Coatings pressure screen

A pressure sieve and paint technology, applied in the field of filter sieves, can solve the problems affecting the coating quality and effect, affecting production efficiency, and prone to air bubbles, etc., to improve coating quality and coating efficiency, reduce uneven wear, Easy to use and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

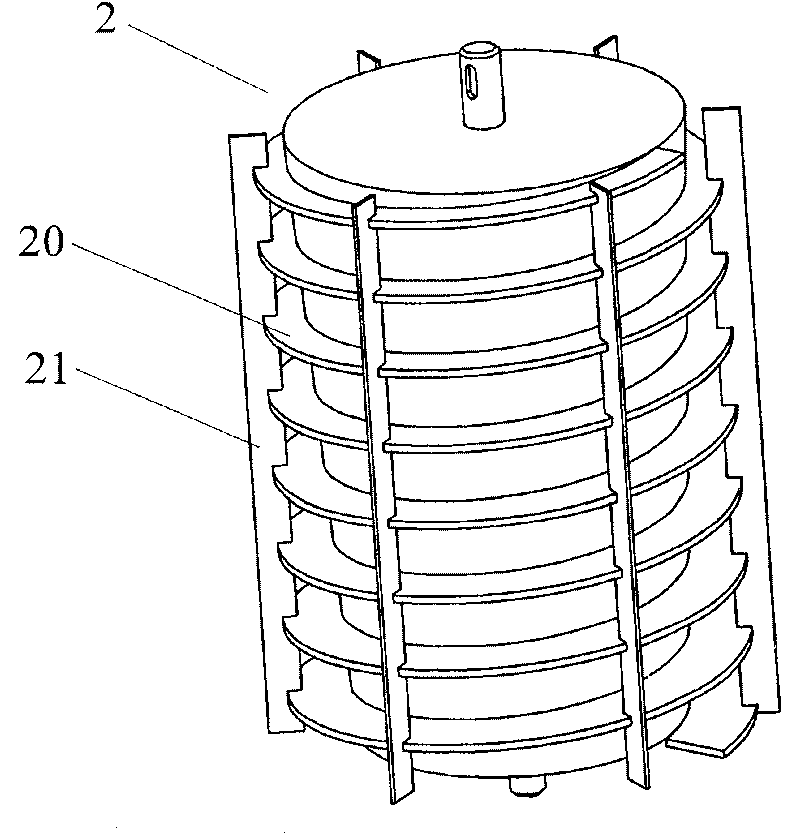

[0013] refer to figure 1 , a coating pressure screen of the present invention, comprising a screen body 1, the screen body 1 is a hollow structure, a screen drum 2 capable of rotating around a central axis is installed in the cavity, and the screen drum 2 is installed on the screen body 1 through the central shaft, A driver 4 is installed outside the screen body 1, and the output end of the driver 4 is connected to the screen drum 2. The surface of the screen drum 2 is provided with a spiral guide plate 20, and a scraper 21 is installed on the outside of the guide plate 20, and a screen mesh 3 is installed outside the screen drum 2. The gap between the screen 3 and the screen drum 2 forms an inner sieve chamber 22 , and the scraper 21 is arranged in the inner sieve chamber 22 and is in close contact with the surface of the screen 3 .

[0014] Taking the paint coating process as an example, when working, the prepared paint is sent from the input pipe 11 to the inside of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com