Oil return monitoring system of compressor and method thereof

A technology for monitoring systems and compressors, applied in refrigerators, refrigeration safety arrangements, refrigeration components, etc., can solve the problems of reducing the outlet pressure of the compressor, large changes in the opening degree, affecting the performance of the air conditioning system, etc. Normal, avoid waste, ensure adequate lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

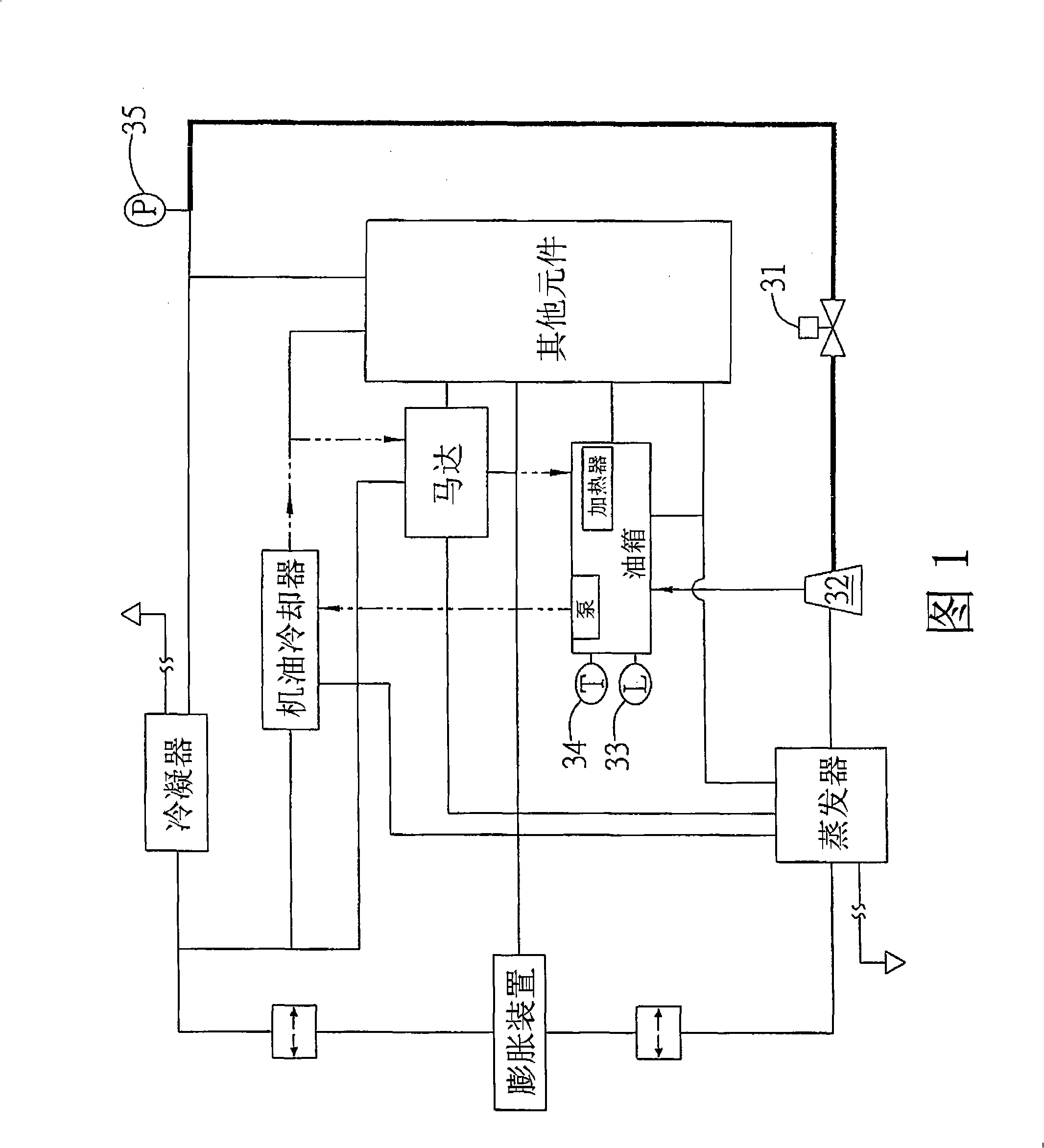

[0044] Please refer to FIG. 1 , which is a schematic diagram showing the oil return monitoring system of the compressor of the centrifugal chiller main engine of the present invention. As shown in the figure, the oil return monitoring system includes a jet pump 32, a pressure sensing device 35, an oil level sensing device 33, a temperature sensing device 34 and a high-pressure gas oil return valve 31. The present invention utilizes the jet pump 32 Feed back the outlet pressure of the compressor as the power source, install the pressure sensing device 35 directly at the outlet of the compressor, and install the oil level sensing device 33 and the temperature sensing device 34 corresponding to the oil tank, so as to measure the oil tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com