Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduce uneven wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

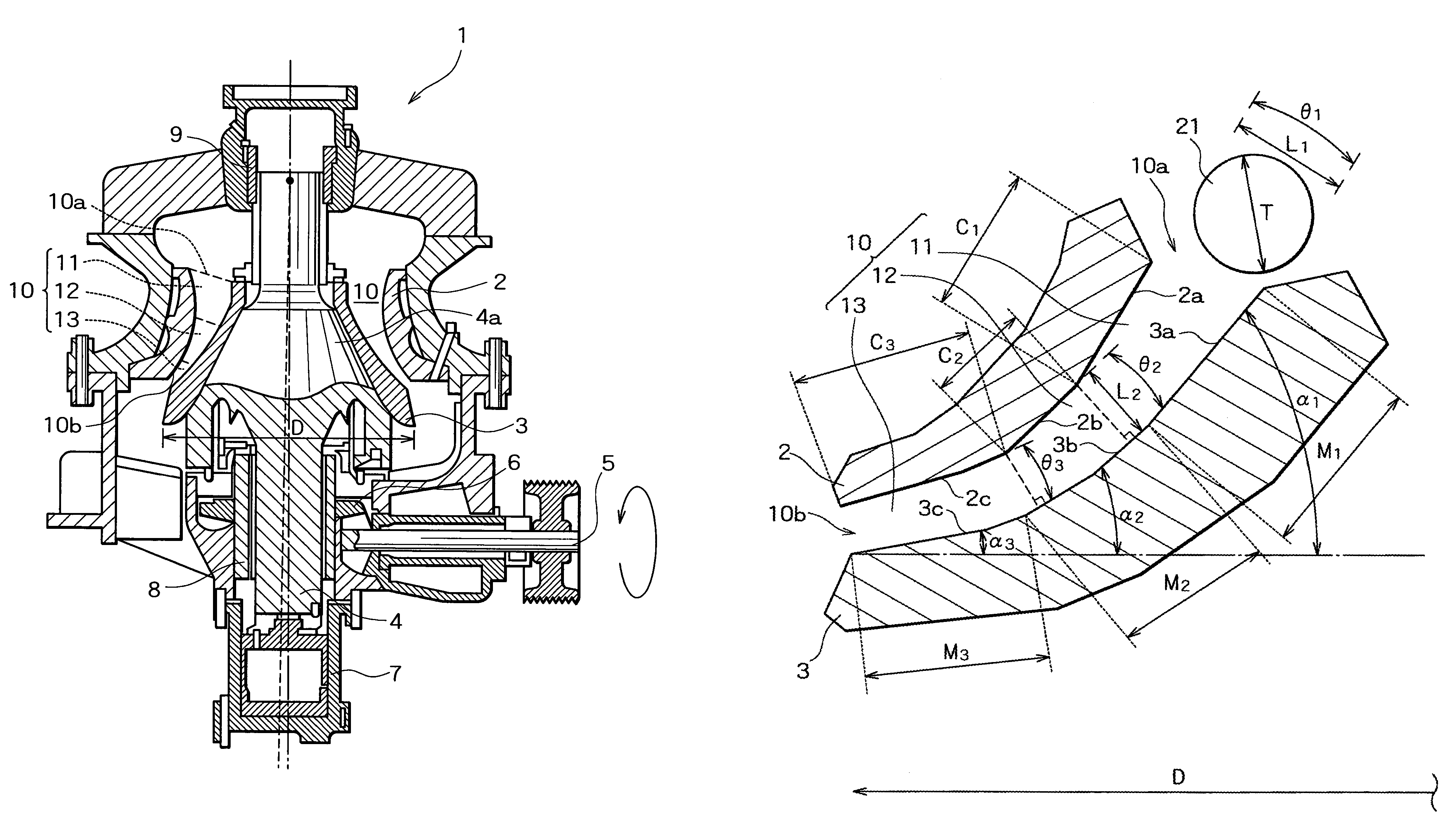

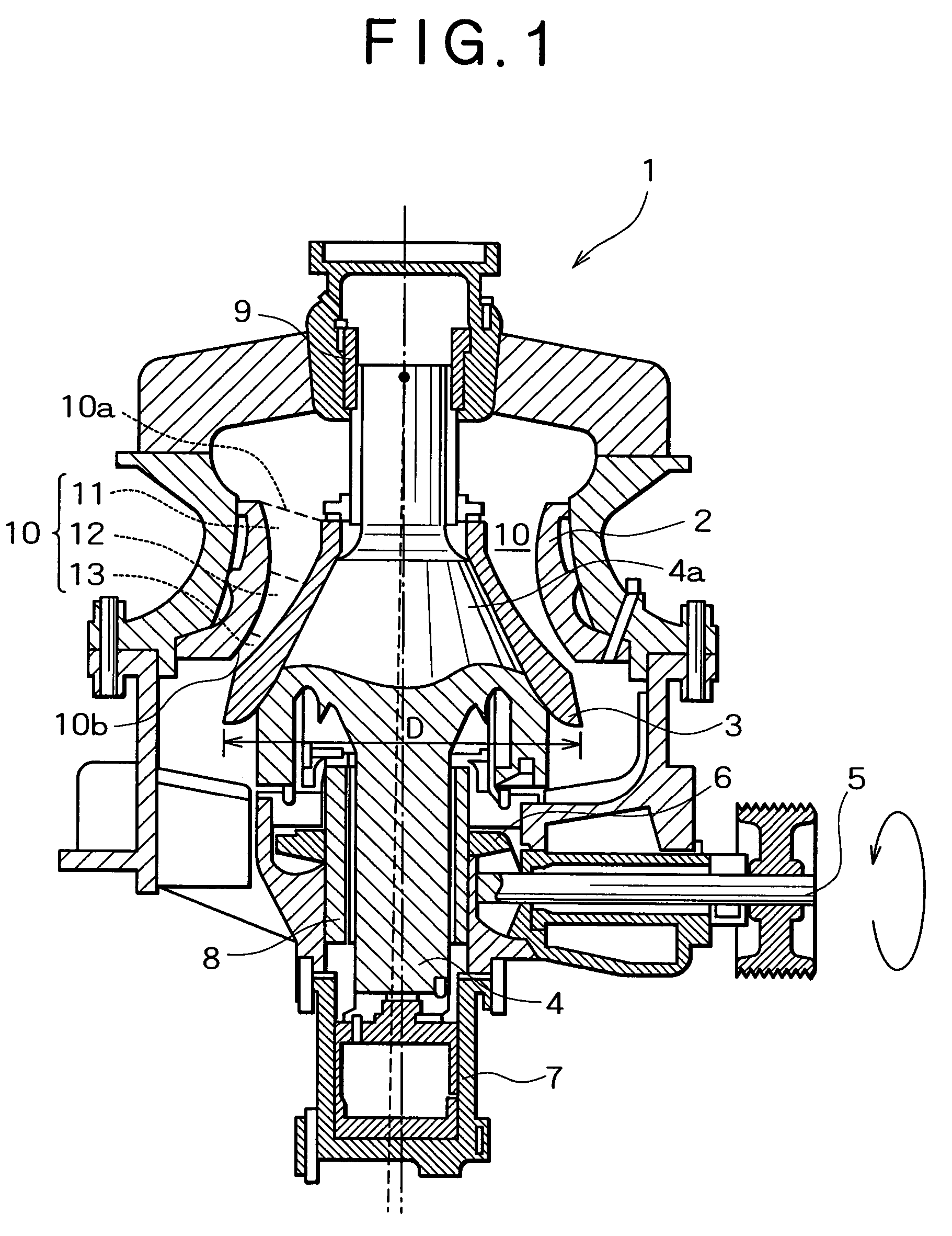

Cone crusher

A crushing chamber is formed between a concave liner and a mantle liner. The concave liner has a first area surface having a length of T to √2T; a second and a third area surface; which surfaces are gradually inclined from the side of the inlet for the crushing chamber. The mantle liner has a first tapered surface having a length of greater than T, a cross angle of less than 20° and an inclination angle of greater than 60°; a second tapered surface having a length of greater than 0.5T and a cross angle of 5° to 10°; and a third tapered surface having an inclination angle of 45° to 50°. The area surfaces as well as the tapered surfaces are continuously arranged in a curvilinear manner. The shapes enhance the throughput of goods in a good fine-crushing performance, reducing the uneven abrasion due to the action.

Owner:EARTHTECHNICA

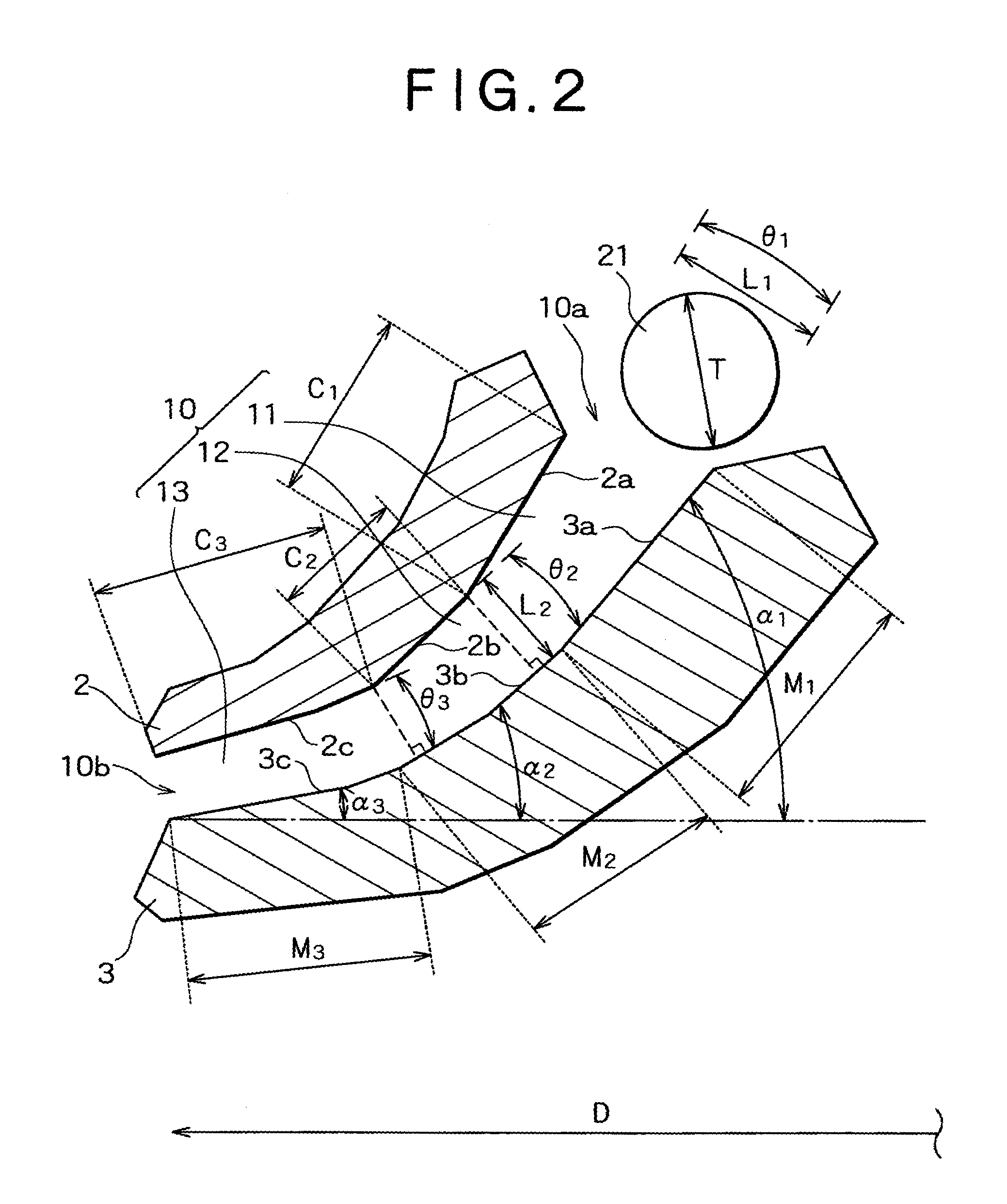

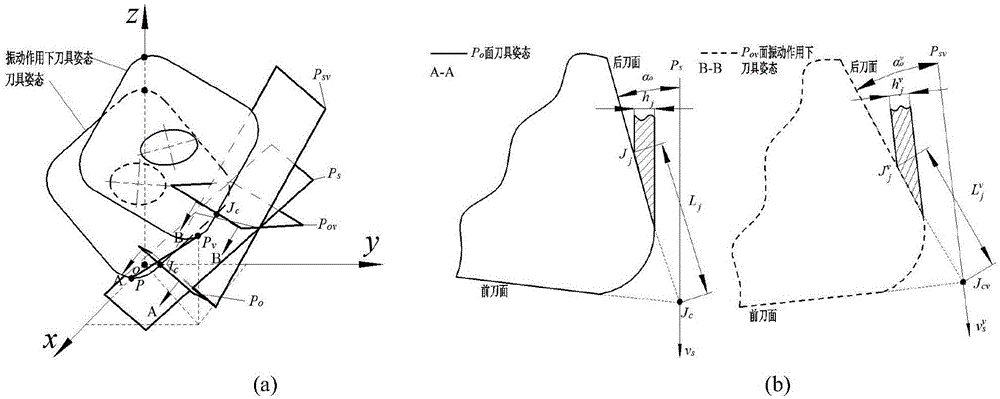

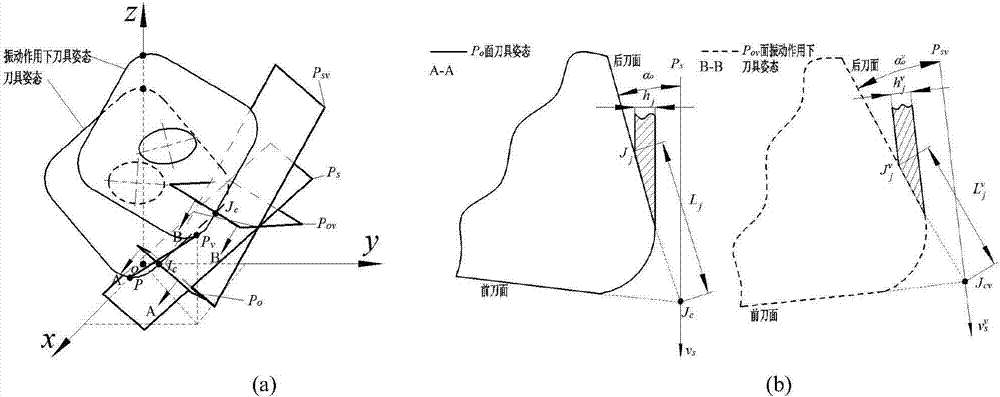

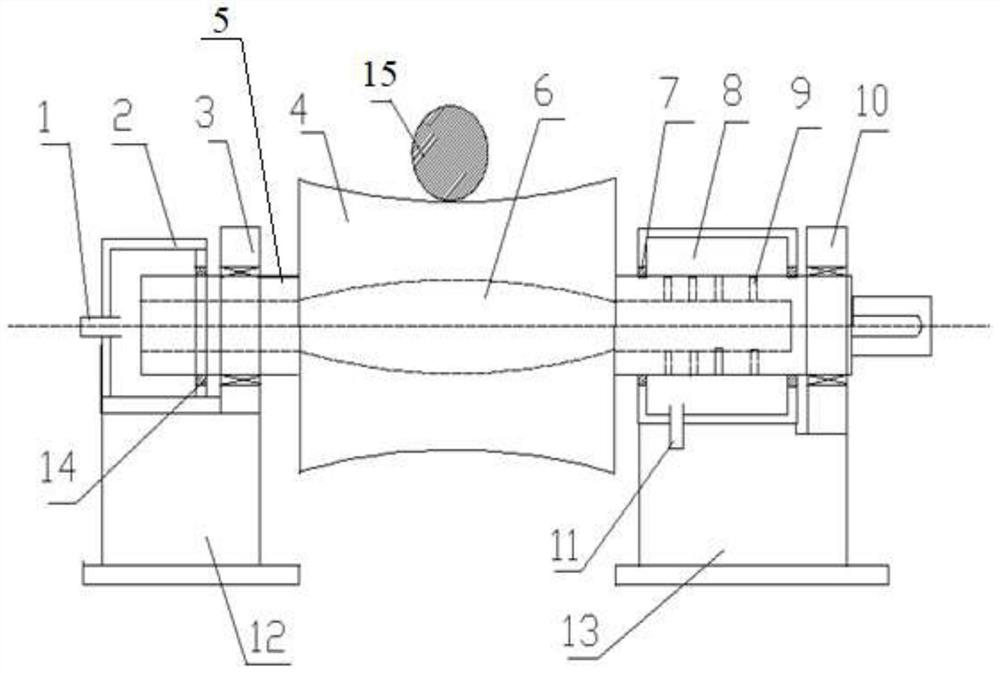

Method for detecting abrasion difference of cutter teeth of high-speed milling cutters under action of vibration

ActiveCN105619180AWear discrepancies revealedImprove reliabilityMeasurement/indication equipmentsMetal working apparatusState modelMilling cutter

The invention discloses a method for detecting the abrasion difference of cutter teeth of high-speed milling cutters under the action of vibration. The method is technically characterized by comprising the steps that firstly, the cutter tooth cutting motion speed and cutter skill contact relation under the action of vibration is built; secondly, a rear angle calculating equation under the action of vibration is calculated; thirdly, a cutter tooth friction contact point position calculating model and a cutter tooth friction contact point friction speed calculating model are constructed; fourthly, cutter tooth friction contact point positions and the cutter tooth friction contact point friction speed are analyzed, and the change rules of the cutter tooth friction contact point positions and the cutter tooth friction contact point friction speed are obtained; fifthly, an abrasion cutting test of the high-speed milling cutters is carried out; sixthly, cutting vibration signals are extracted and processed; seventhly, milling cutter abrasion cutting test data obtained in the fifth step is extracted; eighthly, the test results of the cutter tooth rear cutter face friction contact point positions and the friction contact point friction speed are obtained; and ninthly, a cutter tooth rear cutter face friction contact state model is verified. According to the method, bases are provided for relieving uneven abrasion and weakening fluctuating load excitation, and initial sample cutters are provided for efficient and high-precision cutting.

Owner:HARBIN UNIV OF SCI & TECH

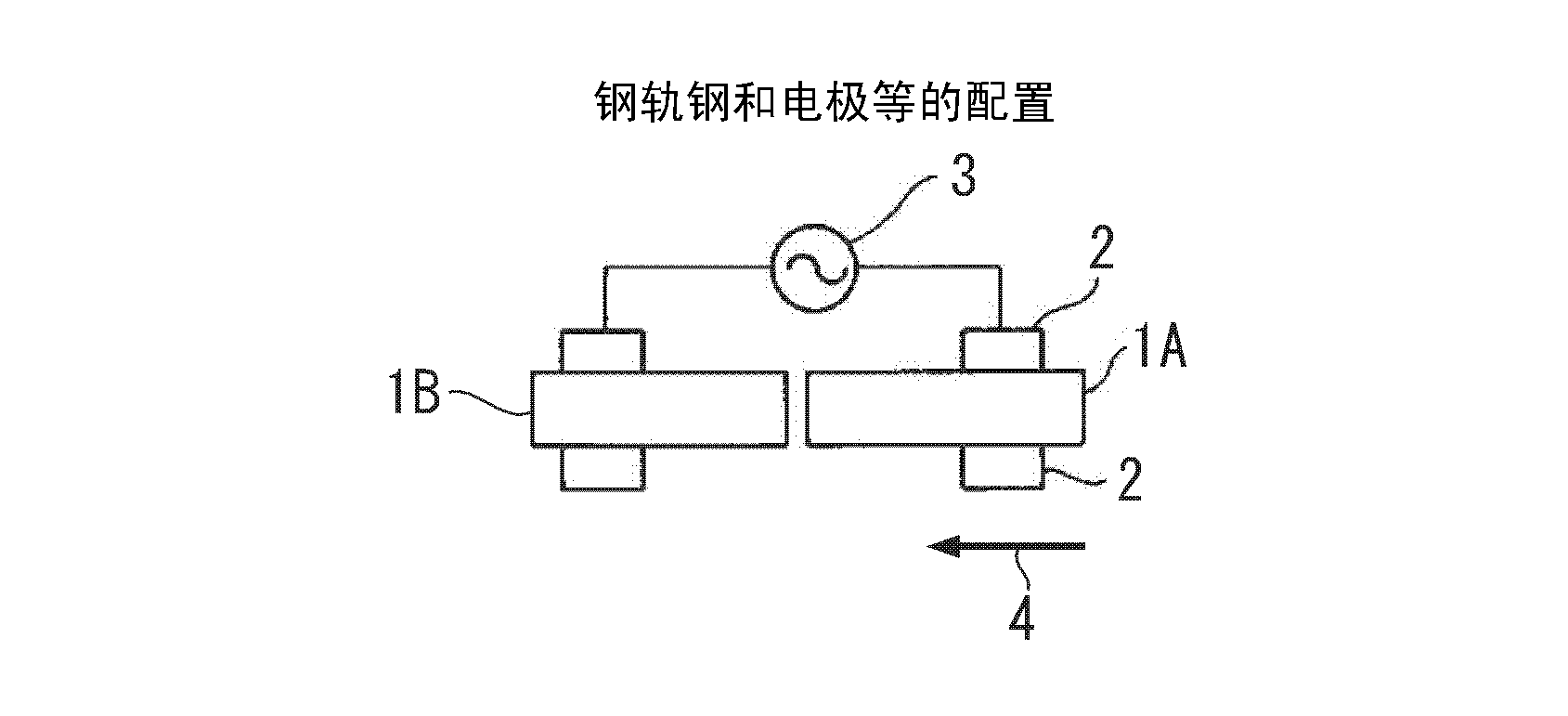

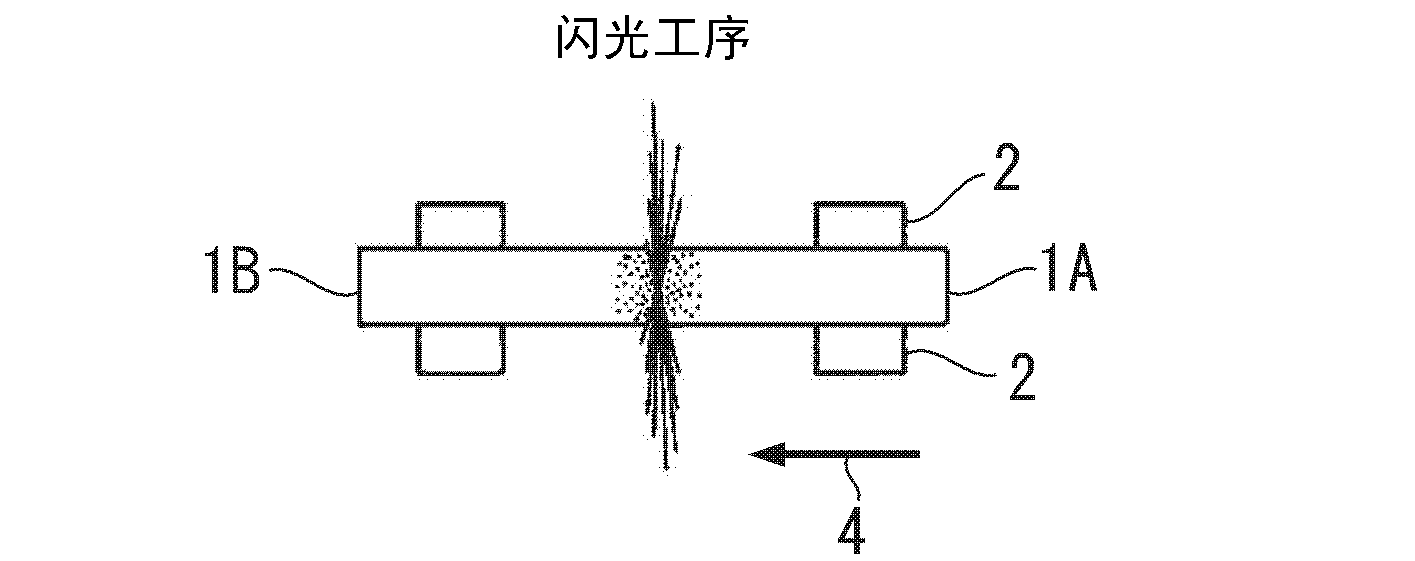

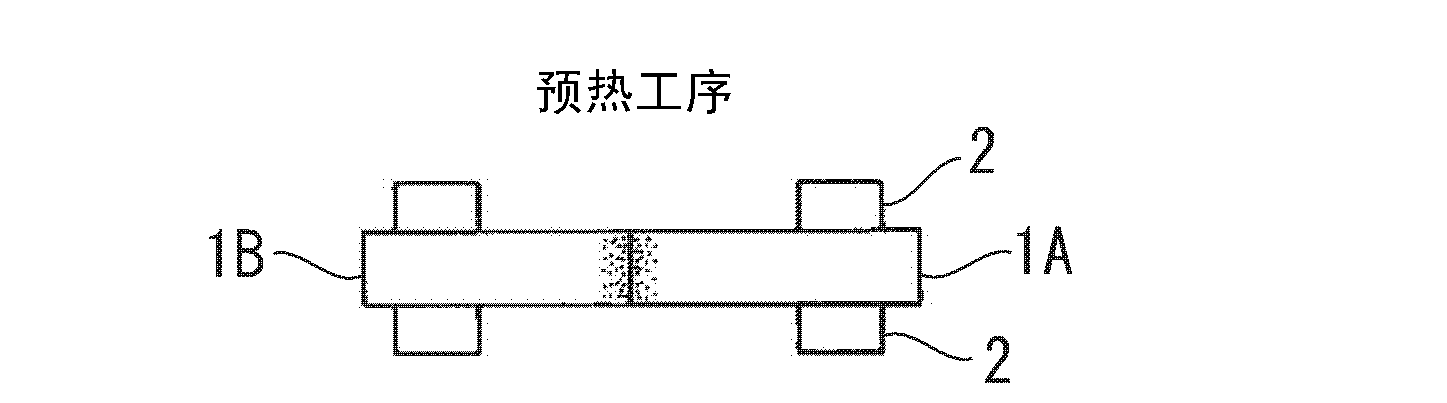

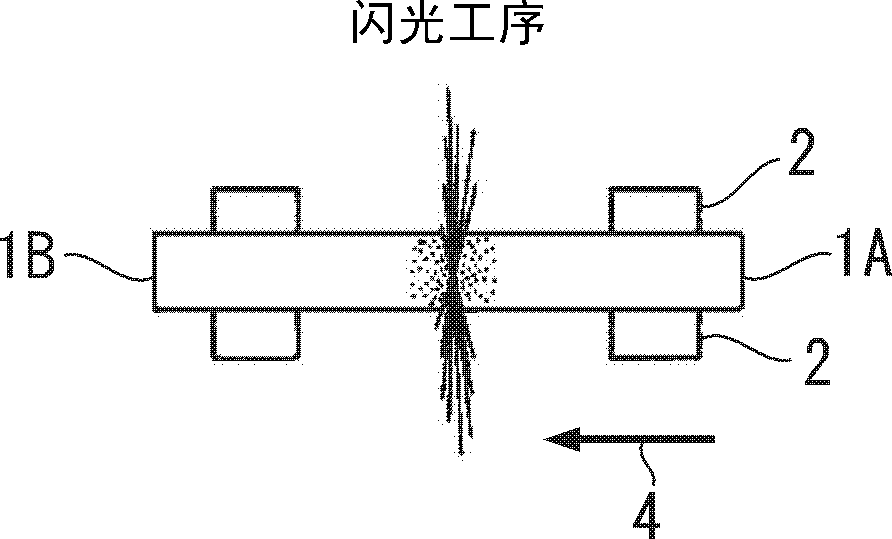

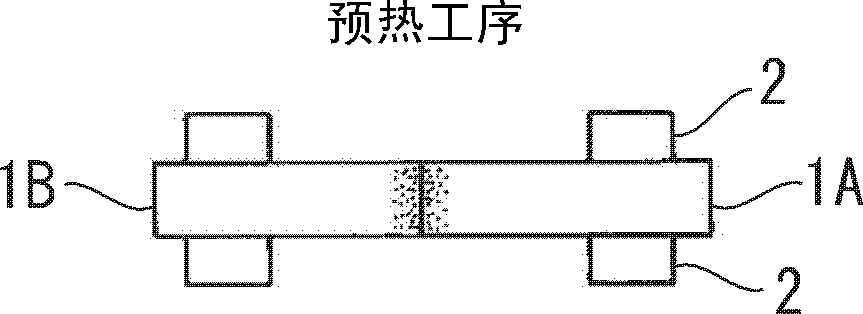

Flash-butt welding method for rail steel

InactiveCN102665994ASteep heat distributionExtend the exchange cycleRailsWelding electric supplyElectrical resistance and conductancePower flow

The invention relates to a welding method. The method is for subjecting a pair of track rail steels to flash- butt welding, which is provided with a preheating step for causing a current to flow for a predetermined time period in a state in which the welding surfaces of the pair of the track rail steels are forced into contact with each other, and heating the vicinity of the welding surfaces by means of resistance heating, a previous flash step for partially generating flash on the welding surfaces, and heating the welding surfaces by means of the resistance heating and electric-arc heating of the flash, and a later flash step for further generating the flash on the entire welding surfaces, and uniformly applying heat to the entire welding surfaces by means of the resistance heating and electric-arc heating of the flash, wherein the later flash speed in the later flash step is 2.1-2.8 mm / sec inclusive.

Owner:NIPPON STEEL CORP

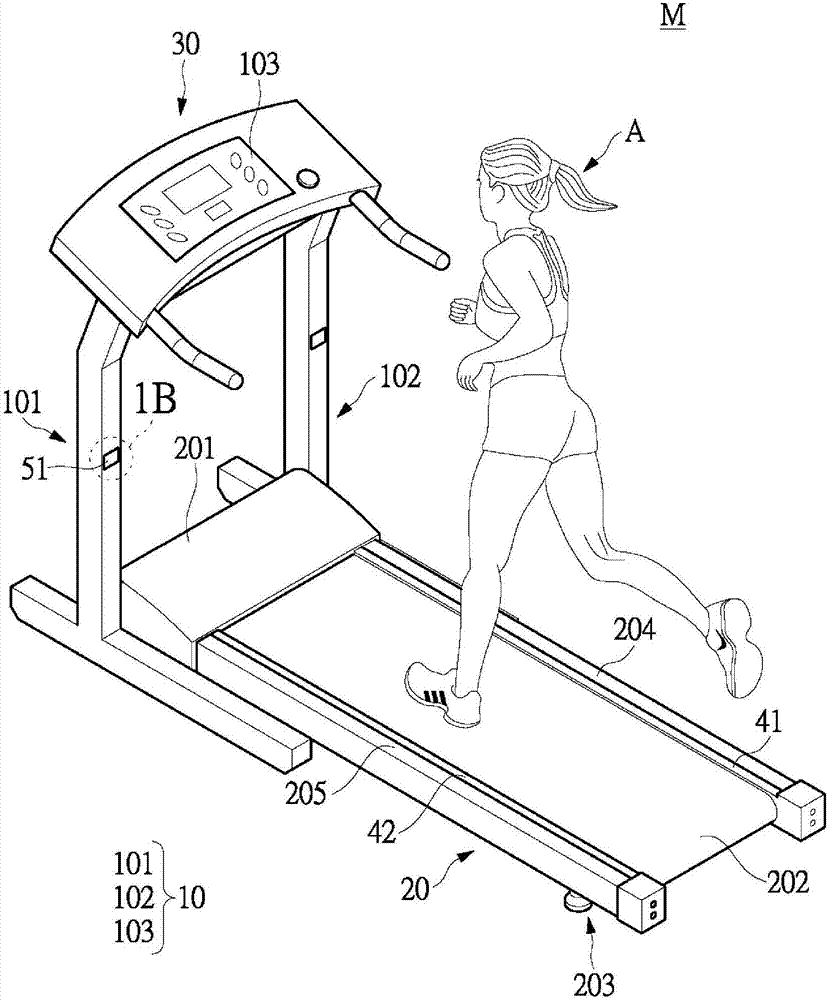

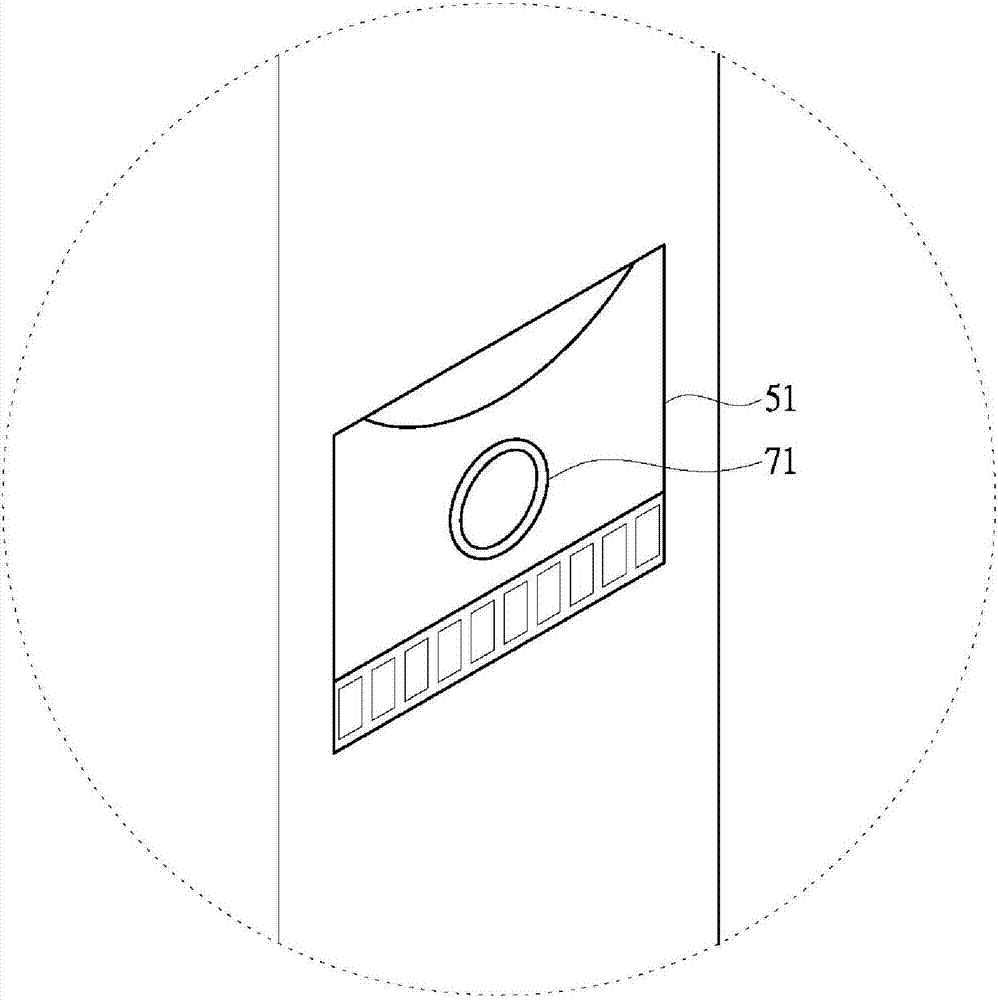

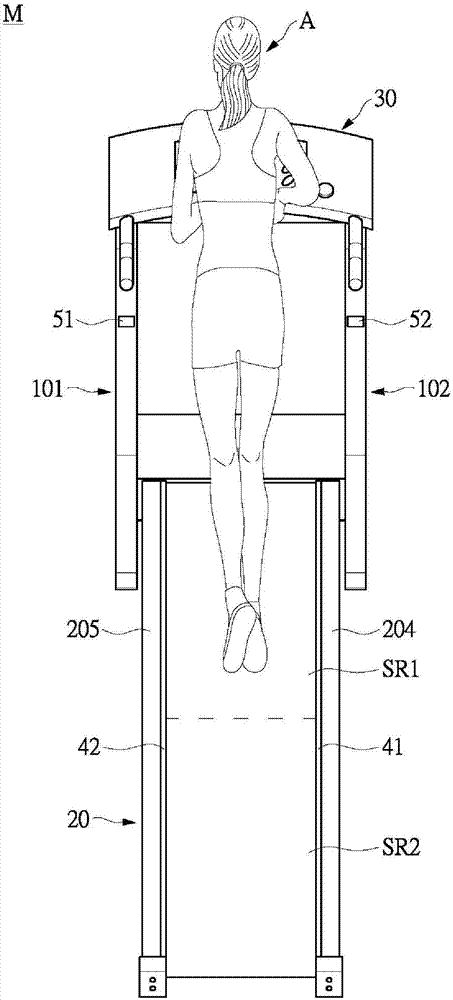

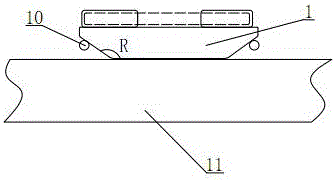

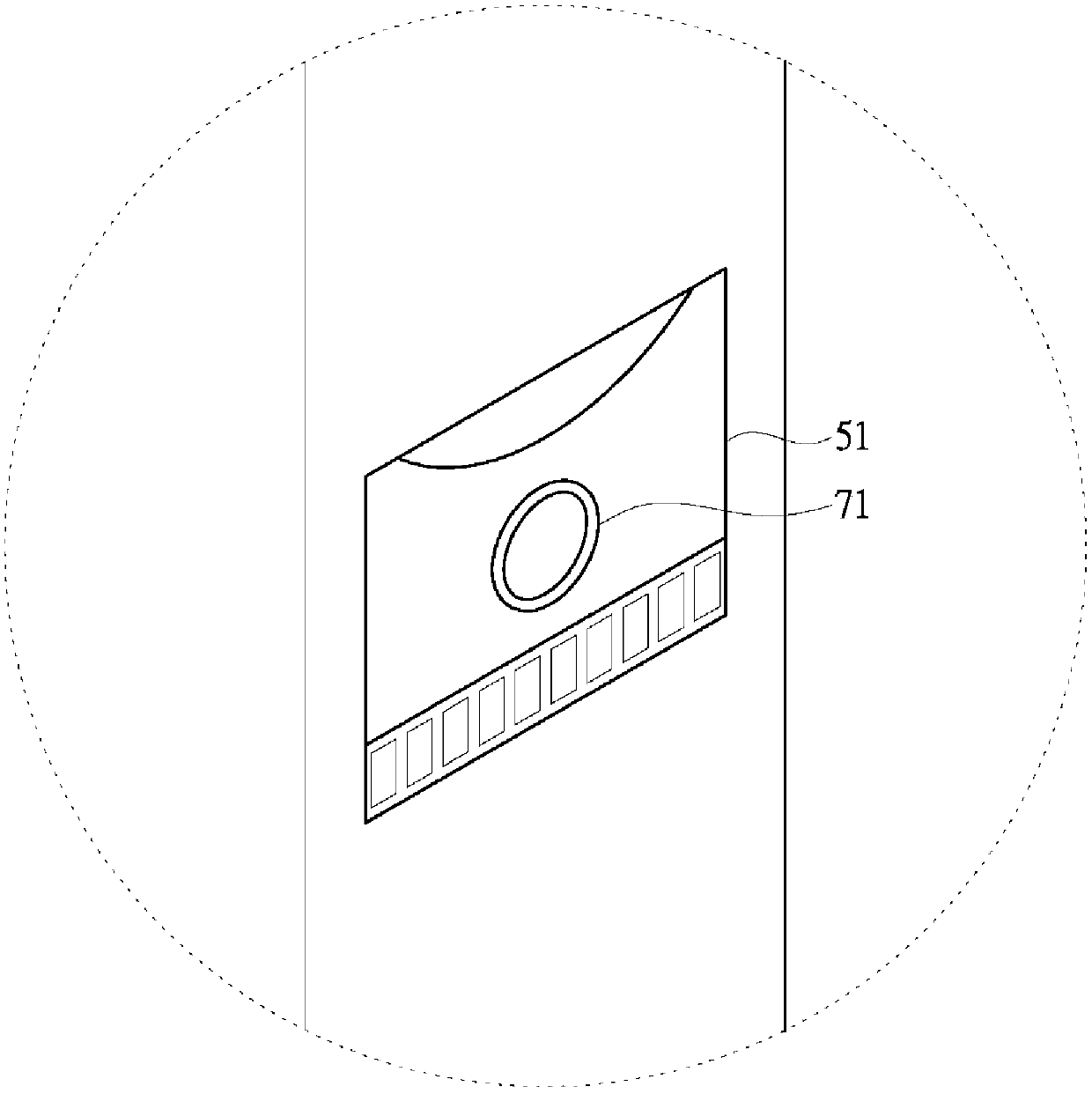

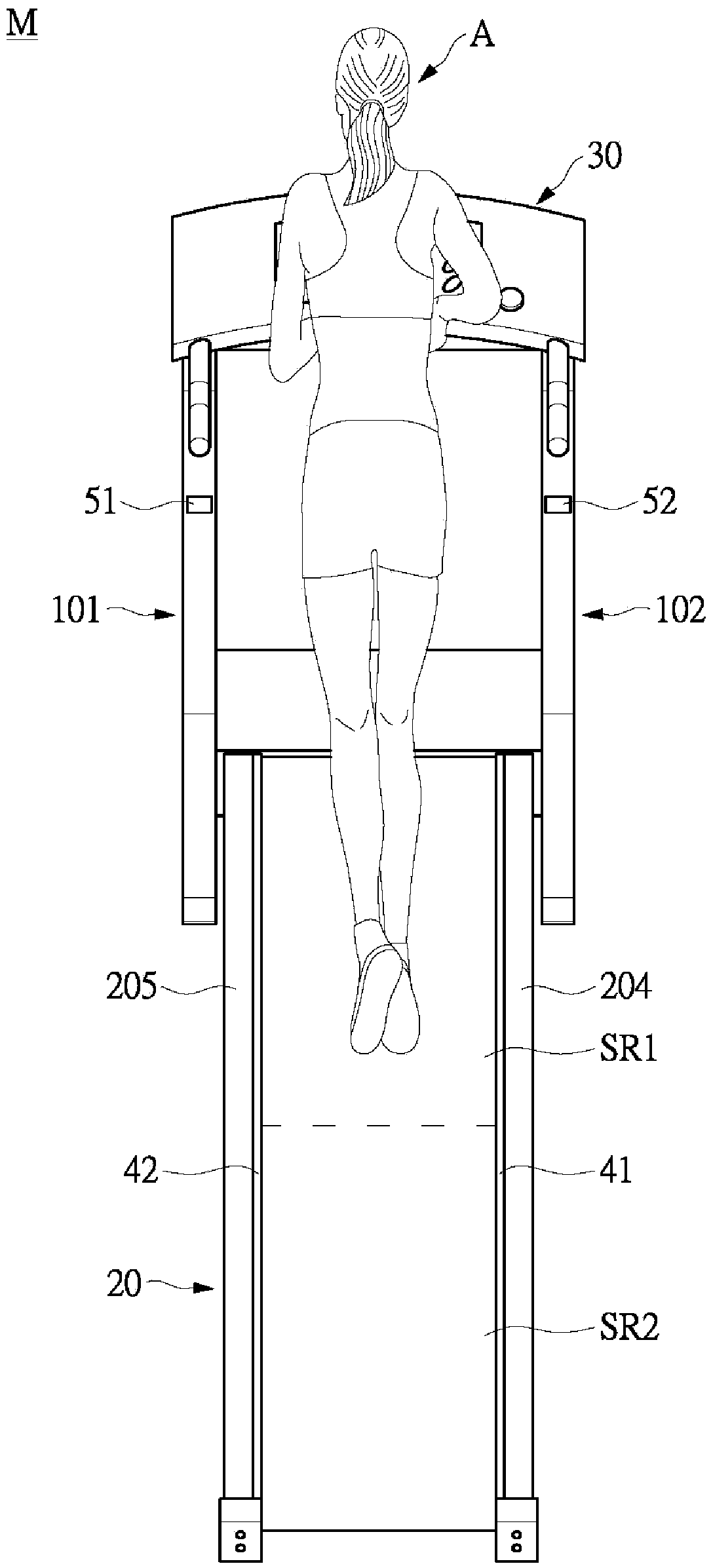

Treadmill and control method for controlling the treadmill belt thereof

ActiveCN107029383AReduce uneven wearExtended service lifeMovement coordination devicesCardiovascular exercising devicesEngineeringTreadmill

A treadmill and a control method for controlling the treadmill belt thereof are provided. The treadmill includes a treadmill belt, a first sensor, an image sensor and a controller. The first sensor retrieves a light pattern or the image sensor measures the characteristic properties of the image of the user so as to control the treadmill belt. The light pattern can be generated by a signal member, which can be disposed on a side or both sides of the treadmill belt.

Owner:PIXART IMAGING INC

Friction plate and method for optimizing same to reduce uneven wear

InactiveCN108536888AImprove efficiencyAvoid wasting timeGeometric CADDesign optimisation/simulationEngineeringSoftware

The invention provides a method for optimizing a friction plate to reduce uneven wear. The method includes steps of building brake discs and friction plate models; carrying out grid division on the brake discs and the friction plate; carrying out thermo-mechanical coupling analysis by the aid of finite element software; acquiring stress values of discrete points of friction pairs according to temperature fields and contact pressure fields; determining maximum parameters of influence factors by the aid of PB (Plackett-Burman) experimental designs so as to obtain first-order fitting curves of the discrete points; acquiring the optimal solution by the aid of response surface design processes. The method has the advantages that influence of uneven contact pressures can be predicted, design variables can be changed, accordingly, the unevenness of wear can be compared, and the method is wide in application range and can be widely applied to designing different types of contact dry friction wear analysis.

Owner:JIANGSU UNIV

Cleaning blade and image forming apparatus

InactiveCN102200746AReduce friction and wear changesSuppression of streaksElectrographic process apparatusSurface roughnessEngineering

A cleaning blade includes a cleaning layer facing an image holding body, and a back layer wich is disposed at a side opposite to the image holding body and removes discharge products and developer residues that are stuck to a surface of the image holding body in such a manner that an edge of the cleaning layer comes into contact with the surface of the image holding body, and the back layer and the cleaning layer are molded integrally and a surface roughness Ra of the cleaning layer is lower than or equal to 0.12 mum.

Owner:FUJIFILM BUSINESS INNOVATION CORP

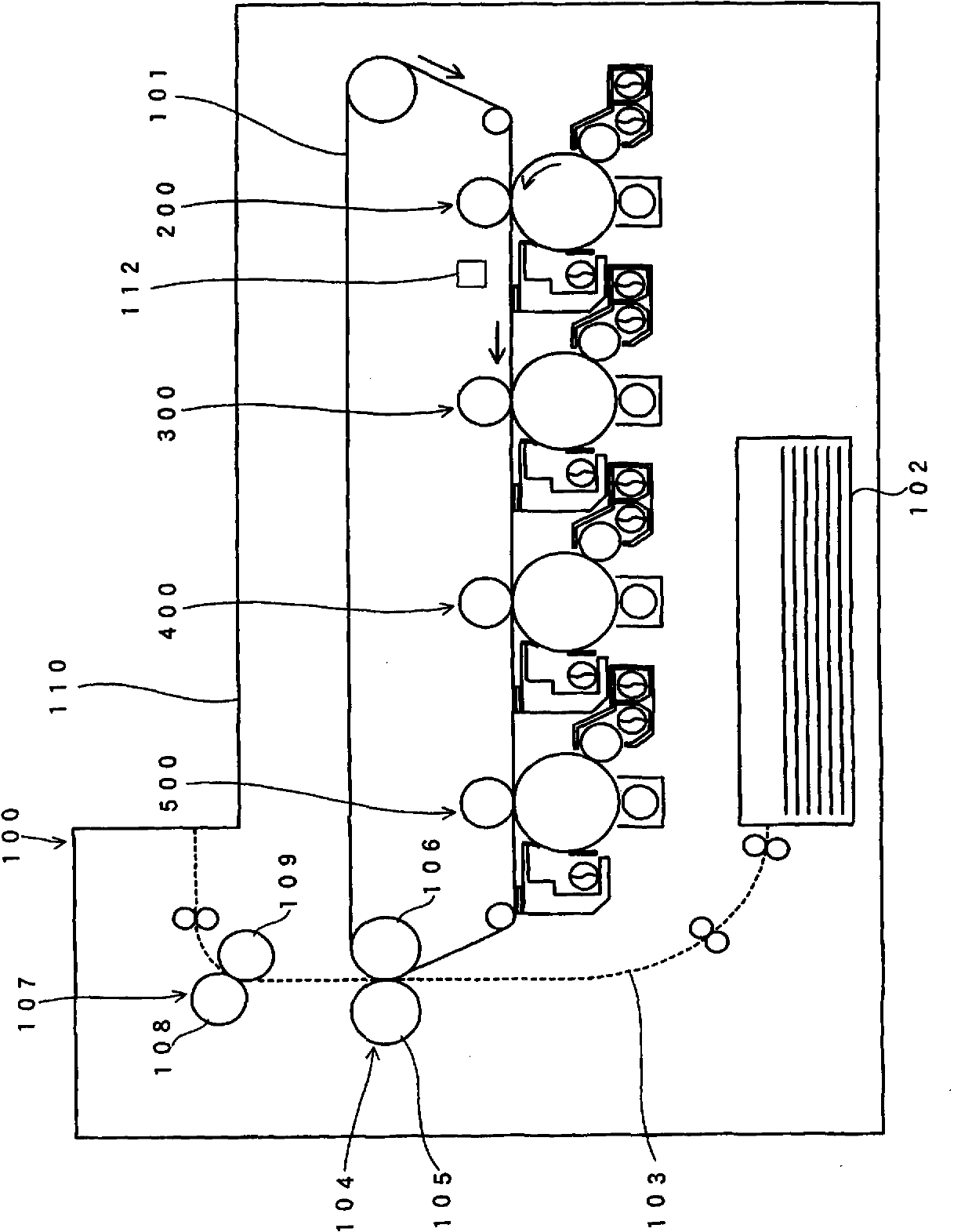

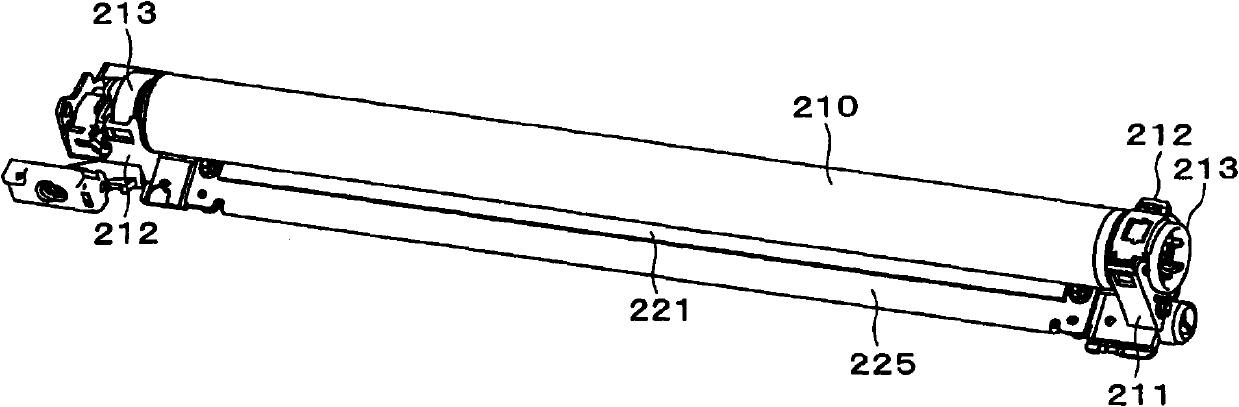

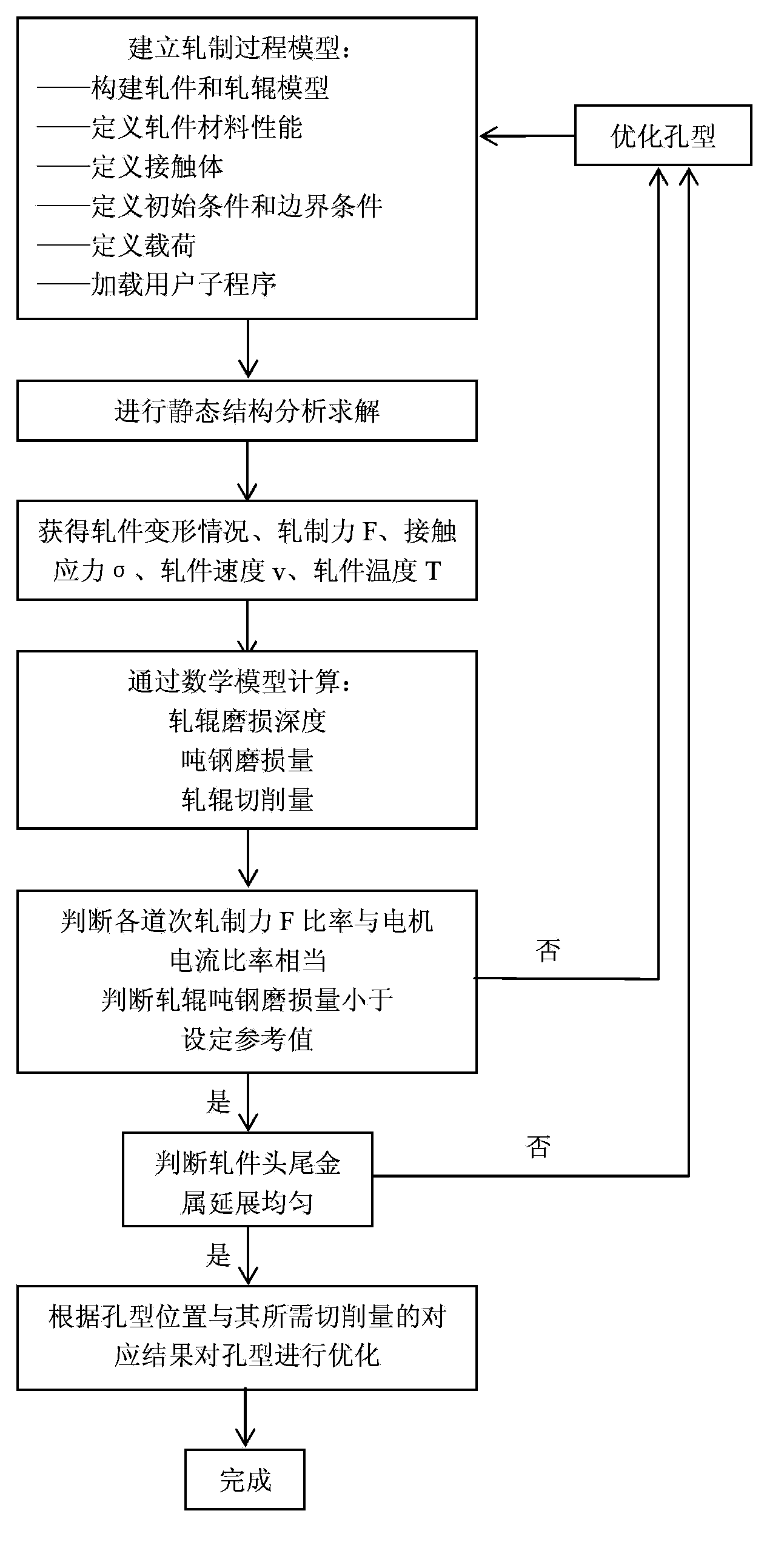

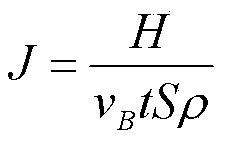

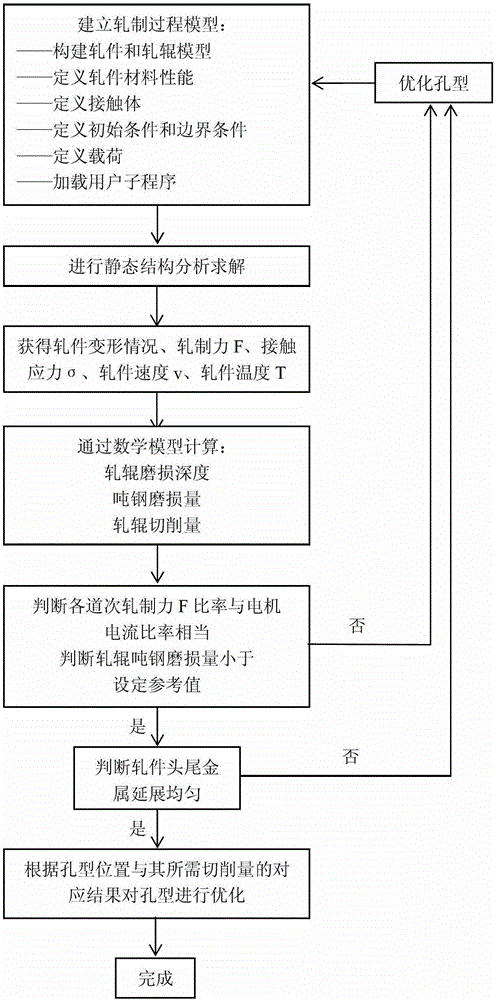

Roll pass optimizing method capable prolonging shaped roll service life

ActiveCN103878181AExtended service lifeEvenly distributed wearMeasuring devicesRollsEngineeringLife time

The invention discloses a roll pass optimizing method capable prolonging shaped roll service life. The method is characterized by including the steps of firstly, building a mathematic model to calculate the rolling state of a rolled piece under a target rolling process; secondly, predicting roll abrasion condition under current production process conditions, evaluating roll abrasion state, and converting roll abrasion quantity into roll repairing quantity; thirdly, optimizing roll passes and the rolling process by evaluating roll cutting quantity. By the method, roll abrasion state is effectively changed during profile rolling, roll uneven abrasion is reduced, cutting nonuniformity during roll repairing is improved, turning quantity required by each roll pass recovery is reduced by 3-10mm, roll turning times are increased by 1-2, and the service life of shaped rolls is prolonged.

Owner:ANGANG STEEL CO LTD

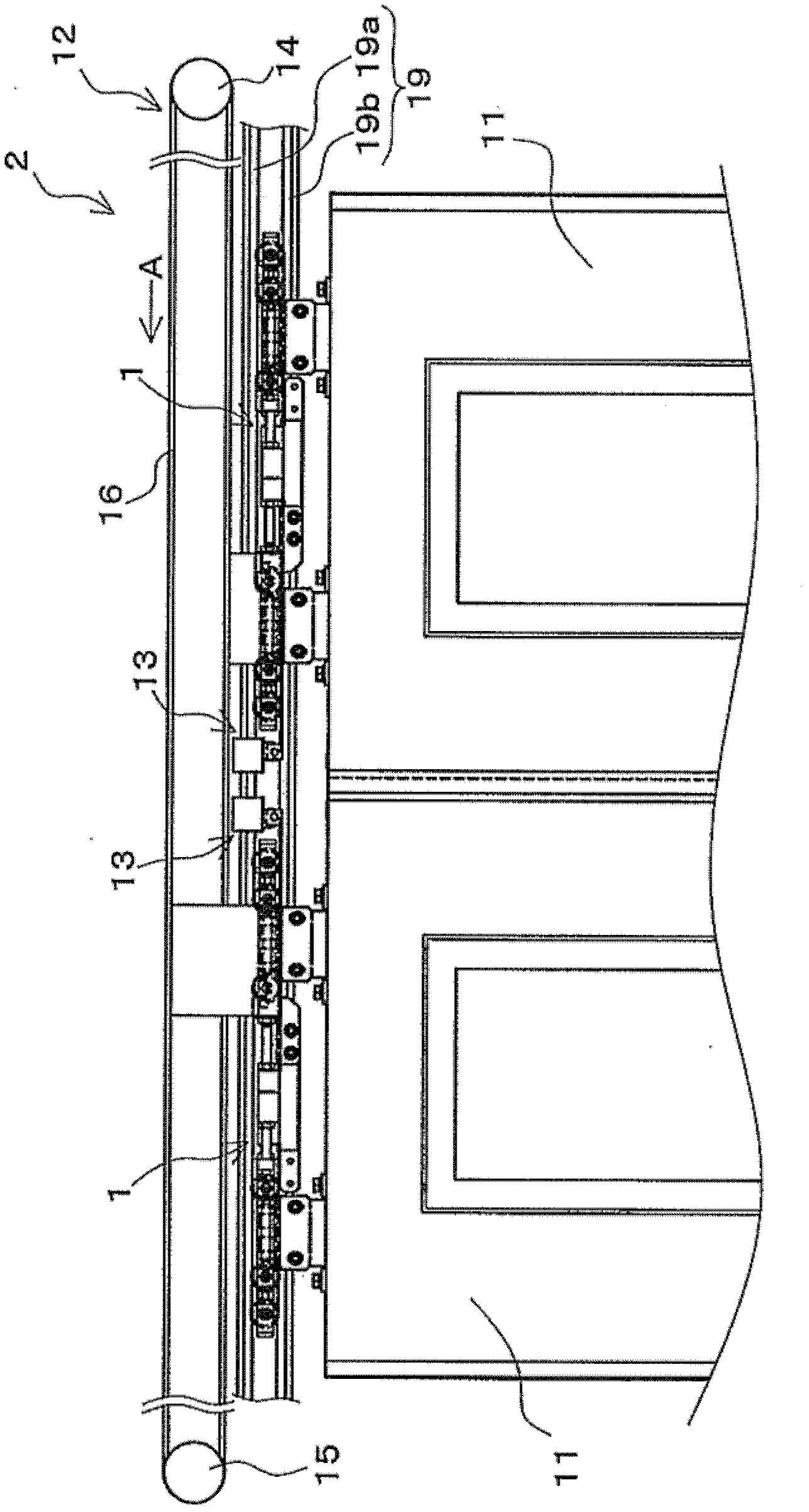

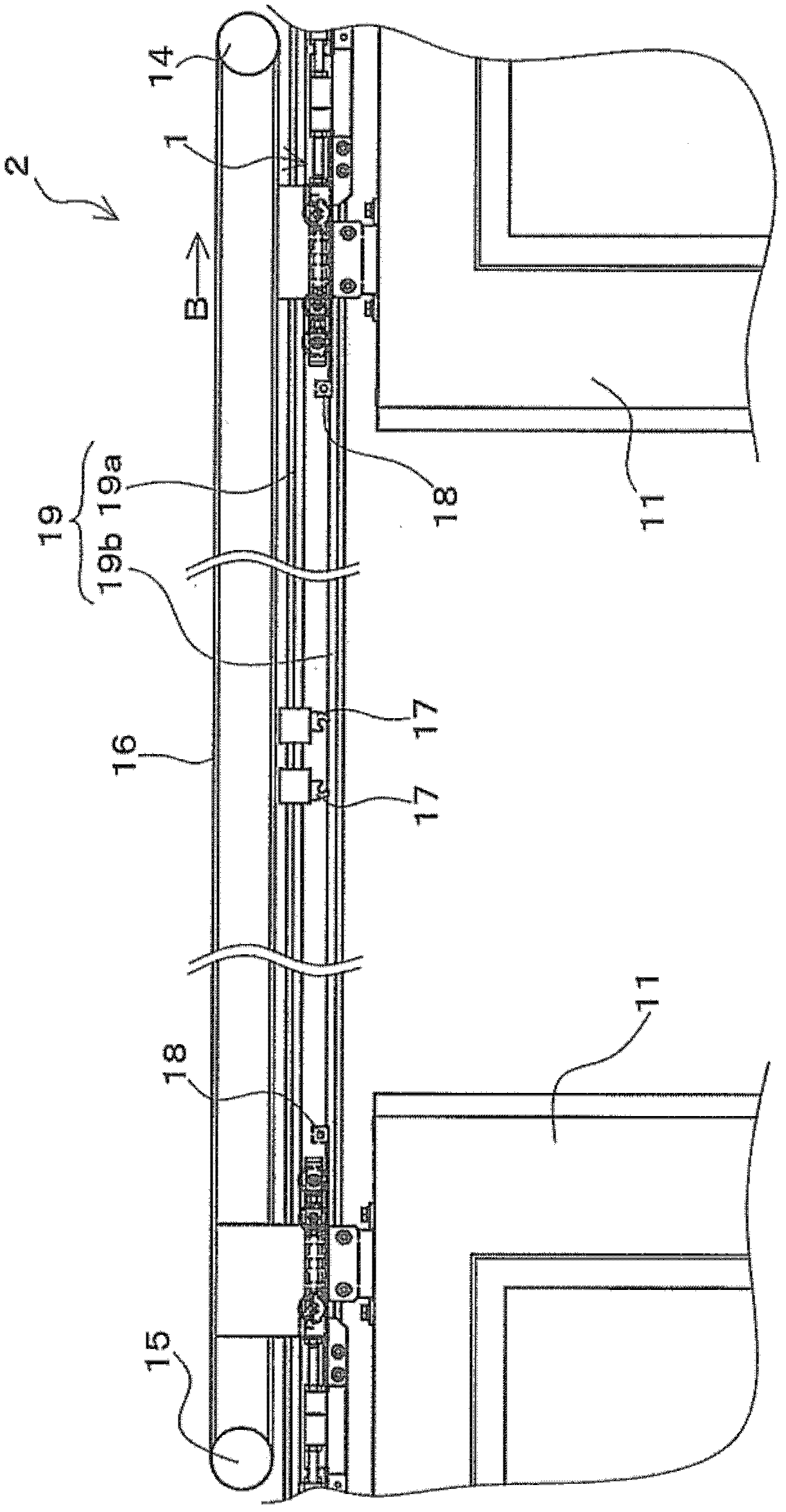

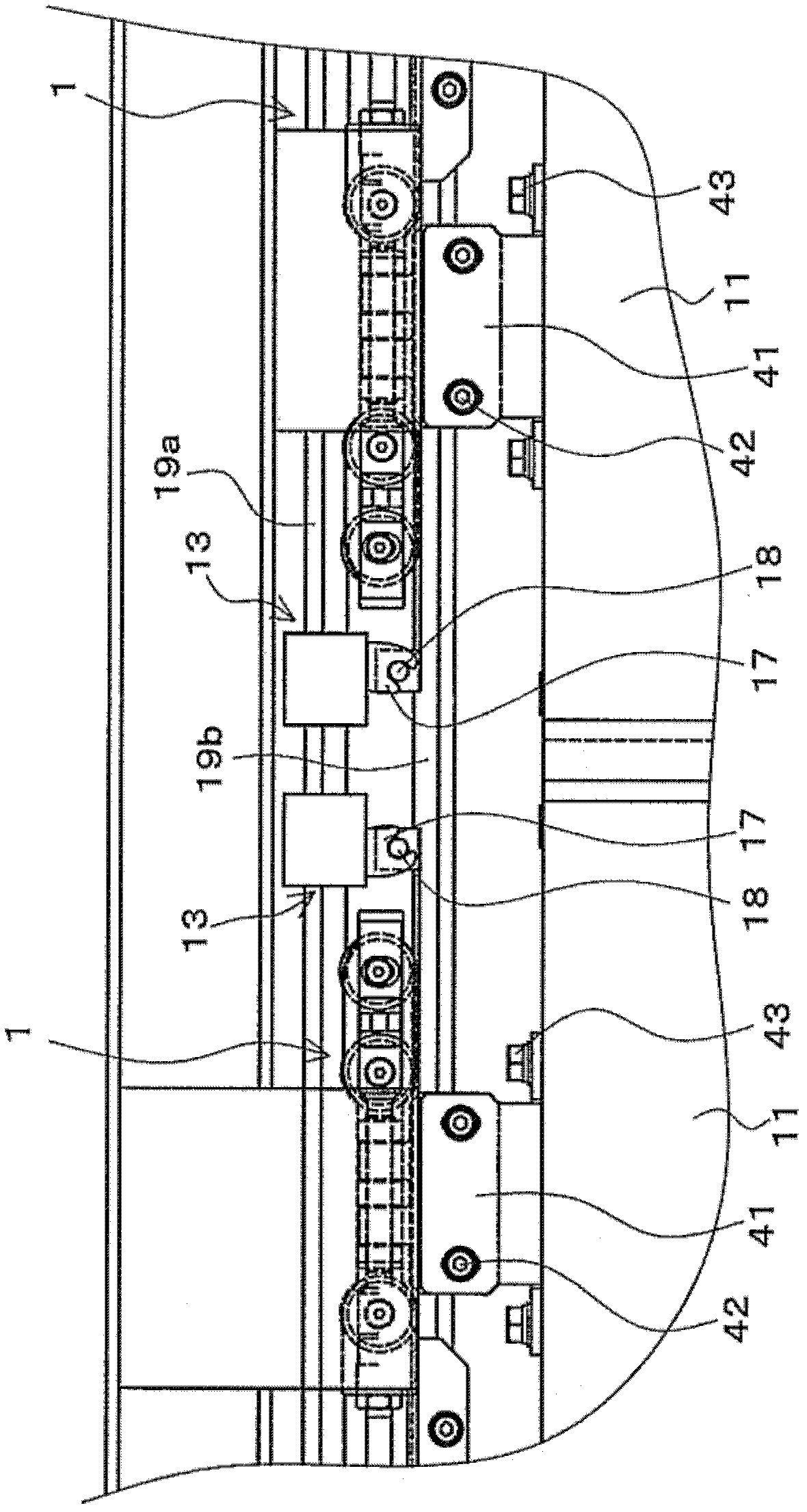

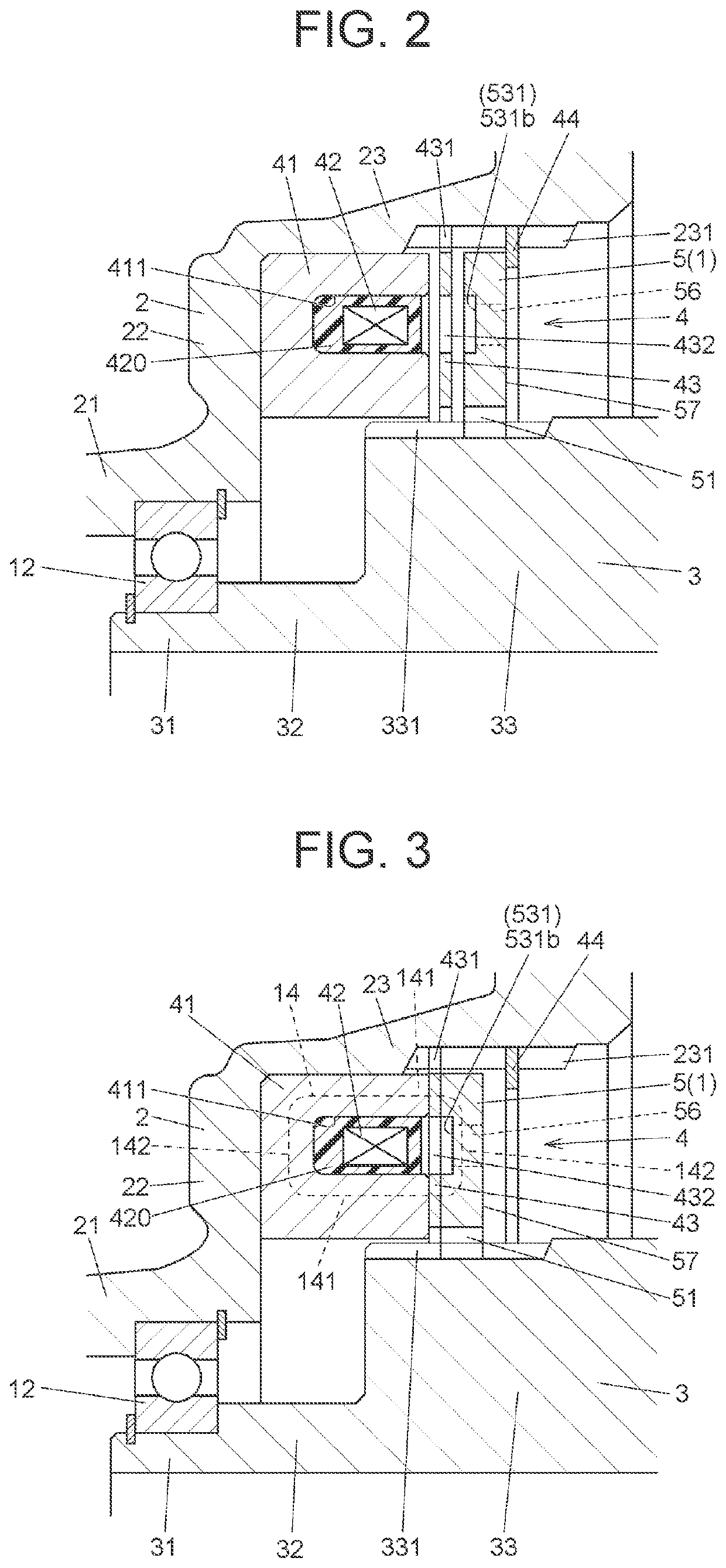

Door suspension apparatus and door apparatus equipped with the same

ActiveCN102482910ASave man hoursShorten working timeVehicle locksMan-operated mechanismEngineeringMechanical engineering

Owner:NABLESCO CORP

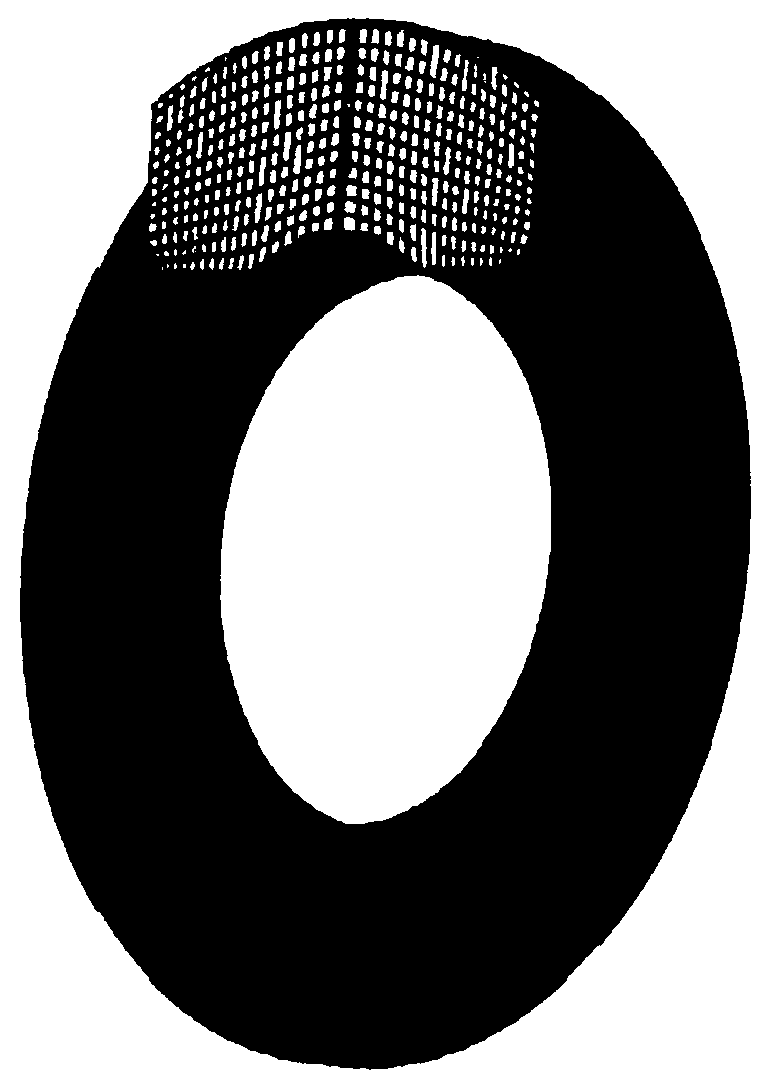

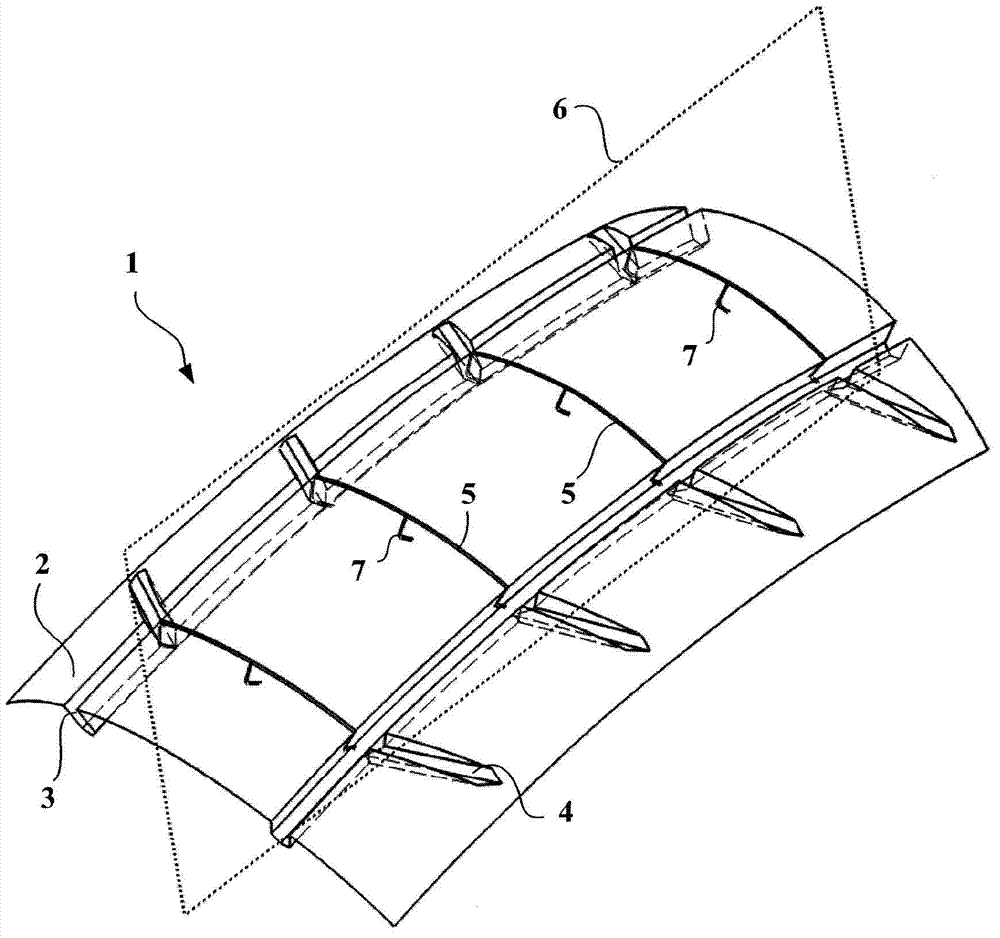

Tire for two-wheeled vehicles, comprising a tread having sipes

ActiveCN102741064AReduce uneven wearReduce unevennessMotorcycle tyresPneumatic tyre reinforcementsEngineeringTread

The invention relates to a tire for a two-wheeled motor vehicle, said tire comprising a tread, wherein the surface at least of the tread consists of a first polymer mixture extending over a portion at least of the central portion and at least a second polymer mixture having physical and chemical properties different from that of said first polymer mixture and covering a portion at least of the axially outer portions of the tread. At least the central portion of the tread comprises at least one sipe (5) in a circumferential plane, at least a portion (7) of a wall of said at least one sipe (5) being formed by at least two straight lines (370, 371) each defining an angle of between 5 and 65 DEG relative to the radial direction, and the direction of the straight lines together defining an angle of between 30 and 120 DEG .

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

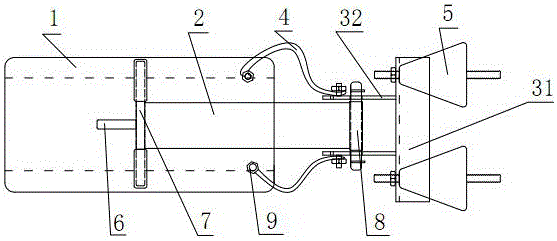

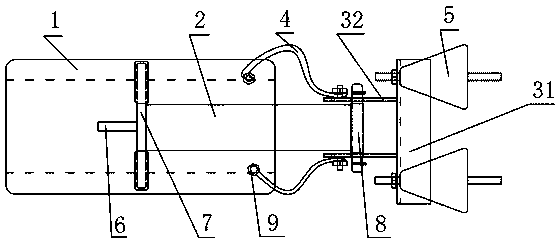

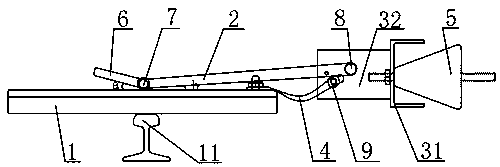

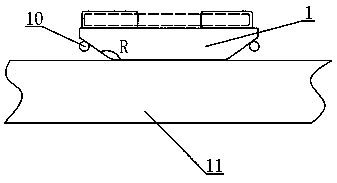

Guide rail current collector

ActiveCN105826786ASimple structureImprove power supply capacityNon-rotary current collectorEngineeringWear resistance

The invention discloses a guide rail current collector and belongs to the technical field of track mobile device power supply apparatuses. The guide rail current collector includes a collector brush which is in sliding fit with a conductor rail, a yoke plate mechanism which is hinged to the collector brush, and a fixing rack which is hinged to the yoke plate mechanism and serves to connect a walking device. The collector brush has two ends that are along the sliding direction of the conductor rail separately provided in an oblique downward manner with a bevel [gamma] which tilts inwardly. The yoke plate mechanism includes a front pin which is hinged to the collector brush, a defining short rod which is connected to one side of the front pin in an oblique upward manner, and a yoke plate which is connected to the other side of the front pin in an oblique upward manner. The defining short rod and the yoke plate constitute an obtuse angle therebetween. The yoke plate is hinged to the fixing rack through a back pin. The collector brush and the fixing rack are connected to a braided wire for conducting electric energy therebetween. An included angle a constituted by the defining short rod and the collector brush constitute an included angle therebetween and an included angle b constituted by the yoke plate and the collector brush therebetween both range from 10 DEG to 30 DEG. According to the invention, the guide rail current collector has the characteristics of simple structure, wear resistance, long service life and deformation resistance.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Treadmill and runway control method thereof

ActiveCN107029383BReduce uneven wearExtended service lifeMovement coordination devicesCardiovascular exercising devicesEngineeringRunway

A treadmill and a control method for controlling the treadmill belt thereof are provided. The treadmill includes a treadmill belt, a first sensor, an image sensor and a controller. The first sensor retrieves a light pattern or the image sensor measures the characteristic properties of the image of the user so as to control the treadmill belt. The light pattern can be generated by a signal member, which can be disposed on a side or both sides of the treadmill belt.

Owner:PIXART IMAGING INC

Application method of friction liner capable of detecting steel wire rope tension and alarming

InactiveCN112254859AImprove acceleration performanceImprove securityTension measurementEconomic benefitsMechanics

According to the use method of the friction liner capable of detecting the tension of the steel wire rope and giving the alarm, friction liners are evenly distributed on a transverse shaft of a roller, the steel wire rope is wound in grooves of the friction liners, at least one sensor is arranged on the lower surfaces of the friction liners, a controller is arranged on one side of the roller, anda wire is arranged between the sensor and the controller; a wire is arranged between the controller and the alarm bell; according to the invention, the elevator can measure and report the current tension and the tension balance state of a plurality of steel wire ropes in real time in a static state and an operation state, can guide the tension adjustment time and numerical values needing to be adjusted, reduces the adjustment auxiliary time, improves the productivity and economic benefits, greatly reduces the unbalanced wear of friction liners, and improves the production efficiency. The maintenance frequency of the rope groove is reduced, the service life of the friction liner is prolonged, the service life of the steel wire rope is prolonged, the hoisting capacity and safety performanceof the hoister are improved, and major production safety accidents are reduced.

Owner:洛阳威卡矿山机械设备有限公司

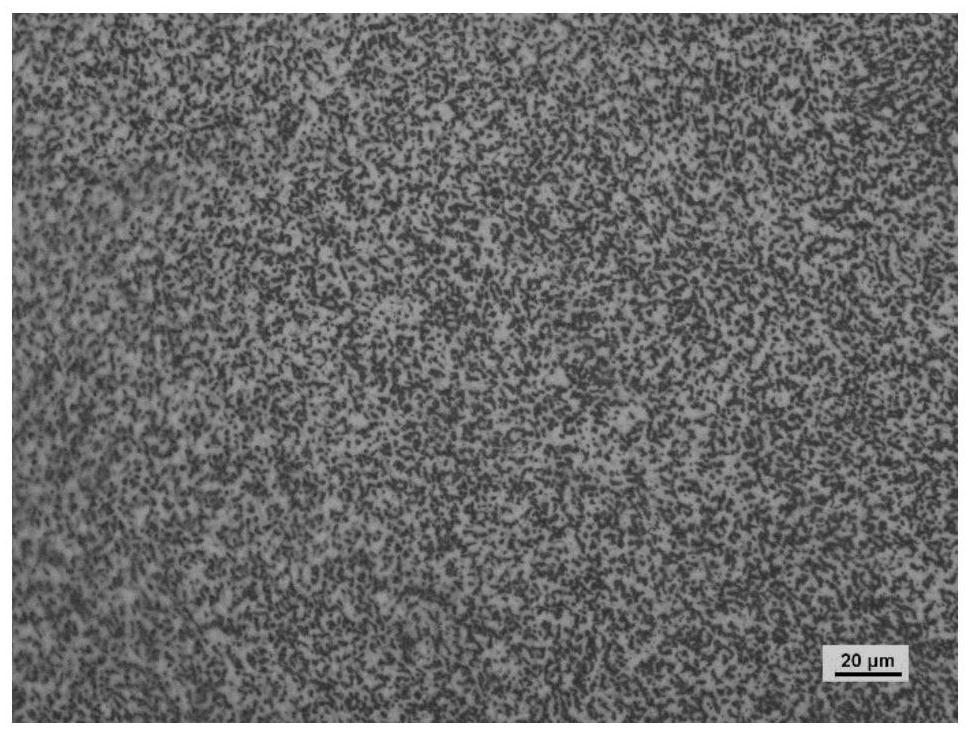

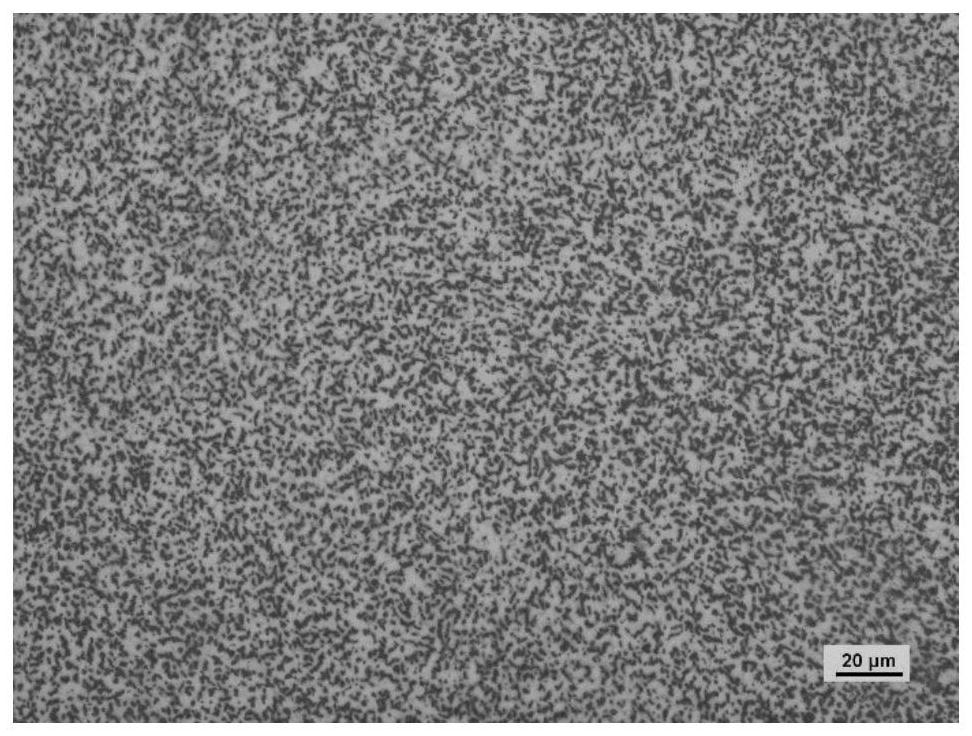

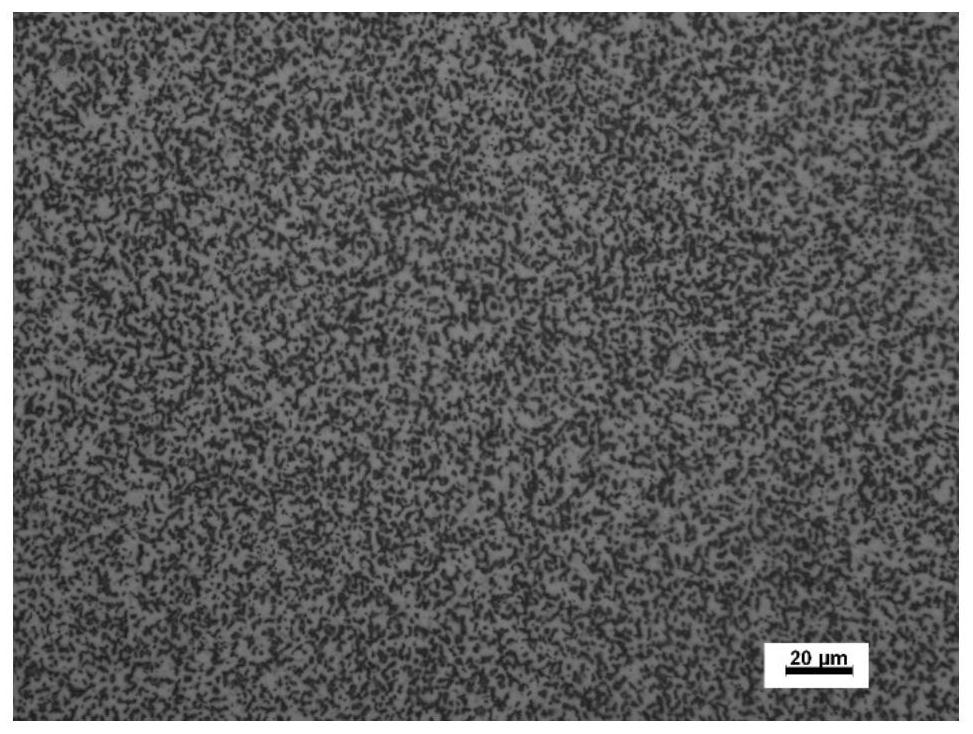

Zr-Nb alloy bar material and extruding and processing method thereof

ActiveCN109692880AImprove corrosion resistanceGood biocompatibilityExtrusion control devicesPre treatmentZirconium alloy

The invention belongs to the technical field of zirconium alloy processing, and particularly relates to a Zr-Nb alloy bar material and an extruding and processing method thereof. The extruding and processing method comprises the following steps of performing pretreatment: coating a lubricating film outside a Zr-2.5Nb semi-finished material free from surface defects, so as to obtain a pretreated Zr-2.5Nb semi-finished material; performing heating: heating the pretreated Zr-2.5Nb semi-finished material to an extruding temperature, and performing temperature insulating; and performing extruding:performing extruding on the heated Zr-2.5Nb semi-finished material according to a pre-set extrusion ratio, so as to obtain the Zr-Nb alloy bar material of target specification. According to the extruding and processing method disclosed by the invention, through the extruding temperature and the extrusion ratio, Zr-Nb alloy bar material tissues are controlled; the finally-obtained Zr-Nb alloy bar material is uniform and tiny in tissue, has 10 or more grain sizes; and when the Zr-Nb alloy bar material is transplanted and applied in human bodies, non-uniform wear can be effectively reduced, and then the service life is prolonged.

Owner:西部超导材料科技股份有限公司

Wet friction disc

ActiveUS20220090639A1Reduce uneven wearEfficient dischargeBraking element arrangementsMechanically actuated brakesGroove widthEngineering

A wet friction disc includes a lubrication groove and a plurality of lands defined by the lubrication groove. The lubrication groove has a plurality of circumferential groove portions that extends in a circumferential direction and has a predetermined groove width in a radial direction, and a plurality of intersecting groove portions that extends in directions intersecting the circumferential direction. At least some of the circumferential groove portions have an arc shape such that an end in the circumferential direction is located adjacent to one of the lands in the circumferential direction and that the groove width is entirely contained within a range in the radial direction spanned by that land.

Owner:JTEKT CORP +1

A rail collector

ActiveCN105826786BSimple structureImprove power supply capacityNon-rotary current collectorEngineeringMobile device

The invention discloses a guide rail current collector and belongs to the technical field of track mobile device power supply apparatuses. The guide rail current collector includes a collector brush which is in sliding fit with a conductor rail, a yoke plate mechanism which is hinged to the collector brush, and a fixing rack which is hinged to the yoke plate mechanism and serves to connect a walking device. The collector brush has two ends that are along the sliding direction of the conductor rail separately provided in an oblique downward manner with a bevel [gamma] which tilts inwardly. The yoke plate mechanism includes a front pin which is hinged to the collector brush, a defining short rod which is connected to one side of the front pin in an oblique upward manner, and a yoke plate which is connected to the other side of the front pin in an oblique upward manner. The defining short rod and the yoke plate constitute an obtuse angle therebetween. The yoke plate is hinged to the fixing rack through a back pin. The collector brush and the fixing rack are connected to a braided wire for conducting electric energy therebetween. An included angle a constituted by the defining short rod and the collector brush constitute an included angle therebetween and an included angle b constituted by the yoke plate and the collector brush therebetween both range from 10 DEG to 30 DEG. According to the invention, the guide rail current collector has the characteristics of simple structure, wear resistance, long service life and deformation resistance.

Owner:XINXING DUCTILE IRON PIPES CO LTD

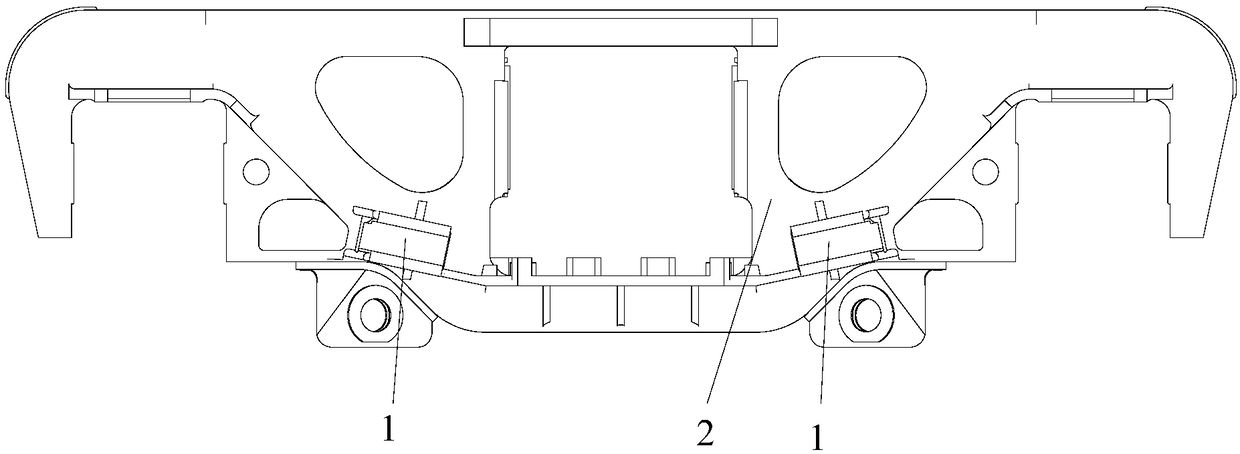

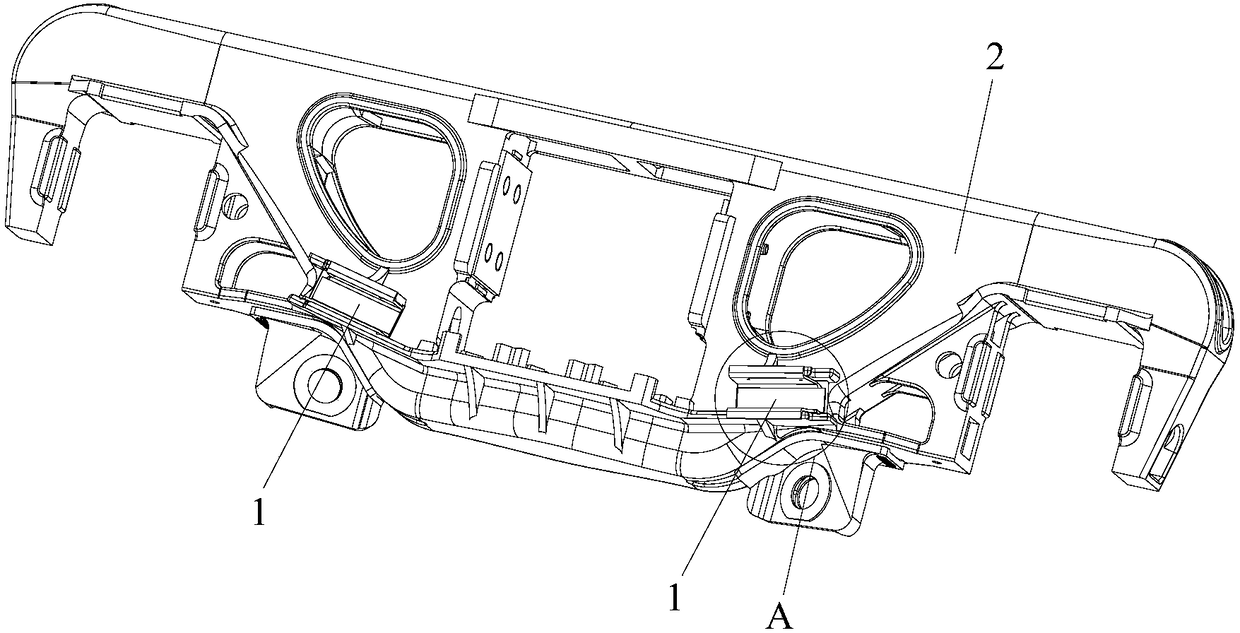

Wear plate and bogie with same

ActiveCN106114544BLimit lateral movementReduce wearBrake wear compensation mechanismBogiesBogieEngineering

The invention provides a wearing plate and a bogie with the wearing plate. The wearing plate comprises a wearing plate body and a limiting part. The wearing plate body comprises a first side board, a second side board and a bottom board connected between the first side board and the second side board, wherein the first side board and the second side board are oppositely arranged. An installation hole is formed in the bottom board. An installation space used for installing a wearing block is formed among the first side board, the second side board and the bottom board. The first end, in the length direction of the bottom board, of the limiting part is connected to the inner wall of the installation hole. The second end of the limiting part is a free end. The free end extends into the installation space to reduce the gap between the wearing block and the bottom board. By the adoption of the technical scheme, the problem that a braking device is likely to move transversely, and consequently wheels are worn unevenly in the prior art is effectively solved.

Owner:CRRC QIQIHAR ROLLING CO LTD

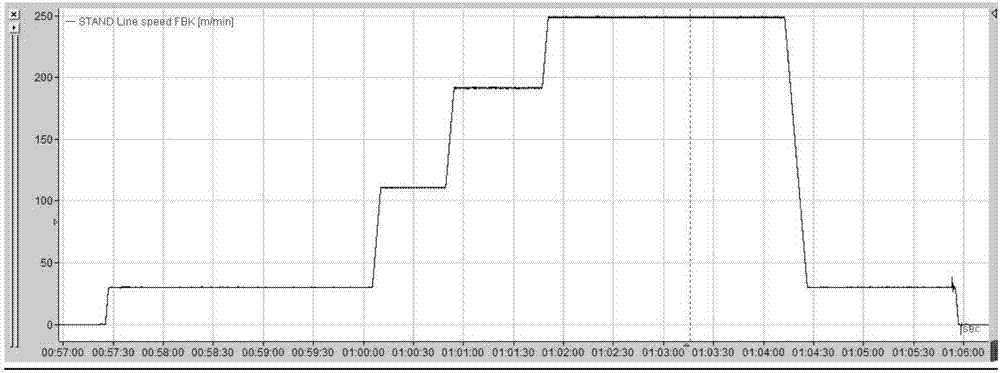

Method for levelling checkered plate through hot-rolling levelling unit

ActiveCN107413851AReduce uneven wearEasy to shapeMetal rolling arrangementsHydraulic cylinderControl system

The invention relates to a method for levelling a checkered plate through a hot-rolling levelling unit, and belongs to the technical field of hot-rolling levelling units. According to the technical scheme of the method for levelling the checkered plate through the hot-rolling levelling unit, the mechanical aspect relates to model selection of a leveling machine HGC hydraulic cylinder and model selection of rolling line adjusting device; the electrical aspect comprises optimization of transmission control system speed slope parameters, optimization of a HGC screwdown control system PI adjuster and a proportionality coefficient and filtering treatment in pressure sensor feedback value; and an original single sine negative convexity or multi-power negative convexity roll shape of a working roll is changed, and an experience curve is used. The method for levelling the checkered plate through the hot-rolling levelling unit has the beneficial effects that the problem of levelling the checkered plate through the hot-rolling levelling unit is solved, meanwhile, the production efficiency is also improved obviously, the levelled checkered plate product quality accords with a technical index requirement, and good economic benefits are created for an enterprise.

Owner:HEBEI IRON AND STEEL

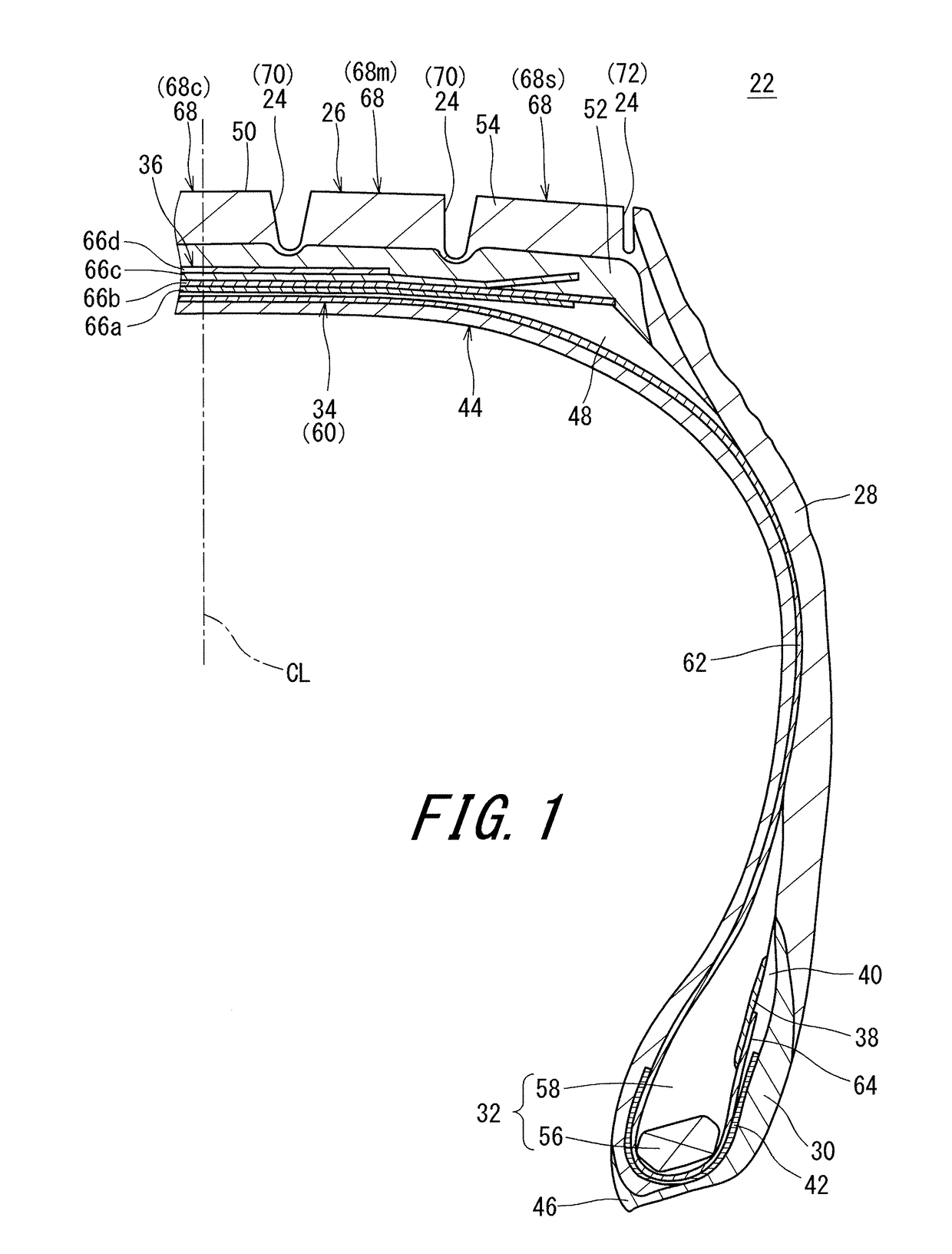

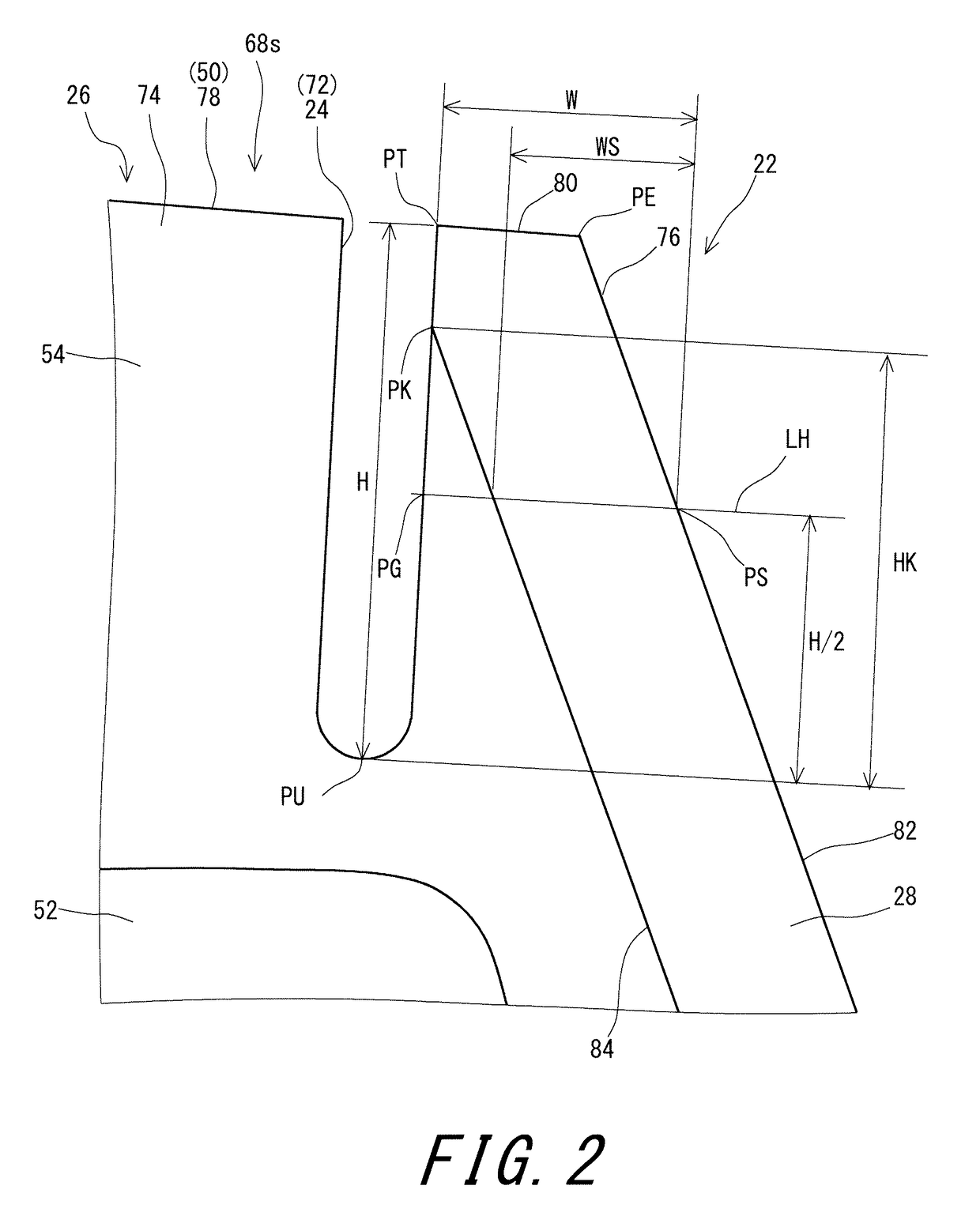

Pneumatic tire

ActiveUS20170341470A1Reduce uneven wearIncreased durabilityHeavy duty tyresHeavy duty vehicleMechanical engineeringTread

A tire 22 includes a plurality of ribs 68 aligned in an axial direction. A rib 68s, among the plurality of ribs 68, disposed on an outer side in the axial direction is sectioned into a body portion 74 and a side portion 76 by a groove 72 that extends in a circumferential direction. The tire 22 includes a tread 26 and a pair of sidewalls 28. The sidewalls 28 extend almost inward from ends, respectively, of the tread 26 in a radial direction. The tread 26 includes a base layer 52, and a cap layer 54 disposed outward of the base layer 52 in the radial direction. The side portion 76 is formed by the cap layer 54 and a corresponding one of the sidewalls 28. The sidewall 28 is stacked on the cap layer 54 in the side portion 76.

Owner:SUMITOMO RUBBER IND LTD

A roll pass optimization method that can improve the service life of section steel rolls

ActiveCN103878181BChange state of wearReduce uneven wearMeasuring devicesRollsEngineeringProcess conditions

The invention discloses a roll pass optimizing method capable prolonging shaped roll service life. The method is characterized by including the steps of firstly, building a mathematic model to calculate the rolling state of a rolled piece under a target rolling process; secondly, predicting roll abrasion condition under current production process conditions, evaluating roll abrasion state, and converting roll abrasion quantity into roll repairing quantity; thirdly, optimizing roll passes and the rolling process by evaluating roll cutting quantity. By the method, roll abrasion state is effectively changed during profile rolling, roll uneven abrasion is reduced, cutting nonuniformity during roll repairing is improved, turning quantity required by each roll pass recovery is reduced by 3-10mm, roll turning times are increased by 1-2, and the service life of shaped rolls is prolonged.

Owner:ANGANG STEEL CO LTD

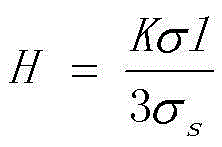

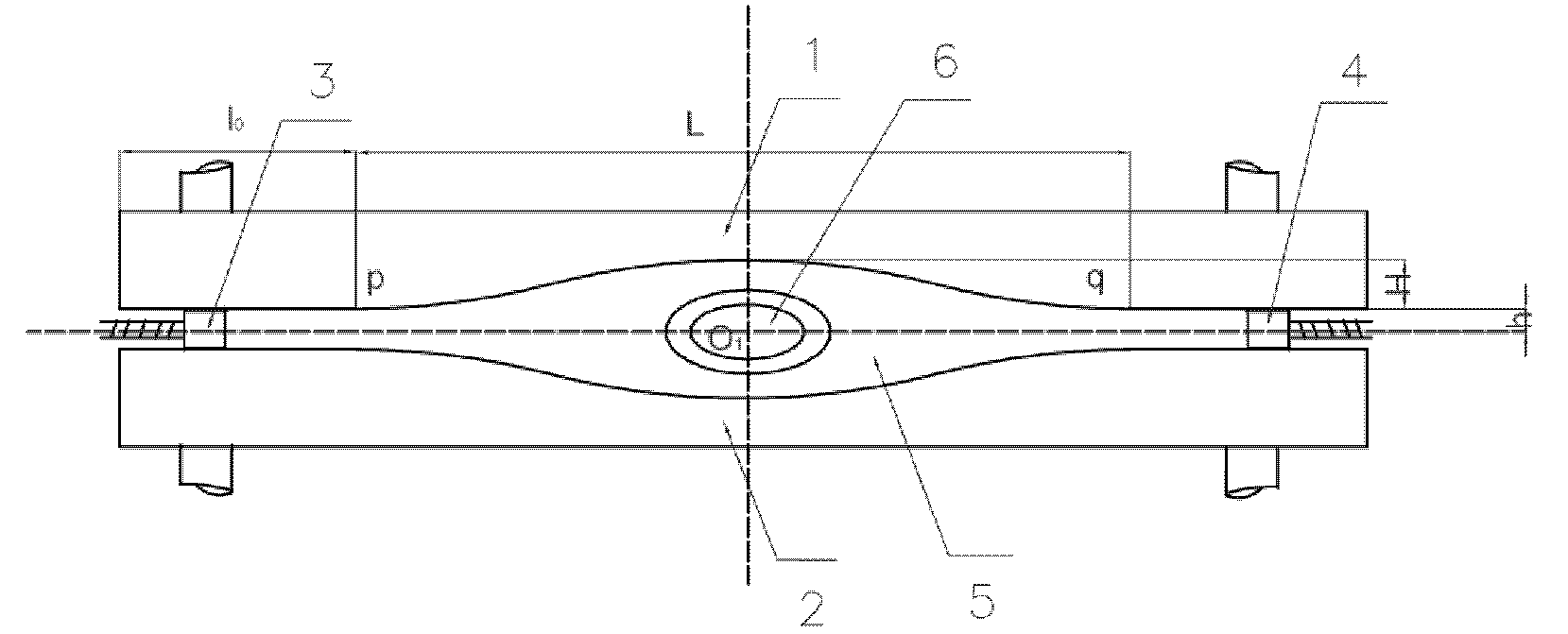

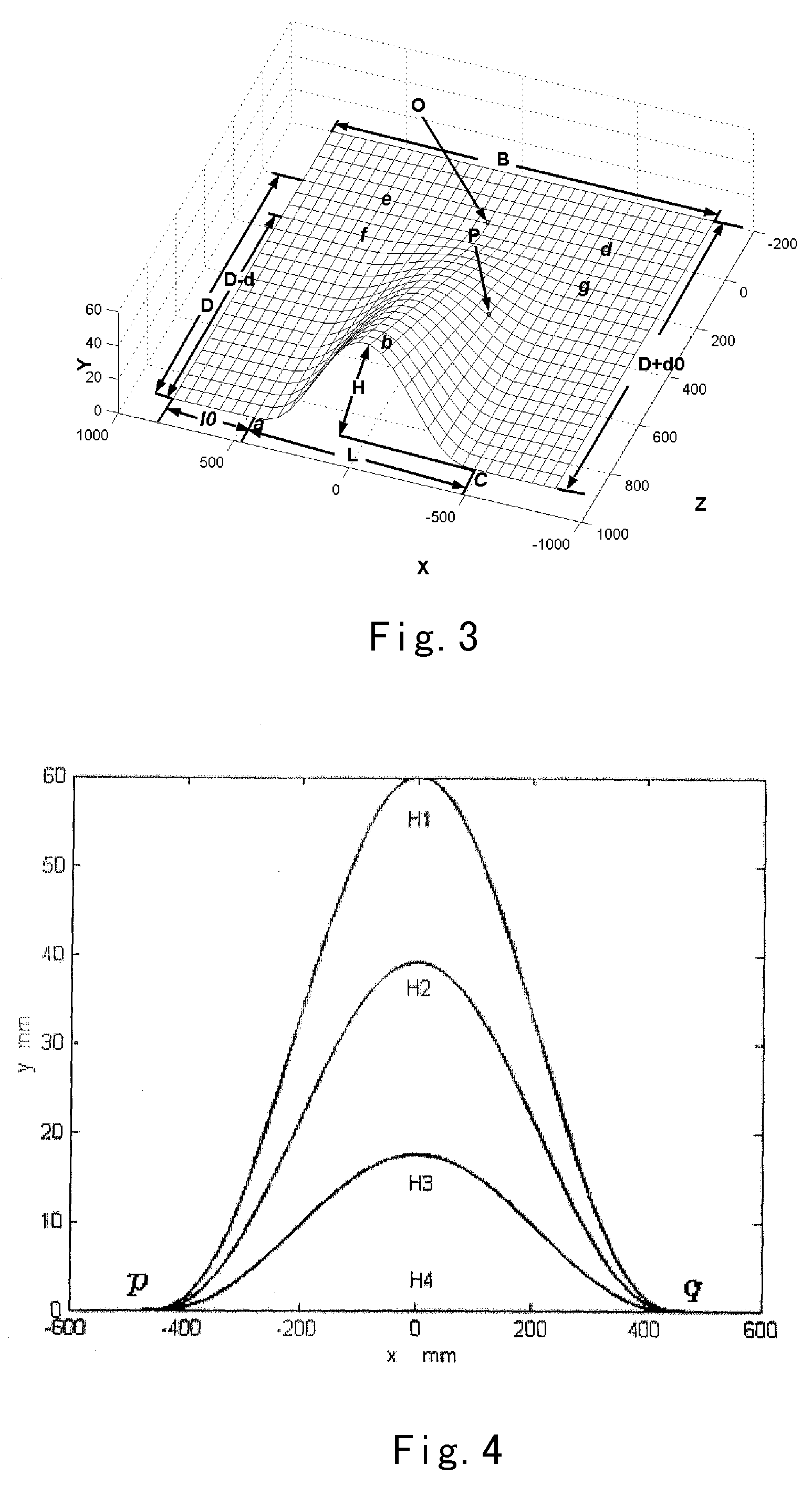

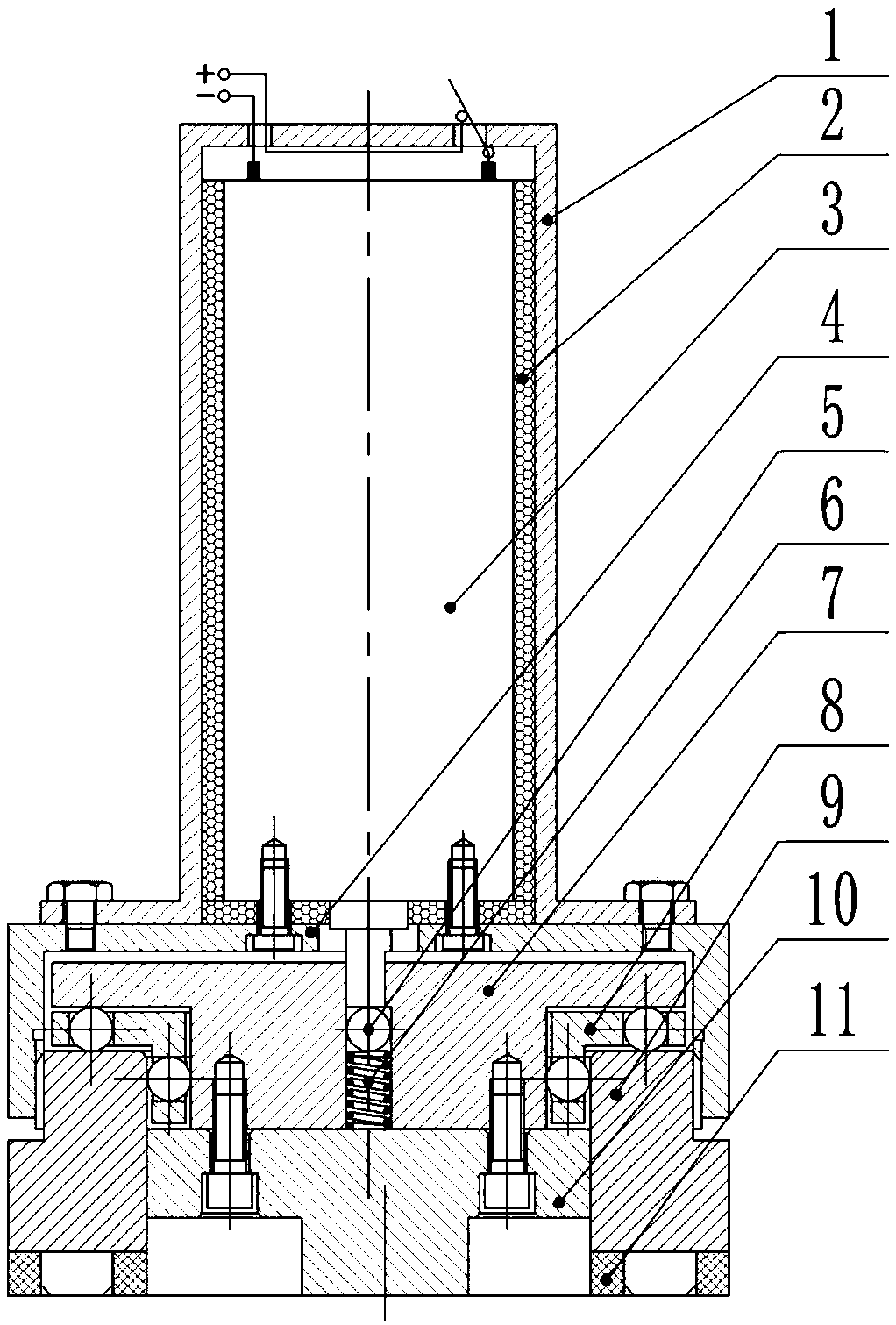

Water-cooling mold for metal continuous casting

A water-cooled mold for continuous casting includes two water-cooled wide copper plates arranged opposite to each other in a front and back direction and two water-cooled narrow copper plates arranged opposite to each other in a left and right direction. The upper portion of the cavity of the mold is a sprue area and the lower portion of the cavity is a mold cavity area. The sprue area is gradually narrowed in the casting direction and smoothly transited into the mold cavity, corresponding to the shape of a slab to be cast. The inside surfaces of the water-cooled narrow copper plates are smooth planar surfaces. A portion of the inside surface of the water-cooled wide copper plates in the sprue area is a curved surface and another portion in the mold cavity area is a planar surface. The curved surface and the planar surface portions form a continuous smooth surface.

Owner:BAOSHAN IRON & STEEL CO LTD

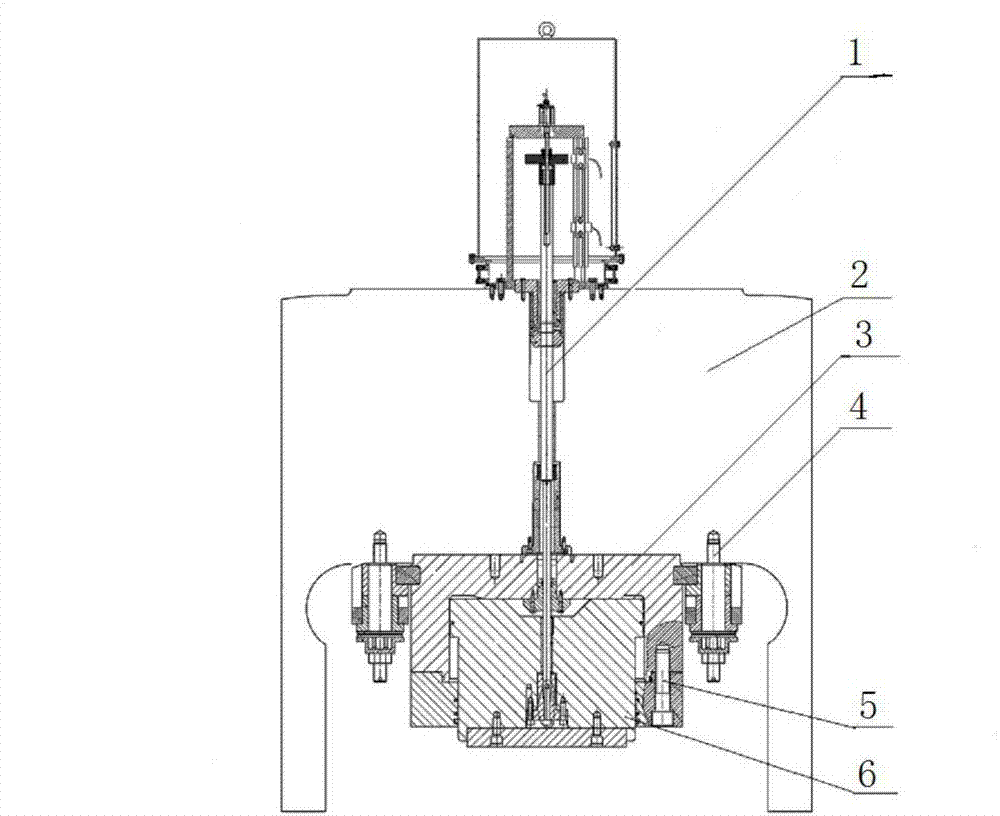

A precision grinding device and parameter determination method for plane local high point removal

ActiveCN107150286BImprove grinding precisionMeet grinding needsLapping machinesBall bearingSteel ball

The invention belongs to the technical field of precise machining and relates to a precise grinding device for the local plane high areas and a parameter determining method. The device comprises a motor shell, a damping washer, a motor, a connecting block, a transmission block, a dense ball bearing, a reference block, an eccentric grinding block, a wool felt seal ring, a precise steel ball and a pressure spring. According to the precise plane grinding device provided by the invention, the flat area around the high points on the surface of a workpiece is used as the reference, and the high points are removed through the grinding process. In the grinding device, the eccentric grinding block is used as a grinding head, non-uniform abrasion of the grinding block is reduced, and the precision of the working surface of the grinding block is improved; a bearing structure composed of a T-shaped dense ball shaft sleeve is adopted, and through the high-precision rotation and the axial limiting function of the eccentric grinding block, excessive grinding of the high point areas is prevented; and the device has the advantages of being simple in structure, convenient to operate and high in grinding accuracy and has the advantage that the eccentric grinding block can be replaced, and the device can meet the requirement for ultra-high precision plane grinding and is good in market application prospect and popularization value.

Owner:金齿传动科技(大连)有限公司

Fixing member, fixing device, and image forming apparatus

InactiveUS9377734B2Reduce uneven wearIncreased durabilityElectrographic process apparatusCross-linkFluoropolymer

Owner:RICOH KK

Flash-butt welding method for rail steel

InactiveCN102665994BSteep heat distributionExtend the exchange cycleRailsWelding electric supplyElectrical resistance and conductanceButt welding

Owner:NIPPON STEEL CORP

A kind of Zr-2.5nb alloy bar and extrusion processing method thereof

ActiveCN109692880BImprove corrosion resistanceGood biocompatibilityExtrusion control devicesZirconium alloyExtrusion

Owner:西部超导材料科技股份有限公司

A method for detection of tooth wear difference of high-speed milling cutter under vibration

ActiveCN105619180BWear discrepancies revealedImprove reliabilityMeasurement/indication equipmentsMetal working apparatusTooth wearMilling cutter

The invention discloses a method for detecting the abrasion difference of cutter teeth of high-speed milling cutters under the action of vibration. The method is technically characterized by comprising the steps that firstly, the cutter tooth cutting motion speed and cutter skill contact relation under the action of vibration is built; secondly, a rear angle calculating equation under the action of vibration is calculated; thirdly, a cutter tooth friction contact point position calculating model and a cutter tooth friction contact point friction speed calculating model are constructed; fourthly, cutter tooth friction contact point positions and the cutter tooth friction contact point friction speed are analyzed, and the change rules of the cutter tooth friction contact point positions and the cutter tooth friction contact point friction speed are obtained; fifthly, an abrasion cutting test of the high-speed milling cutters is carried out; sixthly, cutting vibration signals are extracted and processed; seventhly, milling cutter abrasion cutting test data obtained in the fifth step is extracted; eighthly, the test results of the cutter tooth rear cutter face friction contact point positions and the friction contact point friction speed are obtained; and ninthly, a cutter tooth rear cutter face friction contact state model is verified. According to the method, bases are provided for relieving uneven abrasion and weakening fluctuating load excitation, and initial sample cutters are provided for efficient and high-precision cutting.

Owner:HARBIN UNIV OF SCI & TECH

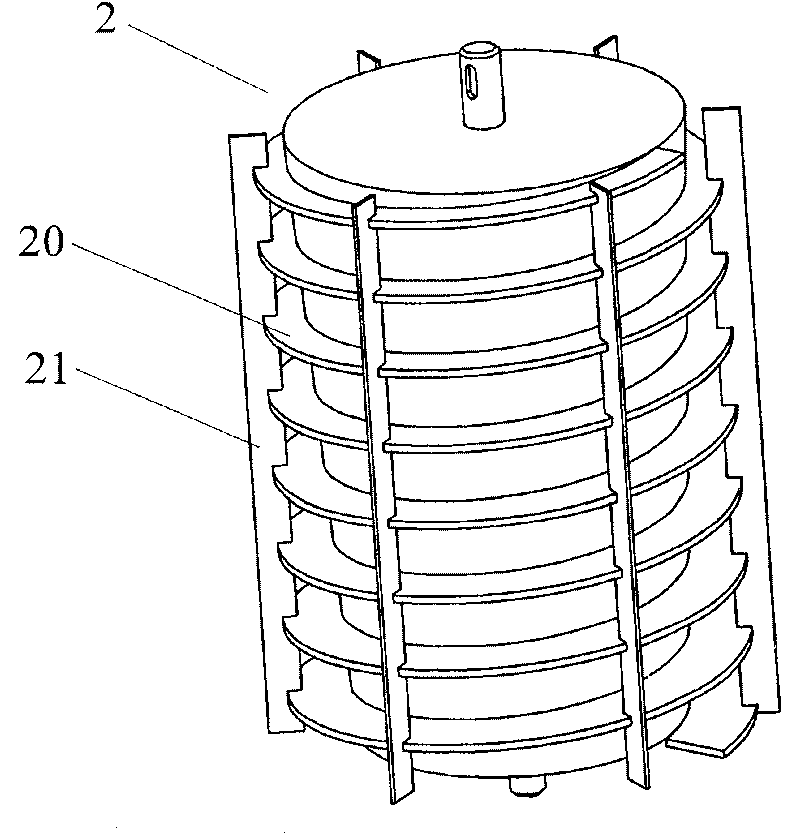

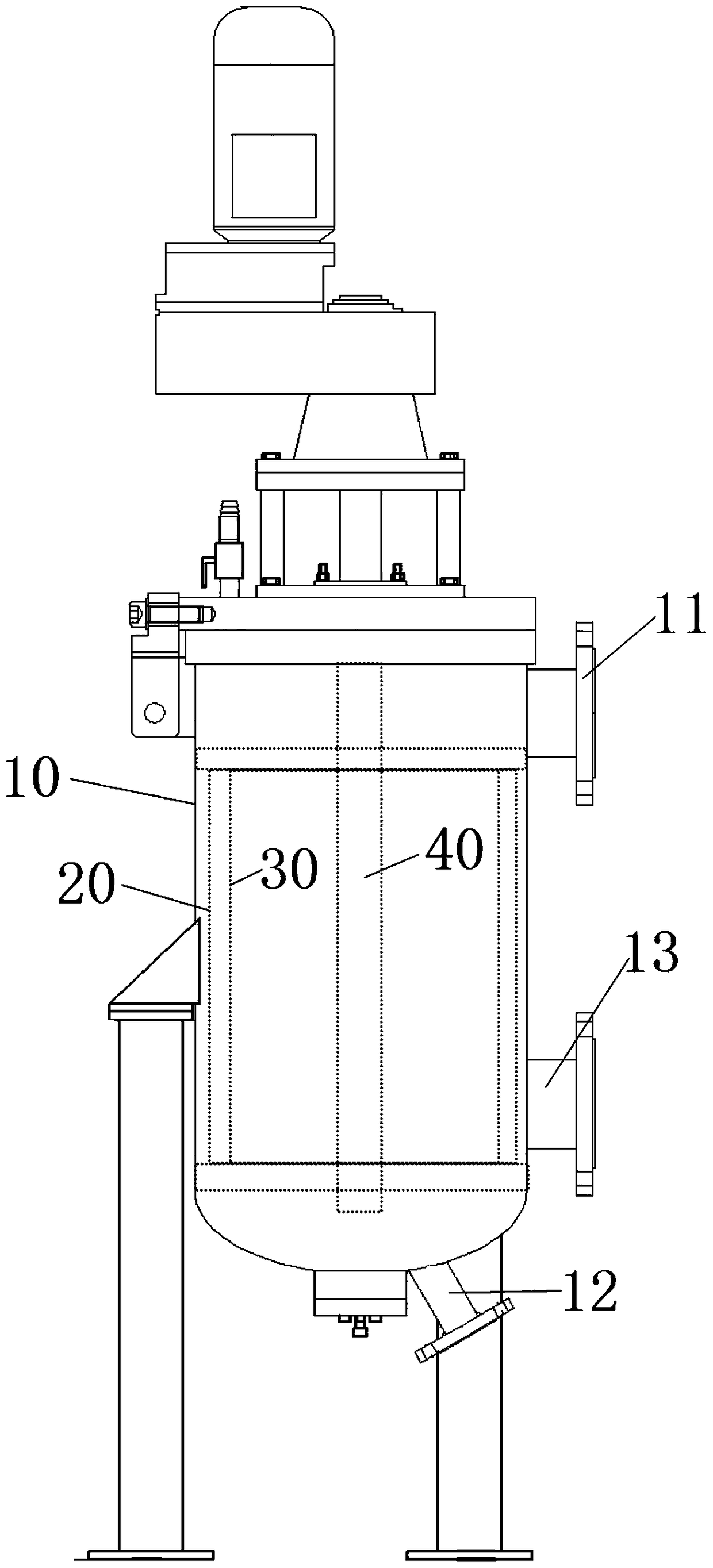

Coatings pressure screen

ActiveCN101417191BAvoid cloggingClose contactPrinting press partsMoving filtering element filtersFiltrationMechanical engineering

The invention discloses a coating pressure sieve, comprising a sieve body which is a hollow structure; a hollow cavity is internally provided with a sieve drum which can rotate around a central shaft;the sieve drum is arranged on the sieve body by the central shaft; a driver is arranged outside the sieve body; the output end of the driver is connected with the sieve drum; the surface of the sievedrum is provided with a spiral guide plate, the external side of which is provided with a scraper; a sieve net is arranged outside the sieve drum; the clearance between the sieve net and the sieve drum forms an internal sieve chamber; and the scraper is arranged inside the internal sieve chamber and closely contacts with the surface of the sieve net. The coating pressure sieve adopts an active type to carry out filtration operation, uses the self-power to drive the sieve drum to rotate, uses the spiral guide plate and the scraper on the sieve drum for effectively scraping and removing the grains attached to the sieve net, so as to prevent the sieve net from being blocked and to generate a downward pushing force simultaneously, thus being beneficial for the coating to flow out of the sievequickly after filtration; full sealing typed pressure sieving is adopted in the whole process, thus avoiding the coating from drying or generating air bubbles after the coating thinner is evaporated;and the coating pressure sieve is convenient for use and can effectively improve the coating quality and coating efficiency.

Owner:JIANGMEN OCEAN POWER DIGITAL MOTOR

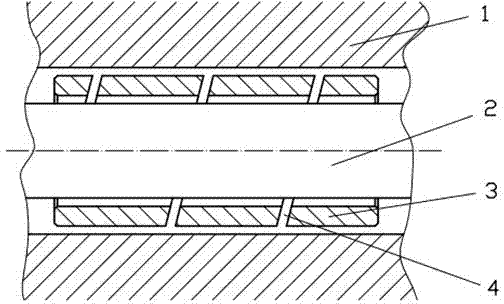

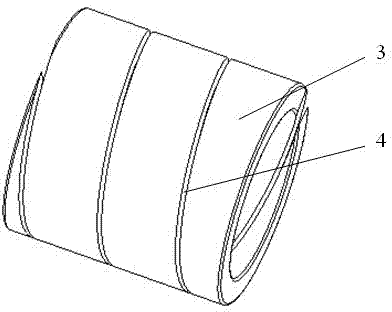

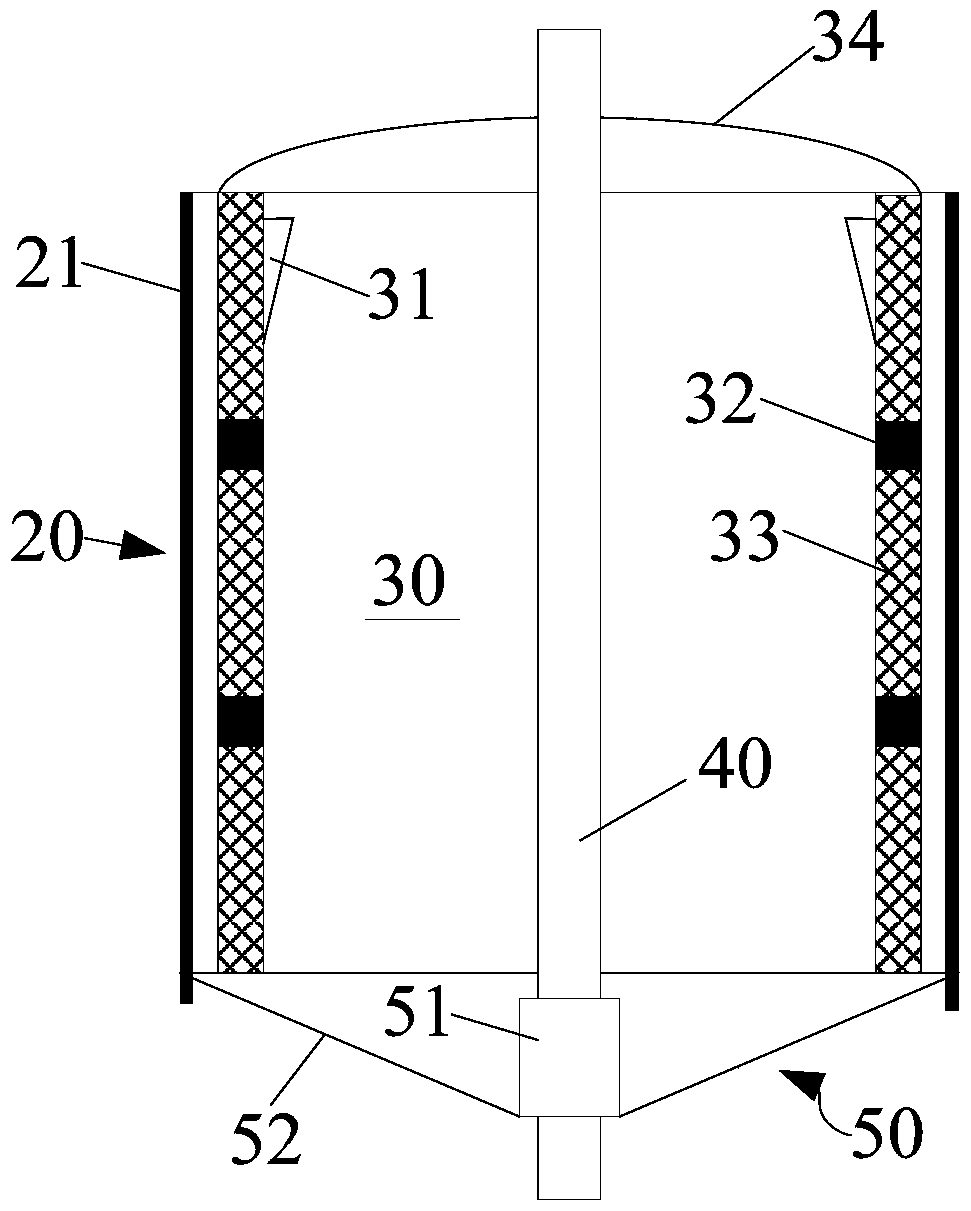

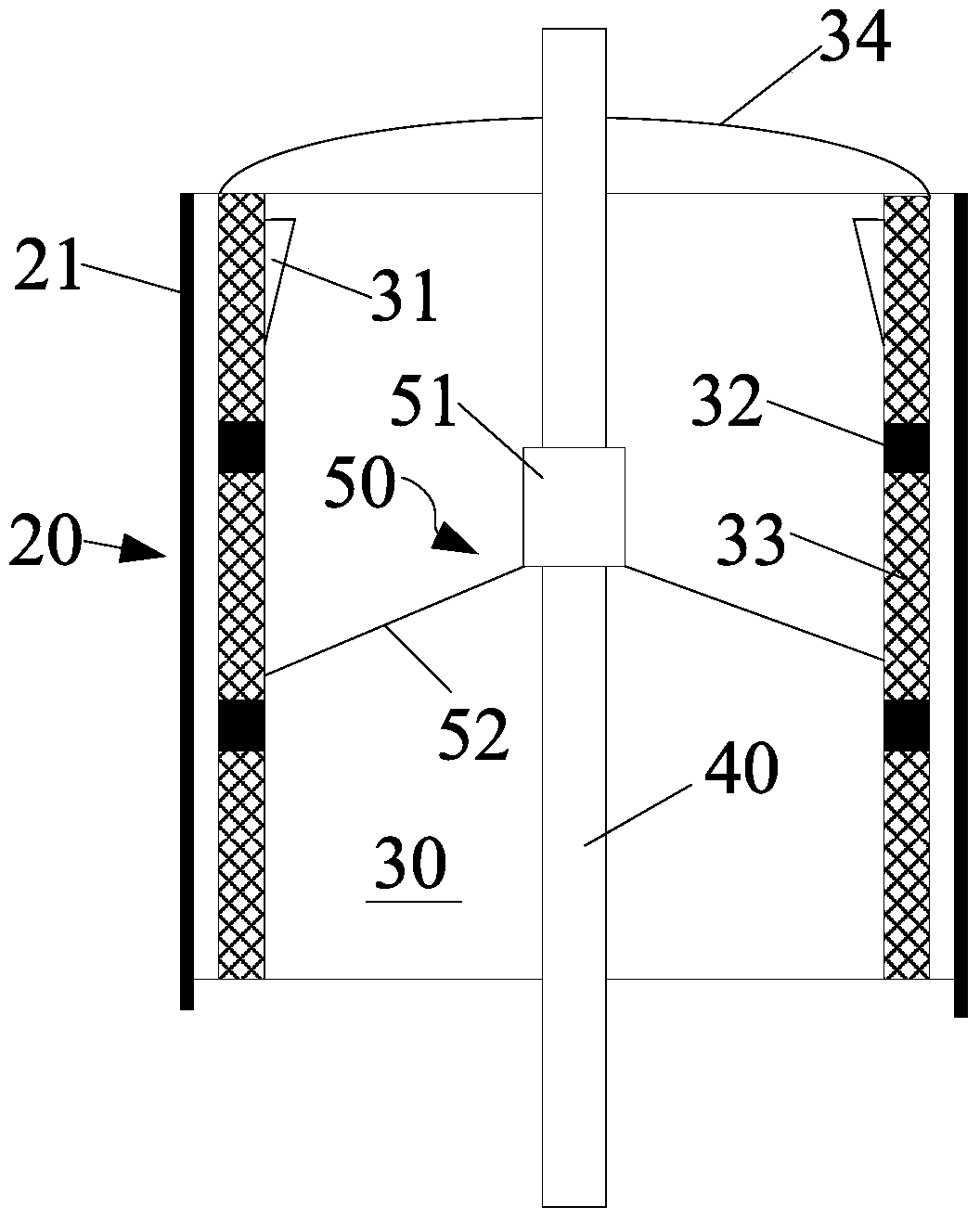

Sliding bearing of spiral floating bushing

ActiveCN102032267BReduce or eliminate uneven wearUniform wearBearing componentsSliding contact bearingsEngineeringLoad distribution

The invention discloses a sliding bearing of a spiral floating bushing, comprising a bearing outer ring (1), a shaft neck (2) and a floating bushing (3), wherein the floating bushing (3) is mounted between the shaft neck (2) and the bearing outer ring (1) and provided with a spiral groove (4) which is through along the radial direction. The invention can ensure that the shaft neck, a shaft hole and the floating bushing of the bearing are loaded more uniformly and worn almost at the same time to reduce uneven abrasion, can improve the floating capability of the floating bushing and the lubricating condition of the bearing, improve the load distribution of the bearing and prolong the service life of the bearing.

Owner:SOUTHWEST PETROLEUM UNIV

Temperature-controllable self-positioning bar hot rolling transportation roller way

PendingCN113145657AAvoid touchingReduce uneven wearGuiding/positioning/aligning arrangementsWork treatment devicesThermodynamicsEngineering

The invention relates to the field of metal pressure machining, in particular to a temperature-controllable self-positioning bar hot rolling transportation roller way. The temperature-controllable self-positioning bar hot rolling transportation roller way comprises a water inlet pipe, a water inlet tank, a water tank sealing ring, a fixed end bearing seat, a V-shaped roller way, a water outlet tank, a water drainage pipe, a transmission end bearing seat, a cooling pipeline, water drainage holes and a base, wherein the water inlet tank and the fixed end bearing seat are installed at the non-transmission end of the roller way and fixed to the base, the water inlet pipe is installed on the water inlet tank, and the water inlet tank and the roller way end are assembled in a sealed mode; and the roller way surface is sunken. The water outlet tank and the transmission end bearing seat are installed at the roller way transmission end and fixed to the base, the water drainage pipe is installed on the water outlet tank, the water drainage holes are formed in the roller way transmission end, and are sealed in the water outlet tank; and due to the fact that the inclination angle exists in the roller way surface, bars are automatically centered to a center area of the roller way surface in the conveying process, the bars are prevented from touching the two sides of the roller way, and uneven abrasion to the roller way surface is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

A dope pressure screen for tissue paper production

ActiveCN105688482BAvoid cloggingFor quick outflowFiltration circuitsStationary filtering element filtersTissue paperHelix

The invention relates to a coating pressure sieve for producing tissue paper. The coating pressure sieve comprises a cylindrical sieve mesh and a sieve drum, wherein the sieve drum and the sieve mesh are coaxially installed by a main shaft; the sieve drum comprises a top surface and a peripheral surface; a plurality of conical surfaces are arranged on the top surface; the peripheral surface is provided with a spiral guiding plate and a scraper arranged along the axis; the scraper is connected with the peripheral surface of the sieve drum by an elastic hinge; and the inner side surface of the sieve mesh is provided with a plurality of ribs which extend along the axis direction. The coating pressure sieve for producing the tissue paper adopts an active mode for filtering; the driver and the sieve drum capable of rotating with the driver are arranged, the spiral guiding plate is arranged on the sieve drum, the scraper is arranged at the outer side of the guiding plate, and in rotation, coating particles without passing through the sieve mesh can be scraped off by the scraper on the sieve drum, so that the particles can be effectively prevented from adhering or accumulating on the surface of the sieve mesh 20 and further blocking the sieve mesh, and the coating quality and the coating efficiency can be effectively improved.

Owner:FOSHAN GAOMING HONGYUAN PAPER IND CO LTD

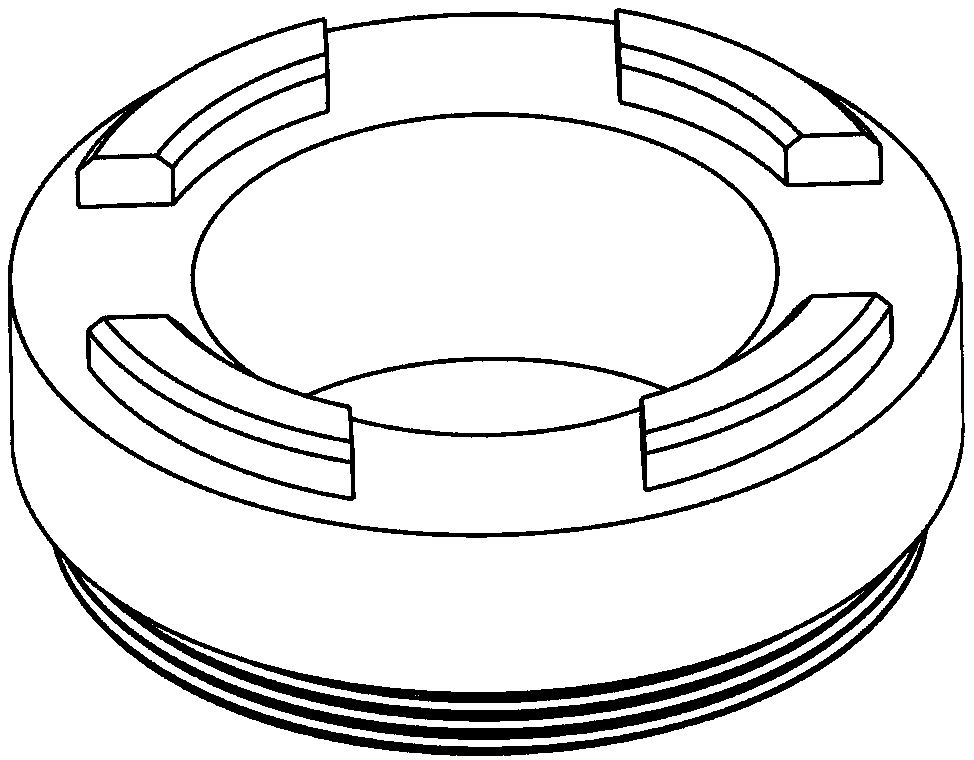

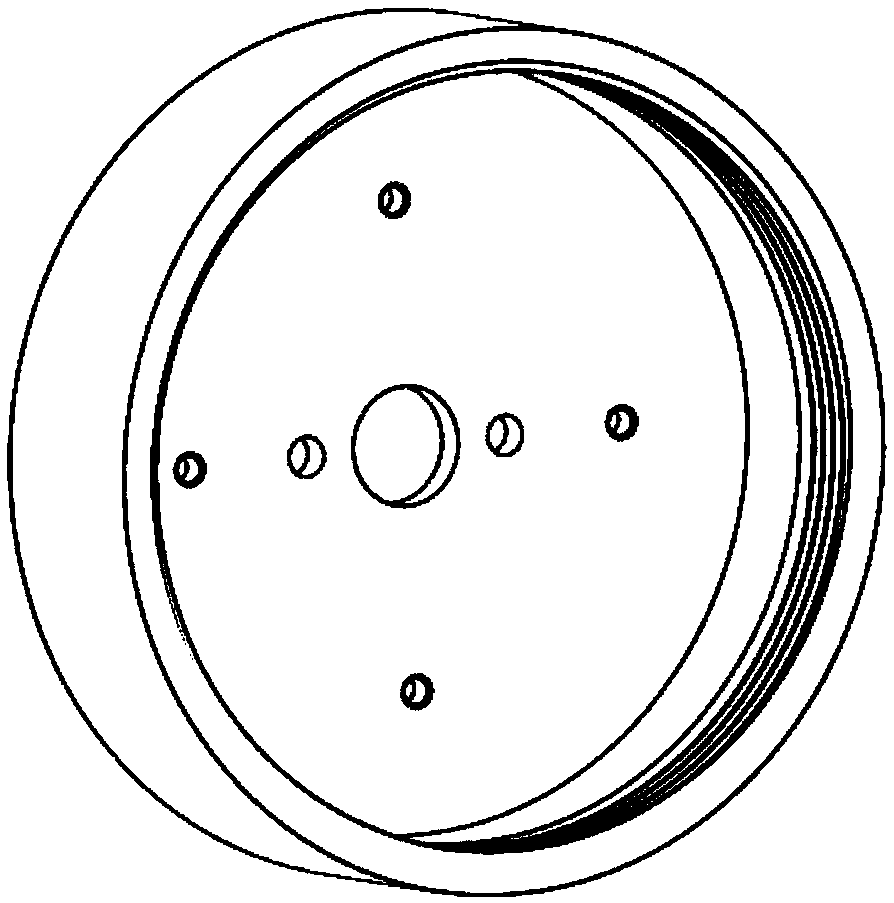

Machining electrode for annular holes and machining method

InactiveCN102069241BReduce uneven wearLow costElectrical-based machining electrodesEngineeringCopper

Owner:XIAN AERO ENGINE CONTROLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com