Efficient centrifugal water cooling unit output energy saving adjusting system and method

A chiller and energy output technology, applied in heating and ventilation control systems, heating and ventilation safety systems, heating methods, etc. The effect of reducing losses and reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

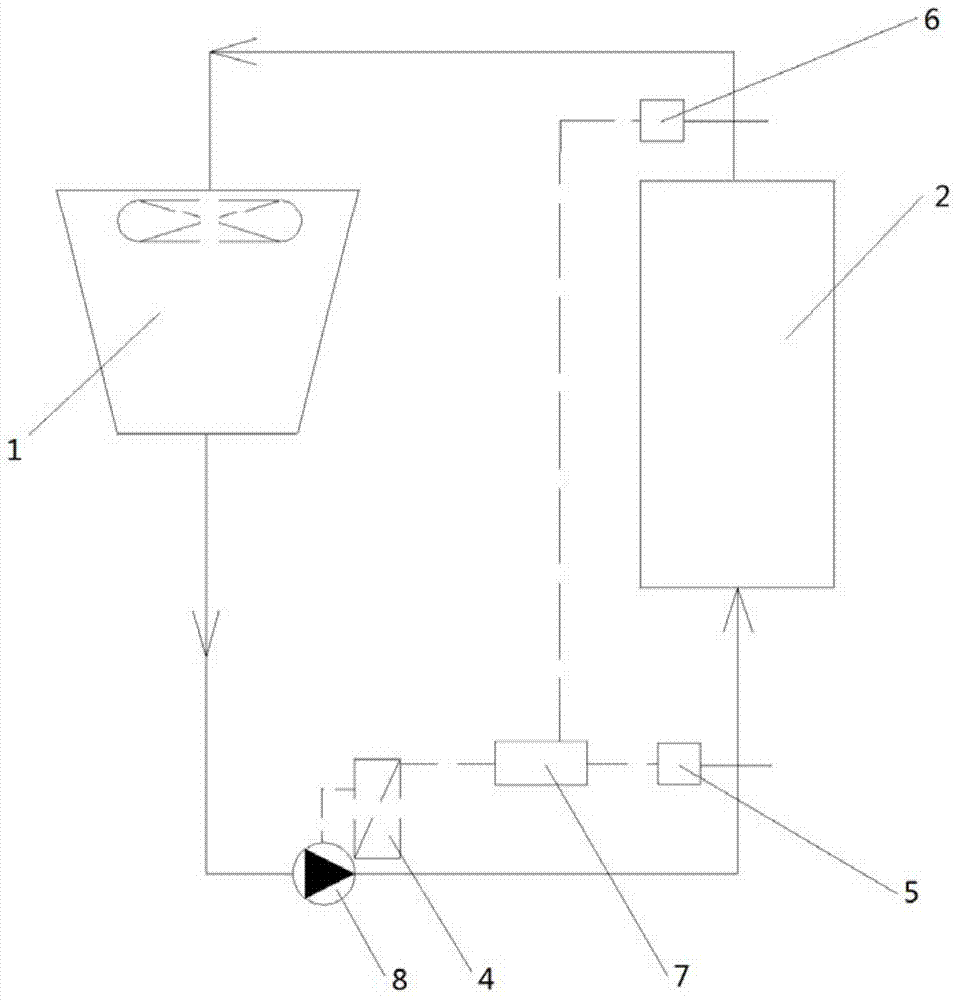

[0030] This embodiment is the No. 1 station building of the third automobile factory. If the speed of the pump is controlled by the frequency converter 4, then corresponding to the load flow, the power consumed by the variable water pump 8 will decrease according to the third power of the speed. Therefore, by changing the frequency conversion The controller 4 is used to control the water pump, which can significantly reduce the annual power consumption.

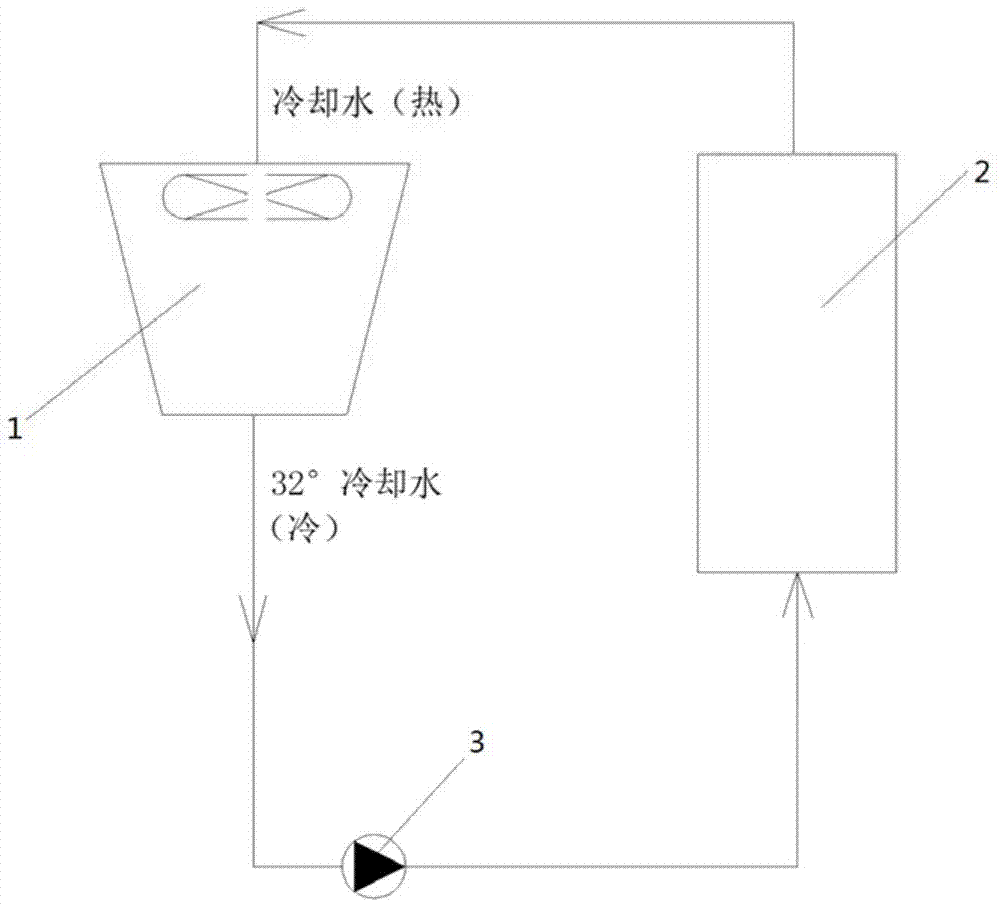

[0031] Such as image 3 As shown, a high-efficiency energy-saving adjustment system for the output energy of a centrifugal chiller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com