Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89 results about "Centrifugal chiller" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A centrifugal chiller utilizes the vapor compression cycle to chill water and reject the heat collected from the chilled water plus the heat from the compressor to a second water loop cooled by a cooling tower.

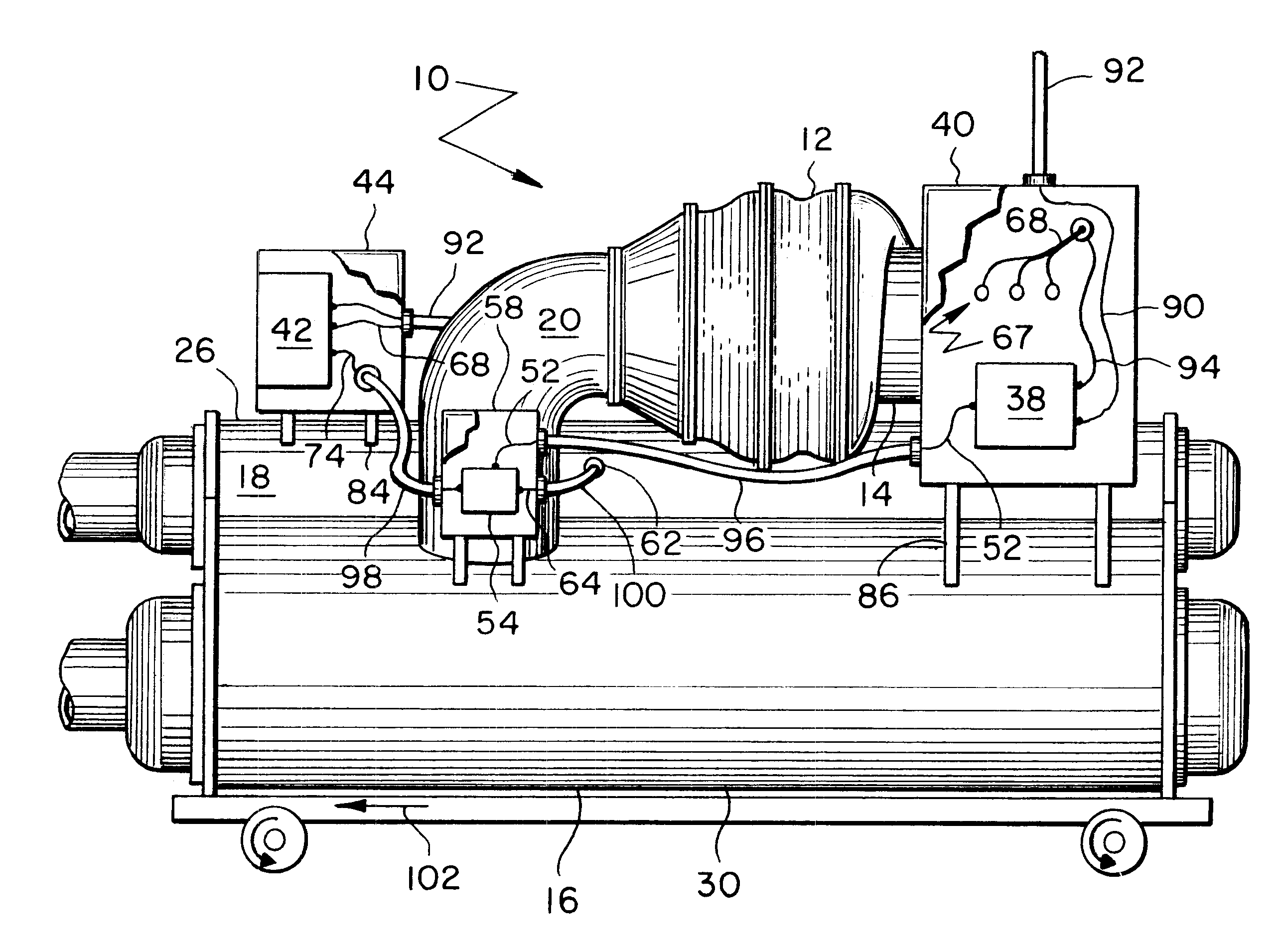

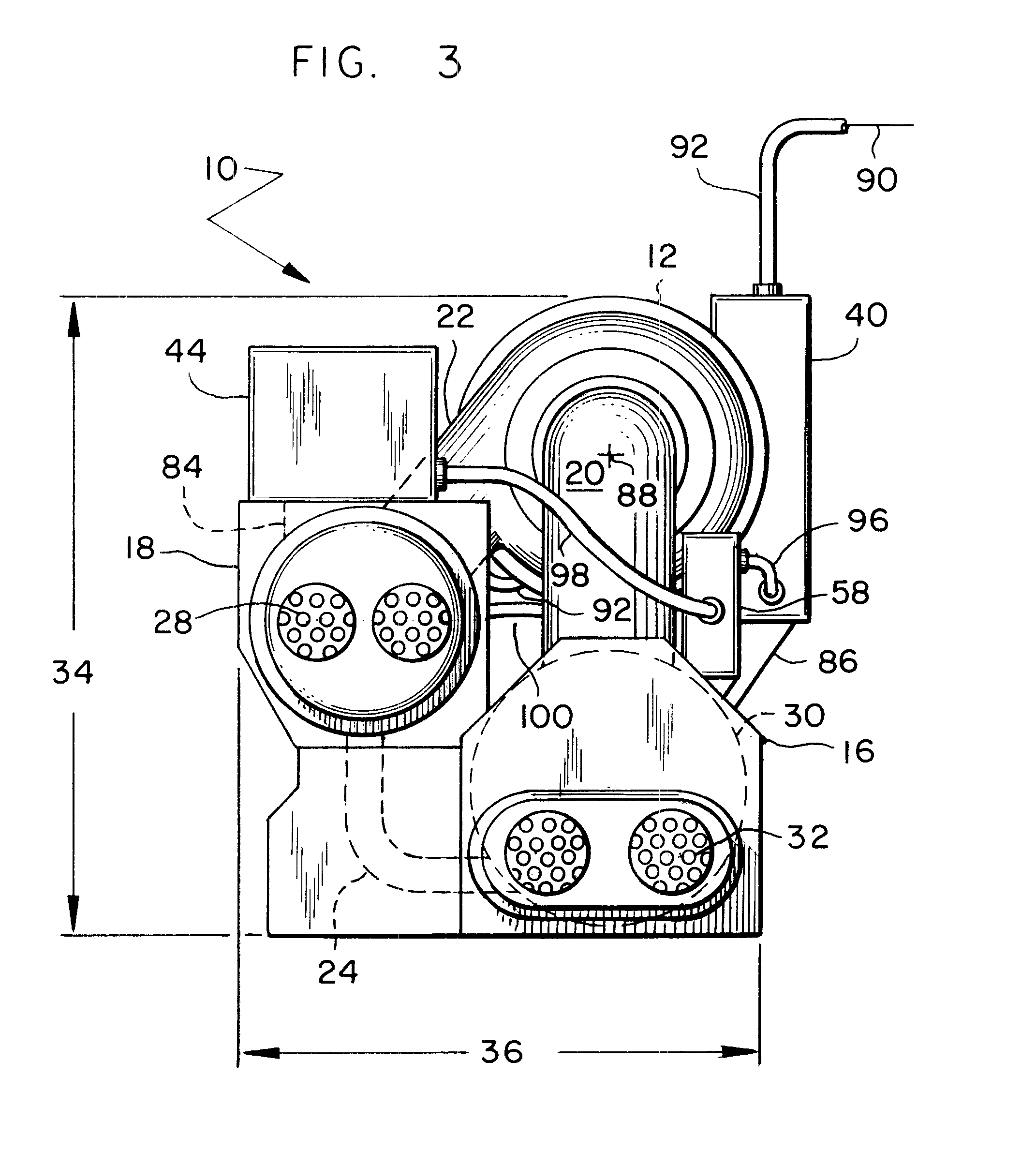

Centrifugal chiller with high voltage unit-mounted starters

InactiveUS6679076B1Compression machines with non-reversible cycleRefrigeration safety arrangementCentrifugal chillerEngineering

A centrifugal chiller includes both a unit-mounted full-voltage starter and a unit-mounted reduced-voltage starter. The chiller is rather large with a rated cooling capacity of at least 300 tons and is driven by a motor that is powered by at least 2,000 volts. The chiller includes an evaporator shell and a condenser shell in a staggered arrangement to provide a combined height of between 6 and 12 feet and a combined width of between 5 and 8.5 feet. The staggered arrangement of the shells plus mounting the two starters at opposite sides of the motor provide a chiller whose outer dimensions permit the chiller to be shipped as a single package without exceeding certain shipping limits.

Owner:TRANE INT INC

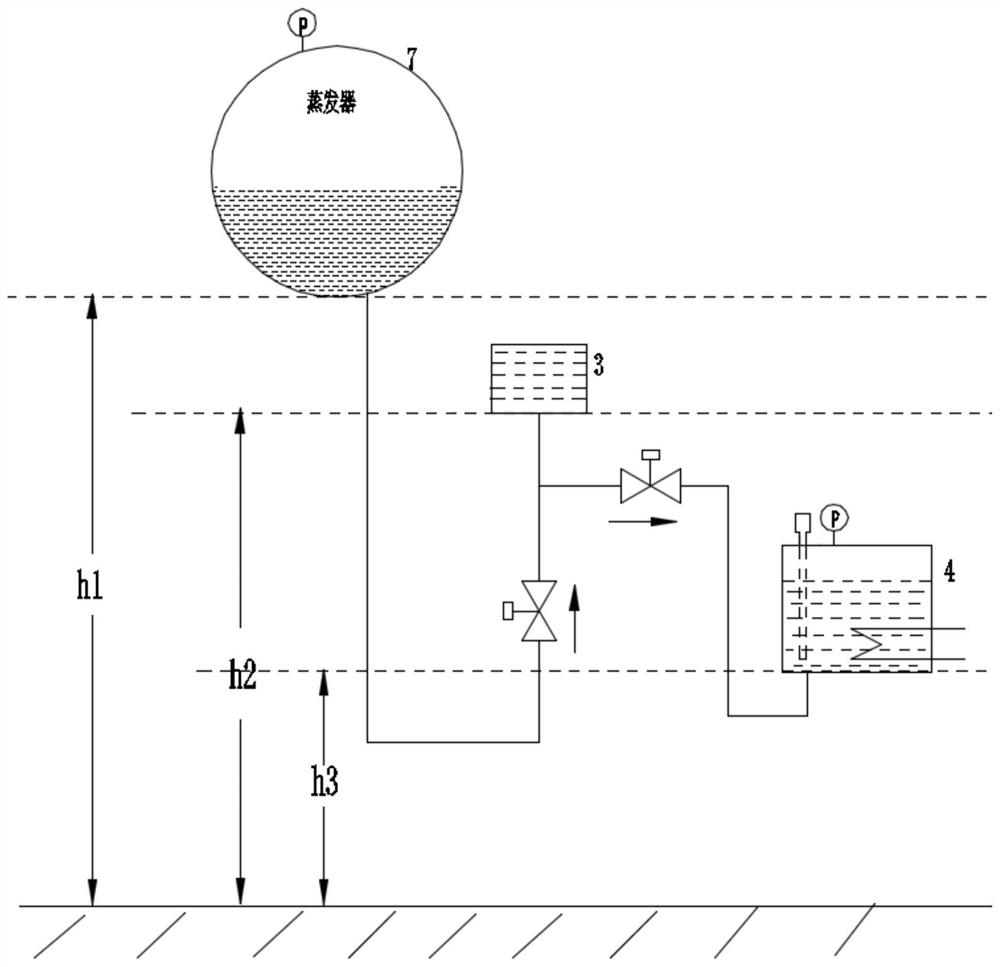

Air suspension bearing air supply system, air supply method and centrifugal water chilling unit

PendingCN111780443AContinuous and stable air supplyGuarantee continuous and stable operationCompression machines with non-reversible cycleFluid circulation arrangementCentrifugal chillerThermodynamics

The invention provides an air suspension bearing air supply system, an air supply method and a centrifugal water chilling unit. The air suspension bearing air supply system comprises an air suspensioncompressor, a refrigerant circulation loop where the air suspension compressor is located and a first air supply loop, wherein a liquid inlet of the first air supply loop is connected to a liquid taking opening of the refrigerant circulation loop, liquid is taken from the liquid taking opening, an air outlet of the first air supply loop is connected to the air suspension compressor, the first airsupply loop comprises a liquid supplementing tank and an air supply tank, the installation height of the liquid supplementing tank and air supply tank is lower than that of the liquid taking opening,and a refrigerant in the refrigerant circulation loop can flow into the first air supply loop from the liquid taking opening under the action of gravity. The air suspension bearing air supply systemis suitable for the centrifugal water chilling unit adopting the air suspension bearing, continuous and stable air supply to the air suspension bearing is achieved through different installation heights of the liquid taking opening, the liquid supplementing tank and the air supply tank by means of gravity and the communicating vessel principle, and reliable and stable operation of the unit is guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

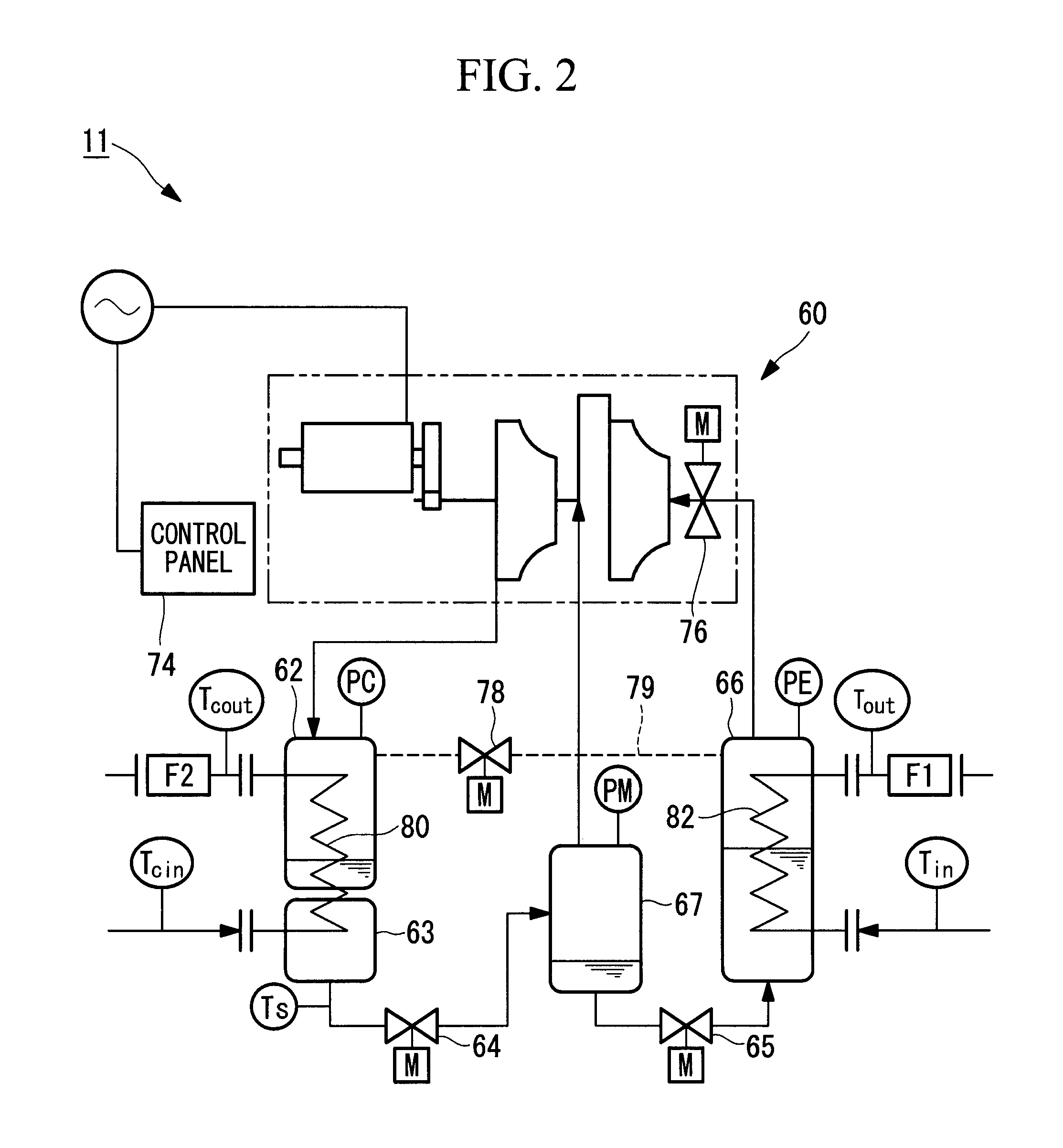

Performance evaluation device for variable-speed centrifugal chiller

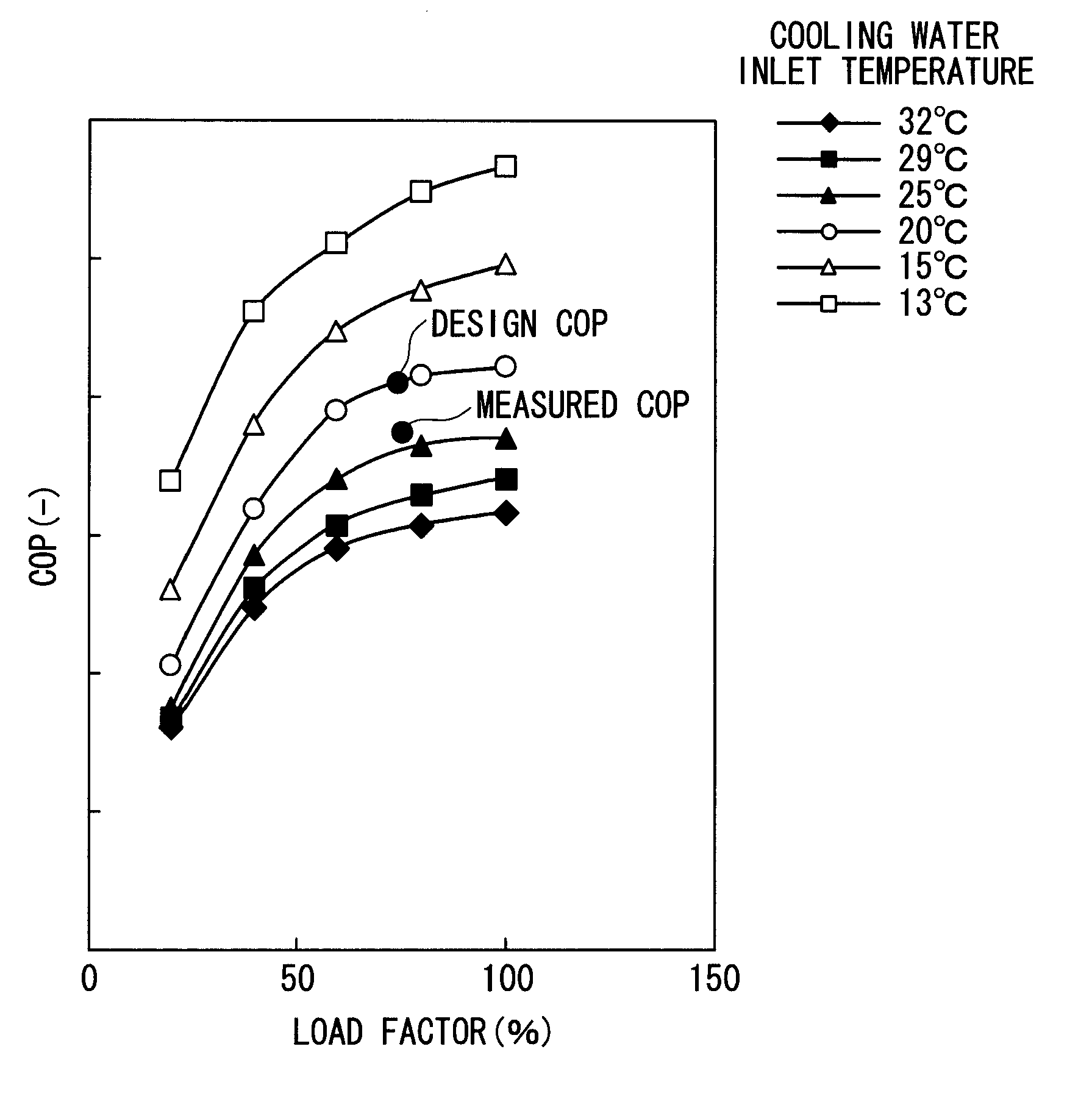

ActiveUS20110120162A1Improve accuracyMechanical apparatusCompression machines with non-reversible cycleCentrifugal chillerCurrent load

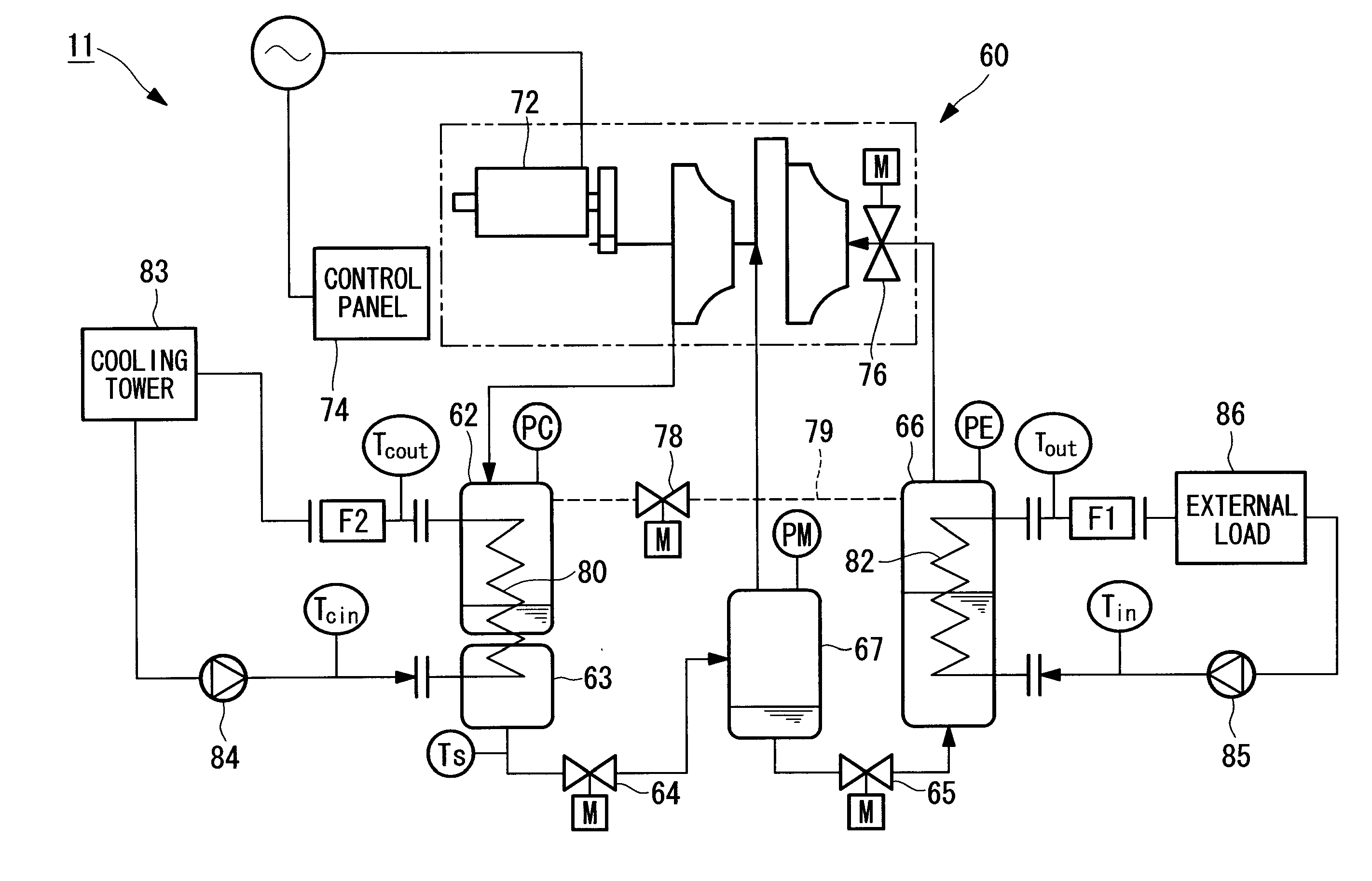

An object is to sequentially calculate planned COPs. Provided is a performance evaluation device for a variable-speed centrifugal chiller that includes a data acquisition unit that acquires operating data of the variable-speed centrifugal chiller as input data; a storage unit that stores a first arithmetic equation derived on the basis of mechanical characteristics of the chiller and used for calculating a relative load factor that relatively expresses a relationship between a current load factor at a current coolant inlet temperature and a predetermined load factor at a predetermined coolant inlet temperature set as a reference operating point, a second arithmetic equation that expresses a relationship between the relative load factor and a correction coefficient, and a third arithmetic equation used for calculating a planned COP by using the correction coefficient to correct a COP calculation equation derived from a reverse Carnot cycle; and an arithmetic unit that calculates the planned COP under current operating conditions by using the operating data acquired by the data acquisition unit in the first, second, and third arithmetic equations stored in the storage unit.

Owner:MITSUBISHI HEAVY IND LTD

Fault diagnosis method for chiller

The invention discloses a fault diagnosis method for chiller. The method comprises the steps of: S1, performing fault simulation experiments on a screw chiller and a centrifugal chiller, and collecting fault simulation experiment data of the screw chiller and the centrifugal chiller; S2, randomly selecting the fault simulation experiment data of the screw chiller and the centrifugal chiller on which a steady state processing and a noise removing processing are performed to form a second training set data and test set data; S3, establishing original training set data; S4, performing oversampling processing on the original training set data to obtain oversampled training sample set data with different oversampling rates; S5, training the oversampled training sample set data using an SVM model to obtain a diagnostic model; and S6, putting the test set into the diagnostic model for testing to obtain diagnosis results of the different chiller fault models. The diagnosis method can perform fault diagnosis on different types of chillers, and has wide application prospect.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

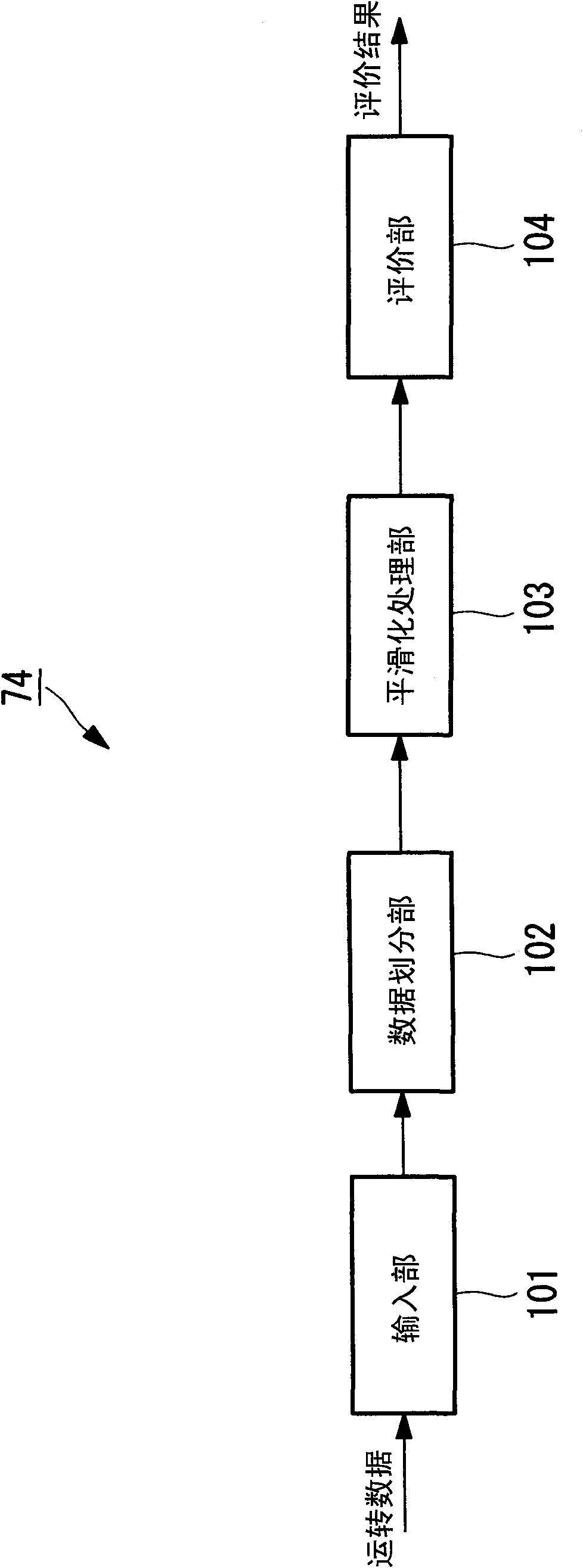

Performance evaluation device for centrifugal chiller

InactiveCN102384855AHigh precisionPump componentsCompression machines with non-reversible cycleCentrifugal chillerControl engineering

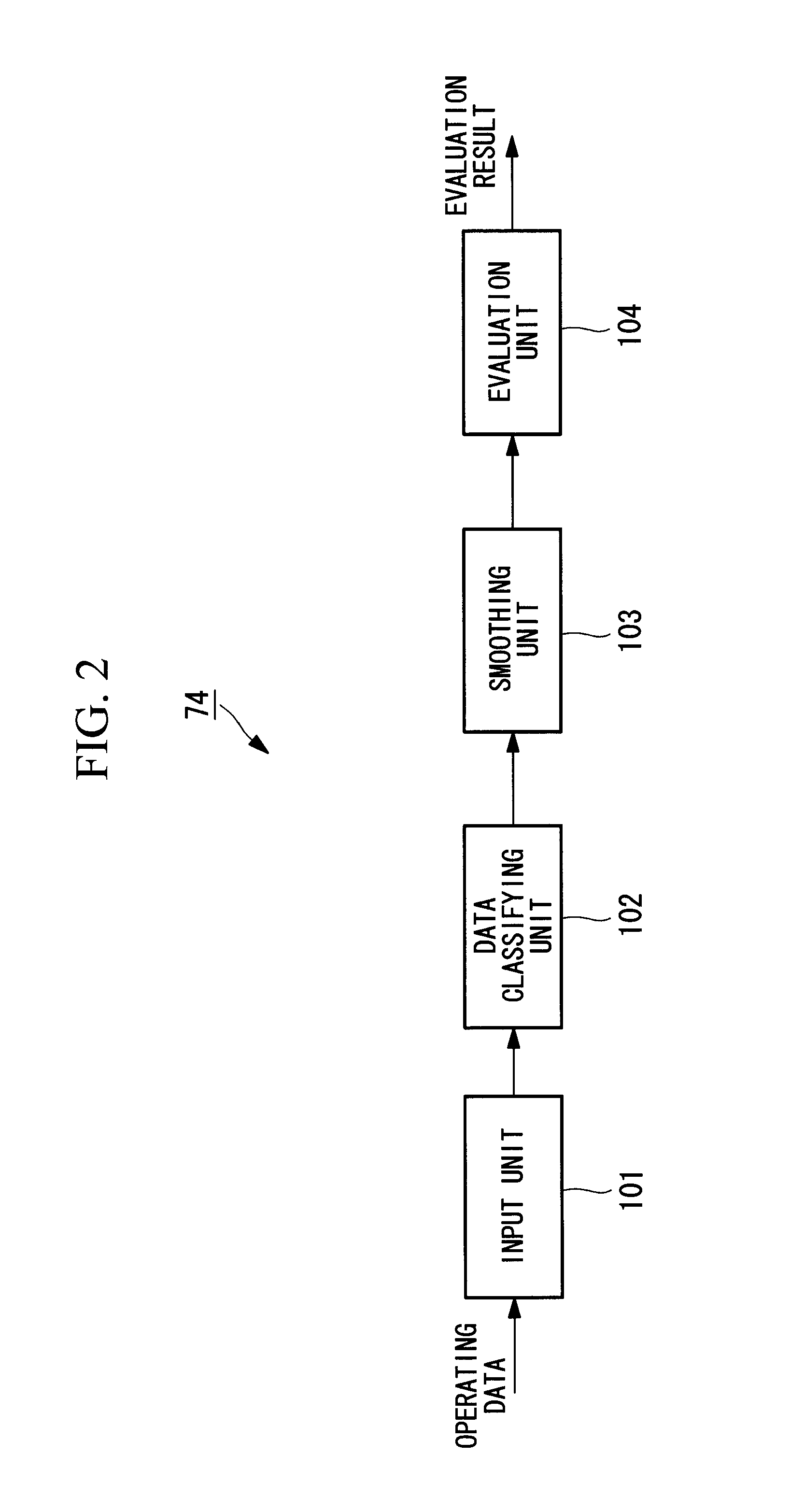

Enhanced accuracy in performance evaluation of a centrifugal chiller is achieved. Provided is a performance evaluation device for a centrifugal chiller, which includes an input unit (101) that receives operating data of the centrifugal chiller; a data classifying unit (102) that acquires evaluated data to be subjected to performance evaluation from the operating data received by the input unit (101) and classifies the evaluated data into multiple groups on the basis of a preset classifying condition; a smoothing unit (103) that smoothes the evaluated data, for each of the groups classified by the data classifying unit (102), by using a predetermined calculation method set in advance so as to obtain an evaluated value; and an evaluation unit (104) that performs performance evaluation for each group by using the evaluated value obtained by the smoothing unit (103) and a reference evaluation value that is set in advance or calculated using the operating data.

Owner:MITSUBISHI HEAVY IND LTD

Adaptive hot gas bypass control for centrifugal chillers

InactiveCN1340145AControl operationAvoid volatilityCompression machines with non-reversible cycleFluid circulation arrangementCentrifugal chillerEngineering

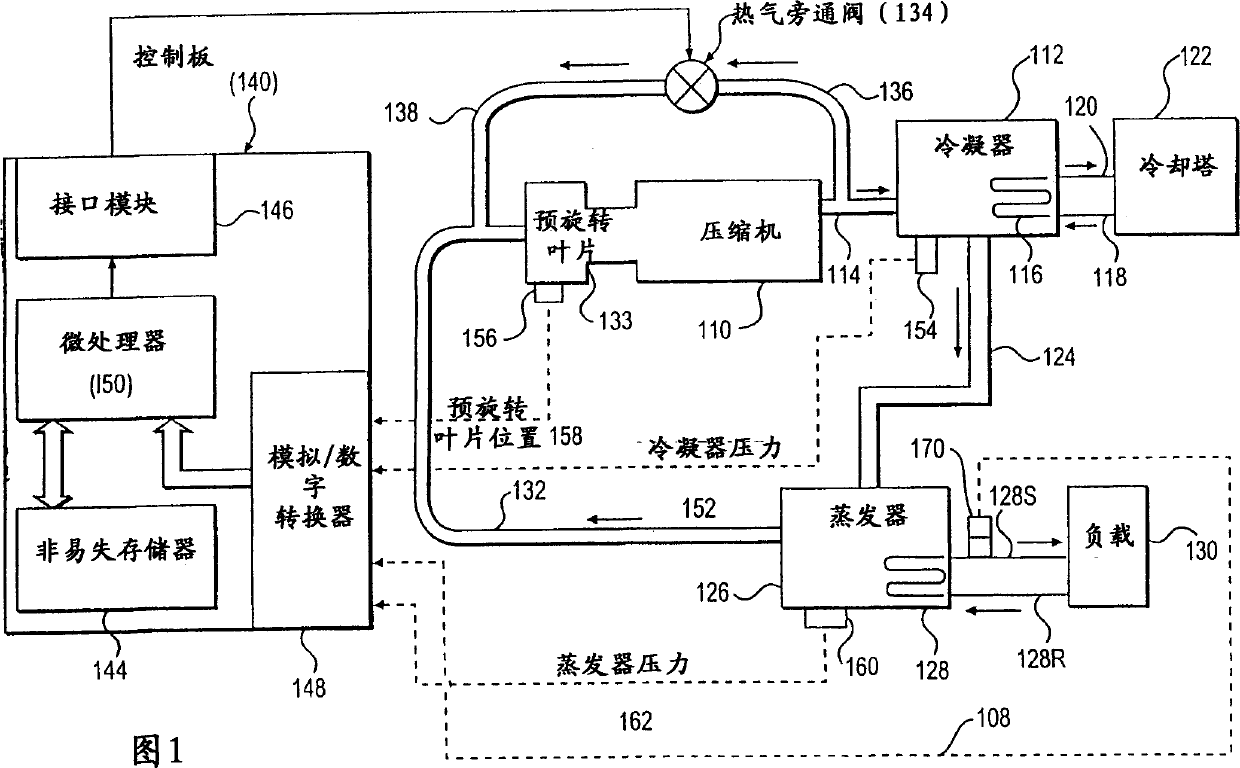

An adaptive control apparatus and a method for automatically controlling a refrigeration system (100) as a function of cooling load and head. A control panel (140) controls the operation of a hot gas bypass valve (134) so as to avoid surging of the compressor (110) in response to cooling load and head. The control apparatus and method also allow for automatic self calibration.

Owner:YORK INT

Chiller apparatus containing cis-1,1,1,4,4,4-hexafluoro-2-butene and methods of producing cooling therein

InactiveUS20120042669A1Improve energy efficiencyReasonable cooling capacityCompressorCompression machines with non-reversible cycleCentrifugal chillerButene

Disclosed herein are chiller apparatus containing cis-HFO-1336mzz. These chillers may be centrifugal chillers or positive displacment (e.g., screw) chillers and may comprise flooded evaporators or direct expansion evaporators. Also disclosed herein are methods for producing cooling comprising evaporating cis-HFO-1336mzz in the vicinity of a body to be cooled.

Owner:THE CHEMOURS CO FC LLC

Compressor energy control circuit and method and centrifugal water chilling unit

ActiveCN104734311ASolve wasteReduce wasteBatteries circuit arrangementsMechanical apparatusCentrifugal chillerElectric machine

The invention discloses a compressor energy control circuit and method and a centrifugal water chilling unit. The compressor energy control circuit comprises a rectifying circuit and a charging loop. The rectifying circuit comprises a direct-current side and an alternating-current side. The alternating-current side of the rectifying circuit is connected with a motor of a compressor to convert the alternating current generated by motor reverse rotation into direct current and output the direct current through the direct-current side of the rectifying circuit. The charging loop is connected with the direct-current side of the rectifying circuit to store the direct current output by the direct-current side of the rectifying circuit. By means of the compressor energy control circuit and method and the centrifugal water chilling unit, the effect that waste of energy in an air conditioner is reduced is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Centrifugal compressor and centrifugal water chilling unit

ActiveCN104653478AAvoid spreadingReduce noisePump componentsRadial flow pumpsCentrifugal chillerEngineering

The invention provides a centrifugal compressor and a centrifugal water chilling unit. The centrifugal compressor comprises an impeller, a diffuser, a volute and a refrigerant channel. The diffuser comprises a pressurizing channel; gas flowing through the impeller enters the inlet of the pressurizing channel; the volute is used for collecting the gas pressurized by the diffuser; the refrigerant channel is used for inletting refrigerant from outside and comprises spray holes formed at the inlet end of the pressurizing channel. By means of the technical scheme of the centrifugal compressor, refrigerant sprayed out of the refrigerant channel can effectively block propagation of noise and further reduce noise.

Owner:GREE ELECTRIC APPLIANCES INC

Performance evaluation device for centrifugal chiller

InactiveUS20120053898A1Improve accuracyPerformance deteriorationPump componentsCompression machines with non-reversible cycleCentrifugal chillerEvaluation data

Enhanced accuracy in performance evaluation of a centrifugal chiller is achieved. Provided is a performance evaluation device for a centrifugal chiller, which includes an input unit that receives operating data of the centrifugal chiller; a data classifying unit that acquires evaluated data to be subjected to performance evaluation from the operating data received by the input unit and classifies the evaluated data into multiple groups on the basis of a preset classifying condition; a smoothing unit that smoothes the evaluated data, for each of the groups classified by the data classifying unit, by using a predetermined calculation method set in advance so as to obtain an evaluated value; and an evaluation unit that performs performance evaluation for each group by using the evaluated value obtained by the smoothing unit and a reference evaluation value that is set in advance or calculated using the operating data.

Owner:MITSUBISHI HEAVY IND LTD

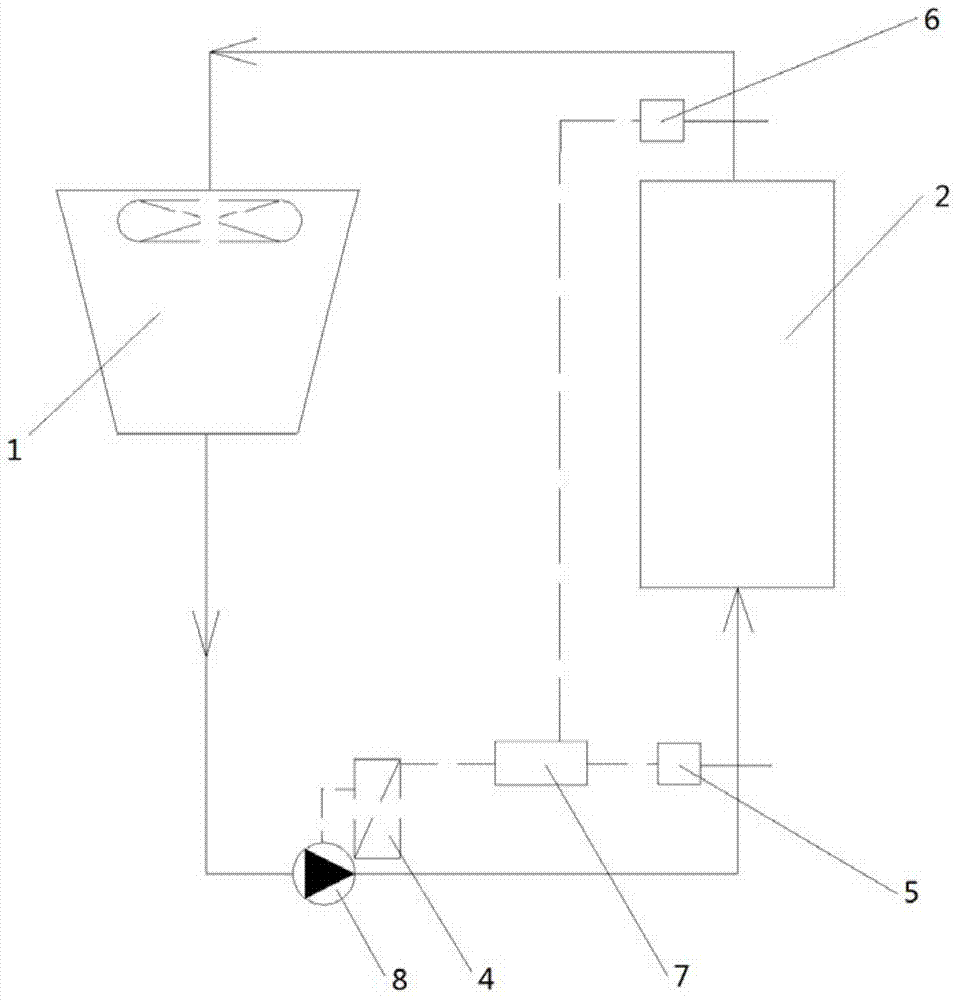

Oil return system for centrifugal water-chilling unit

ActiveCN102967083ATo achieve the purpose of oil returnReduced refrigerant contentCompressorCentrifugal chillerFuel tank

The invention provides an oil return system for a centrifugal water-chilling unit. The oil return system comprises an evaporator, a condenser, a centrifugal compressor, a high-pressure gas pipe, five pipelines, a first Venturi nozzle, an oil pump and a second Venturi nozzle. The centrifugal compressor comprises a blade ring component, a gas suction chamber and an oil tank, wherein the gas suction chamber and the oil tank are arranged at the front end of the blade ring component, one end of the high-pressure gas pipe is connected with a gas suction end of the condenser, and the other end of the high-pressure gas pipe is connected with an ejection end of the first Venturi nozzle; one end of a first pipeline is connected into the evaporator, and the other end of the first pipeline is connected with a leading-in end of the first Venturi nozzle; one end of a second pipeline is connected with a negative pressure end of the first Venturi nozzle, and the other end of the second pipeline is connected into the gas suction chamber of the compressor; one end of a third pipeline is connected with the oil tank, and the other end of the third pipeline is connected with an ejection end of the second Venturi nozzle; the oil pump is connected with a third pipeline; one end of a fourth pipeline is connected with the gas suction chamber of the compressor, and the other end of the fourth pipeline is connected with a leading-in end of the second Venturi nozzle; and one end of a fifth pipeline is connected with a negative pressure end of the second Venturi nozzle, and the other end of the fifth pipeline is connected into the oil tank.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP

Centrifugal-chiller and method for controlling the same

InactiveUS20120055184A1High COPImprove efficiencyCompression machines with non-reversible cycleEfficient regulation technologiesCentrifugal chillerCombined use

Provided is a centrifugal-chiller including one variable-speed centrifugal-compressor and one constant-speed centrifugal-compressor and capable of high-efficiency operation. A centrifugal-chiller comprising a variable-speed centrifugal-compressor whose rotational frequency can be varied by an inverter and which compresses a refrigerant; a constant-speed centrifugal-compressor connected in parallel with the variable-speed centrifugal-compressor and operated at a constant rotational speed to compress the refrigerant; and a control unit that controls the operations of the variable-speed centrifugal-compressor and the constant-speed centrifugal-compressor, wherein in the case where a required load factor of the centrifugal-chiller is less than a predetermined value, the control unit selects a variable-speed-compressor priority operating mode in which only the variable-speed centrifugal-compressor is activated, and in the case where the required load factor of the centrifugal-chiller is the predetermined value or greater, the control unit selects a combined-use operating mode in which the variable-speed centrifugal-compressor and the constant-speed centrifugal-compressor are activated.

Owner:MITSUBISHI HEAVY IND LTD

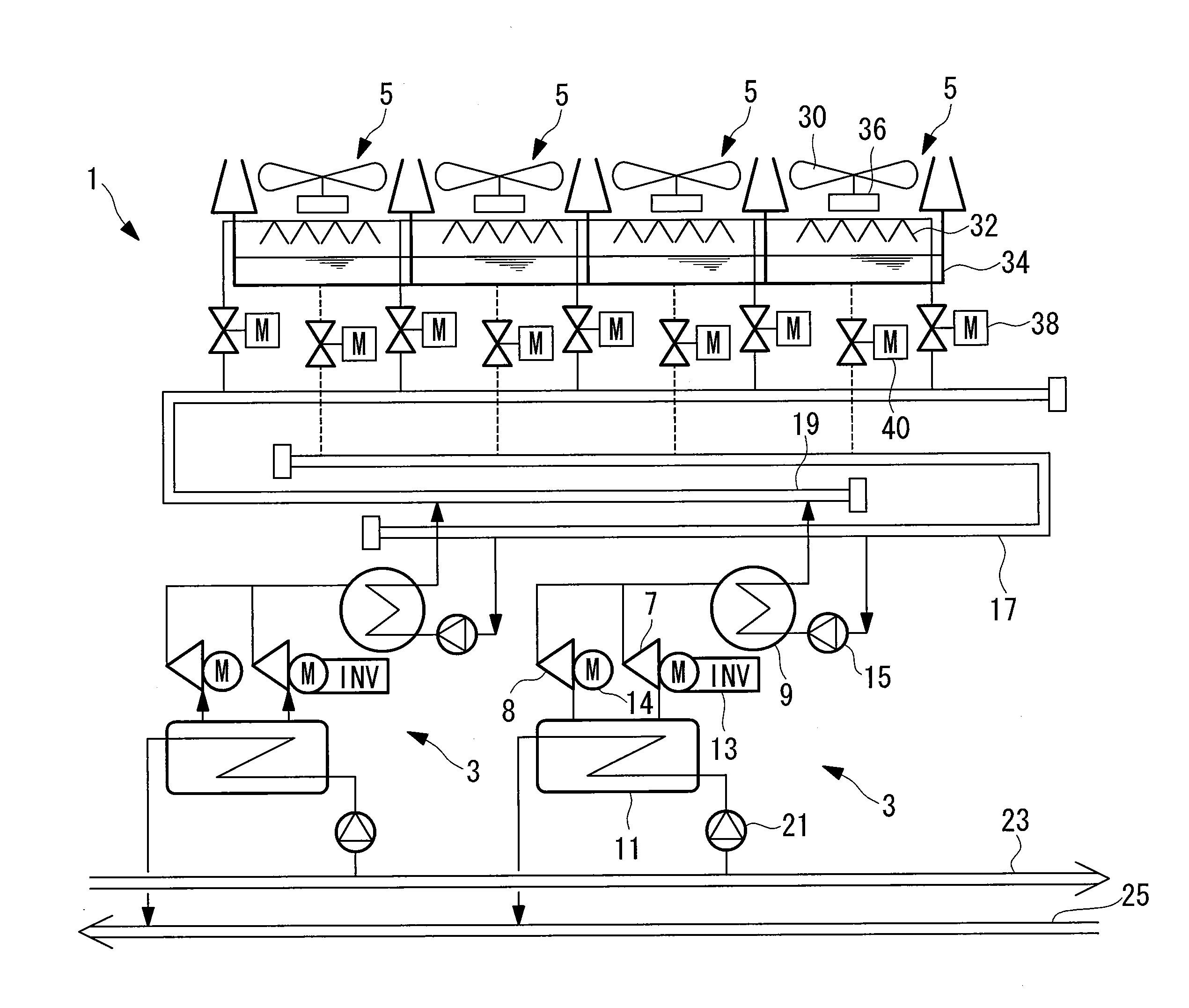

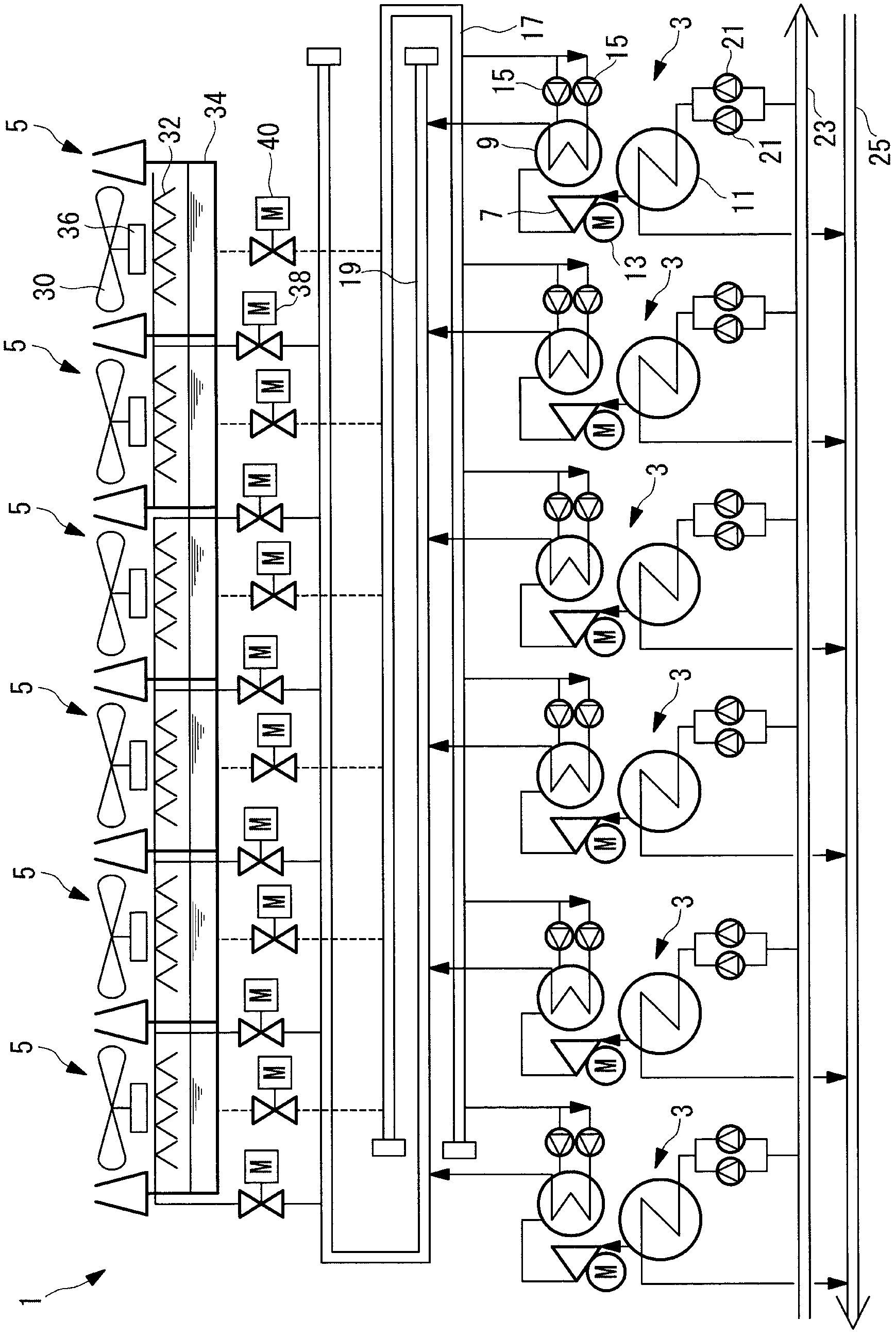

Heat-source system and method for controlling the same

ActiveCN102341656AEasy to controlEasy to operateSpace heating and ventilation safety systemsSpace heating and ventilation control systemsCentrifugal chillerCooling tower

A heat-source system includes centrifugal-chillers, cooling-water pumps, cooling towers, cooling-tower fans, chilled-water pumps, and a control unit for controlling them. A plurality of the cooling towers are provided so as to have a cooling-tower capacity corresponding to the total capacity of the rated capacities of the respective centrifugal-chillers, the cooling towers being commonly connected to the plurality of centrifugal-chillers. The control unit preliminarily prepares an optimum cooling-tower capacity relationship representing the cooling-tower capacity with which the heat-source system efficiency, taking into consideration the centrifugal-chillers, the cooling-water pump, the cooling towers, the cooling-tower fan, and the chilled-water pump, is higher, in relation to the outside-air wet-bulb temperature and the centrifugal-chiller partial load factor. The control unit determines the number of cooling towers to be operated by referring to the optimum cooling-tower capacity relationship, on the basis of the outside-air wet-bulb temperature and the partial load factor of the centrifugal-chillers during operation.

Owner:MITSUBISHI HEAVY IND THERMAL SYST

Efficient electricity, heat and cooling tri-generation supply system

ActiveCN104421044AEmission reductionImprove economyInternal combustion piston enginesExhaust apparatusLithium bromideEngineering

The invention relates to an efficient electricity, heat and cooling tri-generation supply system. The efficient electricity, heat and cooling tri-generation supply system comprises a gas generator set, gas, a mains supply power grid, an absorptive lithium bromide refrigerator set, heat pump type centrifugal refrigerator sets, a heat storage tank, a cooling tank and a water tank. The efficient electricity, heat and cooling tri-generation supply system is characterized in that medium-temperature discharged waste heat of the gas generator set is parallelly connected into an absorber and a hot water manifold of the absorptive lithium bromide refrigerator set, burning discharged smoke of the gas generator set is connected into an SCR (selective catalytic reduction) device, a hot water pipe of the SCR device is connected into the absorber and the hot water manifold of the absorptive lithium bromide refrigerator set in parallel, low-temperature waste heat water of the gas generator set is connected with the hot water manifold, and electric power output of the gas generator set is separately connected with the mains supply power grid and the heat pump type centrifugal refrigerator sets. The efficient electricity, heat and cooling tri-generation supply system has the advantages that smoke and low-to-high-temperature waste heat of the gas generator set are recycled and all utilized, system integration energy utilization rate is ensured at 80% or above by gradient utilization of primary energy, CO2 emission is greatly reduced, and pollutants such as NOx are reduced.

Owner:毛如麟 +1

Centrifugal water chilling unit and control method thereof

InactiveCN109099607ARealize endothermic evaporationImprove evaporation effectMechanical apparatusCompression machines with non-reversible cycleCentrifugal chillerProcess engineering

The invention provides a centrifugal water chilling unit and a control method thereof. The centrifugal water chilling unit comprises a compressor, a heat absorption heat exchanger, an economizer and aheat absorption heat exchanger, wherein the compressor is provided with a third exhaust port, a gas supplementing port and a gas returning port, the heat extraction heat exchanger comprises a first exhaust port and a first liquid discharging port, the economizer comprises a first liquid feeding port, a second exhaust port and a second liquid discharging port, the third exhaust port of the compressor is connected to an inlet of the heat extraction heat exchanger, the first exhaust port is connected to the heat absorption heat exchanger, the first liquid discharging port is connected to the first liquid feeding port of the economizer, the second exhaust port is connected to the heat absorption heat exchanger, and the second exhaust port is connected to the gas supplementing port. Accordingto the centrifugal water chilling unit, the problem that the gas temperature at an inlet of a compressor is too high due to the fact that the compressor directly bypasses hot gas in the prior art canbe solved.

Owner:ZHEJIANG DUNAN ARTIFICIAL ENVIRONMENT +1

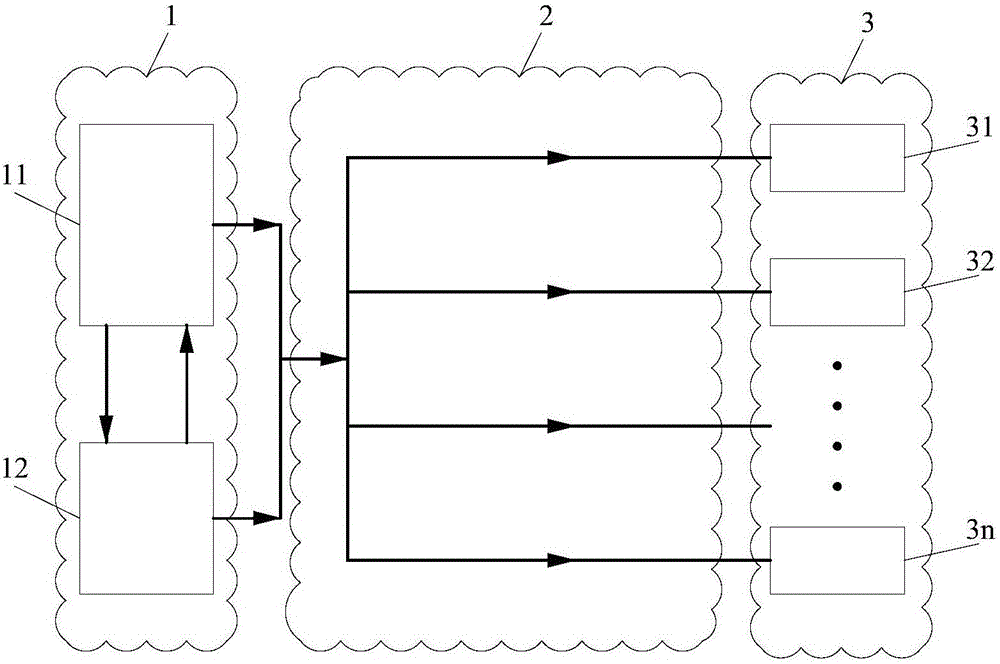

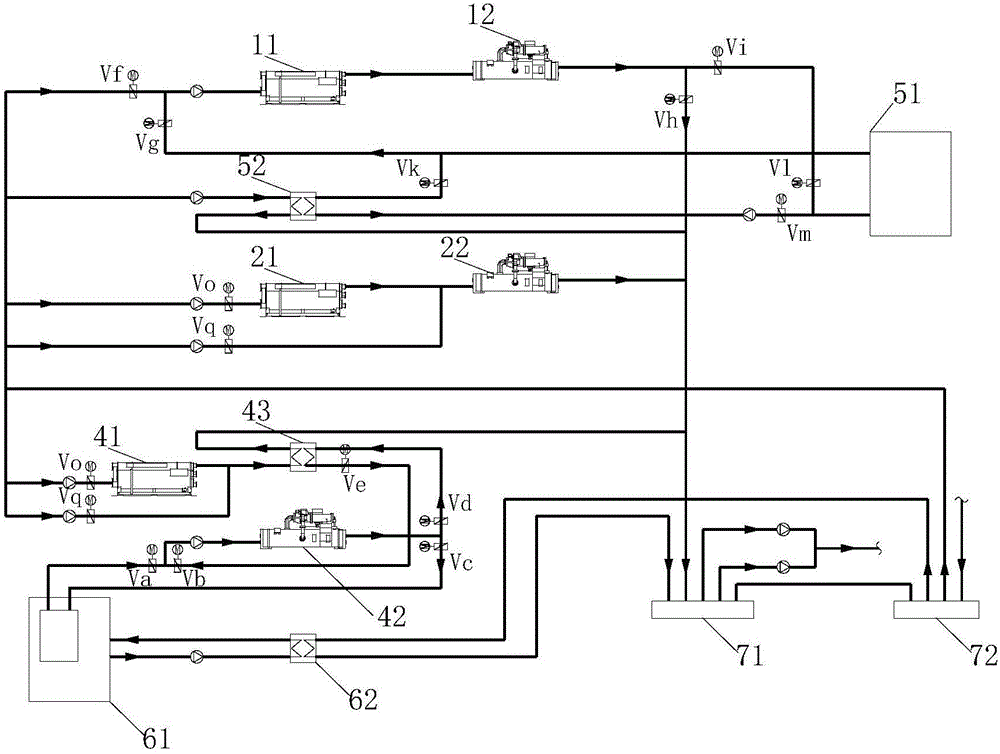

Cooling device for multi-energy-source large-temperature-difference areas

ActiveCN106288577ATake advantage ofRealize cascade utilizationMechanical apparatusFluid circulation arrangementCentrifugal chillerEngineering

The invention discloses a cooling device for multi-energy-source large-temperature-difference areas. The cooling device comprises a cooling station, a transmission pipeline network and a user side, wherein the cooling station comprises a refrigerating system, an energy storage system, a water distributor and a water collector, a mounted absorption water chilling unit and a mounted centrifugal water chilling unit of the refrigerating system are connected in series, an inlet of the mounted absorption water chilling unit is connected with a reservoir and a chilled water return pipe of the water collector through valves respectively, and an outlet of the mounted centrifugal water chilling unit is connected with the reservoir and a chilled water supply pipe of the water distributor through valves respectively; an inlet of the reservoir is connected with the outlet of the mounted centrifugal water chilling unit and a cold exchange end outlet of an impoundment cooling plate through valves respectively, and an outlet of the reservoir is connected with the inlet of the mounted absorption water chilling unit and a cold exchange end inlet of the impoundment cooling plate through valves respectively. Multiple energy sources can be fully utilized, cooling can be achieved by means of waste heat, gradient utilization of energy can be achieved, and primary energy ratio can be increased.

Owner:ARCHITECTURAL DESIGN & RES INST OF SOUTH CHINA UNIV OF TECH

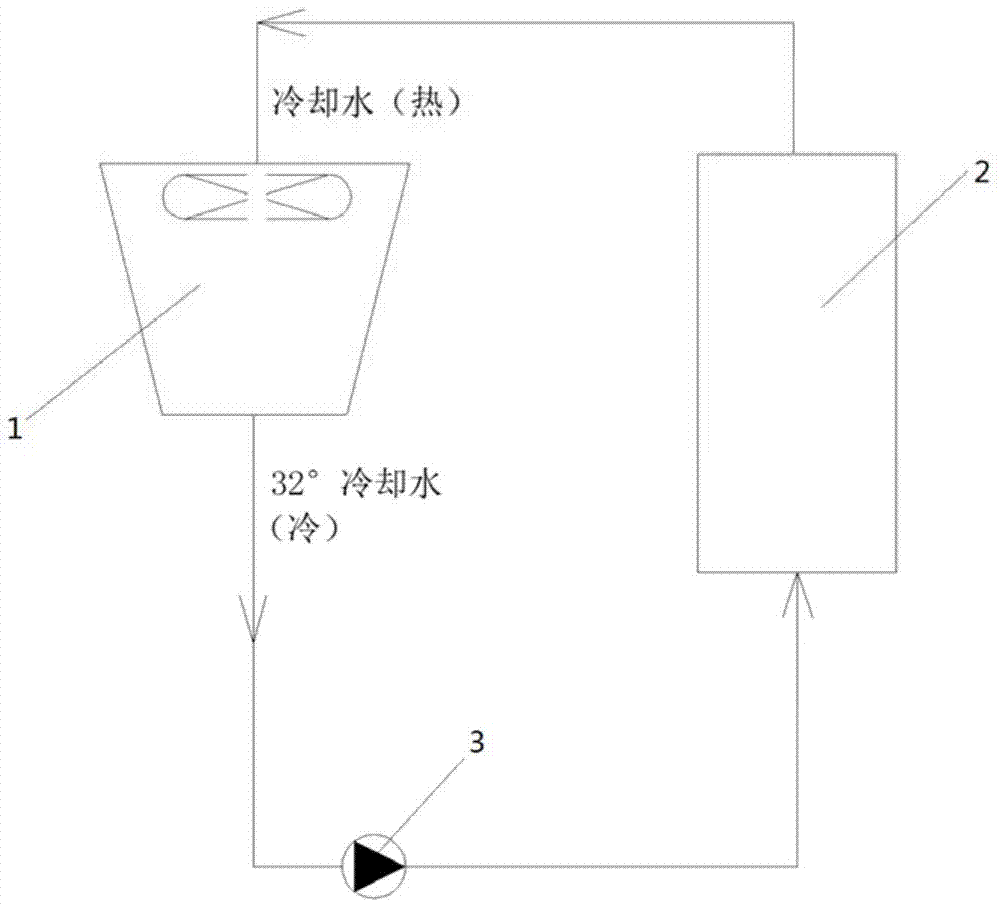

Efficient centrifugal water cooling unit output energy saving adjusting system and method

InactiveCN104713208AReduce speedReduce energy consumptionMechanical apparatusSpace heating and ventilation safety systemsTemperature controlCentrifugal chiller

The invention relates to an efficient centrifugal water cooling unit output energy saving adjusting system and method. A centrifugal water cooling unit is provided with a cooling tower and a condenser. The cooling tower and the condenser form a cooling hoop through a water inlet pipe and a water outlet pipe. The adjusting system comprises a variable water pump, a frequency converter, a first temperature sensor, a second temperature sensor and a temperature controller. Both the variable water pump and the first temperature sensor are arranged on the water inlet pipe. The second temperature sensor is arranged on the water outlet pipe. The input end of the temperature controller is connected with the output end of the first temperature sensor and the output end of the second temperature sensor. The input end of the frequency converter is connected with the output end of the temperature controller. The output end of the frequency converter is connected with the control end of the variable water pump. Compared with the prior art, the frequency converter is controlled through temperature difference, accordingly the flow of the water cooling loop is changed, a good energy saving effect is saved, consumption of cooled water can be obviously lowered, meanwhile the rotating speed is lowered, and the service life of the water pump and a motor can be prolonged.

Owner:SHANGHAI DAZHONG XIANGYUAN POWER SUPPLY

Centrifugal chiller performance evaluation system

ActiveUS8812263B2Improve versatilityCompression machines with non-reversible cycleEvaporators/condensersCentrifugal chillerOperating point

Design COP is iteratively computed. Provided is a centrifugal chiller performance evaluation system including a data acquisition section for acquiring operating data from a centrifugal chiller as input data; a storage section storing a design COP estimation formula obtained by adding correction values corresponding to losses occurring in an actual environment to a computational formula for ideal actual-machine COP expressed using COP characteristics of a reverse Carnot cycle; and a computing section for estimating a design COP at a current operating point using the operating data acquired by the data acquisition section and the design COP estimation formula stored in the storage section. The correction values include a first correction value calculated from a first computational formula including the load factor of the centrifugal chiller as a variable and a second correction value calculated from a second computational formula including a difference between cooling water outlet temperature and chilled water outlet temperature as a variable. The second correction value contains an offset from the first correction value depending on cooling water inlet temperature.

Owner:MITSUBISHI HEAVY IND LTD

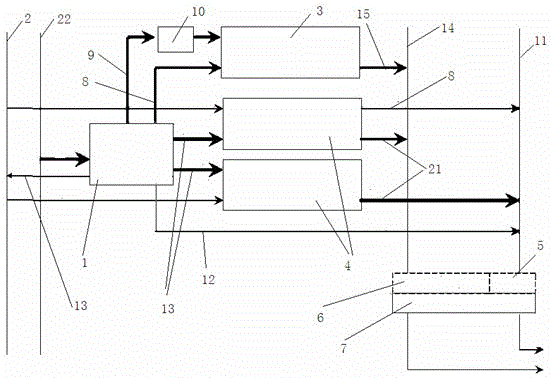

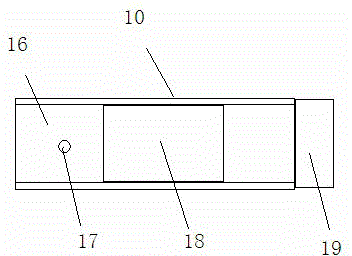

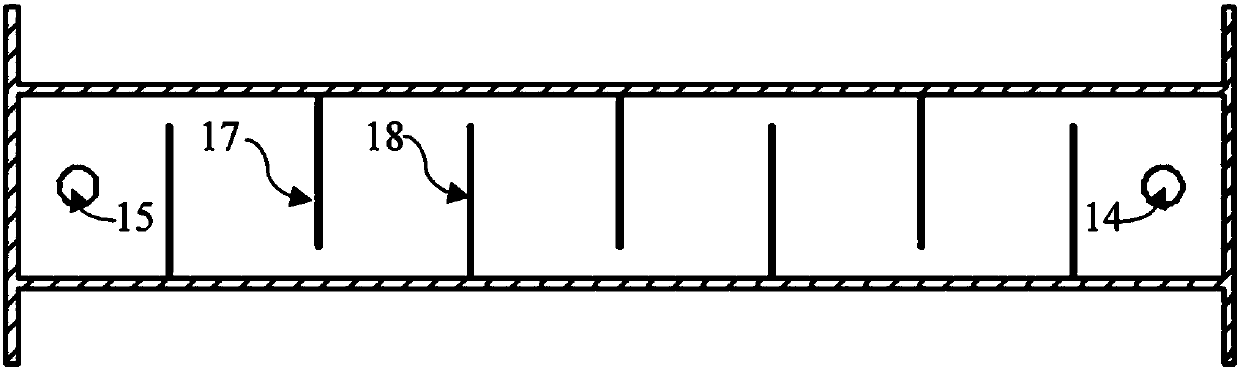

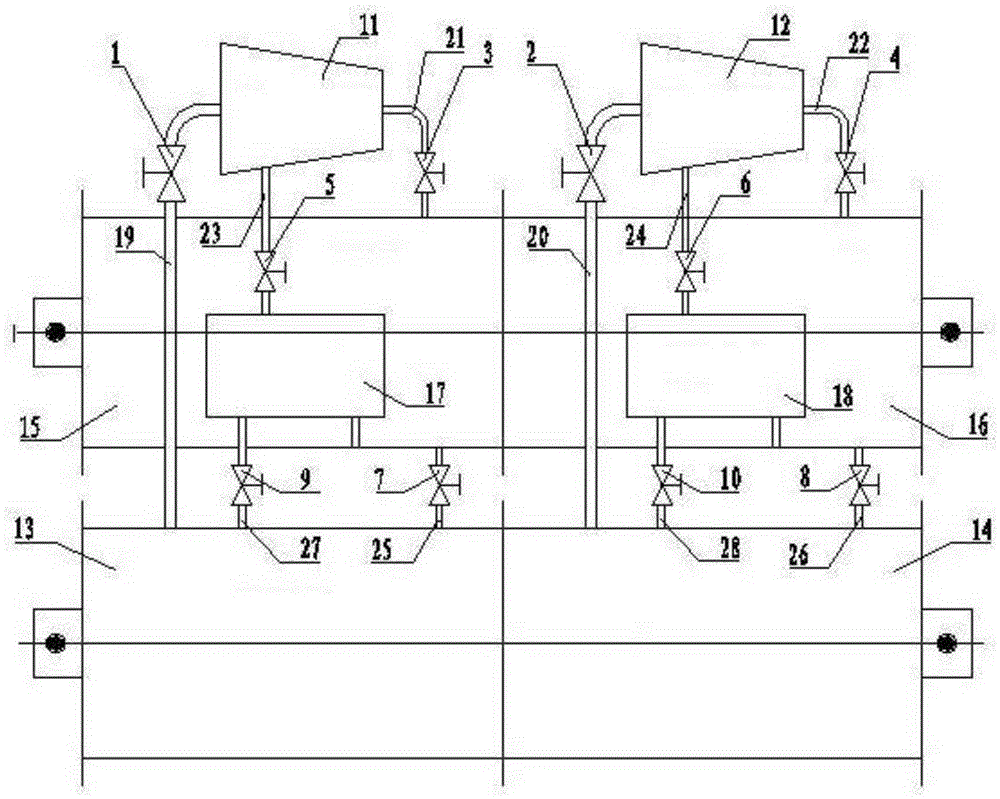

Double-machine head centrifugal chiller system

ActiveCN105299943ASolve the phenomenon of increasing the operating power consumption of the unitSolve the phenomenon of running power consumptionMechanical apparatusCompression machines with non-reversible cycleCentrifugal chillerSystems design

The invention relates to the technical field of centrifugal chillers, in particular to a double-machine head centrifugal chiller system. The double-machine head centrifugal chiller system comprises a first centrifugal compressor intake valve (1), a second centrifugal compressor intake valve (2), a first centrifugal compressor exhaust valve (3), a second centrifugal compressor exhaust valve (4), a first centrifugal compressor gulp valve (5), a second centrifugal compressor gulp valve (6), a first bypass valve (7), a second bypass valve (8), a first throttle valve (9), a second throttle valve (10), a first centrifugal compressor (11), a second centrifugal compressor (12), a first evaporator (13), a second evaporator (14), a first condenser (15), a second condenser (16), a first power saver (17), a second power saver (18), a first centrifugal compressor intake pipe (19) and a second centrifugal compressor intake pipe (20). The system is simple in design, easy to operate, stable, reliable and easy to be installed, cleaned and maintained.

Owner:CHONGQING GENERAL IND (GRP) LTD +1

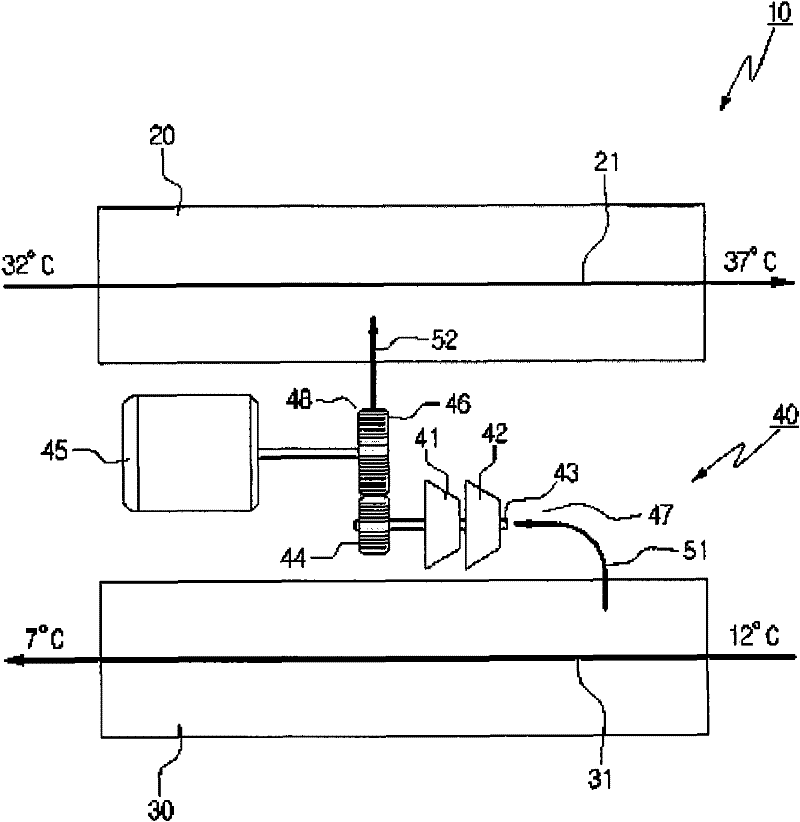

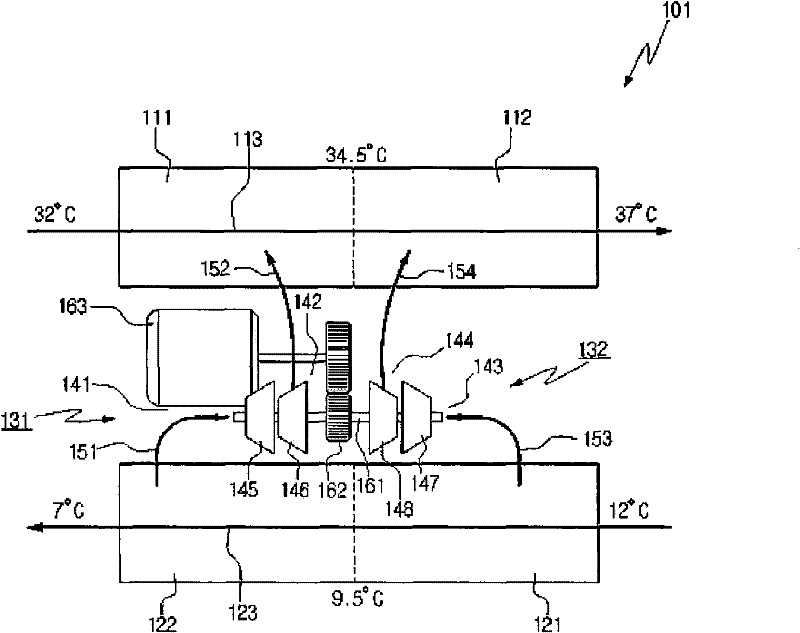

Dual turbo centrifugal chiller

InactiveUS20110094251A1Improve compressor performanceSmall sizeCompression machines with non-reversible cycleEvaporators/condensersImpellerCentrifugal chiller

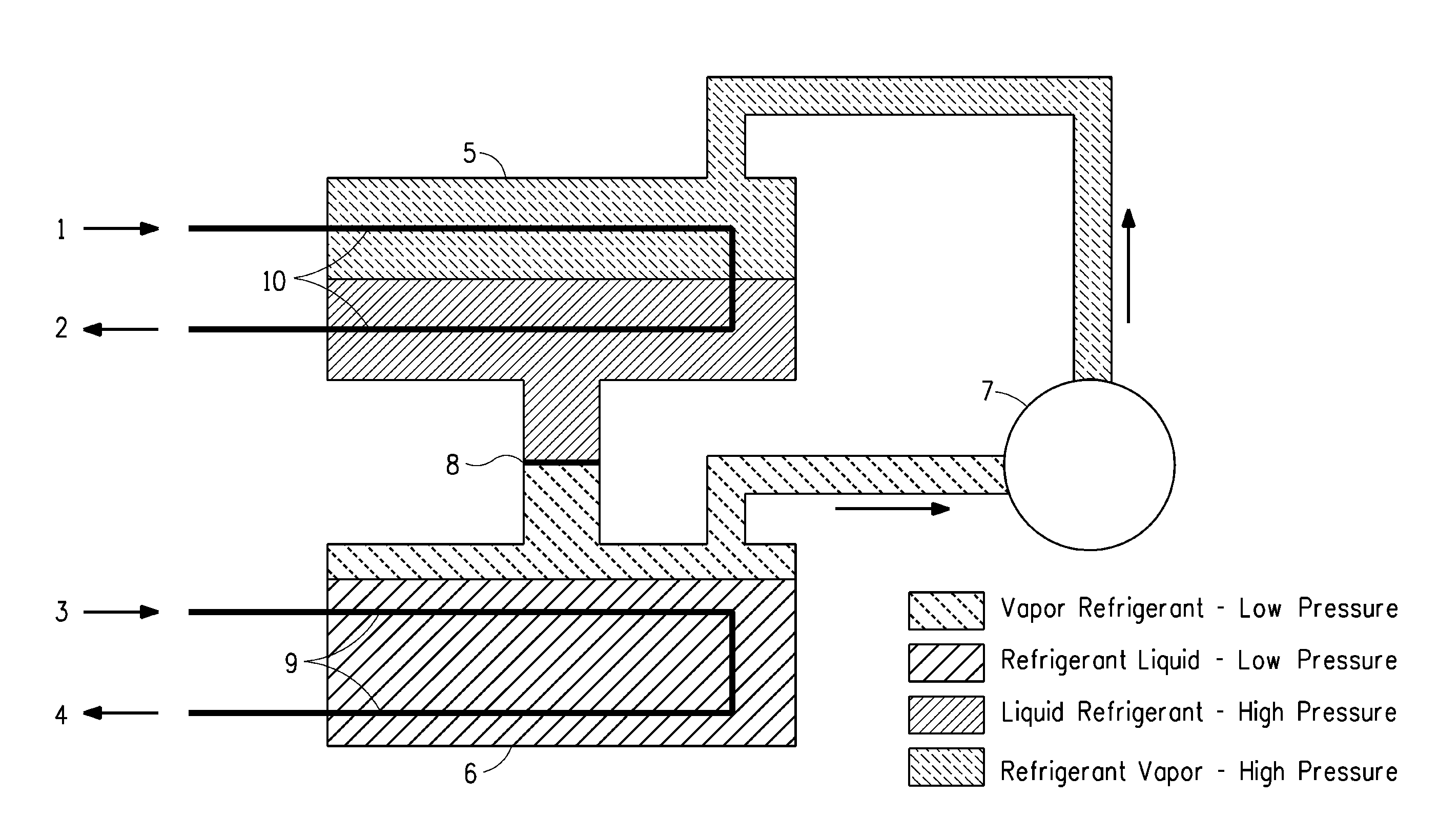

A dual turbo centrifugal chiller includes: first and second evaporators connected in series or in parallel; first and second condensers connected in series or in parallel; and first and second compressors including impellers, wherein cold water passes through the second evaporator after passing through the first evaporator, and cooling water passes through the second condenser after passing through the first condenser, the first compressor containing a refrigerant connects the first condenser to the second evaporator, and the second compressor containing a refrigerant connects the second condenser to the first evaporator, and the impellers of the first compressor and second compressor are rotated simultaneously using a single driving unit.

Owner:LG ELECTRONICS INC

Dual turbo centrifugal chiller

InactiveCN102052796AReduce temperature differenceImprove performanceCompressorCompression machines with non-reversible cycleImpellerCentrifugal chiller

Owner:LG ELECTRONICS INC

Centrifugal chiller performance evaluation system

ActiveUS20120029889A1Improve versatilityCompression machines with non-reversible cycleEvaporators/condensersCentrifugal chillerOperating point

Design COP is iteratively computed. Provided is a centrifugal chiller performance evaluation system including a data acquisition section for acquiring operating data from a centrifugal chiller as input data; a storage section storing a design COP estimation formula obtained by adding correction values corresponding to losses occurring in an actual environment to a computational formula for ideal actual-machine COP expressed using COP characteristics of a reverse Carnot cycle; and a computing section for estimating a design COP at a current operating point using the operating data acquired by the data acquisition section and the design COP estimation formula stored in the storage section. The correction values include a first correction value calculated from a first computational formula including the load factor of the centrifugal chiller as a variable and a second correction value calculated from a second computational formula including a difference between cooling water outlet temperature and chilled water outlet temperature as a variable. The second correction value contains an offset from the first correction value depending on cooling water inlet temperature.

Owner:MITSUBISHI HEAVY IND LTD

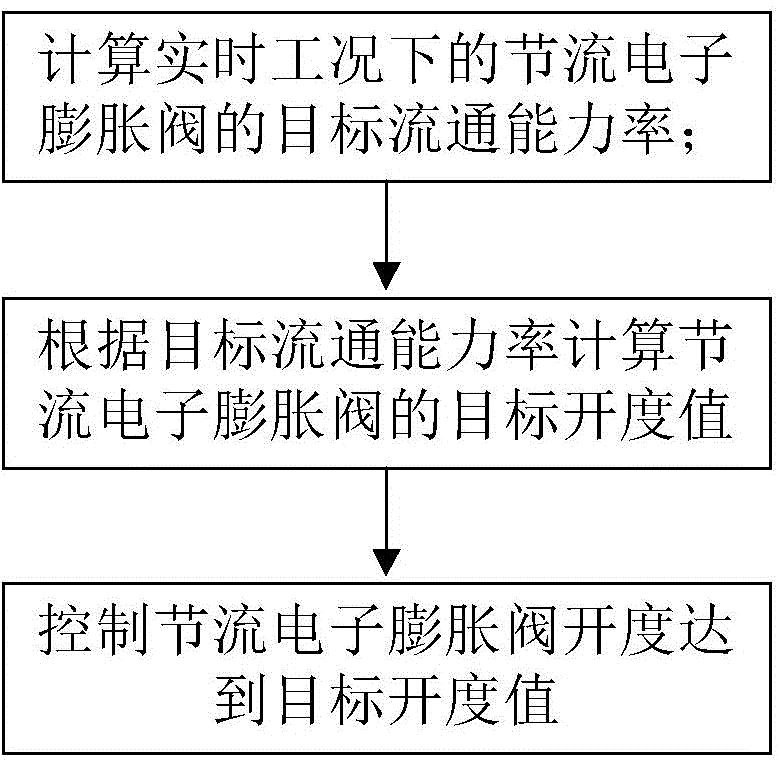

Throttling control method of centrifugal type water chiller

ActiveCN104567154AReduced risk of driftLow costRefrigeration safety arrangementCentrifugal chillerThrottle control

The invention provides a throttling control method of a centrifugal type water chiller, which is used for controlling a throttling electronic expansion valve of an auxiliary throttling loop of the centrifugal type water chiller. The throttling control method comprises the following steps of S1, calculating the target flow capacity rate of the throttling electronic expansion valve under the real-time working condition; S2, according to the target flow capacity rate, calculating the target opening degree value of the throttling electronic expansion valve; S3, controlling the opening degree of the throttling electronic expansion valve to reach the target opening degree value. The throttling control method has the advantages that the opening degree value of the throttling electronic expansion valve is directly used as a control target, so more accuracy, stability and reliability are realized, and the drifting risk in the signal transfer process is effectively reduced; in addition, compared with the existing liquid level control and air exhaust overheat control methods, the arrangement of a liquid level sensor or a temperature sensor is not needed, the cost is reduced, and the reliability is improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

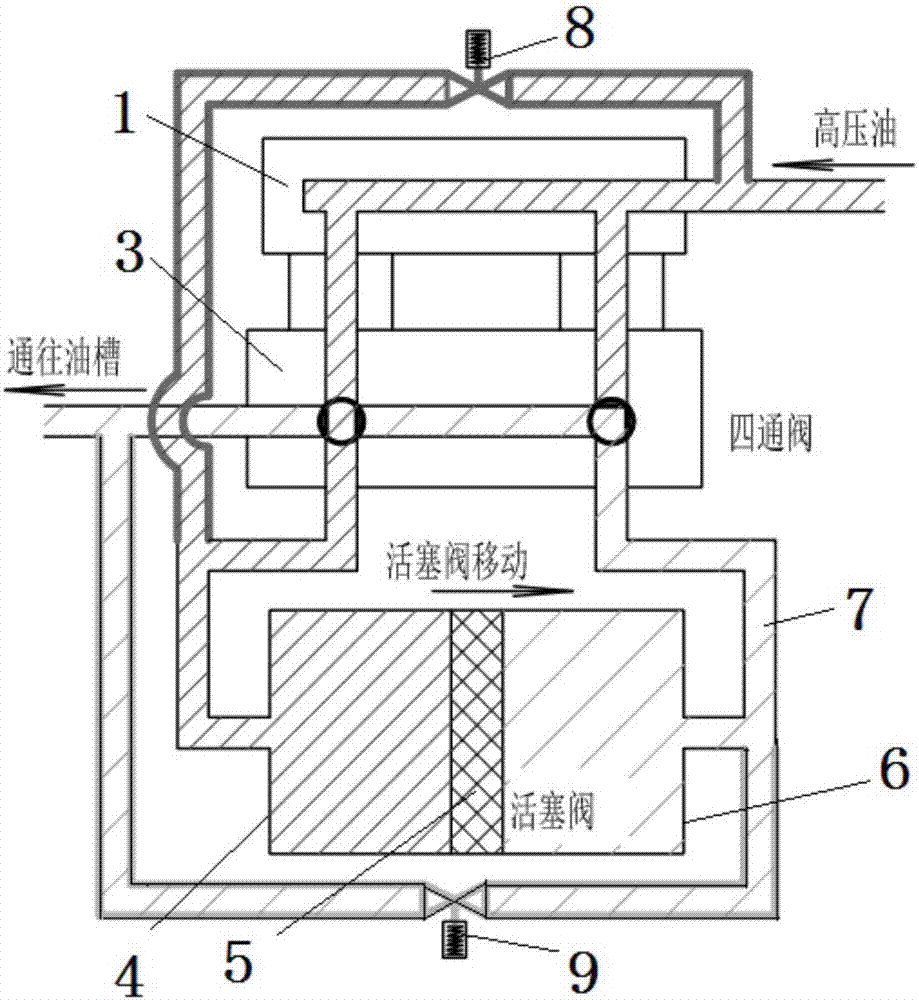

Centrifugal water chilling unit and power failure rapid starting method

ActiveCN107101411AGuaranteed cooling capacity supplyMinor changesMechanical apparatusFluid circulation arrangementCentrifugal chillerInlet channel

The invention discloses a centrifugal water chilling unit and a power failure rapid starting method. The centrifugal water chilling unit is characterized in that a compressor rapid unloading device comprises a four-way valve and rapid unloading valves; specifically, one rapid unloading valve is arranged outside the four-way valve to communicate with a high-pressure oil outlet of the four-way valve and a high-pressure oil cavity of a piston cavity, and a runner where the rapid unloading valve is located and an inflow runner in the four-way valve simultaneously constitute a high-pressure oil inlet channel; the other rapid unloading valve is arranged outside the four-way valve to communicate with a low-pressure oil cavity of the piston cavity and an oil tank, and the low-pressure cavity in the piston cavity simultaneously communicates with the oil tank through the other rapid unloading valve and a backflow runner in the four-way valve; and an adjustable guide vane is arranged at an inlet of a compressor and controlled to be opened and closed through the four-way valve. Rapid starting can be achieved under the condition that a main power source is abnormally disconnected and is recovered for a short time.

Owner:MCQUAY AIR CONDITIONING & REFRIGERATION WUHAN

Integrated whole refrigeration air conditioning unit adopting surface air cooler and working method

InactiveCN104949242AReduce energy consumptionReduce volumeAir treatment detailsCondensate preventionAir filterFiltration

Provided are an integrated whole refrigeration air conditioning unit adopting a surface air cooler and a working method. The integrated whole refrigeration air conditioning unit comprises a modular magnetic suspension centrifugal water chilling unit, a cold water pump, the surface air cooler, a centrifugal fan driven by a brushless direct current motor, a silencer and an air purifier. The surface air cooler is a surface heat exchanger. The air purifier is formed by combining an electret static air filter and a light-free catalytic purifier. The cold water pump is arranged in an air conditioning unit box. A unit controller is arranged in the air conditioning unit box. The working method comprises the steps of performing filtration, sterilization and harmful gas removal on air through the combined air purifier, cooling and drying the air through the surface air cooler, performing noise reduction through a silencer and then blowing out the air. Due to the fact that the integrated whole refrigeration air conditioning unit adopts the modular magnetic suspension centrifugal water chilling unit and the centrifugal fan driven by the brushless direct current motor, the power consumption of the integrated whole refrigeration air conditioning unit is remarkably reduced by adopting the combination, occupied areas and spaces of a refrigerator room and an air conditioner room are decreased remarkably, and the energy-saving and emission-reducing effects are very obvious.

Owner:广东国得科技发展有限公司

Condenser, and centrifugal chiller equipped with the same

InactiveUS20190041100A1Inhibit deteriorationEfficient executionCompression machines with non-reversible cycleEvaporators/condensersCentrifugal chillerHigh concentration

The present invention makes it possible in a centrifugal chiller utilizing a low pressure refrigerant used at a maximum pressure of less than 0.2 MPaG to effectively extract, in high concentration, non-condensible gas that has mixed into the low pressure refrigerant, and thus suppresses reductions in condensing efficiency. This condenser (3) is equipped with: a shell vessel (21) into which a low pressure refrigerant used at a maximum pressure of less than 0.2 MPaG is introduced; a refrigerant inlet (22) which is provided to the top portion of the shell vessel (21); a refrigerant outlet (23) which is provided to the bottom portion of the shell vessel (21); a heat transfer tube bundle (25) in which a plurality of heat transfer tubes (25a) circulating a chilled liquid in the interior thereof are bundled, and which extends along the interior of the shell vessel (21); a gas extraction tube (31) in the heat transfer tube bundle interior, the gas extraction tube being disposed in the center region in the radial direction of the heat transfer tube bundle (25), forming a tubular shape arranged parallel to the axial direction of the heat transfer tube bundle (25), and having formed in the bottom surface thereof non-condensible gas extraction holes (31a) for extracting non-condensible gas that has mixed into the low pressure refrigerant; and a gas extraction device (33) which is connected to the gas extraction tube (31) in the heat transfer tube bundle interior and extracts the non-condensible gas.

Owner:MITSUBISHI HEAVY IND THERMAL SYST

Textile mill air conditioner energy saving method

InactiveCN104633798AReduce mechanical cooling loadLower enthalpyMechanical apparatusSpace heating and ventilation safety systemsTextile millCentrifugal chiller

The invention relates to a textile mill air conditioner energy saving method. The method includes the following steps of firstly, refitting a spraying pump, wherein outdoor air parameters and workshop air parameters are combined, and a method of automatically adjusting the water spraying volume in a variable-frequency mode is adopted; secondly, adjusting the air sending and air returning parameters of an air conditioner, wherein the position of an air sending and air returning fan, the size of an air sending and air returning motor and the weights and angles of blades of the air sending and air returning fan are adjusted; thirdly, adopting a centrifugal water chilling unit, wherein air enters a water spraying chamber after the enthalpy value of the air is decreased, and therefore the mechanical refrigerating loads on the water spraying chamber are reduced. According to the technology, the air conditioner energy conservation is effectively achieved, the environment protection and production are facilitated, and cost can be reduced.

Owner:QINGDAO XINYIFA IND & TRADE

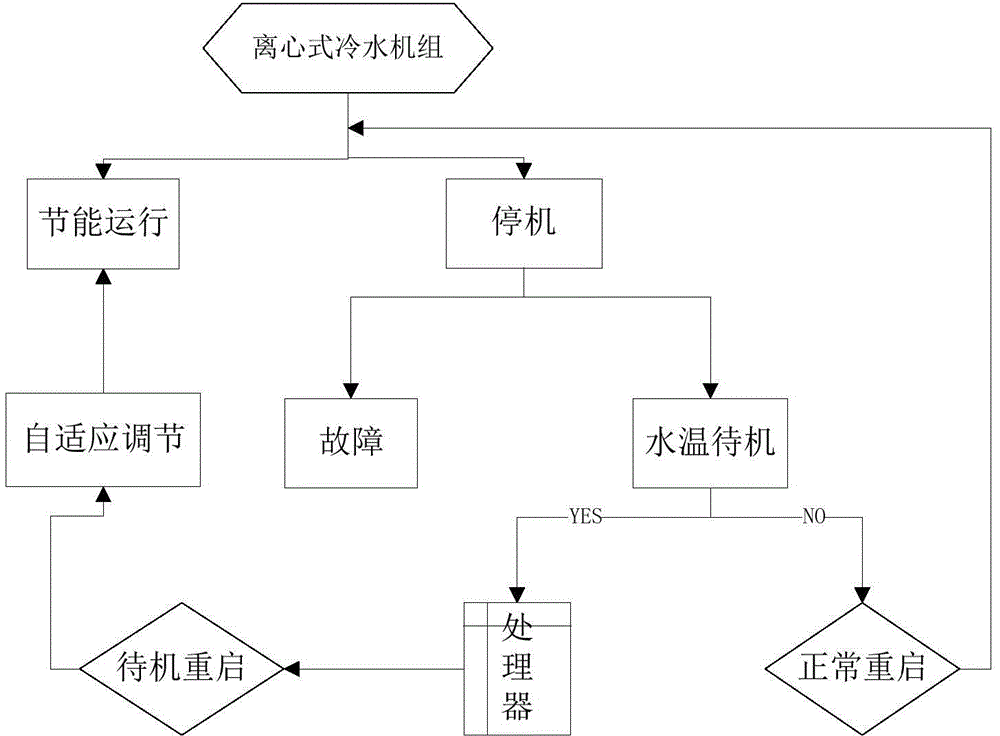

Method for controlling standby restart of centrifugal-type water cooling unit

ActiveCN104567162AGuaranteed uptimeReduce hidden dangersRefrigeration safety arrangementCentrifugal chillerIncremental learning algorithm

The invention provides a method for controlling standby restart of a centrifugal-type water cooling unit. The method includes step S1, acquiring running parameters before standby, and comparing the running parameters with preset parameters to determine a standby reason; step S2, when the standby reason is water temperature standby, setting restart target parameters according to an incremental learning algorithm; step S3, controlling restart of the unit according to the restart target parameters. According to the method, when the standby reason is water temperature standby, the restart target parameters are set according to the incremental learning algorithm, and restart of the unit is controlled according to the restart target parameters, so that running load of the unit is enabled to be matched with working conditions, the unit is enabled to run under small-load working conditions, potential safety hazards caused by frequent start and stop of the unit are lowered, and the unit is enabled to be more energy saving. In addition, high-low pressure difference of the unit can be lowered, so that the unit is enabled to be away from a surge area, and potential surge possibility of the unit is lowered.

Owner:GREE ELECTRIC APPLIANCES INC +1

Data center energy-saving air conditioning system and adjusting method

InactiveCN107166586AImprove cooling efficiencyReduce PUEDucting arrangementsMechanical apparatusCentrifugal chillerCooling tower

The invention discloses a data center energy-saving air conditioning system and an adjusting method. The air conditioning system comprises a centrifugal water chilling unit, a cooling tower, a plate heat exchanger, an air conditioning terminal, a cold water pump, a cooling water pump and valves V1-V8. The centrifugal water chilling unit comprises a condenser and an evaporator. The data center energy-saving air conditioning system has multiple working modes, and a natural cold source is used for indirectly providing the cooling capacity for the air conditioning terminal through the cooling tower in winter and transition seasons. A cooling tower free cold supply mode is adopted in winter, a cooling tower precooling mode is adopted in the transition seasons, and a conventional refrigeration mode is adopted in summer. The cooling efficiency of a data center machine room is improved, and PUE is reduced.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Substitute refrigerant for freon-12 centrifugal cold water machine set

InactiveCN1330122ANot brokenReduce the impact of the greenhouse effectHeat-exchange elementsCentrifugal chillerFreon

A substitute refrigerant for freon-12 centrifugal cold water machine set is prepared from monochlorodifluoromethane, 1,1,1,2,3,3,3-heptafluoropropane, 1-monochloro-1,1-difluoroethane, and optional isobutane through proportionally physical mixing. Its advantages include environmental protection, high safety and refrigerating efficiency, and no need of reforming existing equipment.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com