Self-pressurized high-speed polishing method and device for inner surface of hole by means of abrasive particles and magnetic flow

A technology for the inner surface of a hole and a polishing device, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, used abrasive processing devices, etc., can solve the problems of low polishing efficiency and difficult polishing, and achieve a wide range of applications. Easy operation, processing precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

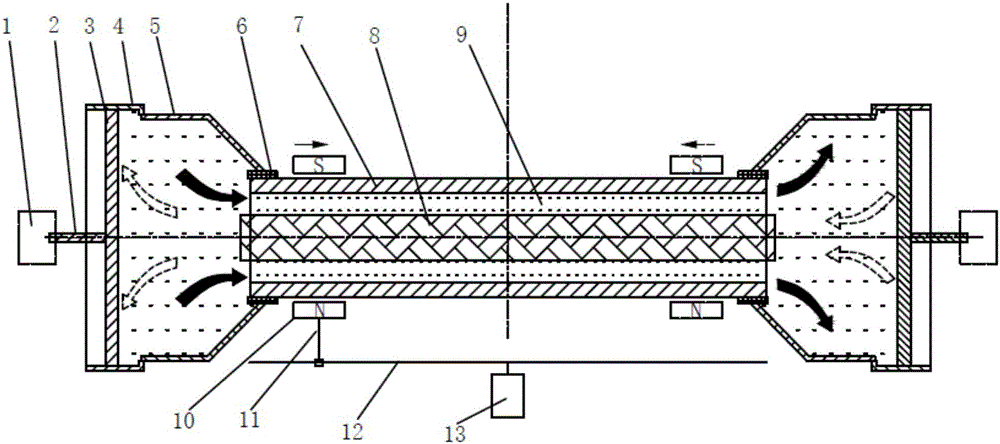

[0030] Attached figure 1 The device shown achieves polishing of the inner surface of an elongated helical bore, such as a rifled bore.

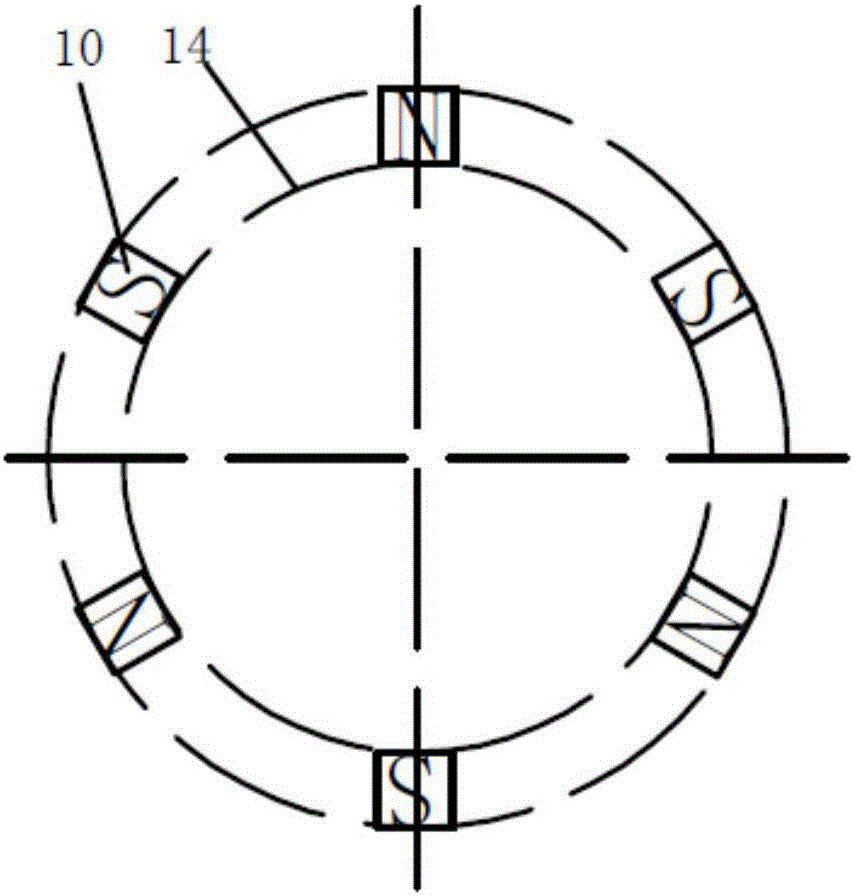

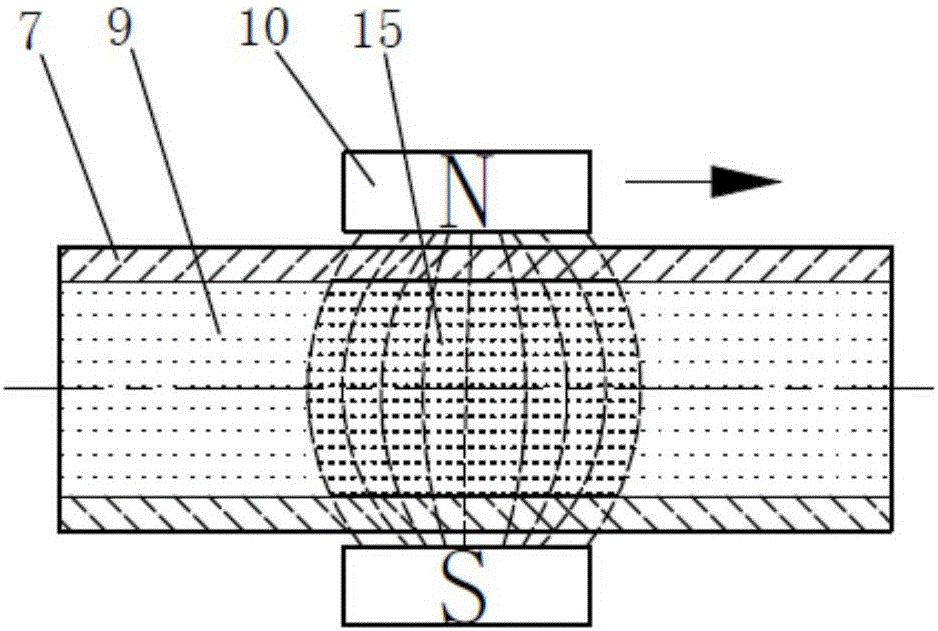

[0031] A self-pressurized high-speed abrasive particle magnetic flow hole inner surface polishing device for polishing applications of slender spiral holes, including a self-pressurized high-speed abrasive particle flow hole inner surface polishing mechanism, a magnetic body 10, an annular magnetic body mounting frame 14, a clamping Mechanism 11, sliding guide rail 12, driving motor 13. The self-pressurized high-speed abrasive flow hole inner surface polishing mechanism includes two groups of fluid pressurized acceleration mechanisms and fixtures 6 symmetrically arranged at the left and right ends of the workpiece 7 to be processed. The fluid pressurization acceleration mechanism includes a fluid pressurization acceleration chamber 5, a piston cylinder 4, a piston 3, a piston rod 2 and a drive unit 1, and one end of the fluid pressurization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com