Resin transfer moulding mold and resin transfer moulding molding system

A technique of resin transfer molding and mould, which is applied in the direction of coating, etc., and can solve the problems of short glue injection time and long process cycle of composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

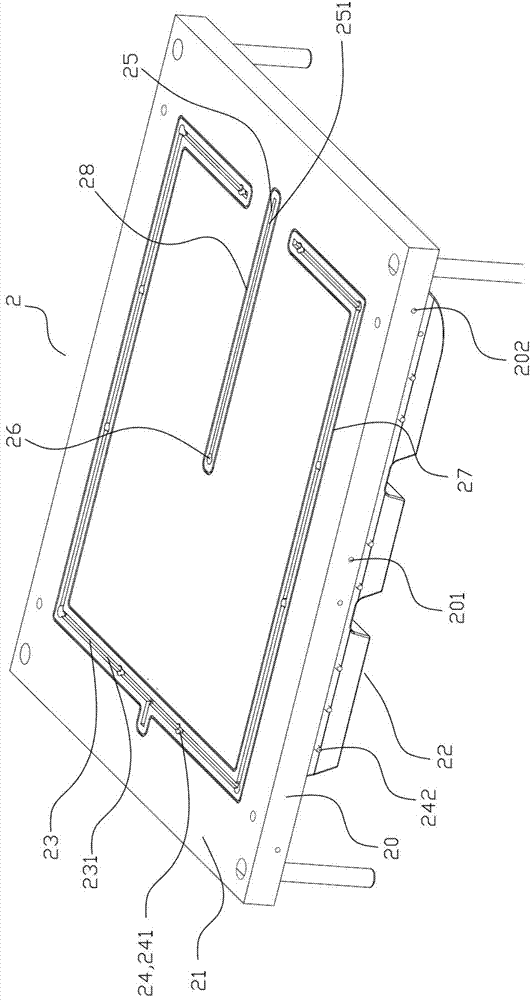

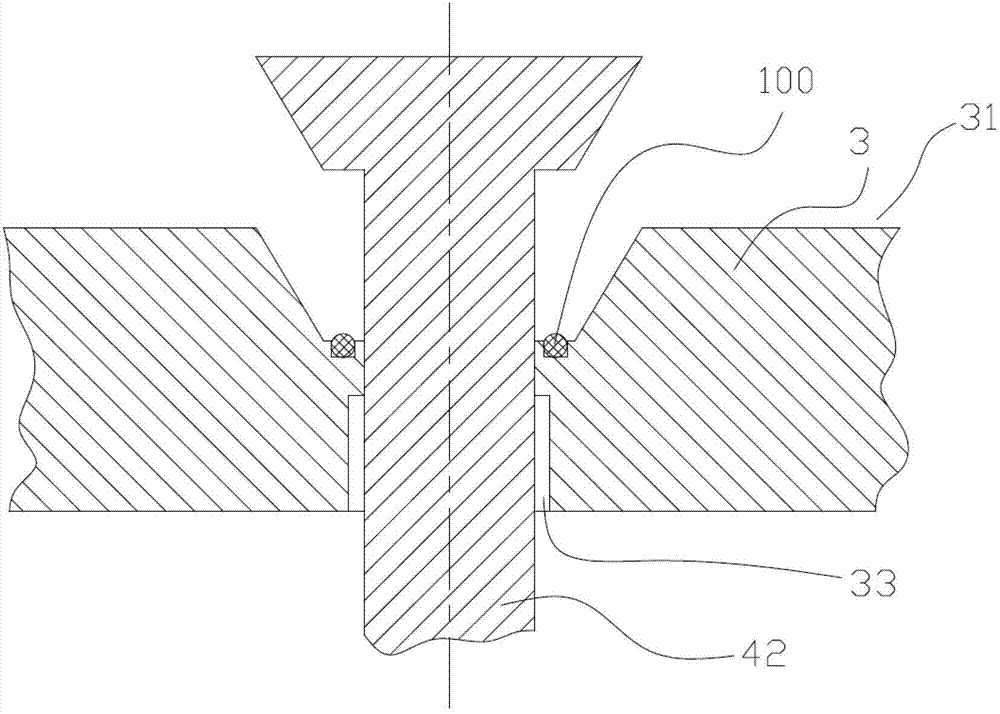

[0015] After extensive and in-depth research, the inventor found for the first time that the ejection device can effectively and quickly release the film, so the resin transfer molding process cycle can be effectively shortened, and moreover, multiple injection through holes can be provided at the same time. Dispensing glue can achieve the purpose of short glue injection time. The present invention has been completed on this basis.

[0016] Preferably, the upper mold pressing plate device can be lifted to a certain position by a mold clamping machine slider when the mold is opened, and then the male mold is pulled up.

[0017] Preferably, the male mold has:

[0018] The top surface of a male mold;

[0019] Bottom surface of a male mold;

[0020] A diversion groove for diverting resin that is recessed downward from the top surface of the male mold and has a diversion groove surface;

[0021] An air guiding groove formed on the top surface of the male mold and having an air guiding groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com