Auxiliary dust collection system

a dust collection system and dust collection technology, applied in the direction of vortex flow apparatus, filtration separation, separation process, etc., can solve the problems of only mildly effective arrangement, no one has attempted to use a true cyclonic separator, and no one has attempted to reduce the level of process noise. , to achieve the effect of simple and straightforward construction, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

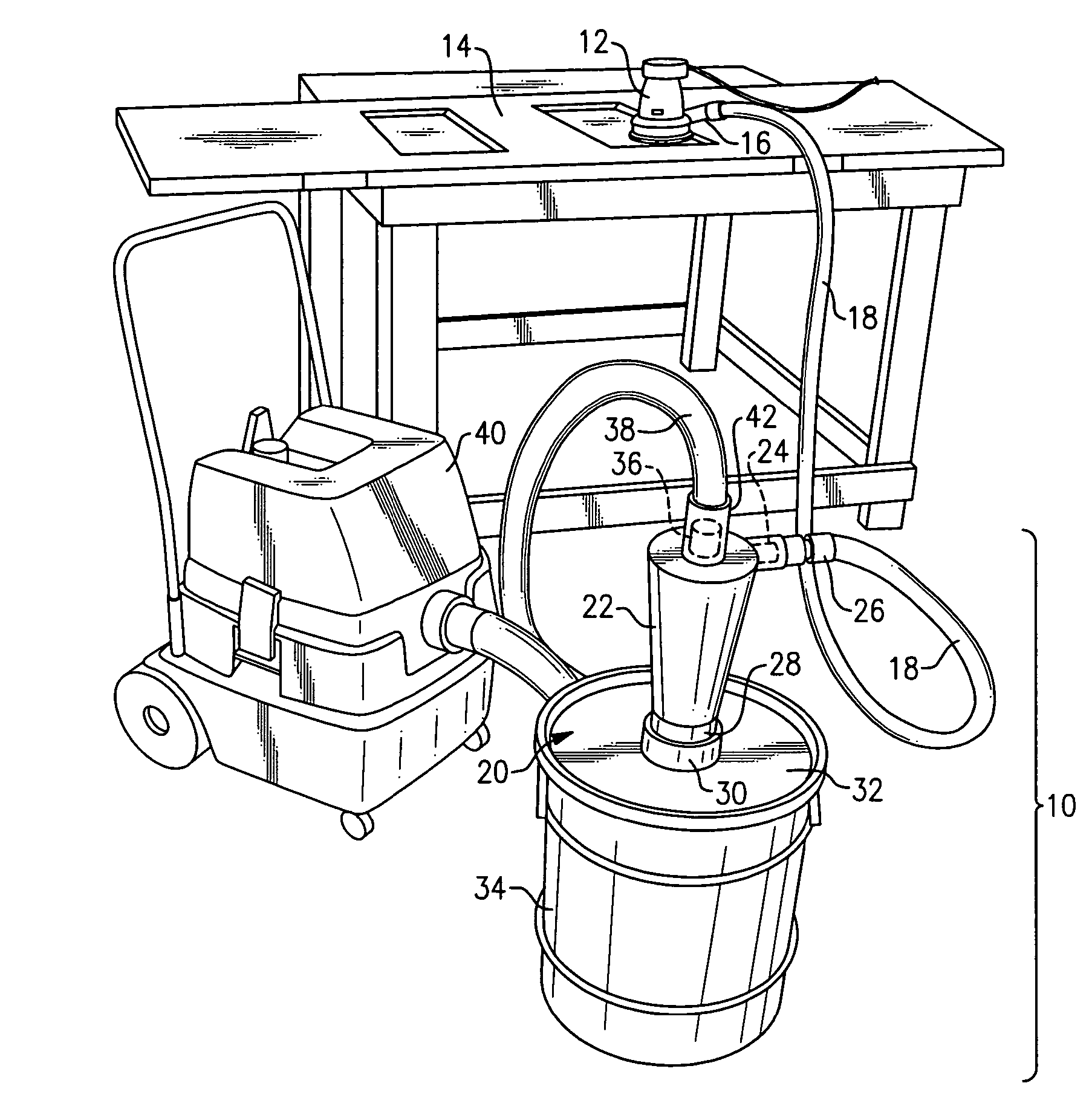

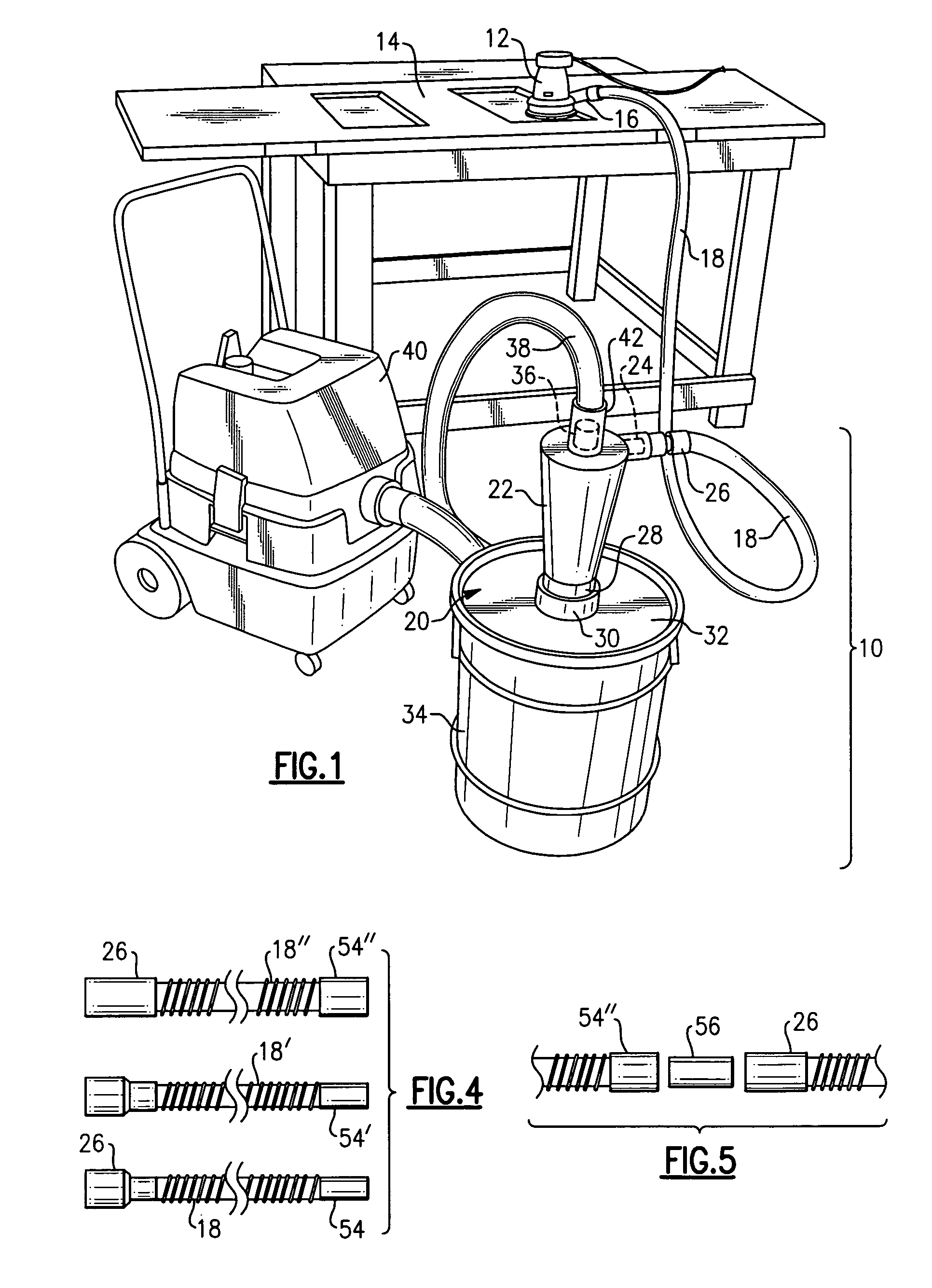

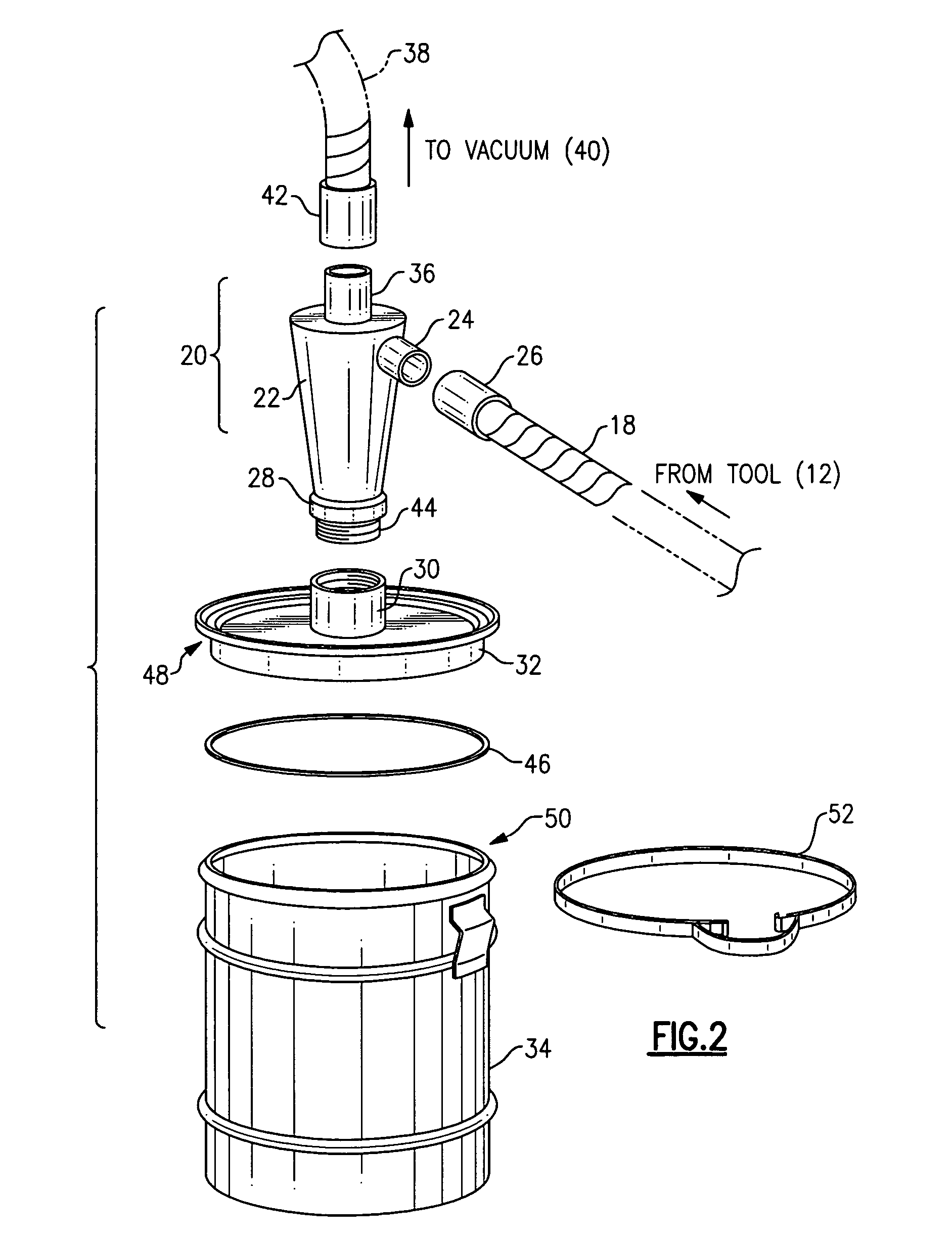

[0031] Now with reference to the Drawing, FIG. 1 shows a woodshop application, which employs an auxiliary dust separation and collection device 10 of present invention. As illustrated, a wood sander device 12 is shown in use on a wood workpiece, e.g., a door 14 or article of furniture. The sander 12 has a dust exhaust duct 16, which is connected by an elongated flexible hose 18 to an intake of the auxiliary separation and collection device. Dust in the air stream emanating from the sander 12 (or from another tool or machine) is intercepted at the auxiliary device 10, in a cyclonic separator 20. This separator comprises a conic body 22, with an intake pipe 24 that is fitted with a connector or cuff 26 of the hose 18. The cuff is favorably a tubular push-on sleeve. The conic body has a nose or vertex 38 at its lower end where it is attached by means of a coupler ring 30 to a lid or cover 32 that is fitted onto a drum or barrel 34. A vortex pipe 36 extends up from within the conic body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com