Key

A button and wall technology, which is applied in the field of button structure, can solve the problems of high final product cost, long time, and long injection molding time, and achieve the effects of short button injection and assembly time, simple mold structure, and easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

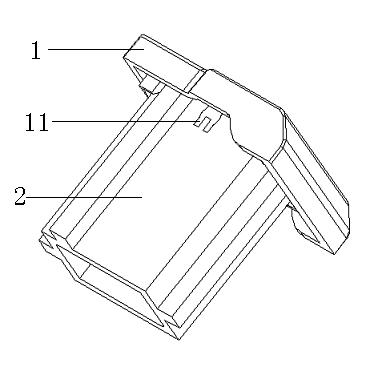

[0018] The button disclosed by the present invention is divided into two parts, the button cap and the button wall. The button cap part is made of light-transmitting material, such as white transparent PC, and the button wall is made of opaque material, such as ABS. When the two parts are assembled, they can be assembled directly by hand or press-fitted with simple air tools, which not only improves production efficiency, but also does not require large-scale equipment such as double-color injection molding and ultrasonic processing, saving investment and reducing costs.

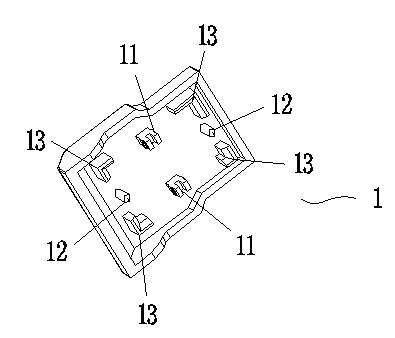

[0019] Such as Figure 1-5 As shown, in this embodiment, the wall body 2 is a hollow structure similar to a cuboid, and its specific fastening structure with the key cap 1 is as follows: two U-shaped buckles 11 and two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com