Feeding system of horizontal cold chamber die casting machine

A technology of cold chamber die casting and feeding system, applied in the field of feeding system of a horizontal cold chamber die casting machine, can solve the problems of difficult control of the injection volume, long die casting cycle, low production efficiency, etc., so as to shorten the injection time and improve the Die casting efficiency, effect of controlling injection amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

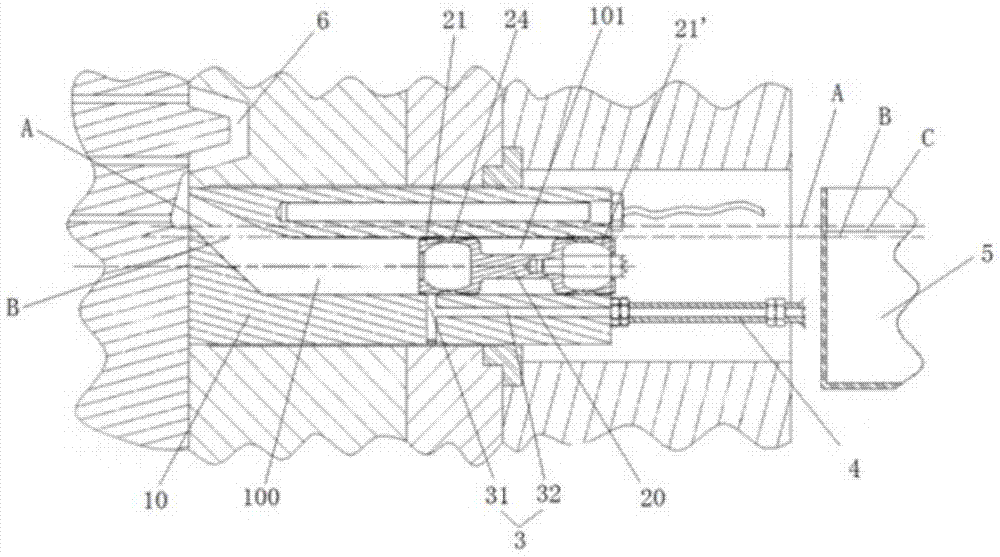

[0047] see Figure 1-3 , a feeding system for a horizontal cold chamber die-casting machine, which includes a barrel 10, and the barrel 10 is provided with a plunger 2 for hydraulically injecting molten metal in the barrel 10 into the mold cavity 6, so The tail end of the plunger 2 is connected to the driving mechanism, and the side wall of the barrel 10 is provided with a molten metal channel 3 for injecting molten metal into the barrel 10, and the molten metal channel 3 is communicated through a pipeline 4 into the metal smelting chamber 5; the plunger 2 includes a first sealing portion for sealing during injection and a second sealing portion for preventing the molten metal in the cylinder 10 from leaking backward Two sealing parts, the cavity between the first sealing part, the inner wall of the barrel 10 and the discharge port 105 of the barrel 10 forms a pressure chamber 100 for storing the molten metal liquid to be shot, so The cavity between the first sealing part, th...

Embodiment 2

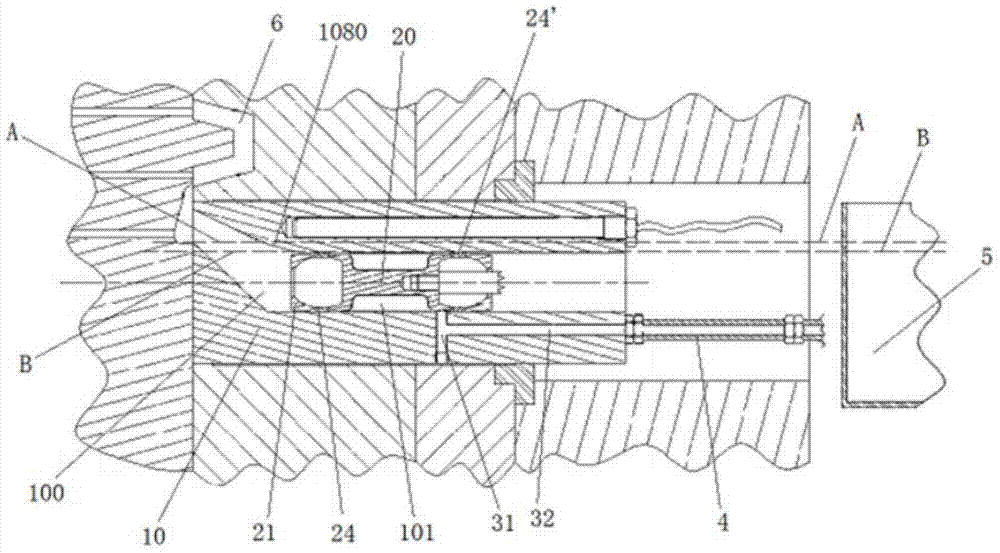

[0068] This embodiment provides a feeding system for a horizontal cold chamber die-casting machine, which is a further improvement on the basis of Embodiment 1. In this embodiment, in order to facilitate the installation of the double-sealed plunger of the present invention to the barrel 10, and to ensure that the plunger has a relatively stable operating state in the barrel 10, on the basis of the first embodiment above, the second plunger head 21' and the plunger head 21 are relatively The structure of the center point in the length direction of the plunger rod 20 is symmetrical, that is, the structure of the second plunger head 21' is consistent with the structure of the plunger head 21. This arrangement is beneficial to ensure that the plunger is in the When the barrel 10 is in operation, the frictional force between the sealing parts at both ends and the inner wall of the barrel is basically equal, and can reciprocate relatively smoothly along the axial direction, thereby ...

Embodiment 3

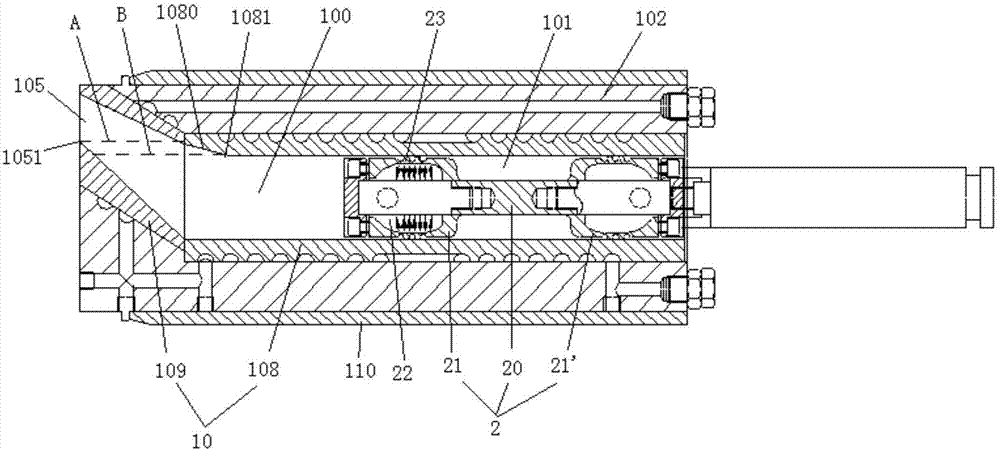

[0071] This embodiment provides a feeding system for a horizontal cold chamber die-casting machine, which is a modification based on Embodiment 1 or 2. In this embodiment, see Figure 7 , Figure 8 (For the convenience of showing the specific structure of the fluid heating device, the structure of the molten metal channel 3 is omitted in these two figures), the outer side of the straight part 108 and the gooseneck 109 is provided with a heating device 102, the The heating device 102 is a thermal fluid heater, and the outer side of the heating device 102 is provided with a heat insulating sleeve 110 for heat preservation. The heating device 102 can properly heat the molten metal in the barrel 10 to keep it at the injection temperature, thereby improving the casting quality and production efficiency. On the one hand, the heat insulating sleeve 110 can prevent the inner wall of the high-temperature barrel and the heating device from heat exchange with the outside air to reduce t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com