Atomic force microscope probe manufacturing method possessing nanoscale spherical tip

An atomic force microscope, nano-scale technology, applied in scanning probe technology, scanning probe microscopy, microstructure technology and other directions, can solve the problems of low alignment accuracy, high cost, long time consumption, etc., to increase the measurement accuracy, Suitable for industrialization, the effect of fast forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

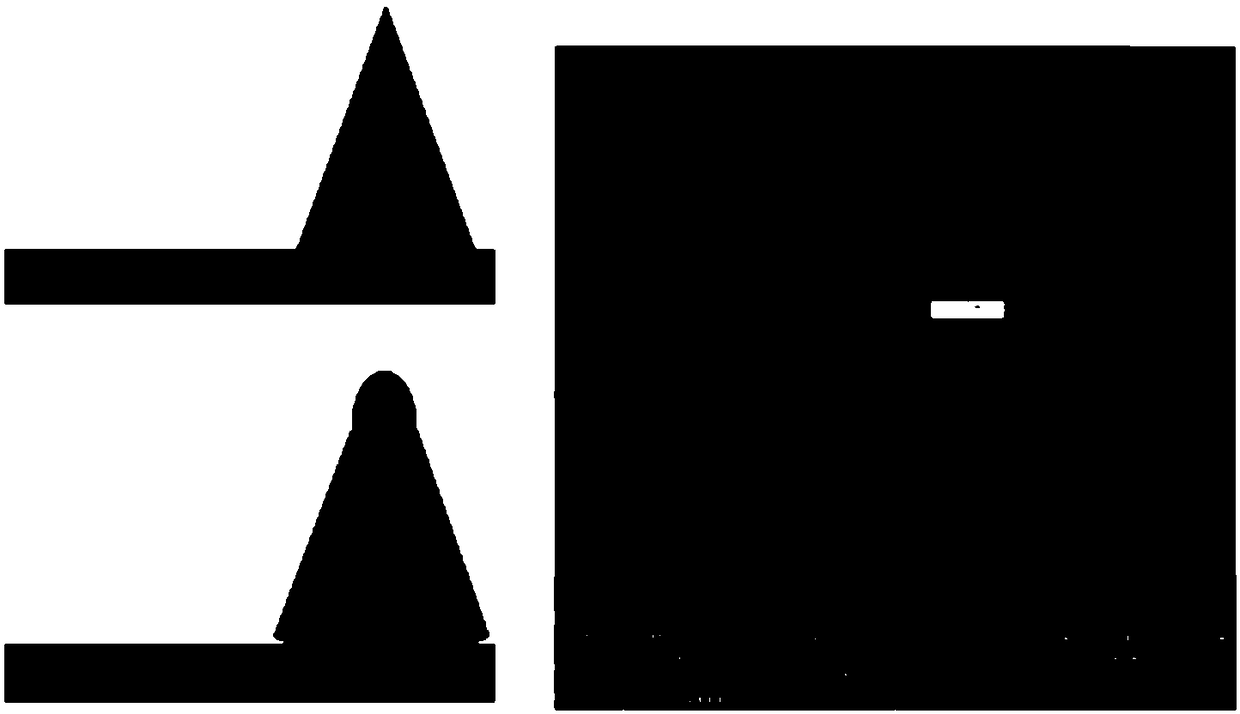

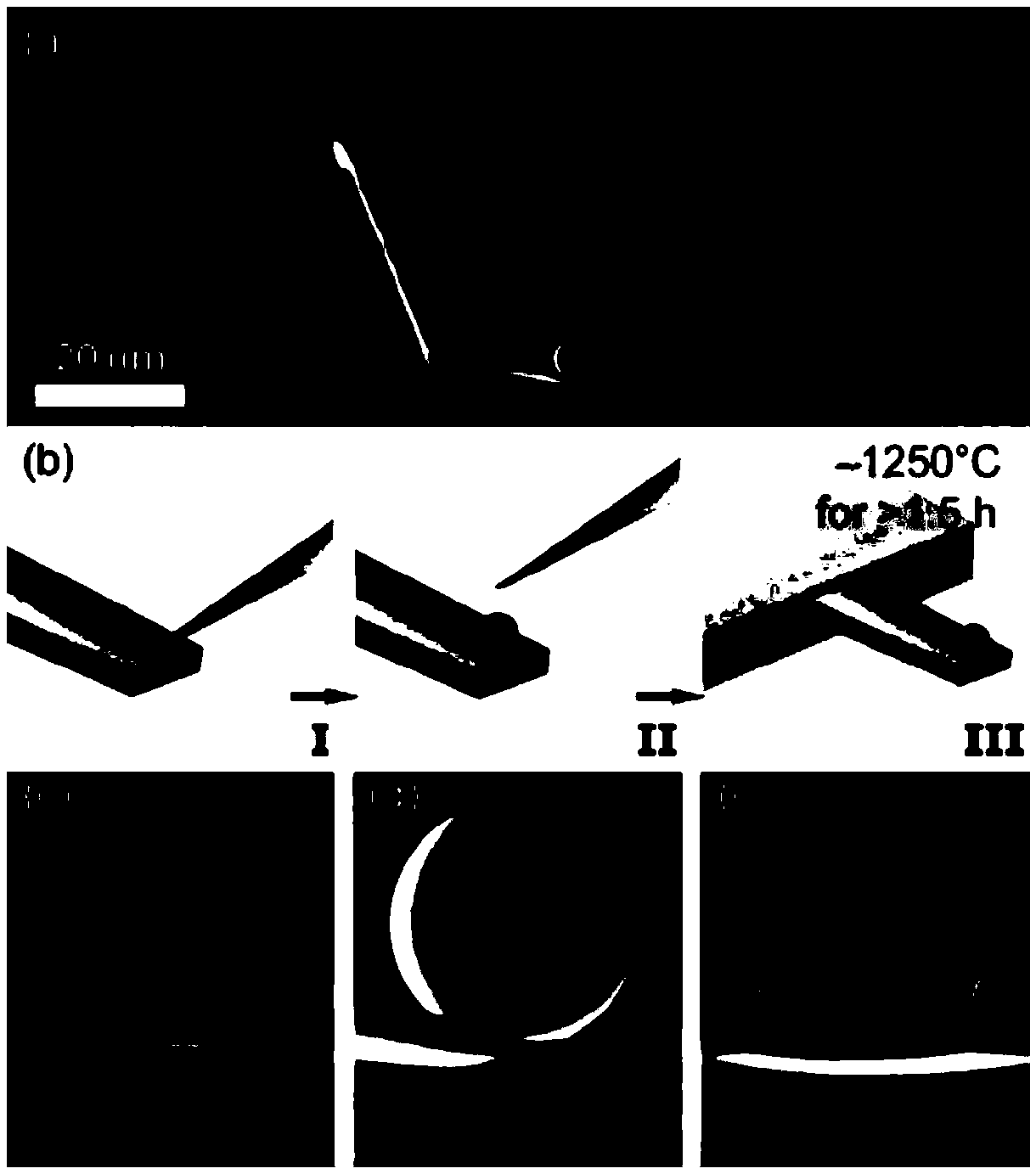

[0036] Such as image 3 , Figure 4 and Figure 5 As shown, a method for fabricating an atomic force microscope probe with a nanoscale spherical tip 3 includes the following steps:

[0037] S1. Take a micro-cantilever beam 1, set a protrusion on the surface of the micro-cantilever beam 1, and use the side where the protrusion is away from the micro-cantilever beam 1 as the substrate;

[0038] S2. Locating a particle injection position on the substrate through particle scanning substrate imaging;

[0039] S3. After applying a high voltage of 1KeV to 10MeV to helium ions, the particle beam is focused to form a high-energy particle beam 2. According to the size of the spherical tip 3, the high-energy particle beam 2 is quantitatively controlled by a timing switch valve in an area with a diameter of 250 nanometers. Inject the particle injection position within the range, so that the particle injection position bulges to form a spherical tip 3 (such as Figure 7 , the dose of h...

Embodiment 2

[0042] Such as Figure 6 As shown, a method for fabricating an atomic force microscope probe with a nanoscale spherical tip 3 includes the following steps:

[0043] S1. Take a micro-cantilever beam 1 and use the surface of the micro-cantilever beam 1 as a substrate;

[0044] S2. By calibrating the position of the high-energy particle beam 2 with the imaging position of the optical microscope or the imaging position of the atomic force microscope, and then positioning a particle injection position on the substrate through the imaging of the optical microscope or the imaging of the atomic force microscope;

[0045] S3. Apply a high voltage of 1KeV to 10MeV to the particles and then focus the particle beam to form a high-energy particle beam 2. According to the size of the spherical tip 3, the high-energy particle beam 2 is quantitatively controlled by a timing switch valve within the area of 250 nanometers in diameter. Inject the particle injection position into the particle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com