Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5402results about "Abrasive machine appurtenances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

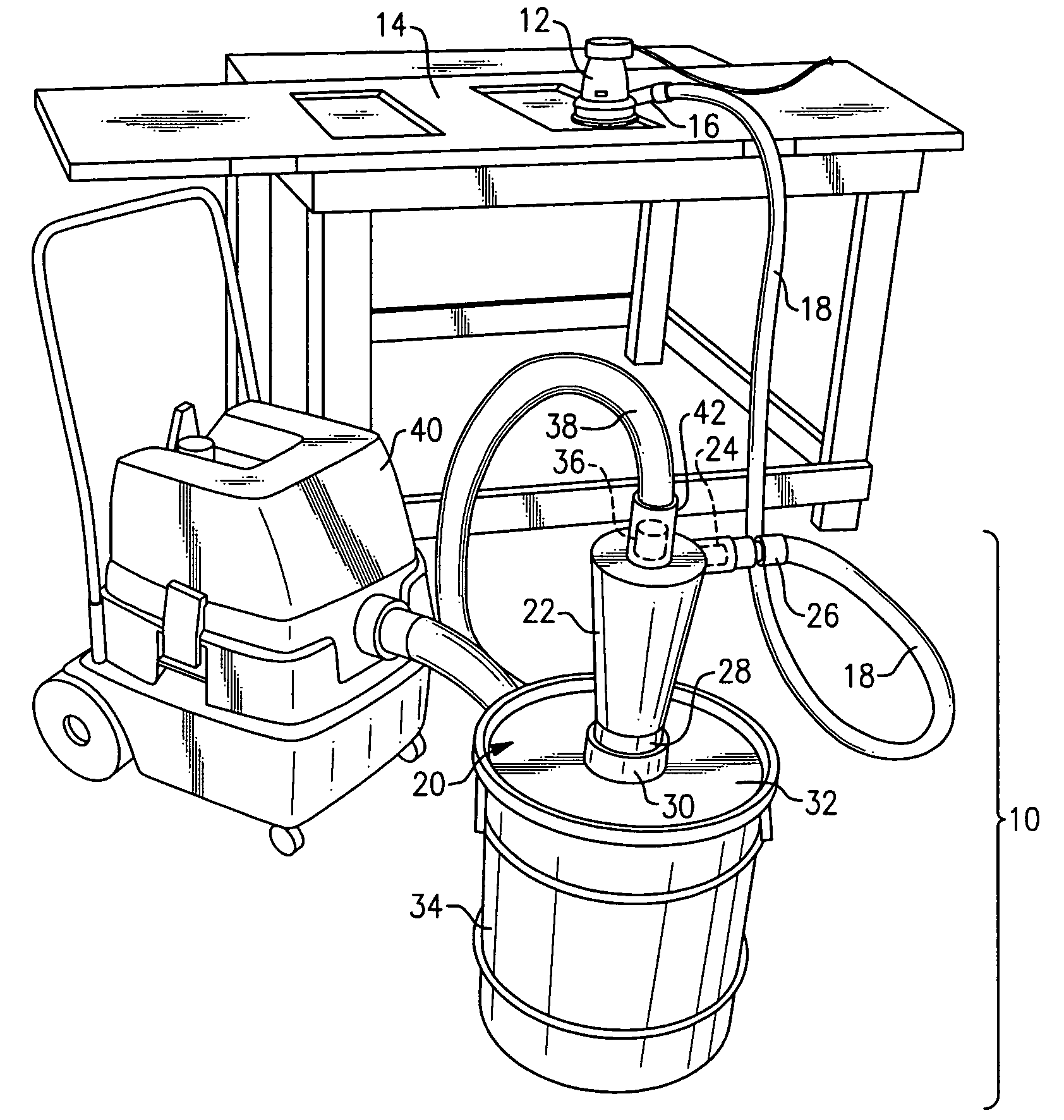

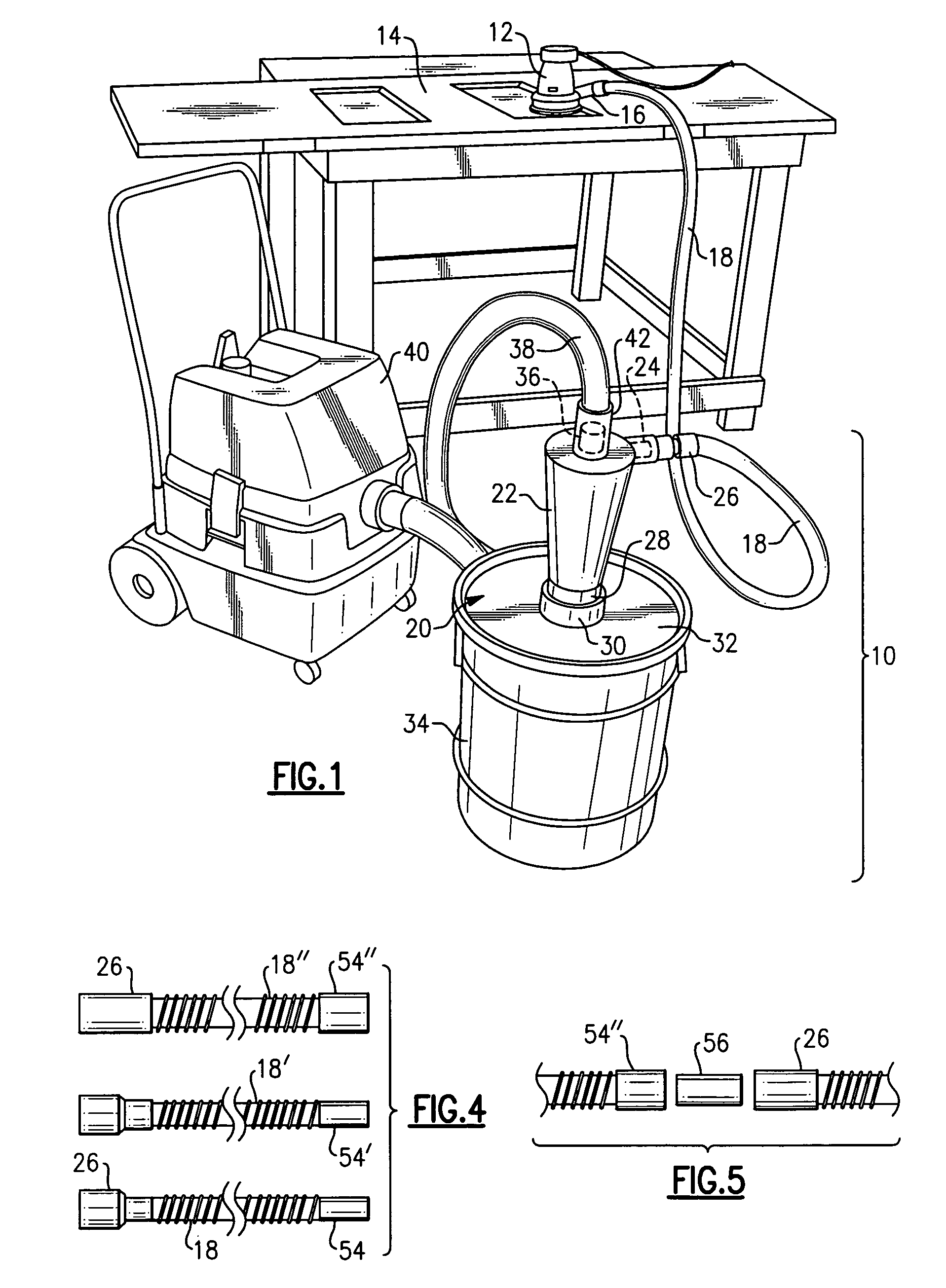

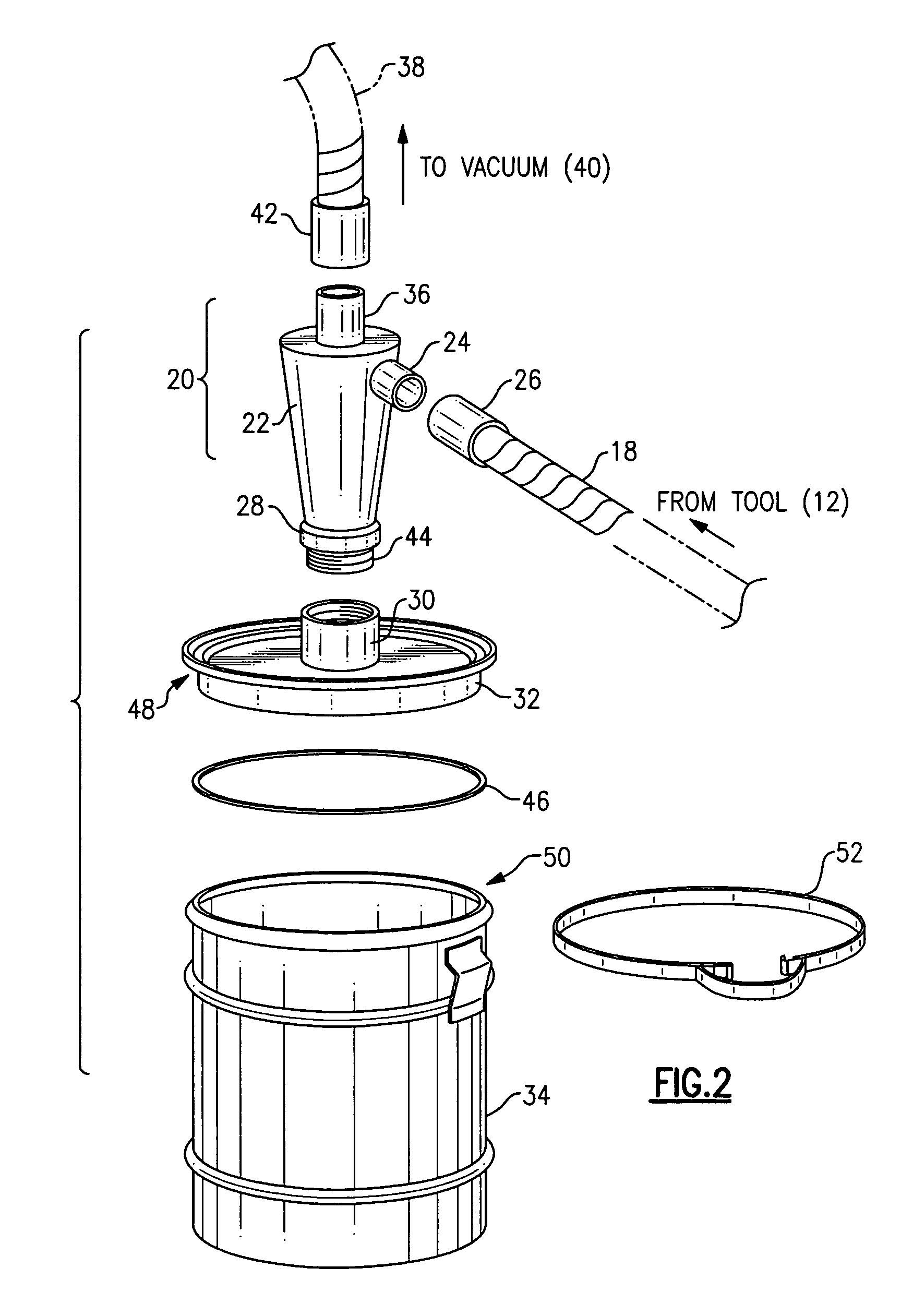

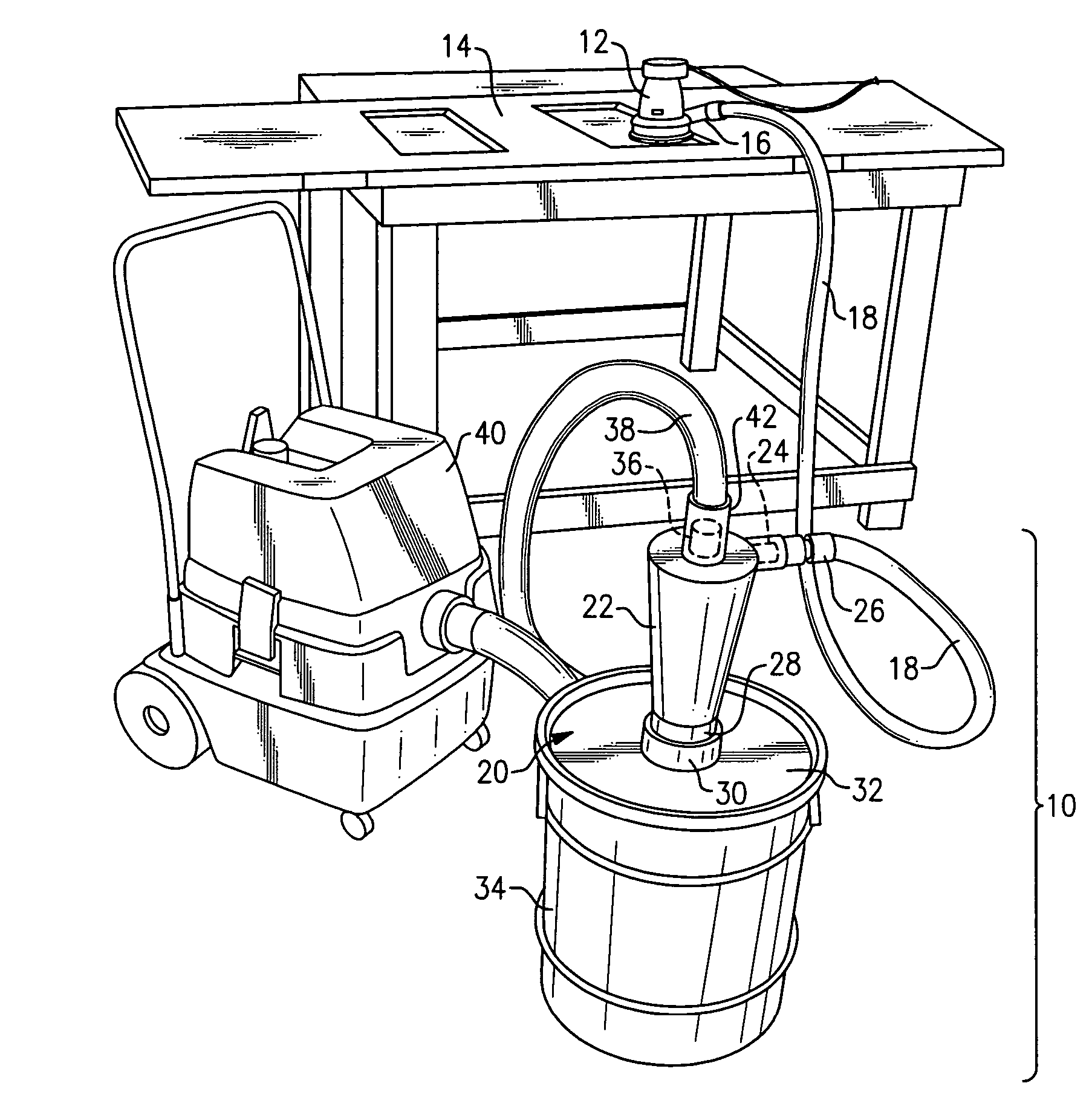

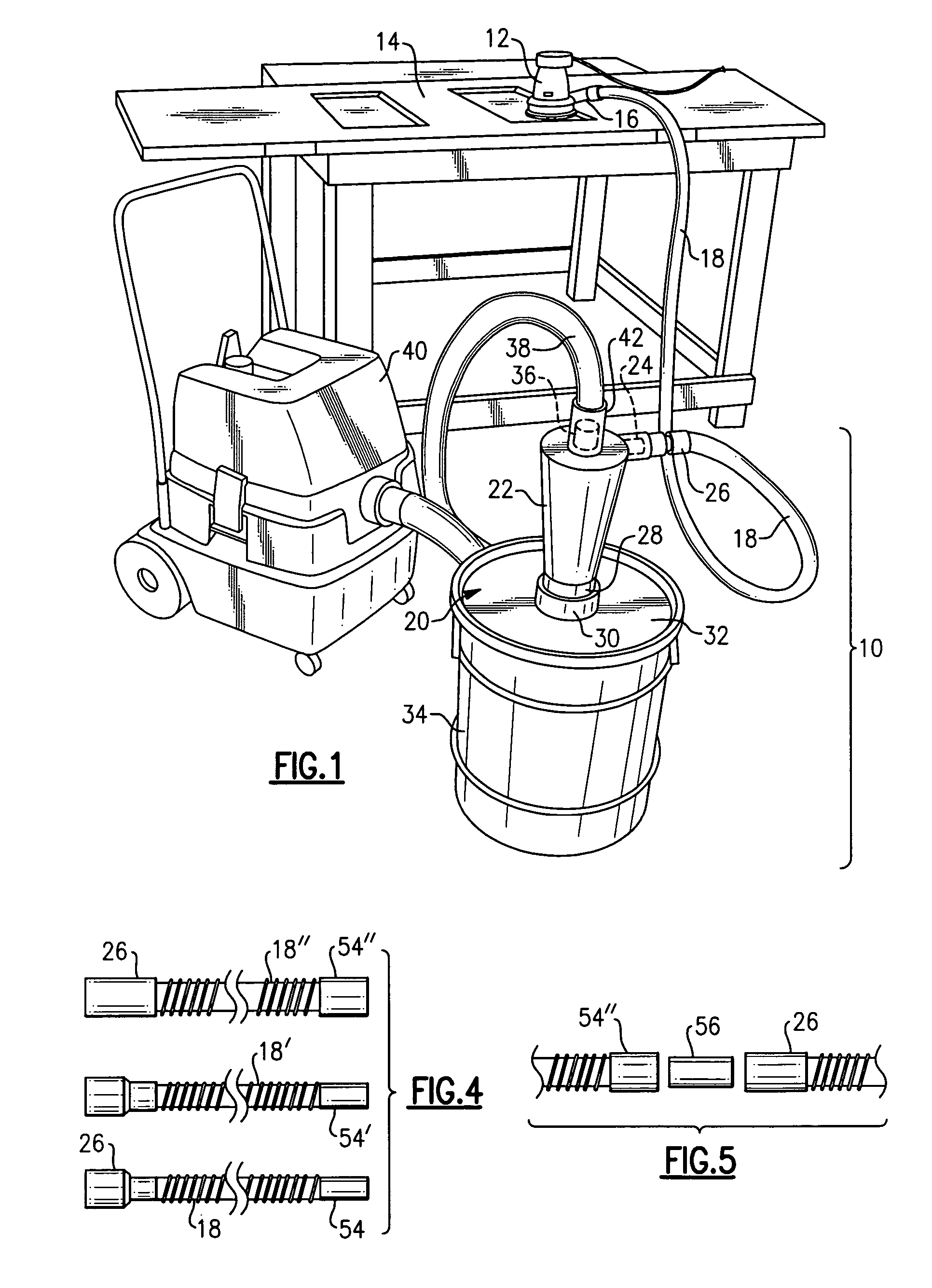

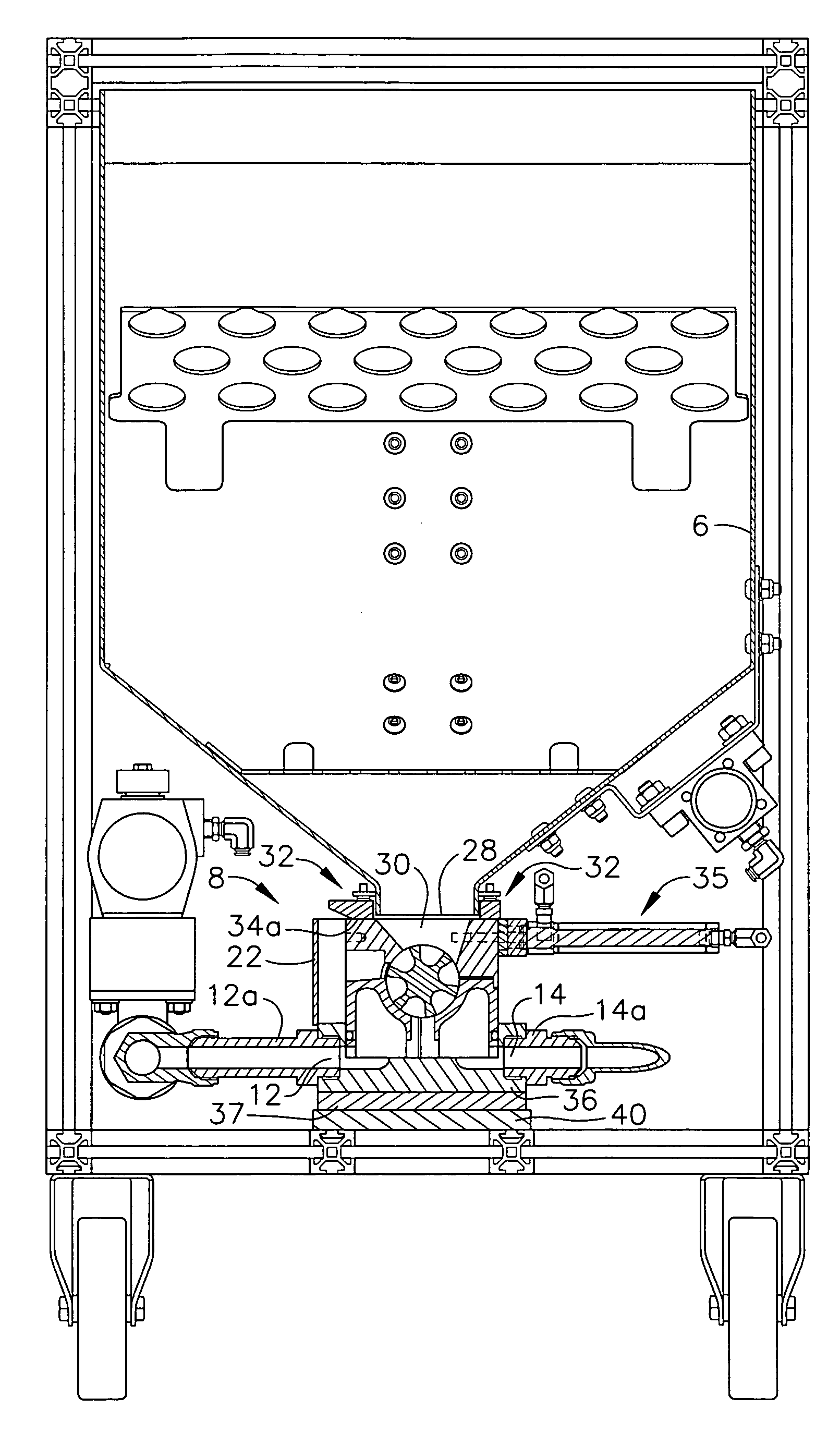

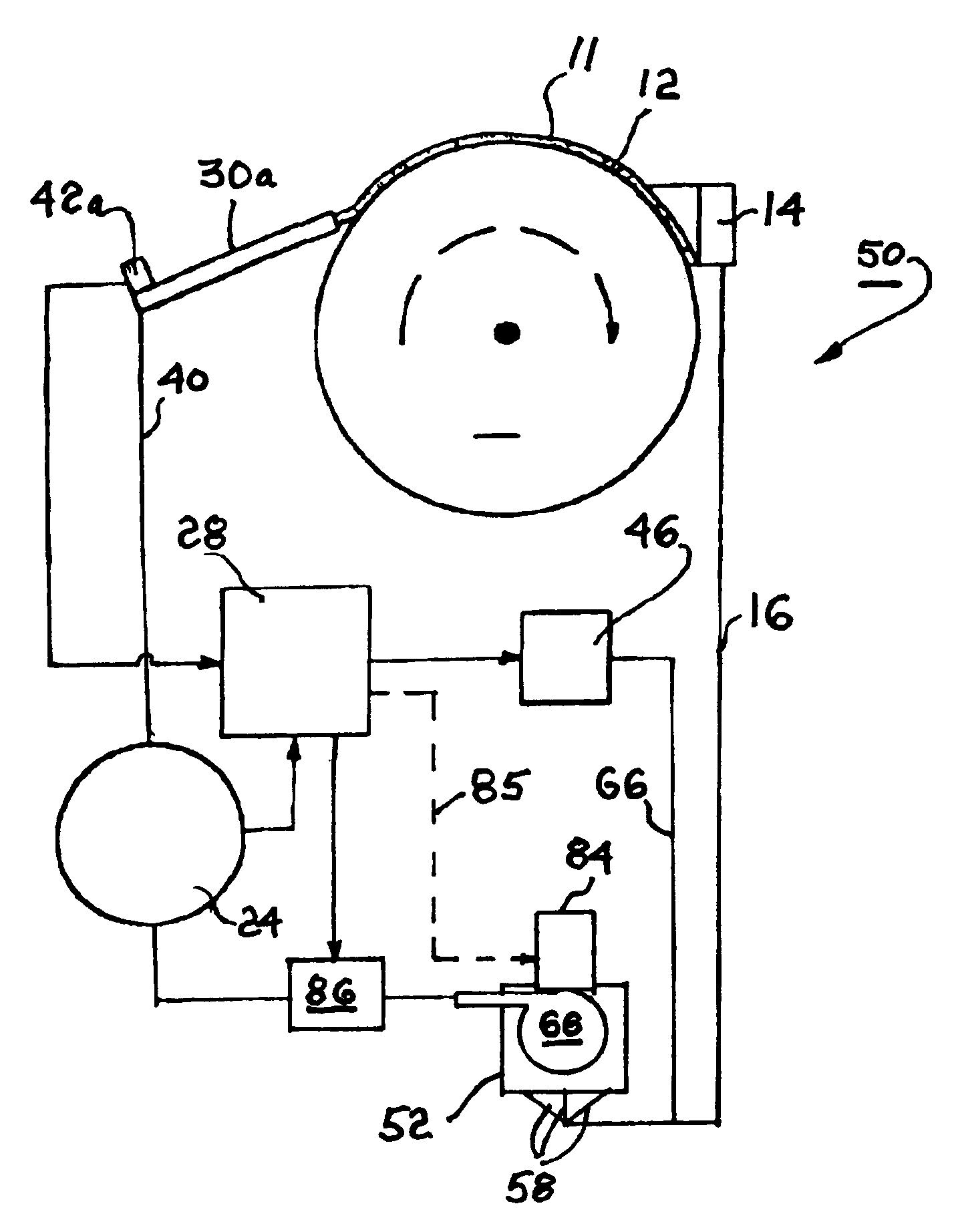

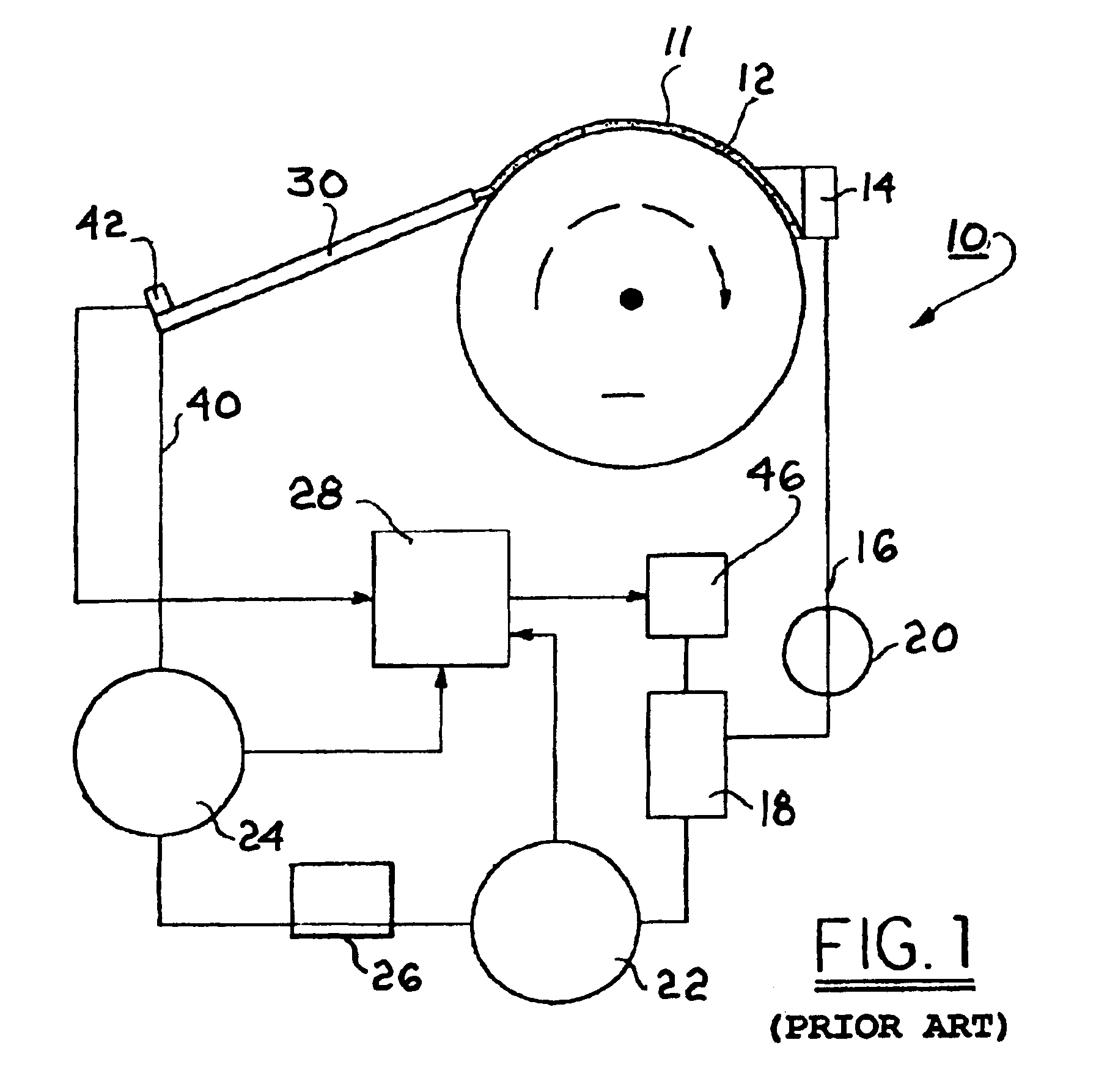

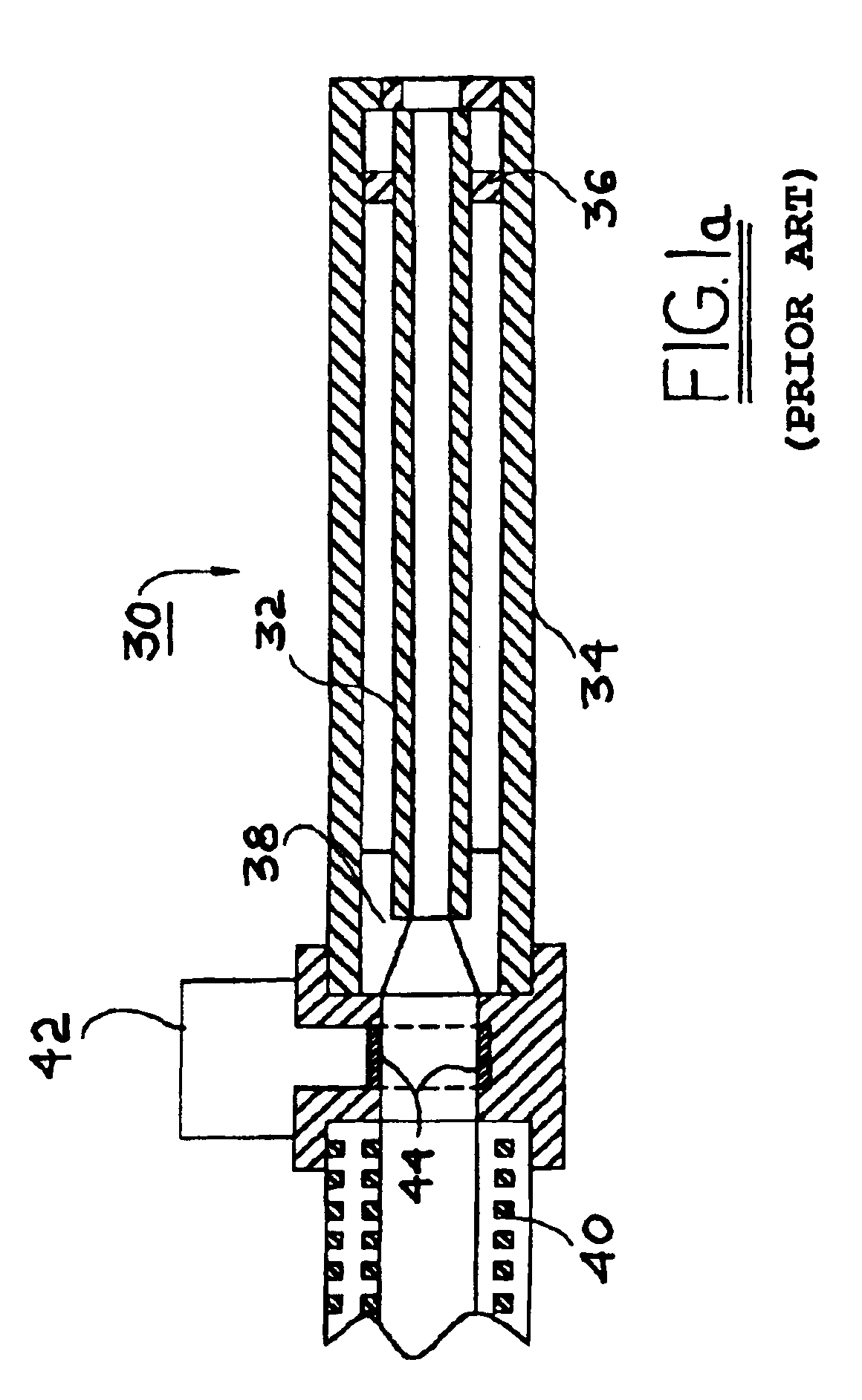

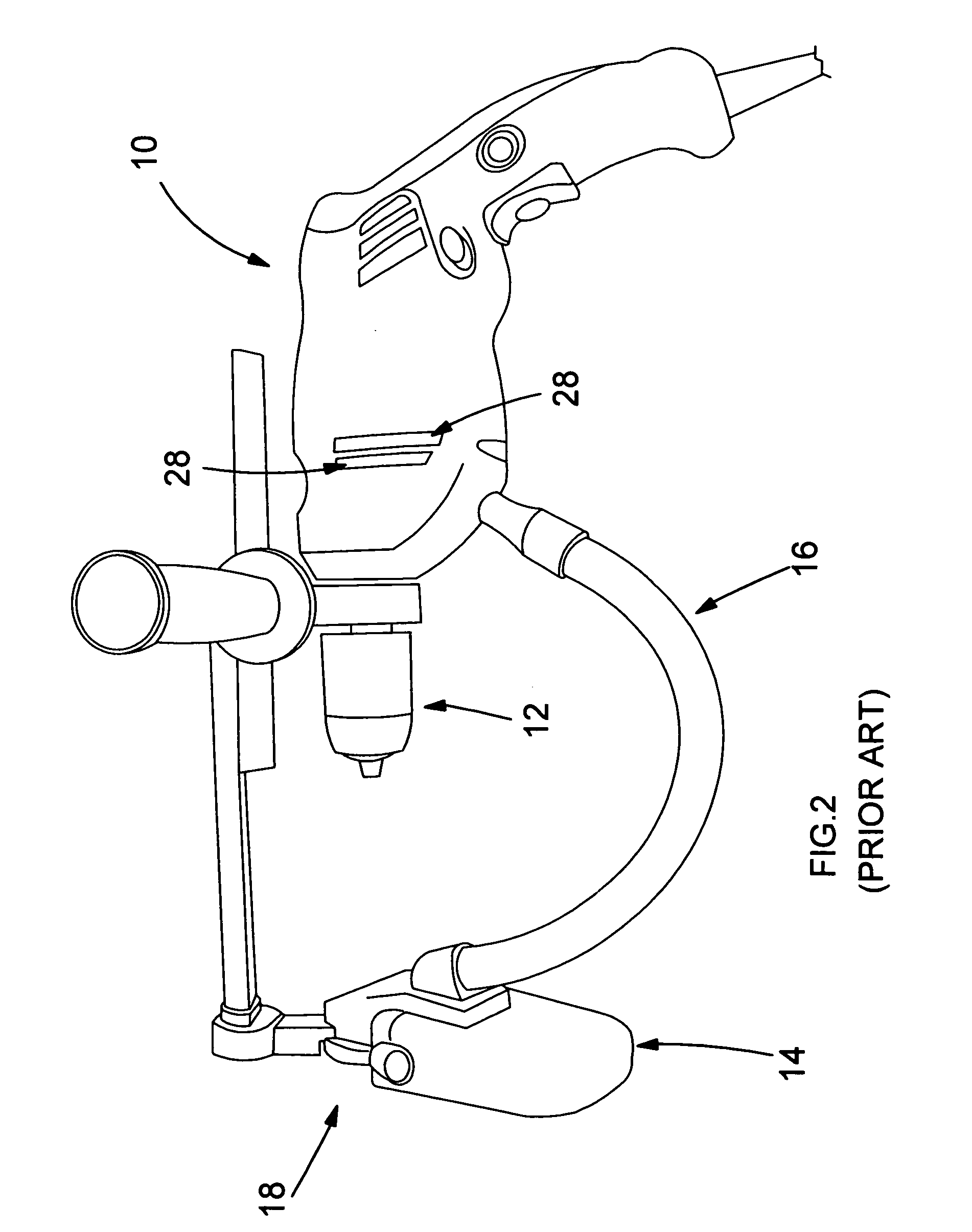

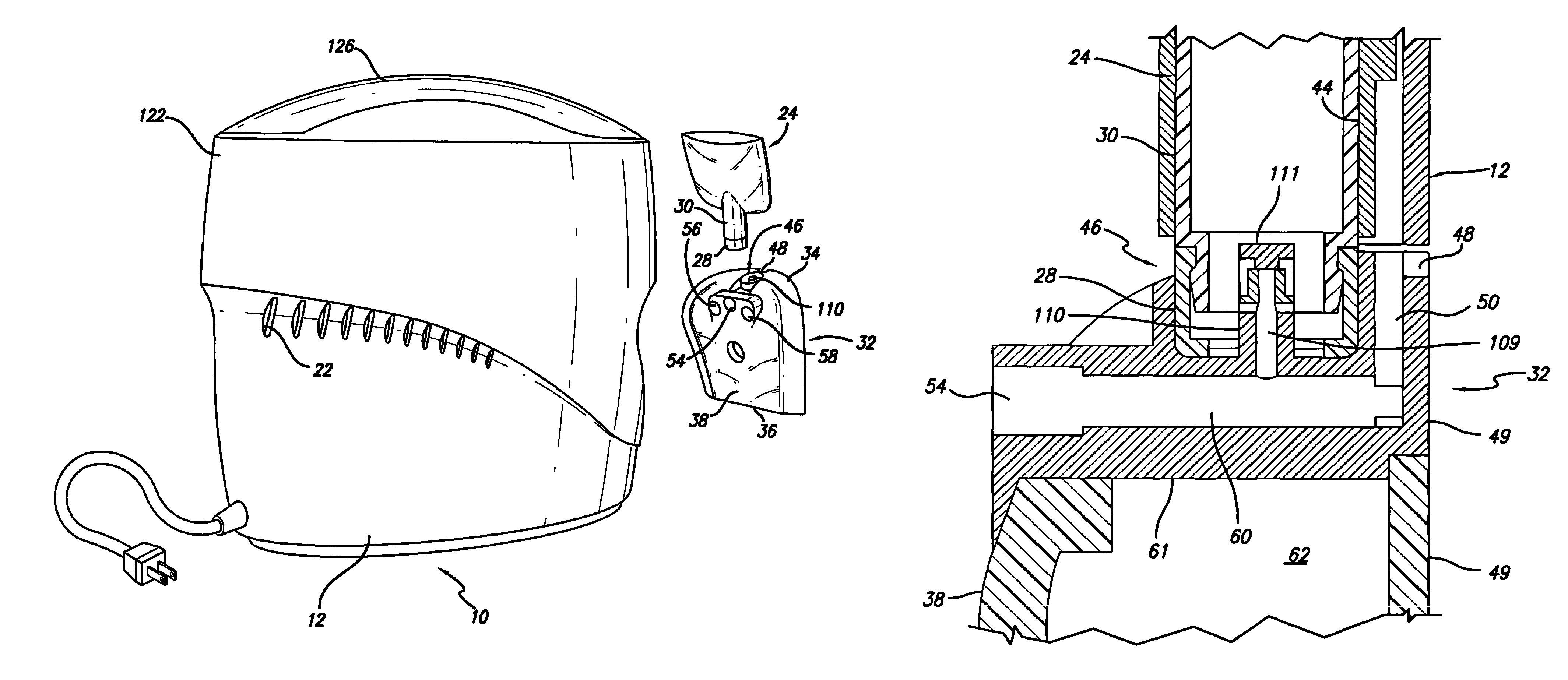

Auxiliary dust collection system

ActiveUS7282074B1Simple and straightforward in constructionImprove reliabilityCombination devicesReversed direction vortexSanderProcess noise

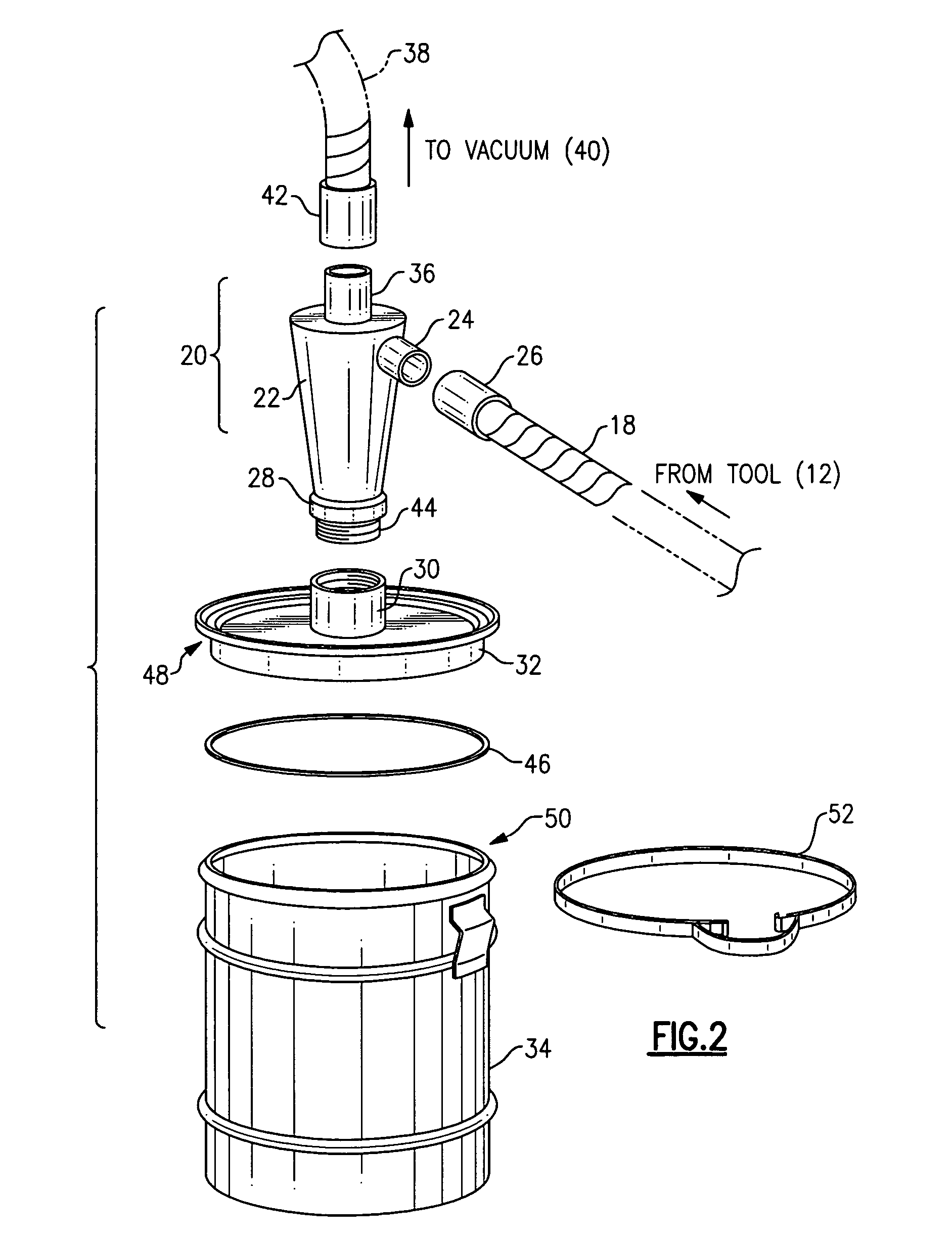

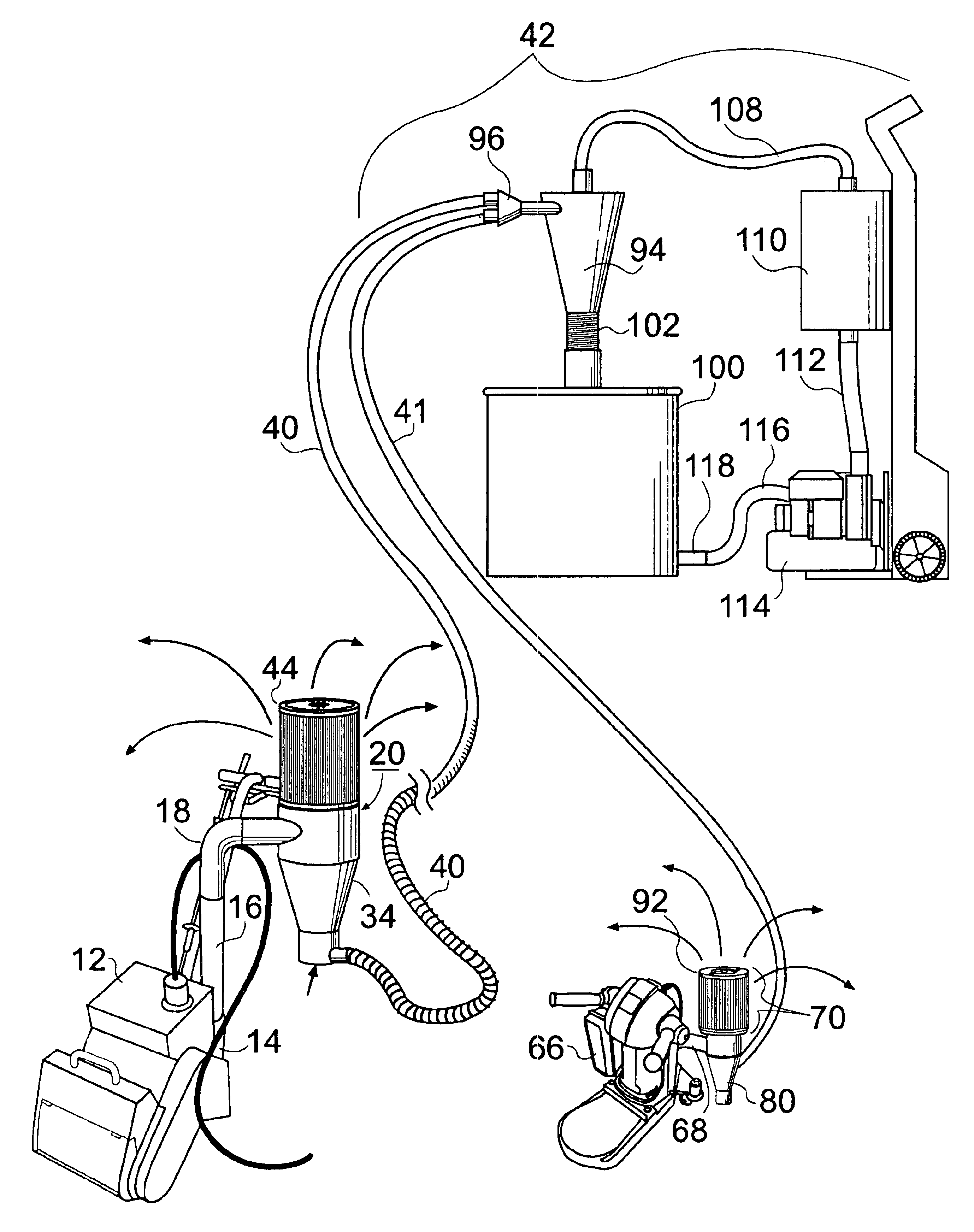

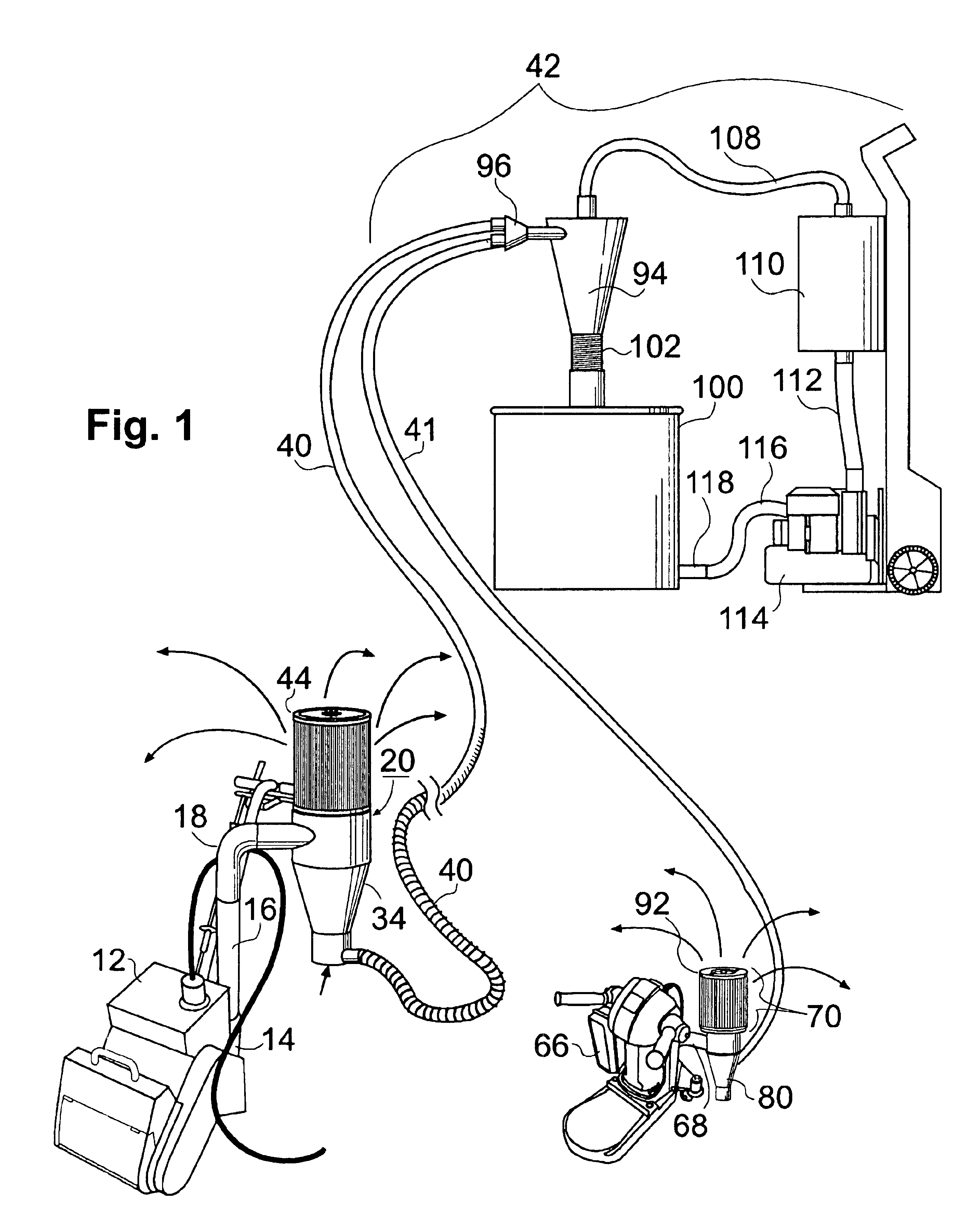

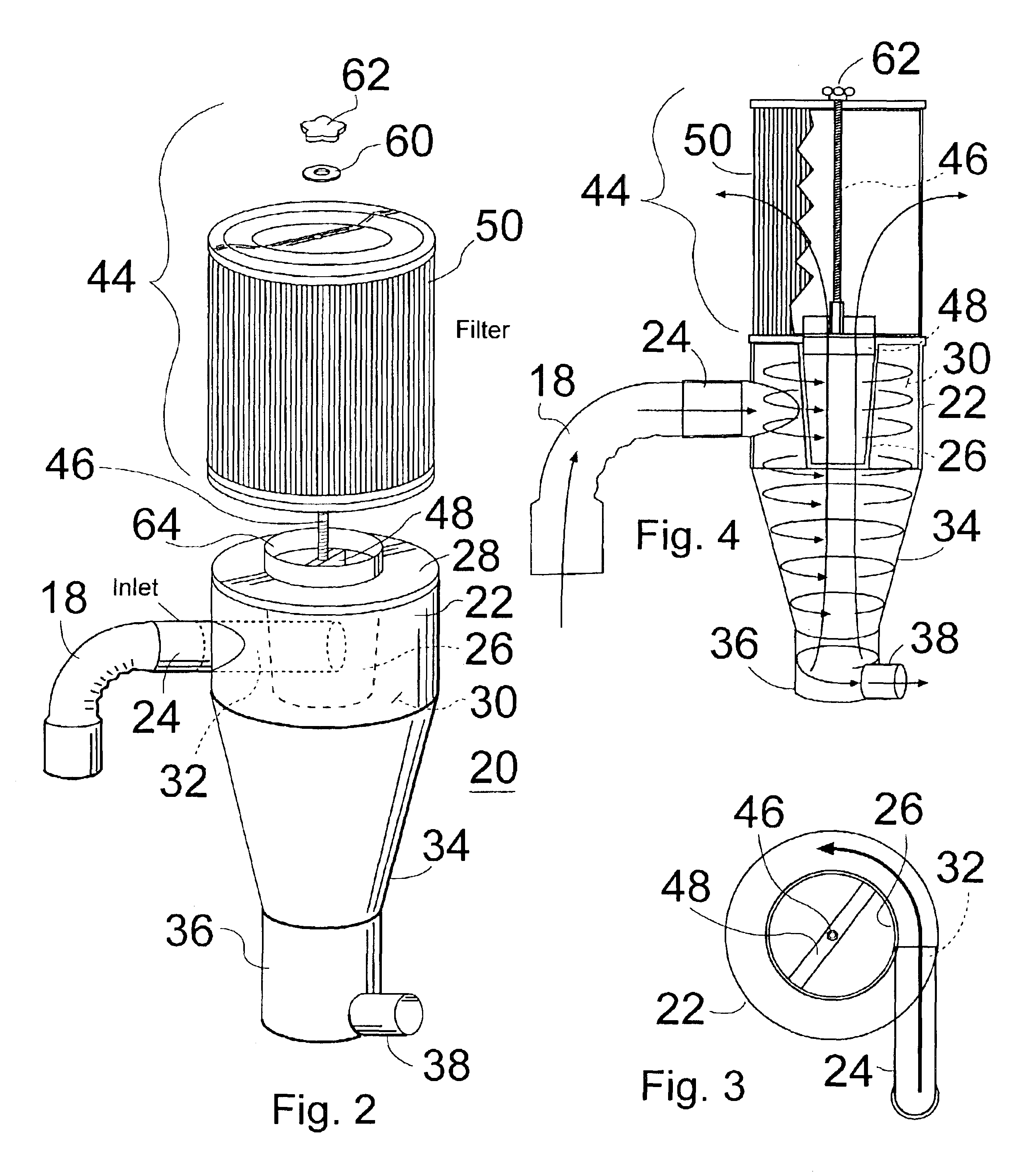

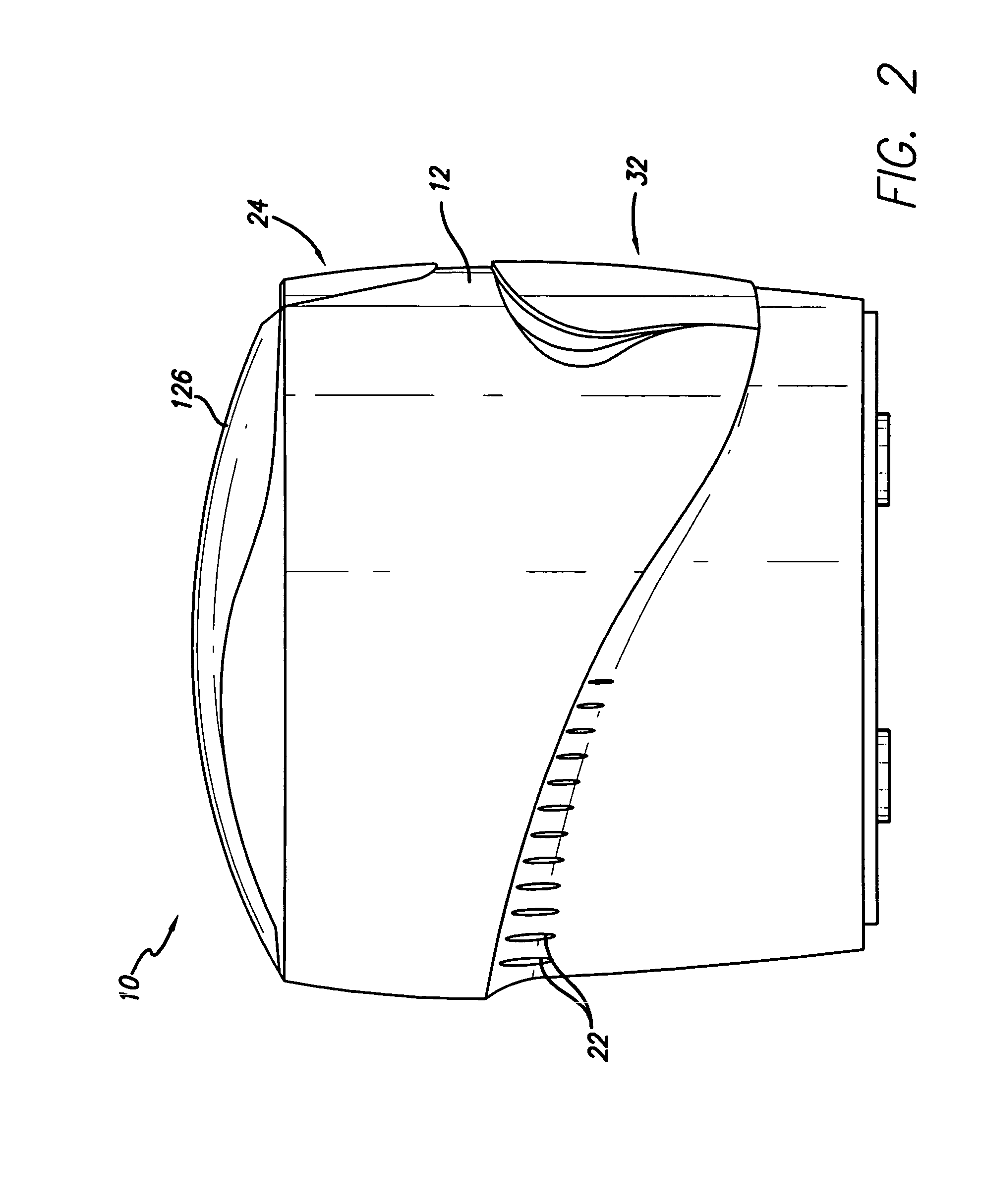

An auxiliary dust collection system can be interposed between a sander or other dust producing tool and a vacuum source, e.g., shop vacuum. This auxiliary system has a cyclonic separator connected by a flexible hose to the tool and by another hose to the vacuum source. The cone of the separator is mounted onto the lid of a drum into which the dust precipitates. For a tool that has its own blower, the vacuum source can be omitted, and the air leaving the outlet duct of the separator can be filtered and returned to the ambient. A drop in silencer formed of a sleeve or tube of acoustic foam can be positioned into the inlet side of a filter cartridge following a cyclonic separator. The silencer absorbs a significant fraction of the process noise.

Owner:WITTER ROBERT M

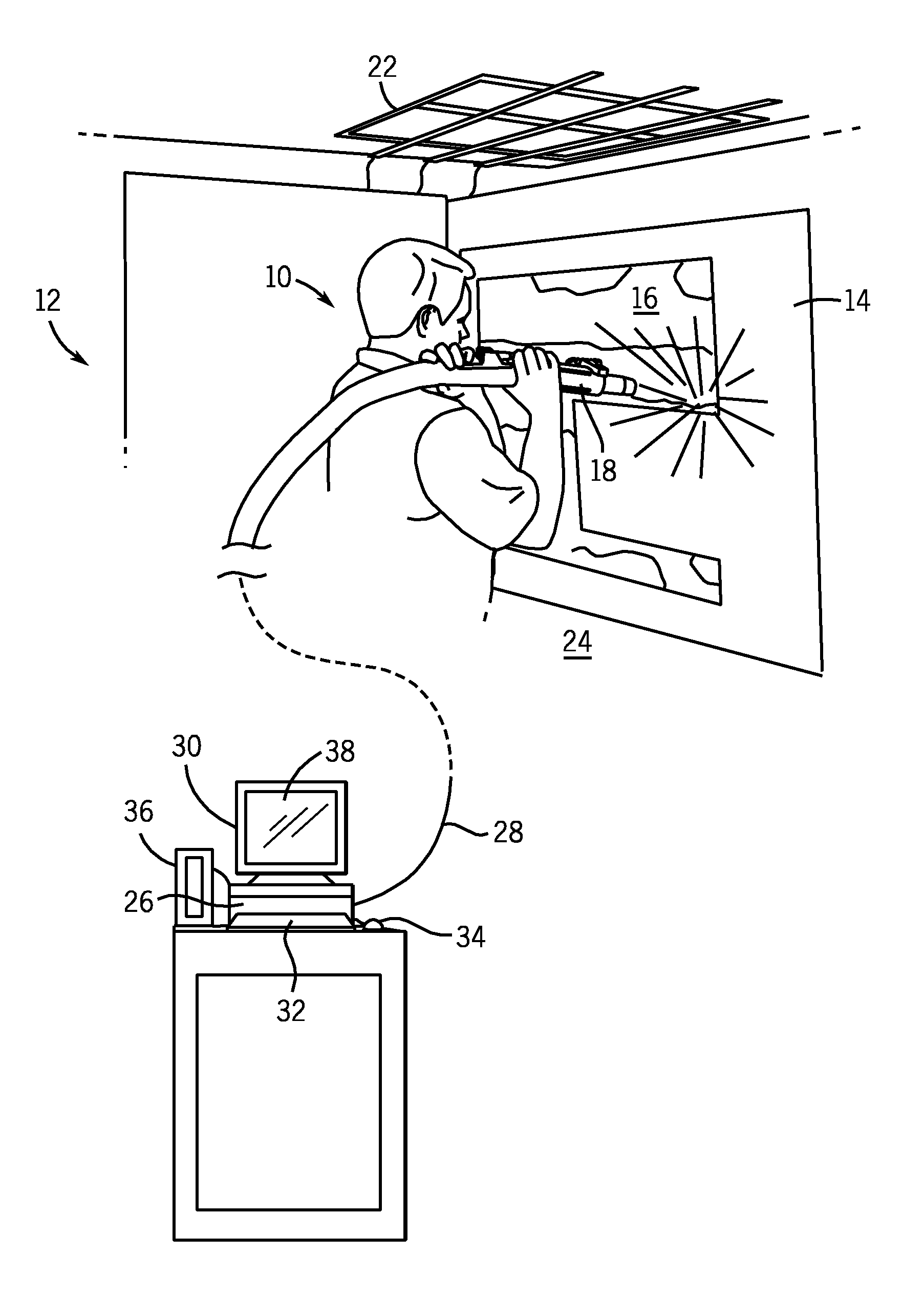

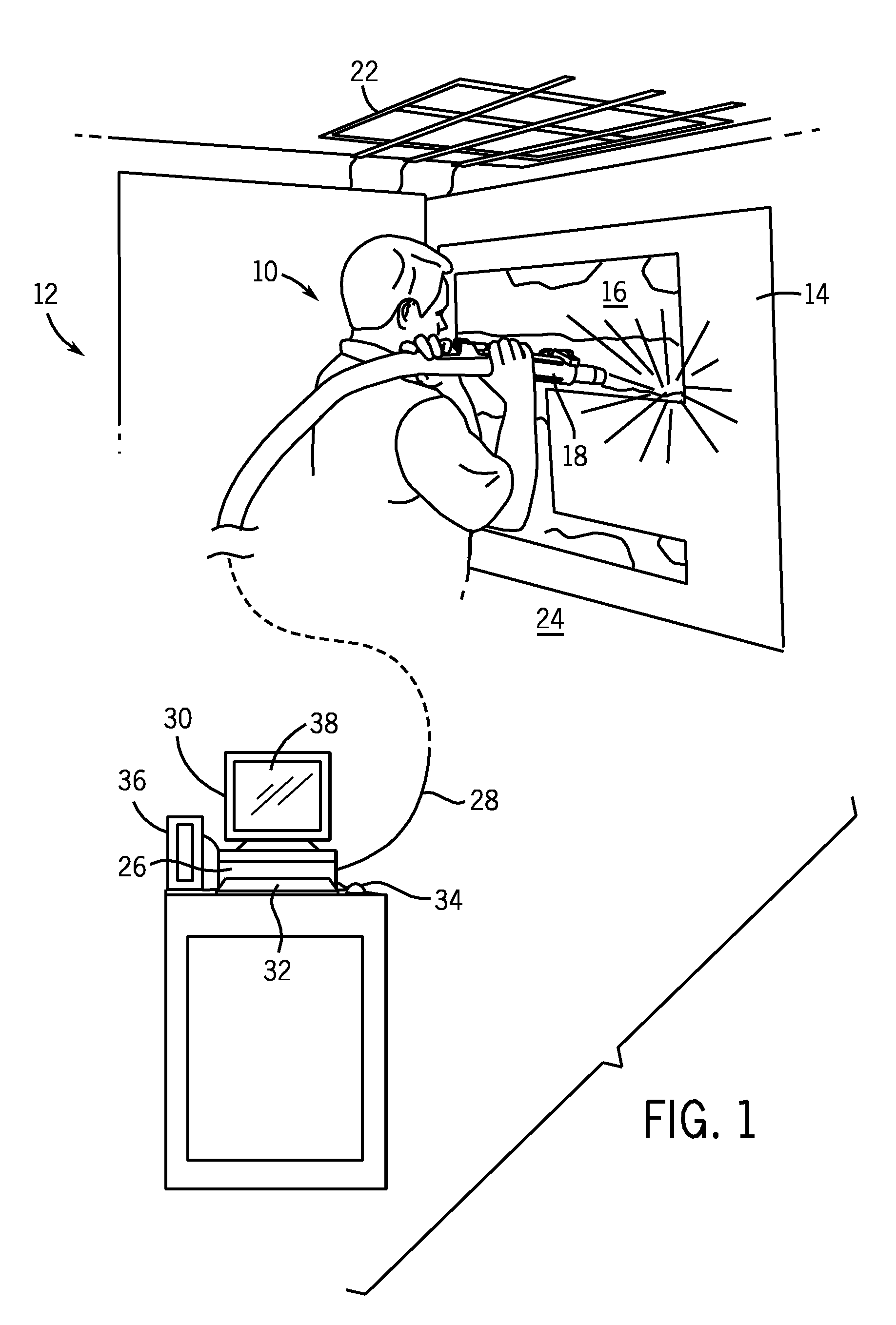

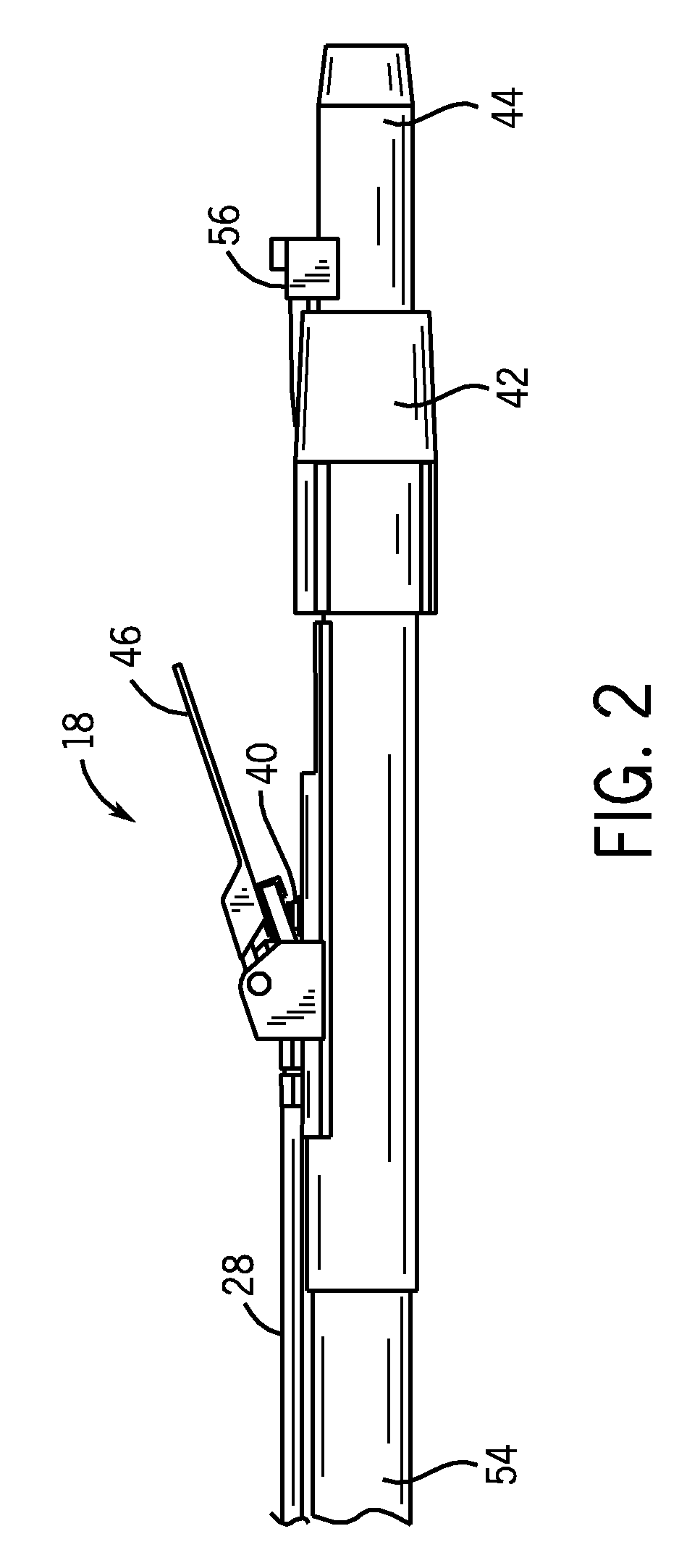

Virtual blasting system for removal of coating and/or rust from a virtual surface

InactiveUS7817162B2High simulationImprove realismCathode-ray tube indicatorsEducational modelsAbrasive blastingElectronic controller

A computer simulation and virtual reality system simulates the use of a blasting nozzle to remove one or more coatings and / or rust from a virtual surface. The user operates an electronic controller in the form of a blasting nozzle that outputs a signal indicating whether the blasting nozzle controller is in an “on” position or in an “off” position. The system also has a motion tracking system that tracks the position and orientation of the blasting nozzle controller with respect to the virtual surface defined on the display screen. Simulation software in a computer generates virtual blast pattern data, and the removal of the virtual coating(s) and / or rust image from the virtual surface is displayed in real time on the display screen.

Owner:UNIV OF NORTHERN IOWA RES FOUND

Auxiliary dust collection system

ActiveUS20070251198A1Avoid disadvantagesSimple and straightforward in constructionCombination devicesReversed direction vortexSanderProcess noise

Owner:WITTER ROBERT M

Dust collection system

InactiveUS6833016B2Reduced Power RequirementsReduce the risk of explosionCombination devicesReversed direction vortexCycloneCollection system

Owner:WITTER ROBERT M

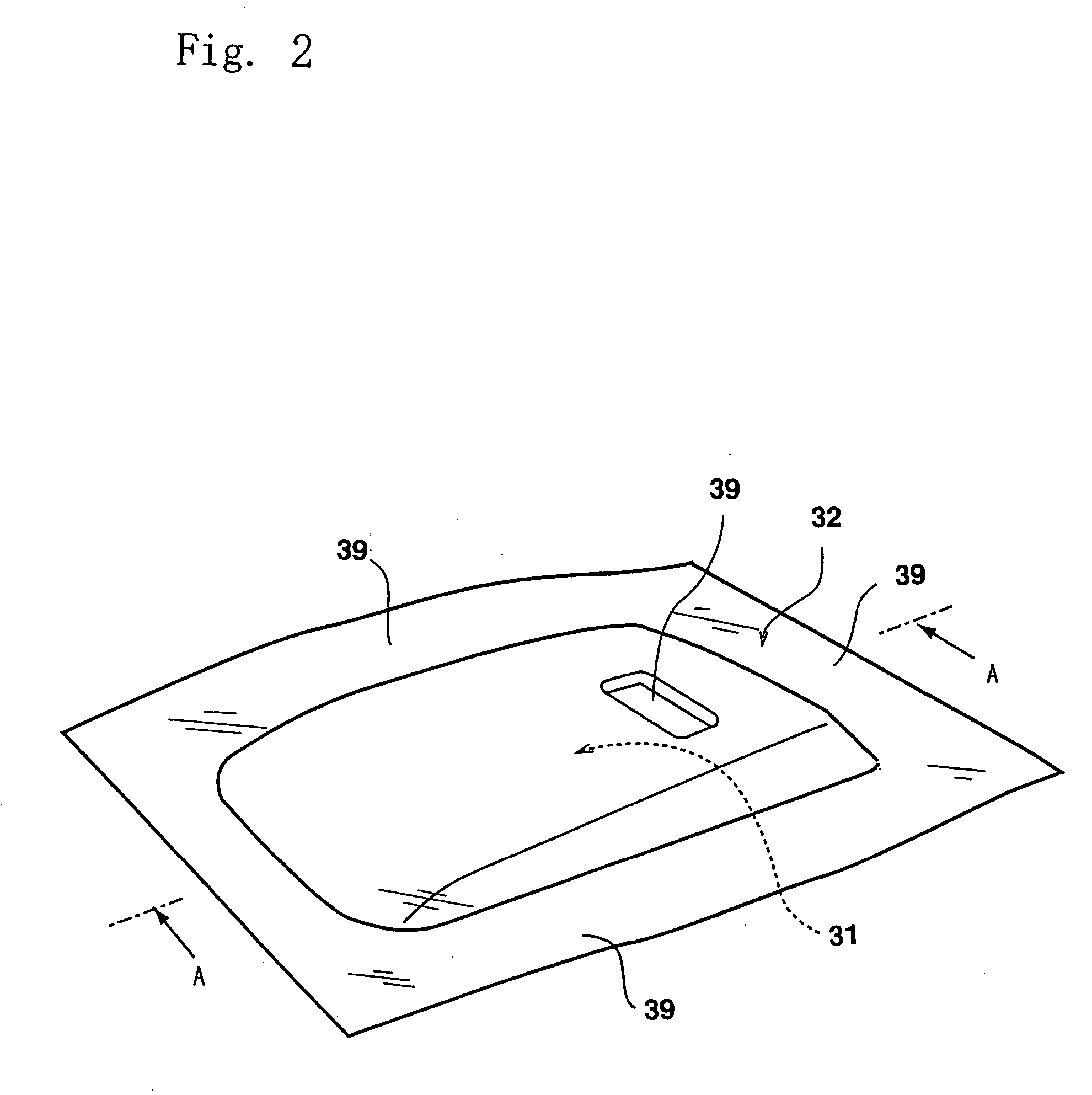

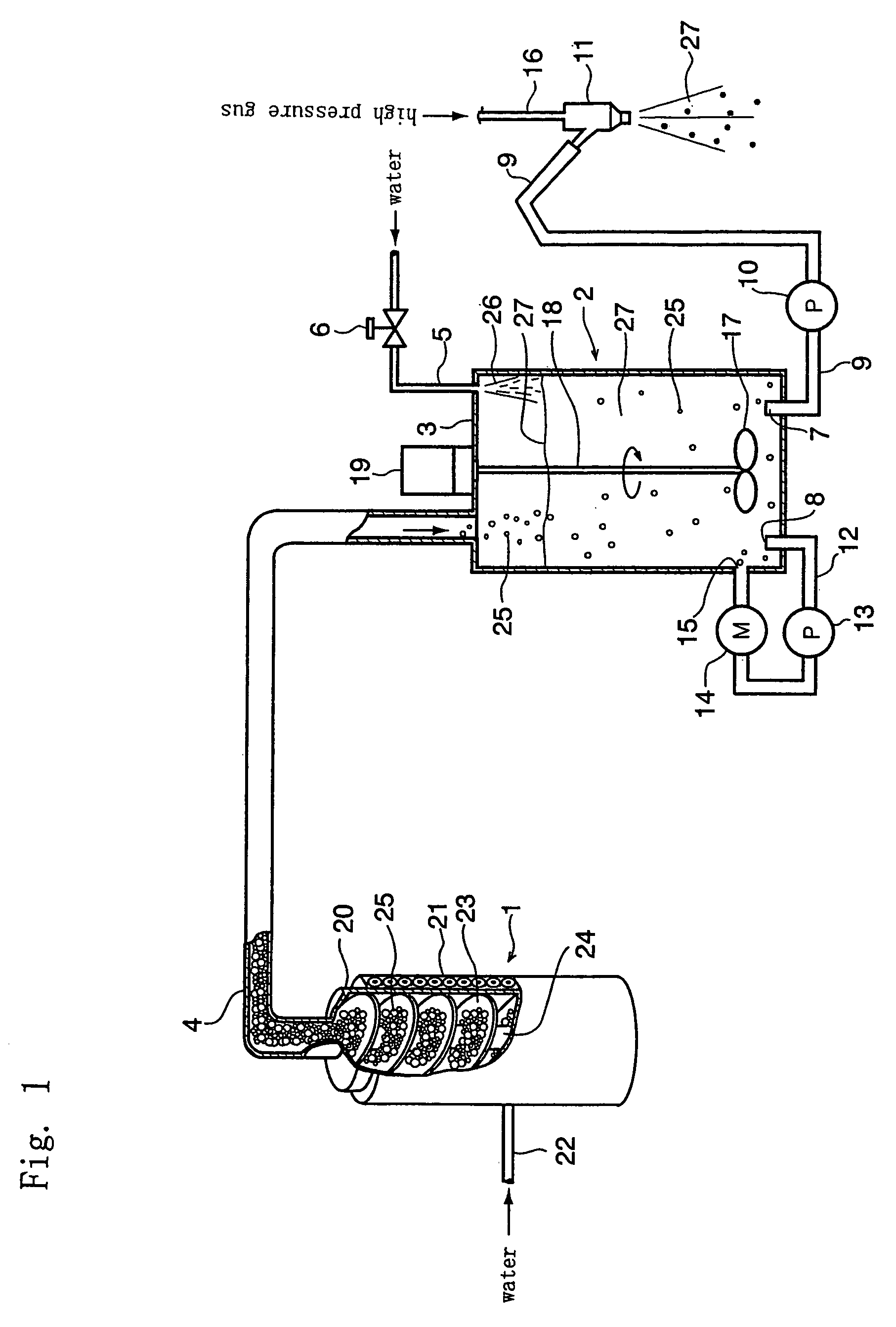

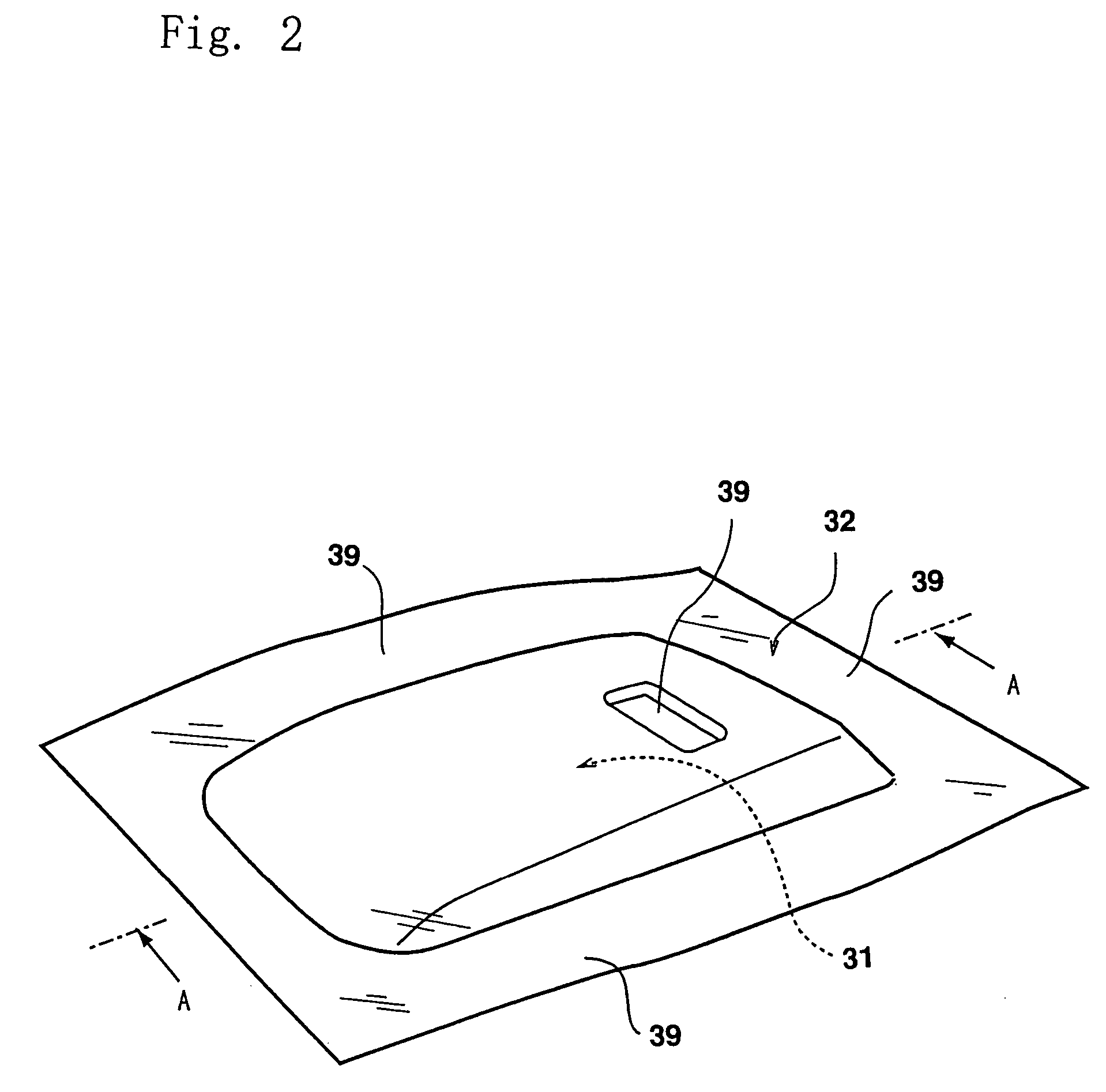

Ice blasting apparatus and trimming method for film insert molding

InactiveUS20050107006A1Lower Reliability RequirementsImprove securityAbrasive feedersAbrasive machine appurtenancesEngineeringSlurry

An ice blasting apparatus comprises: an ice making device operating a cutting blade to shave off ice freezing on an inner wall of the freezing casing and continuously discharges the shaved ice as flake-shaped ice pellets; an ice mixing tank mixing the ice pellets and water and maintaining the resulting ice slurry at a predetermined concentration with a concentration sensor; and a blast gun blasting the ice slurry. A trimming method is performed on a film insert molding with a film material adhering to a face of a resin molding and extending beyond a periphery edge of the resin molding. A blast gun facing the face with the film adhering to it blasts ice slurry of a required concentration toward the vicinity of the periphery edge of the resin molding to remove the unnecessary portion of the film material extending beyond the periphery edge of the resin molding.

Owner:TOSHIBA MASCH CO LTD

Device for comminuting dry ice granules, and dry ice dispensing arrangement having such a device

The invention relates to a device for comminuting dry ice granules, comprising a housing having a flow channel for dry ice granules which can be applied, by means of compressed gas, to a surface to be cleaned, and also comprising a first comminution member for comminuting the dry ice granules which are to be dispensed. In order to provide a device of this kind with which different degrees of comminution of dry ice granules can be achieved in a simple manner, it is proposed according to the invention that the device has at least one second comminution member which can be disposed in the housing in a position in which a total degree of comminution, which is greater than the individual degree of comminution which can be achieved solely by the first comminution member, can be achieved in combination with the first comminution member. A dry ice dispensing arrangement for dispensing a mixture of compressed gas and dry ice granules is also proposed, having a device of the above kind.

Owner:ALFRED KARCHER GMBH & CO KG

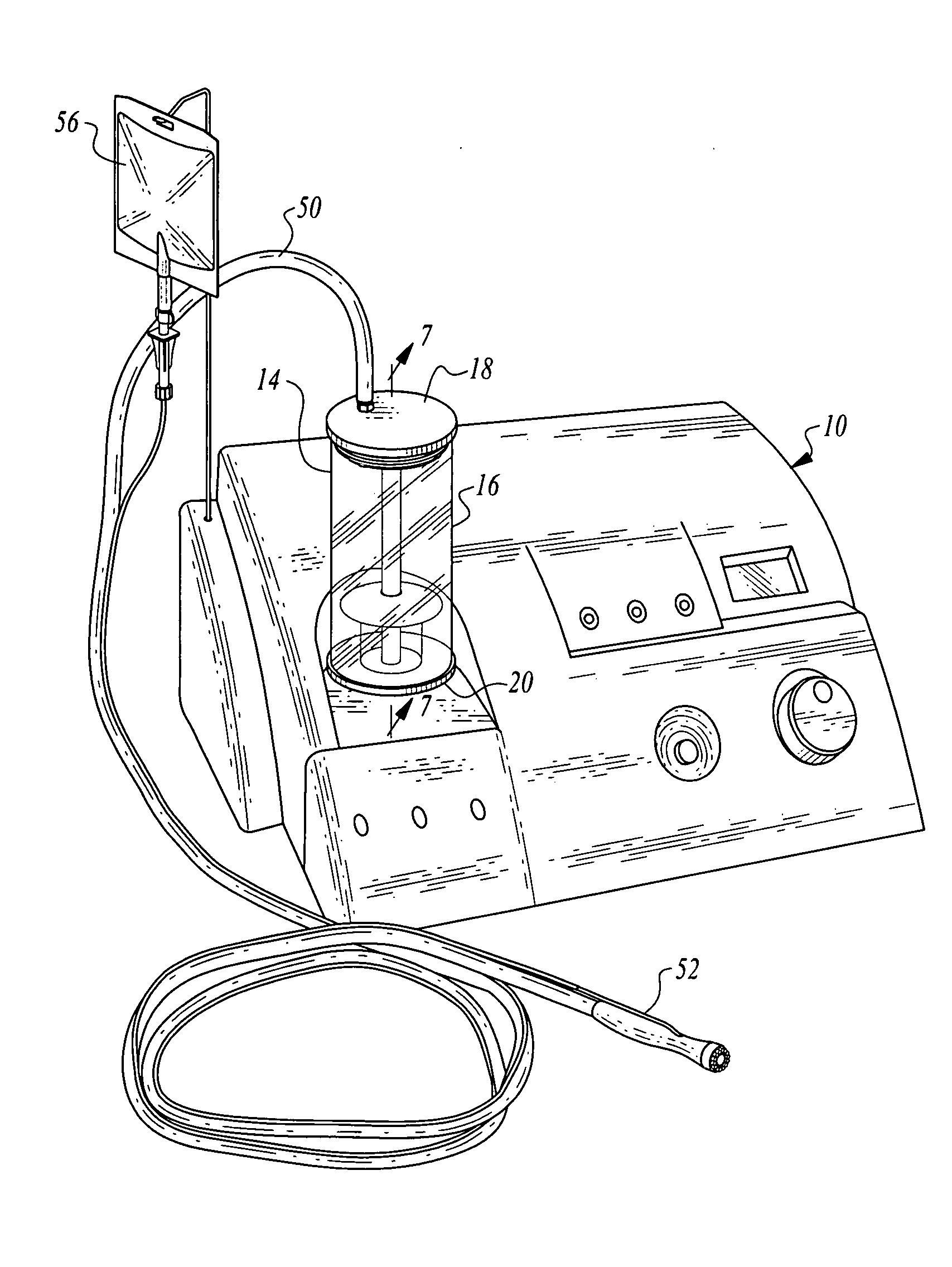

Microdermabrasion and suction massage apparatus and method

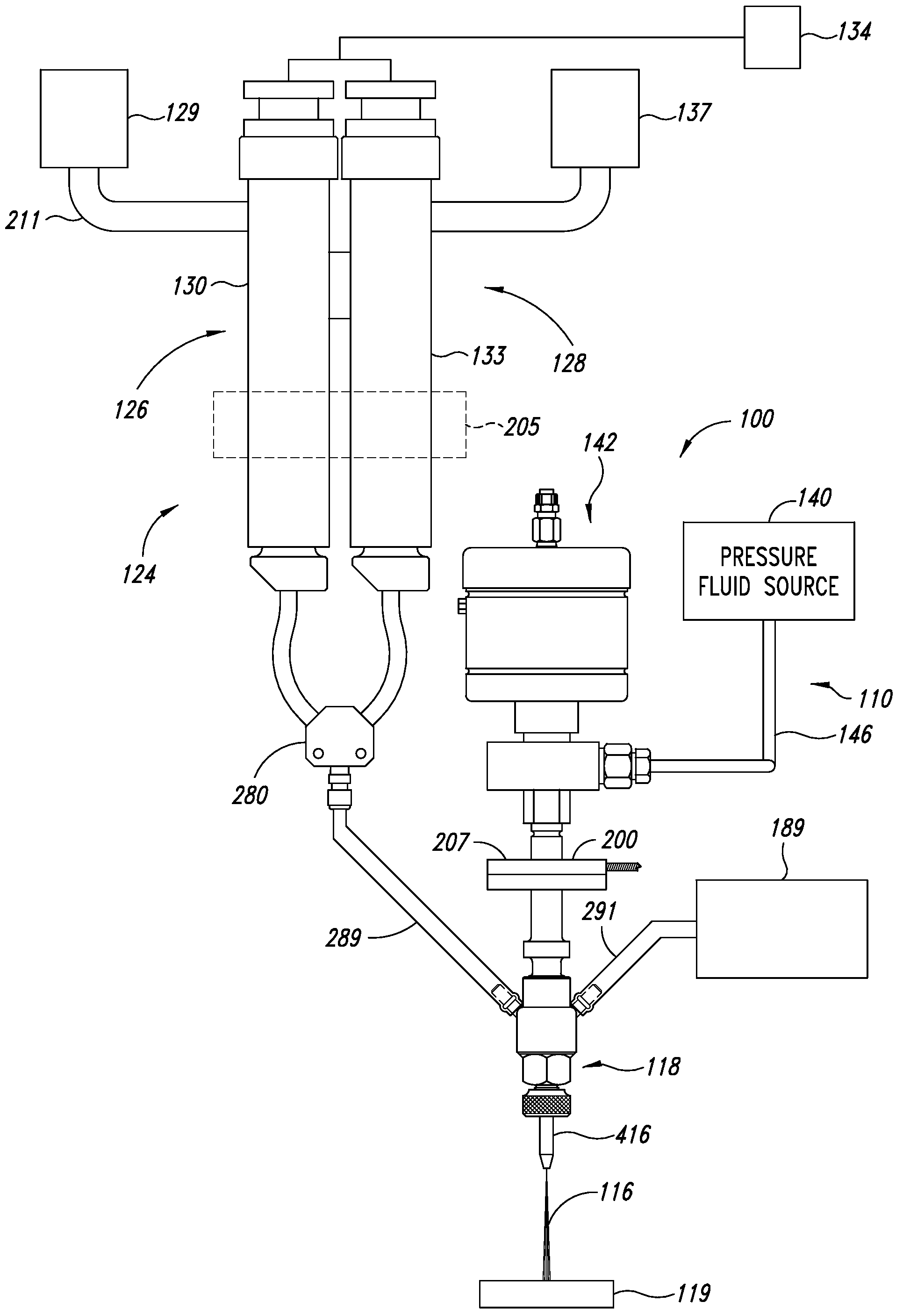

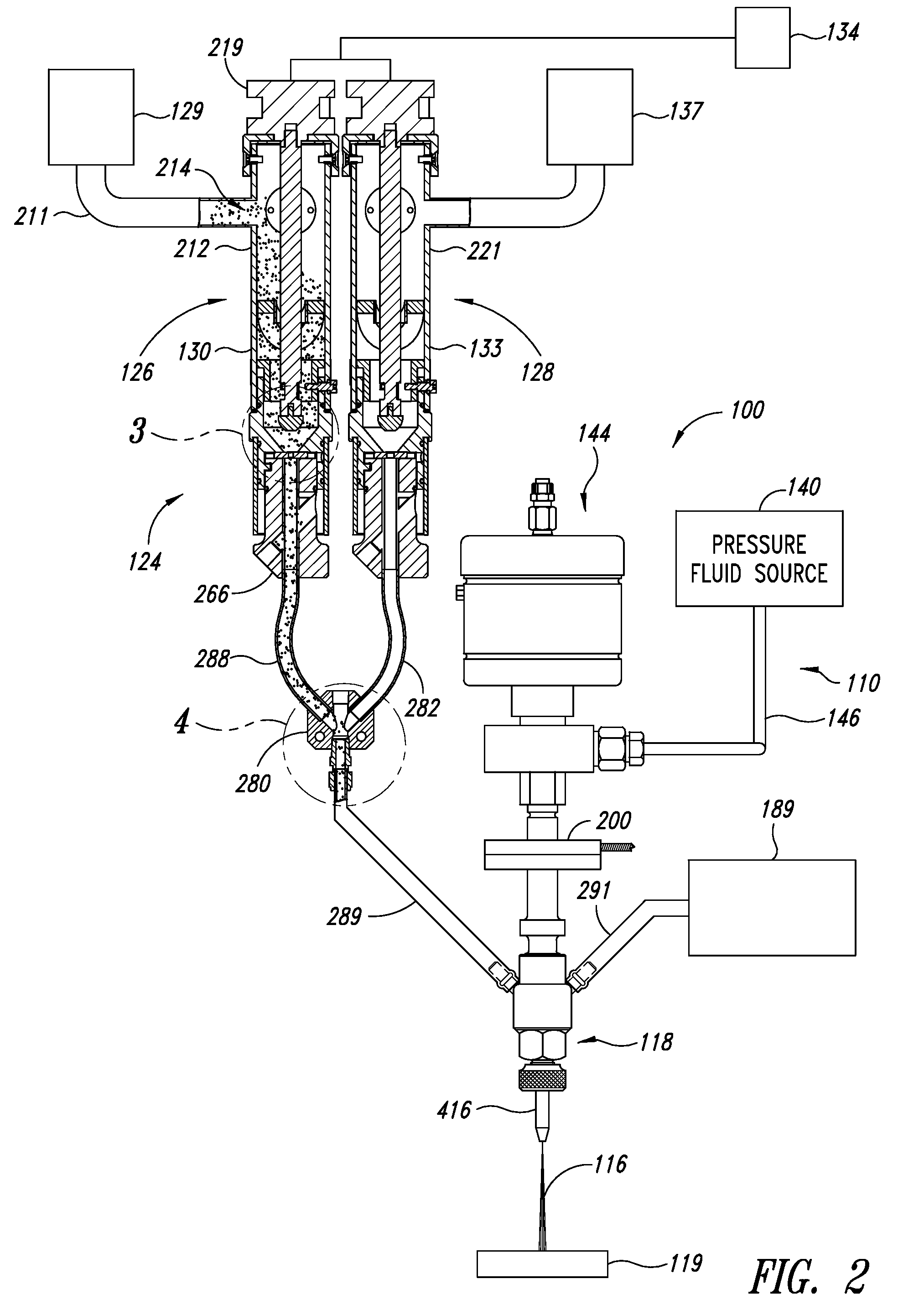

Microdermabrasion and suction massage apparatus are included in a single unit and alternatively connectable through a mode switch to a source of vacuum. The microdermabrasion section of the unit includes a crystal pick up station operating with a venturi effect to draw crystals through a hole into an air stream. The size of the hole is variable to control crystal density. A bleed valve is provided to control crystal velocity without controlling crystal density, while a bypass valve is provided to control crystal density without controlling crystal velocity. In an associated method, a microdermabrasion procedure is performed on the skin of a patient at an operative site. The mode switch is operated to activate the suction massage apparatus within the unit. This step is followed by performing a suction massage procedure at the operative site in order to promote healing of the abraded skin. The unit can be back-flushed by connecting various portions of the unit to a pressurized output of the source of vacuum.

Owner:EDGE SYST CORP

Ice blasting apparatus and trimming method for film insert molding

InactiveUS7040962B2Lower Reliability RequirementsImprove securityAbrasive feedersAbrasive machine appurtenancesSlurryFilm material

Owner:TOSHIBA MASCH CO LTD

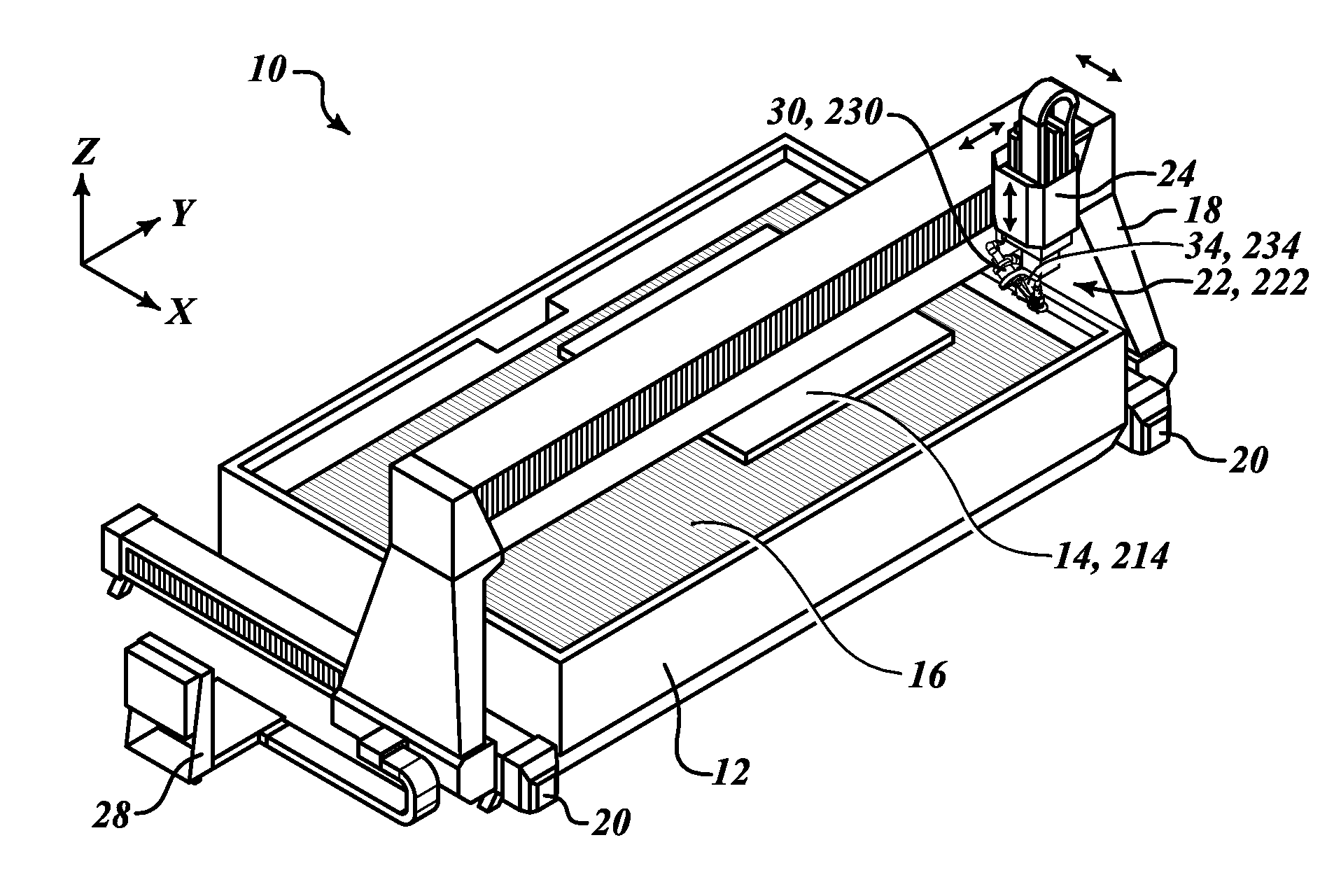

Waterjet cutting system with standoff distance control

ActiveUS20130025422A1Efficient and accurate mannerBlast gunsAbrasive machine appurtenancesMeasurement deviceControl system

A cutting head of a waterjet cutting system is provided having an environment control device and a measurement device. The environment control device is positioned to act on a surface of a workpiece at least during a measurement operation to establish a measurement area on the surface of the workpiece substantially unobstructed by fluid. The measurement device is positioned to selectively obtain information from within the measurement area indicative of a position of the cutting head relative to the workpiece. A control system is further provided and operable to position the cutting head relative to the workpiece at a standoff distance based at least in part on the information indicative of the position of the cutting head relative to the workpiece obtained by the measurement device. A method of operating a waterjet cutting system is also provided.

Owner:FLOW INT

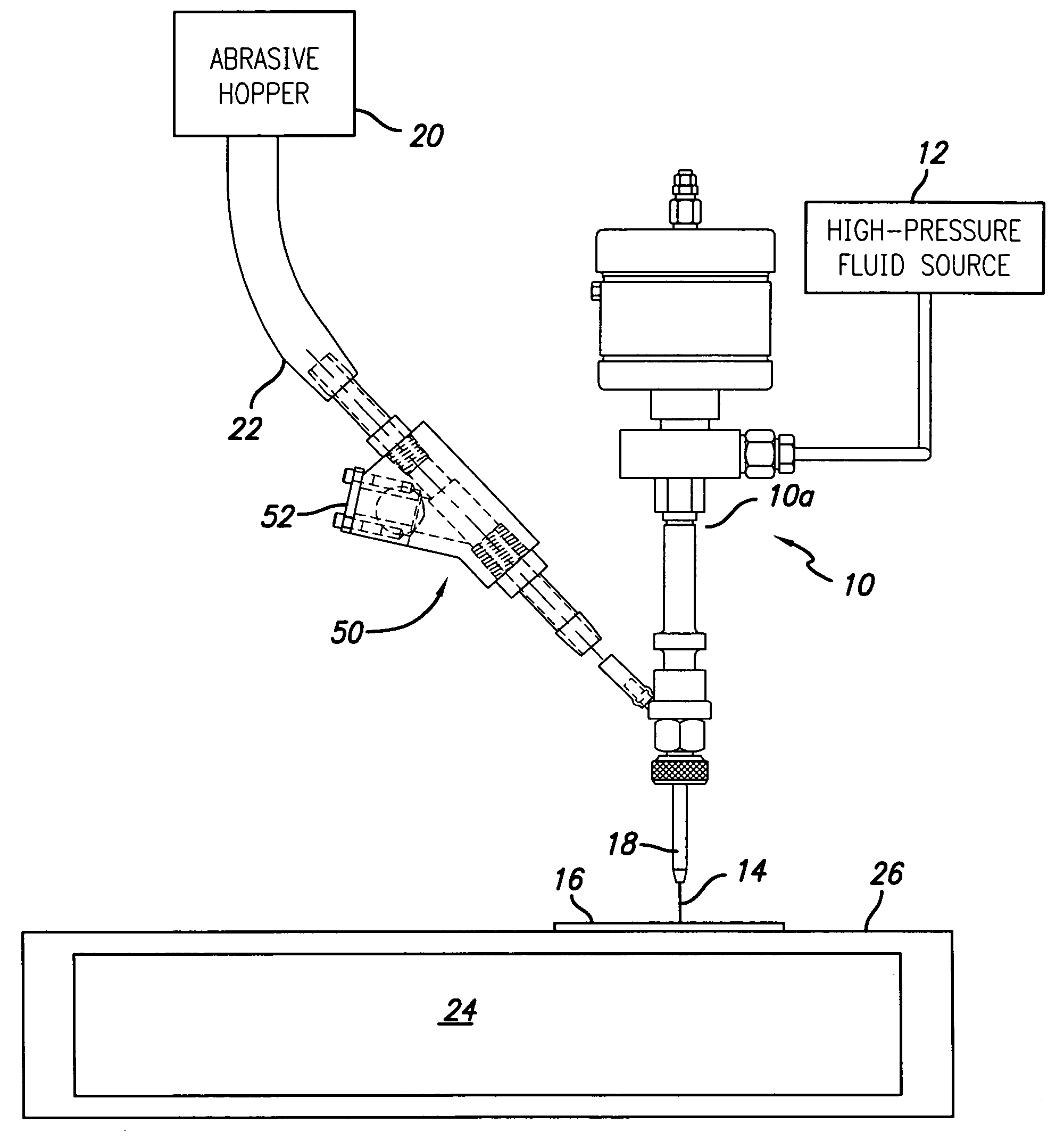

Suspended abrasive waterjet hole drilling system and method

ActiveUS7186167B2High viscosityVelocity increasesBlast gunsLiquid/gas jet drillingEngineeringDrilling system

A suspended abrasive waterjet narrow kerf cutting method is reconfigured to simultaneously drill multiple, closely-spaced holes in a target, including holes in confined non line-of-sight locations. Working fluid nozzles can be located on a flat or non-flat tool surface and arranged in uniform or non-uniform patterns, in an angled or perpendicular orientation, and in parallel or non-parallel arrangements. Individual nozzles or nozzle groups can be easily changed to provide increased or diminished working diameters, allowing control over the hole sizes and resultant airflow thru the drilled workpiece.

Owner:RTX CORP

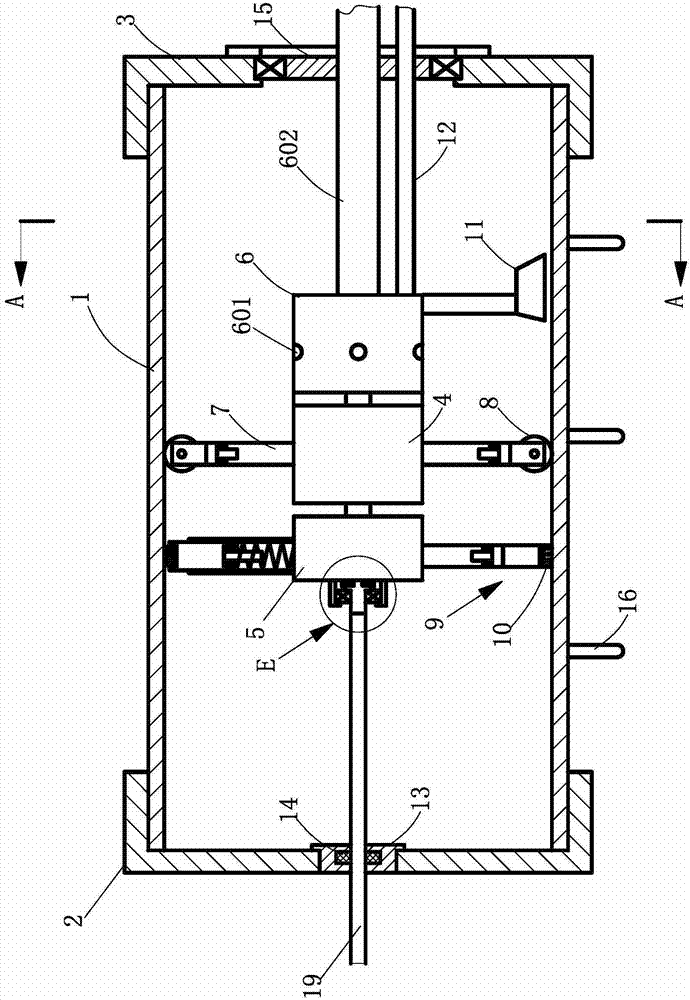

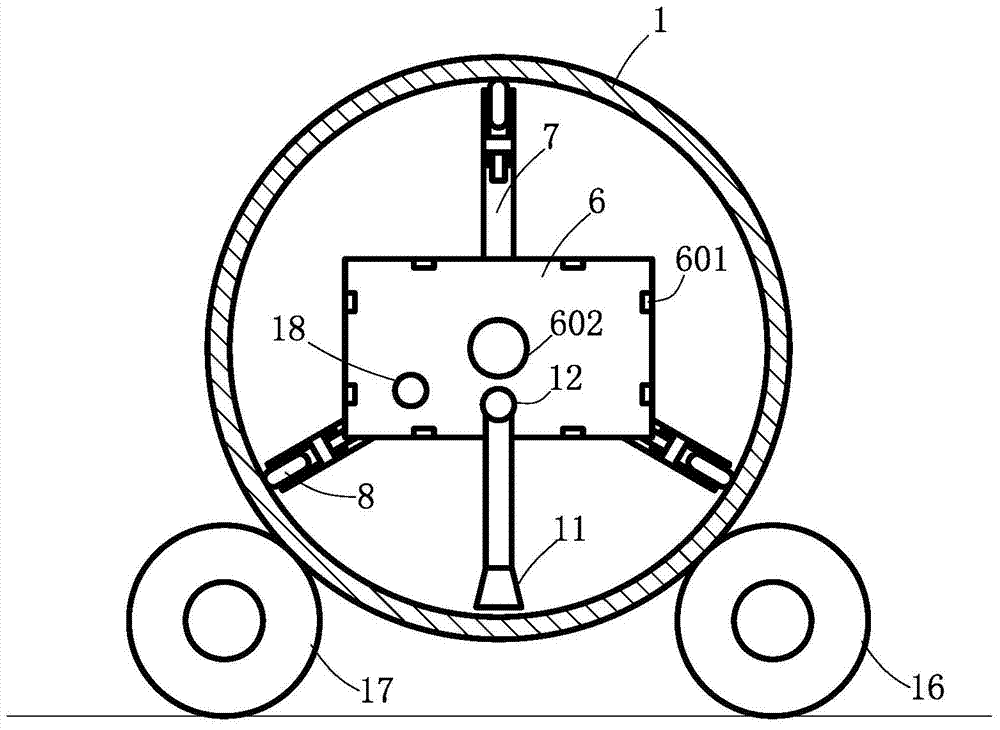

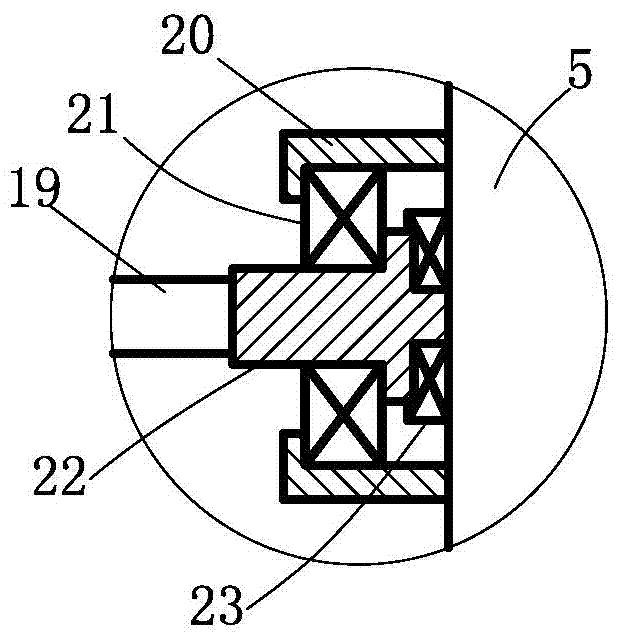

Pipeline inner wall rust removal device

ActiveCN104723223AAvoid pollutionReduce direct damageGrinding machinesAbrasive machine appurtenancesPneumatic motorPollution

The invention discloses a pipeline inner wall rust removal device, belonging to the technical field of polishing units. The device comprises a first end cover and a second end cover which are hermetically installed at two ends of the pipeline, a rust removal trolley is arranged in the pipeline, the dust removal trolley comprises a pneumatic motor with dual output shafts, a shell of the pneumatic motor is provided with a plurality of support shafts, the end part of each support shaft is provided with a roller wheel, a grinding disc is fixedly installed on the output shaft of the pneumatic motor, close to the first end cover, and is provided with a plurality of support rods in the radial direction, the end part of each support rod is provided with an abrasive disc, the output shaft of the pneumatic motor, close to the second end cover, is connected with a shot-blasting machine in a transmission manner; the end part of the grinding disc is connected with a traction rope, the traction rope extends out of the first end cover, one end of the shot-blasting machine, close to the second end cover, is connected with a shot feeding pipe, the pneumatic motor is connected with a gas inlet pipe, the shot feeding pipe and the gas inlet pipe extend out of the second end cover. The pipeline inner wall rust removal device can be used for solving the technical problems that the pipeline inner wall is serious in rust removal pollution and the rust removal effect is poor, and can be widely applied to pipeline cleaning.

Owner:SHANGHAI HONGPU STEEL STRUCTURE ENG

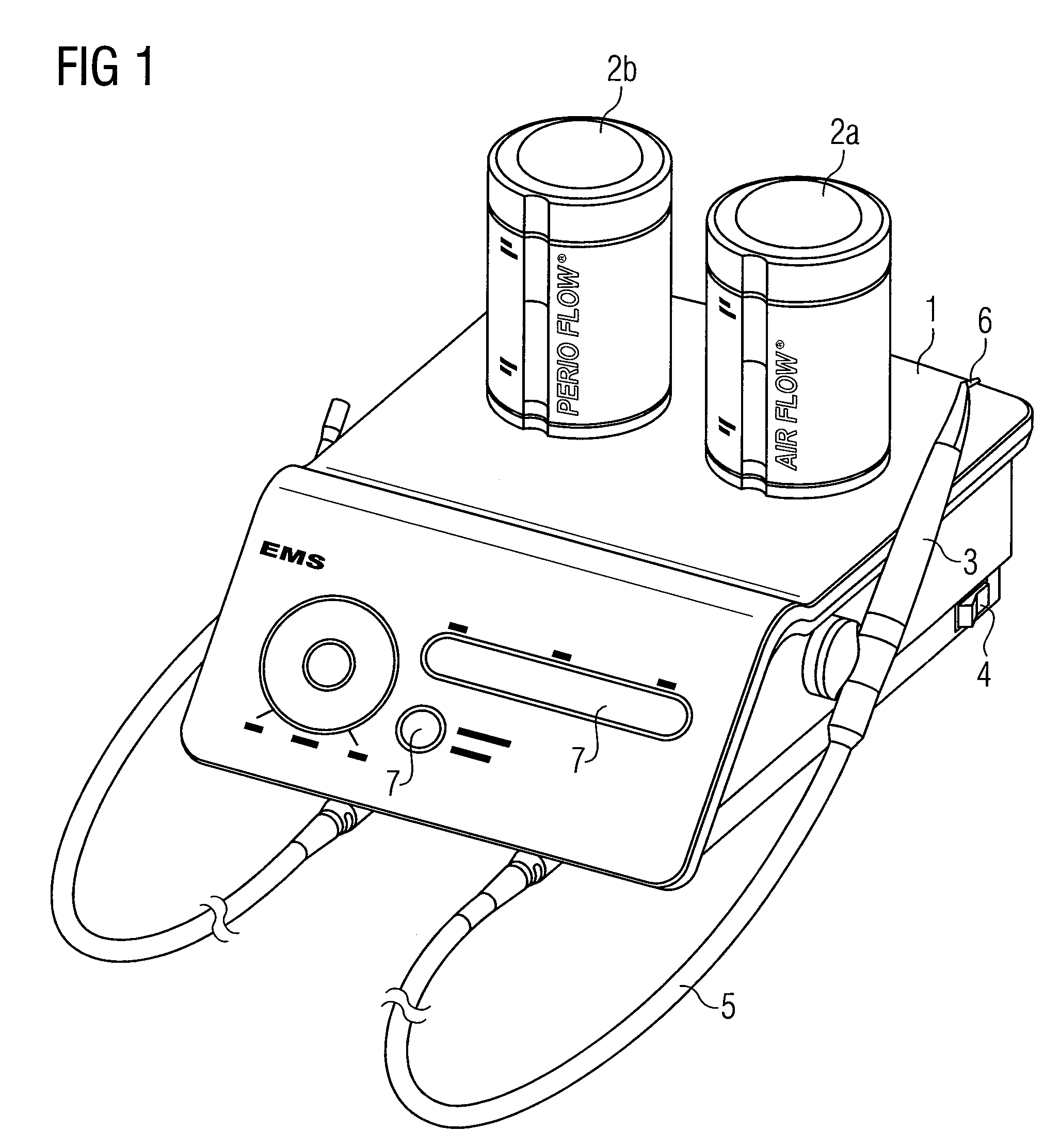

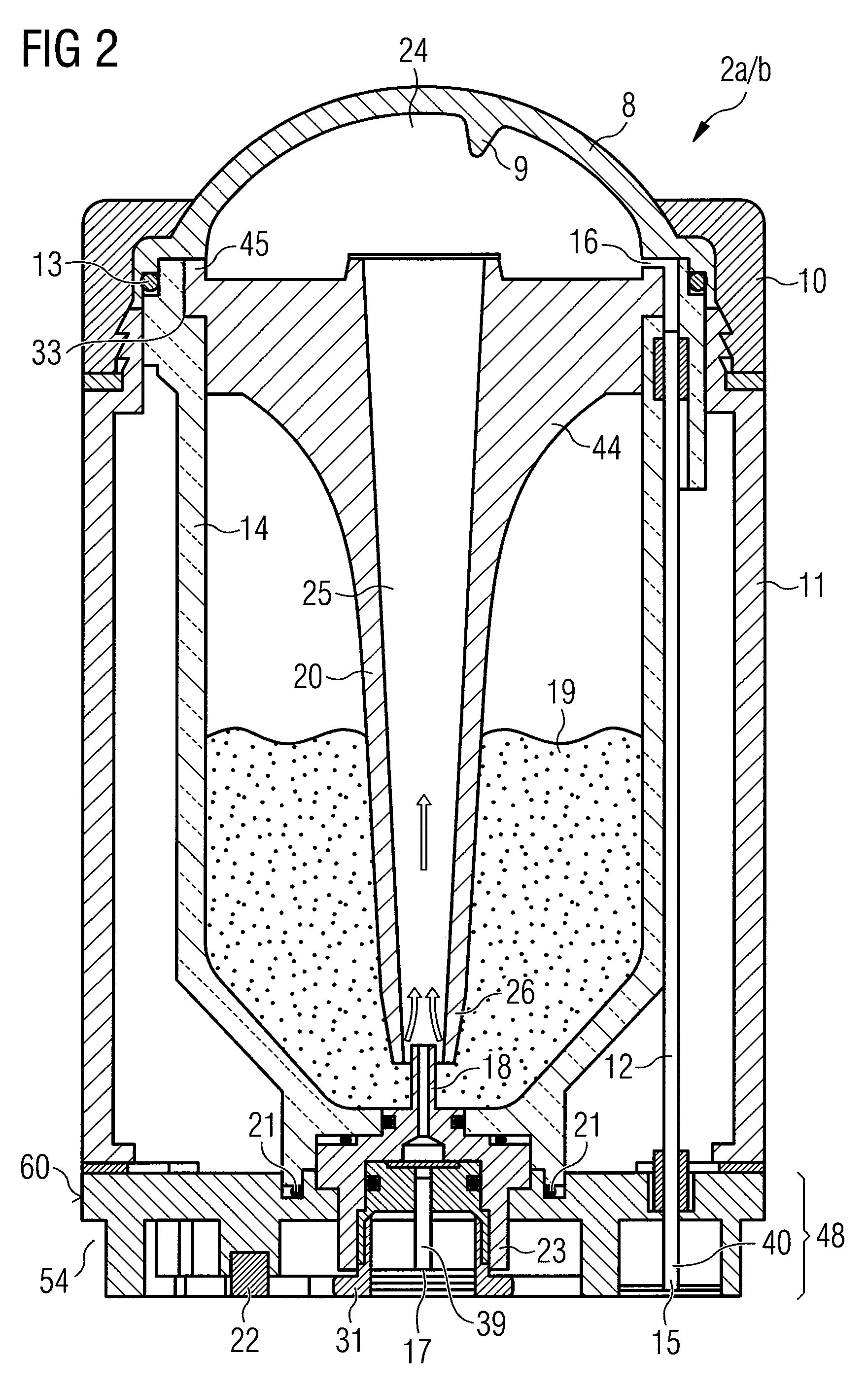

Powder blast tool, powder reservoir, insert for powder reservoir and method of dental treatment

A powder blast tool for mixing a powder with a pressurised gas, having at least one powder reservoir, with supply lines for the pressurised gas, and a discharge line, which is connected to a discharge nozzle, at which a powder-gas mixture and optionally pressurised water are discharged, wherein the powder blast tool can preferably be connected to plural powder reservoirs simultaneously and exchangeably, wherein at least one receiving region with at least one mixture terminal and at least one gas terminal is disposed on the powder blast tool and wherein the powder reservoir has a coupling region for exchangeable connection of the powder reservoir to the powder blast tool. Also disclosed are a suitable powder reservoir and an insert for such powder reservoirs and a corresponding method of dental treatment.

Owner:FERTON HLDG

Skin treatment system

InactiveUS20110054490A1Abrasive machine appurtenancesAbrasive surgical cuttersSkin treatmentsMedicine

Owner:DERMASWEEP

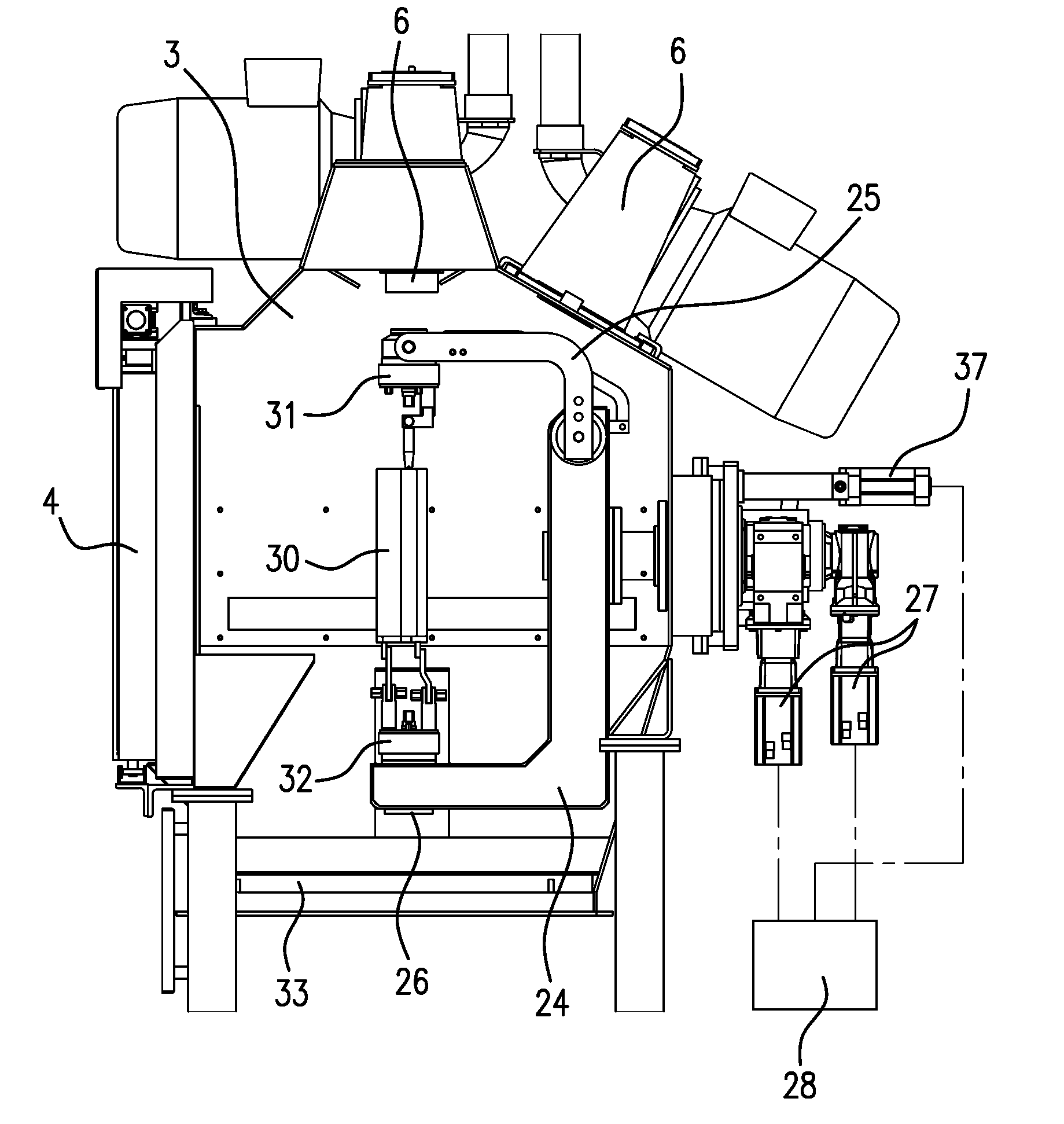

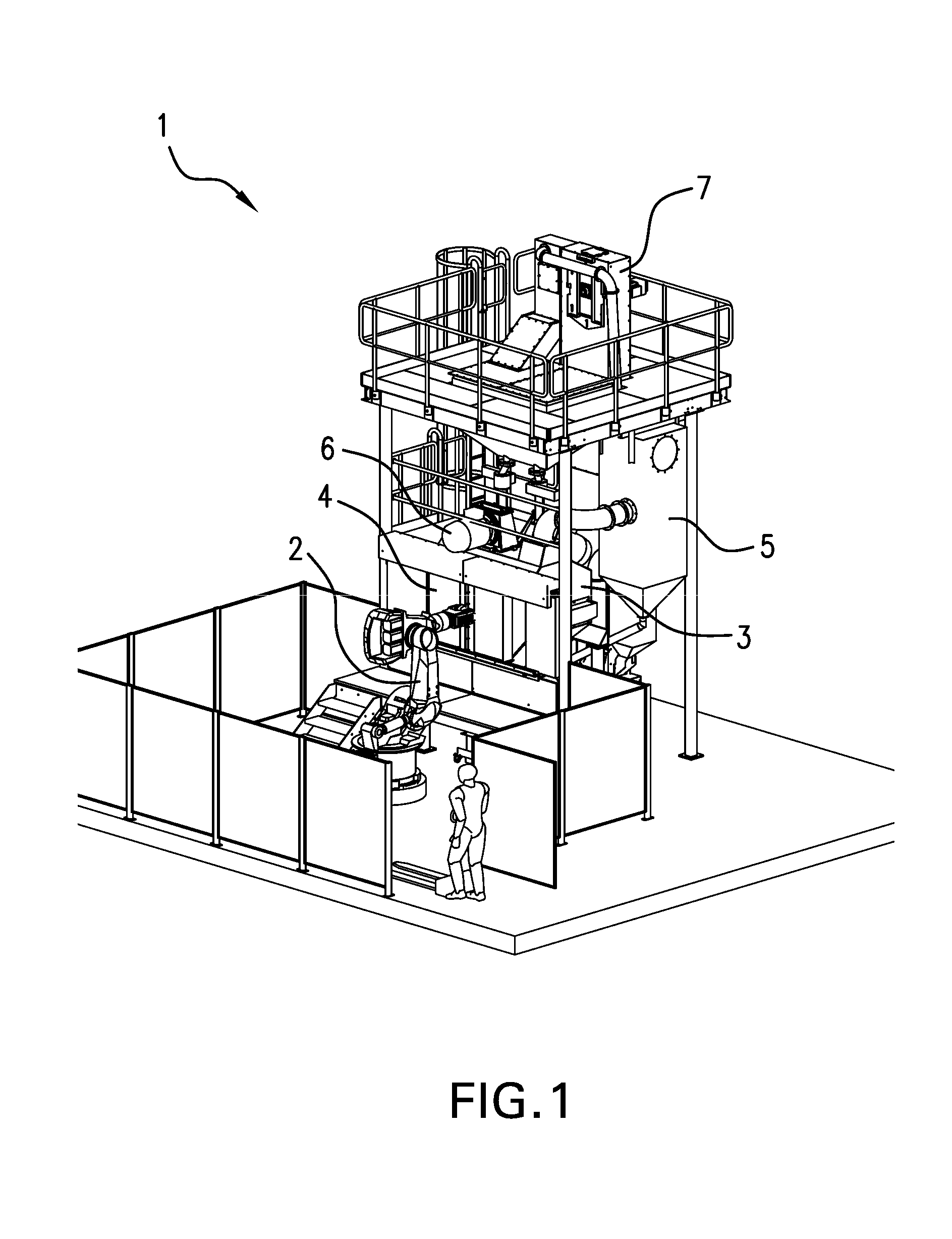

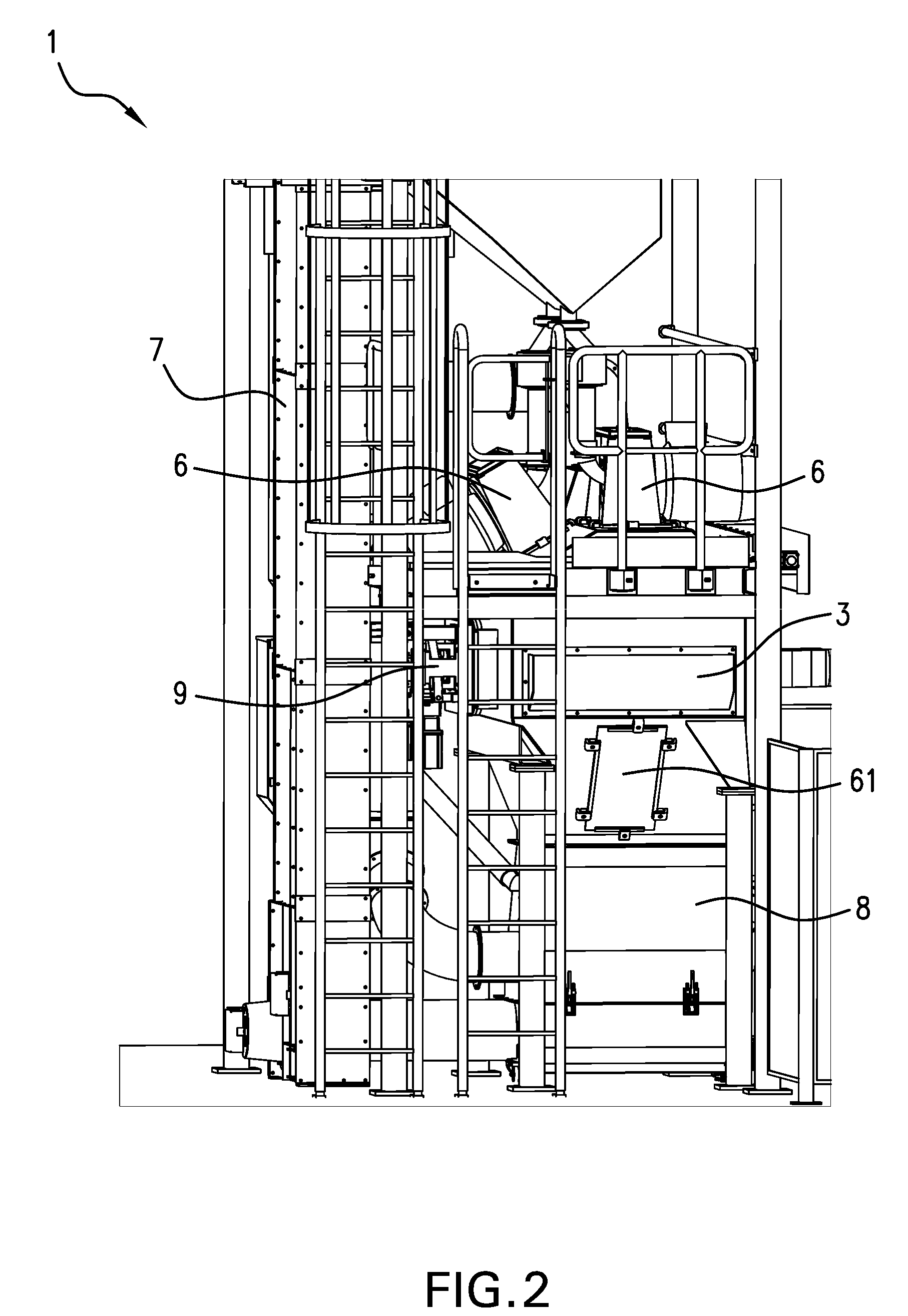

Shot-blasting installation for blasting work pieces made from light metal alloys

InactiveUS7421872B2Promote accumulationValve arrangementsFluid-tightness measurementAbrasive blastingEngineering

A shot-blasting installation (1) for blasting work pieces (30) made from light metal alloys, comprising at least one blasting chamber (3) for receiving the work pieces that are to be blasted, at least two blasting wheels (6) arranged in walls of the blasting chamber for introducing a blasting agent into the blasting chamber, and a separator (8) for separating the mixture of blasting agent and material that has been removed by blasting, wherein the separator (8) is arranged directly beneath the blasting chamber (3), and wherein a manipulator (10) for handling the cast work piece (30) during blasting is arranged in the blasting chamber (3).

Owner:DISA IND

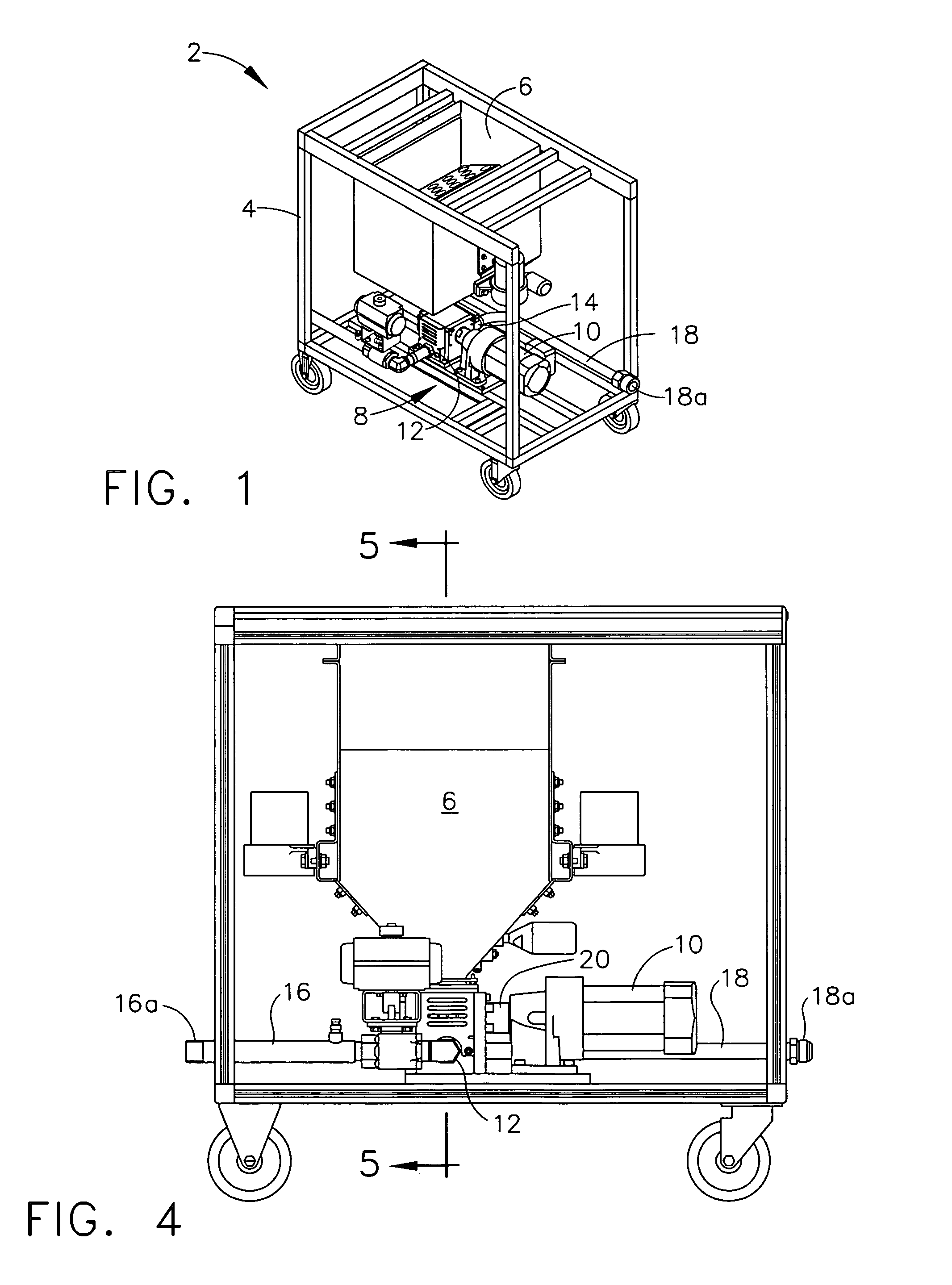

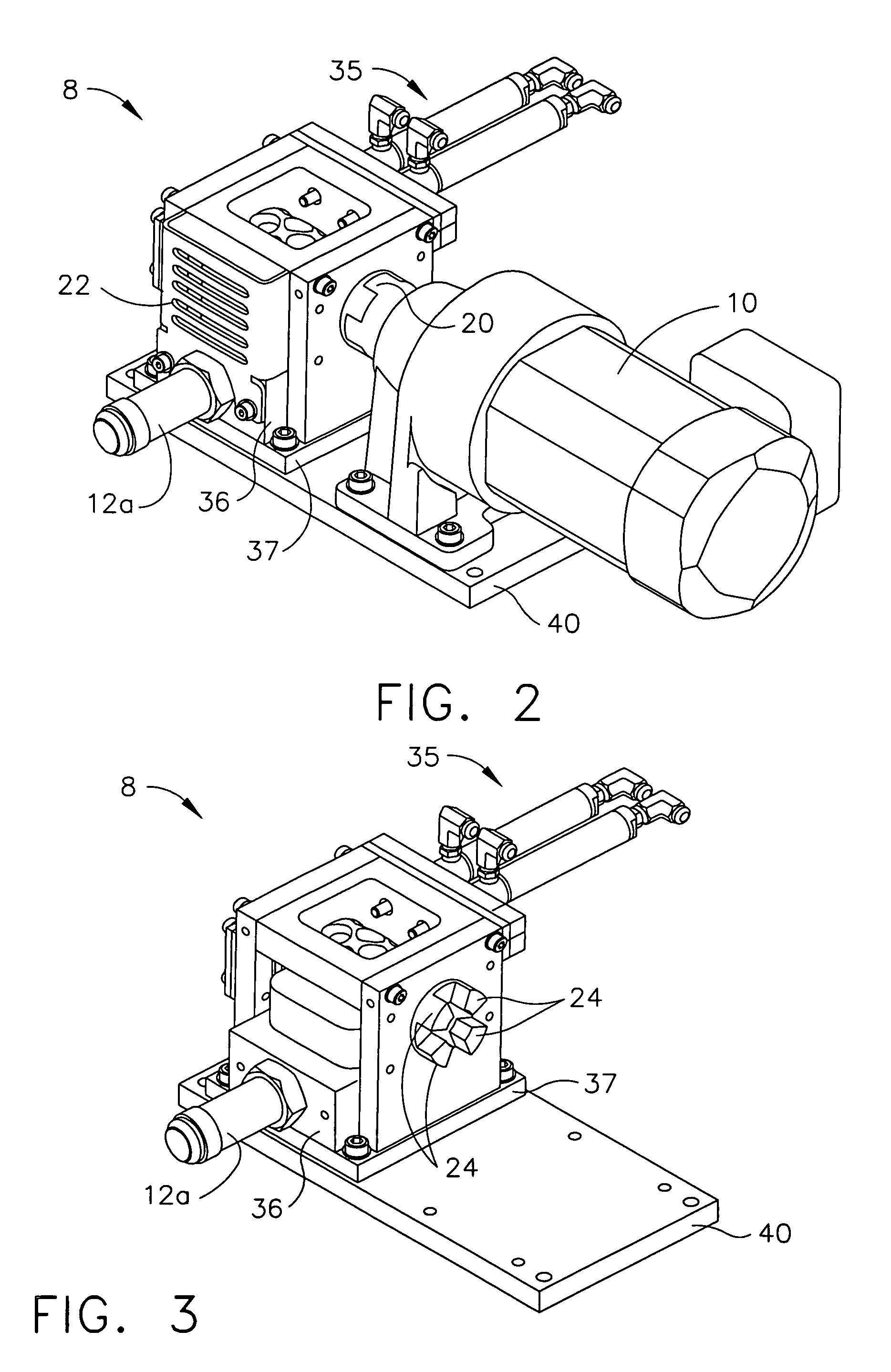

Feeder assembly for particle blast system

A particle blast system includes a feeder assembly having a rotor with a plurality of pockets formed in the peripheral surface. The transport gas flowpath includes the pockets, such that substantially all transport gas flows through the pockets. The seal adjacent the peripheral surface is actuated by the transport gas pressure to urge its sealing surface against the rotor's peripheral surface. At start up, there is no substantial pressure between the seal and the rotor, reducing start up torque requirements.

Owner:COLD JET

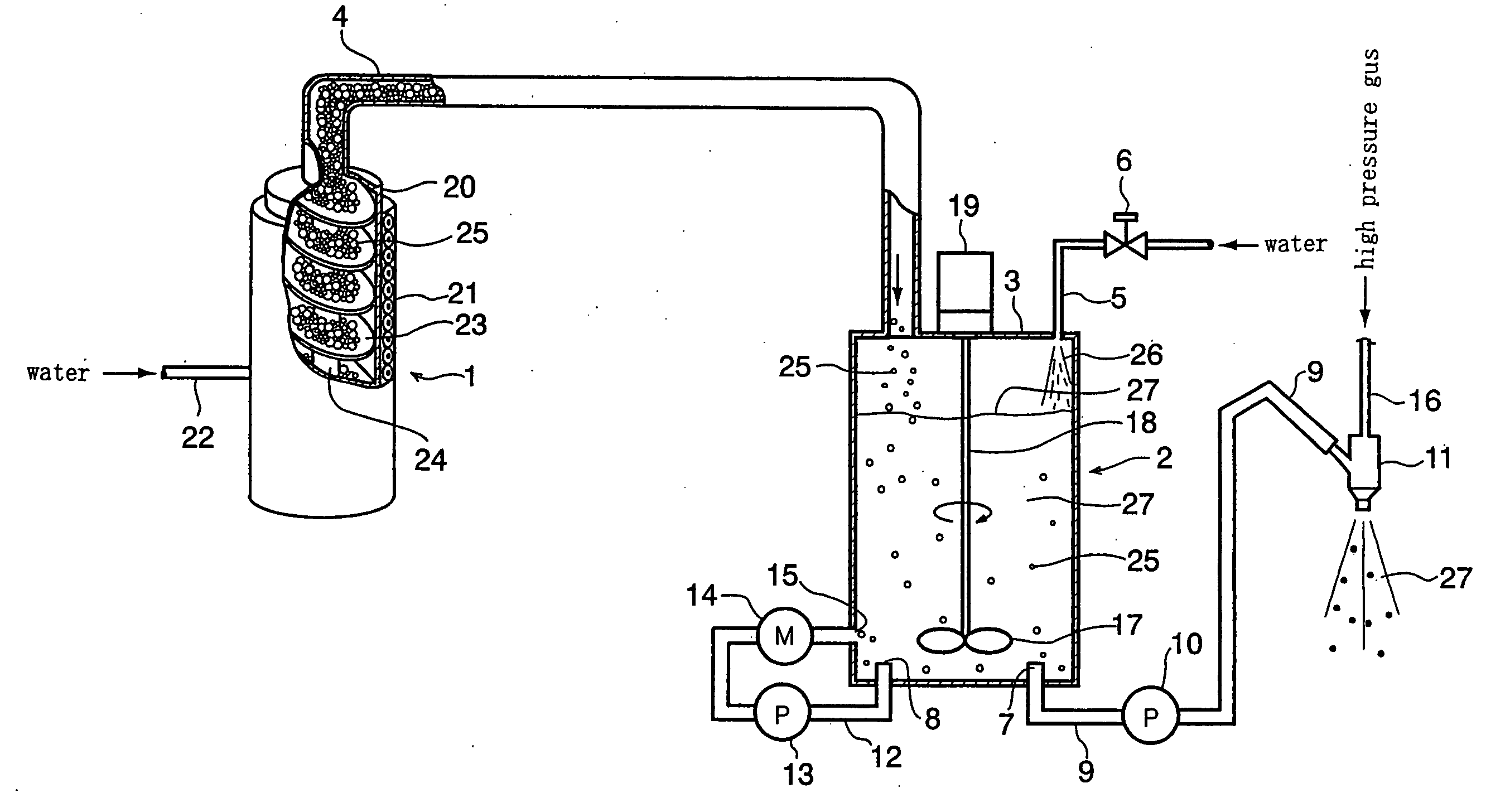

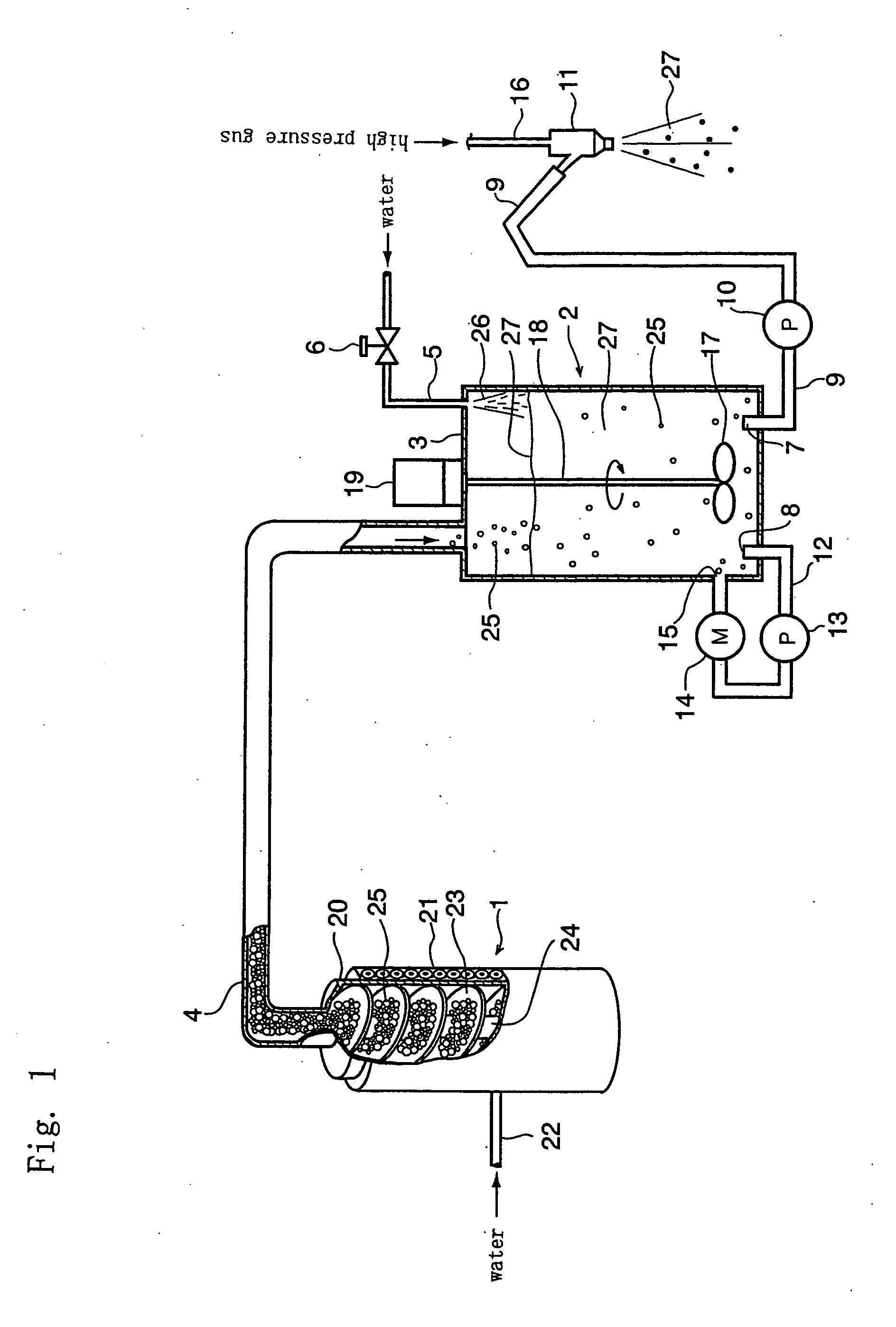

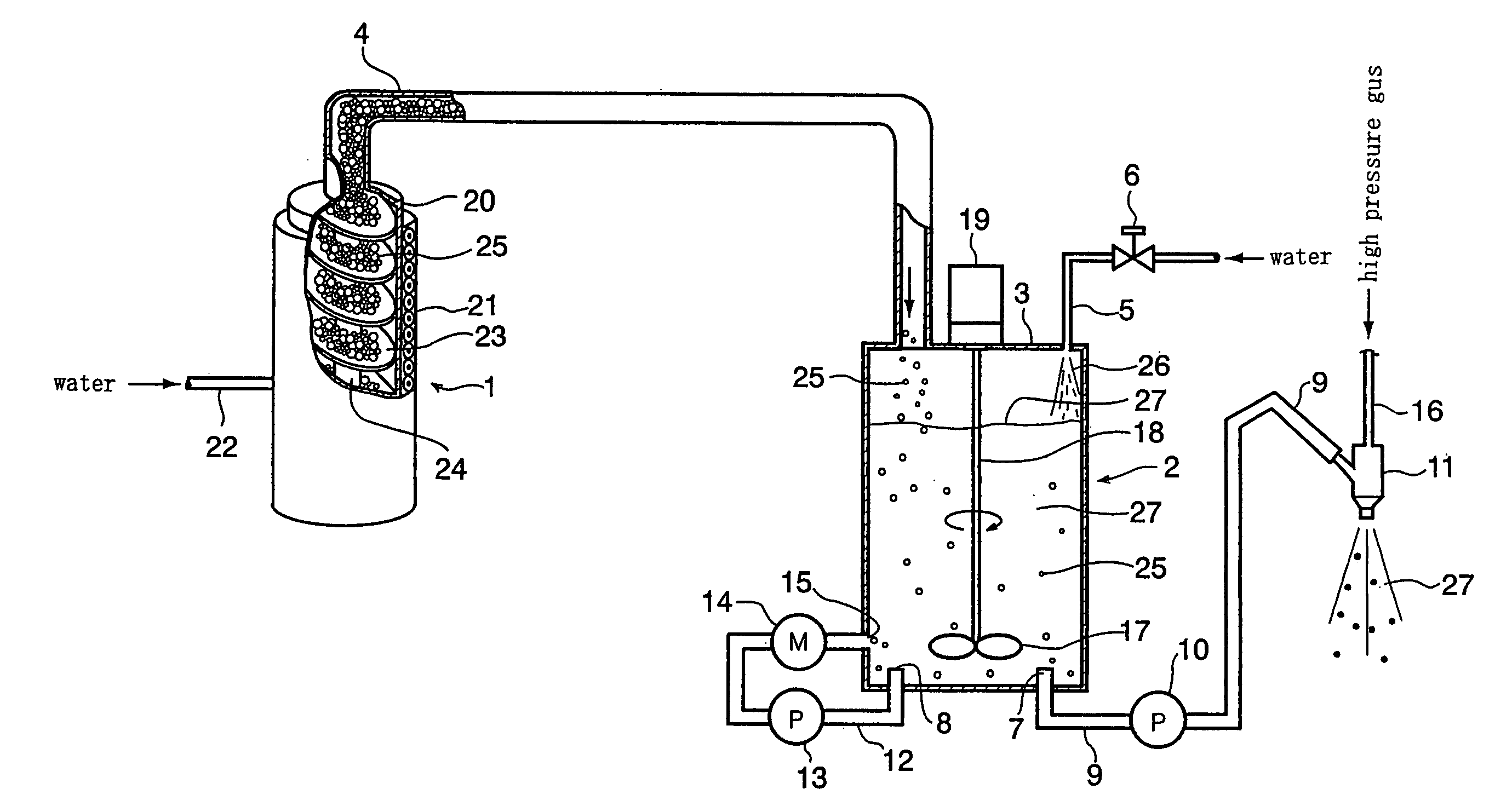

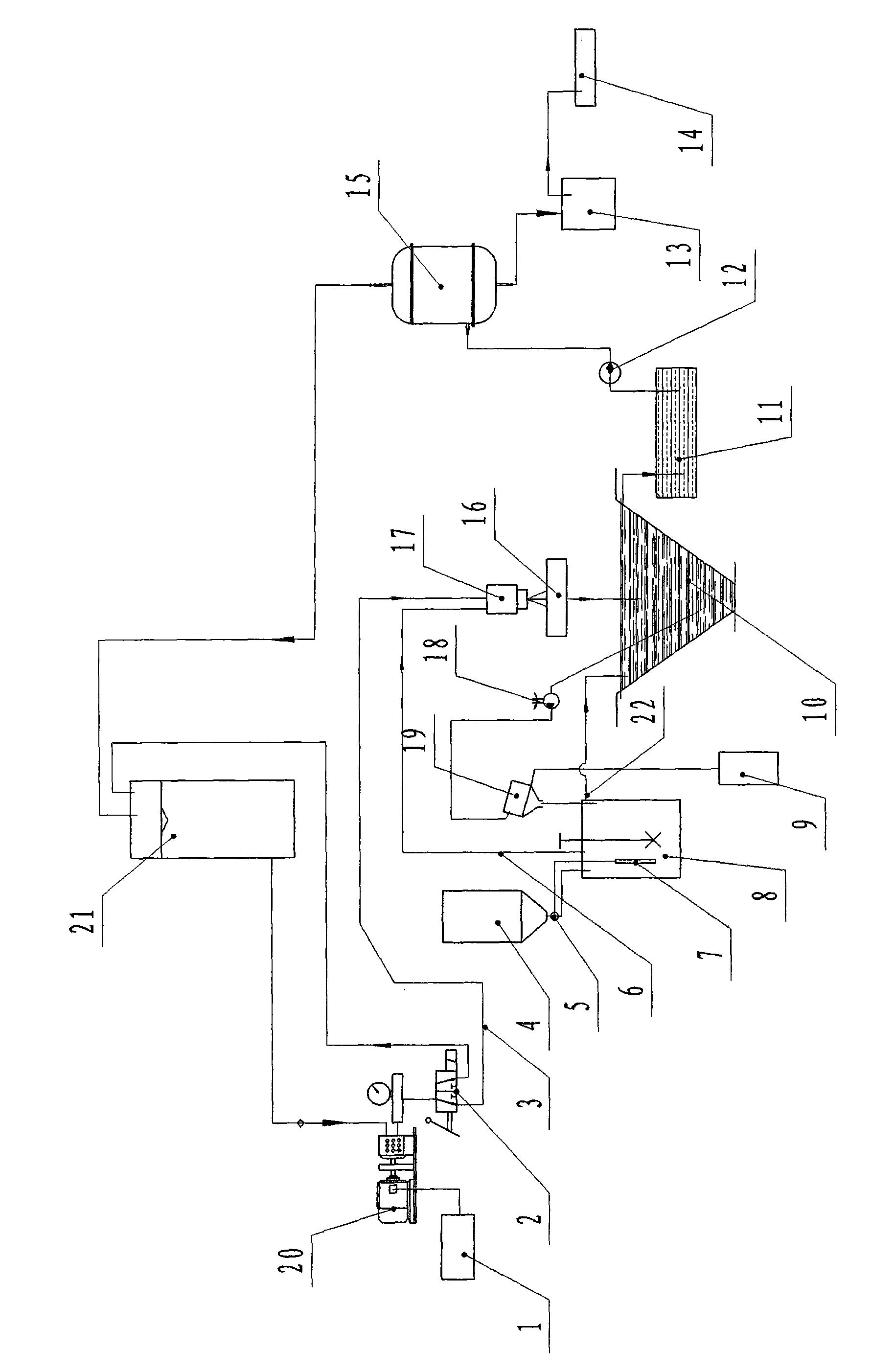

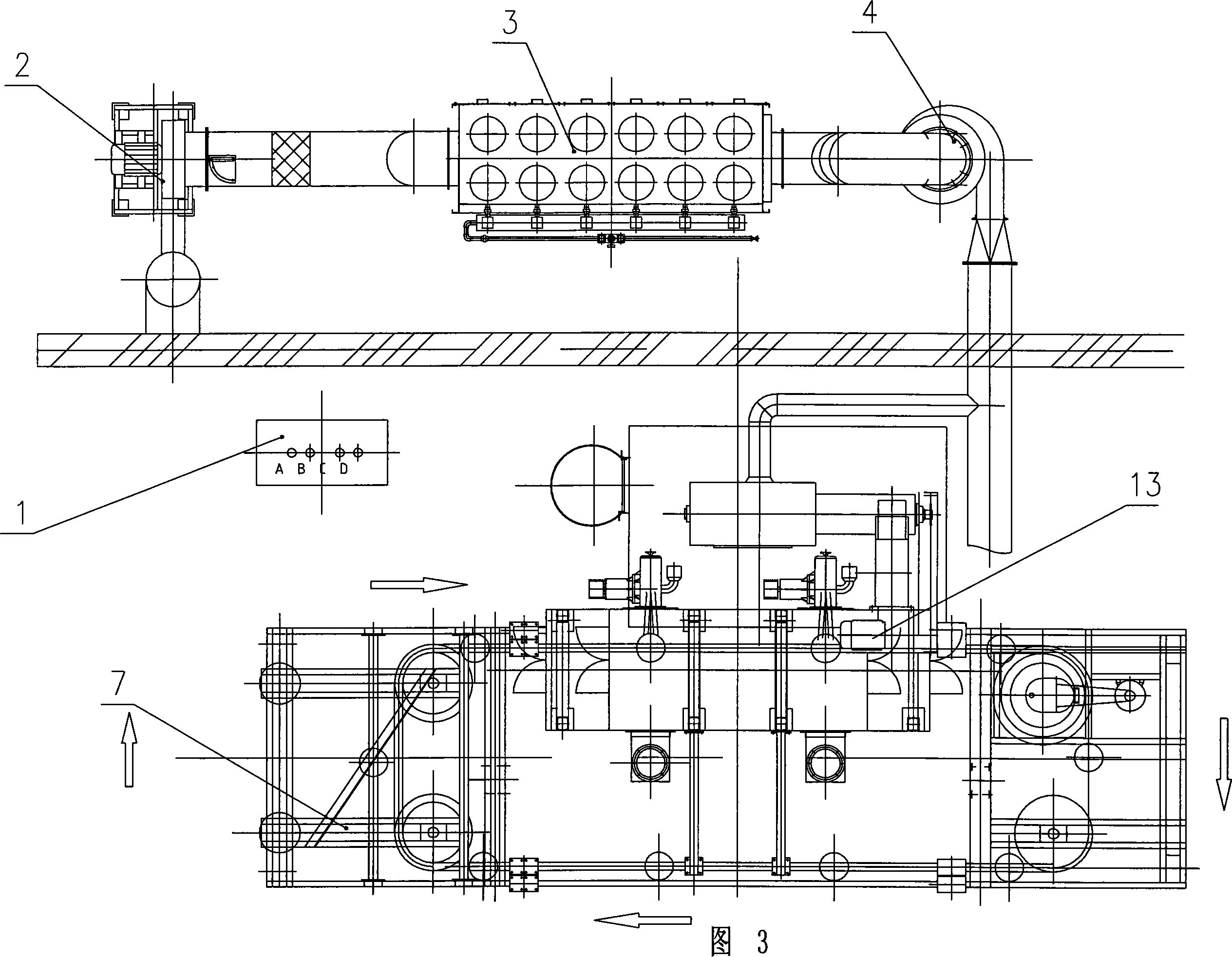

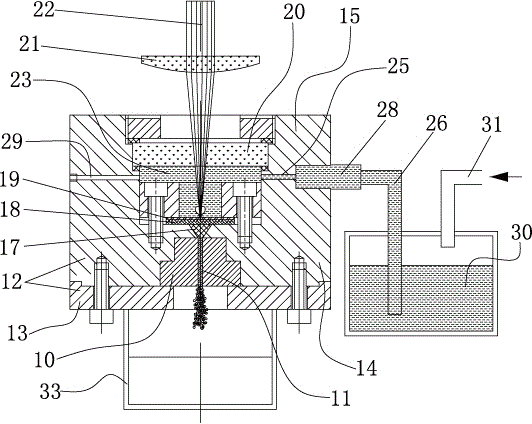

Online high-pressure water-jet blasting surface cleaning system

ActiveCN101633154AUniform supplyGuaranteed uptimeAbrasive feedersAbrasive machine appurtenancesSlagSurface cleaning

An online high-pressure water-jet blasting surface cleaning system comprises a high pressure water feed mechanism, an abrasive material feed mechanism and a spray nozzle. The high pressure water feed mechanism and the abrasive material feed mechanism are communicated with an input end of the spray nozzle, an abrasive material collecting pit is arranged below the spray nozzle, an output end of the abrasive material collecting pit is divided into two paths, one path is connected with an input end of an abrasive material sorting device by an abrasive material cyclical feeding device and a pipeline, and the other path is connected with an input end of a waste water treatment circulating mechanism by a pipeline, an output end of the waste water treatment circulating mechanism is connected with the high pressure water feed mechanism by a pipeline, an output end of the abrasive material sorting device is divided into two paths, one path is connected with the abrasive material feed mechanism, and the other path is connected with a slag collection barrel by a pipeline. The online high-pressure water-jet blasting surface cleaning system has the advantages of simple and compact structure, low energy consumption, good environmental protection, good operational reliability and stability, and recycled water and abrasive materials.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

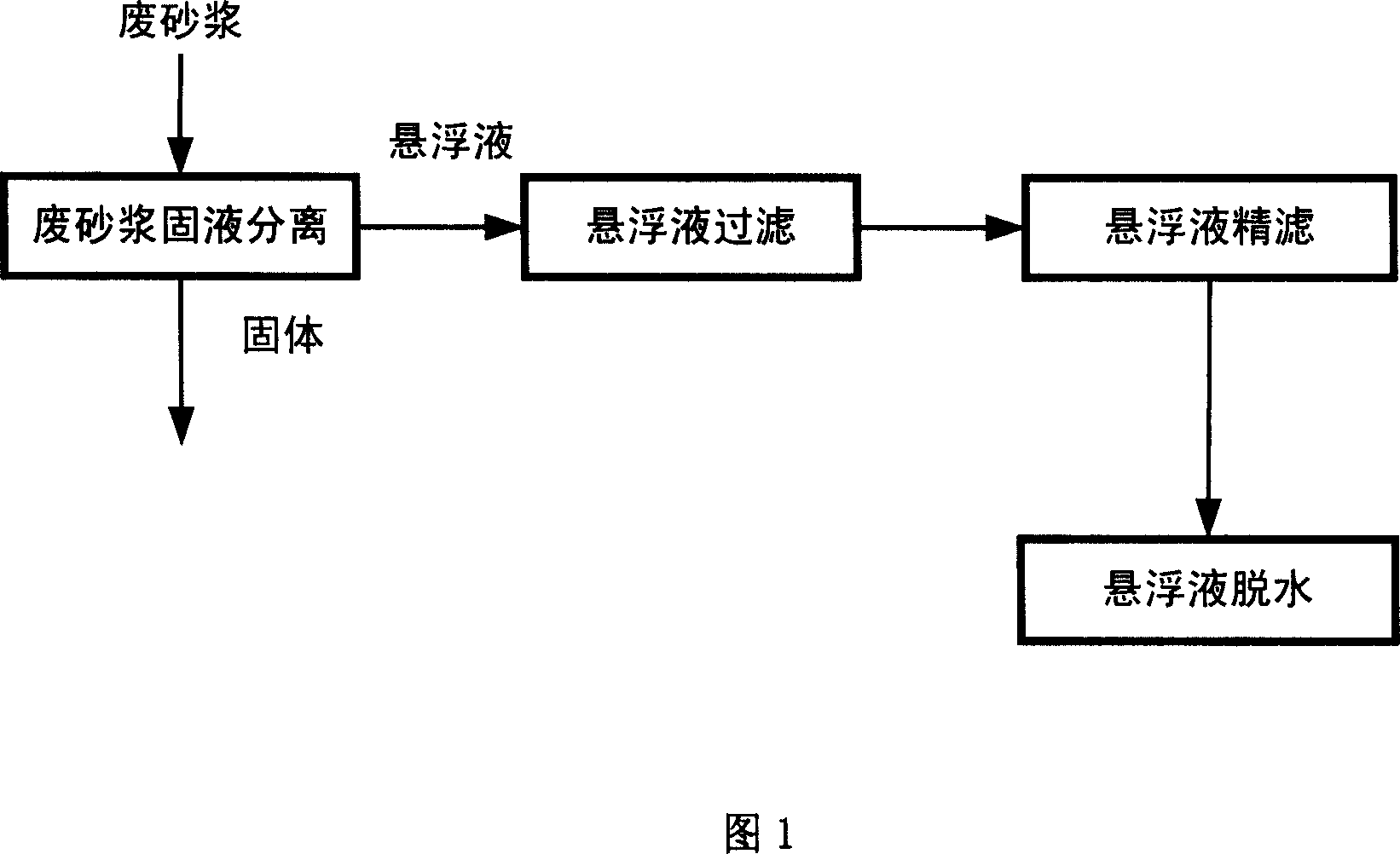

Method of recycling cutting suspension

InactiveCN101032806AGuaranteed purityAvoid adverse effects from re-useAbrasive machine appurtenancesRecovery methodPolyethylene glycol

The waste cutting suspension recovering process features that the waste linear cutting sand pulp from silicon chip processing is multiple stage treated through the steps of solid-liquid separation, initial filtering of the suspension, final filtering of the suspension, and concentrating and drying of the suspension. The process has recovered polyethylene glycol-base or oil-base suspension possess performance the same as or near that of new material and capacity of being reused. The present invention raises material using efficiency, lowers silicon chip producing cost and avoids environmental pollution caused by exhausting waste linear cutting sand pulp.

Owner:PRECISION RECYCLING TECH CO LTD

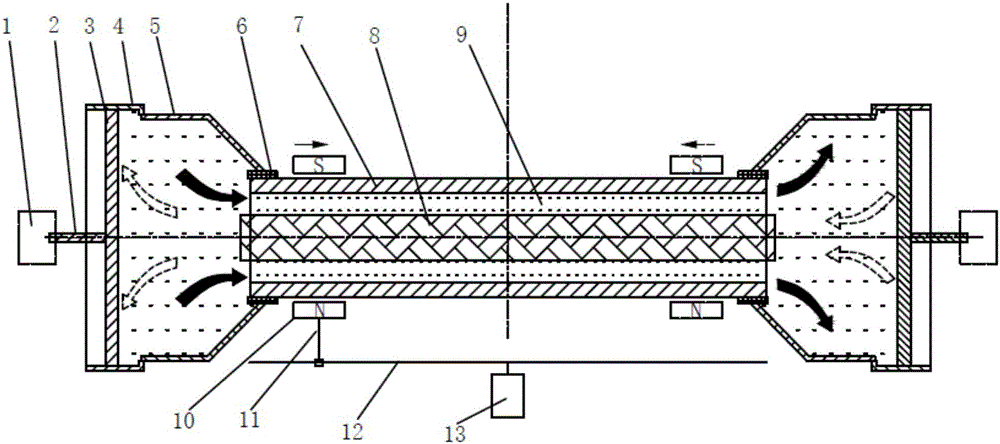

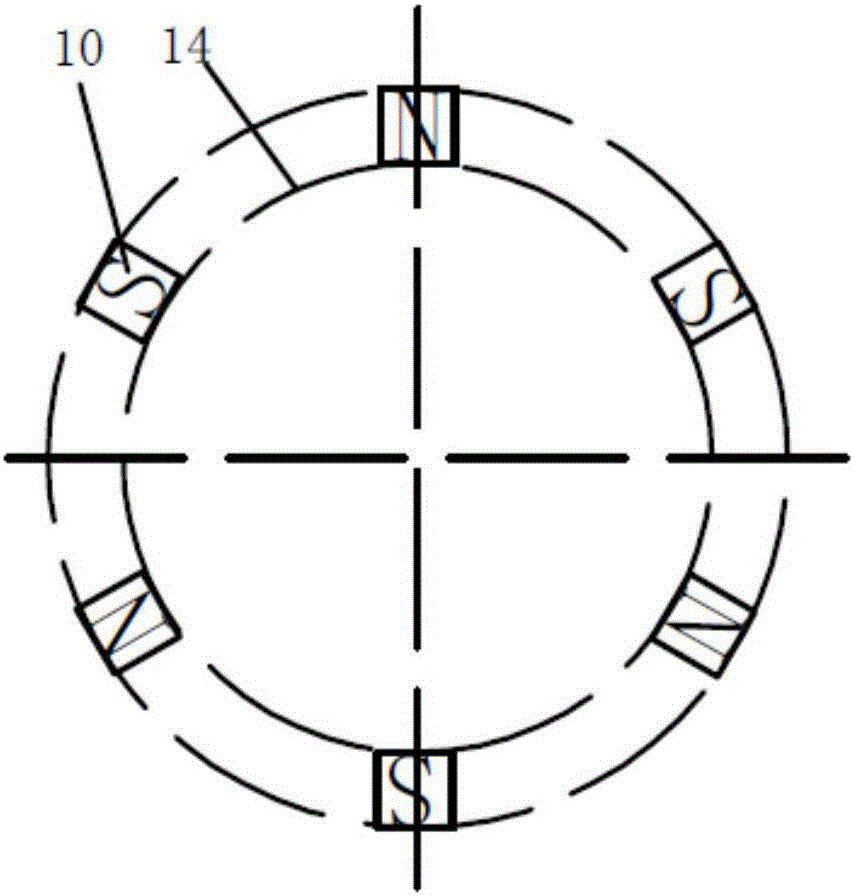

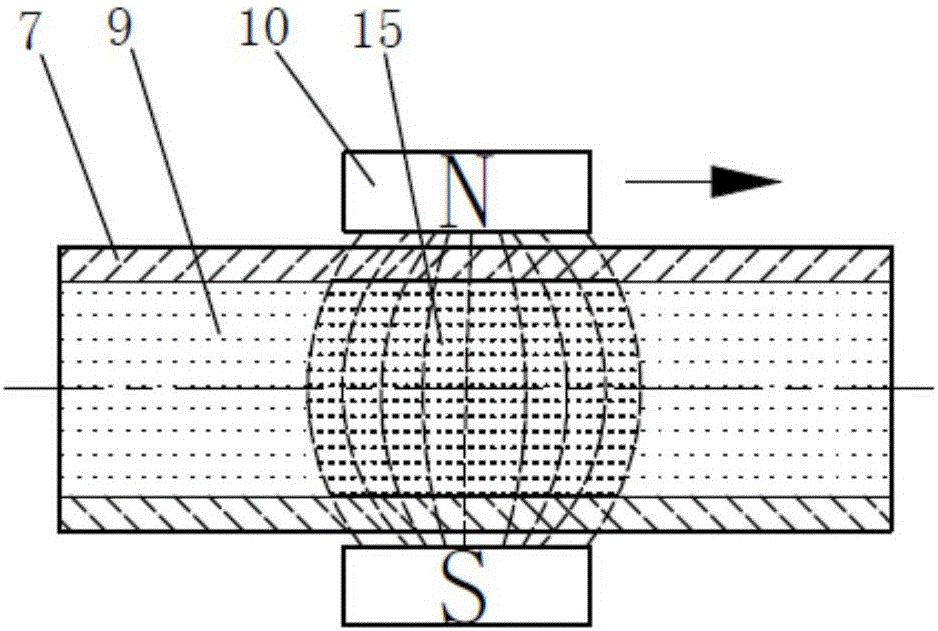

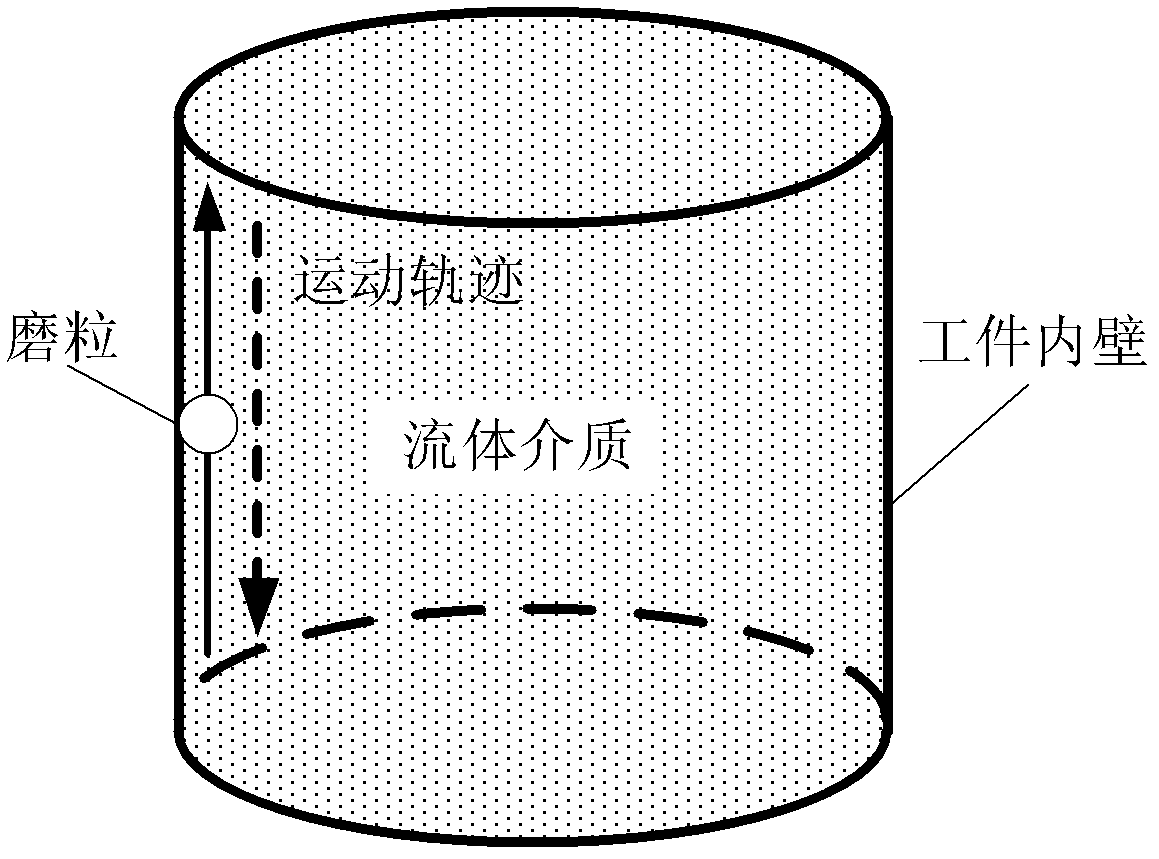

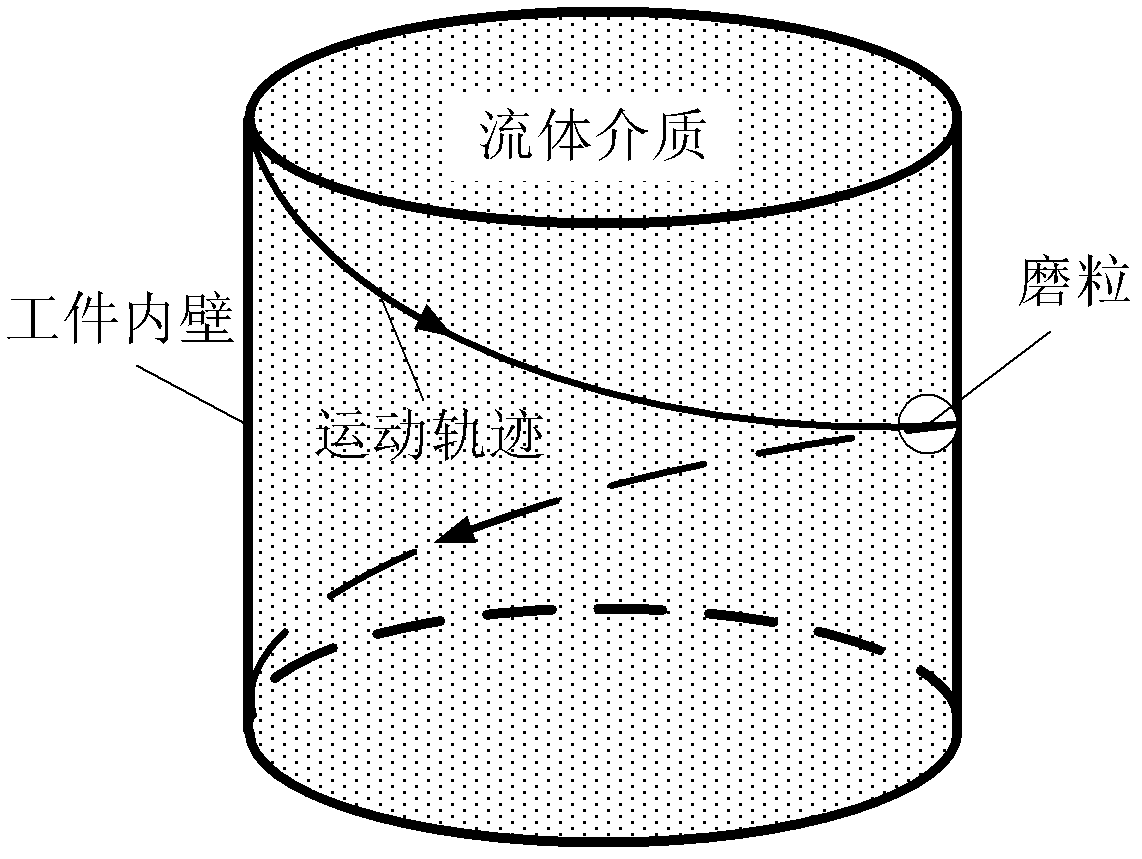

Self-pressurized high-speed polishing method and device for inner surface of hole by means of abrasive particles and magnetic flow

InactiveCN105881185AImprove machining accuracyImprove processing efficiencyEdge grinding machinesPolishing machinesMagnetic currentReciprocating motion

The invention provides a self-pressurized high-speed polishing method for the inner surface of a hole by means of abrasive particles and a magnetic flow. According to the method, the abrasive particles are coated with and restrained on the inner surface of the hole of a workpiece by the aid of ferromagnetic particles in a magnetorheological polishing fluid, which flows at a high speed, under the effect of a magnetic field produced by moving magnetic bodies, a flexible polishing abrasive brush flowing at a high speed is formed and reciprocates to rub against the inner surface of the hole of the machined workpiece to remove burrs and reduce the roughness of the inner surface of the hole, and burr removal and deterministic polishing are realized for various types of inner surfaces of holes. The invention further provides a self-pressurized high-speed polishing device for the inner surface of the hole by means of the abrasive particles and the magnetic flow. The device comprises a polishing mechanism, the magnetic bodies, a clamping mechanism, a sliding guide rail and a driving motor, wherein the driving motor drives the magnetic bodies to enable the polishing fluid to reciprocate in the hole at the high speed for polishing. The method and the device can solve problems that special holes are difficult to polish and the polishing efficiency is low, and have the advantages of high precision, high machining efficiency, low damage and low cost.

Owner:GUANGDONG UNIV OF TECH

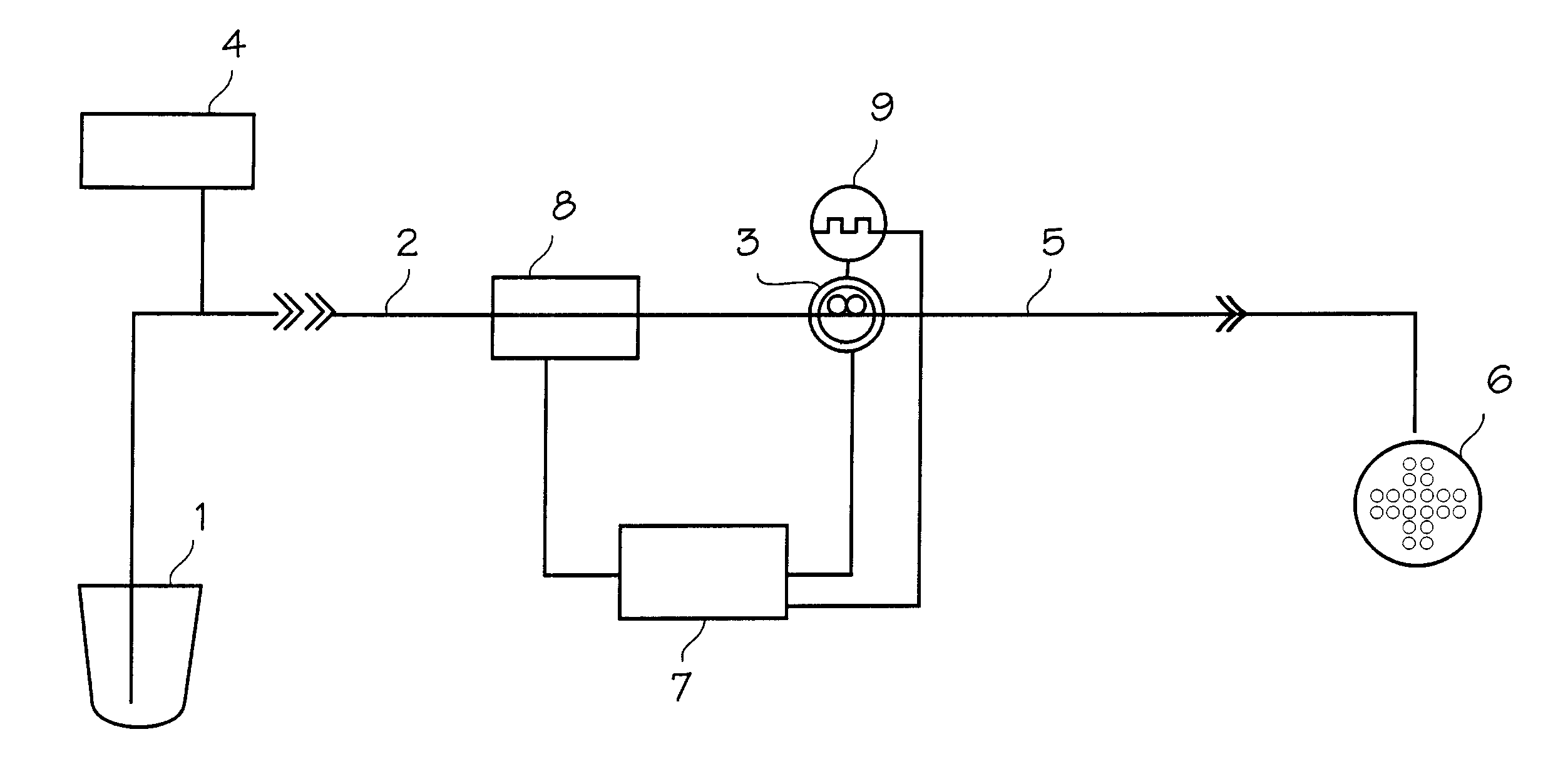

Delivery system for magnetorheological fluid

A magnetorheological fluid delivery system includes a mixing and tempering vessel. Fluid is admitted to the vessel via a plurality of tangential ports, creating a mixing of the fluid in the vessel and promoting homogeneity. Fluid may be reconstituted in the vessel by metered addition of carrier fluid. A fixed-speed centrifugal pump disposed in the vessel pressurizes the system. Fluid is pumped through a magnetic-induction flowmeter and a magnetic flow control valve having solenoid windings whereby MR fluid is magnetically stiffened to restrict flow. A closed-loop feedback control system connects the output of the flowmeter to performance of the valve. A nozzle having a slot-shaped bore dispenses MR fluid for re-use in the work zone. A planar-diaphragm flush-mounted pressure transducer at the entrance to the nozzle and flowmeter inferentially measure relaxed viscosity and provide signals to a computer for dispensing metered amounts of carrier fluid into the mixing vessel to assure correct composition of the reconstituted fluid as it is dispensed.

Owner:QED TECH INT

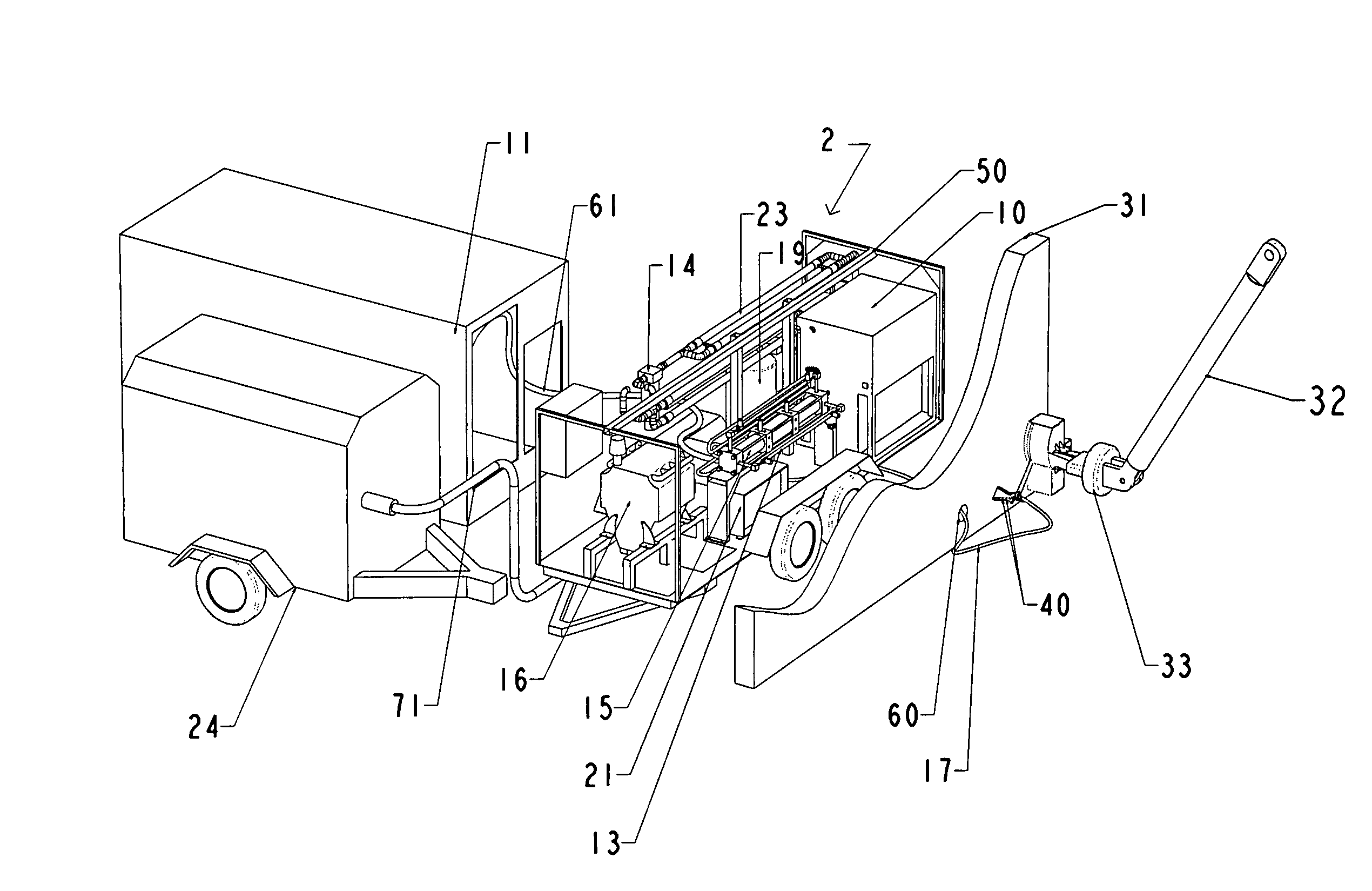

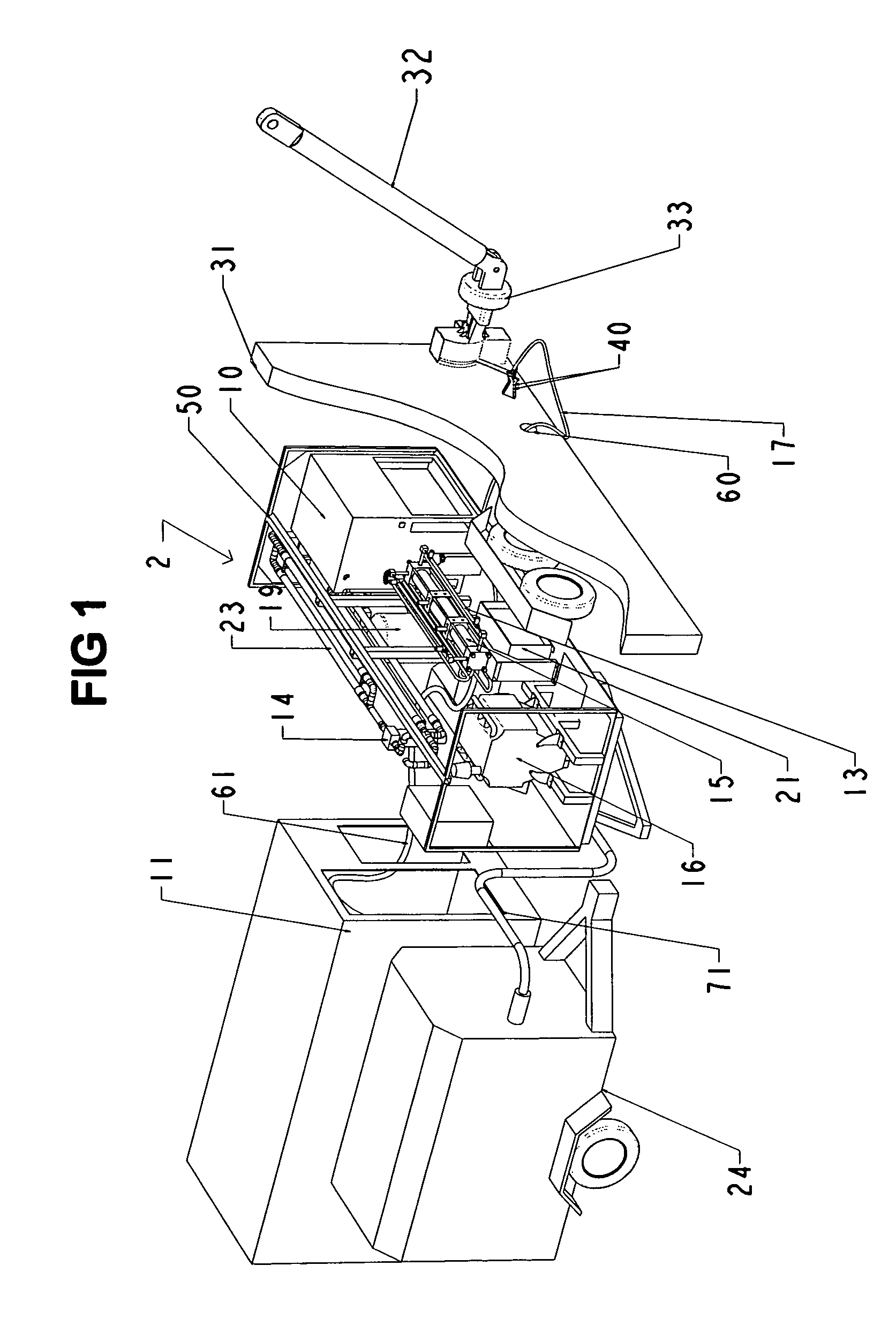

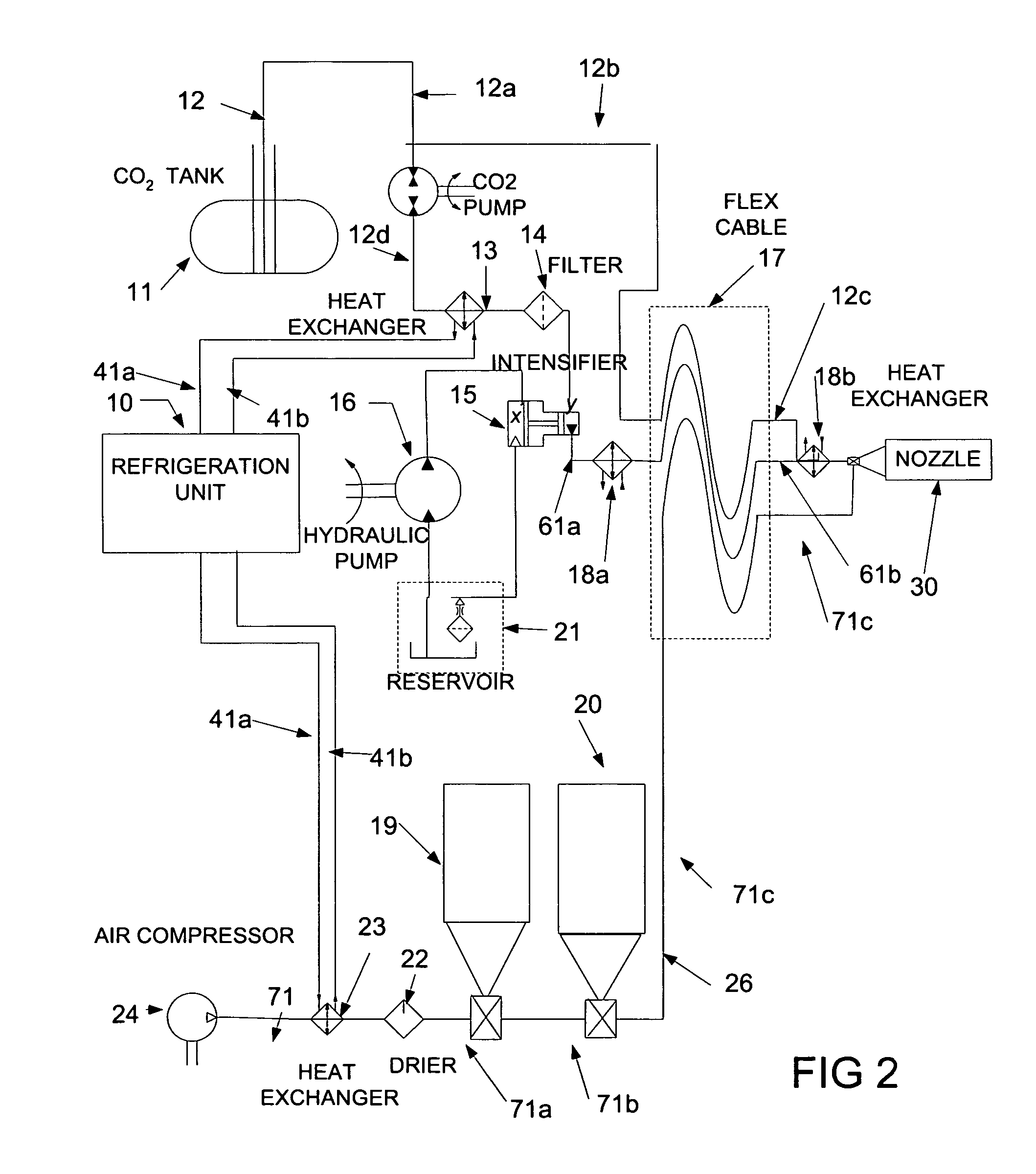

High pressure cleaning and decontamination system

InactiveUS7140954B2Suitable protectionClean effectAbrasive feedersAbrasive machine appurtenancesTriple pointRoom temperature

Abrasive cleaning and decontamination methods and systems are disclosed. The methods and systems use a high pressure liquefied gas, such as carbon dioxide, which produces insignificant quantities of secondary waste. These principles of the invention exploit the properties of the relatively high triple point of CO2 in order to first pressurize it to 35,000 to 60,000 PSI from a pressurized liquid. In the pressurized state, such a fluid can be at or above room temperature, allowing for transport over long distances in a flexible high pressure hose. At a point of use, a heat exchanger may subsequently chill the liquid, so that after expansion through a small high pressure orifice, a significant fraction of the liquid is converted to solid phase crystals exiting at high velocity to effectively clean and decontaminate. For more aggressive cleaning, abrasive particles and / or small diameter solid CO2 pellets can be entrained into the high pressure CO2 slipstream.

Owner:KURION INC

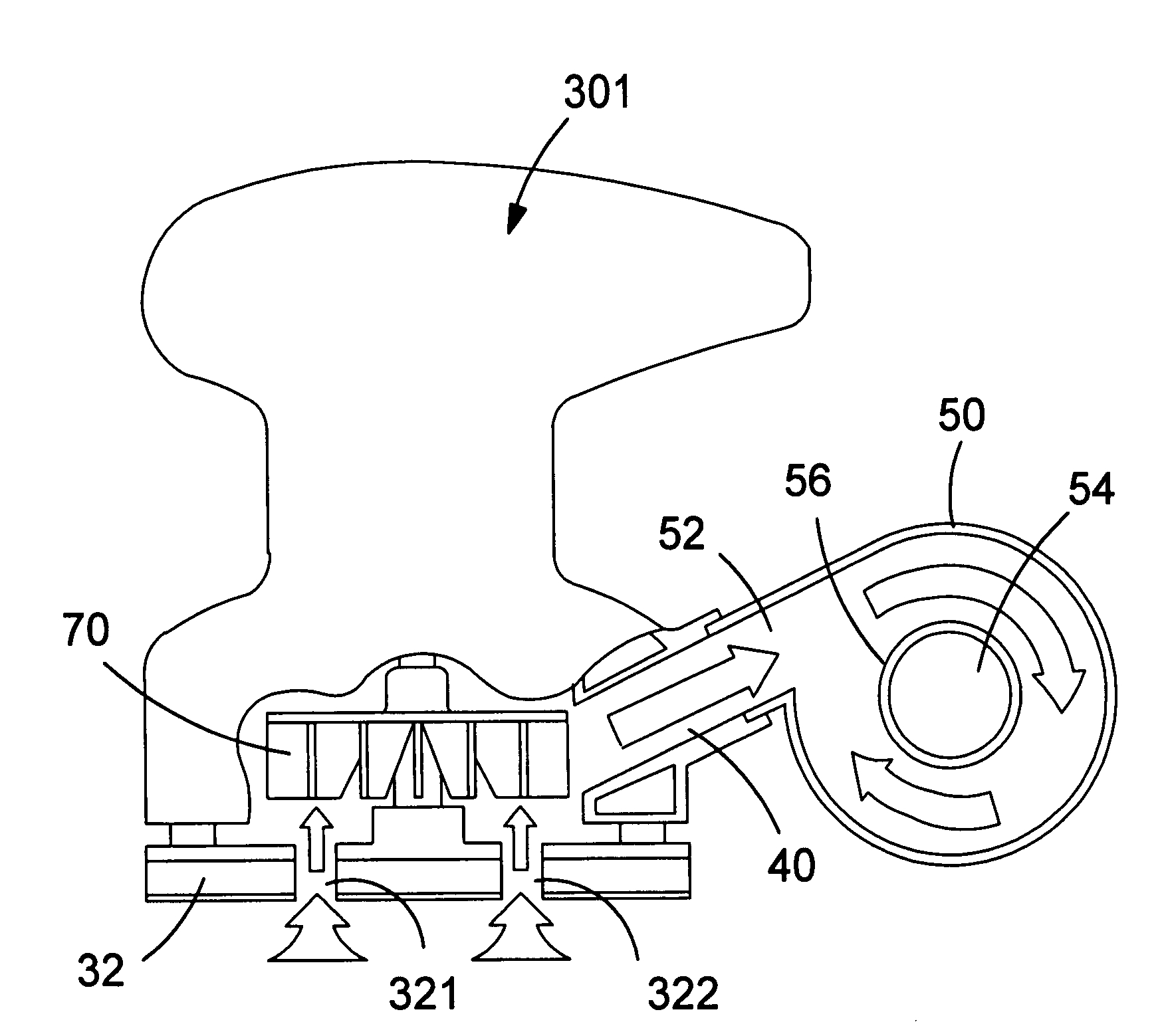

Dust extraction for power tools

ActiveUS7497886B2Throughput of air through the dust extraction system andImprove performanceEdge grinding machinesCombination devicesAtmospheric airPower tool

There is also provided a dust extraction module for use with a power tool, the dust extraction module having: a dust collection chamber (50) having an inlet (52) connectable in fluid communication with an outlet (44) of a dust-extracting duct (40) of the power tool, and having an outlet (54) in fluid communication with atmospheric air; and a filter (60) locatable in fluid flow between the outlet of the dust collection chamber and the atmospheric air; wherein the dust collection chamber (50) has a substantially circular cross section, the inlet (52) to the dust collection chamber is at the perimeter of the circle and the outlet (54) of the dust collection chamber is from the middle of the circle.

Owner:BLACK & DECKER INC

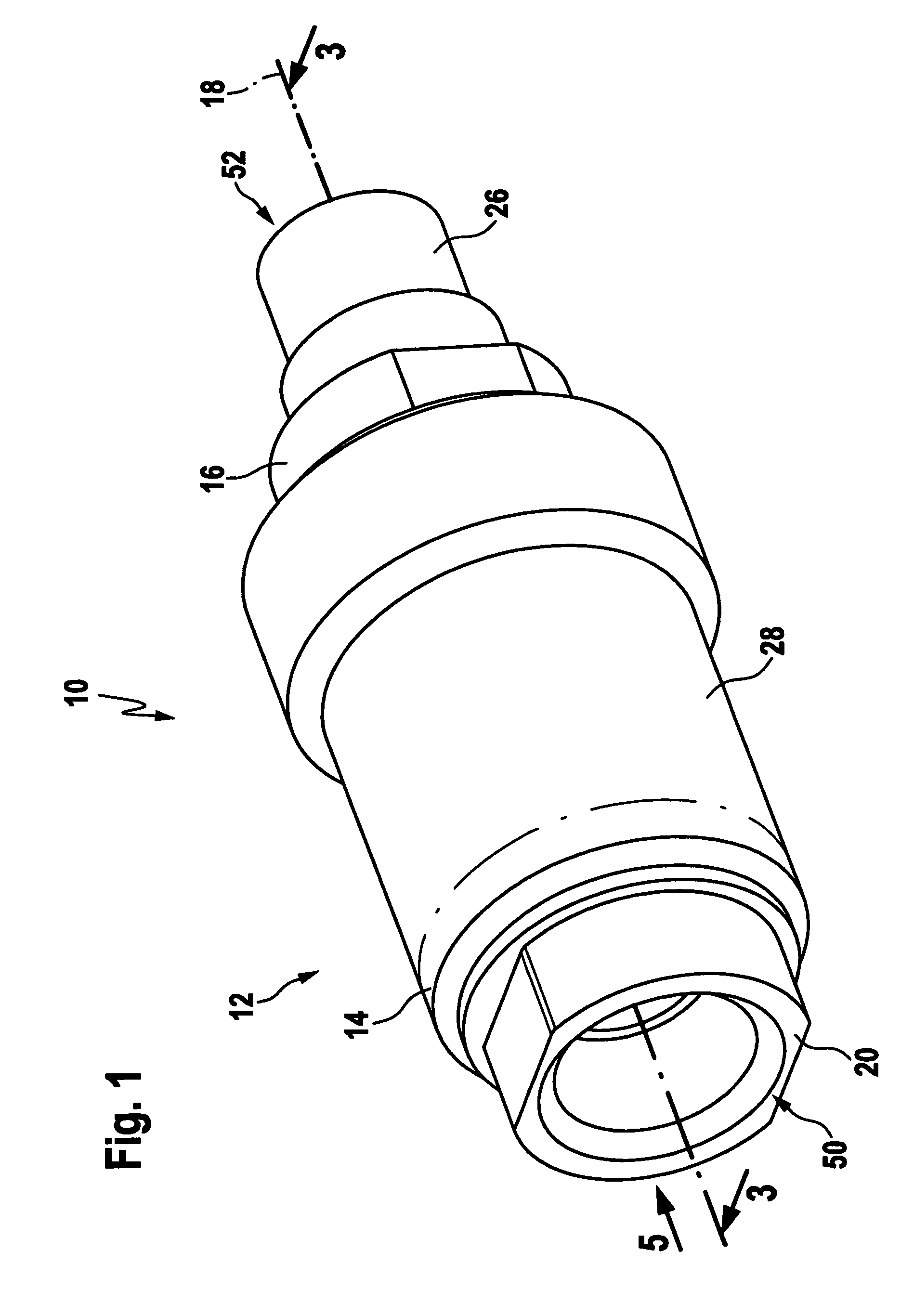

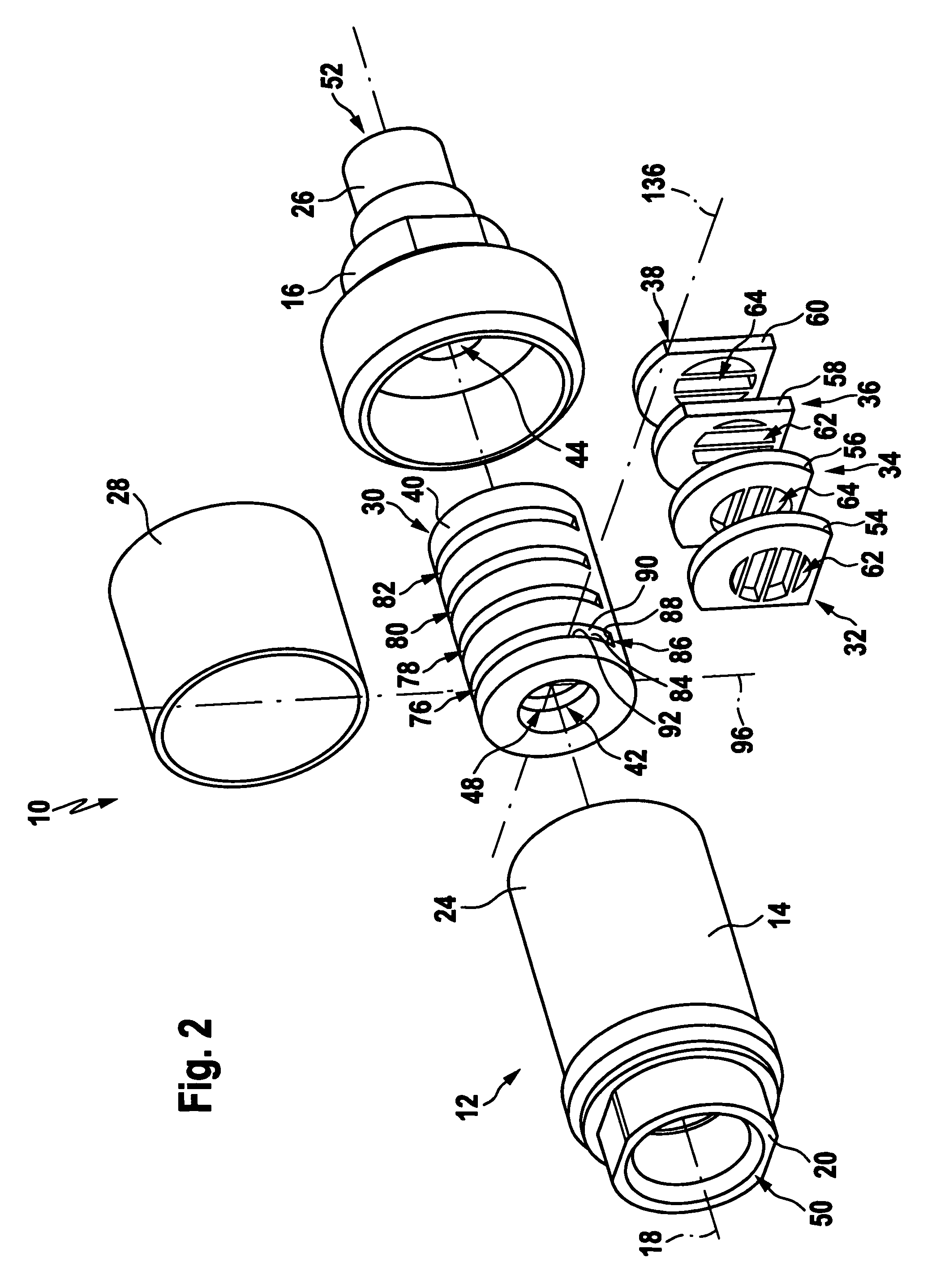

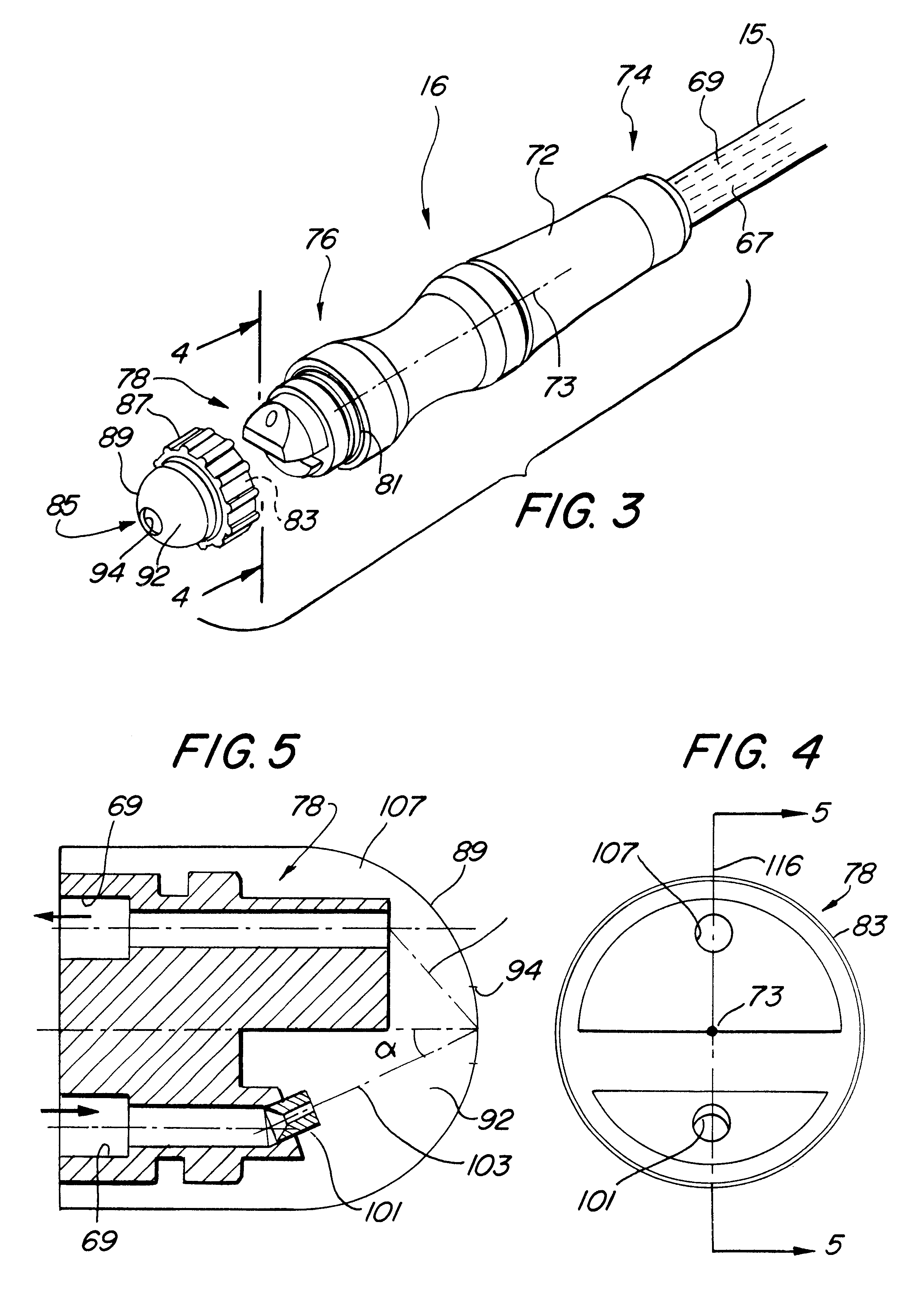

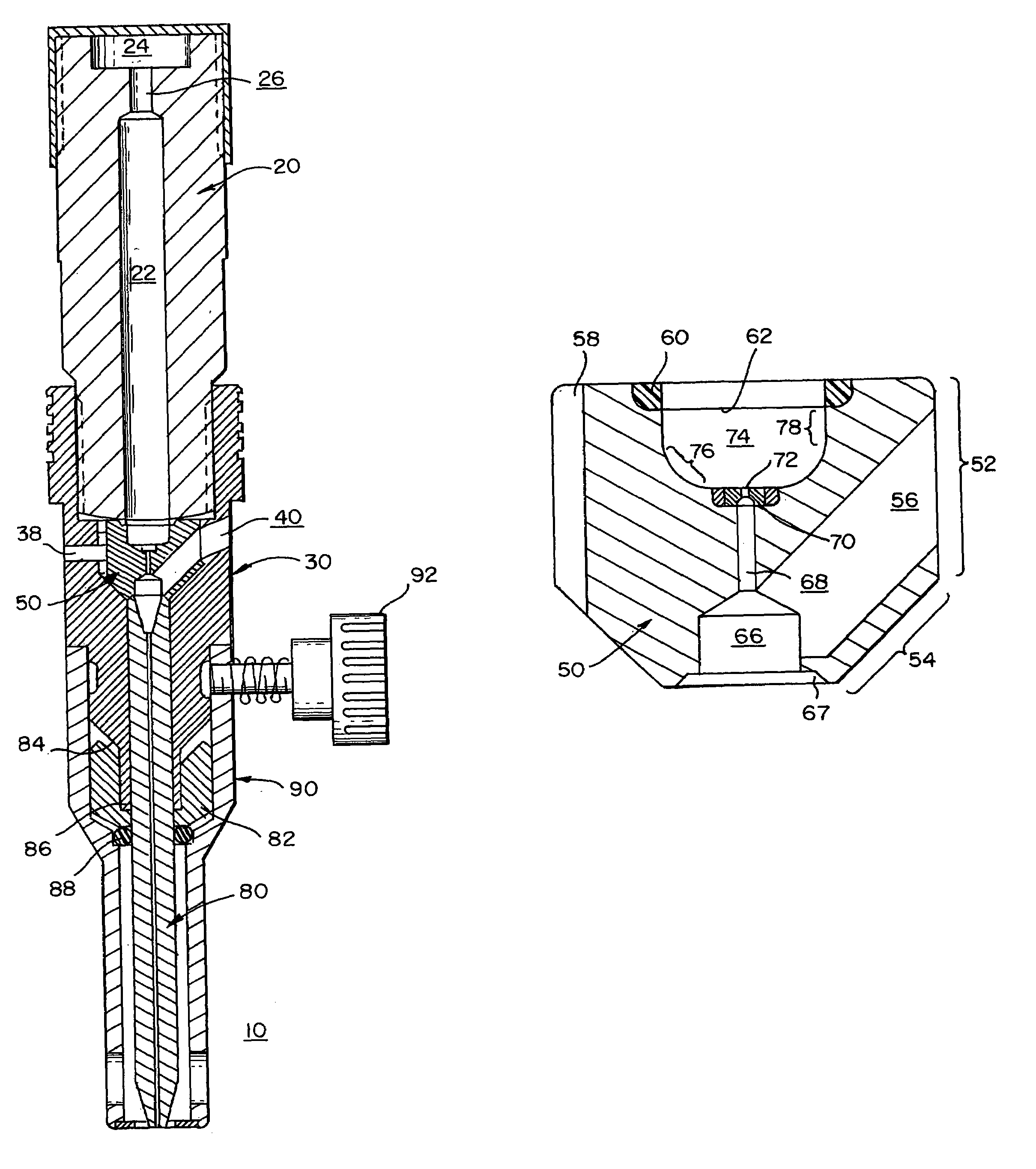

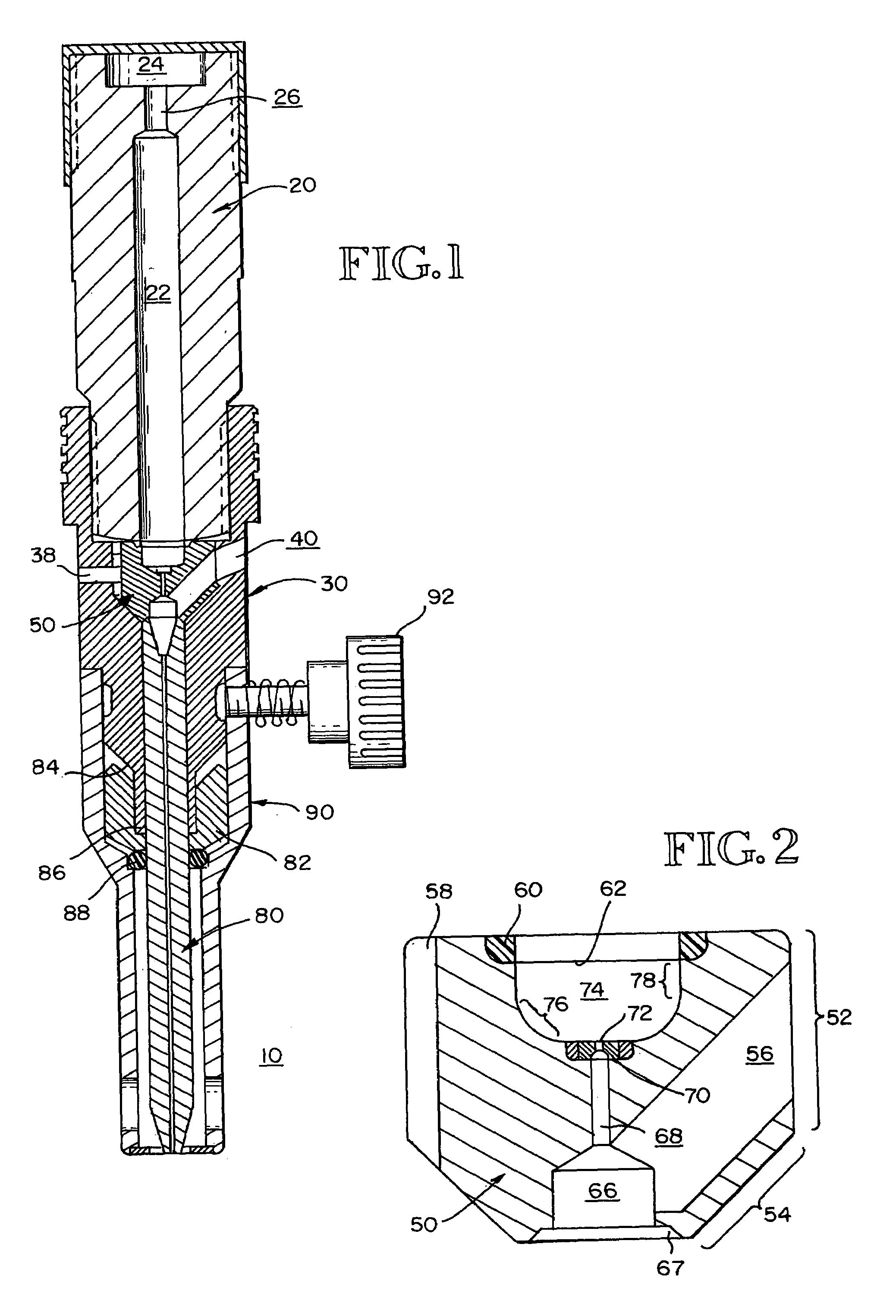

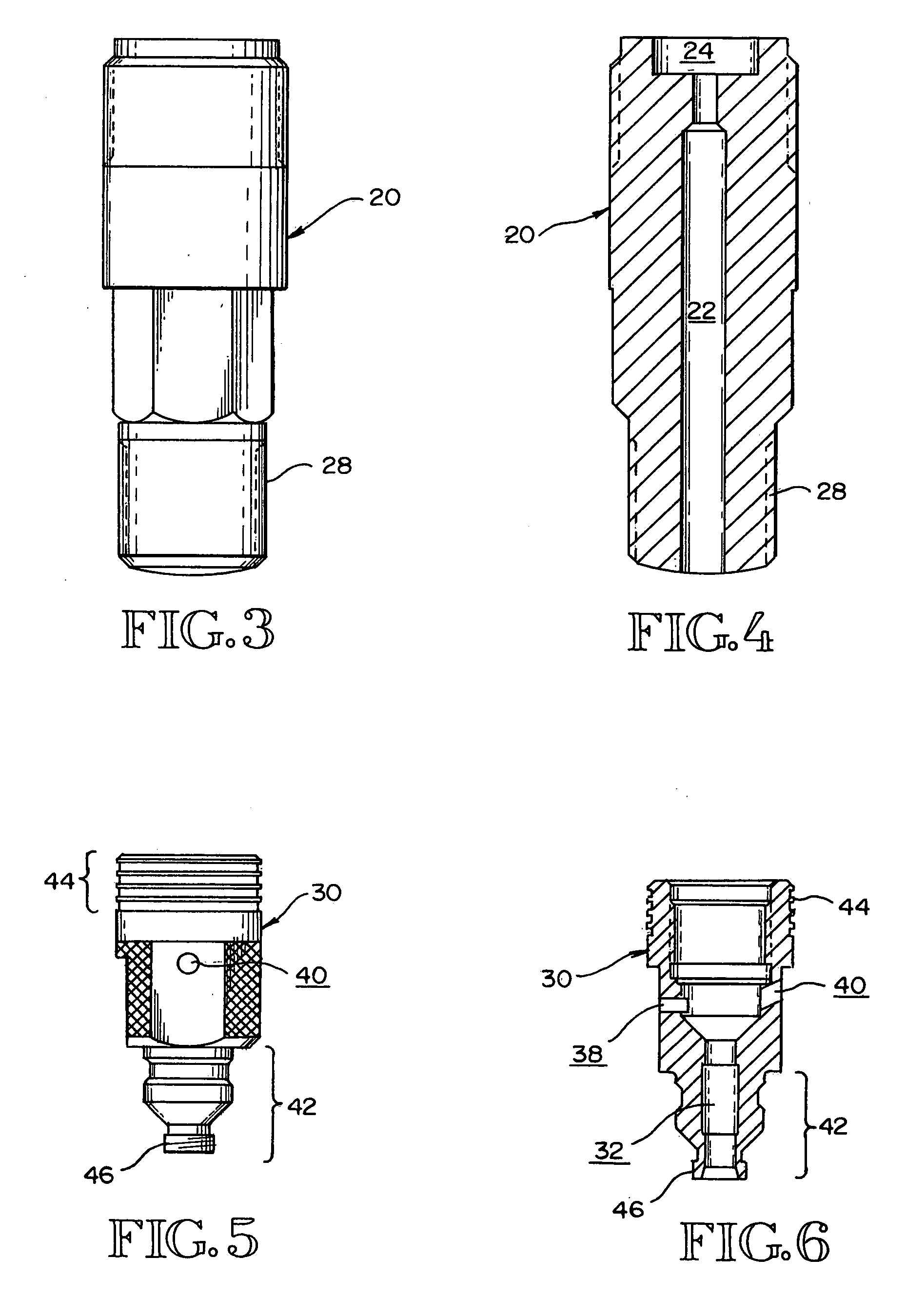

Abrasivejet cutting head with back-flow prevention valve

An abrasivejet cutting head is disclosed that includes a valve assembly for presenting back-flow to the abrasive hopper of abrasive-laden fluid from the cutting head when the discharge path for the abrasivejet becomes clogged or otherwise blocked. The valve assembly is positioned within the abrasive line to conduct abrasive from the hopper towards the abrasivejet nozzle. The valve assembly further includes a discharge path which is scaled off from the abrasive jet nozzle during normal operation in response to the relative lower pressure in the abrasivejet nozzle that results from the flowing fluid therein. If the jet path is blocked or impeded in a manner that causes a backflow of the abrasive-laden slurry therein, the cessation of low-pressure permits the backflowing slurry to exit via the discharge path and bypass the hopper, substantially avoiding the downtime previously required to clean the hopper.

Owner:INT WATERJET PARTS INC AN IDAHO CORP

Automobile hub abrasive flow deburring method

InactiveCN102501179ASolve problems that are difficult to automate productionImprove ergonomicsAbrasive machine appurtenancesHigh volume manufacturingEngineering

The invention aims to provide an automobile hub abrasive flow deburring method which is low in cost and simple in structure and can be suitable for various complex conditions of burr removal of hubs with different structures. In order to fulfill the aim, the technical scheme is that the automobile hub abrasive flow deburring method comprises the following steps: 1, mounting the hub on automobile hub abrasive flow precise deburring and finishing equipment and fixing; 2, preparing viscoelastic abrasive flow with controllable rheological property and leading the abrasive flow into the automobilehub abrasive flow precise deburring and finishing equipment; 3, controlling the abrasive flow to perform rough machining on the hub; 4, controlling the abrasive flow to perform finish machining on the hub which is subjected to rough machining; and 5, finishing machining and the process procedures. Due to adoption of the technical scheme, the problems of difficulty in mass production and automaticproduction in automobile hub deburring and finishing and the like are solved by the abrasive flow, and the aims of improving work efficiency, reducing cost, reducing labor intensity and improving product reliability are fulfilled.

Owner:ZHEJIANG NORMAL UNIVERSITY

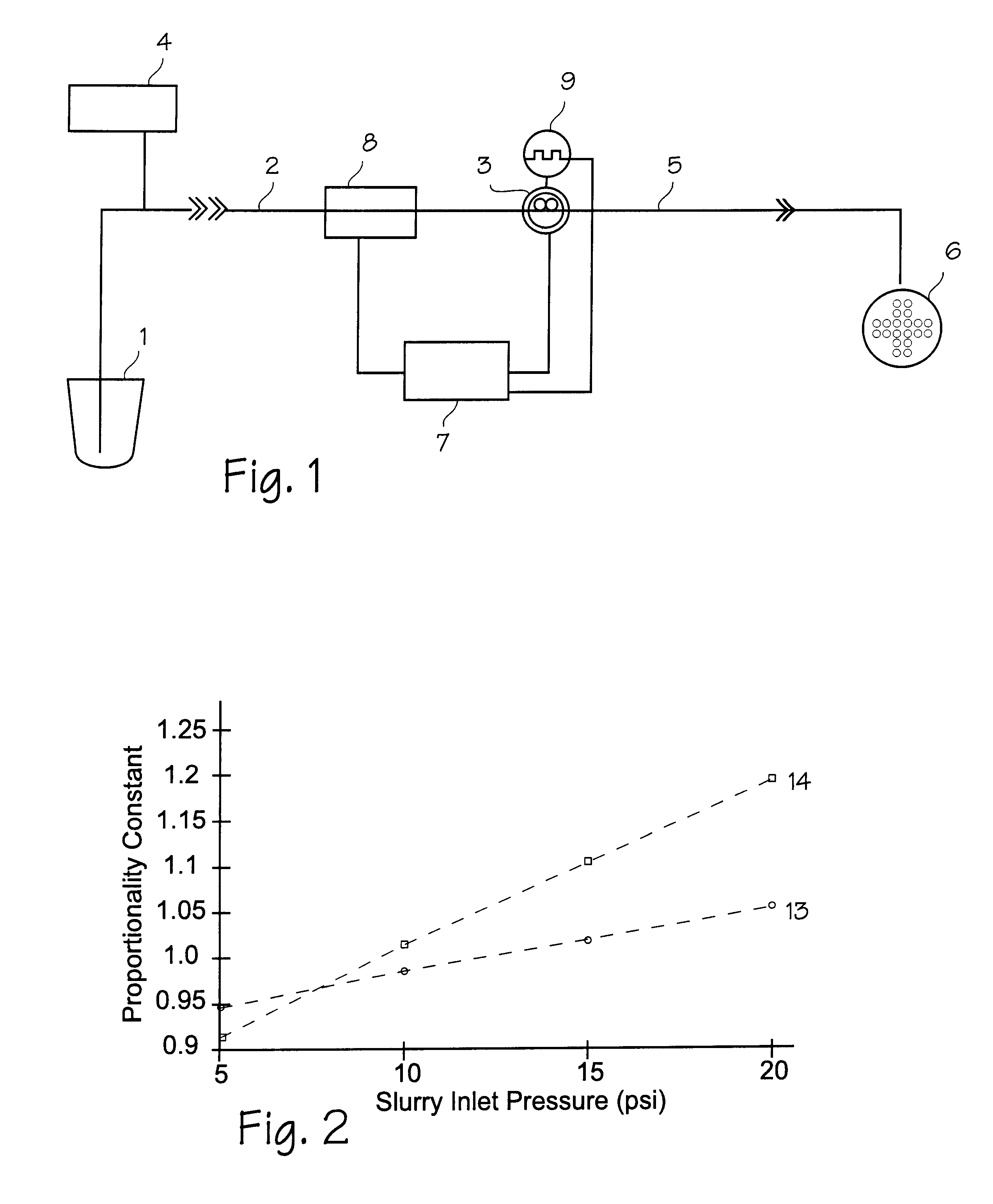

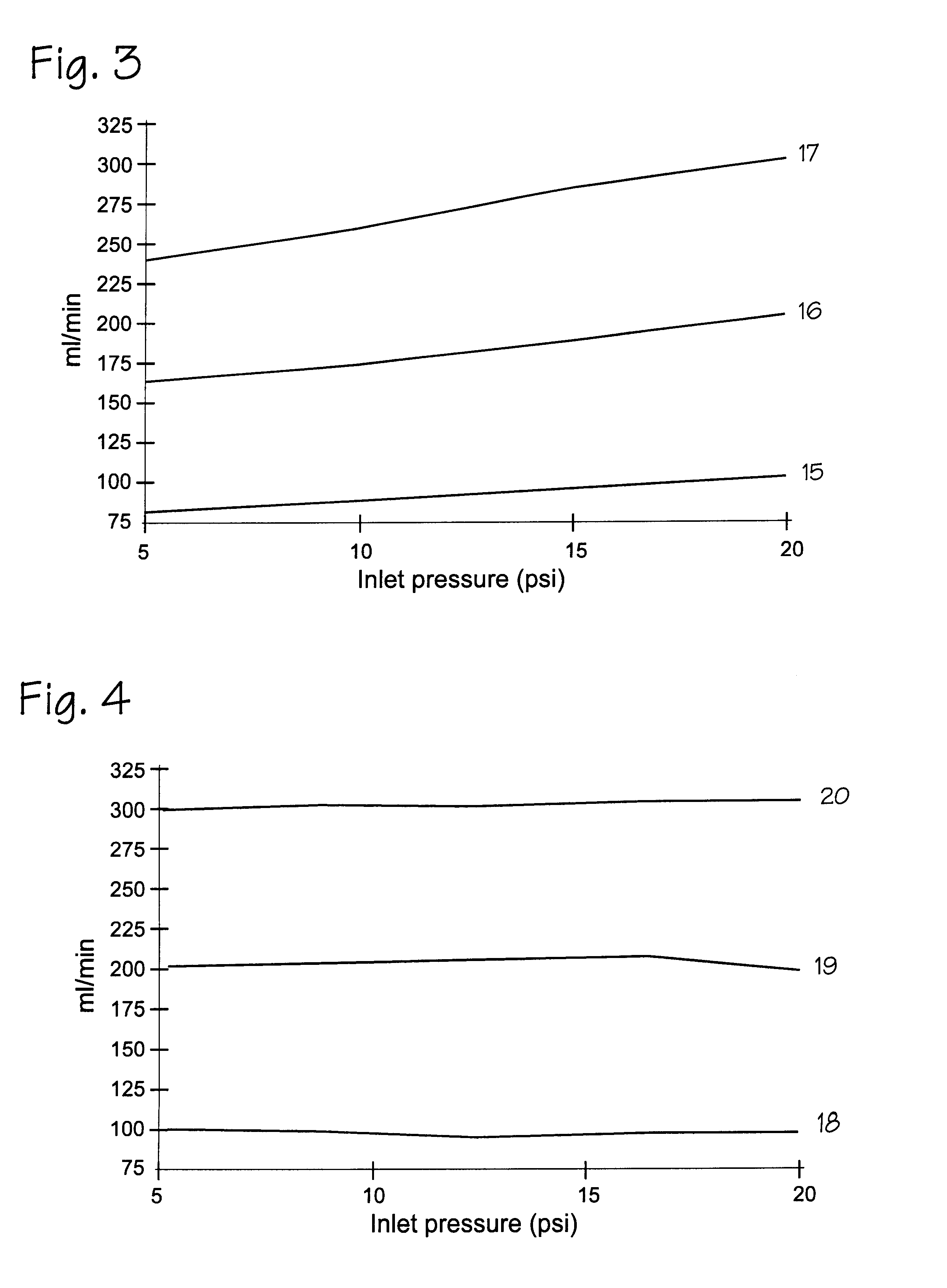

Slurry pump control system

A CMP slurry pumping system which uses the slurry pump inlet pressure as input to the pump controller, and adjusts pump speed to account for variations in inlet pressure.

Owner:REVASUM INC +1

Portable microderm abrasion device

InactiveUS8025669B1Easy to operateEasy to serviceSurgeryAbrasive machine appurtenancesParticulatesLine tubing

A portable microderm abrasion device is comprised of a hollow housing containing an electric motor that operates an air pump having air suction and air exhaust ports. A hollow, disposable exfoliation grit supply cartridge is removably located within an upper bay, while a separate hollow, disposable waste collection cartridge is also located within a lower bay in the housing directly beneath the grit supply cartridge. The two cartridges are separately removable from the housing. Grit from the supply cartridge is mixed with air drawn by a vacuum created by the air pump into a grit entrainment duct located within the waste collection cartridge and carried to a movable wand. A particulate filter located in the waste collection cartridge allows air, but prevents solid waste material, from being discharged to ambient atmosphere. Safety features include a timer and / or a motion sensor to reduce or cut off vacuum in the line if the grit dispensing and retrieval tip of the wand remains in a static condition or exerts a vacuum for too long a period of time upon the skin of the subject.

Owner:BIORENEW LABS

Processes and apparatuses for enhanced cutting using blends of abrasive materials

ActiveUS20100124872A1Composition is limitedBlast gunsControlling ratio of multiple fluid flowsEngineeringDelivery system

A waterjet system selectively produces fluid jets for water jet cutting or abrasive jets for abrasive-waterjet-cutting. The abrasive materials in the abrasive jet are determined based on the properties of the workpiece. The waterjet system includes an abrasive delivery system that is capable of delivering either a single abrasive or a plurality of abrasives as an abrasive blend, to a cutting head assembly. The cutting head assembly entrains the abrasive into a fluid jet to form an abrasive jet.

Owner:FLOW INT

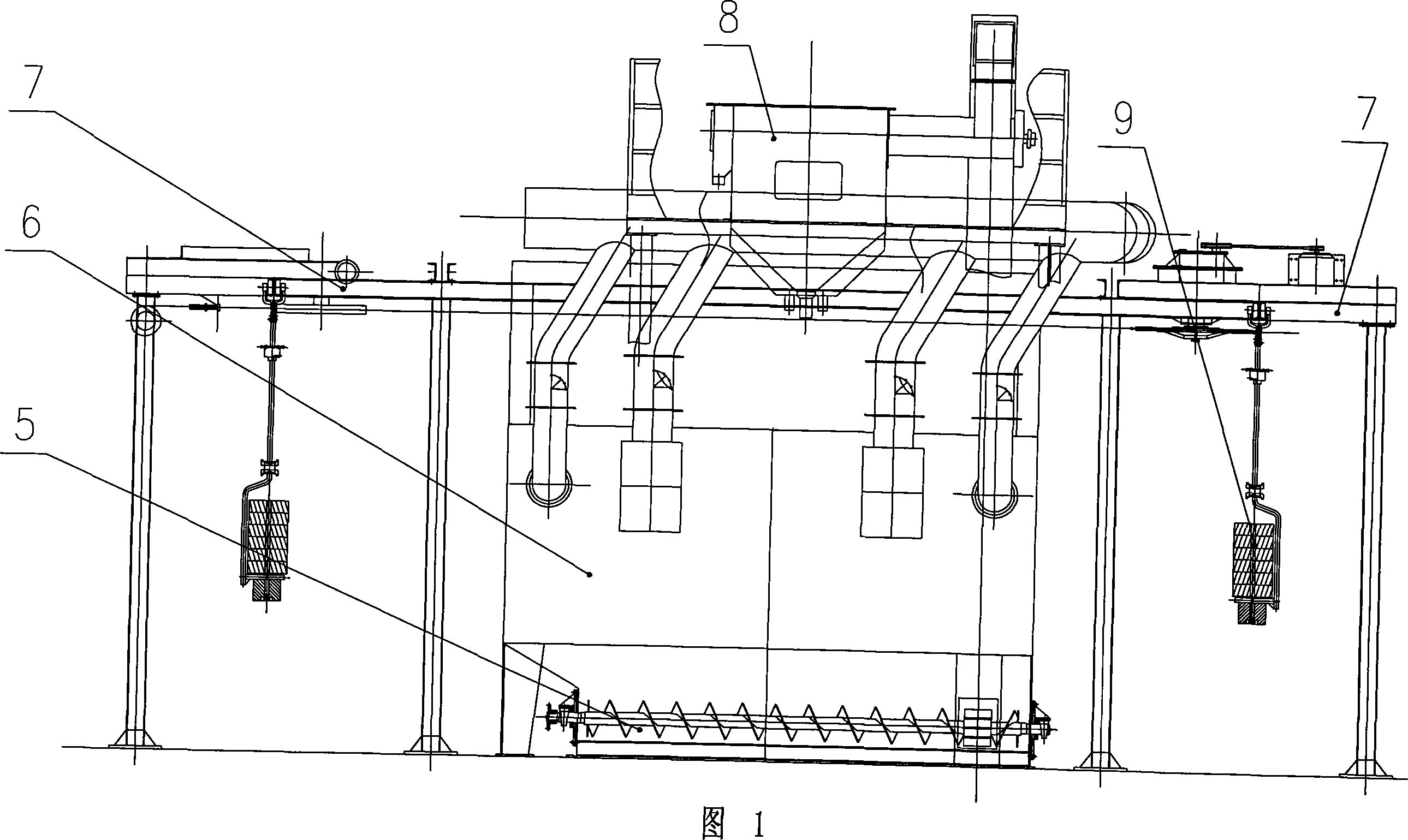

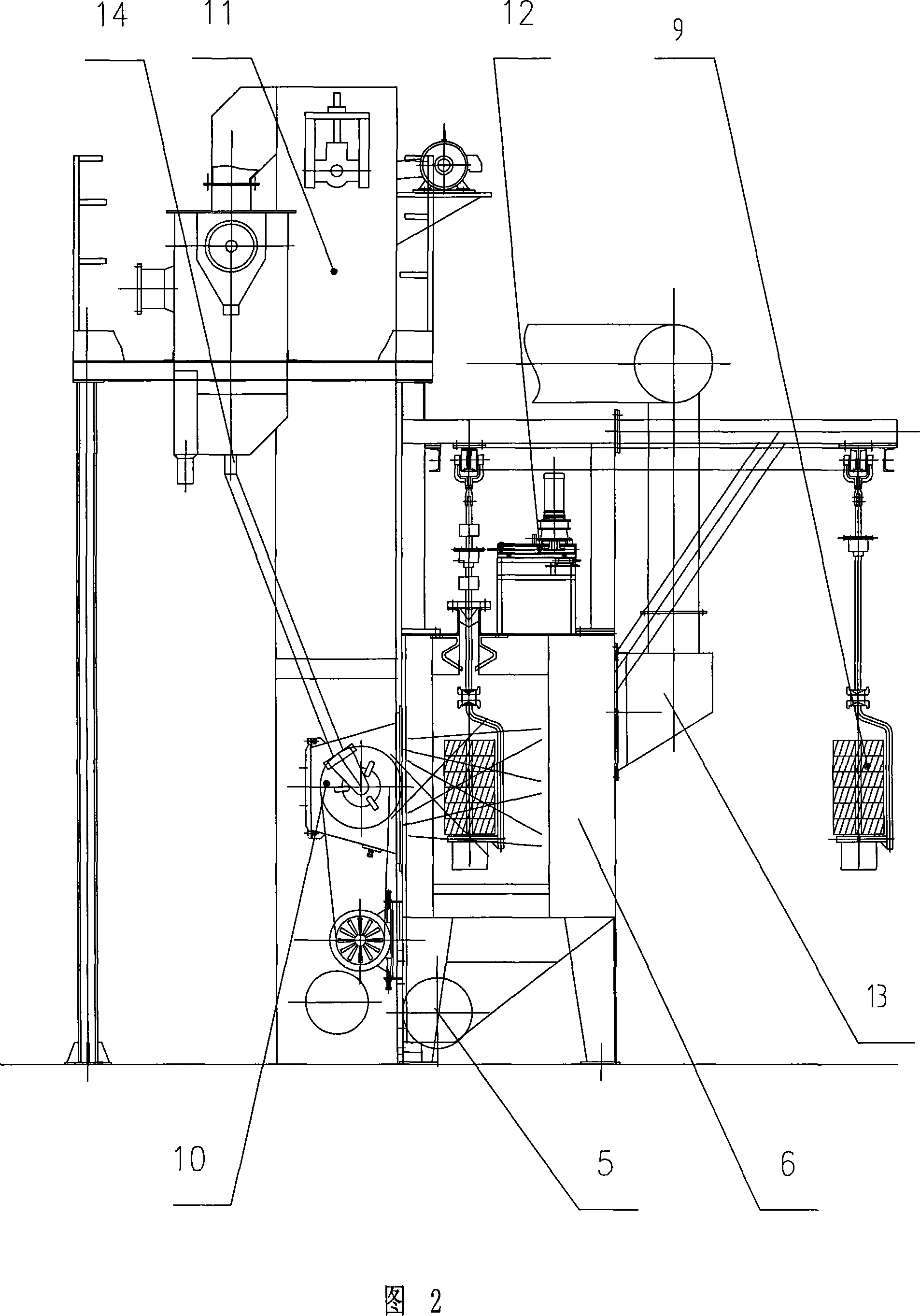

Automobile gear ruggedization shot-blasting machine

InactiveCN101157203AReduce energy consumptionImprove work efficiencyImpeller wheelsBlast gunsGear wheelEngineering

The invention belongs to equipment for cleaning the surface of a machine element by utilizing a shot blasting method, in particular to an automotive gear enhanced shot blasting machine. According to the technical proposal provided by the invention, the shot blasting machine is arranged on a shot blasting cleaning chamber. The invention is characterized in that a suspend conveyer installed on a supporting bracket is arranged at the upper part of the shot blasting cleaning chamber, the suspend conveyer is in a sealed state and circled around the shot blasting cleaning chamber, and one section passes through the shot blasting cleaning chamber, a plurality of rotating racks which can rotate under the driving of the suspend conveyer are suspended on the suspend conveyer, a curtain separator is arranged above / on the shot blasting cleaning chamber, a chamber hoisting gear is arranged on the flank of the shot blasting cleaning chamber, and a worm conveyer is arranged at the bottom of the shot blasting cleaning chamber. The input end of the curtain separator is connected with the output end of the chamber hoisting gear, and the output end of the worm conveyer is connected with the input end of the chamber hoisting gear. The invention can improve the effect of the shot blasting cleaning and the quality of the product.

Owner:无锡国达机械设备有限公司

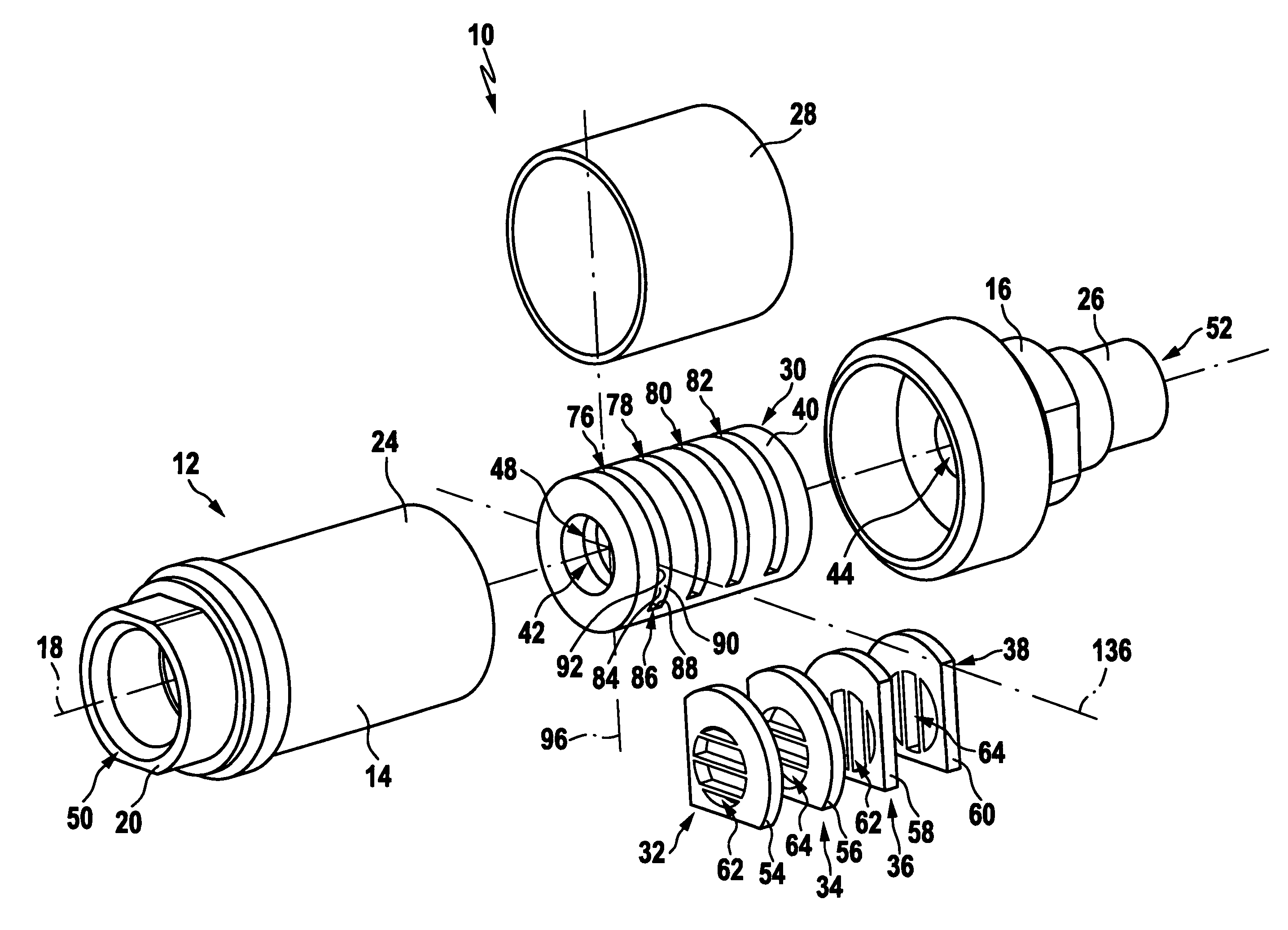

Orifice body with mixing chamber for abrasive water jet cutting

InactiveUS6932285B1Simple designImprove operationDrill bitsBlast gunsUltra high pressureHigh pressure

An improved orifice assembly for use with an ultra high pressure fluid jet cutting apparatus is disclosed. The improved orifice assembly generally includes an orifice body defining a central bore, a high pressure inlet cavity located at an upstream portion of the body, a mixing cavity located at a downstream portion of the body, and an abrasive material inlet bore that is in direct communication with the mixing cavity. The inlet or high pressure cavity preferably has a cylindrical cross section at the side wall portion and a generally flat bottom wall, with a constant radius transition portion between the side and bottom walls. A jeweled orifice is preferably located at the bottom wall and forms a portion thereof. A chamfer at the downstream portion of the mixing chamber permits appropriate coaxial alignment of a mixing tube with the jeweled orifice so as to preserve proper fluid flow characteristics. In addition, the incorporation of a soft seal between the mating surfaces of the inlet body and the orifice assembly permit easy user removal of these components from a cutting jet system.

Owner:SILICON VALLEY BANK

Abrasive flow micropore polishing device and polishing process thereof

InactiveCN104440584AAchieve polishReduce roughnessAbrasive feedersAbrasive machine appurtenancesCavitationWear particle

The invention discloses an abrasive flow micropore polishing device, comprising a clamping tool, a base plate, a cavity, a separation device, a laser high-transparency protective lens, a laser, a focusing lens, a flow guiding passage and a one-way valve, wherein the clamping tool is used for clamping a workpiece and locating micropores of the workpiece; the base plate is arranged on the clamping tool; the cavity is arranged in the base plate and the clamping tool and correspondingly communicate with the micropores; the separation device is arranged in the cavity and divides the cavity into a cavitation cavity and a liquid storage cavity; the laser high-transparent protective lens covers the cavitation cavity; the laser can generate laser beams facing to the cavitation cavity; the focusing lens is arranged between the laser and the laser high-transparent protective lens and is used for focusing laser beams in the cavitation cavity; the flow guiding passage can guide deionized water into the caviation cavity; the one-way valve is arranged in the flow guiding passage. According to the abrasive flow micropore polishing device, lasers are focused to cavitate the deionized water to form a large local pressure and impact the separation device, and the abrasive fluid flows and is pushed into the micropores at high speed and rubs the pore walls of the micropores to reduce the roughness of the inner surface of the micropores, so as to achieve the polishing on the micropores. The invention further discloses an abrasive flow micropore polishing process for highly effectively and ultra-precisely polishing the micropores.

Owner:GUANGDONG UNIV OF TECH

Barrier coating corrosion control methods and systems for interior piping systems

Methods and systems for providing cleaning and providing barrier coatings to interior wall surfaces of small diameter metal and composite piping systems in buildings. An entire piping system can be cleaned in one single pass by dry particulates forced by air throughout the building piping system by an external generator, and the entire piping system can be coated in one single pass by a machine also connected exterior to the piping system. Small diameter pipes can be protected by the effects of water corrosion, erosion and electrolysis, extending the life of small diameter piping systems such as copper, steel, lead, brass, cast iron piping and piping systems made of composite materials. The invention meets the National Sanitation Foundation standard for products and services that come into contact with potable water, and the American Water Works Association. Coatings can be applied to pipes having diameters of approximately ⅜″ up to approximately 6″ so that entire piping systems such as potable water lines, natural gas lines, HVAC piping systems, drain lines, and fire sprinkler systems in buildings such as single-family homes to smaller walk-up style apartments to multi-floor concrete high-rise hotel / resort facilities and office towers, as well as high-rise apartment and condominium buildings and schools, can be cleaned and coated to pipes within existing walls. The barrier coating forms an approximately 4 mils or greater covering to the inside of pipes. Entire buildings can return to service within approximately 24 to approximately 96 hours depending on the size of the building piping system.

Owner:PIPE RESTORATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com