Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Short injection time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

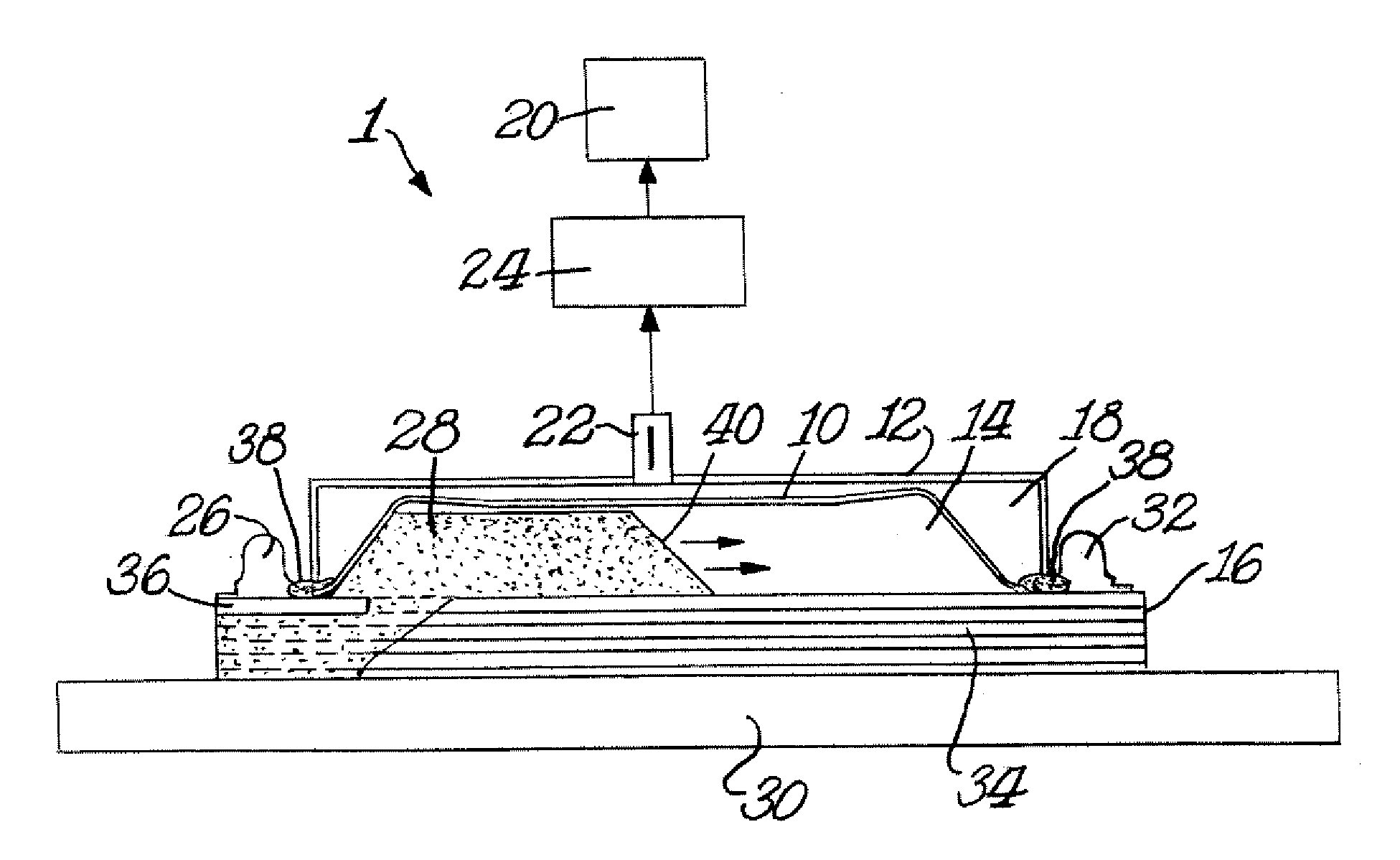

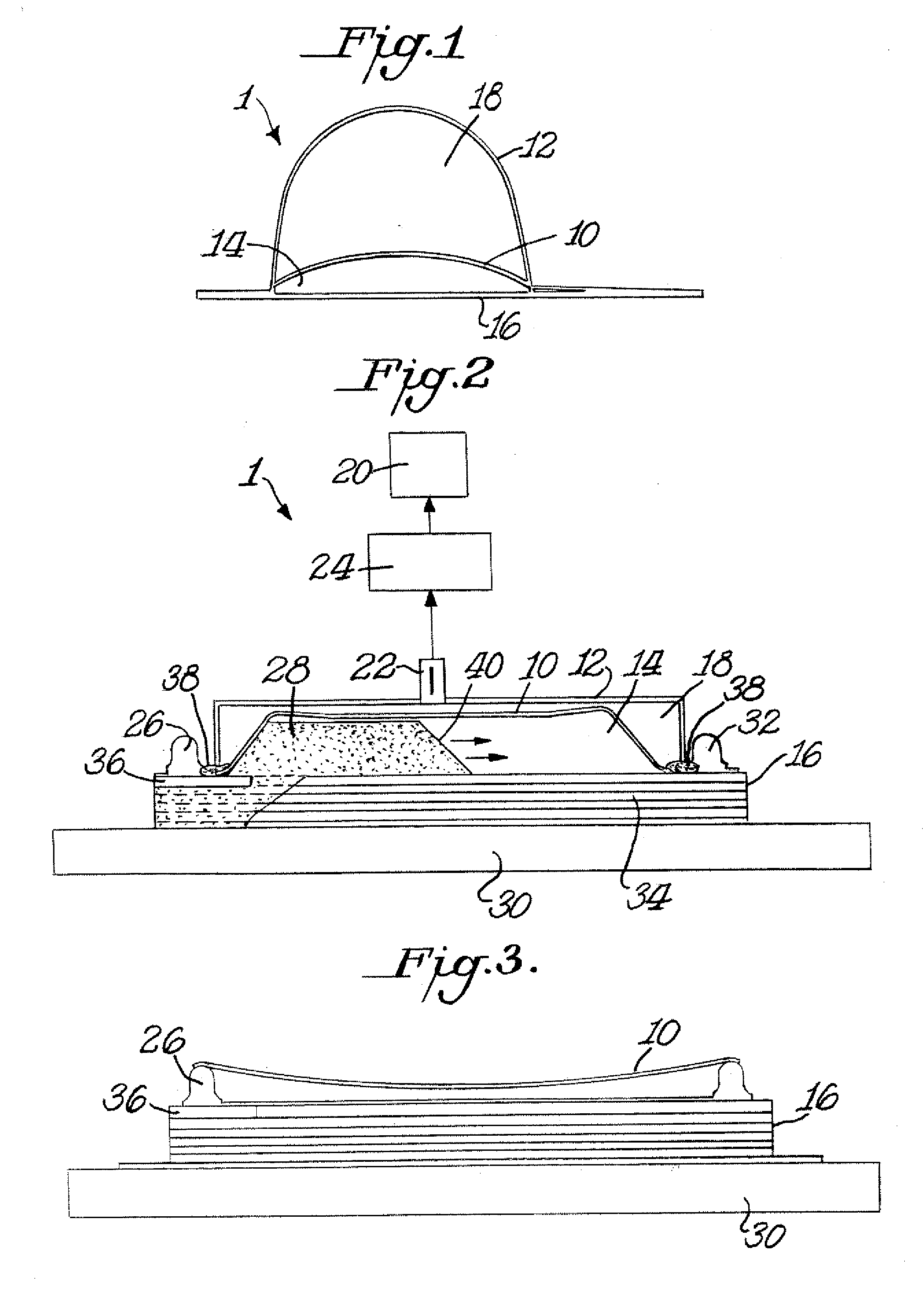

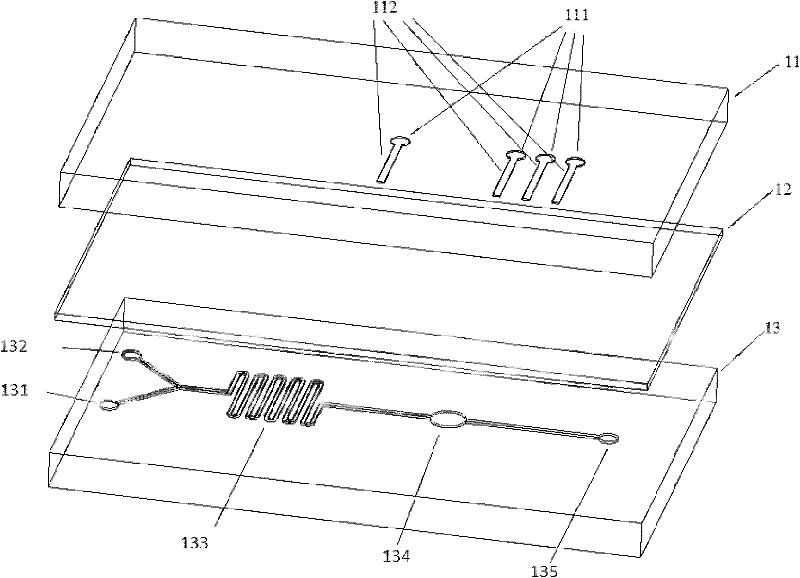

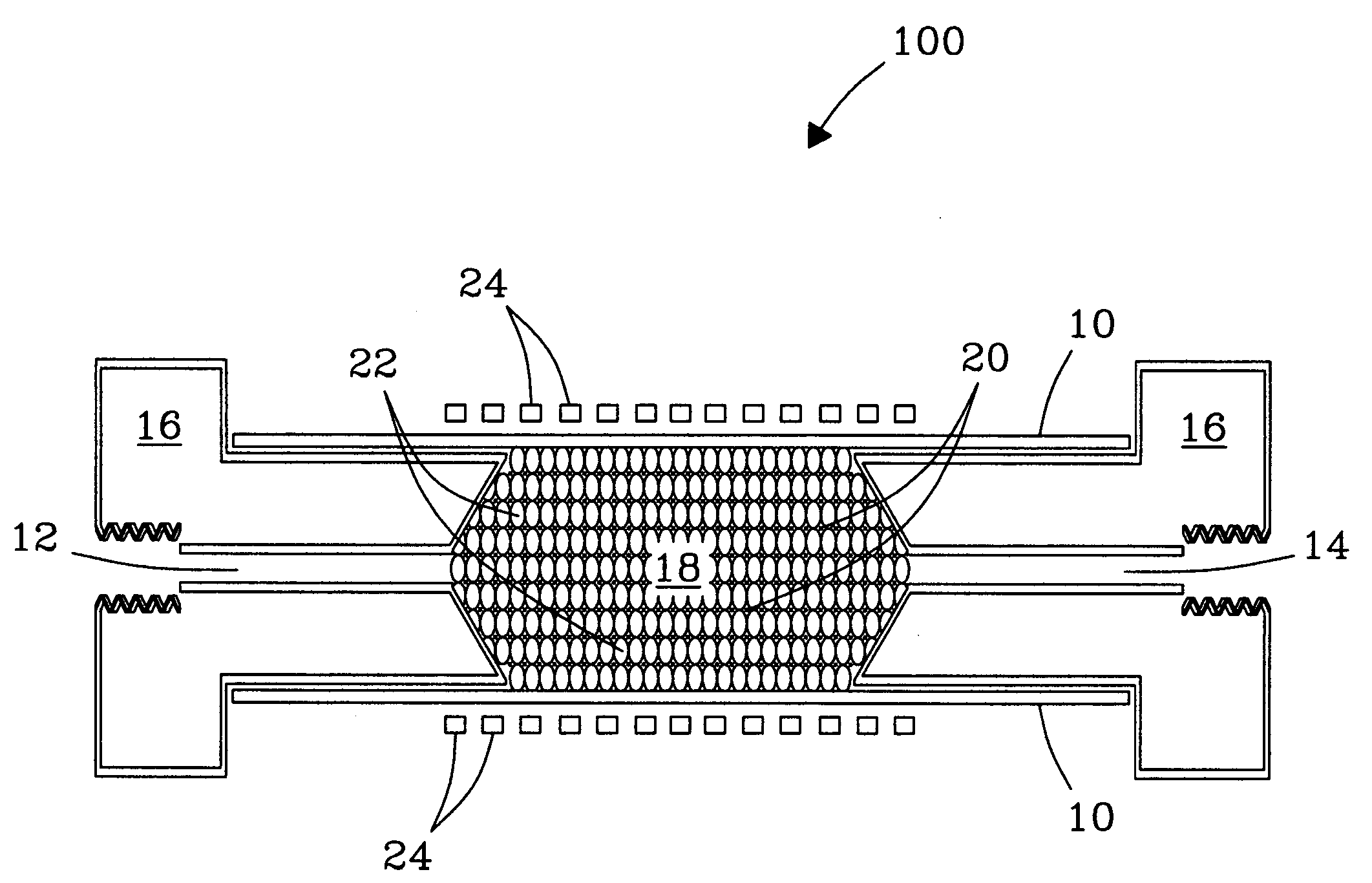

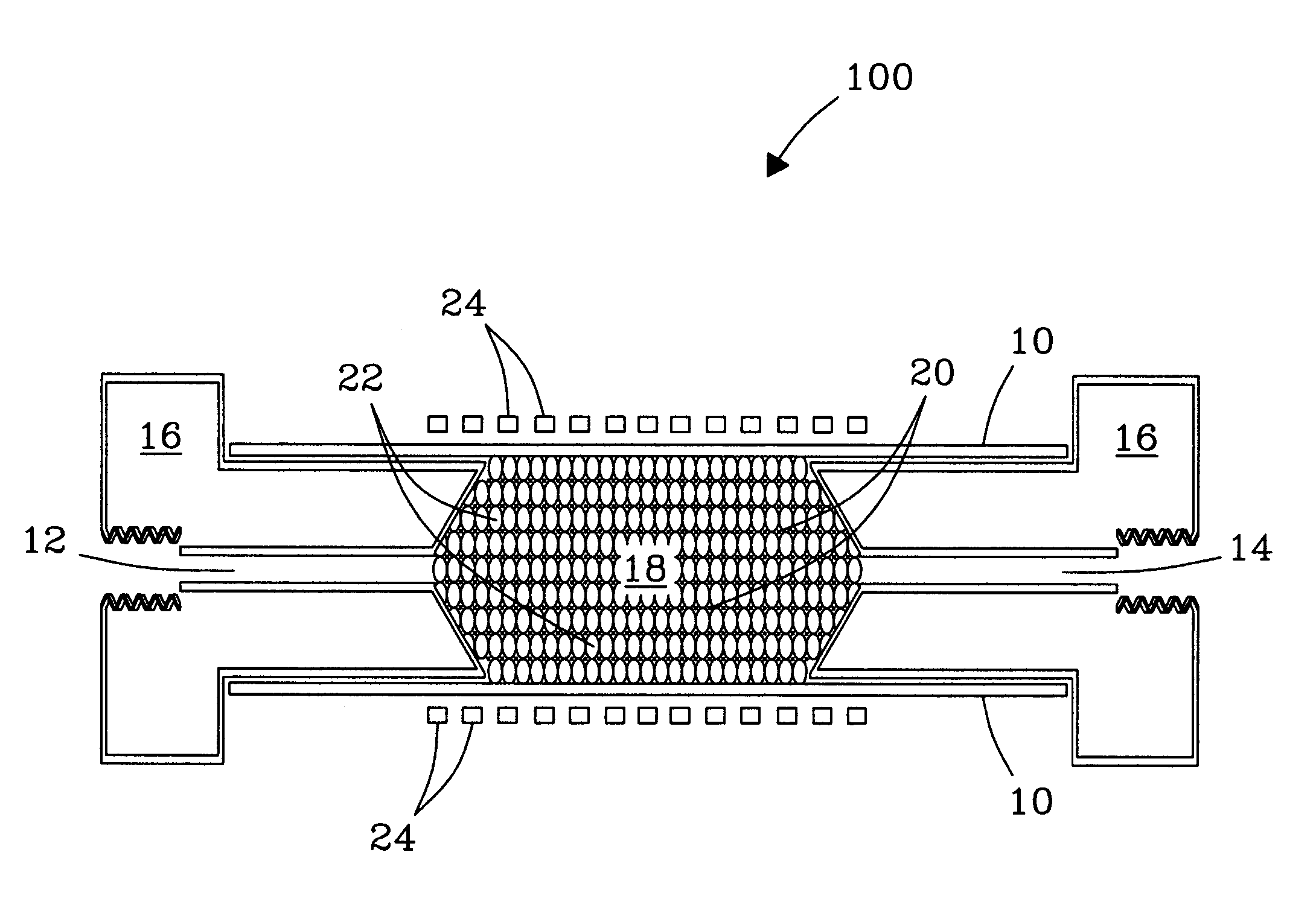

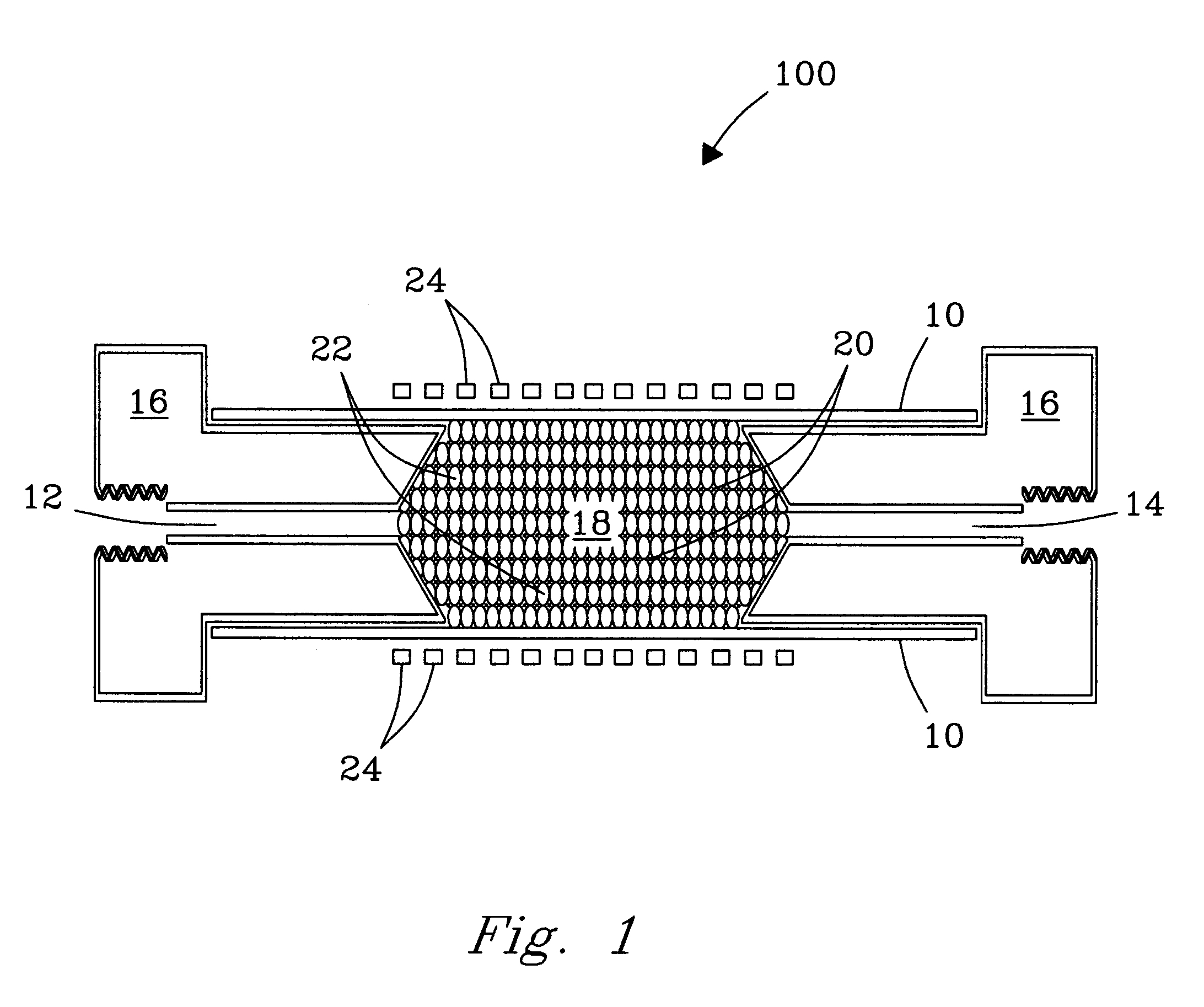

Vacuum assisted resin transfer molding techniques with flow flooding chamber

InactiveUS20070063393A1Short injection timeLabor savingLaminationLamination apparatusMechanical engineeringVacuum assisted resin transfer molding

Vacuum assisted resin transfer molding techniques are improved by mounting a rigid external shell on top of a vacuum bag. The shell is sealed around the vacuum bag so that a vacuum is created between the shell and the vacuum bag, the vacuum causes the vacuum bag to be freely stretched and lifted away from the preform to create a flow flooding chamber which provides a flow channel on the top face of the preform to accelerate the resin flow and reduce the injection time.

Owner:UNIVERSITY OF DELAWARE

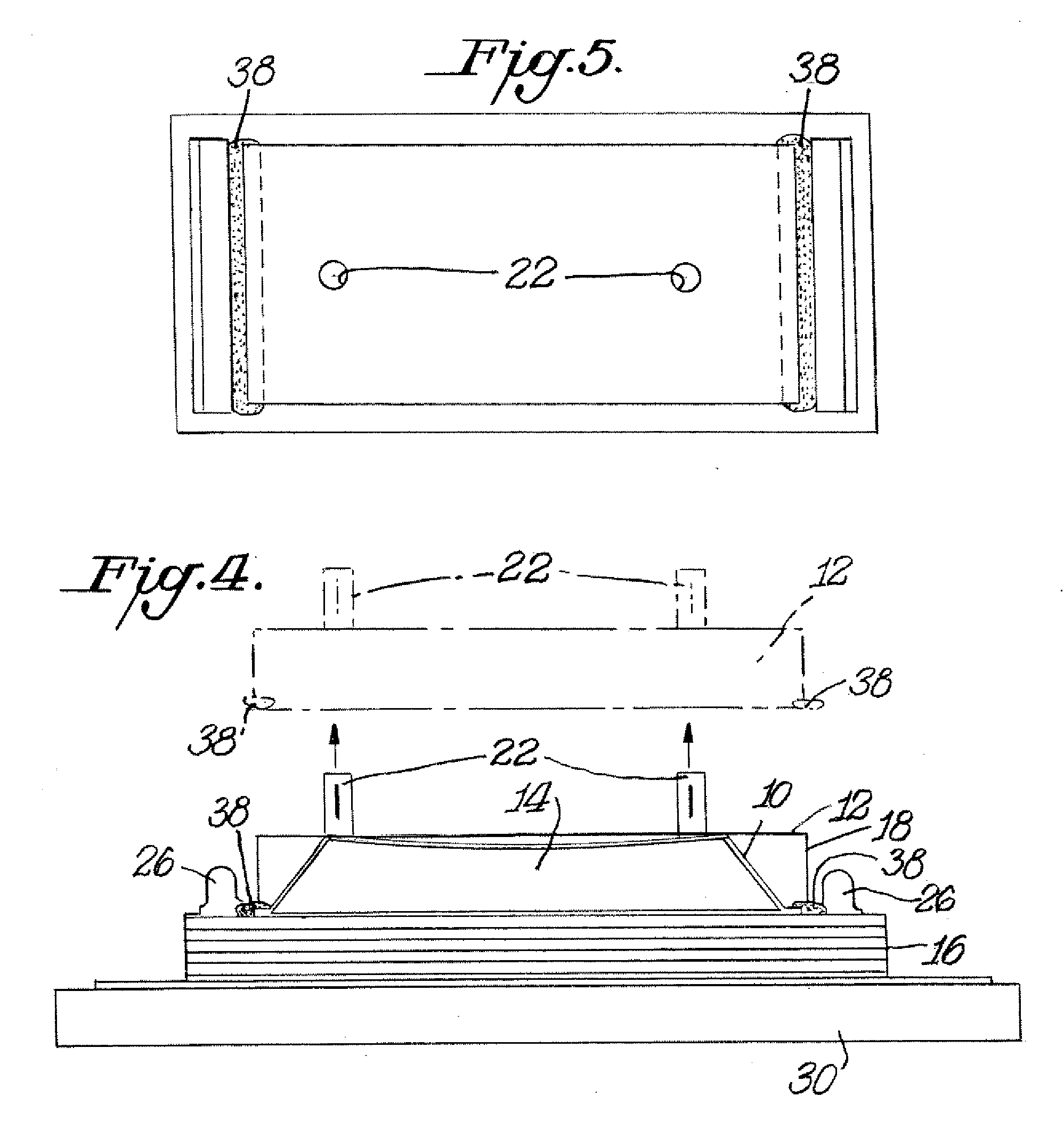

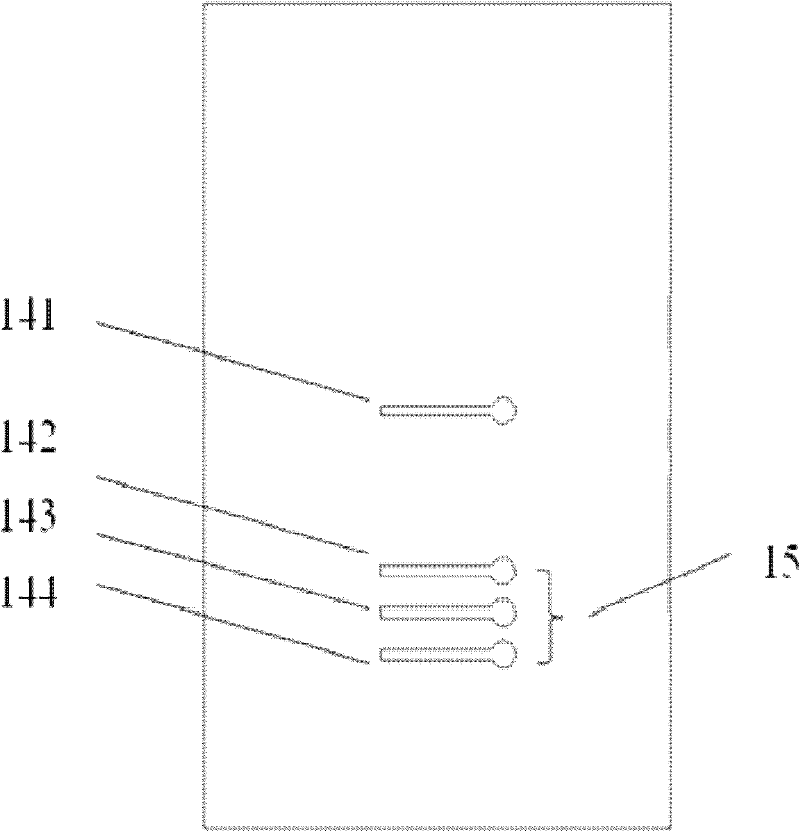

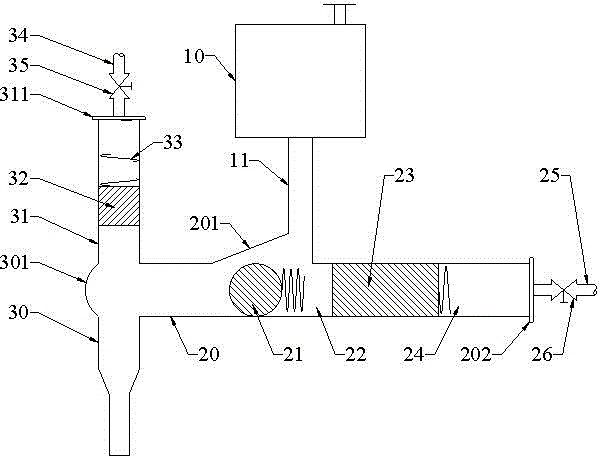

A microfluidic chip for pcr and a real-time pcr virus rapid detection device

InactiveCN102286358AReduce dosageShort injection timeBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlFluorescent pcr

The invention relates to a microfluidic control chip which is formed by bonding and sealing PDMS (Polydimethylsiloxane) material integrated with a micro valve, and comprises an upper layer of air control passage, a middle layer of PDMS membrane and a lower layer of microfluidic passage. A real-time PCR virus quick detection device comprises the microfluidic control chip, a temperature control unit, a signal detection unit and a data processing and control unit. The invention designs the microfluidic control chip which is integrated with the micro valve, is in a three-layer PDMS structure, andis used for virus detection and the real-time fluorescent PCR detection device. Compared with the traditional method, the invention has the advantages of short time, less sample usage, quick detection speed, simpleness and convenience in operation, integration and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

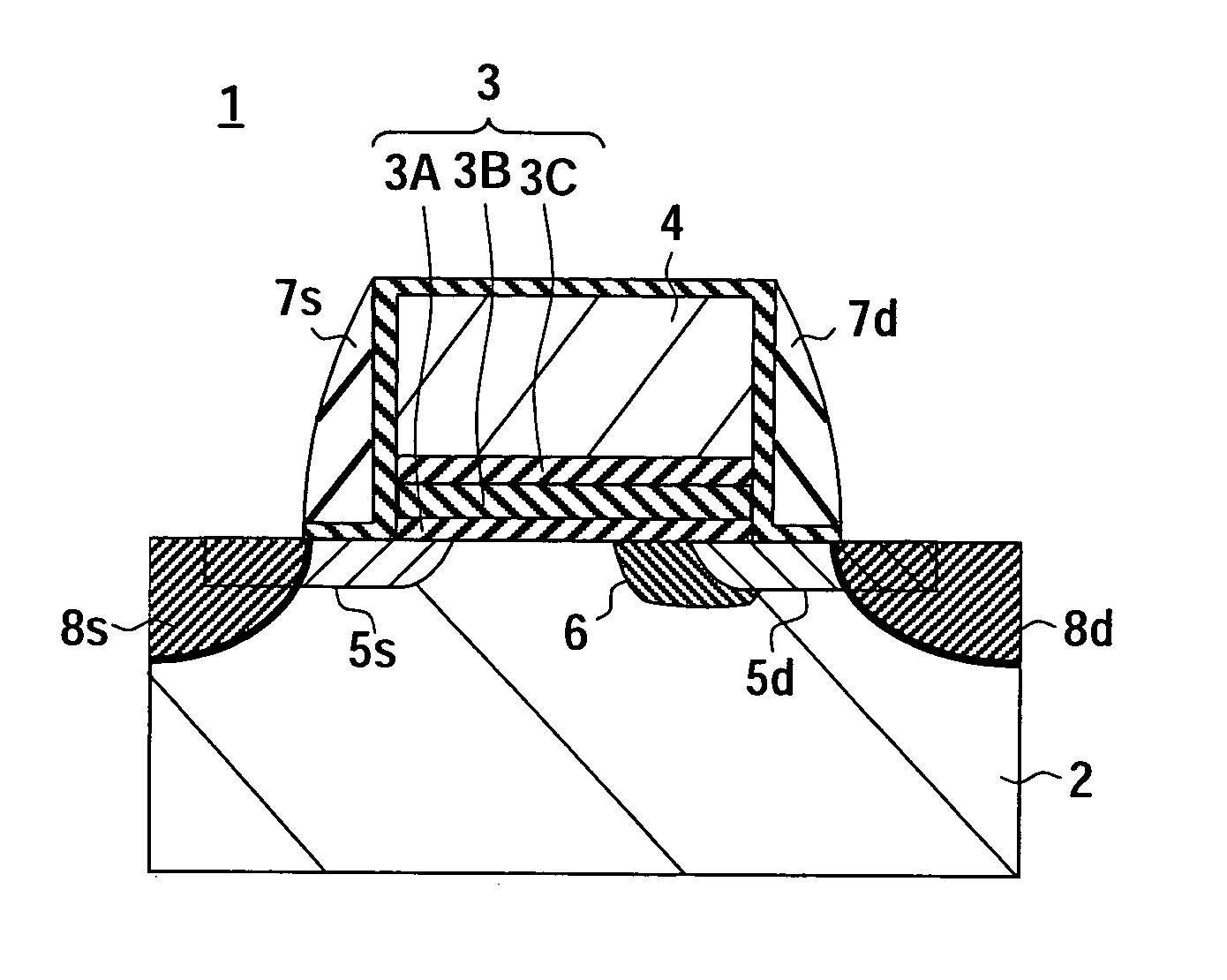

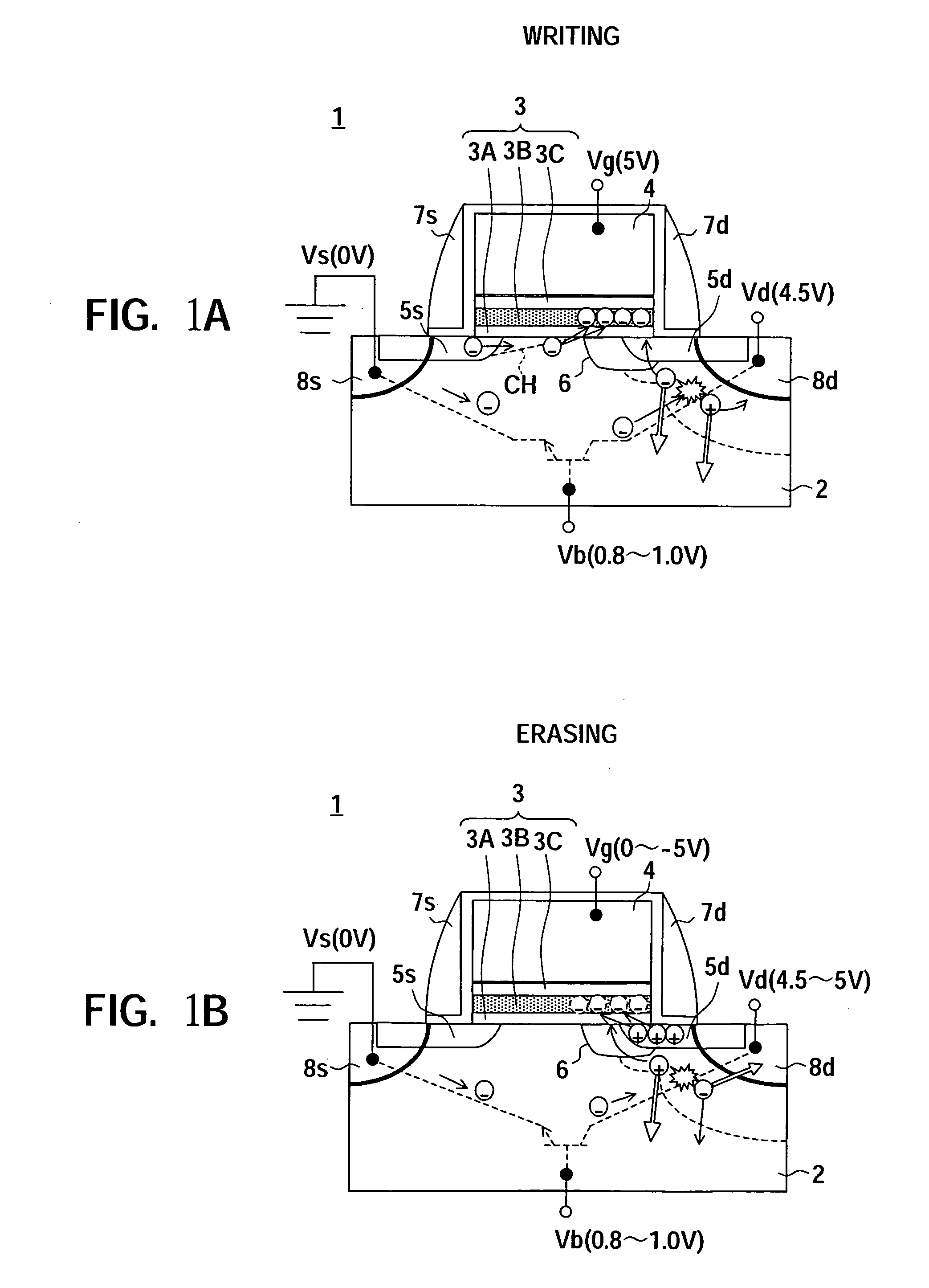

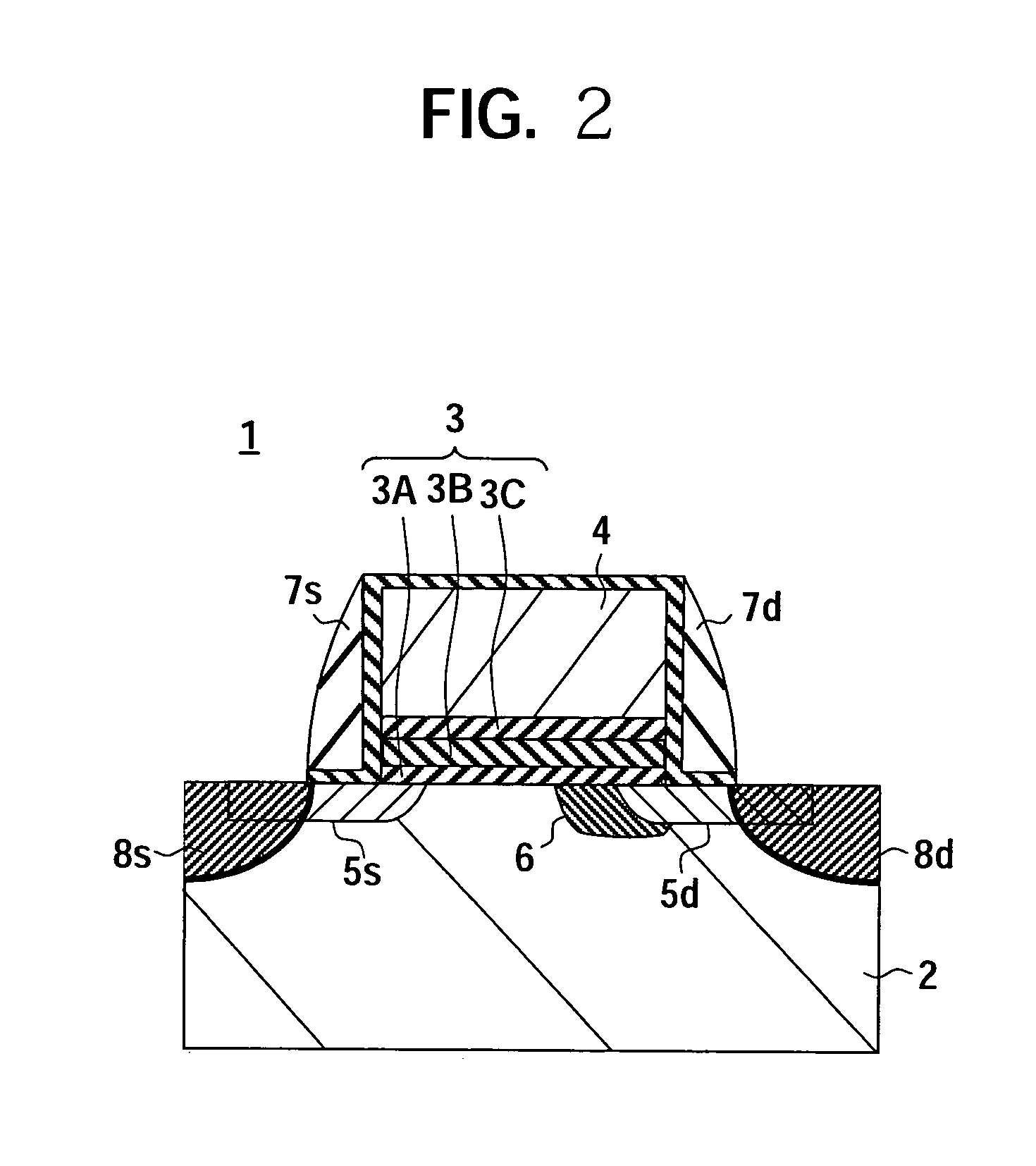

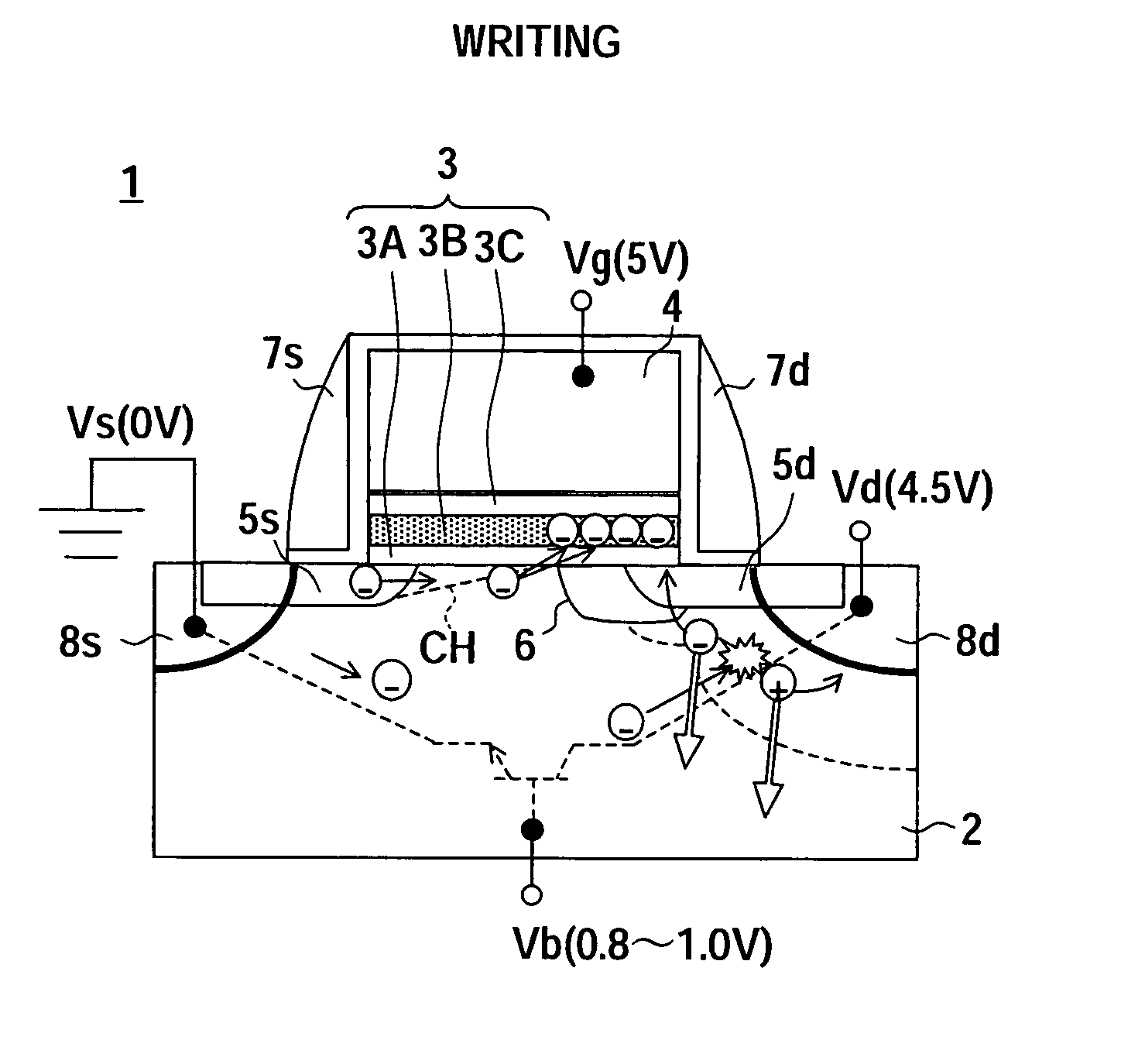

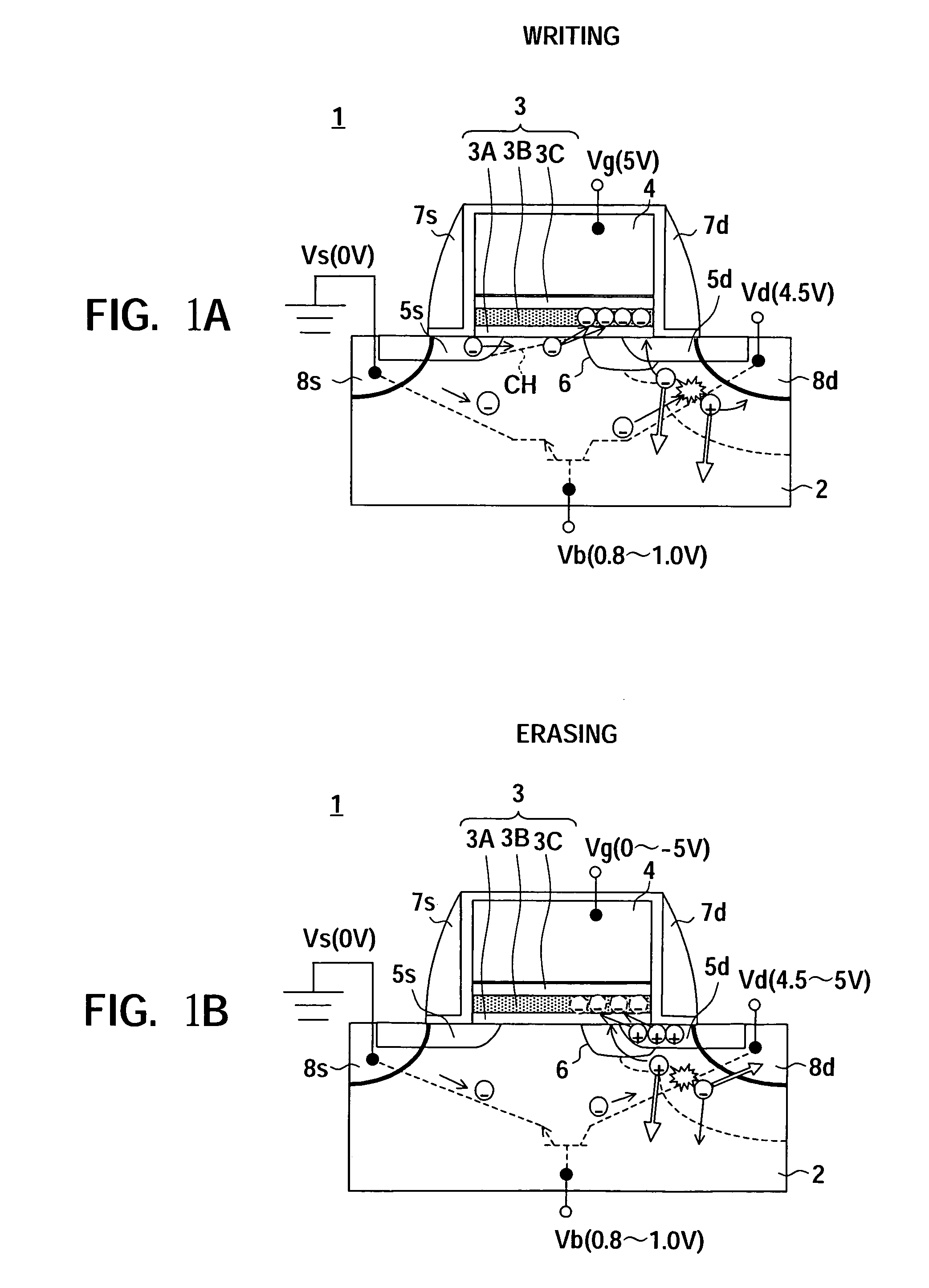

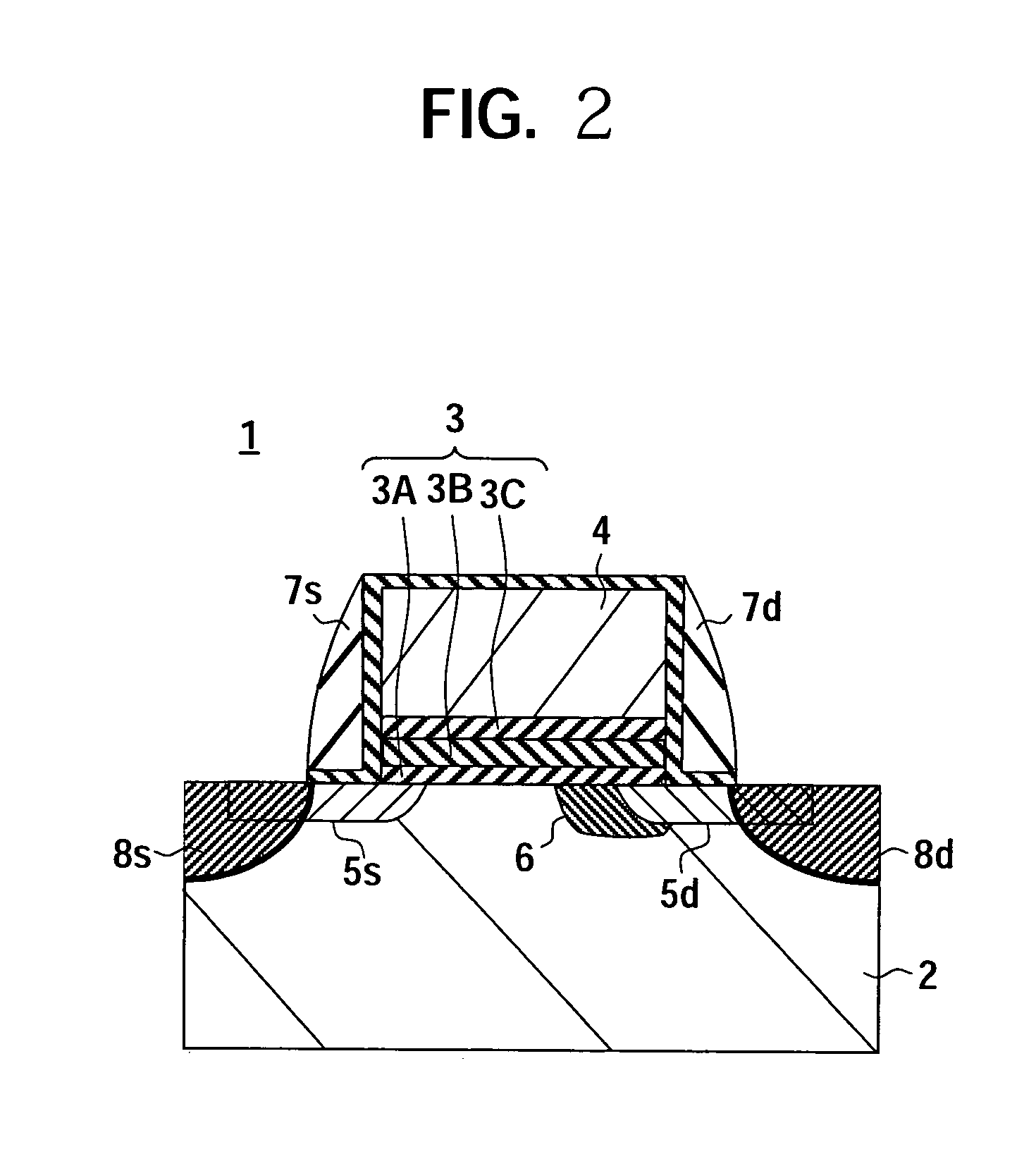

Nonvolatile semiconductor memory device, charge injection method thereof and electronic apparatus

InactiveUS20050194633A1High data re-writing speedLow ON voltage operationTransistorSolid-state devicesCharge injectionParasitic bipolar transistor

A charge injection method for improve efficiency of generating hot carrier, wherein, for example, electrons are injected at writing and holes are injected at erasing to a charge storage layer of a memory transistor. A positive voltage is applied to the drain region by using a voltage of the source region as a reference, and a voltage having a polarity in accordance with charges to be injected is applied to a gate electrode. A voltage having a voltage value between a source voltage and a drain voltage for turning on a diode made by an N-type source region and a P-type body region is applied to the body region. Then a parasitic bipolar transistor turns on, consequently, impact ionization arises on the drain side and an injection charge amount increases.

Owner:SONY CORP

Method and apparatus for concentrating vapors for analysis

ActiveUS20070180933A1Increase the rate of heatingImprove thermal conductivityComponent separationWithdrawing sample devicesImage resolutionDetection limit

An apparatus and method are disclosed for pre-concentrating gaseous vapors for analysis. The invention finds application in conjunction with, e.g., analytical instruments where low detection limits for gaseous vapors are desirable. Vapors sorbed and concentrated within the bed of the apparatus can be thermally desorbed achieving at least partial separation of vapor mixtures. The apparatus is suitable, e.g., for preconcentration and sample injection, and provides greater resolution of peaks for vapors within vapor mixtures, yielding detection levels that are 10-10,000 times better than for direct sampling and analysis systems. Features are particularly useful for continuous unattended monitoring applications.

Owner:BATTELLE MEMORIAL INST

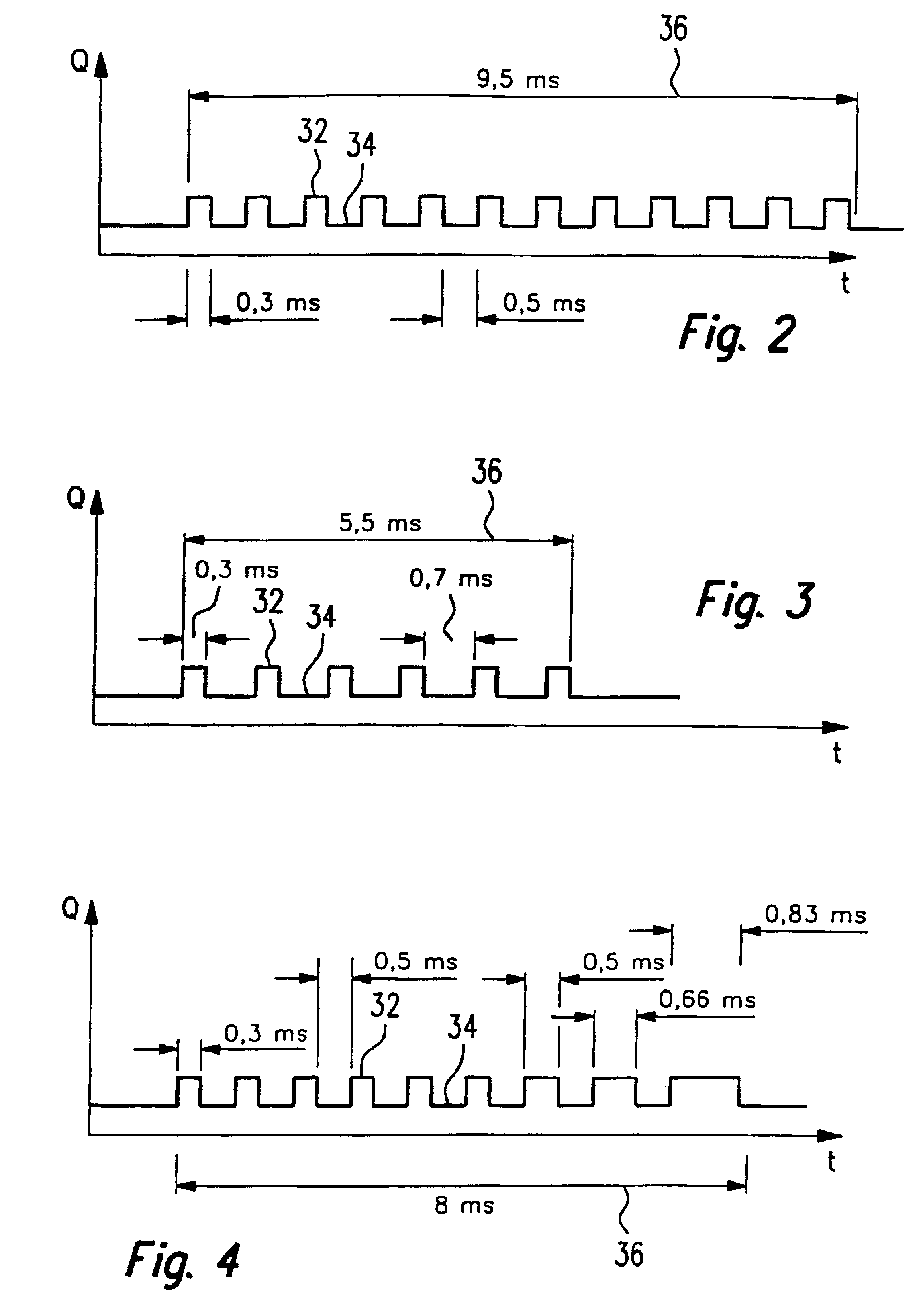

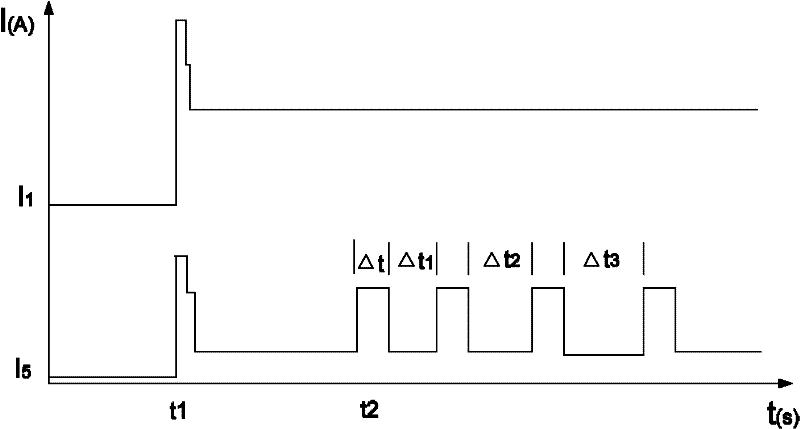

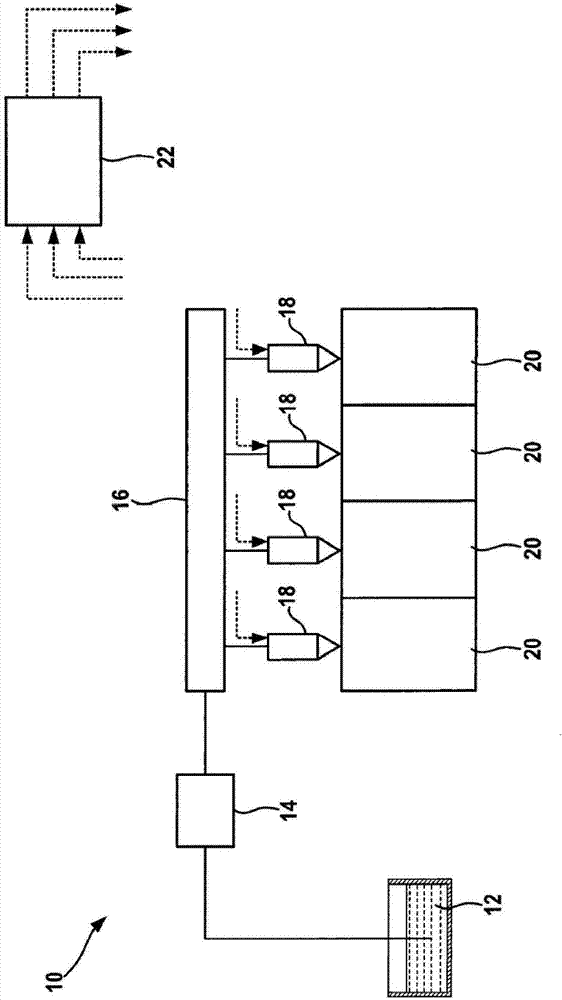

Method, computer program and control and/or regulating appliance for operating an internal combustion engine, and corresponding internal combustion engine

InactiveUS6912991B2Short injection timeIncrease consumptionElectrical controlInternal combustion piston enginesCombustion chamberWork cycle

An internal combustion engine (10), especially of a motor vehicle, is operated with a method wherein the fuel is injected directly into a combustion chamber (12) of the internal combustion engine (10) with at least one injection (36) per work cycle. In order to reduce the fuel consumption and to improve the emission performance of the internal combustion engine (10), it is suggested that a fuel injection (36) includes a plurality of short injection pulses (32) spaced in time from each other.

Owner:ROBERT BOSCH GMBH

Method and apparatus for concentrating vapors for analysis

ActiveUS7430928B2Increase the rate of heatingImprove thermal conductivityComponent separationWithdrawing sample devicesDetection limit

Owner:BATTELLE MEMORIAL INST

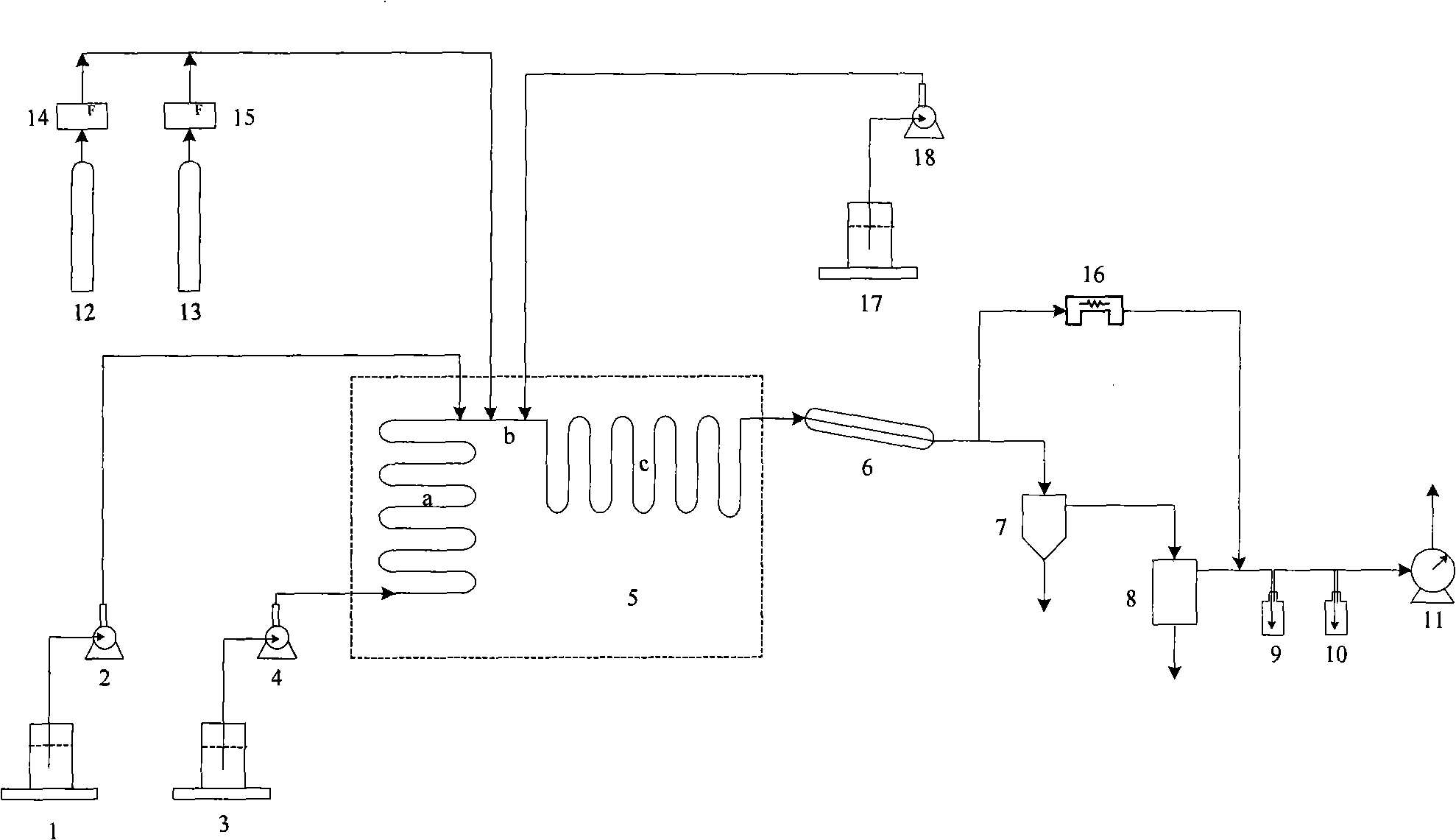

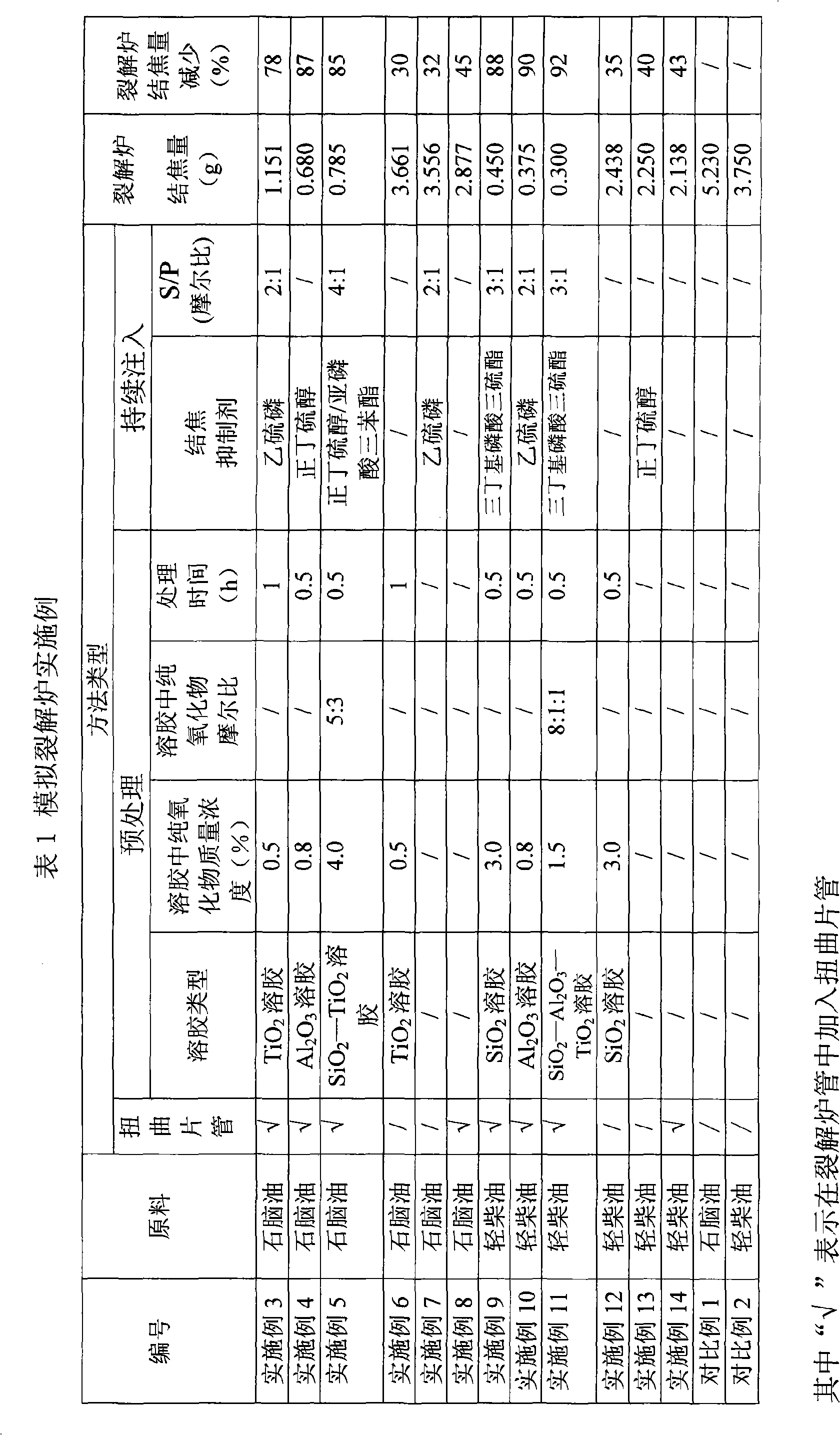

Method for inhibiting hydrocarbons steam cracking furnace from coking and carburizing

ActiveCN101294099AShort injection timeLow costThermal non-catalytic crackingEconomic benefitsPre treatment

The invention relates to a method for suppressing coking and carburizing of hydrocarbon steam cracking furnaces, which comprises the following steps: arranging at least one segment of heat transfer enhancement furnace pipe in the furnace pipe of radiation section of the cracking furnace, and preprocessing the hydrocarbon steam cracking furnace by using a sol composition during heat reserve period of the cracking furnace, wherein the sol composition contains at least one selected from Si sol, Al sol and Zr sol, and the mass concentration of pure oxide in the sol composition is 0.1 to 10% the weight of the sol composition. The method provided by the invention has the advantages of low cost, simple operation, environment friendliness, and no influence on downstream system, and can significantly prolong the service life and the operation cycle of the cracking furnace on the basis of effectively suppressing coking and carburizing of the cracking furnace pipe, thus improving output of ethylene products, etc. and improving the economic benefit of an ethylene plant.

Owner:CHINA PETROLEUM & CHEM CORP +1

High flow polyvinyl halide compound and methods of making and using same

A high flow polyvinyl halide compound is disclosed. The compound employs conventional ingredients plus a combination of phosphite stabilizer and hydrotalcite stabilizer which improve the melt flow index of the compound by at least 20%, as compared with a compound without the two types of stabilizers. The dramatically improved melt flow allows a molding cycle time reduction by as much as 22% because of a five-fold reduction in the fill step.

Owner:GEON PERFORMANCE SOLUTIONS LLC

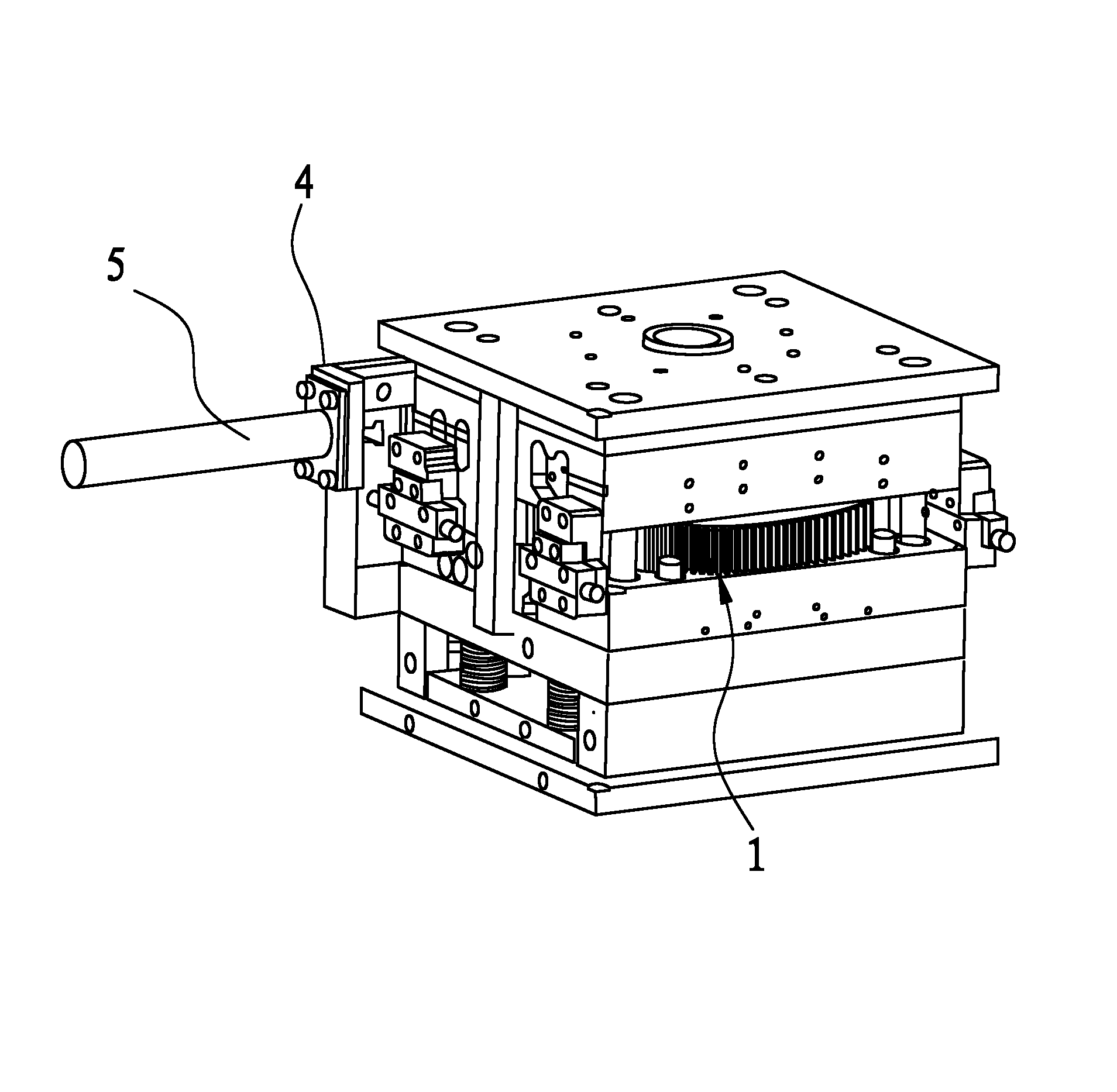

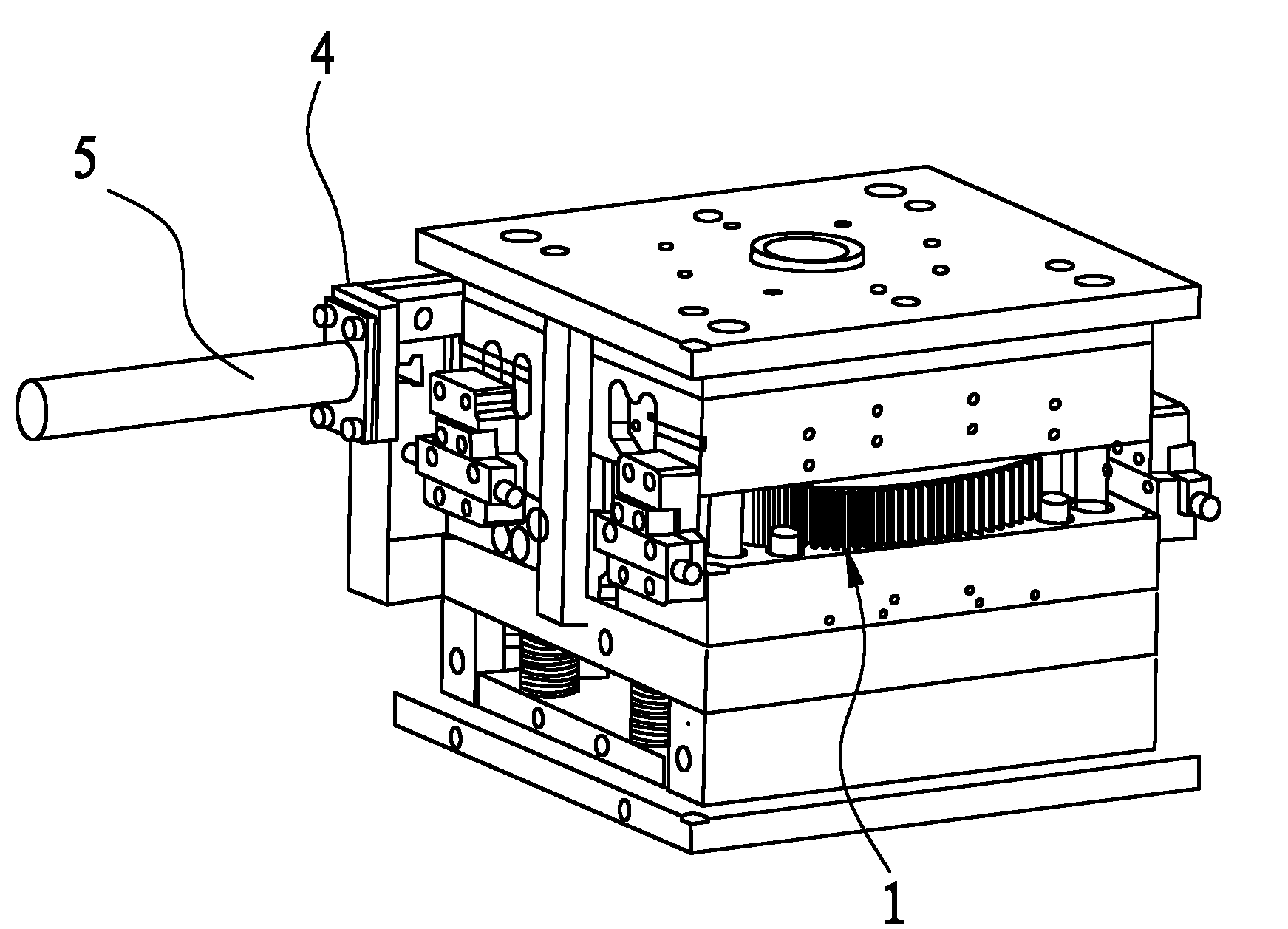

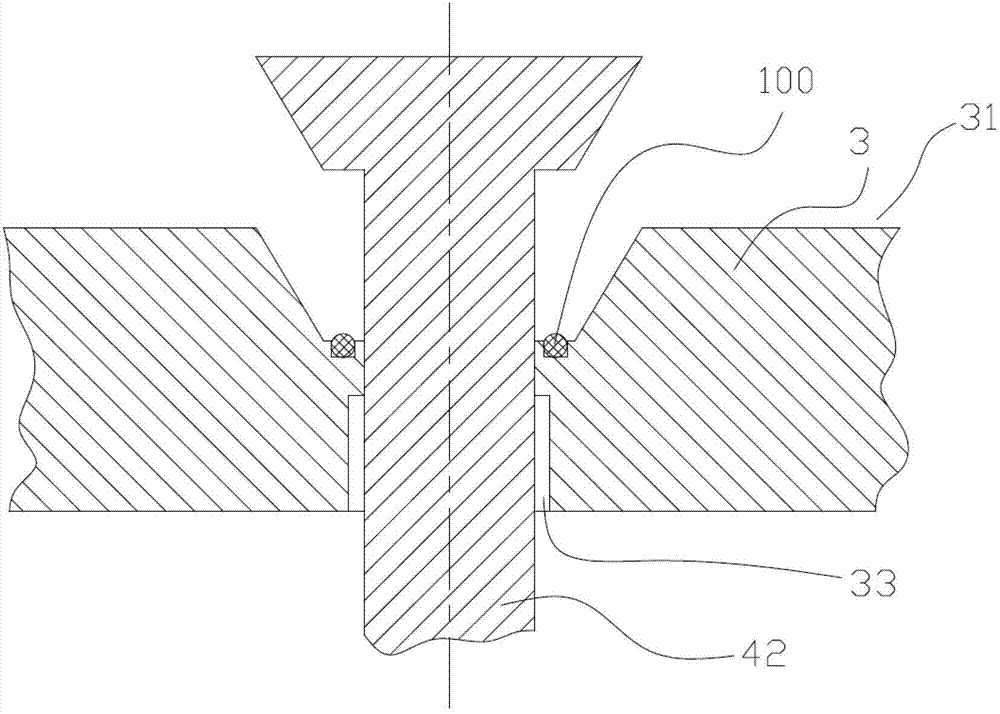

Rotating laminated type injection mould and injection method using same

The invention relates to the technical field of an injection mould, and in particular relates to a rotating laminated type injection mould and an injection method using the same. The mould comprises a fixed mould main body and a movable mould main body, wherein the fixed mould main body comprises a fixed mould plate and a fixed mould chamber, the movable mould main body comprises a movable mould plate, an ejection mechanism and a movable mould chamber, the movable mould chamber is coupled with a rotating disk, one side of the mould is provided with a driving device which drives the rotating disk to rotate, the rotating disk is annularly provided with at least two embedding pieces which are set according to the thickness of a product, and the fixed mould chamber is provided with cavities which are matched with the embedding pieces. As the rotating disk rotates, the embedding pieces arranged at the rotating disk and the cavities arranged at the fixed mould chamber are closed, glued and cooled to be formed and opened, and the transparent product with the special thickness is divided to be subjected to alternated type or laminated type injection at least twice. The invention is reasonable in structure, the size of a mould blank is reduced, the indentation on the surface of the transparent product with the special thickness is controlled, the easily generated air bubble of an inner core is avoided, the injection period is shortened, and the production cost is reduced.

Owner:毅昌金型(东莞)五金制品有限公司

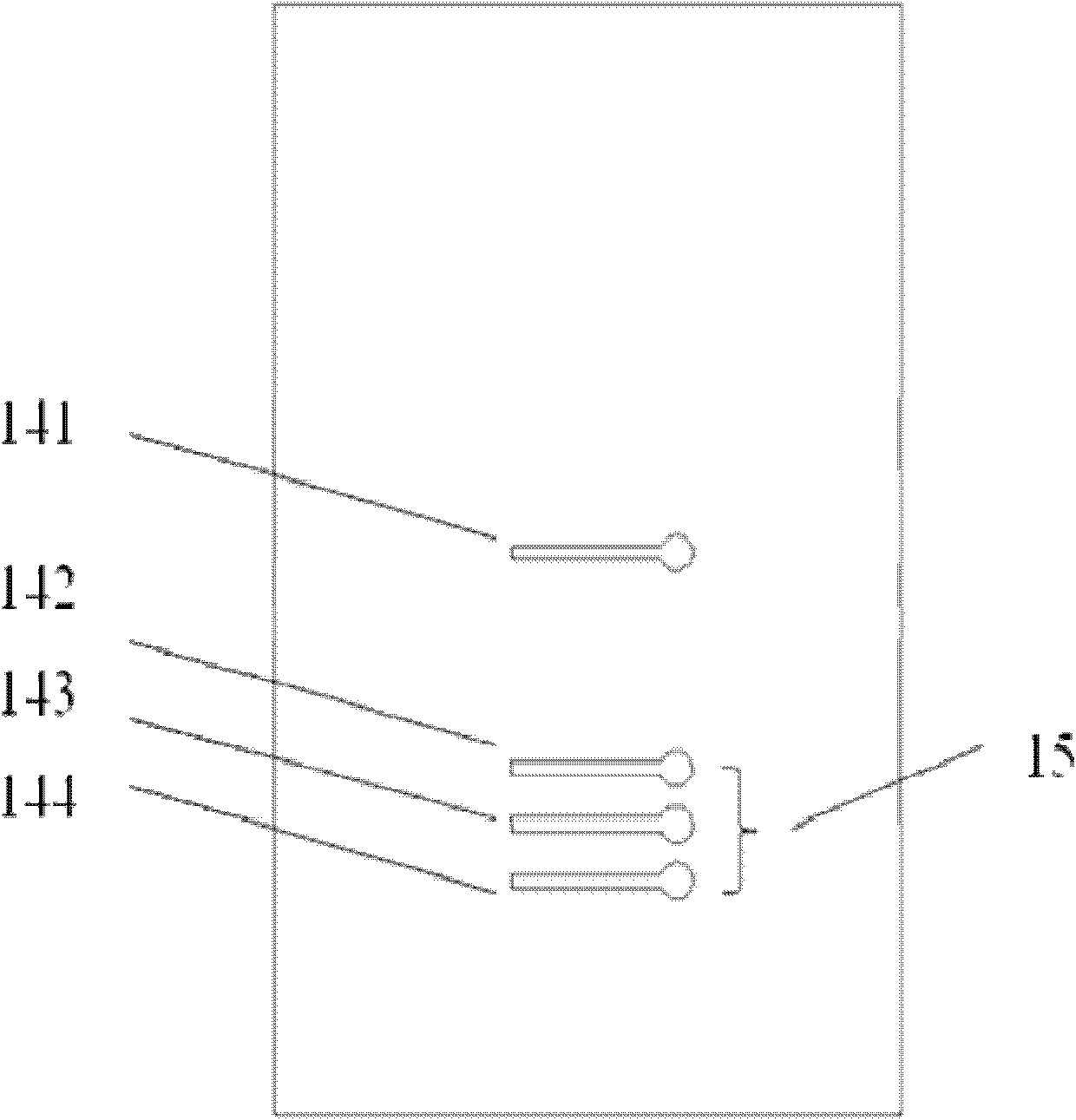

Disposable multi-needle-tube injection needle head and pre-filling syringe comprising injection needle head

ActiveCN103341228AReduce cloggingReduce riskInfusion syringesInfusion needlesManufacturing technologyEngineering

The invention relates to the technical field of medical instruments, in particular to a disposable multi-needle-tube injection needle head and a pre-filling syringe comprising the injection needle. The disposable multi-needle-tube injection needle head comprises a needle seat, a needle tube fixing piece, a locating structure and at least two needle tubes. The needle tubes pass through through holes in a top cover of the needle seat and are fixedly arranged on the top cover of the needle seat through needle tube fixing pieces in a dispersing mode. The needle tube fixing pieces are fixed in the locating structure. The two ends of each needle tube are provided with needle tips. Insulin can be injected under skin through vertical piercing of the injection needle head. The injection needle head is short in injection time, favorable to absorption of insulin, capable of avoiding local subcutaneous fat hyperplasia and induration caused by long-time accumulation, caused by single needle tube injection, of insulin, brings convenience to injection in turns, is simple in structure and manufacture technology and low in cost, and reduces the risk that a needle head can not be used due to the fact that a single liquid-taking needle tube is blocked in the puncture process, and improves the reliability of injection.

Owner:TSINGHUA UNIV

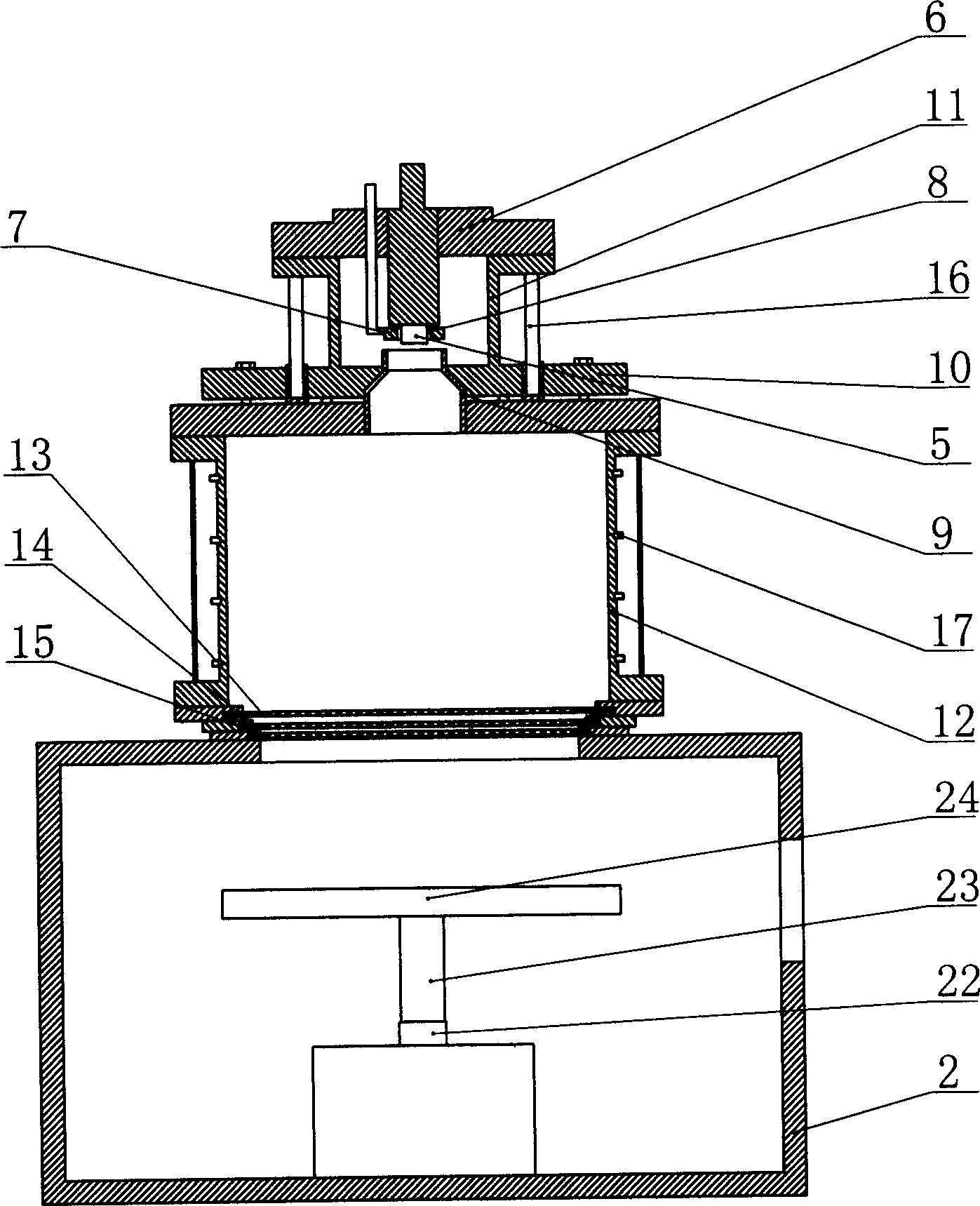

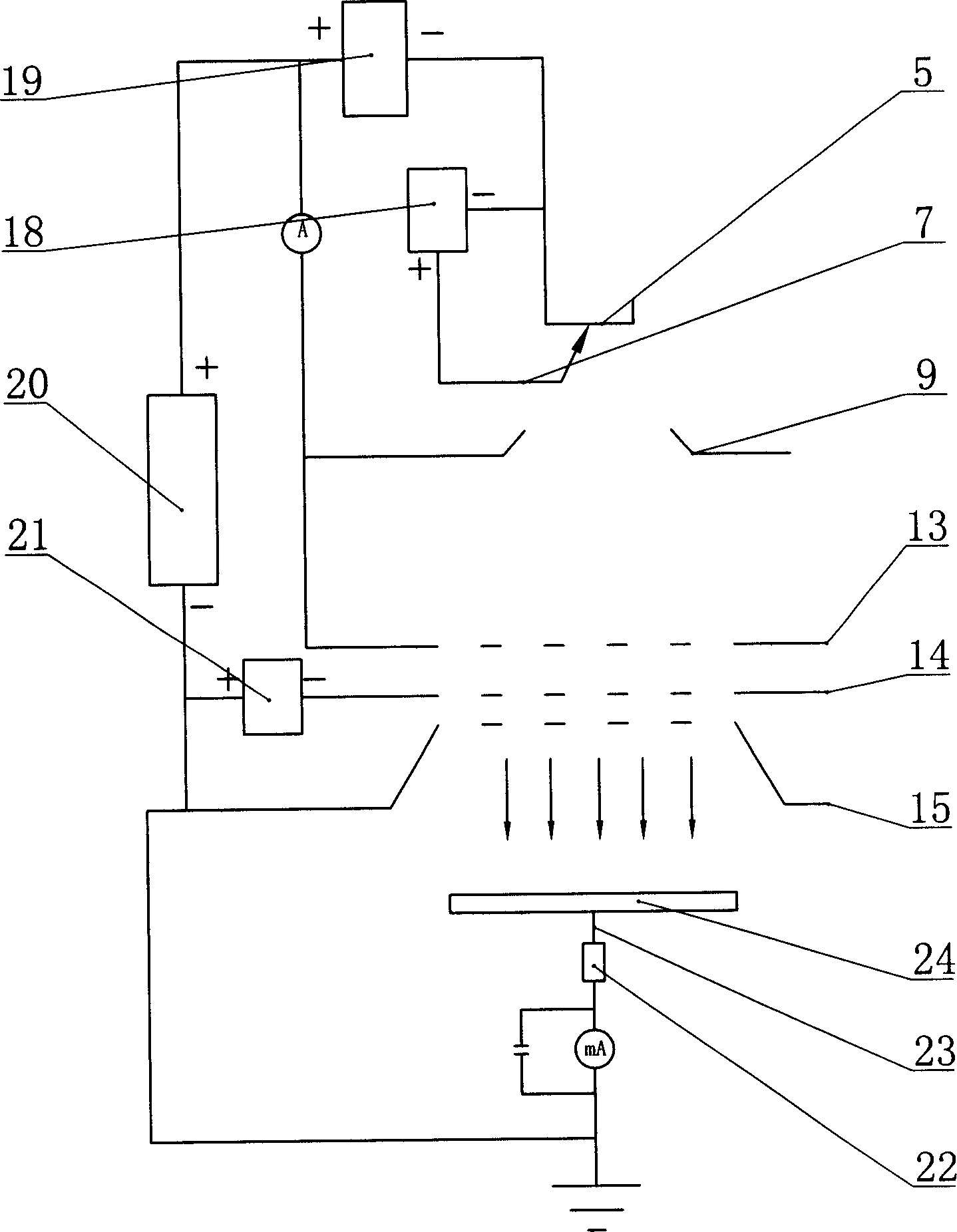

Metal ion implantation machine

InactiveCN1609265ARich varietyBeam intensityVacuum evaporation coatingSputtering coatingThick plateIon beam

The present invention is one metal ion implanter with strong ion beam flow, low ion beam leading out voltage, great ion beam implanting area, short ion implanting period and low workpiece treating cost. The metal ion implanter has metal ion comprising cathode, cathode rack, triggering electrode, insulating cathode sleeve, anode, anode rack, charge chamber, plasma chamber, the first grid, the second grid and the third grid. The interval between the first grid and the second grid is 5-10 mm, and these three grids are 2-5 mm thick plates with 1300-1800 small holes each of 3-5 mm diameter. The arc voltage power source has characteristic impedance of 1 ohm, pulse width of 0.44-0.65 ms and frequency of 5-25 Hz. The present invention is used in the production of metal parts.

Owner:珠海市恩博金属表面强化有限公司

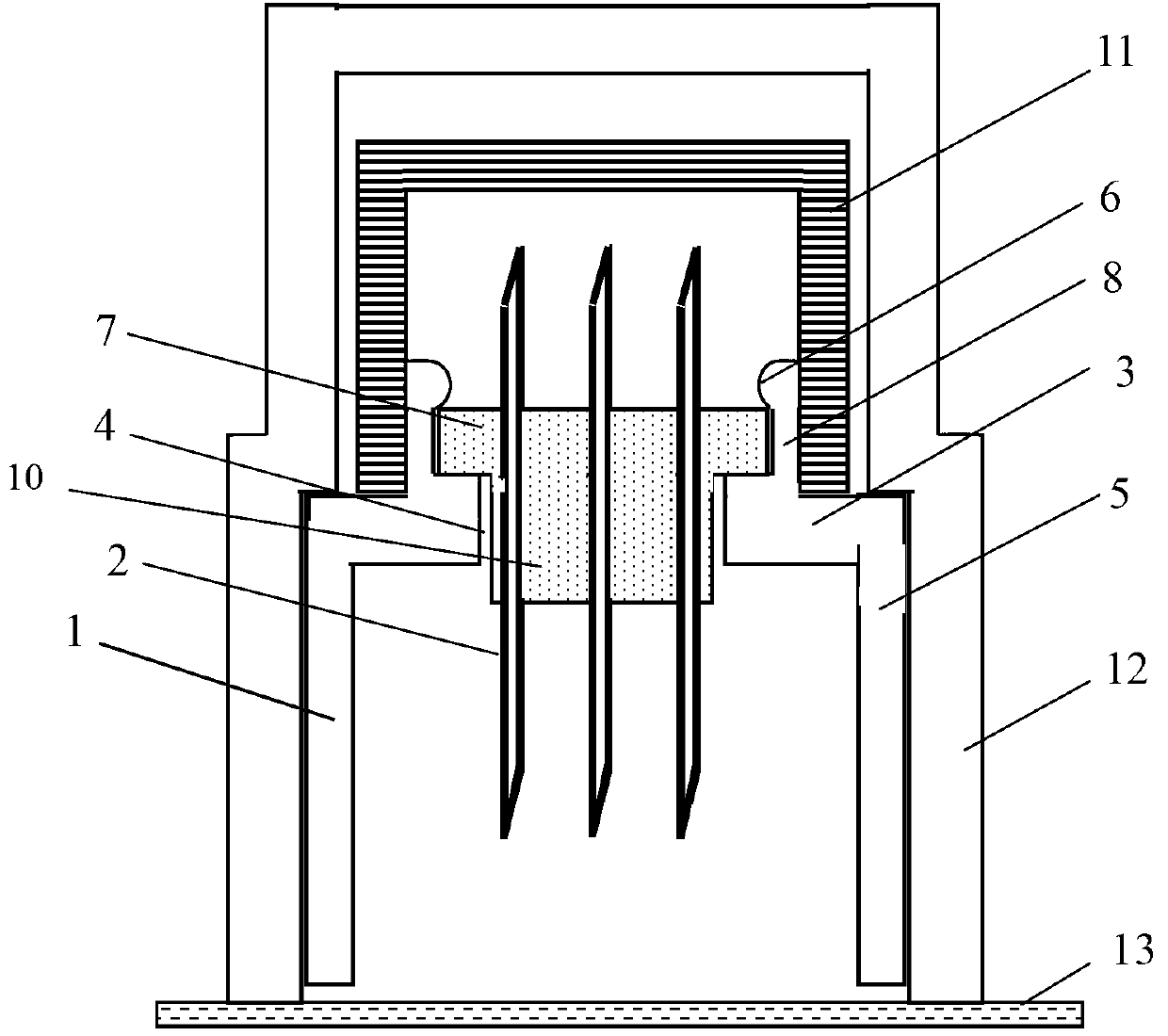

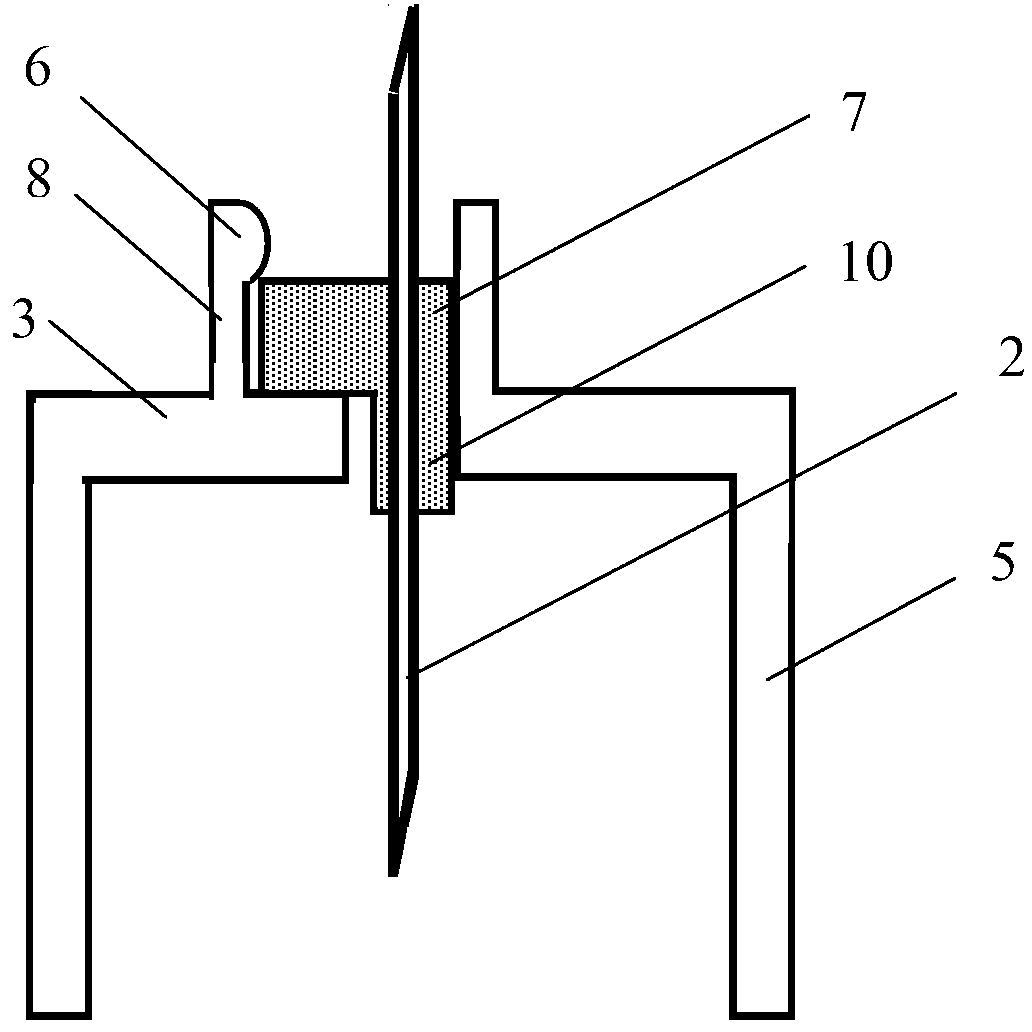

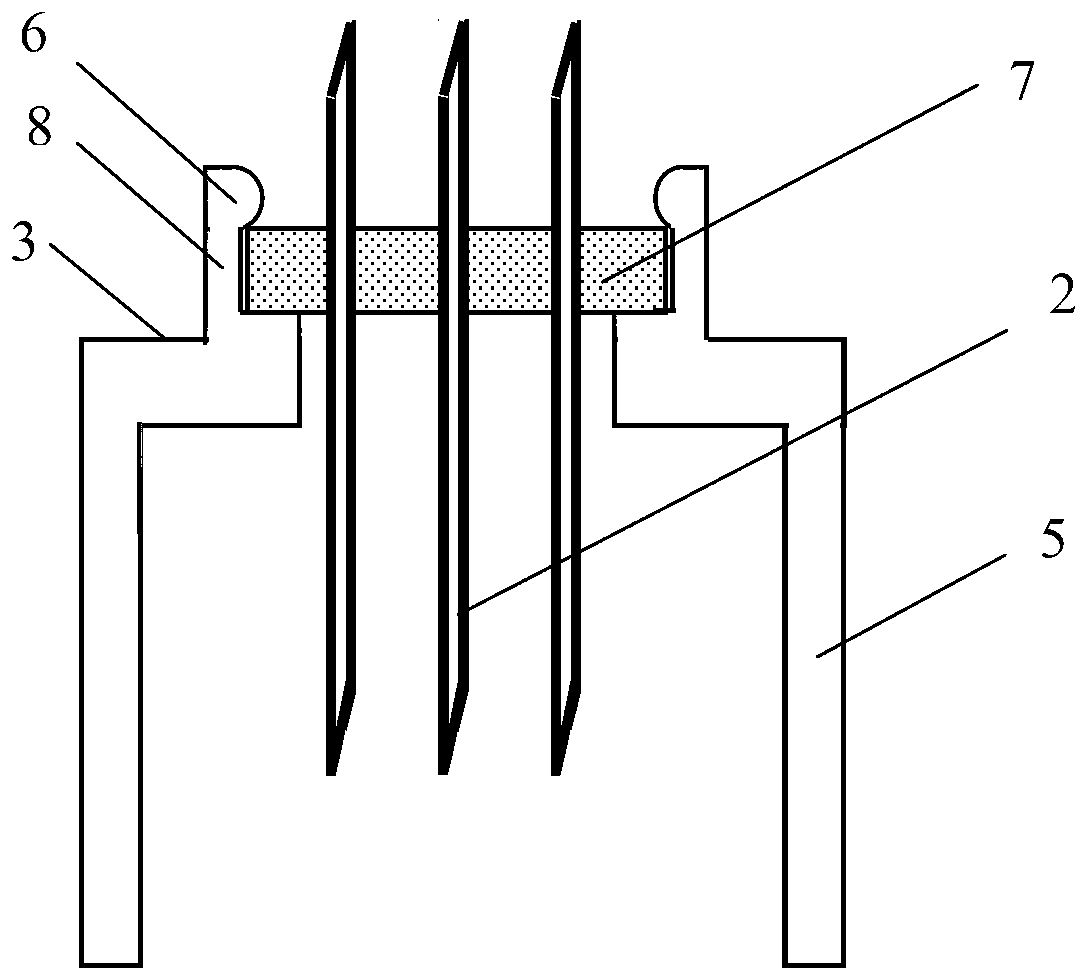

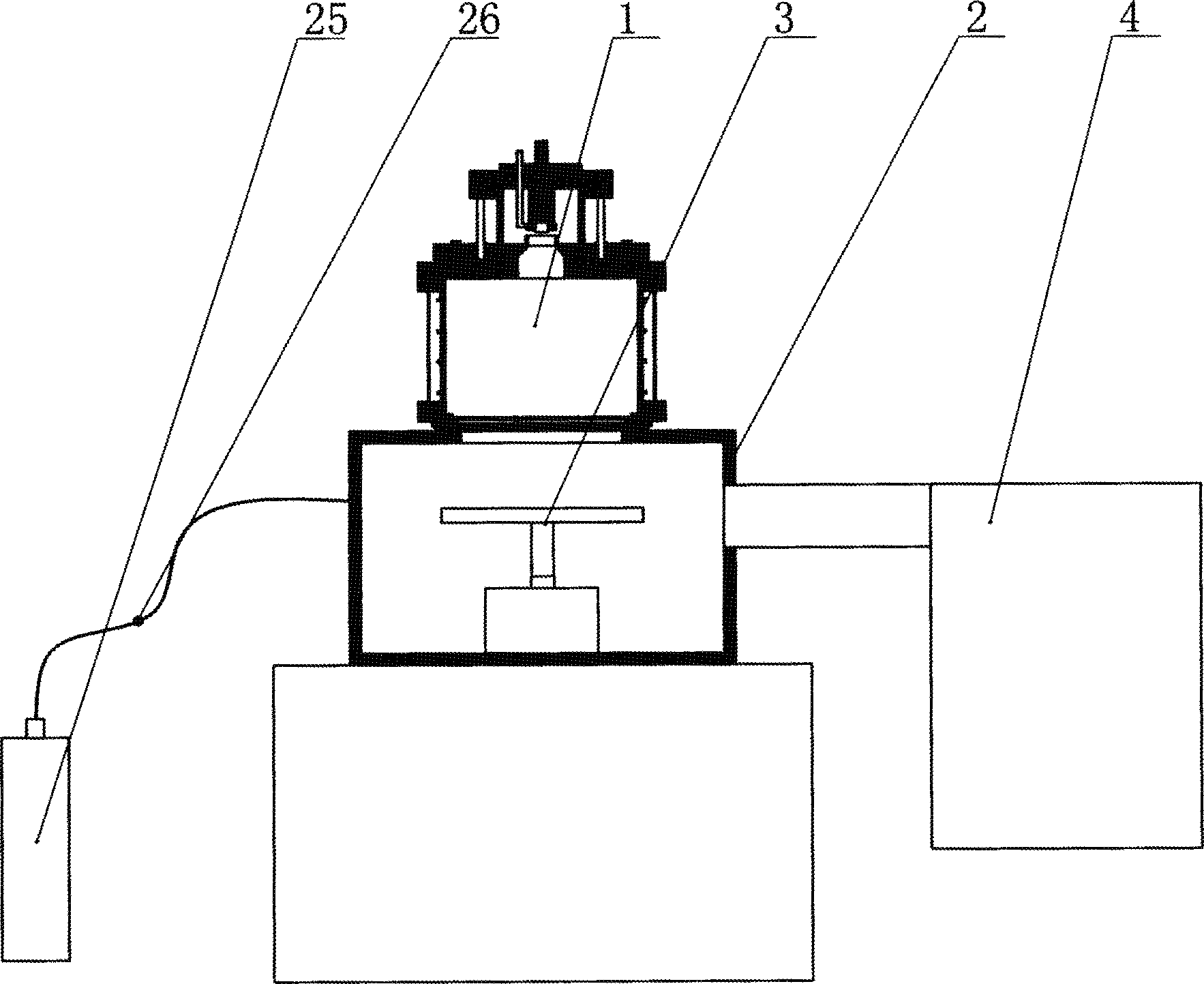

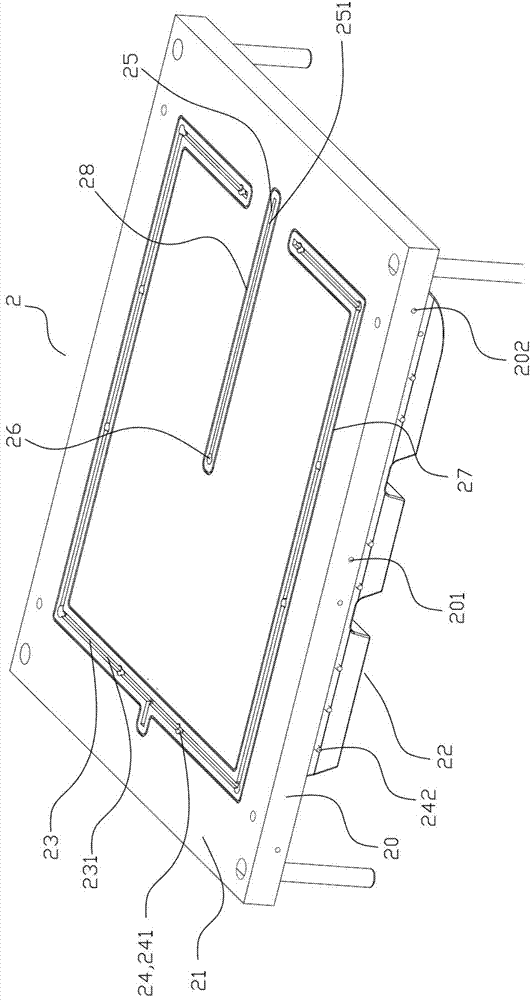

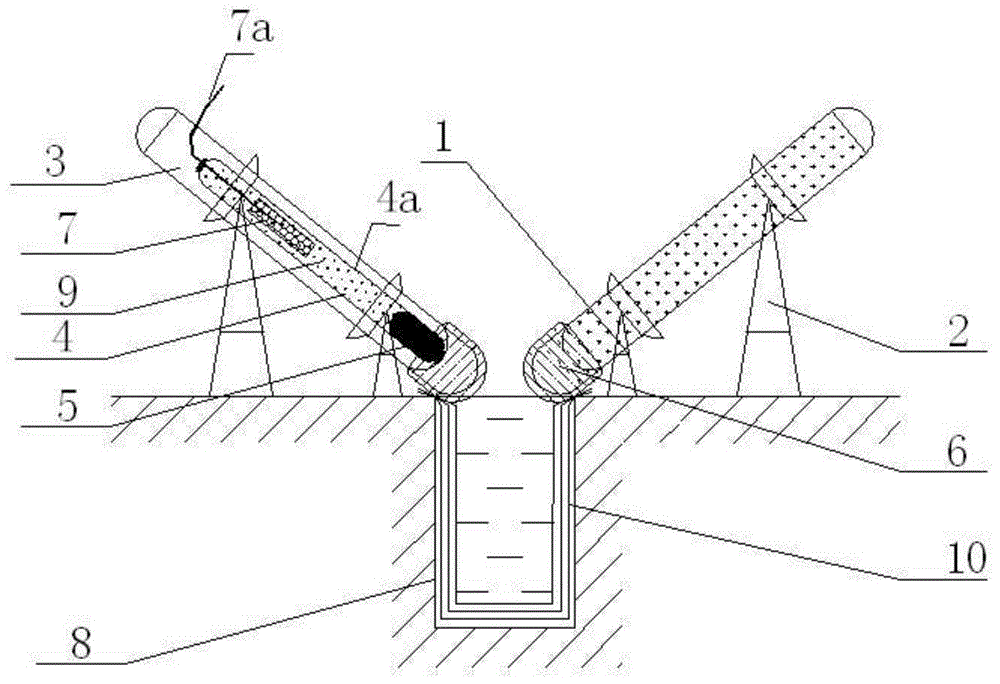

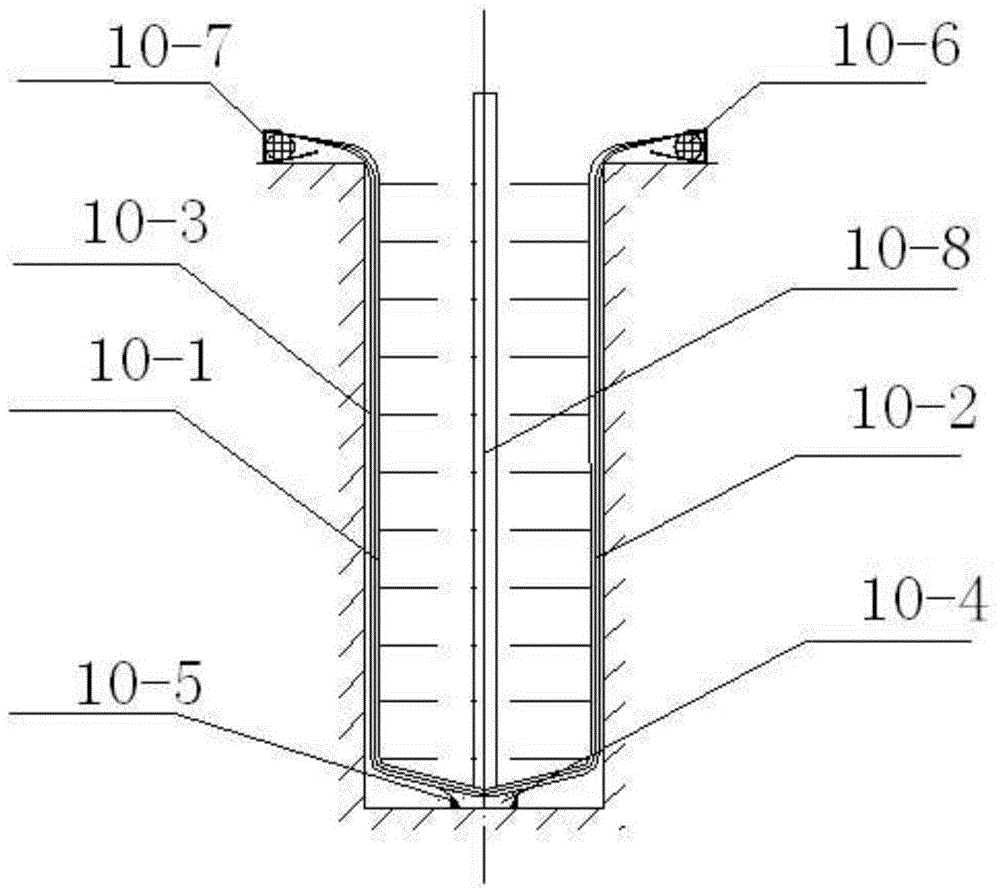

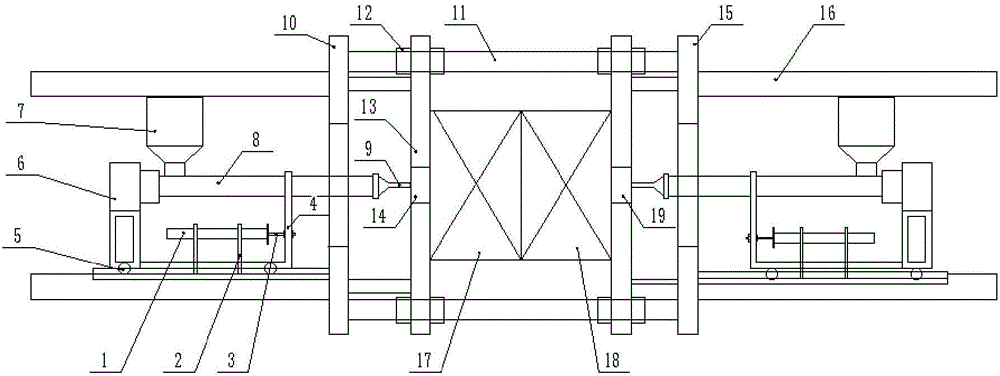

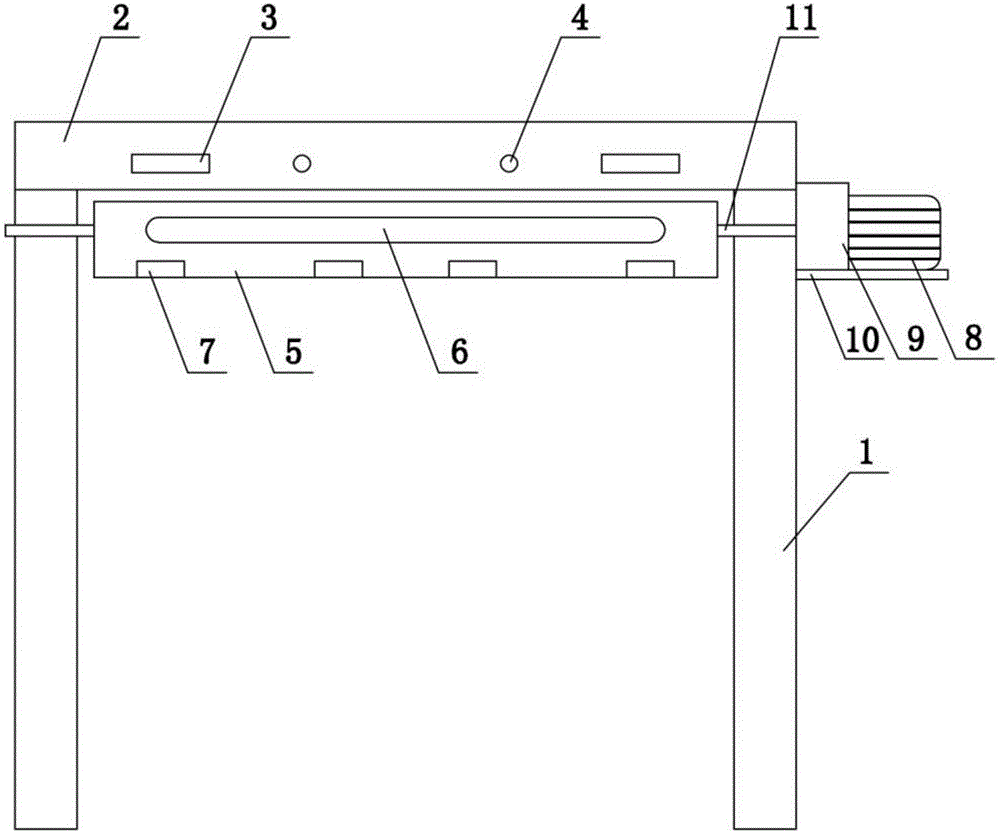

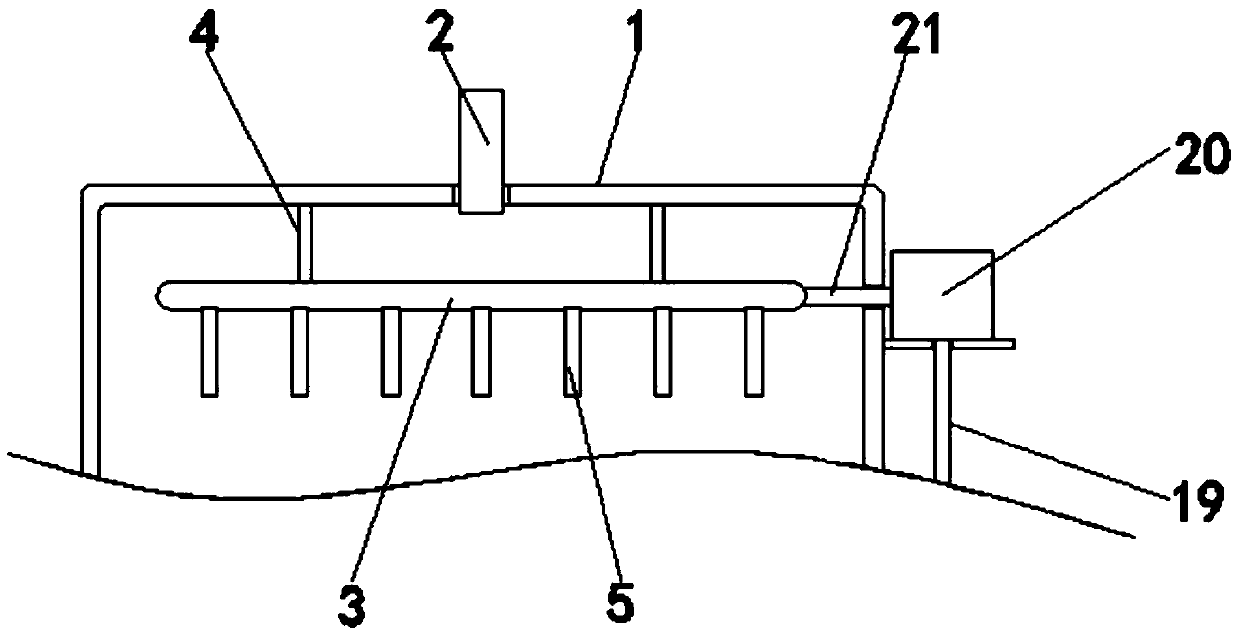

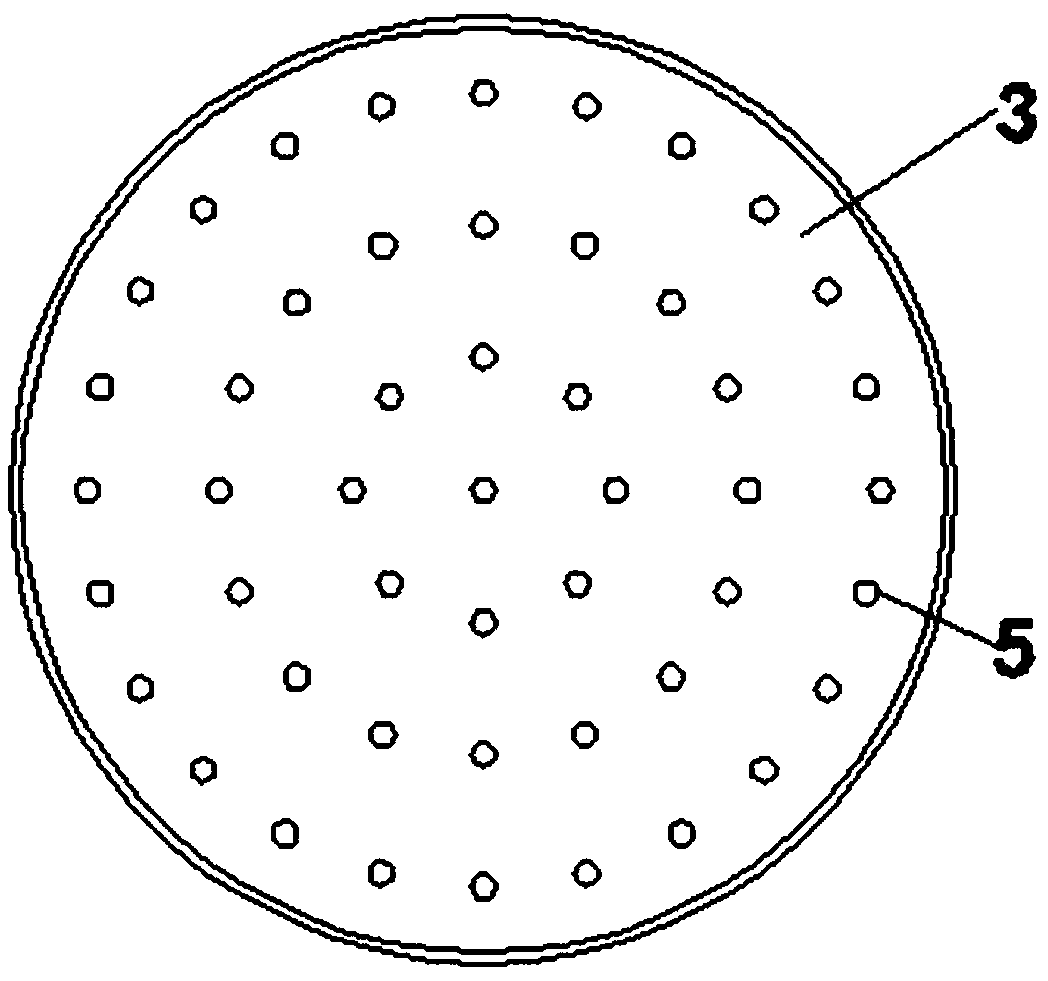

Resin transfer moulding mold and resin transfer moulding molding system

The invention relates to a resin transfer moulding mold for preparing a molded product and a resin transfer moulding molding system containing the mold, wherein the mold comprises an upper moulded board which can be fixedly connected with a mold closing machine and can be lifted to a certain position by the mold closing machine to pull up a male die when the mold is opened, the male die, a female die and an ejecting device which is equipped with one or more ejector rods capable of ejecting upwards to release the molded product from the mold. The mold and the molding system provided by the invention are convenient in mold closing, mold opening and demolding; injection time is short; and a problem of relatively long process periods of composite materials is resolved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Rapid construction device suitable for high temperature fire district

The invention discloses a rapid construction device suitable for high temperature fire district. A blast hole water storing bag is installed in a blast hole; the blast hole water storing bag is the bag body formed by successively adhering a waterproof material layer, a slide-resistant material layer and a high-temperature-resistant material layer from inside to outside; the bag opening of the blast hole water storing bag is fixed on the hole opening of the blast hole; the hole opening of the blast hole is provided with two chutes; the two chutes are respectively installed on the hole opening of the blast hole through a front low bracket and a rear high bracket; the lower end of the chute contacts with the bag opening of the blast hole water storing bag; the lower end of the chute is provided with an end cover; a blast hole stuffing is filled in one chute, and a waterproof charging bag is installed in the other chute; the bottom of the charging bag is provided with a balance weight material; an explosive and an igniting primer are installed above the balance weight material in the charging bag; and a detonating cord of the igniting primer is protruded to outside of the upper end of the charging bag. The rapid construction device suitable for the high temperature fire district is capable of satisfying the basic requirements of injecting water to reduce temperature and rapidly charging to explode in the high temperature fire district, reducing the water injection rate, shortening the period of the water injection, and accelerating the charging speed of the high temperature water hole and the blocking speed.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

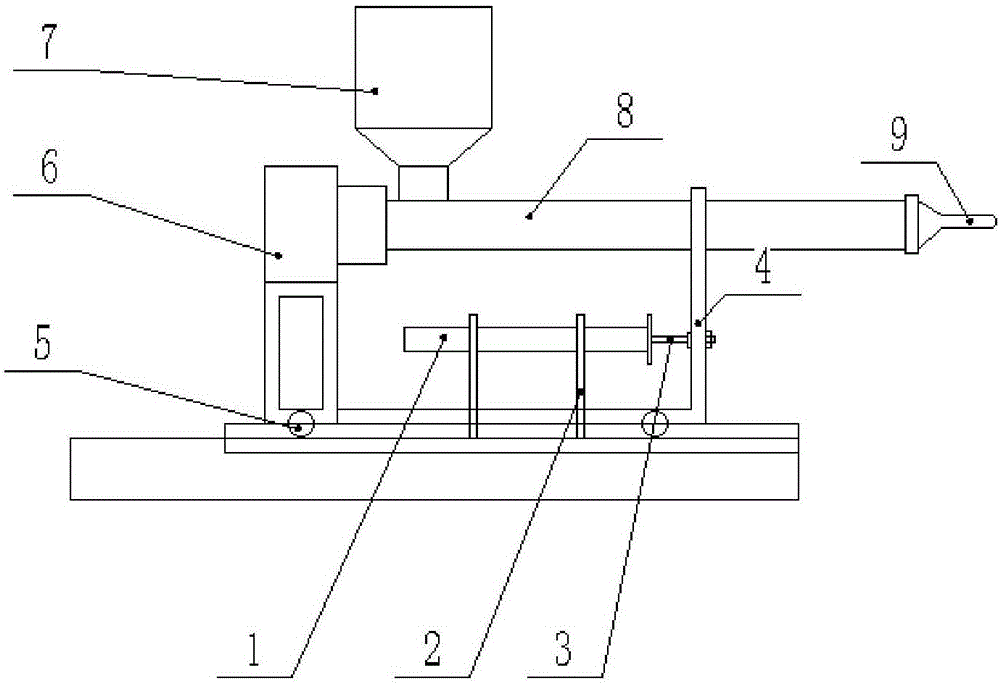

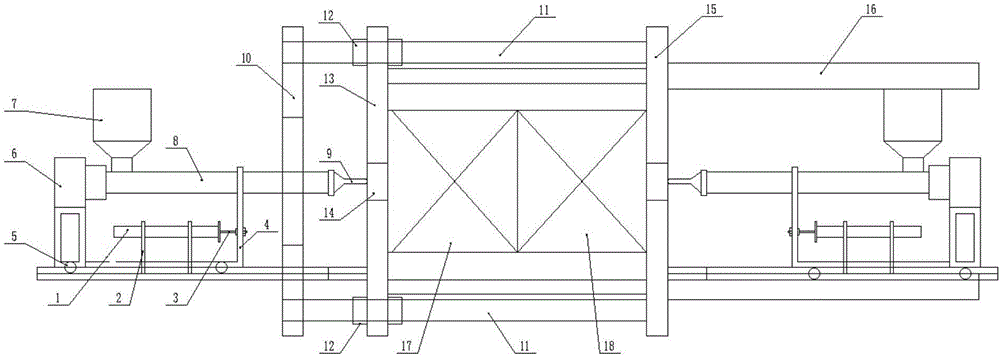

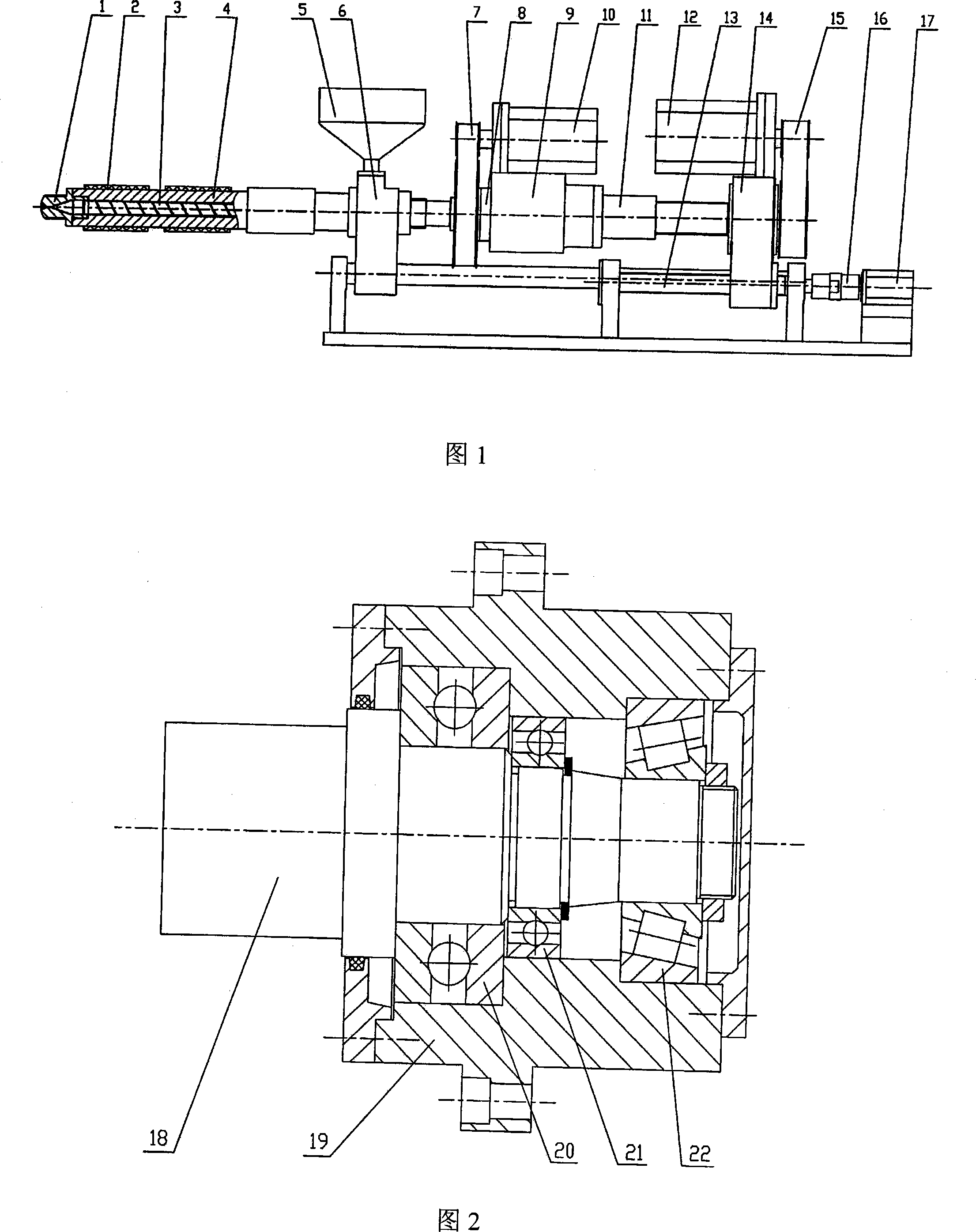

Extrusion feeding mechanism and extrusion injection molding machine

The invention relates to the technical field of extrusion injection molding machines, to solve the problem of low production efficiency of an injection molding machine in the prior art. In particular, the invention relates to an extrusion feeding mechanism, comprising a pushing assembly, a sliding assembly and an extrusion assembly, wherein the pushing assembly drives the extrusion assembly for straight reciprocating motions through the sliding assembly; the pushing assembly comprises a first support frame, a first oil cylinder mounted on the first support frame, and a connecting plate capable of doing straight reciprocating motions under the push of the first oil cylinder; a channel for the first support frame to pass is arranged on the connecting plate; the sliding assembly comprises a substrate and a sliding member; the first support frame passes through the connecting plate to be fixedly connected to the substrate. The invention also specifically relates to an extrusion injection molding machine, comprising the extrusion feeding mechanism, wherein two extrusion feeding mechanisms are arranged, each of which is disposed on each of two sides of an injection mold, and respectively correspond to a first injection molding port and a second injection molding port. The production efficiency of the current injection molding machine can be accelerated, and production costs can be saved.

Owner:昆山普拉斯克机械制造有限公司

Nonvolatile semiconductor memory device, charge injection method thereof and electronic apparatus

InactiveUS7092291B2Improve power generation efficiencyEfficient chargingTransistorSolid-state devicesCharge injectionParasitic bipolar transistor

A charge injection method for improving the efficiency of generating hot carriers, wherein, for example, electrons are injected at writing and holes are injected at erasing to a charge storage layer of a memory transistor. A positive voltage is applied to the drain region by using a voltage of the source region as a reference, and a voltage having a polarity in accordance with charges to be injected is applied to a gate electrode. A voltage having a voltage value between a source voltage and a drain voltage for turning on a diode made by an N-type source region and a P-type body region is applied to the body region. Then a parasitic bipolar transistor turns on, and, consequently, impact ionization arises on the drain side and an injection charge amount increases.

Owner:SONY CORP

Method for inhibiting hydrocarbons steam cracking furnace from coking

ActiveCN101294100AEasy to operateInhibit cokingThermal non-catalytic crackingHomogeneous catalysisHydrocarbon

The invention relates to a method for suppressing coking of hydrocarbon steam cracking furnaces, which comprises the following steps: preprocessing the hydrocarbon steam cracking furnace by using a sol composition selected from at least one of Si sol, Al sol and Ti sol during heat reserve period of the cracking furnace, and continuously feeding a liquid coking suppresser into the cracking furnace during oil injecting operation period of the cracking furnace, wherein at least one segment of heat transfer enhancement pipe is arranged in the furnace pipe of radiation section of the cracking furnace. The method of the invention can suppress heterogeneous catalysis coking and gas-phase free radical coking, and the tube walls can be scoured intensely by the materials under action of the heat transfer enhancement pipe to further sweep away the softened coke rapidly, thus reducing the possibility and the quantity of coke deposited on the tube walls, effectively suppressing coking of the cracking furnace, prolonging the service life and the operation cycle of the cracking furnace and improving the economic benefit of an ethylene plant.

Owner:CHINA PETROLEUM & CHEM CORP +1

Height limiting device and system for preventing vehicle top from being cut and height limiting method thereof

InactiveCN105761493ABlock the line of sightShort injection timeDetection of traffic movementTraffic restrictionsDriver/operatorStructural engineering

The invention discloses a height limiting device and system for preventing a vehicle top from being cut and a height limiting method thereof. The height limiting device comprises speed and height measuring marker posts and a height limiting frame, wherein measurement information is sent to a background computer after the speed and height measuring marker posts measure the speed and height of a running vehicle, and the background computer judges the speed and height of the vehicle and then sends an instrument to the height limiting frame. The height limiting frame comprises vertical supporting rods, a cross rod, a baffle plate, a baffle plate rotation driving assembly and a dye spraying assembly, wherein the vertical supporting rods are arranged on two sides of a road at intervals, the cross rod is arranged between the vertical supporting rods, two ends of the baffle plate are rotatably connected to the two vertical supporting rods, the baffle plate rotation driving assembly is connected to one end of the baffle plate, and when a vehicle with the height exceeding the height limit passes through, the baffle plate rotation driving assembly drives the baffle plate to rotate, and the dye spraying assembly arranged on the baffle plate sprays a dye to the vehicle top so as to warn a vehicle driver. The top is prevented from being cut by adopting the rotation structure design of the baffle plate. In addition, warning is performed in dye spraying, shooting and recording modes.

Owner:肖雨枫

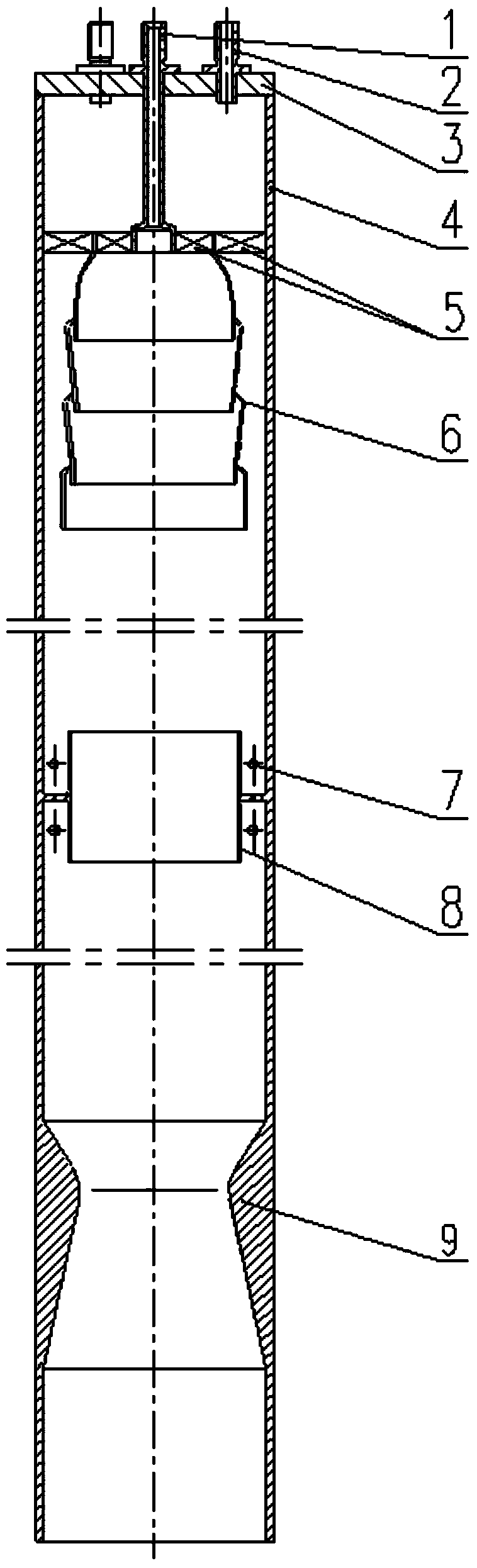

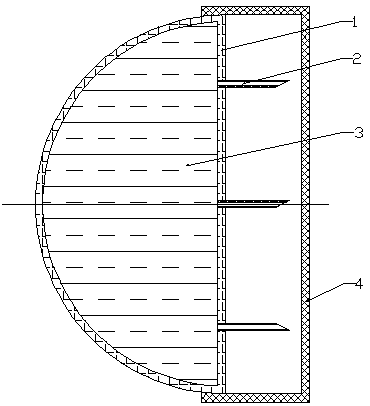

Steam generator used for thickened oil exploitation

InactiveCN103527162AEliminate heat lossShort injection timeSteam generation using pressureFluid removalSpray nozzleEvaporation

The invention discloses a steam generator used for thickened oil exploitation. The steam generator used for thickened oil exploitation comprises a cylindrical barrel body, a dual-ring hydrocyclone, a flame tube, a water film generator and an evaporation converter, wherein the dual-ring hydrocyclone, the flame tube, the water film generator and the evaporation converter are located in the barrel body and are arranged in a coaxial mode in the gas flowing direction in sequence, an end cover provided with a fuel gas inlet connecting pipe and a forced air inlet connecting pipe is fixed at the gas inlet end of the barrel body, forced air is divided into an inner eddy current and an outer eddy current by the dual-ring hydrocyclone fixedly arranged at the position of an inlet of the flame tube, the inner eddy current and the outer eddy current enter the internal space and external space of the flame tube respectively, the forced air entering the flame tube is mixed with fuel gas and then burns to form flame currents, part of the forced air entering a ring runner between the flame tube and the barrel body enters the flame currents through a through-flow hole in the wall surface of the flame tube, most of the forced air entering the ring runner between the flame tube and the barrel body flows out through an outlet, the water film generator is composed of at least one circle of pressure water nozzles arranged on the inner wall of the barrel body, and the evaporation converter is a section of runner with the inner cavity contracting gradually at first and expanding gradually afterwards. The steam generator used for thickened oil exploitation has the advantages of being reasonable in structure, high in reliability, long in service life, saving in energy, and high in efficiency.

Owner:CHENGDU ENGINE GROUP

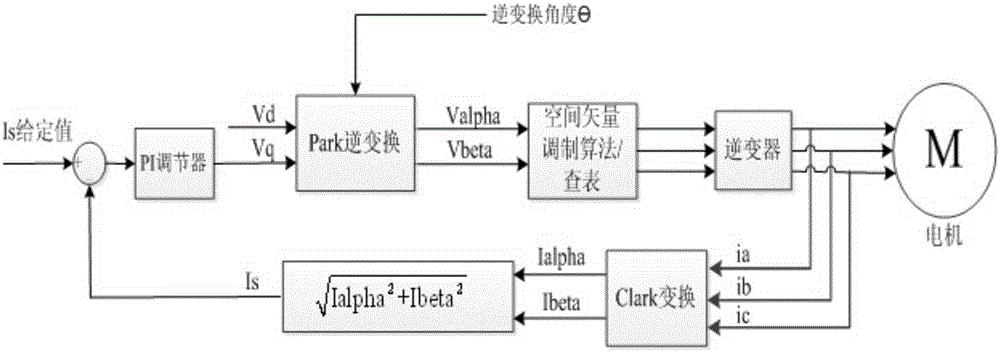

Method for identifying different models of alternating current motors

ActiveCN106026824ASmall pressure dropThere is no out-of-sync problemElectronic commutation motor controlVector control systemsCurrent meterAlternating current

The invention discloses a method for identifying different models of alternating current motors. Firstly alternating current of the same frequency and amplitude is injected into the stator windings of different models of alternating current motors under identification, then current of all phases of stator windings of all the alternating current motors under identification is acquired respectively and then the acquired current of all phases of stator windings of all the alternating current motors is converted into current under a two-phase static coordinate system through Clark transform, and finally the amplitude of the current vectors of each alternating current motor under the two-phase static coordinate system is calculated and different models of alternating current motors are identified according to the amplitude of the current vectors. The problems existing in the present identification method are overcome, additional arrangement of hardware is not required and the accuracy of the identification result is high.

Owner:安庆桐方聚能变频电机有限公司

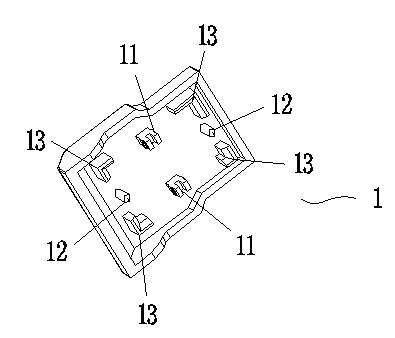

Key

InactiveCN102306579ASimple structureShort injection timeElectric switchesKey pressingUltrasonic welding

The invention relates to a key structure which is used on a vehicle-mounted sound. The key comprises a key cap and a wall, wherein a U-shaped button position and a locating column for being clamped and connected with the key wall are arranged below the key cap, the wall is of a hollow structure, the side wall at the button position of the key cap corresponding to the wall is provided with a groove which is the same as the protruding button position in shape and size, a side wall at the locating column corresponding to the wall is provided with a concave hole; and a locating wall is also arranged corresponding to the peripheral shape of the wall below the key cap. Compared with the prior art, by using the key structure provided by the invention, the key cap and the wall at the lower end can be respectively molded and then assembled for use, the mould structure used for the molding is relatively simple, the injection and assembling time of the key is short, more complex devices such as a double-colored injection machine, a ultrasonic welding device and the like cannot are not required to be used; compared with the existing double-colored key and the key molded by ultrasonic welding, the cost of the key provided by the invention is lower and the quality is easier to control.

Owner:HUIZHOU DESAY SV AUTOMOTIVE

High flow polyvinyl halide compound and methods of making and using same

A high flow polyvinyl halide compound is disclosed. The compound employs conventional ingredients plus a combination of phosphite stabilizer and hydrotalcite stabilizer which improve the melt flow index of the compound by at least 20%, as compared with a compound without the two types of stabilizers. The dramatically improved melt flow allows a molding cycle time reduction by as much as 22% because of a five-fold reduction in the fill step.

Owner:GEON PERFORMANCE SOLUTIONS LLC

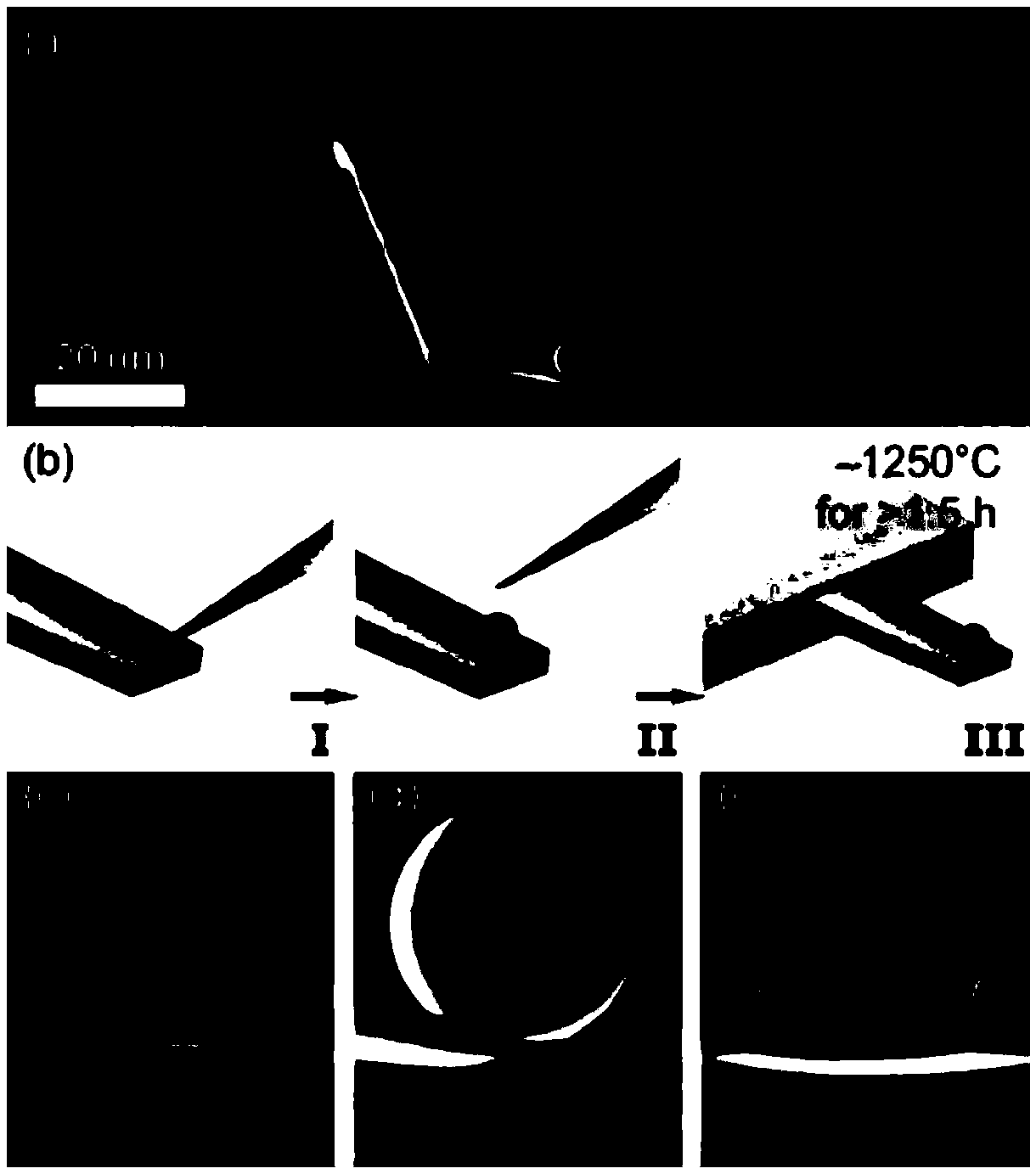

Atomic force microscope probe manufacturing method possessing nanoscale spherical tip

ActiveCN108414794AHigh yieldFast molding speedDecorative surface effectsChemical vapor deposition coatingParticle injectionControllability

The invention relates to an atomic force microscope probe manufacturing method possessing a nanoscale spherical tip. The method comprises the following steps of S1, taking a micro-cantilever beam, making an embossment on the surface of the micro-cantilever beam, taking one surface of the embossment, which is far away from the micro-cantilever beam, as a substrate; or taking the micro-cantilever beam, and taking the surface of the micro-cantilever beam as the substrate; S2, positioning one particle injection position at the substrate; and S3, quantifying one high energy particle beam in a set area range according to the size of the spherical tip which needs to be made and injecting into the particle injection position so that the particle injection position is plumped so as to form the spherical tip. In the invention, a molding speed is fast, a yield is high, cost is low, the method is suitable for industrialization, the controllability of a spherical tip diameter is good and the spherical tip is not easy to shed.

Owner:胡欢

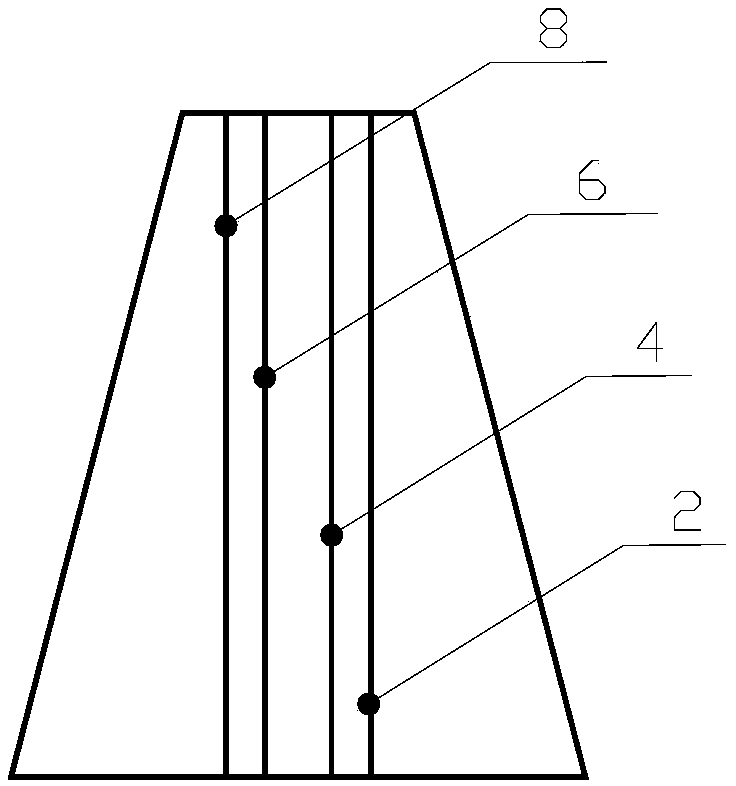

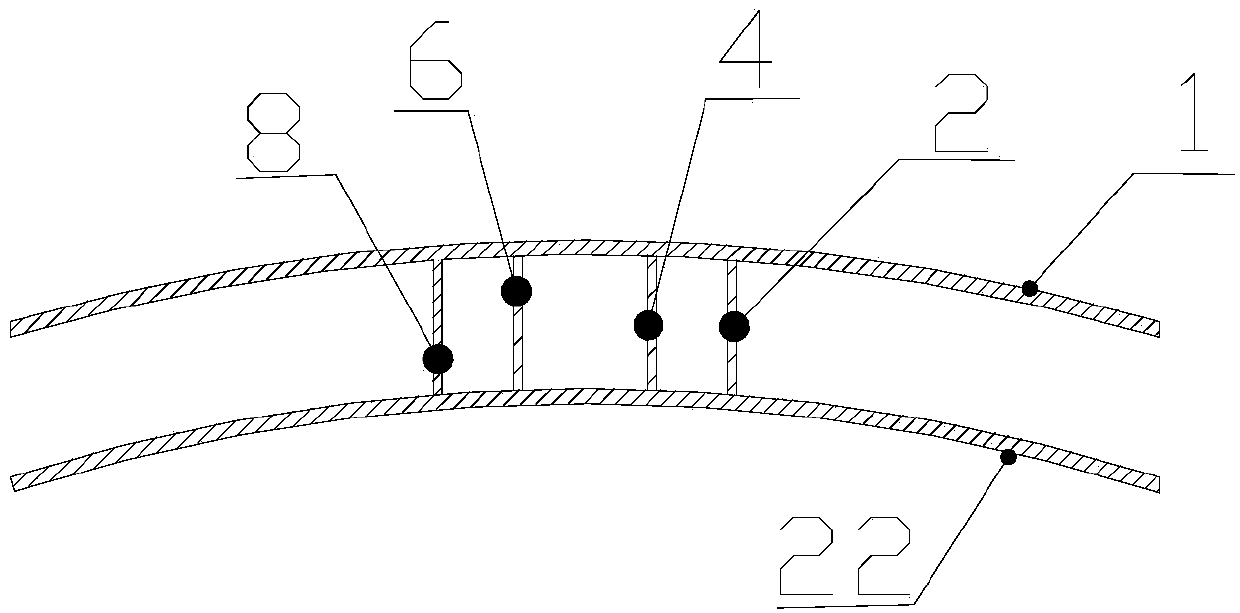

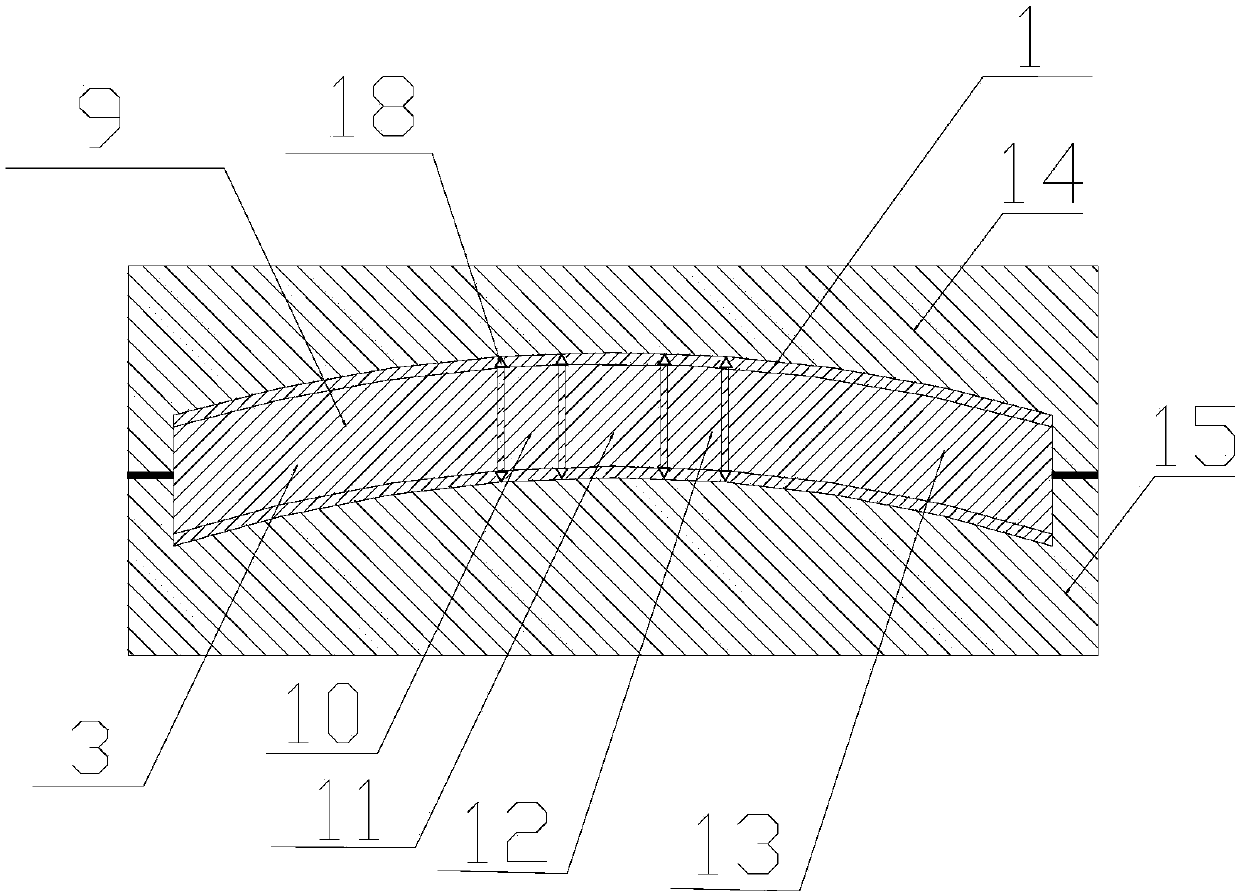

Composite cavity box segment liquid-state forming method

The invention discloses a composite cavity box segment liquid-state forming method. The method comprises following steps of skin and core mold blank body paving and pasting, core mold and secondary runner assembling, upper skin paving and pasting, upper mold and other mold assembly, resin injection, and mold releasing. The forming method is used for liquid-state forming of a composite cavity box segment. Compared with the prior art, the method solves the problems that the injection path is long, the period is long, and deficient glue defects are easily caused, large resin viscosity and difficult injection caused by long-time injection and end injection can be avoided, part manufacturing efficiency is improved, and the manufacturing cost is reduced.

Owner:AVIC BASIC TECH RES INST

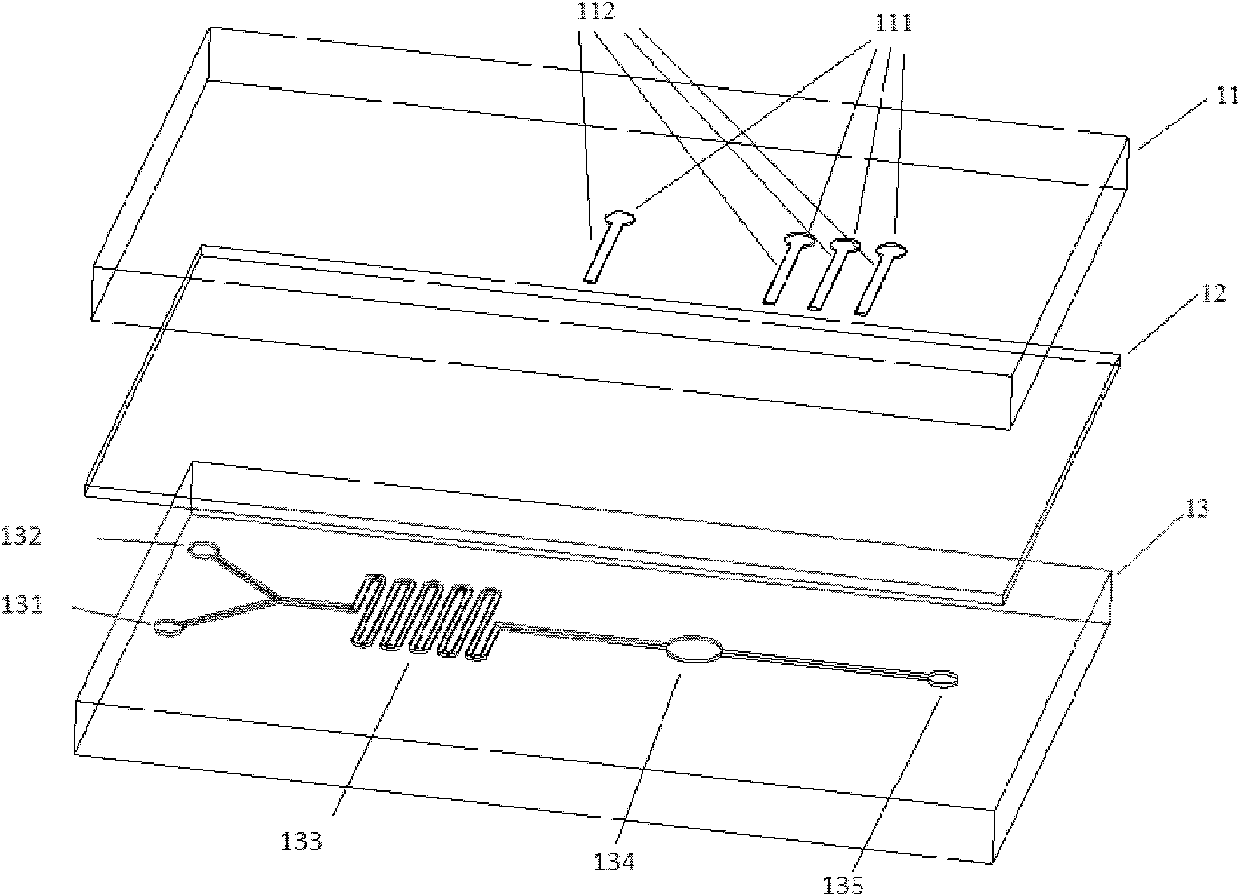

Electrical ejection forming method and device for bonded permanent magnet

InactiveCN101197208AReduce frictional resistanceImprove energy savingCeramic shaping apparatusInductances/transformers/magnets manufactureStructural symmetryDrive shaft

The invention relates to an electric operated injection molding method for bonded permanent-magnets and a device thereof. The method is that: an AC servomotor drives a timing belt and a ball screw to complete plasticization metering, stepless injection molding and guaranteeing the pressure to make up shrinks of a screw to mixed feeding of the bonded permanent-magnets. The device mainly comprises a screw rod, a charging barrel, the timing belt, a transmission shaft, a motor and the ball screw. When the pressure of fusion feeding of the bonded permanent-magnets in the charging barrel reaches the set value, load of the injection servomotor is increased and current of the injection servomotor is increased correspondingly, the injection servomotor rotates reversely to drive the screw rod to retreat in order to realize the plasticization metering of the permanent-magnets feeding; when the fusion feeding of the bonded permanent-magnets in the charging barrel reaches the value of the plasticization metering, the injection servomotor rotates positively to drive the timing belt and the ball screw, the transmission shaft is utilized to make the screw rod advance axially so as to realize the stepless injection molding and guaranteeing the pressure to make up shrinks of the permanent-magnets feeding. The whole device of the invention has good symmetrical structure and movement stationarity, low energy consumption, short injection molding period, and high magnetic performance and dimensional precision.

Owner:WUYI UNIV

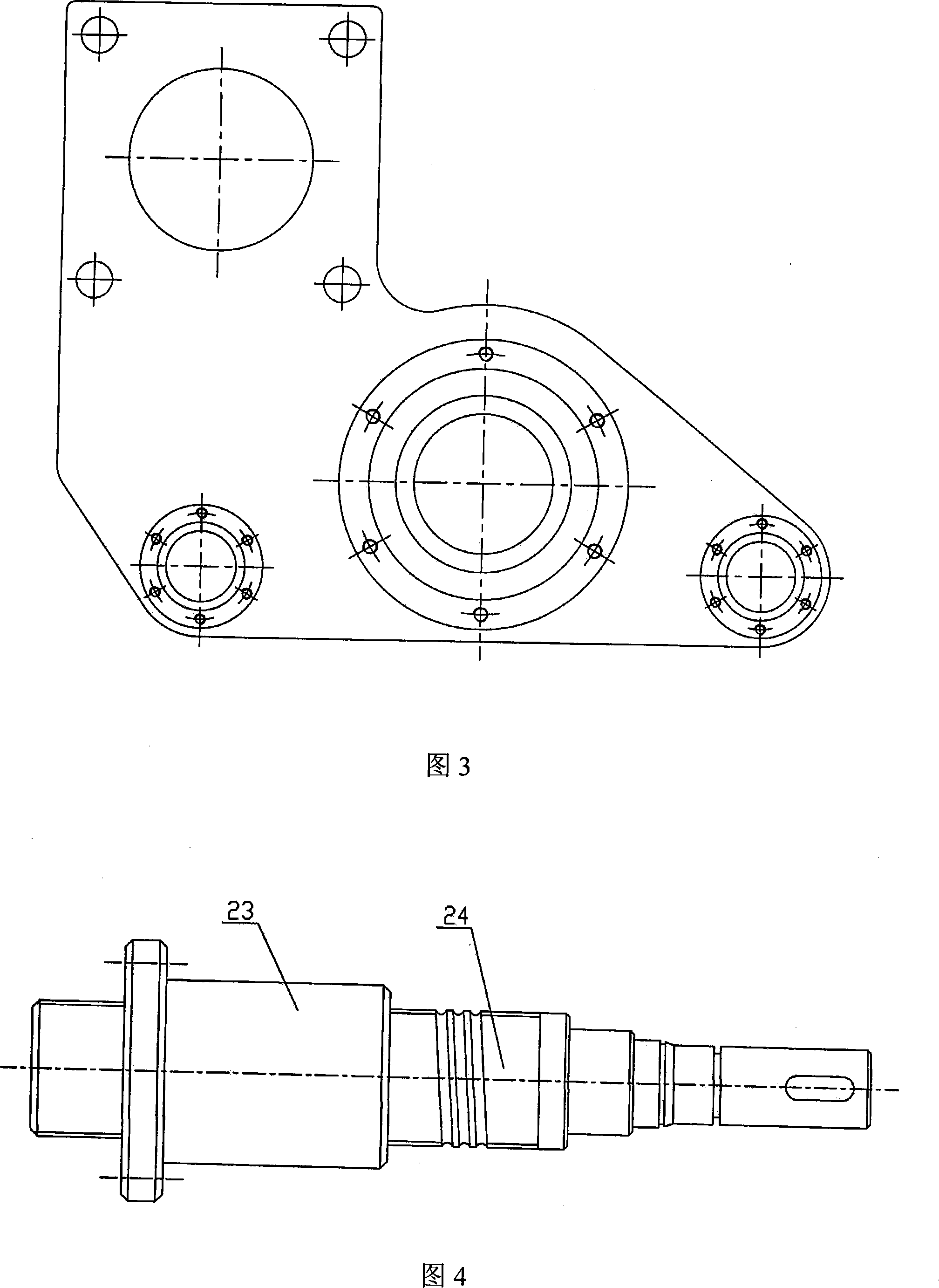

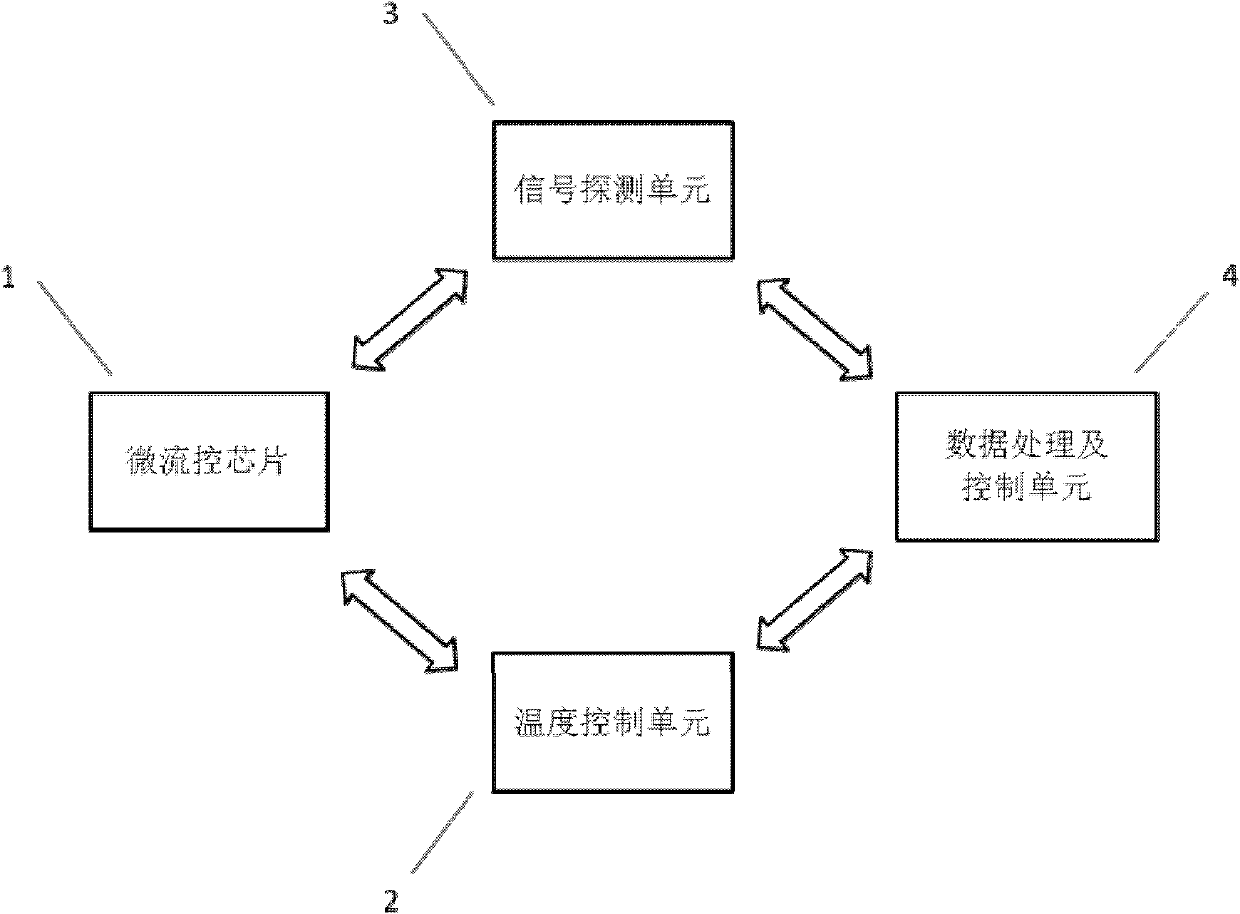

Microfluidic control chip for realizing PCR (Polymerase Chain Reaction) and real-time PCR virus quick detection device

InactiveCN102286358BReduce dosageShort injection timeBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlEngineering

The invention relates to a microfluidic control chip which is formed by bonding and sealing PDMS (Polydimethylsiloxane) material integrated with a micro valve, and comprises an upper layer of air control passage, a middle layer of PDMS membrane and a lower layer of microfluidic passage. A real-time PCR virus quick detection device comprises the microfluidic control chip, a temperature control unit, a signal detection unit and a data processing and control unit. The invention designs the microfluidic control chip which is integrated with the micro valve, is in a three-layer PDMS structure, andis used for virus detection and the real-time fluorescent PCR detection device. Compared with the traditional method, the invention has the advantages of short time, less sample usage, quick detection speed, simpleness and convenience in operation, integration and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Painless injection capsule

PendingCN108686297AShorten the timeAvoid pollutionMicroneedlesMedical devicesBiomedical engineeringMedicine

A painless injection capsule comprises a capsule body and a protecting cover; a hemisphere face is arranged on one end of the capsule body, and a plane is arranged on the other end of the capsule body; the capsule body plane is provided with a plurality of ultrafine syringe needles; the plurality of ultrafine syringe needles are sealed and protected by the protecting cover on the capsule body plane side; the capsule body plane is filled with an injection liquid. The ultrafine syringe needle is very small in diameter, so the patient feels no pain; the plurality of ultrafine syringe needles canshorten the injection process; the injection liquid is stored in the injection capsule in one time so as to prevent pollutions; the protecting cover can protect the plurality of ultrafine syringe needles; the protecting cover can cover the capsule body after usage, thus well storing the injection capsule; the painless injection capsule is sanitary and environmental protective, and low in materialcost.

Owner:SHANDONG HUAYU UNIV OF TECH

Oil spraying device of special coating machine for metallized film

InactiveCN106086780APrevent oil spillsShort injection efficiencyVacuum evaporation coatingSputtering coatingBottleAtmospheric pressure

The invention relates to an oil spraying device of a special coating machine for a metallized film. The oil spraying device comprises an oil bottle, an oil outlet tube, a horizontally-arranged oil control tube and a spray head; the top of the oil control tube is provided with a conical chamber, the tail end of the oil control tube is provided with a first cover plate, and the oil control tube is internally provided with a bead, a first spring, a first piston and a second spring; and the outer part of the first cover plate is provided with a first air inlet tube on which a first air valve is arranged. According to the oil spraying device of the special coating machine for the metallized film, the opening between the bead and the oil control tube is controlled by virtue of air pressure so that oil leakage of the oil spraying device is avoided; and then, the motion of a second piston is controlled by virtue of air pressure to carry out pressurization treatment on coating oil entering the spray head, so that the coating oil sprayed from the head part of the spray head has enough spraying speed and pressure, the oil spraying time is shortened, and the oil spraying efficiency and quality are improved. The oil spraying device is simple in structure, convenient to use, stable in operation, short in oil spraying time, high in oil spraying efficiency and good in oil spraying effect.

Owner:铜陵市铜创电子科技有限公司

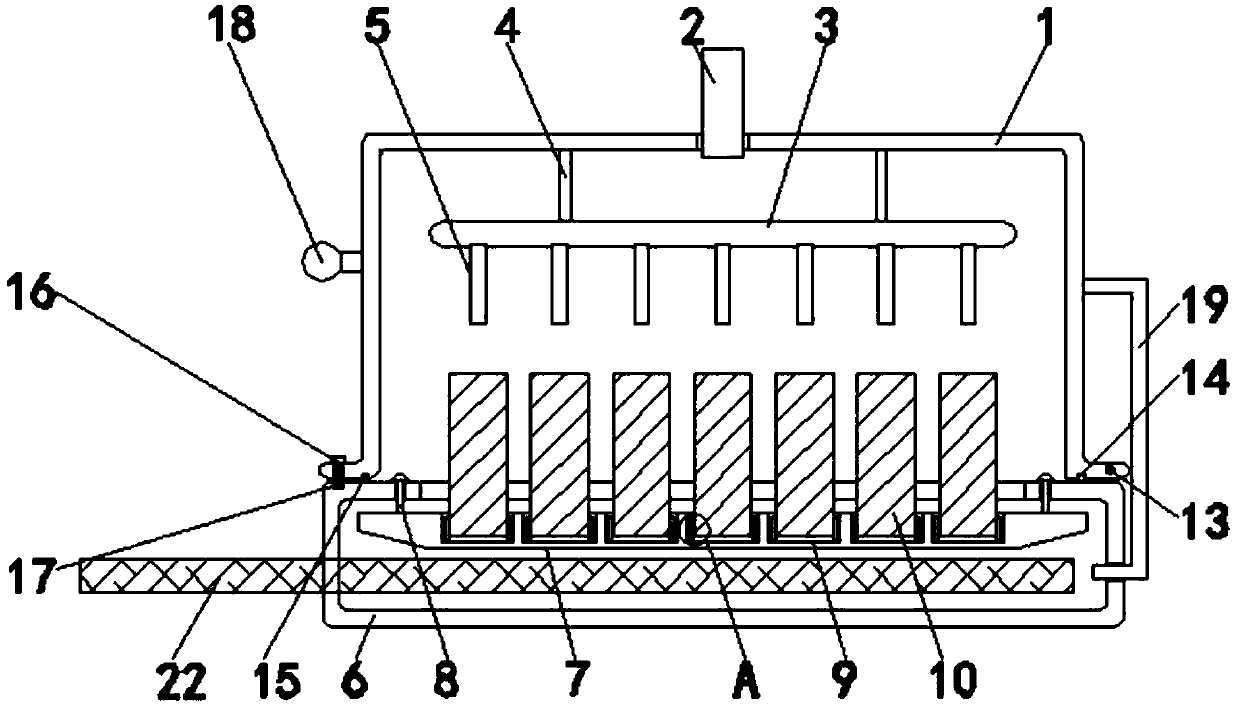

Ultrasonic liquid injection device and method for lithium ion battery

InactiveCN111180653AEasy to useReduce surface tensionFinal product manufactureCell component detailsElectrolytic agentVacuum pressure

The invention relates to the technical field of aluminum alloys, and further discloses an ultrasonic liquid injection device and method for the lithium ion battery. The device comprises a liquid injection box shell, the top of the liquid injection box shell communicates with a vacuum nitrogen pipeline, a conversion box is arranged in the liquid injection box shell, connecting rods which are evenlydistributed are fixedly connected to the top of the conversion box, and the top ends of the connecting rods are fixedly connected with the liquid injection box shell. According to the ultrasonic liquid injection device and method for a lithium ion battery, the vacuum nitrogen pipeline is arranged, the interior of the shell of the liquid injection box can be pumped to a required vacuum pressure value, by arranging the ultrasonic generation device, ultrasonic waves can be emitted into the liquid injection box shell, under the interference of a vacuum environment condition and ultrasonic waves,the surface contact angle between the electrolyte and materials such as positive and negative electrodes of the lithium ion battery and a diaphragm can be destroyed, the surface tension is reduced, the infiltration speed is increased, and the method is short in liquid injection time, convenient to operate, high in reliability, high in practicability and convenient for a user to use.

Owner:钜成新能源(响水)有限公司

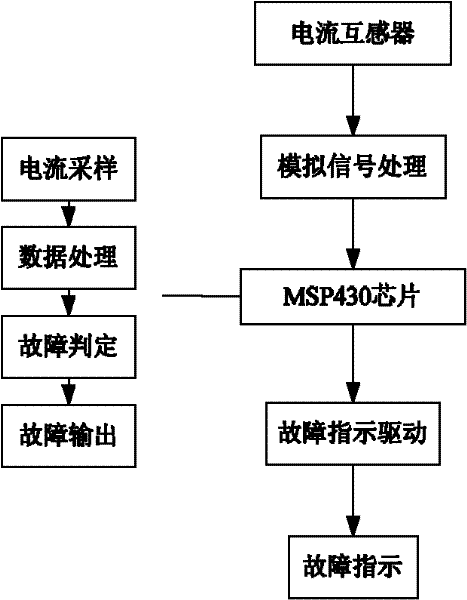

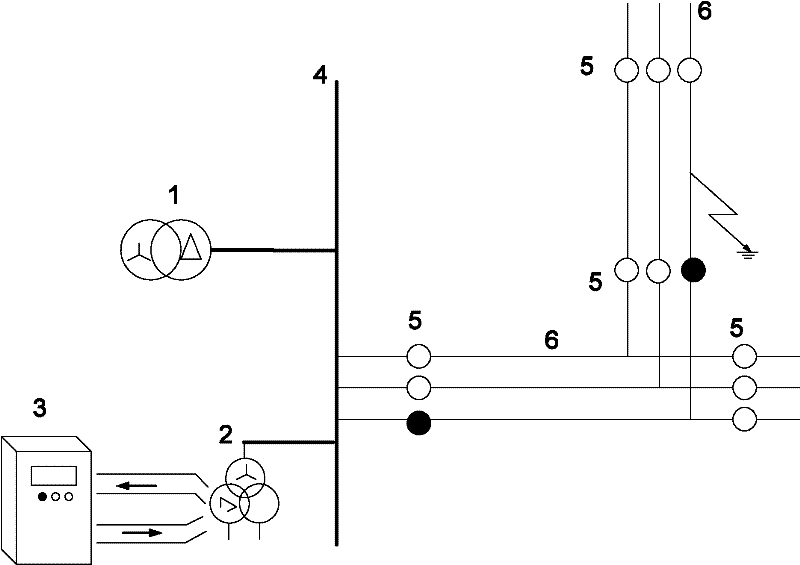

Earth fault judging method for overhead line fault indicator

ActiveCN101975911BOvercome the disadvantage that it is not easy to determine the fault pointImprove accuracyFault locationInformation technology support systemFault indicatorSignal on

The invention discloses an earth fault judging method for an overhead line fault indicator in the technical field of power grids. A voltage signal on an open-delta side of a three-phase potential transformer on a bus of a power grid to be detected is introduced into a signal output end of a quintuple harmonic generator; a plurality of fault indicators are arranged on a plurality of sections of overhead power lines of the power grid to be detected; and after a permanent earth fault reaches the judging time, the quintuple harmonic generator outputs specific coding waves communicating between a system power supply and a fault line of an earth point to the power grid to be detected through the open-delta side of the three-phase potential transformer so as to realize earth fault positioning. The earth fault judging method avoids the defects of the conventional fault indicators in distribution network system application and improves the accuracy of judging the earth fault.

Owner:SIEYUAN ELECTRIC CO LTD +1

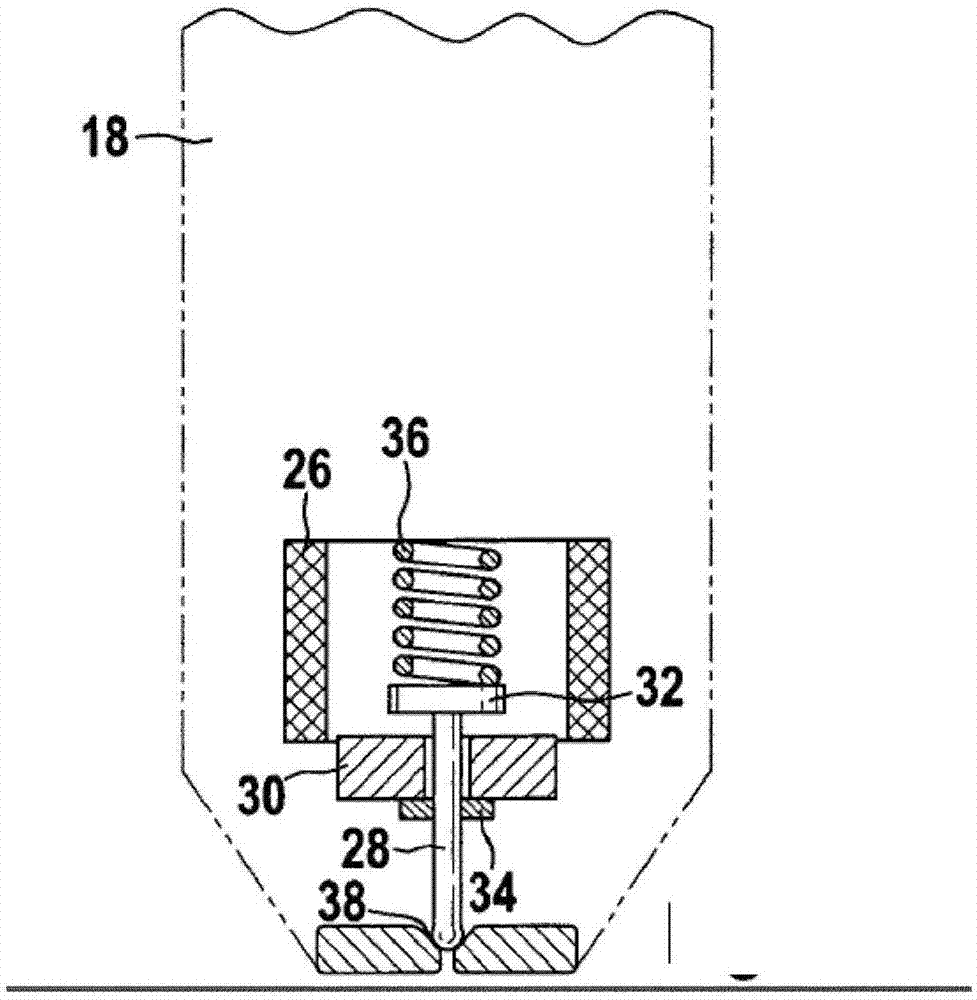

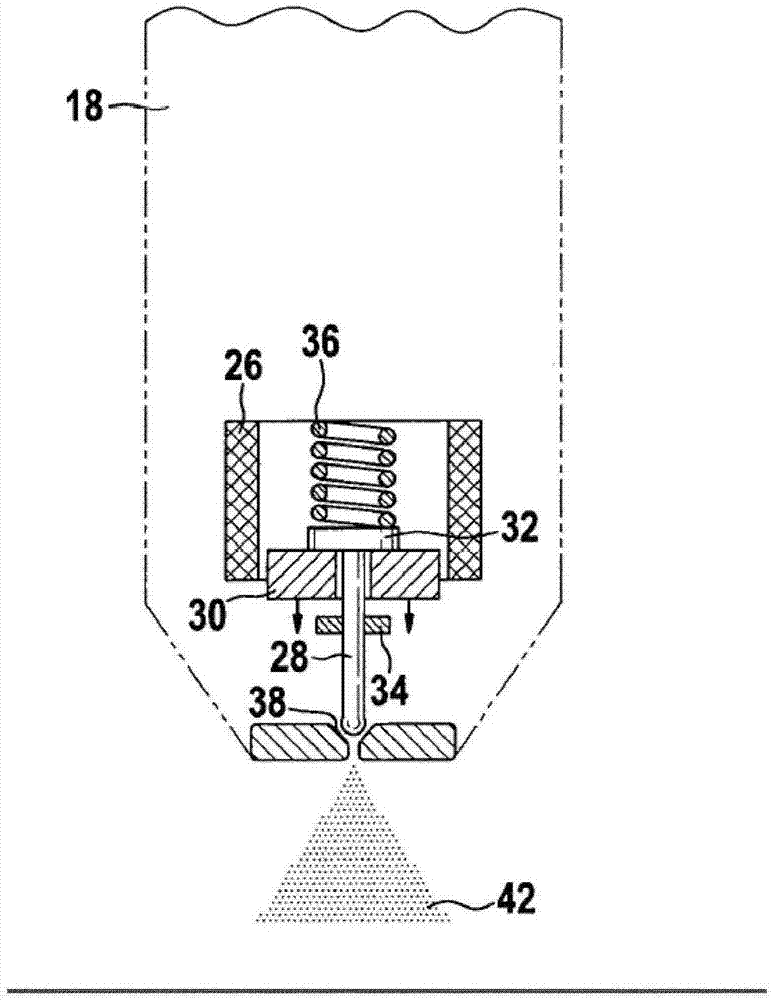

Injection valve for injecting a fluid, use of an injection valve and method for producing an injection valve

ActiveCN107407219AImprove restoring forceShort injection timeElectrical controlMagnetic flux influencing fuel injectionFerromagnetic material propertiesCombustion chamber

The invention relates to an injection valve for injecting a fluid, in particular a fuel fluid, wherein the fuel fluid is injected into a suction duct or into a combustion chamber of a cylinder of an internal combustion engine, wherein the injection valve comprises an electromagnetic actuator with a magnetic circuit, the magnetic circuit comprising a solenoid, an inner pole and a magnet armature cooperating with the magnet coil and the inner pole. The magnetic circuit is configured for generating a controlled force action between the inner pole to the magnet armature when the electromagnetic actuator is controlled by means of a control current and / or control voltage. According to the invention, the injection valve has a gap in the region between the inner pole and the magnet armature, wherein the injection valve has a valve sleeve, said valve sleeve having either continuously - both in the region of the gap between the inner pole and the magnet armature - paramagnetic material properties, or paramagnetic material properties in the region of the gap between the inner pole and the magnet armature and ferromagnetic material properties outside this range.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com