Adaptive hot gas bypass control for centrifugal chillers

A technology of hot gas bypass valve and centrifugal compressor, which is applied in the direction of pump control, refrigerator, refrigeration components, etc., and can solve problems such as fluctuating states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following description of embodiments of the invention refers to the accompanying drawings. Accordingly, the same reference numerals in different figures refer to the same or similar elements.

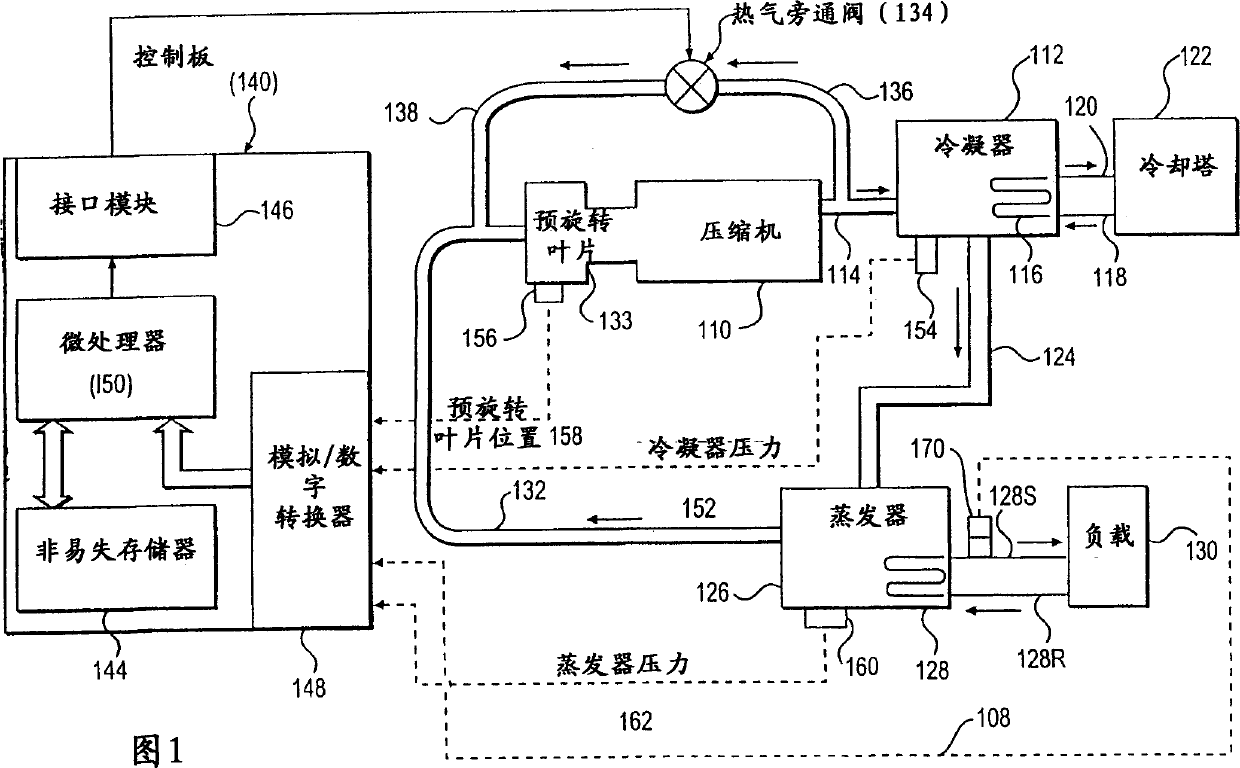

[0017] Figure 1 is a diagram of a refrigeration system 100 and control panel in accordance with the present invention. Refrigeration system 100 includes a centrifugal compressor 110 that compresses refrigerant vapor and provides it to condenser 112 via line 114 . Condenser 112 includes a heat exchanger tube bundle 116 having an inlet 118 and an outlet 120 connected to a cooling tower 122 . Condensed liquid refrigerant from condenser 112 flows to evaporator 126 via line 124 . The evaporator 126 includes a heat exchanger tube bundle 128 having a supply line 128S and a return line 128R connected to a cooling load 130 . Vapor refrigerant in the evaporator 126 returns to the compressor 110 via a suction line 132 containing a pre-rotational vane (PRV) 133 . A hot gas bypass (HG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com