Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

569results about How to "Uniform heat exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

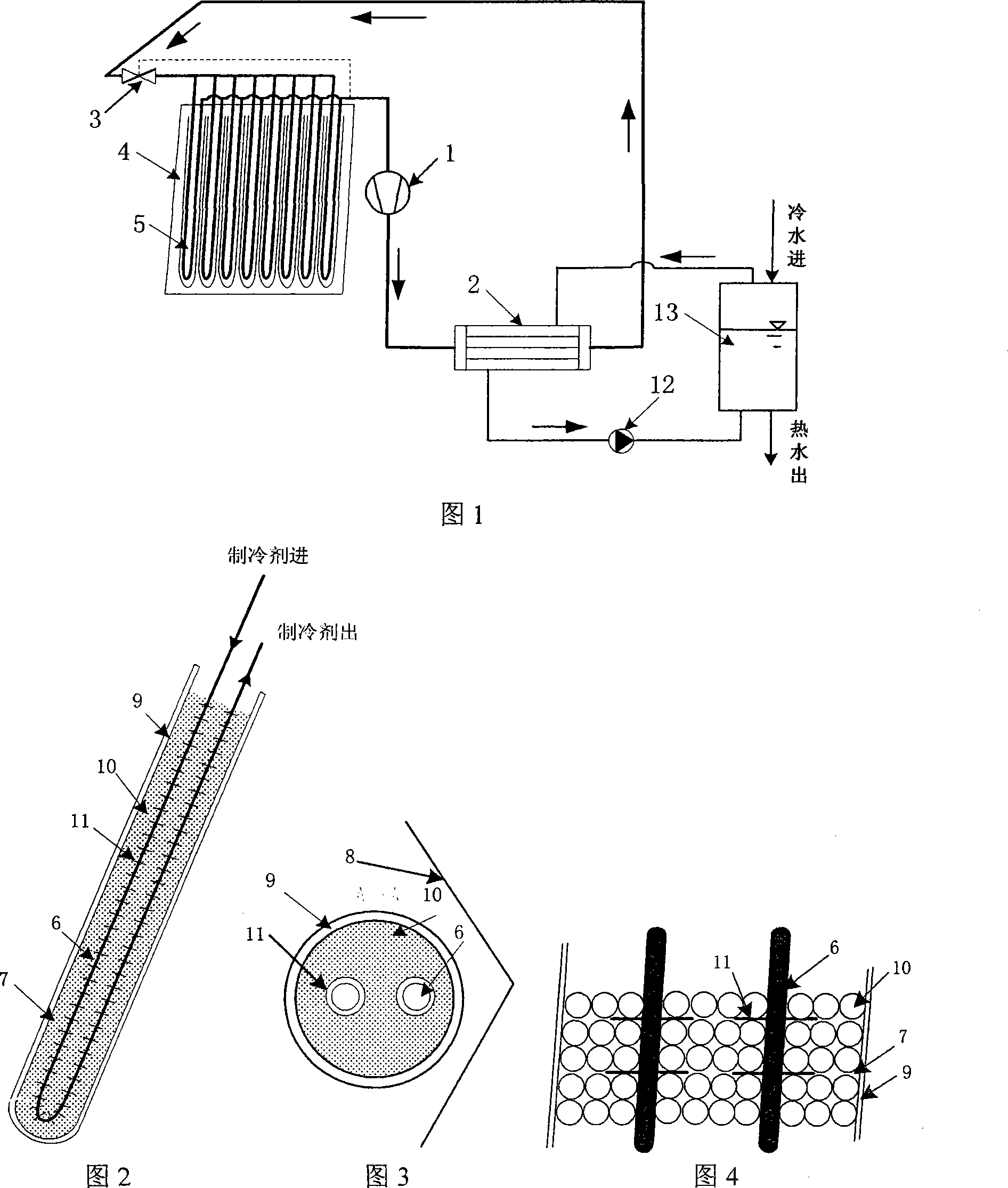

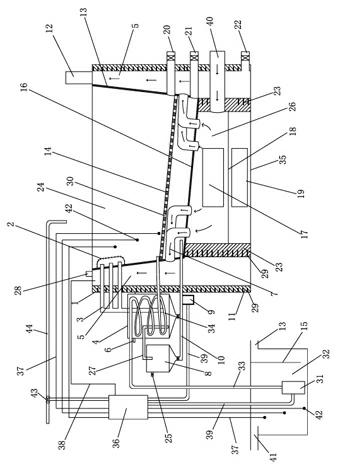

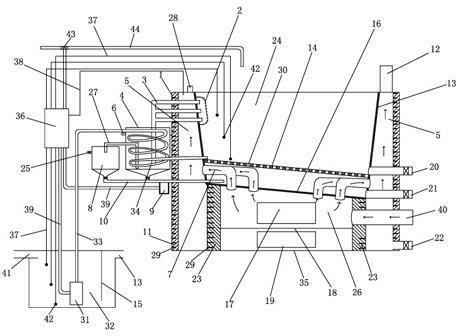

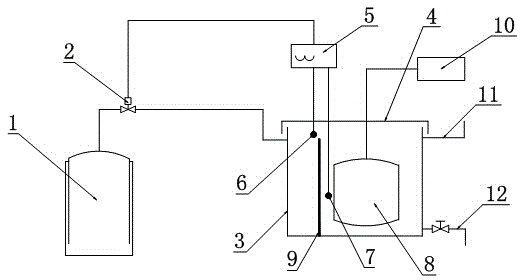

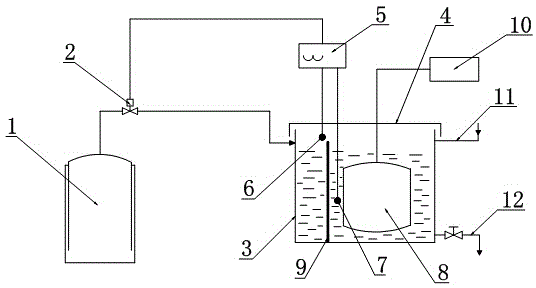

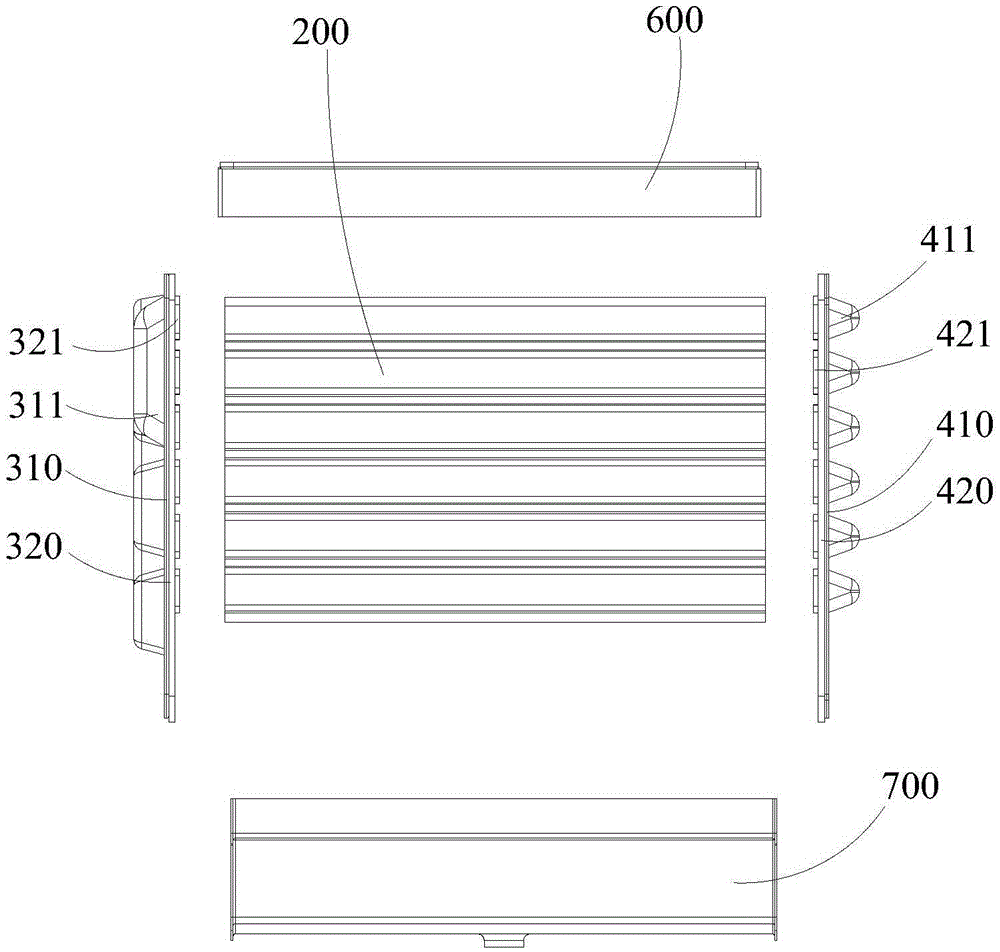

Heat-collecting energy-storage evaporation integral solar energy heat pump system

InactiveCN101169297AAvoid separationUniform heat exchangeSolar heating energyHeat pumpsEvaporationEngineering

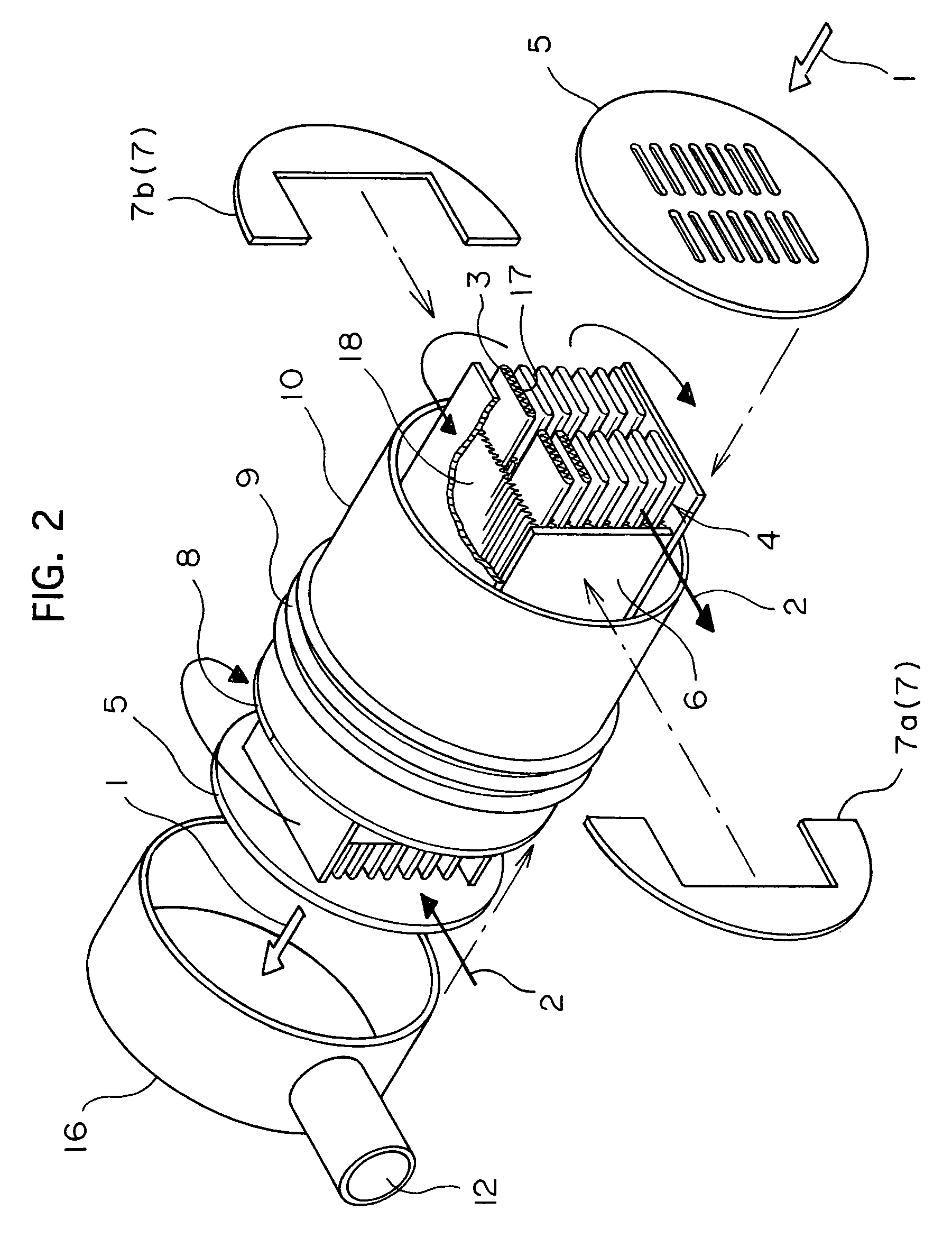

The invention relates to a solar energy hot pump device integrating the functions of heat collection, energy storage and evaporation. Combining a solar energy heat collector, an energy storing container and an evaporator of a hot pump system to a whole, the invention accelerates the heat collecting efficiency of the solar energy heat collector, strengthens the heat exchanging efficiency between the refrigerating fluid in the evaporating tube of the hot pump system and the energy storing medium, thereby ensuring the running with high efficiency and stable ability of the whole energy sorting solar energy hot pump device. The solar energy hot pump device comprises a compressor(1), an enclosed loop which consists of a coolant tube of a water-cooling condenser(2), a heat swelling valve(3), an evaporator(4), a water pump(12) and a water tank(13), wherein, the compressor(1), the coolant tube of the water-cooling condenser(2), the heat swelling valve(3), and the evaporator(4) are serially connected with an enclosed loop, while the water-cooling tube of the water-cooling condenser(2), the water pump(12) and the water tank(13) are connected in series with an enclosed loop, wherein, the evaporator(4) adopts the solar energy heat collecting / hot pump evaporator.

Owner:SOUTHEAST UNIV

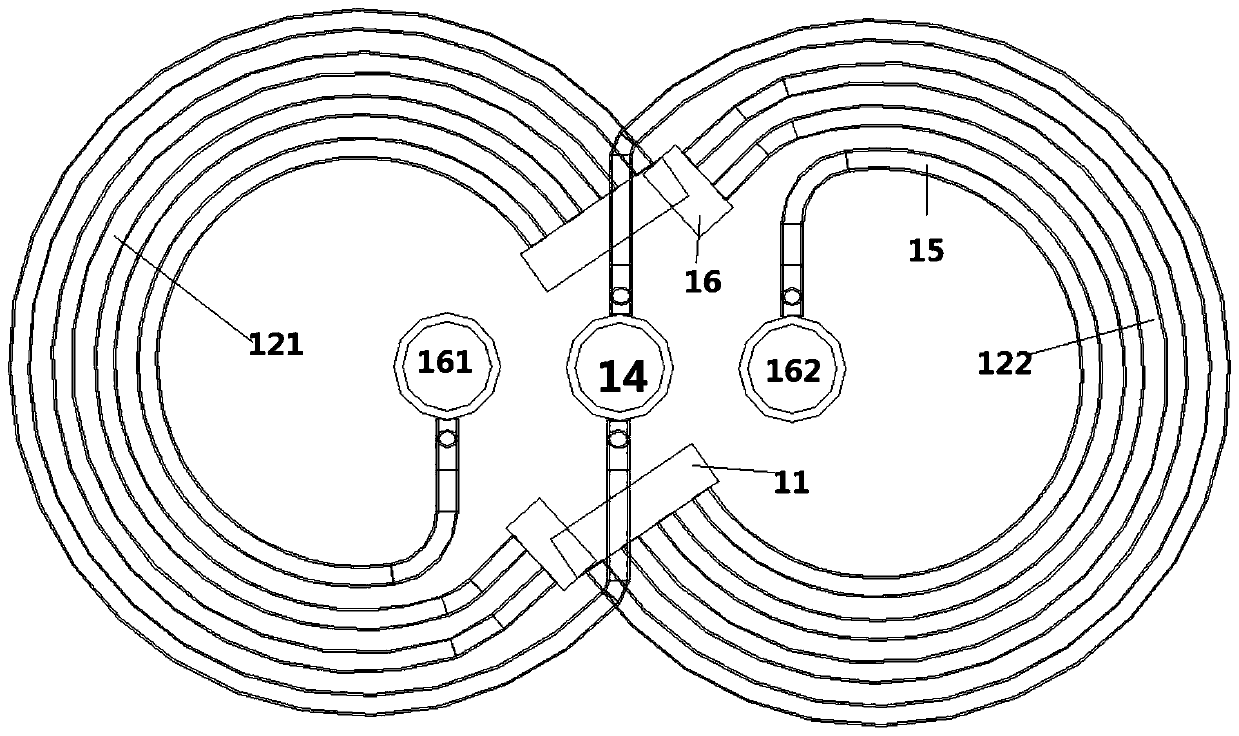

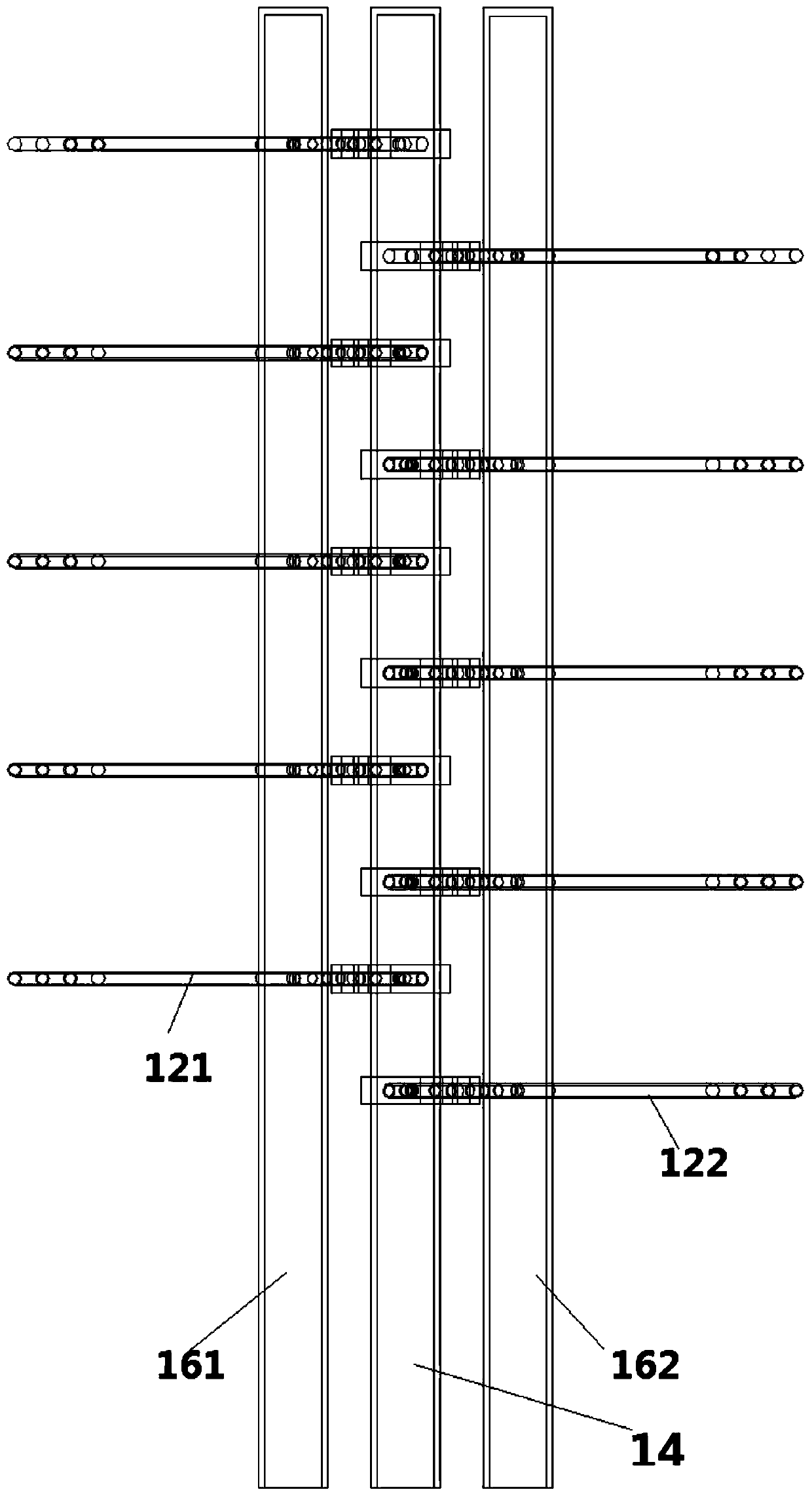

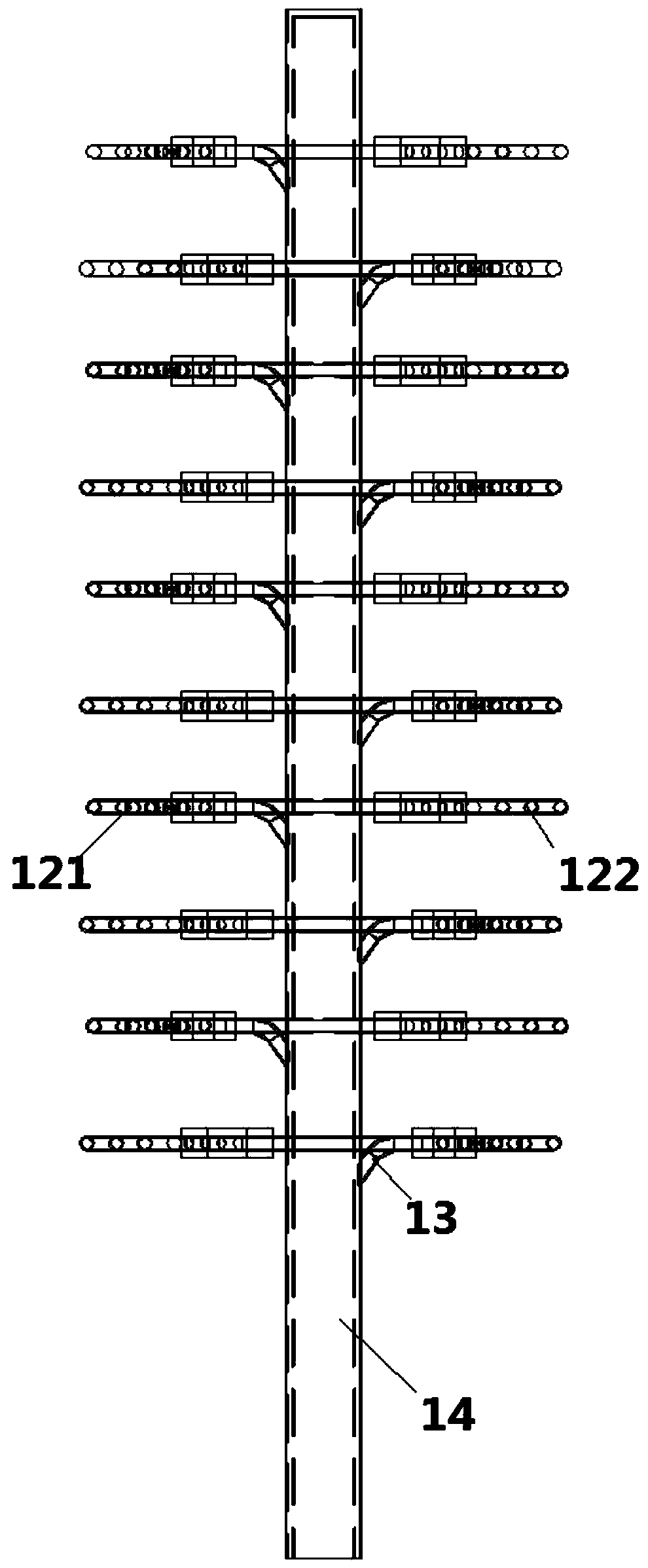

Three-riser pulsating tube bundle

ActiveCN110081739AIncreased vibration rangeImprove heat transfer performanceHeat storage plantsStationary tubular conduit assembliesEngineeringHeat transfer

The invention provides a three-riser pulsating tube bundle. The three-riser pulsating tube bundle comprises a middle riser, a left risers, a right riser and a plurality of coil tubes, wherein each coil tube comprises a plurality of arc-shaped heat exchange tubes, the ends of adjacent heat exchange tubes communicate, the plurality of heat exchange tubes form a series structure, the ends of the heatexchange tubes form free ends of the heat exchange tubes, the inlet of the middle riser is connected with a pulsating flow generating device for generating pulsating flow in the heat exchange tubes,the coil tubes comprise a left coil tube and a right coil tube, one side of the middle riser is connected with the inlet of the left coil tube, the other side is connected with the inlet of the rightcoil tube, the outlet of the left coil tube is connected with the left riser, and the outlet of the right coil tube is connected with the right riser. According to the pulsating tube bundle with the novel structure, more coil tubes are arranged in a limited space to increase the vibration range of the pulsating tube bundle, so that heat transfer and descaling are enhanced.

Owner:SHANDONG UNIV

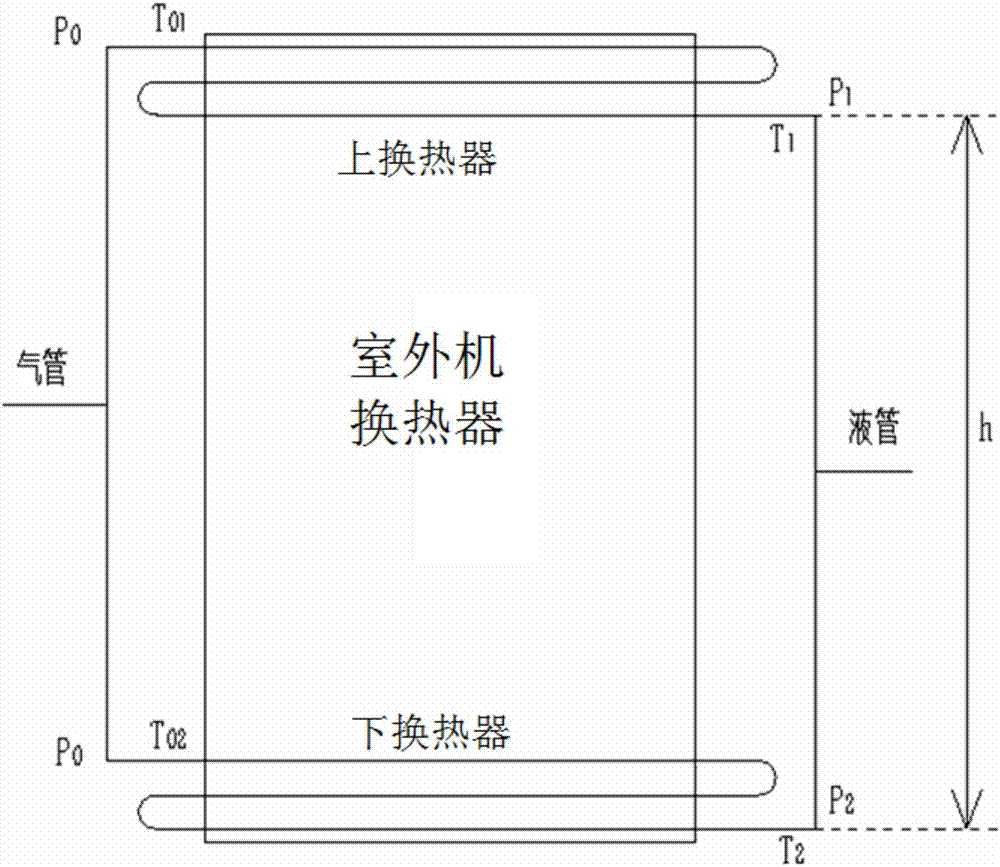

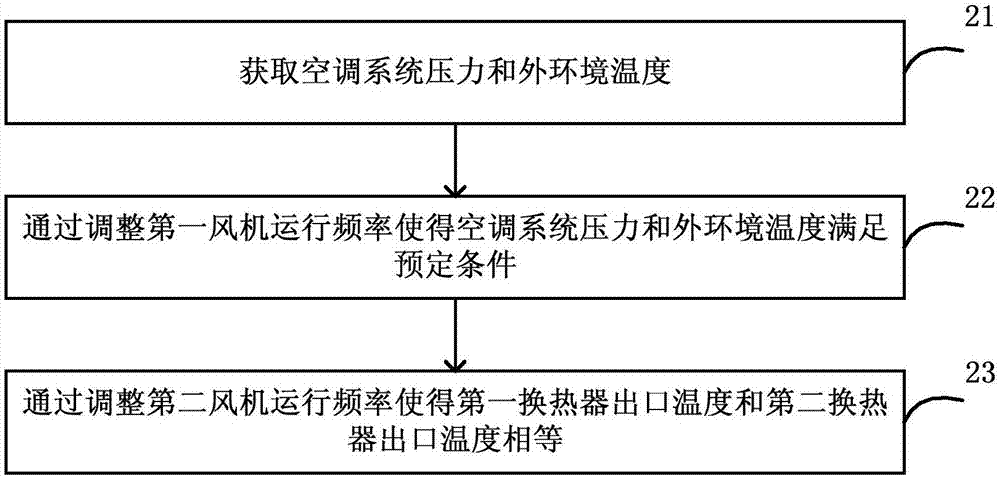

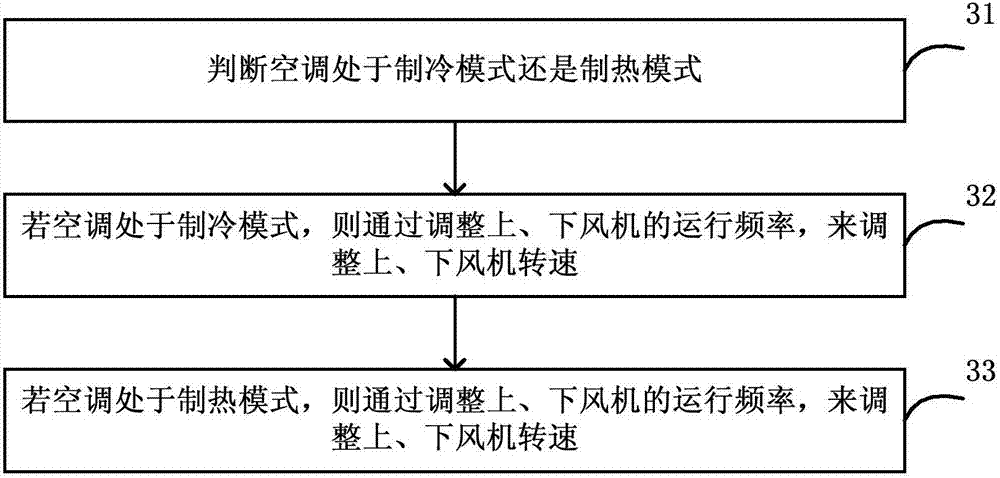

Draught fan control method and device, and air conditioner outdoor unit

ActiveCN107328026AUniform heat exchangeReduce invalid power consumptionSpace heating and ventilation safety systemsLighting and heating apparatusSystem pressureEngineering

The invention discloses a draught fan control method and device, and an air conditioner outdoor unit. The draught fan control method comprises the steps of acquiring the air conditioner system pressure and the external environmental temperature; enabling the air conditioner system pressure and the external environmental temperature to meet preset conditions by adjusting the operating frequency of a first draught fan; and enabling the outlet temperature of a first heat exchanger and the outlet temperature of a second heat exchanger to be equal by adjusting the operating frequency of a second draught fan. According to the method, the upper heat exchanger and the lower heat exchanger of the outdoor unit are made to have the same heat exchange effect, and the heat exchange effect of the heat exchangers of the outdoor unit is improved. By means of the method, the heat exchangers can be conduct heat exchange uniformly, ineffective power consumption of a motor is reduced, and the draught fans can save more energy.

Owner:GREE ELECTRIC APPLIANCES INC

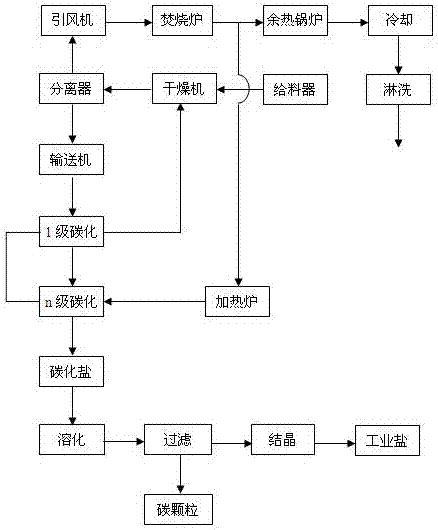

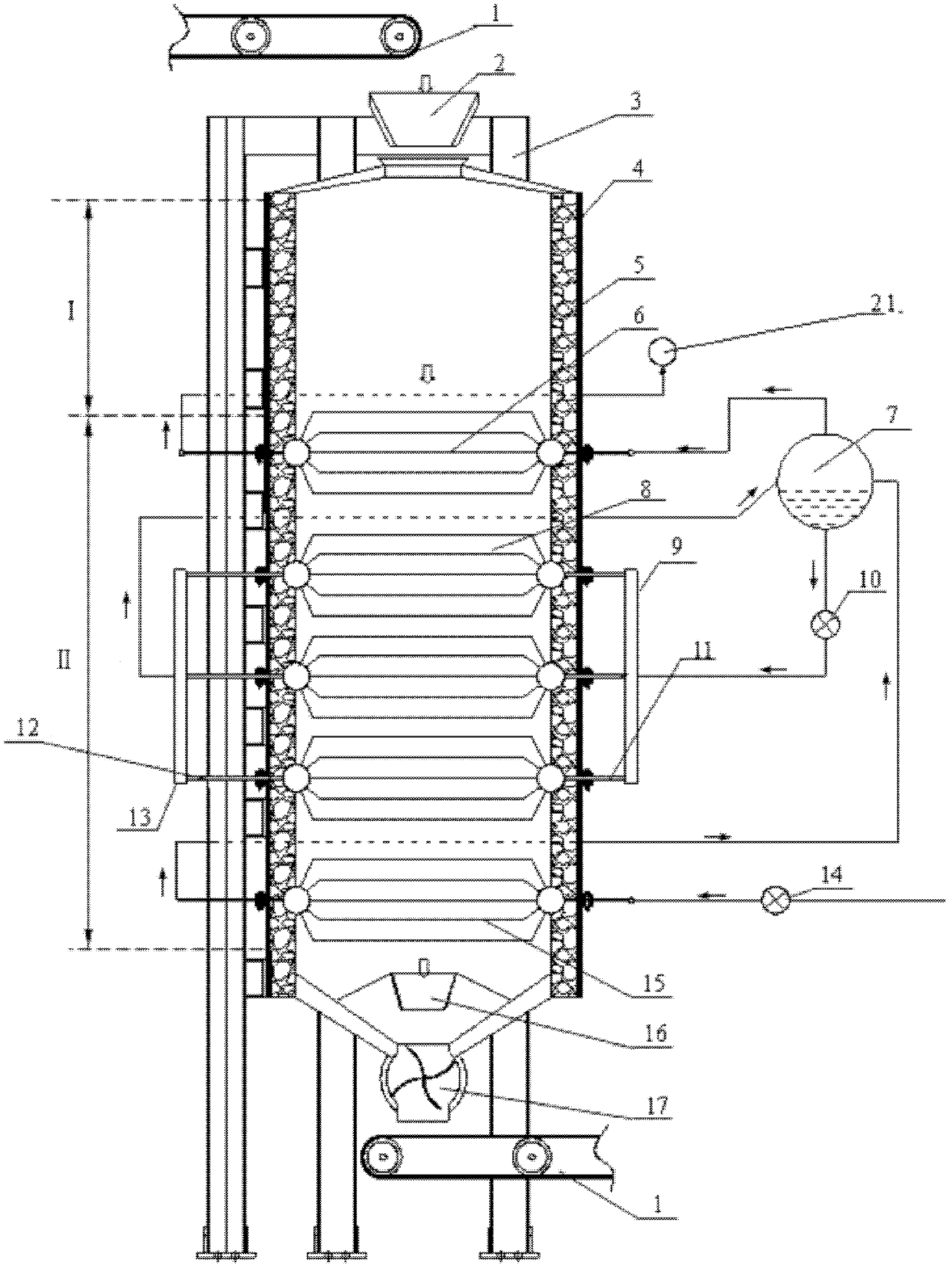

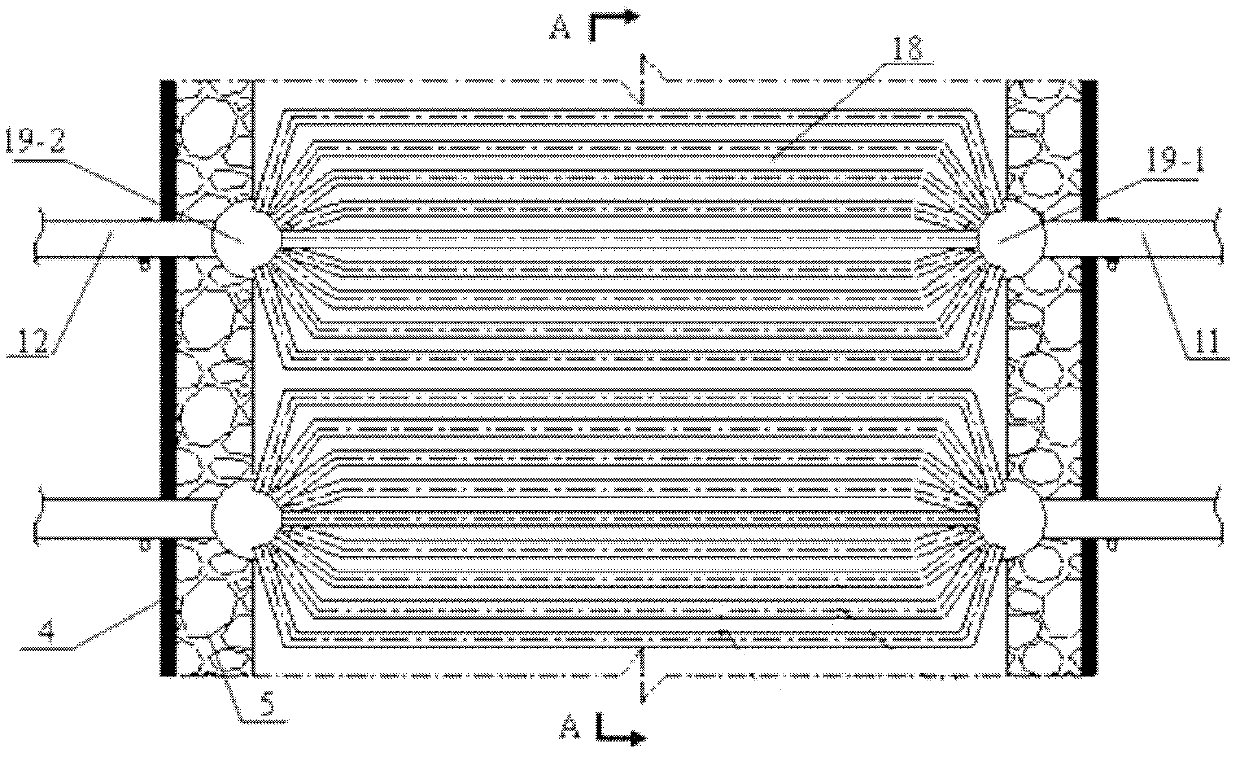

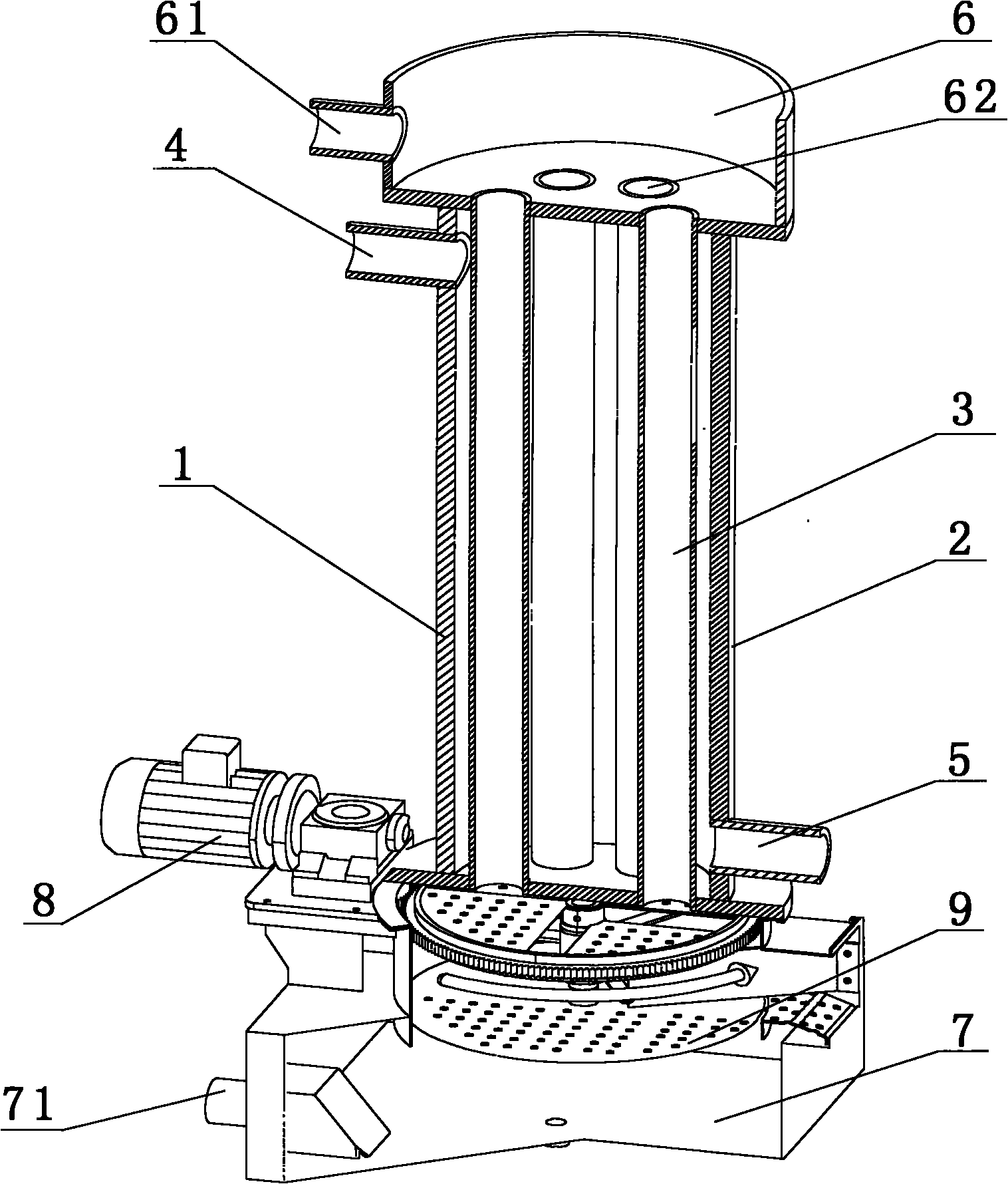

Process and equipment for graded decomposition and carbonization harmless treatment of industrial waste salt

ActiveCN106914474AGood dispersionLarge specific surface areaSolid waste disposalTransportation and packagingEnvironmental resistanceDecomposition

The invention belongs to the field of environmental protection, and particularly relates to a process and equipment for graded decomposition and carbonization harmless treatment of industrial waste salt. According to the process and the equipment disclosed by the invention, aiming at the characteristics that each kind of industrial waste salt contains various organic materials and has different physicochemical properties, a plurality of grades of decomposition and carbonization furnaces are arranged to perform graded heating on the industrial waste salt; the heating process is reasonable; the organic materials are decomposed and carbonized within the respective decomposition and carbonization temperature range; the heat-containing exhaust gas generated by decomposition and carbonization is used as a dry heat source; the exhaust gas generated by drying is introduced into an incinerator for incineration; and the hot gas generated by incineration is recycled. According to the process and equipment disclosed by the invention, continuous industrial production is realized, and during the operation of the system, no melting, agglomeration or bonding of the waste salt occurs, no secondary pollutants are generated, no toxic and harmful gas is exhausted, thermal efficiency is high, energy is saved, environmental protection is achieved, and the investment cost is lower than that of other methods; and the process and equipment have the advantages that the process and equipment are high in practicality, are suitable for the removal and harmless treatment of the organic materials of the industrial waste salt in various fields, and are suitable for popularization in industrial production.

Owner:辽宁东大粉体工程技术有限公司

Waste heat recovering device of high-temperature metallurgy slag particles

ActiveCN102433400AEnhanced horizontal mixing heat transferGuaranteed uniformityIncreasing energy efficiencyRecycling and recovery technologiesSlagRefractory

The invention provides a waste heat recovering device of high-temperature metallurgy slag particles. The device comprises a middle hopper, a boiler body, a steam pocket, a superheater, an evaporator, an economizer and a discharging machine, wherein the middle hopper is arranged above the material inlet of the boiler body; a refractory material is arranged in the boiler body and a rectangle cavityis formed; the boiler body is divided into a storage section and a work section from top to bottom; the superheater, the evaporator and the economizer are successively arranged in the work section from top to bottom and respectively consist of single or multiple heat exchange pipe groups; the two ends of each heat exchange pipe are respectively connected to a water inlet header and a water outletheader of each heat exchange pipe group; the water inlet header is connected with an distribution header through a distribution pipe; the water outlet header is connected with a converge header through a converge pipe; the steam pocket is connected with the water outlet header; the outlet end of the superheater is connected with a steam pipe network or steam turbine; and the discharging machine is installed at the outlet of the boiler. By using the waste heat recovering device, uniform heat exchange can be realized, the yield and the quality of the steam are improved, and the recovery efficiency of waste heat is high.

Owner:NORTHEASTERN UNIV

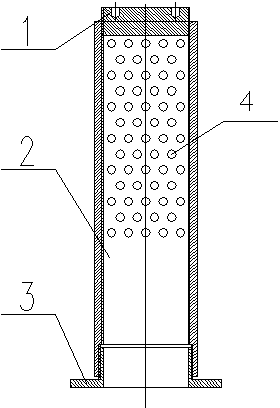

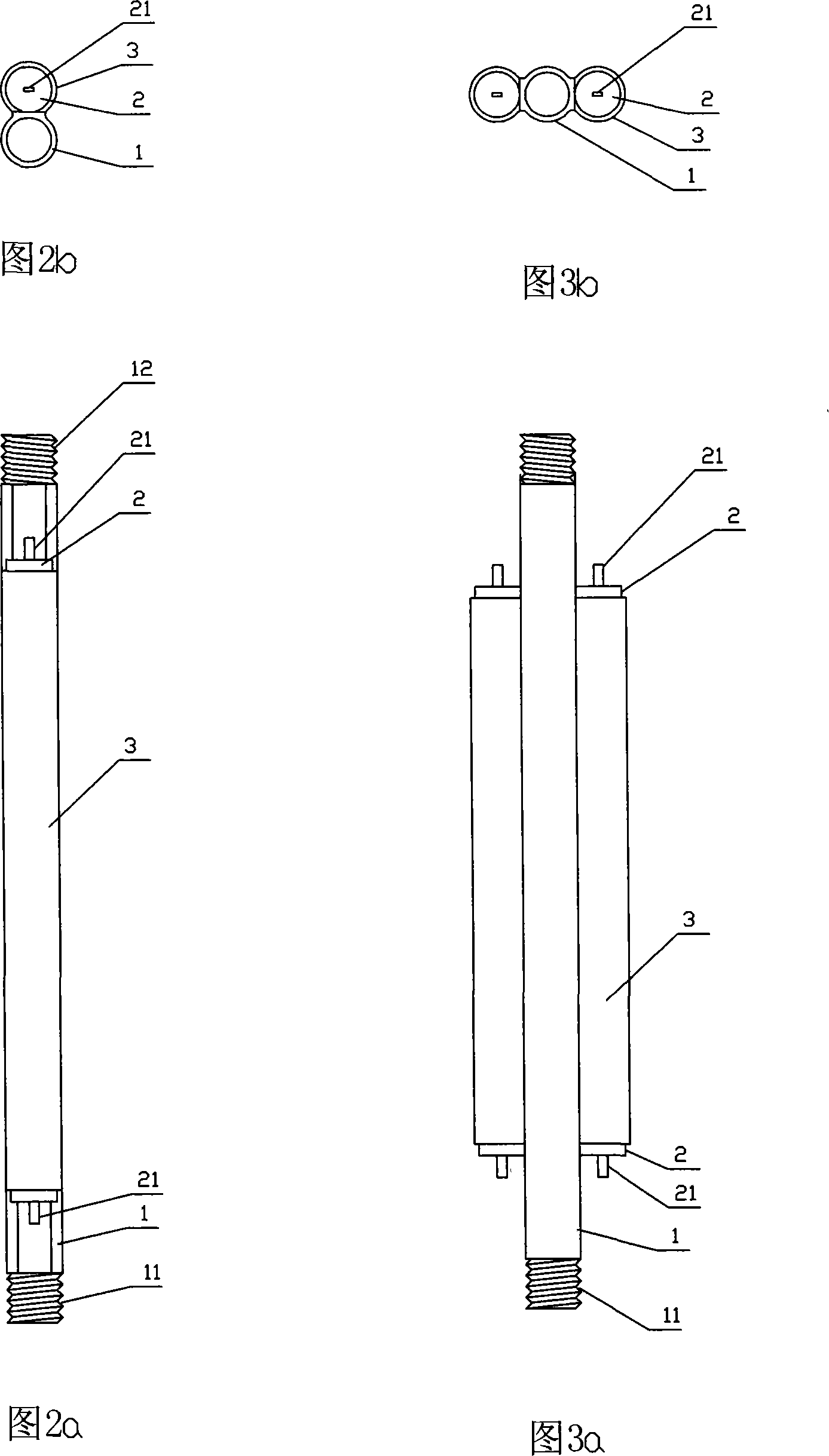

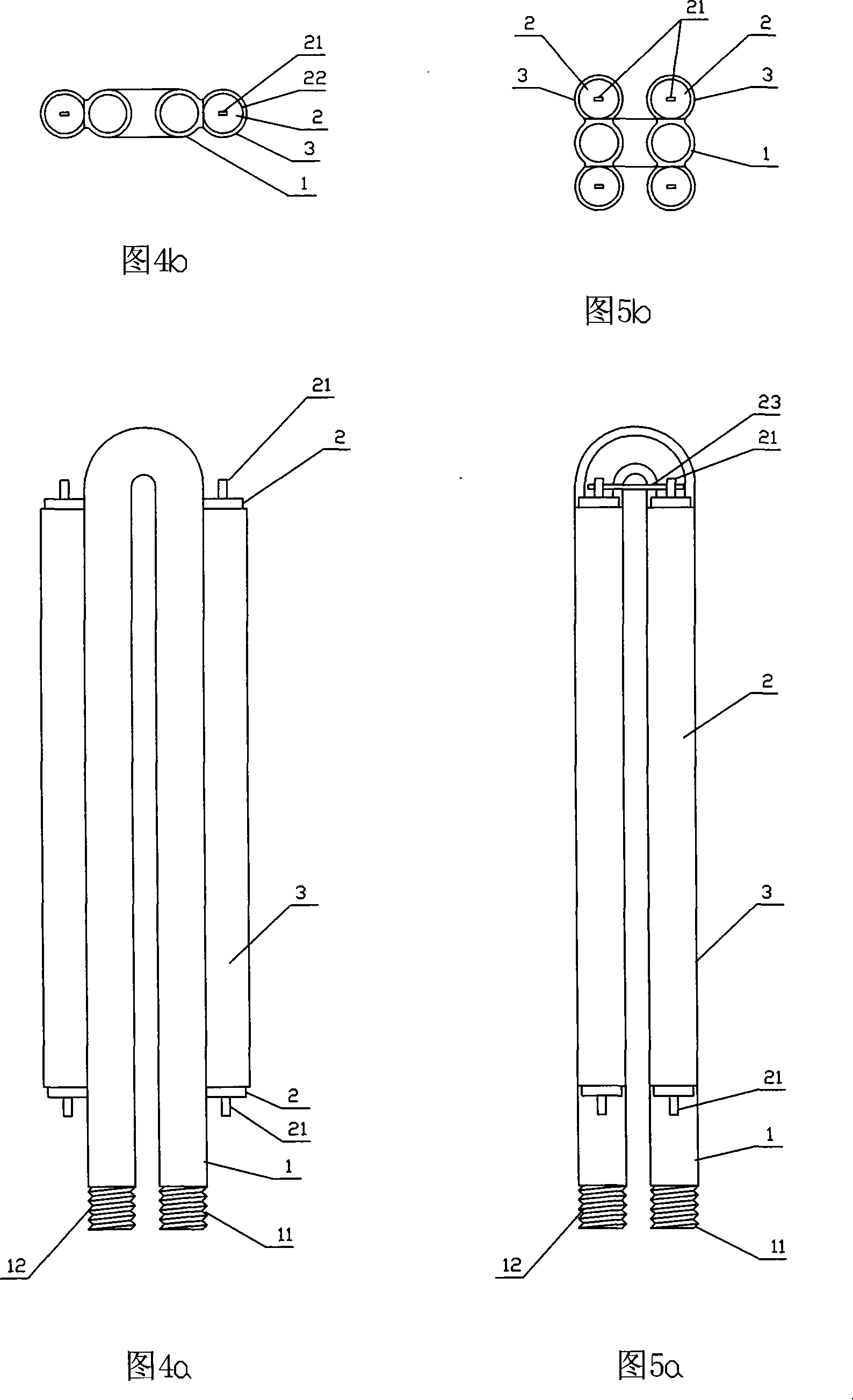

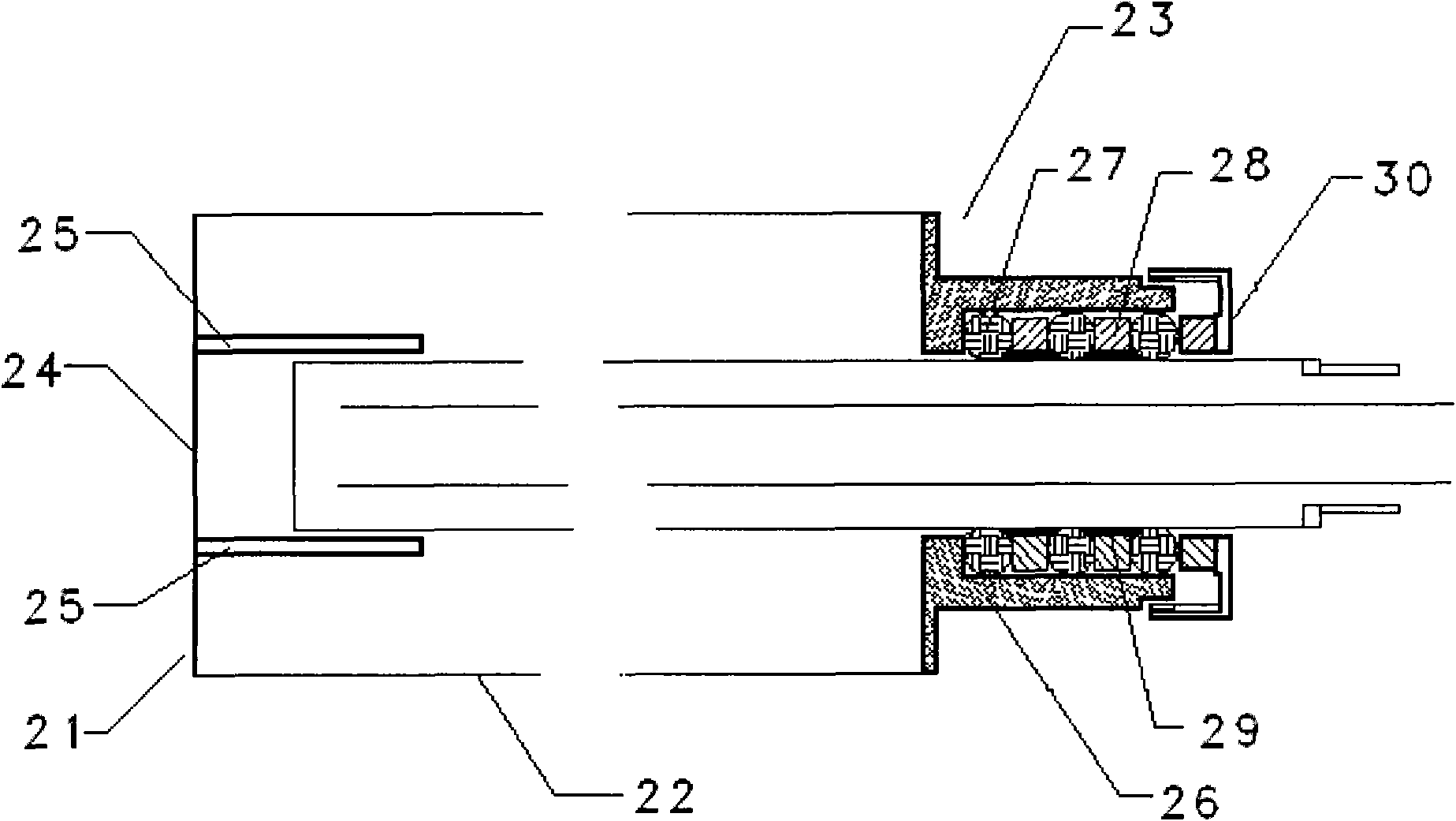

High temperature tail gas anti-impact piece adjustable structure of polycrystalline silicon high temperature tail gas heat exchanger

InactiveCN103896270AControl flow rateThe outlet temperature requirements are metSilicon compoundsEngineeringHigh-temperature corrosion

The invention relates to a high temperature tail gas anti-impact piece adjustable structure of a polycrystalline silicon high temperature tail gas heat exchanger. The structure comprises a column end cap (1), a spiral hole calandria (2) and a fixing connecting piece (3), wherein the column end cap (1) is in threaded connection with inner holes in one end of the spiral hole calandria (2); the fixing connecting piece (3) is in threaded connection with the other end of the spiral hole calandria (2); a plurality rows of spiral holes are formed in the wall of the spiral hole calandria (2). By adopting the structure, an anti-impact piece is high temperature resisting and corrosion resisting, the flowing speed of a high temperature inlet tail gas can be controlled so as to uniformly distribute the high temperature tail gas, an ideal heat exchange effect is achieved, and the service life of the polycrystalline silicon high temperature tail gas heat exchanger is prolonged.

Owner:SHUANGLIANG NEW ENERGY EQUIP

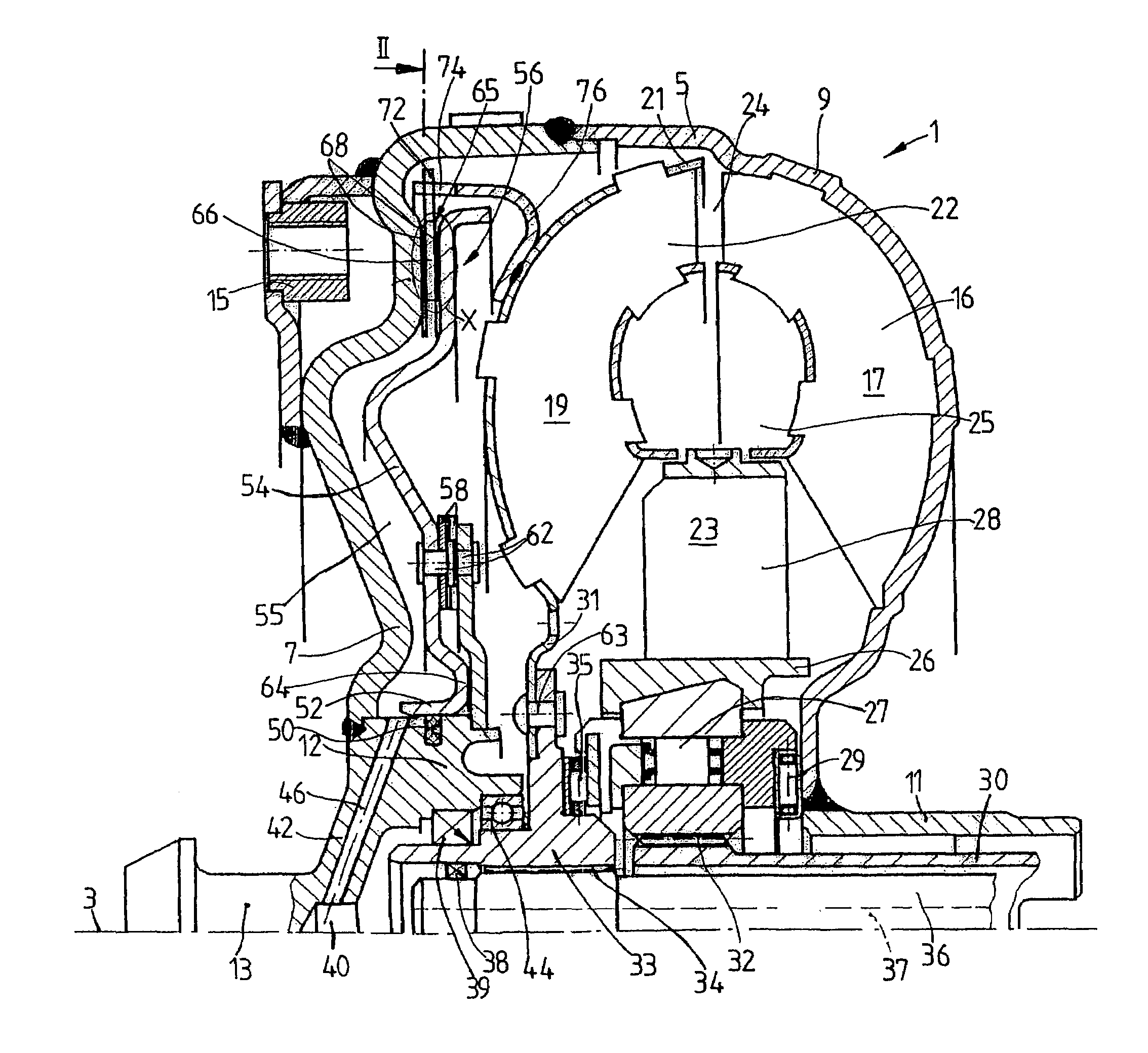

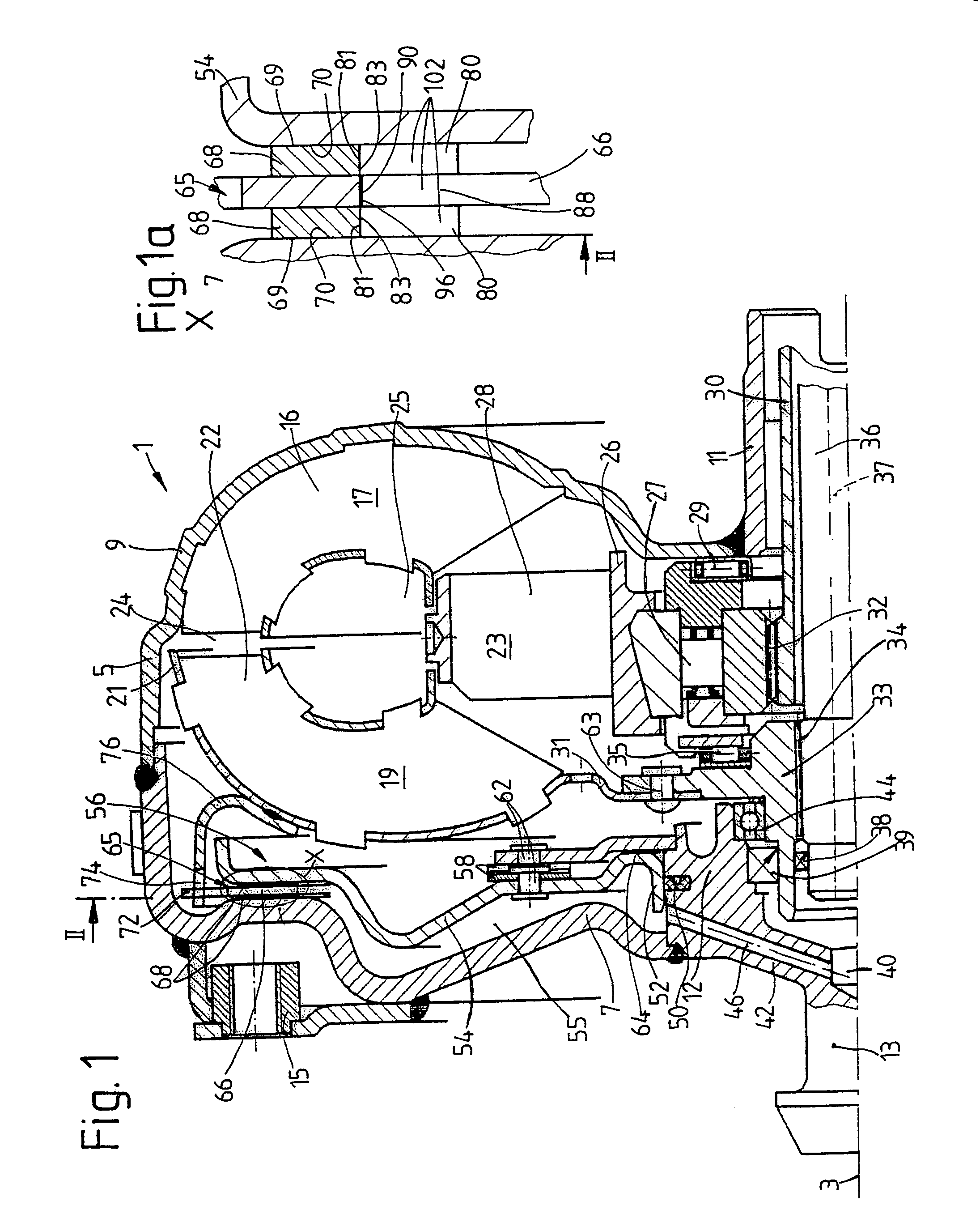

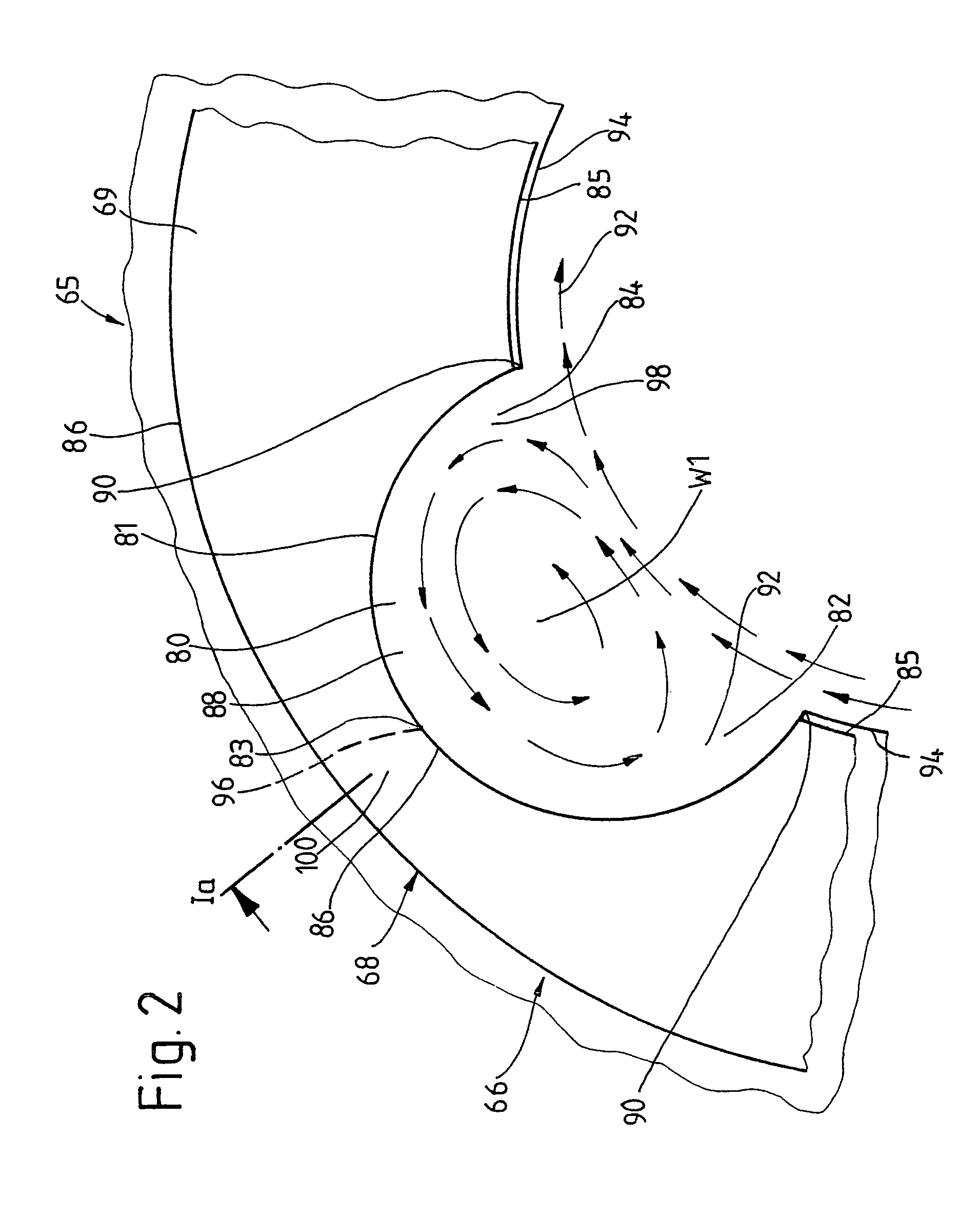

Bridging clutch for a hydrodynamic torque converter

A bridging clutch for a hydrodynamic torque converter which is designed with at least one friction area on a first converter component, which area can be shifted into working connection with at least one opposing friction area provided on a second converter component by means of an engaging movement or which can be separated from this second component by a disengaging movement in the direction opposite to the engaging movement. At least one of the two converter components acts as a friction lining carrier, which carries a friction lining in the friction area or in the opposing friction area, at least one opening being provided in the friction lining to allow the passage of transport medium, the inflow area of the opening being on the same radial side of the friction lining as its outflow area. On at least one of the converter components serving as a friction lining carrier, at least one friction lining is provided with an opening, which, on the radial side with the inflow area and the outflow area, is open continuously over its entire extent in the circumferential direction of the friction lining.

Owner:ZF FRIEDRICHSHAFEN AG

Finned heat exchanger

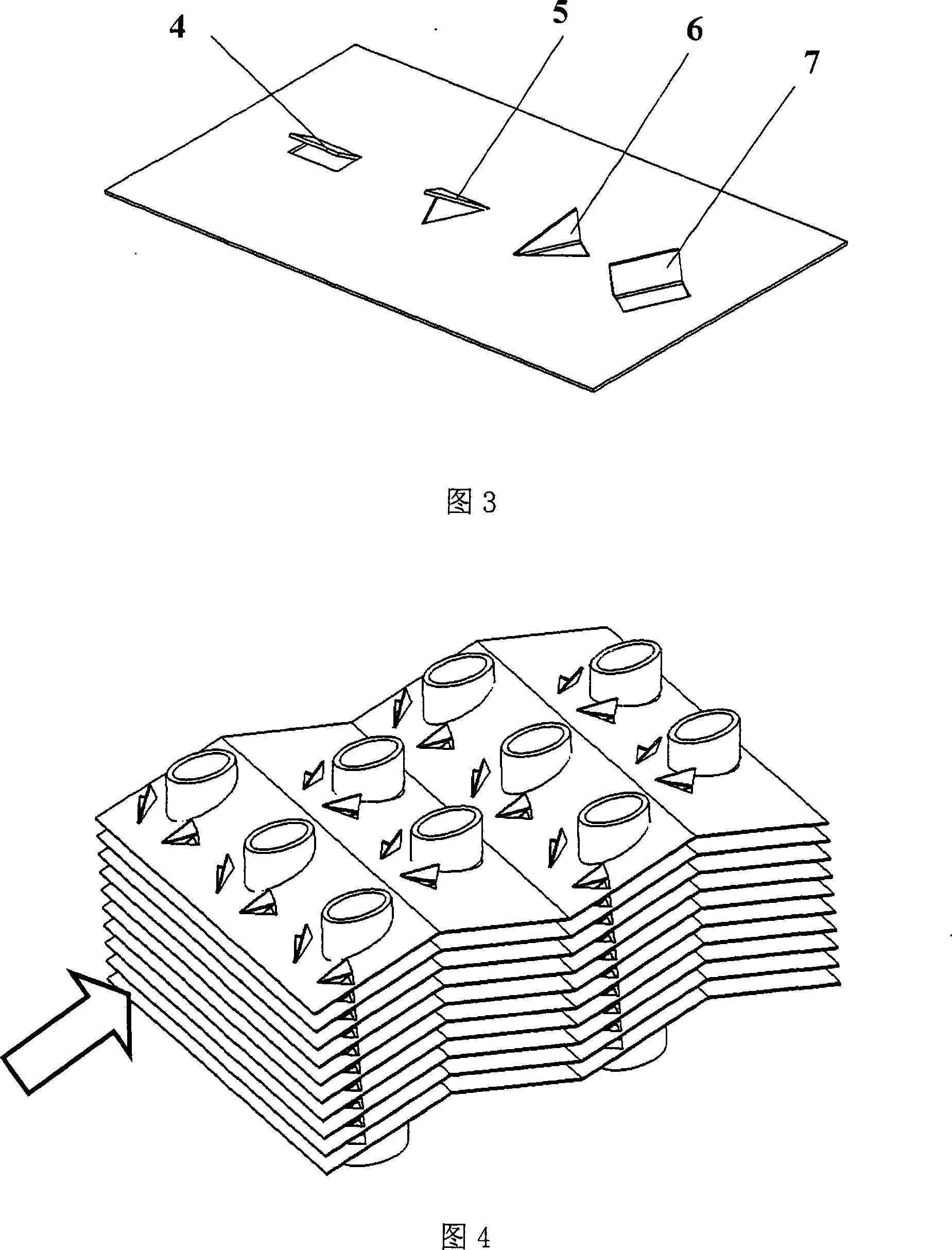

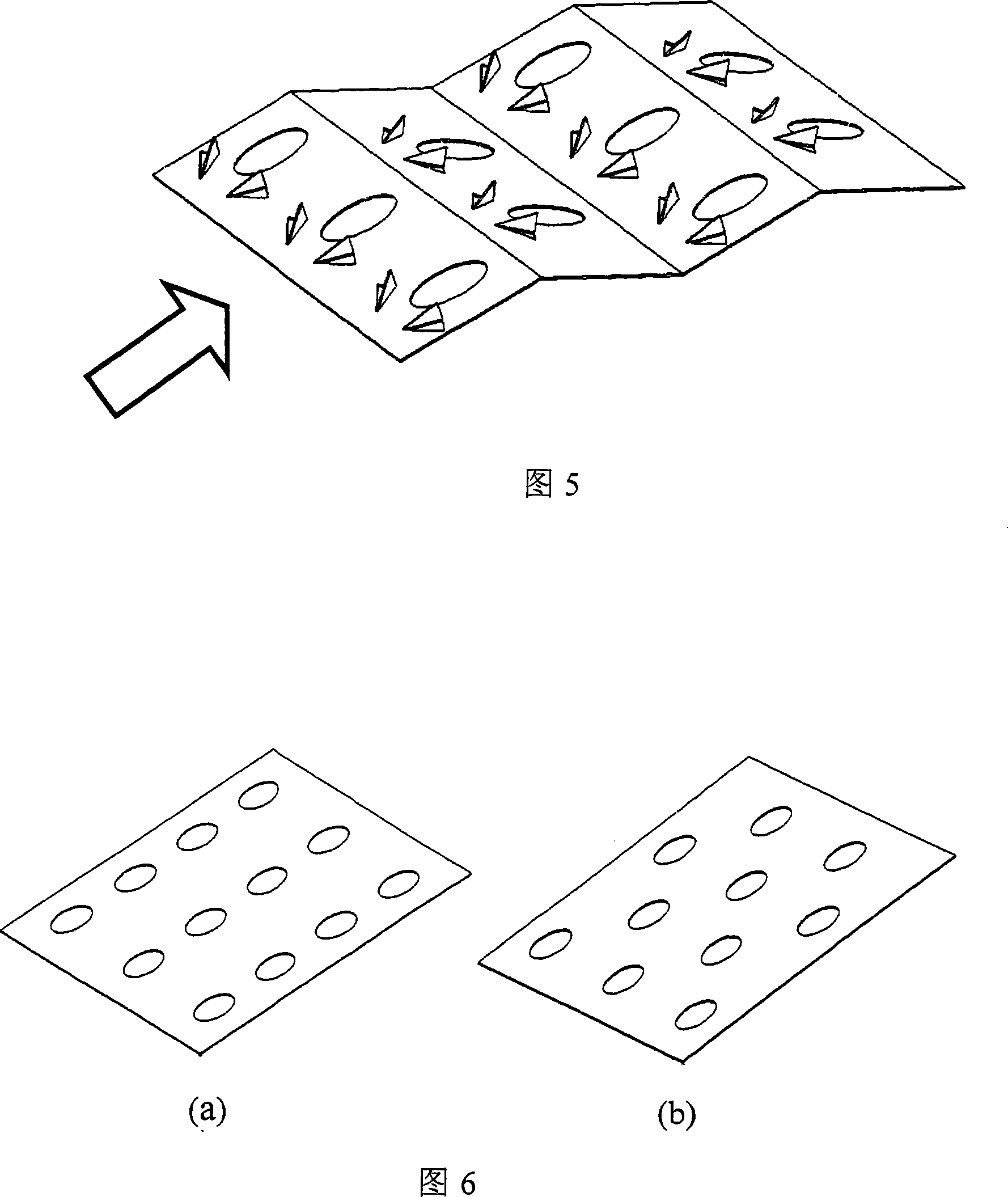

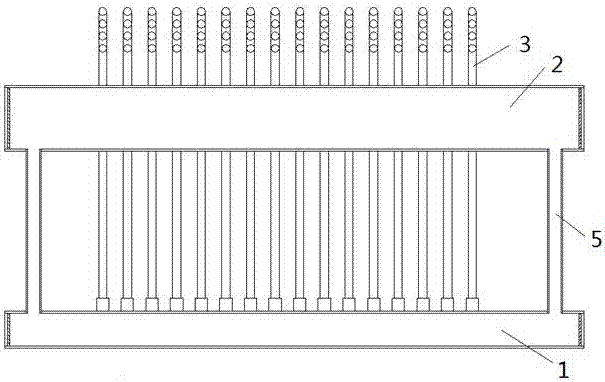

InactiveCN101245974AImprove heat transfer effectSmall sizeTubular elementsPlate heat exchangerGas phase

The invention relates to the field of heat exchangers, in particular to a fin-typed heat exchanger with high efficiency and low resistance, comprising a fin row which consists of fins and a heat exchange pipe which vertically passes through the fin row. The fin-typed heat exchanger is characterized in that the section of the heat exchange pipe is an ellipse shape; the fin is provided with a longitudinal vortex generator. The fin-typed heat exchanger can greatly improve the whole heat exchange performance of the heat exchanger but increases the flow resistance to small extent at the same time, and is mainly applied to gas-liquid heat exchange or gas-phase variable heat exchange.

Owner:XI AN JIAOTONG UNIV

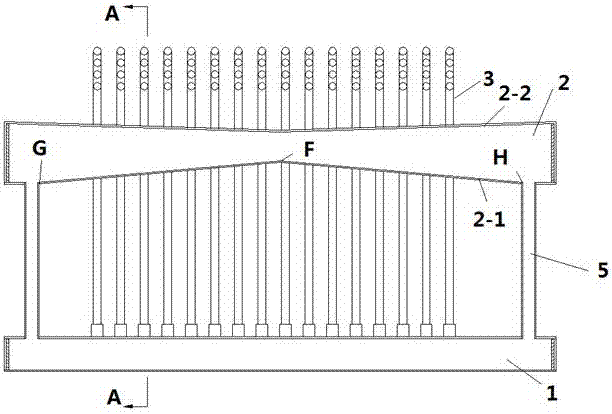

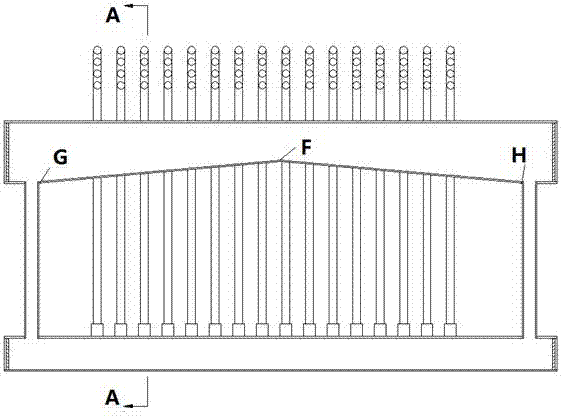

Heat pipe with cross-section-variable upper header pipe

The invention provides a heat pipe which comprises a lower header pipe, an upper header pipe, an ascending pipe and a return pipe, wherein the ascending pipe communicates with the lower header pipe and the upper header pipe; the lower header pipe is an evaporation end; a condensation end comprises the upper header pipe and at least part of the ascending pipe; fluid absorbs heat and evaporates in the lower header pipe and is condensed in the upper header pipe after heat exchange with at least part of the ascending pipe and the upper header pipe, and the condensed fluid returns to the lower header pipe through the return pipe; and cross section of the upper header pipe is gradually increased from the middle of the upper header pipe to the two ends of the upper header pipe. According to the invention, cross section of the upper header pipe is gradually increased from the middle of the upper header pipe to the two ends of the upper header pipe, so that heat exchanging fluid can be distributed to the two ends, heat exchange of the entire upper header pipe is ensured to be uniform, and nonuniformity of heat and temperature distribution of the upper header pipe is avoided to prolong the service life of the heat pipe.

Owner:禹城京都新材料科技有限公司

Energy-saving gas stove

ActiveCN102620321AIncrease profitImprove gas utilizationDomestic stoves or rangesLighting and heating apparatusEngineeringPhase change

The invention discloses an energy-saving gas stove which comprises an energy collecting cavity, a stove wall, a phase change heat accumulator, ribs, an infrared radiation ceramic plate and a gas stove head, wherein the stove wall is of an opening cavity structure; the upper end of an opening is used for holding cookware; the gas stove head is arranged in the opening at the bottom center of the stove wall; the energy collecting cavity is arranged at the lower end in the stove wall cavity and is of a cylindrical cavity structure; the upper surface of the energy collecting cavity is a pot-shaped curved surface; a plurality of ribs are arranged between an upper bottom surface and a lower bottom surface in the cavity of the energy collecting cavity at intervals; the infrared radiation ceramic plate is attached to the upper surface of the energy collecting cavity; and the phase change heat accumulator is arranged in the energy collecting cavity. According to the energy-saving gas stove disclosed by the invention, the infrared radiation ceramic plate reflects and absorbs the heat which is not utilized by an iron pan and part of heat is transmitted to the energy collecting cavity for storing energy. When the energy collecting cavity releases the heat, the heat is transmitted to the infrared radiation ceramic plate and generates infrared radiation for heating the iron pan. According to the gas cooking stove disclosed by the invention, the heat energy utilization rate of the gas cooking stove is increased and the aim of saving energy is achieved.

Owner:GUANGDONG HENGLIAN FOOD MACHINERY

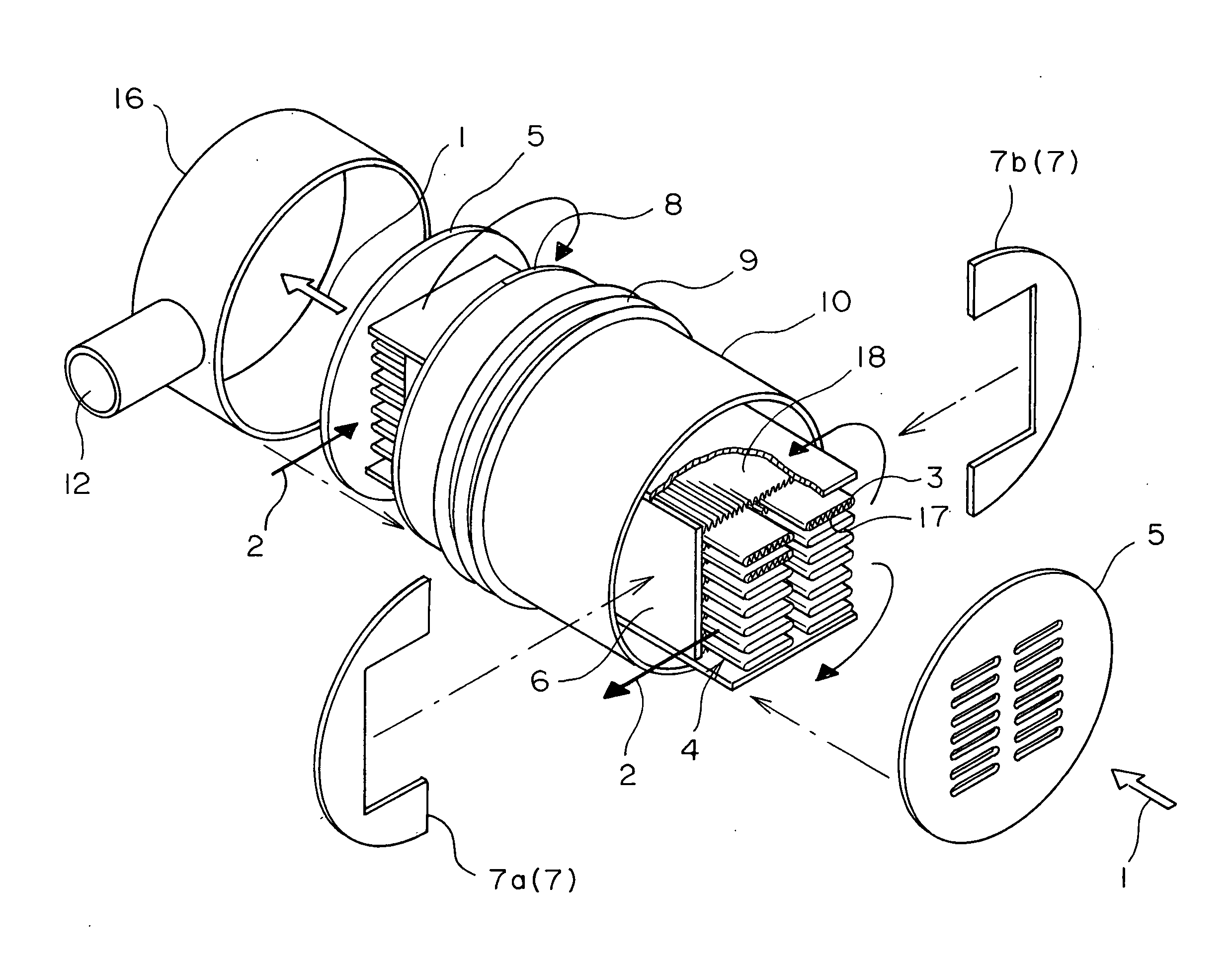

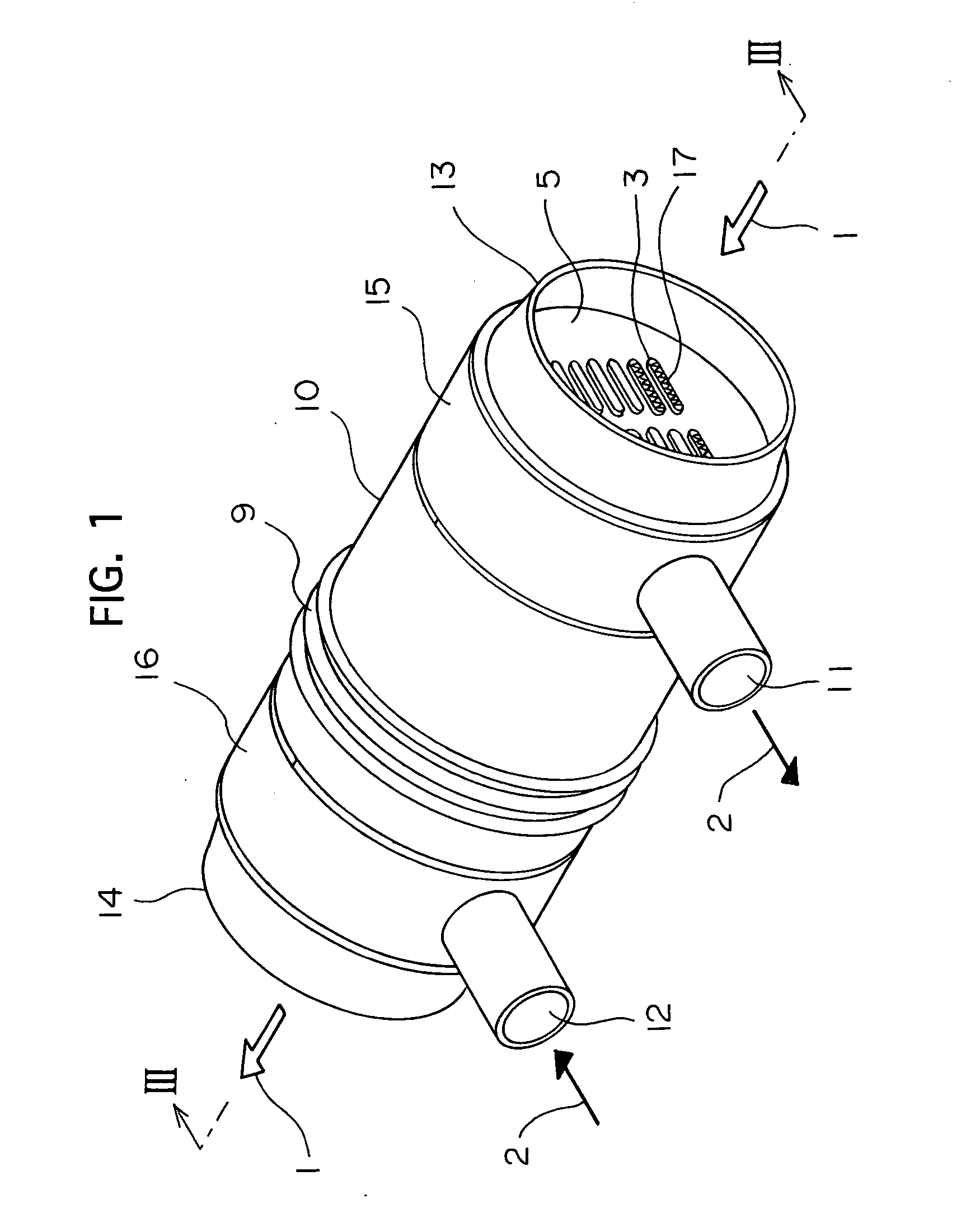

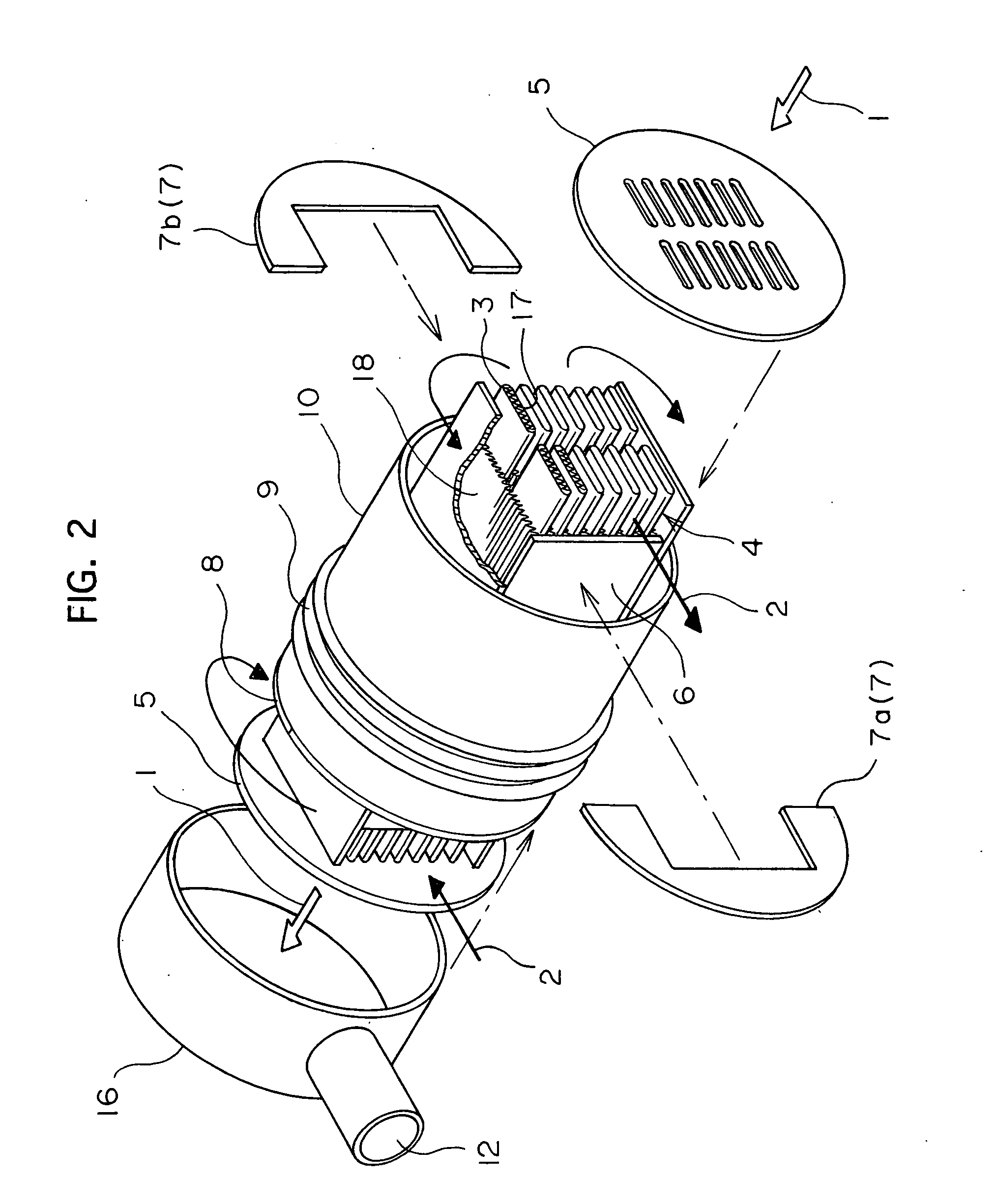

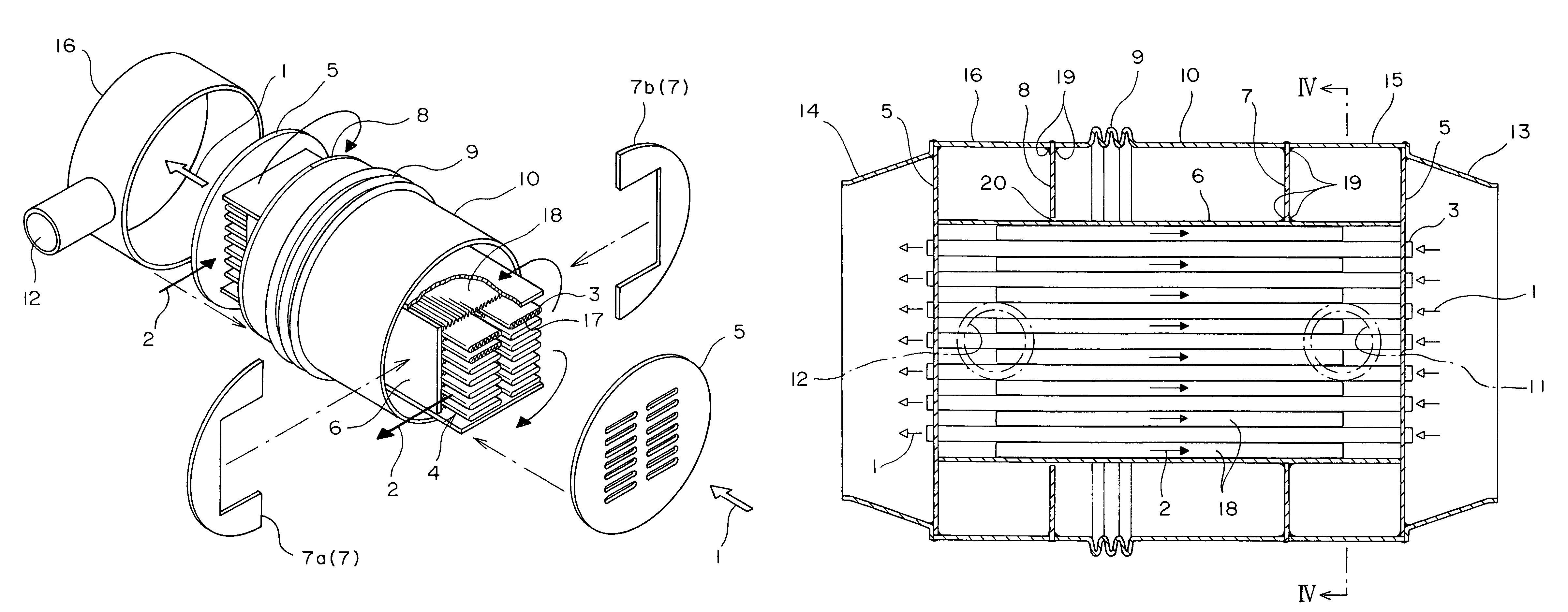

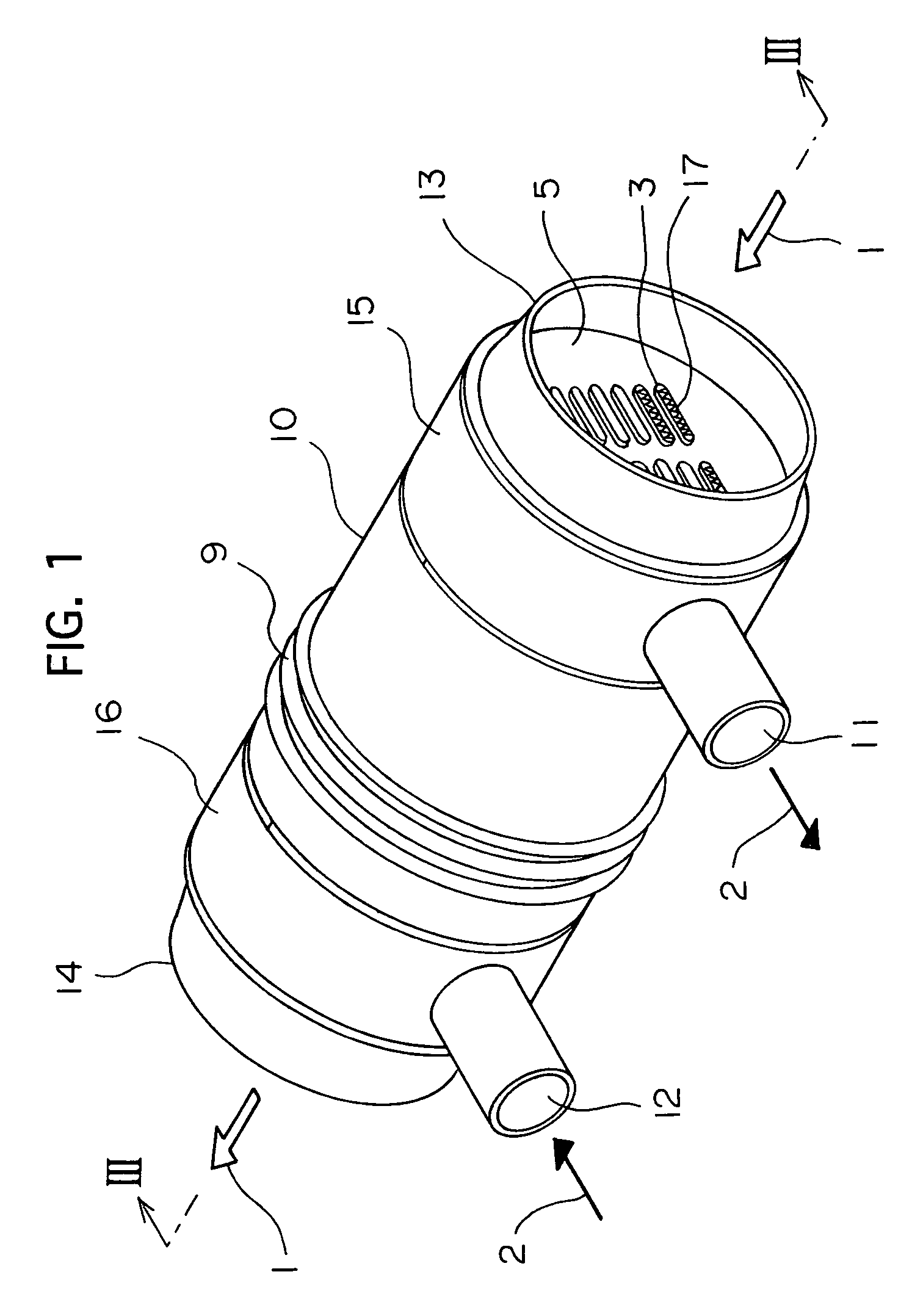

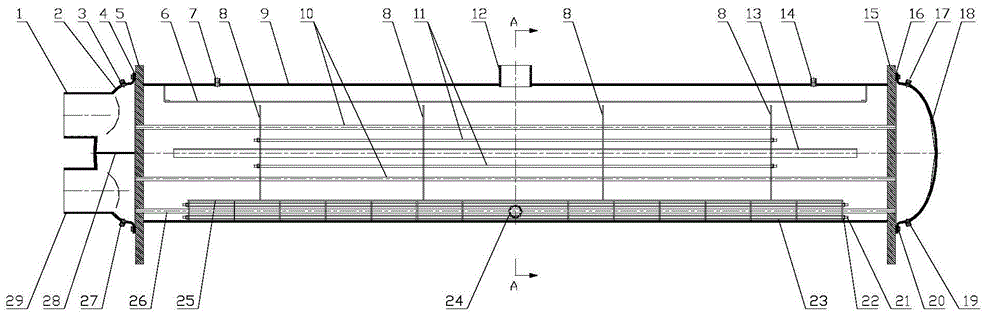

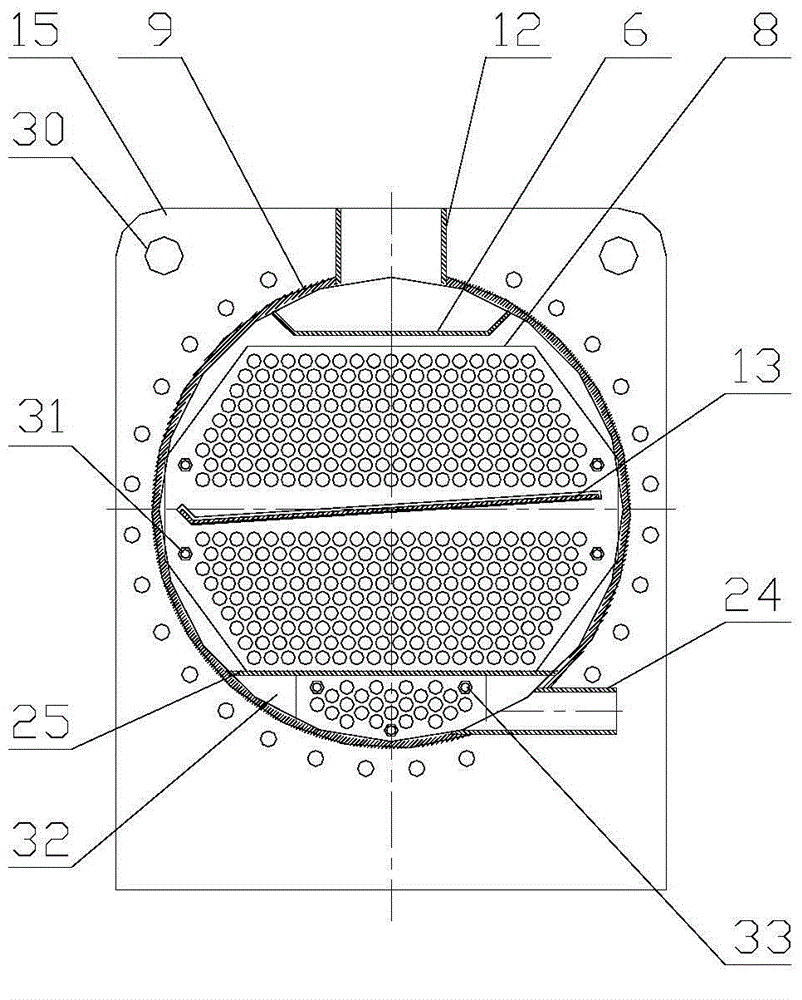

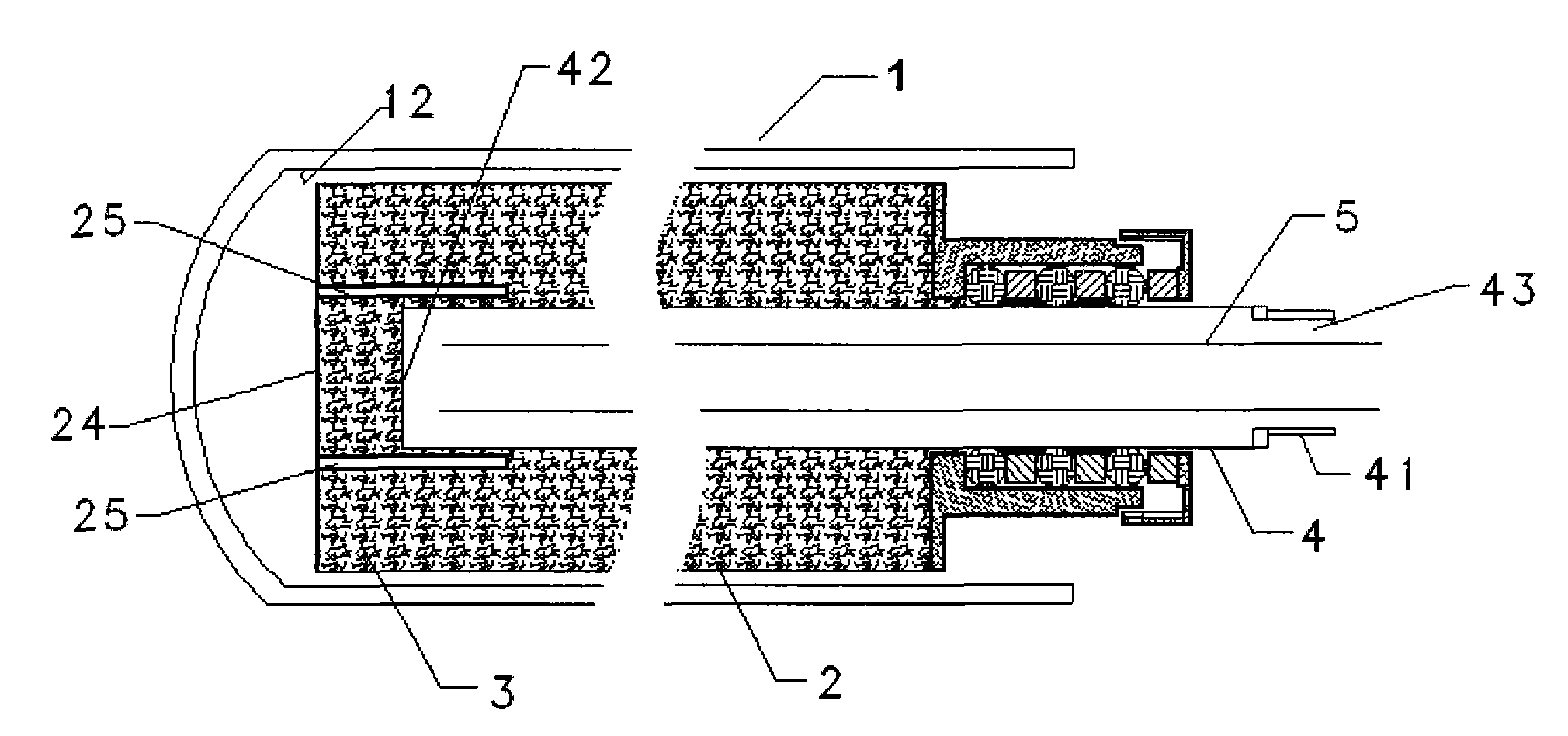

Heat exchanger

InactiveUS20060102321A1Uniform heat exchangeIncreased durabilityHydrogenSafety devices for heat exchange apparatusEngineeringElectrical and Electronics engineering

In order to provide a heat exchanger with casing having a multiplicity of tubes through the interiors of which a high-temperature gas for heating flows, wherein the thermal stress is smoothly accommodated and wherein a fluid to be heated or a heating fluid flows uniformly through the outsides of the tubes, a multiplicity of flat tubes are joined at their opposed ends to a pair of discoidal tube plates, the outer periphery of the flat tubes being enclosed by an inner cylinder having a rectangular cross-section except the opposed end portions of the flat tubes, with a pair of baffle plates being disposed at the opposed ends of the inner cylinder. The pair of baffle plates are covered with an circular outer cylinder having a corrugated portion that is thermally expandable, with an inlet and an outlet for the fluid to be heated or the heating fluid positioned between the pair of baffle plates and the tube plates.

Owner:T RAD CO LTD

Nickel zinc copper ferrite wave-absorbing material and preparation method thereof

InactiveCN101345109AClose contactUniform heat exchangeOther chemical processesInorganic material magnetismSolventOrganic acid

Owner:ZHEJIANG NORMAL UNIVERSITY

Heat exchanger for chemical industry production

InactiveCN107764096AFully contactedFully absorbedChemical industryCorrosion preventionChemical industryPlate heat exchanger

The invention relates to the technical field of heat exchange equipment and discloses a heat exchanger for chemical industry production. The heat exchanger comprises a shell, the upper surface of theshell is provided with a liquid inlet, the surface of the shell is fixedly provided with a first drive motor, the output shaft of the first drive motor runs through the surface of the shell and stretches to the interior of the shell, the right side surface of the output shaft of the first drive motor is fixedly connected with a revolving shaft, one end, which is far away from the output shaft of the first drive motor, of the revolving shaft is actively connected with a connecting plate, the connecting plate is arranged on the inner wall of the shell, the connecting plate and the first drive motor are arranged on the same horizontal plane, the top and bottom of the surface of the revolving shaft are both fixedly connected with a second drive motor. According to the heat exchanger for chemical industry production, by arranging the revolving shaft and the stirring shaft, the heat exchange is more uniform, the heat can be fully adsorbed, the heat exchange efficiency is further improved, the problem that the heat exchange efficiency is relatively low as thermal fluid and a heating device are adopted to exchange heat in the prior art is solved, and the practicability is improved.

Owner:JIANGSU TIANMAI CHEM CO LTD

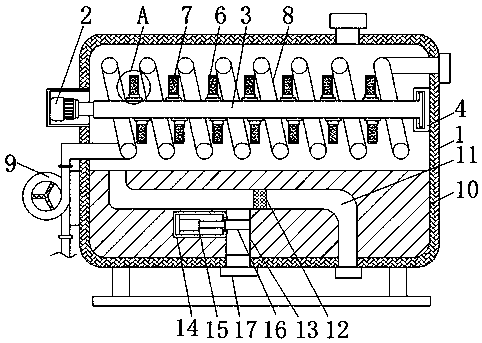

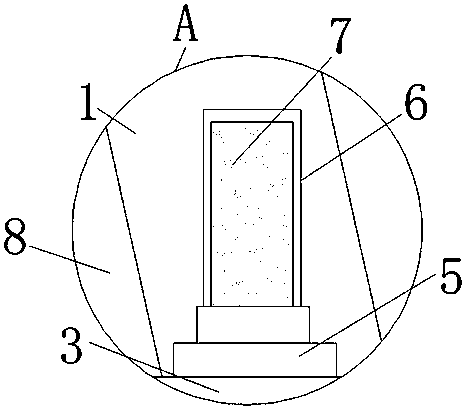

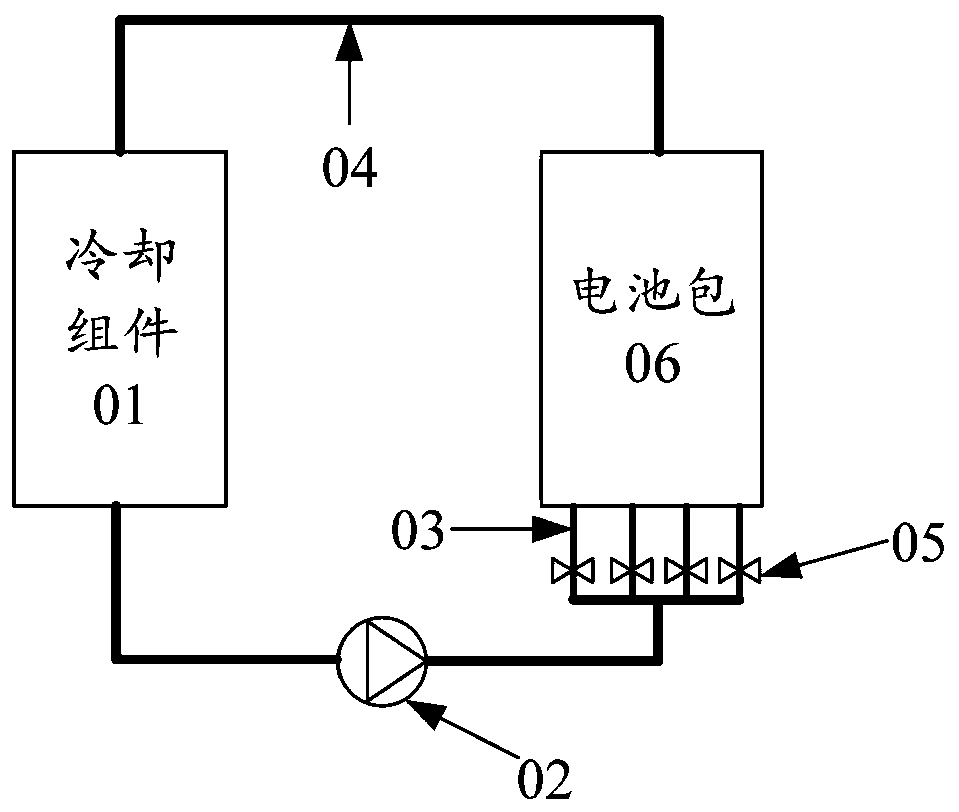

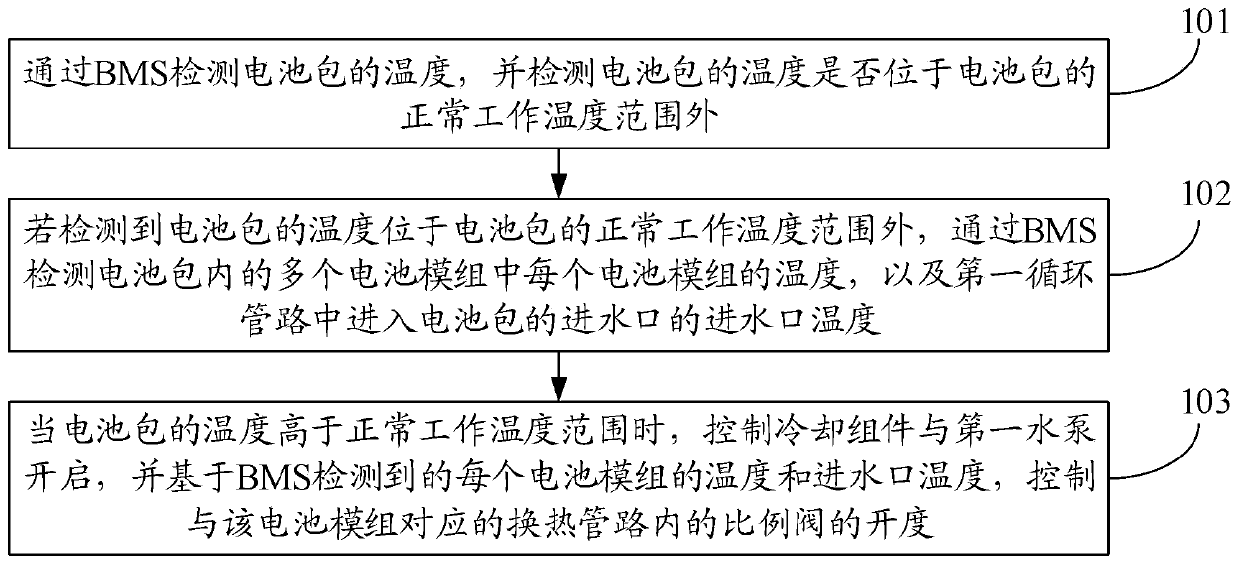

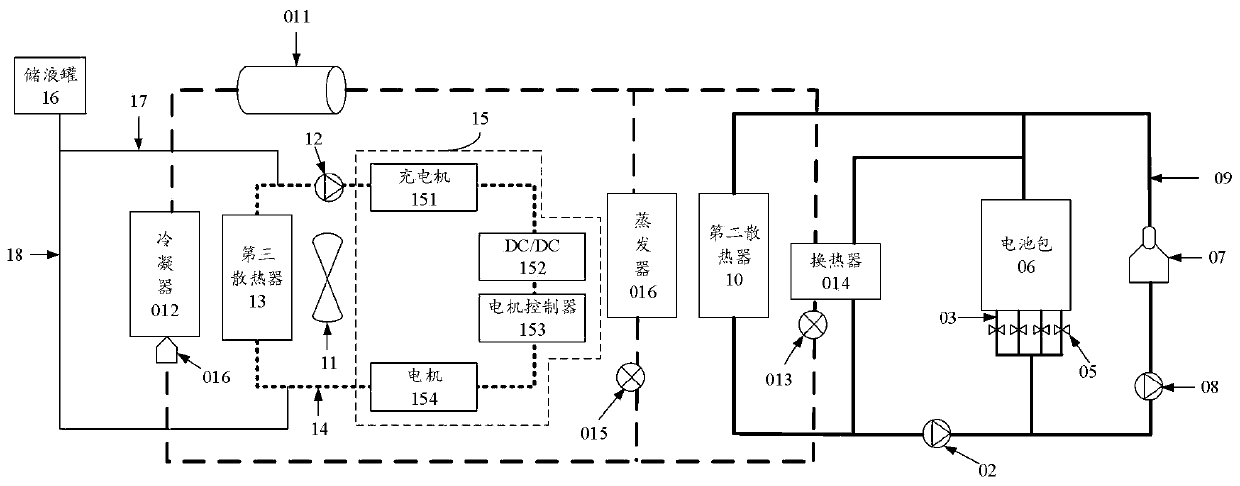

Control method and device for thermal management system of vehicle and vehicle

ActiveCN111055727AGuaranteed cooling effectImprove cooling efficiencyCell temperature controlVehicular energy storageTemperature controlCooling effect

The invention discloses a control method and device for a thermal management system of a vehicle and the vehicle, and relates to the field of vehicles. When a VCU cools a battery pack, the opening degree of a proportional valve in a heat exchange pipeline corresponding to the battery module can be controlled based on the detected temperature of each battery module and the detected temperature of the water inlet, so that balanced heat exchange of the battery modules releasing different heat can be realized, the cooling effect of the battery pack is effectively ensured, and the cooling efficiency of the battery pack is improved.

Owner:奇瑞新能源汽车股份有限公司

Oil-water-solid separation device for kitchen wastes

InactiveCN102642968AEmission reductionReduce dosageFatty/oily/floating substances removal devicesMultistage water/sewage treatmentRefractoryOil separation

The invention discloses an oil-water-solid separation device for kitchen wastes, which comprises a heating furnace, an oil-water separator, a discharging port, a water outlet, a dust exhaust port, an electric controller, an oil separation tank and the like. The heating furnace consists of a furnace body and a feed liquid container, a cavity between the furnace body and the feed liquid container is a hot smoke chamber, a chimney is arranged at the top of the hot smoke chamber, a spare water pipe is arranged at the top of the feed liquid container with a slope bottom, and a high-temperature smoke chamber is arranged below the feed liquid container. Refractory supporting parts are arranged around the high-temperature smoke chamber, a flue inlet and a furnace opening are arranged in the outer middle of the high-temperature smoke chamber, a dust removal port is arranged below the furnace opening, a water material partition plate is arranged on the lower portion of the feed liquid container, a plurality of L-shaped smoke pipes communicated with the high-temperature smoke chamber and the hot smoke chamber are arranged below the water material partition plate, and an oil guide pipe is arranged on one side of the upper portion of the feed liquid container and communicated to the lower portion of the oil-water separator. The oil-water-solid separation device has the advantage of capabilities of using waste heat, removing smoke and dust, avoiding pan sticking, turning wastes into wealth and purifying environment.

Owner:卢瑞琳

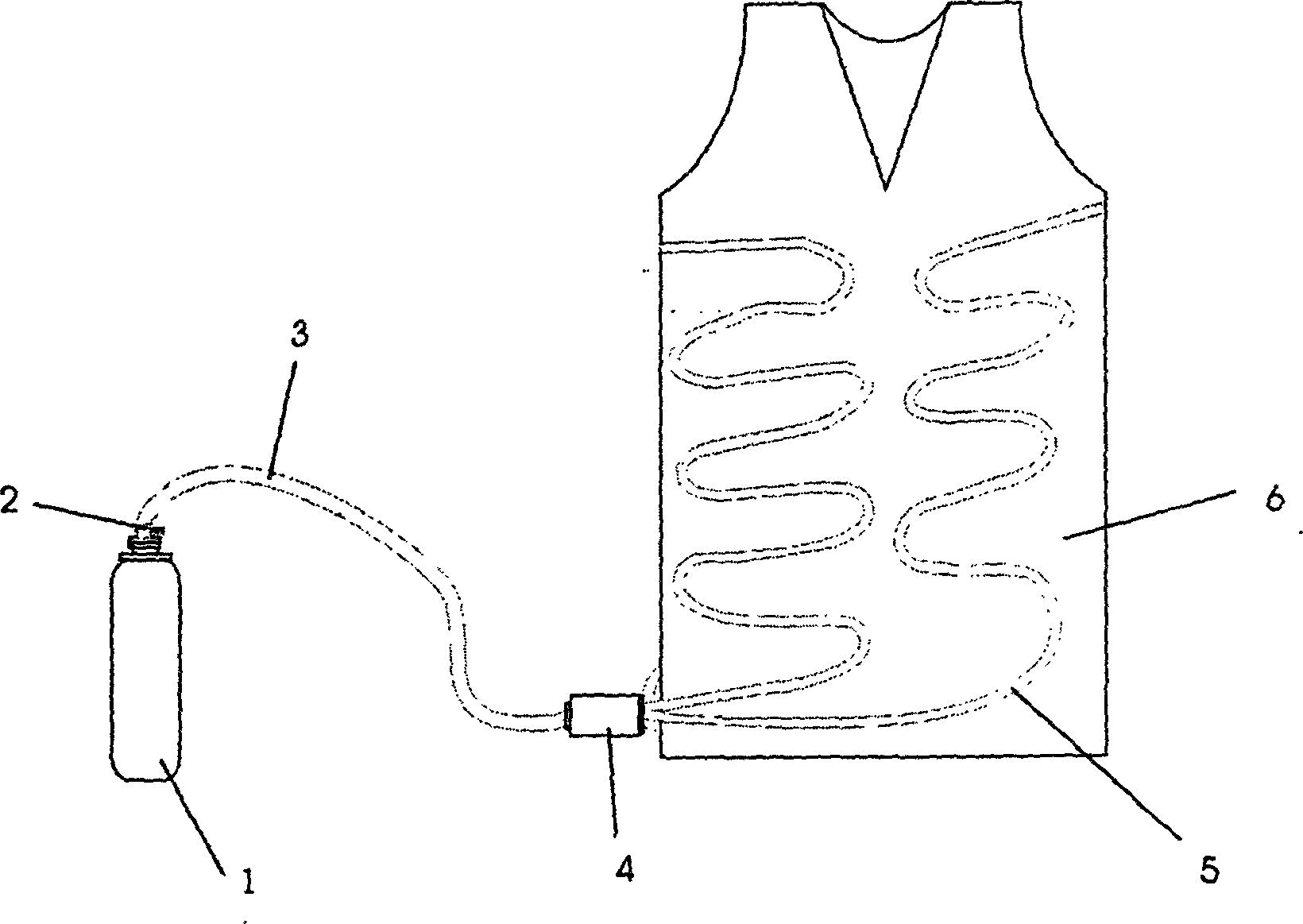

Cooling clothing, and cooling method thereof

A method for lowering the temp of human body features that the compressed liquefied cold medium is evaporated and expanded to become low-temp gas, and the low-temp gas flows through the clothes close to surface of human body to carry out the heat from the surface of human body. Said temp lowering clothes system is composed of a cooling assembly, a clothes and a guide tube in said clothes. Said cooling assembly consists of compressed cold medium tank, flow regulator, cold medium distributor, and cold medium flowing channel.

Owner:GUANGZHOU SHENGJIE INTELLIGENCE TECH

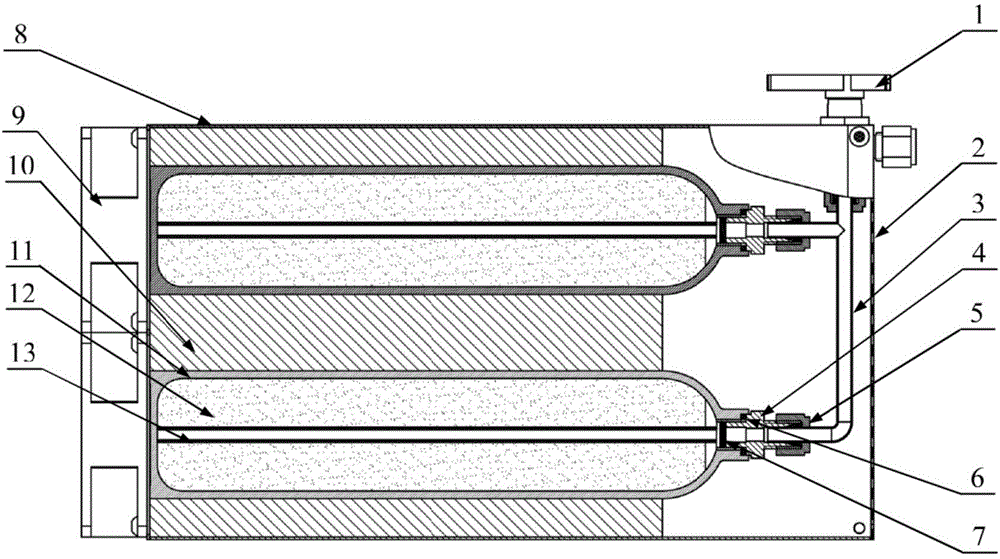

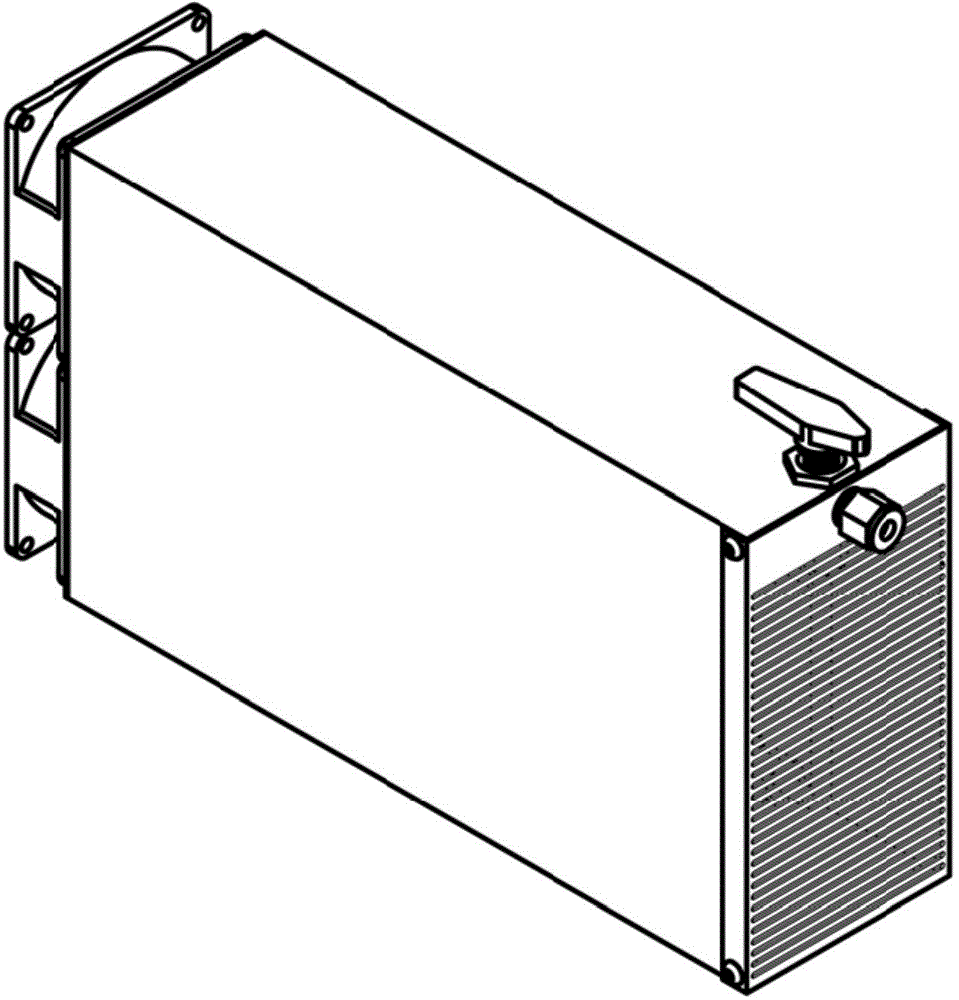

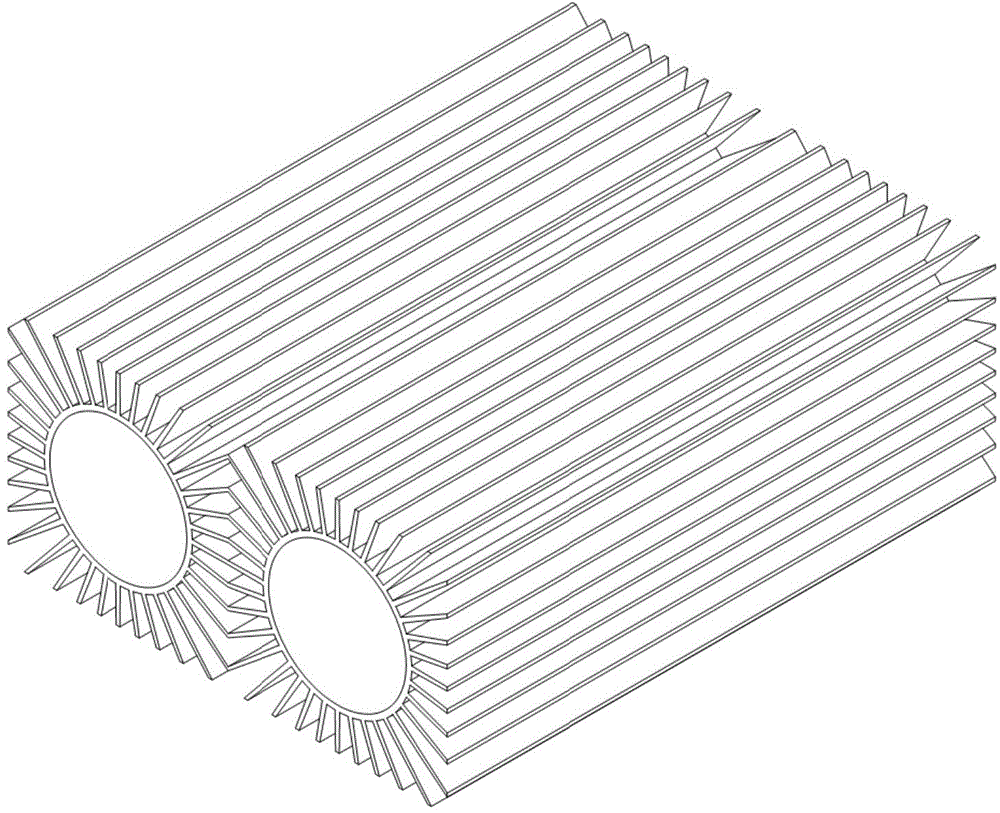

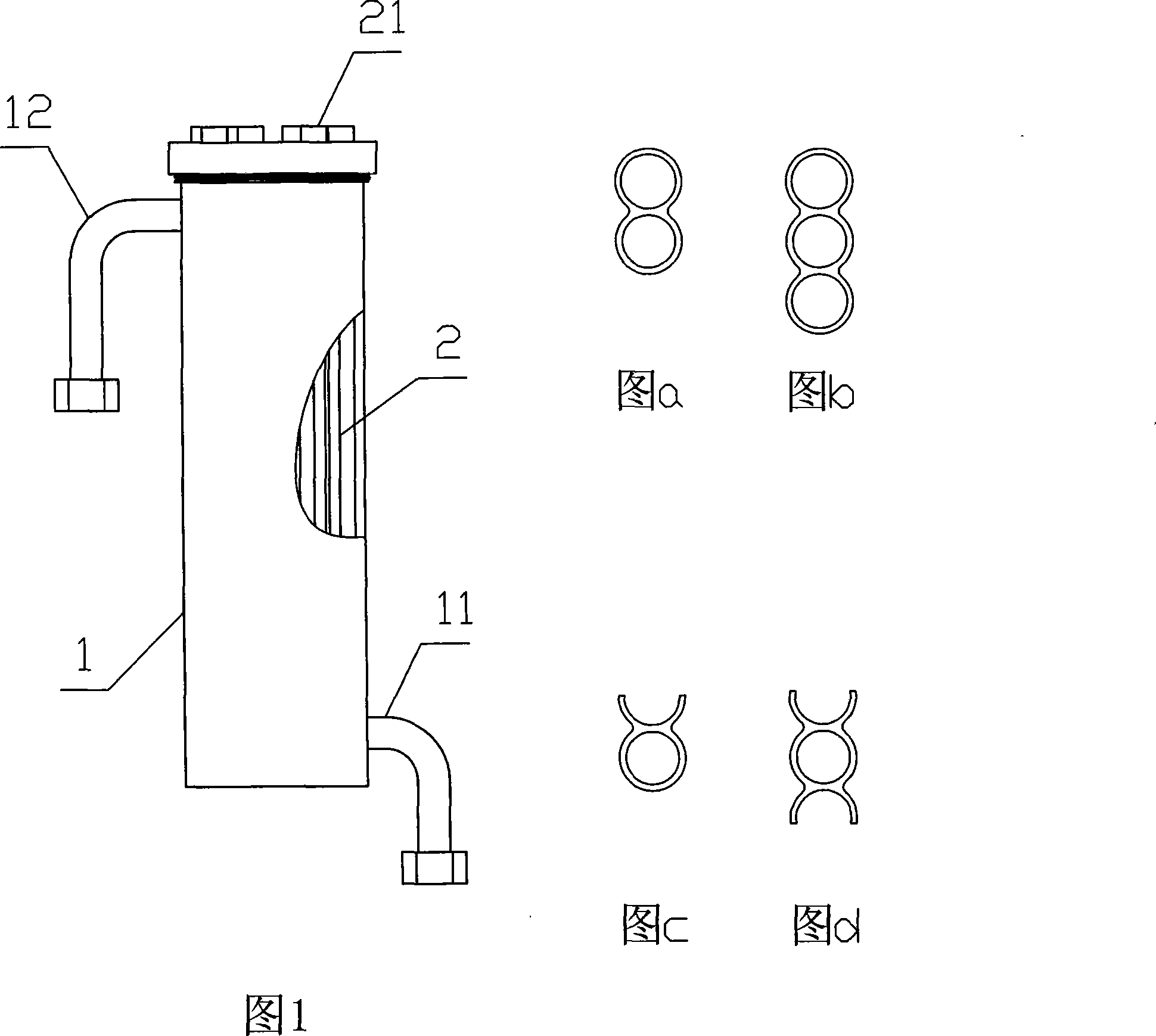

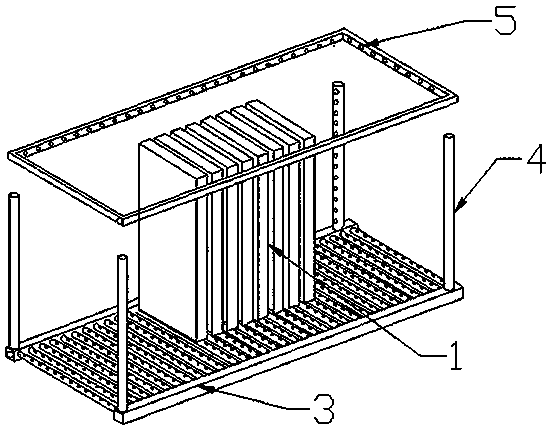

Metal hydride hydrogen storage device

InactiveCN104676239ASimple structureEasy to processContainer filling methodsPressure vesselsEngineeringHeat transfer efficiency

The invention discloses a metal hydride hydrogen storage device, which belongs to the technical field of hydrogen storage. The device is composed of a valve, a front cover, a gas path tube, a bottleneck connector, a clamping sleeve, a sealing gasket, a filter disc, a shell, two fans, a longitudinal heat transfer finned tube, a hydrogen storage container, a hydrogen storage material bed body, and a porous gas guide tube, wherein the bottleneck connector is connected with a hydrogen storage bottle body and the gas path tube by the sealing gasket and the clamping sleeve; the gas path tube is connected with the porous gas guide tube and the valve by the filter disc; the front cover and the two fans are arranged on the shell, and the longitudinal heat transfer finned tube and a hydrogen storage bottle are arranged in the shell; and the hydrogen storage material bed body and the porous gas guide tube are arranged in the hydrogen storage bottle body. The metal hydride hydrogen storage device disclosed by the invention is simple in structure, and easy to manufacture and process; and the longitudinal heat transfer finned tube can ensure the uniform heat transfer of the hydrogen storage container while the heat transfer efficiency of the hydrogen storage container is improved, so that the uniformity of hydrogen desorption of the hydrogen storage material bed body in the hydrogen storage container is ensured, and the hydrogen desorption performance is significantly improved.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Liquid nitrogen cooling cryogenic device and implementation method for same

ActiveCN104677000AReduce equipment input costsLow running costLighting and heating apparatusCooling fluid circulationProcess engineeringTemperature measurement

The invention discloses a liquid nitrogen cooling cryogenic device and an implementation method for the same. The cryogenic device comprises a self-pressurization liquid nitrogen tank, a cryogenic container, a liquid nitrogen dedicated cryogenic electromagnetic valve, a temperature control alarm and a sample container, wherein the cryogenic container is connected with a liquid outlet of the self-pressurization liquid nitrogen tank through a liquid nitrogen pipeline; the liquid nitrogen dedicated cryogenic electromagnetic valve is arranged in the liquid nitrogen pipeline; the temperature control alarm is connected with the liquid nitrogen dedicated cryogenic electromagnetic valve, and is provided with a first temperature measurement probe and a second temperature measurement probe; the sample container is arranged in the cryogenic container; both the first and second temperature measurement probes are positioned in the cryogenic container; the second temperature measurement probe is lower than the first temperature measurement probe; an organic matter medium filling pipe and an organic matter medium discharging pipe are further arranged on the cryogenic container respectively. The cryogenic device is simple in structure, low in cost and convenient to control, and has good cryogenic cooling and cryogenic constant temperature control effects, so that the requirements of a miniature cryogenic device in a laboratory can be met, and the requirements of larger-sized engineering operation can further be met.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Heat exchanger

InactiveUS7267160B2Uniform heat exchangeIncreased durabilityHydrogenSafety devices for heat exchange apparatusEngineeringProduct gas

In order to provide a heat exchanger with casing having a multiplicity of tubes through the interiors of which a high-temperature gas for heating flows, wherein the thermal stress is smoothly accommodated and wherein a fluid to be heated or a heating fluid flows uniformly through the outsides of the tubes, a multiplicity of flat tubes are joined at their opposed ends to a pair of discoidal tube plates, the outer periphery of the flat tubes being enclosed by an inner cylinder having a rectangular cross-section except the opposed end portions of the flat tubes, with a pair of baffle plates being disposed at the opposed ends of the inner cylinder. The pair of baffle plates are covered with an circular outer cylinder having a corrugated portion that is thermally expandable, with an inlet and an outlet for the fluid to be heated or the heating fluid positioned between the pair of baffle plates and the tube plates.

Owner:T RAD CO LTD

Electric oven

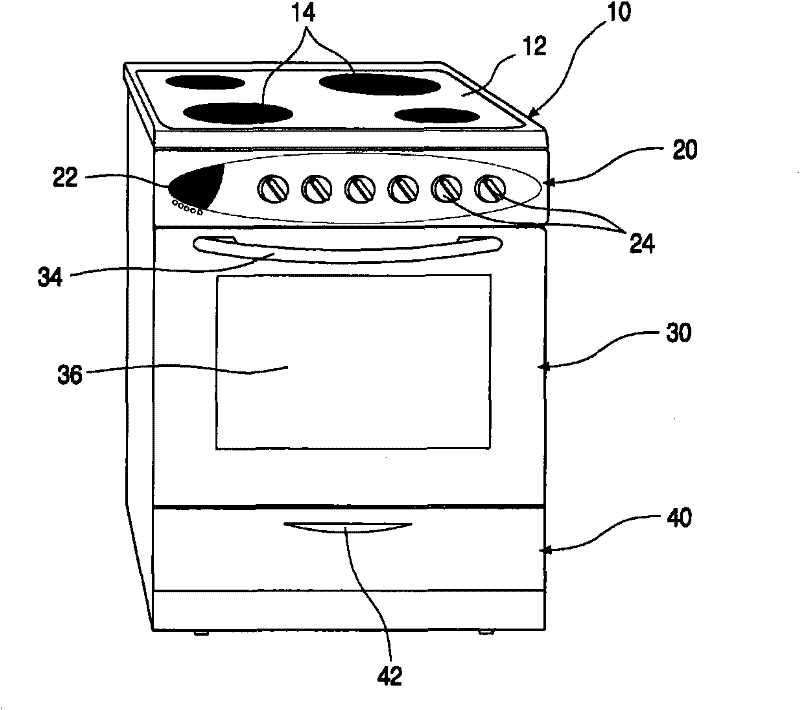

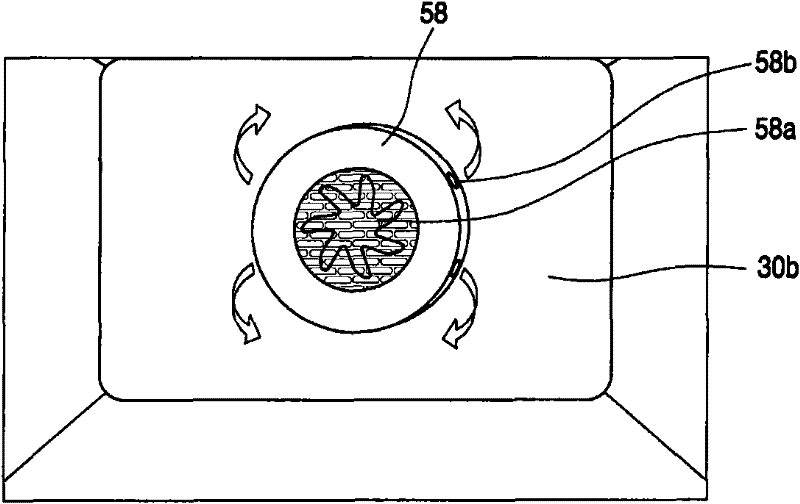

InactiveCN102232799AThe temperature rise remains stableSpeed up cookingRoasters/grillsCentrifugal forceCentrifugal fan

The invention relates to an electric oven, which comprises a housing, an oven part, an oven cavity, an oven door, electric heaters and convection fans, wherein the convection fans include two cross-flow fans and a centrifugal fan, the two cross-flow fans are arranged on the same side outside the oven cavity in the oven part, the centrifugal fan is arranged on the other side outside the oven cavity, and the electric heaters are respectively arranged near the cross-flow fans and the centrifugal fan. The electric oven has the following positive effects: airflow which keeps the flow direction relatively stable and flows circularly is formed in the oven cavity, thereby enabling heat in the oven cavity to be distributed more uniformly; and when flowing through the food, the hot air can carry out heat exchange with the food more uniformly, thereby keeping the temperature rise status of all the parts of the food stable and improving the cooking speed of the food.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Device and method for producing polylactic acid material

The invention relates to a device for producing a polylactic acid material. The device comprises a pre-melting kettle, a pre-polymerization kettle, a tubular reactor and an extruder, wherein the pre-melting kettle is used for melting lactide monomers; the pre-polymerization kettle is used for pre-polymerization of lactide monomer melt; the tubular reactor is used for directly polymerizing the prepolymer; the extruder is used for removing residual lactide monomers from the obtained polymer; and the pre-melting kettle, the pre-polymerization kettle, the tubular reactor and the extruder are sequentially connected together. The invention also relates to a method for producing the polylactic acid material. The method comprises the following steps of: a) melting the lactide monomers; b) pre-polymerizing the lactide monomer melt; c) directly polymerizing the prepolymer obtained in the b) in the tubular reactor; and d) removing the residual lactide monomers from the polymer obtained in the c), and thus obtaining the polylactic acid material. The device and the method can be used for producing the polylactic acid material with high monomer conversion rate and low monomer residue.

Owner:CHINA PETROLEUM & CHEM CORP +1

Efficient condenser

ActiveCN104990315AImprove heat transfer efficiencyReduce thicknessEvaporators/condensersHeat transfer modificationEngineeringRefrigeration

The invention discloses an efficient condenser which comprises a shell. A condensation heat exchange area and a supercooling area are formed in the shell from top to bottom through a plurality of heat exchange pipes and a supercooling pipe. The condensation heat exchange area is divided into an upper layer and a lower layer. The heat exchange pipes on the upper layer and the lower layer are separated by a fluid baffle penetrating through supporting plates. The whole fluid baffle tilts by 10-15 degrees towards one side in the width direction. The condensation heat exchange area and the supercooling area are separated by a supercooling area upper sealing plate covering the supercooling area. According to the efficient condenser, due to the fact that the fluid baffle is arranged between the upper layer and the lower layer of the condensation heat exchange area and the supercooling area upper sealing plate is arranged between the condensation heat exchange area and the supercooling area, the thickness of fluid films outside the heat exchange pipes below the fluid baffle is effectively reduced, the heat exchange performance of the supercooling area is enhanced, and the energy efficiency of a refrigeration system is obviously improved.

Owner:南京冷德节能科技有限公司 +1

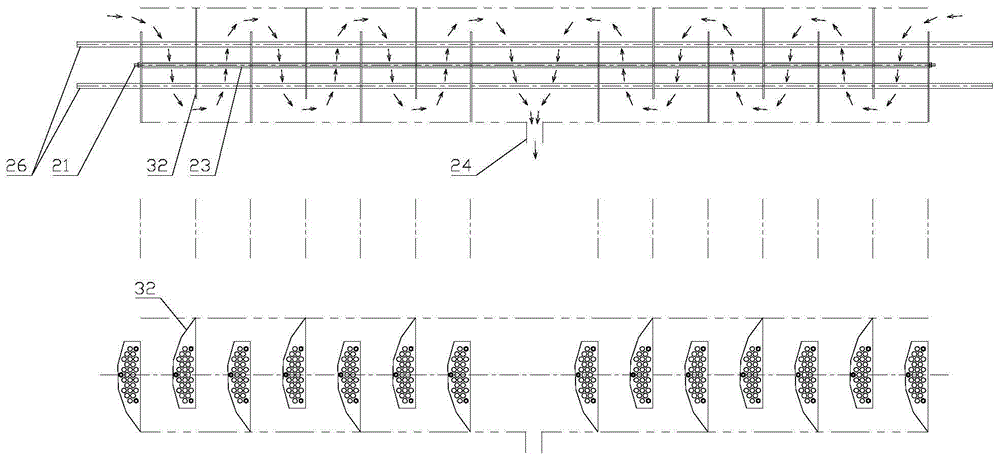

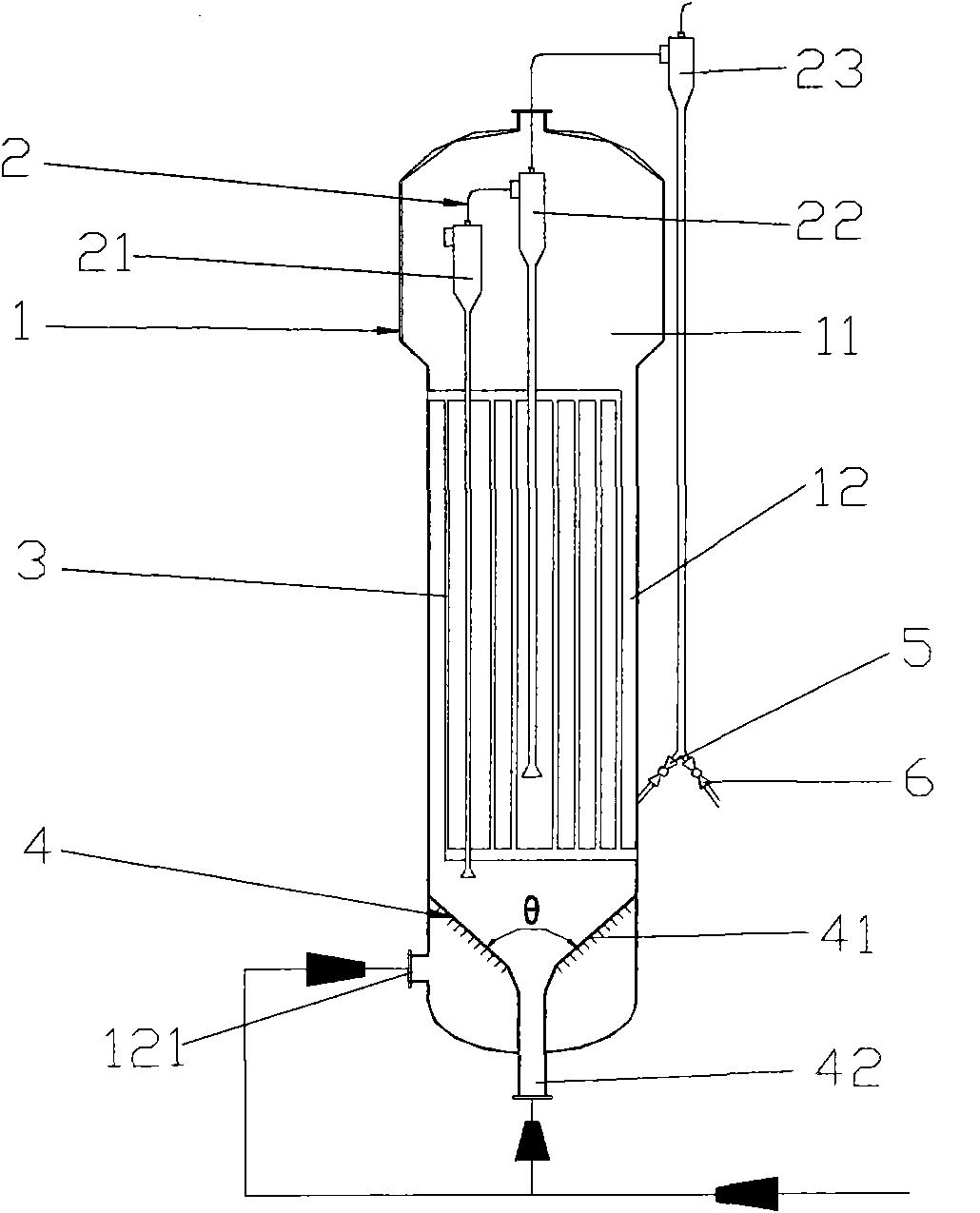

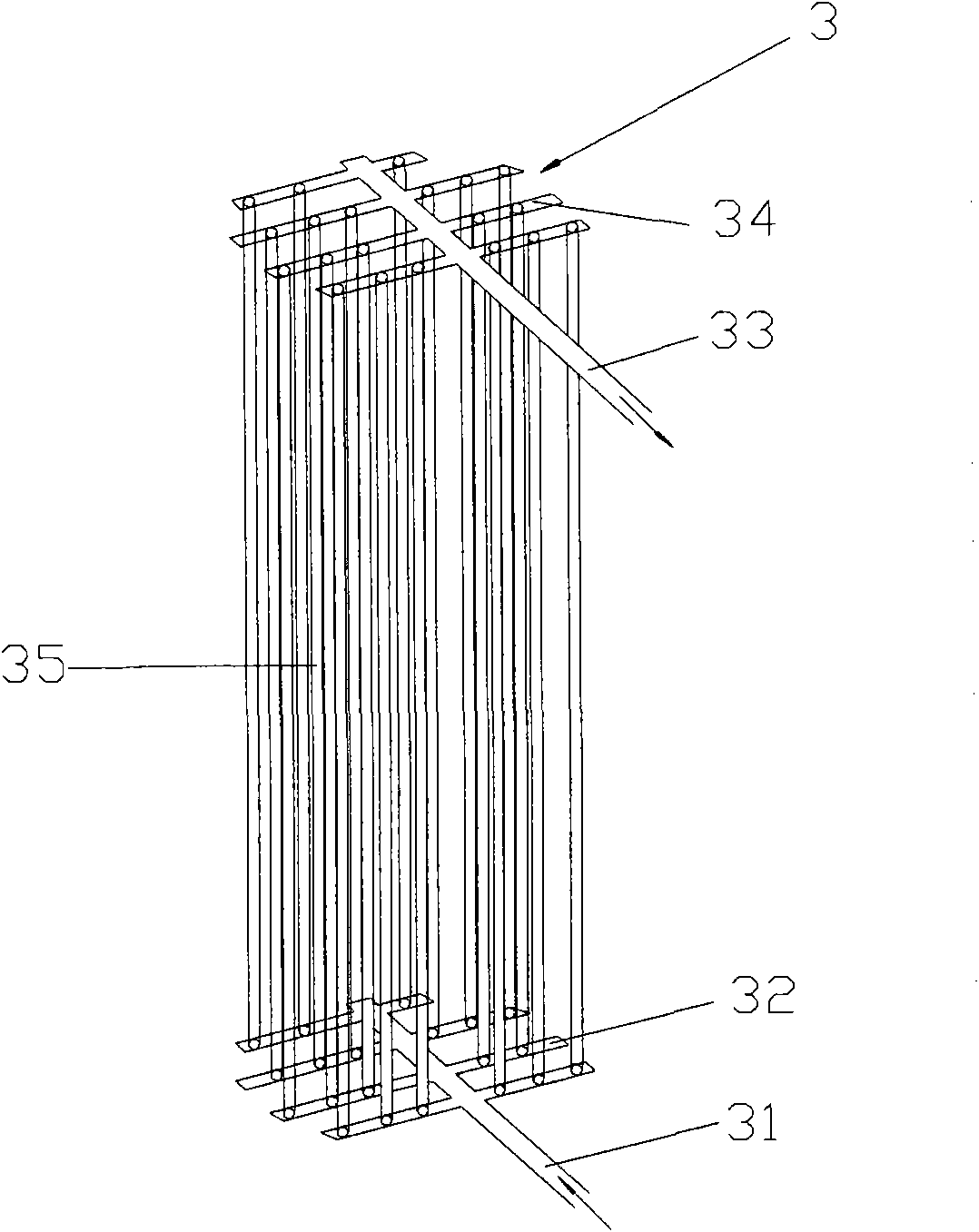

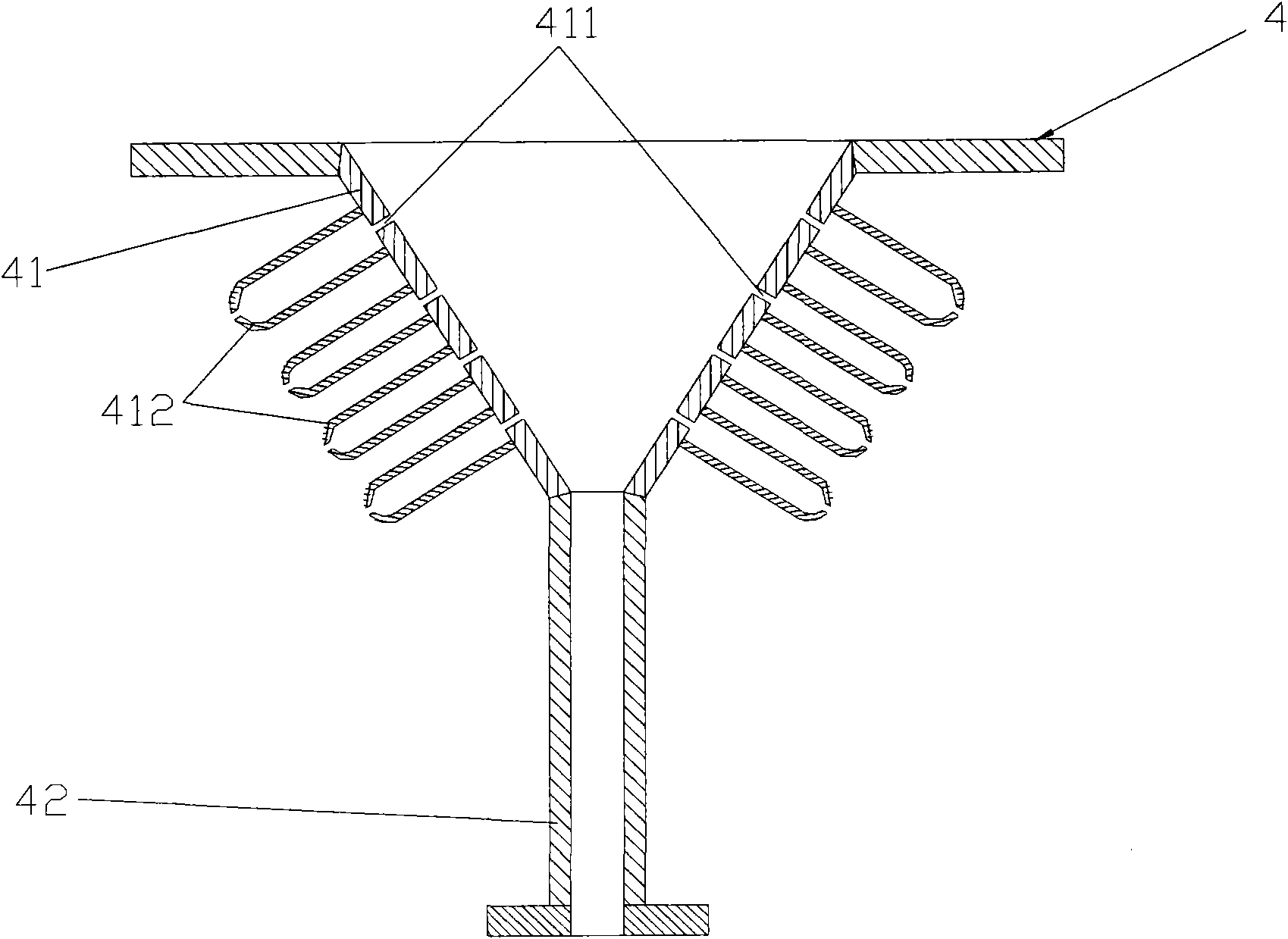

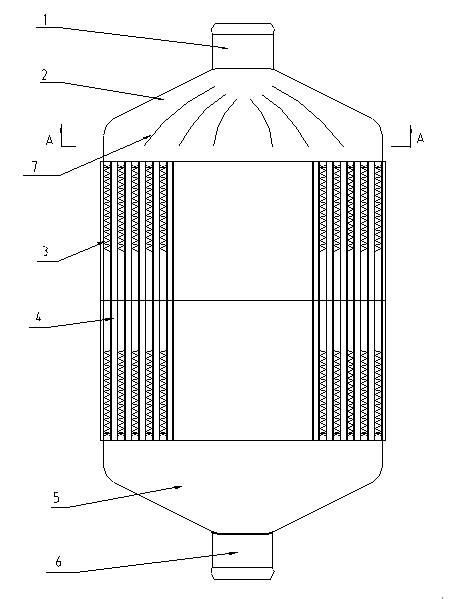

Spout type fluidized bed reactor for synthesis of organic silicon

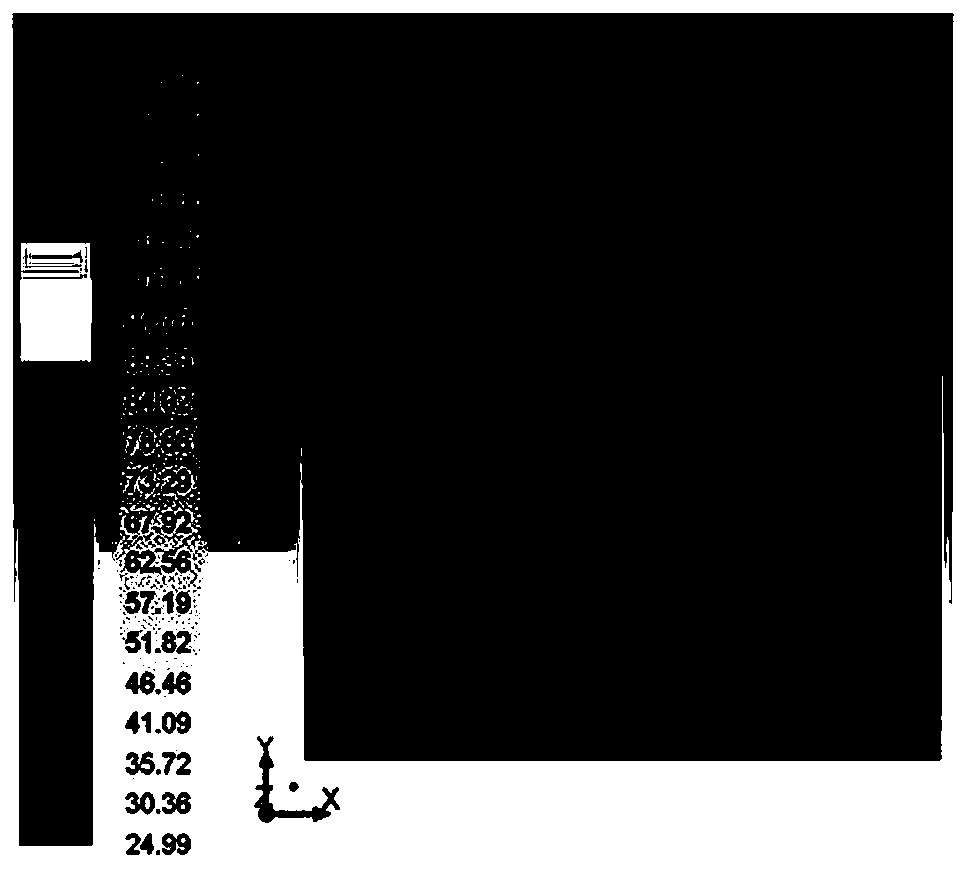

ActiveCN102078784AUniform heat exchangeAxial temperature difference is smallGroup 4/14 element organic compoundsChemical/physical processesCycloneFluidized bed

A spout type fluidized bed reactor for synthesis of organic silicon comprises a reactor body, an expanded section, tube bore-hole type combination distributors, cyclone separator components, a back-to-bed valve, a powder-ridding tank valve and tubular heat exchangers, wherein the tube bore-hole type combination distributor is arranged at the bottom of the reactor bed body and comprises a conical gas distributor, a straight tube pore-type distributor and a spouted gas tube; the tubular heat exchangers are arranged in the reactor bed body, heat exchange carriers flowing through the heat exchanging tubes from bottom to top, to achieve single-tube pass heat transfer, so that the heat transfer between the tube surfaces and reacting fluid is even, and radial and axial temperature difference aresmall; particles separated by the cyclone separating device are directly returned back to the bed by the inner and external cyclone separating devices in time and not be taken out of the bed or partial particles are taken out, thereby reducing the catalyst content in the bed and the temperature fluctuation and being beneficial to improving reaction efficiency.

Owner:HOSHINE SILICON IND CO LTD

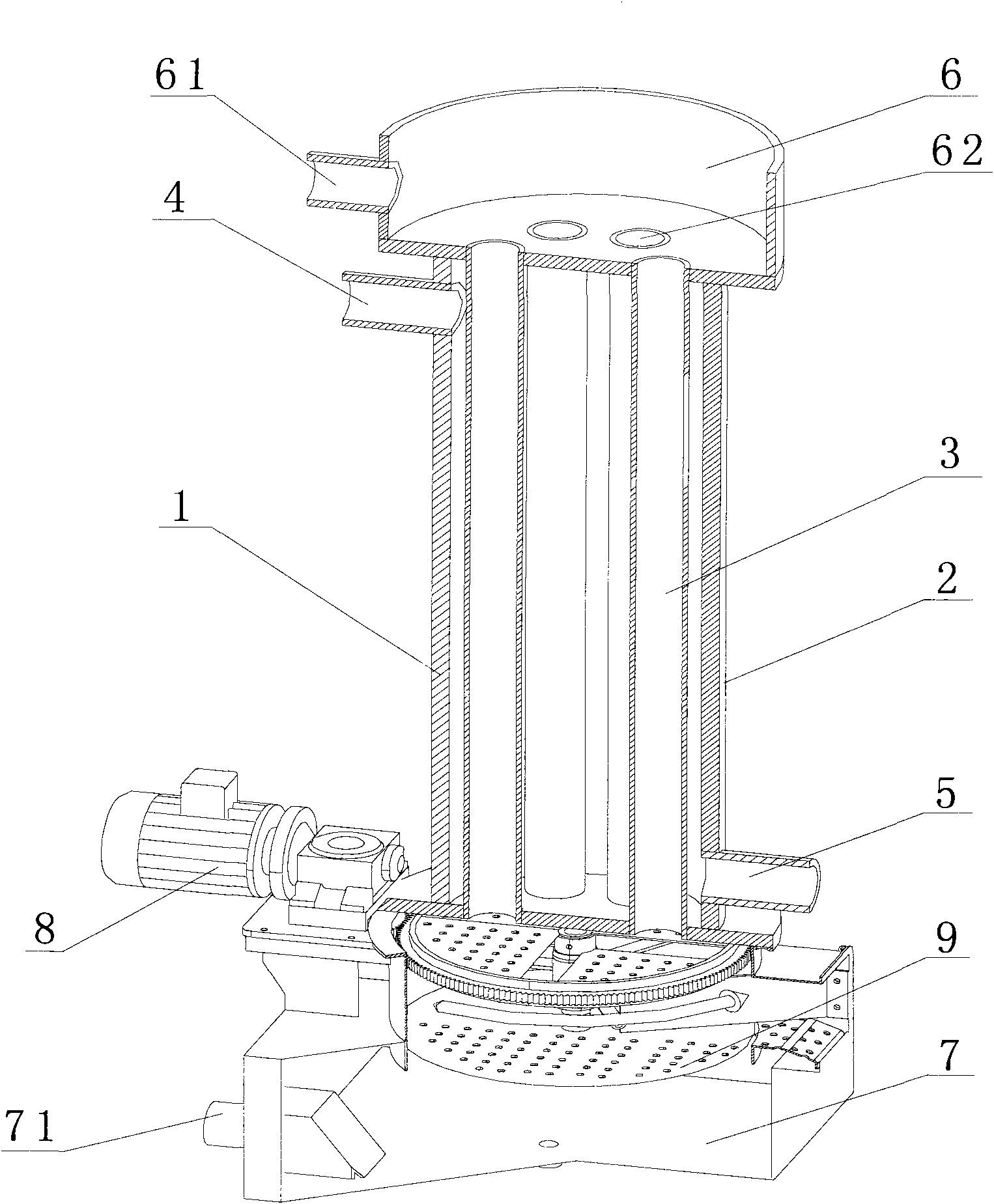

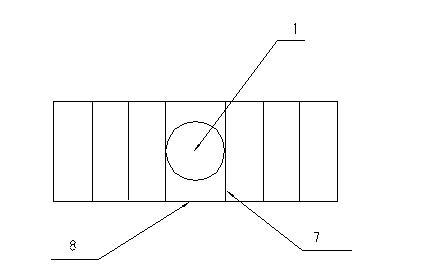

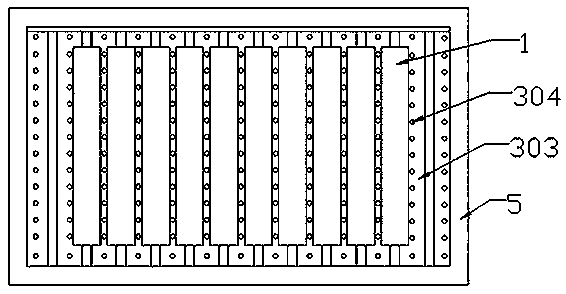

Ice machine for making tube ice

InactiveCN101881536ASimple structureRealize automatic controlIce productionHeat exchange apparatusPlate heat exchangerControl system

The invention relates to an ice machine for making tube ice, which comprises an evaporator, a round heat exchange tube and a full closed heat exchanger. The evaporator is a vertical shell and tube evaporator and is controlled by a control system, a vertical heat exchange tube is arranged in the shell of the evaporator and contains water supplied constantly from outside and flowing from top to bottom, the shell is provided with a low temperature fluid outlet at the upper end and a low temperature fluid inlet at the lower end, and low temperature fluid is transmitted in the shell from outside and flows from bottom to top along the outer wall of the heat exchange tube so as to gradually ice the water flowing in the heat exchange tube into tube ice through heat exchange. The whole ice making and unloading process can be controlled in an automated way and is suitable for automation production in large scale. In addition, the round heat exchange tube has a large heat exchange area and can ice an ice layer from the external circumference to the circle center, thereby achieving even heat exchange; the full closed heat exchanger can realize lowest loss of refrigeration capacity and achieve a most energy-saving and most effective heat exchange effect; and moreover, parts in contact with the water are all made of stainless steel or aluminum alloy, and thereby, produced ice blocks are clean and sanitary and can be eaten directly.

Owner:上海弗格森制冷设备有限公司

Vehicle intercooler based on heat medium splitting technology

InactiveCN102042075AAvoid collisionImprovement of disordered flowInternal combustion piston enginesHeat exchanger casingsInlet channelProcess engineering

The invention discloses an intercooler gas chamber based on a heat medium splitting technology. In the intercooler gas chamber based on the heat medium splitting technology, the gas inlet direction of a gas inlet channel and the position of a gas inlet are adjusted by improving the structure of the gas chamber, and since well-designed guide vanes are inserted into the gas chamber, for an intercooler, good heat exchange performance is maintained, and simultaneously the internal drag energy consumption is greatly reduced.

Owner:ZHEJIANG UNIV

A tube type heater for electric water heater

InactiveCN101166380ASimple structureEasy to manufactureFluid heatersHeating element shapesStraight tubeEngineering

The disclosed tubular heater in use for electric water heater (EWH) includes heat exchange unit (HEU) and heating unit (HU). HEU is in metal multiple tube structure, in which at least one piece of tube is heating tube for the heating unit to be placed, and at least one piece of tube is as liquid passage tube (LPT). Tube connectors are setup at two ends of LPT. The heating tube can be in multiple tube structure for more than one HU to be installed in. HU can be bent to U shape, square shape, snake shape etc. Advantages are: (1) producing smaller EWH; (2) simple structure of HU, easy producing and low cost; (3) LPT is continuous tube without soldered dot so as to not produce leaking phenomena; (4) reasonable heat exchanging structure, and high thermal efficiency; (5) being not contacted to liquid, electric heating tube (EHT) is not be eroded, generates scale, and has long service life; (6) being in U shape or straight tube shape, EHT possesses low factory cost and steady quality.

Owner:奥特朗电器(广州)有限公司

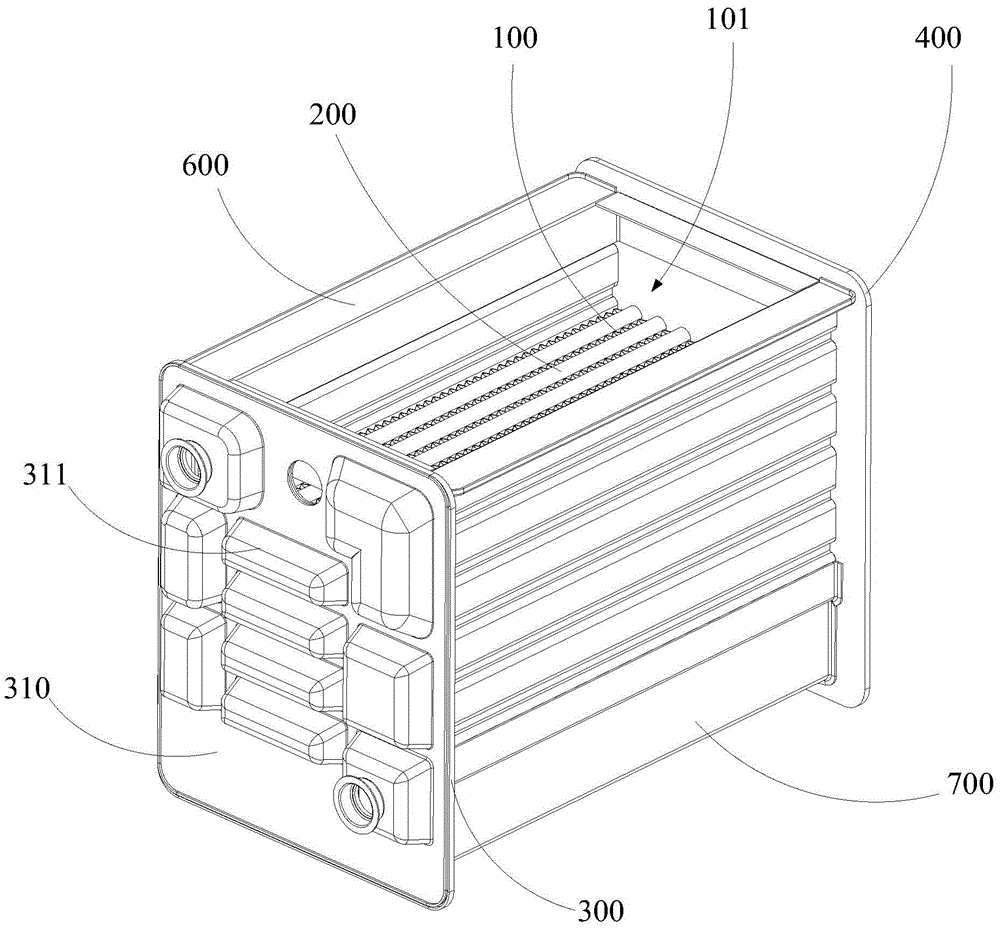

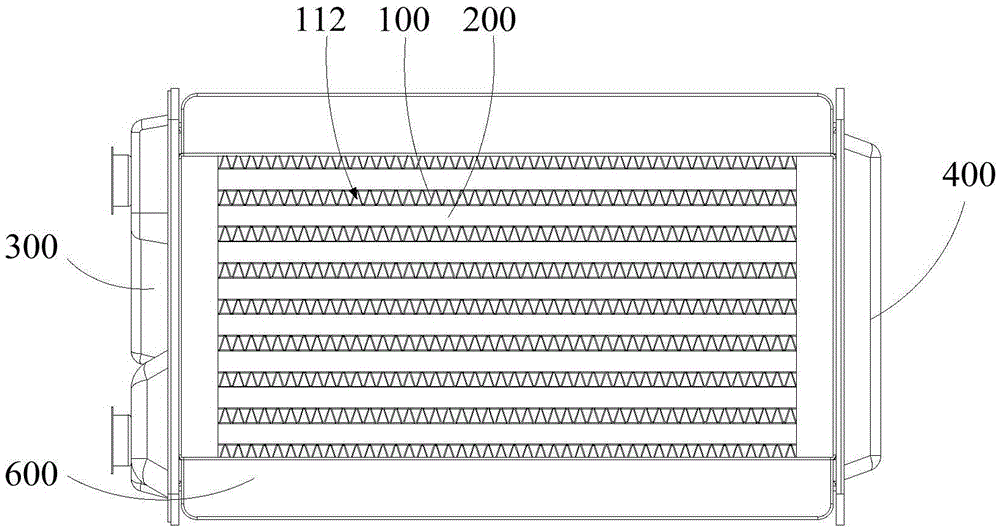

Heat exchanger and water heater

ActiveCN105486125AUniform heat exchangeImprove heat transfer efficiencyStationary tubular conduit assembliesWave shapeMetallic materials

The invention discloses a heat exchanger and a water heater. The heat exchanger comprises heat exchange parts, a plurality of rows of heat exchange pipes, a first flow concentration end cover, and a second flow concentration end cover. An installation gap is formed between every two adjacent rows of heat exchange pipes. The heat exchange parts are arranged in the installation gaps, and each heat exchange part is arranged by attaching the corresponding two adjacent heat exchange pipes in the heat exchanger. The heat exchange parts comprise heat exchange pieces which are made of metal materials. The heat exchange pieces are bent back and forth in the thickness direction of the heat exchange pieces to form a wave shape, and therefore protrusions which are arranged at intervals are formed on the front faces and the back faces of the heat exchange pieces. A smoke passing way is formed between every two adjacent protrusions on the surface of the same side of each heat exchange piece, and smoke channels of the heat exchange pieces are composed of the smoke passing ways. The smoke channels of the heat exchange parts are communicated with a smoke inlet and a smoke outlet. The first flow concentration end cover and the second flow concentration end cover correspondingly cover the two ends of the multiple rows of heat exchange pipes, and the corresponding heat exchange pipes in the multiple rows of heat exchange pipes are communicated. According to the technical scheme, the heat exchange efficiency of the heat exchanger can be improved.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

Immersed self-flow-interfering shell-and-tube-type heat exchanger

ActiveCN110631301AEnhanced perturbation strengthImprove heat transfer effectIndirect heat exchangersModifications using liquid coolingTemperature controlPlate heat exchanger

The invention provides an immersed self-flow-interfering shell-and-tube-type heat exchanger. The heat exchanger comprises a shell, a liquid distribution device, a self-flow-interfering device and a liquid collection device; a cooling liquid inlet and a cooling liquid outlet are formed in the shell; the cooling liquid inlet communicates with the liquid distribution device; the liquid distribution device communicates with the self-flow-interfering device; the liquid collection device is located on the upper part of the shell and below the liquid surface of cooling liquid; the liquid collection device communicates with the cooling liquid outlet; the cooling liquid enters the shell sequentially through the cooling liquid inlet, the liquid distribution device and the self-flow-interfering device, and flows out of the cooling liquid outlet through the liquid collection device; a heat source is immersed in the cooling liquid in the shell; and the liquid distribution device comprises a liquiddistribution mother tube which communicates with the cooling liquid inlet. The immersed self-flow-interfering shell-and-tube-type heat exchanger is controlled through liquid outlet temperature, so that the effects of automatic controlling and energy saving are realized; the interfering strength of a cooling liquid flowing field in the shell is enhanced; and the heat exchanging efficiency is improved.

Owner:SHANDONG UNIV

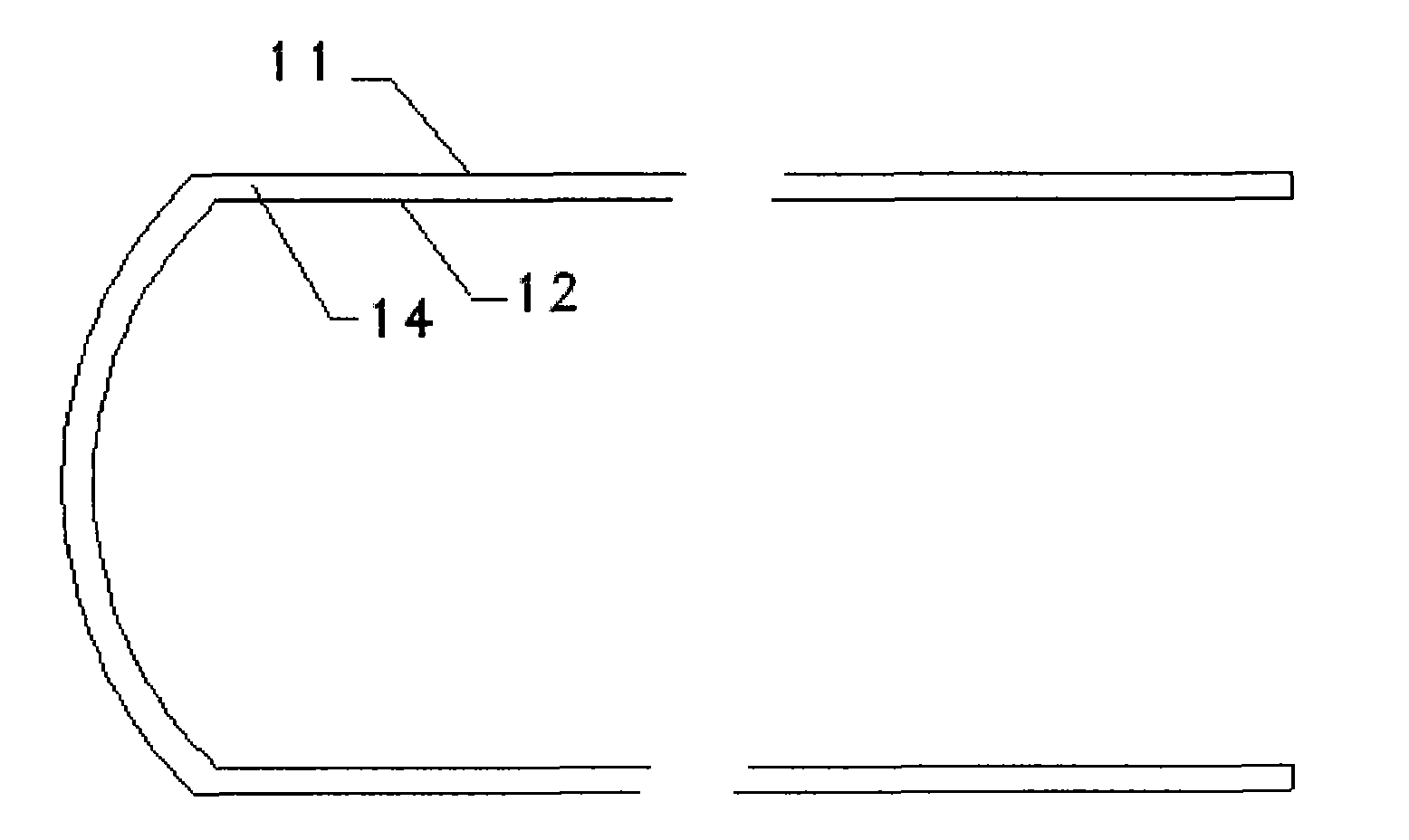

Solar phase-change heat collecting and storing tube

InactiveCN101846398AImprove securityOverheating will notSolar heating energySolar heat devicesEngineeringHigh pressure

The invention relates to a solar phase-change heat collecting and storing tube, which comprises a solar vacuum heat collecting tube, a heat exchange tube, a phase-change material, a phase-change heat accumulator and a draft tube. The phase-change heat accumulator is arranged in the solar vacuum heat collecting tube; the heat exchange tube is embedded in the phase-change heat accumulator, and the upper part of the heat exchange tube is slidably connected with the phase-change heat accumulator; the phase-change material is filled between the phase-change heat accumulator and the heat exchange tube; and the draft tube is inserted into the heat exchange tube. In the solar phase-change heat collecting and storing tube, the fastening end cover of the phase-change heat accumulator is provided with sealing grease, so the heat exchange tube is slidably connected with the phase-change heat accumulator; when the phase-change material is overheated, high pressure in the tube body of the phase-change heat accumulator can push the heat exchange tube to move outwards to release high pressure so as to complete overheated unloading, so the safety performance when the heat collecting tube is overheated is greatly improved and the phase-change material is ensured not to be overheated.

Owner:皇明太阳能(上海)有限公司

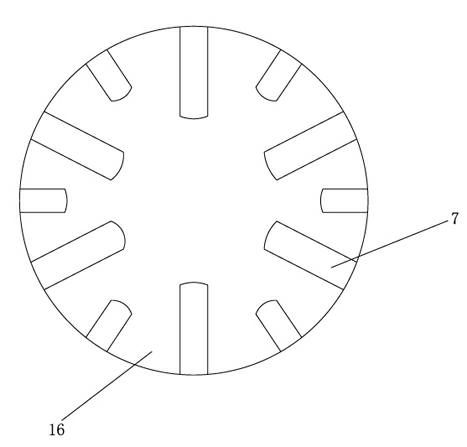

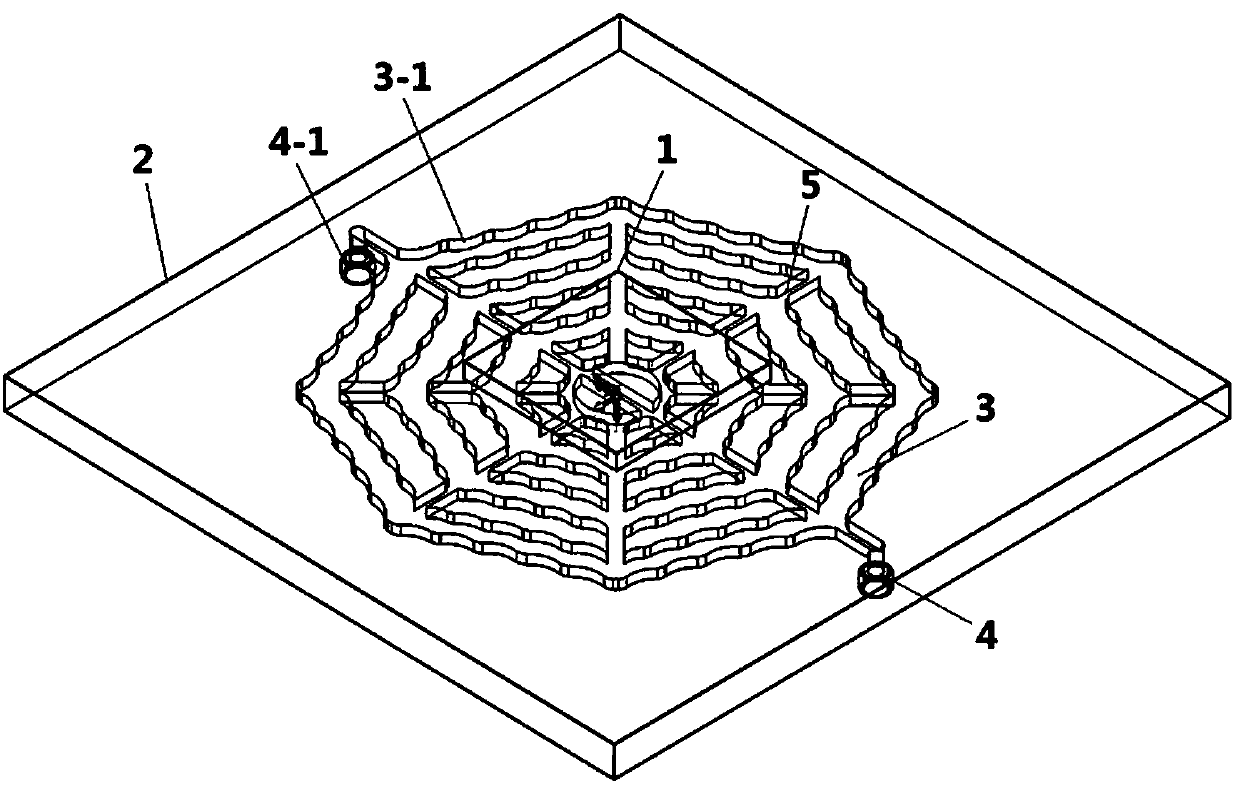

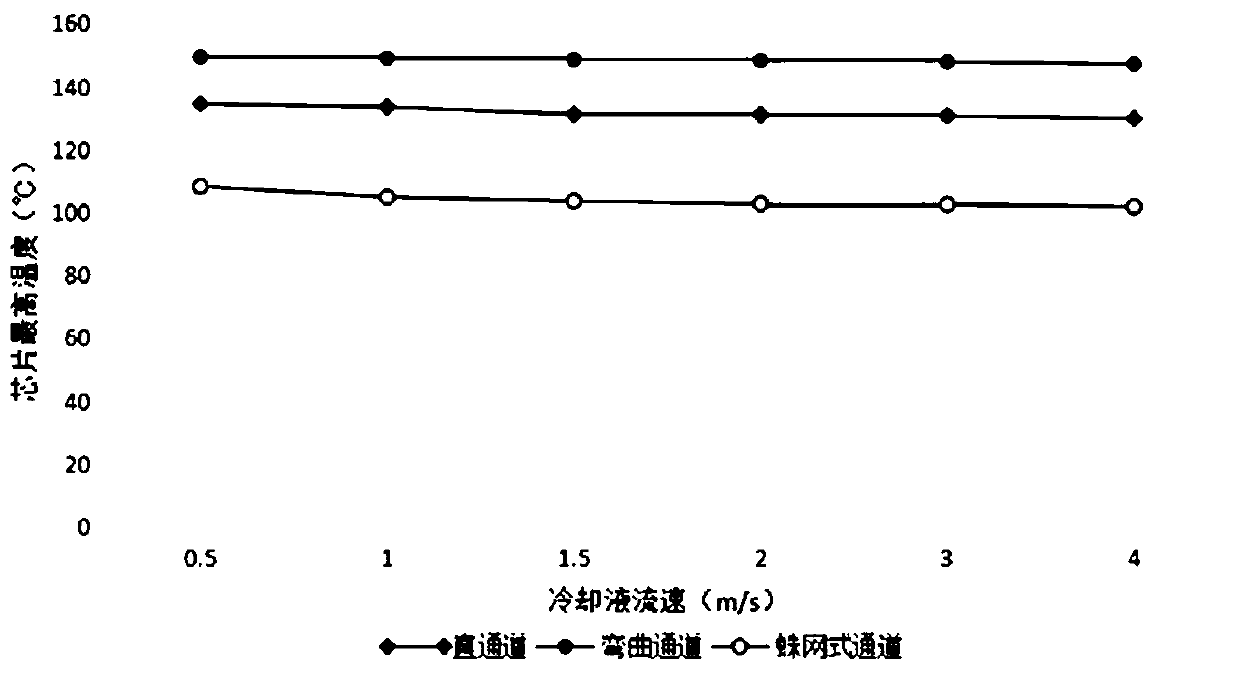

Cobweb type micro channel heat radiation apparatus

PendingCN108172557ALower coefficient of frictional resistanceImprove heat transfer effectSemiconductor/solid-state device detailsSolid-state devicesThermodynamicsWave shape

The invention discloses a cobweb type micro channel heat radiation apparatus. The cobweb type micro channel heat radiation apparatus includes a substrate, and is characterized in that the bottom of the substrate is provided with a fluid micro channel which is distributed uniformly in a cobweb shape; the center of the substrate is the central position of the fluid micro channel; the fluid micro channel radiates outward from the central position, and is displayed in the shape of circles with different diameter; the fluid micro channel takes the central position as the base to set *-shaped fluidmicro straight channels; the *-shaped fluid micro straight channels divide the fluid micro channel into 8 equal symmetrically distributed sectors; two ends of one of the *-shaped fluid micro straightchannels are respectively connected with cooling working medium inlet and outlet at the bottom of the substrate; and the inner wall of the fluid micro channel is wave-shaped, and a heat source is arranged at the central position of the substrate. The cobweb type micro channel heat radiation apparatus has the advantages of being simple in structure, being more uniform in overall heat radiation, andbeing able to improve heat radiation performance of a radiator.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com