Method for levelling checkered plate through hot-rolling levelling unit

A patterned plate and tempering machine technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of affecting enterprise benefits, the quality of plate shape cannot reach users, and there are many quality objections, and achieve good results. The effect of reducing uneven wear and accelerating the process smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

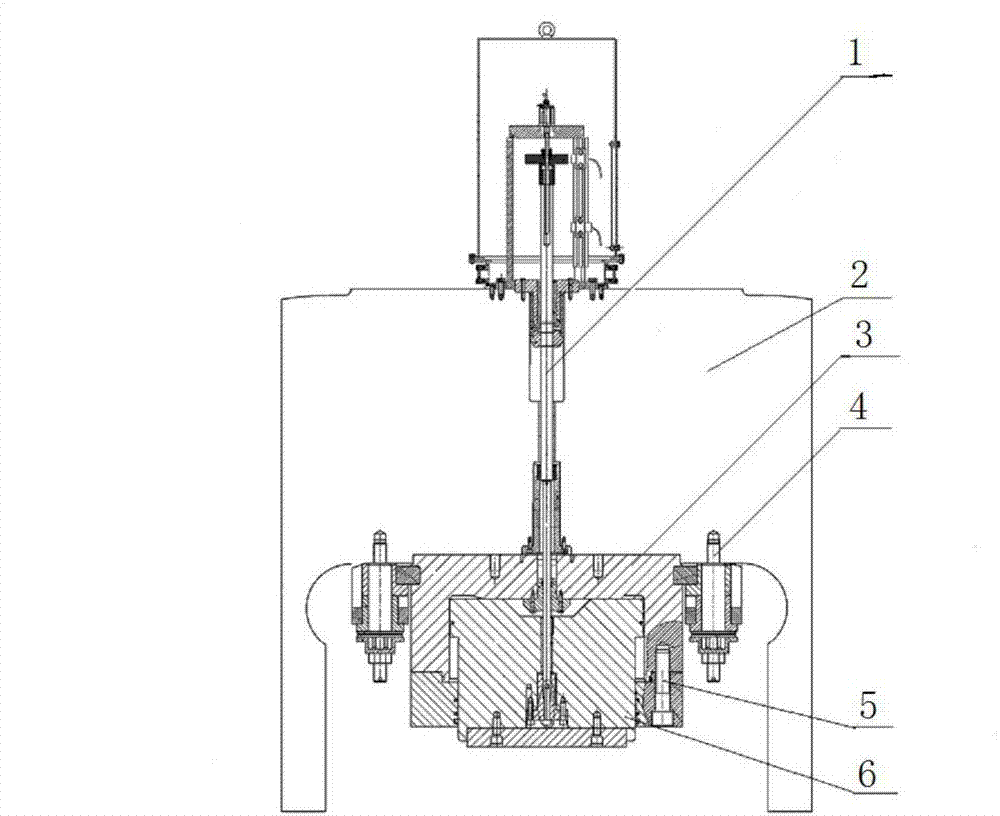

[0035] (1) The HGC hydraulic cylinder of the tempering machine is the core device for leveling the checkered plate, so it is very important to control the technical indicators of the HGC hydraulic cylinder body. The surface roughness of the inner diameter of the cylinder and the outer diameter of the piston needs to reach Ra0.4μm. The cylinder body and the piston need to be plated with hard chrome. The thickness of the coating is 0.08-0.1mm. ~0.05mm, after grinding, the surface roughness of the inner surface of the cylinder and the outer surface of the piston can reach the mirror precision of Ra0.2μm or more, this precision can greatly reduce the friction coefficient between the guide belt and the seal and the cylinder, prolong the service life of the seal, reduce Leakage, reduce start-up pressure, improve frequency response time, reduce same-plate difference and different-plate difference, and improve checker plate leveling accuracy.

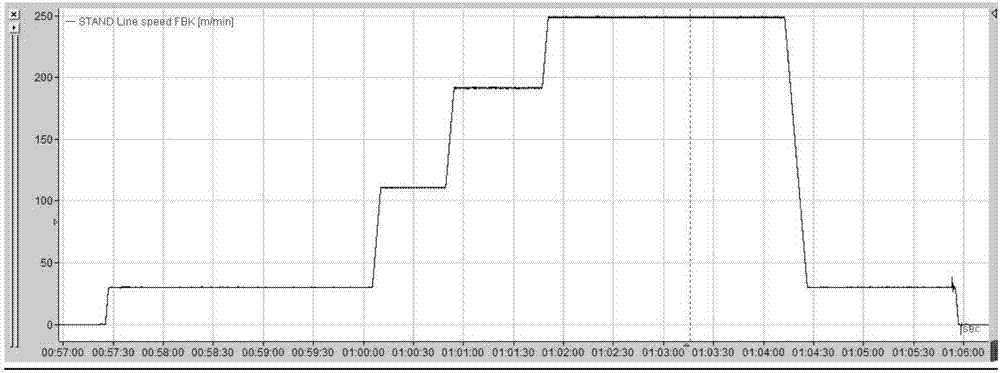

[0036] (2) The rolling line adjustment d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com