A roll pass optimization method that can improve the service life of section steel rolls

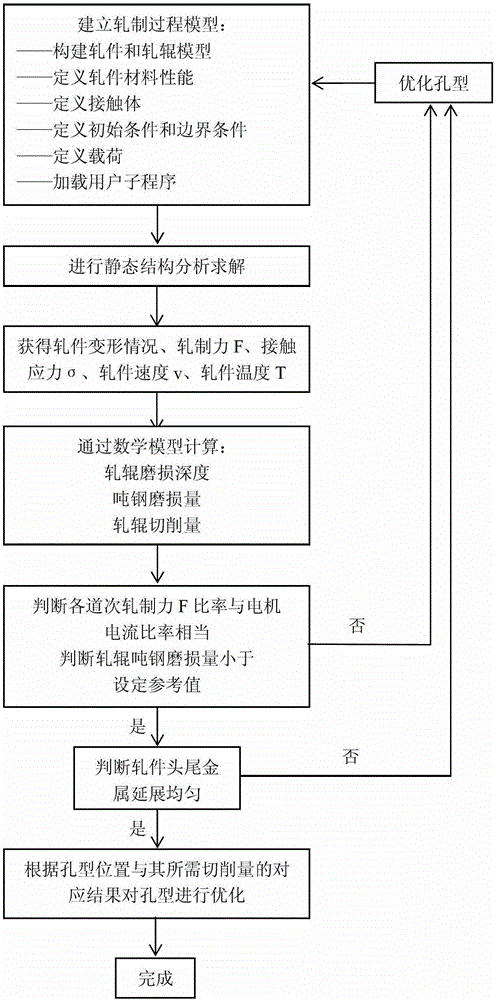

A technology of pass optimization and rolling, applied in the direction of rolling, metal rolling, metal rolling, etc., to reduce uneven wear, improve wear state, and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 160

[0044] Example 1 Take the optimization of the roll pass of a 60kg / mU75V rail roughing mill as an example

[0045] (1) Model and calculate the rolling process under the target rolling process

[0046] First, the rolling process prediction model is established, and the cross-sectional size of the billet of the 60kg / m rail rolling stock is 230mm×230mm, and the three-dimensional model of the rolling stock is established. Initial pass and roll model establishment; then input the rolling material U75V performance parameters (specific heat, thermal conductivity, stress-strain curve, elastic modulus, Poisson's ratio, thermal expansion coefficient, density), contact friction coefficient between the roll and the rolling piece 0.4 and the contact heat transfer coefficient 6, define the thermal work conversion coefficient as 0.9. The deformation, rolling force F, contact stress and temperature change of the rolled piece were obtained by using the finite element method.

[0047] (2) Pred...

Embodiment 275

[0090] Embodiment 2 Take the optimization of roll pass of 75kg / mU71Mn rail roughing mill as an example

[0091] (1) Model and calculate the rolling process under the target rolling process

[0092] Firstly, the rolling process prediction model is established, and the cross-sectional size of the 75kg / m rail rolling stock is 230mm×230mm, and the three-dimensional model of the rolling stock is established. The 75kg / mU71Mn rail roughing mill adopts the five-pass rolling method, and the roll specification and Initial pass and roll model establishment; then input the performance parameters of rolling material U71Mn (specific heat, thermal conductivity, stress-strain curve, modulus of elasticity, Poisson’s ratio, thermal expansion coefficient, density), contact friction coefficient between roll and rolling piece 0.43 and a contact heat transfer coefficient of 6, define the thermal work conversion coefficient as 0.9. The deformation, rolling force F, contact stress and temperature ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com