Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Acoustic foam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acoustic foam is an open celled foam used for acoustic treatment. It attenuates airport creasing air resistance, thus reducing the amplitude of the waves. The energy is dissipated as heat. Acoustic foam can be made in several different colors, sizes and thickness.

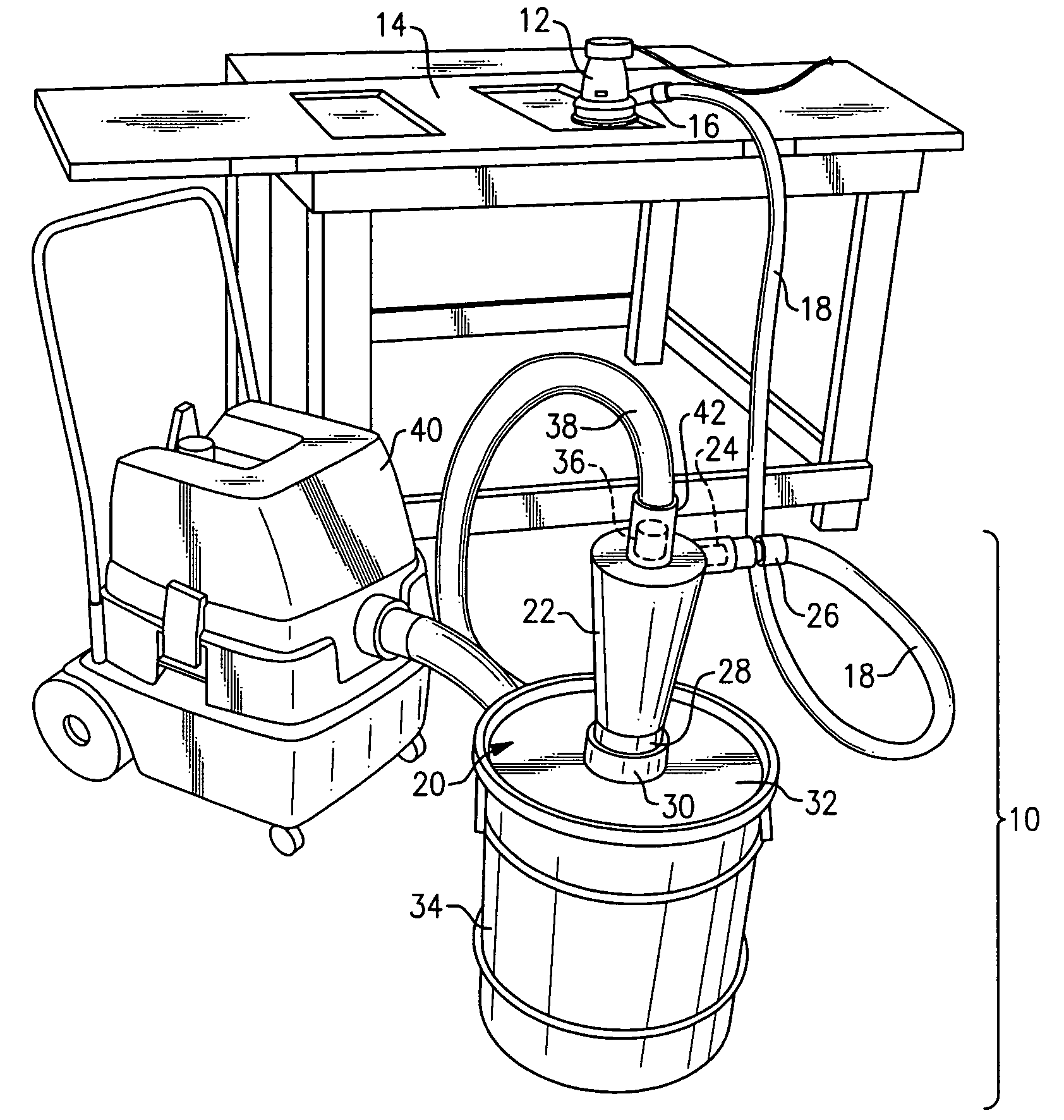

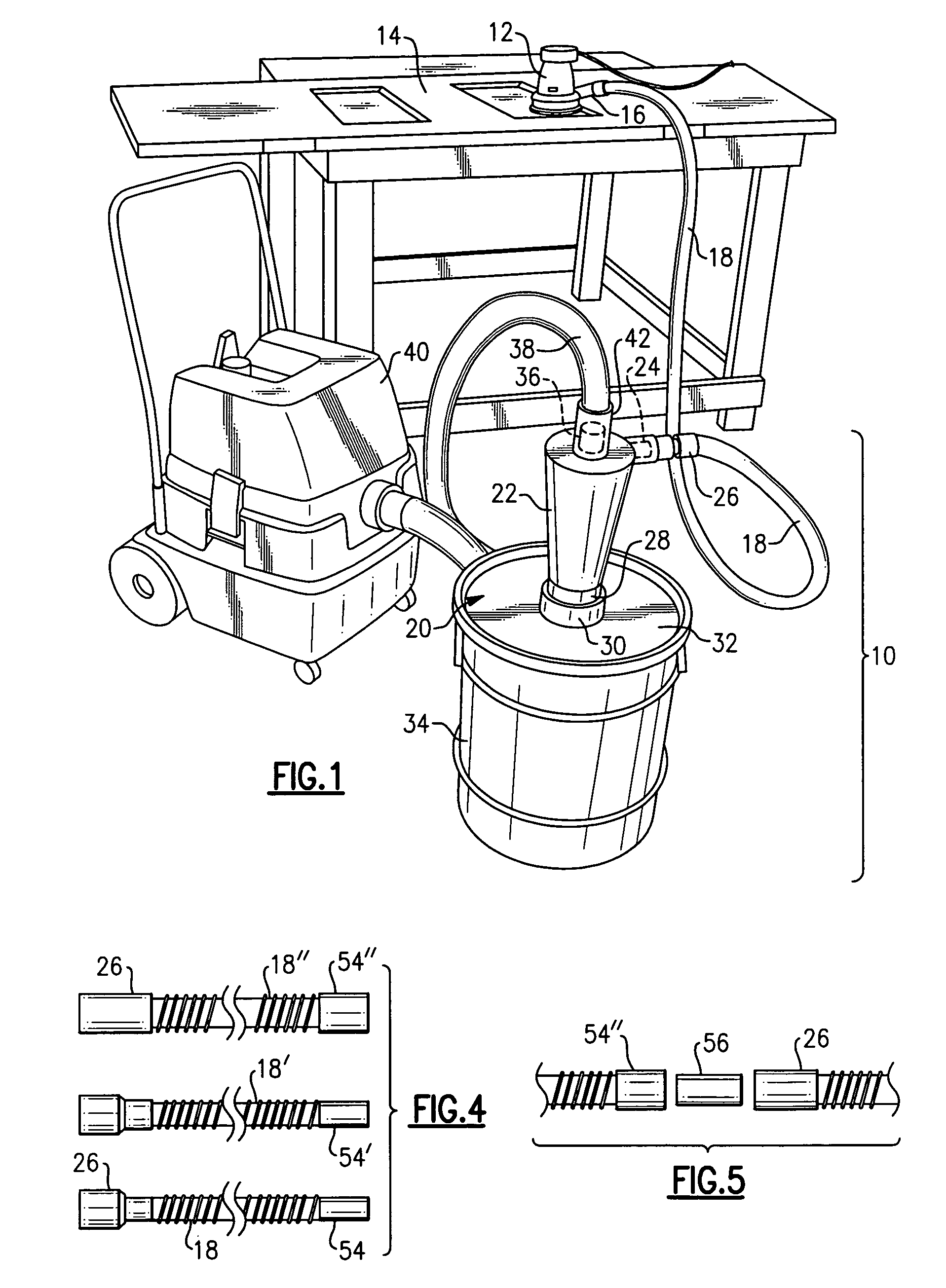

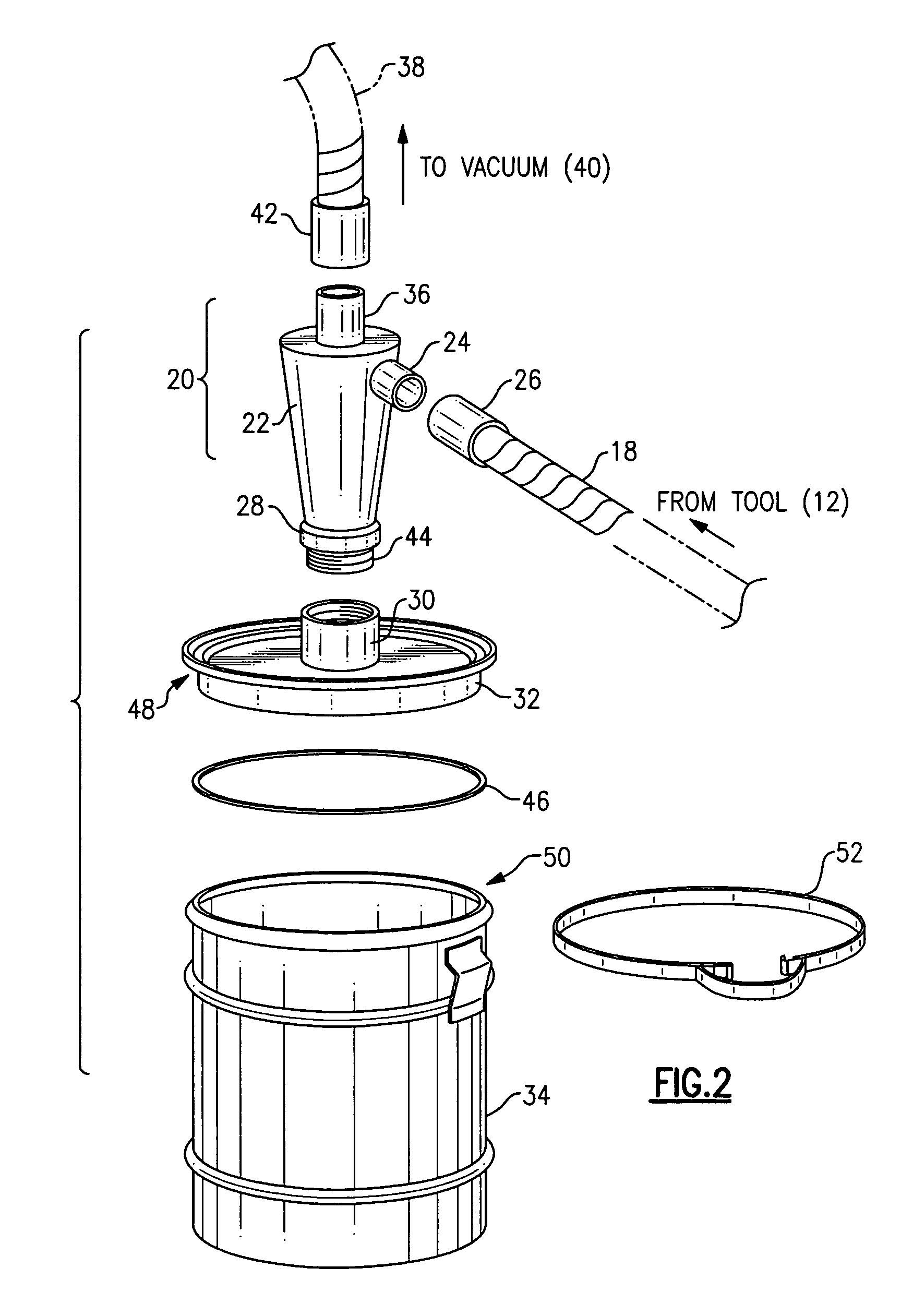

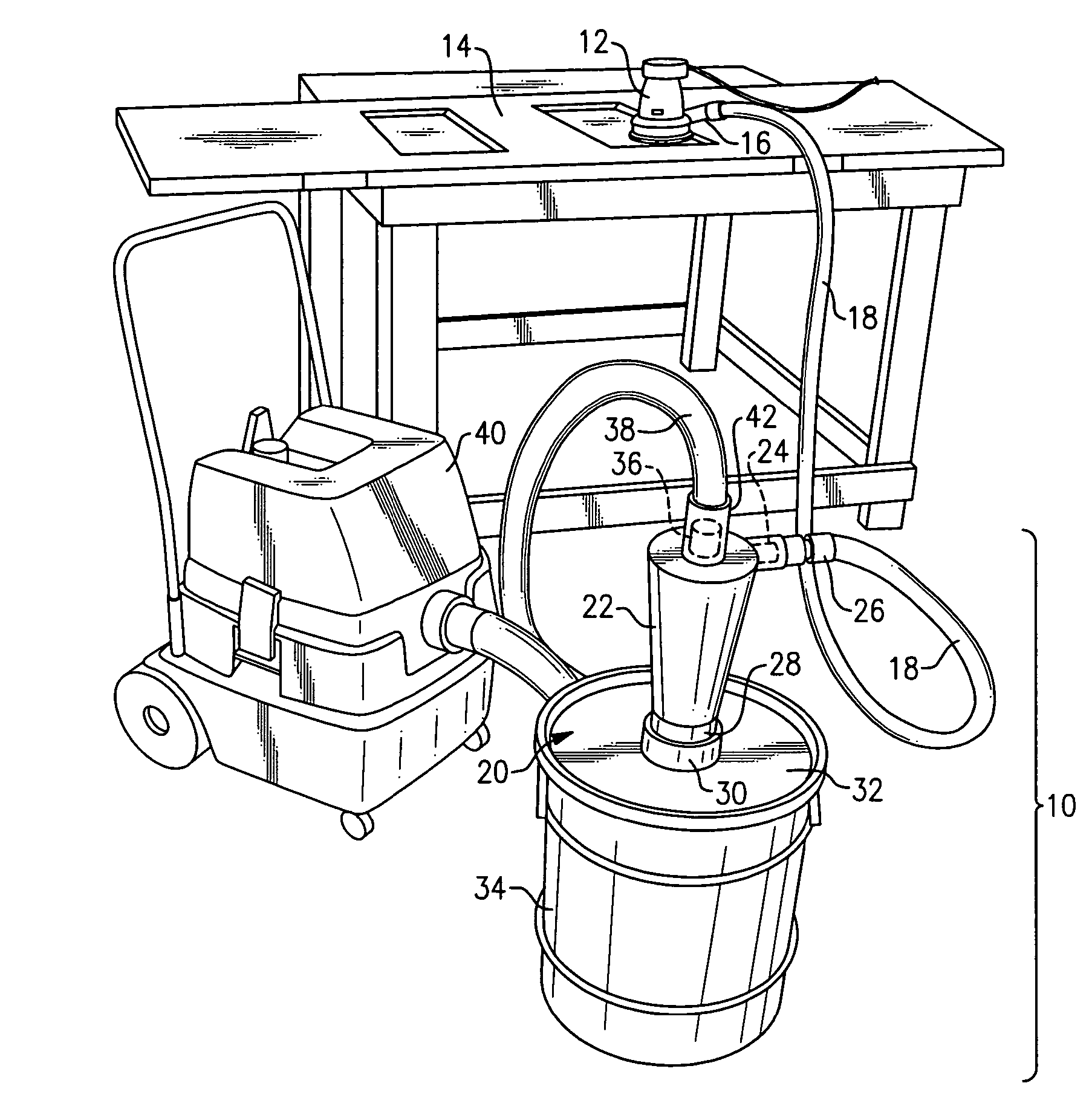

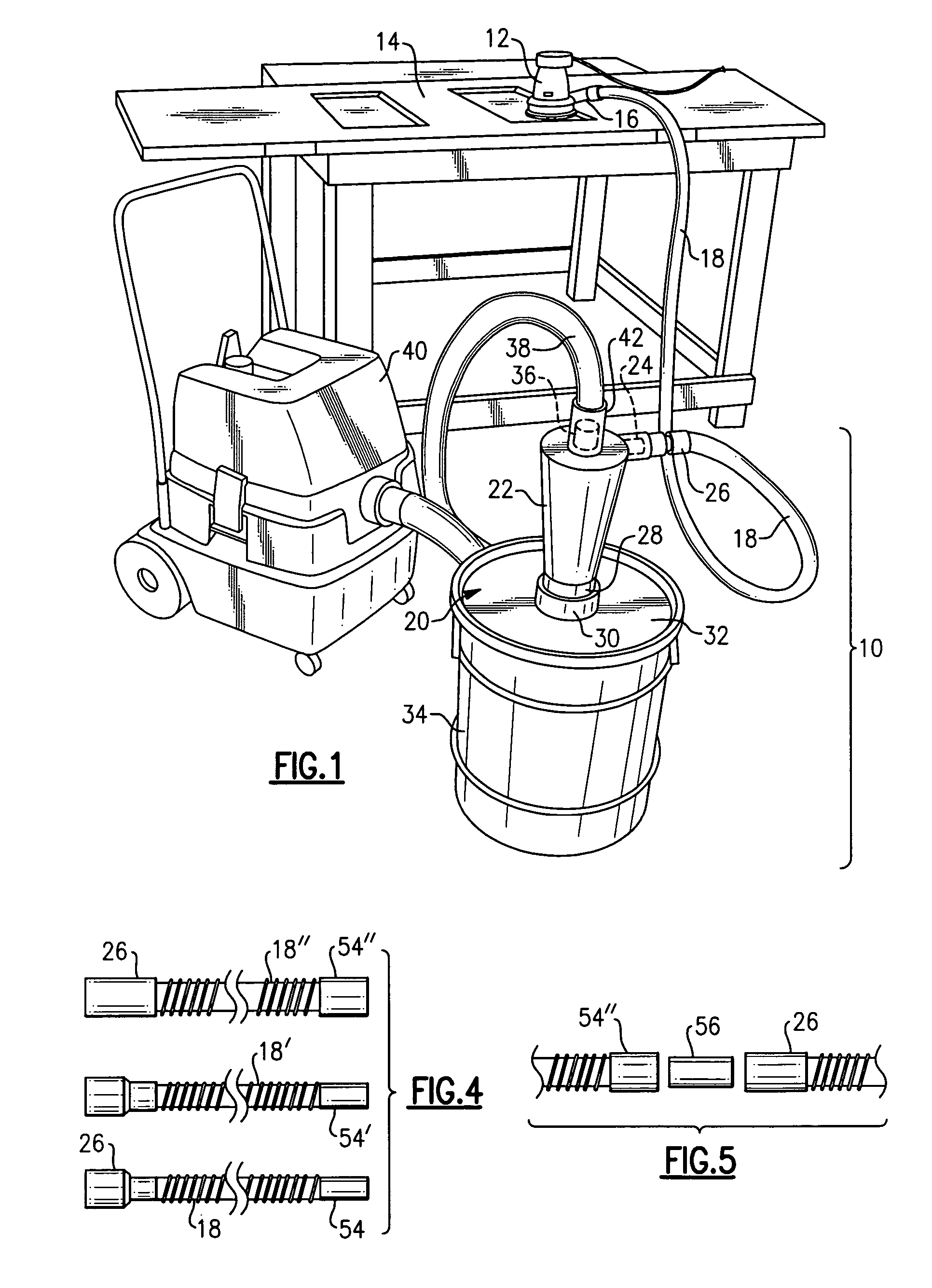

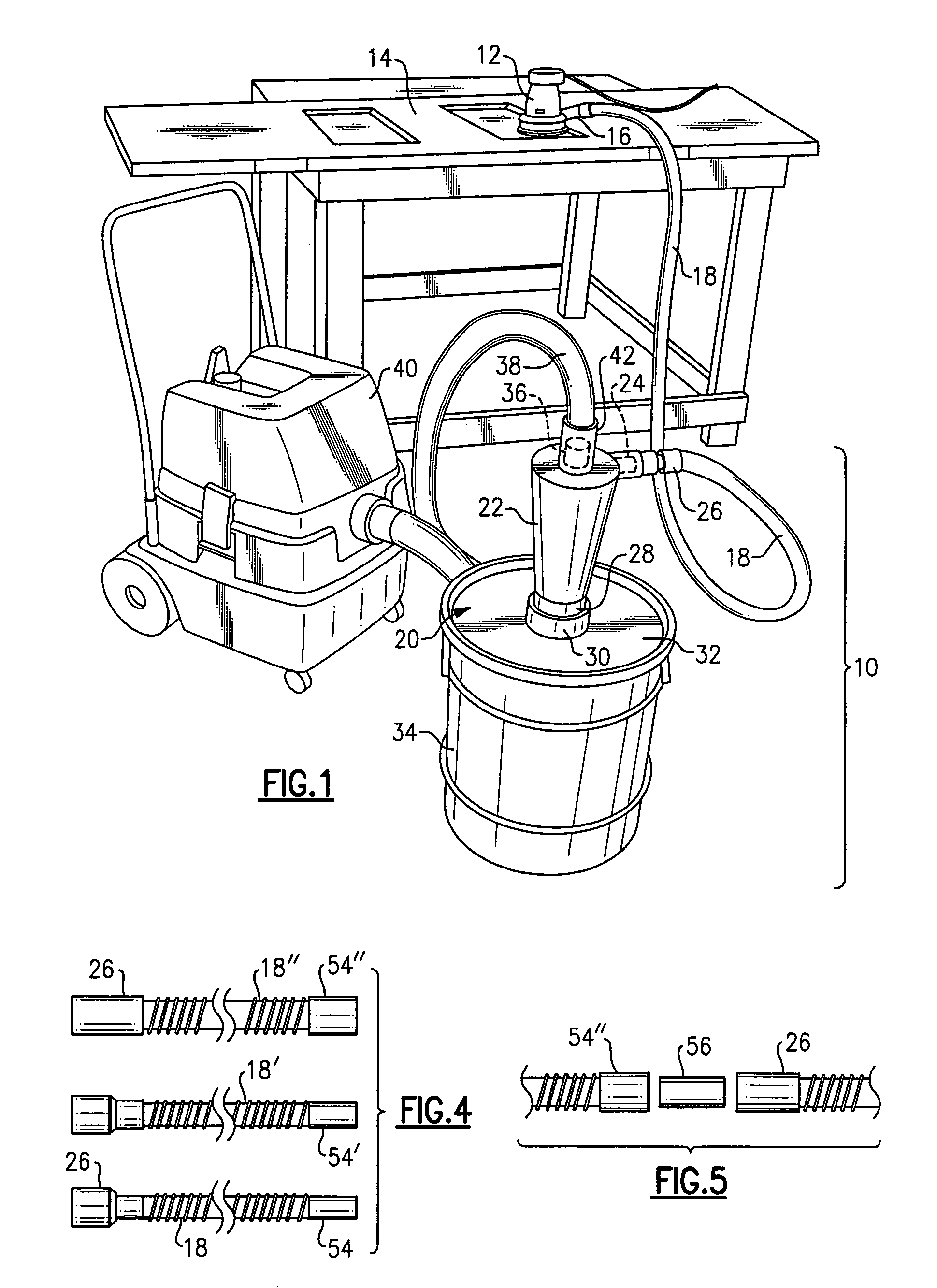

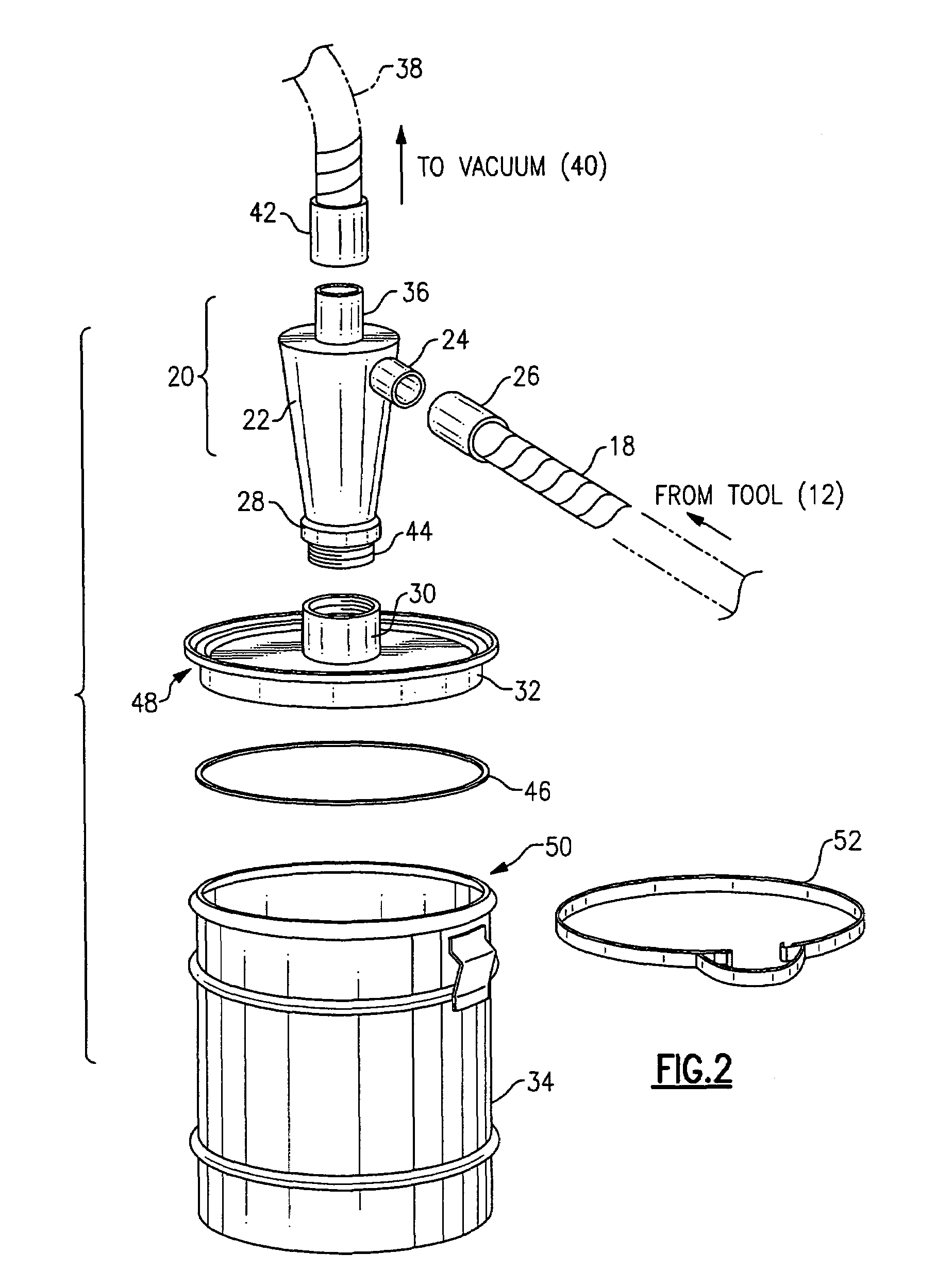

Auxiliary dust collection system

ActiveUS7282074B1Simple and straightforward in constructionImprove reliabilityCombination devicesReversed direction vortexSanderProcess noise

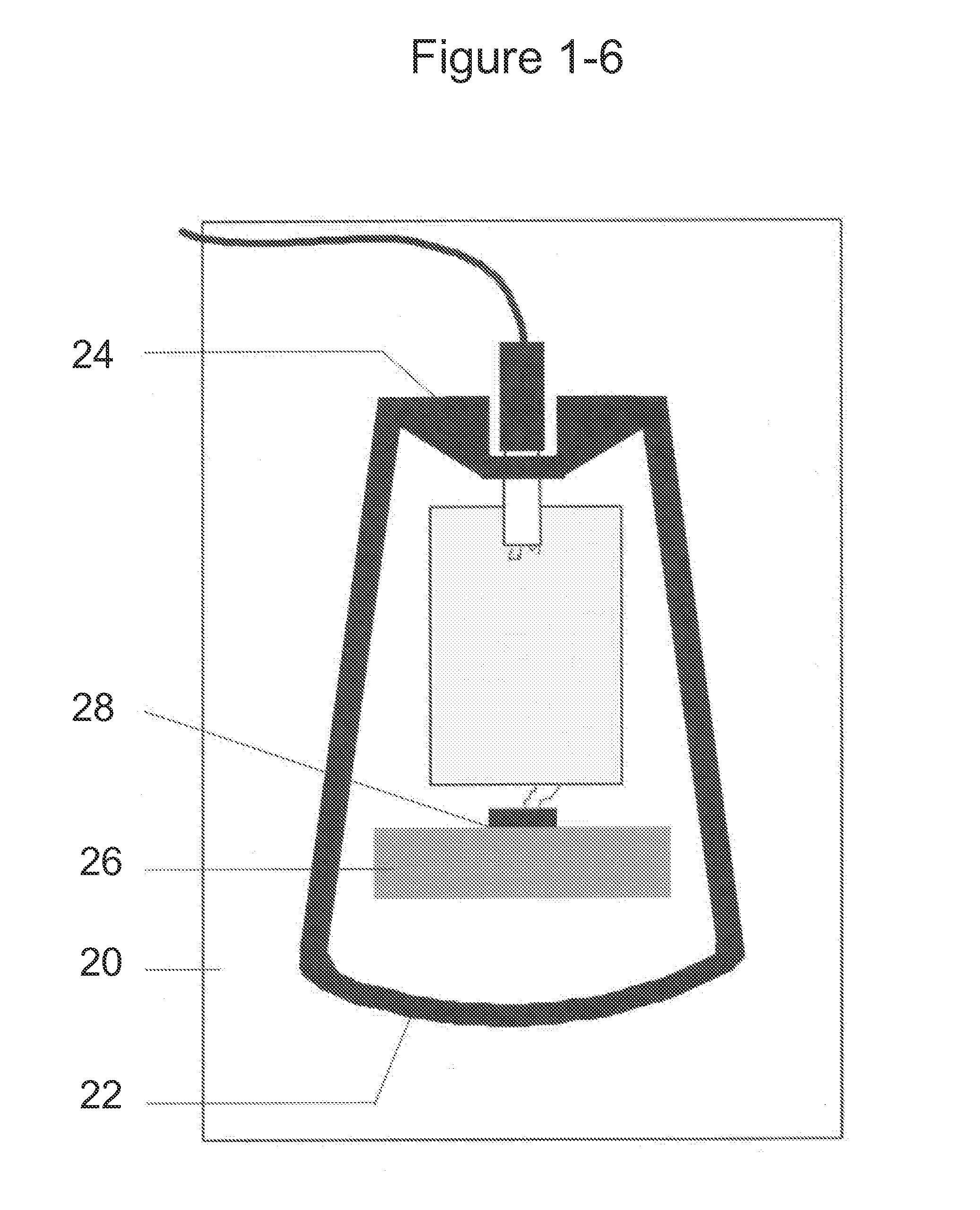

An auxiliary dust collection system can be interposed between a sander or other dust producing tool and a vacuum source, e.g., shop vacuum. This auxiliary system has a cyclonic separator connected by a flexible hose to the tool and by another hose to the vacuum source. The cone of the separator is mounted onto the lid of a drum into which the dust precipitates. For a tool that has its own blower, the vacuum source can be omitted, and the air leaving the outlet duct of the separator can be filtered and returned to the ambient. A drop in silencer formed of a sleeve or tube of acoustic foam can be positioned into the inlet side of a filter cartridge following a cyclonic separator. The silencer absorbs a significant fraction of the process noise.

Owner:WITTER ROBERT M

Auxiliary dust collection system

ActiveUS20070251198A1Avoid disadvantagesSimple and straightforward in constructionCombination devicesReversed direction vortexSanderProcess noise

Owner:WITTER ROBERT M

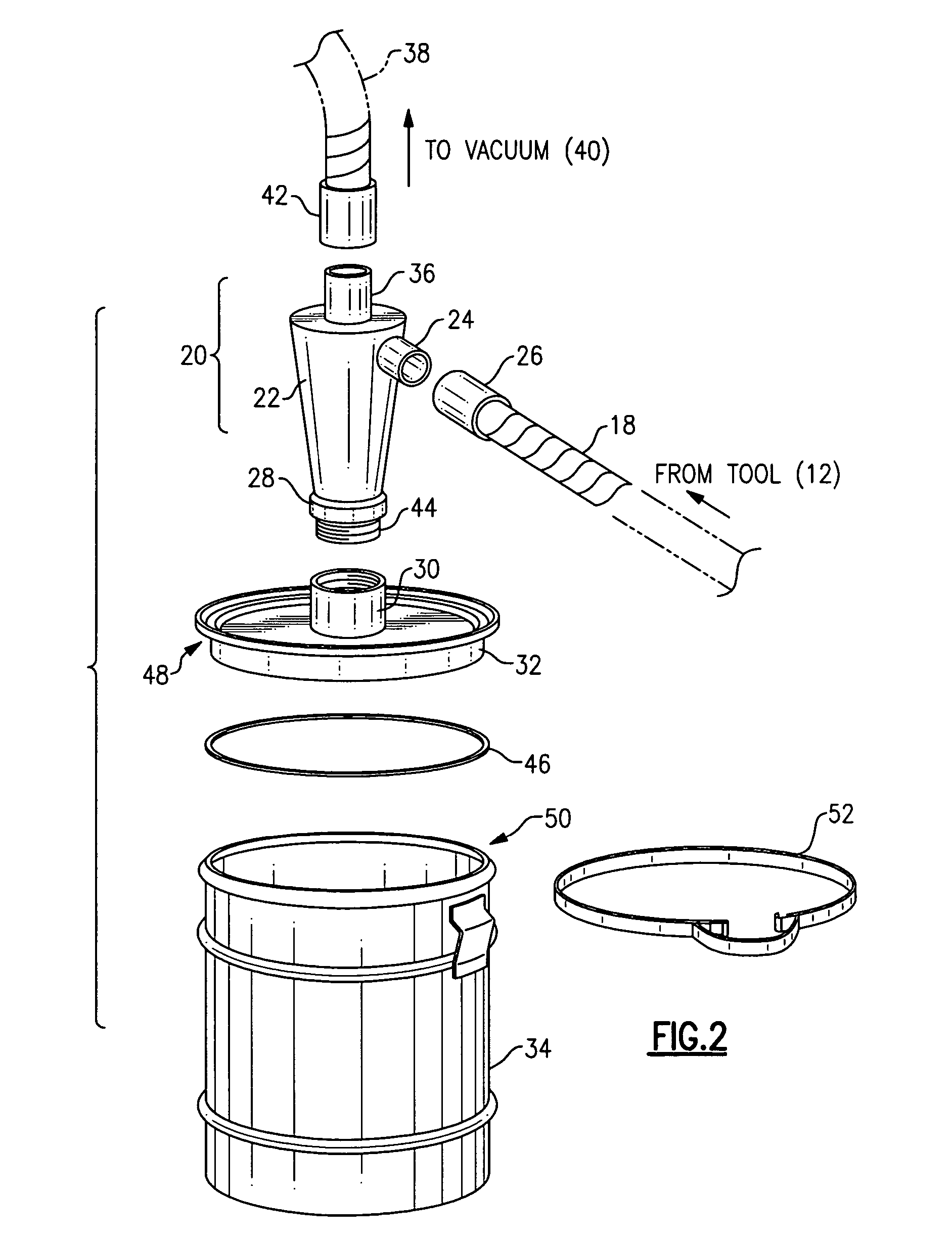

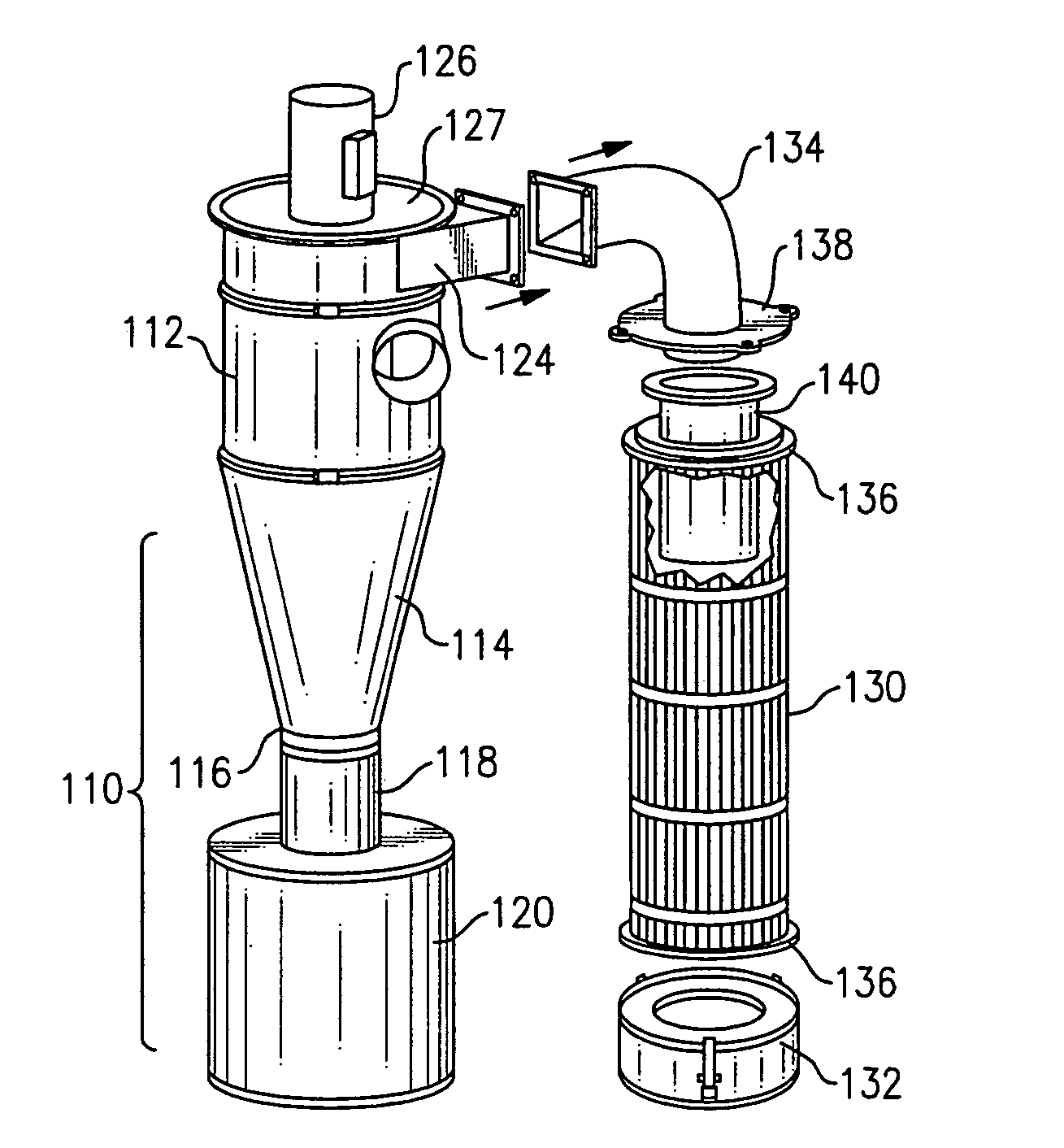

Silencer for dust collection system

ActiveUS7247180B1Simple and straightforward in constructionImprove reliabilityCombination devicesAuxillary pretreatmentProcess noiseSander

An auxiliary dust collection system can be interposed between a sander or other dust producing tool and a vacuum source, e.g., shop vacuum. A cyclonic separator is connected by a flexible hose to the tool and by another hose to the vacuum source. The cone of the separator is mounted onto the lid of a drum into which the dust precipitates. For a tool that has its own blower, the vacuum source can be omitted, and the air leaving the outlet duct of the separator can be filtered and returned to the ambient. A drop in silencer formed of a sleeve or tube of acoustic foam can be positioned into the inlet side of a filter cartridge following a cyclonic separator. The silencer absorbs a significant fraction of the process noise. The acoustic foam can have a textured surface on the sound-facing side.

Owner:ONEIDA AIR SYST

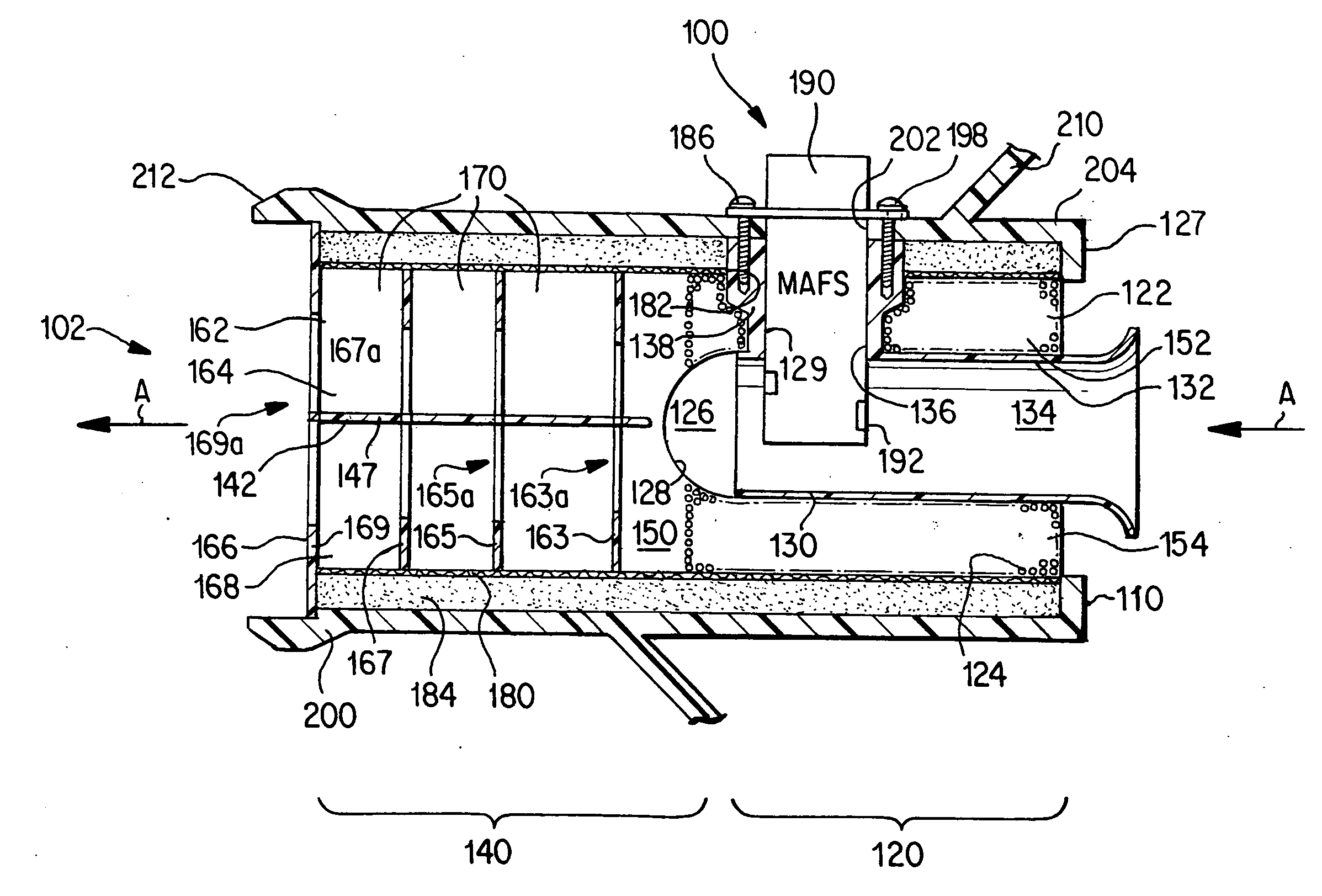

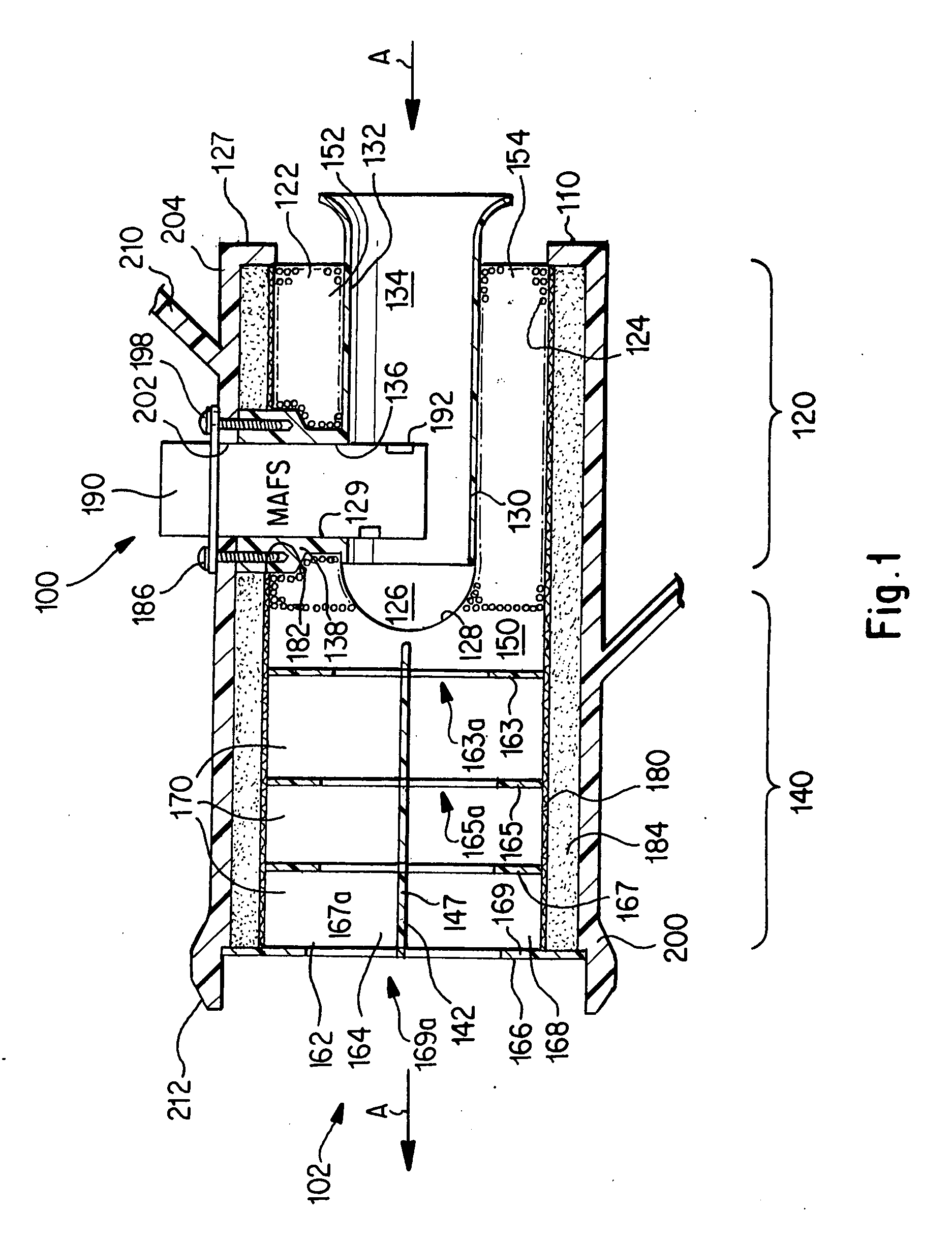

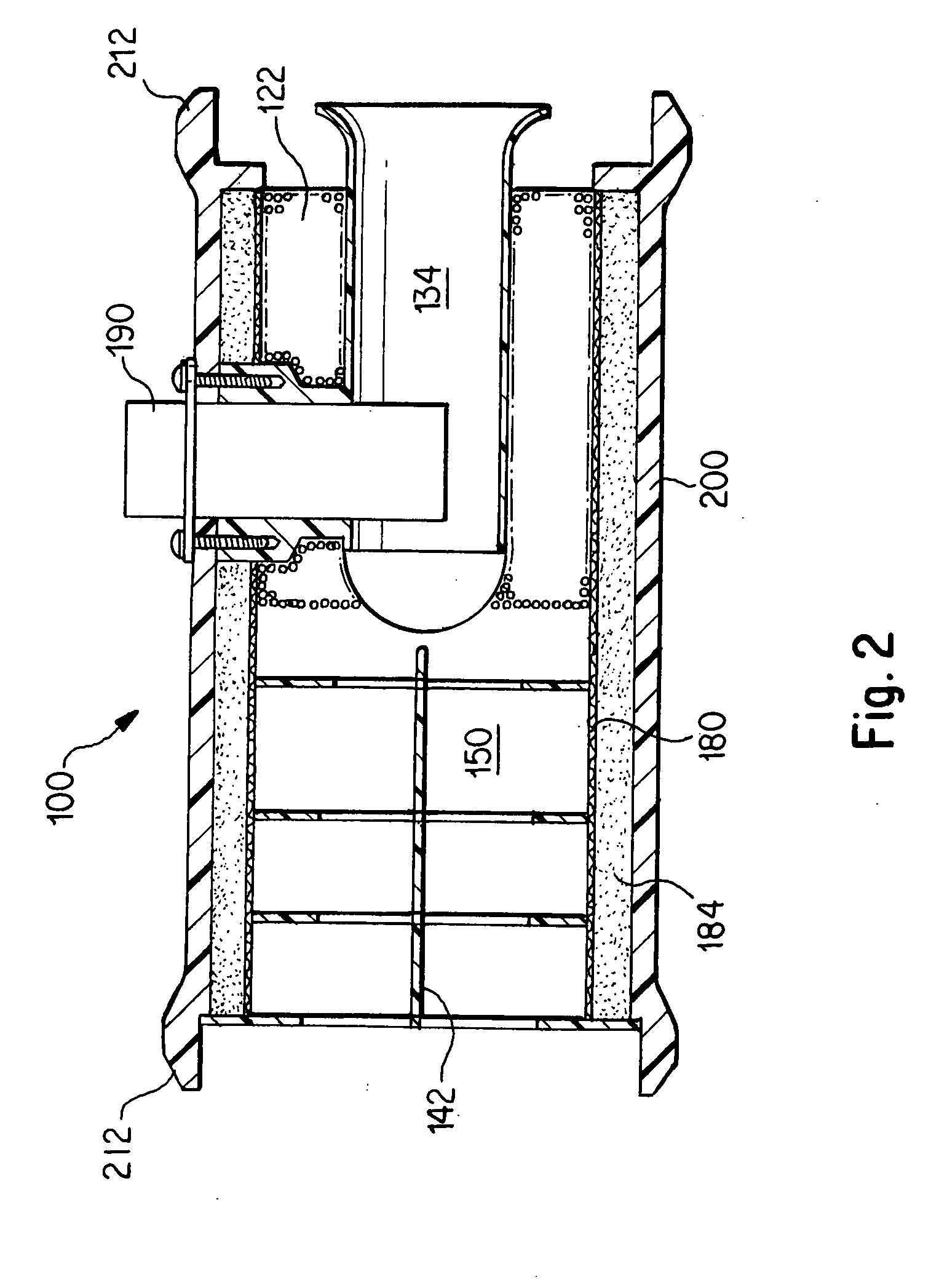

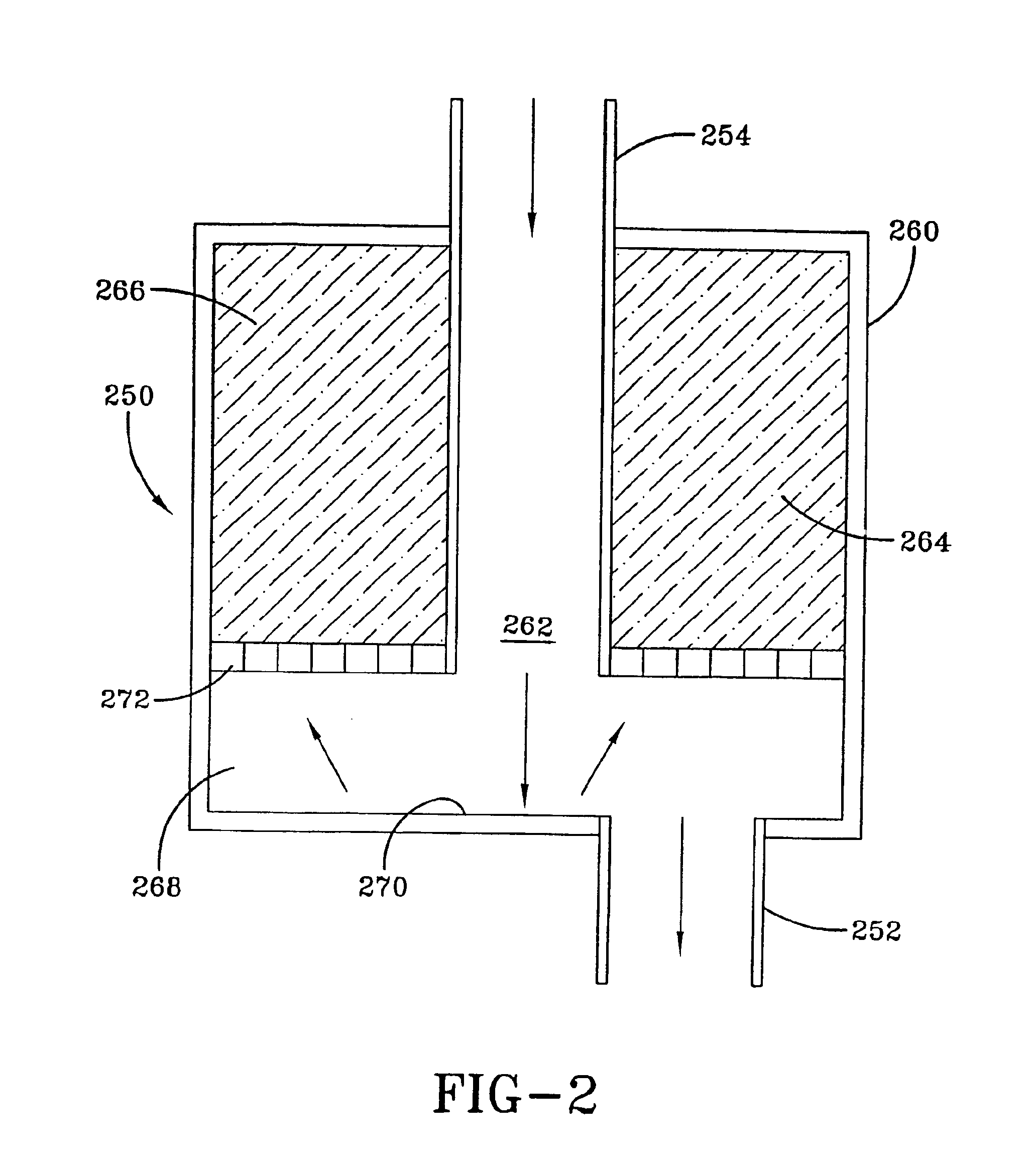

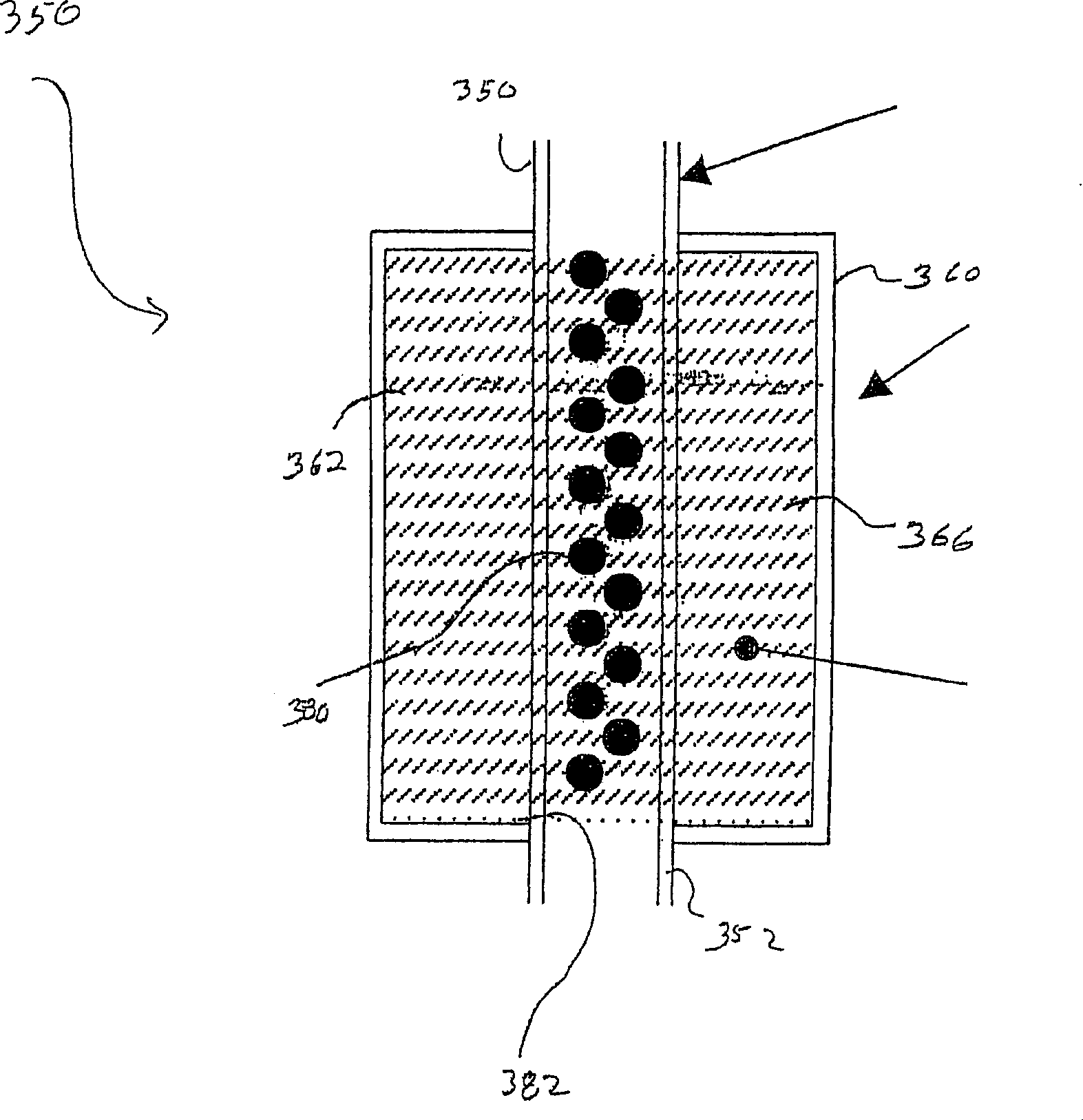

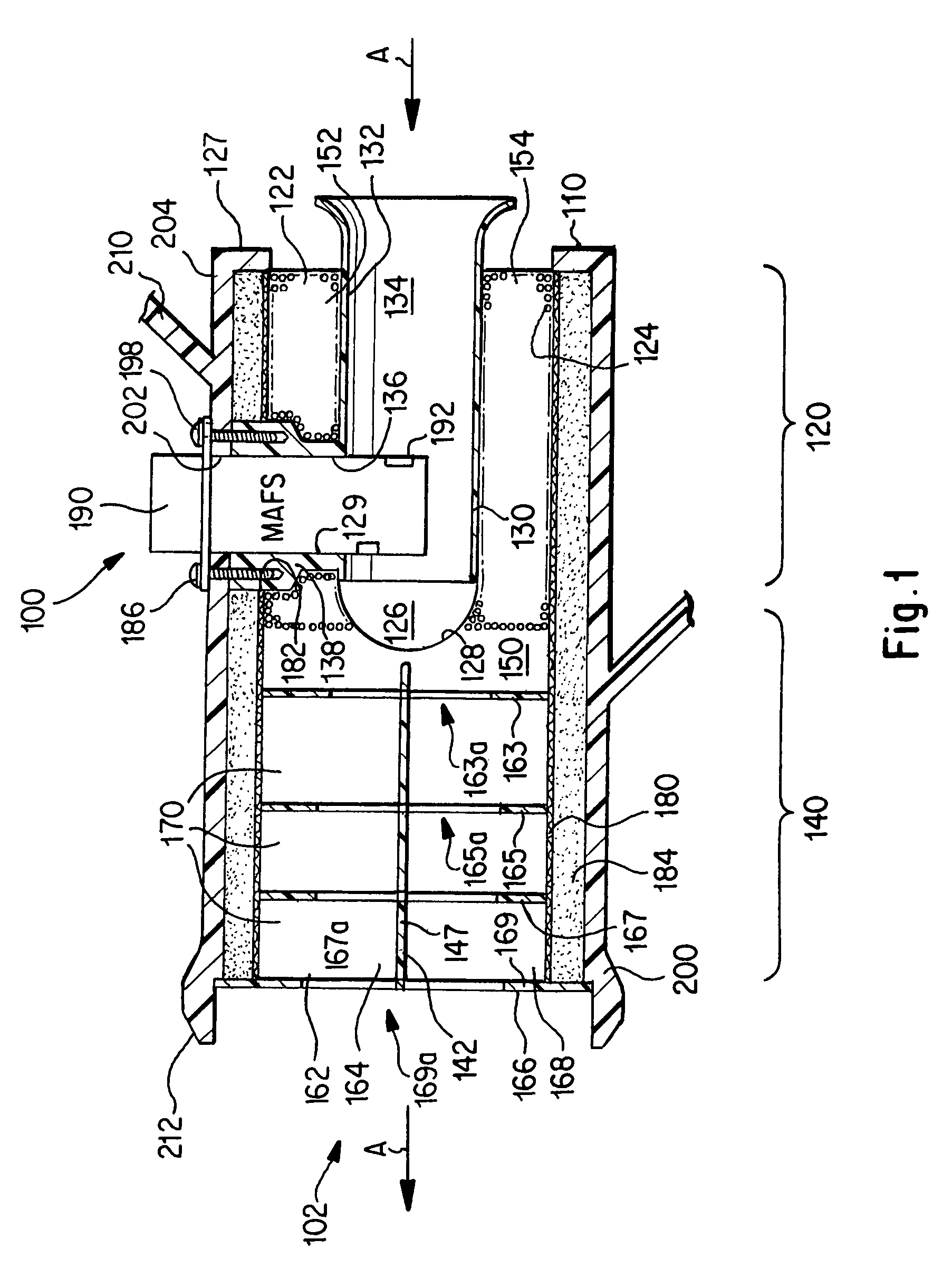

Integrated mass air flow sensor and broadband silencer

InactiveUS20070292816A1Reduce intensityAcoustic emission reductionElectrical controlExhaust apparatusInterior spaceAcoustic foam

An integrated mass air flow sensor / broadband silencer assembly comprises a molded body having a plurality of walls formed therein. The molded body is over-wrapped with a layer of acoustic foam that, together with the plurality of walls, define a plurality of chambers within an interior volume of the assembly. A mass air flow sensor can be inserted into one of the chambers. The chambers are sized and spaced to provide a uniform velocity, low turbulence air flow to the sensor, and a minimally-restricted air flow to an internal combustion engine located downstream of the assembly.

Owner:MANN HUMMEL GMBH

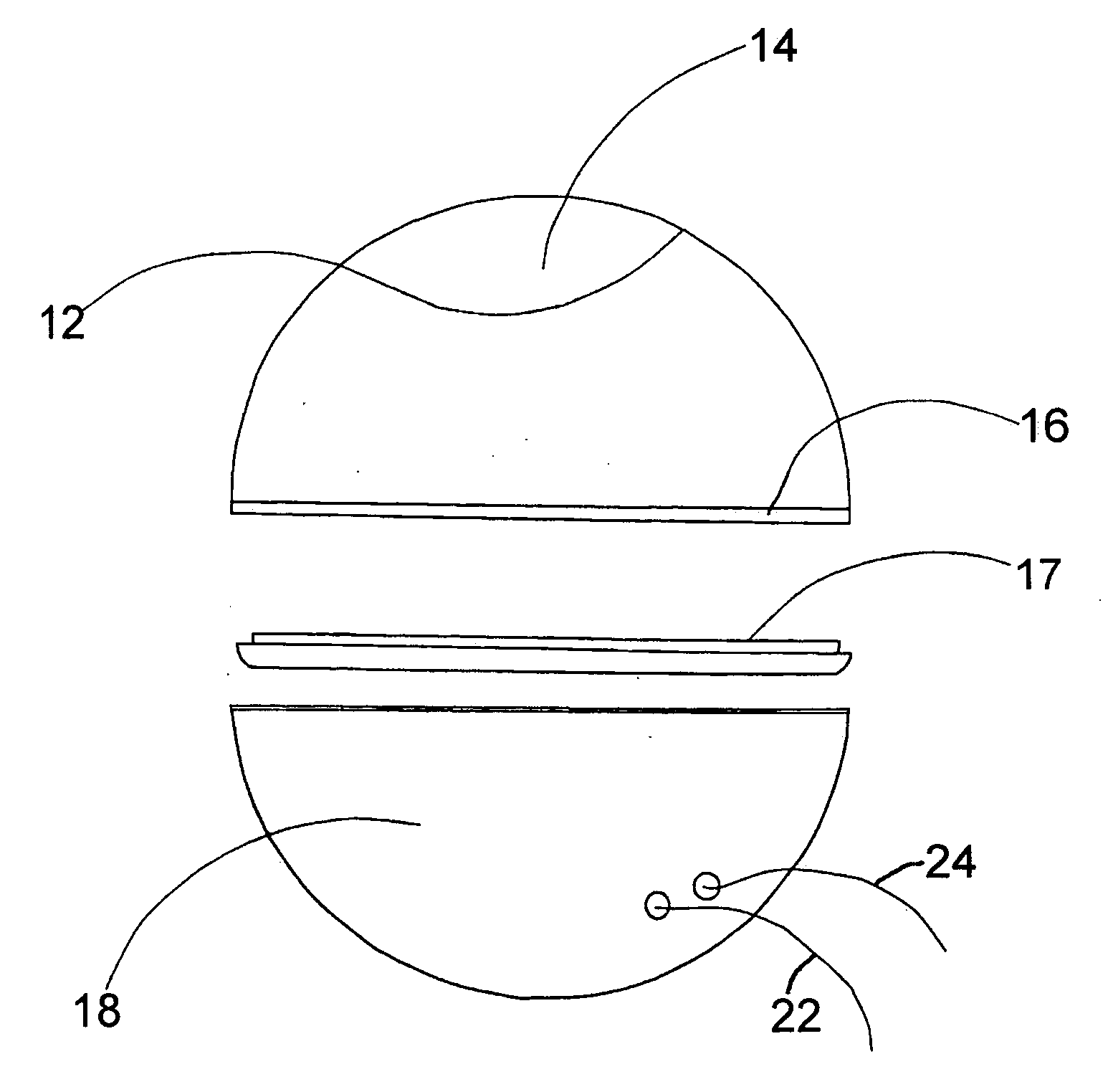

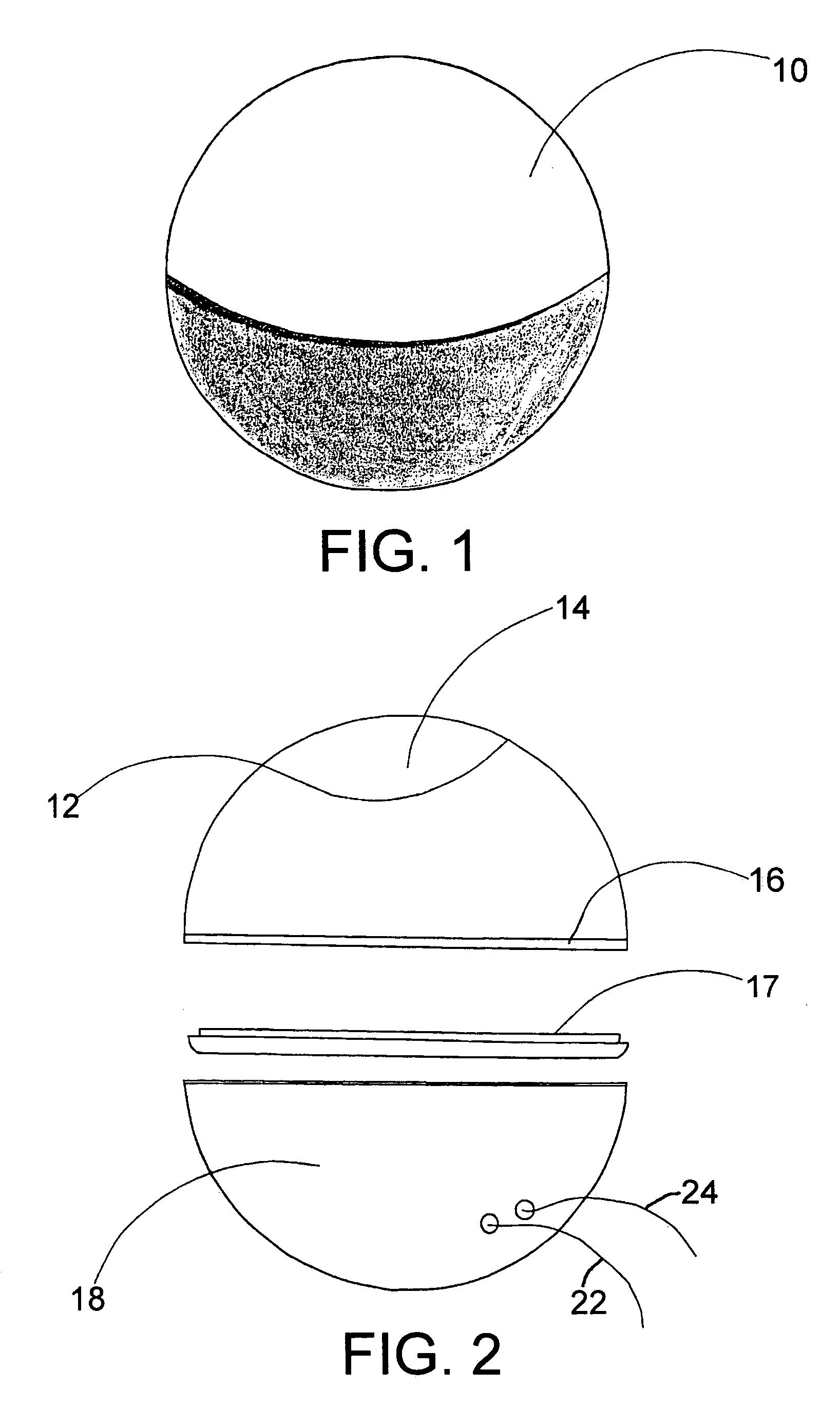

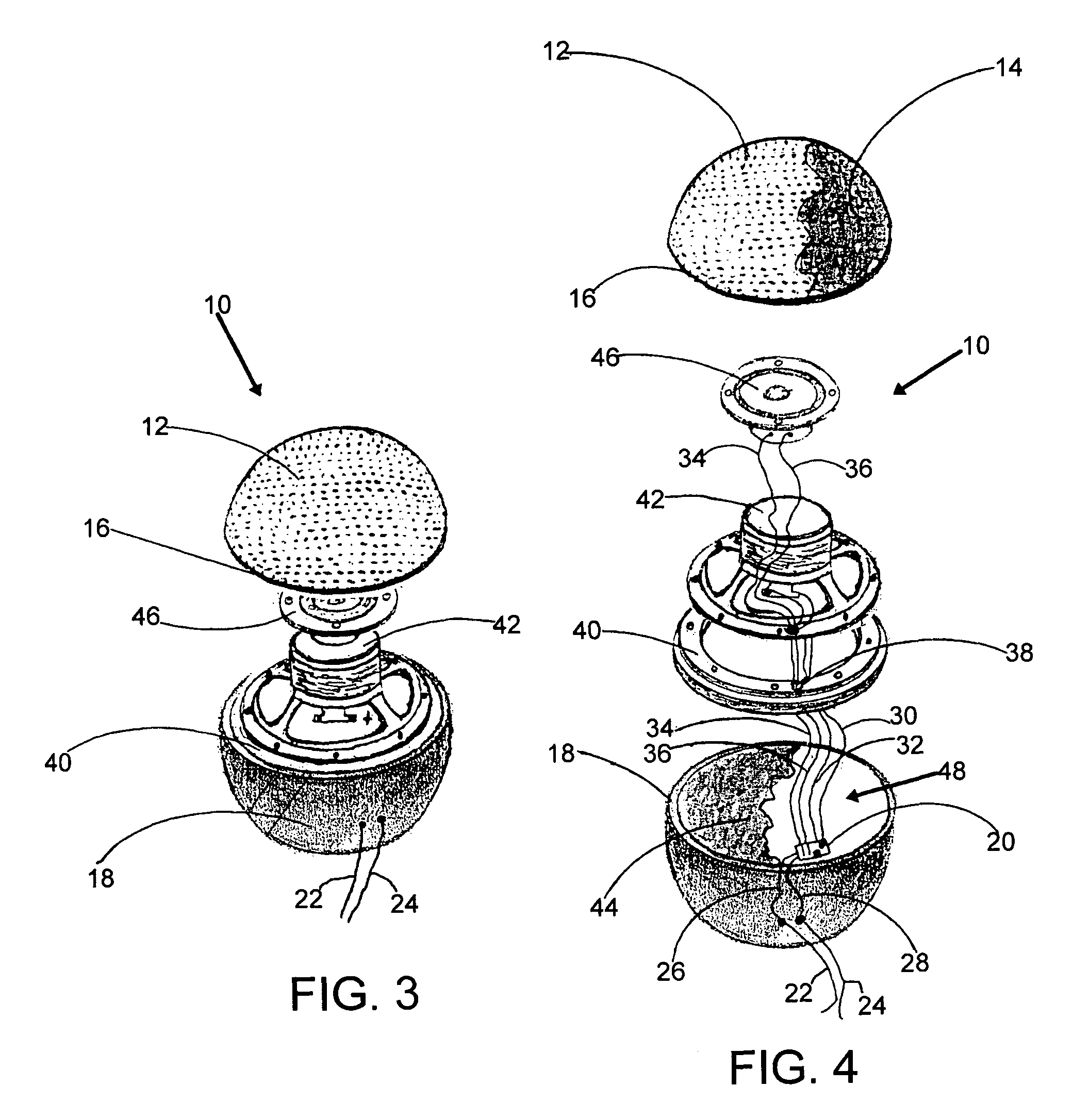

Spherical loudspeaker for omnipresent sound reproduction

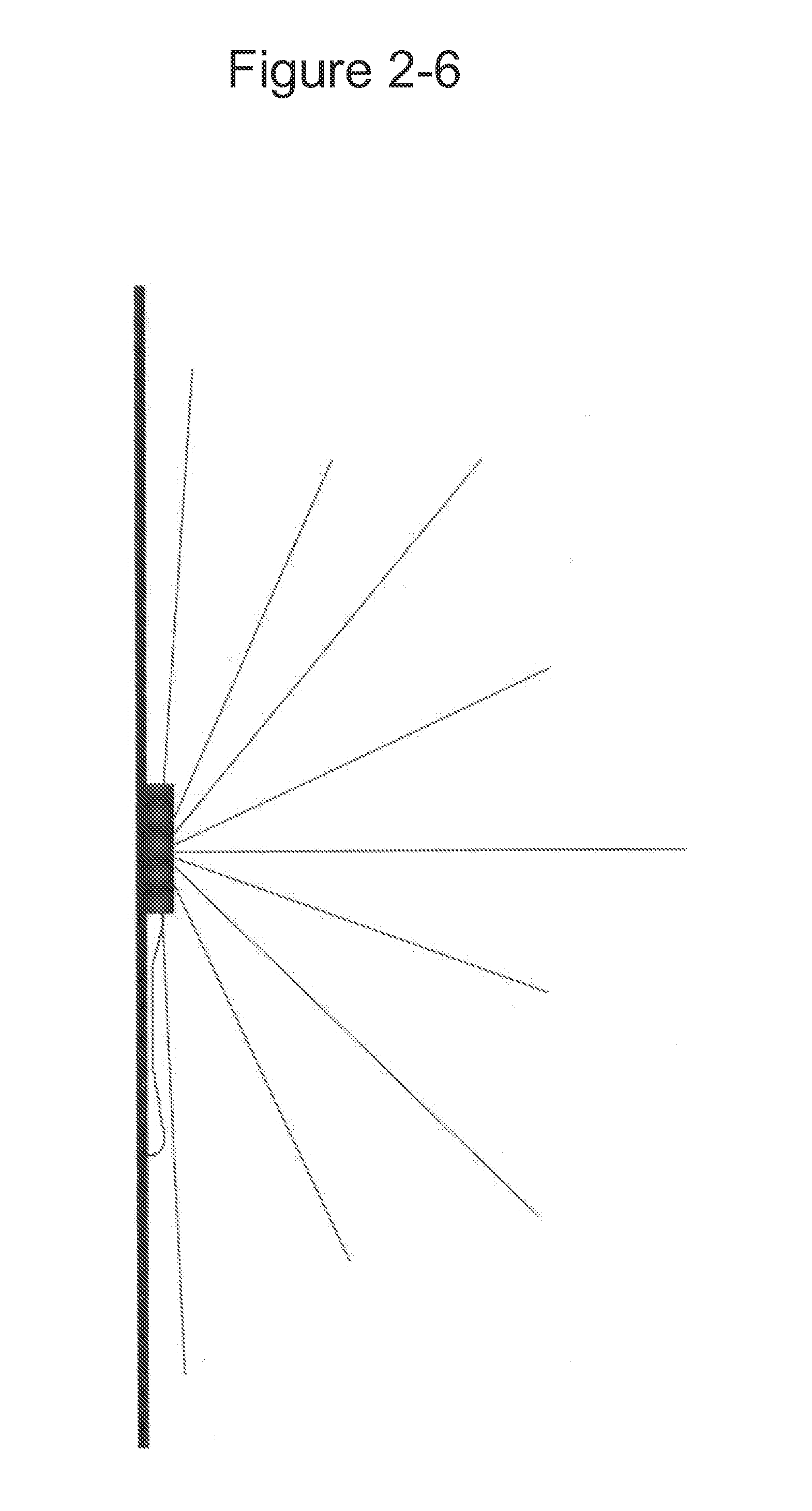

ActiveUS20070160246A1Inexpensive and dependable and fully effectiveLoudspeaker screensTransducer combinationsAcoustic foamSound wave

A highly compact loudspeaker system having a spherical housing produces time and phase coherent sound waves in an omnipresent manner throughout a spatial listening environment. Within is a relatively low frequency sound driver and a relatively high frequency sound driver. The spherical housing has upper and lower hemispherical halves. The upper half is hollow and has holes through its surface over most of its surface. The lower half forms a sound compression propagation vacuum chamber for the low frequency driver. Mounted within the lower half is a crossover network conventionally connected to the sound drivers. Acoustic foam lines the interior wall surface of the lower half. The low frequency sound driver is mounted inverted, into the open end of the lower half, and then sealed air tight, at a lowered atmospheric pressure, while the high frequency sound driver is mounted upwardly, affixed to the backside of the low frequency driver.

Owner:VOLLMER EDWARD G

Macrocellular acoustic foam containing particulate additive

ActiveUS20050086823A1Avoid corrosionImprovement factorSound producing devicesDrying machinesParticulatesPolymer science

A cellular thermoplastic polyolefin foam comprising at least one particulate additive in admixture with a polymer matrix is disclosed, along with a process and foamable gel for manufacturing the same, wherein the polyolefin matrix comprises at least one polymer resin graft-modified with at least one polar group selected from the group consisting of acid, acid ester, and acid anhydride, and salts thereof. The invention facilitates the manufacture of macrocellular foams useful for acoustic absorption having increased amounts of particulate additives that provide certain desired properties difficult to achieve without the particulate additives, such as improved flame retardancy.

Owner:SEALED AIR U S

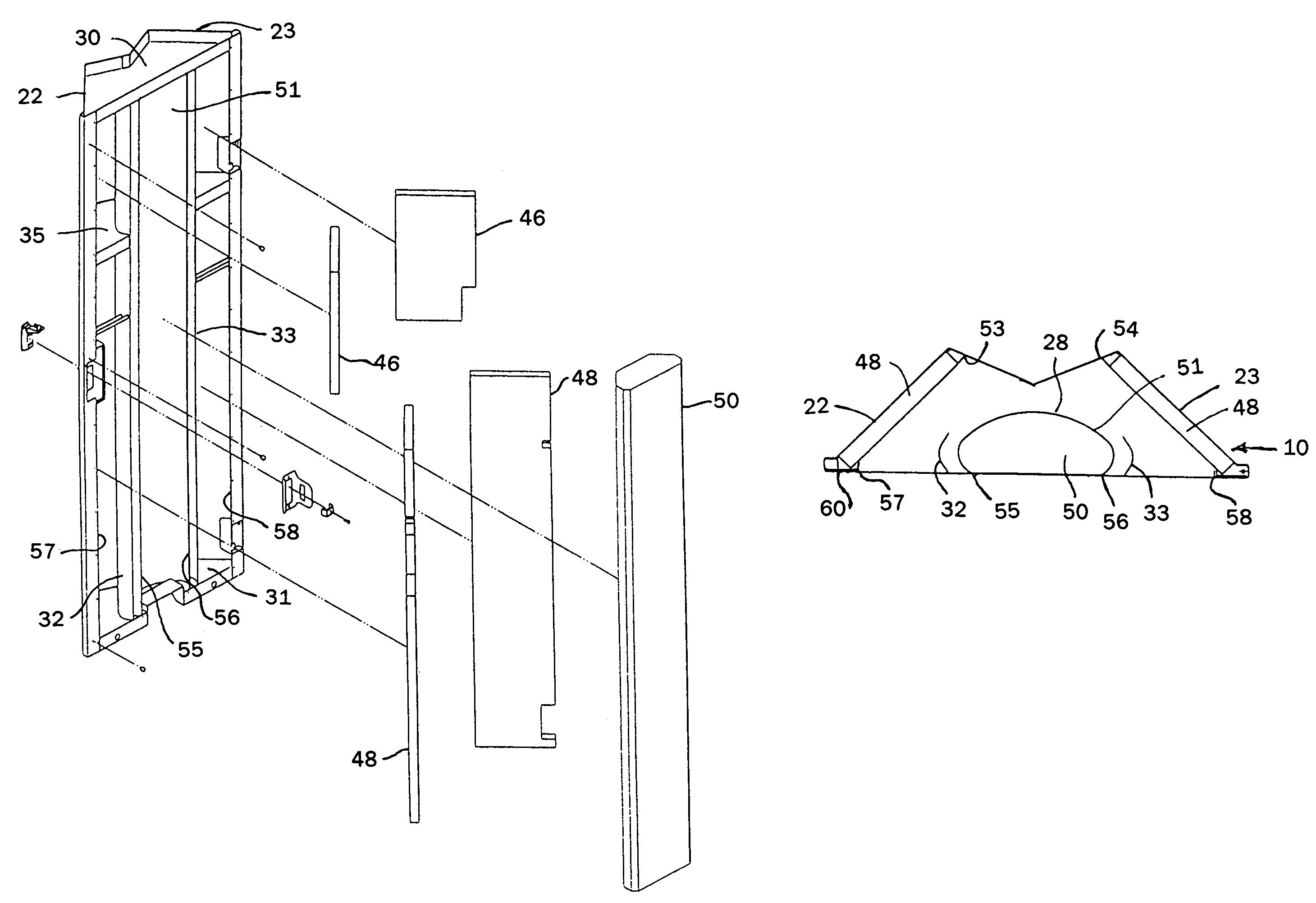

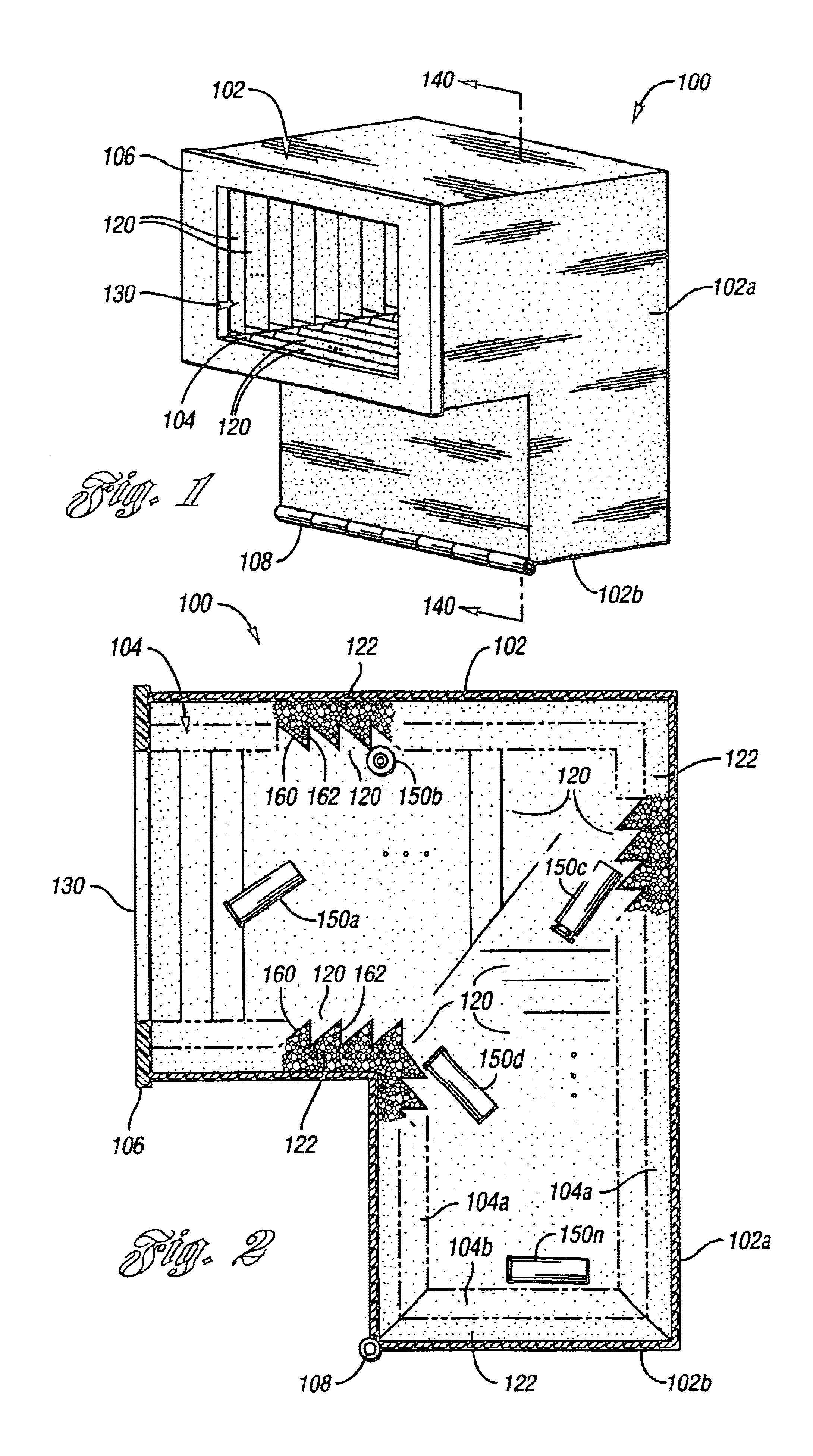

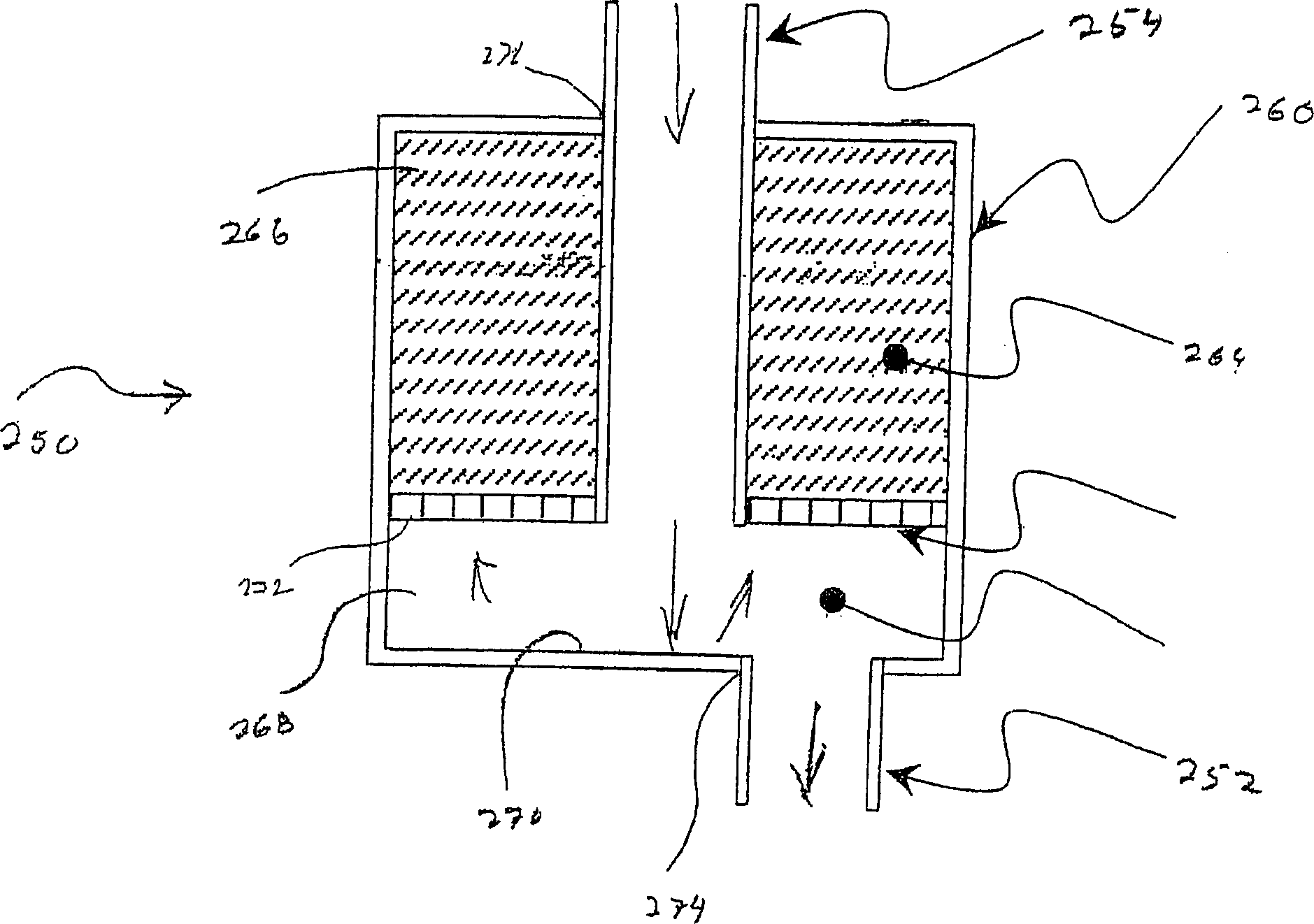

Equipment enclosure acoustical door with low impedance distributed air flow

InactiveUS7334662B1Easy to disassembleMinimizes flow impedanceDigital data processing detailsCasings/cabinets/drawers detailsAcoustic foamEngineering

An acoustic door for an equipment enclosure, such as a rack mount cabinet, also provides a low impedance air flow uniformly delivered across the cabinet opening. A pair of metal panels, with acoustic foam along the rear surfaces, extend angularly outward and toward one another to form an air inlet opening between the outer edges. A central column is positioned between the panels which, in a horizontal section, forms an aerodynamic dome which has a continuously curved sheet metal surface at the front and sides that also captures a core of acoustic foam that is exposed at the rear. A rigid vane is disposed at each lateral side and parallel to the central column to cause air to follow the column surface, deflecting air behind the column and effecting uniform delivery of air flow across the cabinet front opening at the rear opening of the door.

Owner:GOOGLE LLC

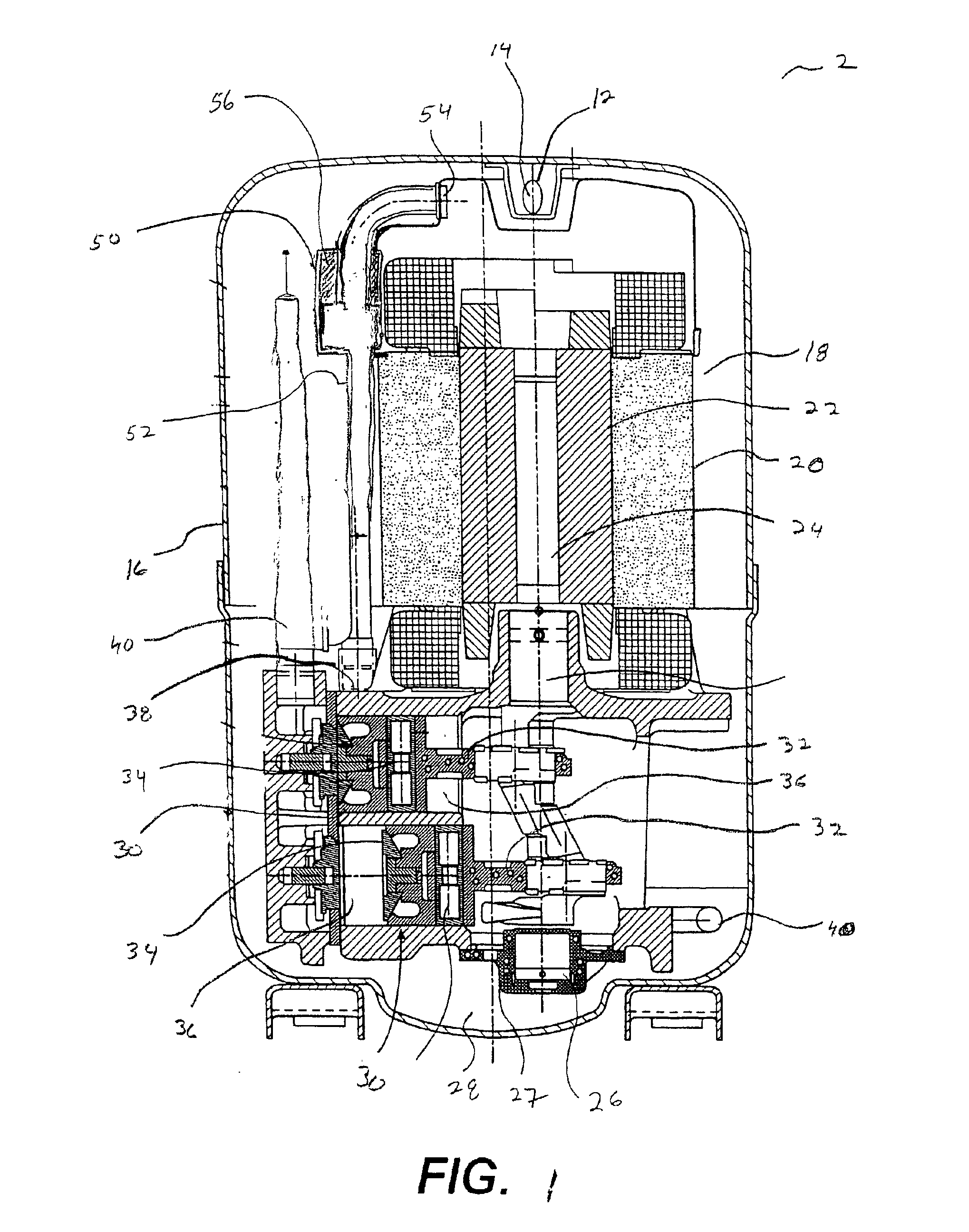

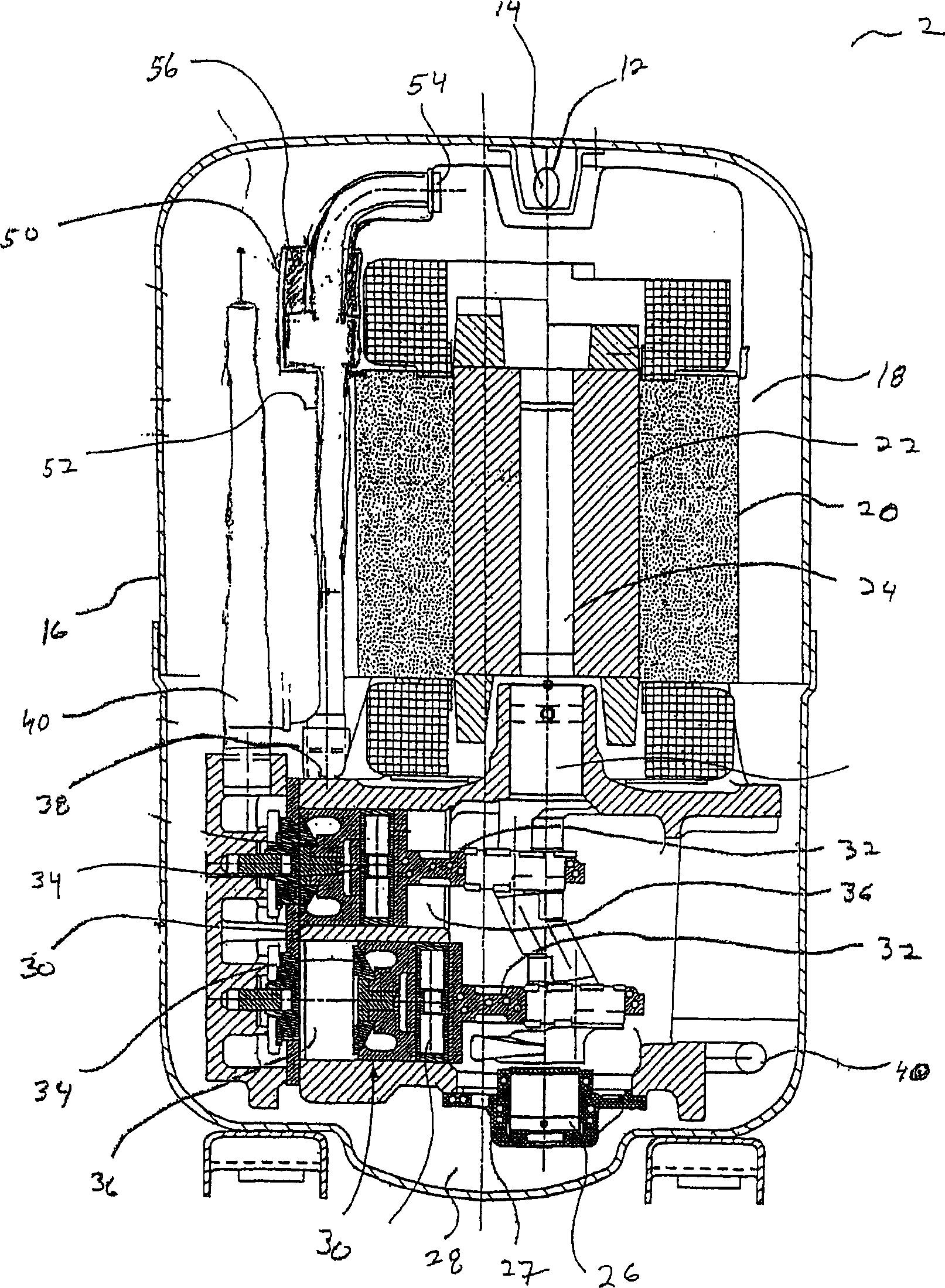

Resistive suction muffler for refrigerant compressors

InactiveUS6840746B2Reduce sound levelWide frequency rangeExhaust apparatusPipe elementsAcoustic foamEngineering

Owner:BRISTOL COMPRESSORS INT

Low density acoustic foams based on biopolymers

Rigid polyurethane foams are described. The foams are made using a prepolymer that is the reaction product of at least one polyisocyanate component, at least one hydroxy-functional acrylate component, and at least one polyol component. The prepolymer is then reacted at specified volume ratios and isocyanate indices with at least one polyol component that includes at least one polyol that is a biopolymer, including but not limited to castor oil, soybean oil, and the like. The foam is made in the presence of at least one blowing agent and at least one catalyst.

Owner:DOW GLOBAL TECH LLC

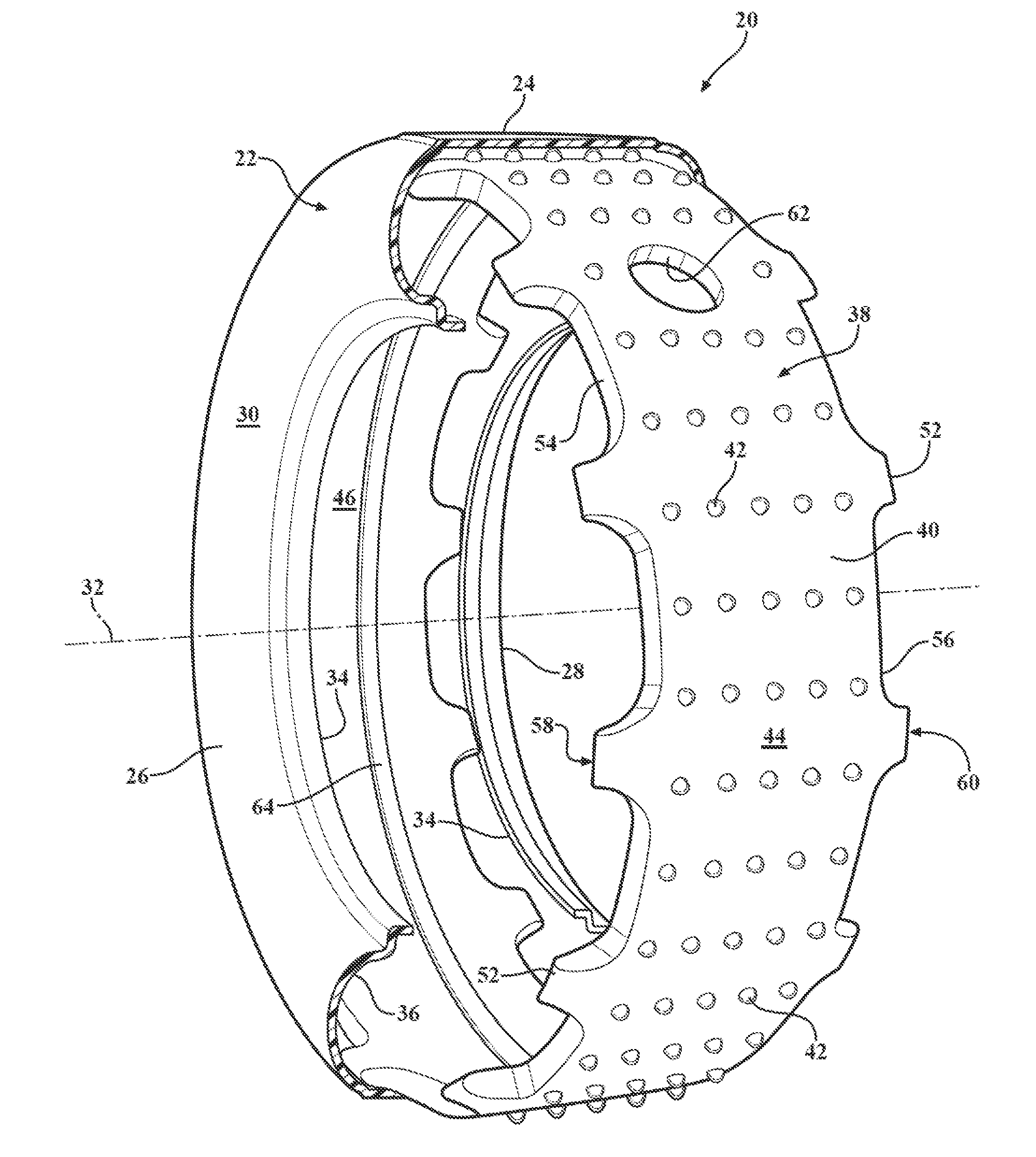

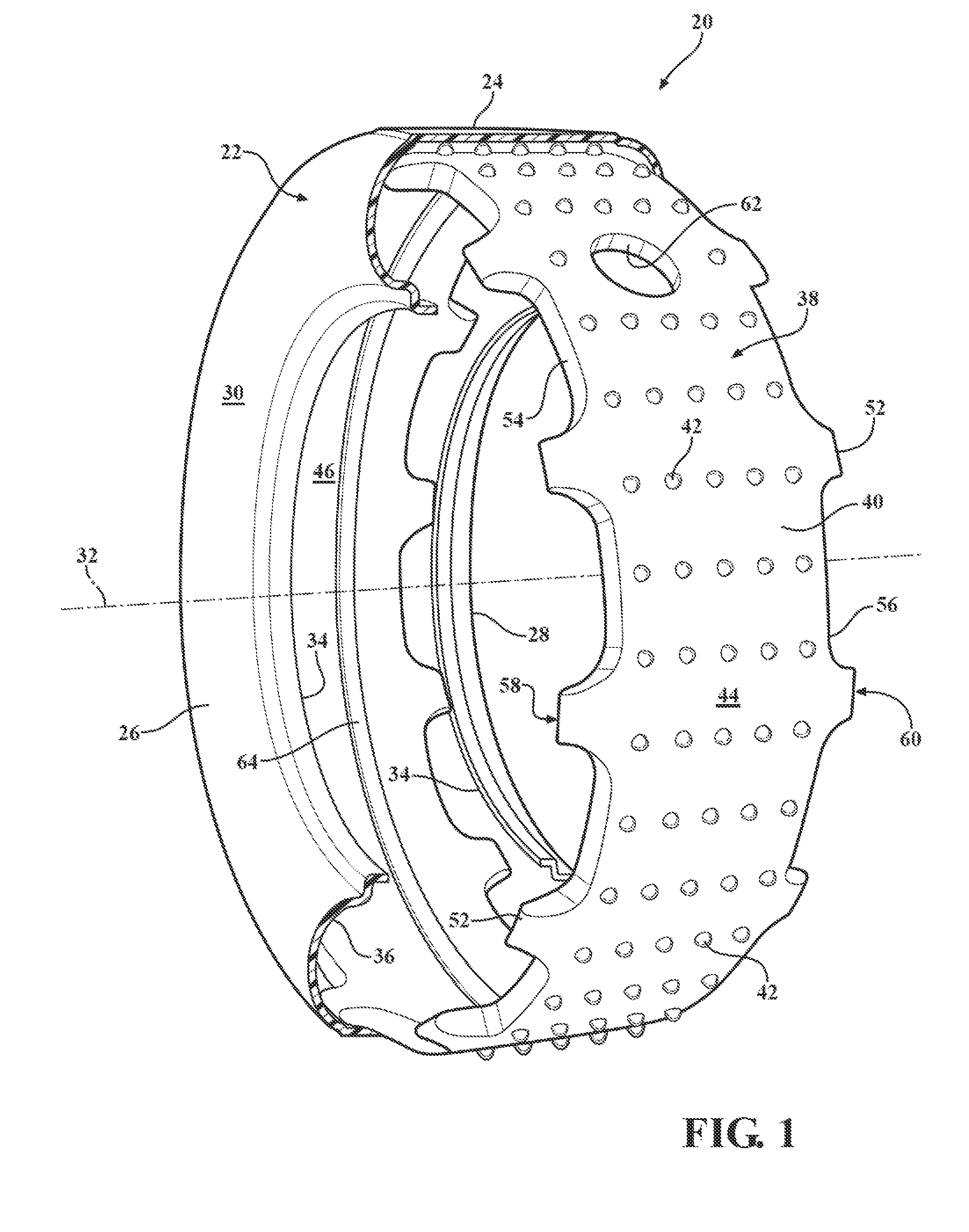

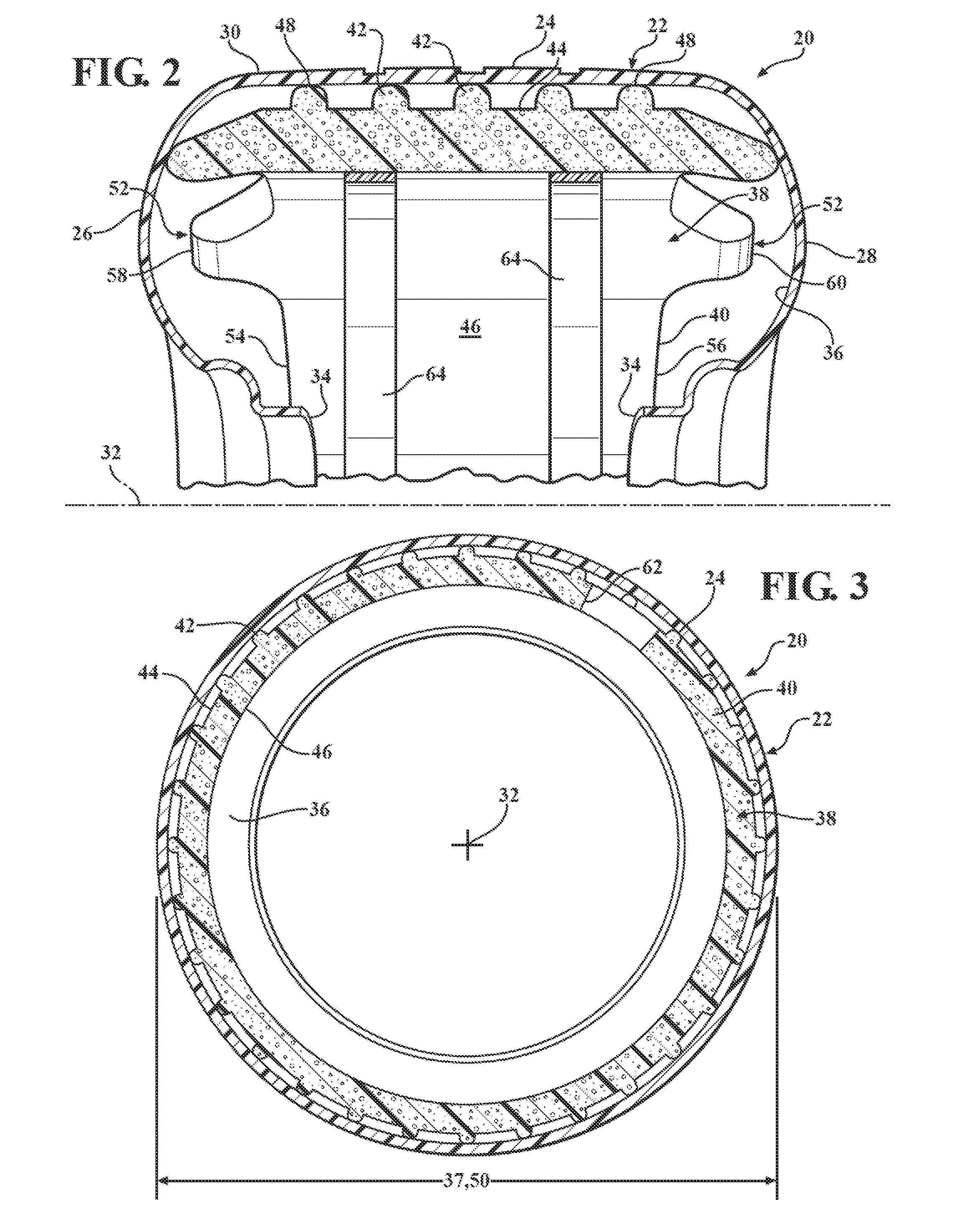

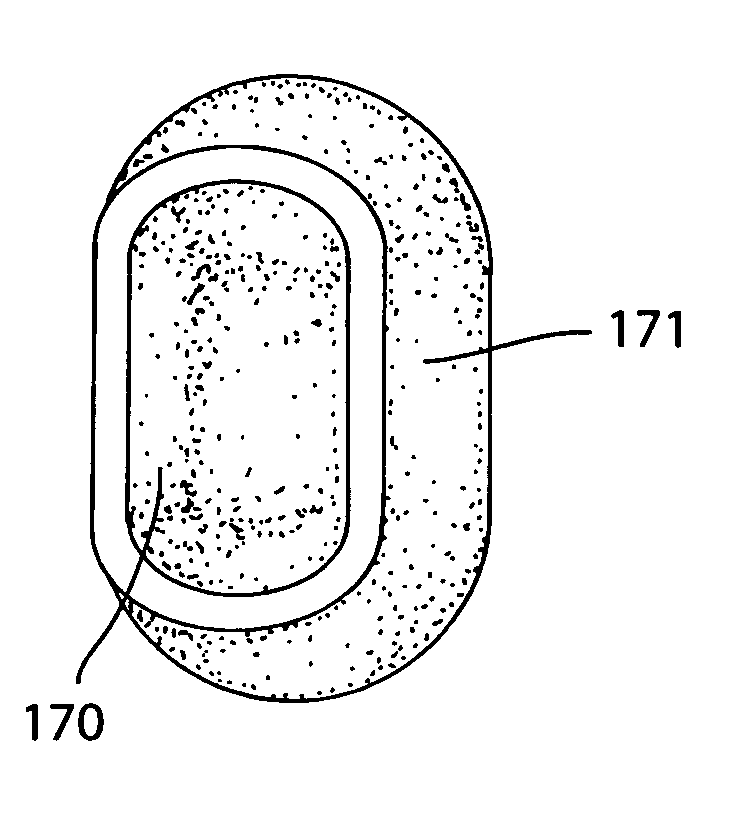

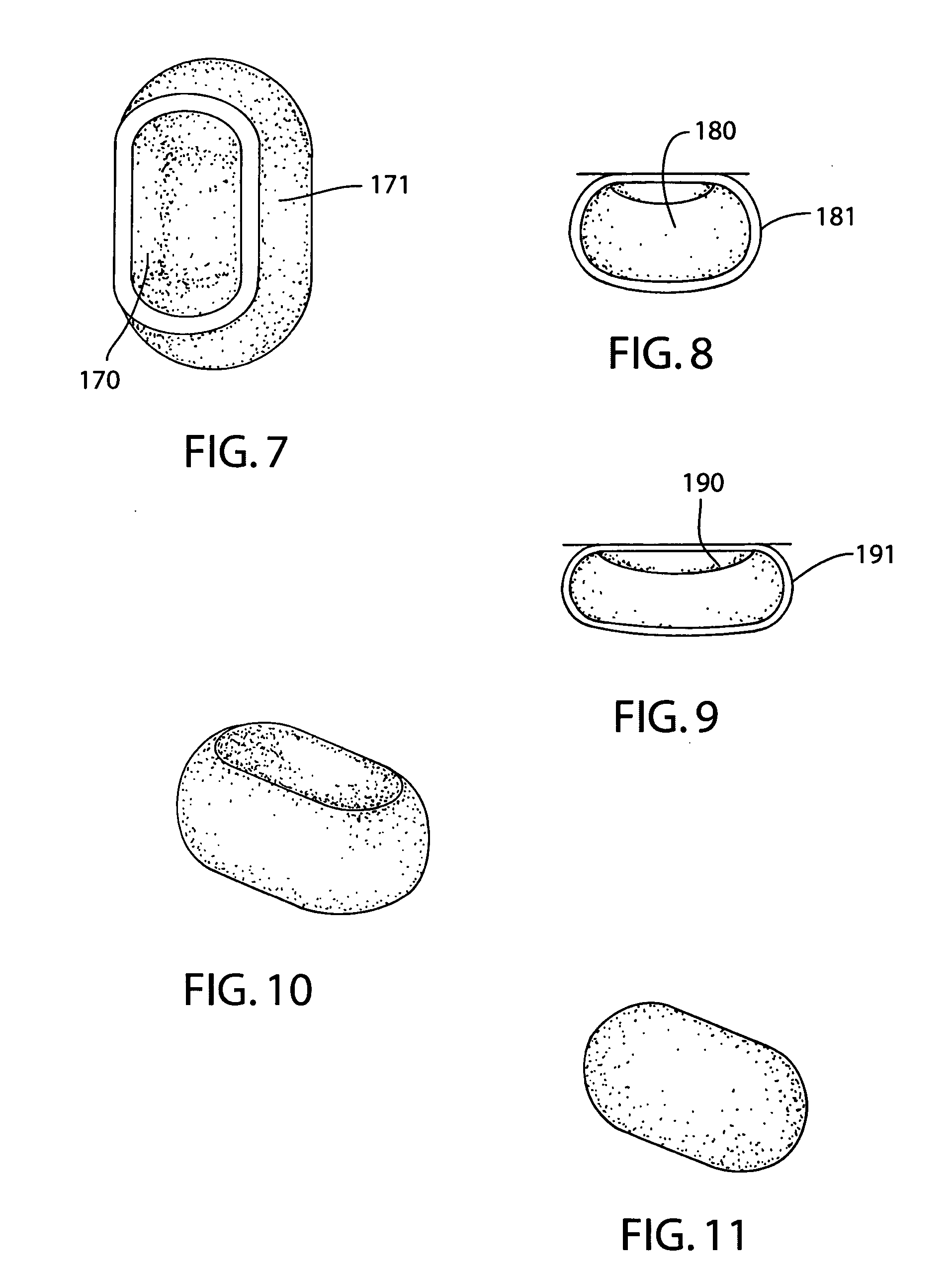

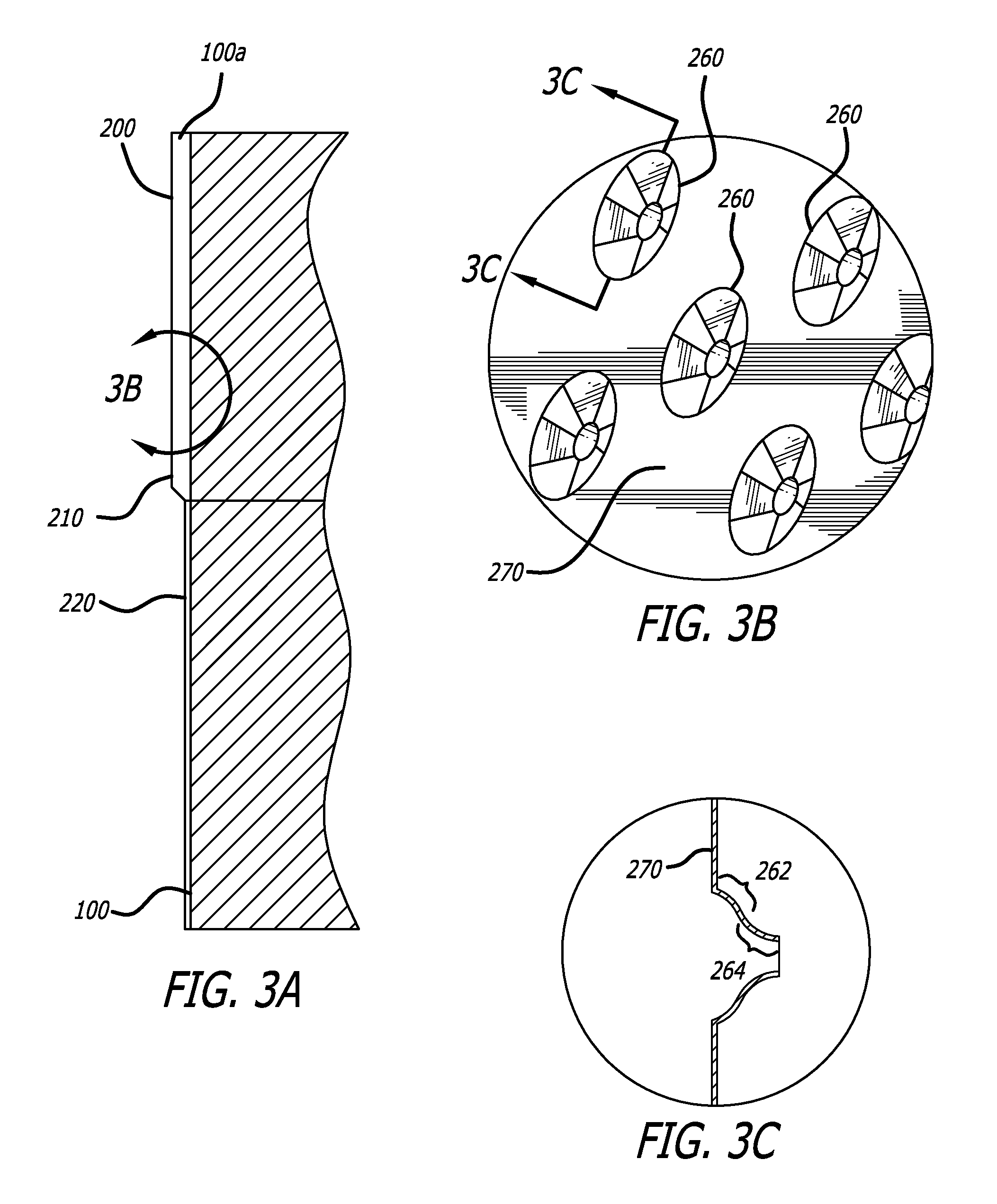

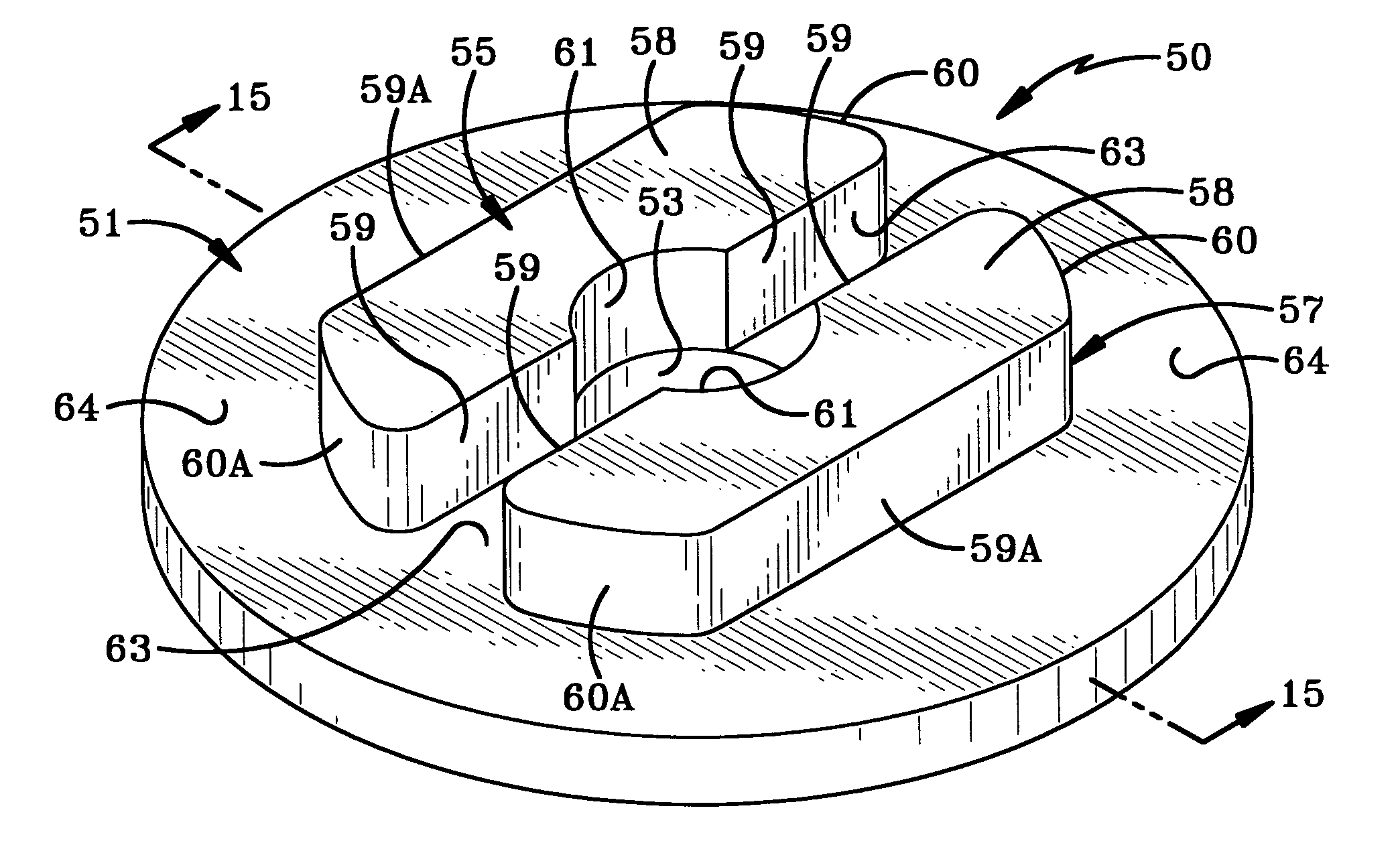

Acoustical core for absorbing noise within a tire interior cavity

A tire assembly includes an acoustic foam core disposed within a cavity of the tire for attenuating noise. The foam core defines an expanding radial force that biases the foam core against an inner surface of the tire to secure a position of the foam core relative to the tire. The foam core may include an annular base having a plurality of nodules disposed on an outer periphery of the annular base for engaging the inner surface of the tire and to position the annular base away from the inner surface of the tire. The foam core may further include a plurality of positioning tabs disposed on opposing axial ends of the annular base for engaging side walls of the tire to position the annular base away from the side walls of the tire.

Owner:GM GLOBAL TECH OPERATIONS LLC

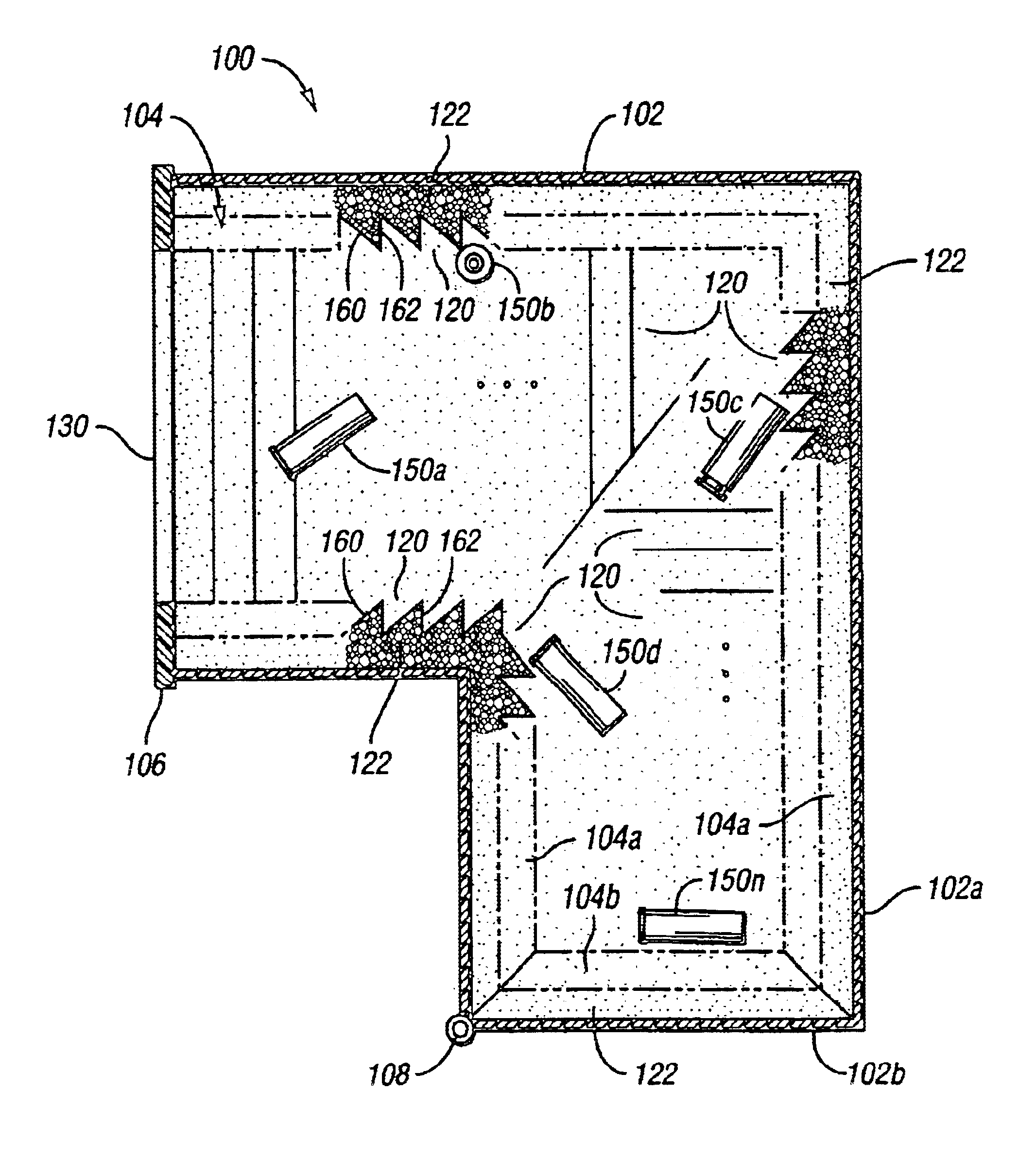

System and method for a cartridge casing catcher

InactiveUS6836991B1Reduce and eliminate jammingReduce noiseCartridge extractorsAmmunition loadingAcoustic foamRigid wall

A catcher for receiving expended shell casings from a firearm having an ejection port as the firearm is discharged, the catcher includes a hollow housing and a lining. The hollow housing having a plurality of rigid walls, wherein one of the walls has an opening in communication with the ejection port when the catcher is mounted to the firearm for receiving the shell casings. The lining is fixed inside the rigid walls, wherein the lining includes an acoustic foam having a plurality of wedges and the wedges are configured to deflect the shell casings into the catcher.

Owner:SAUR THOMAS W

Macrocellular acoustic foam containing particulate additive

InactiveUS7226955B2Avoid corrosionImprovement factorSound producing devicesDrying machinesParticulatesAcoustic absorption

A cellular thermoplastic polyolefin foam comprising at least one particulate additive in admixture with a polymer matrix is disclosed, along with a process and foamable gel for manufacturing the same, wherein the polyolefin matrix comprises at least one polymer resin graft-modified with at least one polar group selected from the group consisting of acid, acid ester, and acid anhydride, and salts thereof. The invention facilitates the manufacture of macrocellular foams useful for acoustic absorption having increased amounts of particulate additives that provide certain desired properties difficult to achieve without the particulate additives, such as improved flame retardancy.

Owner:SEALED AIR U S

Spherical loudspeaker for omnipresent sound reproduction

ActiveUS8068618B2Inexpensive and dependable and fully effectiveLoudspeaker screensTransducer combinationsAcoustic foamEngineering

Owner:VOLLMER EDWARD G

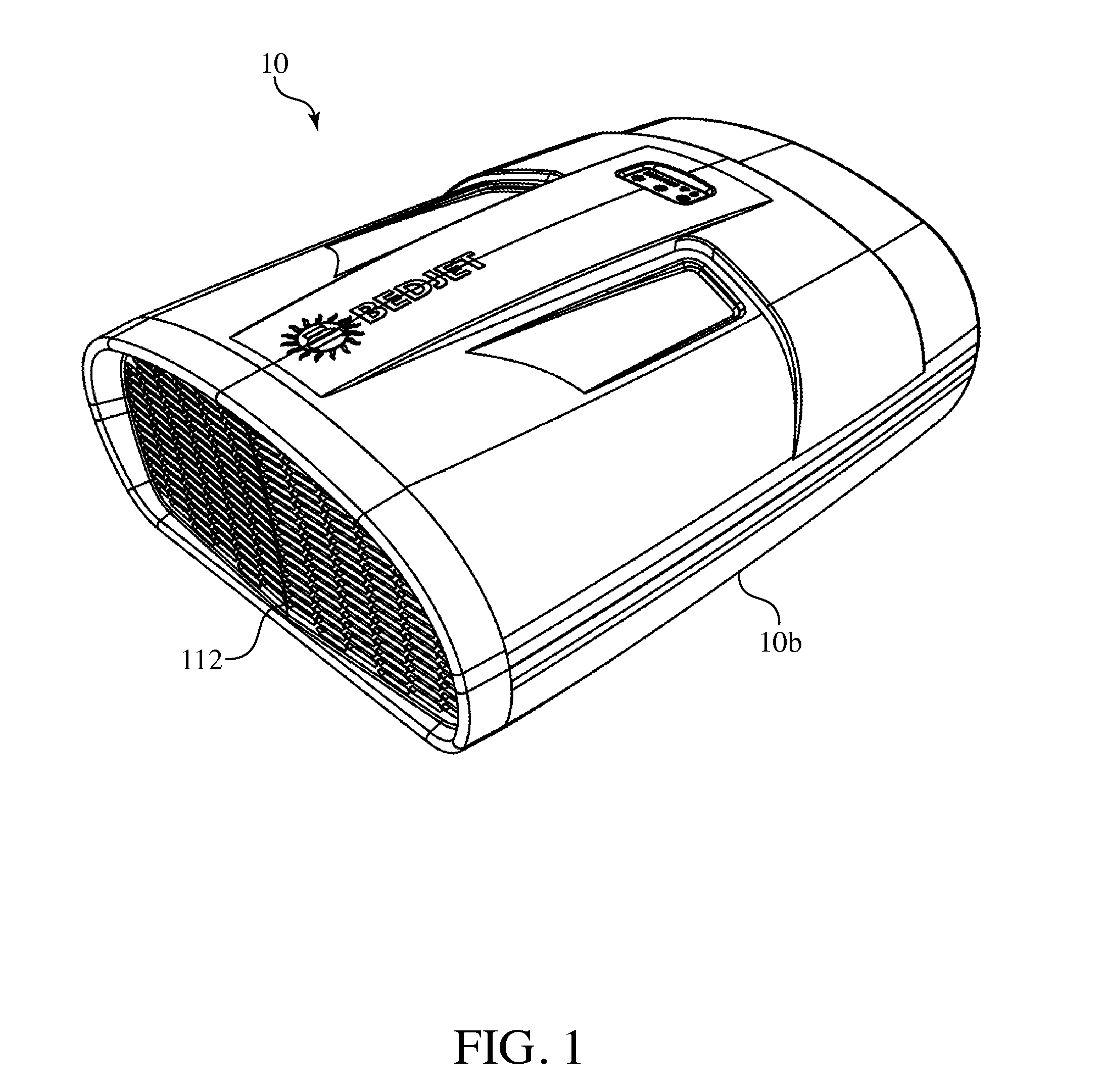

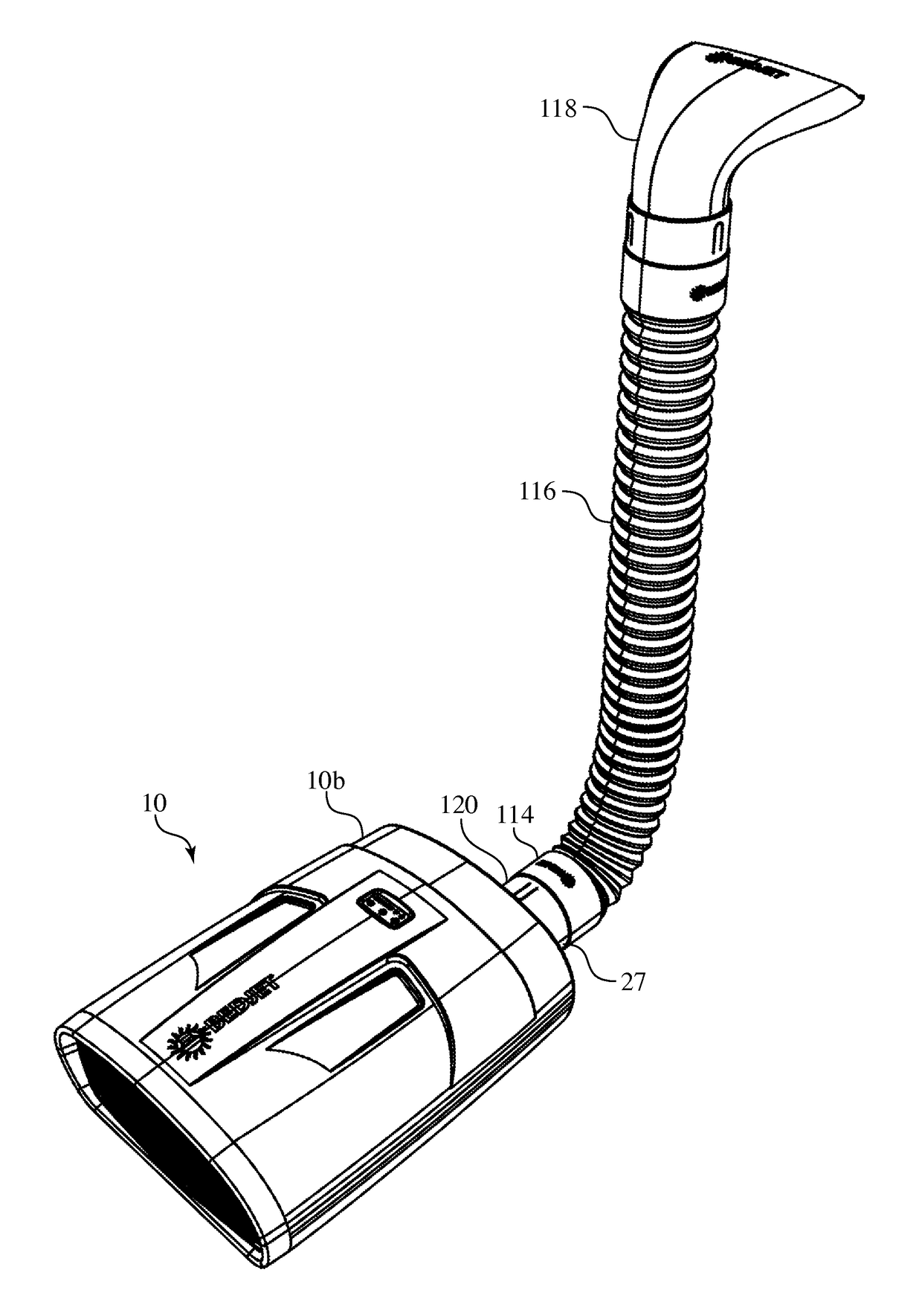

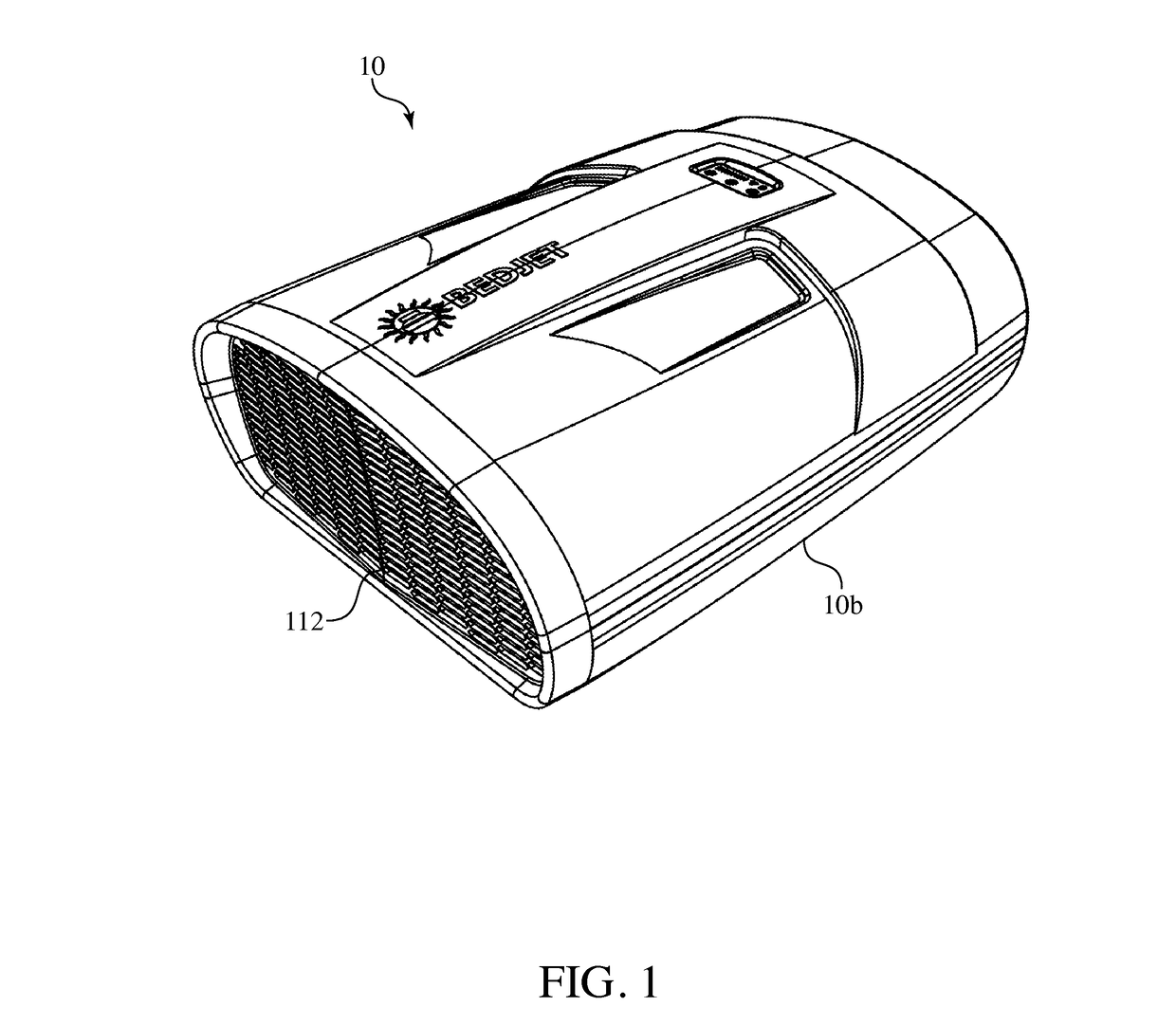

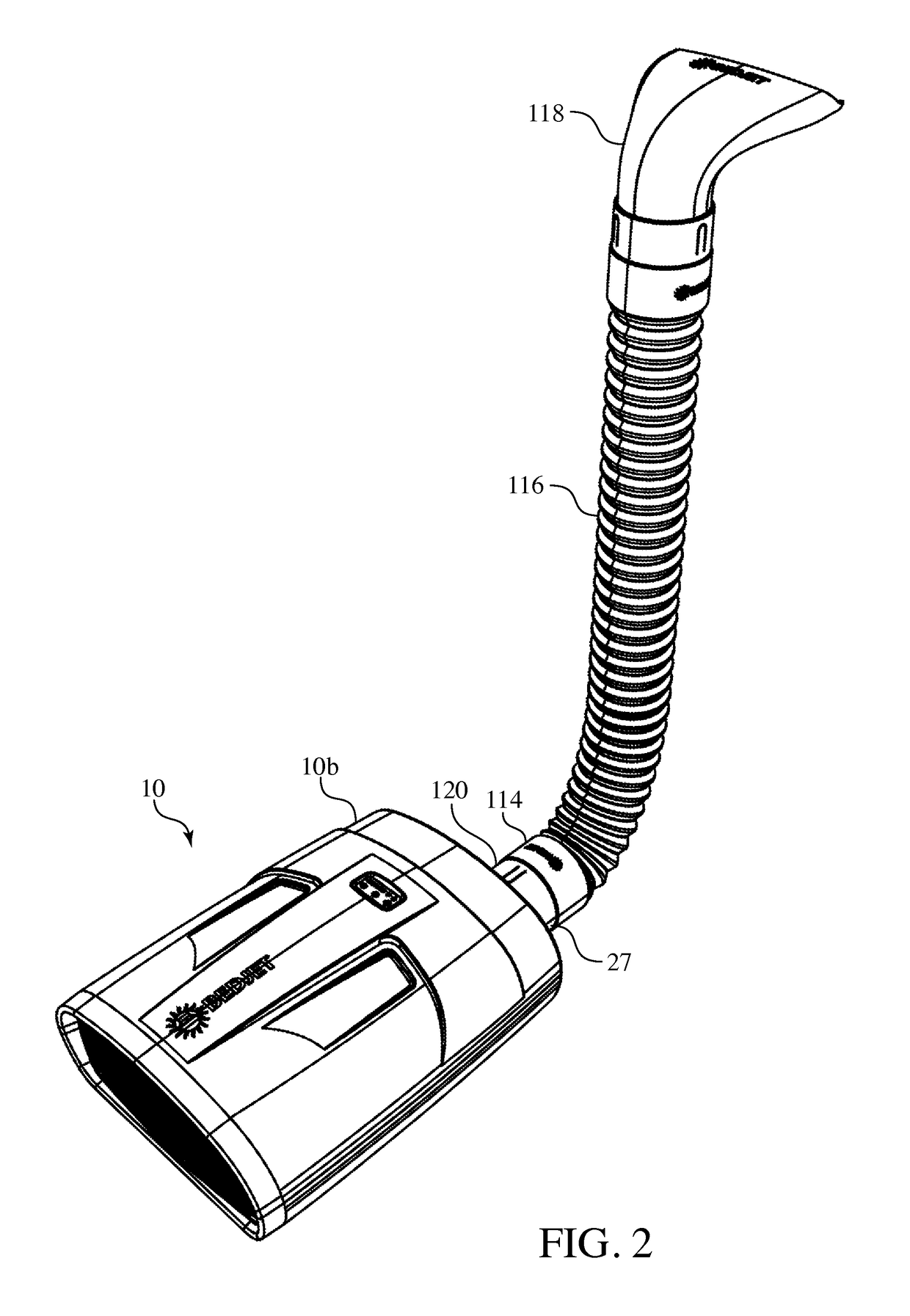

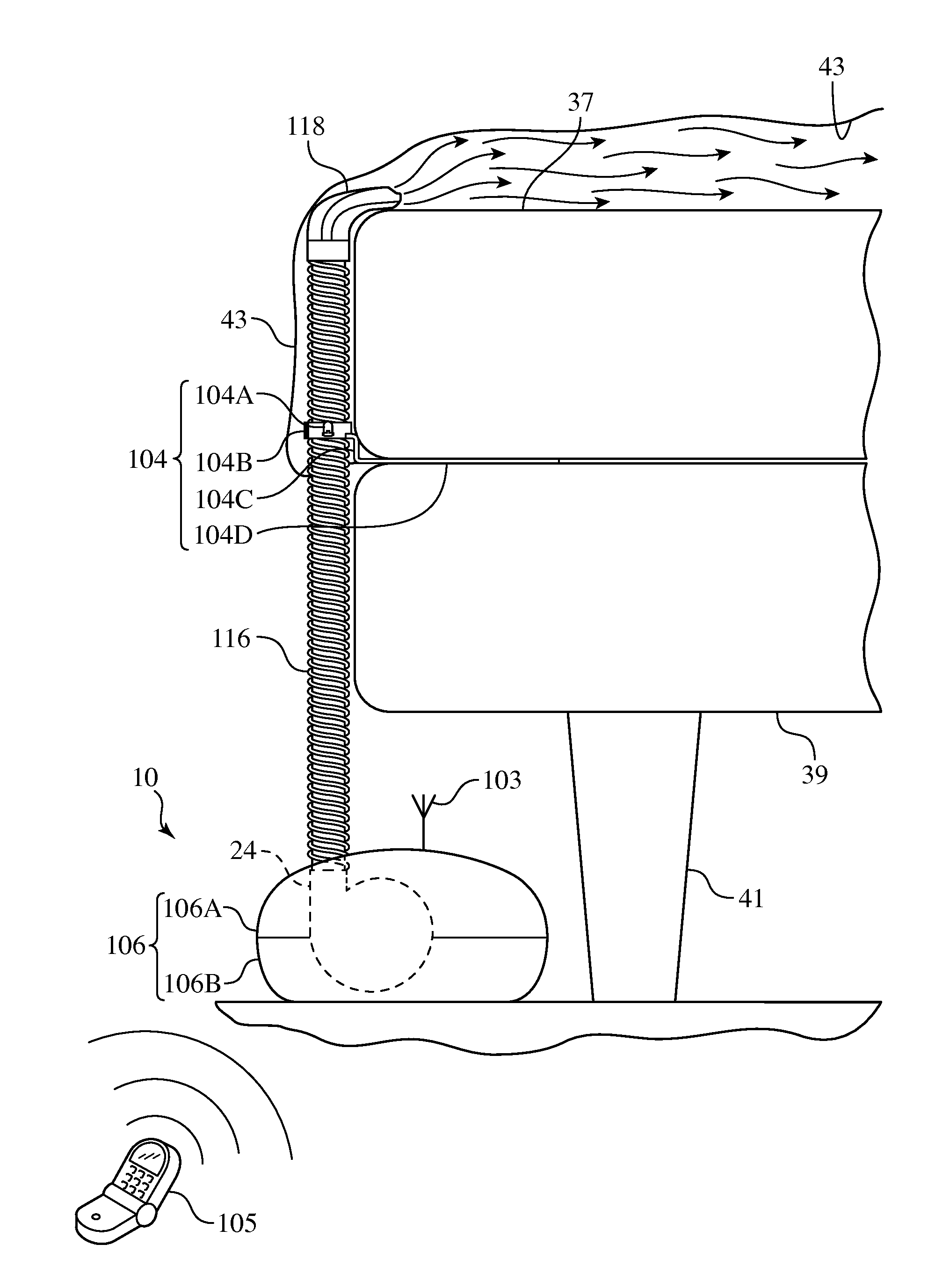

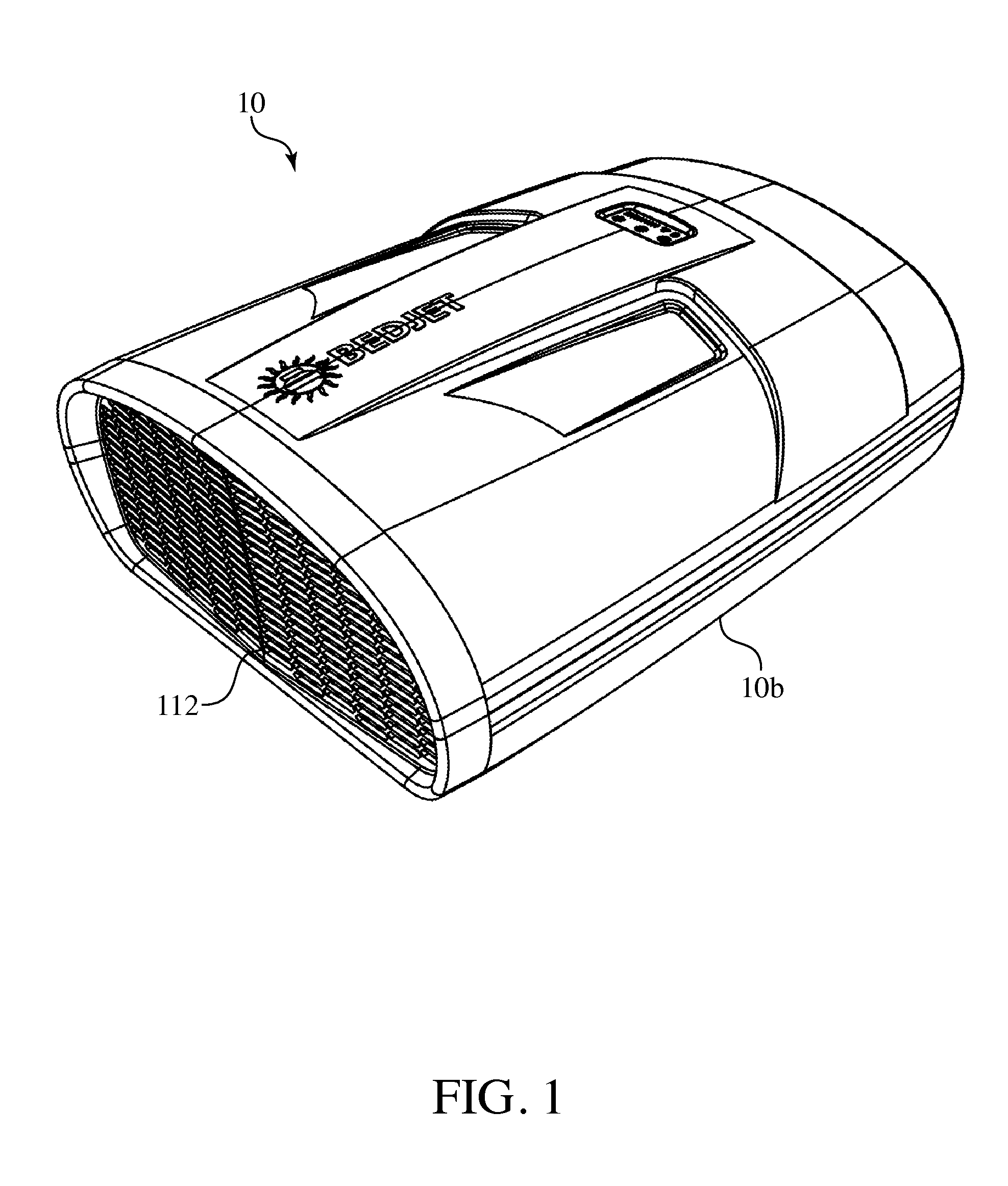

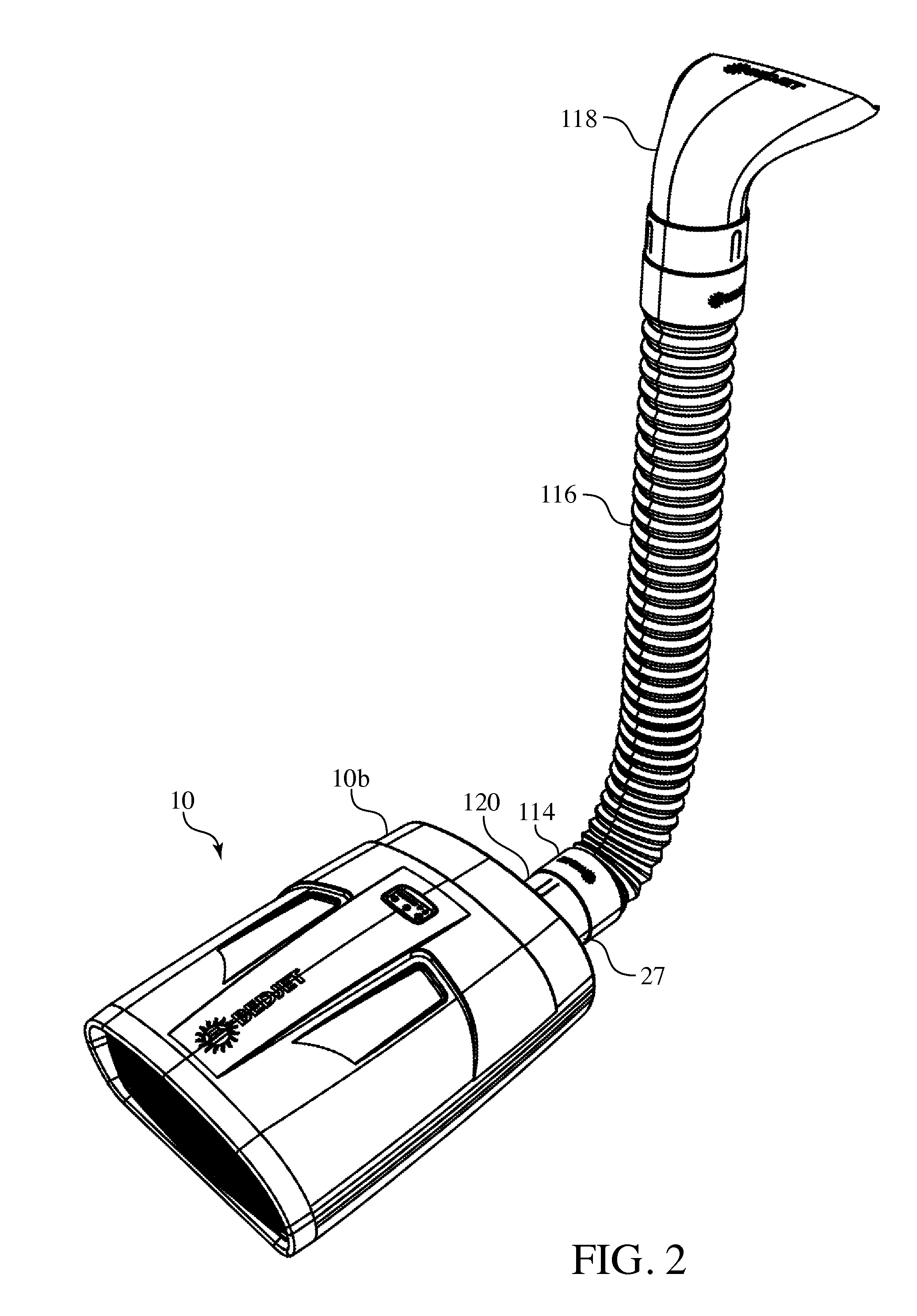

Remote operation of a bedding climate control apparatus

InactiveUS20150121621A1Dampen sound generationSuppress soundStuffed mattressesBlanketTraffic capacityAcoustic foam

Owner:ARAMLI MARK

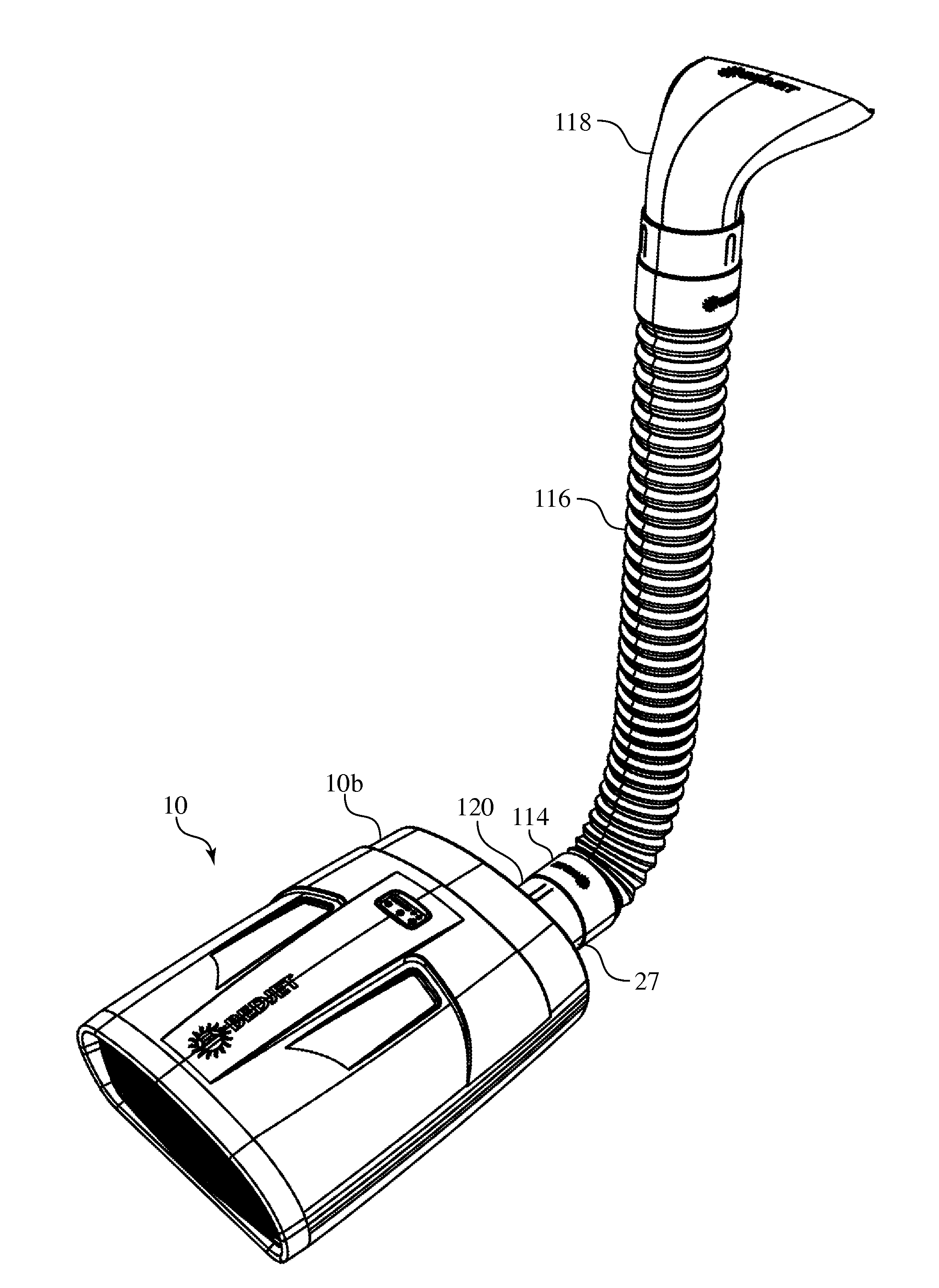

Bedding climate control apparatus with forced airflow for heating and ventilating

A bedding climate control apparatus that delivers, in a quiet manner, forced airflow from a fan / blower within a housing to selectively deliver tempered (heated via a thermal element) and untempered (room temperature) air through a flexible hose to bedding. The quiet manner is attained with acoustic foam in the path of incoming airflow to the fan / blower and by oversizing each of the components that create a pressure drop including the capacity of the fan / blower over what is needed to deliver a required amount of airflow. Temperature may be set remotely via a wireless remote control and via a Bluetooth enabled device.

Owner:BEDJET LLC

Bedding climate control apparatus with forced airflow for heating and ventilating

ActiveUS20150121620A1Reduce noiseLess pressure dropStuffed mattressesSpring mattressesAcoustic foamRemote control

A bedding climate control apparatus that delivers, in a quiet manner, forced airflow from a fan / blower within a housing to selectively deliver tempered (heated via a thermal element) and untempered (room temperature) air through a flexible hose to bedding. The quiet manner is attained with acoustic foam in the path of incoming airflow to the fan / blower and by oversizing each of the components that create a pressure drop including the capacity of the fan / blower over what is needed to deliver a required amount of airflow. Temperature may be set remotely via a wireless remote control and via a Bluetooth enabled device.

Owner:BEDJET LLC

Weatherproof Windscreen for Microphone

InactiveUS20140211974A1Improve integrityAvoid damagePiezoelectric/electrostrictive microphonesMicrophonesContinuous useLiquid water

A sealed enclosure providing a microphone contained therein extended protection from the weather and some other outdoor hazards while not substantially altering the dynamic range of said microphone. The enclosure consists of a layer of liquid-water impermeable fabric, a layer of acoustical foam, a protective cage, and a wind noise dampening external cover. The enclosure is assembled around a microphone and a commercial foam windscreen, or around a custom high-wind foam windscreen first assembled around the microphone. As such, the weatherproof enclosure enables continuous use of boundary microphones and many other types and styles of microphones outdoors year round while supplementing the wind noise reduction of the enclosed foam windscreen.

Owner:PIELSTICKER WILLIAM J

Indirect acoustic transfer control of noise

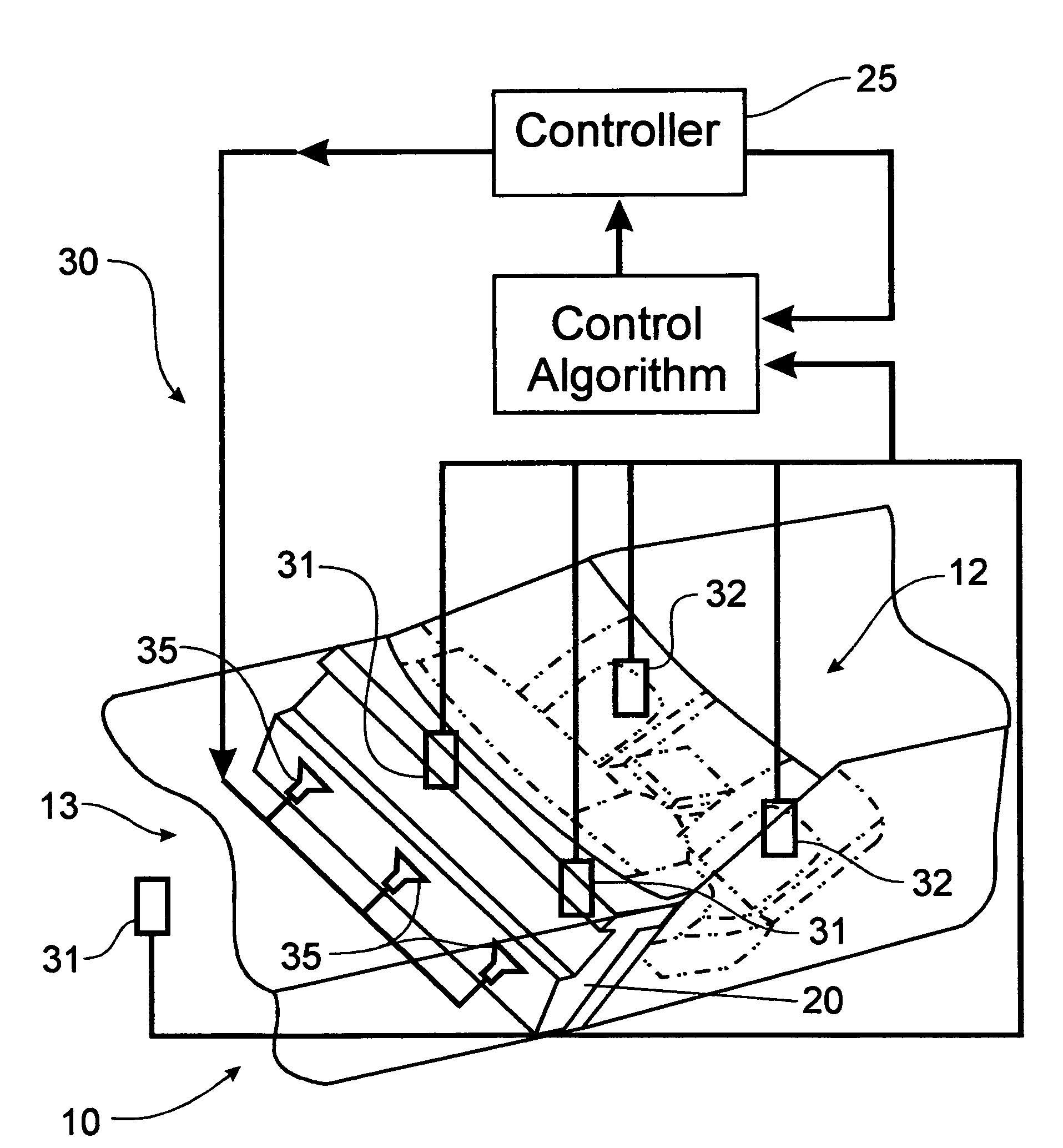

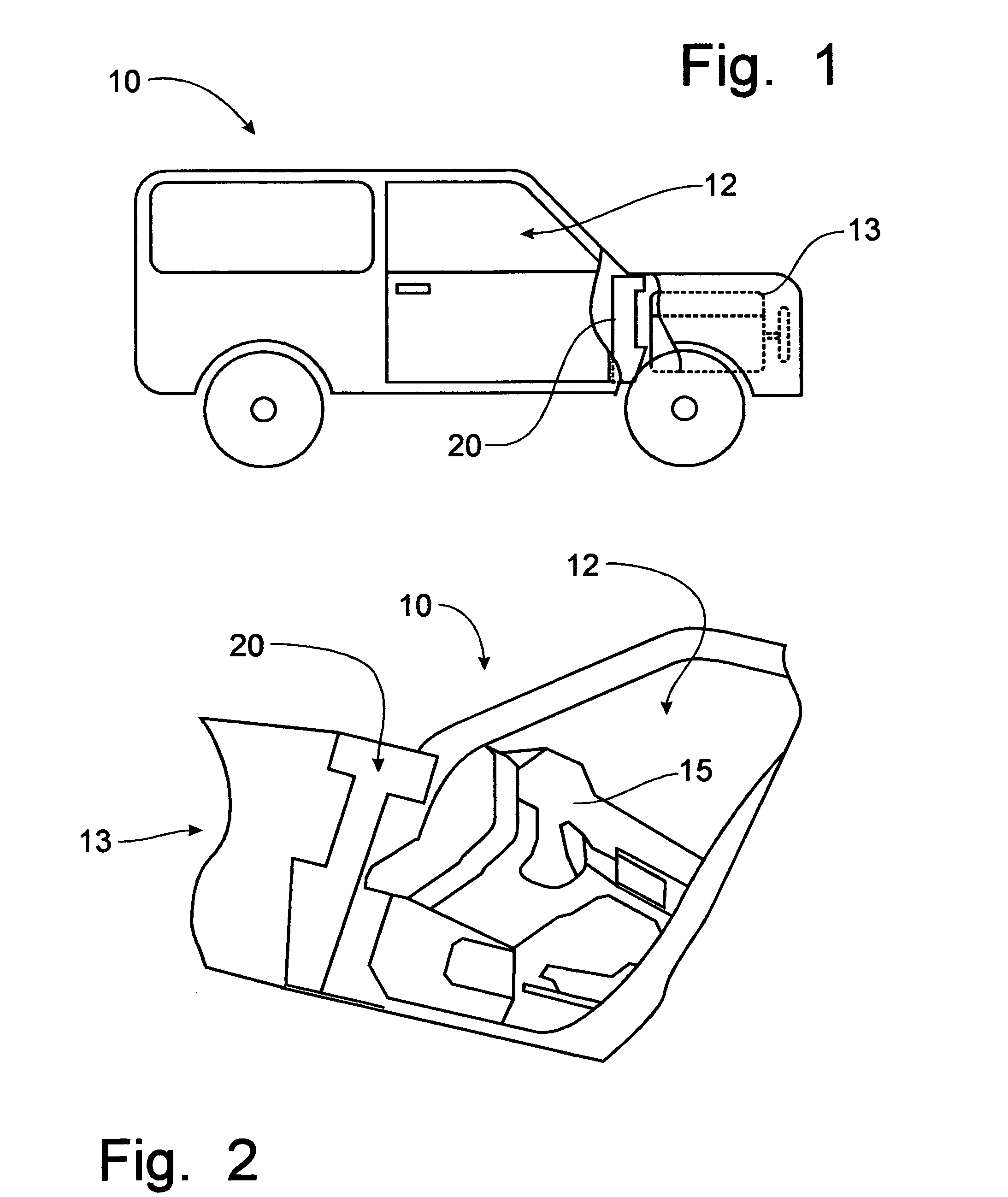

ActiveUS20080144850A1Reliable constructionReduce manufacturing costEar treatmentSilencing apparatusNoise controlViscoelastic damping

A noise control system is directed to the path along which the noise is transmitted from the source of the noise being generated to the receiver of the noise in the passenger compartment of an automotive vehicle. The noise control system is deployed in a box structure, such as the dual bulkhead of the dashboard of the vehicle, to provide a constrained volume within which engine noise can be controlled. The dual bulkhead plenum houses an active noise control apparatus, such as a speaker or a vibrating device, between the bulkheads to be operable with a control algorithm to generate sound that can control the noise or vibrations generated by the engine. The plenum can also be treated with passive noise control materials, such as viscoelastic damping materials, acoustical foam or heavy vinyl barrier and foam to block airborne sound and vibrations, in addition to the active noise control.

Owner:FORD GLOBAL TECH LLC

Resistive suction muffler for refrigerant compressors

InactiveCN1671963ALower levelWon't get worsePositive displacement pump componentsPumpsAcoustic foamEngineering

A resistive muffler attenuates sound generated by the gas intake and suction valve during compressor operation of a refrigerant compressor. The resistive muffler is assembled inline with the suction gas flow of the compressor and is positioned within the compressor housing. The resistive muffler attenuates the sound generated by the compressor during its operation as refrigerant gas is drawn into the compressor from an evaporator and passes through the resistive muffler in transit to the suction valve and hence to the region of the compressor where the gas is physically compressed. The resistive muffler includes a muffler housing having an intake end and an exhaust end. An acoustic foam assembly is incorporated into the muffler housing. The acoustic foam assembly is selected on the basis of its ability to absorb sound over a broad range of frequencies and is the muffler containing the acoustic foam is assembled within the compressor so that the sound does not bypass the muffler and transmit significant amounts of the sound to the compressor housing. The acoustic foam remains chemically inert when exposed to the compressor fluids at elevated temperatures of operation, and retains its ability to absorb sound over a broad range of frequencies even when saturated with compressor fluids. The foam assembly should also be able to withstand very large pressure fluctuations without experiencing deterioration.

Owner:BRISTOL COMPRESSORS INC

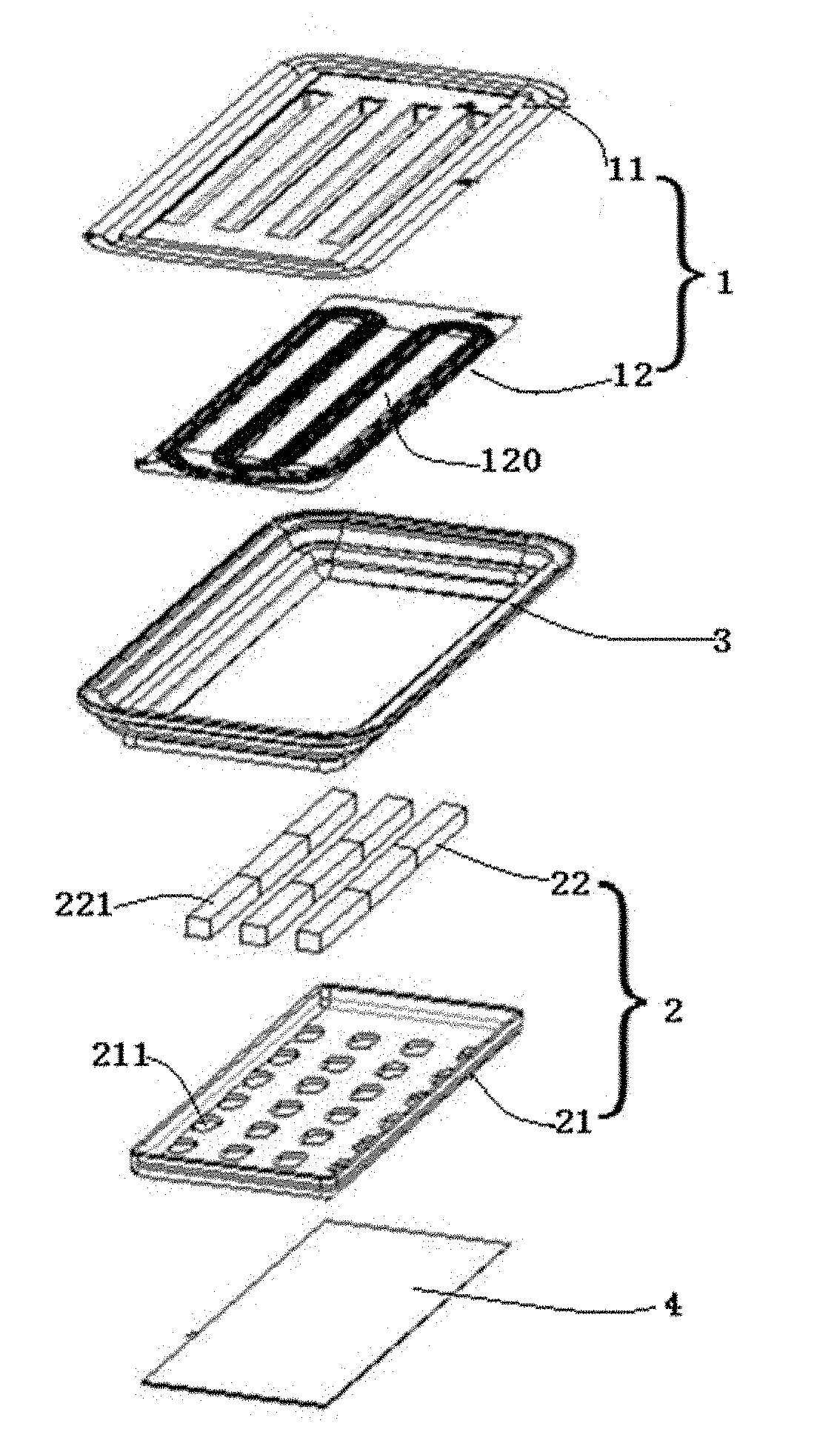

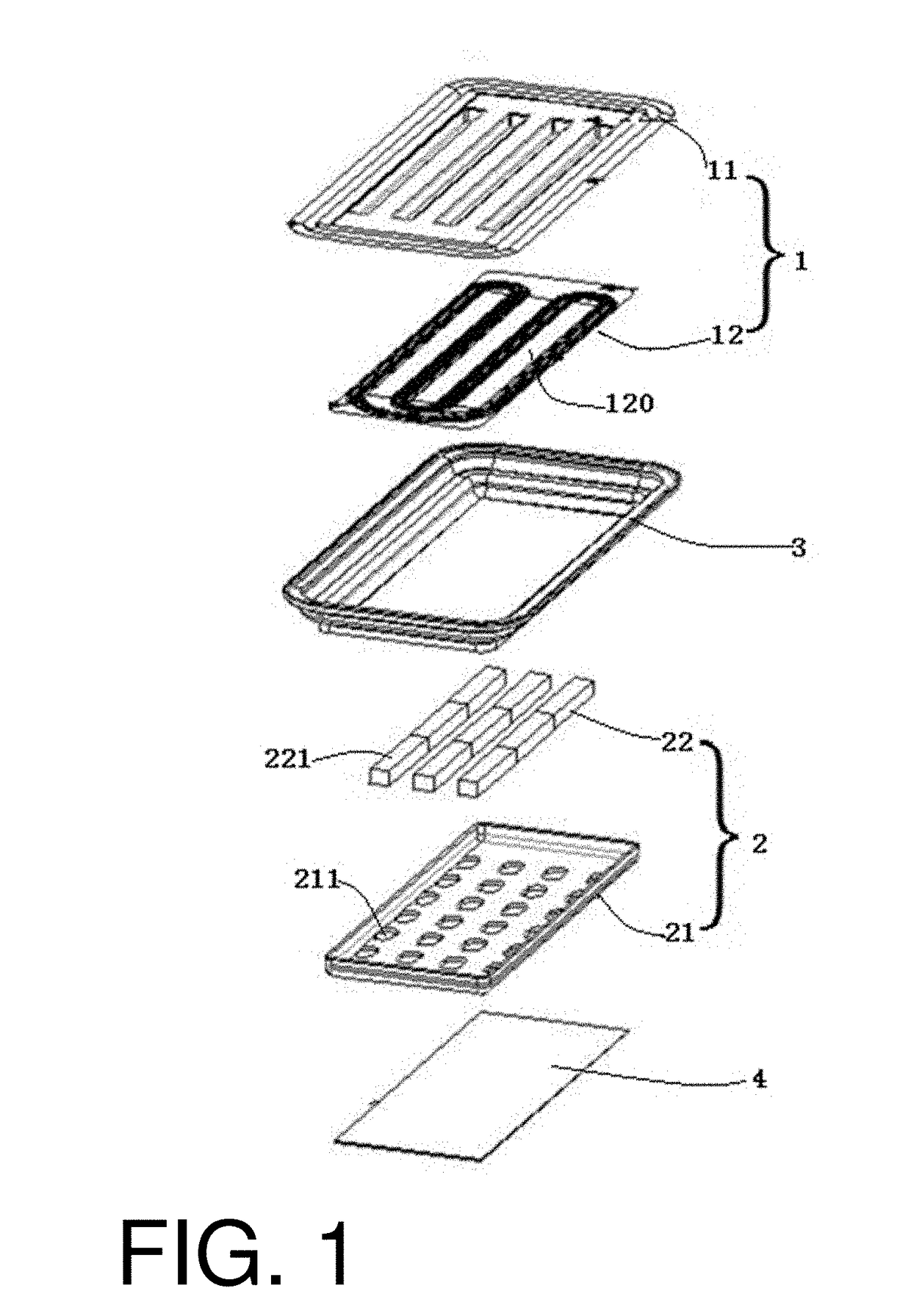

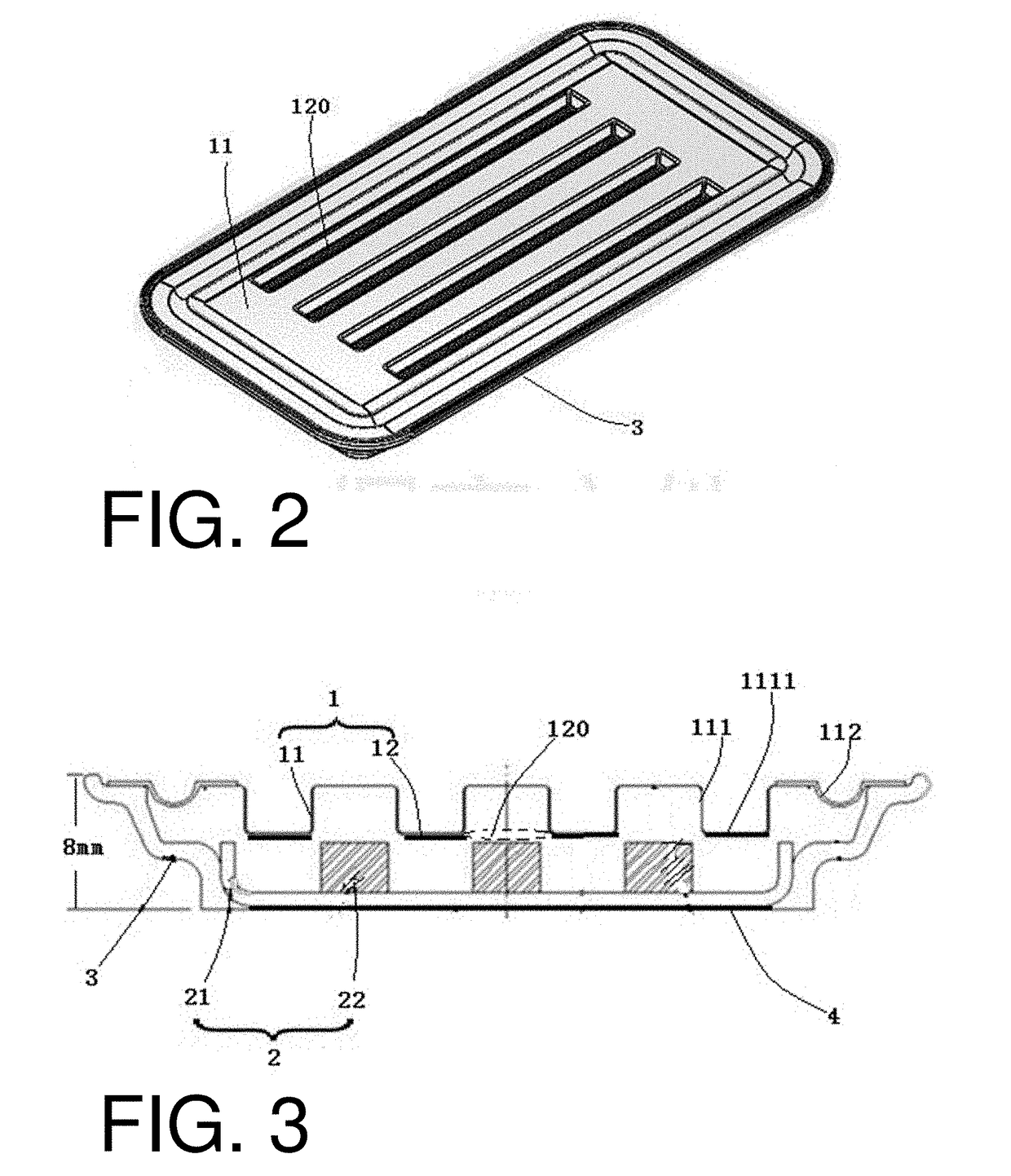

Ultra-thin planar magnetic film full-frequency speaker

ActiveUS20180332400A1Simple and compact structureLower resonance frequencyPolymeric diaphragmsMetallic diaphragmsAcoustic foamLoudspeaker

An ultra-thin planar magnetic film full-frequency speaker comprises a vibration system, a magnetic system, a frame, and an acoustic foam. The vibration system and the magnetic system are received and fixed in the interior of the frame. The vibration system comprises a vibration film and a planar voice coil, the vibration film forming a contiguous inward recess structure in the middle thereof, the planar voice coil being provided with a bar-like aperture, and the planar voice coil being adhered and fixed to the vibration film The magnetic system comprises a U-shaped soft iron and a bar-shaped magnet, the bar-shaped magnet being disposed above the U-shaped soft iron and disposed beneath the bar-shaped aperture, the U-shaped soft iron being connected to the frame by means of injection molding, and the acoustic foam being adhered to a bottom face of the U-shaped soft iron.

Owner:TYMPHANY ACOUSTIC TECH (HUIZHOU) CO LTD

Attenuating foam insert and method for manufacture

InactiveUS20050126845A1Promote lowerImprove the attenuation effectEarpiece/earphone attachmentsEarmuffsEar AuricleAcoustic foam

A shaped acoustic foam insert for use in improving the performance of circumaural hearing protectors is described. A foam block having a cross-section and shape is adapted to occupy the entire interior volume of an earcup of a circumaural hearing protector. The insert has no folds or open acoustic cavities. The surface of the insert that faces the ear of the user of the circumaural hearing protector comprises a curvilinear groove. The groove has no sharp angles and accommodates the average human pinna. A system and method of manufacturing the attenuating foam insert are provided.

Owner:VAUDREY MICHAEL A +2

Acoustical foam with improved performance

Disclosed is a thermally expandable composition, comprising at least one polymer P, cross-linkable by peroxide, and between 1 wt.-% and 2.5 wt.-%, based on the total weight of the composition, of at least one acrylate A, and between 0.2 wt.-% and 2.5 wt.-%, based on the total weight of the composition, of at least one peroxide, and at least one blowing agent, characterised in that the equivalent ratio of said peroxide to said acrylate A is between 0.01 and 0.5, preferably between 0.13 and 0.41, and the weight ratio of said peroxide to said acrylate A is lower than 0.33 and said polymer P comprises or essentially consists of at least two polymers PI and P2, wherein PI exhibits a melt flow index (MFI) of between 100 and 200 g / 10 min, and P2 exhibits a melt flow index of between 0.1 and 60 g / 10 min, wherein MFI is determined by ASTM D1238. The thermally expandable composition shows excellent properties in terms of expansion stability and minimised buckling and is especially suitable for baffle and / or reinforcement elements, e.g. in automotive manufacturing.

Owner:SIKA TECH AG

Aircraft monument with improved thermal insulation and acoustic absorption

A protective shell for an aircraft galley wall is disclosed having an above work deck area and a below work deck area, the protective shell having an outer skin, an intermediate layer comprising vacuum insulated panels, and an interior layer comprising carbon fiber composite having a thickness that is greater than a thickness of the intermediate layer. In a preferred embodiment, the protective shell also includes an acoustic insulating layer made of an open cell acoustic foam that absorbs galley noise.

Owner:BE AEROSPACE INCORPORATED

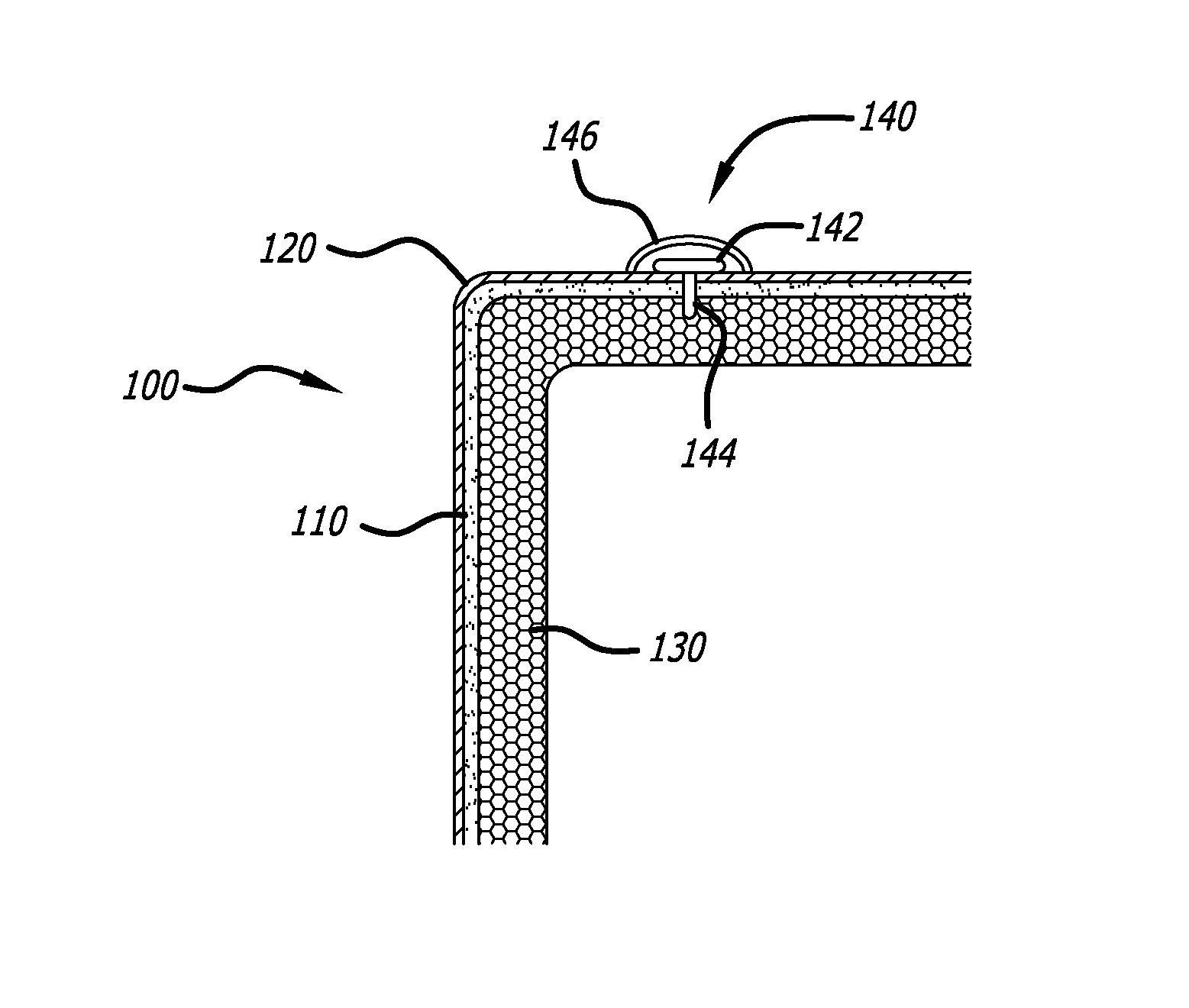

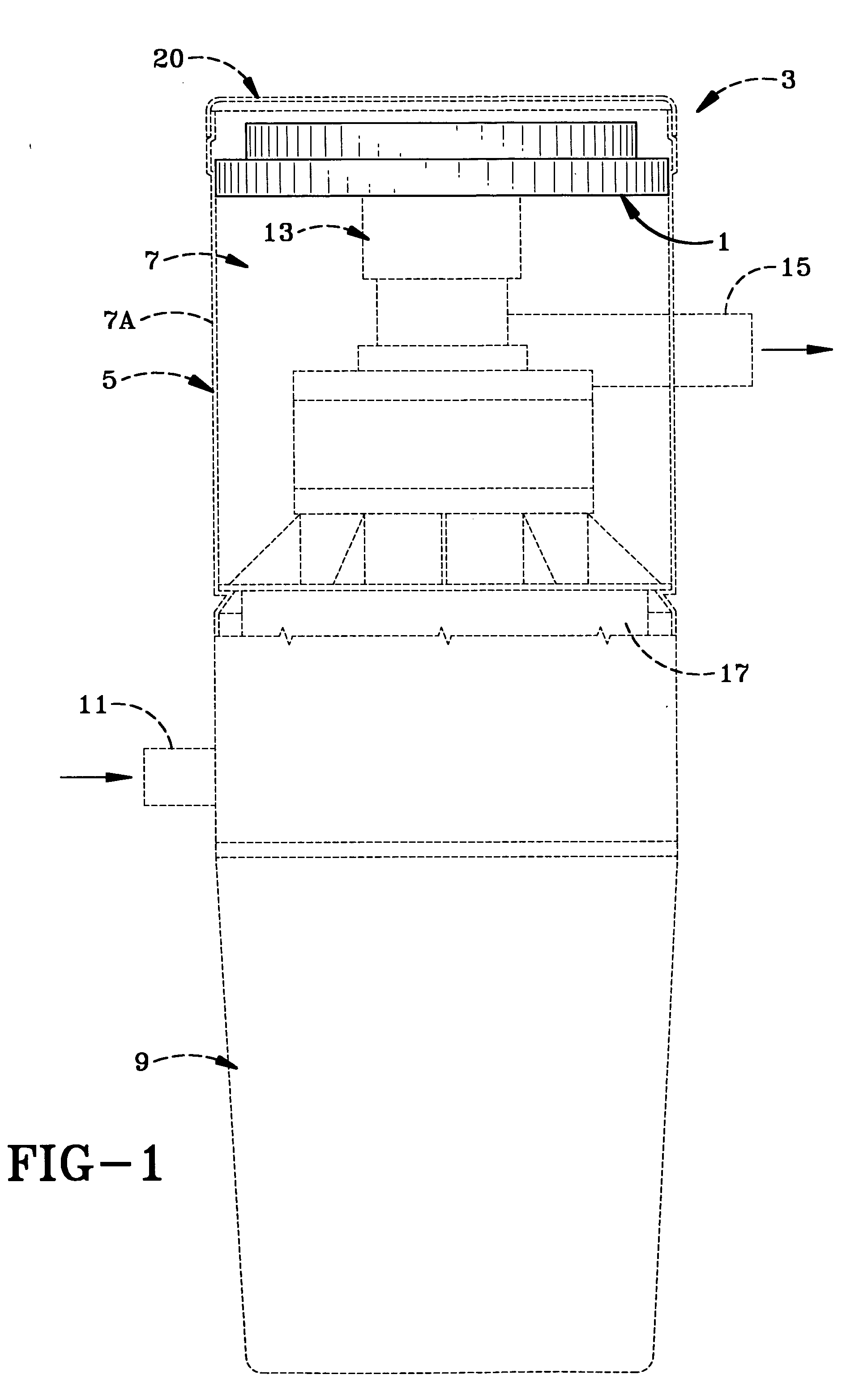

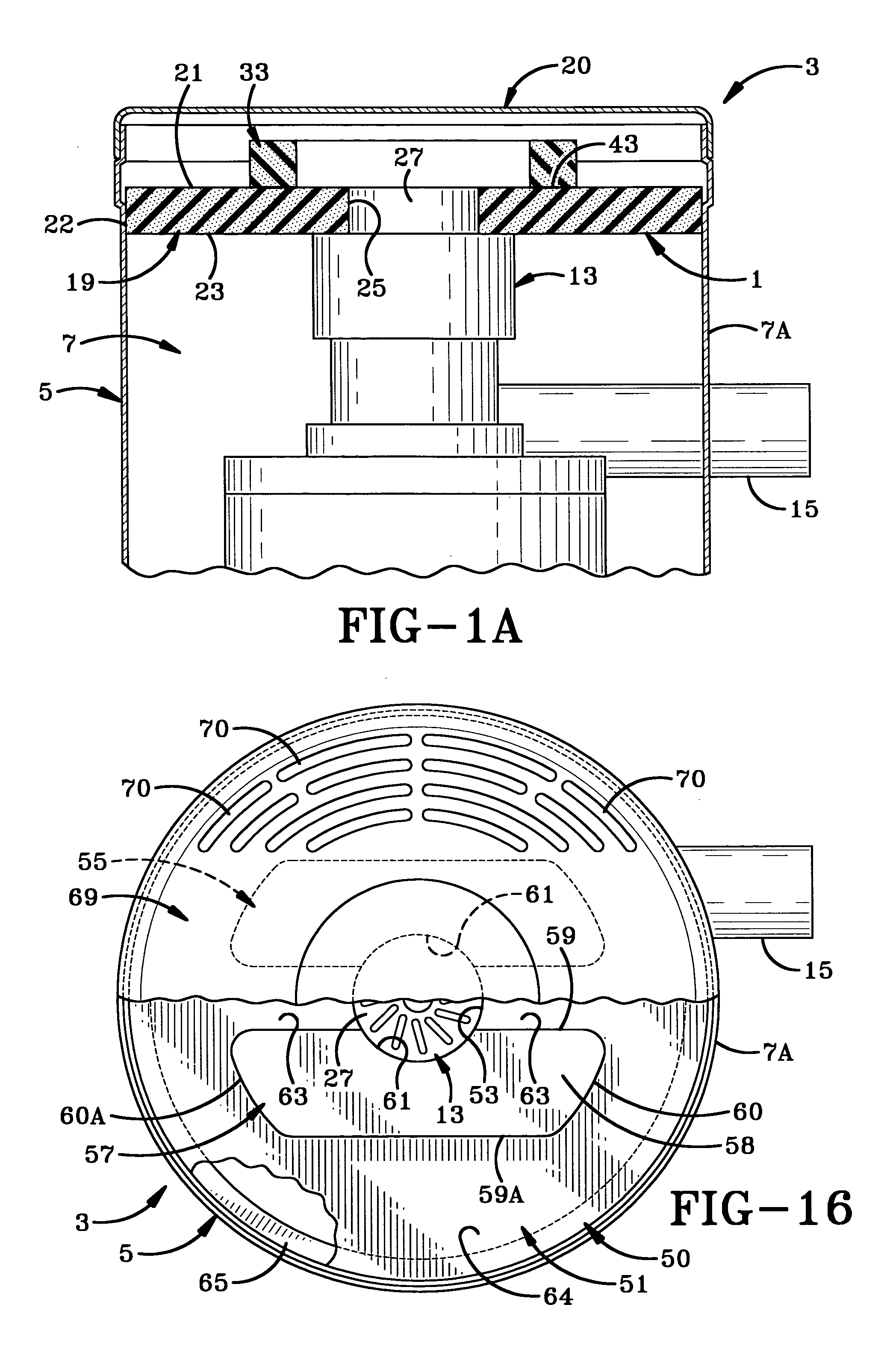

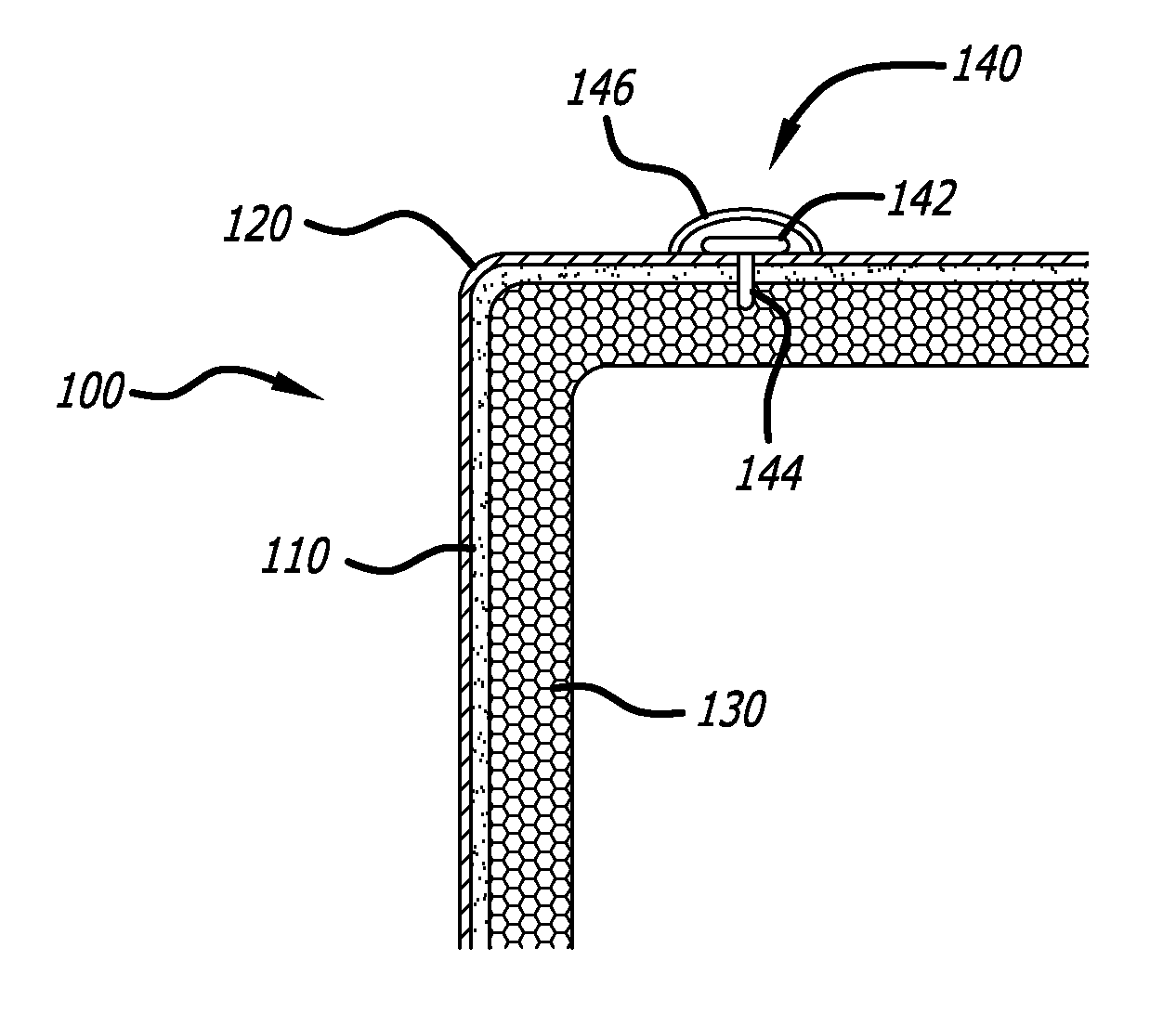

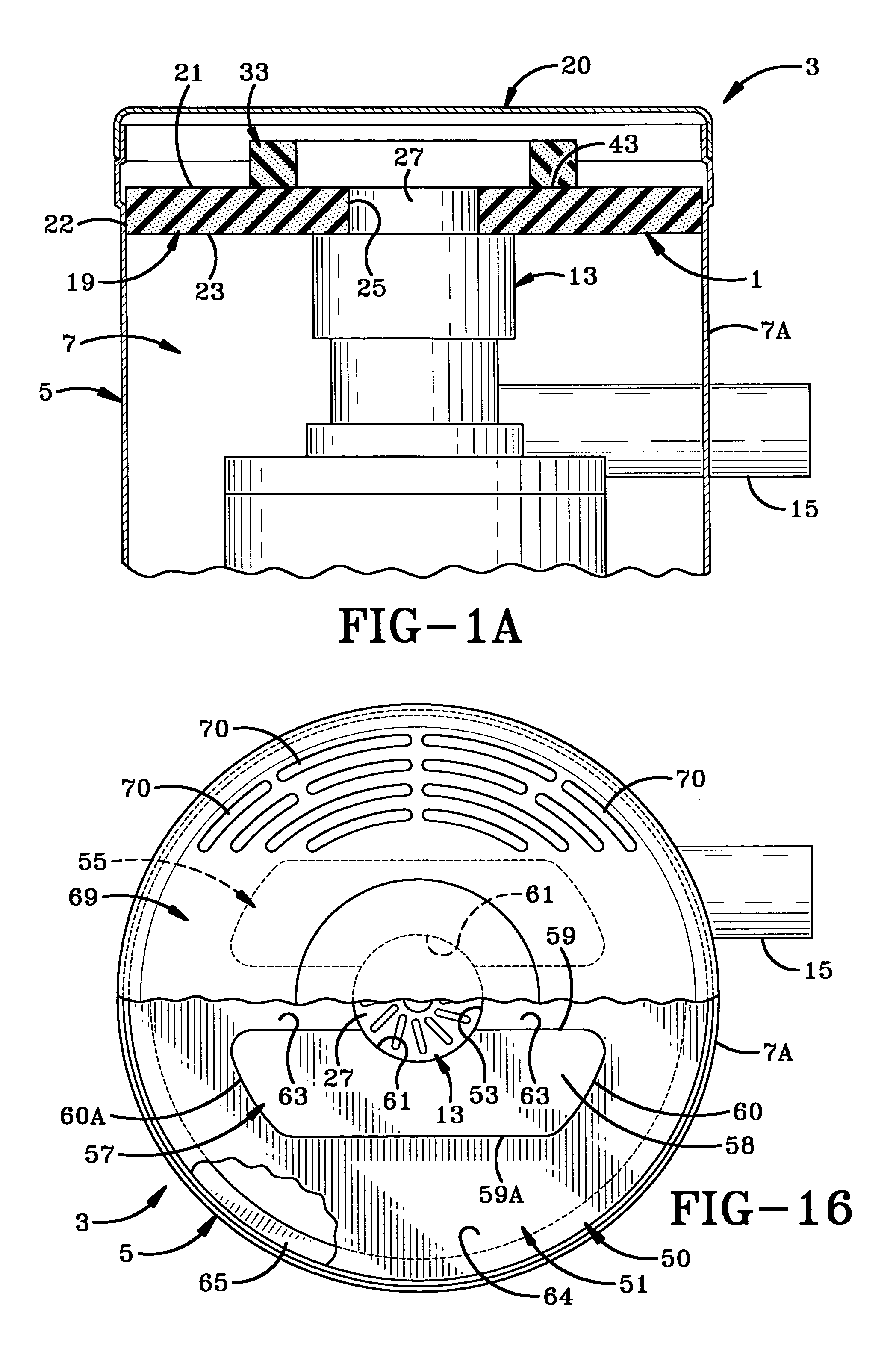

Acoustic foam sound reducer for vacuum power unit

ActiveUS20060070797A1Improve efficiencySuppression amountCombination devicesAuxillary pretreatmentAcoustic foamEngineering

A power unit for an in-wall vacuum cleaning system has a first compartment which contains a motor for producing a vacuum at remote wand receptacles and a second compartment for separating and collecting the debris. An improved sound reducer is mounted in the motor compartment for reducing the sound level emitted by the motor and providing good cooling airflow for the motor. The sound reducer includes a disc-shaped base having a central opening for receiving a portion of the motor and a pair of partitions mounted on the base and forming a plurality of irregularly-shaped sound passages for breaking up the sound waves traveling therethrough. The base and partitions are formed of an acoustic foam which assist in absorbing the sound waves.

Owner:H P PROD

Aircraft monument with improved thermal insulation and acoustic absorption

A protective shell for an aircraft galley wall is disclosed having an above work deck area and a below work deck area, the protective shell having an outer skin, an intermediate layer comprising vacuum insulated panels, and an interior layer comprising carbon fiber composite having a thickness that is greater than a thickness of the intermediate layer. In a preferred embodiment, the protective shell also includes an acoustic insulating layer made of an open cell acoustic foam that absorbs galley noise.

Owner:BE AEROSPACE INCORPORATED

Integrated mass air flow sensor and broadband silencer

InactiveUS8360199B2Acoustic emission reductionCompact designElectrical controlExhaust apparatusInterior spaceAcoustic foam

An integrated mass air flow sensor / broadband silencer assembly comprises a molded body having a plurality of walls formed therein. The molded body is over-wrapped with a layer of acoustic foam that, together with the plurality of walls, define a plurality of chambers within an interior volume of the assembly. A mass air flow sensor can be inserted into one of the chambers. The chambers are sized and spaced to provide a uniform velocity, low turbulence air flow to the sensor, and a minimally-restricted air flow to an internal combustion engine located downstream of the assembly.

Owner:MANN HUMMEL GMBH

Environment-friendly flame-retardant efficient nonwoven acoustic foam

InactiveCN103710869AImprove sound absorption and noise reduction effectDense clothSynthetic resin layered productsNon-woven fabricsFiberEpoxy

The invention relates to acoustic foam, in particular to environment-friendly flame-retardant efficient nonwoven acoustic foam comprising a top layer, a back layer, and a fiber bulk layer between the top layer and the back layer. Both the top layer and the back layer are made of nonwoven. The nonwoven is made with, by weight, 100 parts of isotactic polypropylene, 2-3 parts of decabromodiphenylethane, 3-4 parts of antimonous oxide, 1-2 parts of calcium stearate, 1-2 parts of methyl cellulose ether, 6-8 parts of cassava starch, 2-3 parts of triphenyl phosphate, 12-15 parts of epoxy fatty acid butyl ester, 3-5 parts of peony root, 1-2 parts of tea tree root, 2-3 parts of burdock, 1-2 parts of light yellow Sophora root, 2-3 parts of scandent hop, 1-2 parts of peach blossom, and 4-5 parts of aid. The environment-friendly flame-retardant efficient nonwoven acoustic foam with the outer layer of soft, solid, fireproof and flame-retardant nonwoven has the advantages of environmental friendliness, safety, capability of absorbing noise and reducing noise and the like and has promising application prospect.

Owner:芜湖跃飞新型吸音材料股份有限公司

How to make soundproofing material

InactiveCN102264984AImprove buffering effectHigh mechanical strengthLayered productsSound proofingAcoustic foamEngineering

The present invention relates to a manufacturing method for acoustic foam. More specifically, the manufacturing method for acoustic foam including resin foam containing an open cell and a closed cell includes physically blowing up the closed cell by applying impact to one or both sides of the acoustic foam in a contact or non-contact manner. The method improves shock-absorption, mechanical strength, workability, heat insulation, and noise blocking / dispersion of the acoustic foam.

Owner:LG HAUSYS LTD

Acoustic foam sound reducer for vacuum power unit

ActiveUS7434657B2Improve efficiencySuppression amountCombination devicesAuxillary pretreatmentAcoustic foamEngineering

Owner:H P PROD

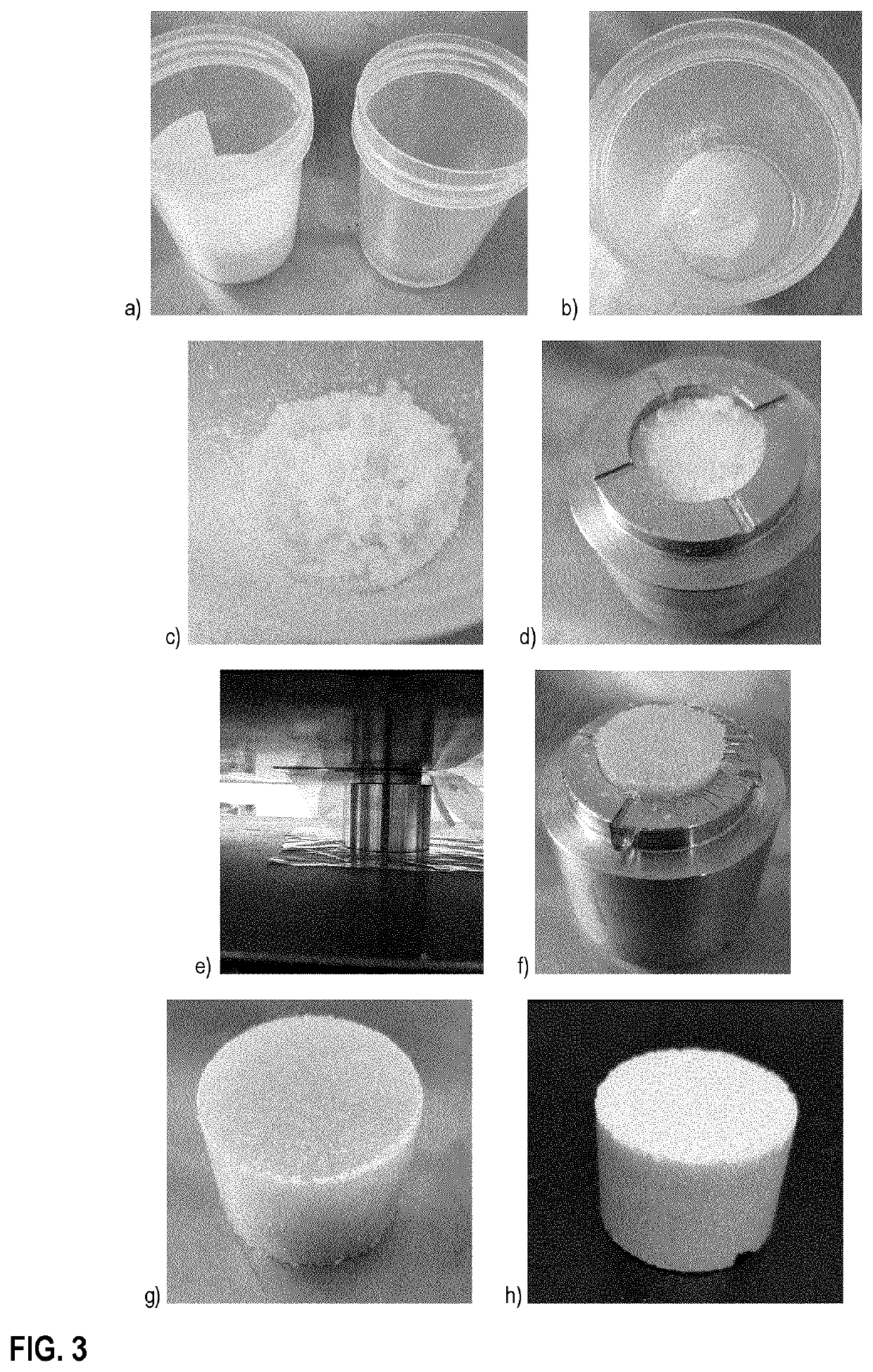

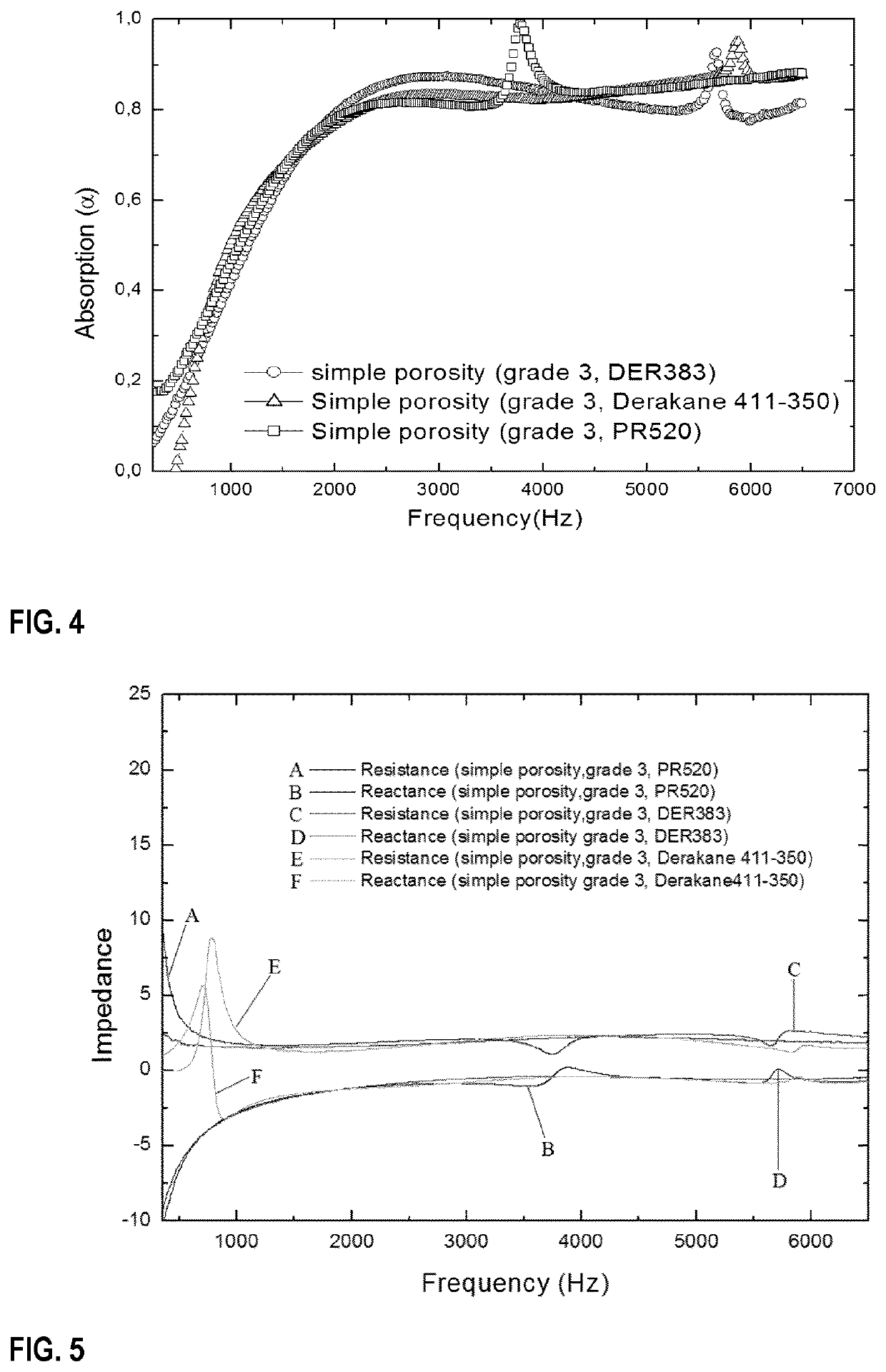

Openly porous acoustic foam, process for manufacture and uses thereof

ActiveUS20200157305A1Improve acoustic propertiesReduce manufacturing costSound producing devicesCoatingsPolymer scienceAcoustic foam

There is provided a method of manufacturing an openly and highly porous thermoset foam, the method comprising the steps of mixing a thermosetting resin and crystals to form a mixture; applying pressure to the mixture to expel excess thermosetting resin, thereby producing a network of crystals touching each other with the thermosetting resin filling the interstices between the crystals of said network; curing the thermosetting resin in the mixture under pressure to produce a cured material; and contacting the cured material with a solvent for the crystals, thereby leaching the crystals out of the cured material, thereby obtaining said openly and highly porous thermoset foam. There is also provided a thermoset foam made of a thermoset and having a porosity of at least about 70%, wherein more than about 75% of the pores in the foam are connected to a neighboring pore.

Owner:SAFRAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com