Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87 results about "District cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

District cooling is the cooling equivalent of district heating. Working on broadly similar principles to district heating, district cooling delivers chilled water to buildings like offices and factories needing cooling. In winter, the source for the cooling can often be sea water, so it is a cheaper resource than using electricity to run compressors for cooling. Alternatively, District Cooling can be provided by a Heat Sharing Network which enables each building on the circuit to use a heat pump to reject heat to an ambient ground temperature circuit.

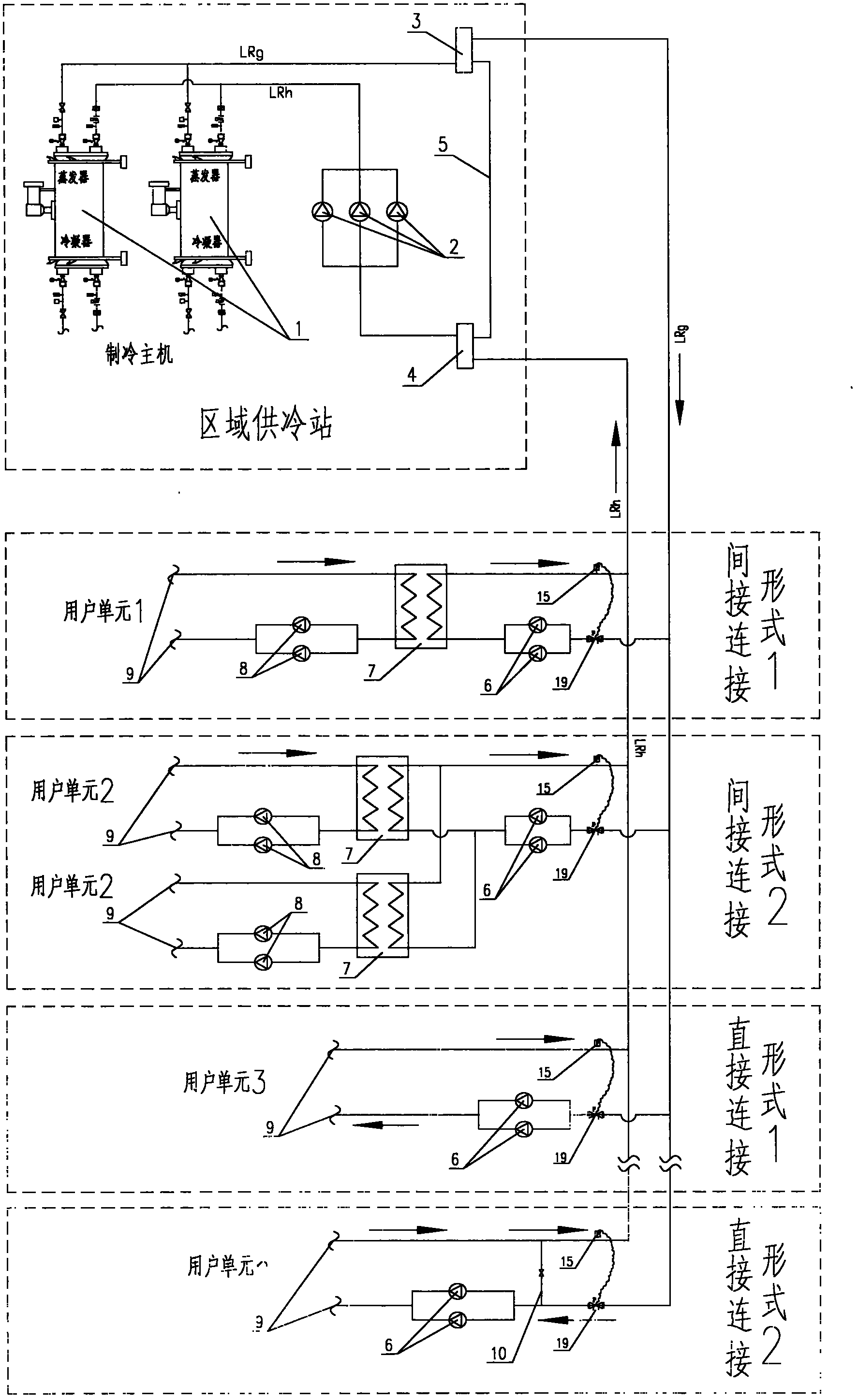

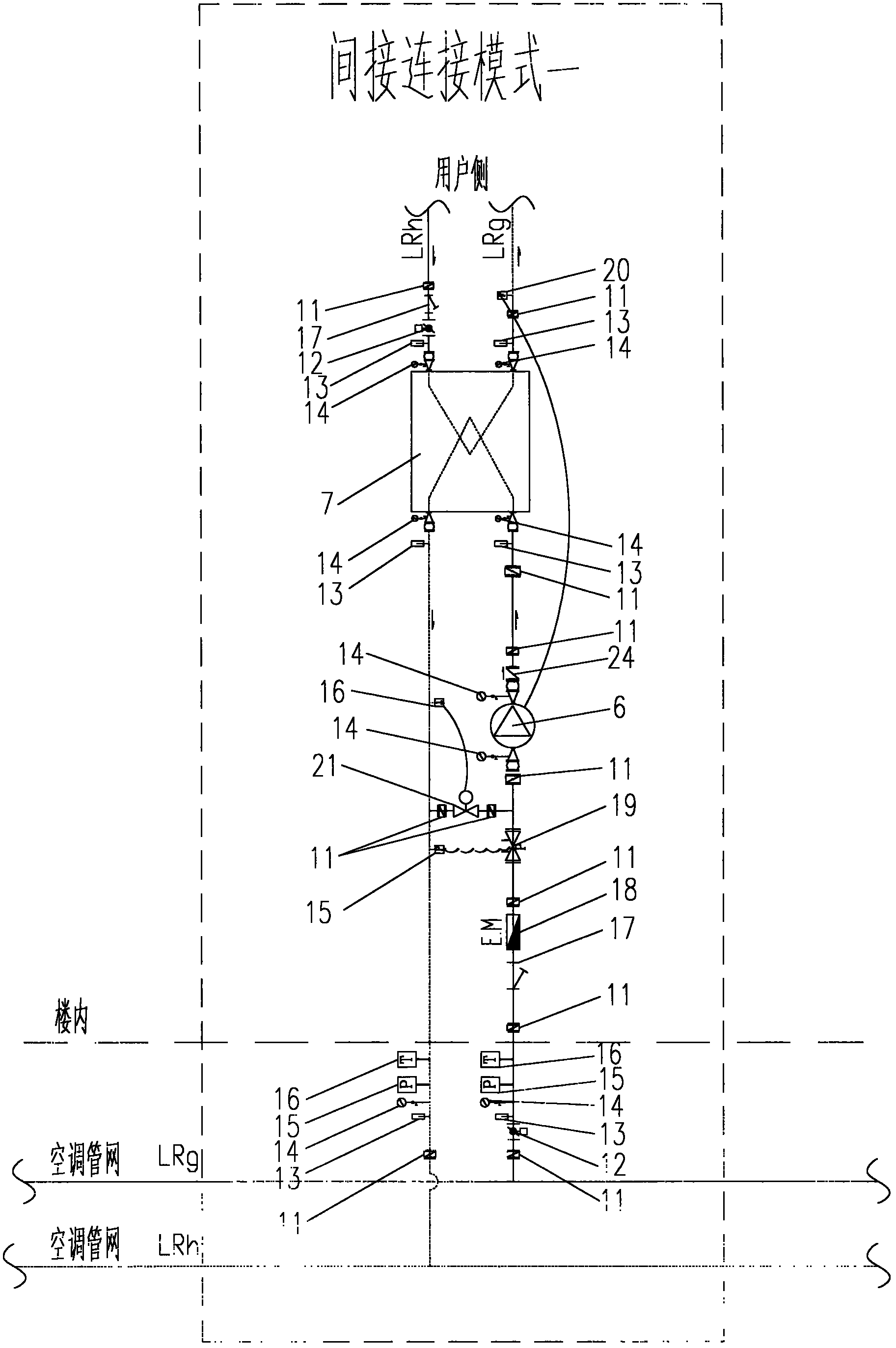

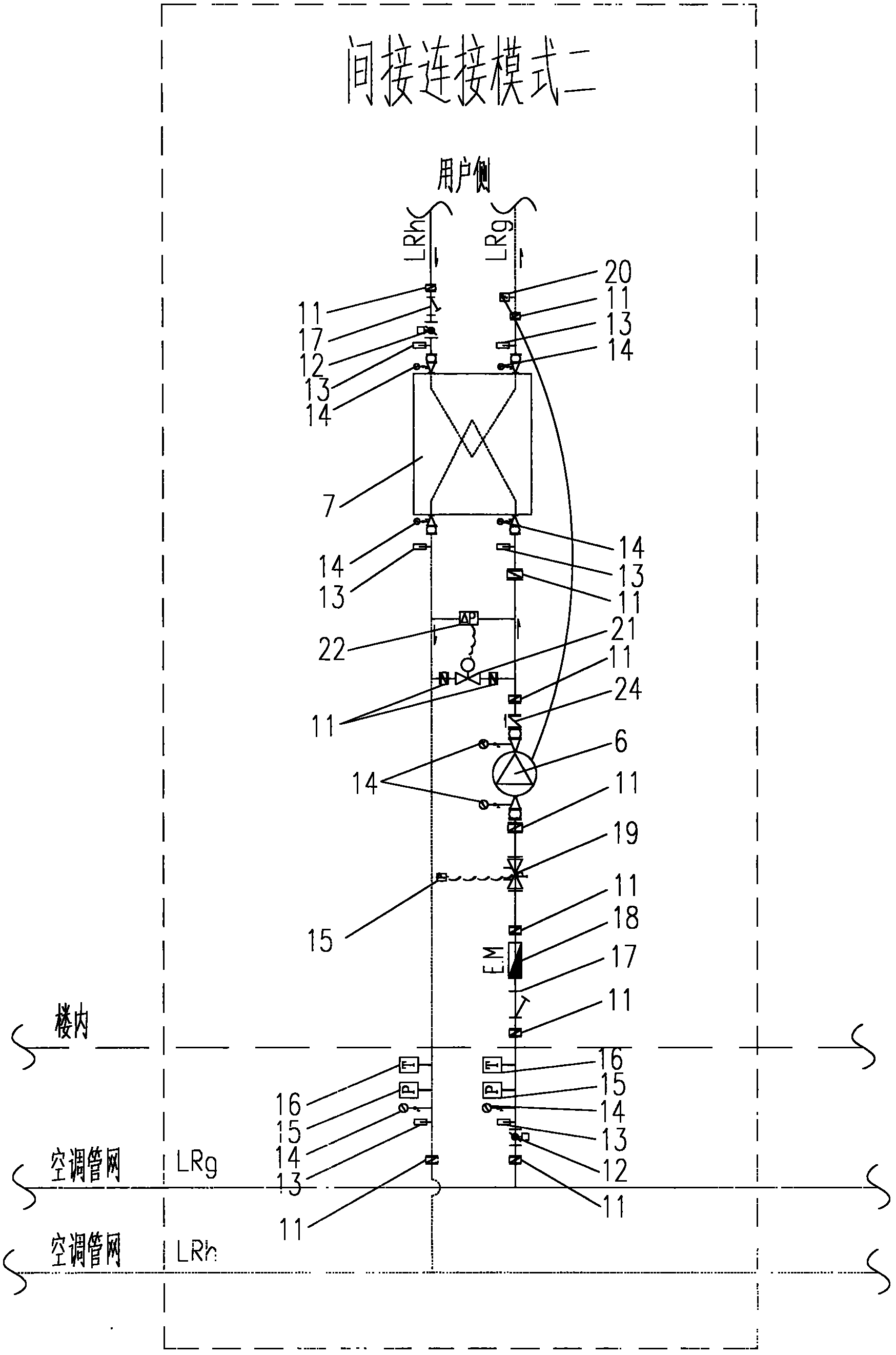

District air-conditioner distributed secondary pump system

ActiveCN103383121AAccurate science of energy measurementIncrease flexibilitySpace heating and ventilation safety systemsLighting and heating apparatusChilled waterEngineering

The invention aims to provide a district air-conditioner distributed secondary pump system, which comprises refrigeration main engines 1, chilled water primary pumps 2, a water segregator 3, a water collector 4, and a profit and loss tube 5. According to the invention, in the two forms of an indirect connection 1 and an indirect connection 2, a chilled water secondary pumps 6, plate heat exchangers 7, user chilled water circulating pumps 8, and user tail end air processing devices 9 are mainly arranged on a user side; in the direct connection form, the chilled water secondary pumps 6, the user tail end air processing devices 9, and a bypass pipe 10 of a secondary pump suction inlet with a control valve are mainly arranged in the user side. The invention also provides a connecting form of distributively arranging the secondary pumps to a chilled water distribution system of each user building, and a corresponding operation control method. The system can well realize the hydraulic equilibrium of each paralleled loop circuit of a district cooling system transmission and distribution network, improves the operation efficiency of the secondary pumps, and greatly reduces the water pump energy consumption, thereby improving the energy efficiency ratio of the overall system, and increasing the safety of the overall district cooling system.

Owner:南京市建筑设计研究院有限责任公司

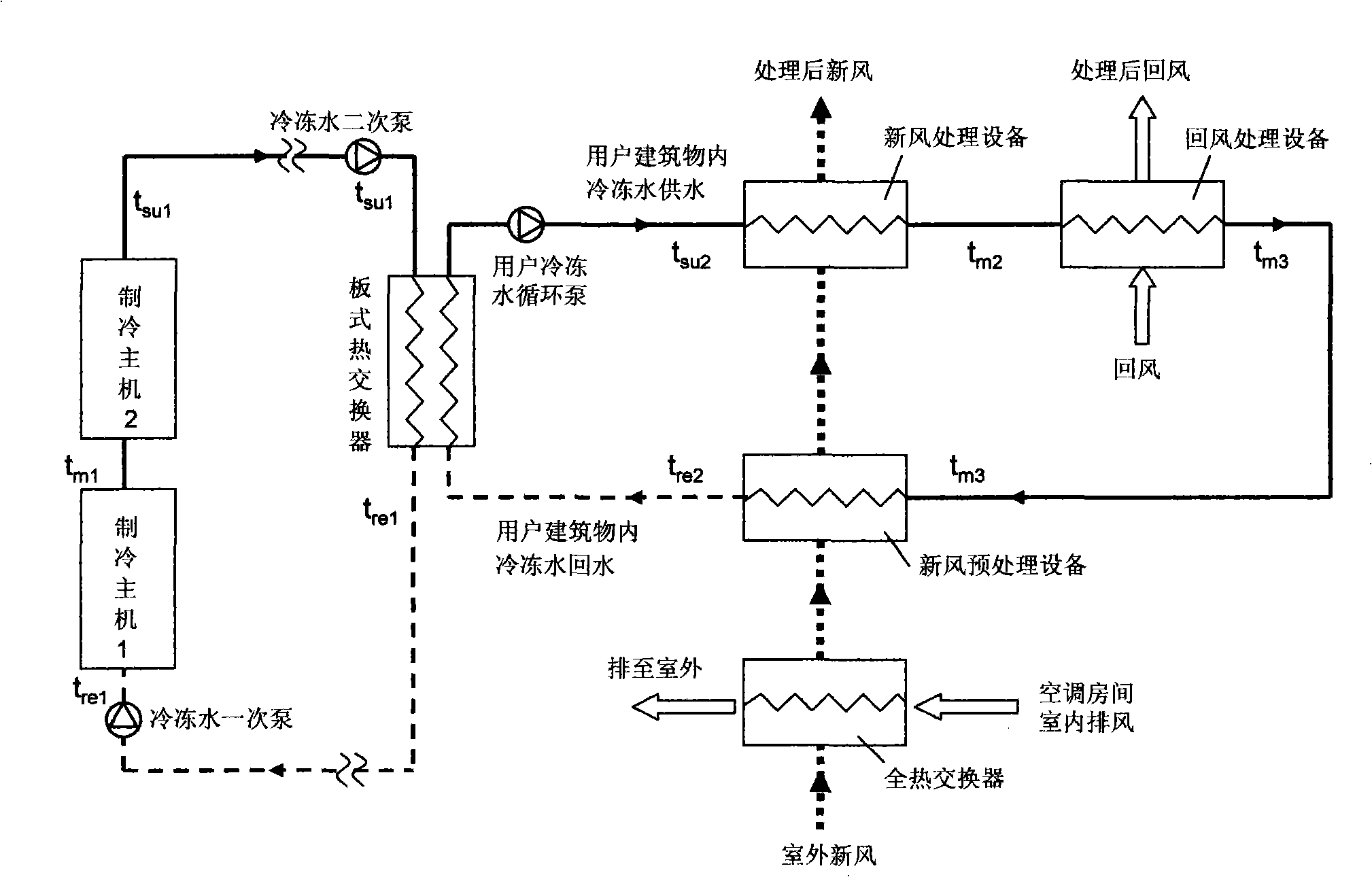

High-efficiency energy-saving air conditioning system used for area cold supplying and its implementing method

InactiveCN101344291AReduce energy consumptionReduce initial investmentLighting and heating apparatusAir conditioning systemsPlate heat exchangerEconomic benefits

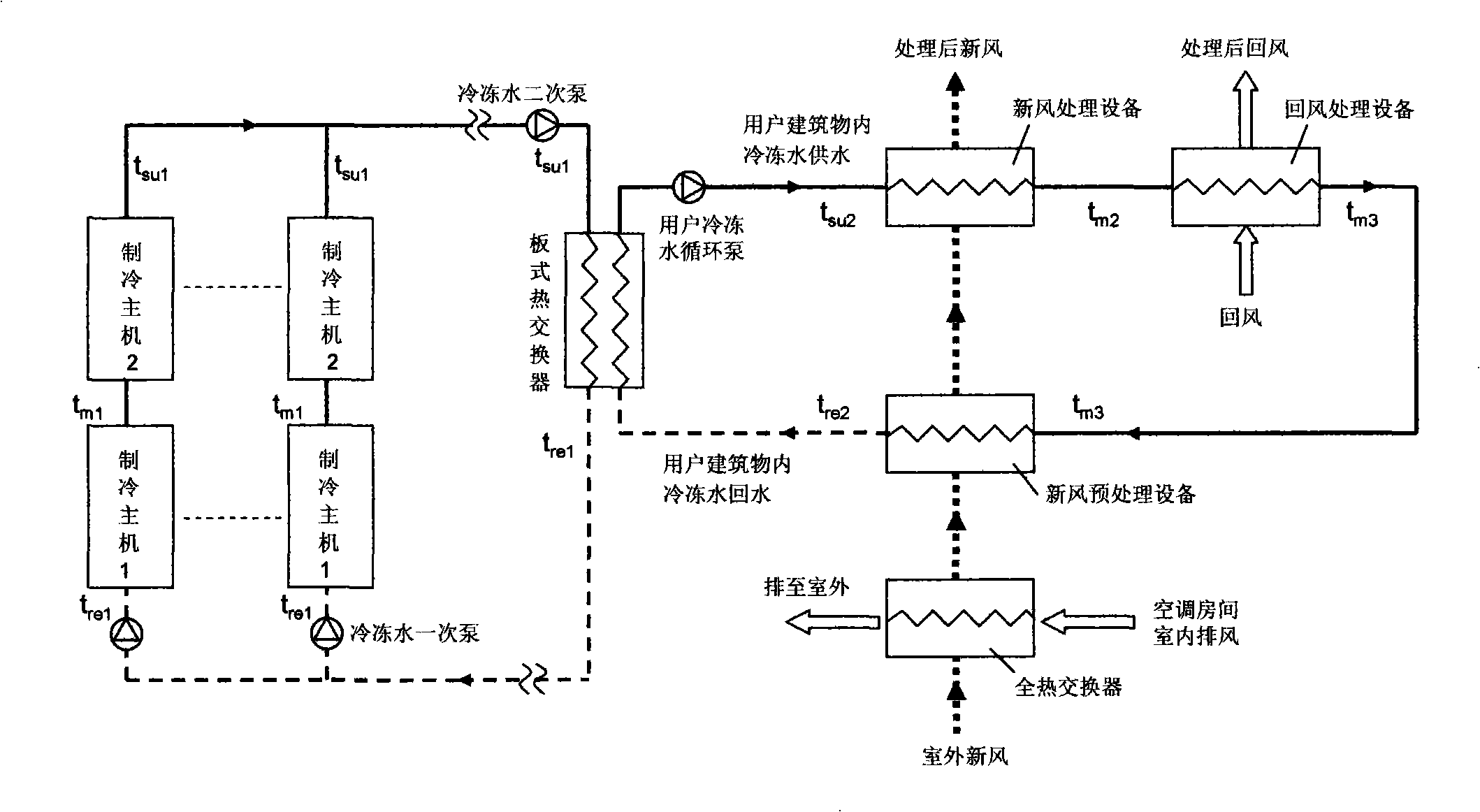

The invention provides a high-efficient and energy-saving air-conditioning system used for district cooling, which comprises a refrigeration host, a chilled water primary pump, a chilled water secondary pump, a plate heat exchanger, a new air processing device, a return air processing device, a new air pre-processing device, a user chilled water circulating pump and a total heat exchanger. The invention further provides a realization method of the air-conditioning system. The high-efficient and energy-saving air-conditioning system and the realization method of the invention are based on the second law of thermodynamics and the economic optimized scientific energy utilization principle, and realizes the purposes of increasing the temperature difference between the supply water and the return water of a chilled water secondary pipeline and reducing the flow rate thereof by the method of connecting two levels of refrigeration with the refrigeration host in series and the innovative cold energy gradual utilization of a tail-end device. Therefore, the energy consumption of the chilled water secondary pump and the initial investment of the secondary pipeline network are reduced, the economic benefits and the energy utilization ratio are improved, and the advantages of the district cooling system are further played.

Owner:SOUTH CHINA UNIV OF TECH

Zoning cold supply energy saving system and method of data center air conditioner

ActiveCN102425821AReduce installed capacityLow costLighting and heating apparatusHeat proofingCold airData center

The invention relates to a zoning cold supply energy saving system and method of a data center air conditioner; the zoning cold supply energy saving system is characterized in that a machine room space is formed by an overhead floor, an indoor ceiling and a wall, wherein a common cold supply air conditioner and an accurate cold supply air conditioner are arranged in the machine room space; the machine room space comprises an accurate cold supply space and an external common refrigerating space; the accurate cold supply space is formed by a lower space of the overhead floor, an inner space of a machine cabinet, an air supply pipeline, an air return pipeline and the accurate cold supply air conditioner, and the external common refrigerating space is formed by an upper space of the overhead floor and the common air conditioner. The common air supply conditioner sends out cold air to the common refrigerating space; the same amount of cold air is returned; and the accurate air supply conditioner sends out cold air to the accurate refrigerating space. The zoning cold supply energy saving system completely changes the mode that for the traditional precise data center air conditioner, the total power of display cold of the air conditioner is calculated by the area of the whole machine room, thereby the required cold quantity is accurately calculated by using the area of the cold supply space; and therefore, under the condition that the energy consumption is greatly reduced, the installed capacity and the cost of the air conditioner are simultaneously reduced; and the requirement of equipment inside a cabinet for high-efficiency cold supply is also ensured.

Owner:GUANGZHOU HOLDSTORM SCI & TECH

Dynamic high temperature cool accumulation air conditioner system

ActiveCN101021348ARunning concentration is stableStabilize the ice making processLighting and heating apparatusAir conditioning systemsEnd systemWorking temperature

The present invention relates to a dynamic cold storage air-conditioning system, specially, it is a high-temperature cold storage air-conditioning system by adopting eutectic solution as cold storage medium. It includes refrigeration system, cold storage system, cold release system and tail end system. The refrigeration output of said refrigeration system is parallel connected with cold storage system, cold release system and tail end system, its cold storage medium is an eutectic solution, said eutectic solution is sodium sulfate Na2SO4 .10H2O solution, and its cold storage mode adopts a semi-transparent film device and its system working temperature is above zero deg.C. Said invention is simple in structure and high in working efficiency and reliability.

Owner:广东吉荣空调有限公司

Ice-chilling air conditioning system

InactiveCN101487613AReduce usageReduce pollutionSpace heating and ventilation safety systemsLighting and heating apparatusCold airElectricity

The invention relates to an ice accumulating cold air-conditioning system. By adopting the proposal, the air-conditioning system can work in five cooling modes, so as to utilizing the electrical power at trough period of electricity utilization to the utmost extent, and use the way of double series connection for conveniently changing various current states with suitability; due to the unique serpent-type steel coiled pipe structure and excellent heat transfer property, the ice accumulating cold air-conditioning system leads the water to be frozen into ice layers having the thickness of 25MM to be covered on the outer wall of the coiled pipe in final period of refrigeration, gaps exist among the ice layers, the temperature of the water is still 0 DEG C, and no ice bridge is formed; therefore, uniform heat exchange can be ensured, the temperature at the glycol outlet is consistent when refrigeration agent is adopted, the cold extraction process can be controlled, and the ice extraction rate reaches 100%. A single serpentine tube with the length of 100m is wound on a support frame, external-melt ice equipment can provide chilled water with consistent 1 DEG C, and the use of CFC and the emission of CO2 can be reduced by district cooling. The invention also provides a method for effectively balancing electrical load.

Owner:ICE BANK ENERGY TECH CO LTD

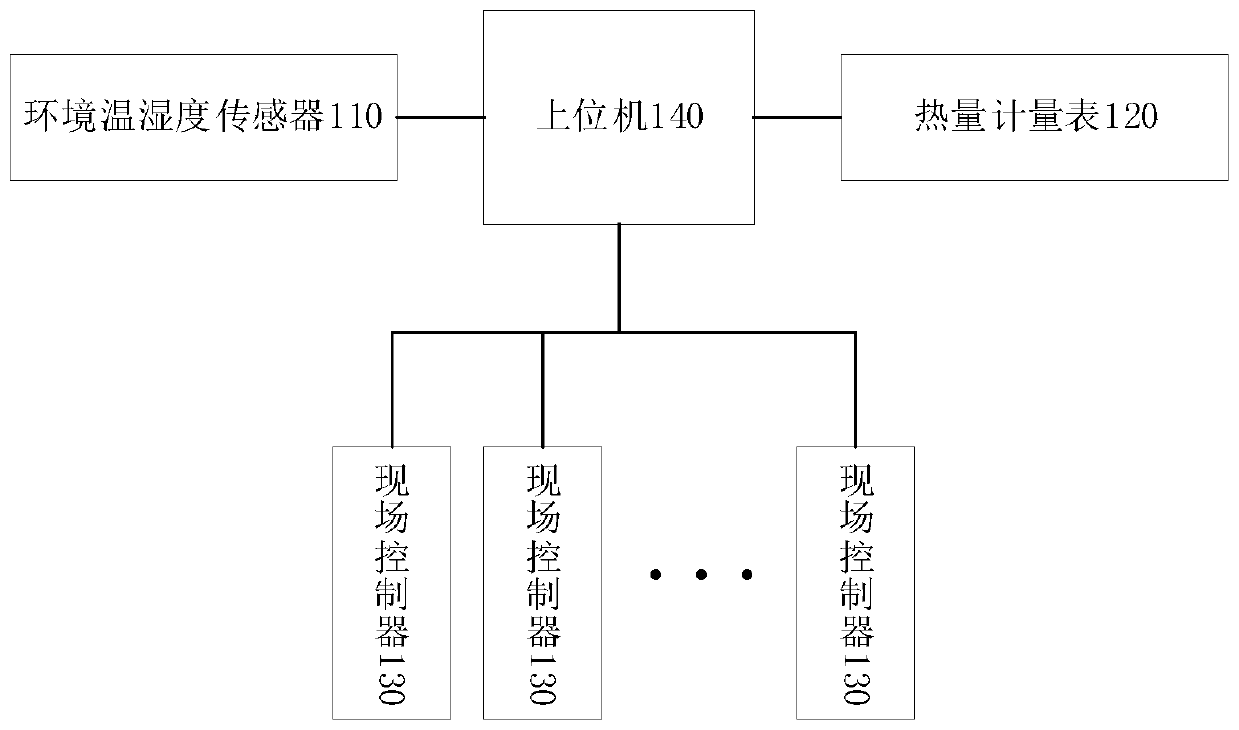

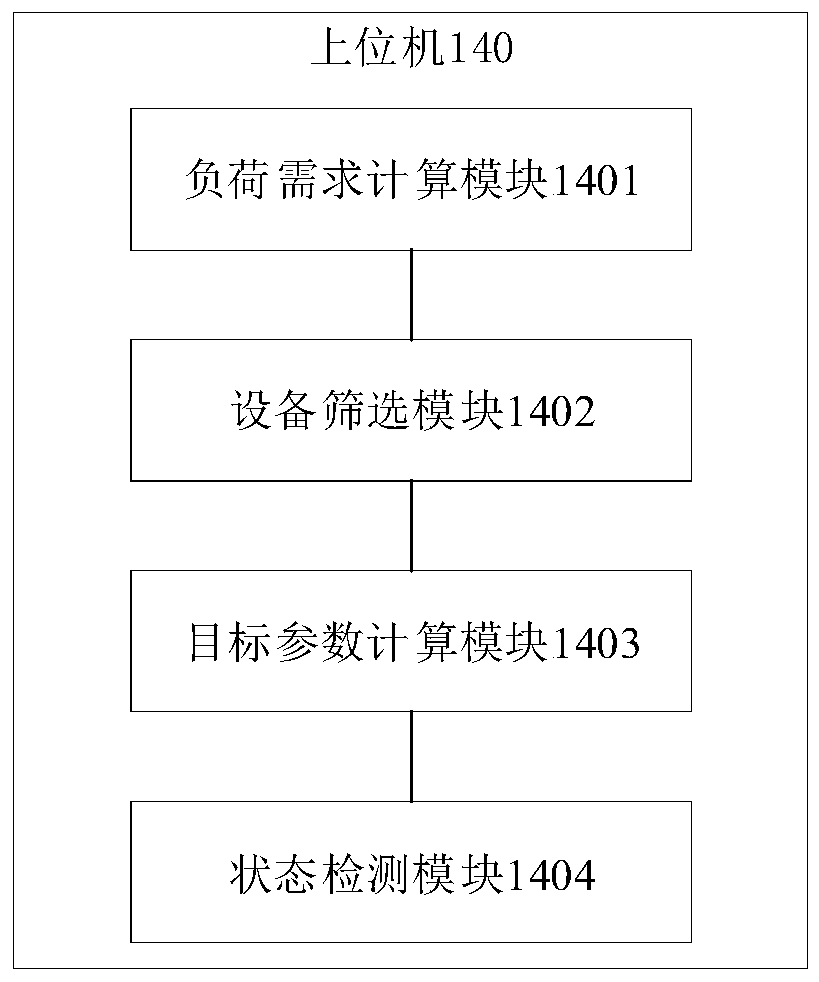

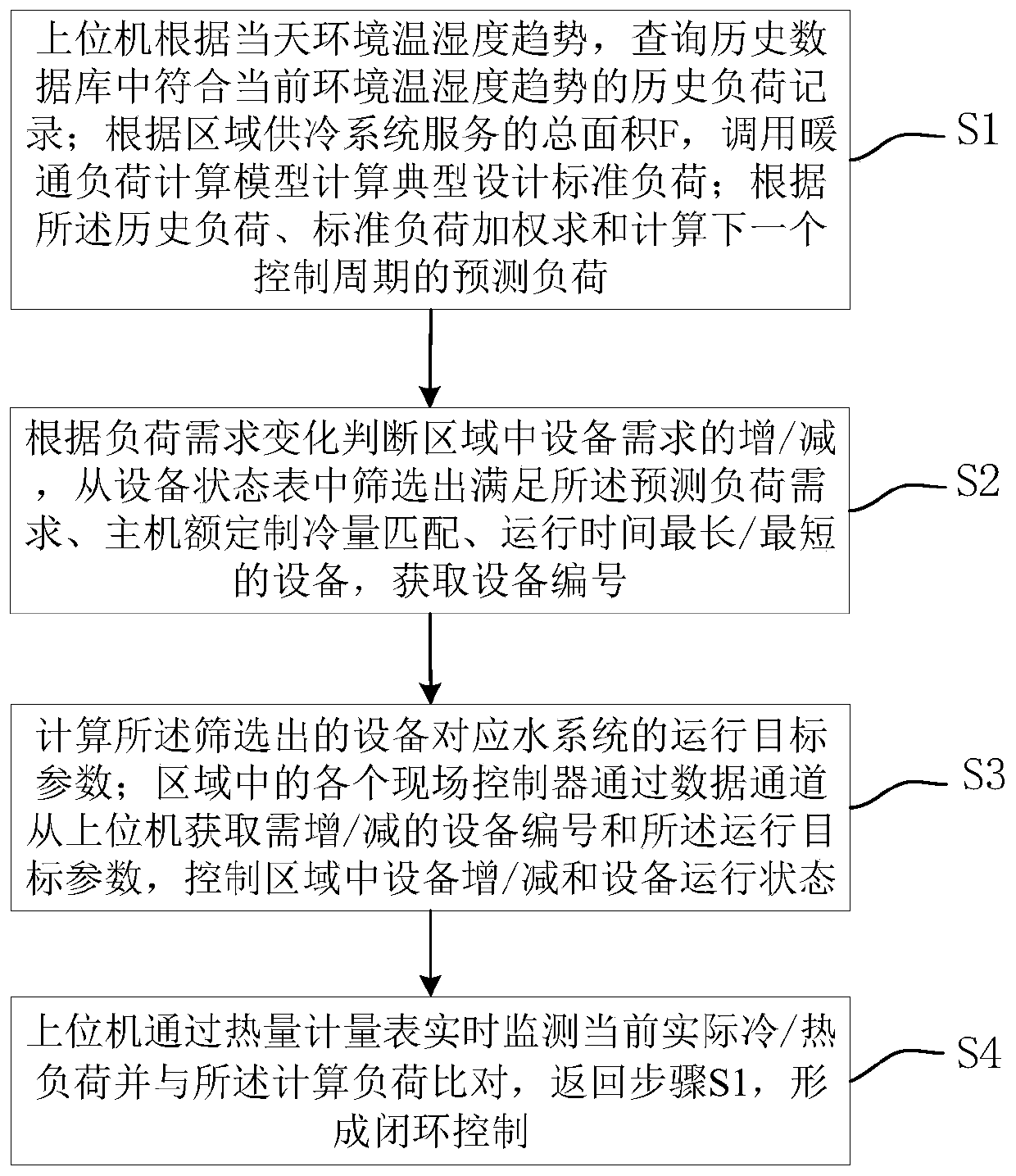

System and method for optimizing operation of cooling and heating devices in area

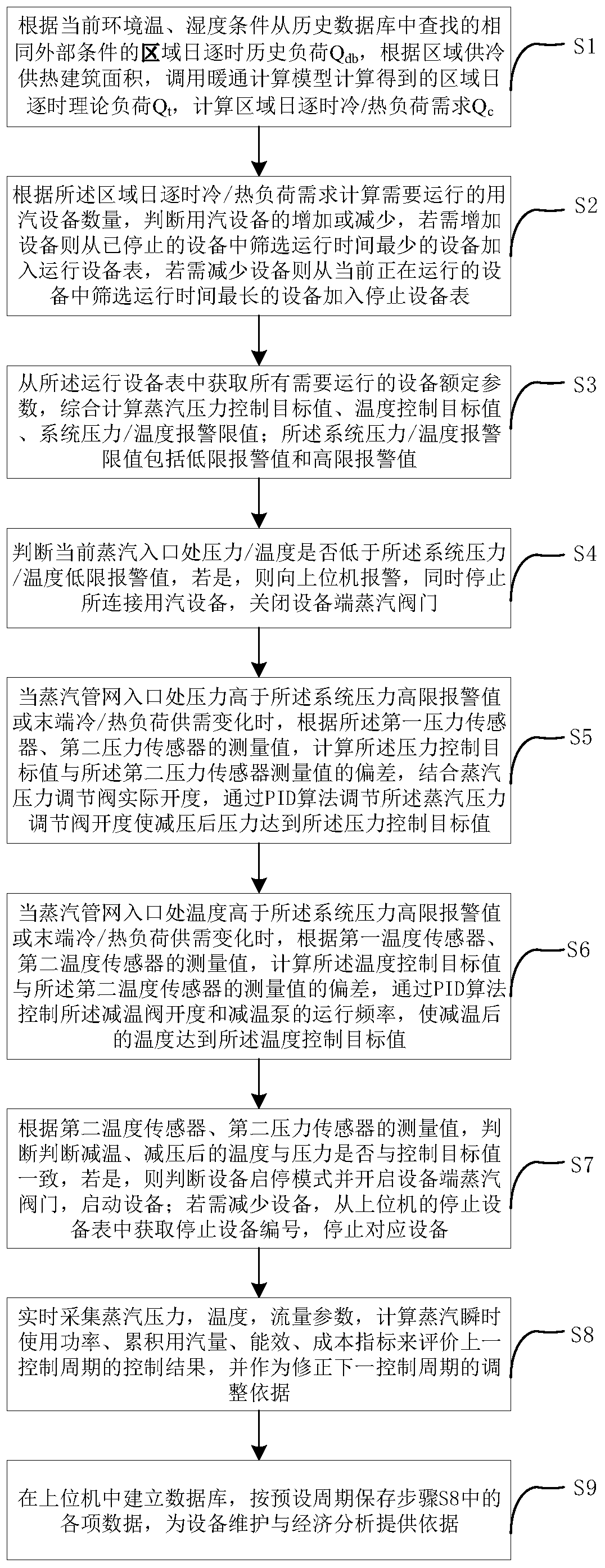

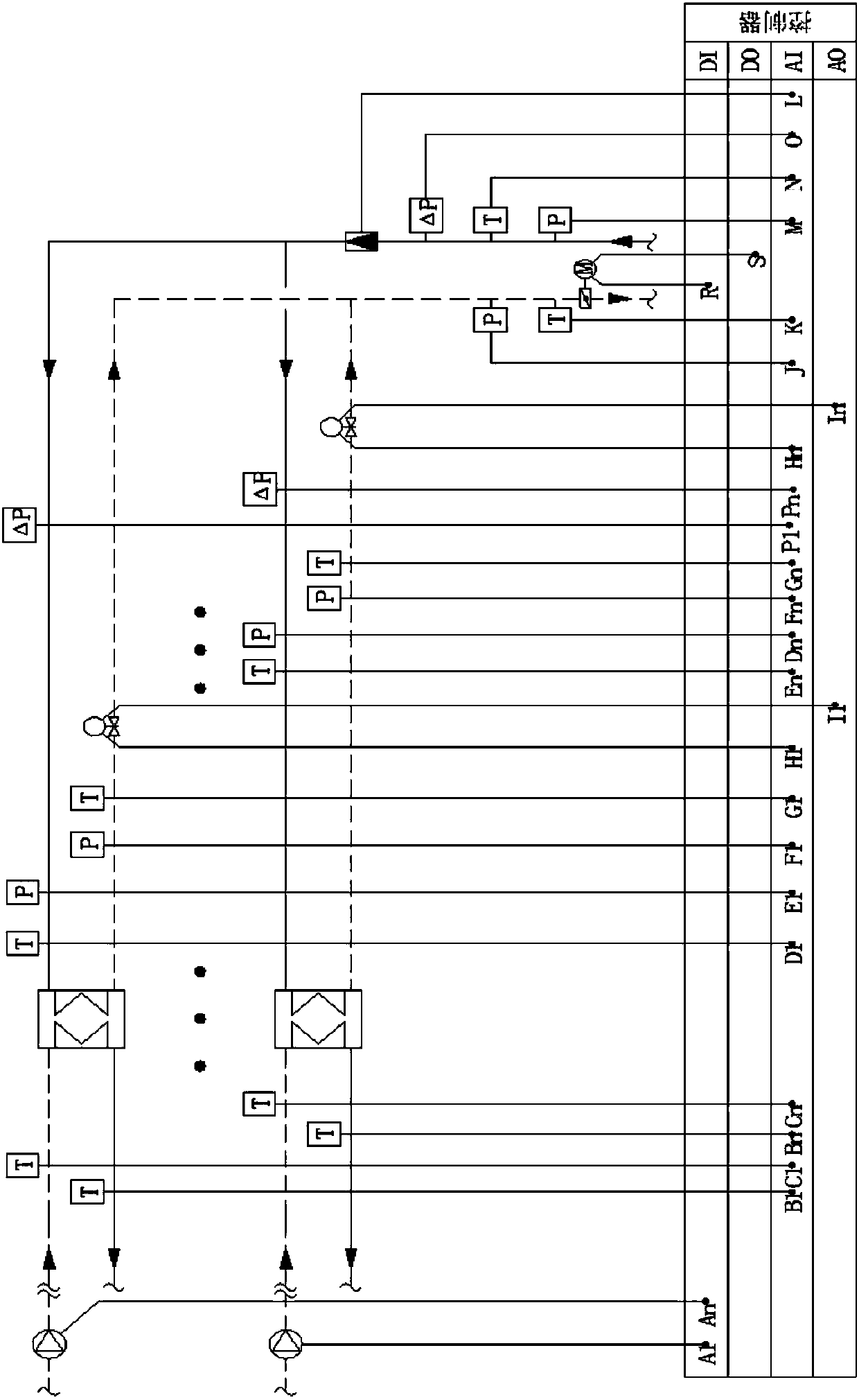

The invention provides a system and method for optimizing the operation of cooling and heating devices in an area. The method comprises the following steps that: S1, an upper computer queries historical load records, conforming to a current environmental temperature and humidity trend, in a historical database according to the according to a current environment temperature and humidity trend; a heating and ventilation load calculation model is invoked to calculate a typical design standard load; and weighted summation is carried out based on the historical load and the standard load, and a predicted load of a next cycle is calculated; S2, devices that meet the load need, have the matched host rated cooling capacities, and having the longest / shortest operation time are screened and serial numbers of the devices are obtained; S3, operation target parameters of the corresponding systems of the devices are calculated; and a field controller acquires a serial number of a device needing to be added or removed as well as the operation target parameters through a data channel and controls device increasing / decreasing and device operation states in the area; and S4, the S1 is performed again and closed loop control is formed. Therefore, the equipment operation efficiency is improved; the cost is lowered; and the energy consumption is reduced.

Owner:武汉中电节能有限公司

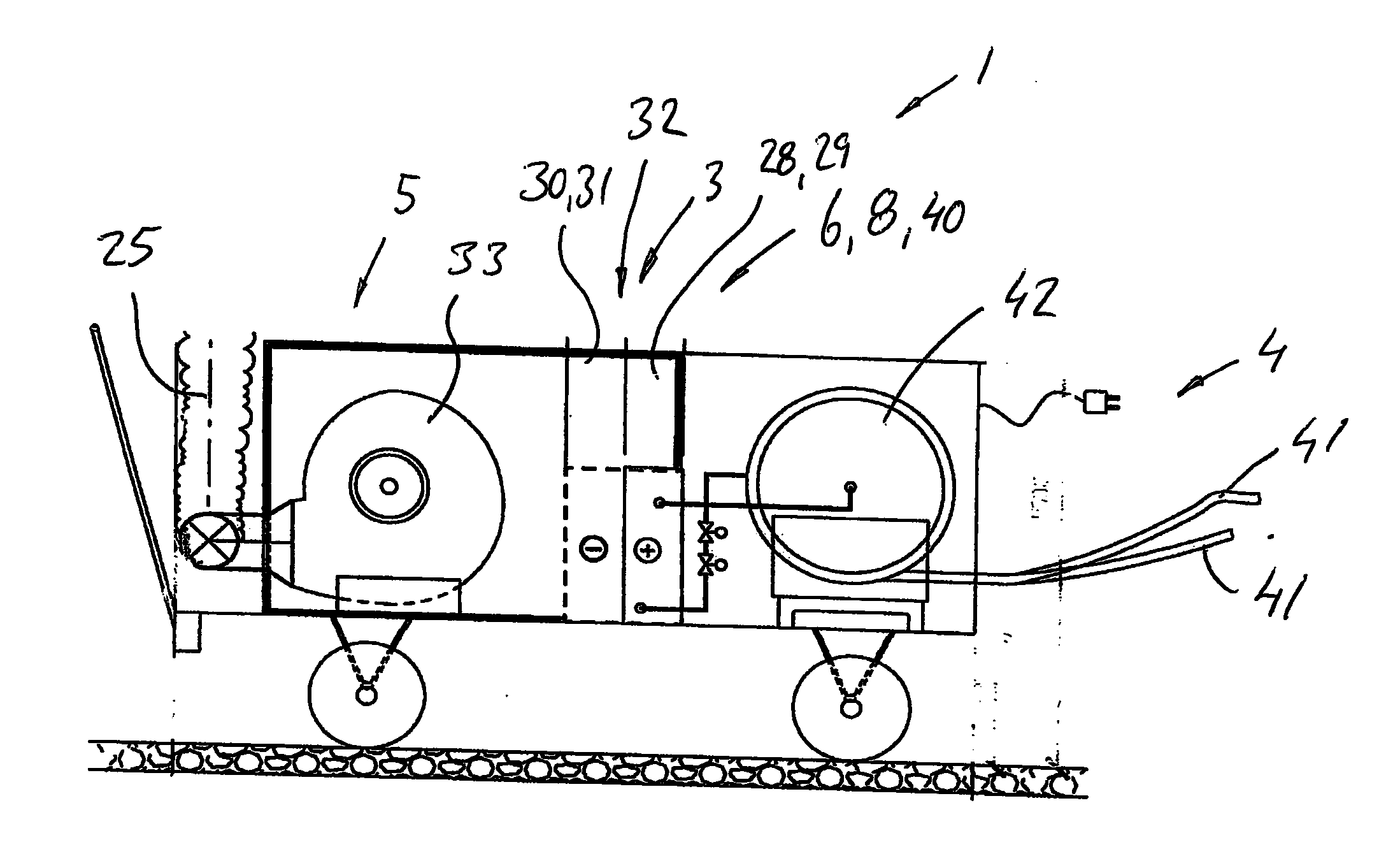

Climate control system for aircraft

InactiveUS20160001895A1Space heating and ventilation safety systemsSpace heating and ventilation control systemsNacelleControl system

A climate control system (1), intended to be temporarily connected to at least one aircraft (2), when the aircraft is on the ground, with which handled air with at least one flexible conduit (23) is supplied to the aircraft's cabin from at least one air handling unit (3). The air handling unit (3) is comprised of at least one heating and cooling package (29) with which air to the cabin is heated or cooled and that the climate control system includes a transfer device (6) with which the air handling device may be moved in relation to the aircraft. The transfer device (6) is comprised of a telescopic boarding bridge (7). The climate control system (1) includes a subsystem for conveying heated or cooled fluid between the combined heating and cooling package (29) and a district heating network alternatively a network for district cooling, whose subsystem includes at least one flexible conduit (18) that includes at least one conduit for the input of fluid to the air handling unit and at least one conduit for return of fluid from the air handling unit.

Owner:SMART CLIMATE SCANDINAVIA

Heat-work conversion and dispatching optimization decision-making assisting system and heat-work conversion and dispatching optimization decision-making assisting method for complementary DMG (distributed multi-generation) system

InactiveCN104808638AImprove thermal efficiencyImprove emission efficiencyEnergy industryTotal factory controlHeat balanceDistrict cooling

The invention discloses a heat-work conversion and dispatching optimization decision-making assisting system and a heat-work conversion and dispatching optimization decision-making assisting method for a complementary DMG (distributed multi-generation) system. The heat-work conversion and dispatching optimization decision-making assisting system comprises a fuel characteristic parameter module, a combustion adjustment experimental module, a reference pattern module, a heat balance and consumption quantity computing module, a combustion condition adjustment and management module, a heat-work conversion management module, a variable-working-condition signal transmission module, a full-working-condition operation parameter management module, a district cooling network circulation mode module, an energy efficiency and environmental benefit evaluation module and a dispatching optimization and decision-making assisting management module. The heat-work conversion and dispatching optimization decision-making assisting system and the heat-work conversion and dispatching optimization decision-making assisting method have the advantages that district cooling network circulation match is achieved flexibly for a multi-heat-source system different in temperature to construct the complementary DMG system with multi-energy-source input and multi-product output, and high flexibility and advancement are achieved; an advanced system for process engineering is applied to production device design, steady-state simulation and optimization, sensitivity analysis and economic evaluation of a whole process of the complementary DMG system, so that accurate and timely dispatching optimization and decision-making assisting are achieved.

Owner:SUN YAT SEN UNIV

Automatic control system and method for regional cooling and heating steam desuperheating and decompression

ActiveCN109976419AImprove securityImprove work efficiencySimultaneous control of multiple variablesSteam pressureAutomatic control

The invention provides an automatic control system and method for regional cooling and heating steam desuperheating and decompression. The method comprises the steps that a regional cold / heat load demand is calculated; the number of steam devices to be operated is calculated, and the increase or decrease of the steam devices is judged to screen the devices; the steam pressure control target value,the temperature control target value, and the system pressure / temperature alarm limit are comprehensive calculated; whether the pressure / temperature of the current steam inlet is lower than the pressure / temperature low limit alarm value of the system is judged, and if so, an alarm is sent to an upper computer; when the pressure at the inlet of a steam pipe network is higher than the pressure of the system, automatic adjusting of the opening degree of a steam pressure regulating valve is realized through a PID algorithm for decompression control; when the temperature at the inlet of the steampipe network is higher than the temperature limit of the system, automatic control of the opening degree of a desuperheating valve and the operating frequency of a desuperheating pump is realized through the PID algorithm to perform desuperheating control; and if the temperature meets a requirement after desuperheating and decompression, the device is started. According to the invention, the working efficiency is improved; the operating cost is reduced; and energy is saved.

Owner:武汉中电节能有限公司

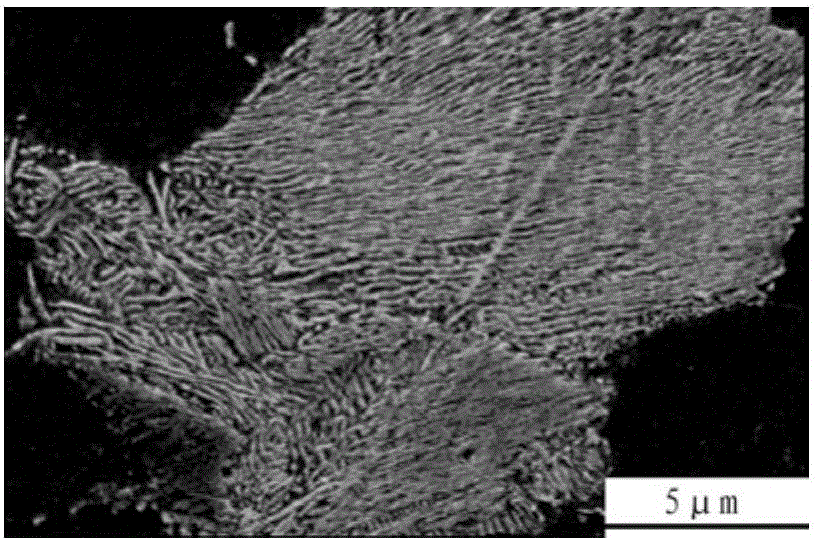

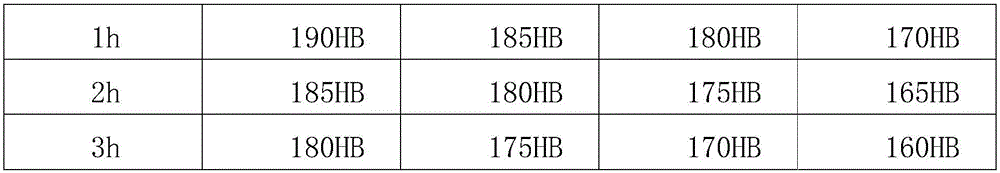

Gear steel 20CrMnTiH isothermal normalizing treatment method

ActiveCN106350648APrecise control of cooling speedProcess stabilityHeat treatment process controlCooling chamberHardness

The invention discloses a gear steel 20CrMnTiH isothermal normalizing treatment method, and belongs to the field of material thermal treatment. The gear steel 20CrMnTiH isothermal normalizing treatment method comprises the steps: adopting a warm-air district cooling technology after austenitizing heating: in district I, the warm air temperature is 50 to 55 DEG C, the air speed is controlled to be 8 to 12 m / s, and the air cooling time of parts is controlled to be 2 to 3 minutes; in district II, the air temperature is 55 to 60 DEG C, the air speed is 5 to 8 m / s, and the air cooling time of parts is controlled to be 3 to 4 minutes; regulating an isothermal normalizing furnace to be in two-stage control: first stage, the temperature is controlled to be 550 to 570 DEG C, and the heat preservation time is 1 to 1.5 hours; second stage, the temperature is controlled to be 570 to 600 DEG C, and the isothermal control time is 1 to 1.5 hours; after isothermal normalizing, entering an air cooling chamber, controlling the air temperature to be 30 to 40 DEG C and the air speed to be 5 to 8 m / s, and carrying out air cooling after cooling to 200 to 250 DEG C. The hardness of gear blank treated by the technology can be up to 165 to 180 HB, the pearlite interlamellar spacing is controlled to be 0.18 to 0.24 mu m, the grade of a banded structure is controlled to be 1 to 1.5, the cutting performance is good, deformation after quenching can be stably controlled, and the reject ratio is basically zero.

Owner:SHOUGANG CORPORATION

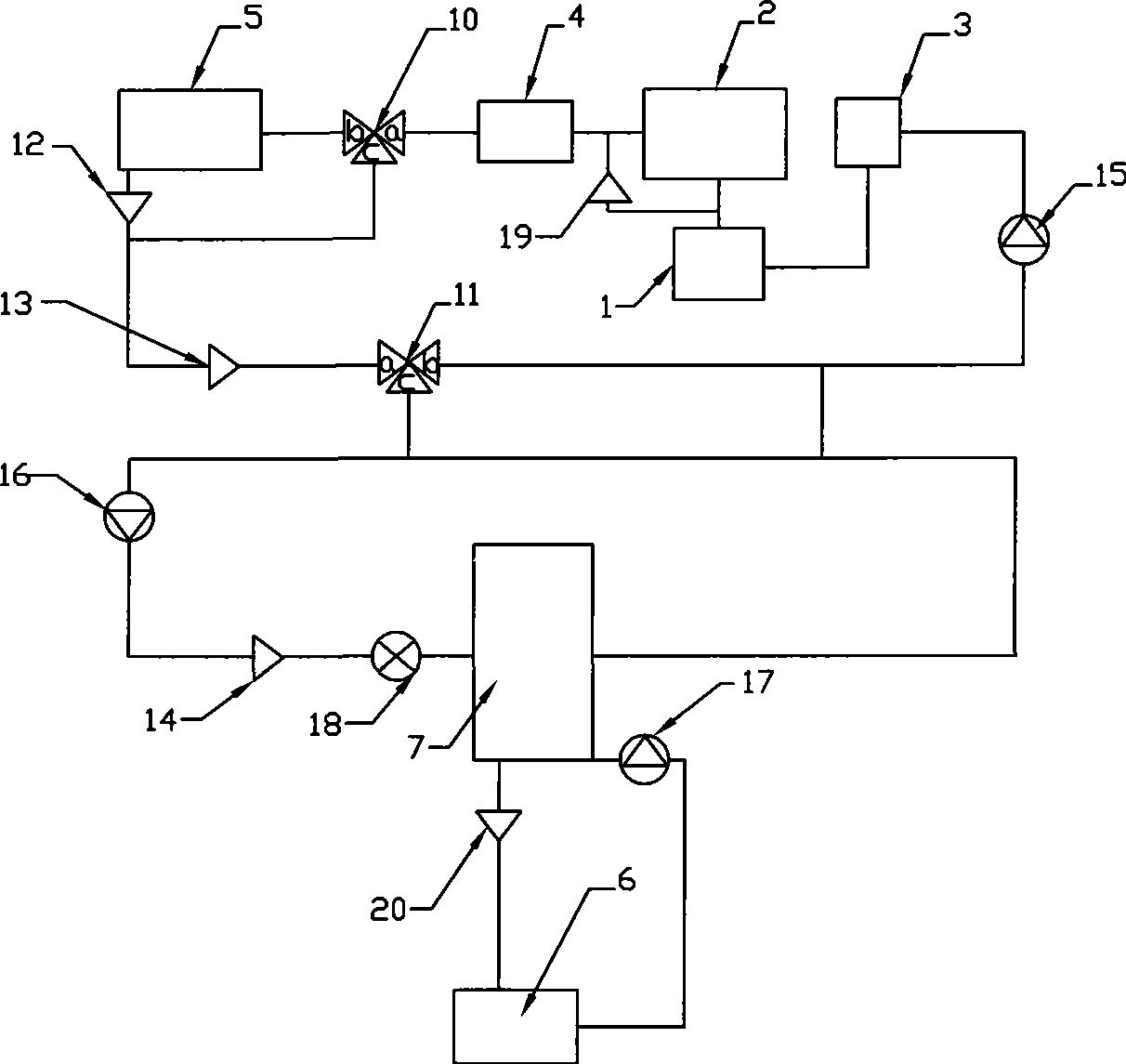

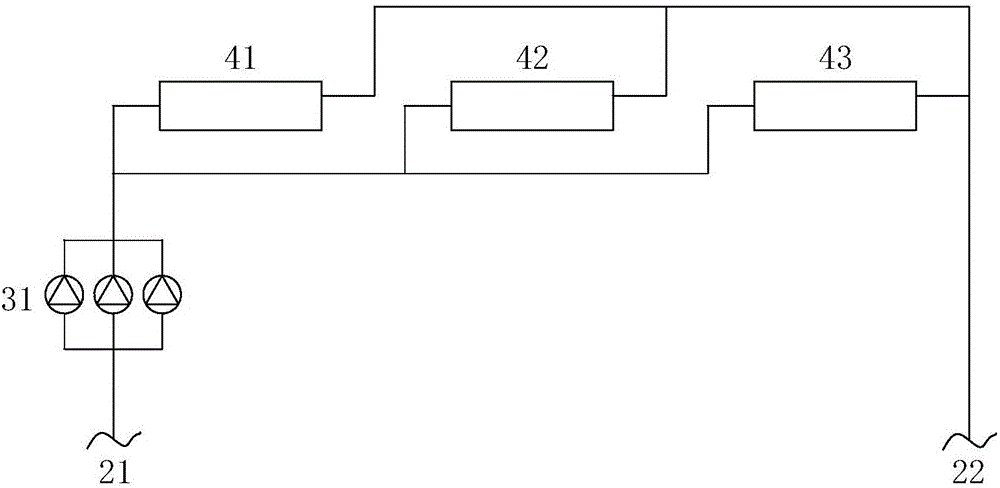

District cooling system and method adopting distributed variable-frequency triple-stage pumps

ActiveCN106765776AReduce residual headAlleviate the current situation of high energy consumption for coolingMechanical apparatusFluid circulation arrangementChilled waterEngineering

The invention discloses a district cooling system adopting distributed variable-frequency triple-stage pumps. The system comprises a district cooling station, a cooling delivery pipe network, a user distribution pump and a user heat exchange room; the triple-stage pumps comprise a chilled water primary pump, a chilled water secondary pump and a chilled water tertiary pump; the chilled water primary pump provides circulating power for the district cooling station; the chilled water secondary pump provides power for the cooling delivery pipe network; the chilled water tertiary pump is the user distribution pump; and chilled water prepared by the district cooling station is delivered to the user distribution pump through the cooling delivery pipe network, the user distribution pump pumps the chilled water as required from the cooling delivery pipe network to the user heat exchange room, and the chilled water is subjected to heat exchange through the user heat exchange room and then is delivered back to the cooling delivery pipe network. With the cooling system and method, the energy waste and the cold loss caused by full-flow high-lift secondary pumps in traditional cooling pipe networks can be fully reduced, and the lift of a delivery water pump inside the cooling station can be reduced to the great extent.

Owner:ARCHITECTURAL DESIGN & RES INST OF SOUTH CHINA UNIV OF TECH

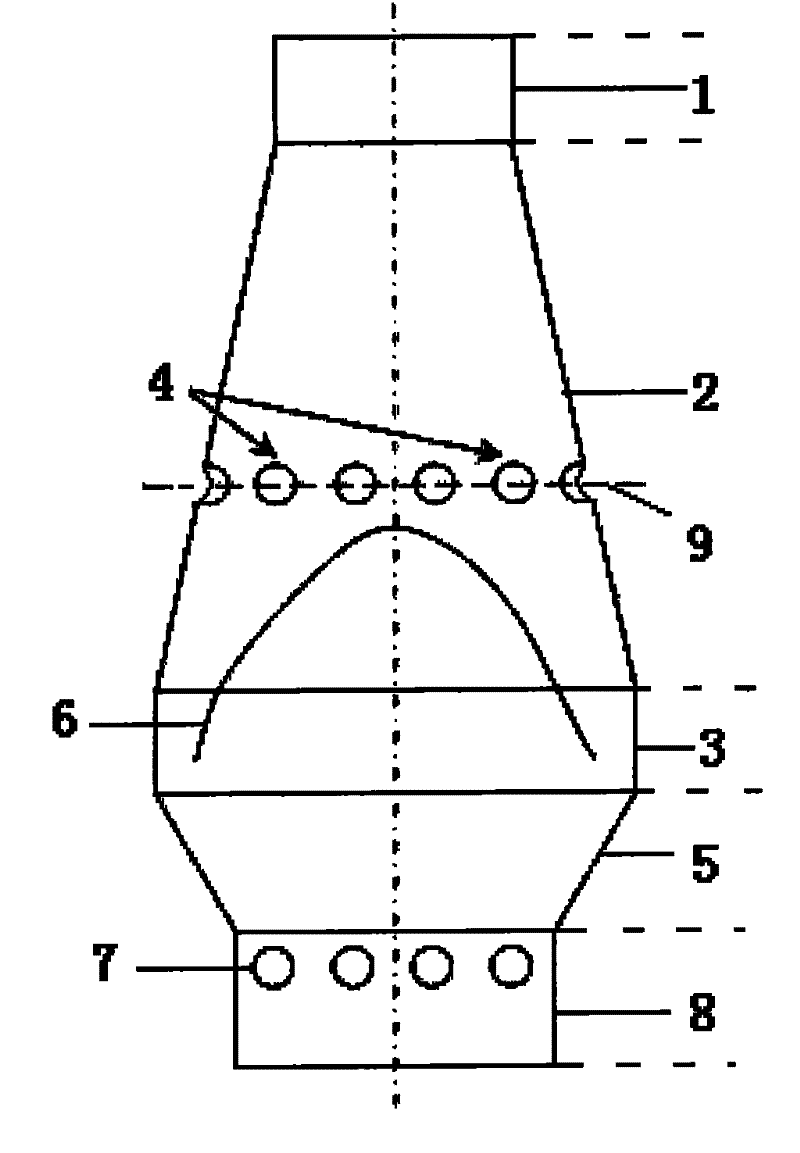

Quenching cooling device for large seal head

ActiveCN106702122AAchieving Zoned CoolingGuarantee the quality of quenchingFurnace typesHeat treatment furnacesPropellerOperability

The invention discloses a quenching cooling device for a large seal head. The quenching cooling device comprises a groove body. The seal head is placed in the groove body. The groove body is connected with a cooling medium pipeline through a driving pump. A cooling medium is arranged in the cooling medium pipeline. The quenching cooling device further comprises a propeller stirring jet device, a diving stirring jet device, a centrifugal pump water pumping device and a position adjusting device. According to the quenching cooling device, the propeller stirring jet device, the diving stirring jet device and the centrifugal pump water pumping device are arranged in different positions in the groove body, thus district cooling of the outer wall, the inner wall and other areas of the seal head is achieved, and overall circular flowing of the cooling medium in the groove body is also achieved. Therefore, the quenching cooling device can effectively ensure the quenching quality of the seal head, the utilization ratio of the cooling medium is improved, the structure is simple, and the practical operability is high.

Owner:SHANGHAI DIANJI UNIV

Method and device for cooling and waste heat recovery of flash smelting furnace body

ActiveCN103206866ARaise the gradeRaise the water temperatureEnergy industryIncreasing energy efficiencyThermal insulationRefractory

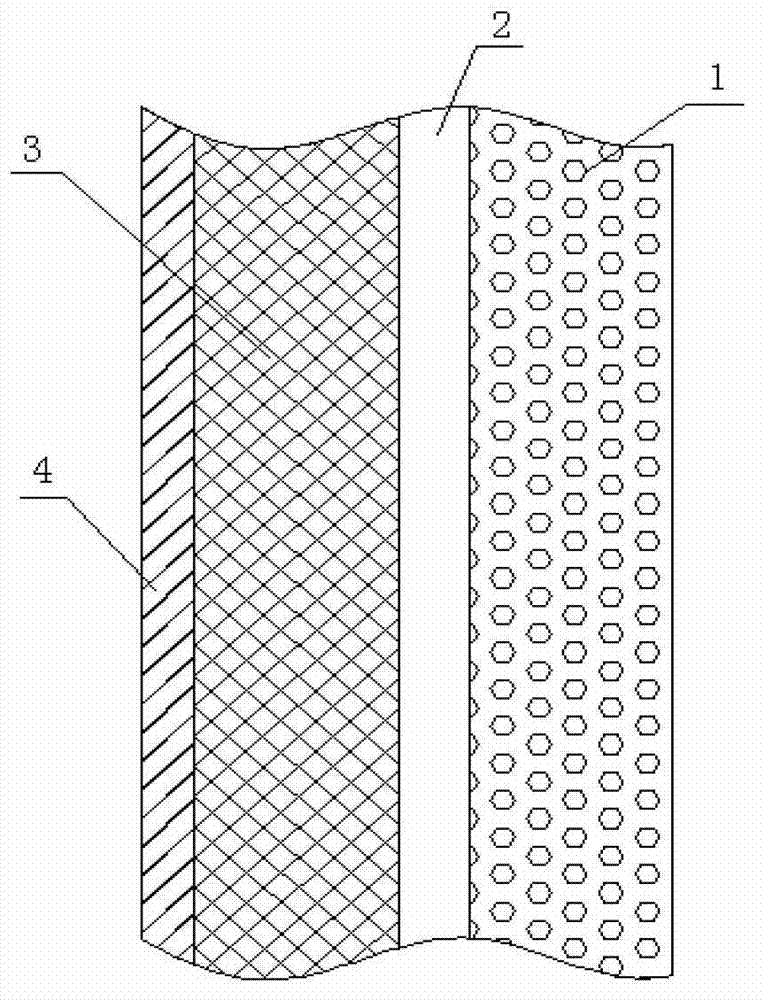

The invention discloses a method and a device for cooling and waste heat recovery of a flash smelting furnace body. The method comprises the steps of carrying out district cooling on a flash smelting furnace; carrying out forced circulation cooling in a sedimentation tank and membrane-type natural circulation water-cooled vaporization in a reaction tower; keeping the temperature of a water-cooled wall of the reaction tower to be lower than 280 DEG C; and recovering the waste heat cooled in the flash smelting furnace body to generate low-pressure steam with the pressure of lower than 1.5 MPa and simultaneously meet the requirement of load change of the reaction tower on cooling. A thermal insulation material layer (3) is arranged on the inner wall of an outer housing (4) of the reaction tower (14), a membrane-type water-cooled wall (2) is arranged inside the thermal insulation material layer (3), and a ramming flame-proof material layer (1) is coated on the inner side the membrane-type water-cooled wall (2). According to the method and the device for cooling and waste heat recovery of the flash smelting furnace body, the amount of cooling water is saved, and simultaneously the cooling requirement of load change of the reaction tower is met.

Owner:CENT SOUTH UNIV

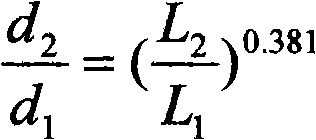

District cooling system and method capable of achieving dynamic cold storage

PendingCN110848839AReduce energy consumptionImprove cooling efficiencyMechanical apparatusLighting and heating apparatusWater storageIce storage

The invention discloses a district cooling method capable of achieving dynamic cold storage. A district cooling system capable of achieving dynamic cold storage is included. The method comprises the following steps that the following corresponding stages, the dynamic water storage cooling stage, the dynamic cold storage switching cooling stage, the ice storage cooling and onboard refrigerating unit cooling stage and the ice cold cooling and onboard refrigerating unit and dual-condition refrigerating unit cooling stage, are distributed according to the actual load rates. On the premise of meeting user requirements, cold storage schemes are set in a staged manner by combining the stage construction condition of a cooling station, cold is rationally divided into the corresponding cooling stages according to the actual load rates of district users, cold of various cooling sources is utilized to the largest degree in the stages, the cooling efficiency of the district cooling system is remarkably improved, and energy consumption is reduced.

Owner:珠海新源热力有限公司

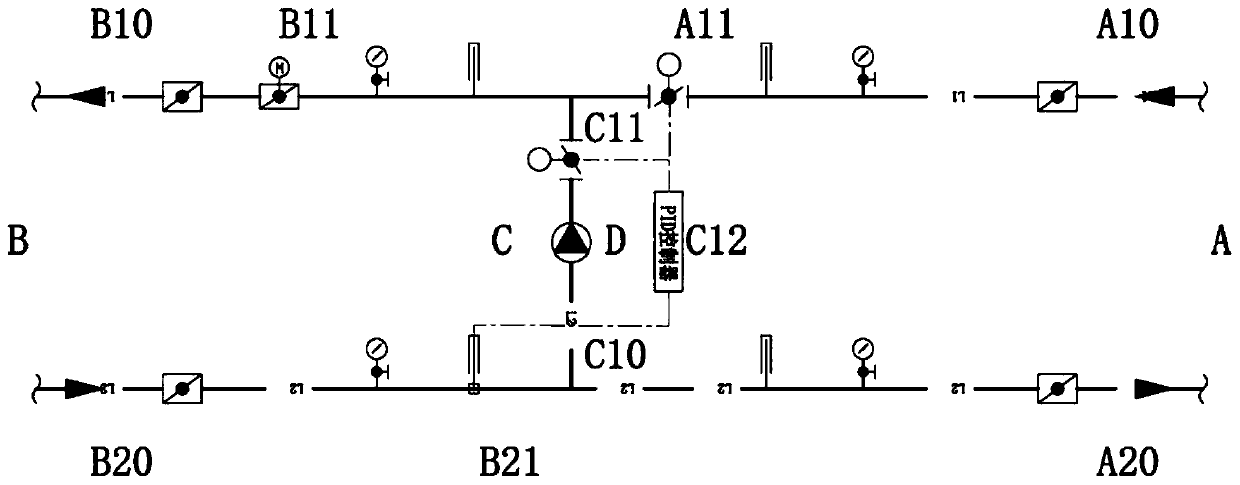

User access system for district heating and cooling system

PendingCN107726581AReduce pump headReduce transportation energy consumptionMechanical apparatusLighting and heating apparatusAutomatic controlEngineering

The invention discloses a user access system for a district heating and cooling system. The system comprises a static flow balancing valve, a self-operated pressure difference control valve, a proportional-integral electric valve, a temperature transmitter and a PID controller. The PID controller is connected with the proportional-integral electric valve and the temperature transmitter. The proportional-integral electric valve is installed on a water return pipe of each user branch cooling and heating primary side pipe net, the temperature transmitter is installed on a water return pipe of each user cold water and hot water secondary side pipe net, the temperature transmitter transmits detected temperature information to the PID controller, and the PID controller controls the valve openingof the proportional-integral electric valve based on the information. Pipe net conveyed cold-hot water home-entry flow and pressure are adjusted to be within the working range of the proportional-integral electric valve, and automatic control is convenient.

Owner:ARCHITECTURAL DESIGN & RES INST OF SOUTH CHINA UNIV OF TECH

Vending machine

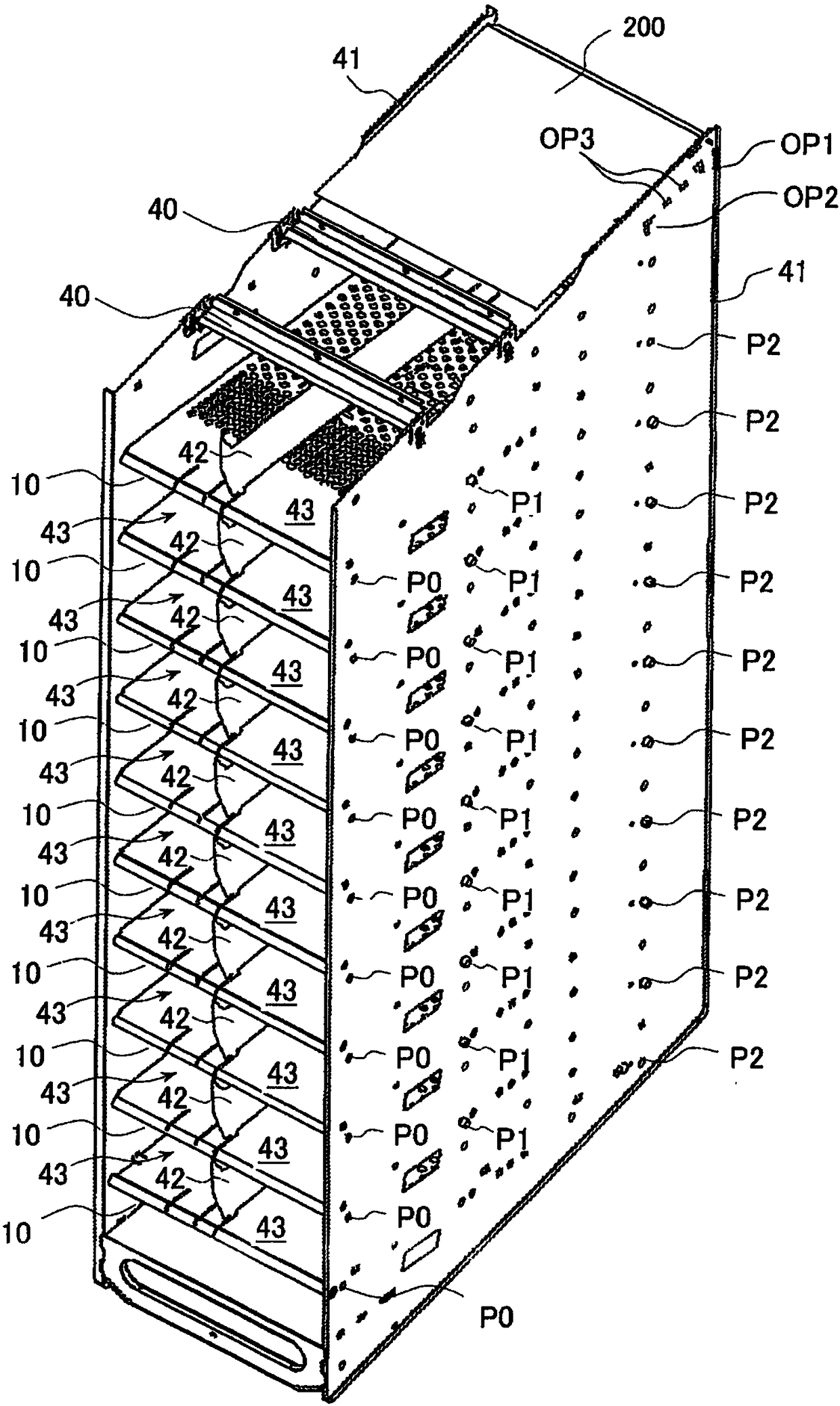

ActiveCN109147167ASuitable temperatureCoin-freed apparatus detailsApparatus for dispensing discrete articlesCold airLow speed

The present invention provides a vending machine capable of performing overall cooling heating and district cooling heating, respectively, and can automatically cool the product to a temperature suitable for sale. The vending machine is provided with a tilting frame in the product storage of the main cabinet, and is provided with an upper duct member that guides the air in the chamber blown by thelower fan in the cabinet along the back wall of the main cabinet, and an in-storage upper fan which conveys the cold air or hot air from the upper duct member downwards, wherein vent holes are arranged from the central area of the board surface to the lower area, when the whole cooling and heating is carried out, the in-storage lower fan is driven at the rated rotation speed, and stops the driving of the in-storage upper fan; when the local cooling and heating is carried out, the in-storage lower fan is driven at the specified low-speed rotation speed lower than the rated rotation speed, andthe in-storage upper fan can be driven at the rated rotation speed.

Owner:FUJI ELECTRIC CO LTD

Method for district cooling of blast furnace during blast furnace dissection

InactiveCN101748224AEasy to dissectAvoid breakingBlast furnace componentsBlast furnace detailsGranularityWater flow

The invention provides a method for district cooling of a blast furnace during blast furnace dissection, belonging to the technical field of ironmaking. The method comprises the following steps: calibrating a district cooling datum line; drilling a cooling medium filling opening on the datum line; estimating the heat produced in unit time after the blast furnace blows out as well as cooling water flow required in cooling the blast furnace; carrying out district cooling; and finishing district cooling. Compared with the background technology, the method combines a blast furnace smelting technology with the need of blast furnace dissection to formulate a special blast furnace cooling method during blast furnace dissection, thus the method can truly keep information in the blast furnace smelting process, and is favourable for knowing the furnace burden distribution state, the furnace burden granularity variation, the furnace burden reducing process, the slag and molten iron distribution state, chemical element distribution state and the like in the blast furnace smelting process.

Owner:SHANDONG IRON & STEEL CO LTD +1

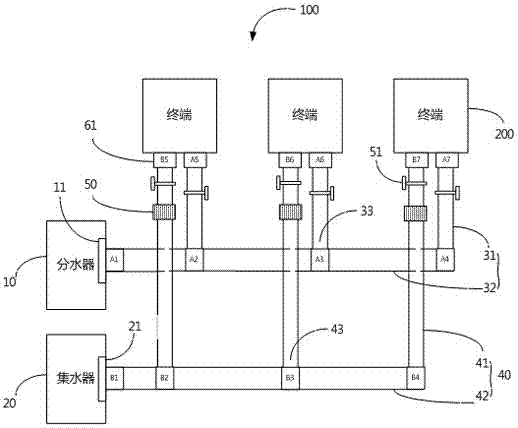

District cooling and heating transmission and distribution network health inspection system

ActiveCN104214520BRealize real-time monitoringAvoid energy lossMeasurement of fluid loss/gain ratePipeline systemsDifferential pressureElectrical control

The invention provides a regional cooling and heating transmission and distribution pipeline network health inspection system, which includes a water separator, a water collector, a water inlet pipeline, a water return pipeline, multiple filters and multiple electric control valves; the water distributor It is connected to multiple terminals through the water inlet pipeline, and the water inlet pipeline includes multiple water diversion ports; the water collector is connected to the terminal through the return water pipeline, and the return water pipeline includes multiple water collection ports; the filter is set in the return water pipeline close to the terminal The collection unit includes a plurality of water pressure sensors, and the connection between the water inlet pipe and the water distributor and the terminal, the water distribution port, the connection between the return water pipe and the water collector and the terminal, and the water collection port are all equipped with water pressure sensors. ; Each filter is located between two water pressure sensors; the electric control valve is set in the water inlet pipeline and the water return pipeline. By arranging a plurality of water pressure sensors in the pipeline, and judging whether there is blockage in the pipeline and the location of the blockage according to the pressure difference detected by the water pressure sensors, real-time monitoring of the pipeline is realized.

Owner:武汉中电节能有限公司

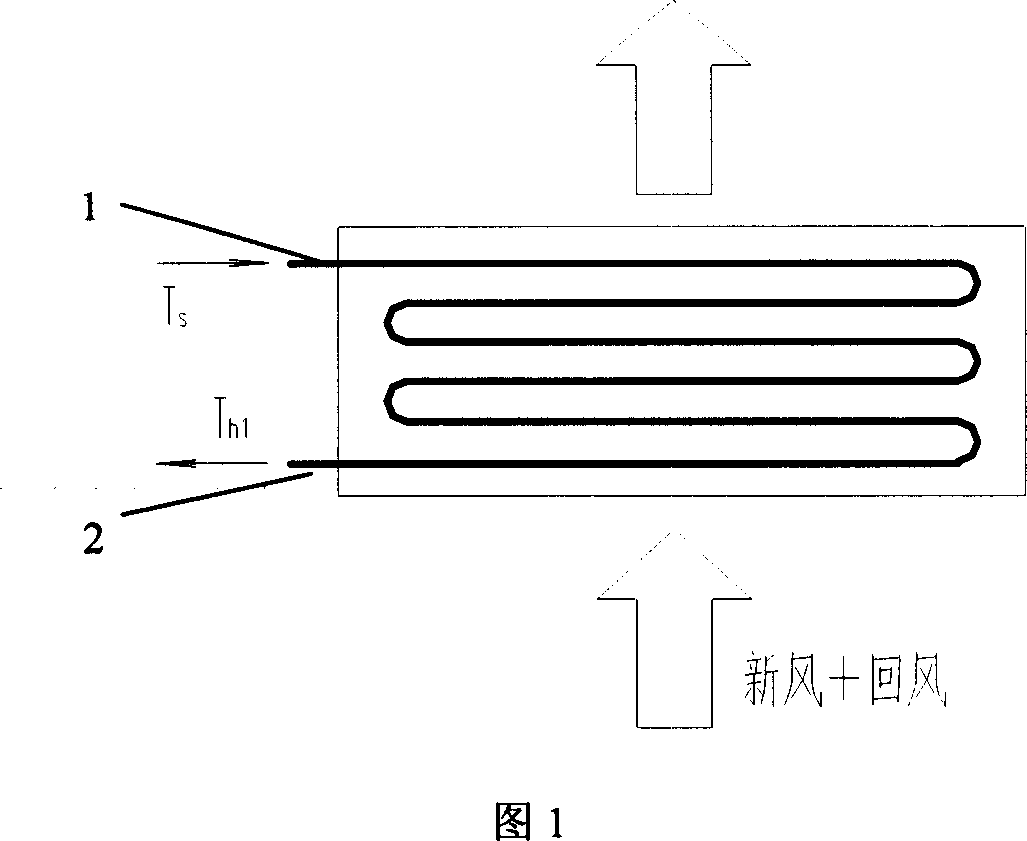

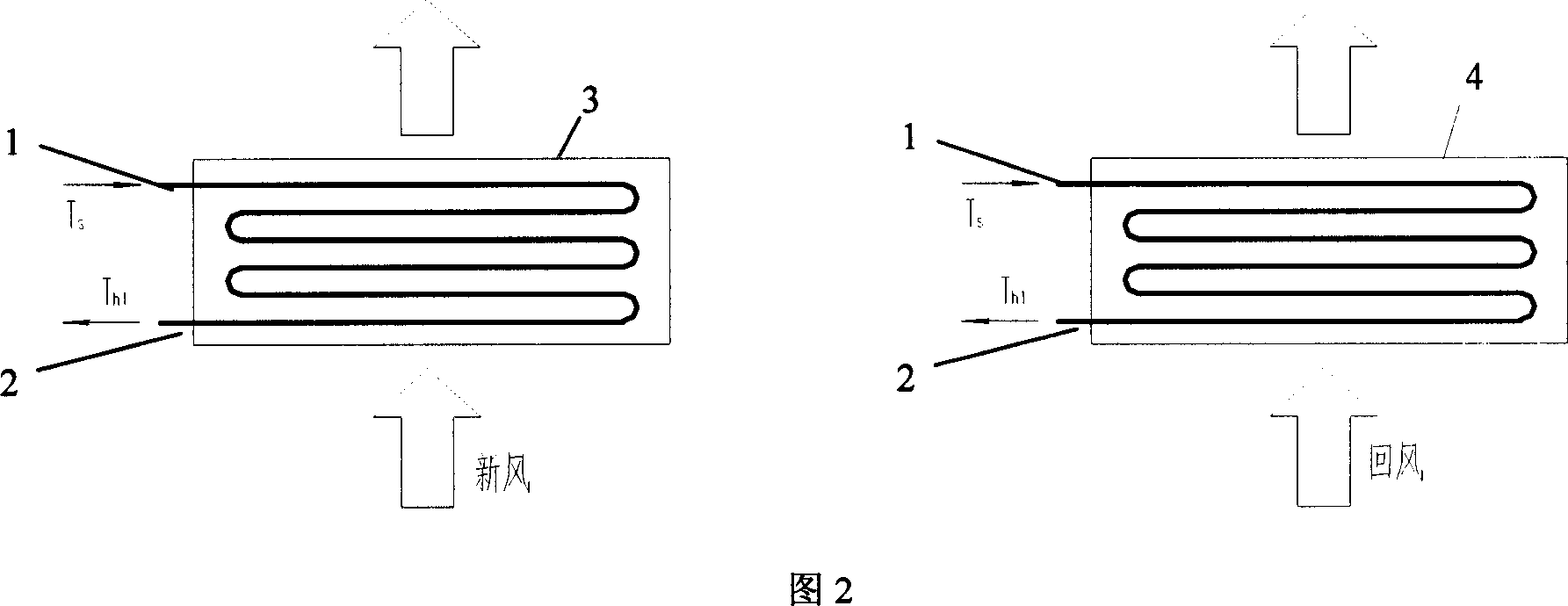

Regional cold supply system and its cold step utilizing method

InactiveCN1945137AReduce cold lossExtend the distance of economic transportationLighting and heating apparatusAir conditioning systemsFresh airTemperature difference

The present invention relates to provides one kind of regional cold supply system, which includes one secondary refrigerated water pipeline with refrigerated water supplying pipe, refrigerated water returning pipe, fresh air cooler and returned air cooler. The fresh air cooler and the returned air cooler are independent, the returned air cooler has water inlet connected to the refrigerated water supplying pipe and water outlet connected to the water inlet of the fresh air cooler, and the fresh air cooler has water outlet connected to the refrigerated water returning pipe. The present invention has increased water supply and water return temperature difference of the secondary refrigerated water pipeline, lowered cold loss, lowered pump power consumption and lowered cost.

Owner:SOUTH CHINA UNIV OF TECH

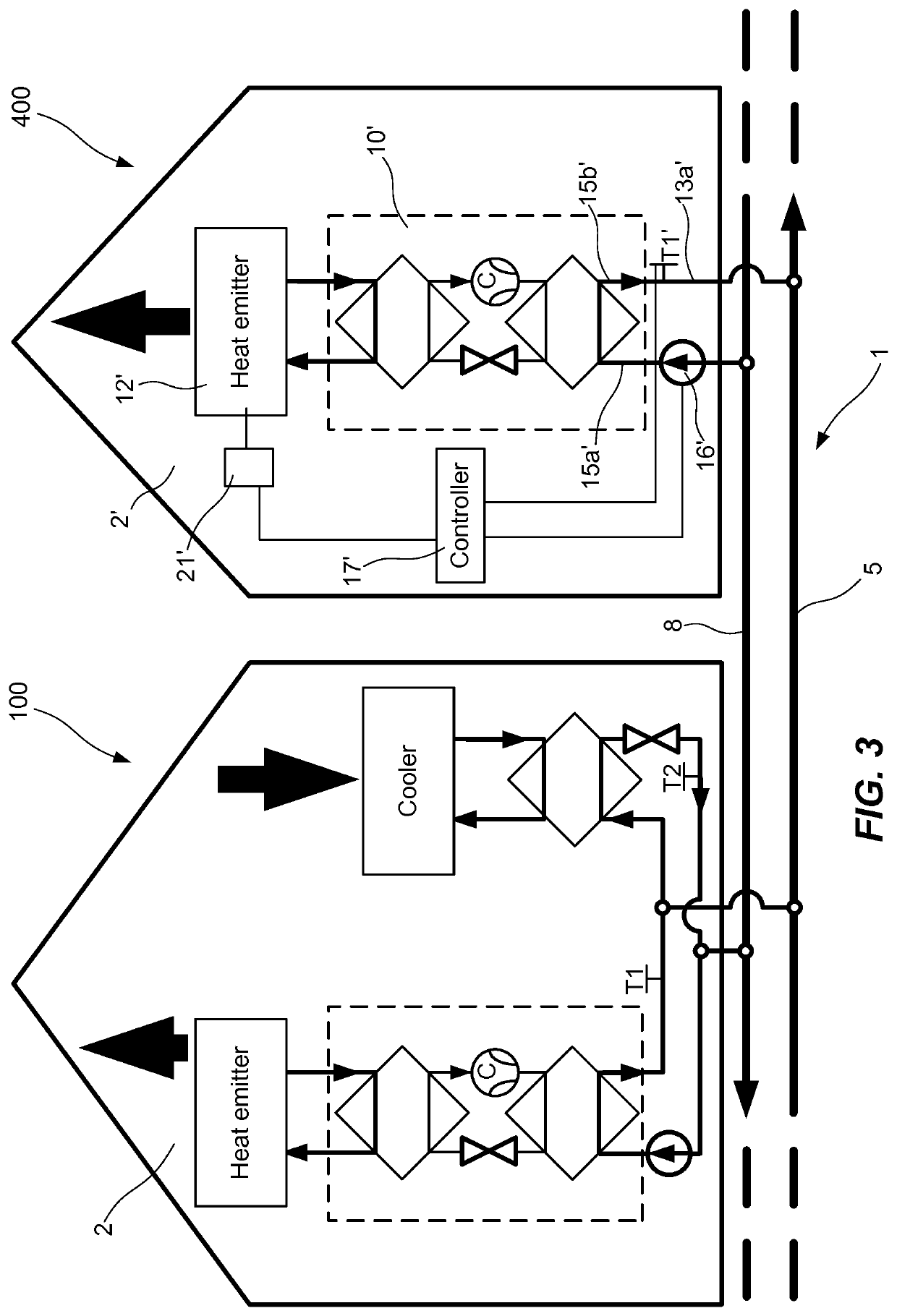

Heating system

InactiveCN109790983AReduce energy consumptionReduce loadDistrict heating systemHot-air central heatingTap waterEngineering

The invention refers to a heating system (100) comprising a district cooling grid (1) and a local heating system (200) configured to heat a building and / or to heat tap water for the building. The heating system has a feed conduit (5) for an incoming flow of cooling fluid having a first temperature, and a return conduit (8) for a return flow of cooling fluid having a second temperature, the secondtemperature being higher than the first temperature. The local heating system (200) comprises a heat pump (10) having an inlet (10a) connected to the return conduit (8) of the district cooling grid (1) and an outlet (10b) connected to the feed conduit (5) of the district cooling grid (1).

Owner:E ON SVERIGE

District cooling and heating transportation and distribution pipe network health check system

ActiveCN104214520ARealize real-time monitoringAvoid energy lossMeasurement of fluid loss/gain ratePipeline systemsDifferential pressureHealth check

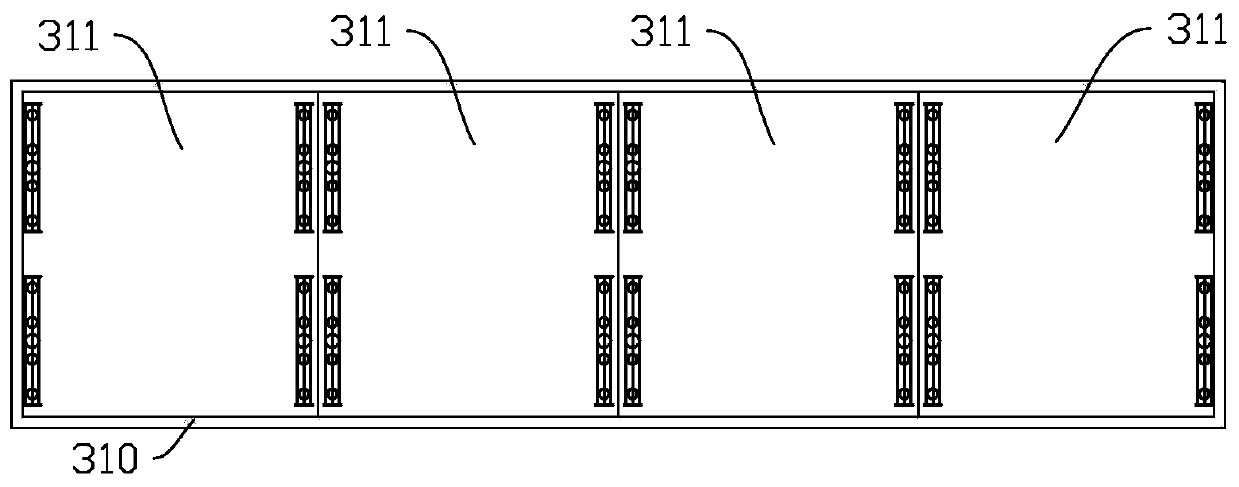

The invention provides a district cooling and heating transportation and distribution pipe network health check system. The district cooling and heating transportation and distribution pipe network health check system comprises a water distributor, a water collector, water inlet pipelines, water return pipelines, a plurality of filters and a plurality of electrical control valves; the water distributor is connected with a plurality of terminals through the water inlet pipelines, and the water inlet pipeline comprises a plurality of water distribution openings; the water collector is connected with the terminals through the water return pipelines, and the water return pipeline comprises a plurality of water collection openings; the filters are arranged on positions, adjacent to the terminals, of the water return pipelines; the collection unit comprises a plurality of water pressure sensors, the junctions between each water inlet pipeline and the water distributor and between each water inlet pipeline and each terminal, the junctions among each water distribution opening and each water return pipeline and the water collector and the terminal as well as the water collection openings are respectively provided with a water pressure sensor; each filter is arranged between every two adjacent water pressure sensors; the electrical control valves are arranged in the water inlet pipelines and the water return pipelines. A plurality of water pressure sensors are arranged in the pipelines, and whether the pipeline is blocked or not and the blockage position of the pipeline are judged according to the pressure difference detected by the water pressure sensors, so that real-time monitoring of the pipelines can be realized.

Owner:武汉中电节能有限公司

Thermal power plant coupling data center integrated energy system and operation method

PendingCN113803709AReduce operating electricity costsMeet cooling needsLiquid degasificationHeat pumpsIntegrated energy systemData center

The invention discloses a thermal power plant coupling data center integrated energy system and an operation method. The thermal power plant coupling data center integrated energy system comprise an absorption refrigerating unit, the absorption refrigerating unit is driven by heat of boiler flue gas of a thermal power plant, boiler steam, steam extraction of a steam turbine or steam exhaust of the steam turbine, or the absorption refrigerating unit is driven by heat lost by a cold source of a thermoelectric unit, and low-temperature cold water produced in summer is injected into a heat supply pipe network or a newly-built cold water pipe network; the absorption refrigerating unit communicates with a refrigerating user through the heat supply pipe network or the newly-built cold water pipe network, low-temperature cold water is conveyed to a heat exchange unit or a tail end fan coil of a central air conditioner of the refrigerating user, and therefore the cooling capacity of the thermal power plant is conveyed to the refrigerating user. According to the system, an existing external supply pipe network is utilized to carry out regional cooling, so that the pipe network investment with the maximum capital investment of a common regional cooling project is reduced; by means of steam turbine exhaust steam or circulating water waste heat and other cold source losses of the thermal power generating unit, the operation heat efficiency of the thermal power plant in summer is greatly improved, and unit coal consumption is reduced.

Owner:HEPU ENERGY ENVIRONMENTAL TECHNOLOGY CO LTD

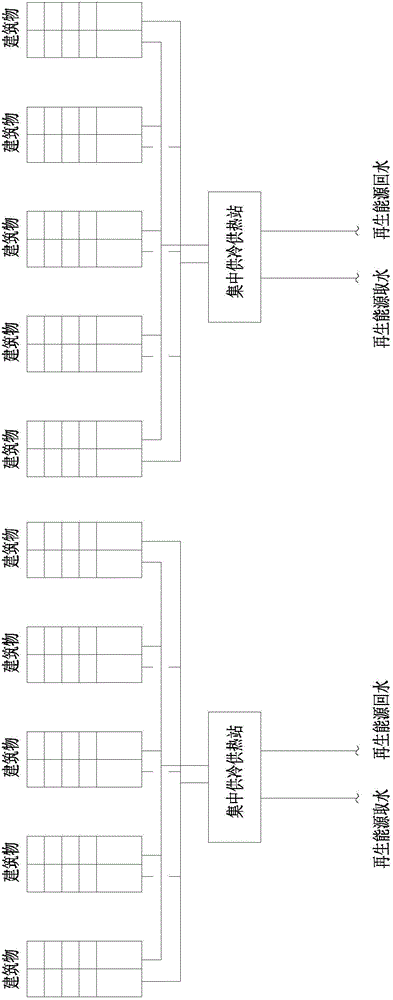

Regional cooling and heating system

ActiveCN104566599ARealization of large area energy supplyImprove energy efficiencyDistrict heating systemSpace heating and ventilation safety systemsEngineeringEnergy supply

The invention relates to a regional cooling and heating system comprising a main concentrate cooling and heating station and a plurality of cooling and heating substations. The cooling and heating substations are connected to the main concentrate cooling and heating station and are used for cooling and heating regionally. A main bypass circulating pipe is connected between a main discharging pipe and main returning pipe of the main concentrate cooling and heating station; a main control valve used for controlling the medium flowing and a detector used for detecting the temperature of medium in the main discharging pipe and main returning pipe are arranged on the main bypass circulating pipe; the detector transmits the detected temperature to a controller, and the controller compares a received temperature signal with a preset temperature value and controls the operation state of the main control valve according to the comparing result. The energy supply capability of the unit flow can be 11.6kW to 23.3 kW, the capability for supplying energy to substations is increased by 2 to 4 times as compared with that of the single utilization, the energy supplying radius is increased greatly by 2 to 3 kM ordinarily, and the energy supply construction area is larger than 2 million m2.

Owner:江苏氿川能源科技有限公司

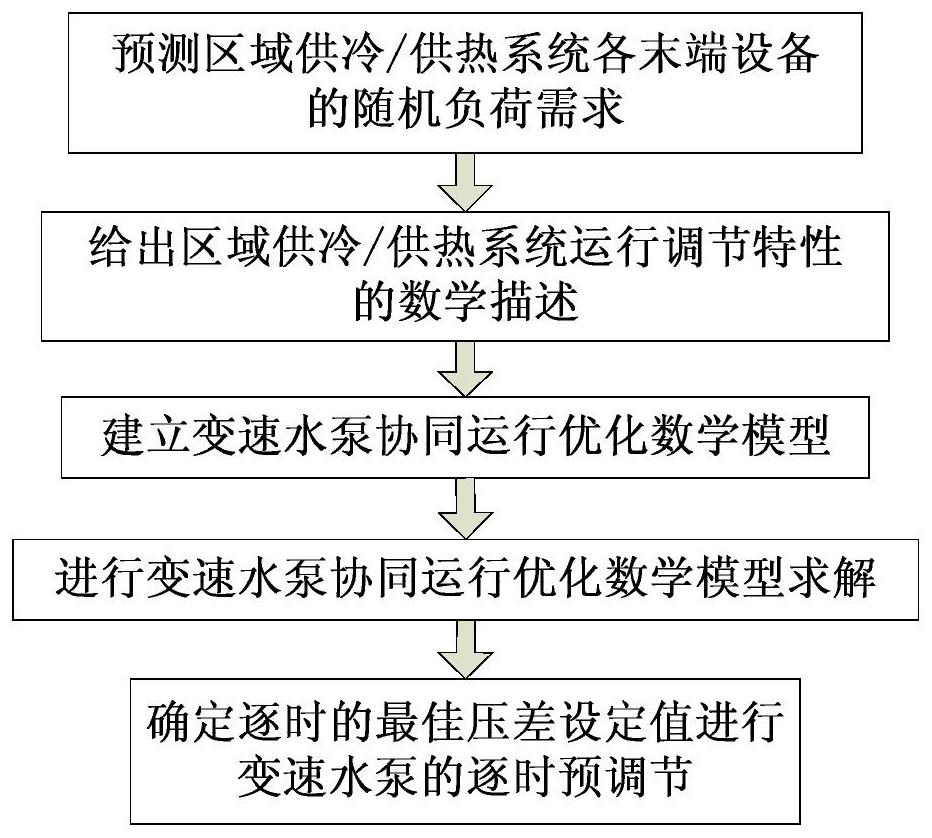

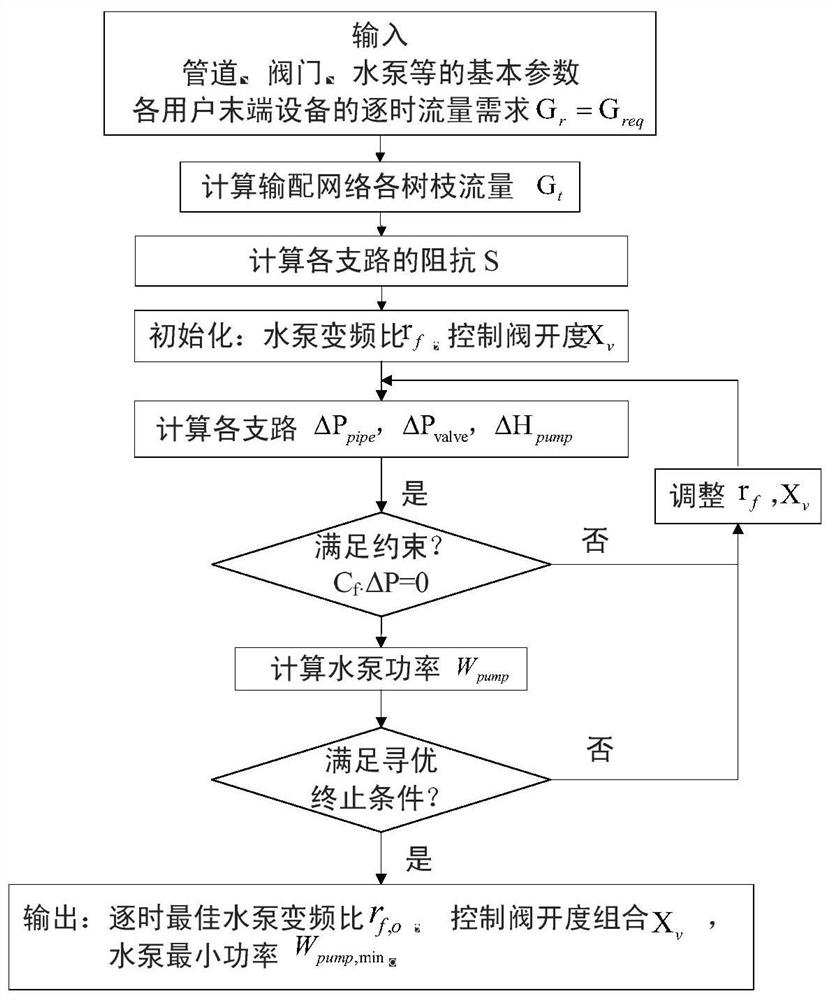

Variable-speed water pump operation adjusting method based on collaborative optimization strategy

InactiveCN111623491AReduce energy consumptionEasy to operateMechanical apparatusMathematical modelProcess engineering

The invention discloses a variable-speed water pump operation adjusting method based on a collaborative optimization strategy. The method comprises steps as follows: predicating random load demands ofend equipment of a district cooling / heating supply system; performing mathematical description of operation adjusting characteristics of the district cooling / heating supply system; establishing a variable-speed water pump collaborative operation optimization mathematical model; carrying out solving of the variable-speed water pump collaborative operation optimization mathematical model; pre-conditioning a variable-speed water pump hour by hour, and realizing operation optimization of the centralized variable-speed water pump of the district cooling / heating supply system with independently regulatable terminal cooling / heating supply equipment. According to the variable-speed water pump operation adjusting method based on the collaborative optimization strategy, demands of actual engineering can be met well, water pump energy consumption of the district cooling / heating supply system is effectively reduced, operation expense is saved, operation is convenient for administrative staff, andthe method has quite good application prospects.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Combined heating and cooling system

ActiveUS20210231319A1Reduce energy consumptionReduce loadDistrict heating systemHeating fuelEngineeringCooling fluid

A combined cooling and heating system including a district cooling grid having a feed conduit for an incoming flow of cooling fluid having a first temperature, and a return conduit for a return flow of cooling fluid having a second temperature, the second temperature being higher than the first temperature; a local cooling system being configured to absorb heat from a first building and comprising a heat exchanger having a heat exchanger inlet and a heat exchanger outlet; and a local heating system being configured to heat the first or a second building and comprising a heat pump having a heat pump inlet and a heat pump outlet. The heat exchanger inlet is connected to the feed conduit of the district cooling grid; and the heat pump inlet is connected to the return conduit of the district cooling grid and to the heat exchanger outlet.

Owner:E ON SVERIGE

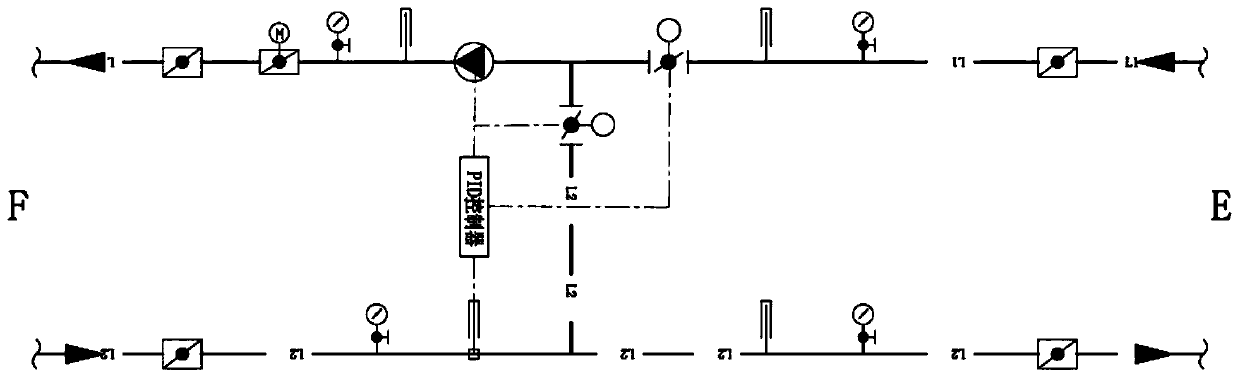

User frequency conversion distributed water mixing access system for area cooling system and method thereof

PendingCN109708226AReduce complexityImprove operational efficiencyMechanical apparatusLighting and heating apparatusAutomatic controlEngineering

The invention discloses a user frequency conversion distributed water mixing access system for an area cooling system and a method thereof. The system comprises distributed variable frequency water pumps, a static flow balance valve, a self-operated pressure difference control valve, a proportional integral electric valve, a temperature transmitter, a PID controller and a water mixing pipe; the distributed variable frequency water pumps are installed on a water mixing pipe or a user water supply pipe of each user according to user requirements, the proportional integral electric valve is respectively arranged on a water supply pipe-level water mixing pipe of each user branch supply cold primary side pipe network, the temperature transmitter is installed on a water return pipe of the cold water secondary side pipe network of each user, the temperature transmitter transmits detected temperature information to the PID controller, the PID controller controls the operation frequency of thevariable-frequency water pump and the valve opening degree of the proportional integral electric valve according to the detected temperature. According to the system, the water inlet flow and the pressure of the water inlet flow are adjusted to be within the working range of the proportional integral electric valve, and automatic control is facilitated.

Owner:ARCHITECTURAL DESIGN & RES INST OF SOUTH CHINA UNIV OF TECH

District cooling system pipe network path planning method and system

InactiveCN107330169AImprove the problem of excessive cold lossHigh precisionGeometric CADSpecial data processing applicationsSystems designDirected graph

The invention relates to the technical field of air conditioners and discloses a district cooling system pipe network path planning method and system. The method comprises the steps that a planning system establishes a pipe network path planning directed graph according to a district cooling system design drawing, wherein the pipe network path planning directed graph comprises multiple vertexes and multiple sides and each side has a weight value; for two selected vertexes, the shortest path between the two vertexes is determined according to connection relations between the two selected vertexes, other vertexes between the two selected vertexes and the sides and weight values of all the sides; according to the shortest path, a district cooling system pipe network path is determined. The district cooling system pipe network path planning method solves the problems that in the prior art, a pipe network is overlong because the pipe network of a district cooling system is designed according to experience of designers, and therefore cold energy loss of the district cooling system is too much.

Owner:ENN ENERGY SERVICE

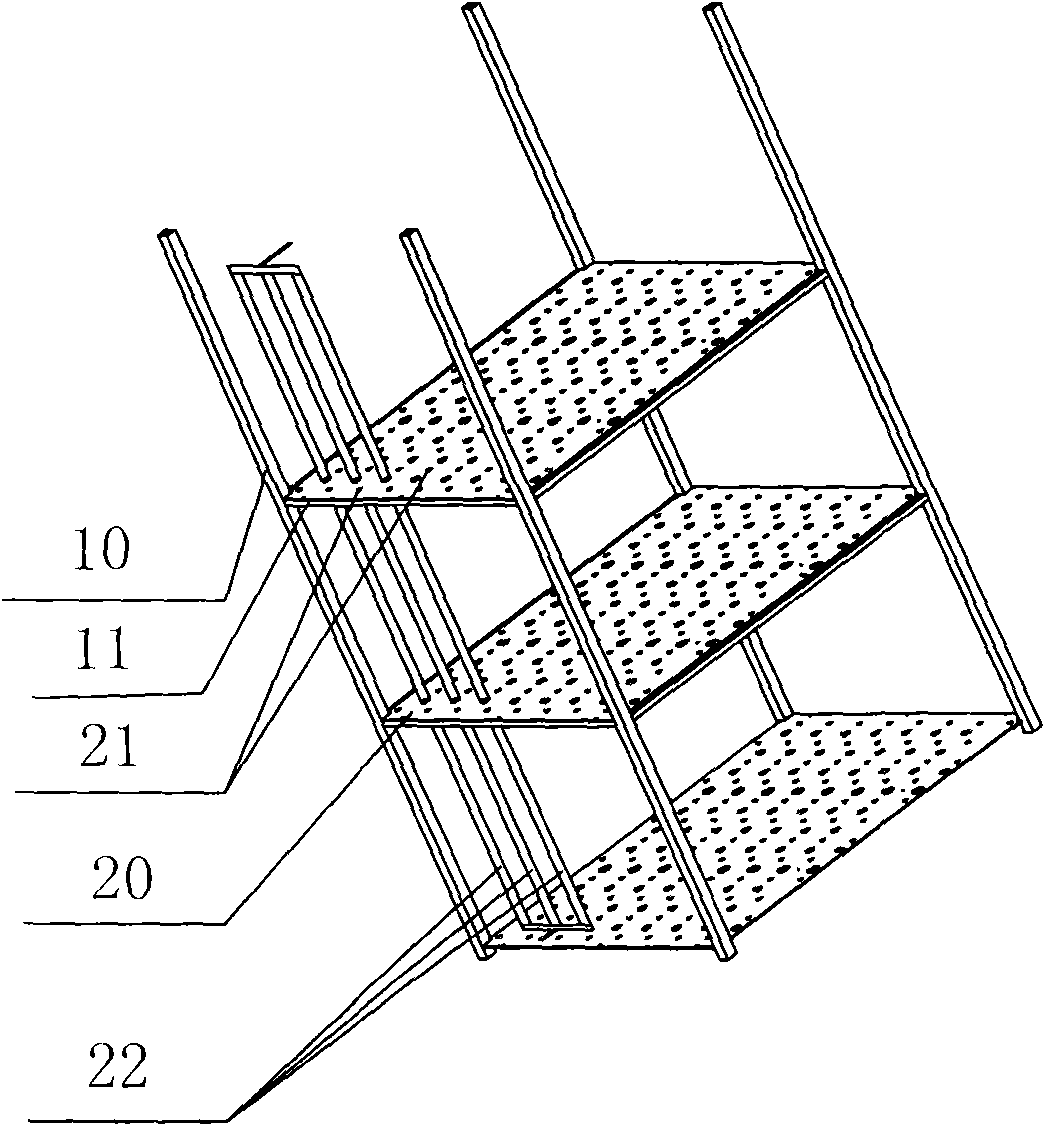

District cooling type ice-storage tank device

InactiveCN101581545BSmall temperature differenceUniform temperatureStationary conduit assembliesHeat exchanger casingsIce storageHeat conducting

A district cooling type ice-storage tank device comprises a heat-exchanging coil; a bracket is arranged in an ice-storage tank; a plurality of layers of heat-conducting panels are arranged on the bracket along the water surface direction; through holes are evenly designed in the heat-conducting panels for conducting heat exchange between the water at the upper layer and the lower layer; the heat-exchanging coil is inserted in a layer frame structure and the heat-conducting panels; and the heat-conducting panels are vertical to the flow direction of refrigerant in the heat-exchanging coil. As the heat-conducting panels are additionally arranged to conduct incomplete fault segmentation to the water body, on one hand, the temperature difference between the upper water layer and the lower water layer adjacent to the heat-conducting panels at the enhancing layers is reduced; on the other hand, the through holes in the heat-conducting panels can lead the high-temperature water at the bottomof the upper layer thereof and the low-temperature water on the top of the lower layer to be effectively diffused and convected, thereby ensuring the temperature at the upper water layer and the lowerwater layer to be more uniform. In addition, by adopting a vertical heat-exchanging coil with an isometric or unequally spaced design layout to form subsection heat exchange, the heat-exchanging amount at each section at a certain height can be ensured basically the same, and the liquid accumulated in a tube can be effectively avoided, thereby leading the heat exchange to be more uniform.

Owner:GUANGDONG CHIGO AIR CONDITIONING

Zoning cold supply energy saving system and method of data center air conditioner

ActiveCN102425821BReduce installed capacityLow costLighting and heating apparatusHeat proofingCommon coldCold air

The invention relates to a zoning cold supply energy saving system and method of a data center air conditioner; the zoning cold supply energy saving system is characterized in that a machine room space is formed by an overhead floor, an indoor ceiling and a wall, wherein a common cold supply air conditioner and an accurate cold supply air conditioner are arranged in the machine room space; the machine room space comprises an accurate cold supply space and an external common refrigerating space; the accurate cold supply space is formed by a lower space of the overhead floor, an inner space of a machine cabinet, an air supply pipeline, an air return pipeline and the accurate cold supply air conditioner, and the external common refrigerating space is formed by an upper space of the overhead floor and the common air conditioner. The common air supply conditioner sends out cold air to the common refrigerating space; the same amount of cold air is returned; and the accurate air supply conditioner sends out cold air to the accurate refrigerating space. The zoning cold supply energy saving system completely changes the mode that for the traditional precise data center air conditioner, the total power of display cold of the air conditioner is calculated by the area of the whole machine room, thereby the required cold quantity is accurately calculated by using the area of the cold supply space; and therefore, under the condition that the energy consumption is greatly reduced, the installed capacity and the cost of the air conditioner are simultaneously reduced; and the requirement of equipment inside a cabinet for high-efficiency cold supply is also ensured.

Owner:GUANGZHOU HOLDSTORM SCI & TECH

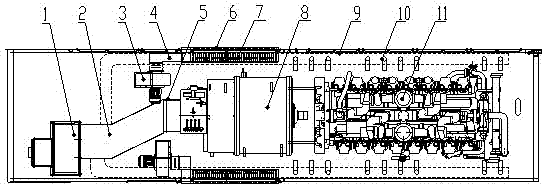

Positive pressure ventilation system of power chamber of diesel locomotive

The invention discloses a positive pressure ventilation system of a power chamber of a diesel locomotive. The positive pressure ventilation system comprises a sealed clean air chamber and a power chamber, wherein the clean air chamber is internally provided with a ventilation fan; the power chamber is internally provided with a main generator, a diesel engine and original equipment; the outlet end of an air filter is connected with the ventilation fan; the ventilation fan is respectively connected with the main generator, the diesel engine and the original equipment by virtue of a main air duct; the main air duct is externally connected with an air duct which is connected and communicated with an air outlet pipe of the power chamber. The positive pressure ventilation system has the advantages that air is clean; the air entering into the power chamber is filtrated by the air filter, so that the dust removal rate is up to 90%, and the power chamber is prevented from being polluted by outside dust and sand; positive pressure ventilation is adopted, so that the positive pressure station in the power chamber is ensured, and dust, sand and the like outside a vehicle are prevented from being sucked into the power chamber; district cooling is adopted, and cooling air is guided to different regions of the power chamber by virtue of air distribution ducts, so that the cooling target is explicit; the outlets of the air distribution ducts are provided with throttling plates, so that the air outlet quantity can be regulated.

Owner:CRRC ZIYANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com