Flash-butt welding method for rail steel

一种闪光对焊、钢轨钢的技术,应用在钢轨的接头、钢轨、轨道等方向,能够解决加重、硬度下降、软化部不均匀磨损等问题,达到不均匀磨损减少、表面损伤降低、降低不均匀磨损的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0172] Hereinafter, the practicability and effects of the present invention will be further described using examples. In addition, the conditions used in the Example are an example for confirmation, and this invention is not limited to this example.

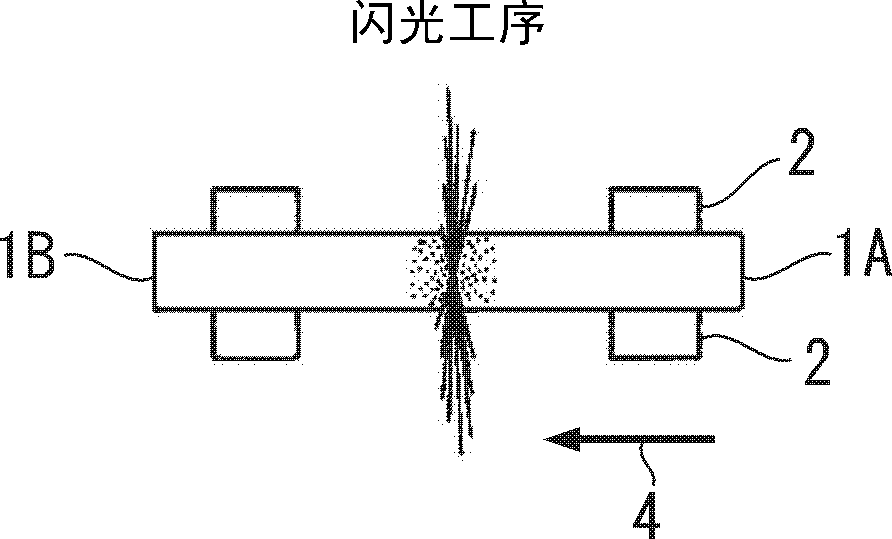

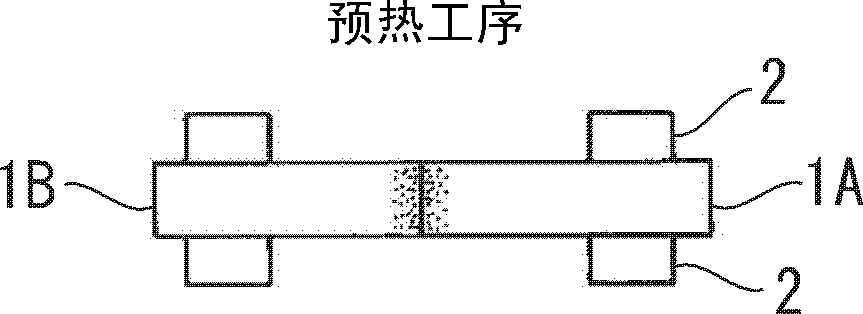

[0173] The AREA standard 136RE rail steel containing C: 0.85-1.2%, Si: 0.1-2.0%, Mn: 0.1-2.0% in mass %, and having a pearlite structure and a weight of 136 pounds per 1 m was used for flashing. Butt welding.

[0174] As the flash butt welding machine, a flash welding machine using an AC power source, a transformer capacity of 400kVA, and an upsetting load of 70kN was used. Regarding welding, in the combined flashing process and preheating process, the number of preheating times is 10, and the total time of the initial flashing process and the early flashing process is specified as 90 seconds, so that the post-flash speed and post-flash retention in the post-flash process Changes were performed as shown in Table 1.

[0175] Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com