Heat-source system and method for controlling the same

A technology of heat source system and control unit, which is applied in the direction of heating mode, heating and ventilation control system, heating and ventilation safety system, etc. It can solve the problems of efficiency increase, overall efficiency increase of heat source system, and large power consumption of cooling tower fans. Achieve efficient heat source system operation, realize heat source system operation, and reduce cooling water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

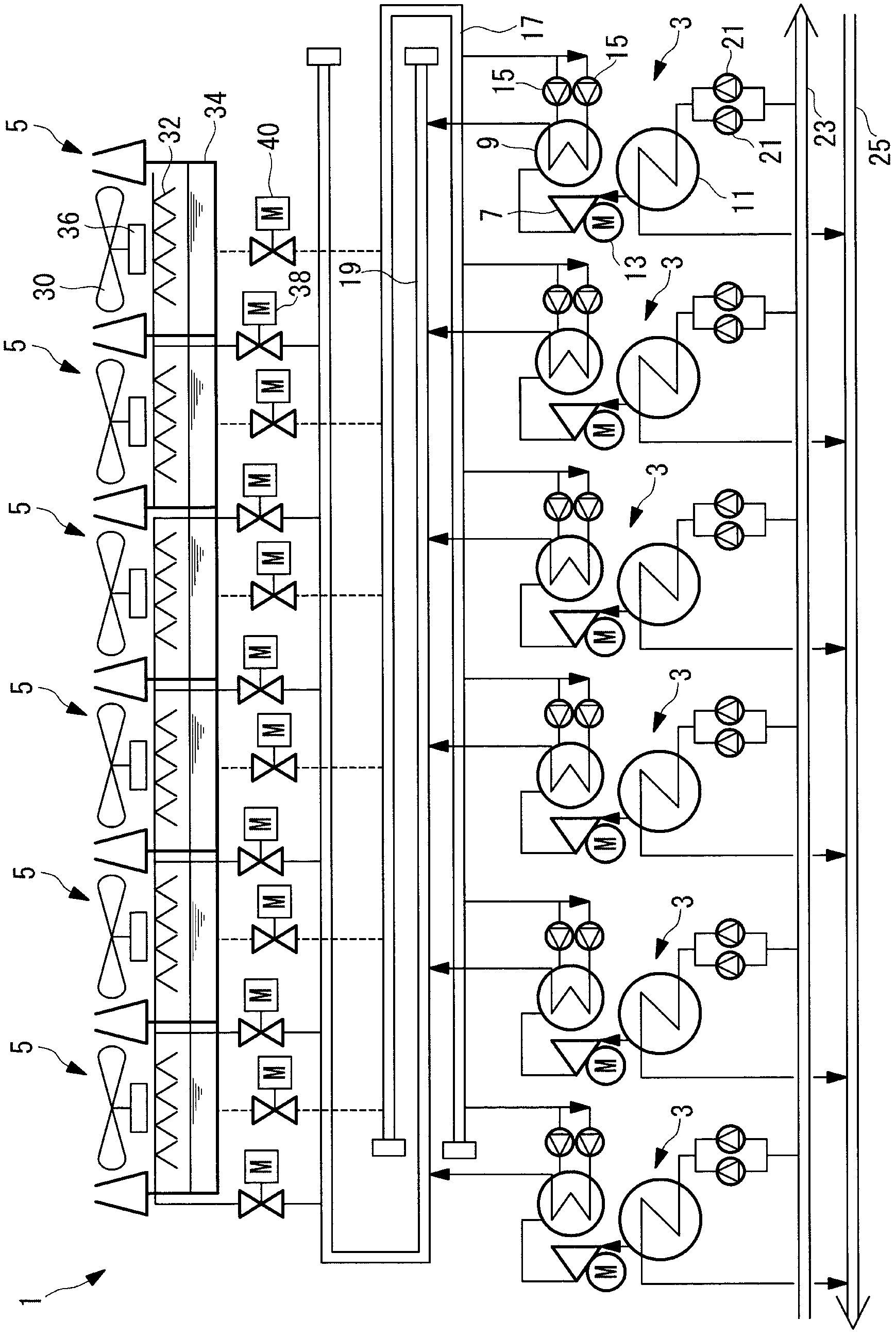

[0049] figure 1 One embodiment of the heat source system of the present invention is shown. The heat source system 1 includes a plurality of (six in this embodiment) turbo refrigerators 3 arranged in parallel, and a plurality of (six in this embodiment) cooling towers 5 arranged in parallel.

[0050] The turbo refrigerator 3 includes a turbo compressor 7 that compresses refrigerant, a condenser 9 that condenses and liquefies the refrigerant compressed by the turbo compressor 7 , and an expansion valve (not shown) that expands the refrigerant condensed and liquefied by the condenser 9 . Figure), the evaporator 11 that evaporates the refrigerant expanded by the expansion valve.

[0051] The turbo compressor 7 is driven by an electric motor 13 whose rotational frequency can be varied by inverter means.

[0052] Cooling water supplied by a cooling water pump 15 is introd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com