Zr-Nb alloy bar material and extruding and processing method thereof

A technology of alloy bar and extrusion processing, which is applied in the field of zirconium alloy processing, can solve the problems of easy flow of metal, difficult grain size of structure to meet the requirement of refinement degree, uneven structure, etc., to achieve uniform structure and reduce uneven wear , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The invention provides a method for extrusion processing of Zr-Nb alloy rods, comprising the following steps:

[0027] (1) pretreatment, wrapping lubricating film outside the Zr-2.5Nb blank without surface defects, to obtain the Zr-2.5Nb blank after pretreatment;

[0028] (2) heating, the Zr-2.5Nb billet after pretreatment is heated to extruding temperature and insulation;

[0029] (3) Extruding, extruding the heated Zr-2.5Nb billet according to a preset extrusion ratio to obtain Zr-2.5Nb alloy rods of target specifications.

[0030] Further, the lubricating film in the step 1 is a copper film or a low carbon steel film.

[0031] Further, the thickness of the lubricating film in the step 1 is 0.5mm-2mm.

[0032] Further, the extrusion temperature in the step 2 is 600°C-750°C.

[0033] Further, the heat preservation time in the step 2 is 60min-180min.

[0034] Further, the preset extrusion ratio in step 3 is 6-15, and the extrusion ratio is the ratio of the cross-sec...

Embodiment 2

[0040] The present invention also provides a method for extrusion processing of Zr-Nb alloy rods, comprising the following steps:

[0041] (1) Select a Φ175mm Zr-2.5Nb billet, and wrap a lubricating film with a thickness of 0.5 to 2 mm on the outside of the billet with a low-carbon steel coil;

[0042] (2) Heating the pretreated Zr-2.5Nb billet obtained in step 1 to 680°C and keeping it warm for 180min;

[0043] (3) Extrude the Zr-2.5Nb billet heated in step 2 with an extrusion ratio of 6 to obtain a Zr-2.5Nb alloy rod with a target specification of Φ70 mm.

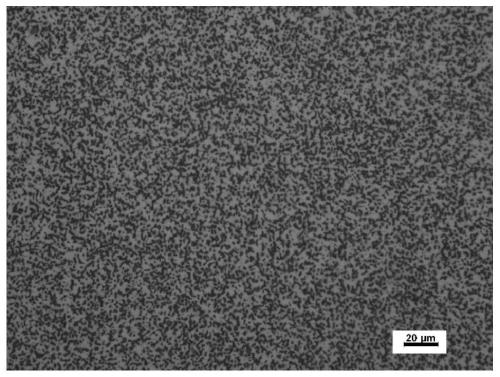

[0044] In Example 2, Zr-2.5Nb alloy rods with a size of Φ70mm were obtained by first-fire extrusion at a heating temperature of 680°C and an extrusion ratio of 6. The structure is fine and uniform, see figure 1 and figure 2 , the grain size rating of the obtained Zr-2.5Nb alloy rod is 12 grades.

Embodiment 3

[0046] The present invention also provides a method for extrusion processing of Zr-Nb alloy rods, comprising the following steps:

[0047] (1) Select a Φ165mmZr-2.5Nb billet, and use a low-carbon steel coil to wrap a 0.5-2mm thick lubricating film on the outside of the billet;

[0048] (2) Heating the pretreated Zr-2.5Nb billet obtained in step 1 to 600°C and keeping it warm for 120min;

[0049] (3) Extrude the Zr-2.5Nb billet heated in step 2 with an extrusion ratio of 10 to obtain a Zr-2.5Nb alloy rod with a target specification of Φ50 mm.

[0050] Example 3 The Φ50mm Zr-2.5Nb alloy rod obtained by first-fire extrusion at a heating temperature of 600°C and an extrusion ratio of 10 has a fine and uniform structure, see image 3 and Figure 4 , the grain size rating of the obtained Zr-2.5Nb alloy rod is 13 grades.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com