Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Less pressure drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

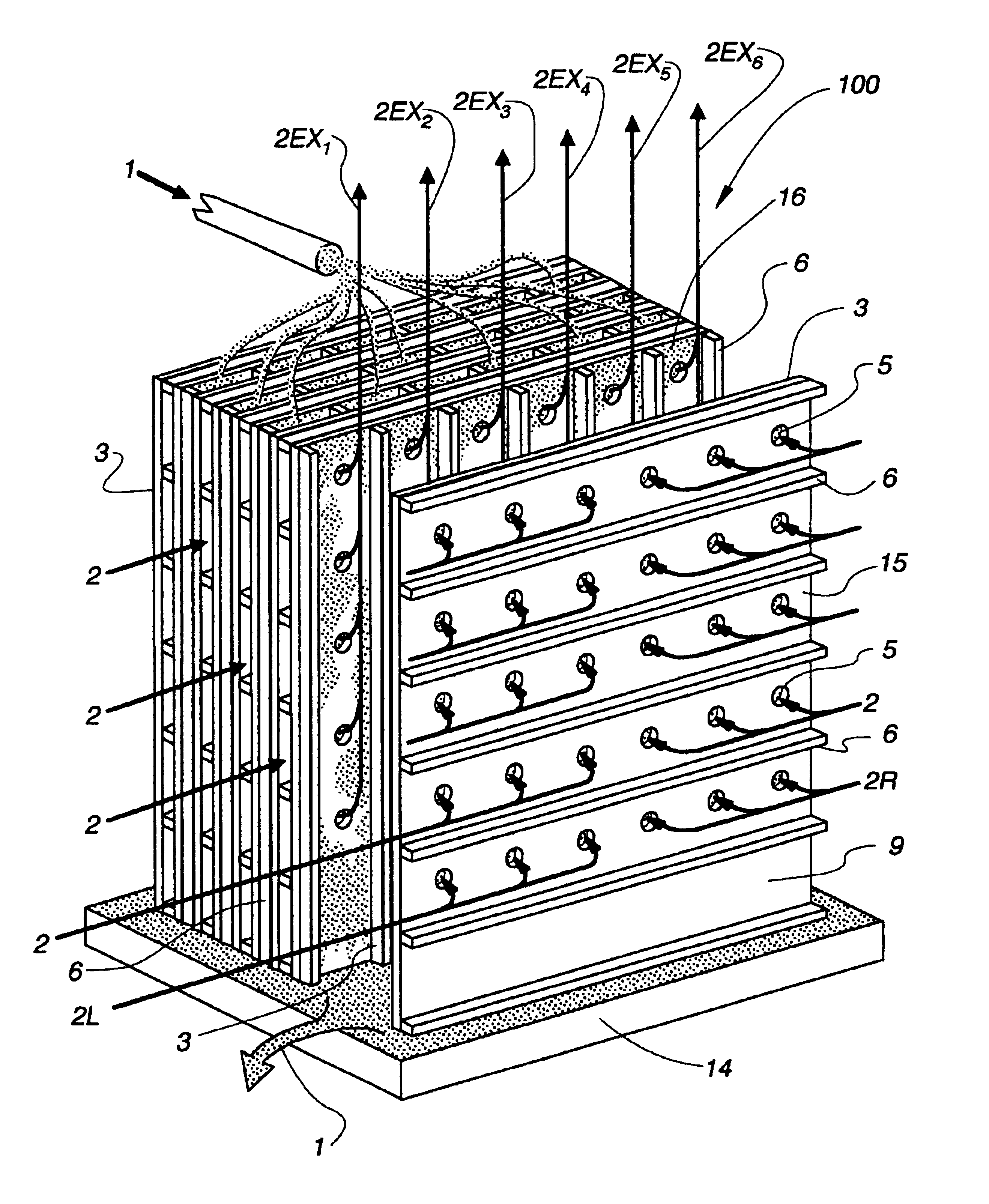

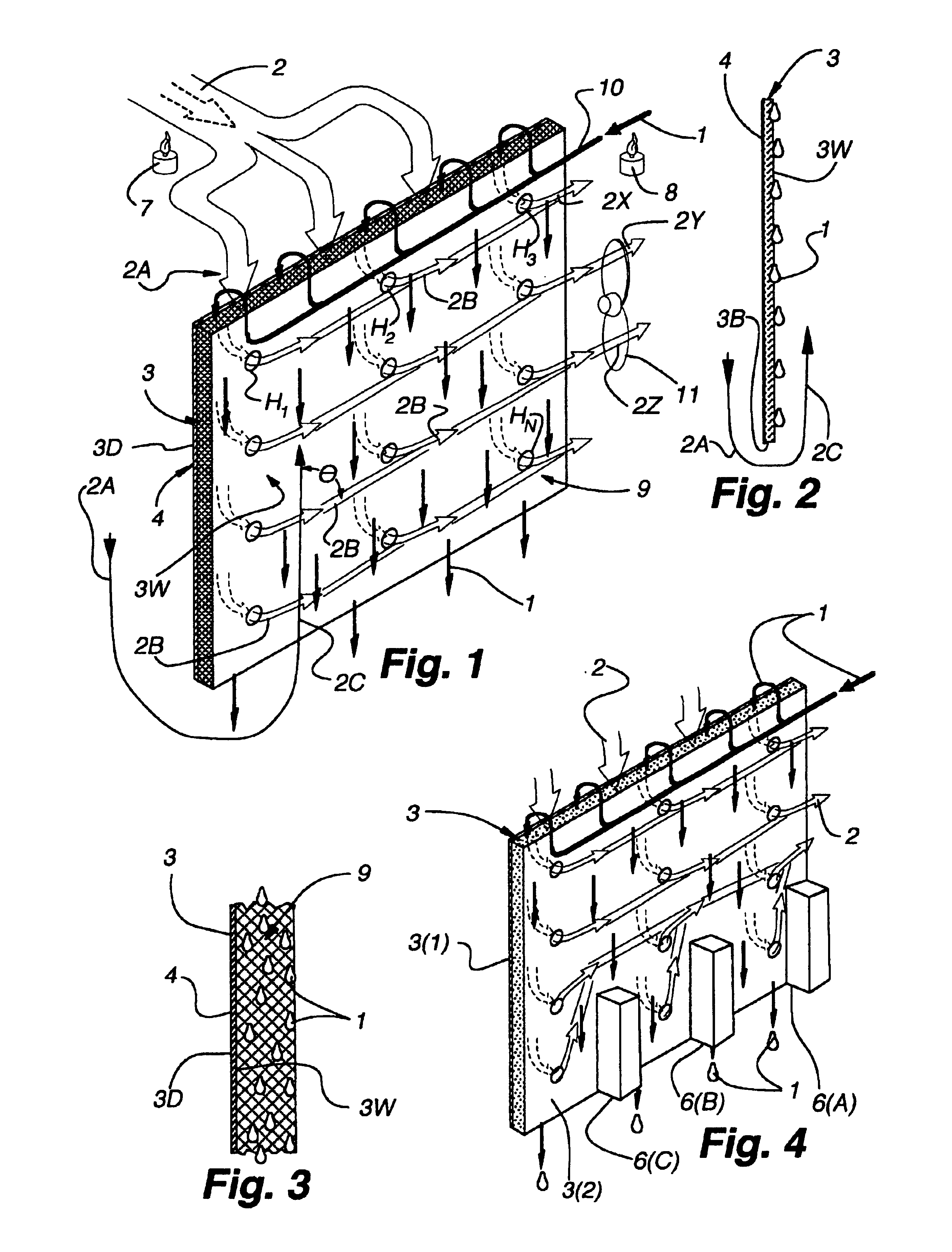

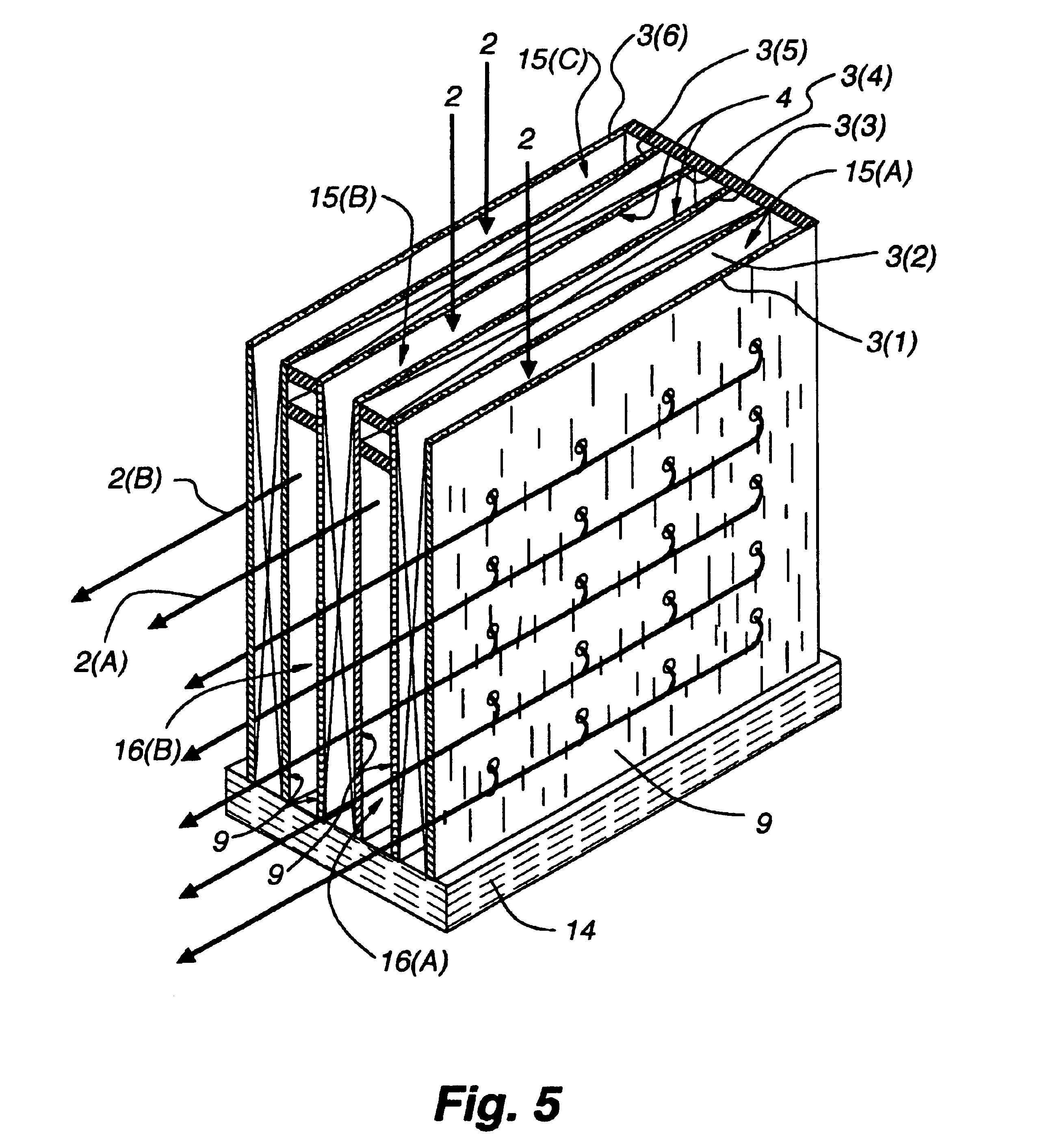

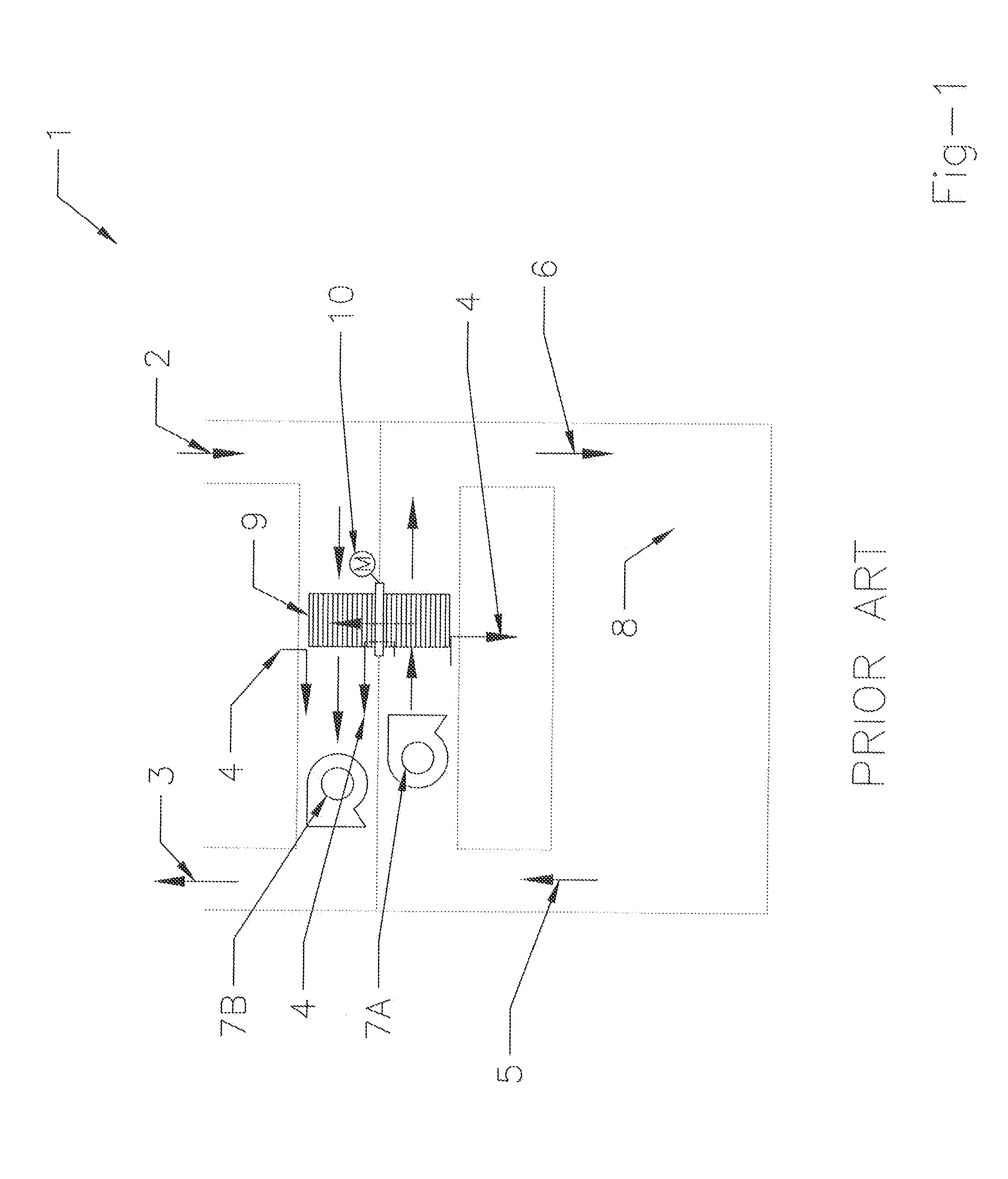

Method of evaporative cooling of a fluid and apparatus therefor

InactiveUS6854278B2Reduce the temperatureLess pressure dropMechanical apparatusSpace heating and ventilation safety systemsDesiccantMechanical engineering

The operating efficiency of indirect evaporative cooling processes and indirect evaporative cooling apparatus employing a dry side channel and a wet side channel separated by a heat exchange plate are improved by placement of holes in the heat exchange plate. Further improvements are obtained when the flow direction in the wet side channel is cross-current to the flow direction in the dry side channel. Placement of desiccant materials in the dry side channel also serve to improve the operating efficiencies of these processes and apparatus.

Owner:IDALEX TECH INC

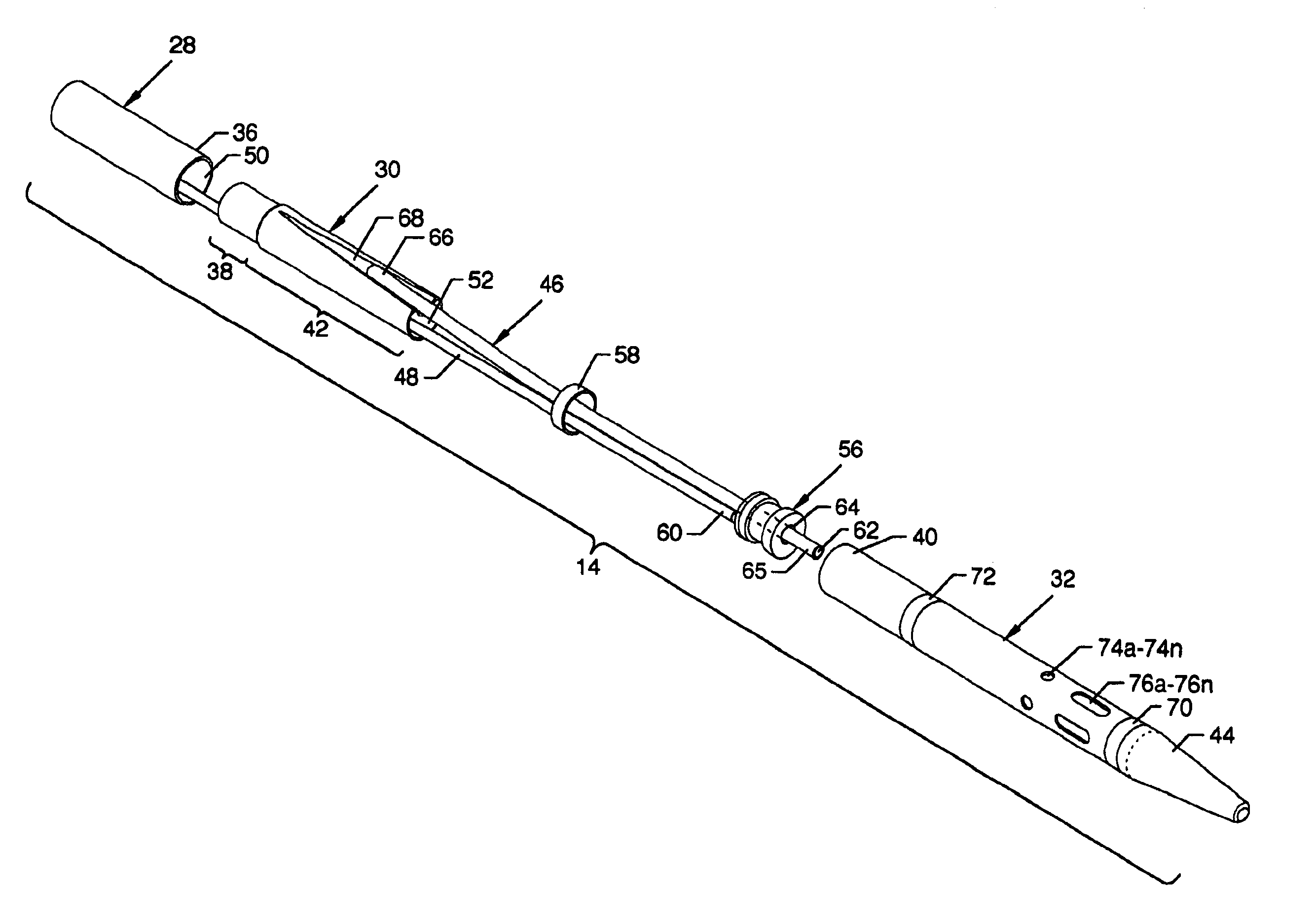

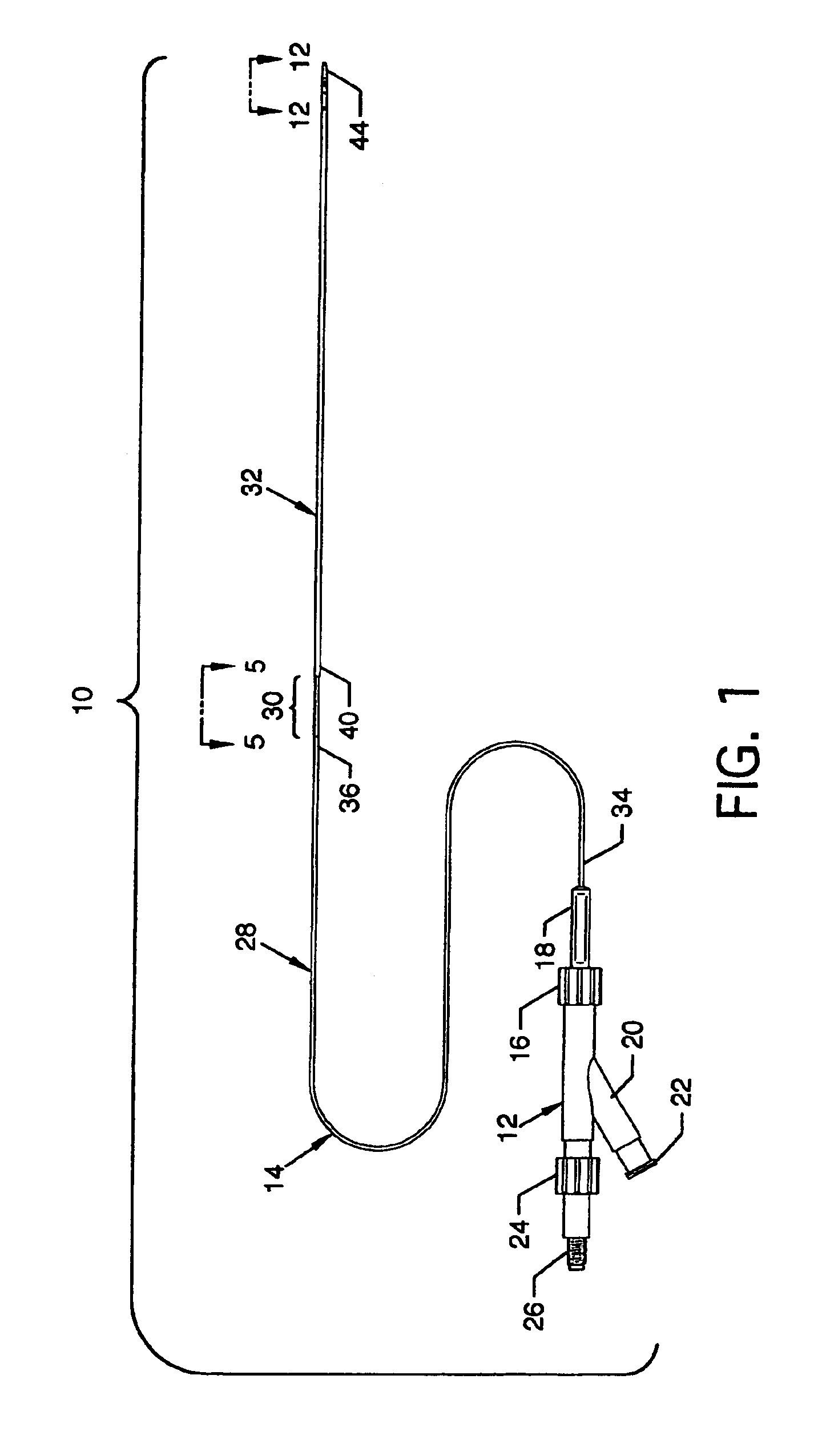

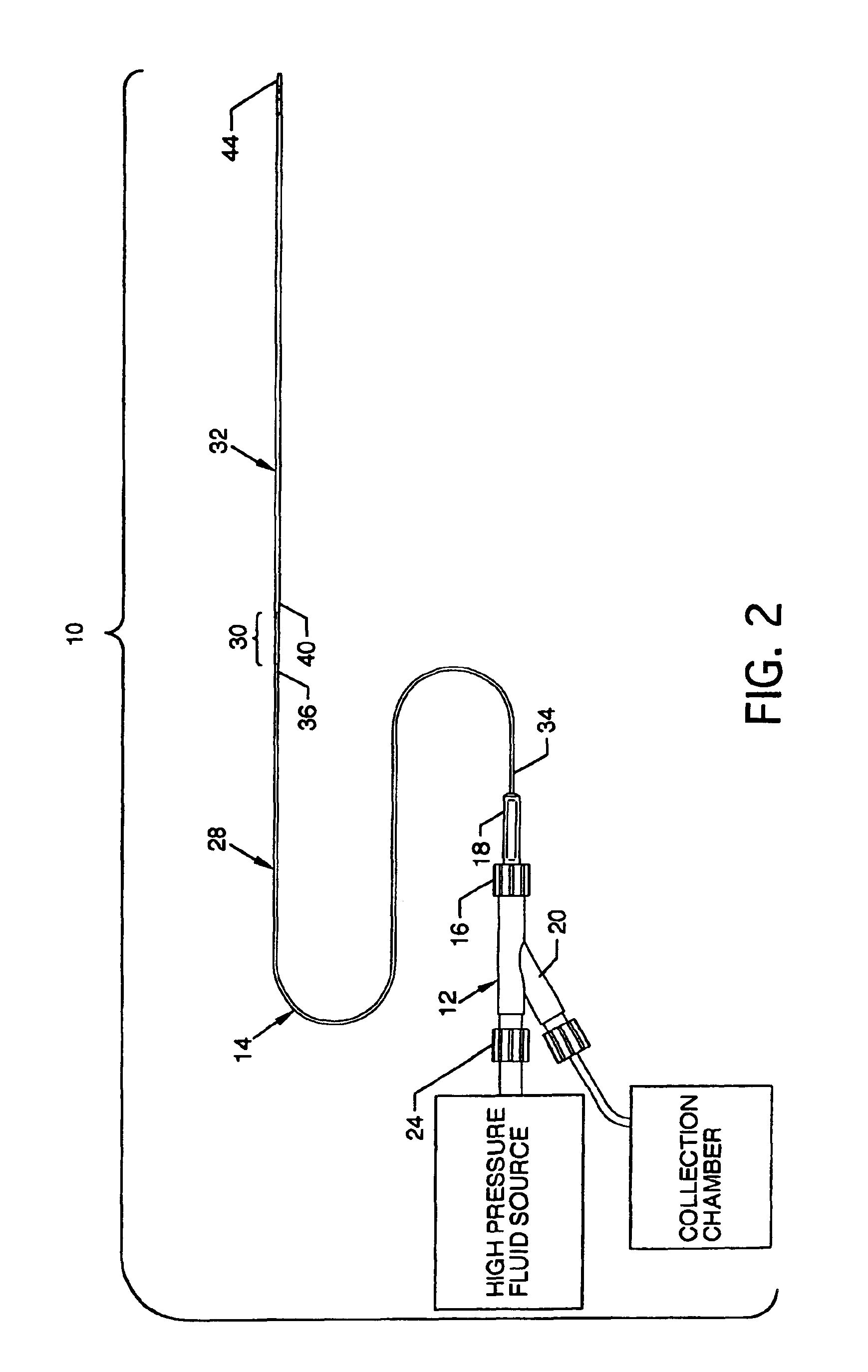

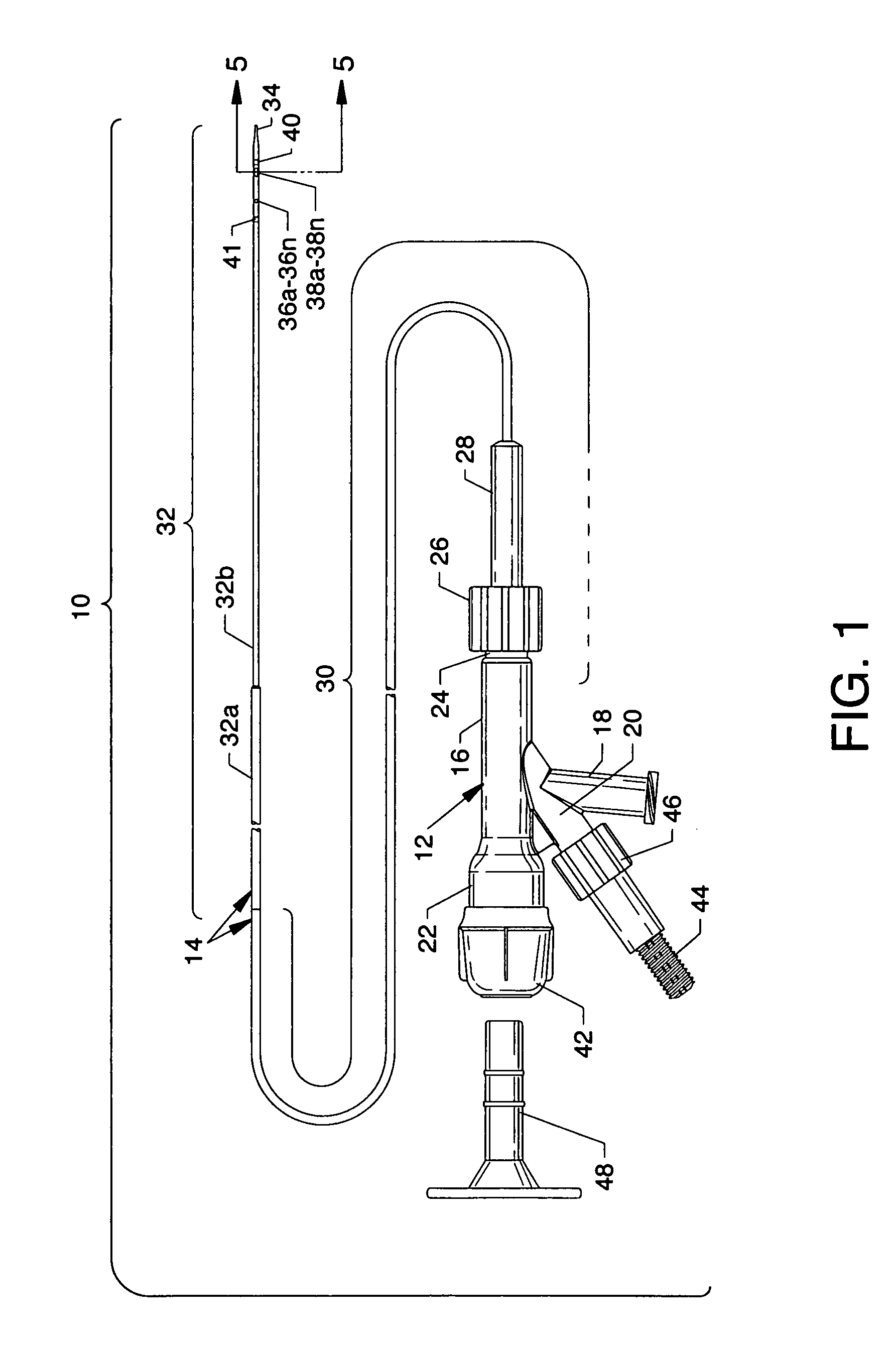

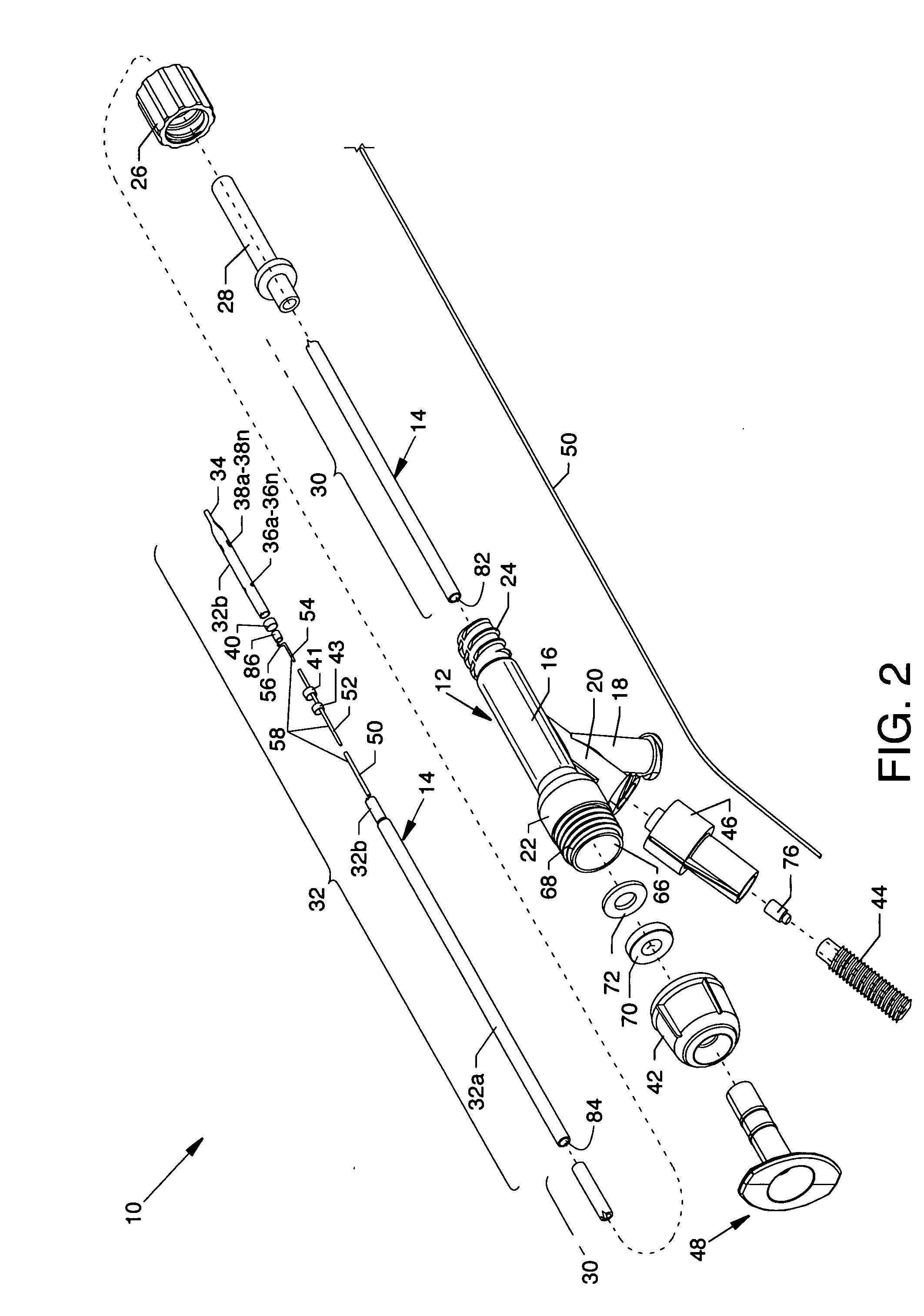

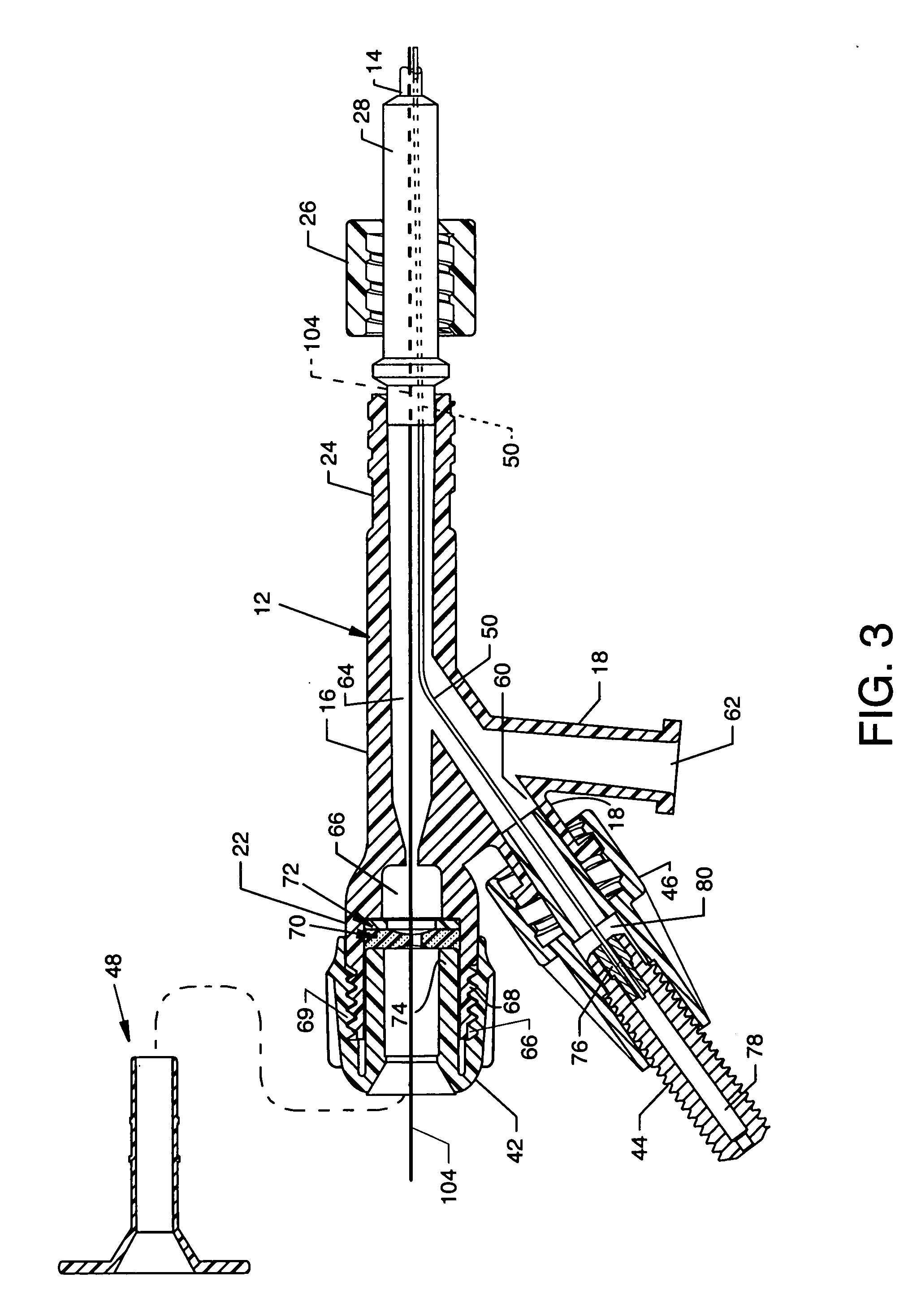

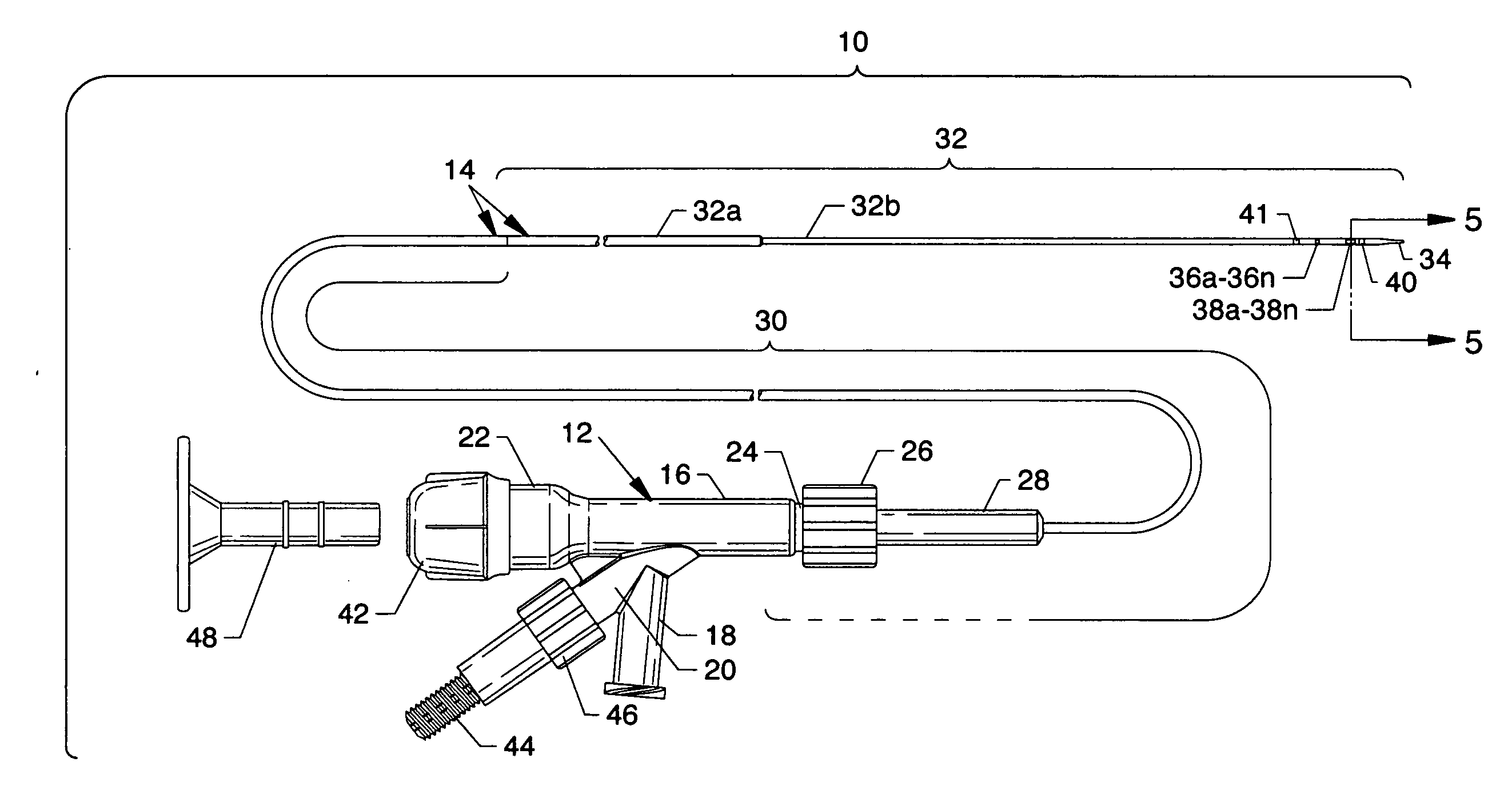

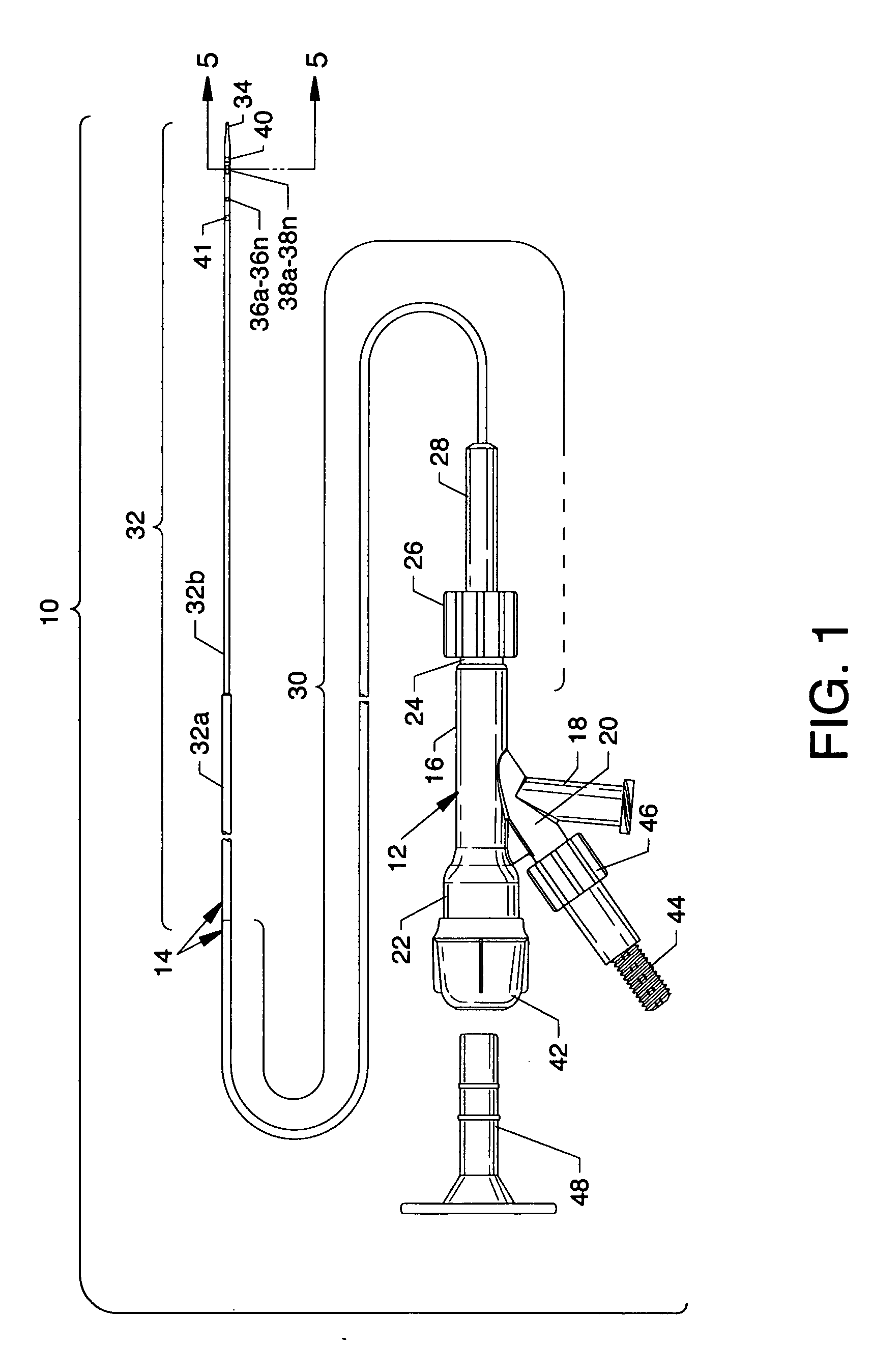

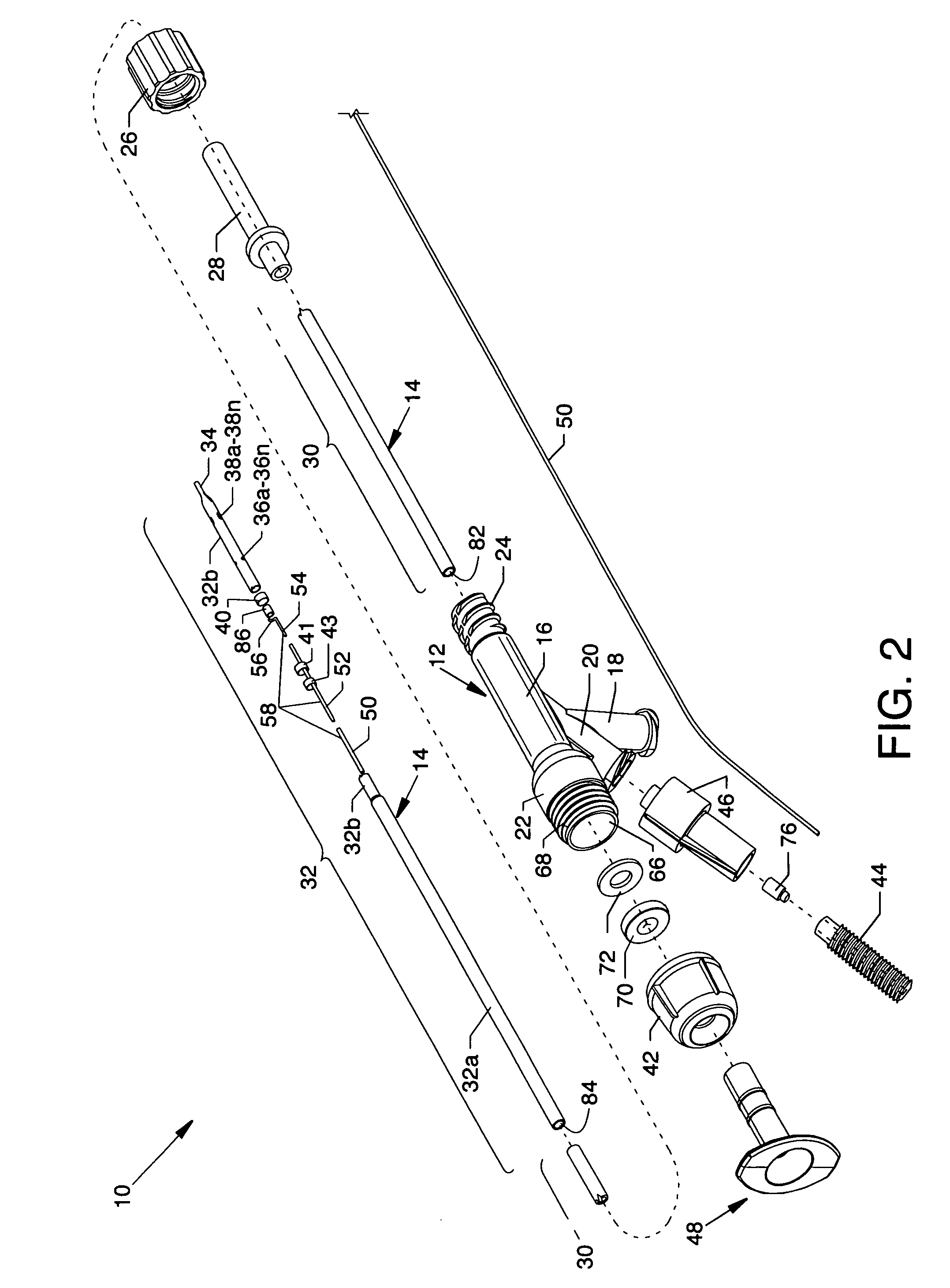

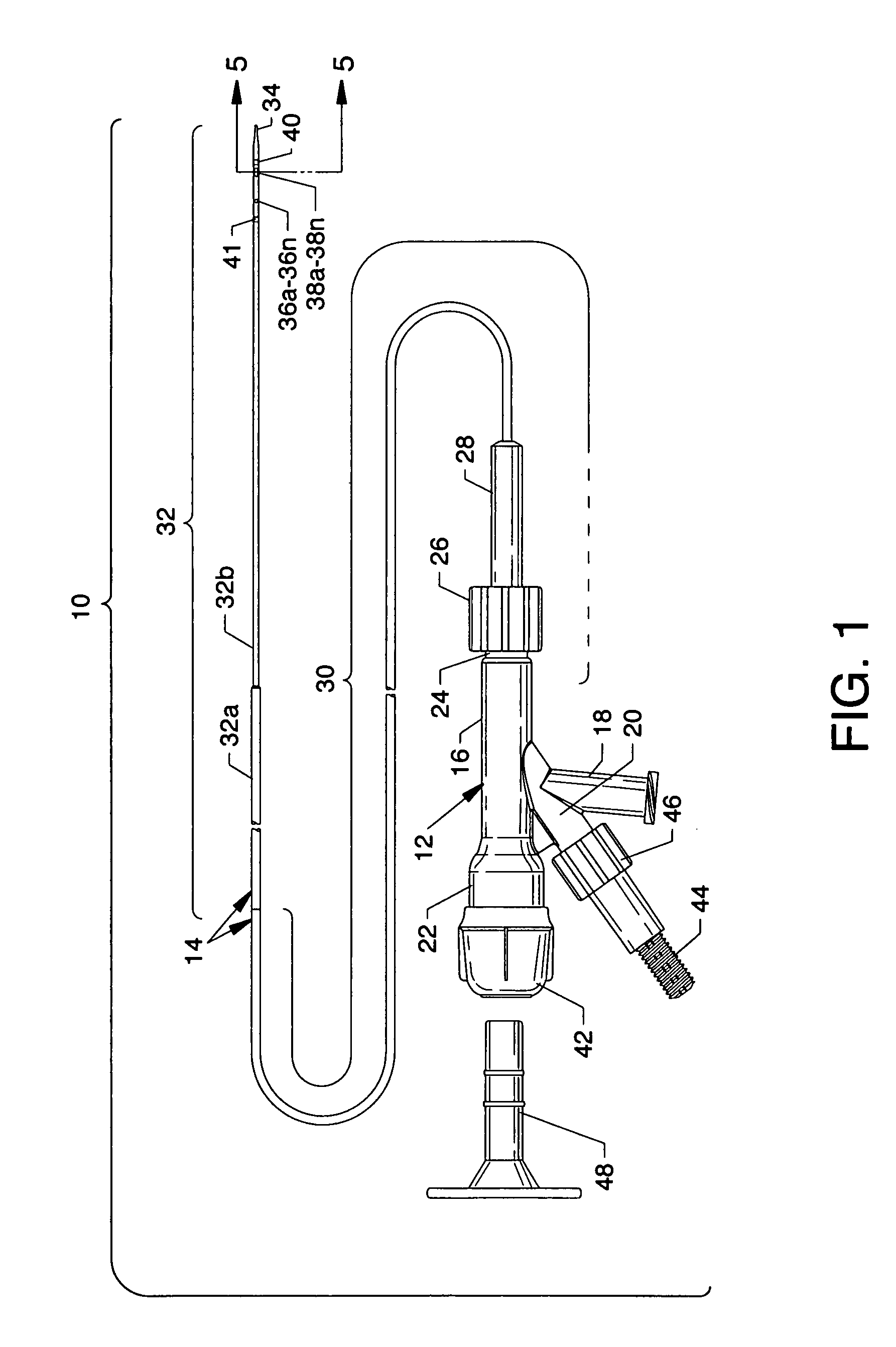

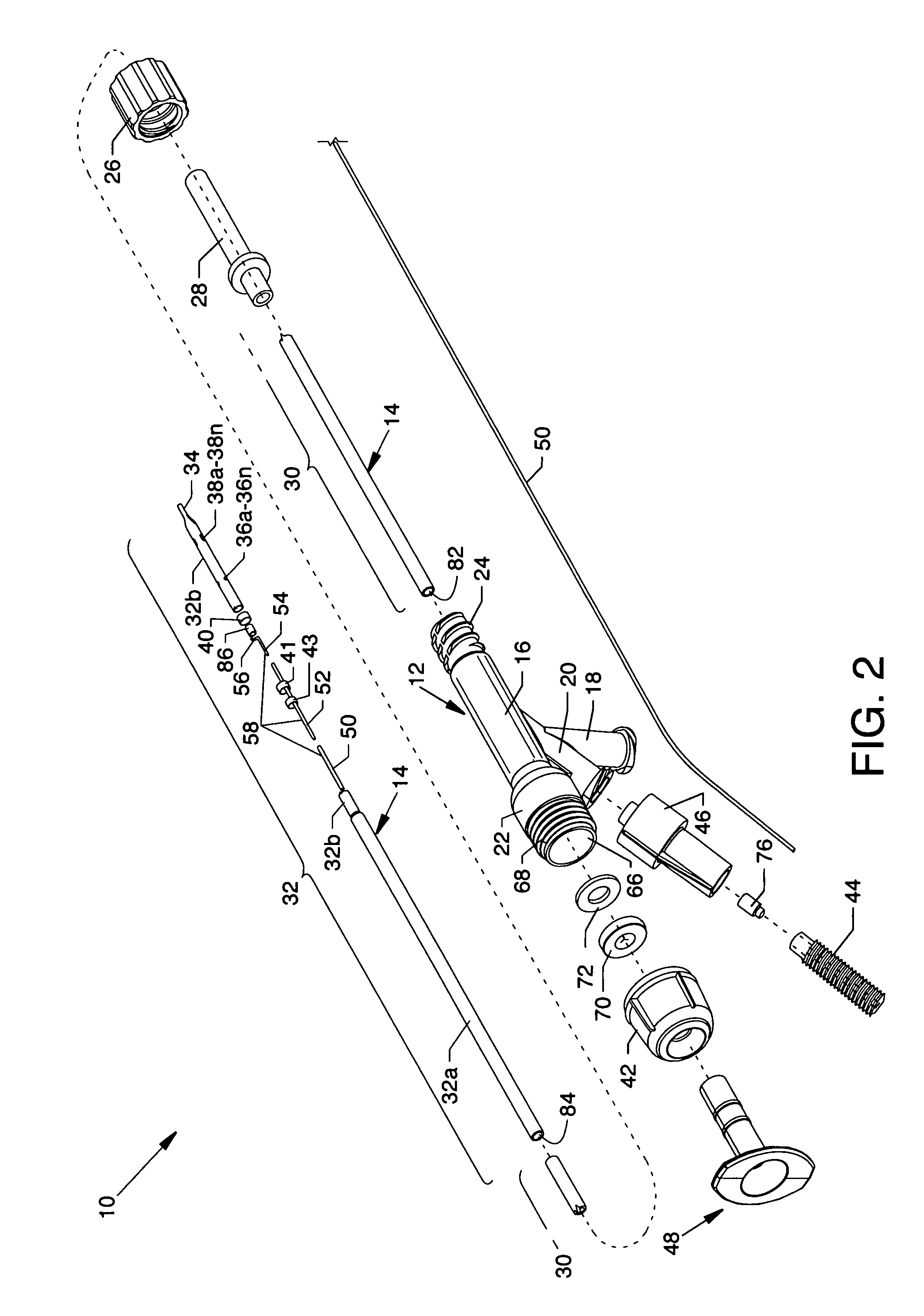

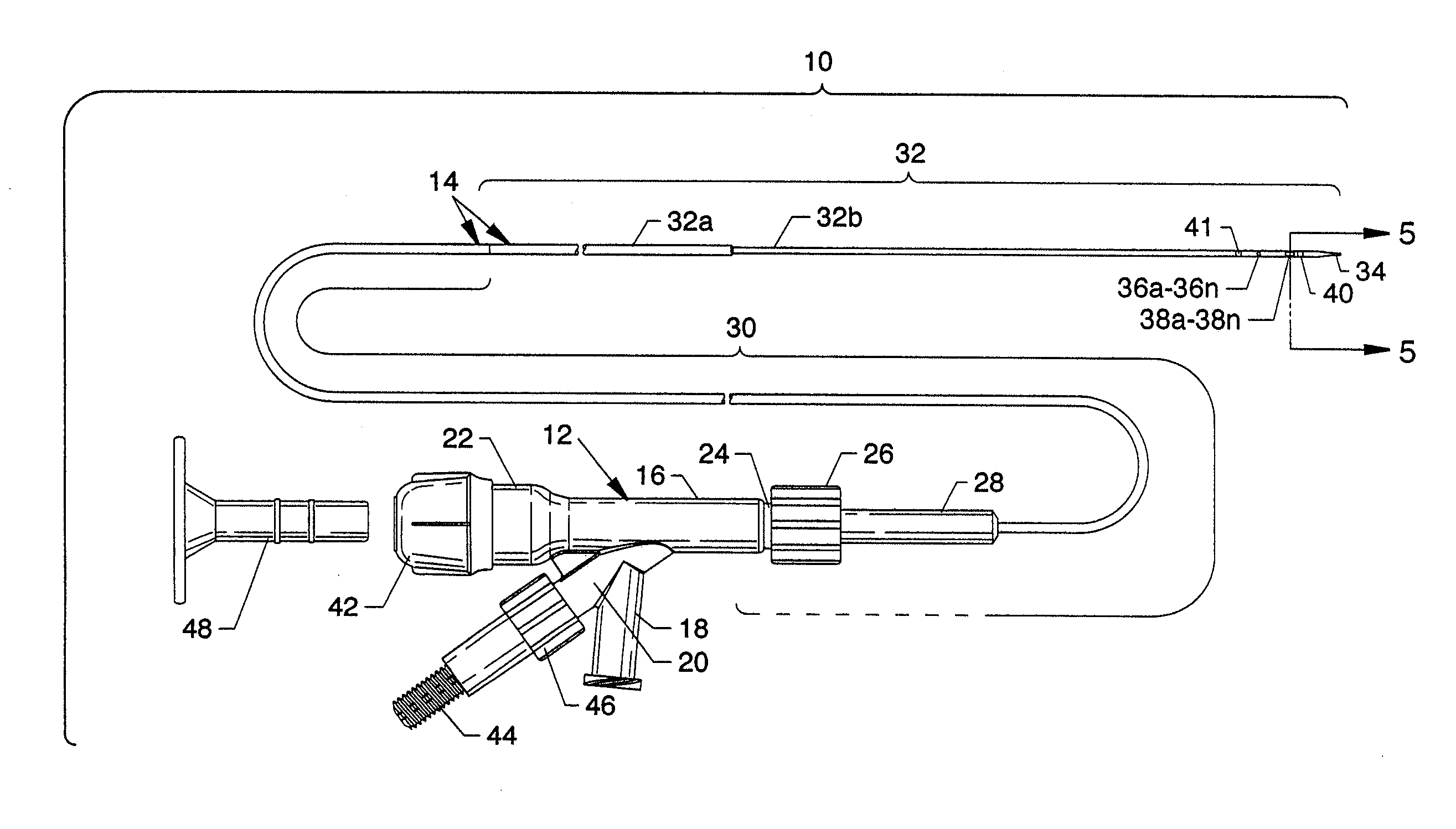

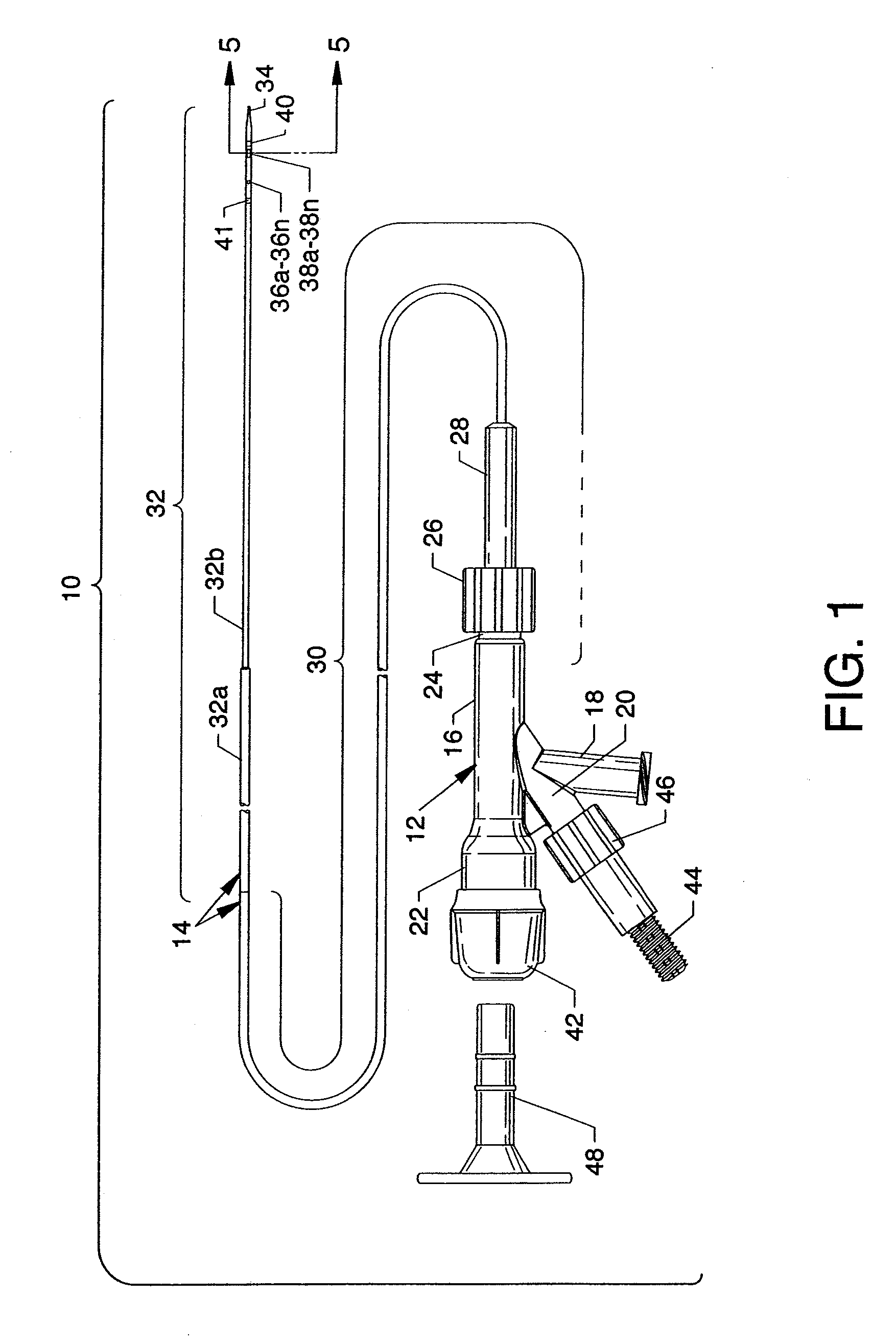

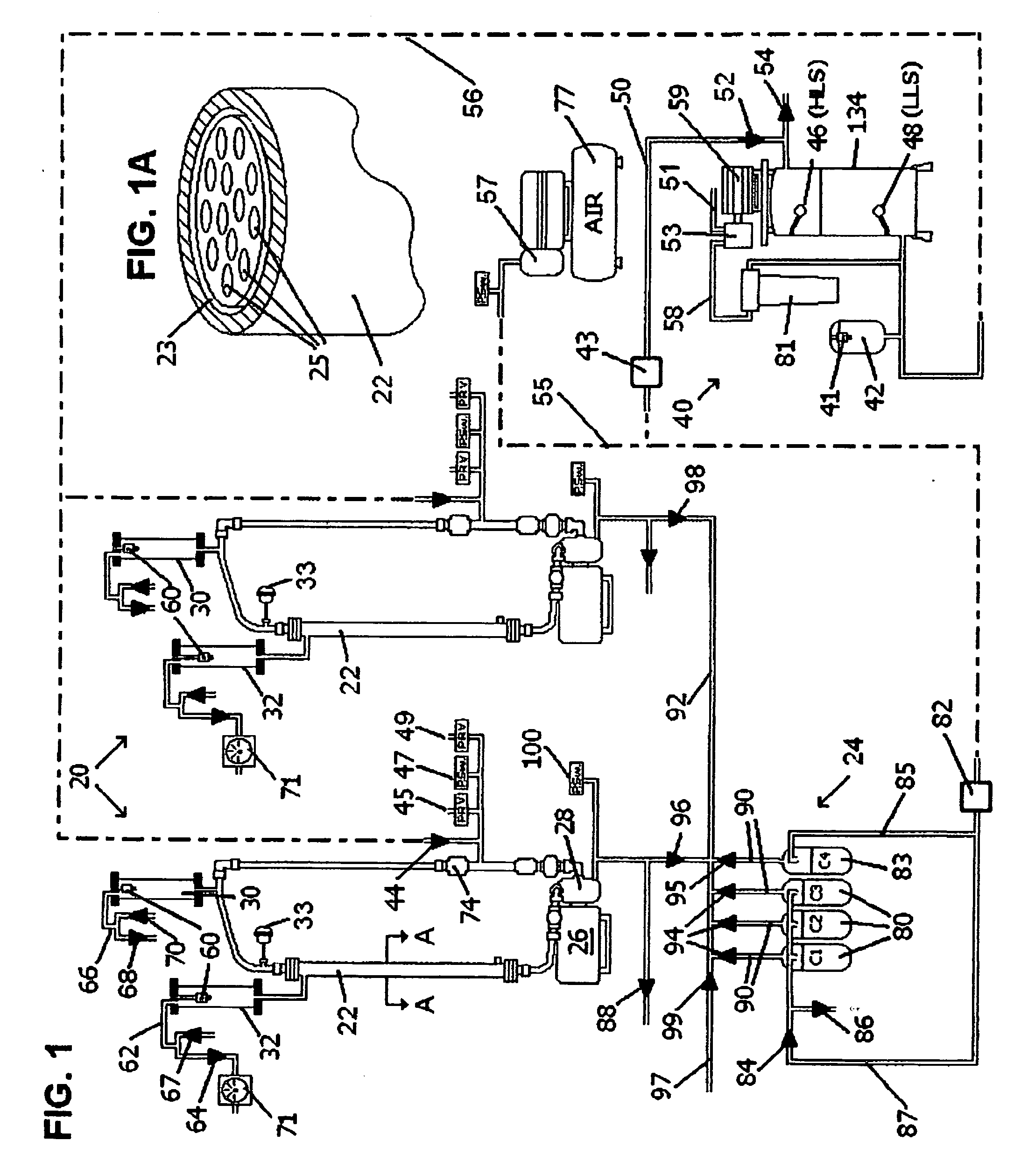

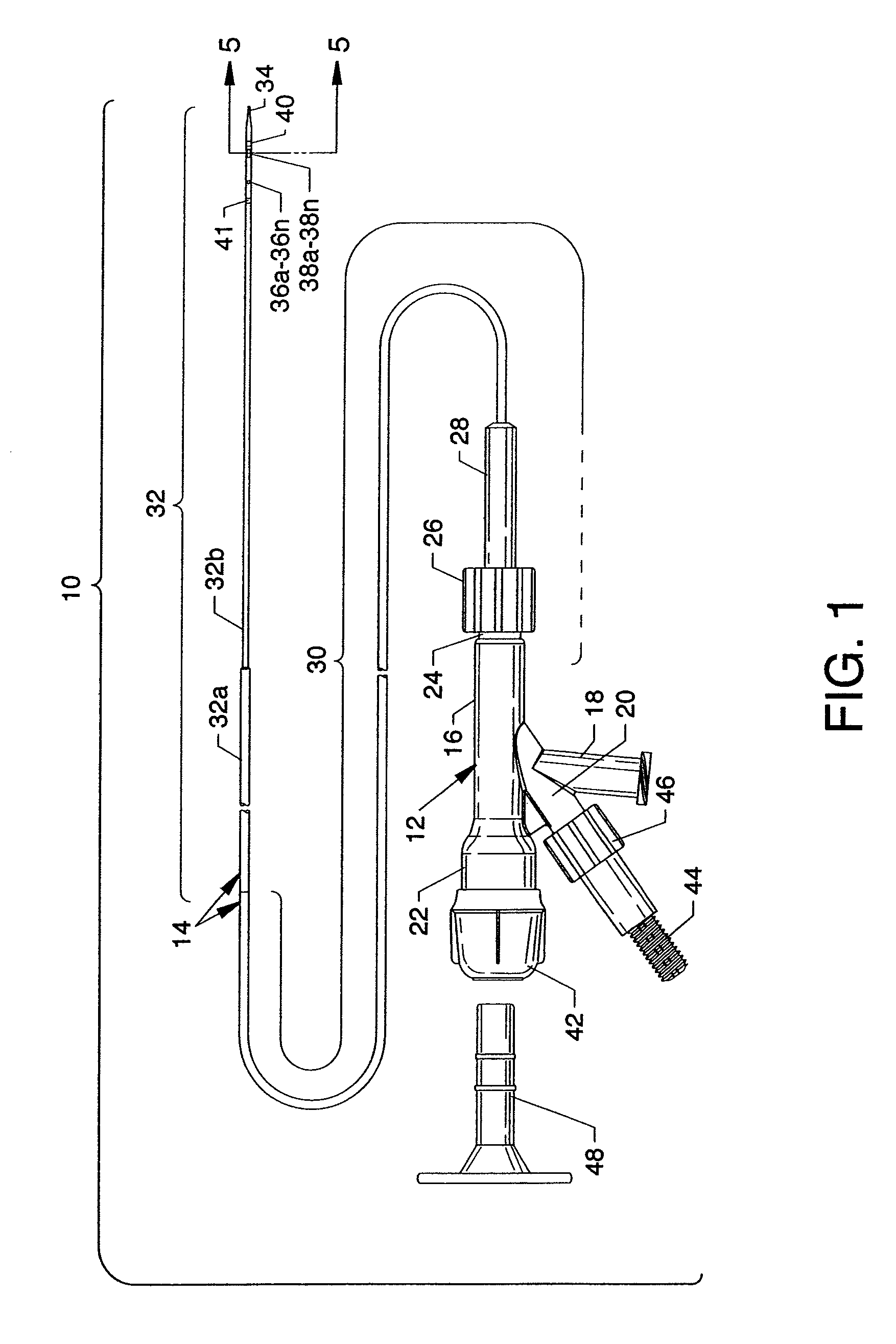

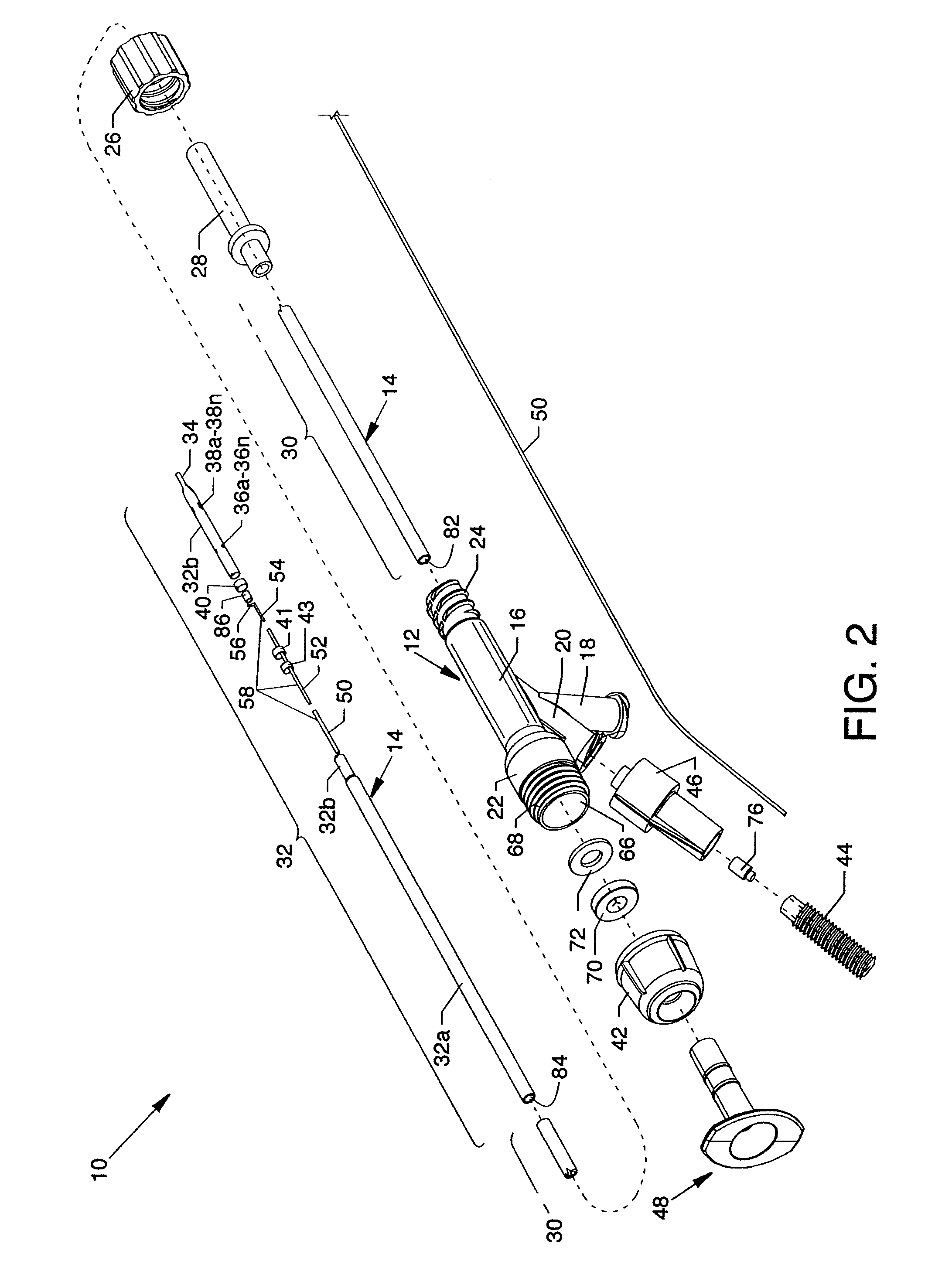

Rapid exchange fluid jet thrombectomy device and method

A rapid exchange fluid jet thrombectomy device for removal of thrombus or unwanted tissue debris from a vein, artery or the like. The device includes a semi-rigid intermediate tube between a proximal and a distal exhaust tube which accommodates a guidewire tube exit located along the catheter at less than one-half the length of the catheter measured from the catheter most distal point. Such a location of the guidewire is convenient for maneuvering and longitudinal advancement of the guidewire, as well as maneuvering and longitudinal advancement of the catheter by one practitioner.

Owner:BOSTON SCI LTD

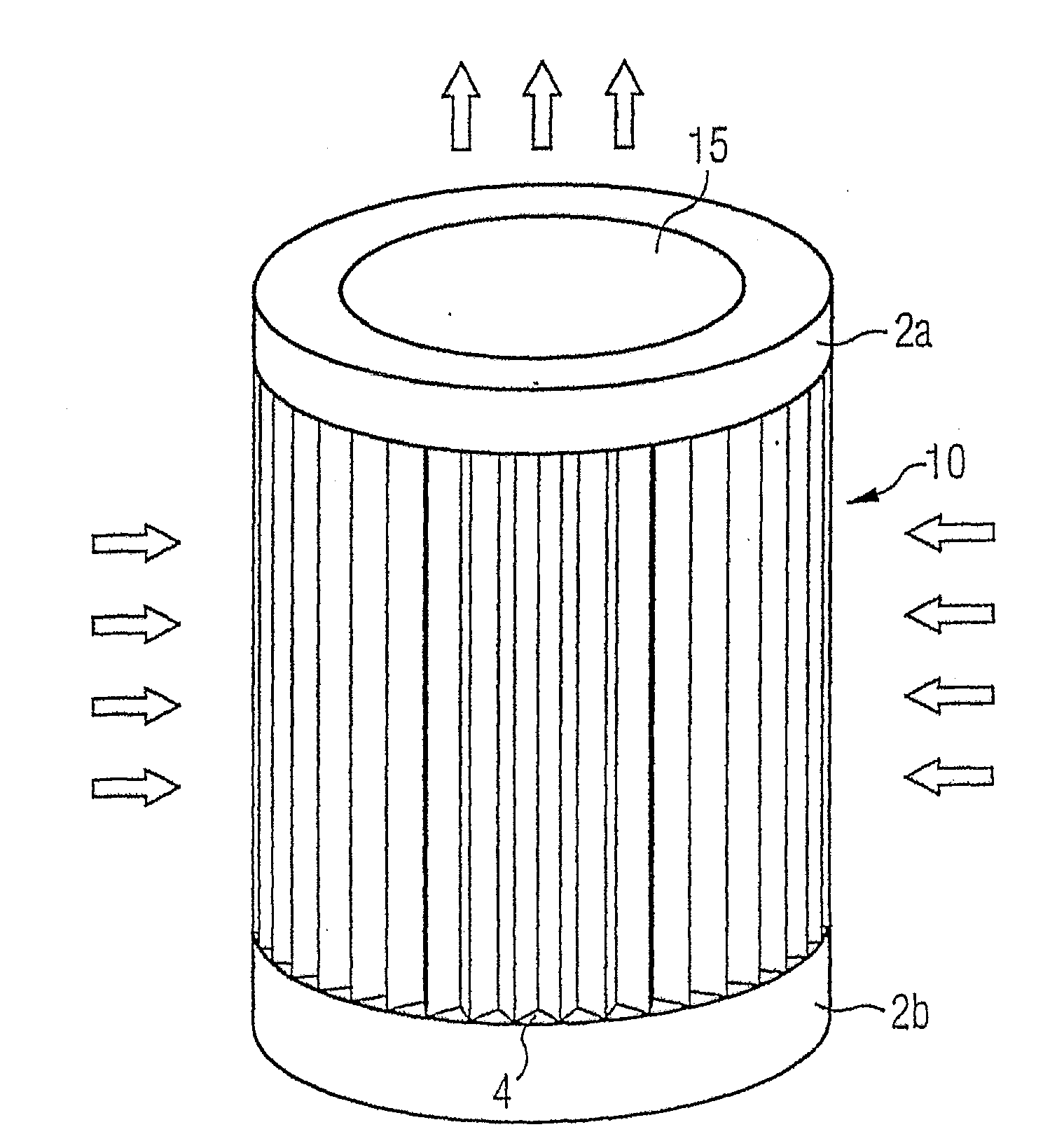

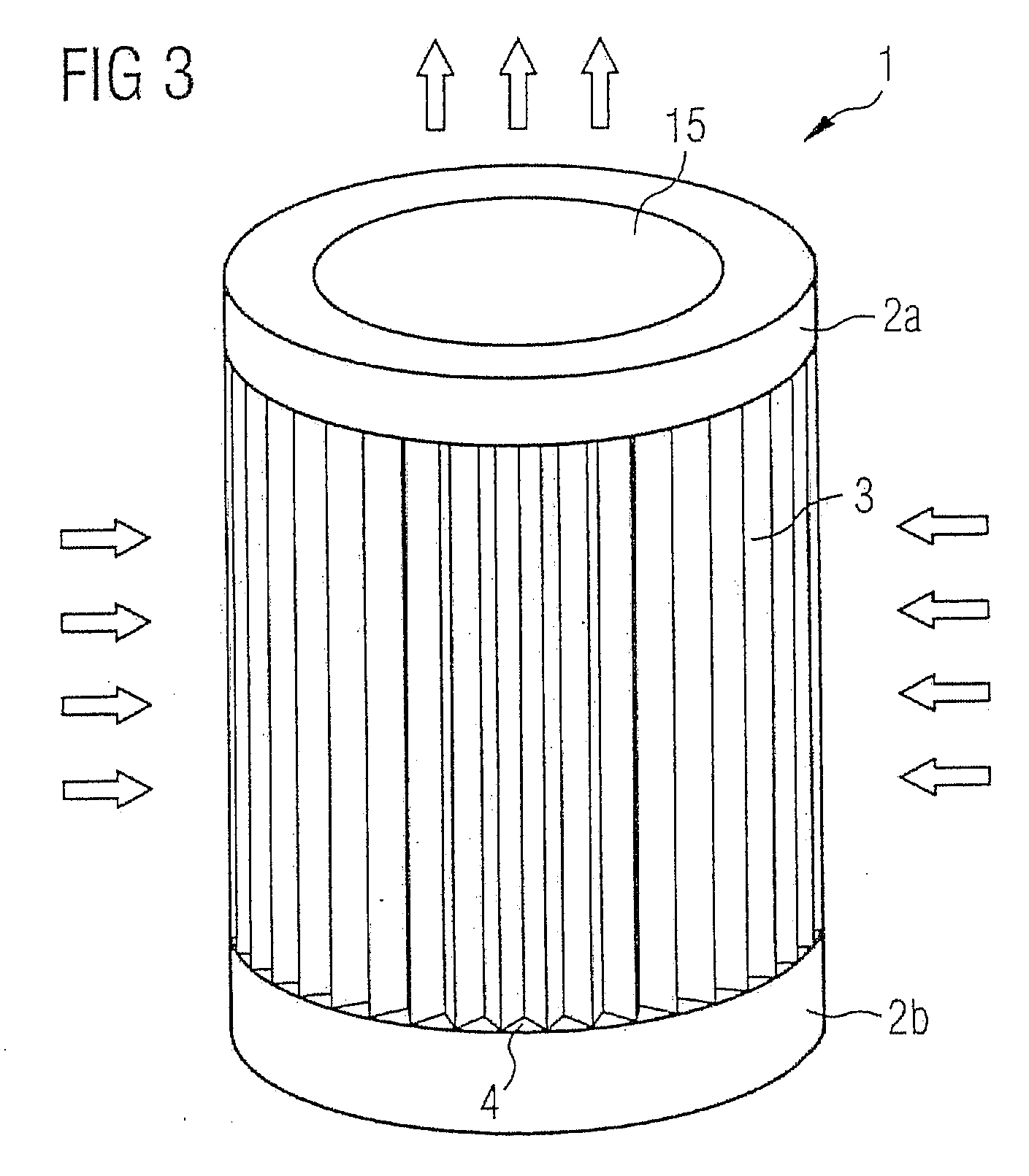

Turbine Air-Intake Filter

InactiveUS20090266048A1Improve filtering effectSimple wayGas treatmentDispersed particle filtrationFiberFiltration

A turbine air-intake filter for removal of particles from an air stream entering a gas turbine comprises a composite filter media (10) being made from a membrane filtration layer (20) comprising a porous polymeric membrane, such as porous polytetrafluoroethylene (ePTFE), and at least one depth filtration media layer (18) comprising fibers, such as a melt blown web, and being disposed on an upstream side of the membrane filtration layer (20) relative to a direction of gas flow through the filter. The fibers of the depth filtration media layer (18) have an electrostatic charge. The ePTFE membrane is preferably made from a blend of a PTFE homopolymer and a modified PTFE polymer.

Owner:SCHWARZ ROBERT

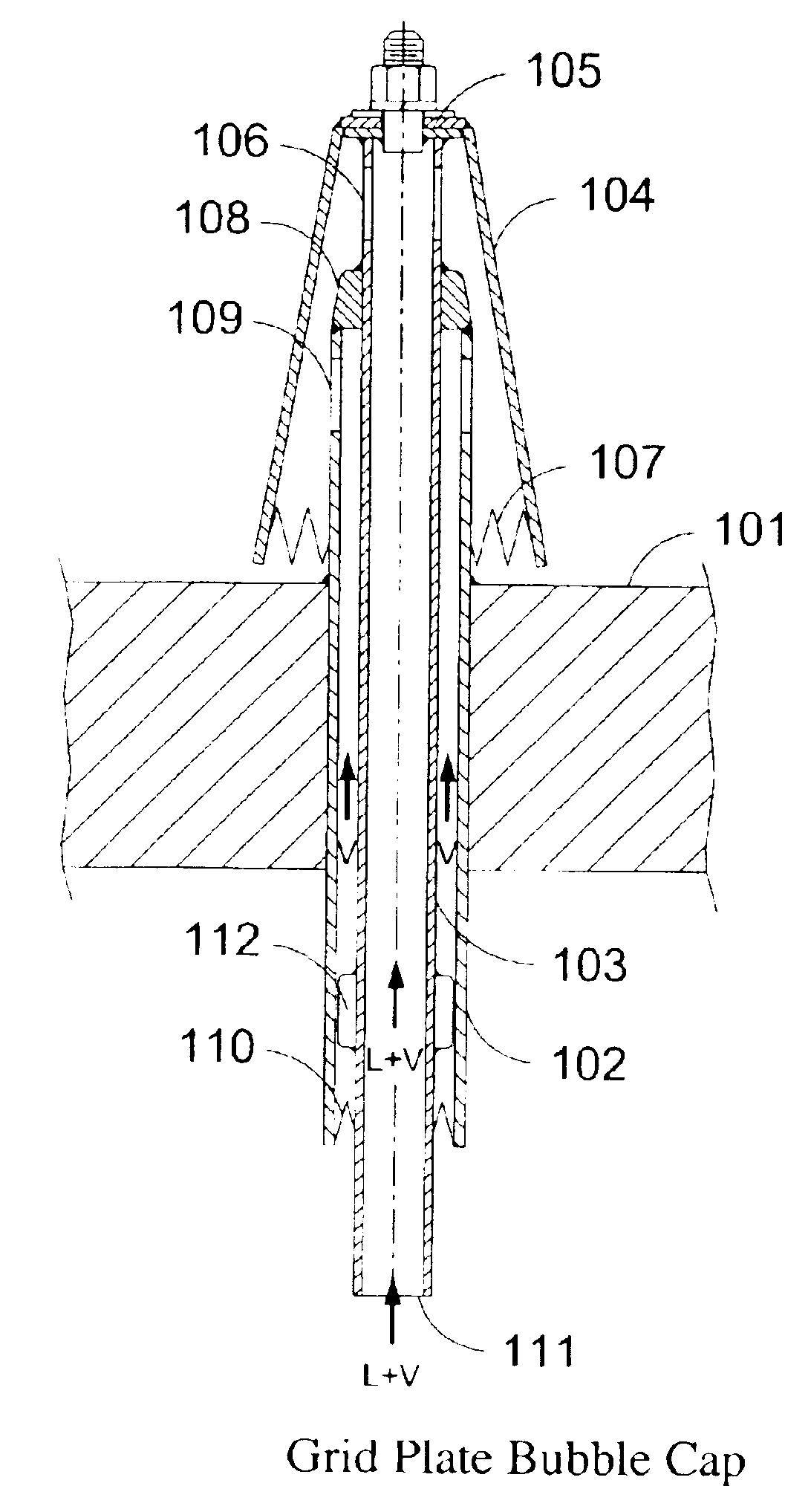

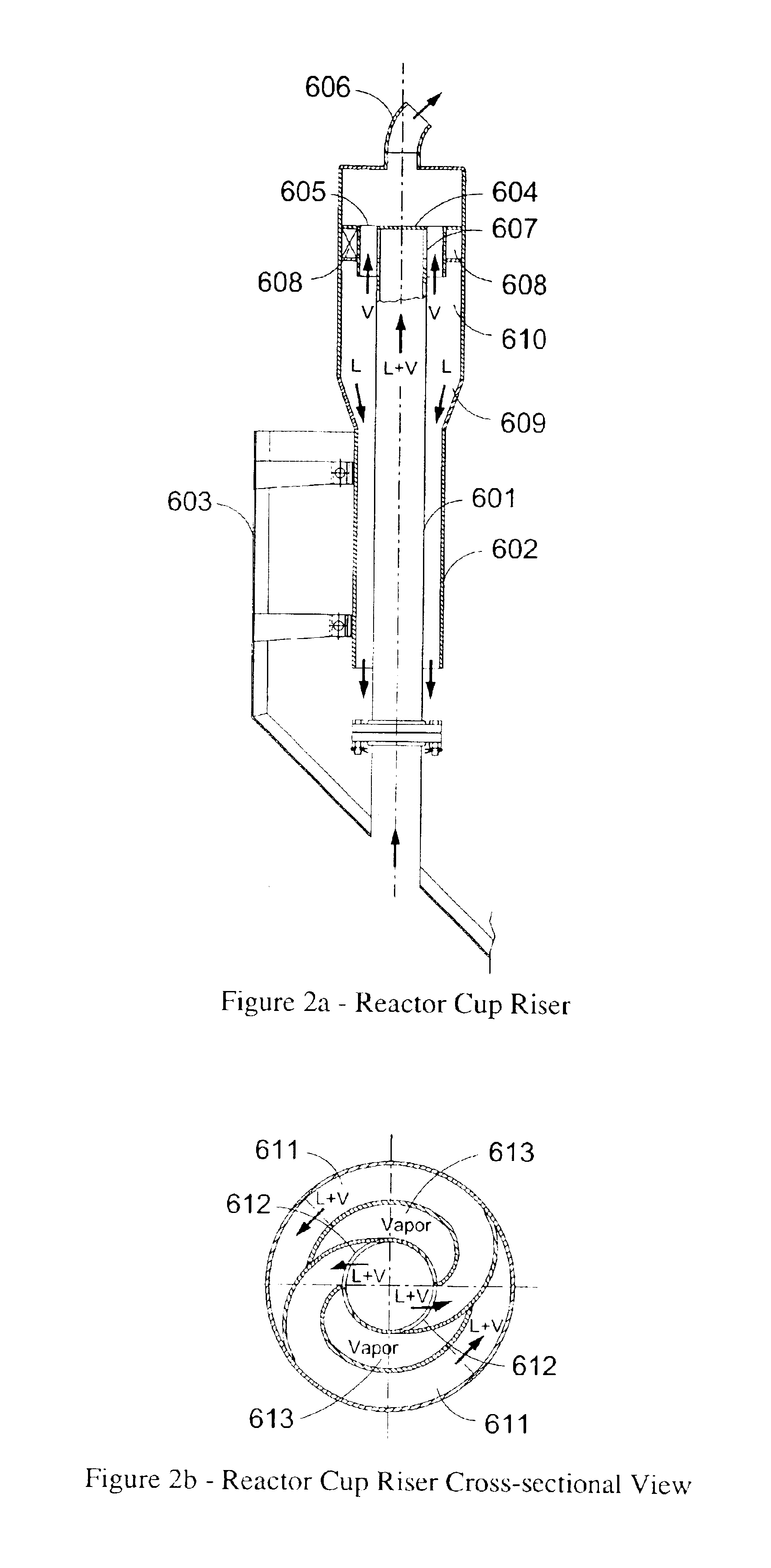

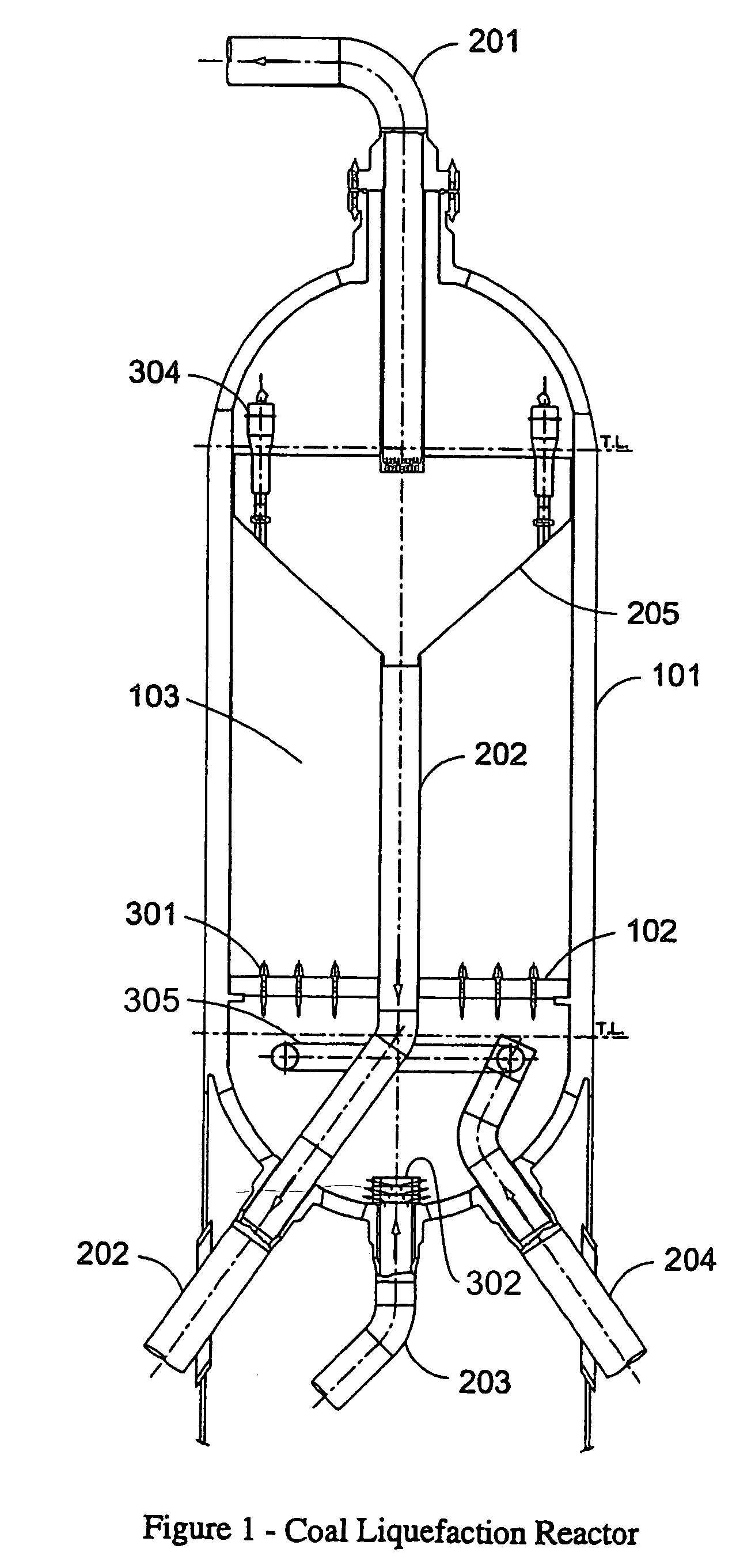

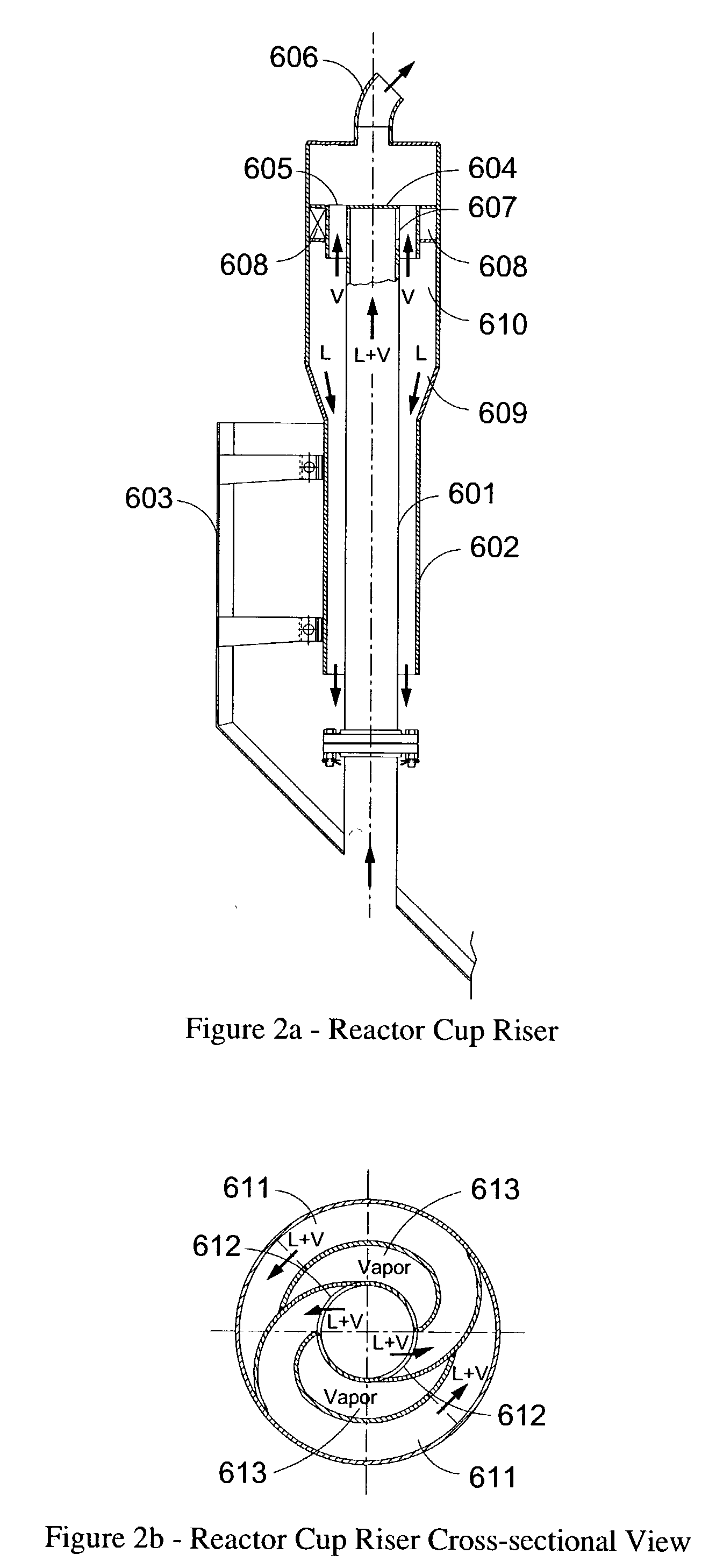

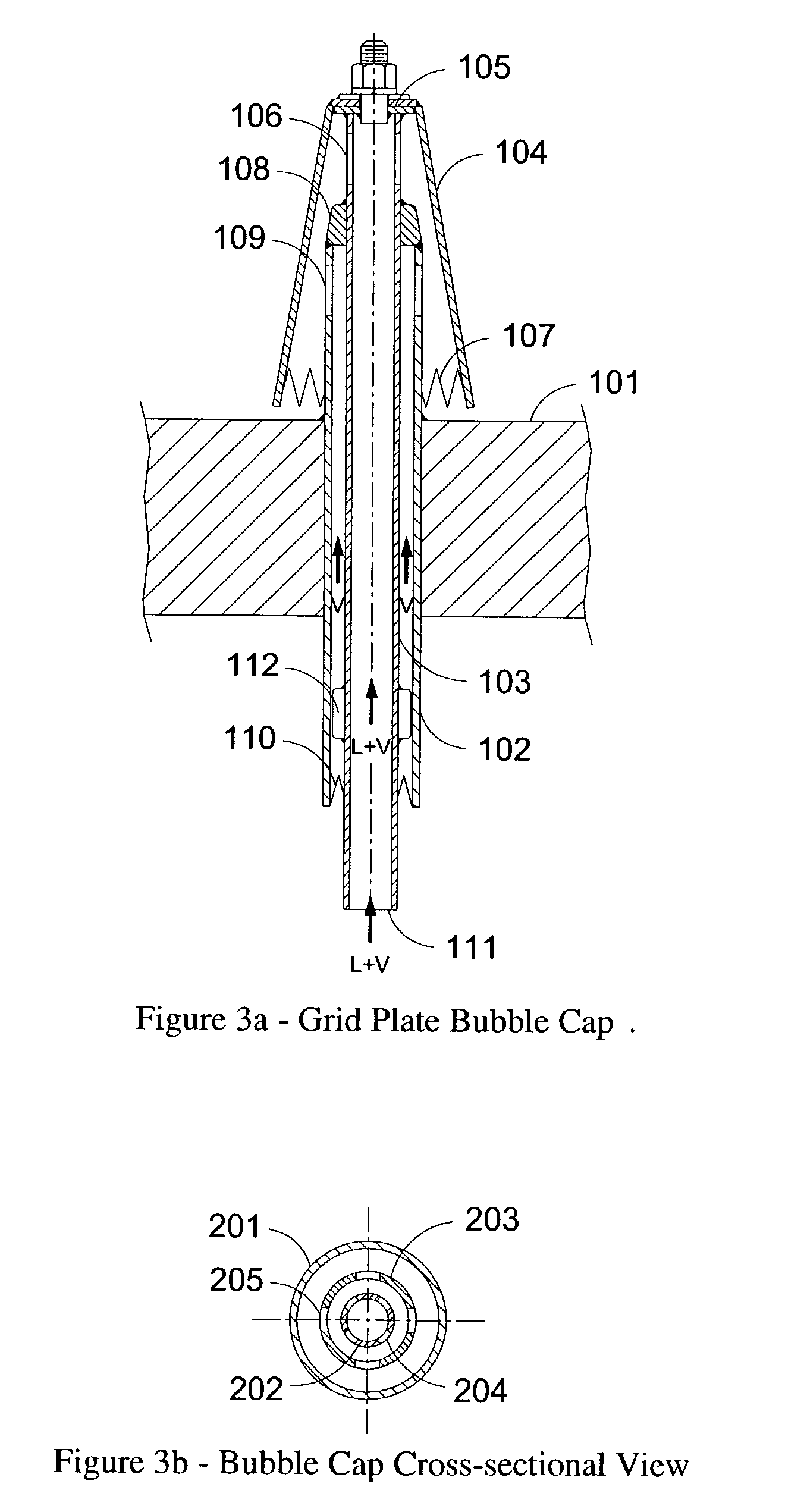

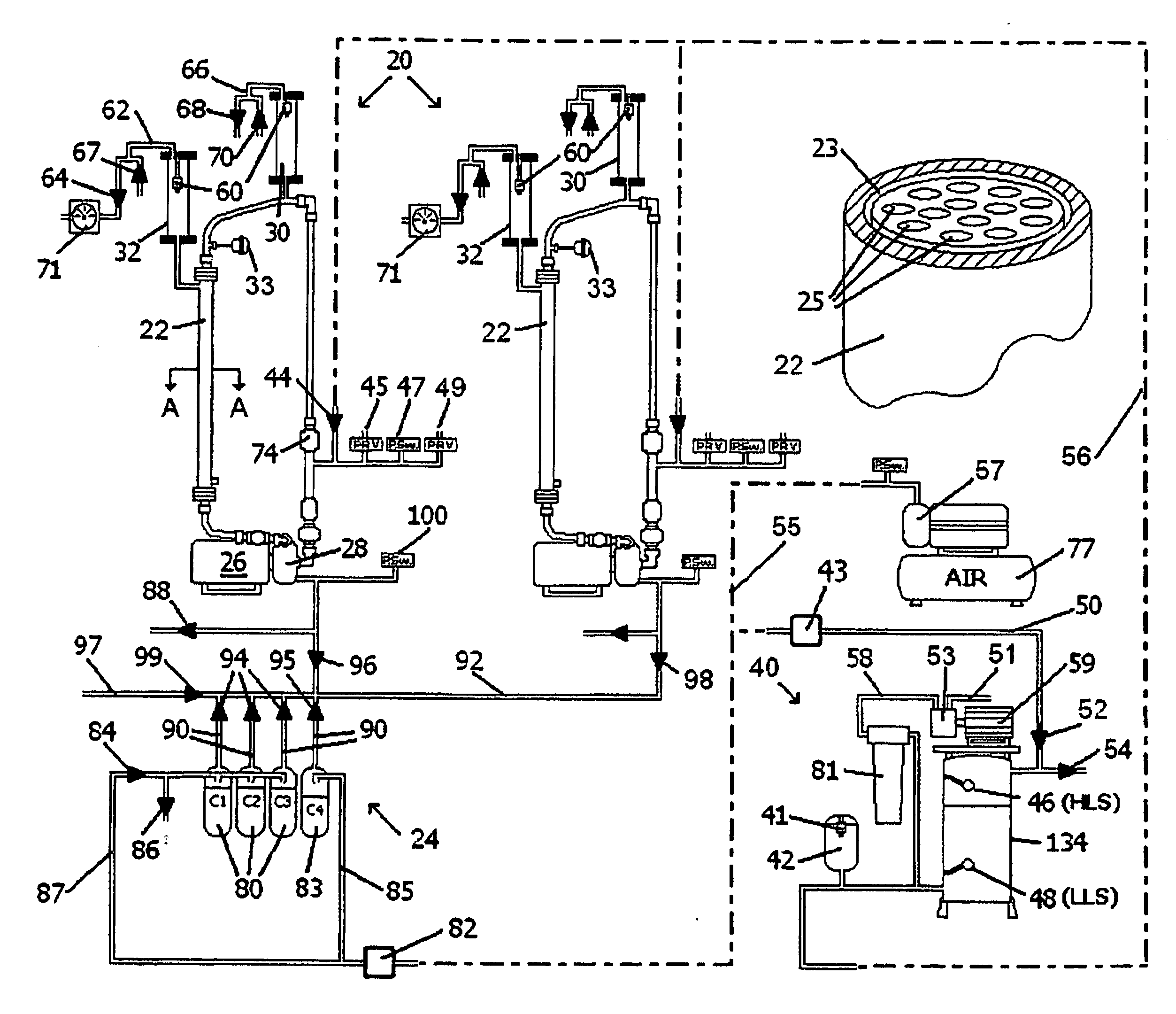

Apparatus for hydrocracking and/or hydrogenating fossil fuels

InactiveUS6960325B2Liquid mixed wellIncrease surface areaCarburetting airUsing liquid separation agentLiquid hydrocarbonsSolid particle

A catalytic hydrocracking reactor vessel for the conversion of a hydrogen gas and fossil fuel feedstream to light liquid hydrocarbons. The reactor vessel comprises reactor cup riser with a helical cyclonic separator conduit for separating a liquid and vapor product stream to provide an essentially vapor-free liquid recycle stream, a grid plate bubble cap with a tapered bell cap wall housing having serrated edges for producing small hydrogen bubbles of increased total surface area of bubbles at lower pressure drop, optionally a feedstream inlet pipe sparger containing rows of downward directed slots for even distribution of the feedstream across the cross-sectional area of the reactor and providing free drain of solid particles from the sparger, and optionally a liquid recycle inlet distributor containing vertically curved plates for creating a whirling motion in the liquid recycle stream for better mixing with the feedstream with minimal solids settling.

Owner:HEADWATERS TECH INNOVATION LLC +1

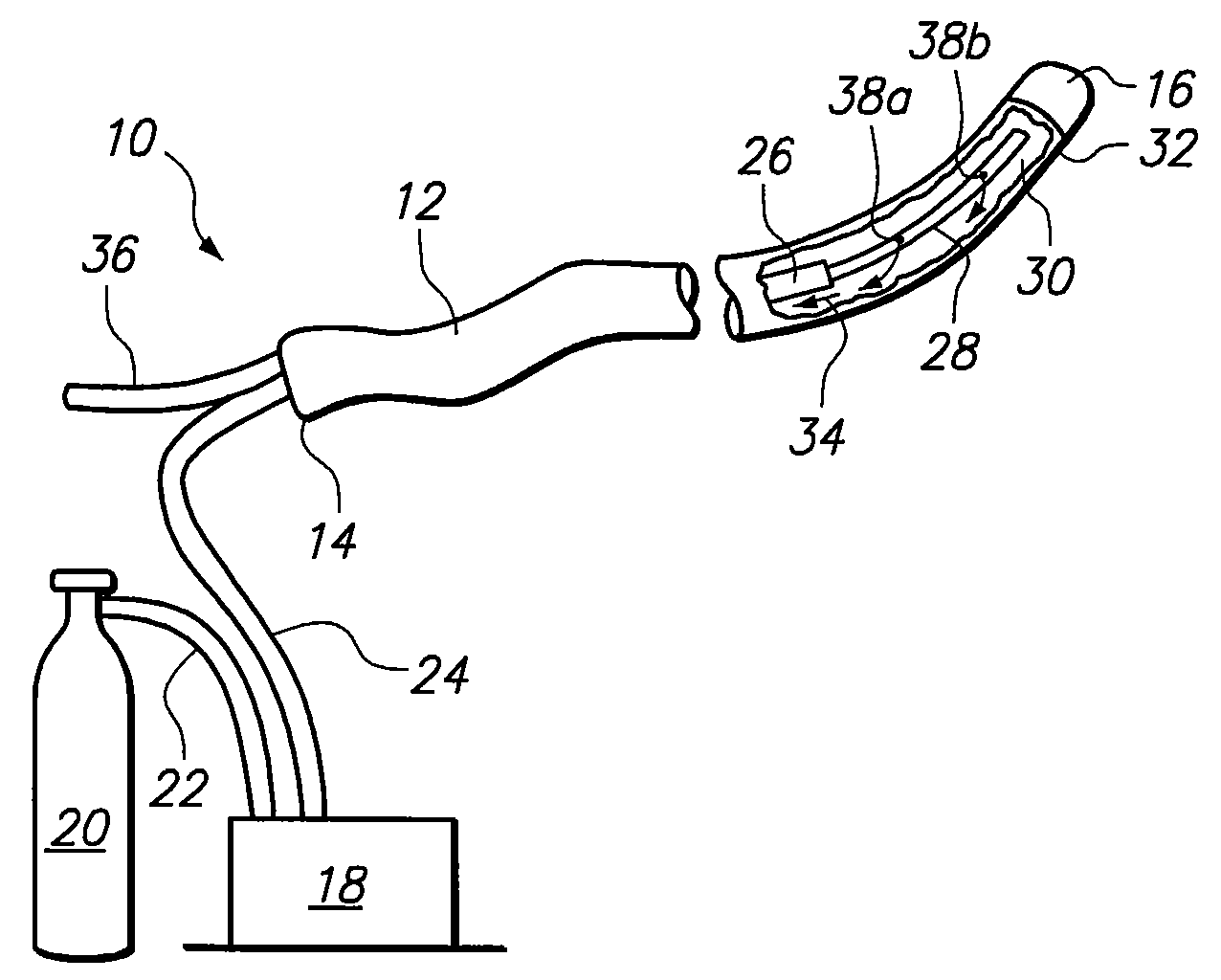

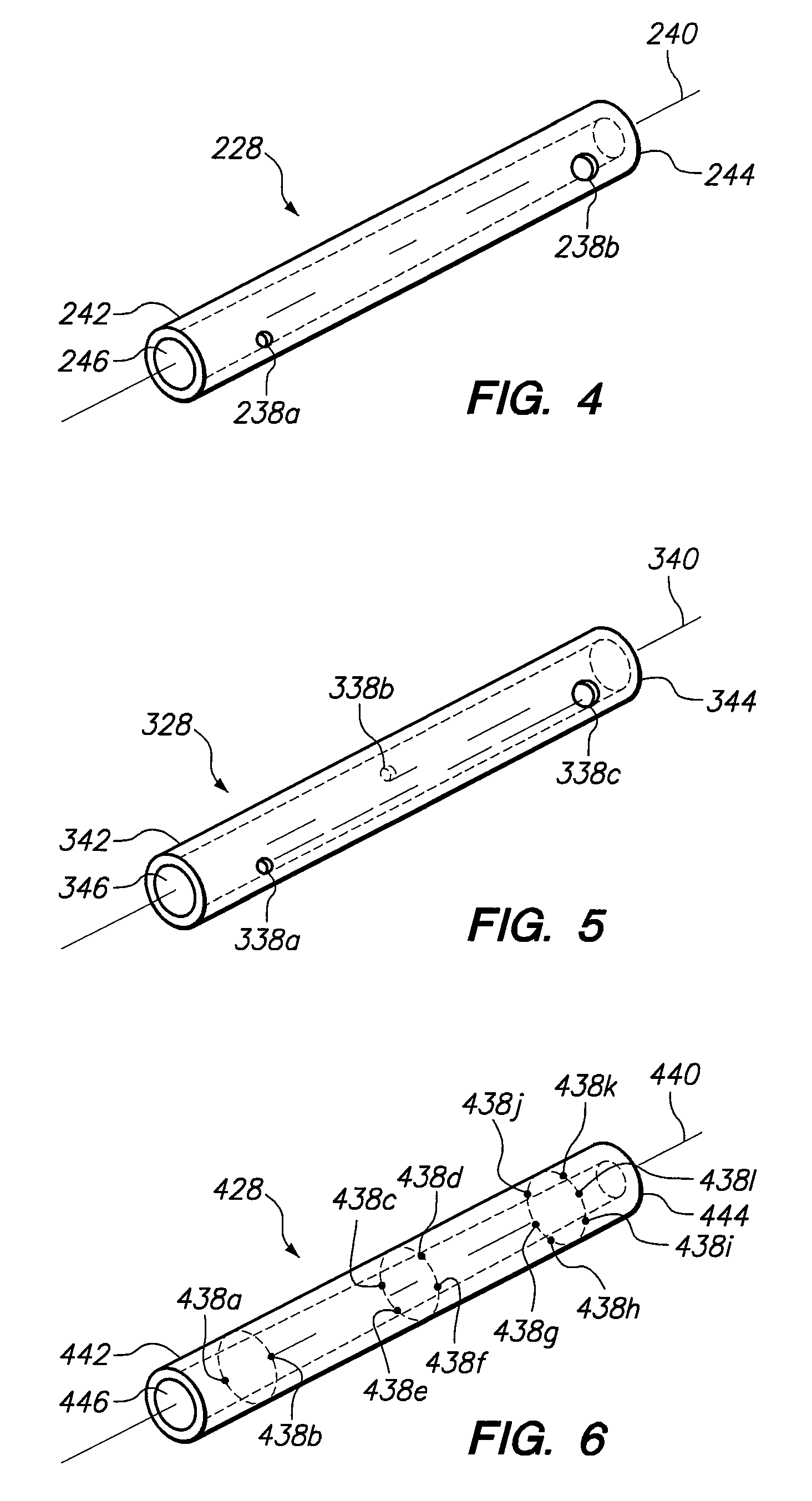

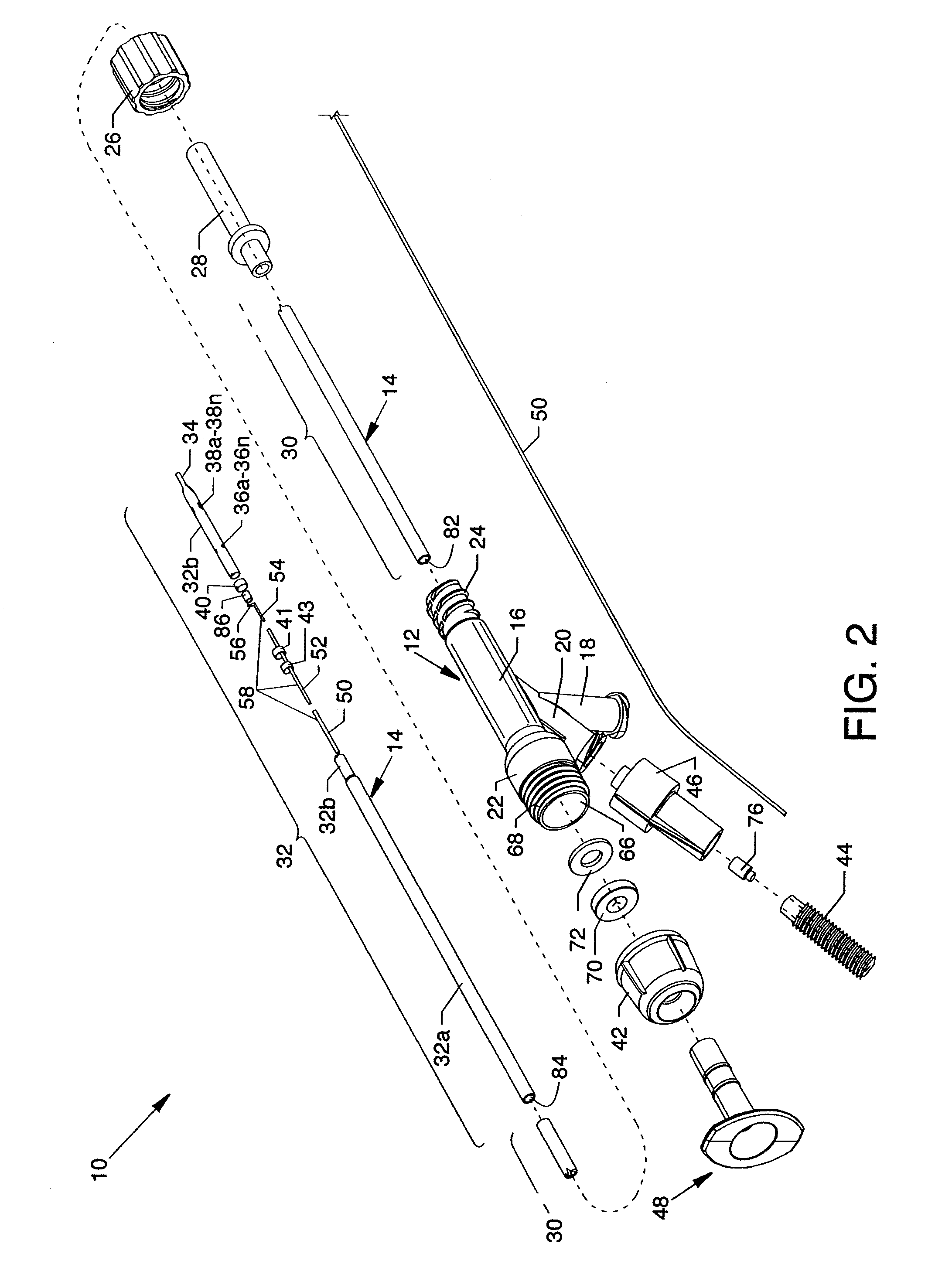

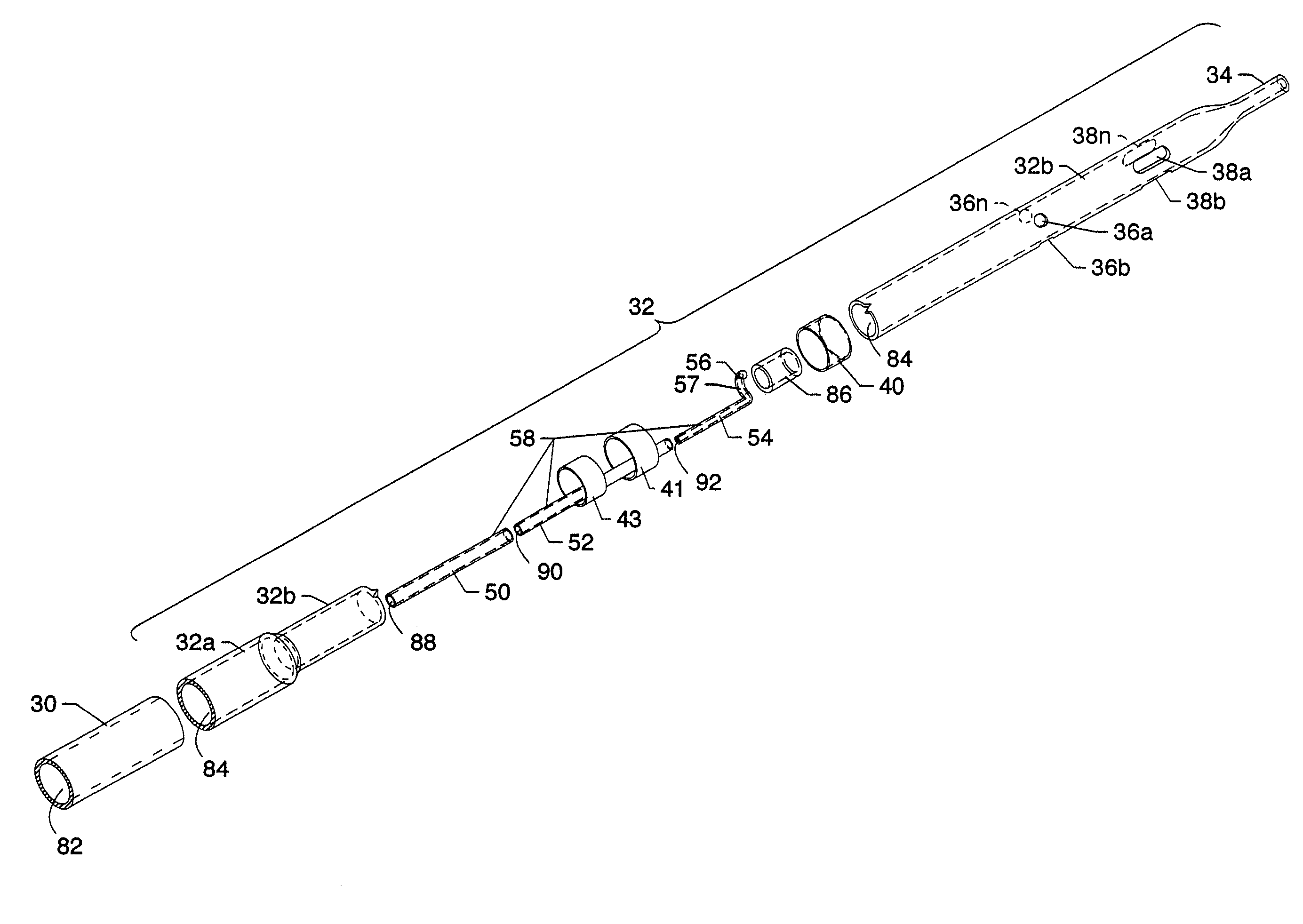

Miniature flexible thrombectomy catheter

ActiveUS20080188831A1Maximize thrombectomy actionGood effectGuide wiresFluid jet surgical cuttersDistal portionGuide tube

The present invention pertains to a miniature flexible thrombectomy catheter having one or more flexible miniature noncollapsing tubular portions including pushable and torqueable structure for introduction into the smaller vessels in neurovascular regions. A jet body having an arcuate fluid jet emanator is incorporated in order to minimize size at the distal portion of a minimally sized catheter tube.

Owner:BOSTON SCI LTD

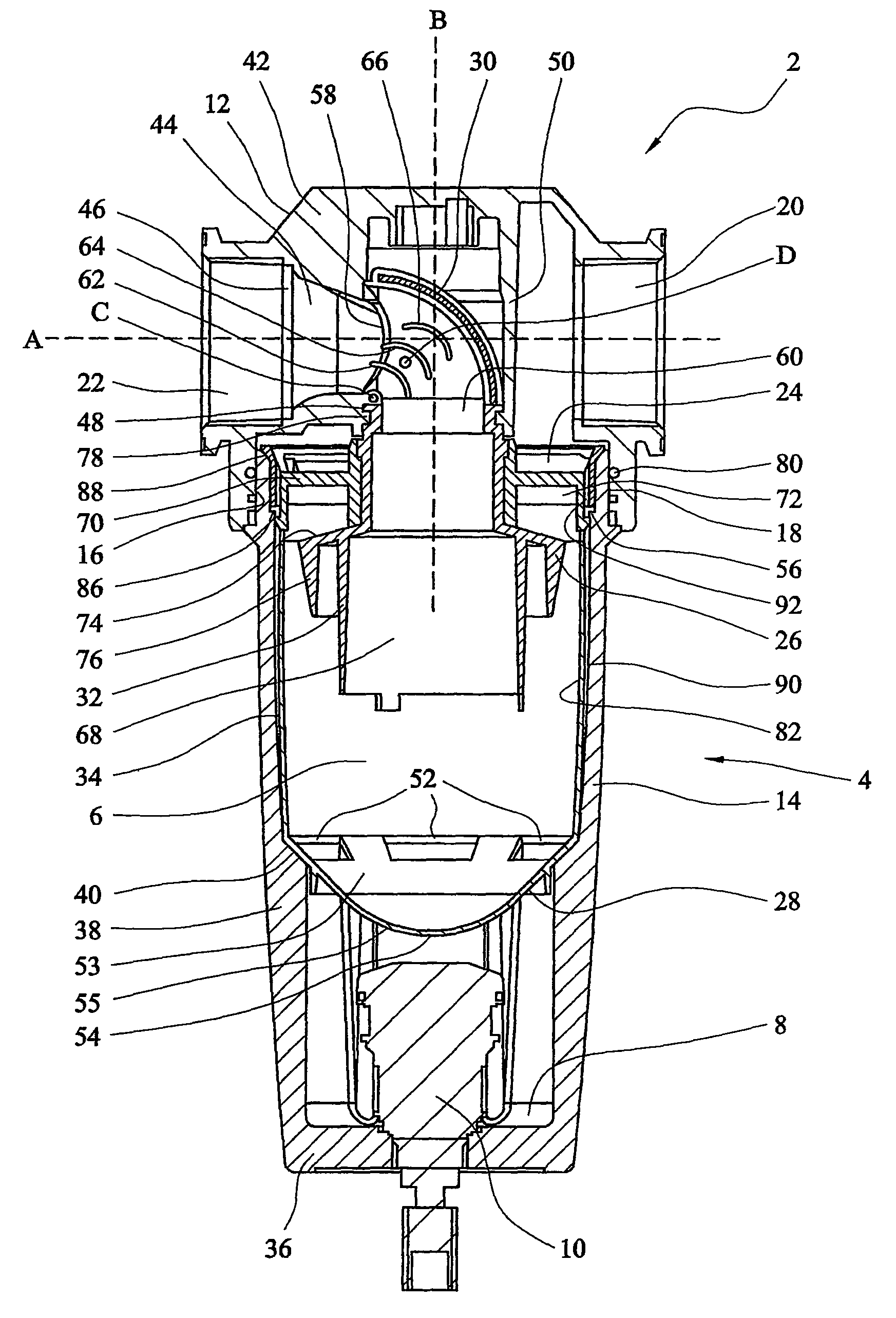

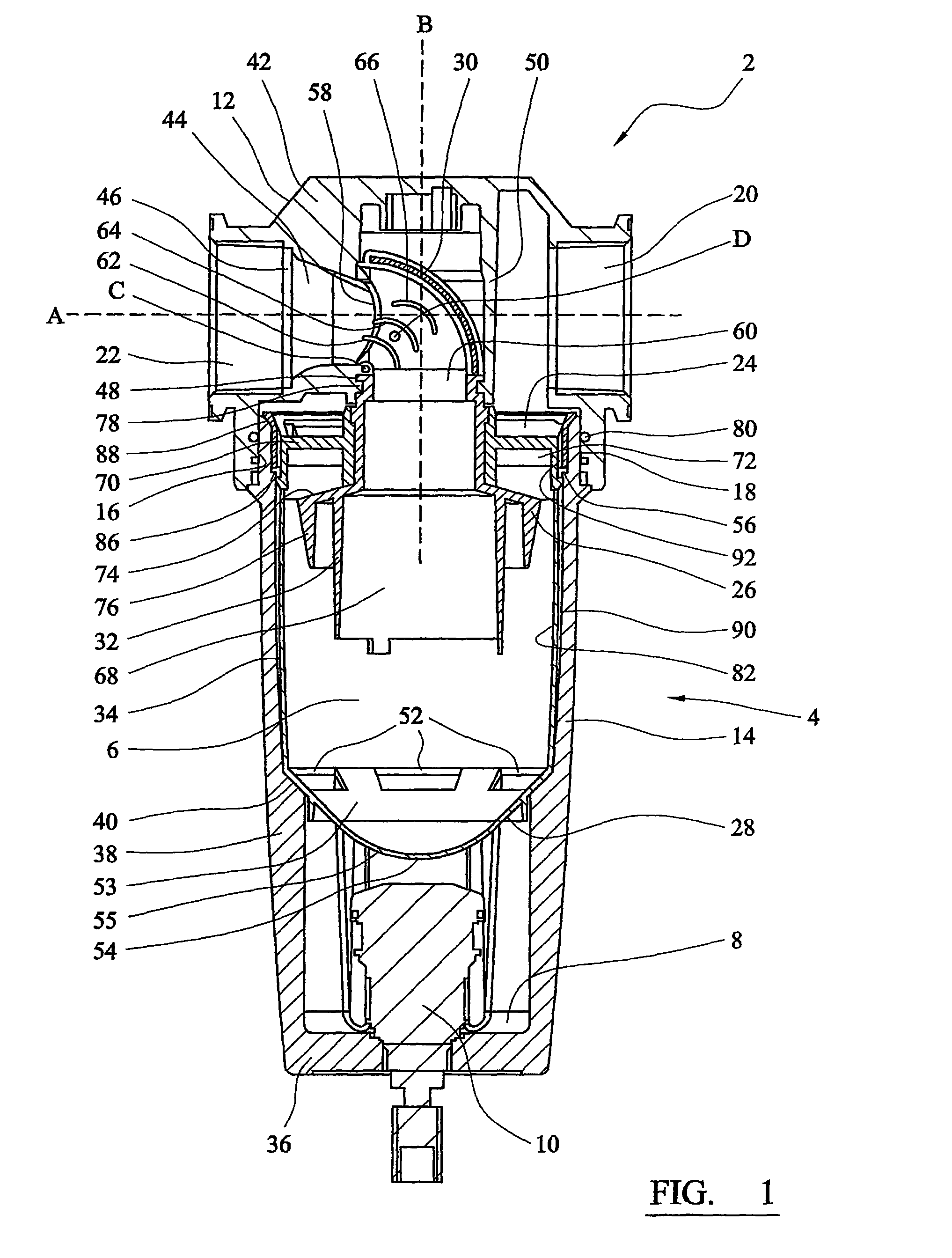

Separator assembly

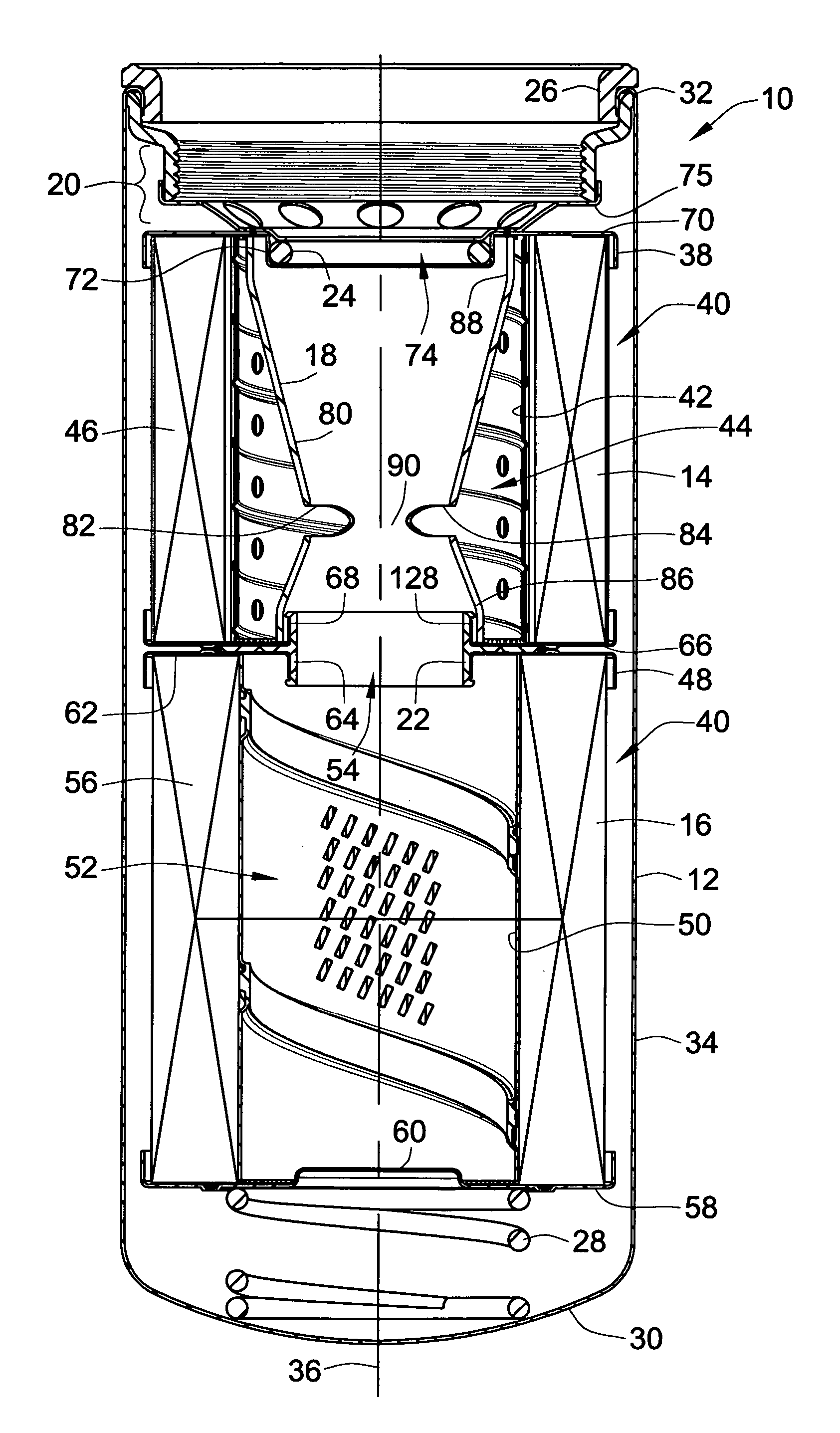

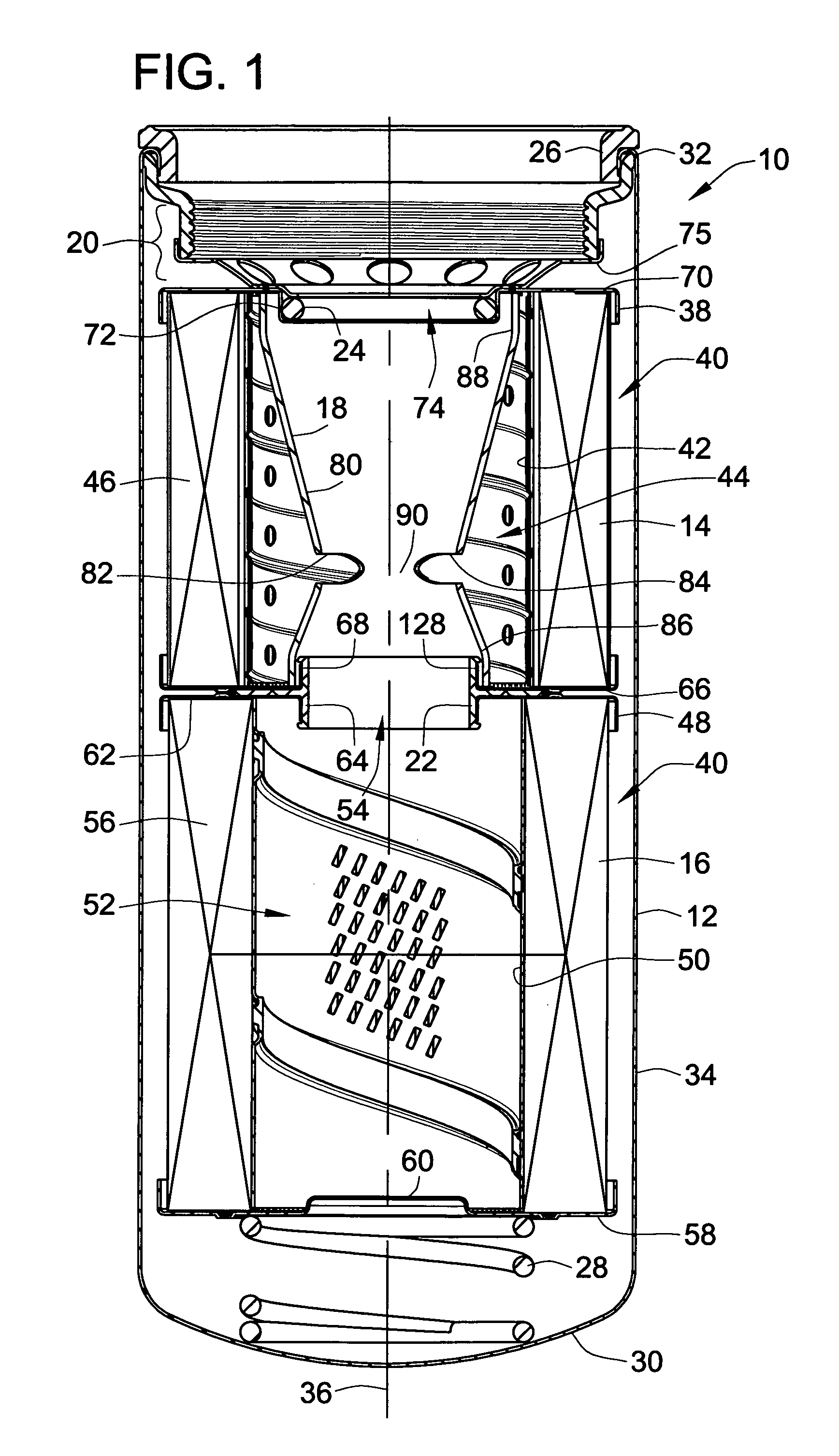

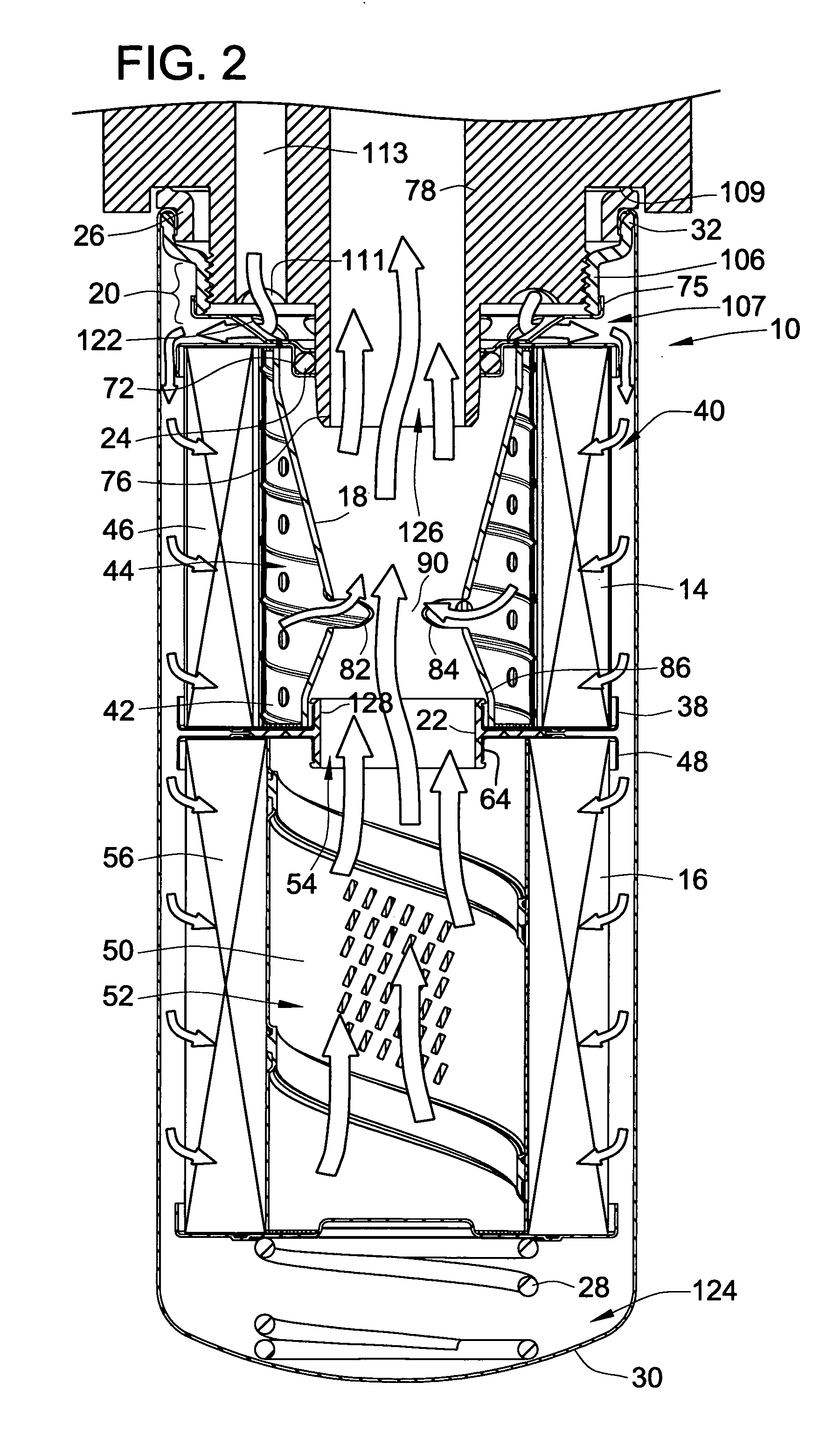

ActiveUS7766989B2Improve efficiencyReducing re-entrainmentCombination devicesAuxillary pretreatmentEngineeringAirflow

A separator assembly for removing material that is entrained in a gas stream. The separator assembly comprises a housing having a head part which provides the upper end of the housing and a body part which provides the lower end of the housing. The separator assembly also comprises a shield which extends across the housing towards the lower end thereof so as to leave a collection space between it and the lower end in which material that is separated from the gas stream can collect. There is at least one opening in or around the shield through which the material can flow past the shield into the collection space. The separator assembly further comprises a liner sleeve which covers at least a part of the inside wall of the body part between the shield and the upper end of the body part.

Owner:PARKER HANNIFIN LTD HEMEL HEMPSTEAD

Miniature flexible thrombectomy catheter

InactiveUS20080188793A1Efficient and reliable and less-costlyImprove pushabilityCannulasCatheterDistal portionBlood vessel

The present invention pertains to a miniature flexible thrombectomy catheter having one or more flexible miniature noncollapsing tubular portions including pushable and torqueable structure for introduction into the smaller vessels in neurovascular regions. A jet body having an arcuate fluid jet emanator is incorporated in order to minimize size at the distal portion of a minimally sized catheter tube.

Owner:MEDRAD INC.

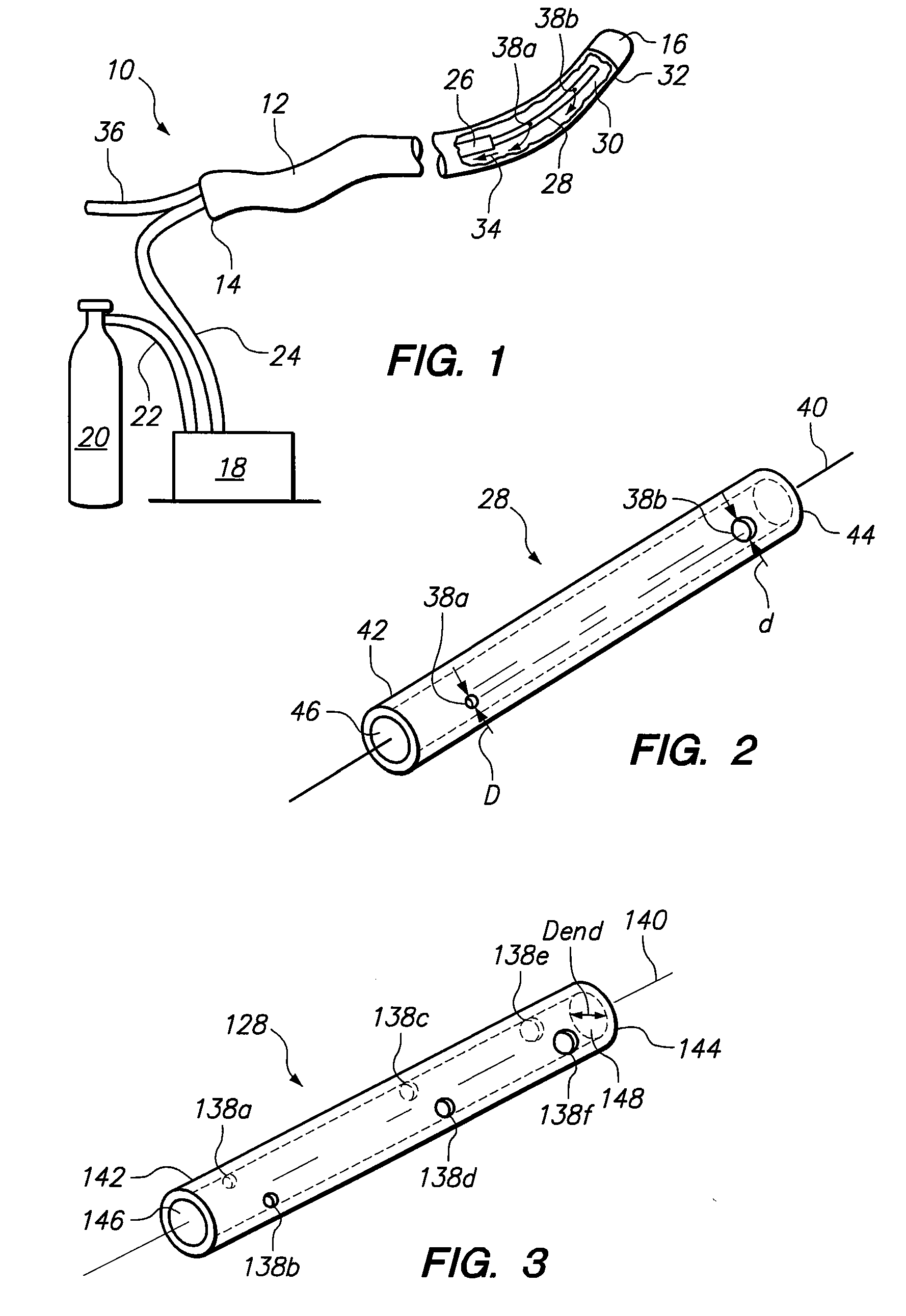

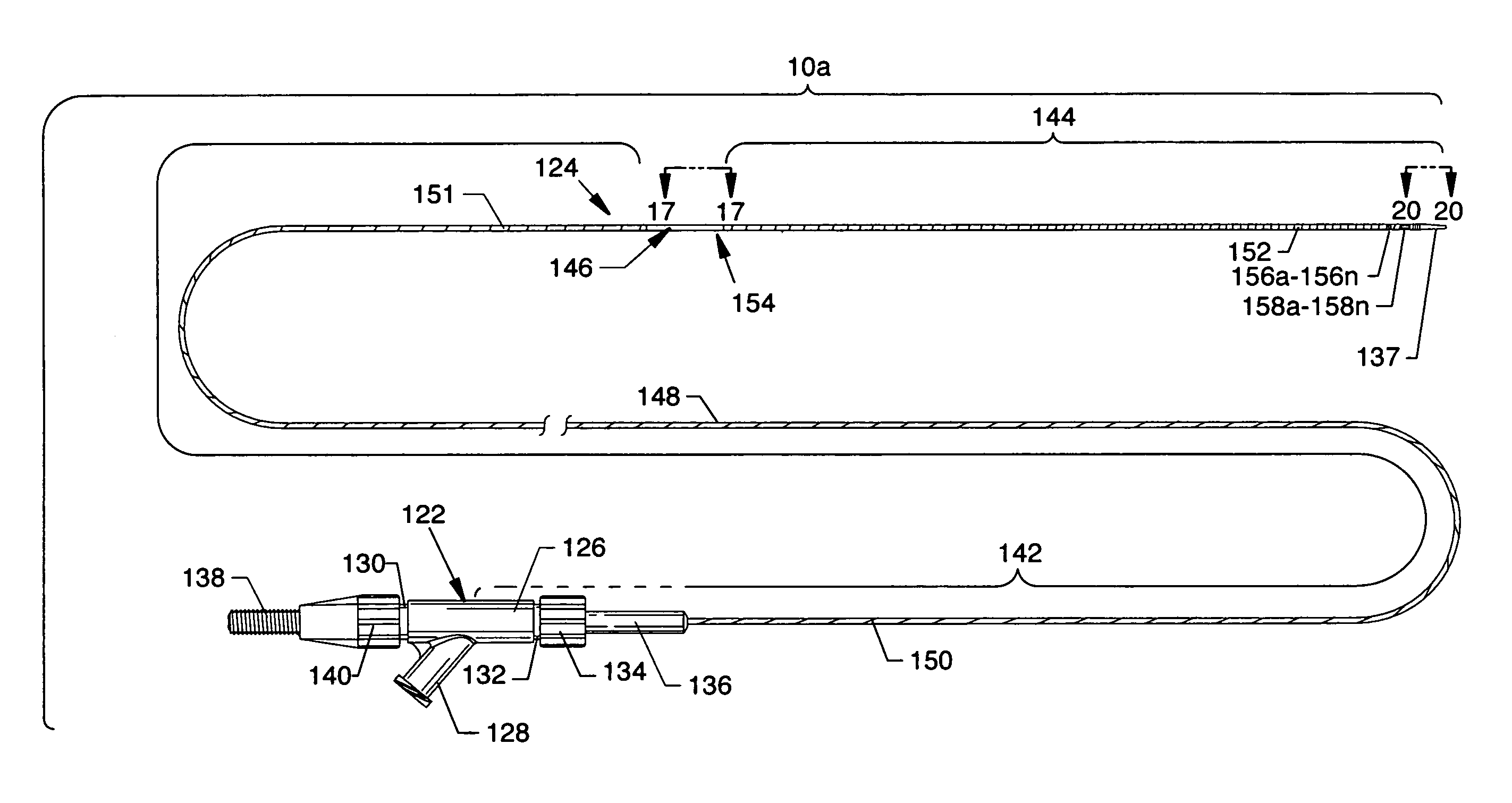

Cryoablation segment for creating linear lesions

ActiveUS20080300584A1Reduce the cross-sectional areaLess pressure dropCatheterSurgical instruments for coolingFrozen tissueRefrigerant

An applicator for cryoablating tissue to form linear (i.e. straight line and curvilinear) lesions in targeted tissue includes a fluid refrigerant delivery system having a source of a fluid refrigerant and a tubular cryoablation segment. Structurally, the segment has an open proximal end and a distal end, and is formed with a lumen. Also, the segment is formed with at least one distal port and at least one proximal port, with each port connected in fluid communication with the segment's lumen. The proximal end of the tubular segment is operably connected in fluid communication with the source of fluid refrigerant. For the system, the ports can be selectively sized to outflow liquid refrigerant through the distal and proximal ports at a substantially same mass flow rate.

Owner:CRYOCOR

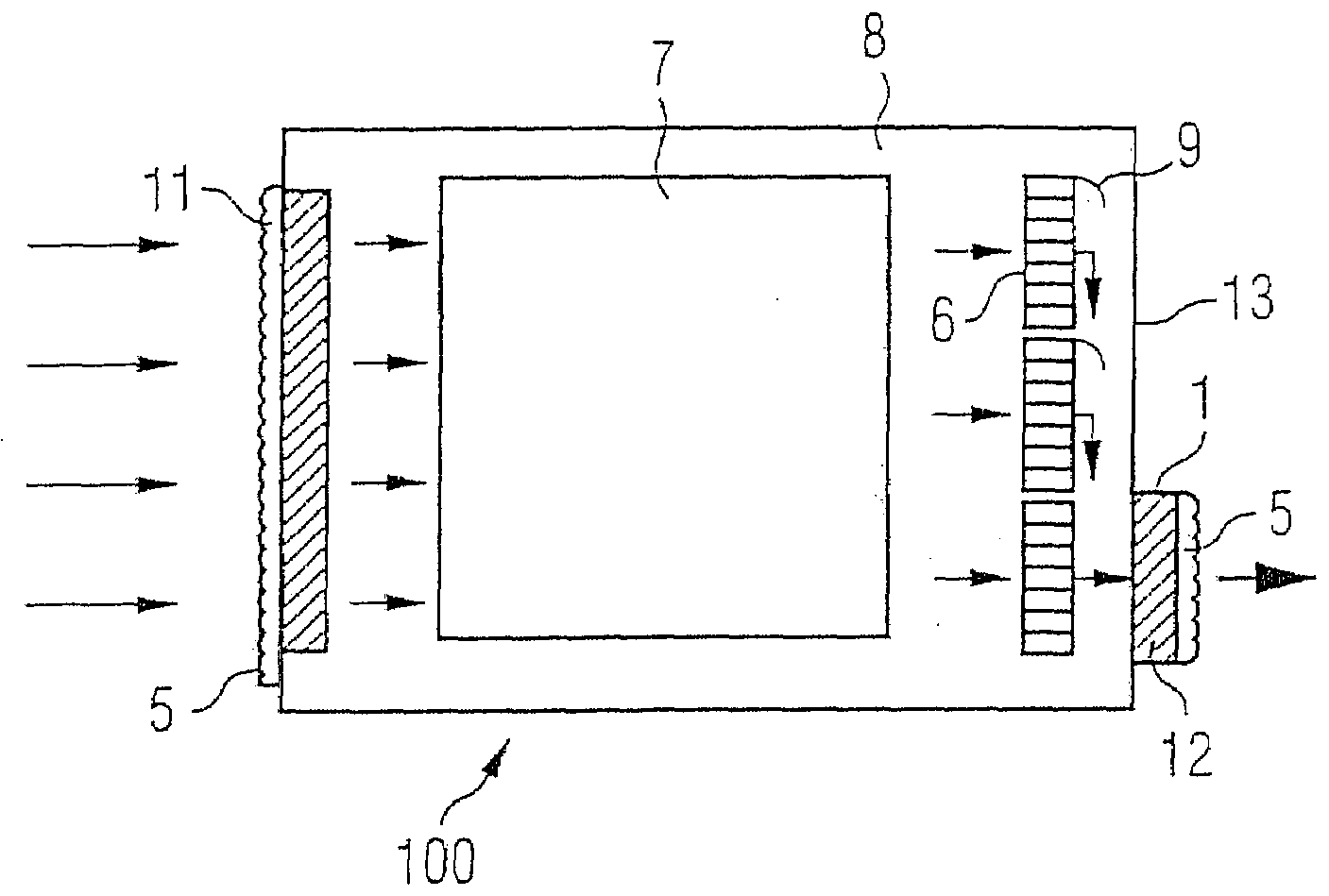

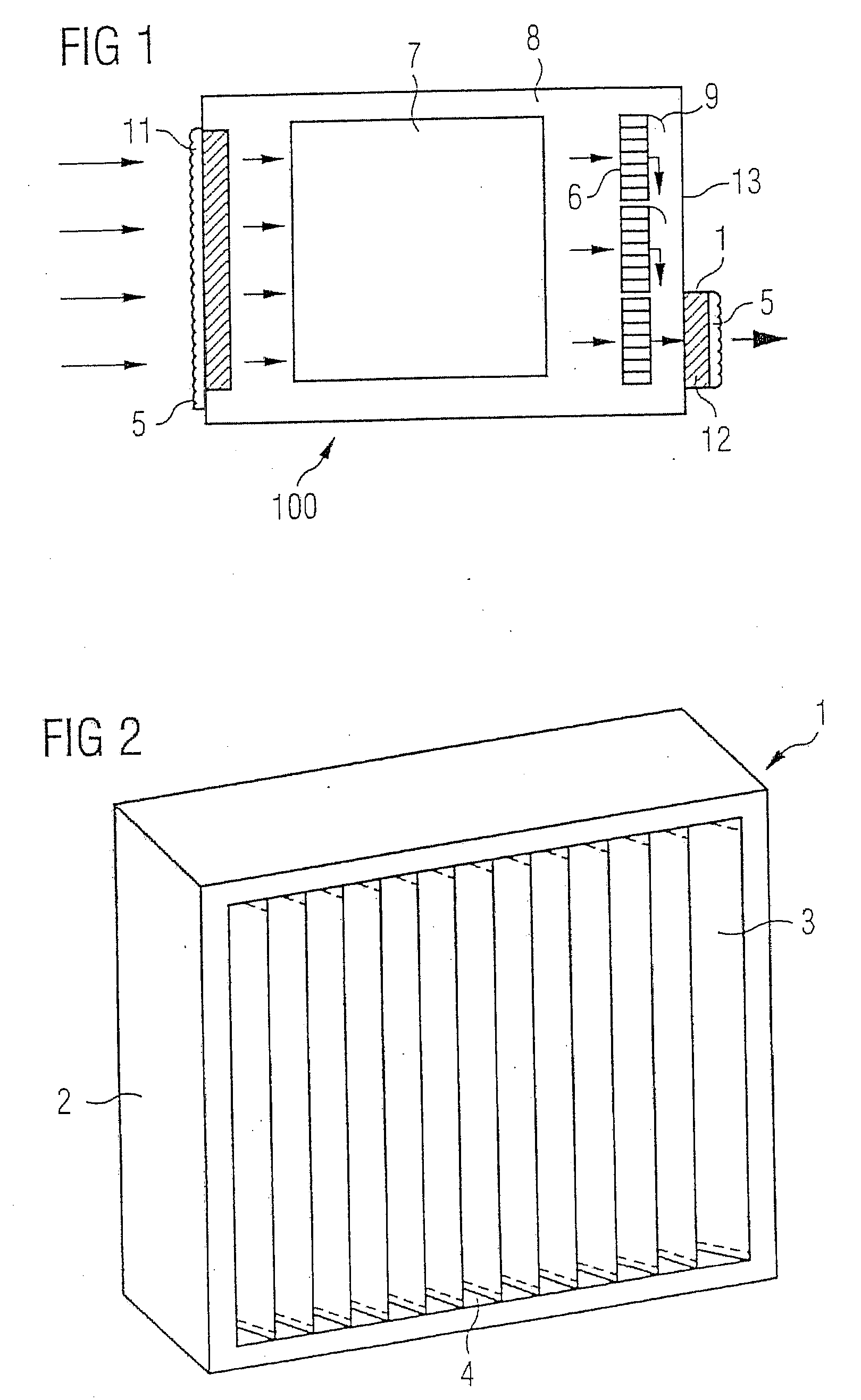

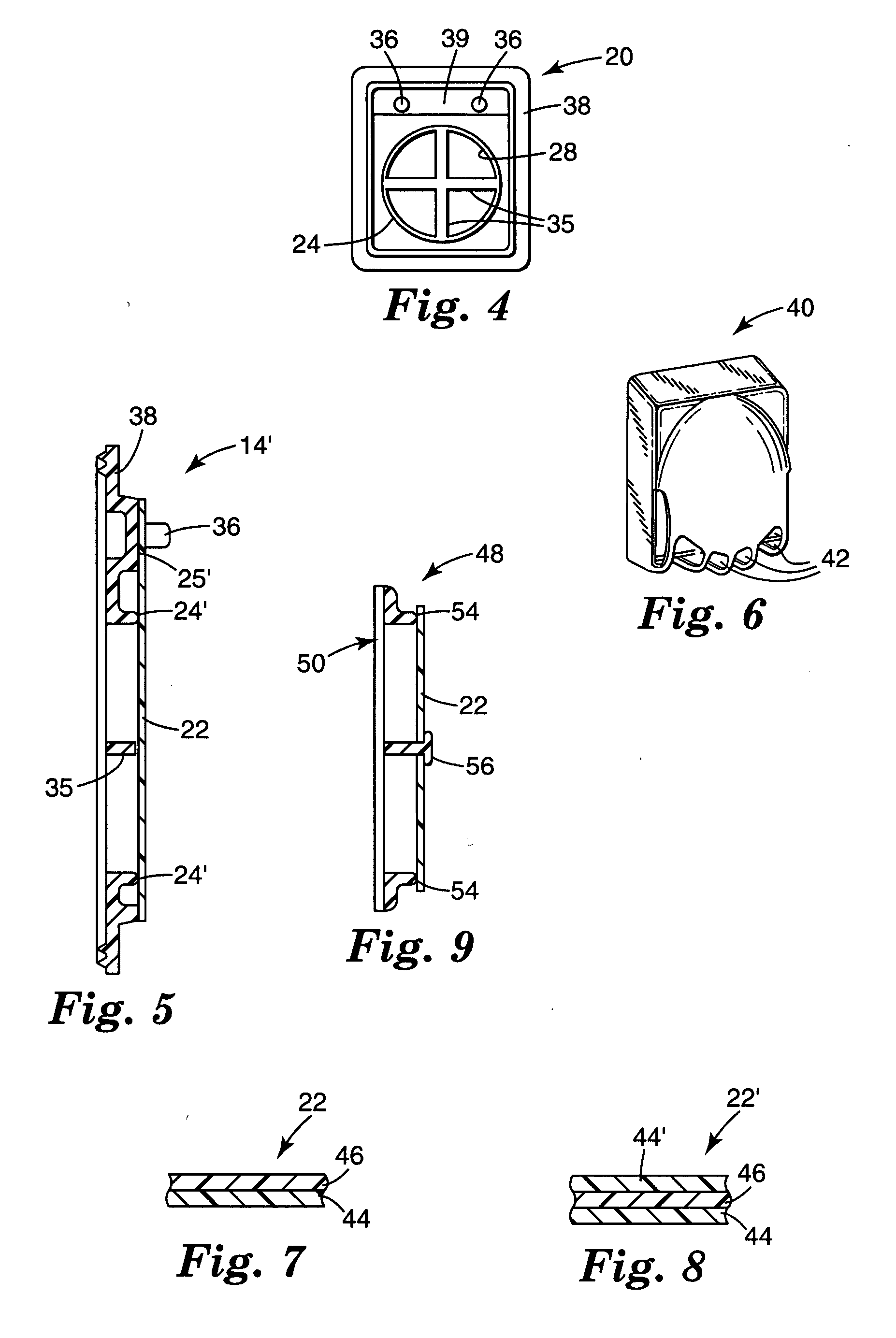

Fan cooling unit for cooling electronic components

InactiveUS20090139405A1Improve filtering effectEasy to chargeElectrostatic separationFiltration separationFiberEngineering

A fan cooling unit (10) for cooling electronic components, such as for an air-cooled telecommunications base station, comprises a protective covering for at least the air inlet opening (11) of a casing (8) in which the electronic components are housed. The protective covering (1) has a frame (2) into which a composite filter media (3) is mounted so as to create an air-tight fit. The composite filter media (3) comprises a membrane filtration layer (20) with a porous polymeric membrane, such as expanded polytetrafluoroethylene (ePTFE), and at least one depth filtration layer (18) disposed on an upstream side of the membrane filtration layer (20). The depth filtration media layer comprises fibers having an electrostatic charge. The ePTFE membrane is preferably made from a blend of a PTFE homopolymer and a modified PTFE polymer.

Owner:SCHWARZ ROBERT +3

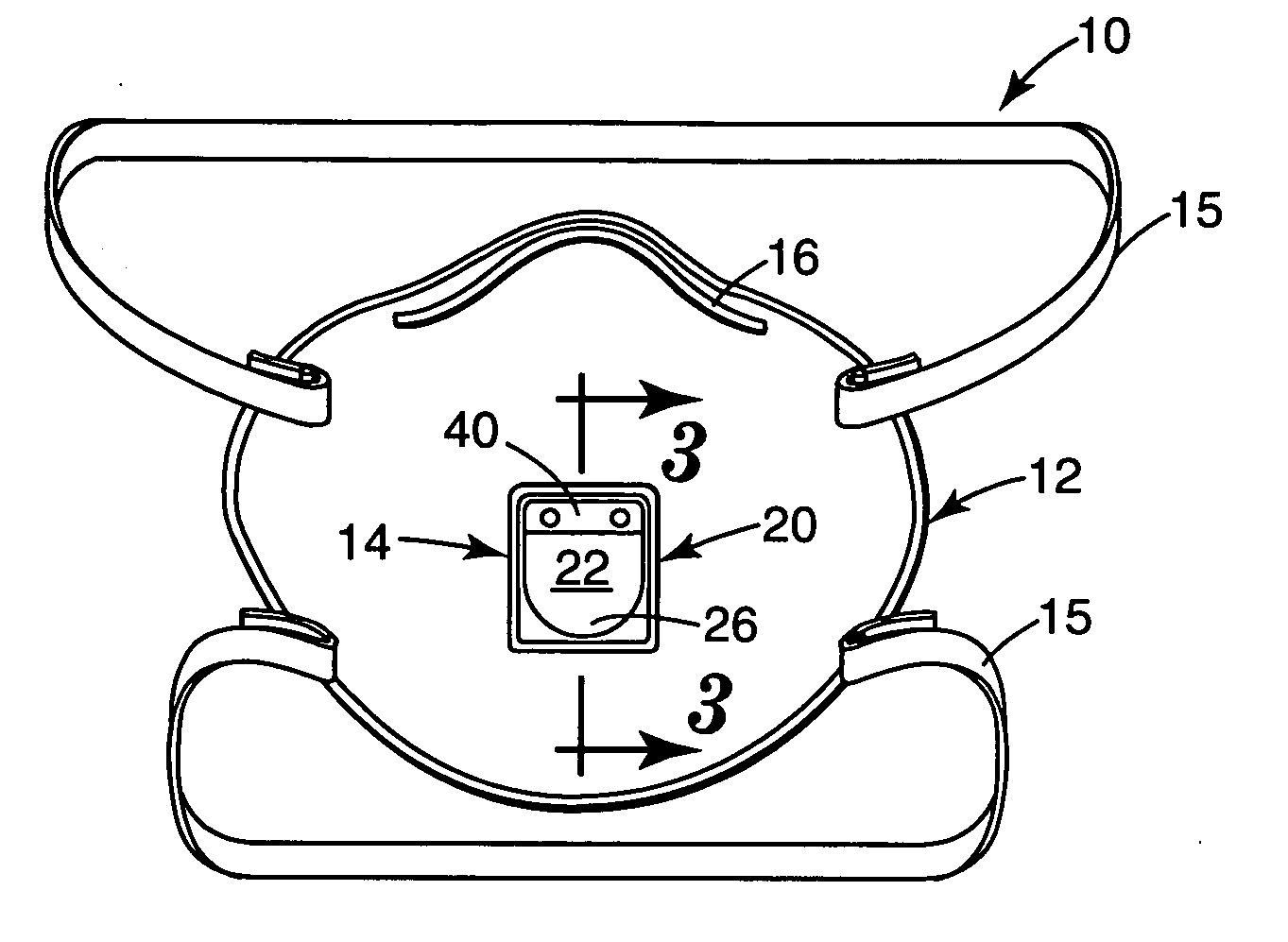

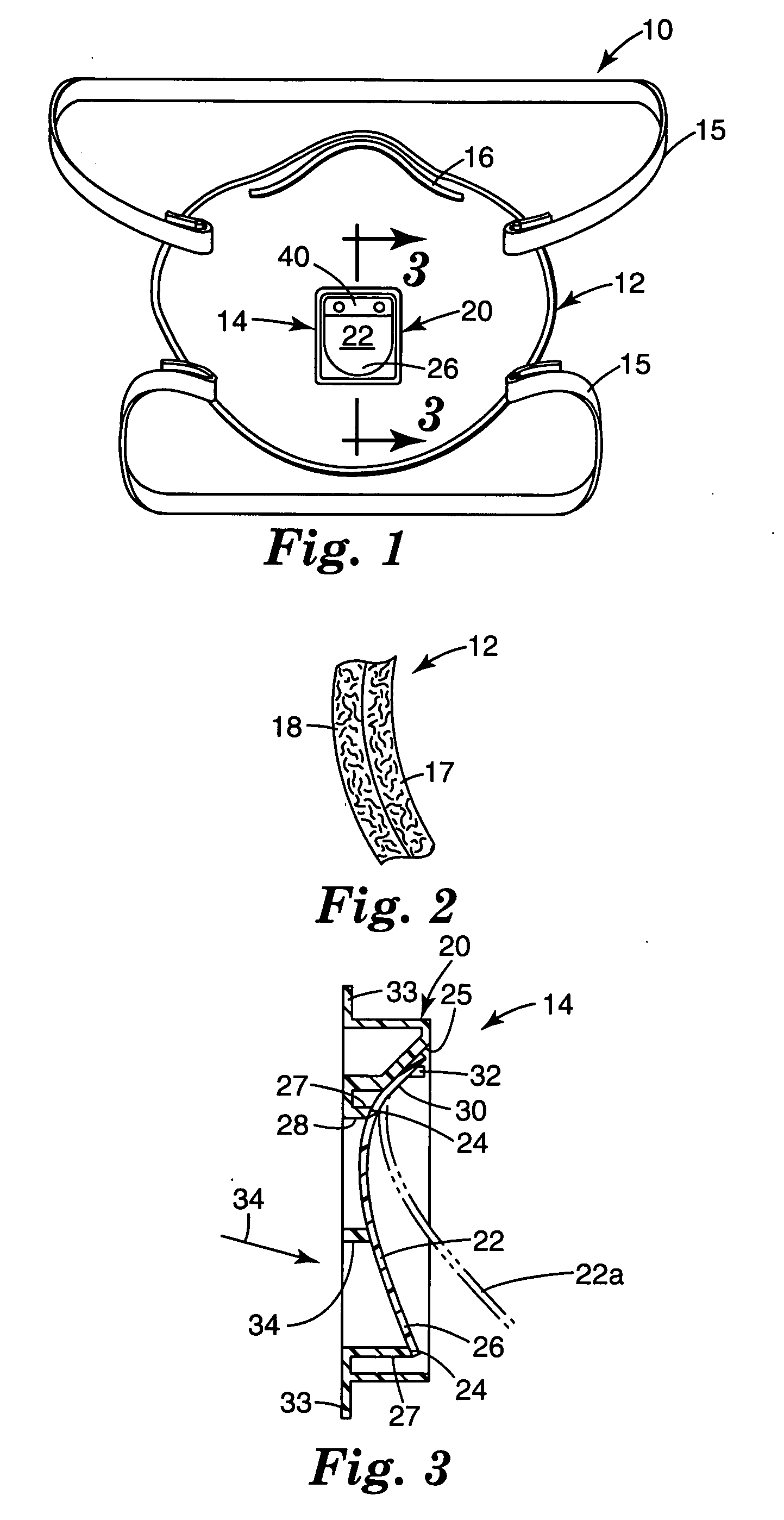

Exhalation and inhalation valves that have a multi-layered flexible flap

InactiveUS20050155607A1Improve comfortEasy to openBreathing filtersBreathing masksEngineeringRespiratory mask

Exhalation and inhalation valves that are sized and adapted to fit on a mask body of a personal respiratory protection device. The exhalation and inhalation valves comprise a valve seat that has a seal surface and an orifice through which an exhale flow stream may pass to leave the interior gas space. A flexible flap is mounted to the valve seat such that the flap makes contact with the seal surface when the valve is in its closed position and such that the flap can flex away from the seal surface during an exhalation to allow exhaled air to pass through the orifice to ultimately enter an exterior gas space. The flexible flap has at least first and second juxtaposed layers where at least one of the layers is stiffer or has a different elastic modulus than the other layer. These valves provide extraordinarily lower pressure drop in use, and they operate more efficiently and require less actuation power to operate. The end user therefore derives greater comfort when wearing a respiratory mask that uses the inventive valve.

Owner:3M INNOVATIVE PROPERTIES CO

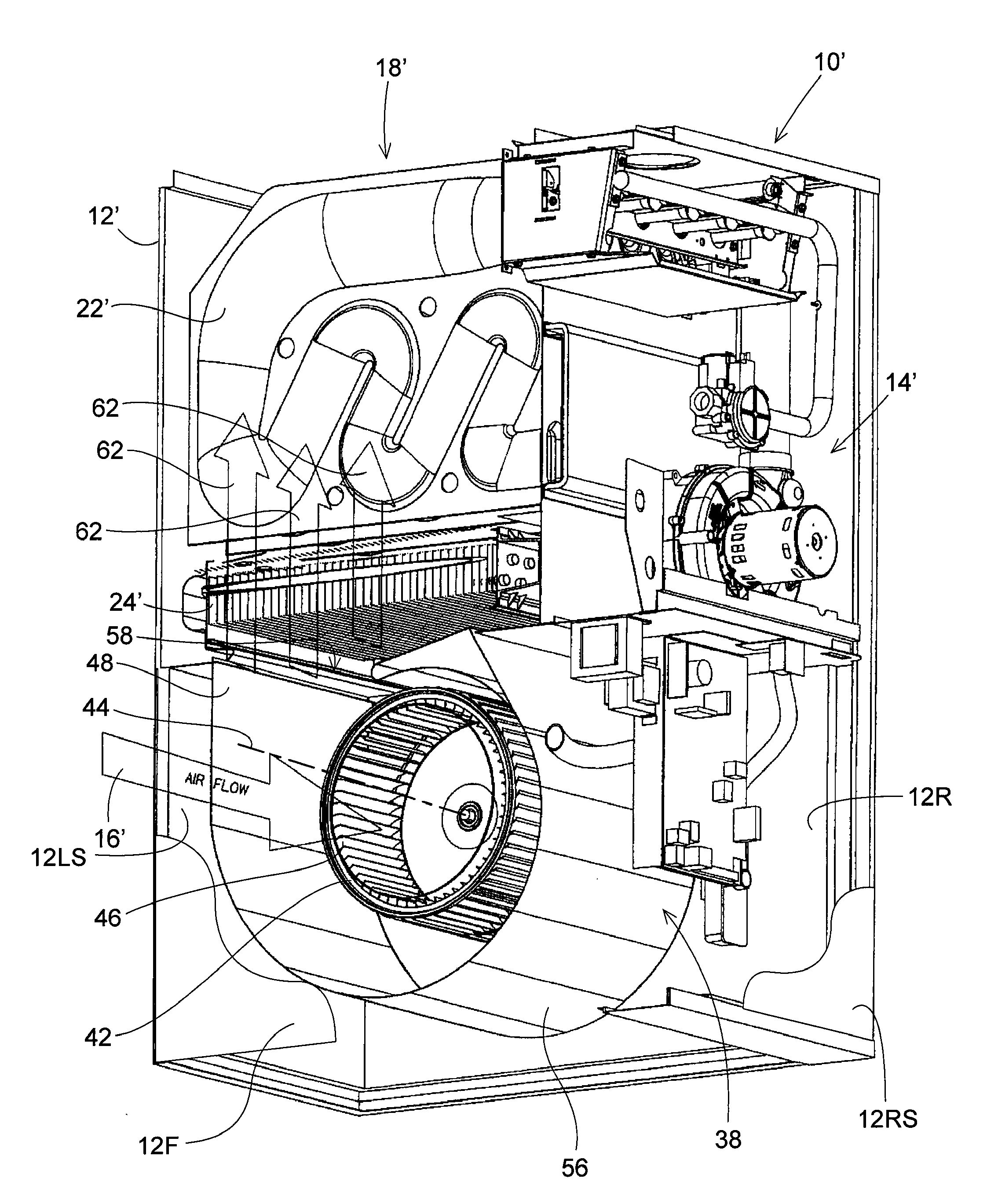

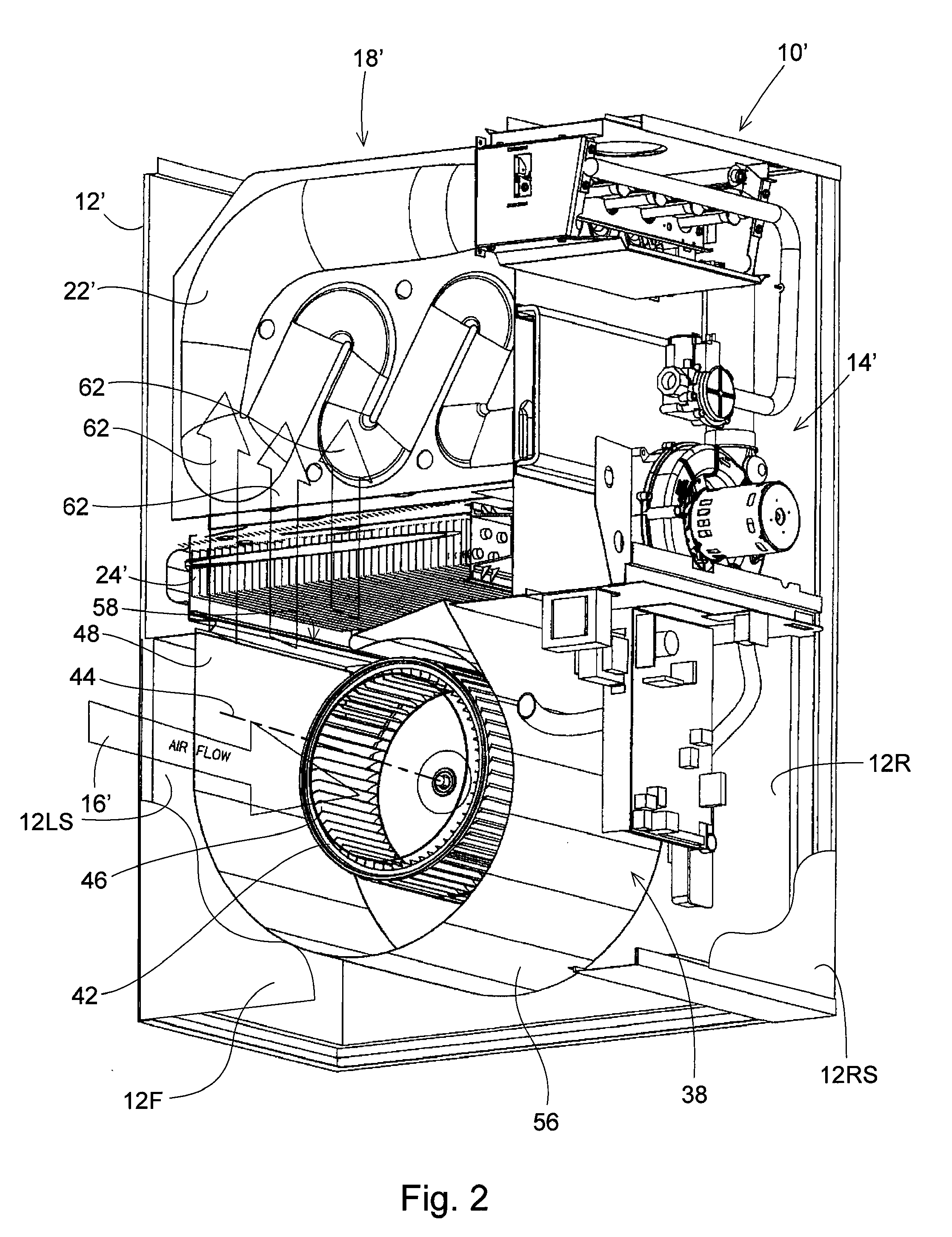

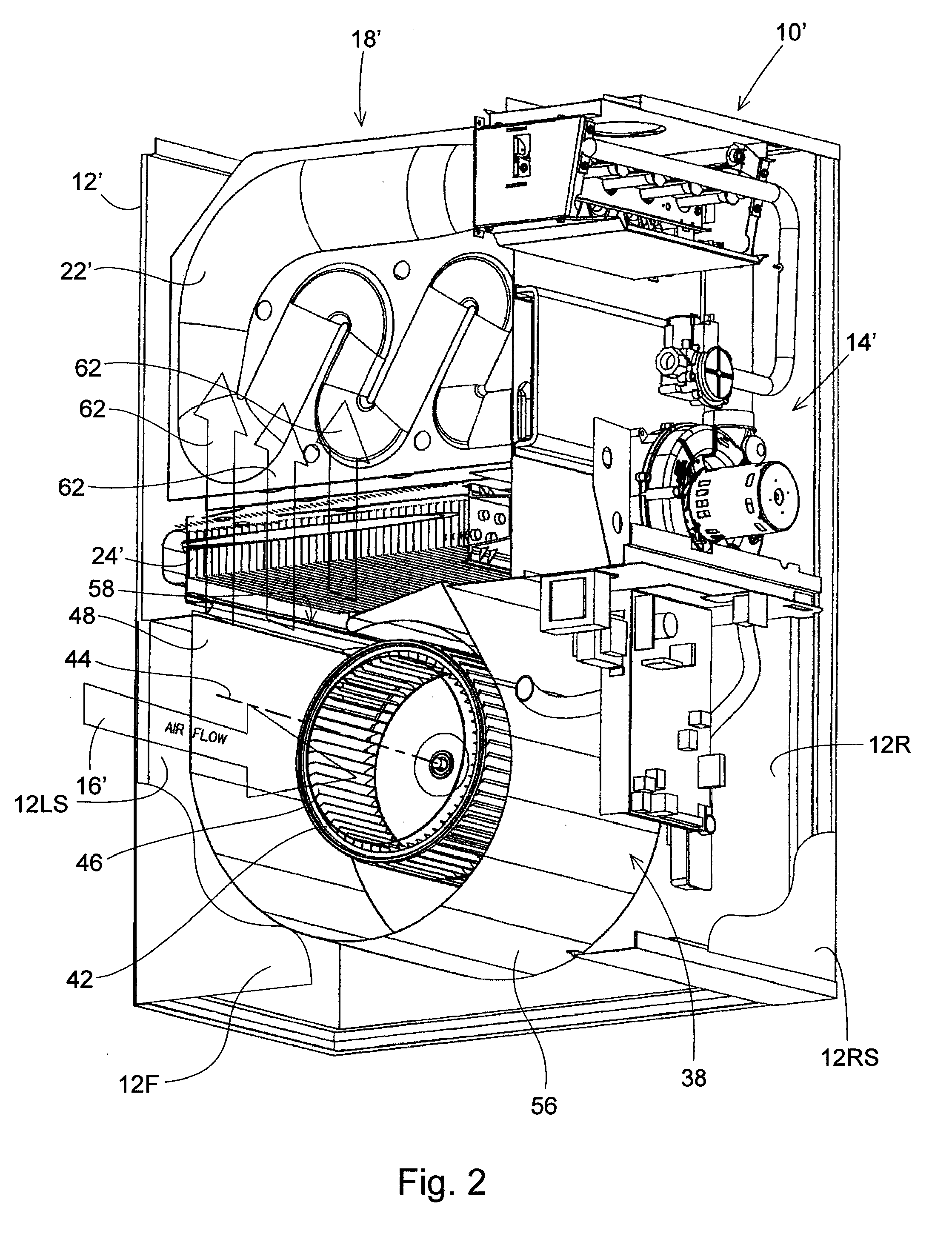

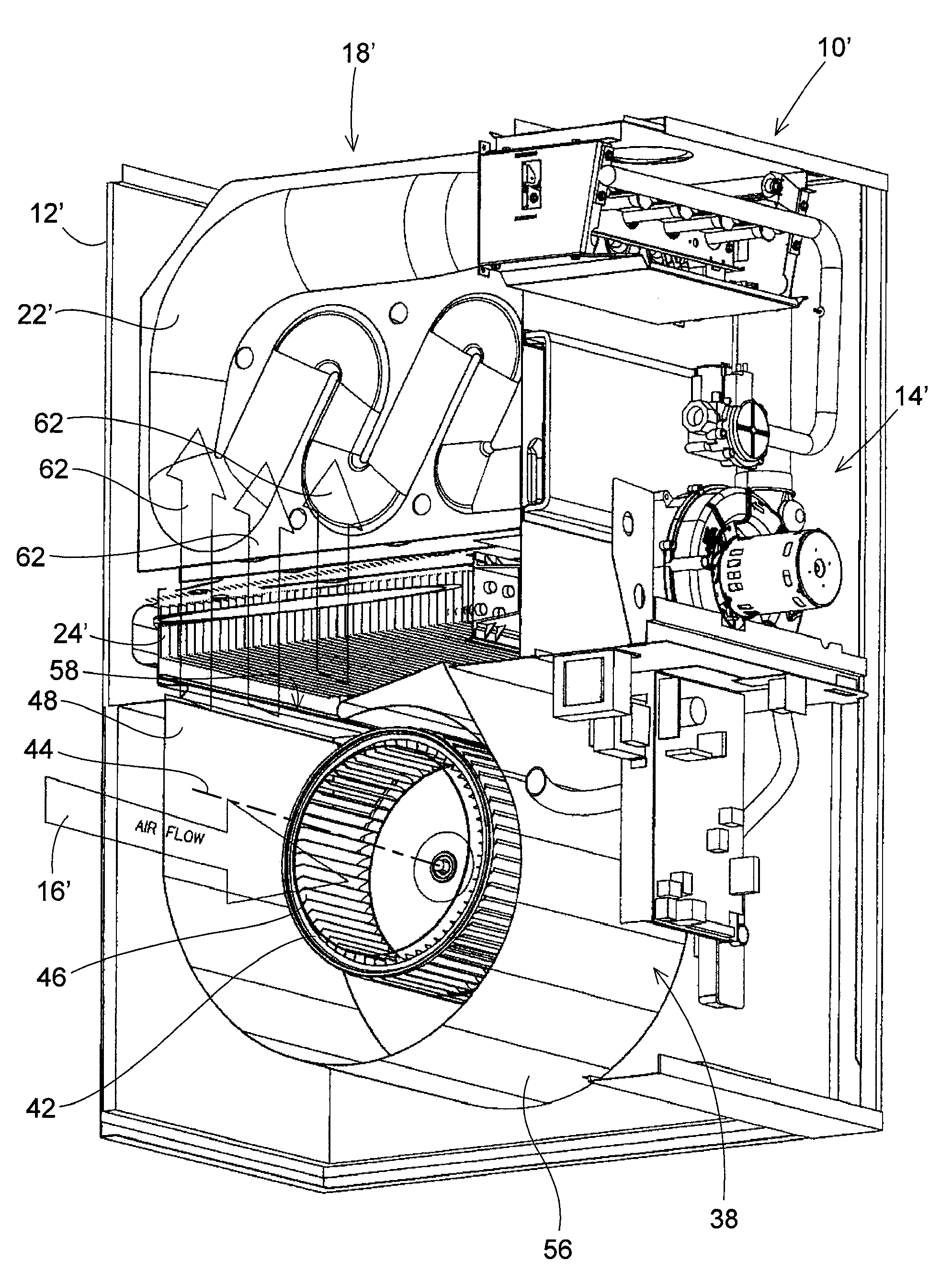

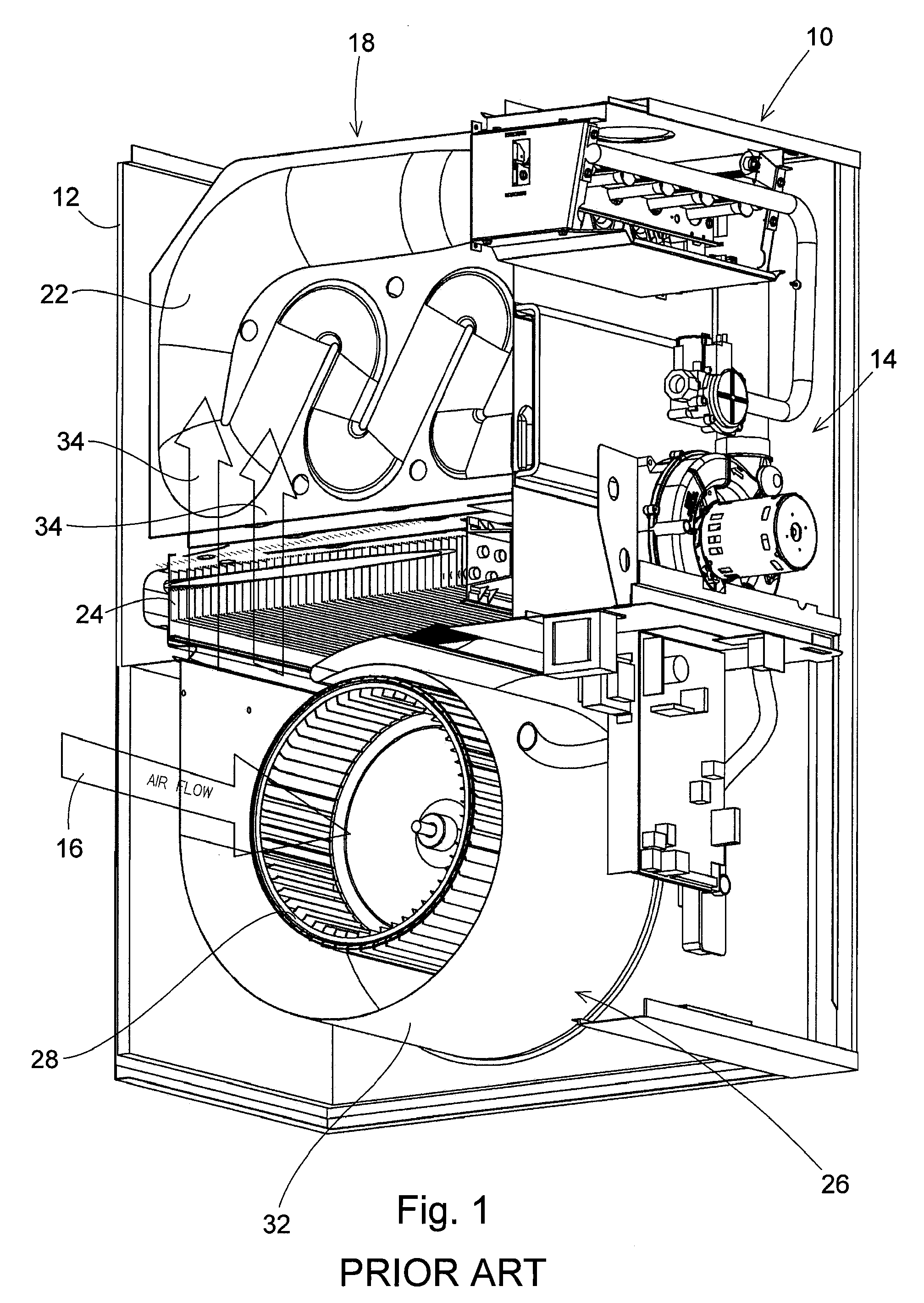

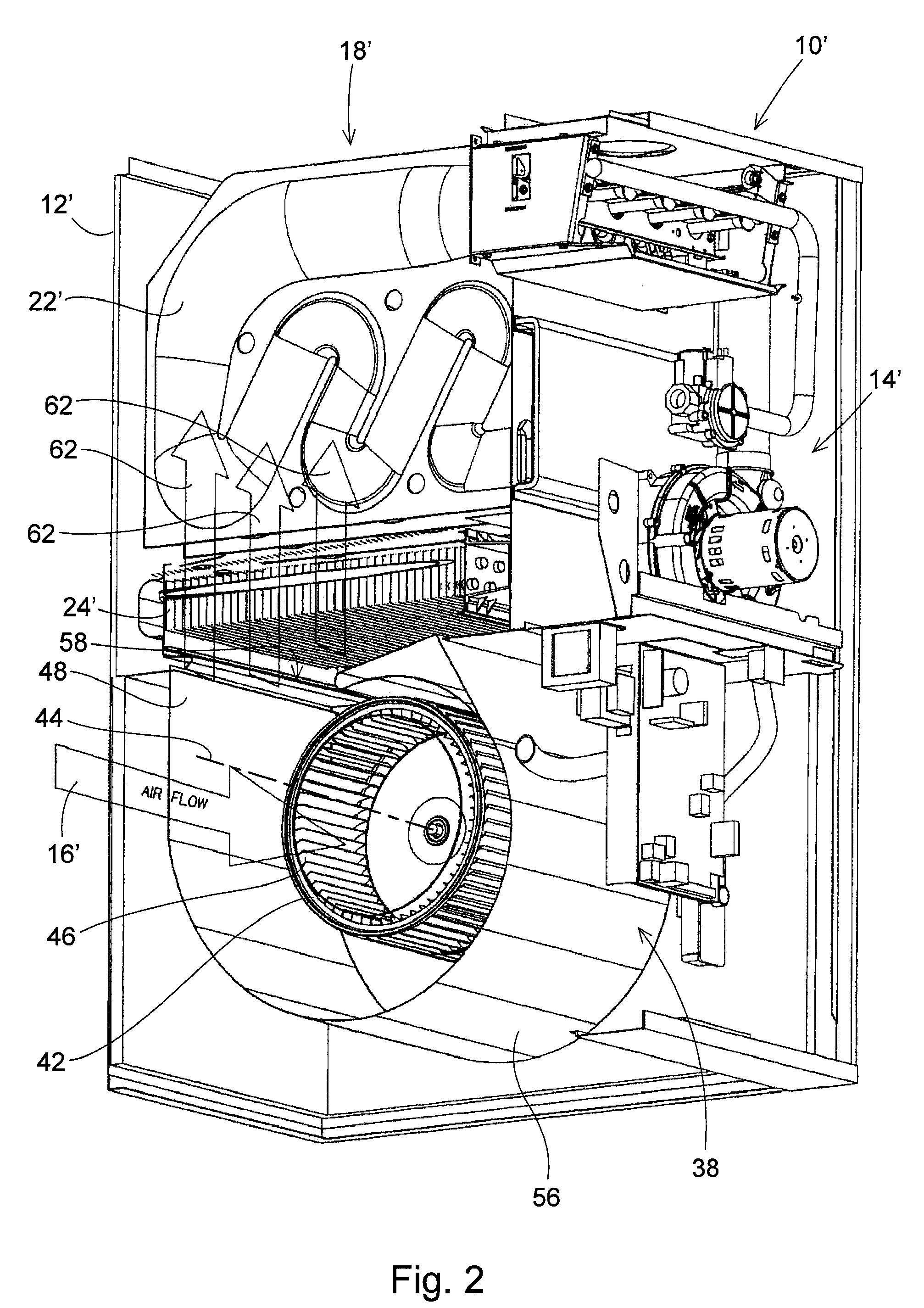

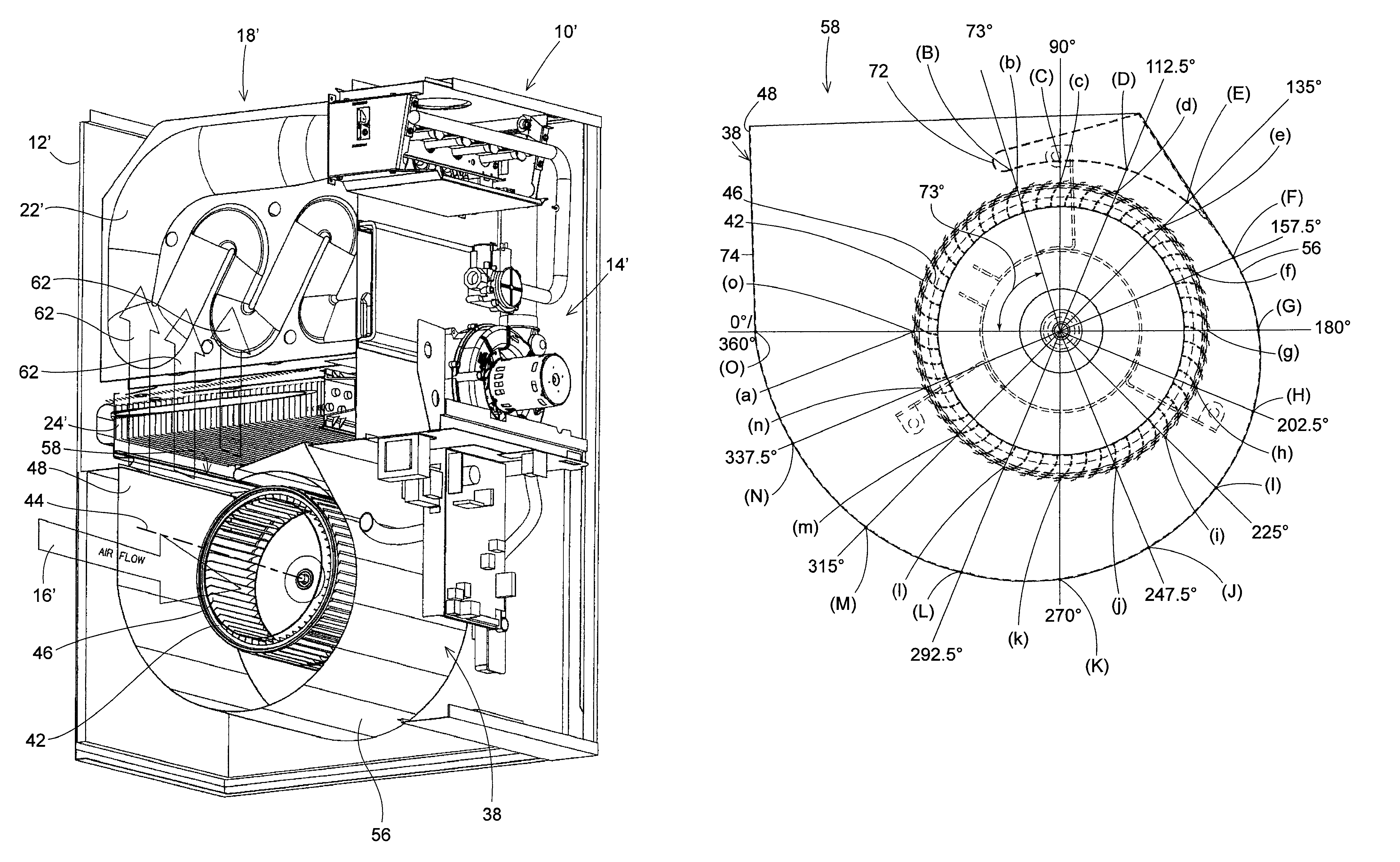

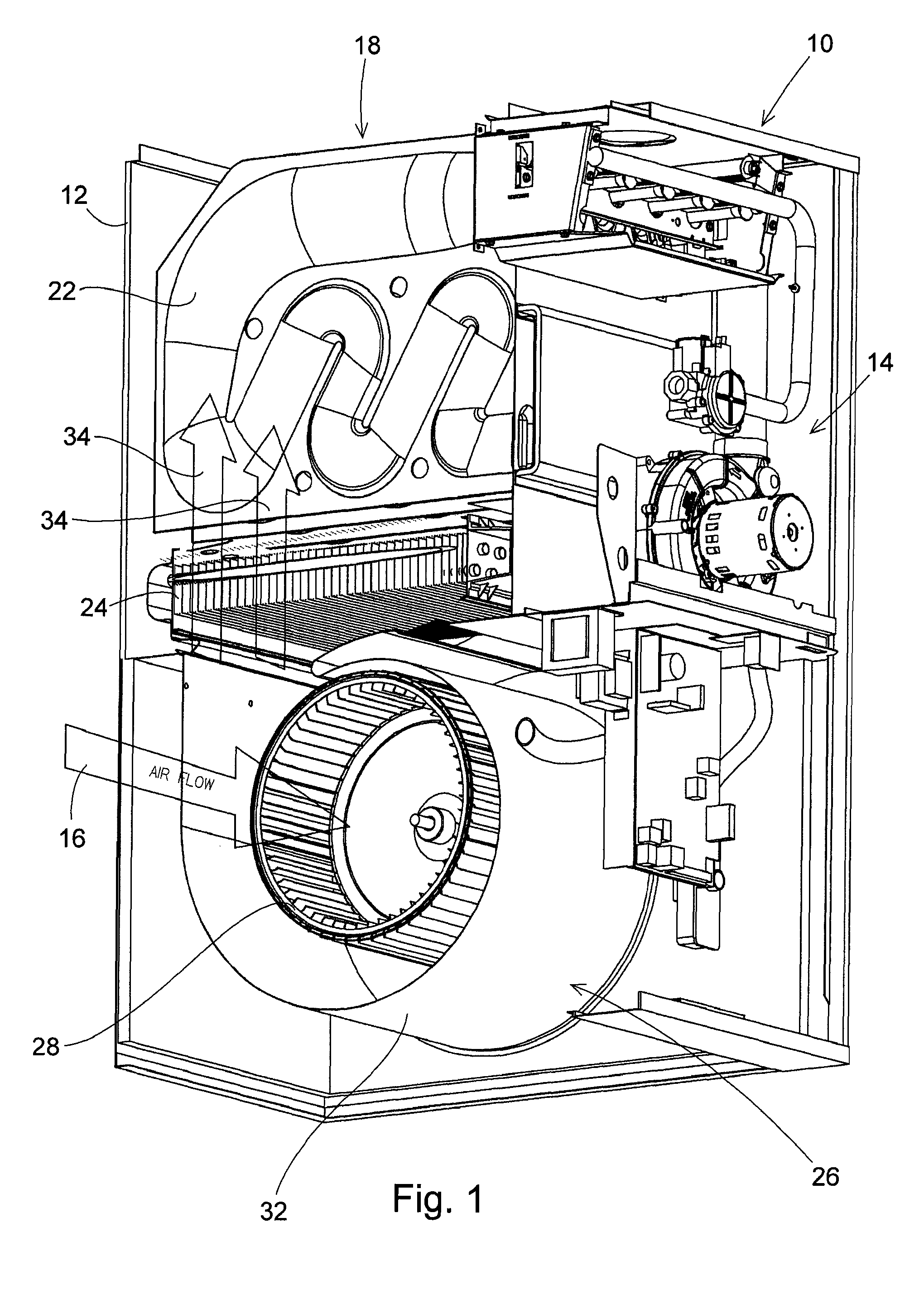

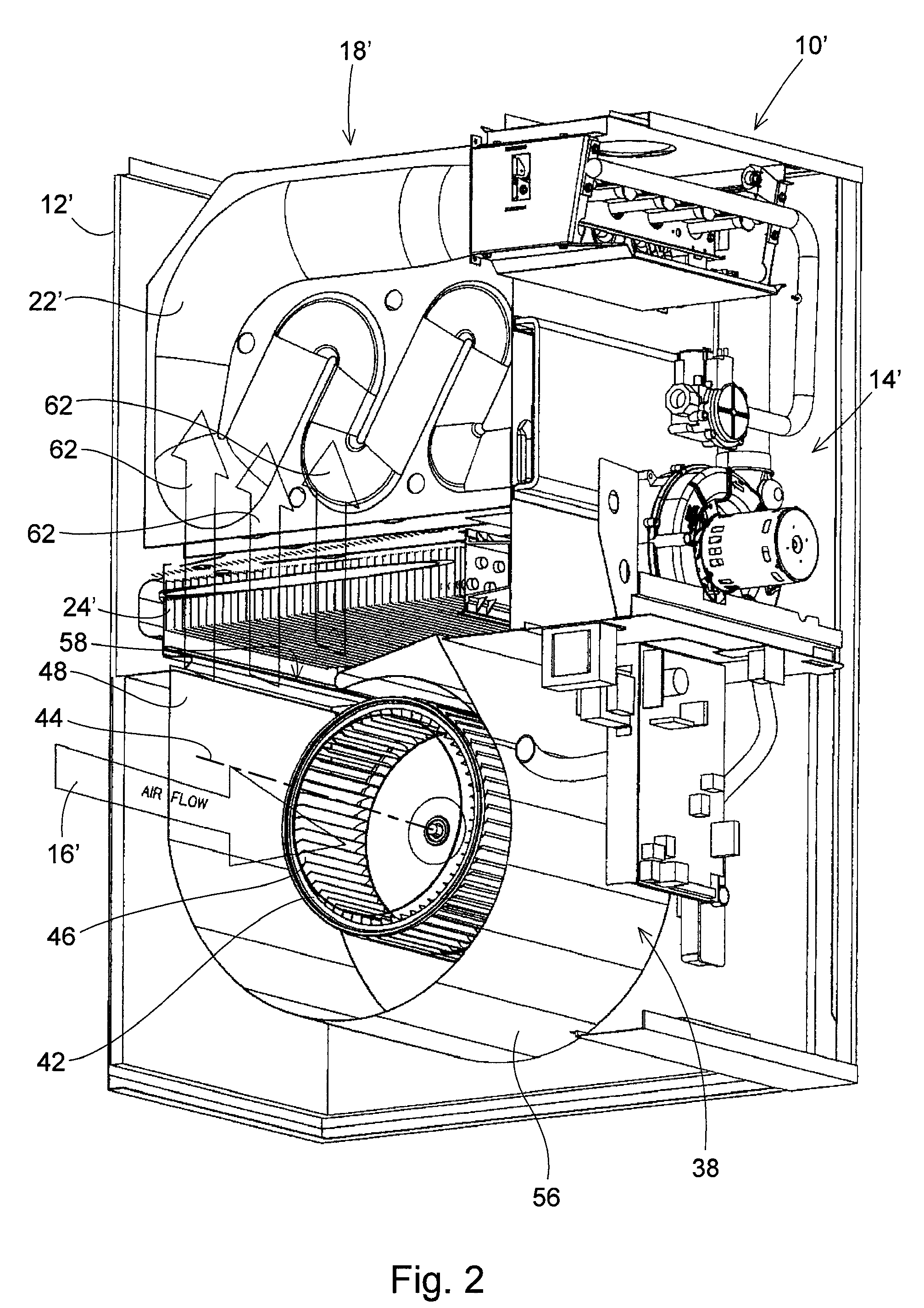

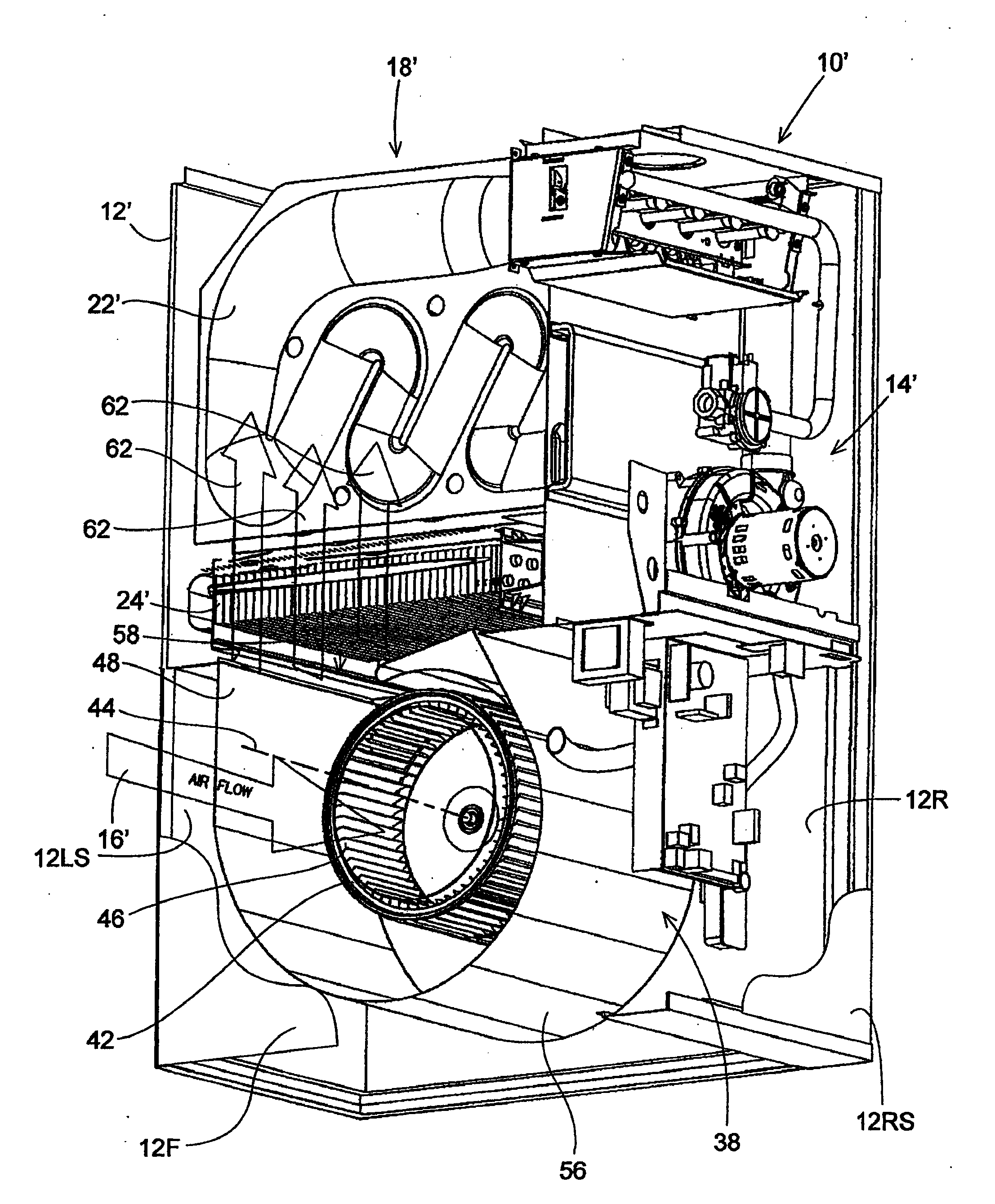

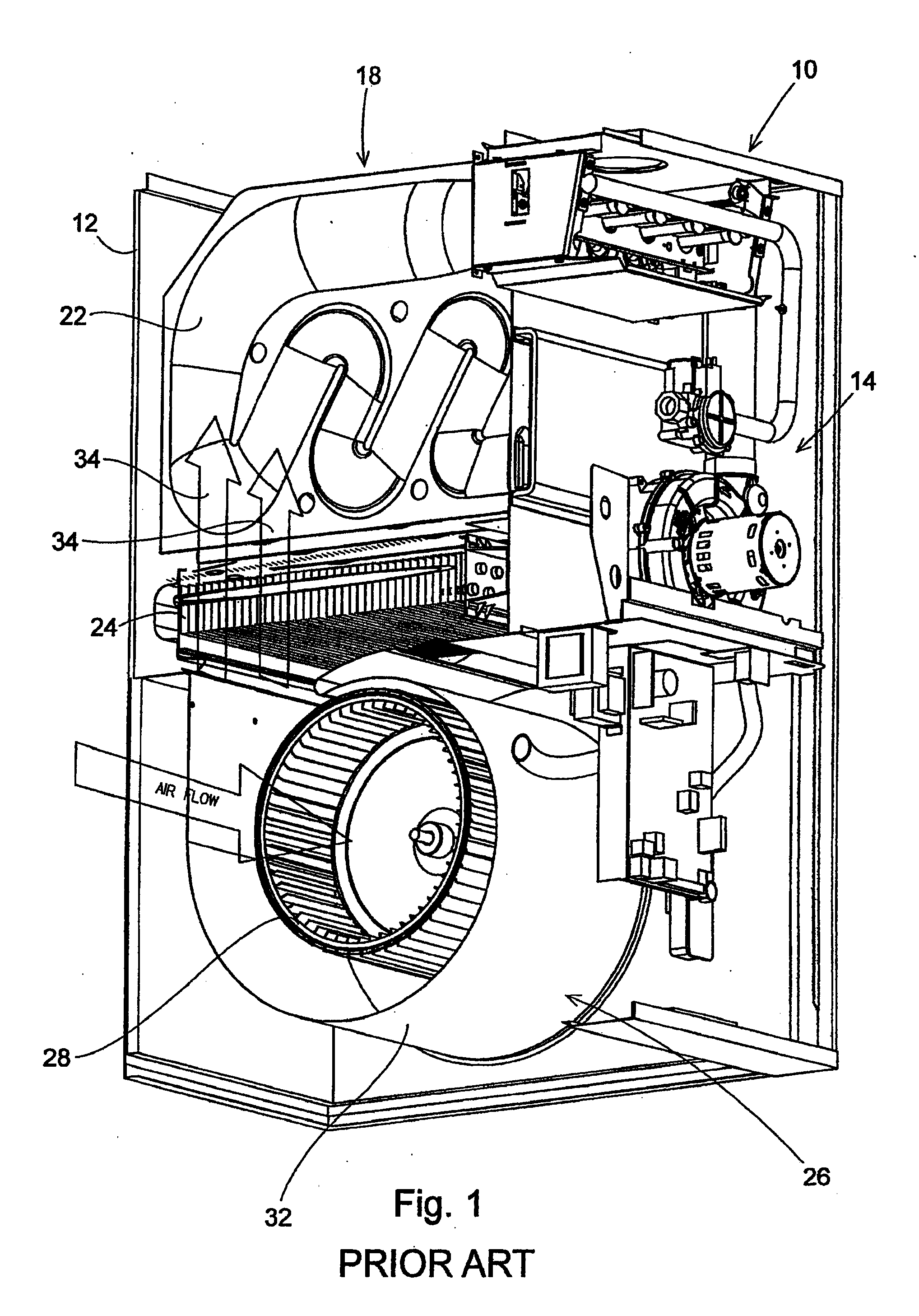

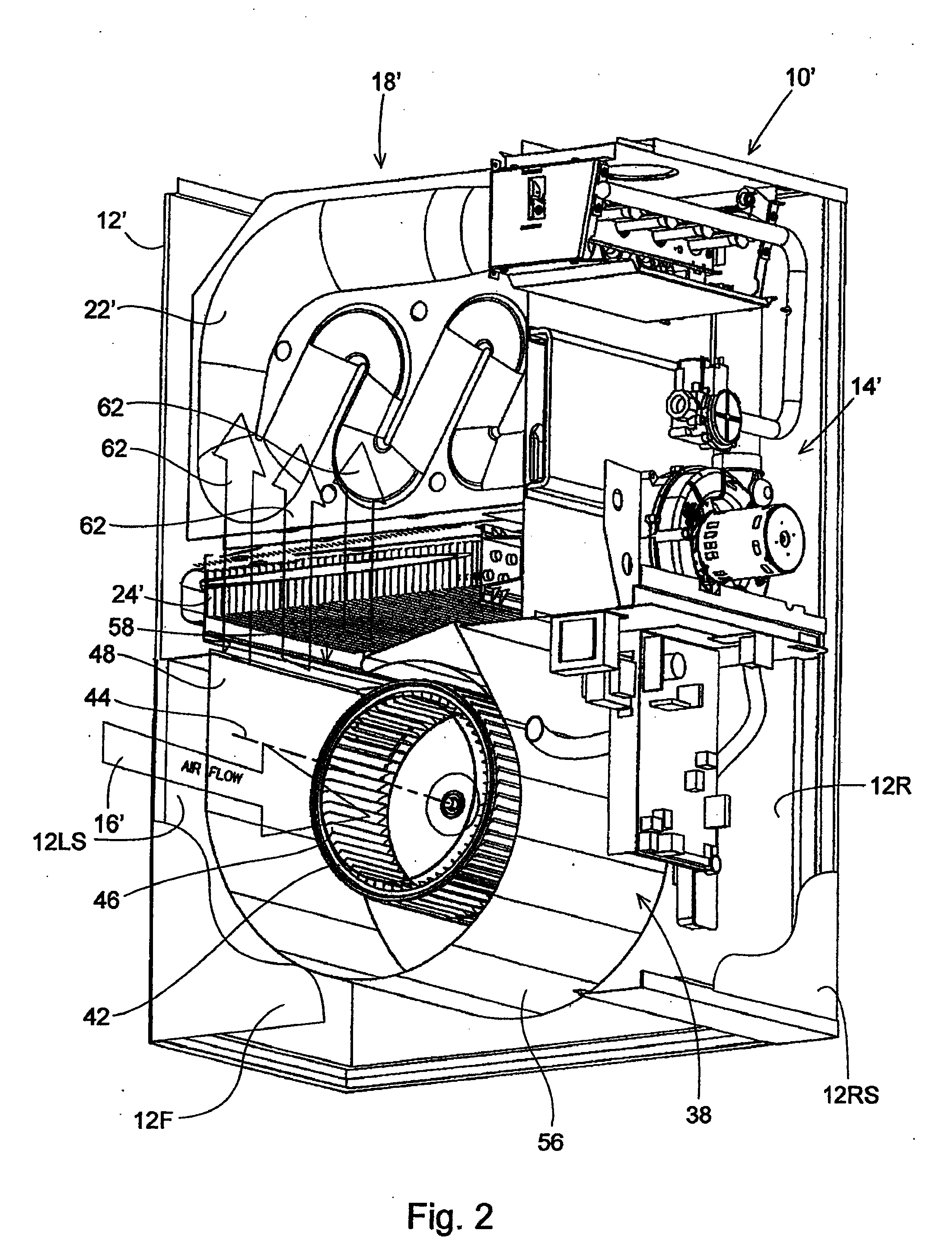

Furnace Air Handler Blower Housing with an Enlarged Air Outlet Opening

ActiveUS20090114206A1Overcomes efficiency problemLess pressure dropPump componentsAir heatersAir handlerWaste management

An air distribution blower housing for an air handler such as a residential furnace is designed with an enlarged air outlet opening that slows down and spreads out the air flow from the blower housing over a greater area of the furnace heat exchanger. The blower housing thereby enables less air pressure drop through the heat exchanger, which increases the efficiency of the blower motor operation. The design of the blower housing also efficiently turns the velocity head of the air flow through the housing to usable static air pressure at the housing air outlet. The enlarged air outlet opening of the blower housing is achieved without increasing the exterior diameter dimensions of the blower housing whereby the blower housing is used in a compact enclosure for residential use. This is accomplished by utilizing a volute outer wall of the blower housing that has an exponentially increasing expansion angle in the direction of air flow through the blower housing.

Owner:REGAL BELOIT AMERICA

Miniature flexible thrombectomy catheter

ActiveUS8012117B2Maximize thrombectomy actionGood effectCatheterFluid jet surgical cuttersDistal portionCatheter

The present invention pertains to a miniature flexible thrombectomy catheter having one or more flexible miniature noncollapsing tubular portions including pushable and torqueable structure for introduction into the smaller vessels in neurovascular regions. A jet body having an arcuate fluid jet emanator is incorporated in order to minimize size at the distal portion of a minimally sized catheter tube.

Owner:BOSTON SCI MEDICAL DEVICE LTD

Apparatus for hydrocracking and /or hydrogenating fossil fuels

InactiveUS20050129586A1Efficient separationEliminate failure problemsCarburetting airUsing liquid separation agentLiquid hydrocarbonsEngineering

A catalytic hydrocracking reactor vessel for the conversion of a hydrogen gas and fossil fuel feedstream to light liquid hydrocarbons. The reactor vessel comprises reactor cup riser means with a helical cyclonic separator conduit for separating a liquid and vapor product stream to provide an essentially vapor-free liquid recycle stream, grid plate bubble cap means with tapered bell cap wall housing having serrated edges for producing small hydrogen bubbles of increased total surface area of bubbles at lower pressure drop, optionally feedstream inlet pipe sparger means containing rows of downward directed slots for even distribution of the feedstream across the cross-sectional area of the reactor and providing free drain of solid particles from the sparger, and optionally liquid recycle inlet distributor means containing vertically curved plates for creating a whirling motion in the liquid recycle stream for better mixing with the feedstream with minimal solids settling.

Owner:HEADWATERS TECH INNOVATION LLC +1

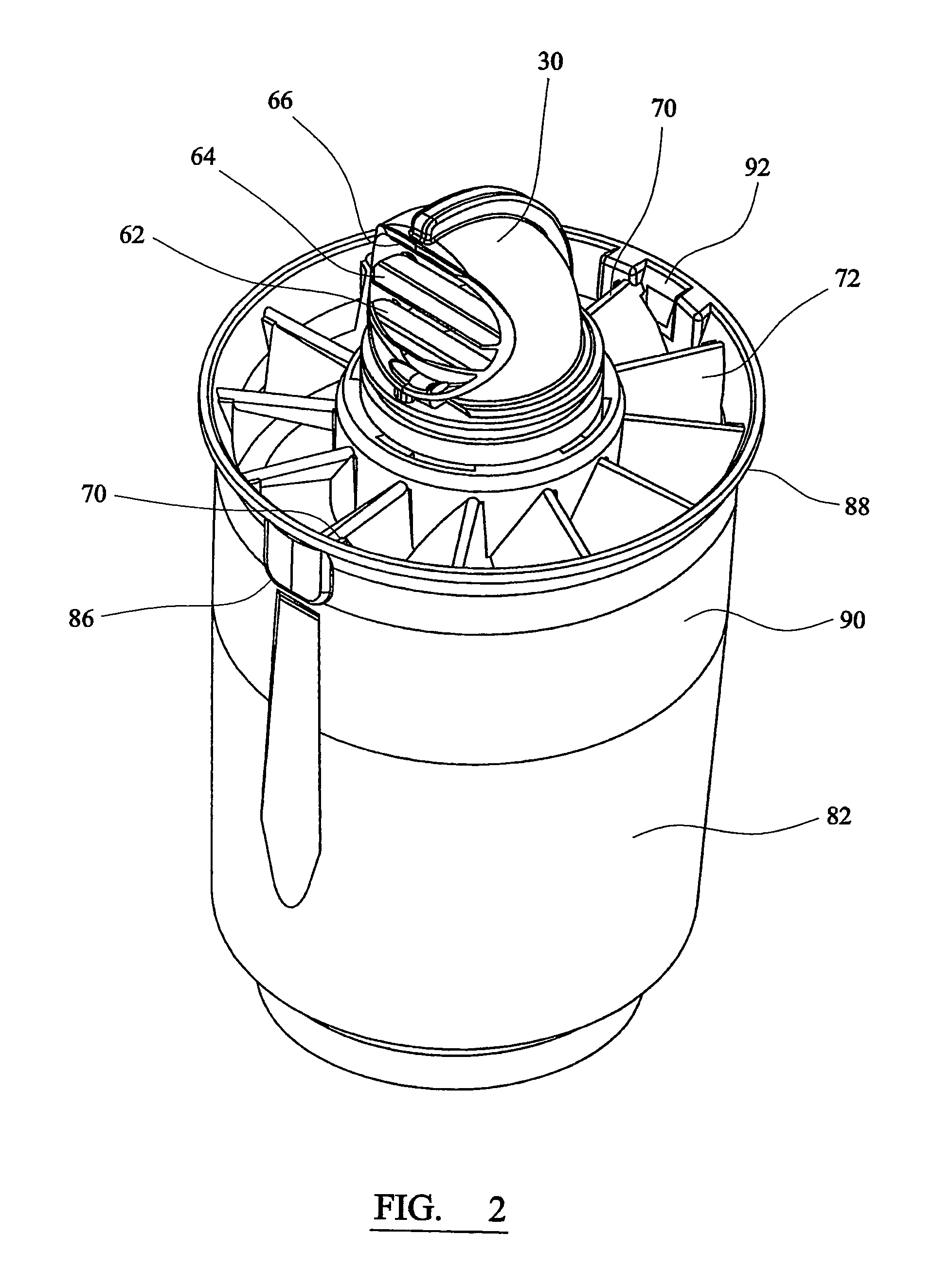

Fluid filtration apparatus and method

InactiveUS20050252838A1Less pressure dropHigh trafficSettling tanks feed/dischargeSeparation devicesEngineeringFluid filtration

An apparatus and method for filtering a liquid utilize a filter apparatus including a bypass filter, a full flow filter, and a flow balancing element for dividing a total inlet flow of fluid to the filter apparatus into a bypass portion, passing through the bypass filter, and a full flow portion, passing through the full flow filter. The bypass filter has a lower filtering efficiency than the full flow filter element, so that a venturi tube is not required for causing the bypass portion to pass through the bypass filter. The flow balancing element divides the flow into a desired bypass portion and a desired full flow portion, at a predetermined operating temperature. Below the operating temperature, the bypass portion increases and the full flow portion decreases, the bypass portion becoming greater that the full flow portion at a second predetermined temperature below the operating temperature.

Owner:FUJIFILM HEALTHCARE CORP +1

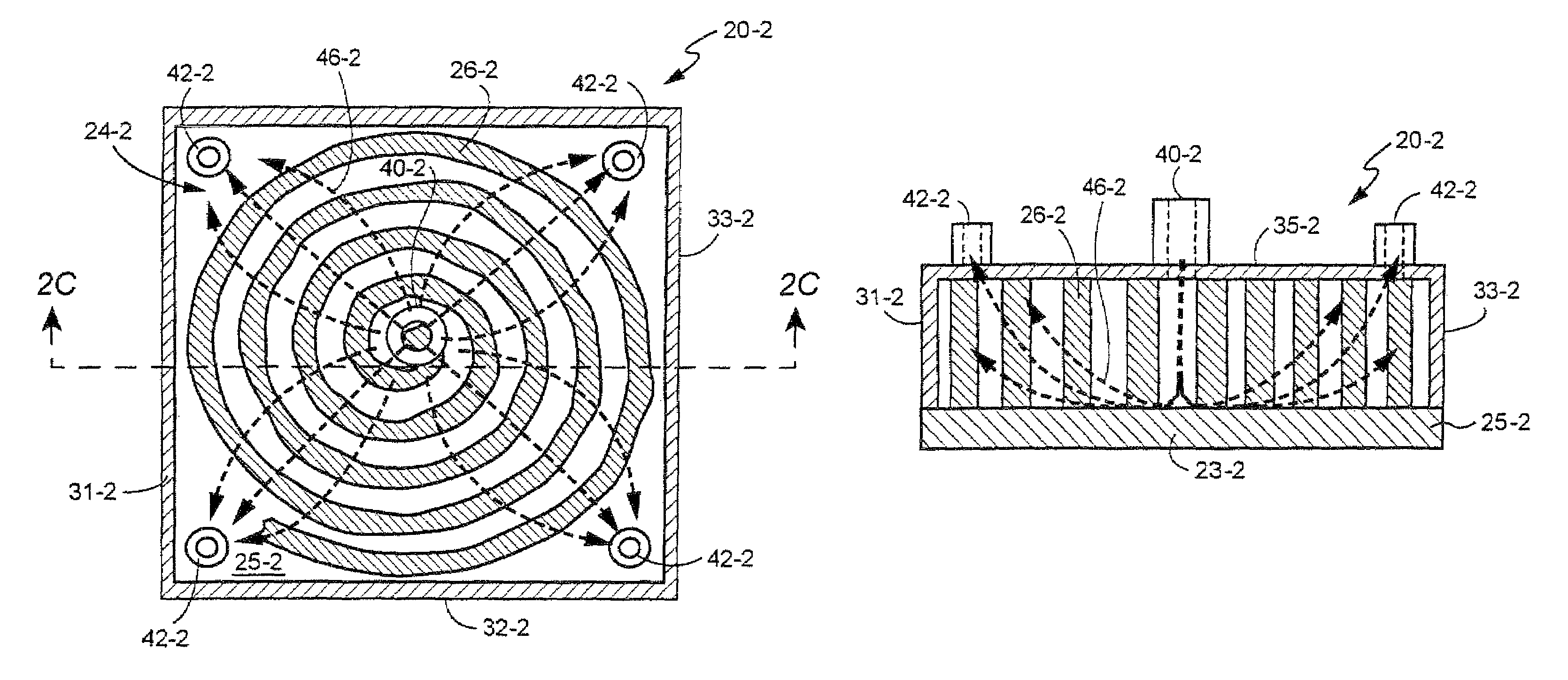

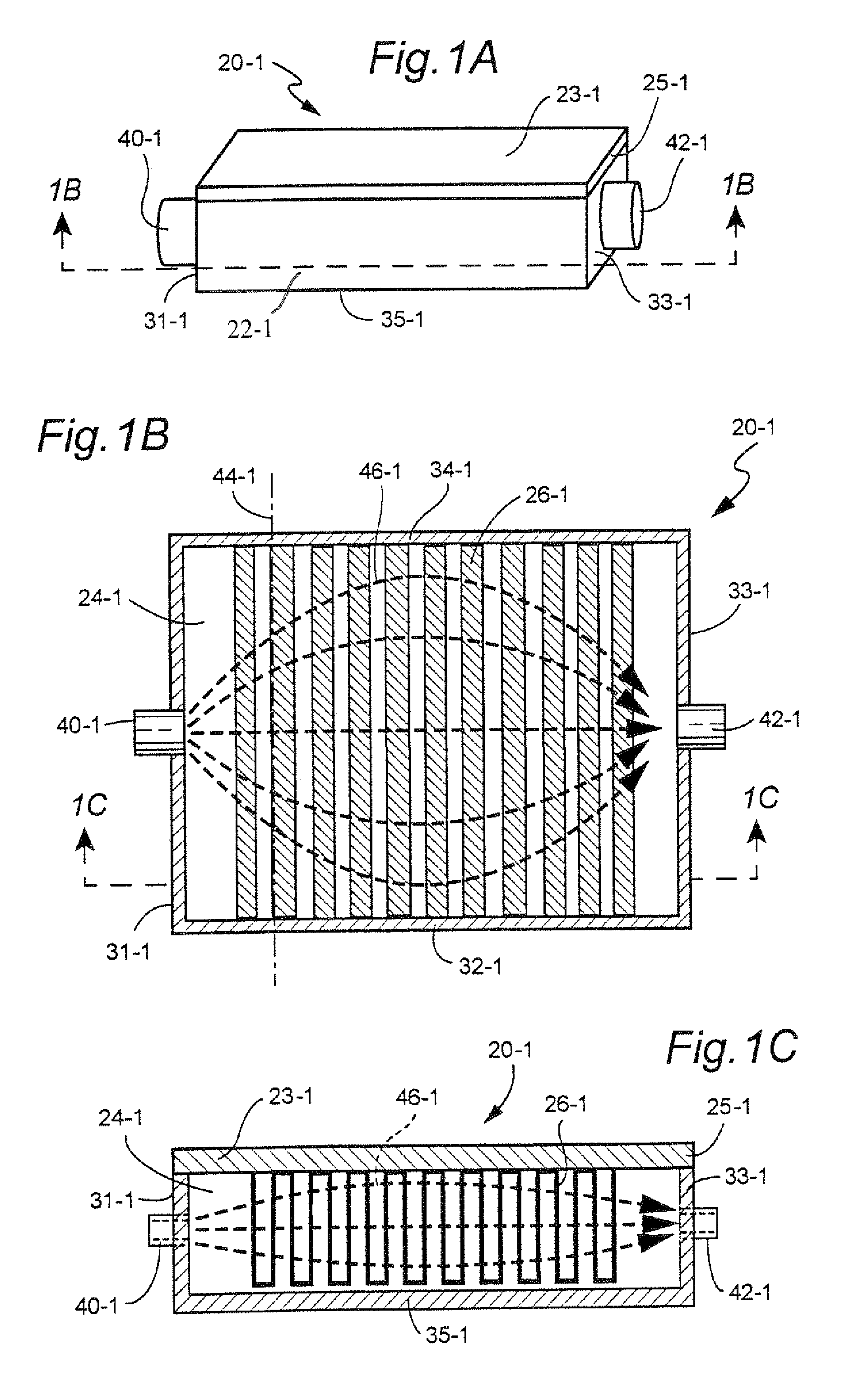

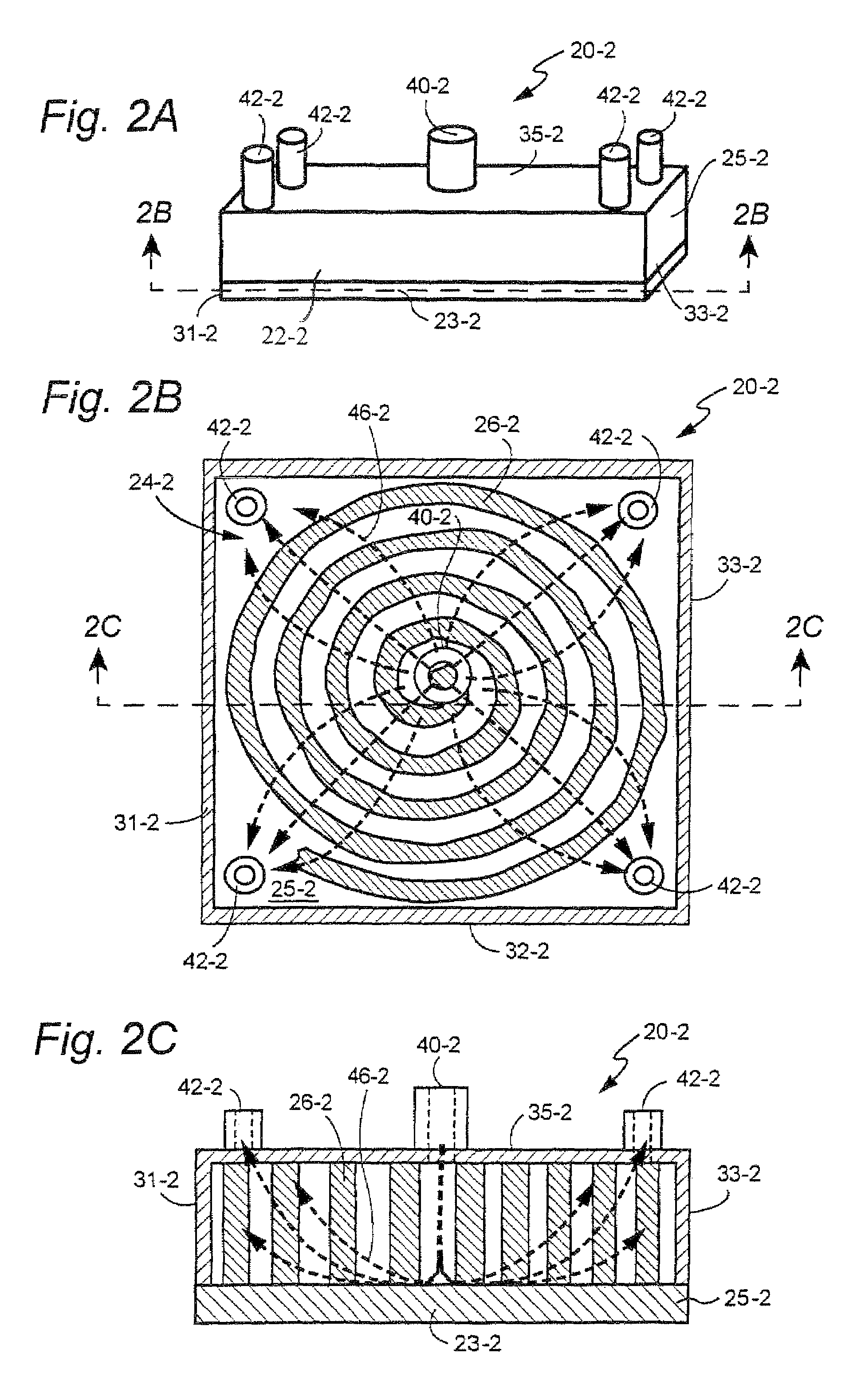

Thermal transfer devices with fluid-porous thermally conductive core

InactiveUS7549460B2Easy to pushReducing size and powerSemiconductor/solid-state device detailsSolid-state devicesEngineeringMetal

A thermal transfer device (20) comprises a housing having a base assembly (23) and a cover (22). The base assembly (23) comprises a thermal transfer base (25) and a fluid-porous, thermally conductive mesh structure (26). The thermal transfer base (25) and the cover (22) cooperate to define a thermal transfer chamber (24). The thermally conductive mesh structure (26) is configured and positioned in the chamber (24) to provide a tortuous, thermal conduction path for fluid (e.g., a coolant) which turbulently travels from an inlet (40) of the chamber to one or more outlets (42) of the chamber (24). In some embodiments, the mesh structure comprises wires which are fused by diffusion bonding into a mesh, in other embodiments the mesh comprises a metallic wool. Within the chamber the mesh structure (26) can have various configurations for providing an exposure interface between fluid pumped through the chamber and the mesh.

Owner:PAR TECH

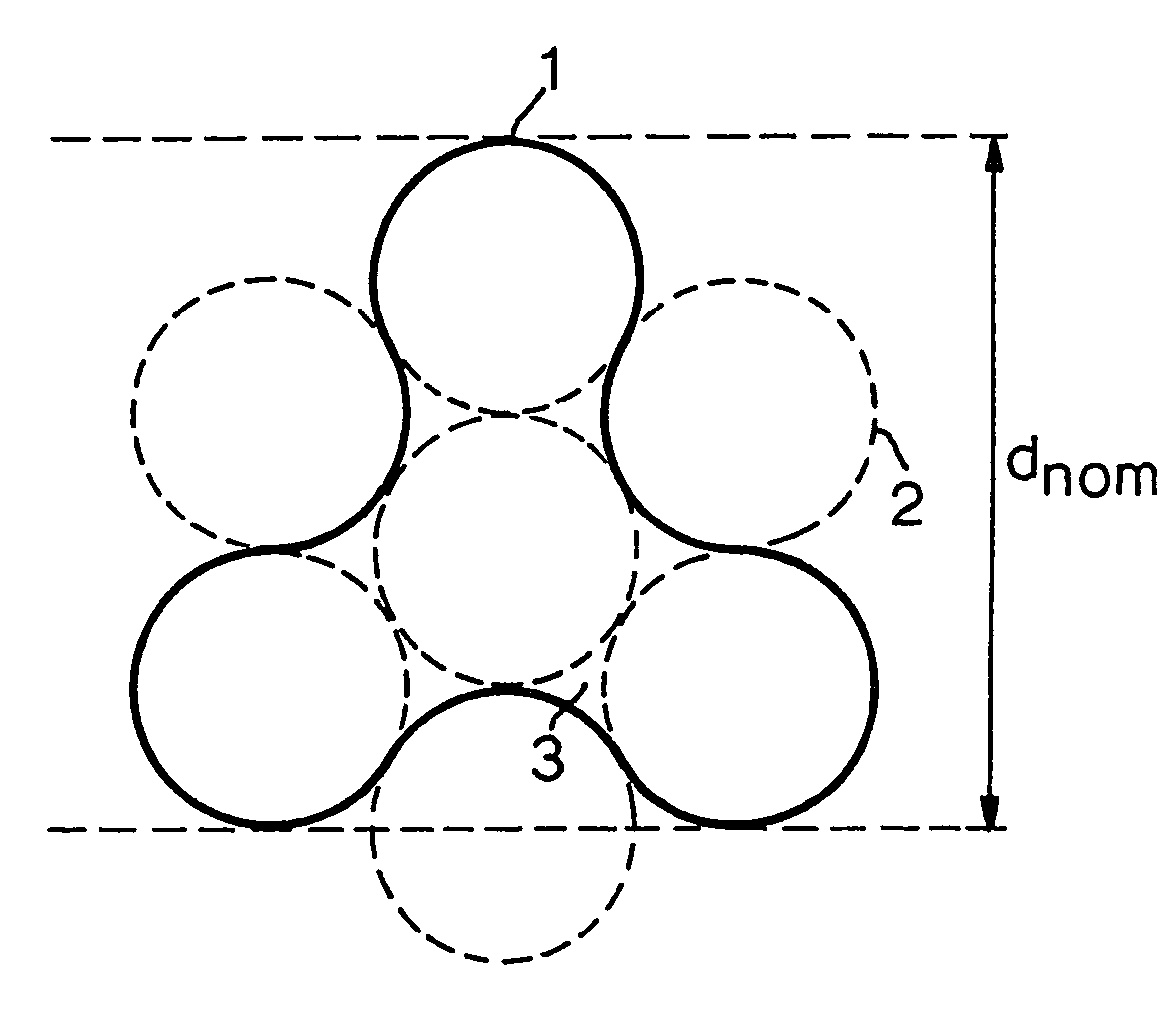

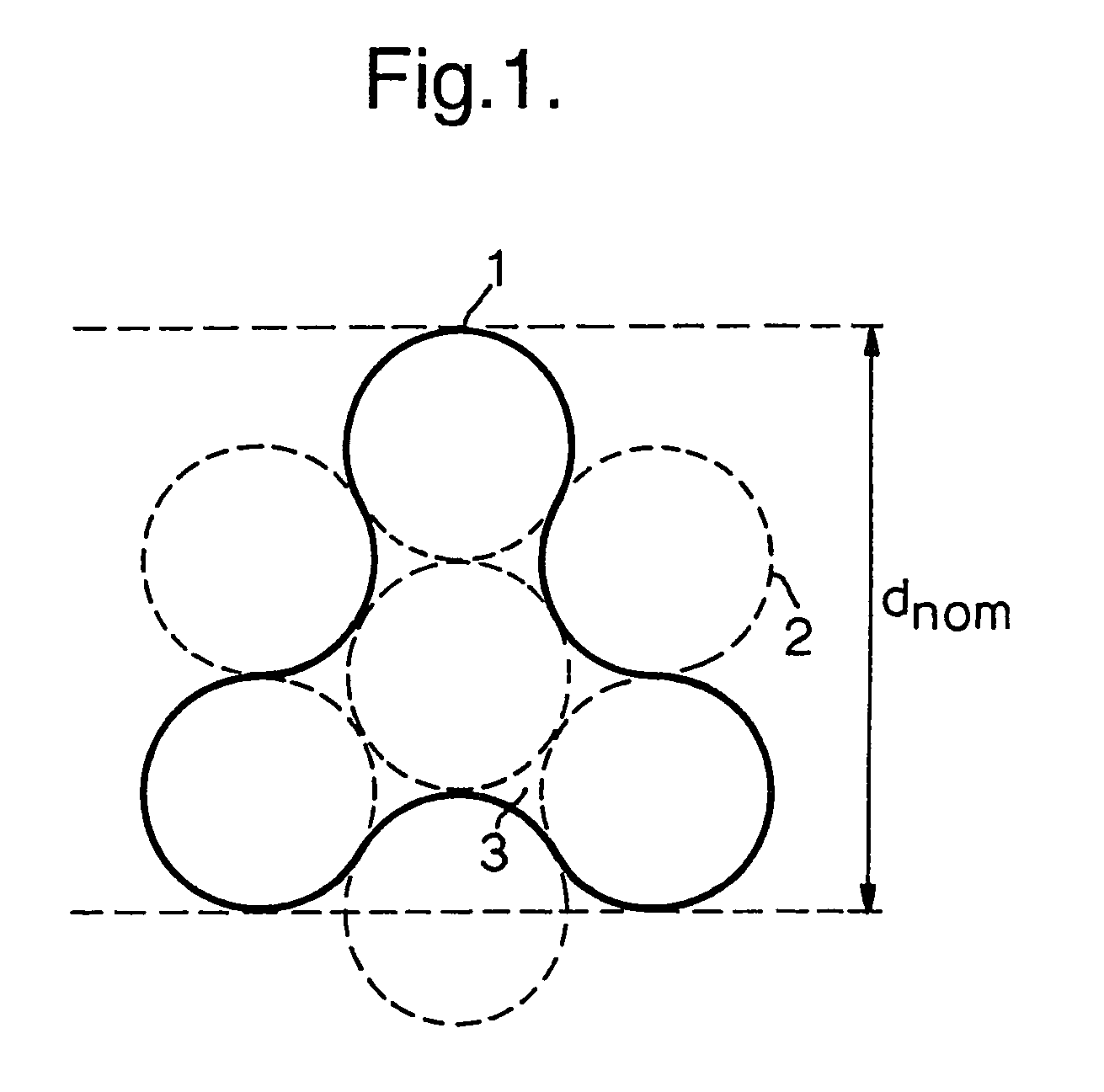

Shaped trilobal particles

InactiveUS7198845B2Less pressure dropOrganic chemistryPhysical/chemical process catalystsEngineeringMechanical engineering

An elongate, shaped particle having three protrusions each extending from and attached to a central position aligned along the central longitudinal axis of the particle, the cross-section of the particle occupying the area encompassed by the outer edges of six outer circles around a central circle minus the area occupied by three alternating outer circles, wherein each of the six outer circles is touching two neighbouring outer circles and wherein three alternating outer circles are equidistant to the central circle, have the same diameter, and may be attached to the central circle.

Owner:SHELL OIL CO

Method of manufacturing a miniature flexible thrombectomy catheter

ActiveUS20080289181A1Maximize thrombectomy actionGood effectMedical devicesCatheterDistal portionGuide tube

The present invention pertains to a miniature flexible thrombectomy catheter having one or more flexible miniature noncollapsing tubular portions including pushable and torqueable structure for introduction into the smaller vessels in neurovascular regions. A jet body having an arcuate fluid jet emanator is incorporated in order to minimize size at the distal portion of a minimally sized catheter tube.

Owner:BOSTON SCI MEDICAL DEVICE LTD

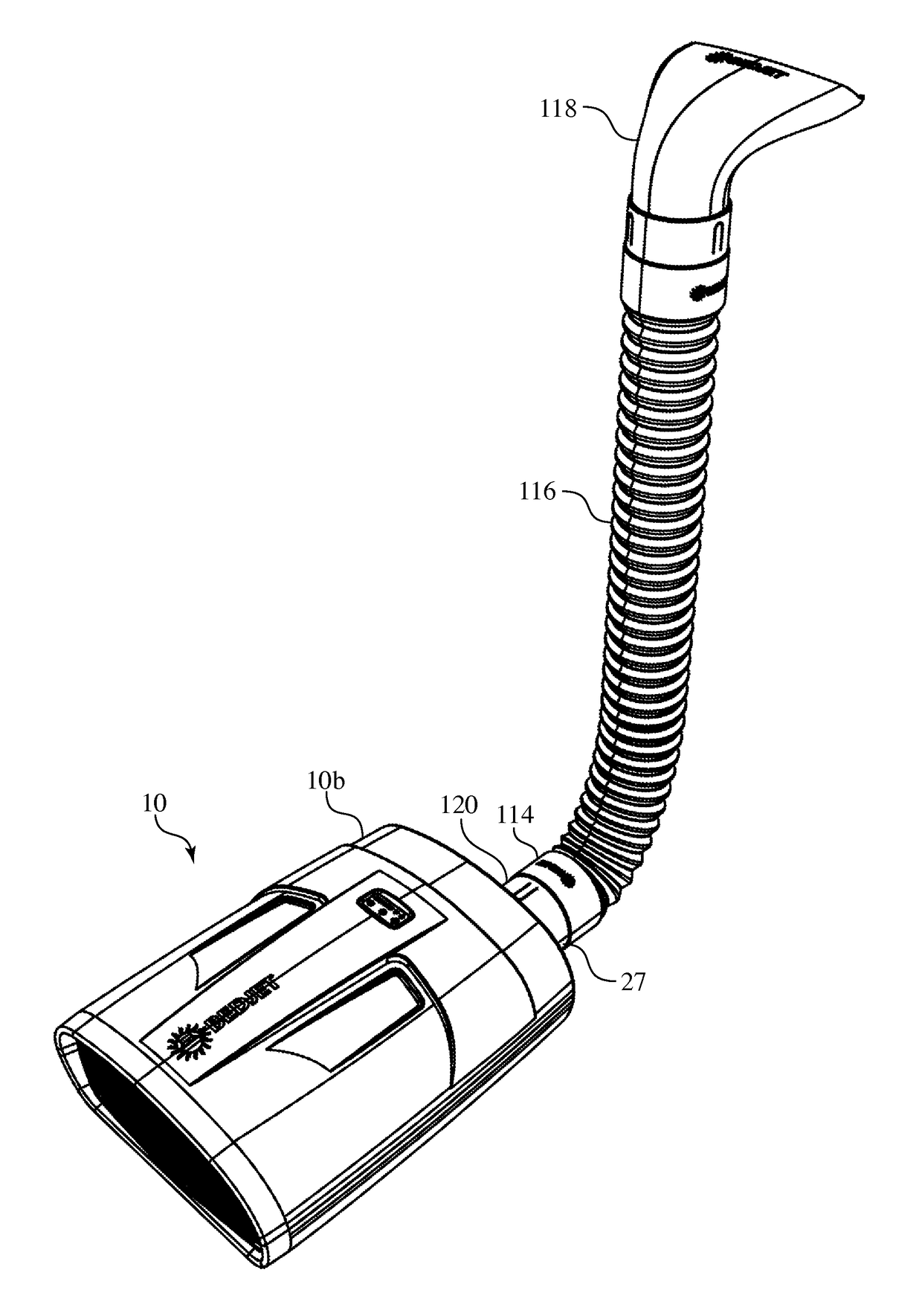

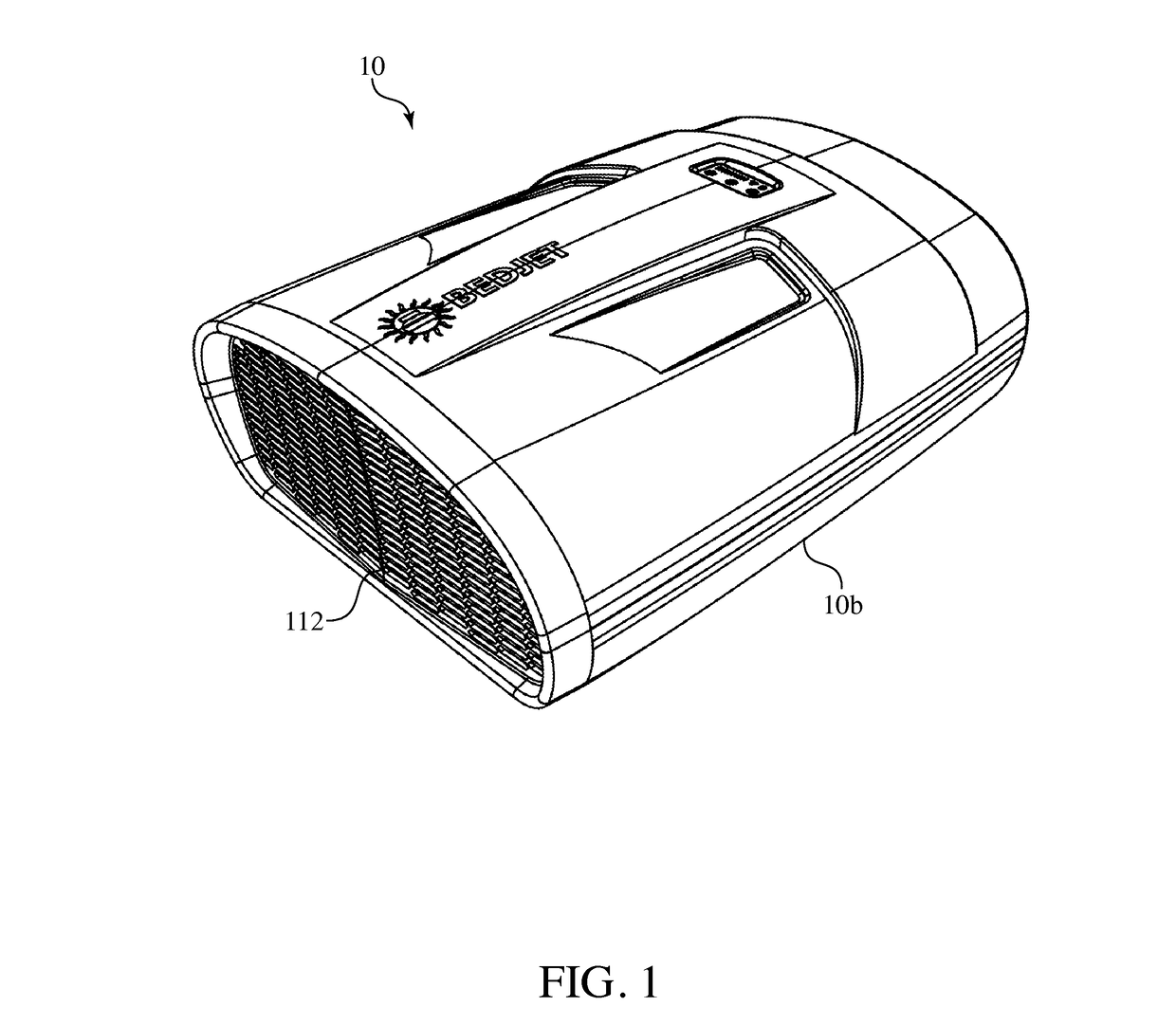

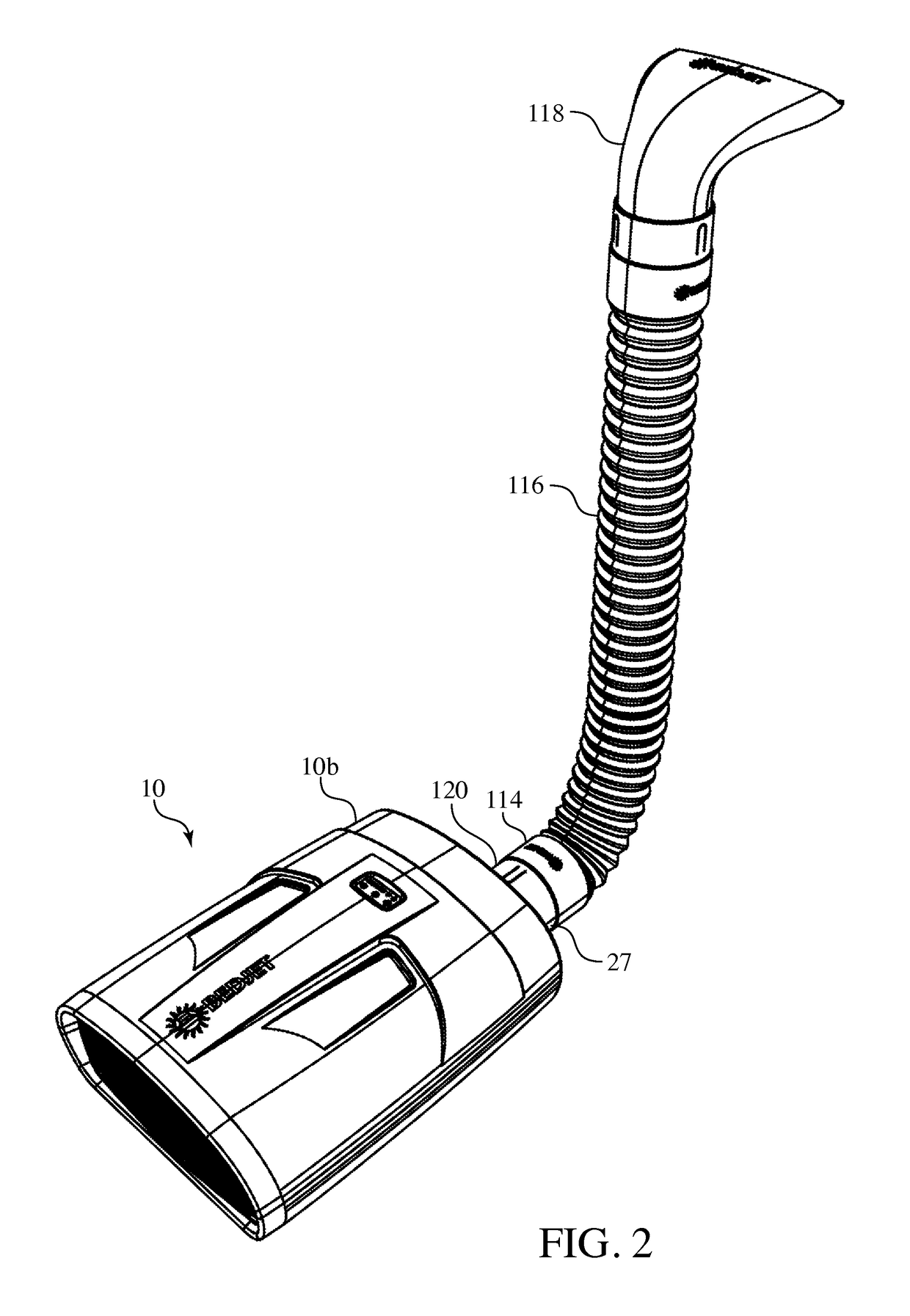

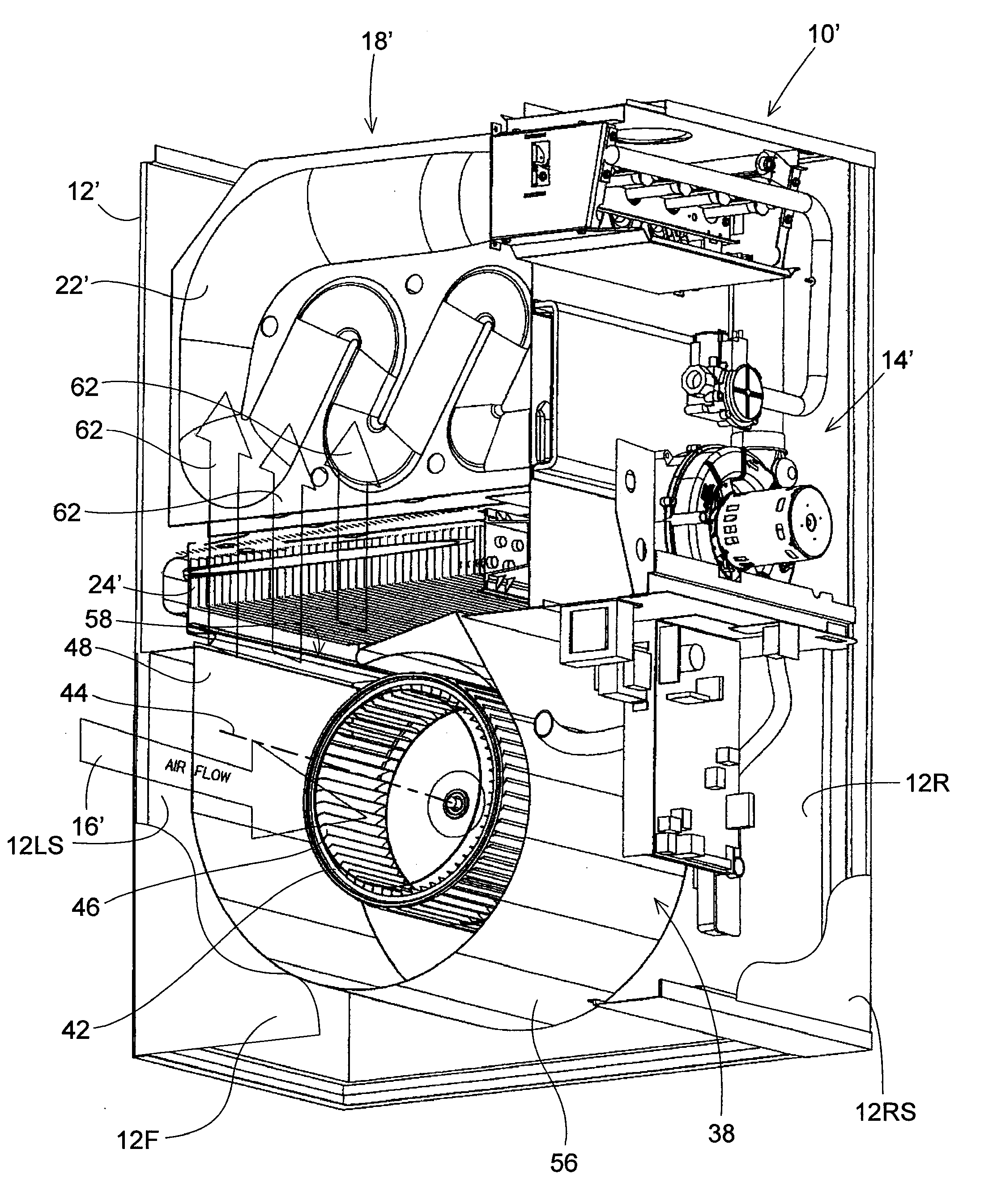

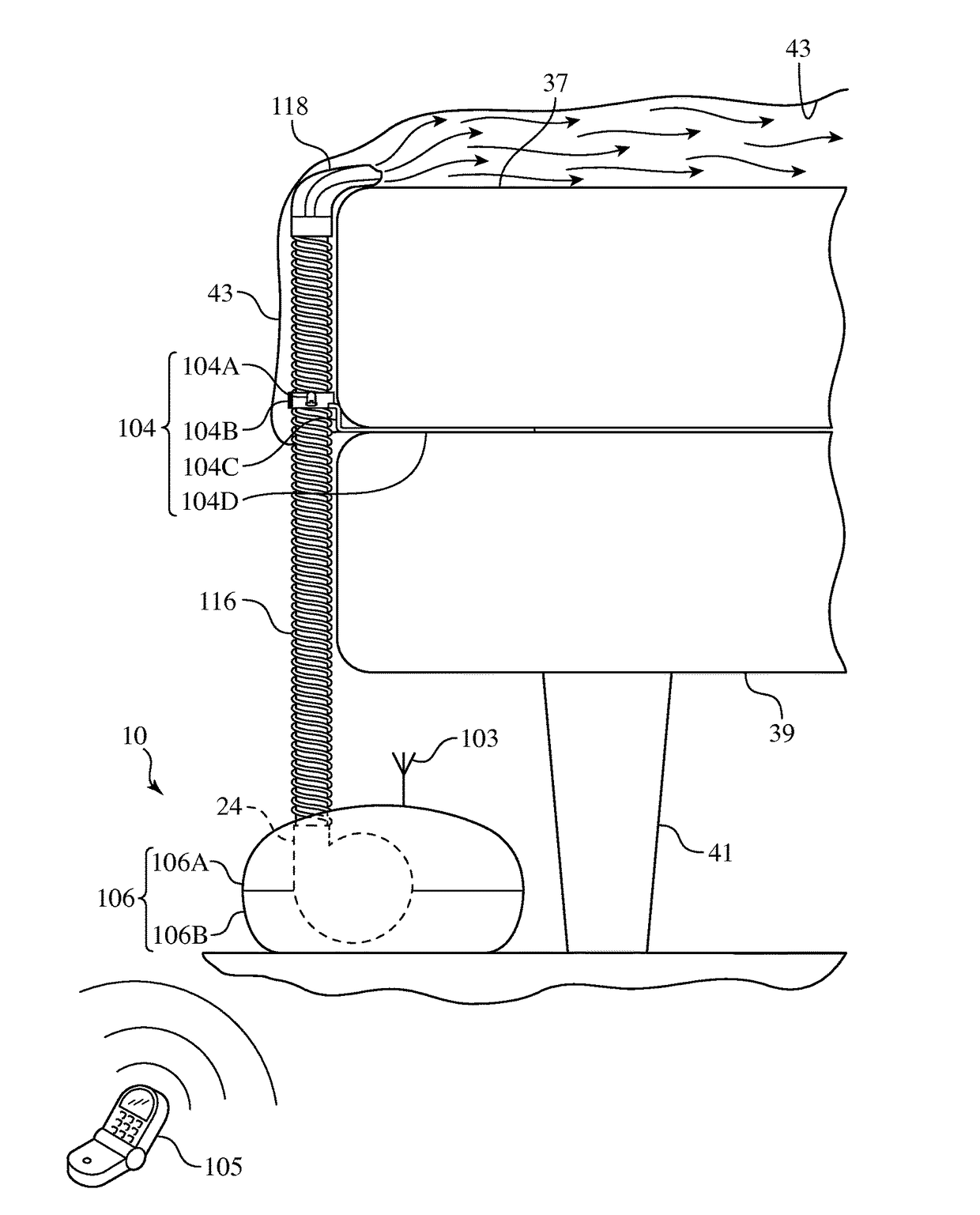

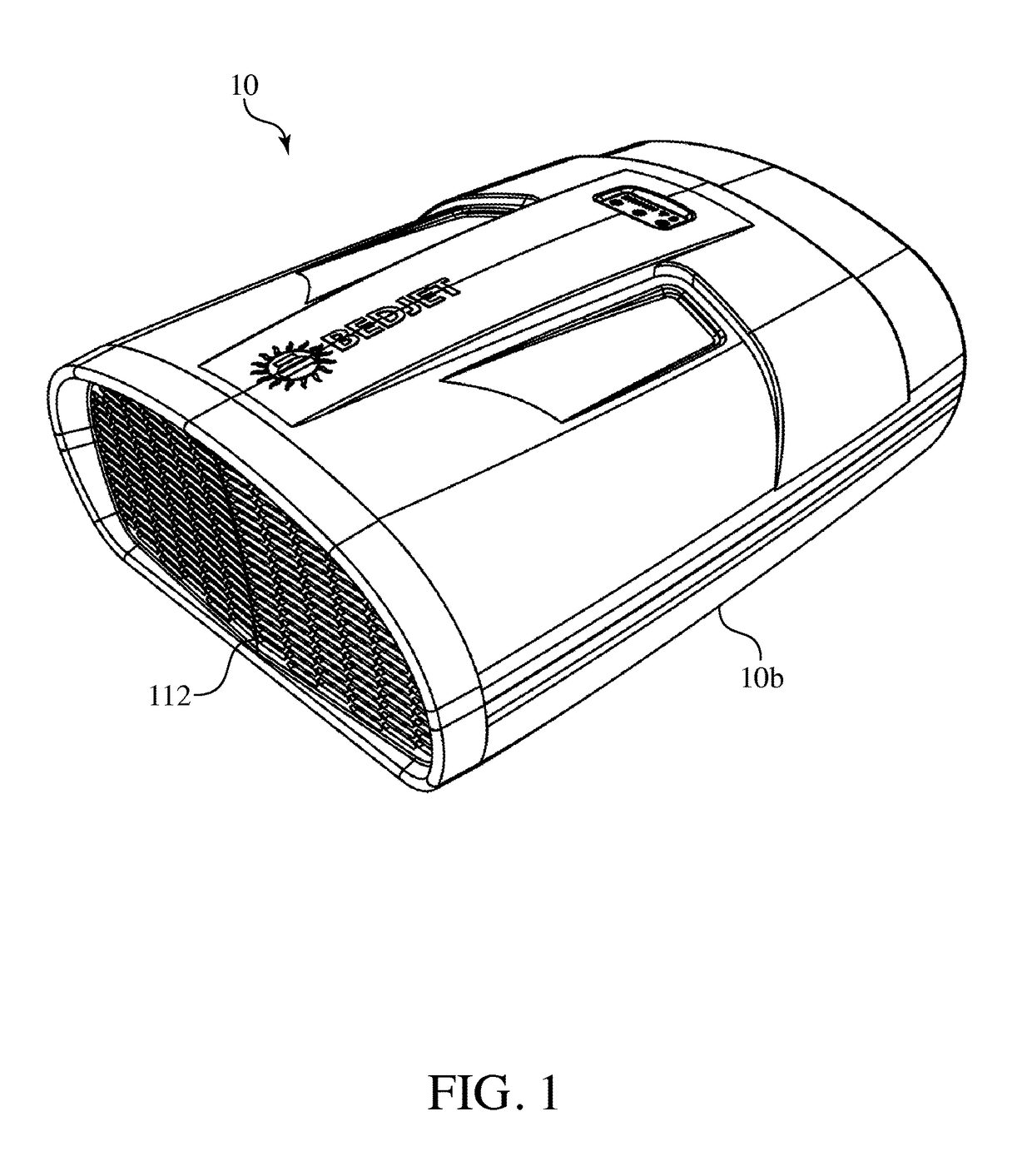

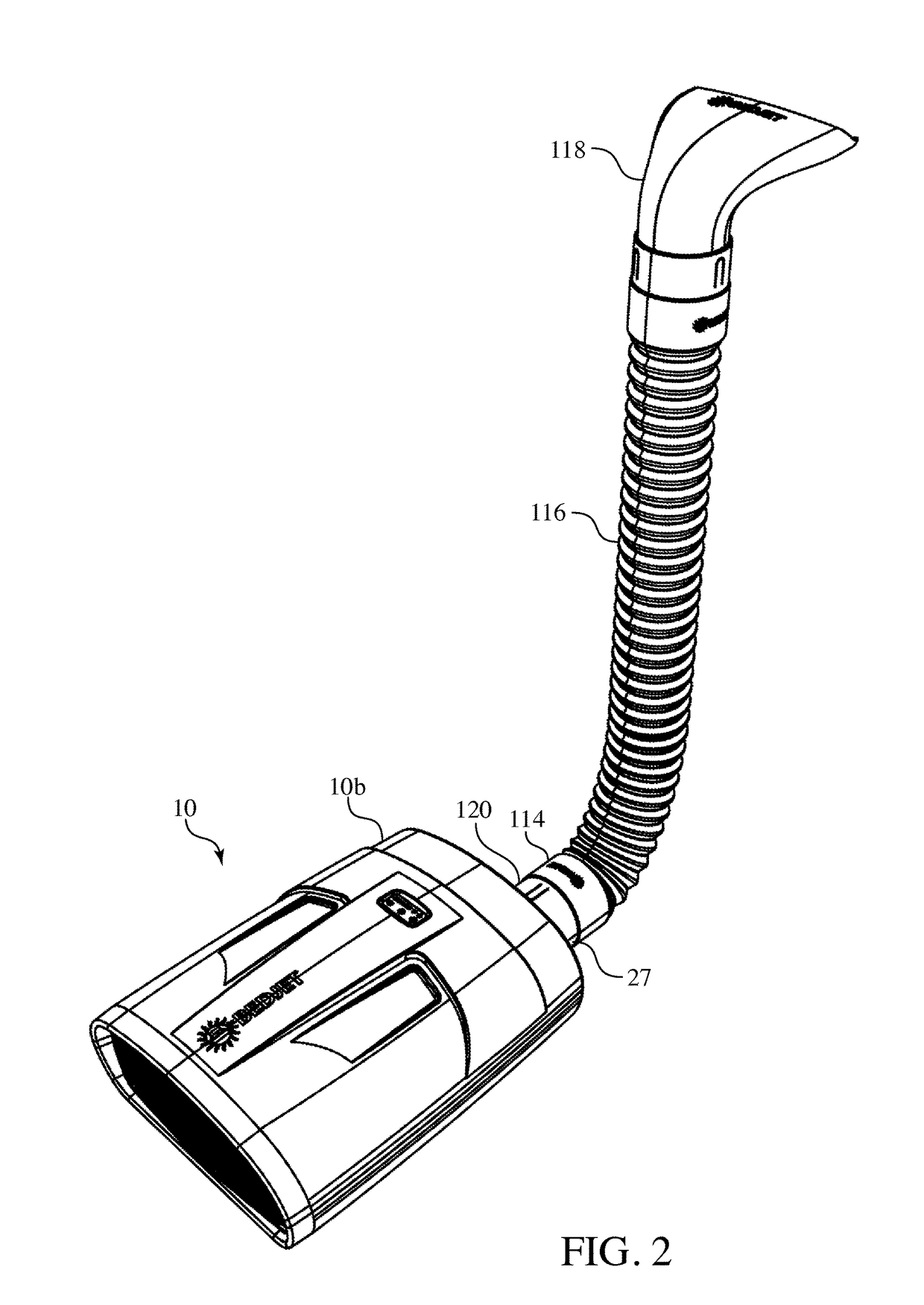

Bedding climate control apparatus with forced airflow for heating and ventilating

A bedding climate control apparatus that delivers, in a quiet manner, forced airflow from a fan / blower within a housing to selectively deliver tempered (heated via a thermal element) and untempered (room temperature) air through a flexible hose to bedding. The quiet manner is attained with acoustic foam in the path of incoming airflow to the fan / blower and by oversizing each of the components that create a pressure drop including the capacity of the fan / blower over what is needed to deliver a required amount of airflow. Temperature may be set remotely via a wireless remote control and via a Bluetooth enabled device.

Owner:BEDJET LLC

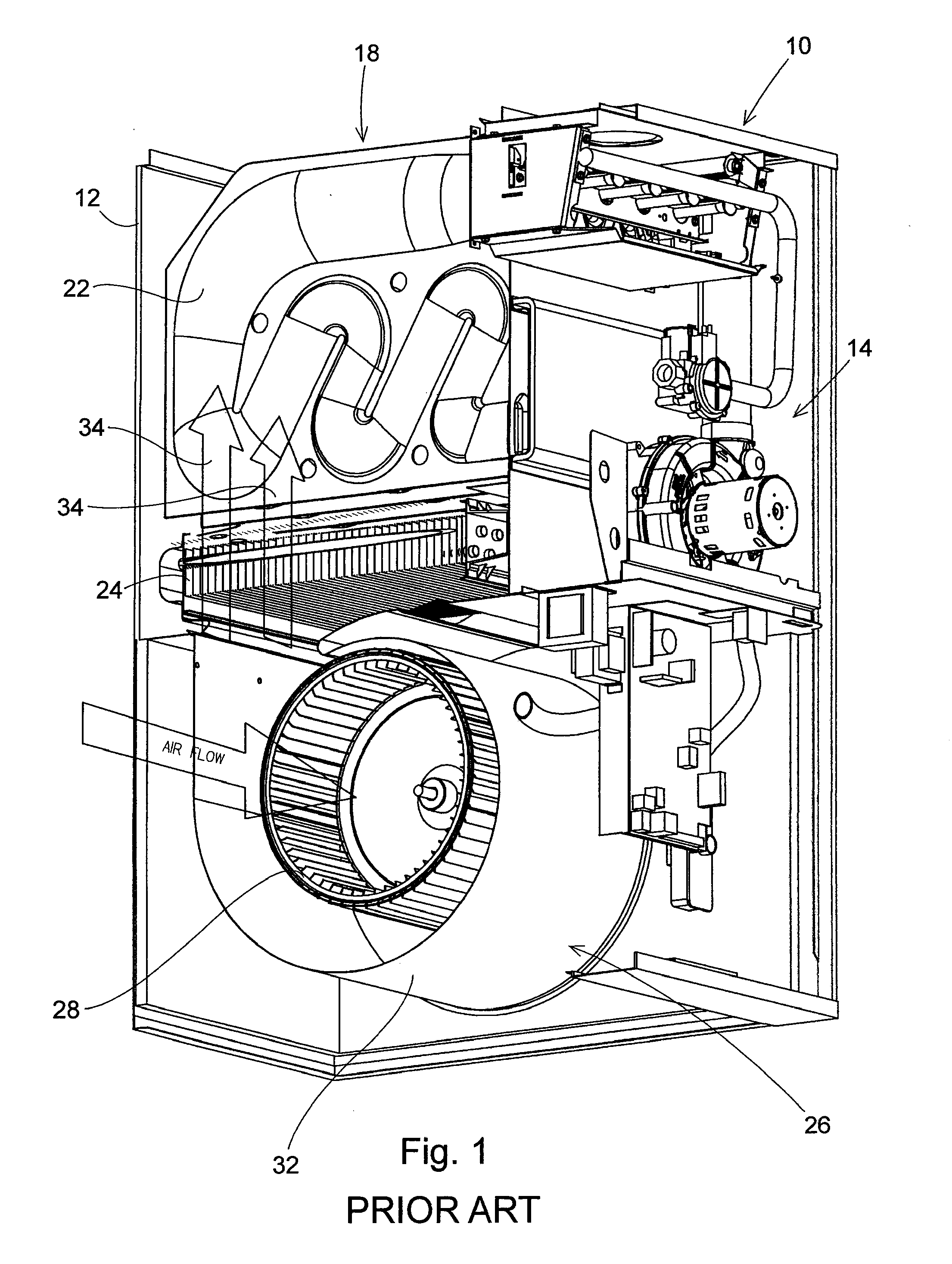

High Efficiency Furnace/Air Handler Blower Housing with a Side Wall Having an Exponentially Increasing Expansion Angle

ActiveUS20100078007A1Improve efficiencyEffectively turningPump componentsAir heatersAir handlerEngineering

An air distribution blower housing for an air handler such as a residential furnace is designed with a volute-shaped outer wall that has an exponentially increasing expansion angle in the direction of air flow through the blower housing for at least a portion of the volute-shaped outer wall length. This results in the blower housing having an enlarged air outlet opening that slows down and spreads out the air flow from the blower housing over a greater area of the furnace heat exchanger. The blower housing thereby enables less air pressure drop through the heat exchanger, which increases the efficiency of the blower motor operation. The design of the blower housing also efficiently turns the velocity head of the air flow through the housing to usable static air pressure at the housing air outlet.

Owner:REGAL BELOIT AMERICA

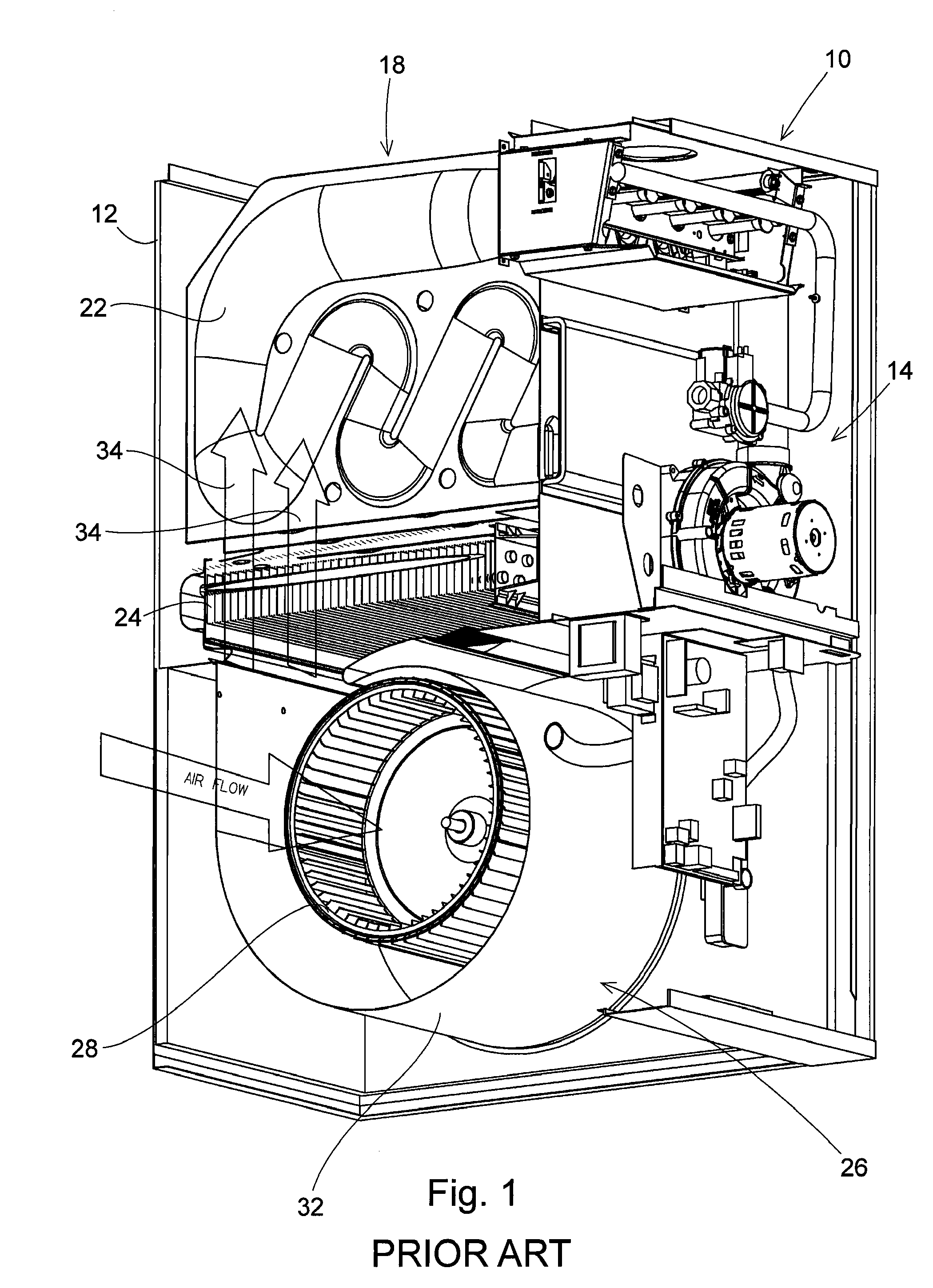

High Efficiency Furnace Having a Blower Housing with an Enlarged Air Outlet Opening

ActiveUS20090114205A1Overcomes efficiency problemLess pressure dropPump componentsAir heatersAirflowEngineering

An air distribution blower housing for a furnace is designed with an enlarged air outlet opening that slows down and spreads out the air flow from the blower housing over a greater area of the furnace heat exchanger. The blower housing thereby enables less air pressure drop through the heat exchanger, which increases the efficiency of the blower motor operation. The design of the blower housing also efficiently turns the velocity head of the air flow through the housing to usable static air pressure at the housing air outlet. The enlarged air outlet opening of the blower housing is achieved without increasing the exterior diameter dimensions of the blower housing by utilizing a volute outer wall of the blower housing that has an exponentially increasing expansion angle in the direction of air flow through the blower housing.

Owner:REGAL BELOIT AMERICA

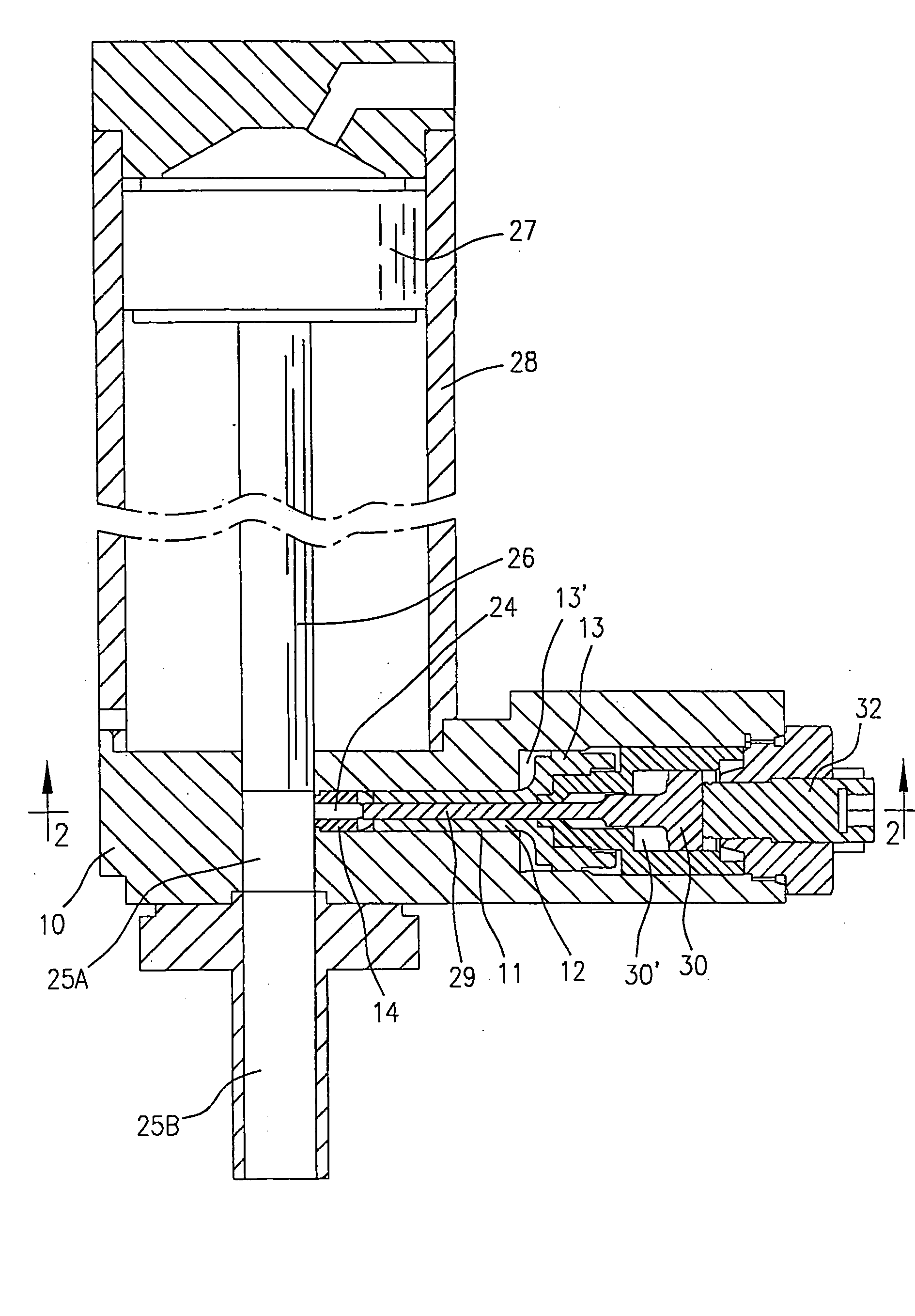

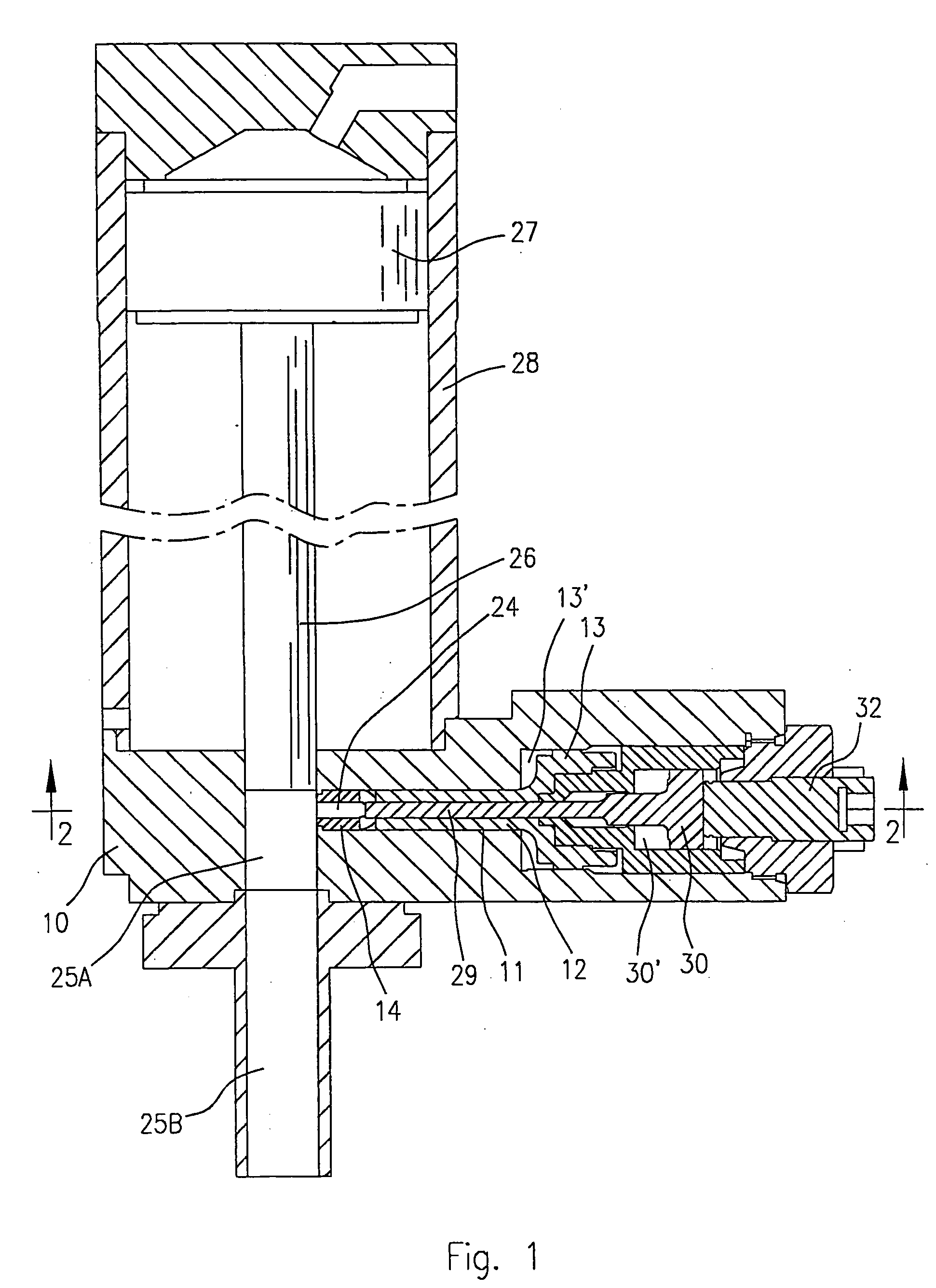

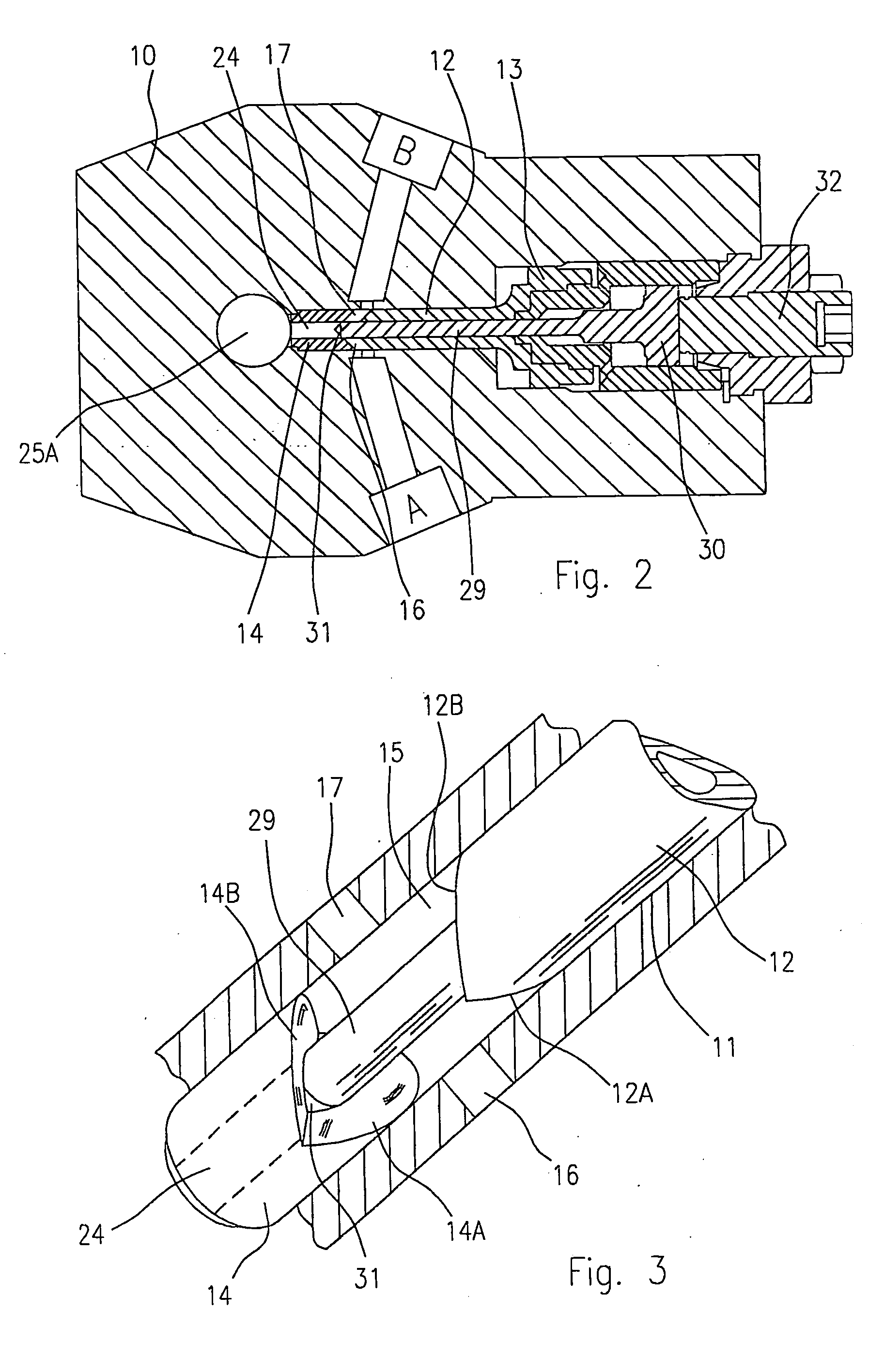

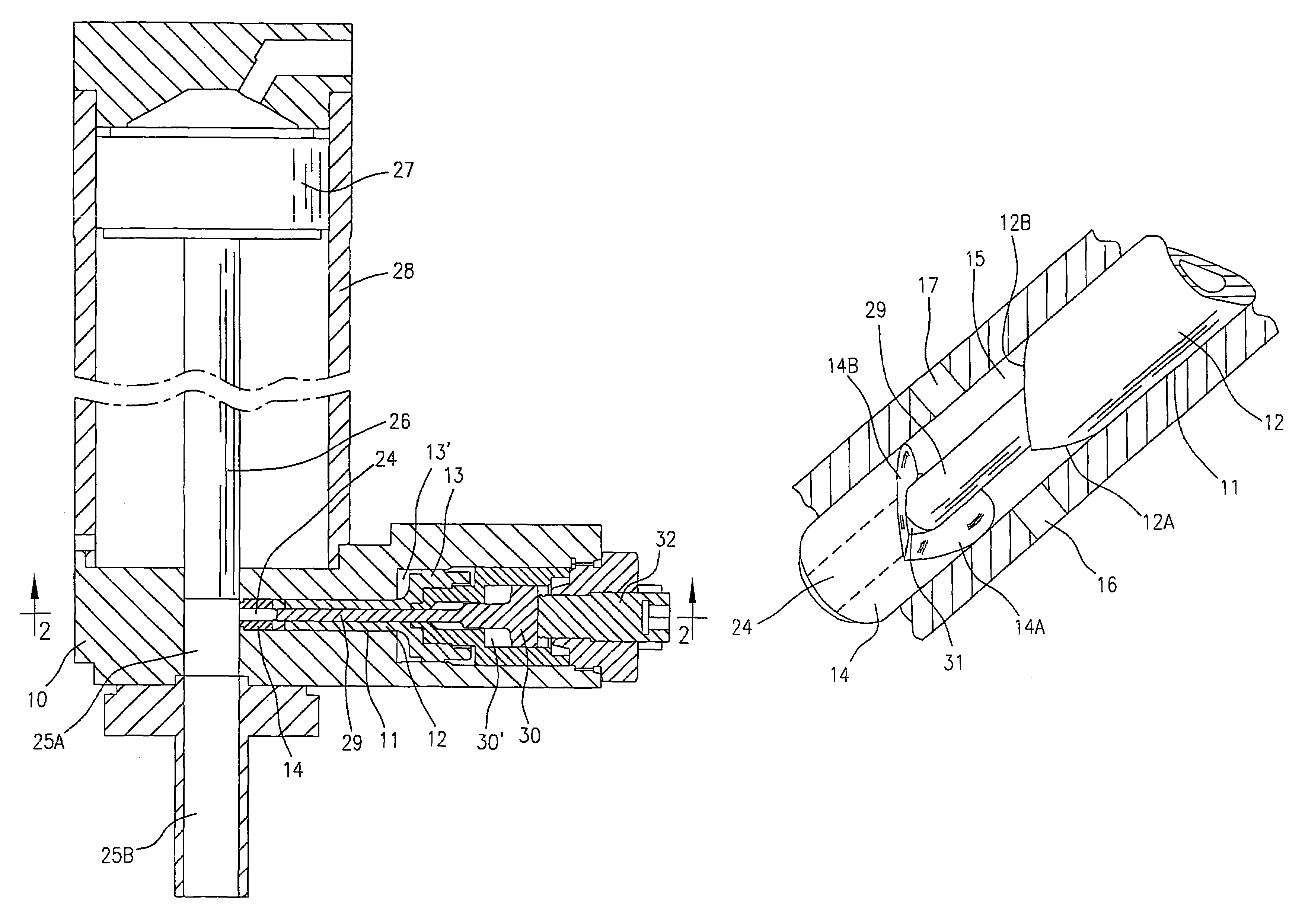

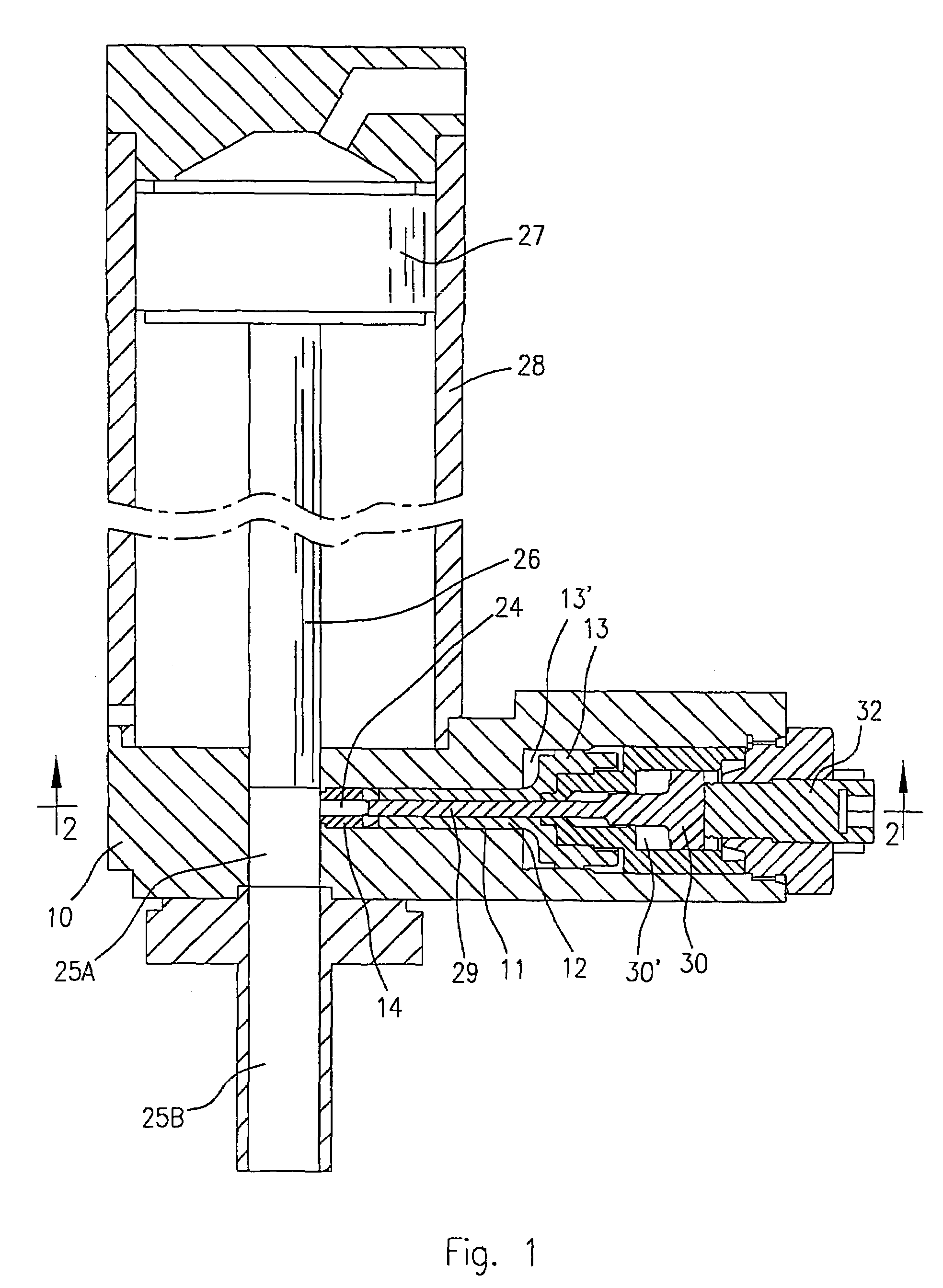

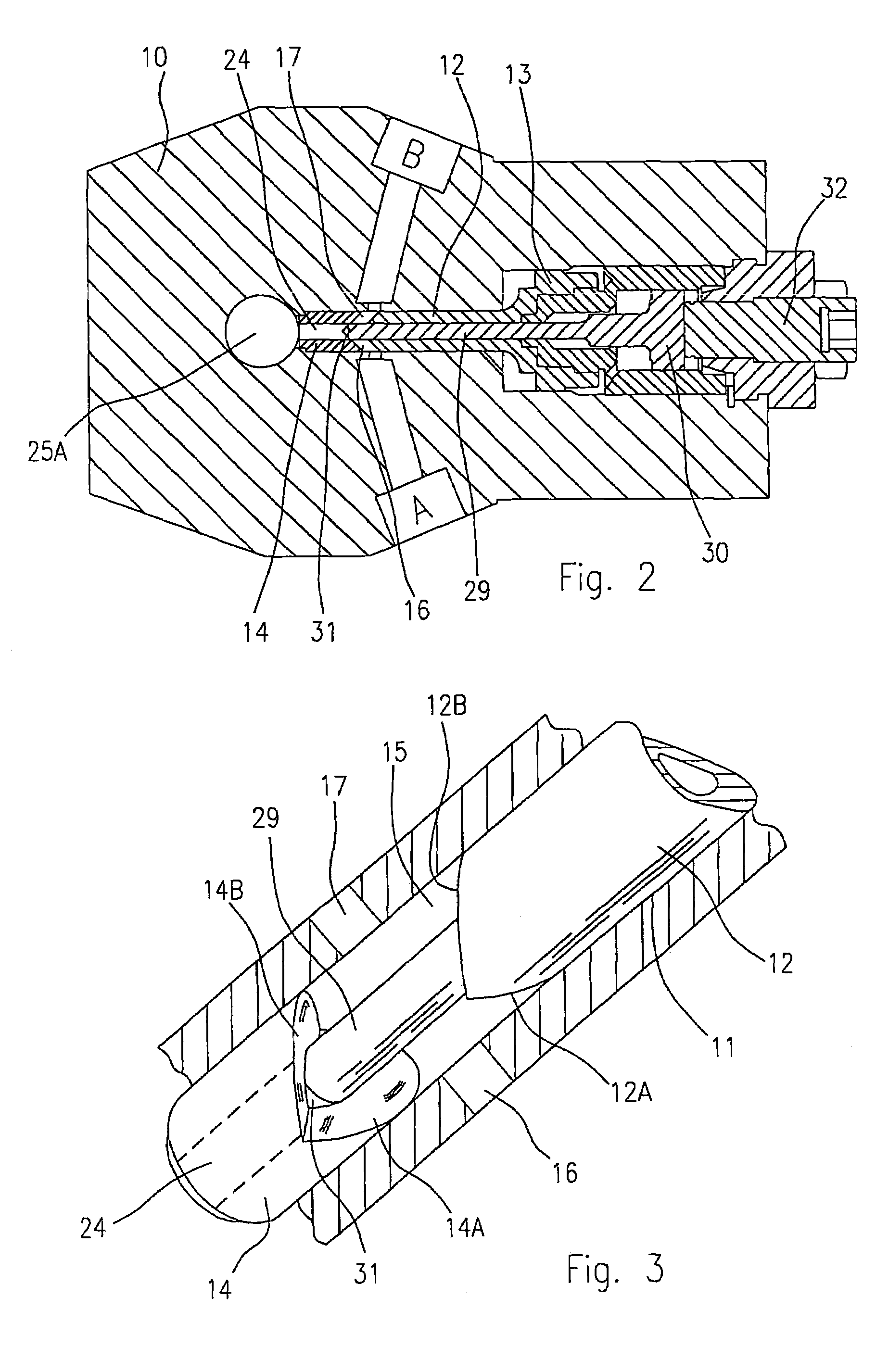

Co-injection mixing method and apparatus

InactiveUS20060104155A1Inhibition formationEasy to controlMixer accessoriesChemical compositionProcess engineering

Method and device (10) for mixing polyurethane—forming reactive chemical components; at least first and second chemical components (A, B) are introduced into a common pressure and feeding chamber, from where the chemical components are made to flow and co-injected through one or more narrow orifices (31) into a mixing chamber. During co-injection of the chemical components (A, B) a first mixing takes place into the jet strim, while a final intimate mixing is performed by impingement and collision into the mixing chamber (24) of the device; selectively actuable cleaning members (12, 29) eject the residual chemical material remaining into the common pressure and feeding chamber (15), and the mixing chamber (24) of the mixing device (10).

Owner:AFROS

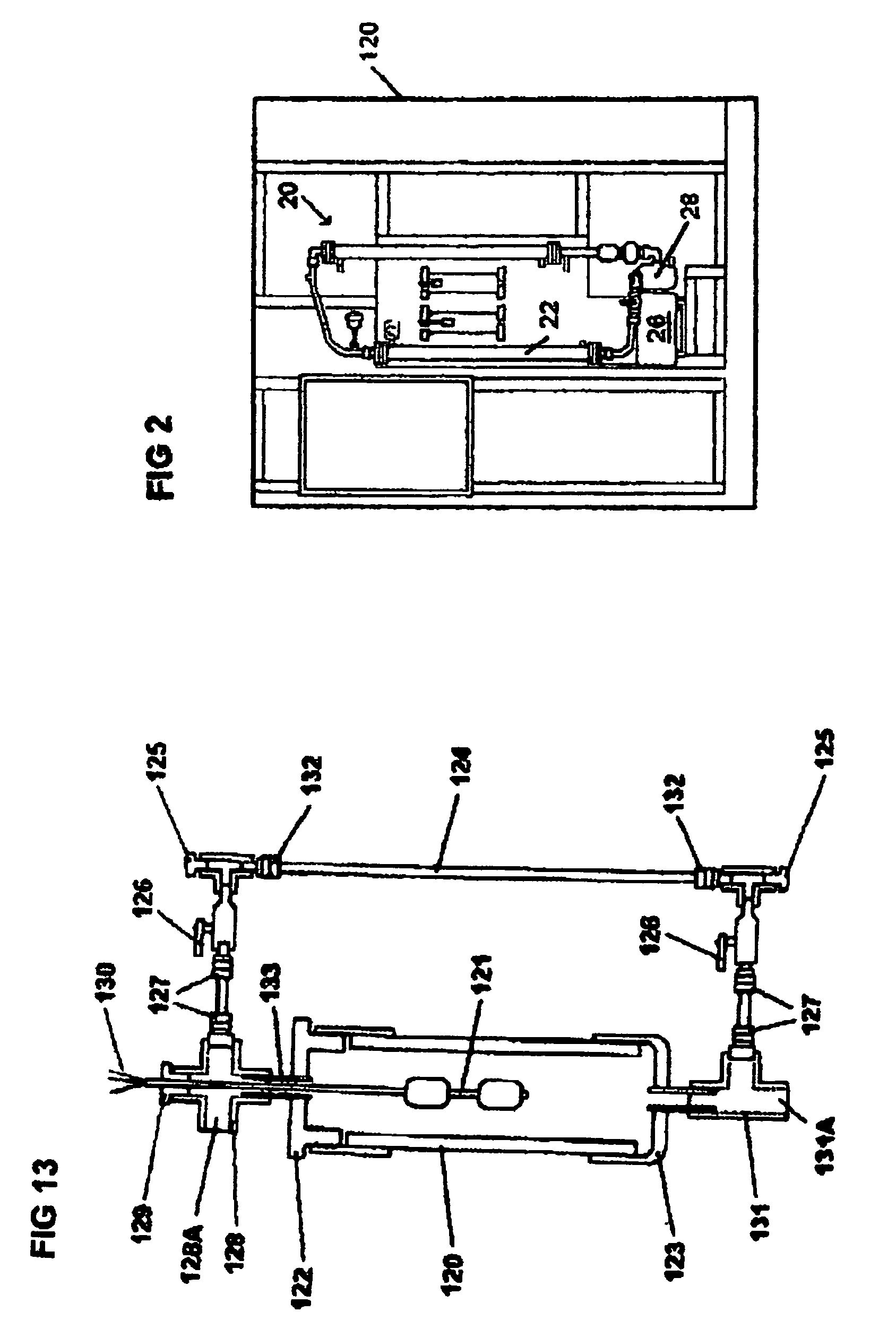

Water separation system

InactiveUS20070039883A1Levels of of wasteTreatment of wasteMembranesWater contaminantsFiltration membraneHigh rate

Waste oily water is dewatered by expelling water through ceramic ultra filtration membranes of a cross-flow filter, located in a circulation ring, which is routinely cleaned in situ. The ring has two auxiliary reservoirs, with removable sight glasses, between which reservoirs the cleaning fluid is see-sawed during cleaning cycles, the reversing chemical flow being controlled by float switches. Heating for cleaning purposes is by way of closed-loop high-rate ring circulation. Frequent automated cleaning by a Programmable Logic Controller (PLC) maintains high flux rates with sustainable large volume annual throughput in the range of 1 to 2 million litres per year per square meter of filter membrane surface area. The system is fail-safe and environmentally friendly.

Owner:GLYNN DONALD R

Bedding climate control apparatus and method to operate thereof

ActiveUS20170340128A1Suppress generationSuppress soundLighting and heating apparatusBlanketRemote controlRoom temperature

A bedding climate control apparatus that delivers, in a quiet manner, forced airflow from a fan / blower within a housing to selectively deliver tempered (heated via a thermal element) and untempered (room temperature) air through a flexible hose to bedding. The quiet manner is attained with acoustic dampening material in the path of incoming airflow to the fan / blower and by oversizing each of the components that create a pressure drop including the capacity of the fan / blower over what is needed to deliver a required amount of airflow. Temperature may be set remotely via a wireless remote control and via a protocol access enabled device.

Owner:BEDJET LLC

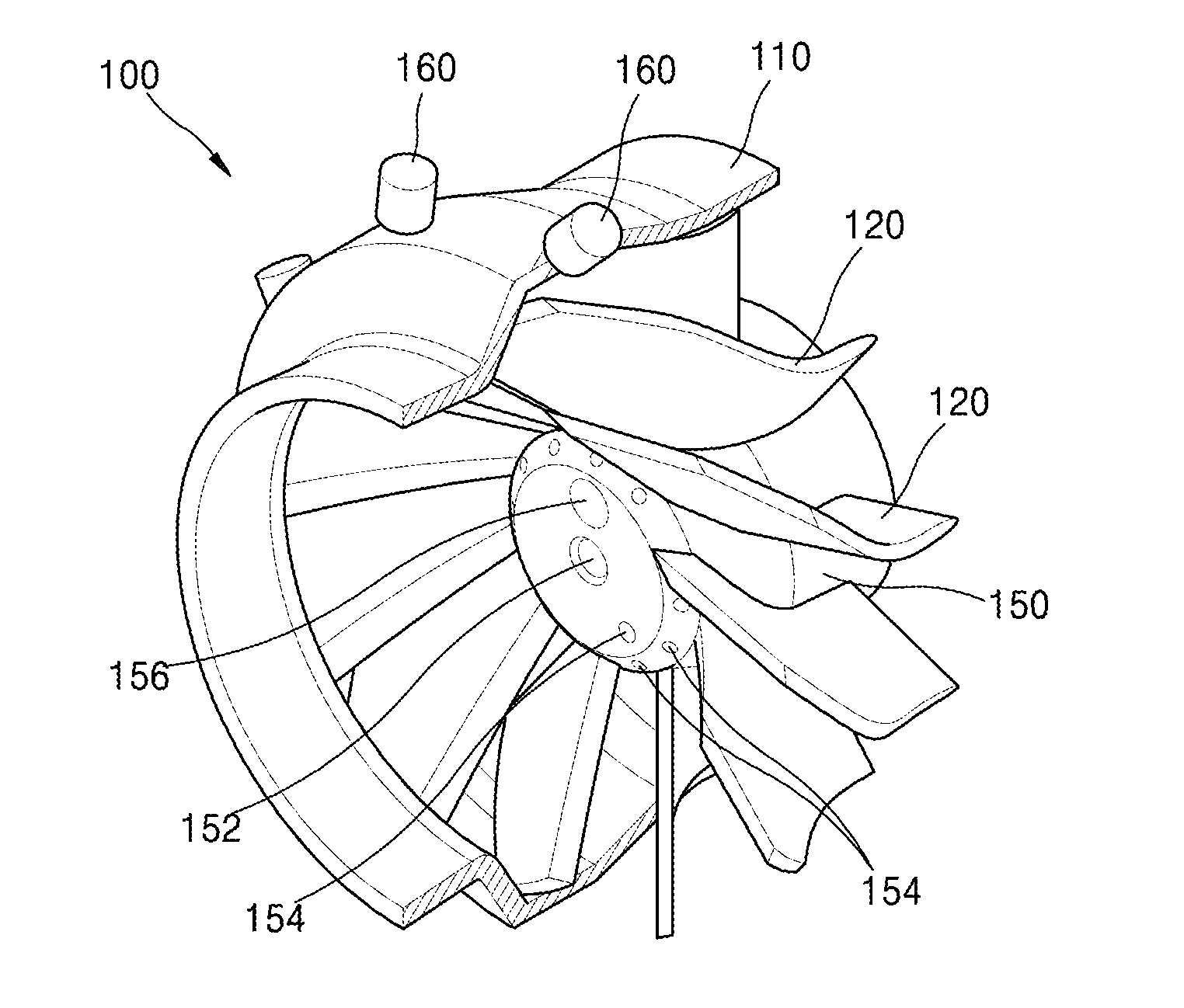

Swirler

ActiveUS20160195266A1Improve performanceLess pressure dropContinuous combustion chamberCapillary burnersEngineeringExtremity Part

The inventive concept relates to a swirler. According to an aspect of the inventive concept, there is provided a swirler including a casing, a pilot body disposed in the casing, and a plurality of vanes arranged along a circumference of the pilot body, wherein at least a part of the vane protrudes further to a downstream than an end portion of the pilot body.

Owner:HANWHA AEROSPACE CO LTD

High efficiency furnace having a blower housing with an enlarged air outlet opening

ActiveUS8025049B2Overcomes efficiency problemLess pressure dropPump componentsAir heatersEngineeringHeat exchanger

An air distribution blower housing for a furnace is designed with an enlarged air outlet opening that slows down and spreads out the air flow from the blower housing over a greater area of the furnace heat exchanger. The blower housing thereby enables less air pressure drop through the heat exchanger, which increases the efficiency of the blower motor operation. The design of the blower housing also efficiently turns the velocity head of the air flow through the housing to usable static air pressure at the housing air outlet. The enlarged air outlet opening of the blower housing is achieved without increasing the exterior diameter dimensions of the blower housing by utilizing a volute outer wall of the blower housing that has an exponentially increasing expansion angle in the direction of air flow through the blower housing.

Owner:REGAL BELOIT AMERICA

Low Profile, High Efficiency Blower Assembly

InactiveUS20110189005A1Overcomes efficiency problemLess pressure dropPump componentsStatorsAir handlerEngineering

An air distribution blower housing for a low profile air handler such as a residential furnace is designed with a volute-shaped outer wall that has an exponentially increasing expansion angle in the direction of air flow through the blower housing for at least a portion of the volute-shaped outer wall length. This results in the blower housing having an enlarged air outlet opening that slows down and spreads out the air flow from the blower housing over a greater area of the furnace heat exchanger. The blower housing thereby enables less air pressure drop through the heat exchanger, which increases the efficiency of the blower motor operation. The design of the blower housing also efficiently turns the velocity head of the air flow through the housing to usable static air pressure at the housing air outlet.

Owner:REGAL BELOIT AMERICA

Co-injection mixing method and apparatus

A method and device (10) for mixing polyurethane-forming liquid chemical components for the production of polyurethane foams, in which positive use is made of the turbulency and swirling action caused by the injection of pressurized jets of chemical components, in order to provide a methodology tending to improve the mixing processes by impingement and by the turbulency induced by a pressure drop in conventional self-cleaning apparatuses.

Owner:AFROS

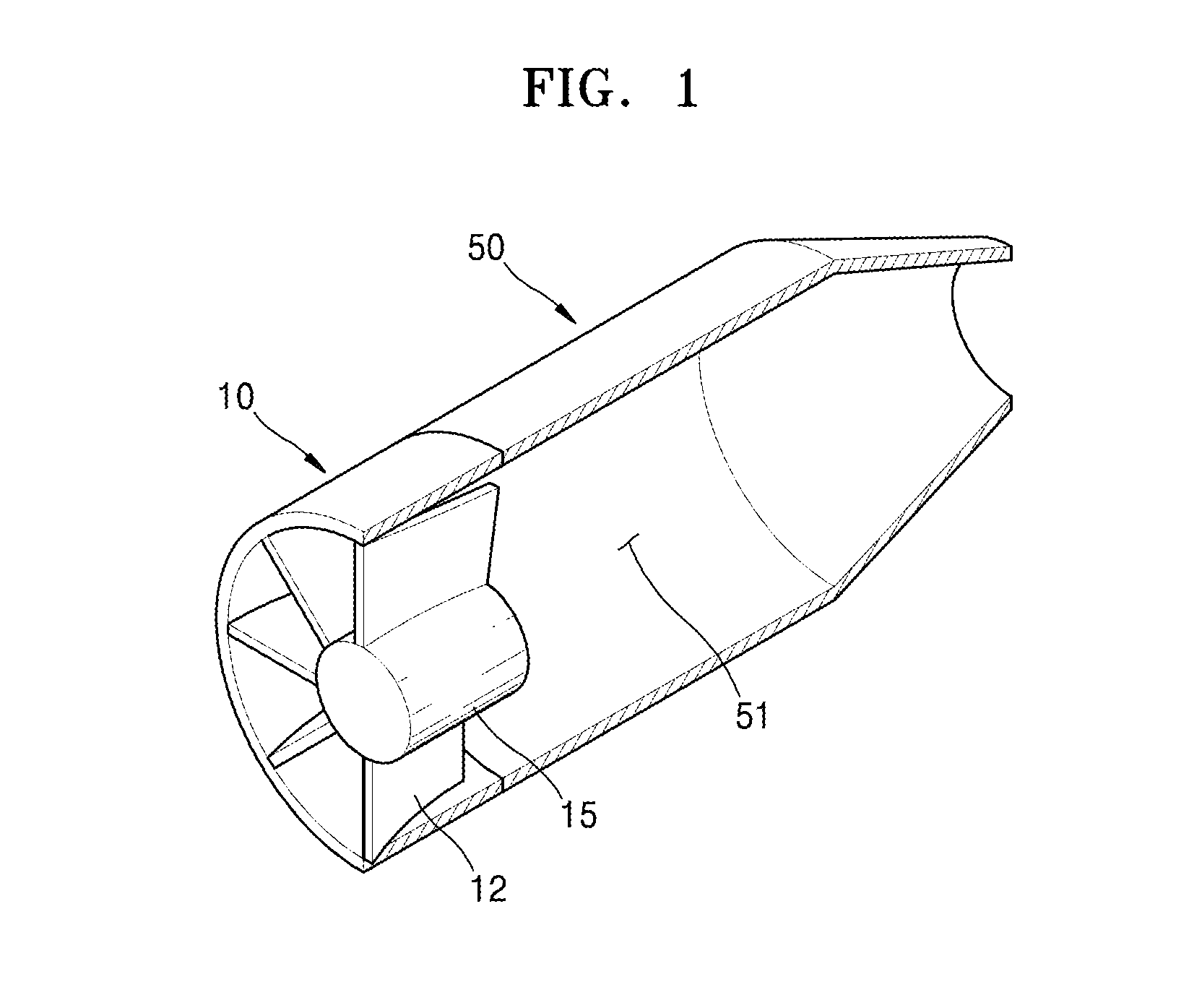

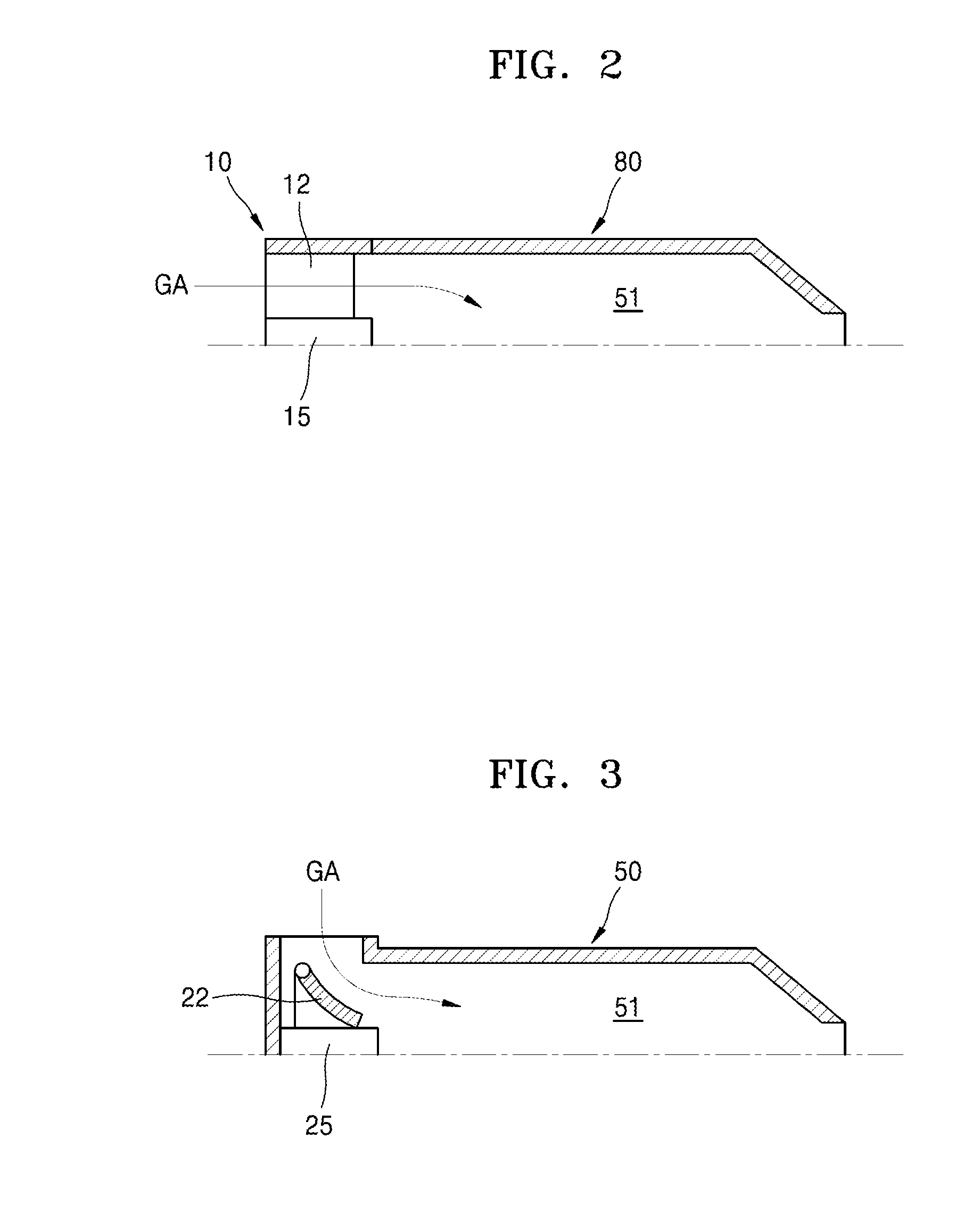

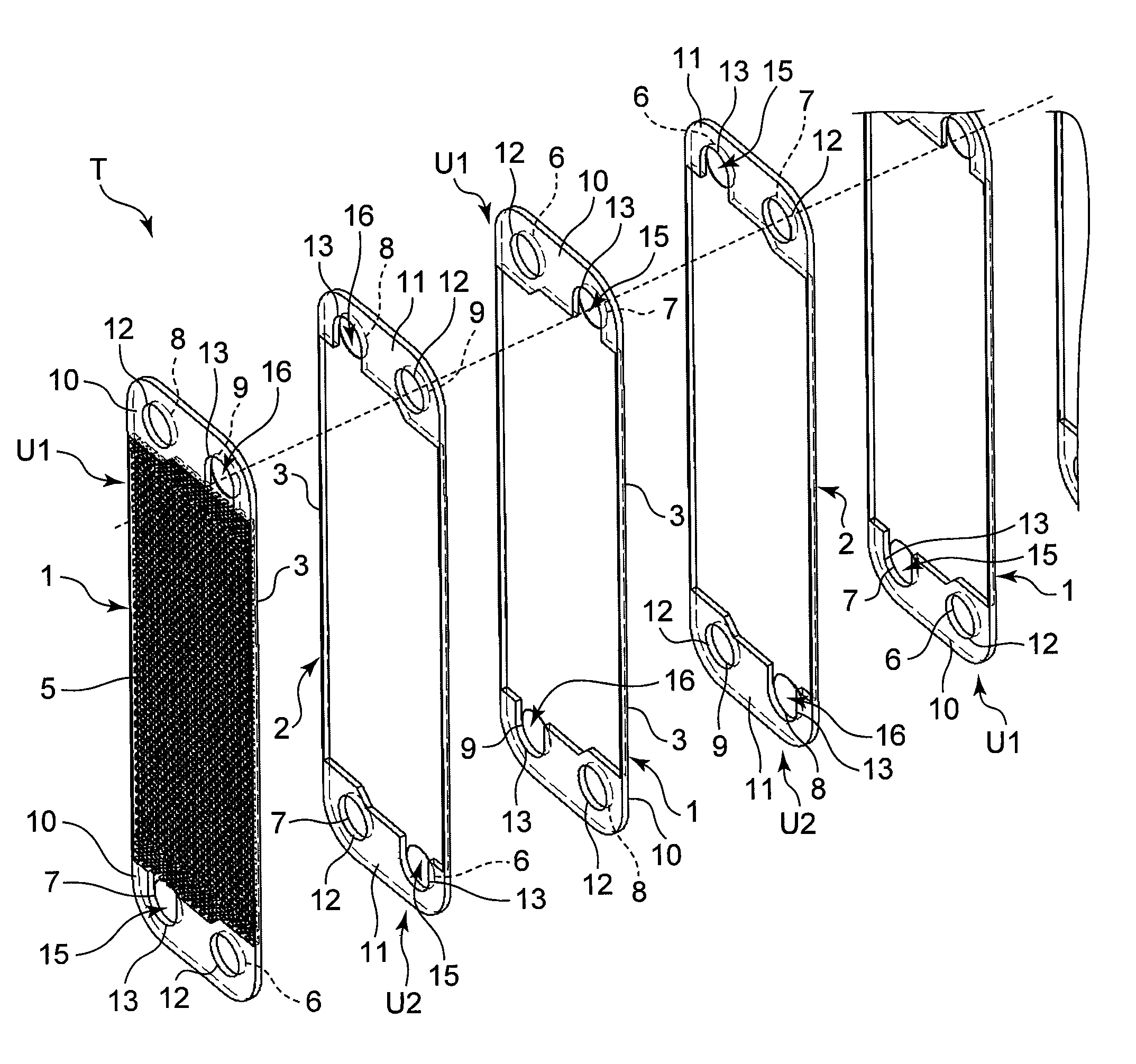

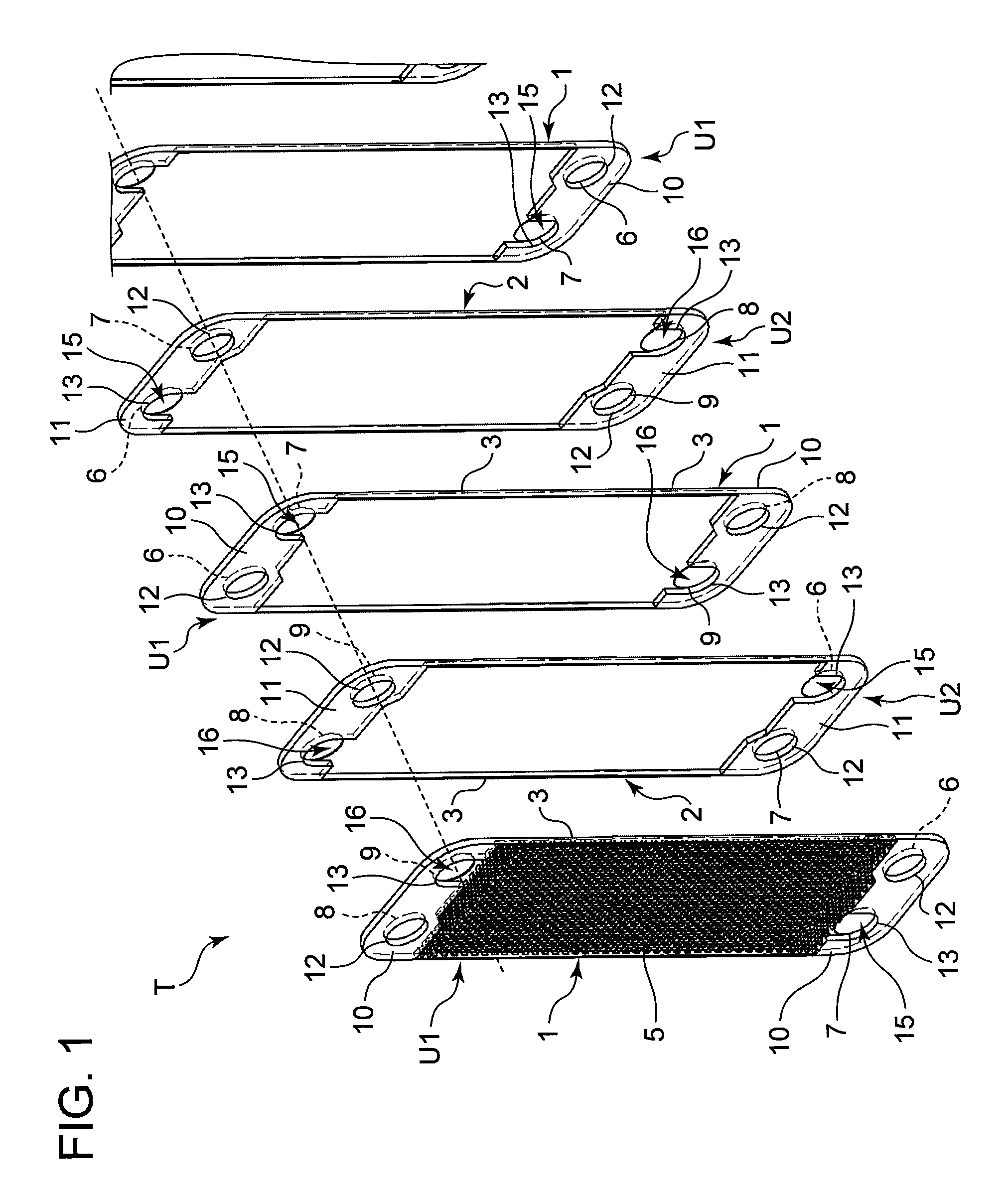

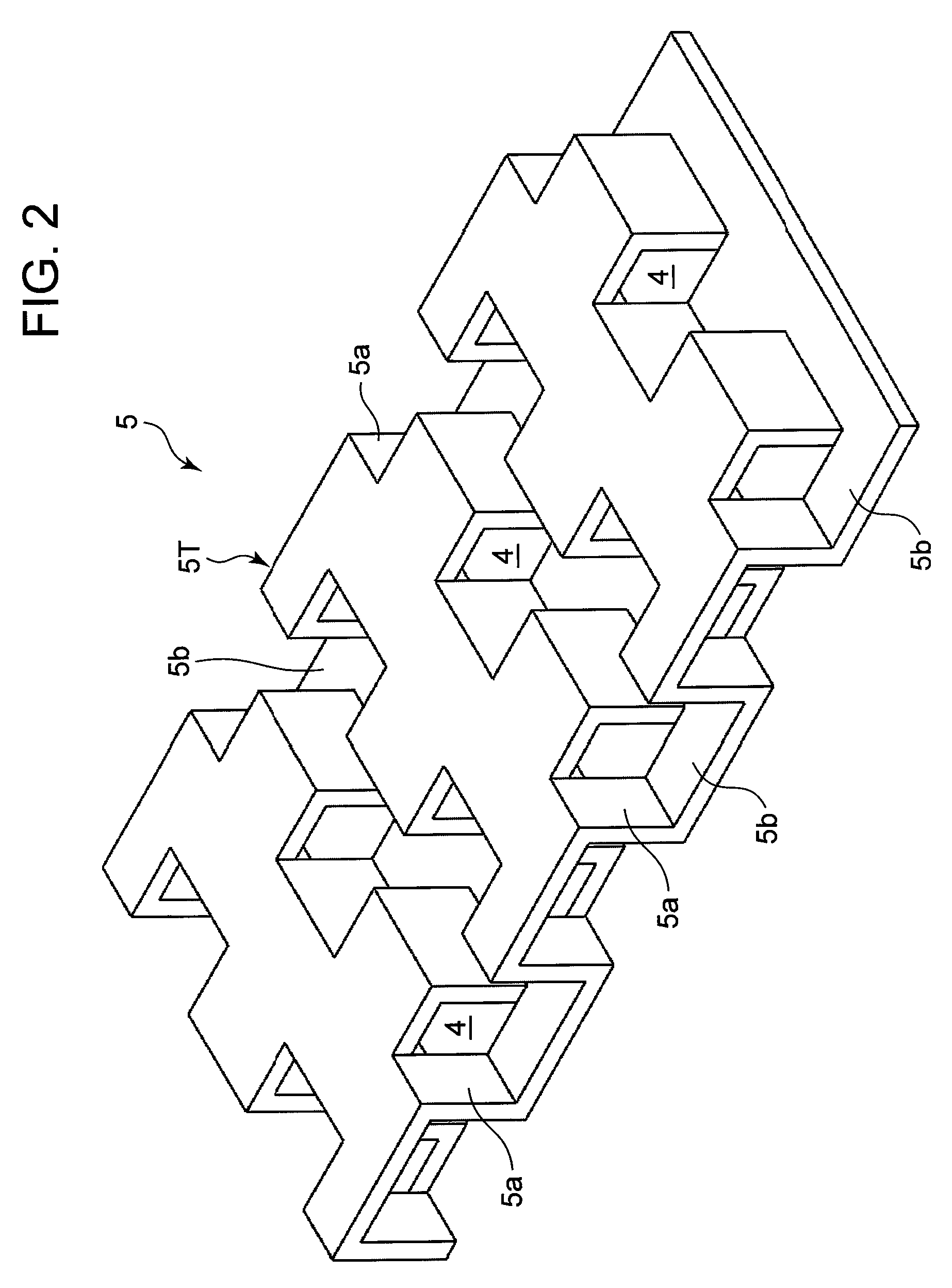

Heat exchanger and manufacturing method of the same

InactiveUS20100025025A1Speed up the flowImproving non-uniform rate distributionEvaporators/condensersMetal-working apparatusPlate heat exchangerEngineering

There is disclosed a heat exchanger capable of suppressing the increase of a pressure drop while improving a non-uniform rate distribution of a fluid. A heat exchanger T of the present invention is constituted of flat plates 1, 2 each having an inflow port 15 of the fluid on one end thereof and an outflow port 16 of the fluid on the other end, and offset type fins 5 provided in the flat plates 1, 2, and includes a fin orthogonal region H where the plate fins 5 cross the flow direction of the fluid from the inflow port 15 to the outflow port 16 at right angles and a fin parallel region V where the plate fins 5 are disposed in parallel with the flow direction of the fluid from the inflow port 15 to the outflow port 16, the fin orthogonal regions H are provided on the sides of the inflow port 15 and the outflow port 16, and the fin parallel region V is provided between the respective fin orthogonal regions H.

Owner:SANYO ELECTRIC CO LTD +1

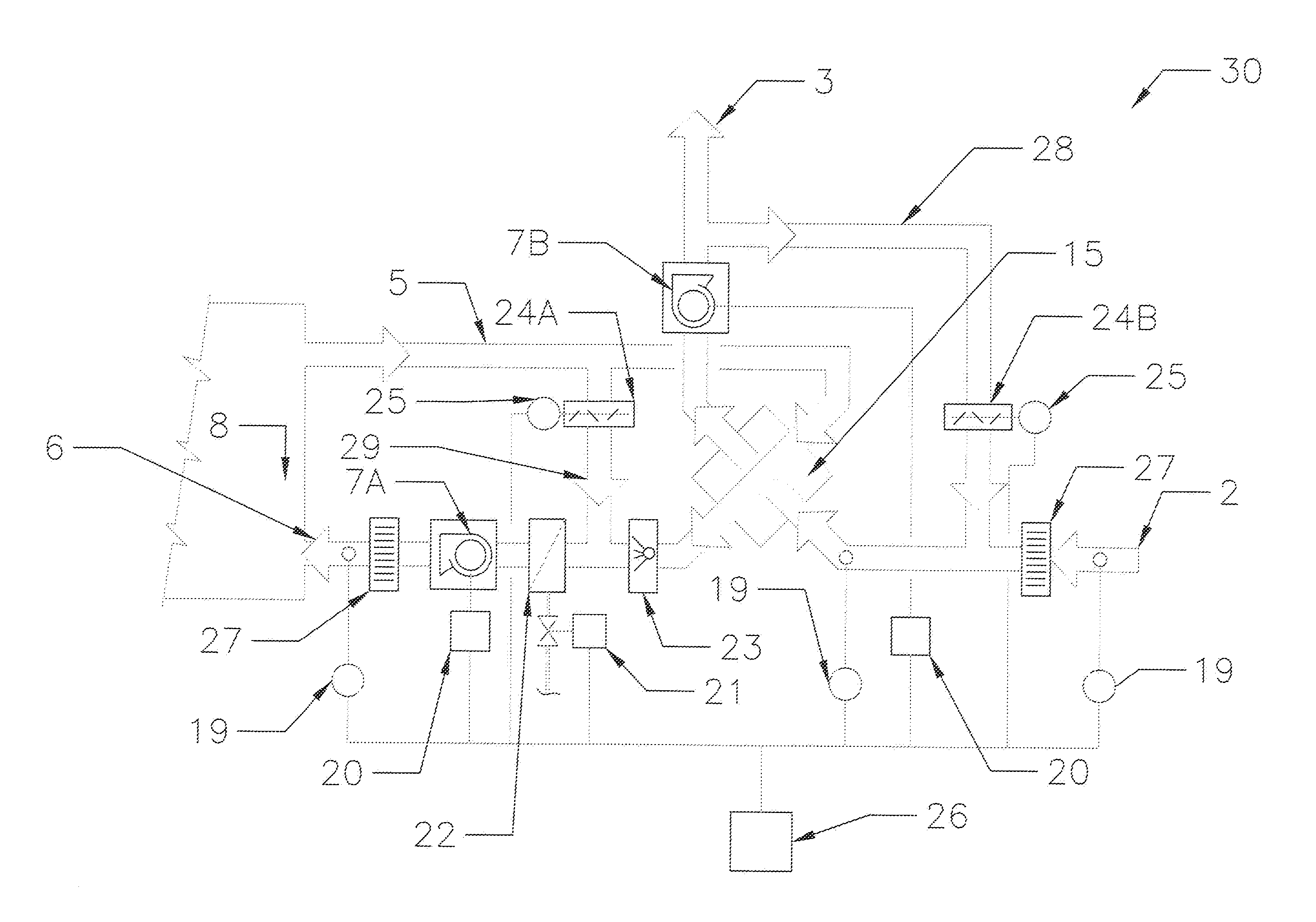

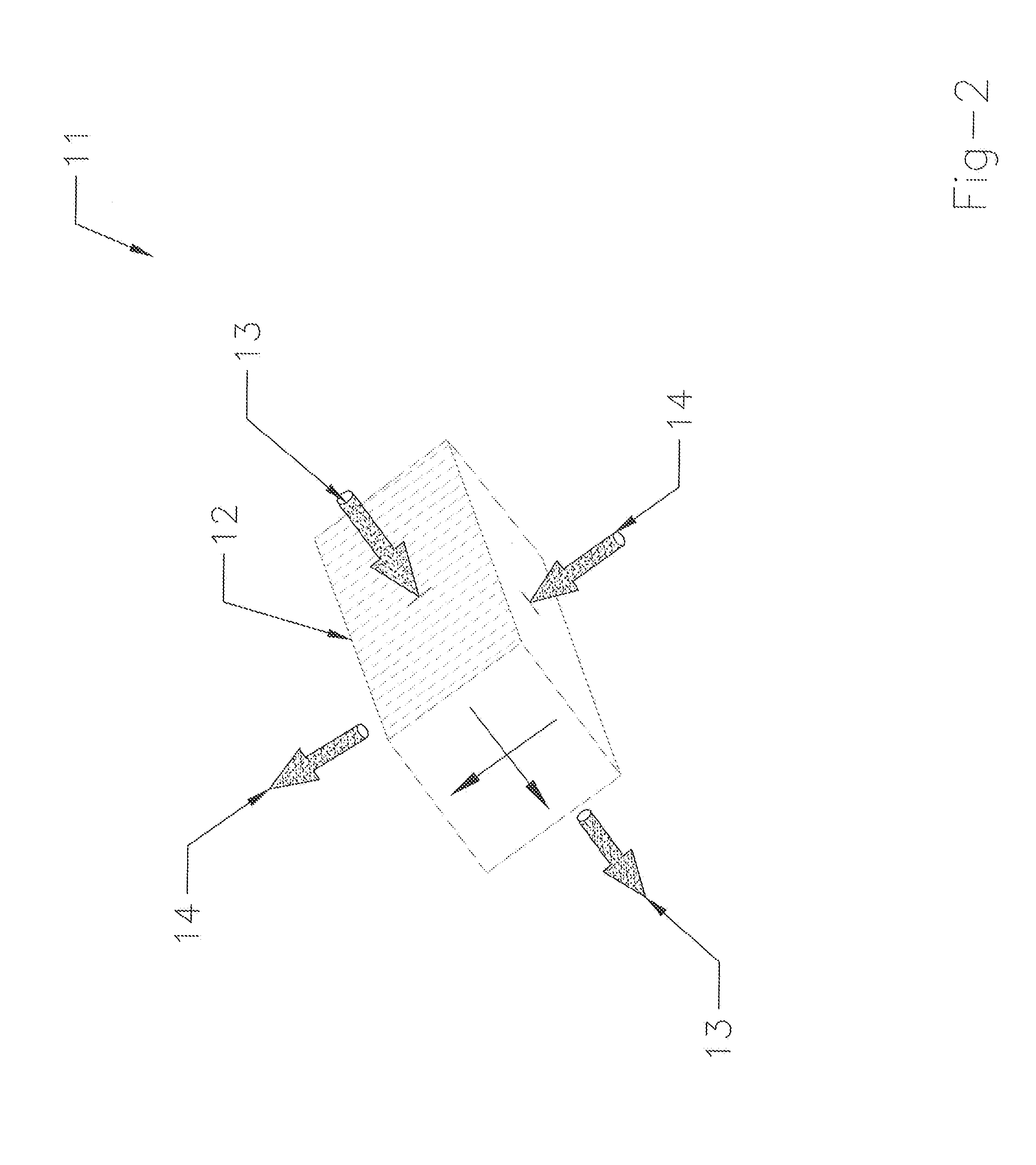

Climate Control System for Data Center

ActiveUS20150208552A1Avoid cross contaminationAvoid efficiency lossSpace heating and ventilation safety systemsSpace heating and ventilation control systemsData centerEngineering

Optimized conditioning of Information and Communication Technology (ICT) centers containing sensible heat generating equipment is achieved by indirect air-side economizing. In this process, the conditioned primary air stream is recirculated through a plate-type cross-flow heat exchanger, in which the cross-flow consists of a completely segregated cooler secondary ambient air stream. The air-to-air cross-flow heat exchanger comprises a series of parallel square or rectangular plates, which define a series of orthogonally alternating air passageways. This cross-flow design effectively prevents the mixing or blending of the primary and secondary air streams and thus avoids the efficiency losses and process airstream cross-contamination due to leakage, which is inherent in wheel type heat exchangers. The unique modular tunnel design of the cross-flow plate heat exchanger arrangement offers unit scalability and adjustability for various capacities and space demands. Real-time sensing of thermal demands and variable capacity control, coupled with on-demand mechanical cooling and humidification provisions, facilitate continuous operational optimization in all demands and ambient conditions.

Owner:DYNA TECH SALES CORP

Method of manufacturing a miniature flexible thrombectomy catheter

ActiveUS7996974B2Maximize thrombectomy actionGood effectMedical devicesMeasurement/indication equipmentsDistal portionBlood vessel

The present invention pertains to a miniature flexible thrombectomy catheter having one or more flexible miniature noncollapsing tubular portions including pushable and torqueable structure for introduction into the smaller vessels in neurovascular regions. A jet body having an arcuate fluid jet emanator is incorporated in order to minimize size at the distal portion of a minimally sized catheter tube.

Owner:BOSTON SCI MEDICAL DEVICE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com