Pressure control isolation and flood preventative tank for a hot water based heating system

a technology of pressure control and flood prevention, which is applied in the direction of hot water central heating, lighting and heating apparatus, heating types, etc., can solve the problems of system leakage, high price of glycol makeup systems, and extensive damage to the surrounding objects as well as the heating or cooling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention shall now be described in accordance with a number of varying embodiments, although care should be taken not to limit the scope of the invention to those embodiments, but must be determined according the claims that follow herein.

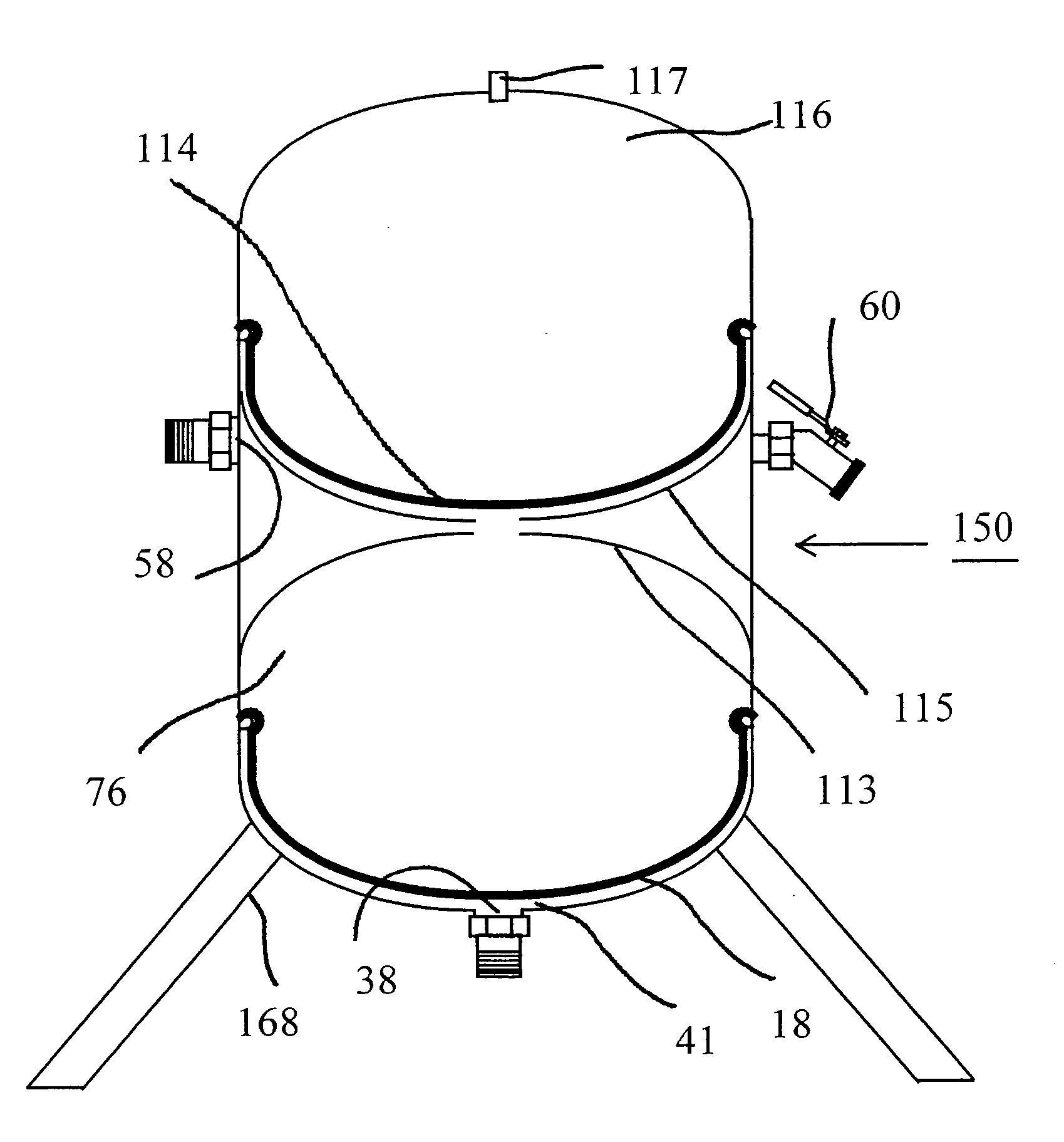

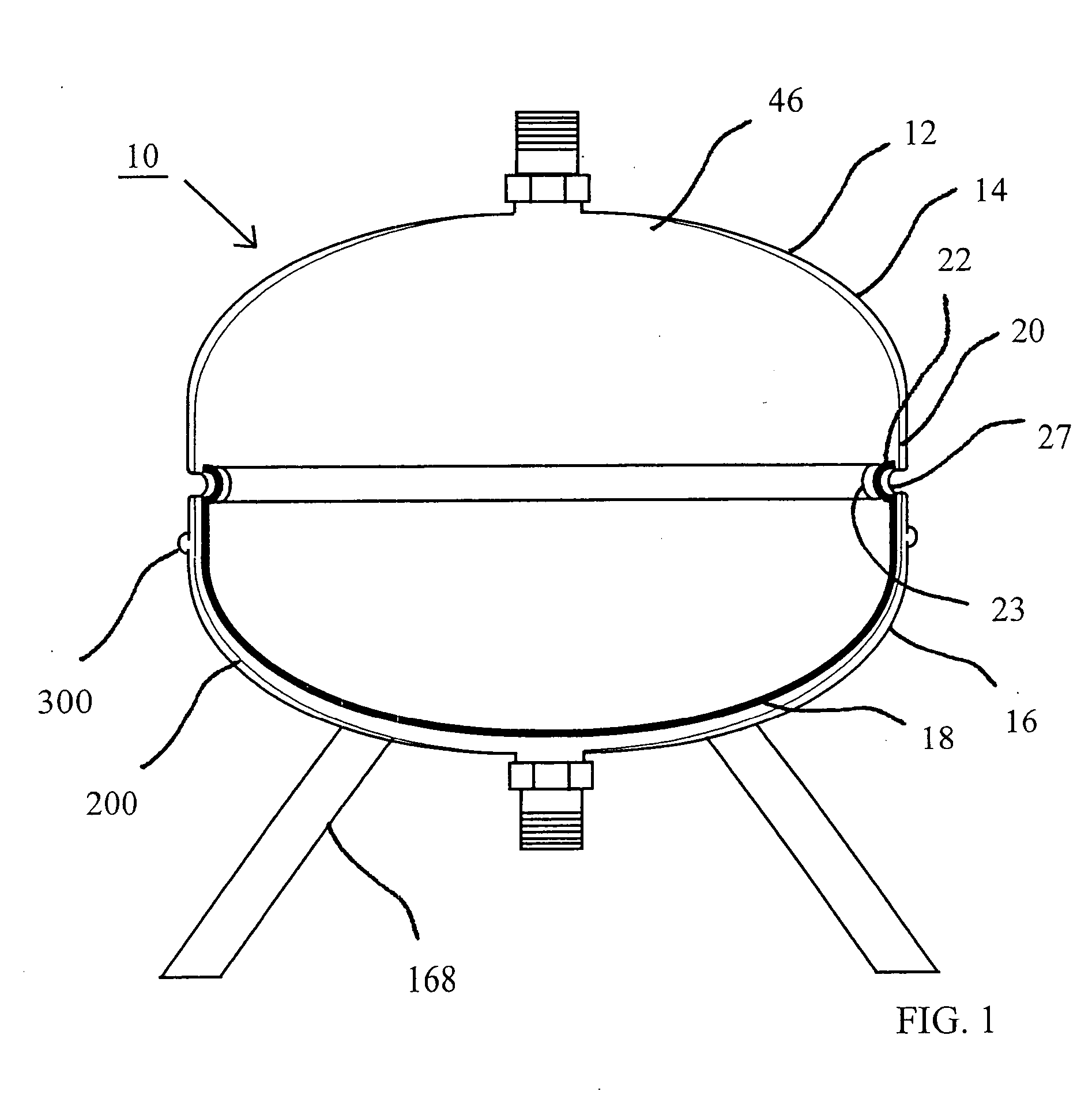

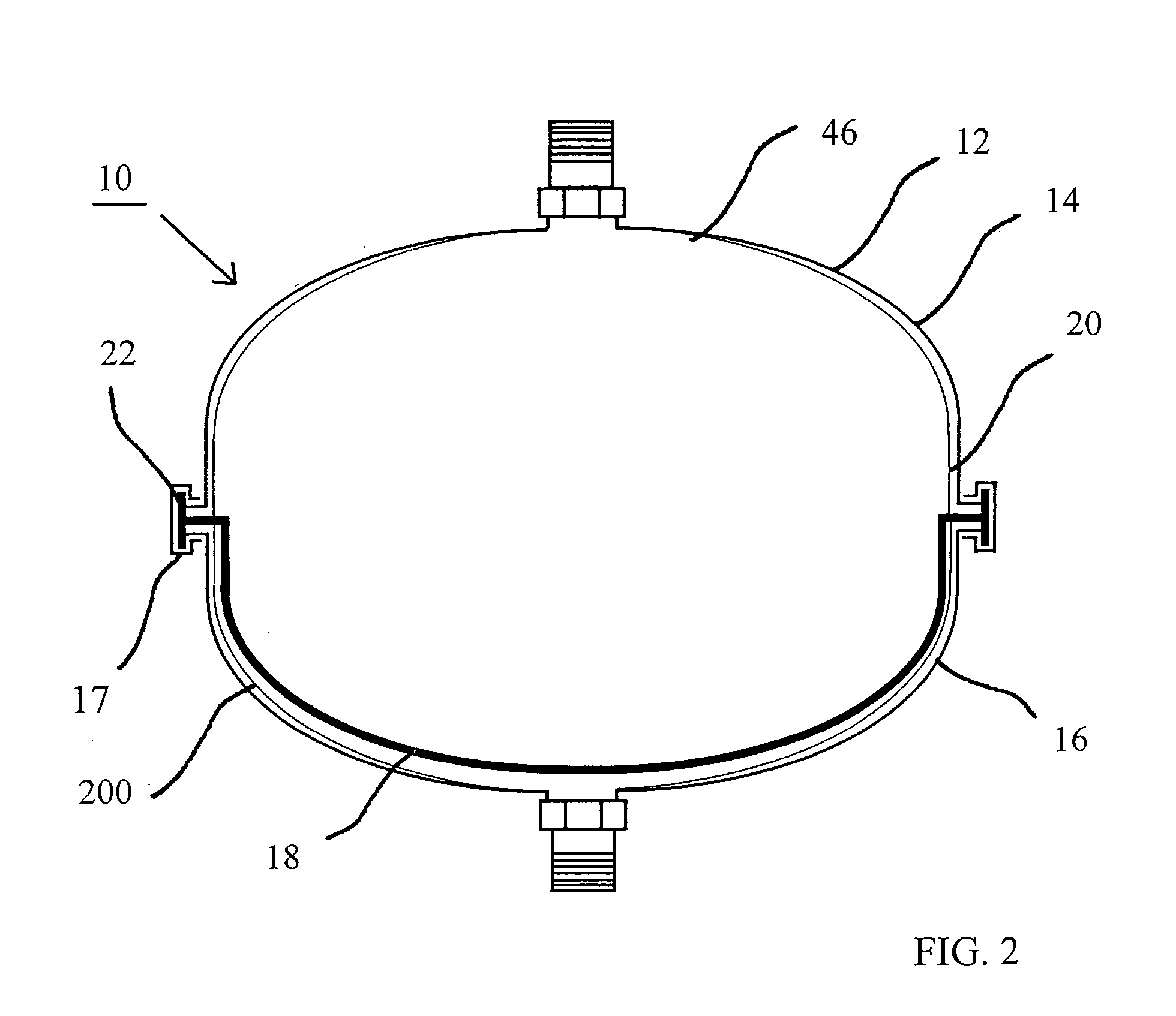

[0048] Referring now to FIG. 1, there is shown a pressure control isolation tank 10 for a closed loop heating, namely a hot water based heating system, in which the pressure control isolation tank 10 prevents an interchange between fluid of the heating system and the service supply water and also helps maintain a constant pressure within the heating system fluid. The heating system fluid is typically hot water, antifreeze of a combination thereof.

[0049] The pressure control isolation tank 10 has a desirable feature of preventing a major flood in the event of a rupture within the heating system. In the event of a leak, the heating system fluid leaks from the system through the rupture. However, service water cannot escape throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com