District cooling type ice-storage tank device

A technology of partitioned cooling and ice storage tanks, which is applied to the types of heat exchangers, heating methods, fixed conduit components, etc., can solve problems such as difficult uniform heat transfer, compressor liquid compression, and low heat transfer efficiency of coils, and achieve Uniform heat, uniform temperature, avoiding the effect of liquid accumulation in the tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

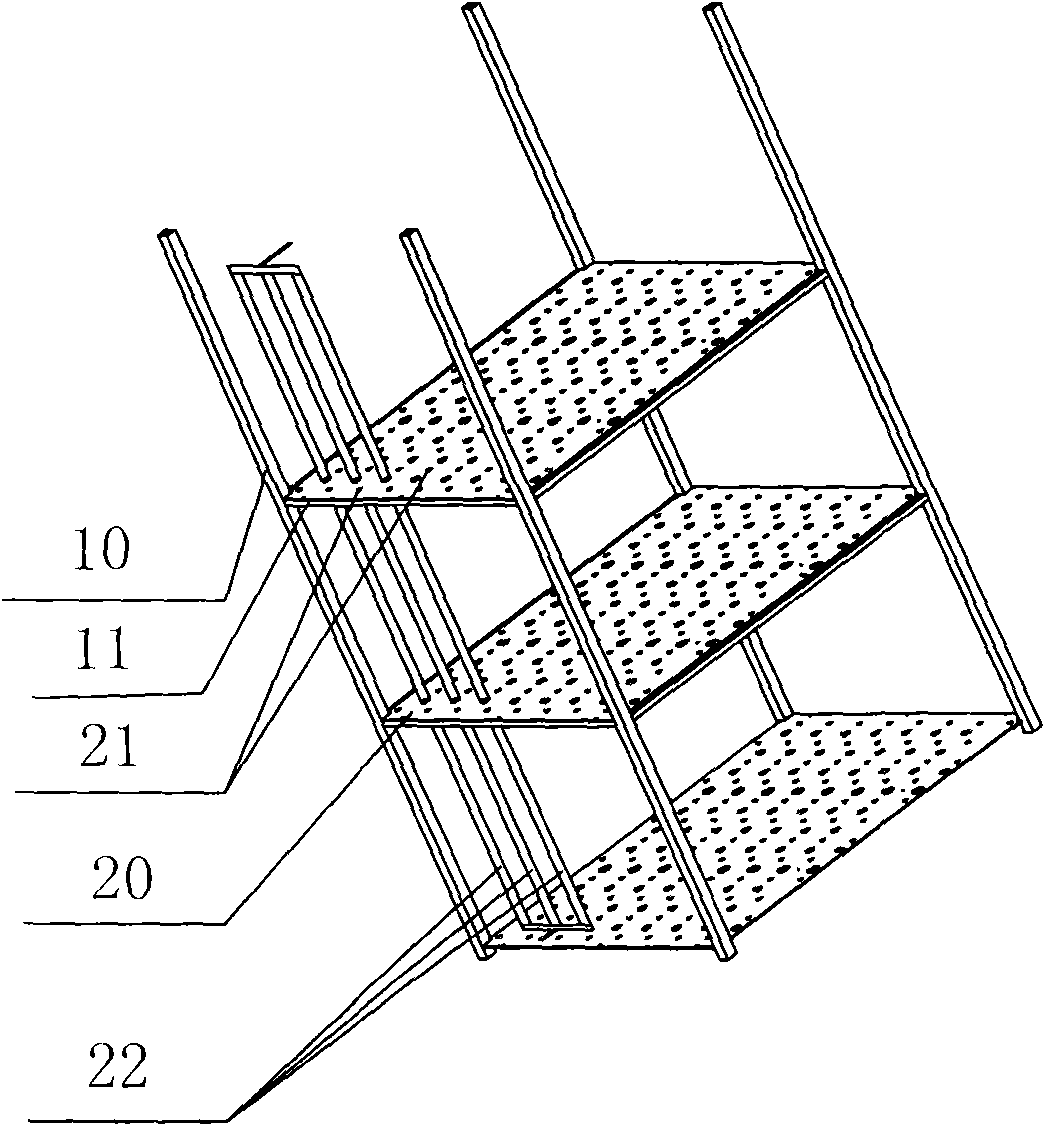

[0013] refer to figure 1 , the partition cooling type ice storage device of the present invention is aimed at the phenomenon that water is prone to produce a large temperature difference between the upper and lower sides during the process of solidification and dissolution at low temperatures. There are heat exchange coils and brackets in the ice storage tank, and the brackets include four columns 10 And vertically connected with the column 10, a plurality of partitions 11 arranged at intervals of 30 to 50 cm at equal or unequal intervals, as can be seen from the figure, four columns 10 are arranged at the four corners of the partition 11, and each partition 11 A heat conduction plate 20 is provided on the heat conduction plate 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com