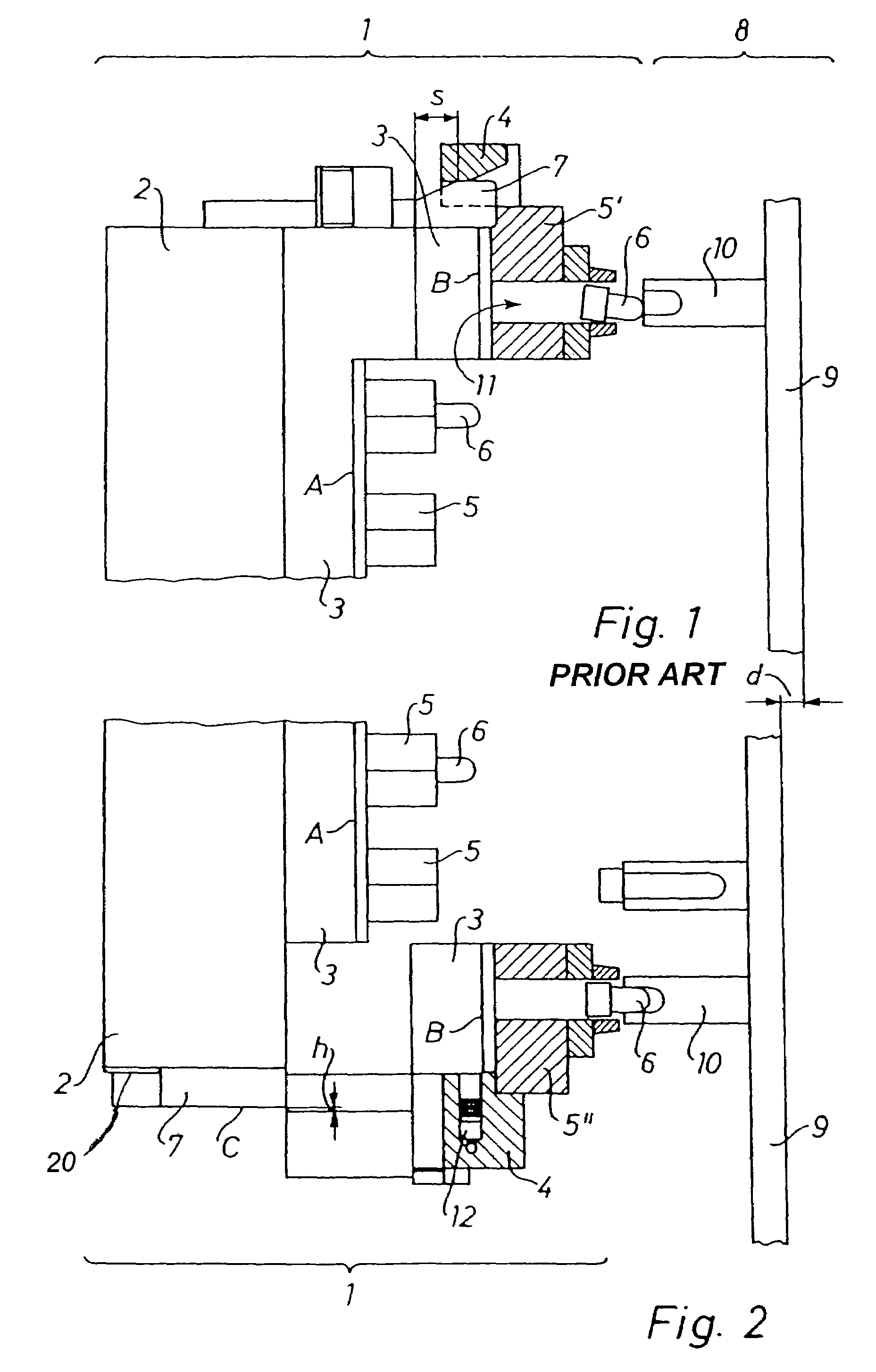

Hydraulic system for a slide

Owner:OTTO HOFSTETTER WERKZEUG UND FORMENBAU

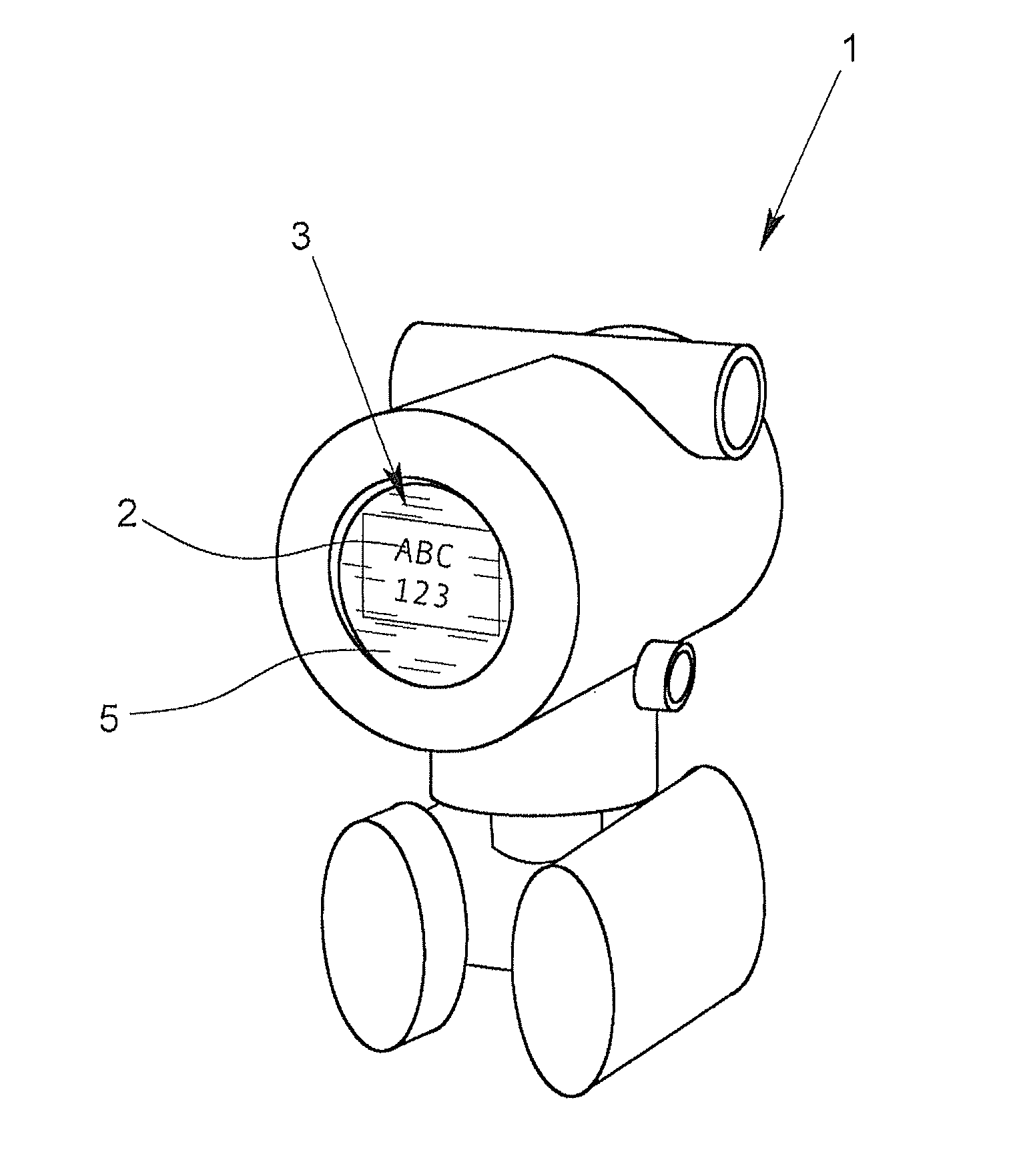

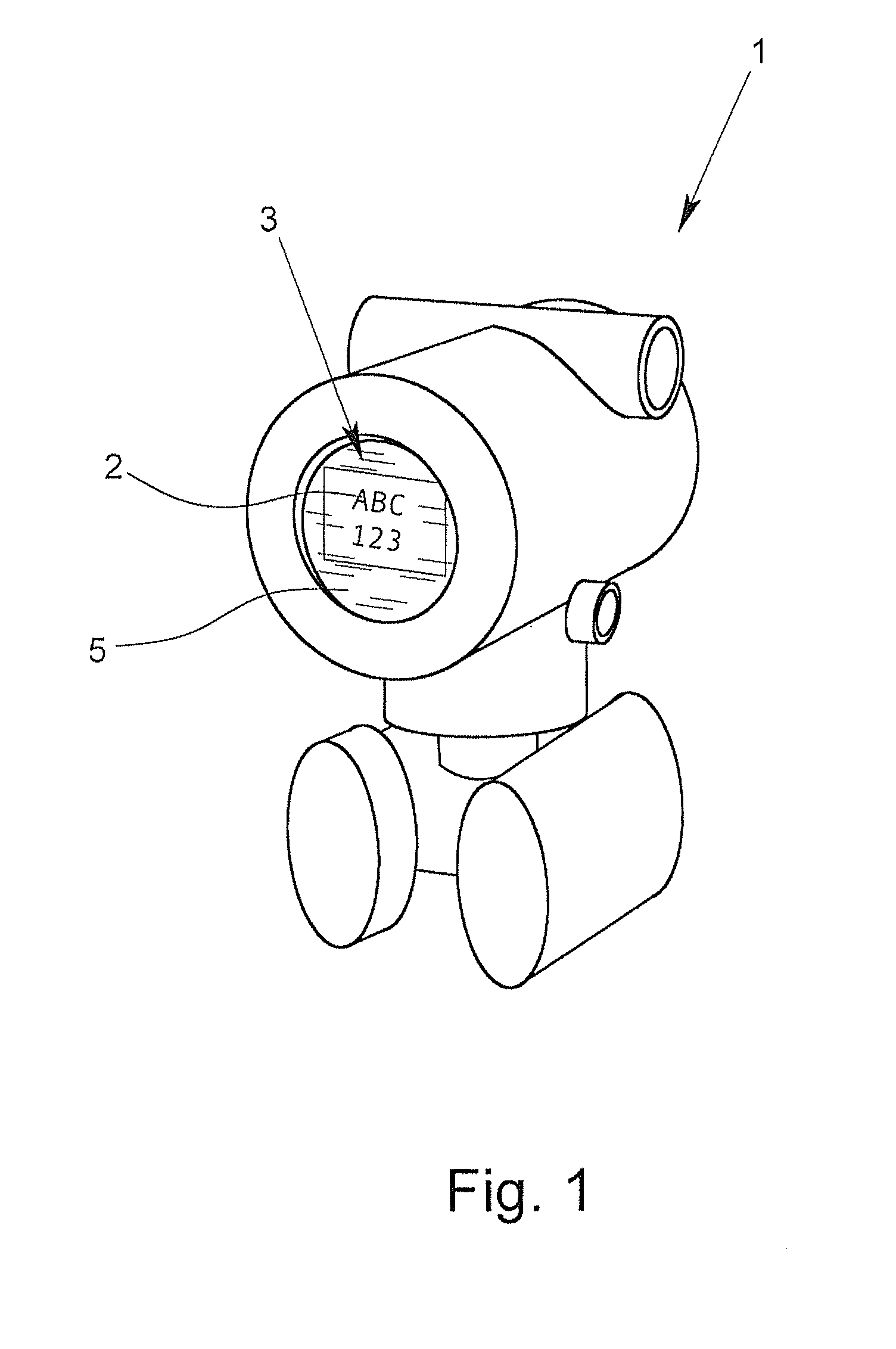

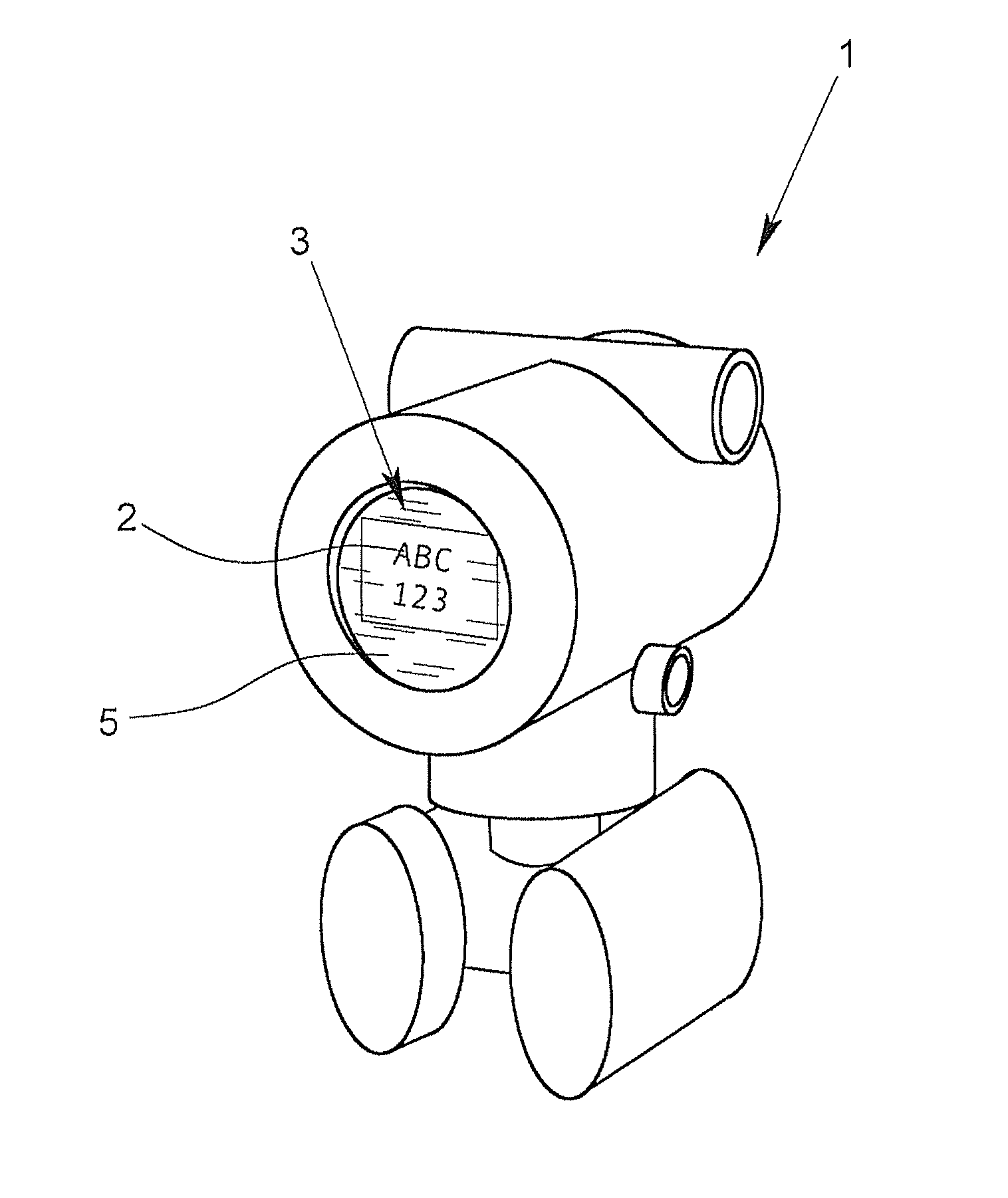

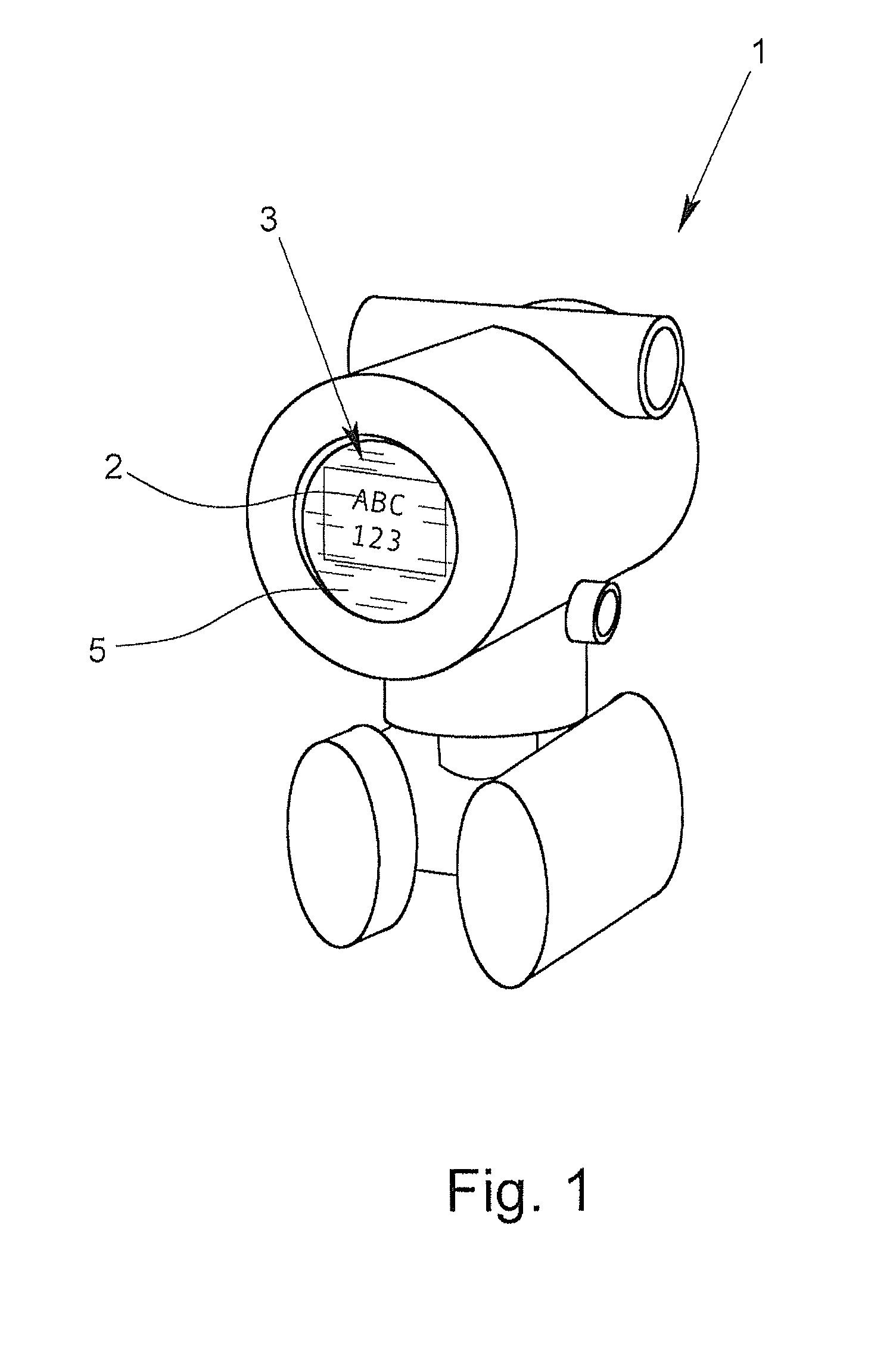

Measuring Instrument Housing with a Display Panel

InactiveUS20130255375A1Improved resin sealingSolving the Insufficiency of ElasticityFluid pressure measurementSpeed/acceleration/shock instrument detailsMeasuring instrumentInstrumentation

An intrinsically safe housing for a measuring instrument, having a viewing window for the display panel of a measuring instrument, an instrument display panel holding fixture for receiving an instrument display panel provided around the viewing window, said holding fixture having an inner void having a volume greater than a volume of the instrument display panel, a difference between said volumes forming a resin slot surrounding the instrument display panel upon its insertion, and a seal holding fixture provided around the viewing window containing a seal for sealing a front surface of said display panel, wherein the seal and the display panel holding fixture form a resin receptacle for a flowable resin, and the resin slot receives an overflow of said resin upon insertion of said instrument display panel.

Owner:KROHNE MESSTECHNICK GMBH & CO KG

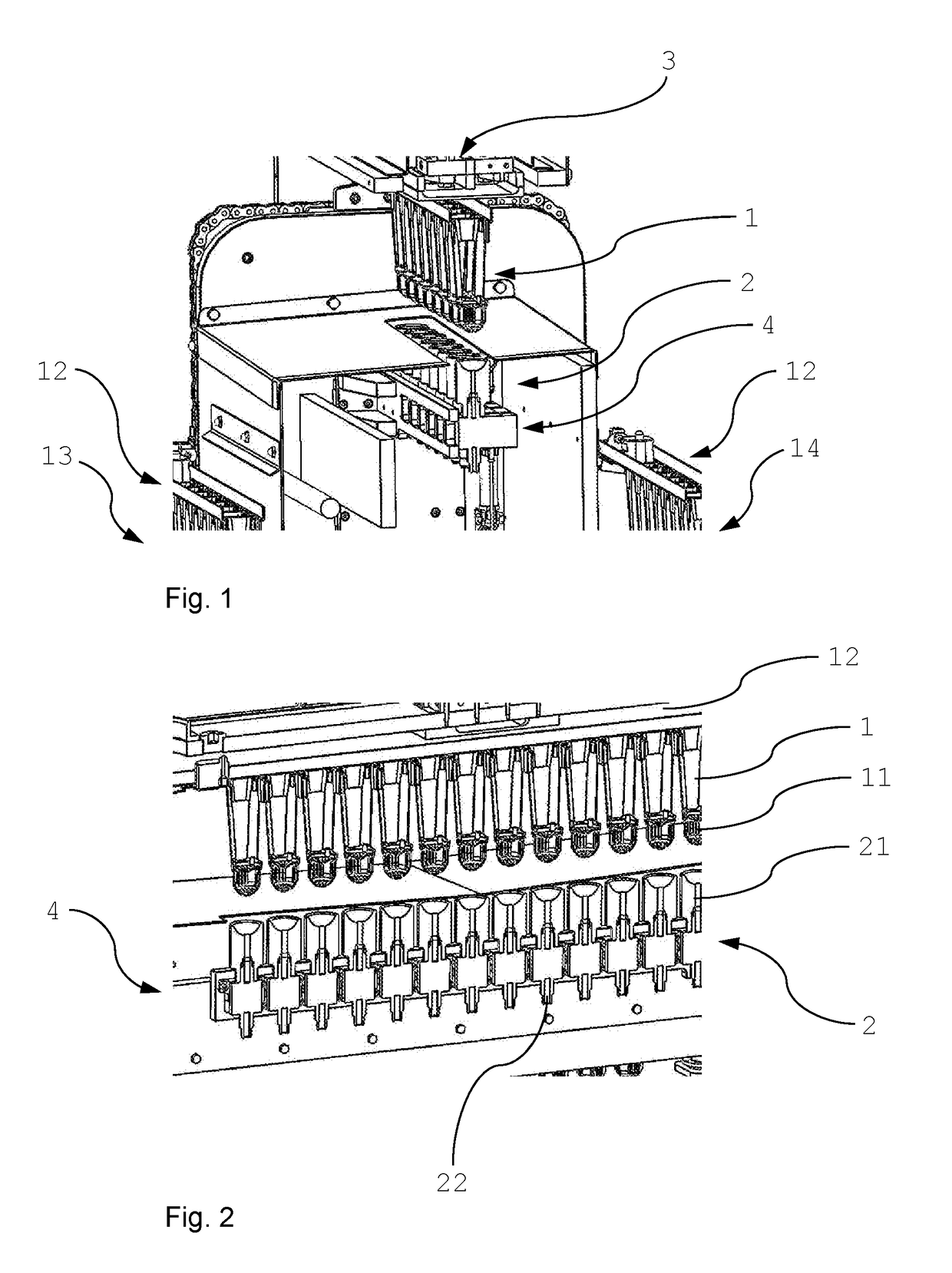

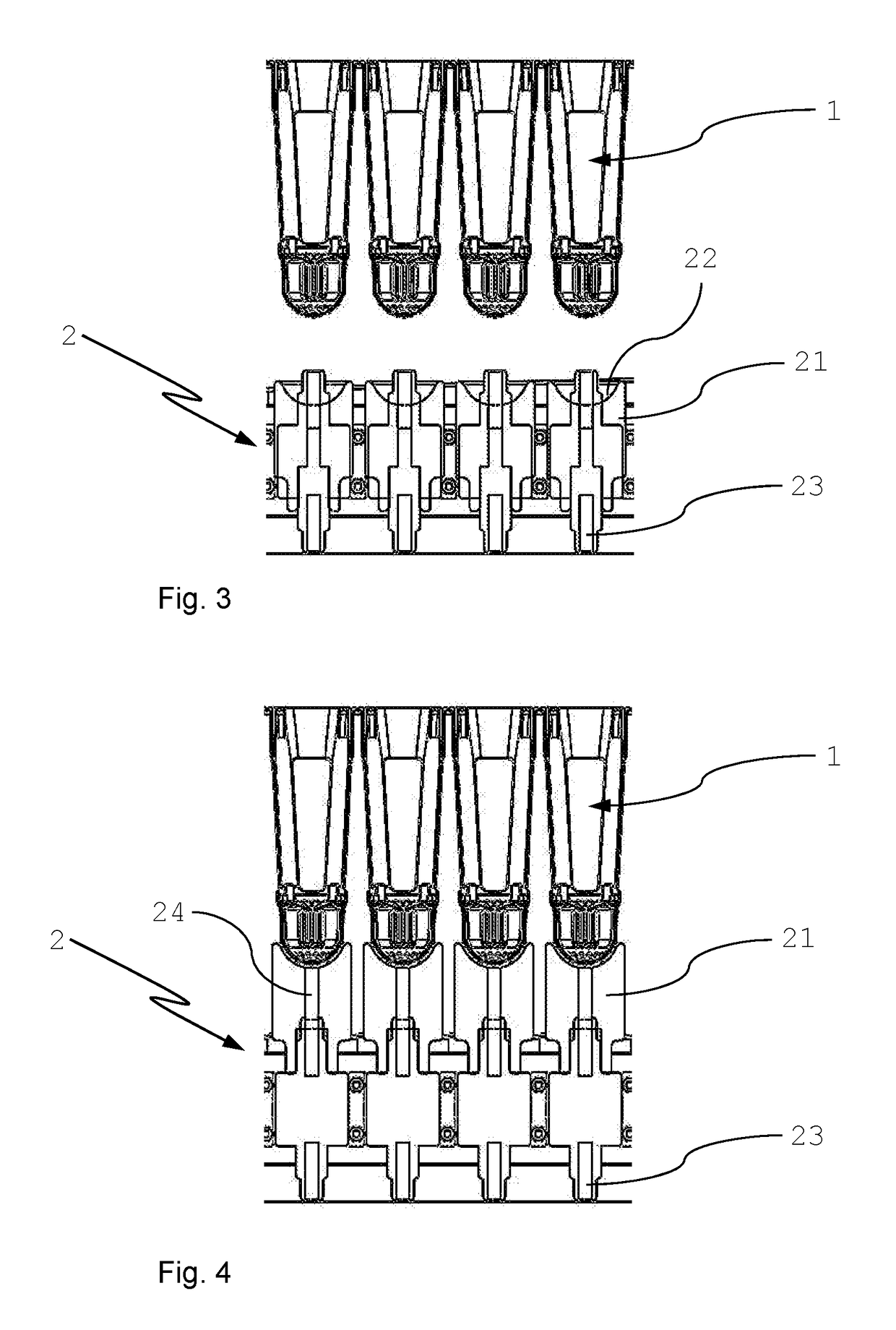

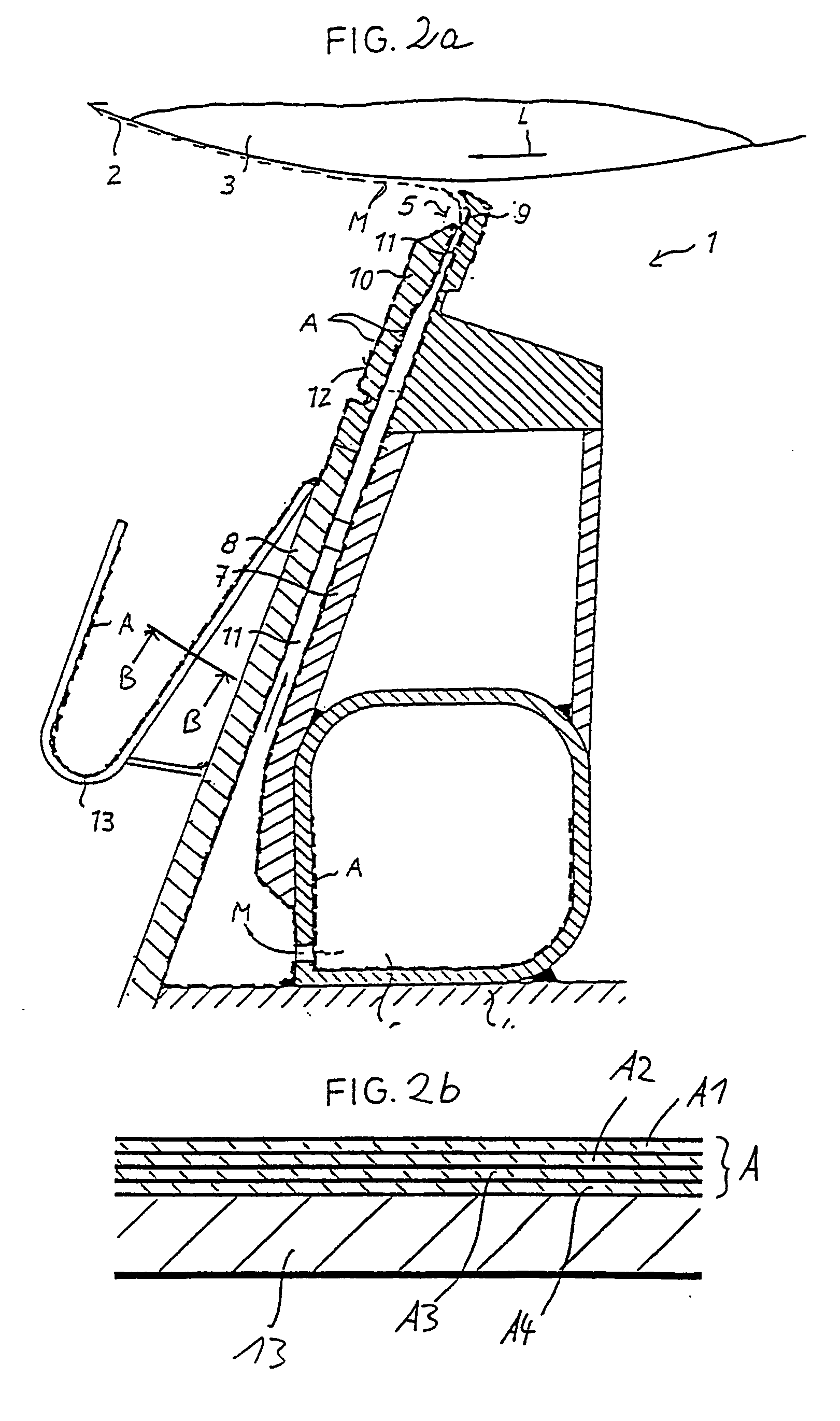

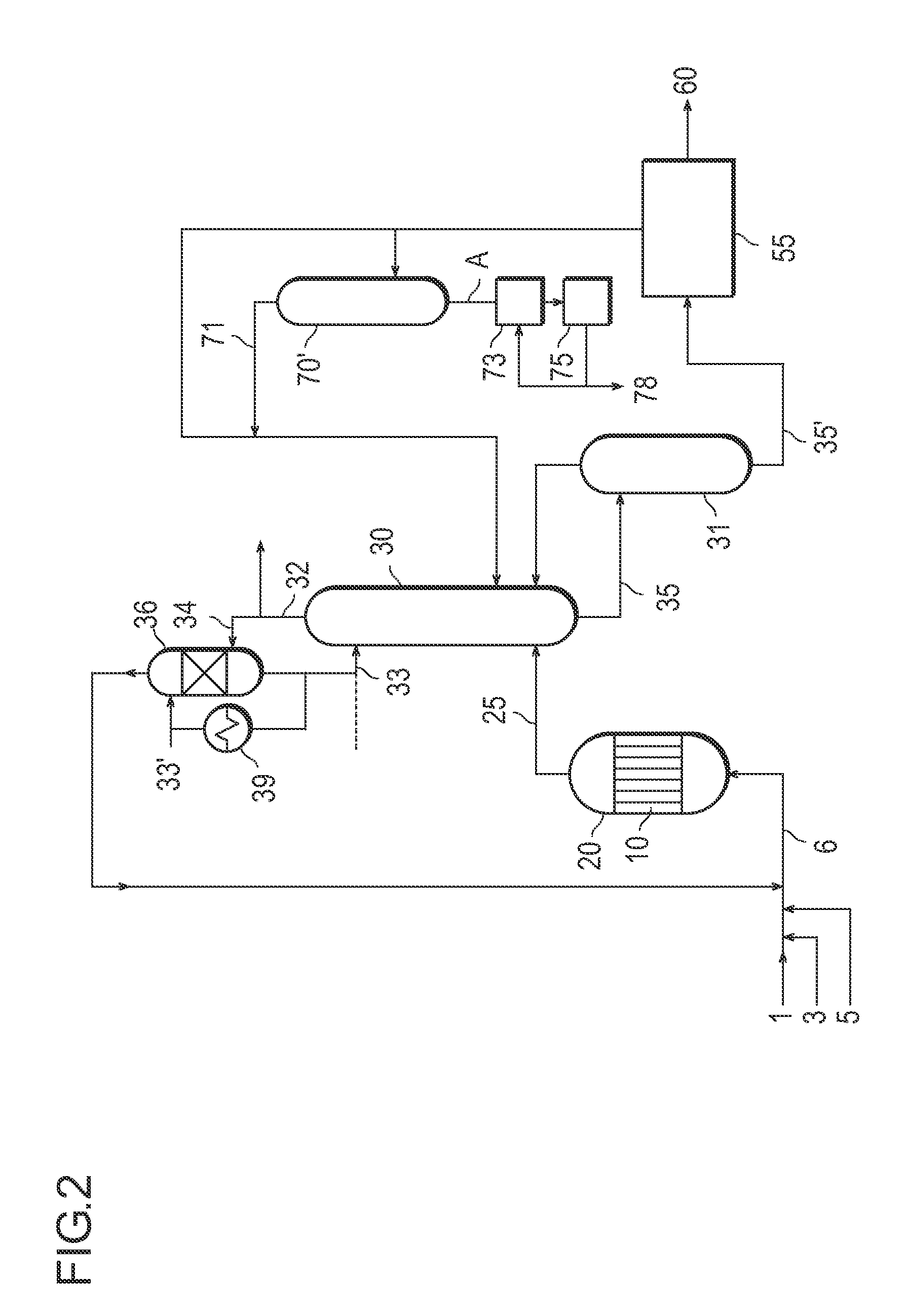

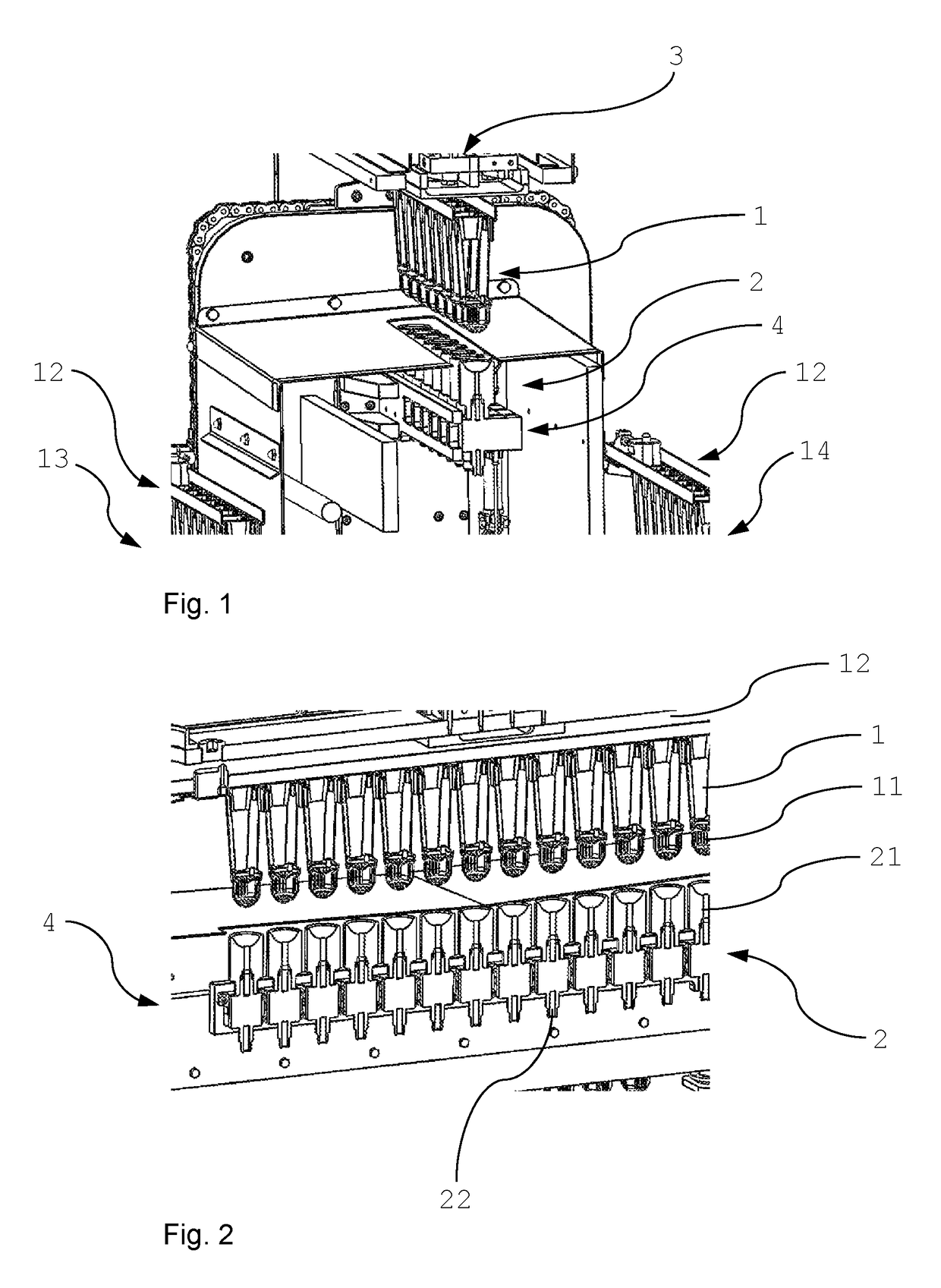

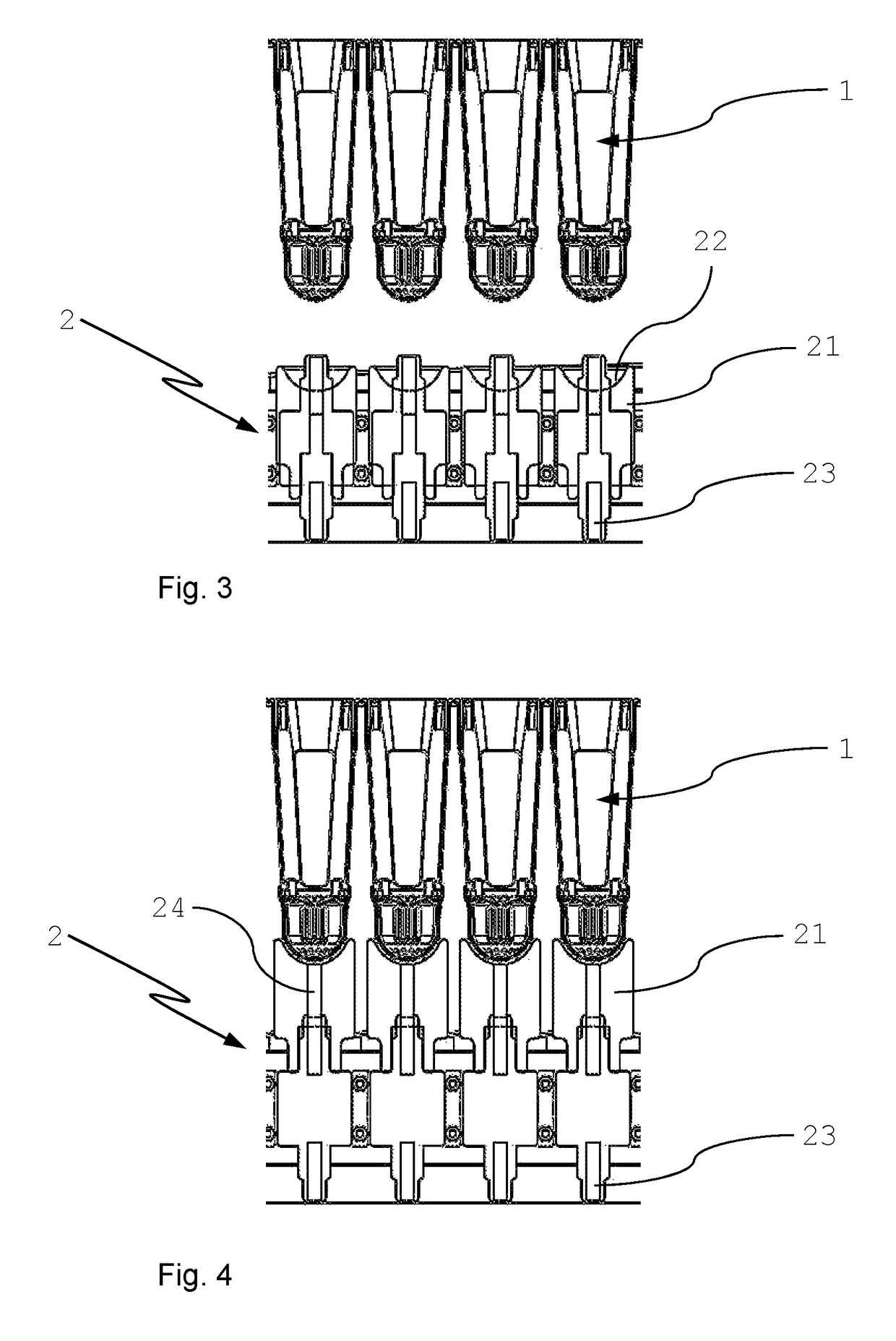

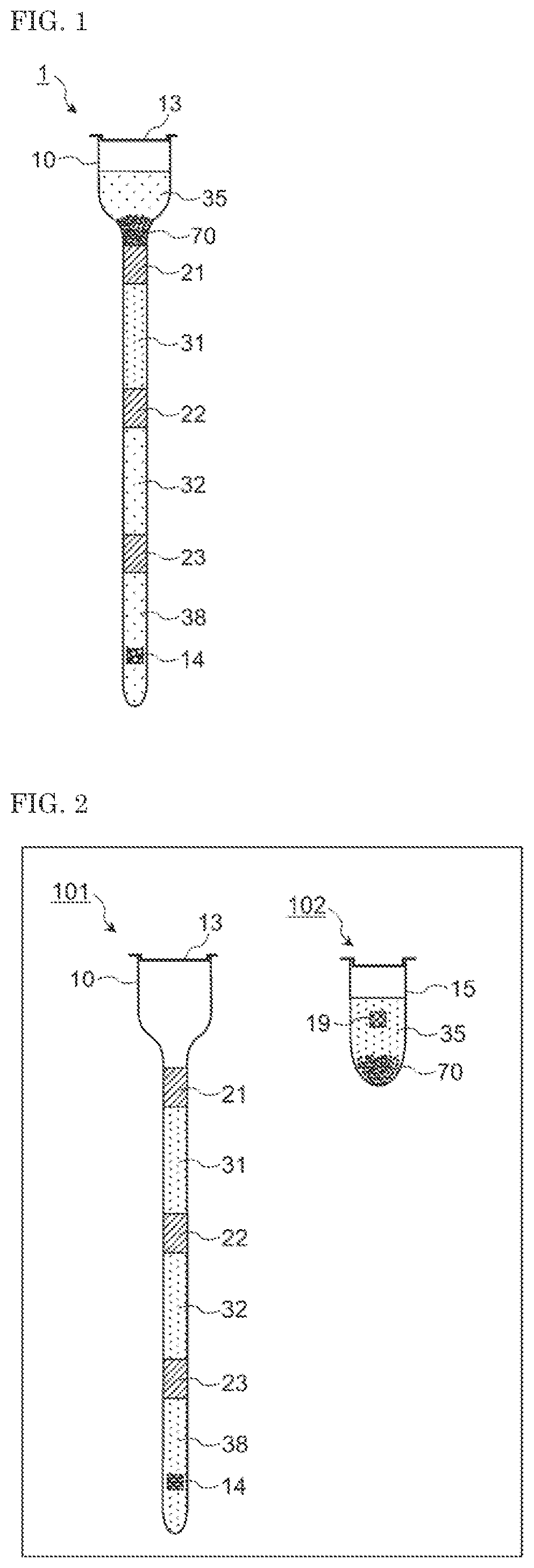

Method and system for removing a liquid from a container for accommodating an ophthalmic lens

ActiveUS20170165393A1Effective treatmentEfficient removalDrying solid materials without heatOptical articlesEngineeringShipping container

A method of removing a liquid from a container (1) for accommodating an ophthalmic contact lens, in particular a soft contact lens, during transporting the container (1) from a liquid bath (13) to a subsequent processing station (14), the method including the steps of:transporting the container (1) from the liquid bath to the subsequent processing station,generating suction (20), andapplying the suction (20) to a bottom (11) of the container (1) during the step of transporting the container (1) from the liquid bath to the subsequent processing station, thereby removing the liquid from the container (1).

Owner:ALCON INC

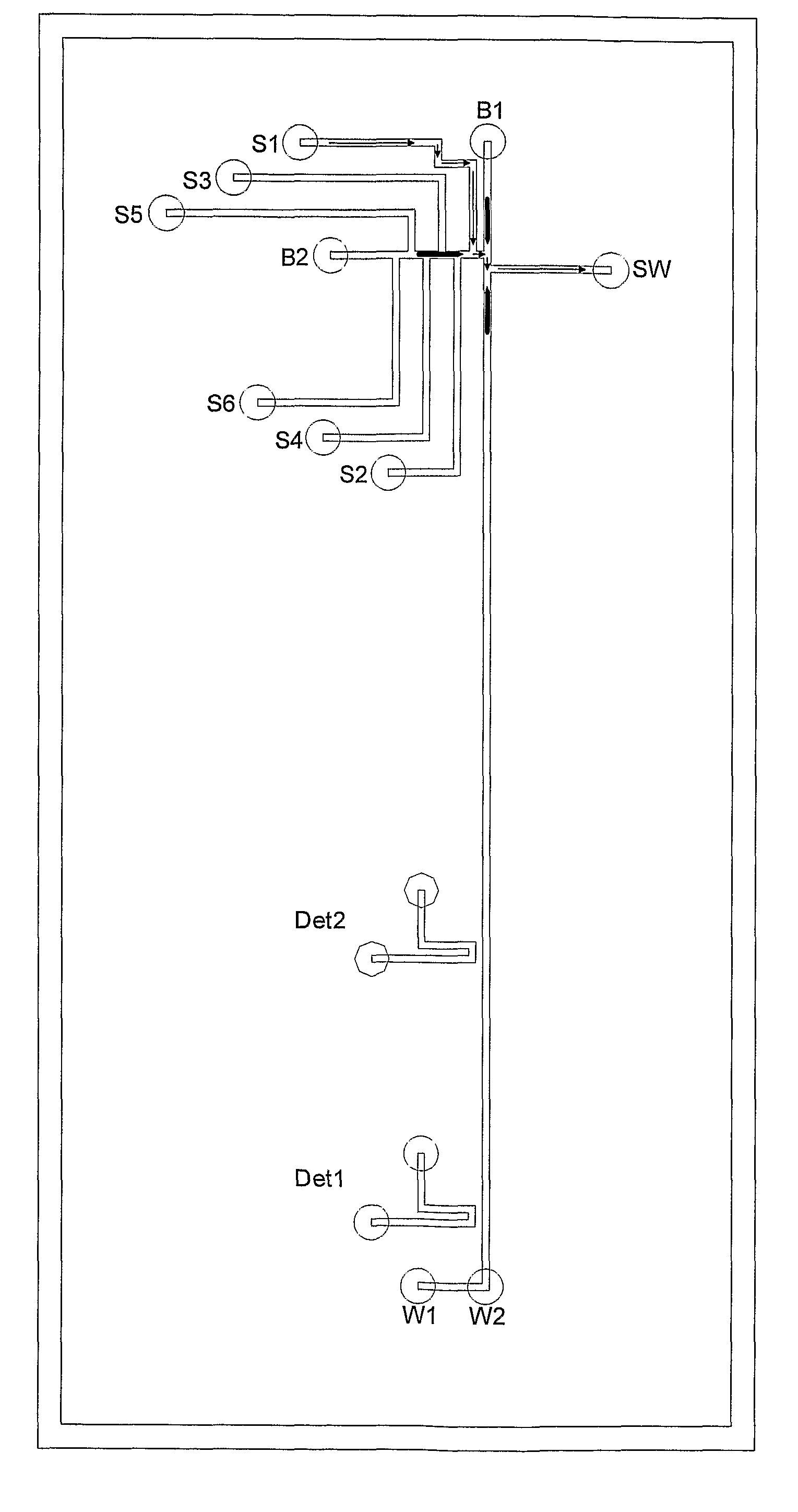

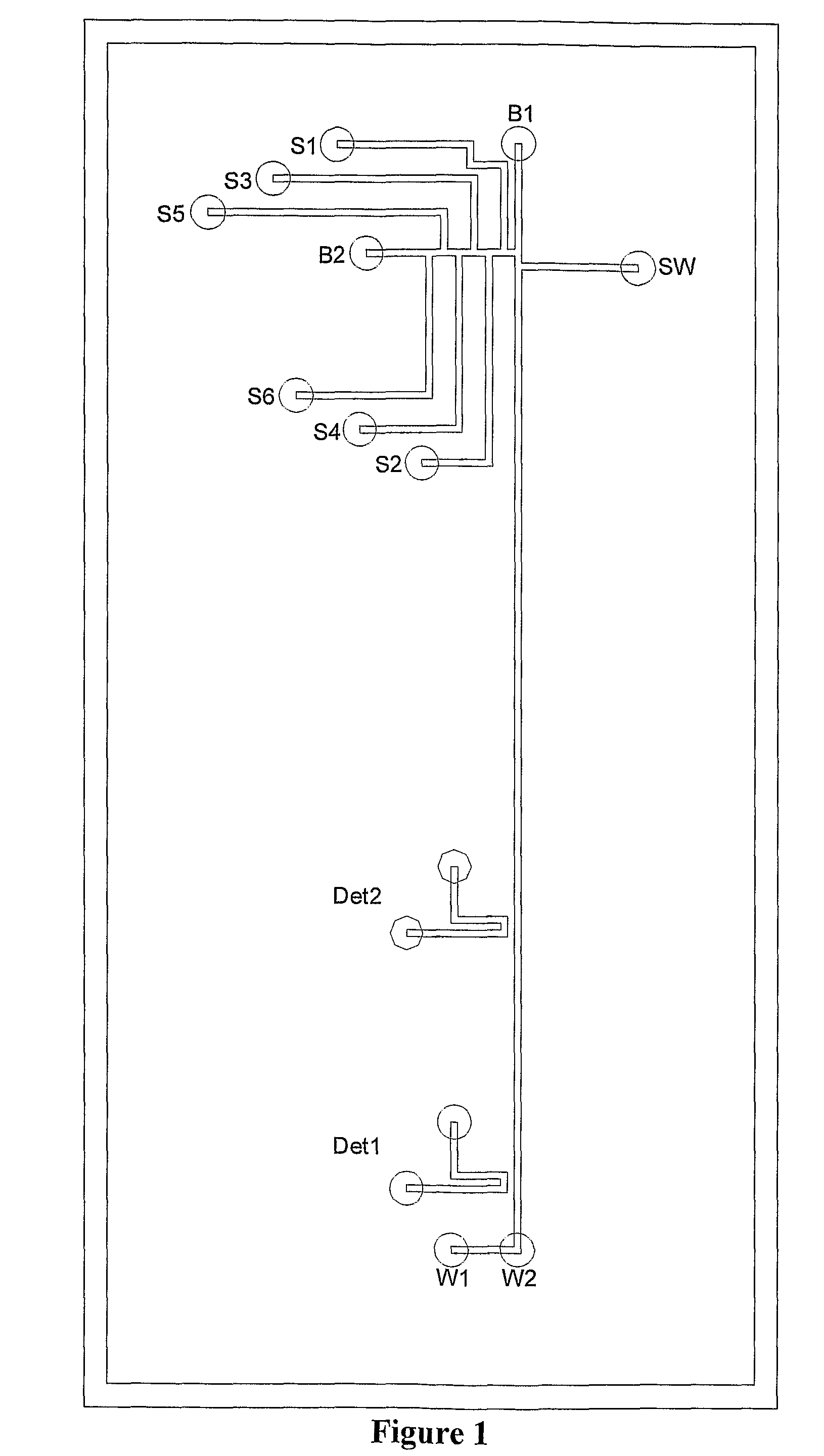

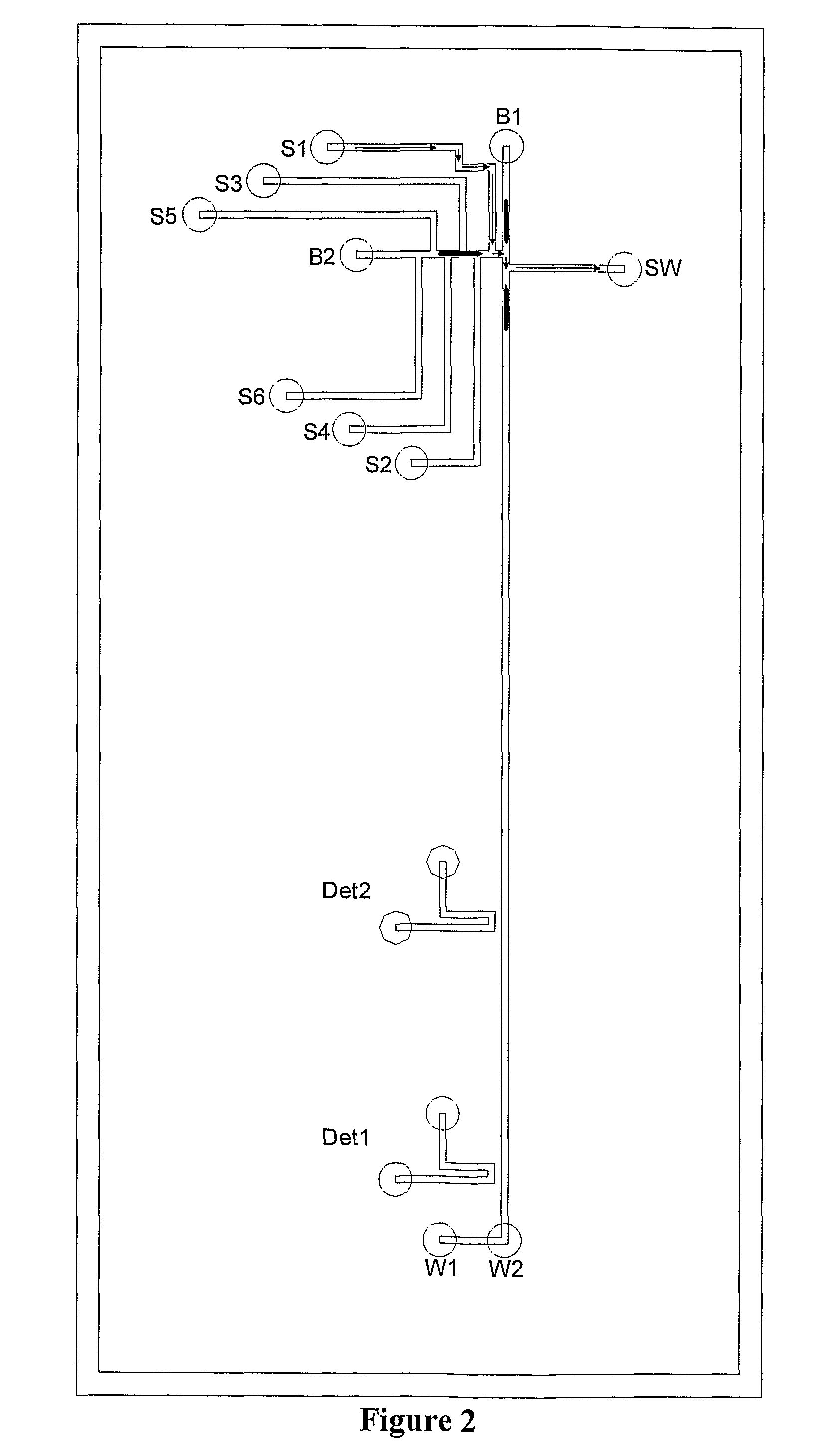

Multi-channel capillary electrophoresis microchips and uses thereof

InactiveUS20090127114A1ContaminationAvoid pollutionSludge treatmentVolume/mass flow measurementCapillary electrophoresisElectrophoresis

A multi-channel capillary electrophoresis microchip for analysis of multiple samples comprising: at least two sample reservoirs, at least two sample channels corresponding to said sample reservoirs, a sample buffer reservoir, a sample waste reservoir, a separation buffer reservoir, a separation waste reservoir, a sample loading channel, and a separation channel, wherein each of said sample channels is connected at one end to said sample loading channel at a place between said sample buffer reservoir and said intersection of said sample loading channel and said separation channel, and the other end of each of said sample channels is connected to each of said sample reservoirs. A method of capillary electrophoresis separation for sequentially analysis of multiple samples.

Owner:CAPITALBIO CORP +1

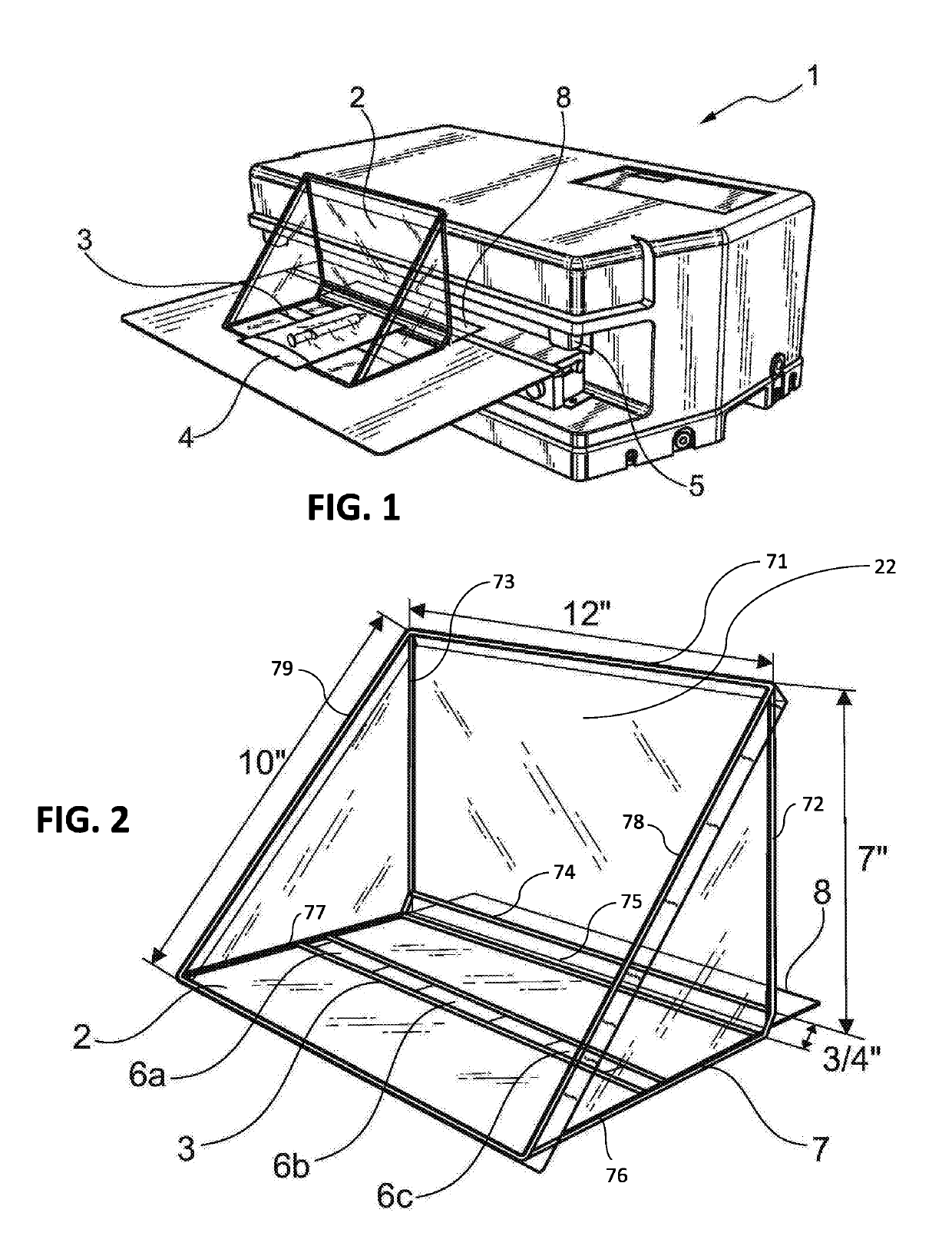

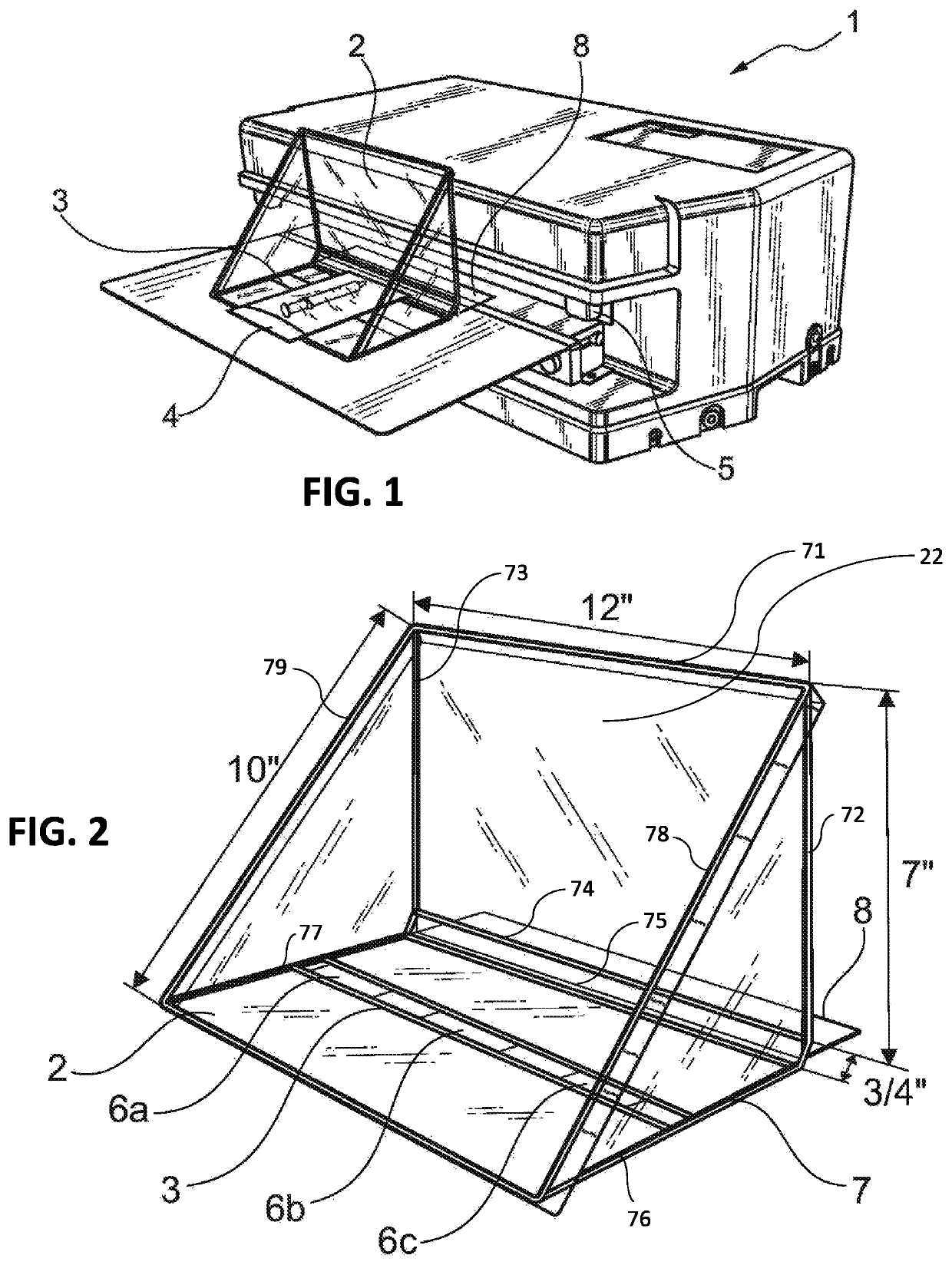

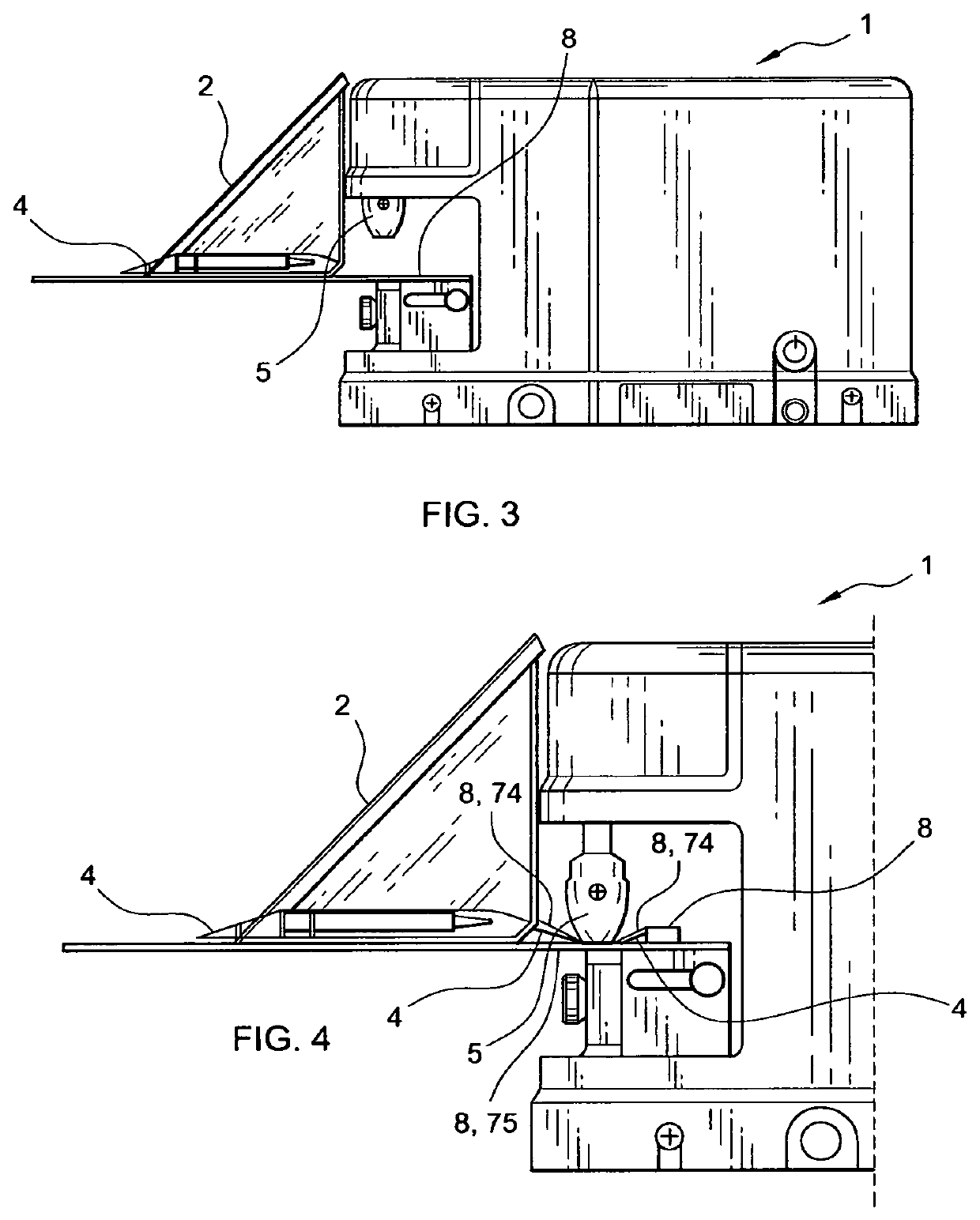

Human Tissue Isolation Pouch For Use With Pouch Sealer

ActiveUS20190092506A1Avoid pollutionAvoid cross contaminationDead animal preservationWrapper twisting/gatheringHumans tissuesContamination

A human tissue isolation pouch for use with a sealer machine to indirectly seal human tissue medical pouches while avoiding cross contamination is herein disclosed. The human tissue isolation pouch comprises a rigid frame supporting a high temperature material and having one or more magnets for removably attaching the human tissue isolation pouch to a sealer machine.During use a medical pouch, which may contain a human tissue sample, is inserted within the human tissue isolation pouch. The jaws of the sealer machine clamp down directly on the high temperature material, thus indirectly heating and sealing the medical pouch inside the human tissue isolation pouch. The sealing machine jaws do not physically contact the medical pouch at any time during the sealing process, and in this way contamination of the sealer machine (and cross contamination of medical pouches from distinct donor cases) is avoided. The rigid frame of the human tissue isolation pouch may be sterilized after each donor event. And the containment bag formed of a high temperature material may be disposed of after each donor event.

Owner:VAN DER STAHL SCI

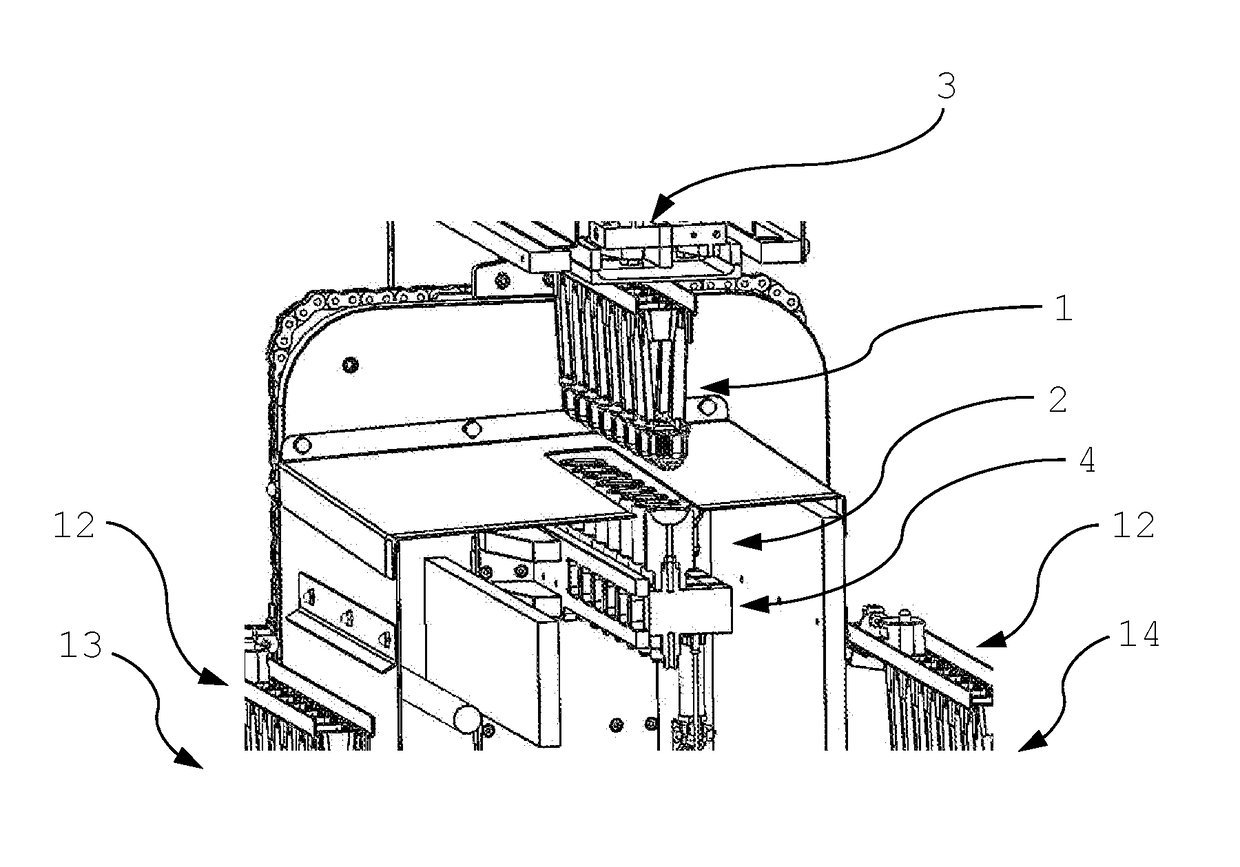

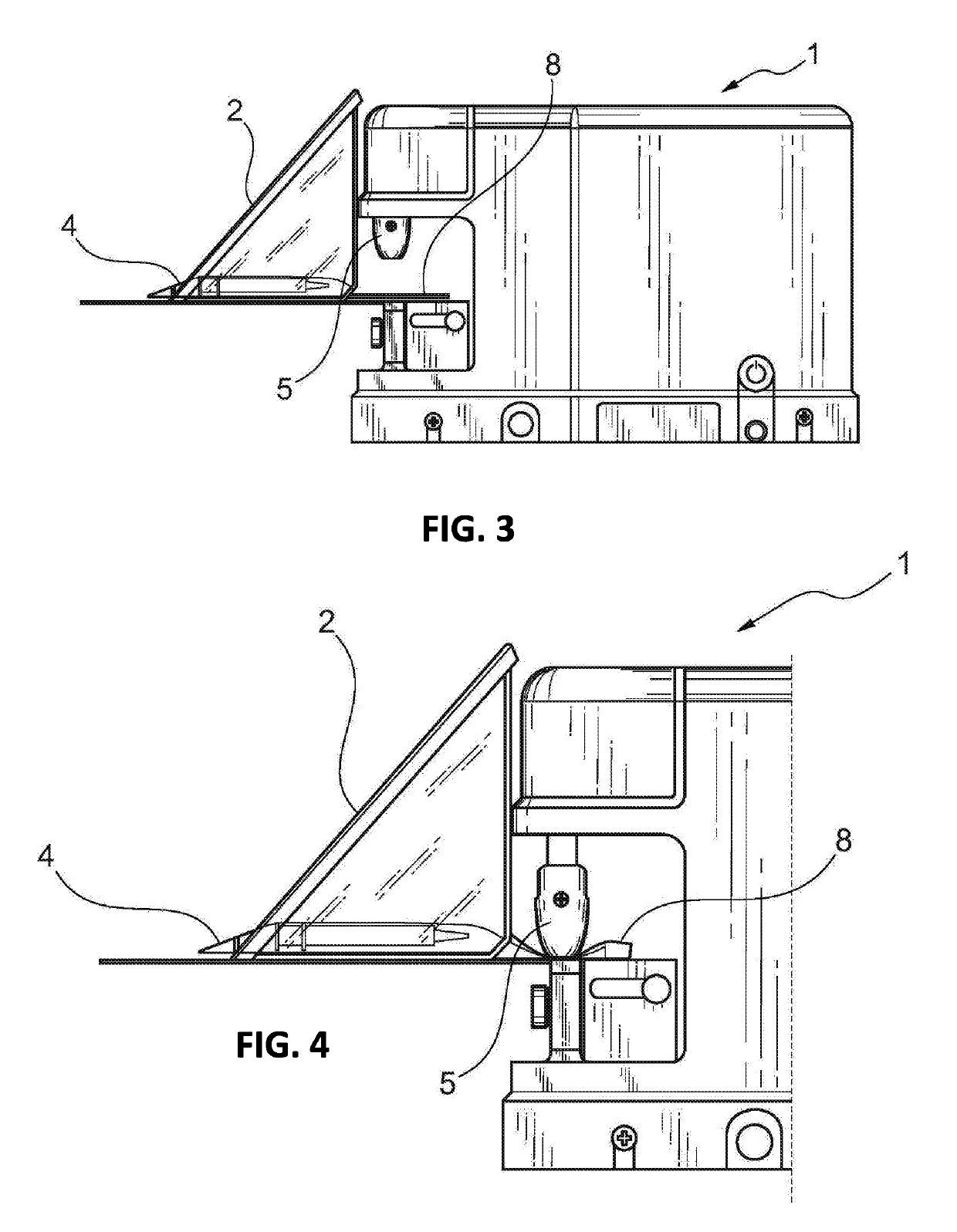

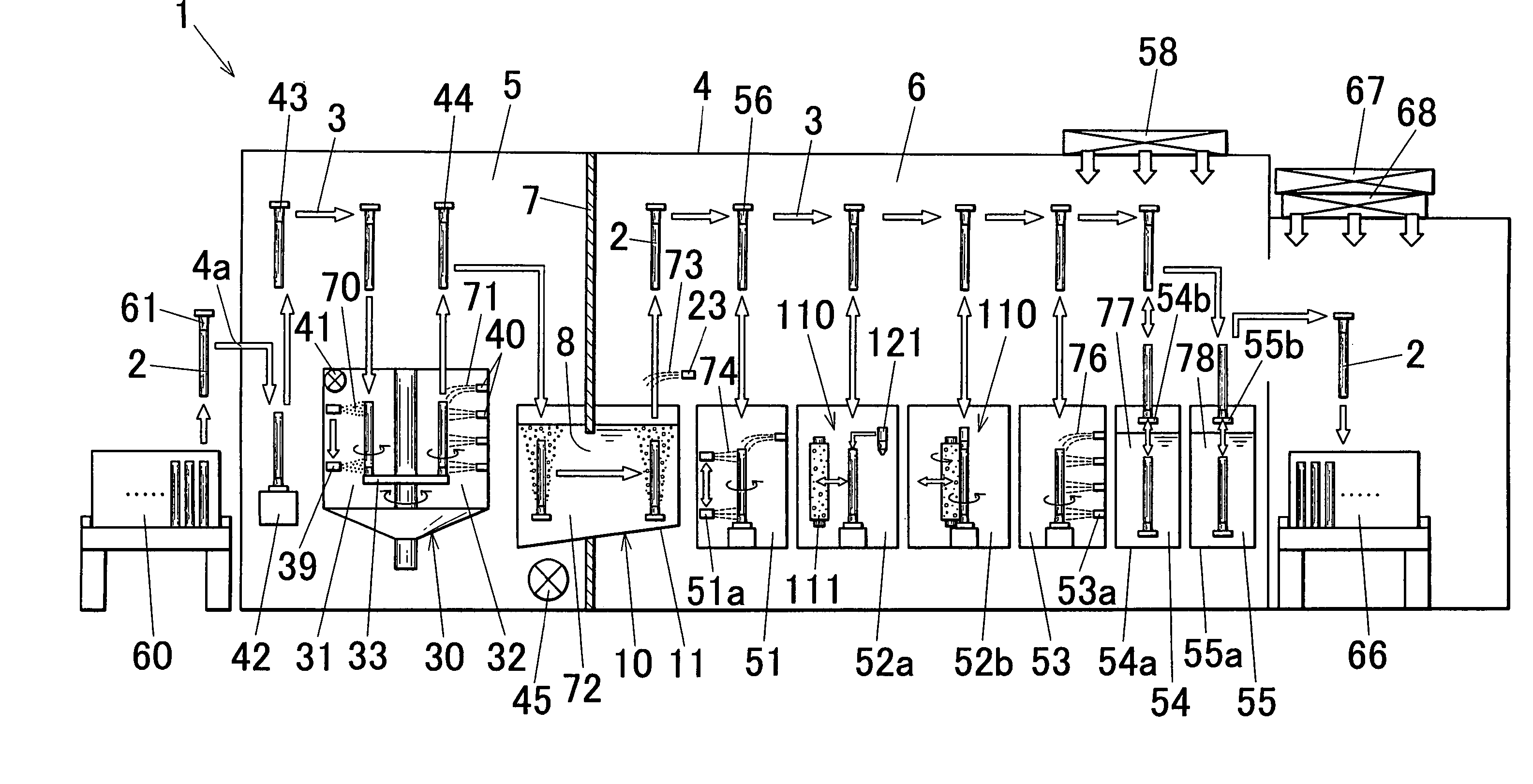

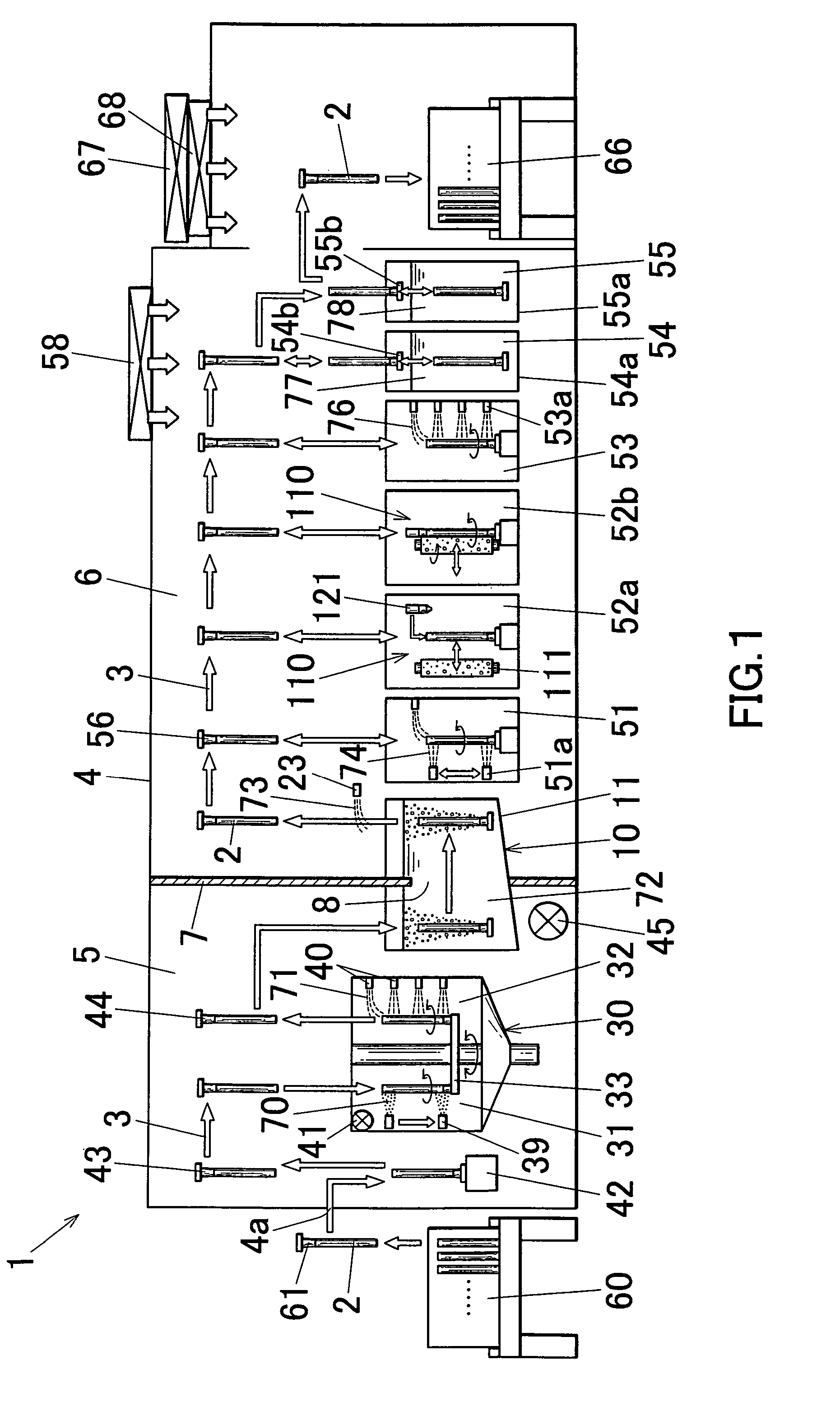

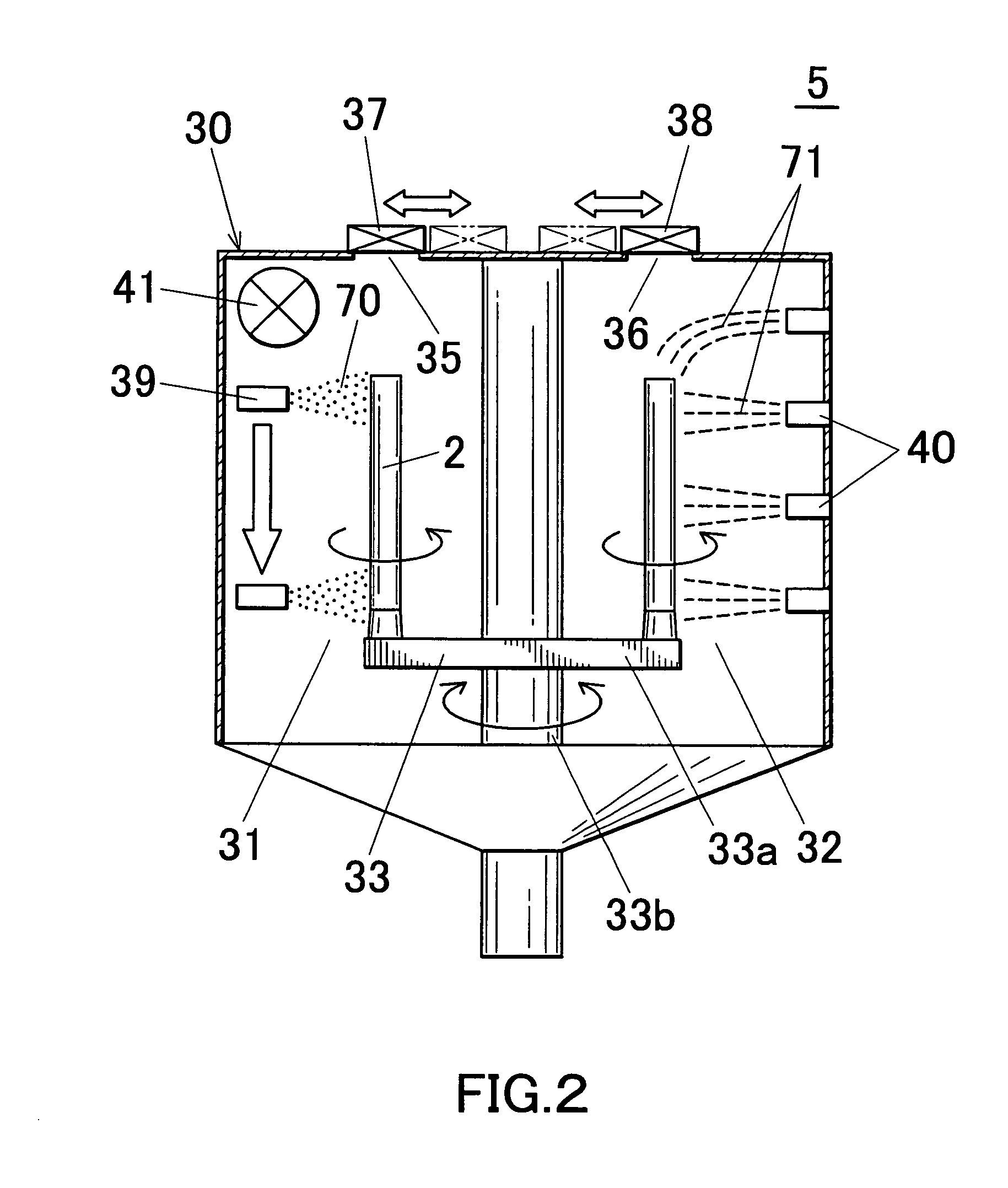

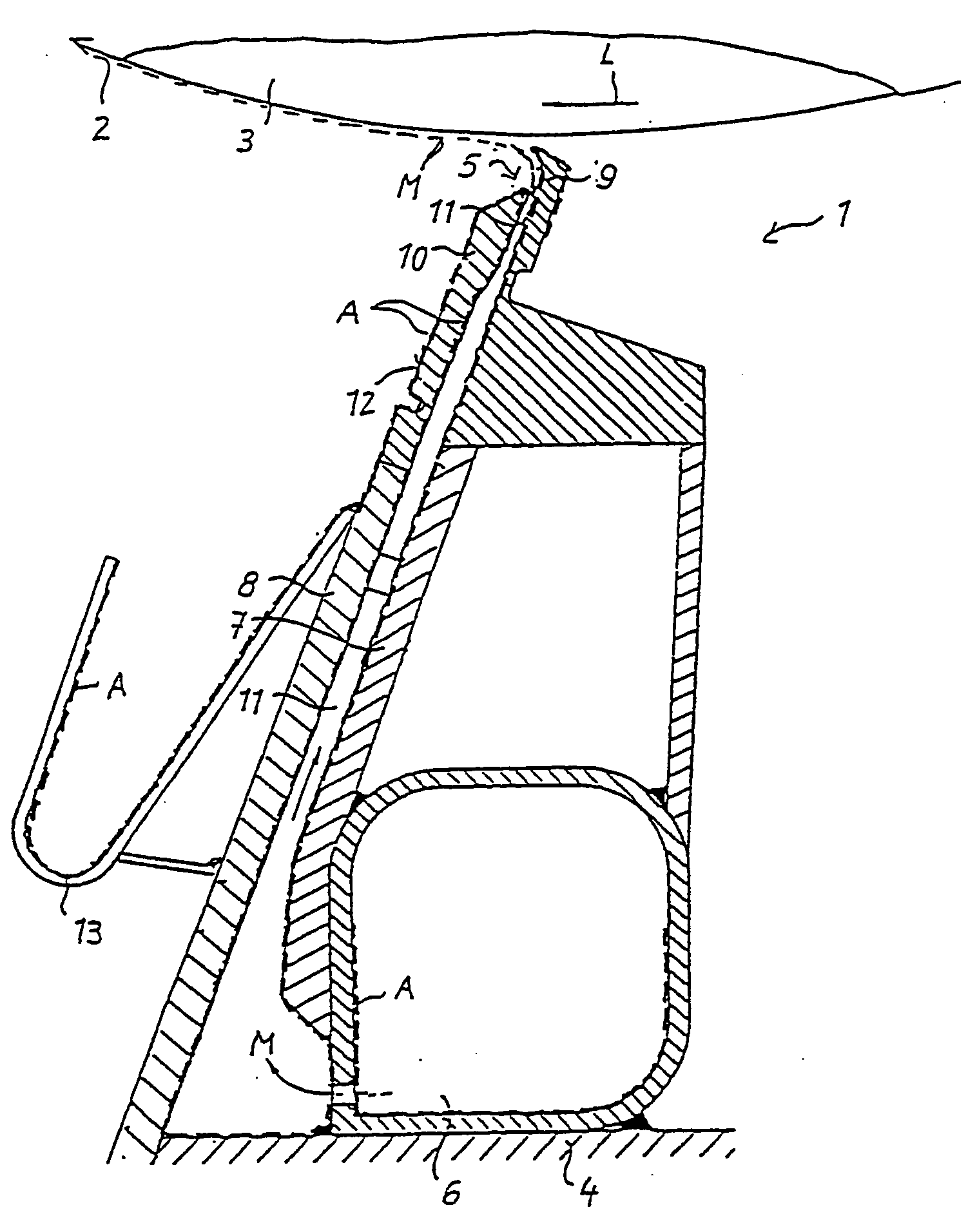

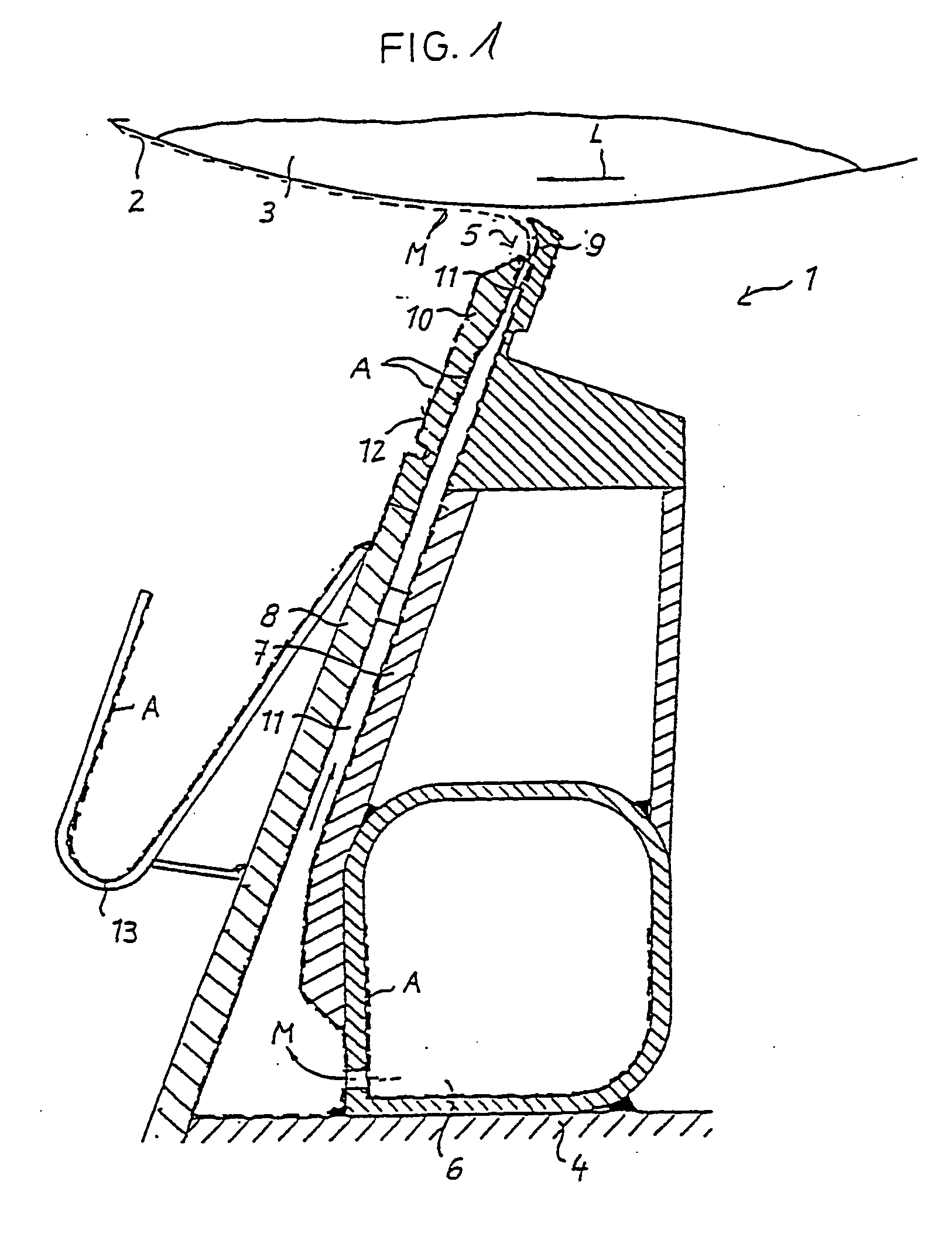

Liquid honing machine and liquid honing method

InactiveUS20060128275A1Avoid it happening againAvoid defectsEdge grinding machinesAbrasive machine appurtenancesProcess engineeringThermodynamics

A honing machine 1 is provided with a honing zone 5 for subjecting a work 2 to a liquid honing process and a washing zone 6 for subjecting the work 2 to which the liquid honing process was executed at the honing zone 5 to a washing process in a housing 4 shielded from an external air, the honing zone 5 and the washing zone 6 being disposed adjacently. A partition wall 7 for preventing an ambient gas of the honing zone 5 from entering into the washing zone 6 is disposed between the honing zone 5 and the washing zone 6 in the housing 4. An in-liquid conveying apparatus 10 for conveying the work 2 to which the liquid honing process was executed at the honing zone 5 from the honing zone 5 to the washing zone 6 with the work kept immersed in the liquid 72 in a carrying bath 11 is disposed in the housing 4.

Owner:SHOWA DENKO KK

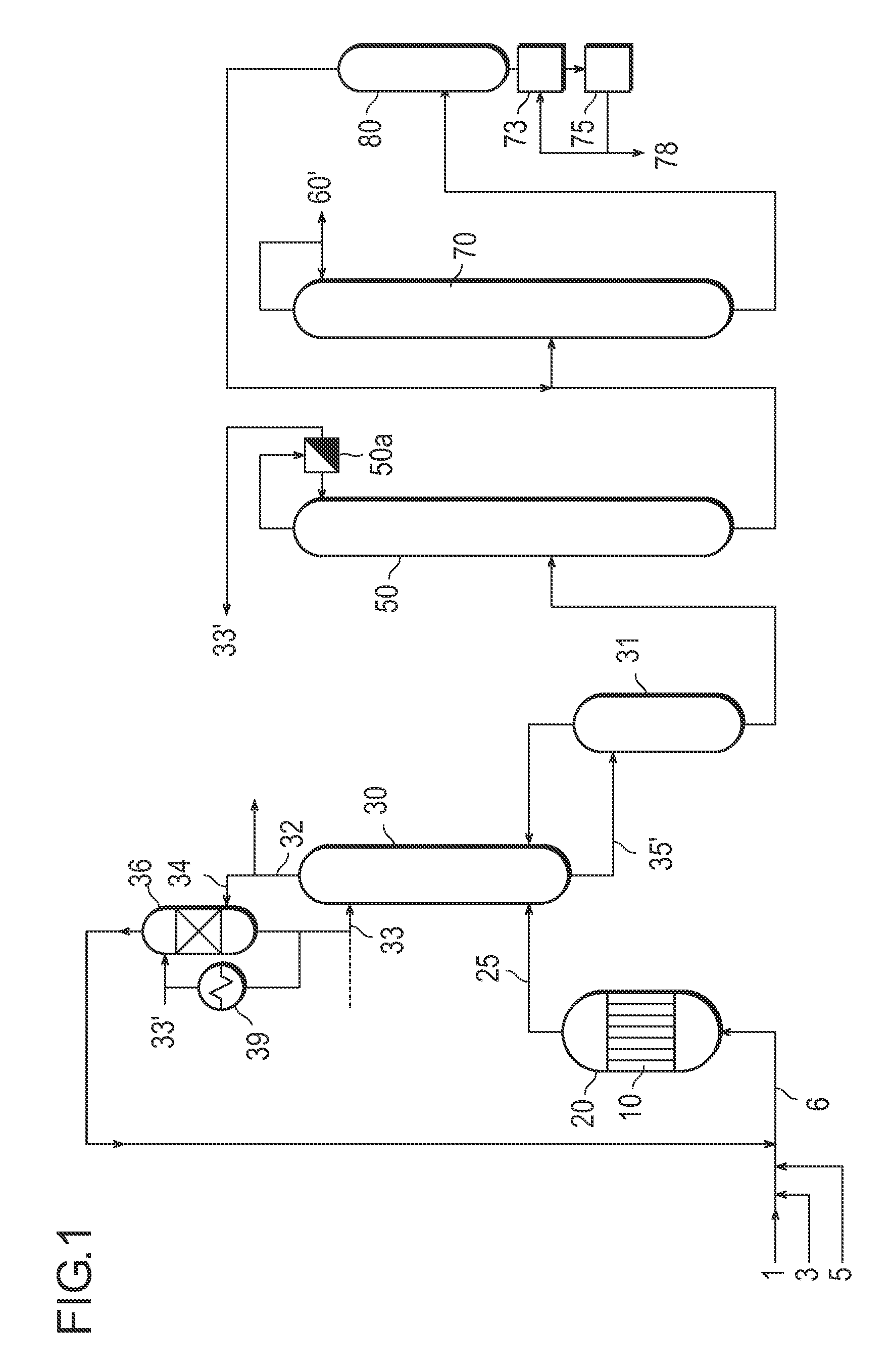

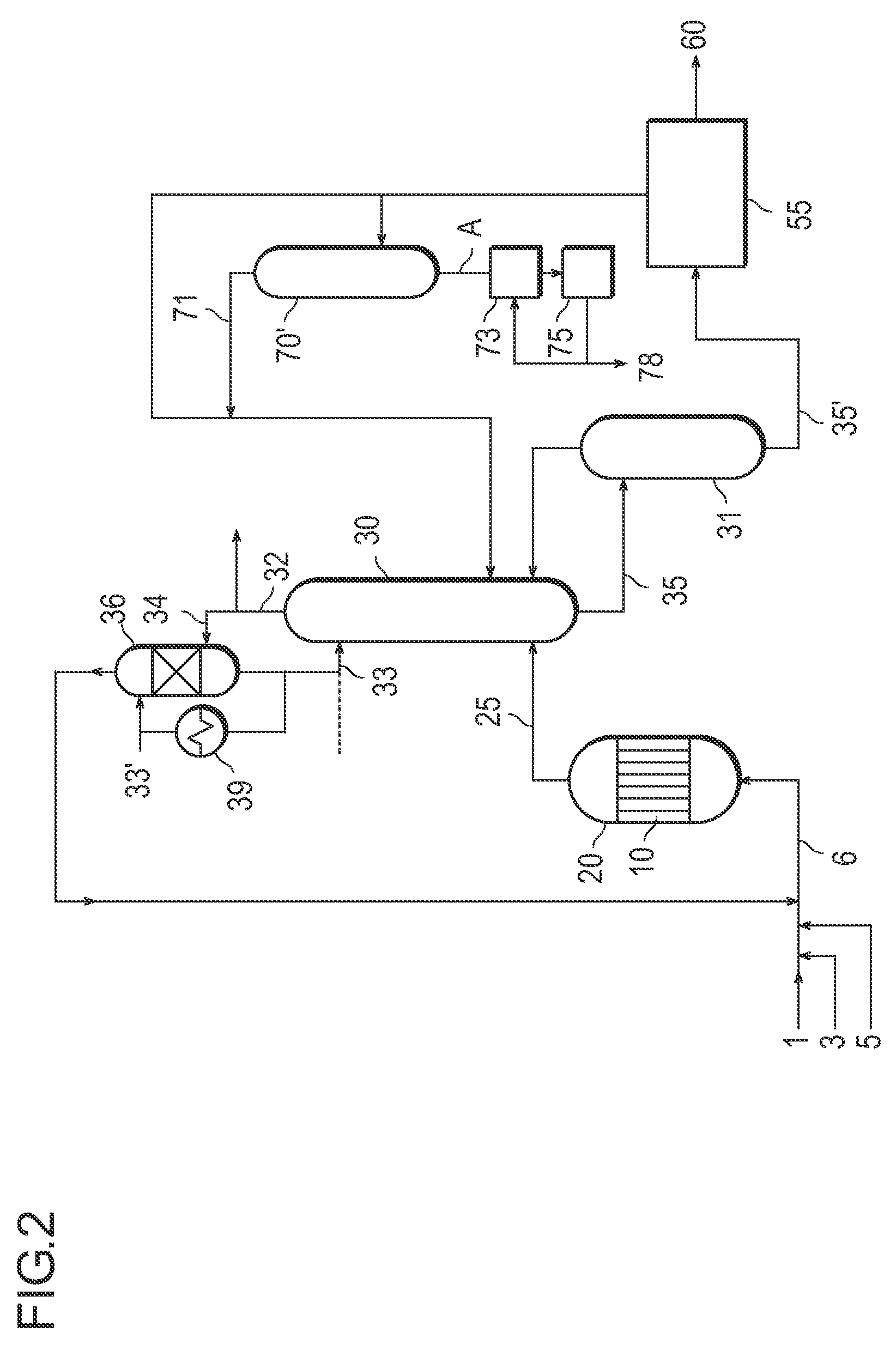

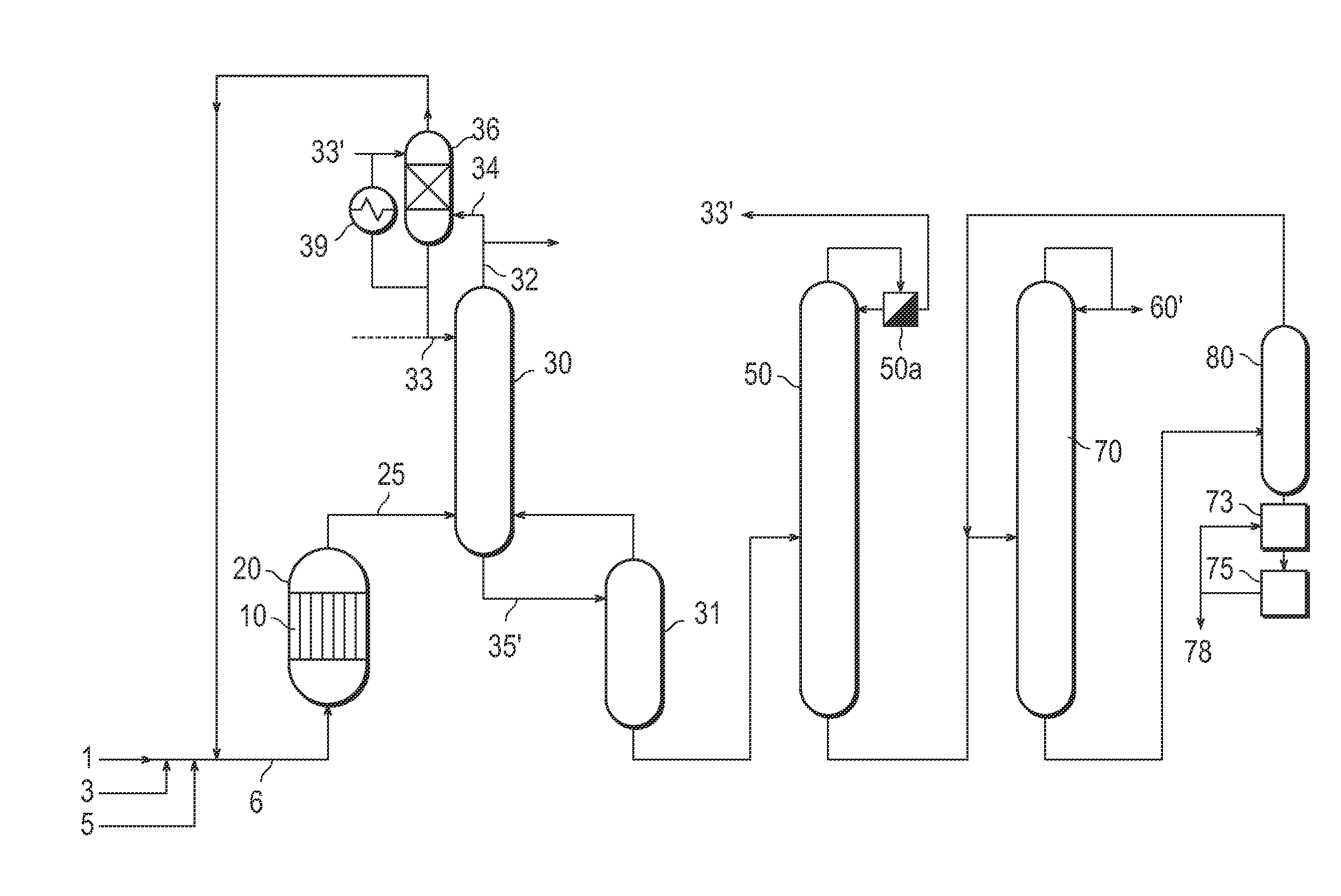

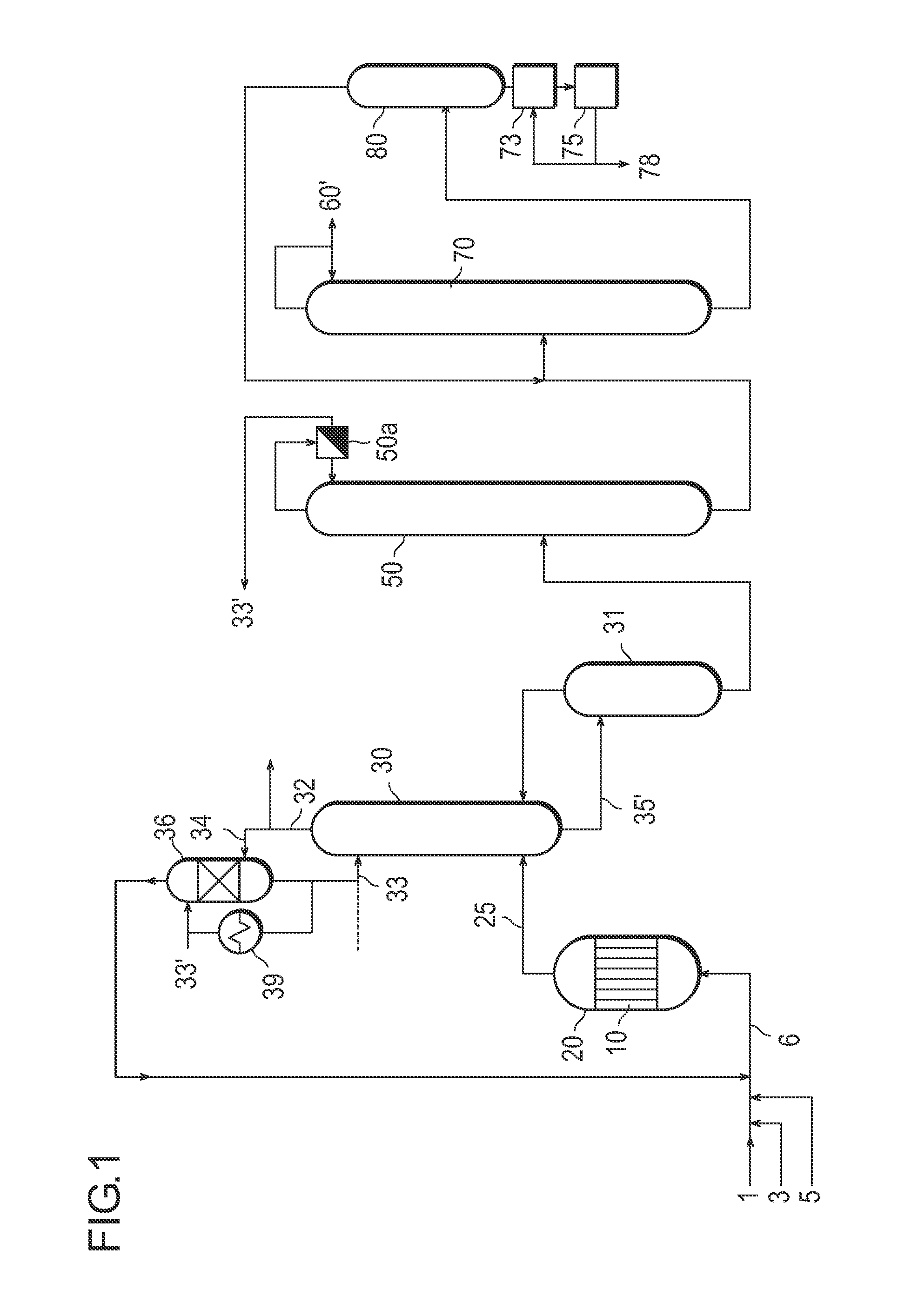

Method for producing acrylic acid, and method for producing hydrophilic resin and method for producing water-absorbing resin using production method thereof

ActiveUS8426640B2Simple methodIncrease productionOrganic compound preparationCarboxylic preparation by oxidationGas phaseFractionating column

[Problem]There is provided, in a process for producing acrylic acid having a catalytic gas-phase oxidation reaction step, a condensation step, a collection step, a distillation step, a crystallization step, an acrylic acid recovering step or the like, a production method for acrylic acid, in which contamination of acrylic acid with protoanemonin without providing any additional purification treatment to the resultant purified acrylic acid can be reduced.[Solution]The problems described above can be solved by providing the production method for acrylic acid comprising A) a step obtaining an acrylic acid-containing gas by a catalytic gas-phase oxidation reaction of gas containing a acrylic acid raw material; B) a step of obtaining the acrylic acid-containing solution by introducing the acrylic acid-containing gas to the collection column or the condensation column and performing collection or condensation; C) a step of obtaining the crude acrylic acid by introducing the acrylic acid-containing solution to the distillation column or the crystallizer and performing distillation or crystallization, wherein a step of heat treating the acrylic acid-containing solution or the crude acrylic acid containing 100 ppm by mass or more of protoanemonin, under the condition of 100° C. or more of temperature, 1 hour or more of time and a step of introducing the heat-treated acrylic acid-containing solution or the crude acrylic acid to the collection column, the condensation column, the distillation column or the crystallizer, are included.

Owner:NIPPON SHOKUBAI CO LTD

Measuring instrument housing with a display panel

InactiveUS8695423B2Improved resin sealingSolving the Insufficiency of ElasticityFluid pressure measurementSpeed/acceleration/shock instrument detailsMeasuring instrumentEngineering

Owner:KROHNE MESSTECHNICK GMBH & CO KG

Machine for the production and/or converting of a material web and methods for removing contaminations in regard to such machinery

InactiveUS20050069635A1ContaminationEasy to disassembleLiquid surface applicatorsSpraying apparatusCartonPulp and paper industry

A machine for the production and / or converting of a material web, especially a paper or carton web, such as a coating machine for single sided or two-sided application of liquid or viscid coating medium onto a moving web by way of at least one application device. At least one carrier surface, or partial surface, and / or at least one area or partial area, of the machine that is exposed, or could be exposed, during the operation and / or during start-up of the machine and / or during slow-down of the machine and / or during at least an exceptional operational condition of the machine to the medium is a focus of the present invention. Application medium, that is used in the production or converting process, and / or is subjected to another contamination hazard, is formed by or furnished with a permanent or temporary, protective layer, also referred to as barrier layer, that is applied to the carrier surface. The protective layer possesses anti-adhesive properties with regard to the medium or contaminating materials and / or is removable, together with the adhering medium or contaminating material.

Owner:VOITH PATENT GMBH

Vessel including automatic ballast system using tubes

InactiveUS7789031B2ContaminationLow costHull interior subdivisionAuxillariesMarine engineeringEngineering

A double-hulled vessel has a ballast draft line previously set at an empty state thereof. The double-hulled vessel of the present invention comprises an outer shell formed on bottom and side portions of the vessel; an inner shell formed on bottom and side portions of the vessel within the outer shell; an air tube positioned between the inner and outer shells; and a seawater tube positioned between the inner and outer shells, wherein seawater holes are formed in the outer shell to be connected to the seawater tube, the seawater tube is capable of containing seawater to substantially fill a space between the inner and outer shells extending from the bottom portion of the vessel up to the ballast draft line of the side portion of the vessel when the vessel is not loaded with cargo, and the air tube is capable of containing air to substantially fill the space between the inner and outer shells of the bottom and side portions of the vessel when the vessel is loaded with cargo.

Owner:KIM YONG KYUNG

Process for producing acrylic acid, and process for producing hydrophilic resin and process for producing water absorptive resin using the process

ActiveUS20110118426A1Simple methodIncrease productionOrganic compound preparationCarboxylic preparation by oxidationGas phaseFractionating column

[Problem]There is provided, in a process for producing acrylic acid having a catalytic gas-phase oxidation reaction step, a condensation step, a collection step, a distillation step, a crystallization step, an acrylic acid recovering step or the like, a production method for acrylic acid, in which contamination of acrylic acid with protoanemonin without providing any additional purification treatment to the resultant purified acrylic acid can be reduced.[Solution]The problems described above can be solved by providing the production method for acrylic acid comprising A) a step obtaining an acrylic acid-containing gas by a catalytic gas-phase oxidation reaction of gas containing a acrylic acid raw material; B) a step of obtaining the acrylic acid-containing solution by introducing the acrylic acid-containing gas to the collection column or the condensation column and performing collection or condensation; C) a step of obtaining the crude acrylic acid by introducing the acrylic acid-containing solution to the distillation column or the crystallizer and performing distillation or crystallization, wherein a step of heat treating the acrylic acid-containing solution or the crude acrylic acid containing 100 ppn by mass or more of protoanemonin, under the condition of 100° C. or more of temperature, 1 hour or more of time and a step of introducing the heat-treated acrylic acid-containing solution or the crude acrylic acid to the collection column, the condensation column, the distillation column or the crystallizer, are included.

Owner:NIPPON SHOKUBAI CO LTD

Method and system for removing a liquid from a container for accommodating an ophthalmic lens

ActiveUS10195303B2Effective treatmentContaminationDrying solid materials without heatOptical articlesLens plateContact lens

A method of removing a liquid from a container (1) for accommodating an ophthalmic contact lens, in particular a soft contact lens, during transporting the container (1) from a liquid bath (13) to a subsequent processing station (14), the method including the steps of:transporting the container (1) from the liquid bath to the subsequent processing station,generating suction (20), andapplying the suction (20) to a bottom (11) of the container (1) during the step of transporting the container (1) from the liquid bath to the subsequent processing station, thereby removing the liquid from the container (1).

Owner:ALCON INC

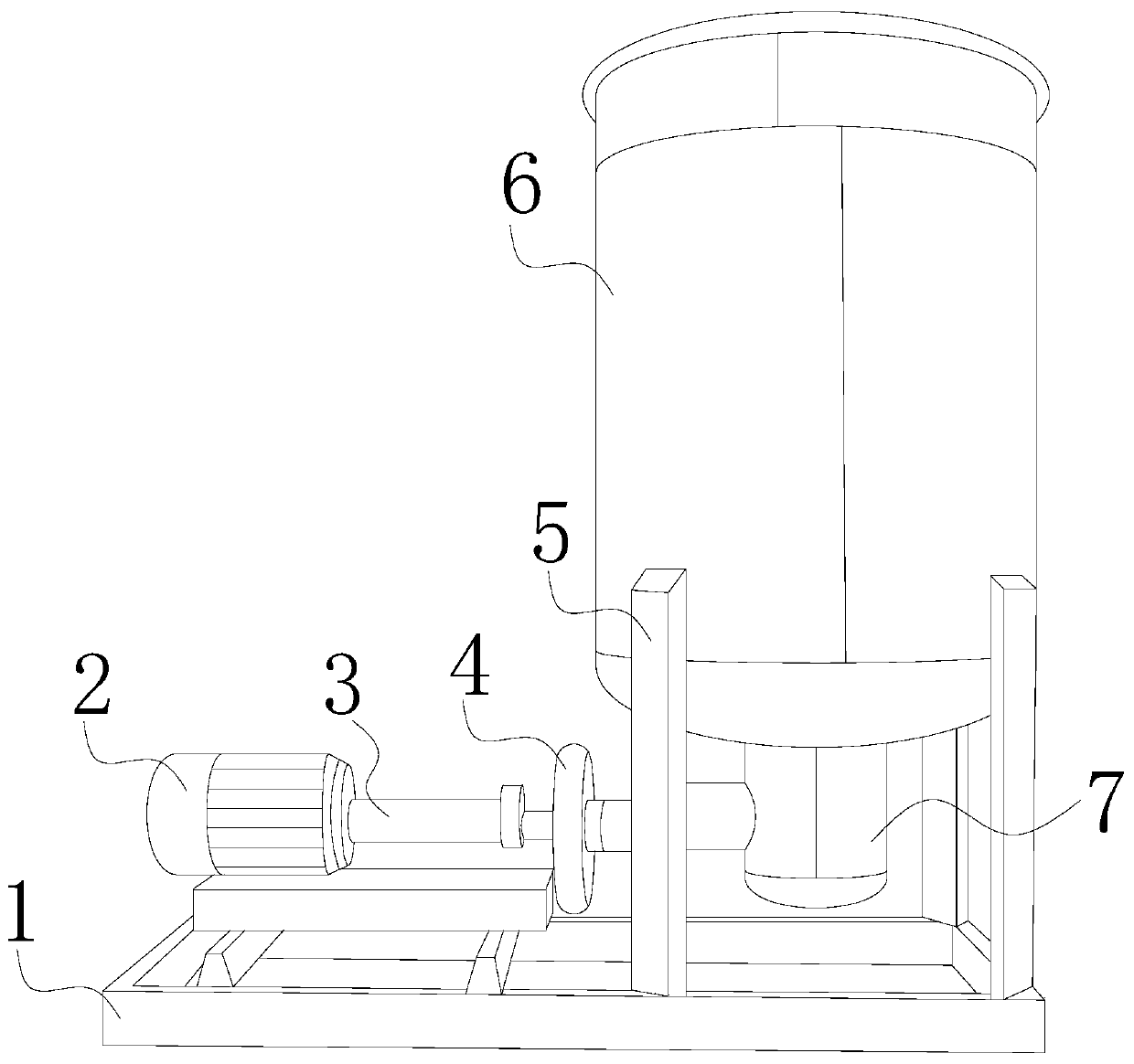

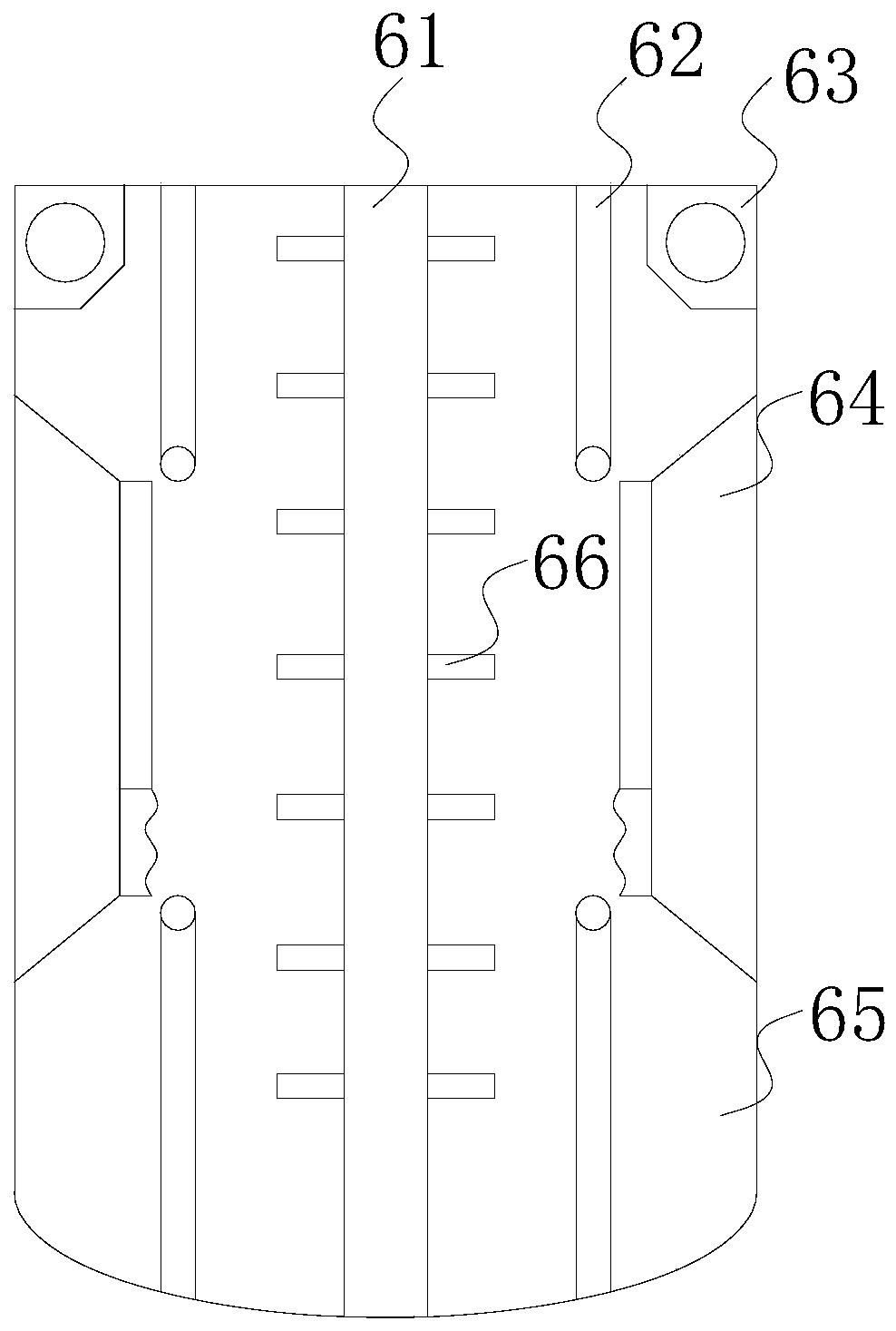

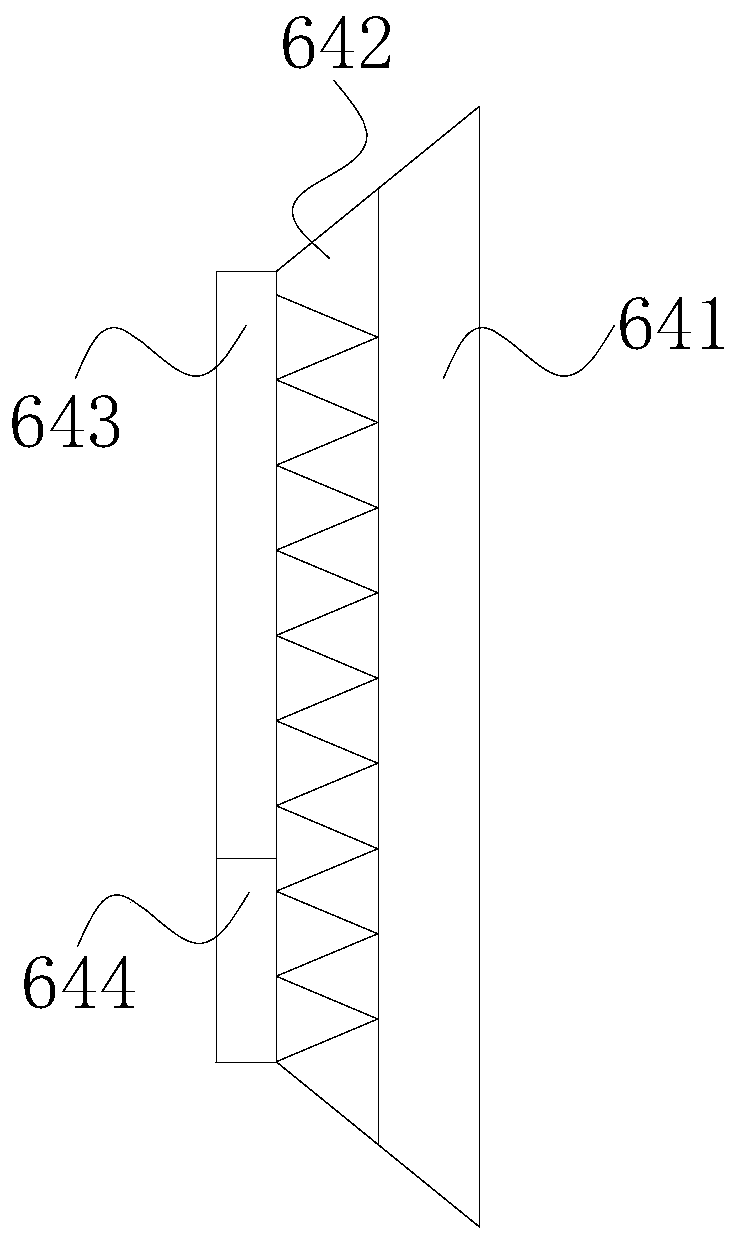

Uniform dyeing machine for textiles

InactiveCN110205758ANot easy to fadeContaminationTextile treatment machine arrangementsTextile treatment by spraying/projectingEngineeringPush out

The invention discloses a uniform dyeing machine for textiles. The uniform dyeing machine structurally comprises a bracket, a conveying pump, a guide pipe, a control valve, four frame rods, a dyeing tank and a stirrer, the frame rods are electrically welded on four sides of the dyeing tank, the right half of the bracket is vertically welded at the bottoms of the frame rods, the conveying pump is connected at the left end above the bracket through nails. Dye can be patted in through a stony block when the front of a trouser leg is dyed, an inner clamping pad is allowed to limit a trouser seam when the trouser seam is dyed, the trouser seam is color-washed through an attaching brush and an arc-shaped sharp tip, and the attaching brush is enabled to go deep into a gap of a needle thread, so that clothes after being dyed are less prone to fading; when encountering bottom protrusions of the trouser leg during dyeing, pressure is caused on a pressure resisting block to enable the same to squeeze a pull-expanding column, and the pull-expanding column pushes out a concave-convex pad to enable the concave-convex pad to spray more dyeing agent to the bottom of the trouser leg, so that the protrusions at the bottom of the trouser leg can stain more dyeing agent, thereby being less prone to fading.

Owner:莆田城厢晟铭网络有限公司

Human tissue isolation pouch for use with pouch sealer

ActiveUS10752393B2Avoid pollutionAvoid cross contaminationMeasurement of fluid loss/gain rateDead animal preservationHuman bodyEngineering

A human tissue isolation pouch for use with a sealer machine to indirectly seal human tissue medical pouches while avoiding cross contamination is herein disclosed. The human tissue isolation pouch comprises a rigid frame supporting a high temperature material and having one or more magnets for removably attaching the human tissue isolation pouch to a sealer machine.During use a medical pouch, which may contain a human tissue sample, is inserted within the human tissue isolation pouch. The jaws of the sealer machine clamp down directly on the high temperature material, thus indirectly heating and sealing the medical pouch inside the human tissue isolation pouch. The sealing machine jaws do not physically contact the medical pouch at any time during the sealing process, and in this way contamination of the sealer machine (and cross contamination of medical pouches from distinct donor cases) is avoided. The rigid frame of the human tissue isolation pouch may be sterilized after each donor event. And the containment bag formed of a high temperature material may be disposed of after each donor event.

Owner:VAN DER STAHL SCI

Fuel cell, fuel cell system and electronic device

InactiveUS9059443B2Stable and good power generation characteristicImprove securityReactant parameters controlActive material electrodesIn planeFuel cells

There are provided a fuel cell having stable and good power generation characteristics and good safety, a fuel cell system including the fuel cell and an electronic device equipped with the fuel cell. The fuel cell includes at least an electrolyte membrane, an anode formed on one surface of the electrolyte membrane, a cathode formed on the other surface of the electrolyte membrane, a liquid fuel chamber for supplying a liquid fuel to the anode, and a separating layer formed between the anode and the liquid fuel chamber. The separating layer and / or the anode has an exhaust passage that is continuously formed in an in-plane direction to discharge exhaust gas generated at the anode. The separating layer allows the liquid fuel to pass from the liquid fuel chamber to the anode and blocks the movement of gas from the anode to the liquid fuel chamber.

Owner:SHARP KK

Nucleic acid pretreatment kit, and base sequence analysis method

PendingUS20210139954A1ContaminationReduce riskElectrostatic separationMicrobiological testing/measurementBiochemistryOrganic chemistry

Owner:SHIMADZU CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com