Chiller apparatus containing cis-1,1,1,4,4,4-hexafluoro-2-butene and methods of producing cooling therein

a technology of cis-1,1,1,4,4,4-hexafluoro-2-butene and chiller apparatus, which is applied in the field of refrigerants, can solve the problems that the working fluids with zero odp cannot be environmentally acceptable, and achieve the effects of low gwp, reasonable cooling capacity and good energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

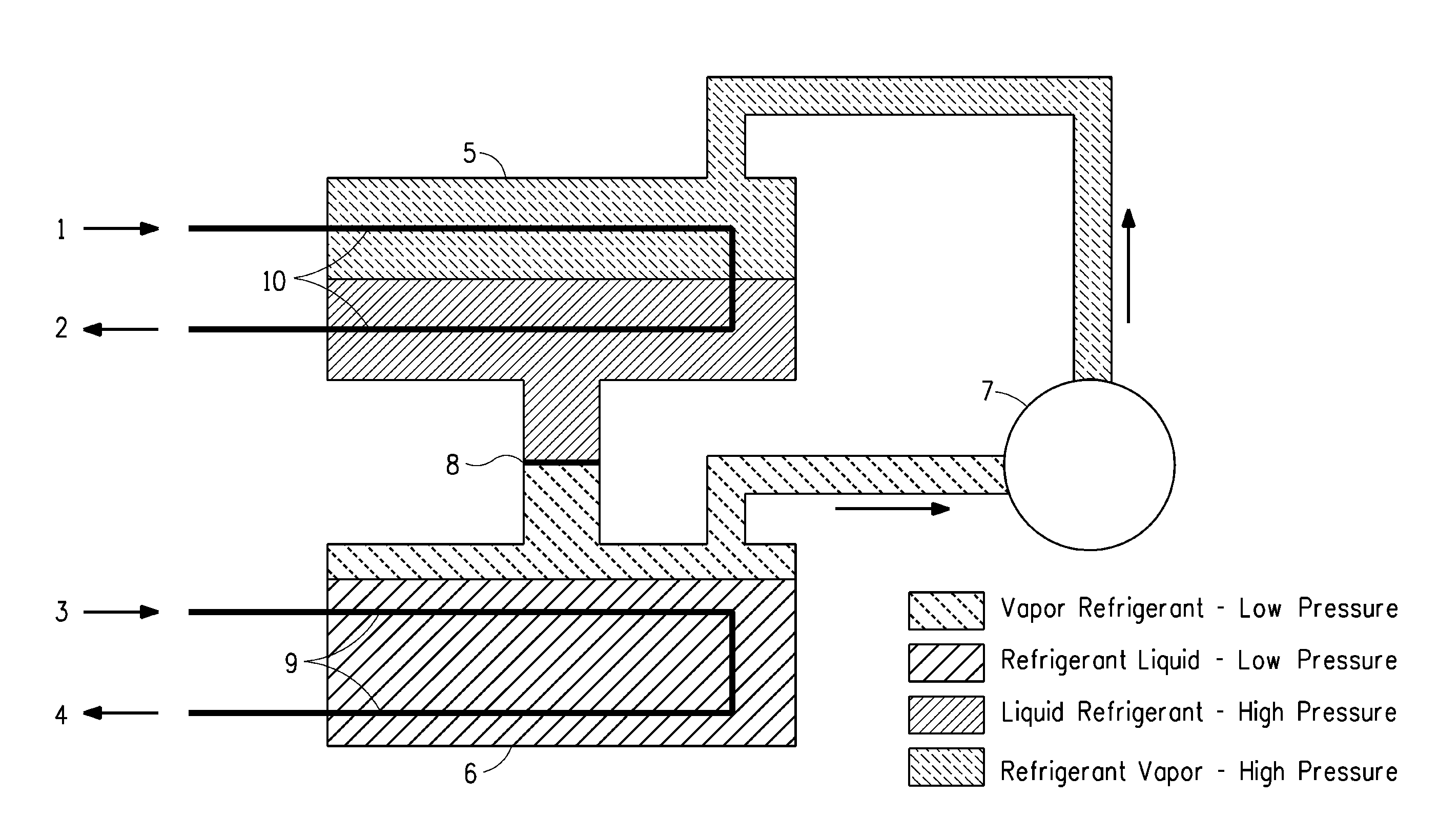

Image

Examples

example 1

Cooling Performance for cis-HFO-1336mzz in a Centrifugal Chiller

[0085]The performance of cis-HFO-1336mzz in a centrifugal chiller is determined and compared to performance for HCFC-123. The data are shown in Table 1.

[0086]This Example assumes that an air conditioning application requires nominally 3,517 kJ / s (1,000 RT) of cooling. The evaporator temperature is to be kept at an average value of 4.44° C. (40° F.) to satisfy the requirements for building chilled water. The available cooling water to the condenser is to maintain an average condenser temperature of 37.78° C. (100° F.).

[0087]The requirements of the above application are met by a centrifugal chiller operating with HCFC-123 as the refrigerant. If no liquid subcooling and no vapor superheat are to be employed by such a chiller, the chiller performance approximates the performance summarized in Table 1 under column “HCFC-123.” An isentropic coefficient of performance of 7.36 is achieved. For a reasonable compressor isentropic...

example 2

Retrofit of a Chiller Using HCFC-123

[0090]This Example describes a retrofit scenario (Table 2), where cis-HFO-1336mzz replaces HCFC-123 in a chiller originally designed for HCFC-123. In this Example, the impeller rotational speed is reduced by 1.48%, from 79.49 rps to 78.32 rps, when using HFO-1336mzz instead of HCFC-123, to achieve the impeller tip speed of 187.46 m / s required to lift the new refrigerant from evaporator to condenser conditions. The required reduction in impeller rotational speed is achieved by adjusting the gears in the impeller drive box or by adjusting the motor operating frequency. It is reasonable to assume that the impeller flow coefficient under retrofit conditions remains approximately equal to its value for the original HCFC-123 design. Then the existing impeller, with a diameter of 0.762 m, rotating at the new speed of 78.32 revolutions per second (rps) provides a refrigerant vapor volumetric flow rate of 8.80 m3 / sec. This refrigerant flow rate provides a ...

example 3

Non-Flammability Testing

[0092]Lack of flammability of cis-HFO-1336mzz is determined according to the ASTM E681-2001 test procedure as required in ASHRAE Standard 34-2007 and described in Addendum p to ASHRAE Standard 34-2007. Test conditions were 60° C. and 100° C., with 50% relative humidity as prepared at 23° C.

[0093]Cis-HFO-1336mzz was found to be nonflammable at 60° C. and 100° C. This shows another property of importance to the air conditioning and refrigeration industries. Non-flammable refrigerants are required by many applications. Thus the nonflammable rating of cis-HFO-1336mzz will allow broad use of cis-HFO-1336mzz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com