High temperature tail gas anti-impact piece adjustable structure of polycrystalline silicon high temperature tail gas heat exchanger

A tail gas heat exchanger technology, applied in the direction of silicon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems that the metal anti-shock plate cannot adjust the gas flow rate, the gas cannot pass through the heat exchange tube uniformly, and the service life is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

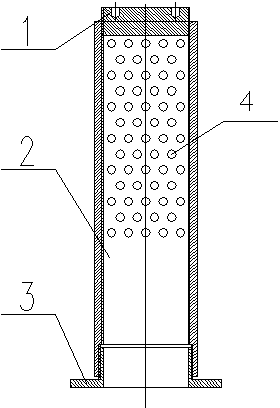

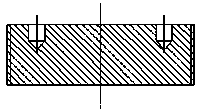

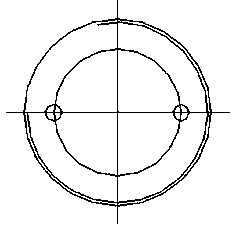

[0024] see figure 1 , figure 1 It is a schematic diagram of the adjustable structure of the high-temperature exhaust gas anti-shock parts of the polysilicon high-temperature exhaust gas heat exchanger of the present invention. Depend on figure 1 It can be seen that the adjustable structure of the high-temperature tail gas anti-shock parts of the polysilicon high-temperature tail gas heat exchanger of the present invention includes a cylindrical plug 1 (see figure 2 and image 3 ), spiral hole pipe 2 (see Figure 4 and Figure 5 ) and fixed connector 3 (see Figure 6 and Figure 7 ), the cylindrical plug 1 is threadedly connected with the inner hole of one end of the spiral hole pipe 2, and the fixed connector 3 is threaded with the inner hole of the other end of the spiral hole pipe 2. The spiral hole pipe 2 is provided on the pipe wall. row of screw holes.

[0025] The spiral hole row pipe 2 is made of graphite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com