Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Control temperature distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

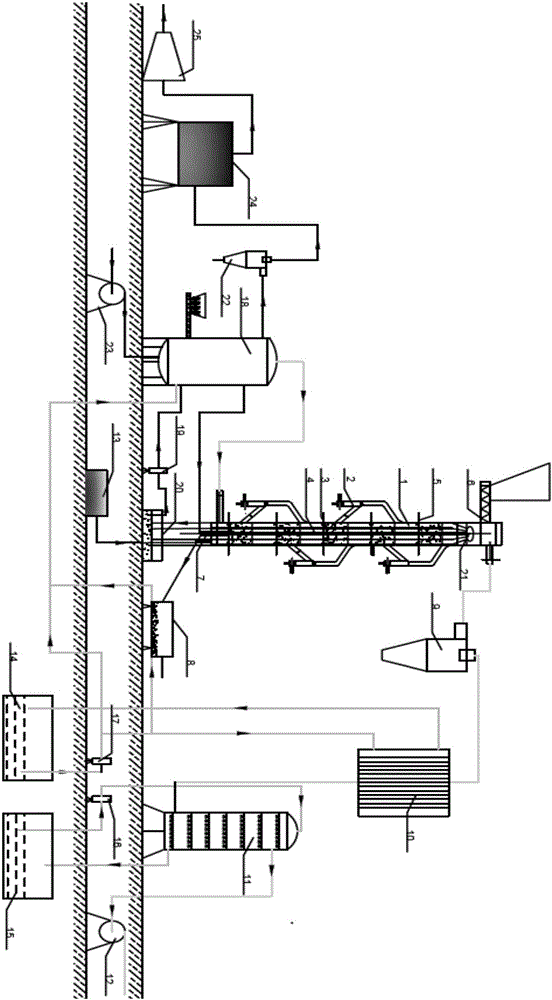

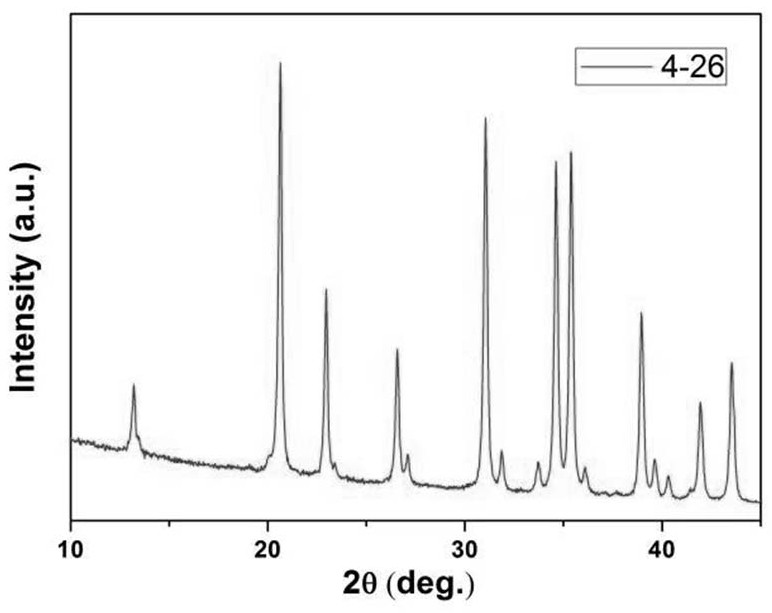

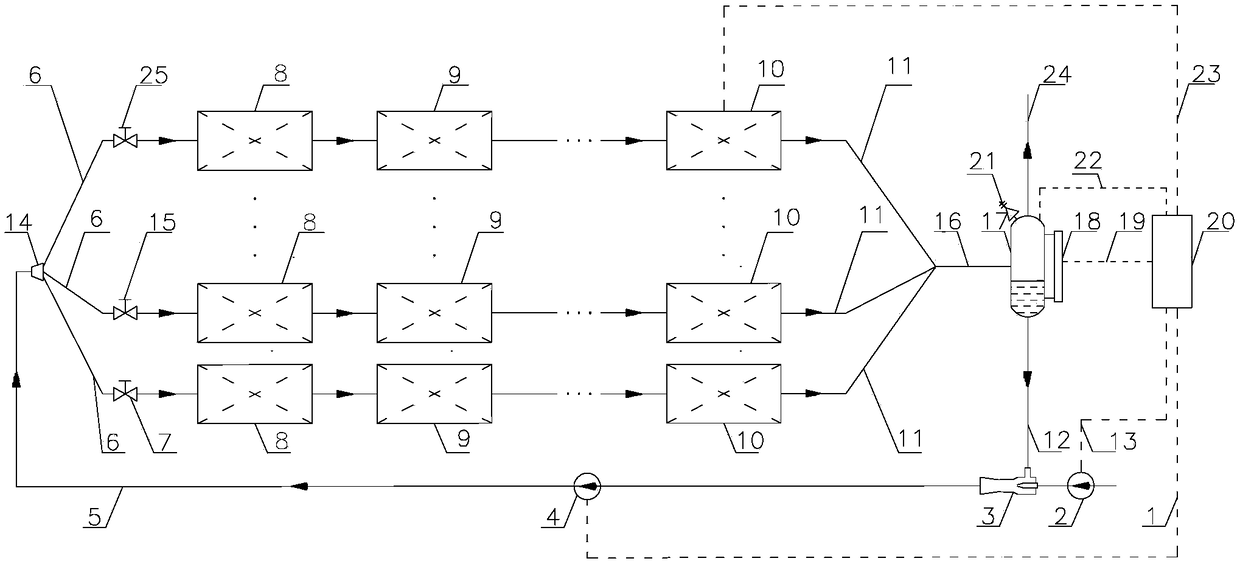

Method used for preparing methyl acetate via carbonylation of dimethyl ether

ActiveCN103896769AExtend your lifeControl temperature distributionPreparation by carbon monoxide or formate reactionHydrogenReaction temperature

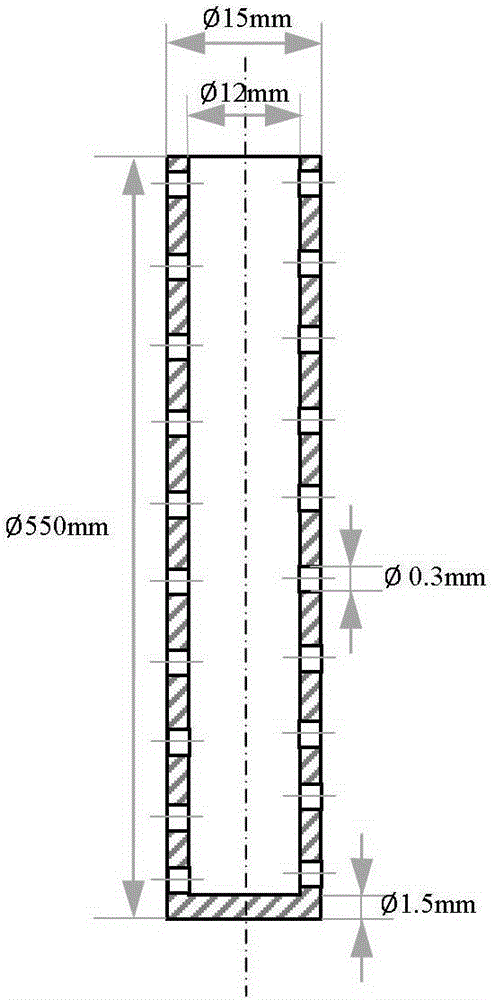

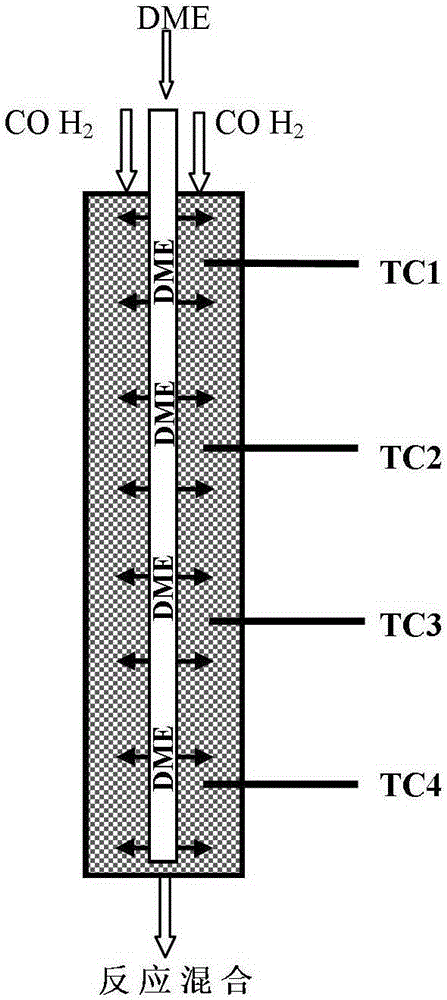

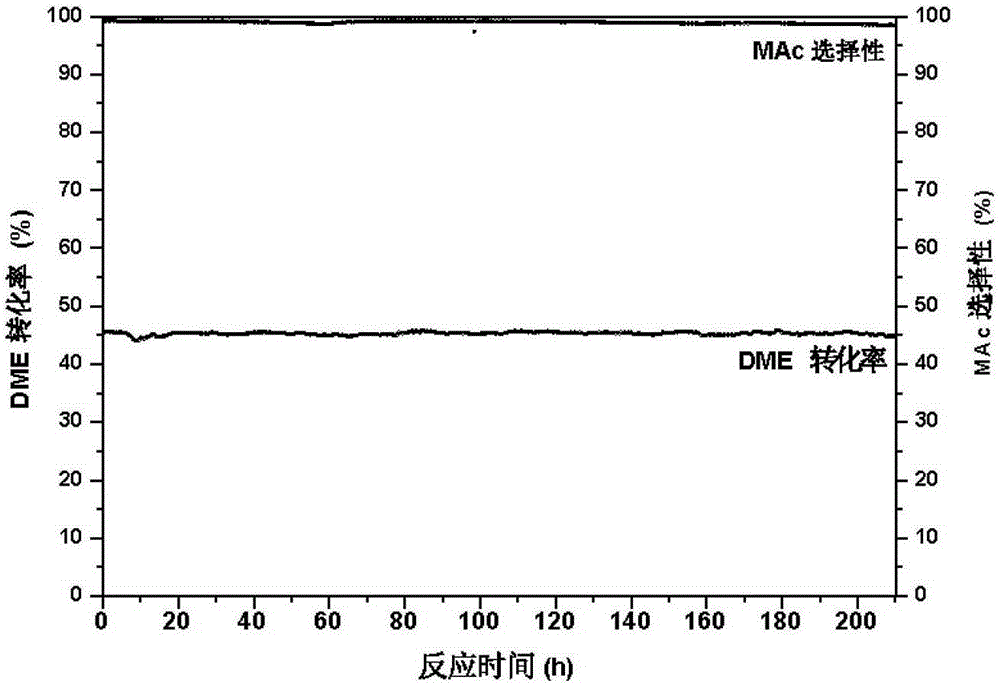

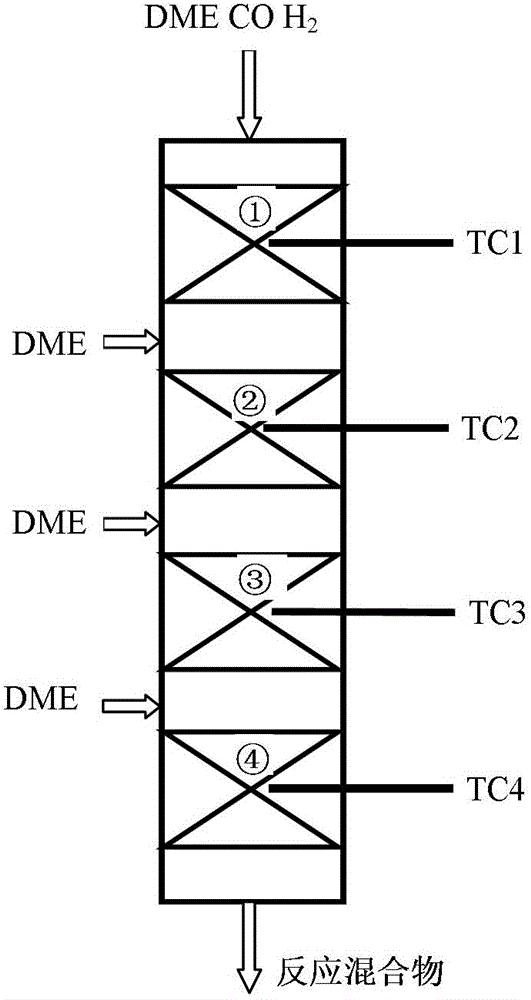

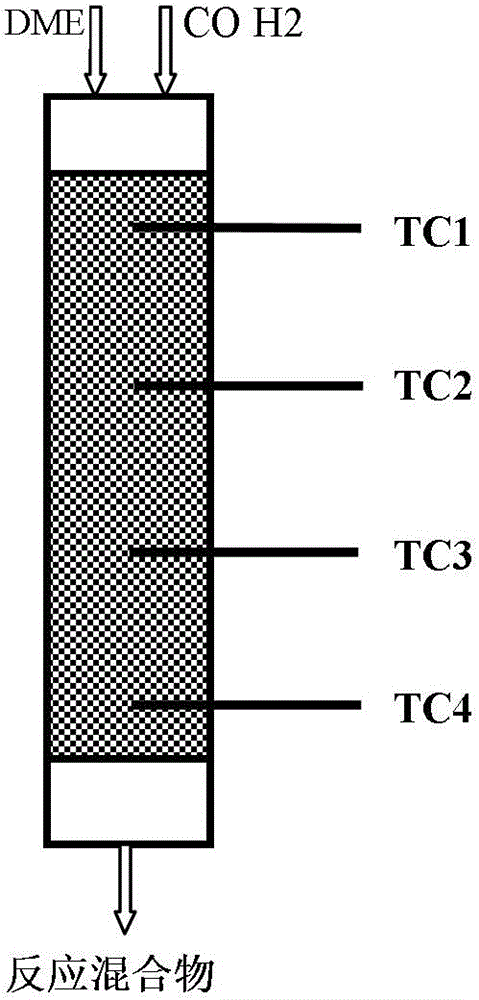

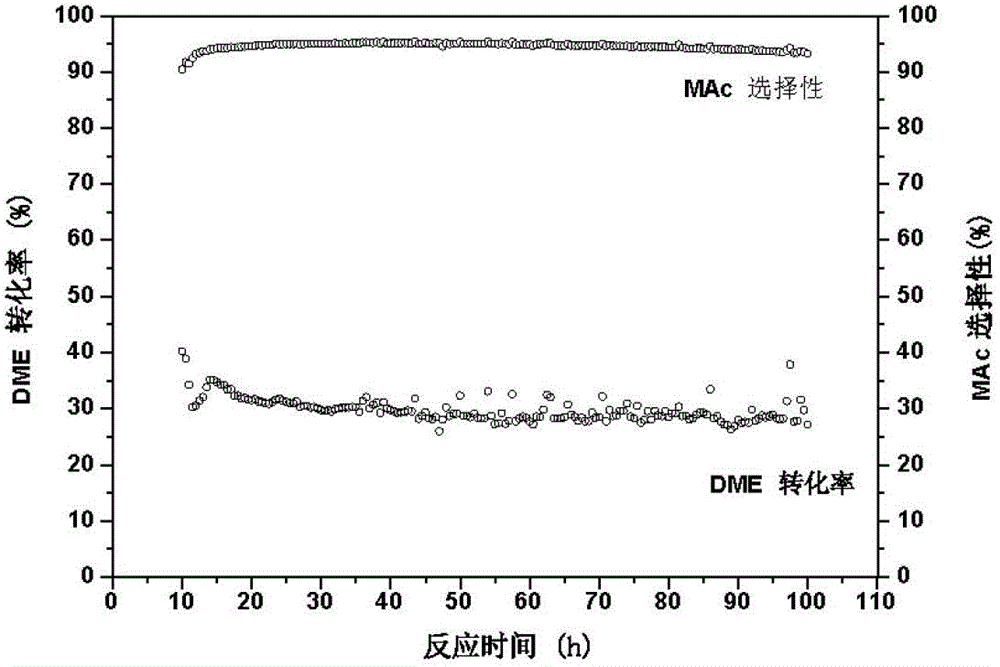

Provided is a method for preparing methyl acetate by dimethyl ether carbonylation, comprising passing a feed gas including dimethyl ether, carbon monoxide and optional hydrogen through a reactor filled with a mordenite and / or ferrierite molecular sieve based catalyst and reacting at a reaction temperature of 190-320°C, a reaction pressure of 0.5-20.0 MPa and a gas space velocity of 500-5000 h-1 so as to prepare methyl acetate, wherein the molar ratio of dimethyl ether to carbon monoxide is DME / CO=1 / 1-1 / 15, the molar ratio of hydrogen to carbon monoxide is H2 / CO=0-10 / 1, and the feed gas is distributed into each catalyst bed layer in a segmental feeding manner. A feed gas including dimethyl ether and carbon monoxide is uniformly distributed into each catalyst bed layer via a gas distributor, in a segmental feeding manner, which can remarkably improve the conversion rate of dimethyl ether, effectively control or adjust the temperature distribution of a catalyst bed layer, avoid the appearance of a hot spot, and prolong the service life of a catalyst.

Owner:YANCHANG ZHONGKE (DALIAN) ENERGY TECH CO LTD

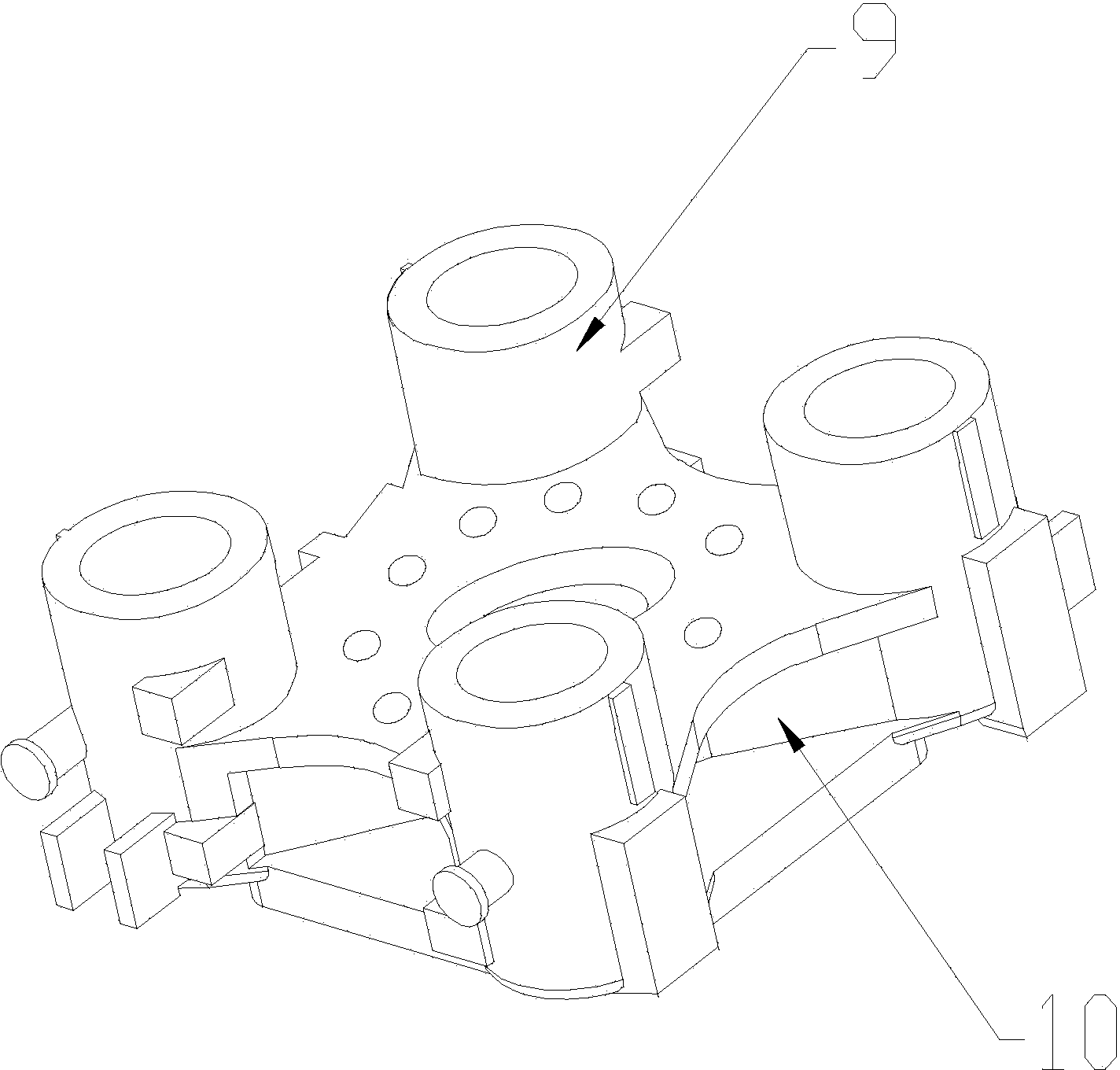

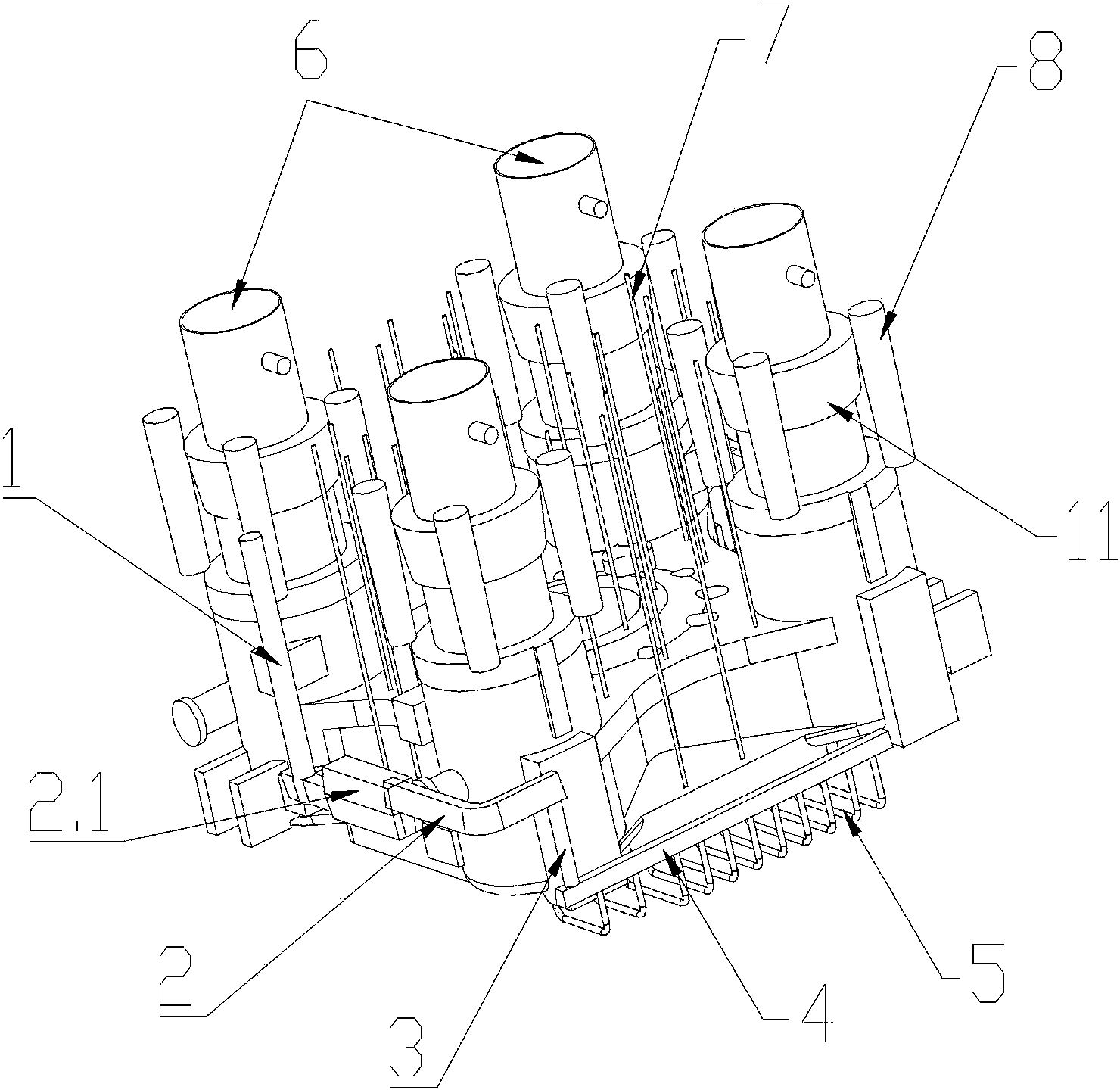

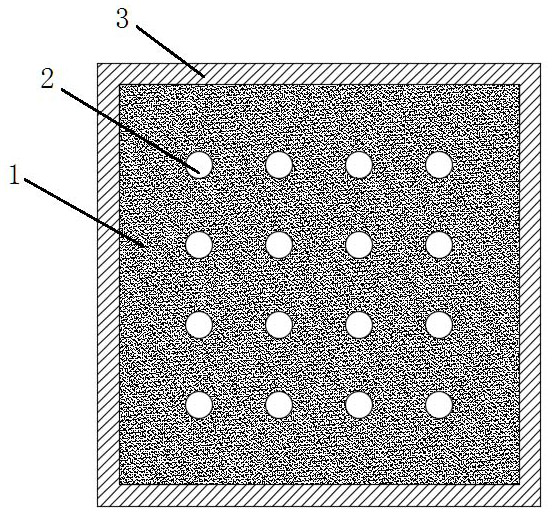

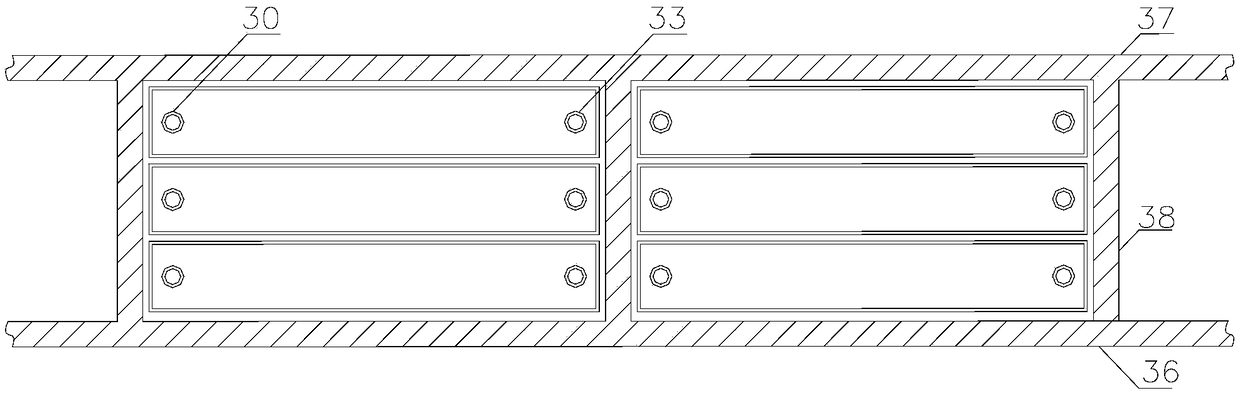

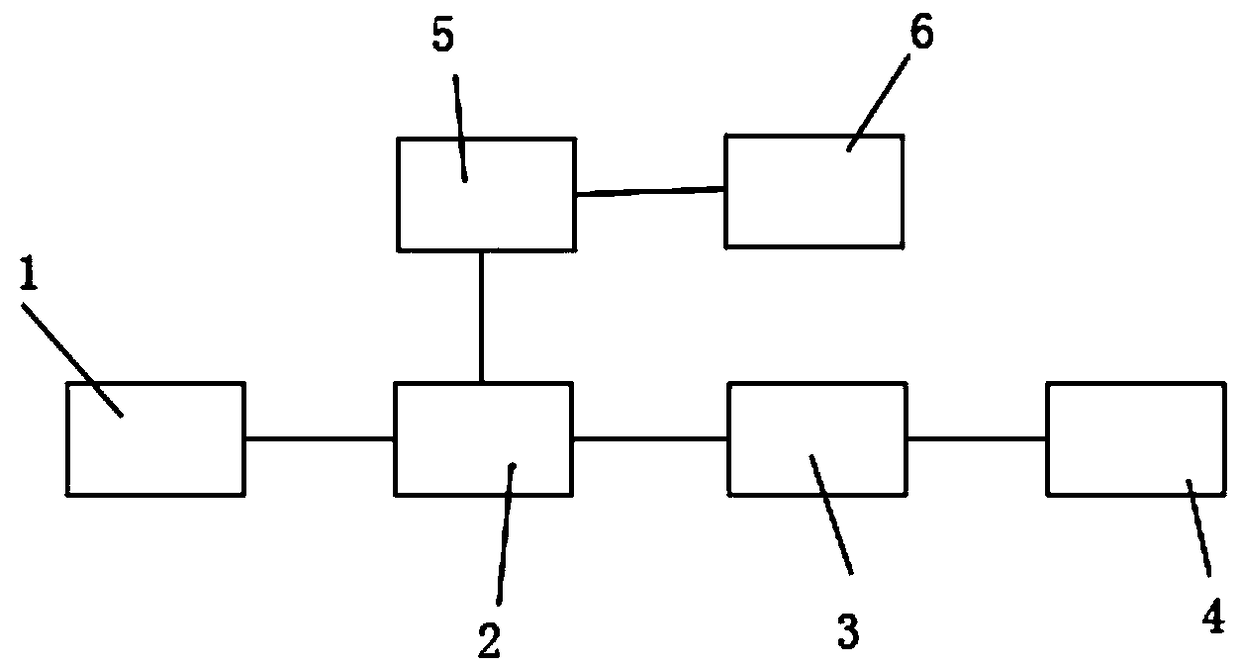

Casting method of large-scale high pressure resisting multi-cylinder-block cast

ActiveCN102699282AControl temperature distributionUniform temperature distributionFoundry mouldsFoundry coresSlagHigh pressure

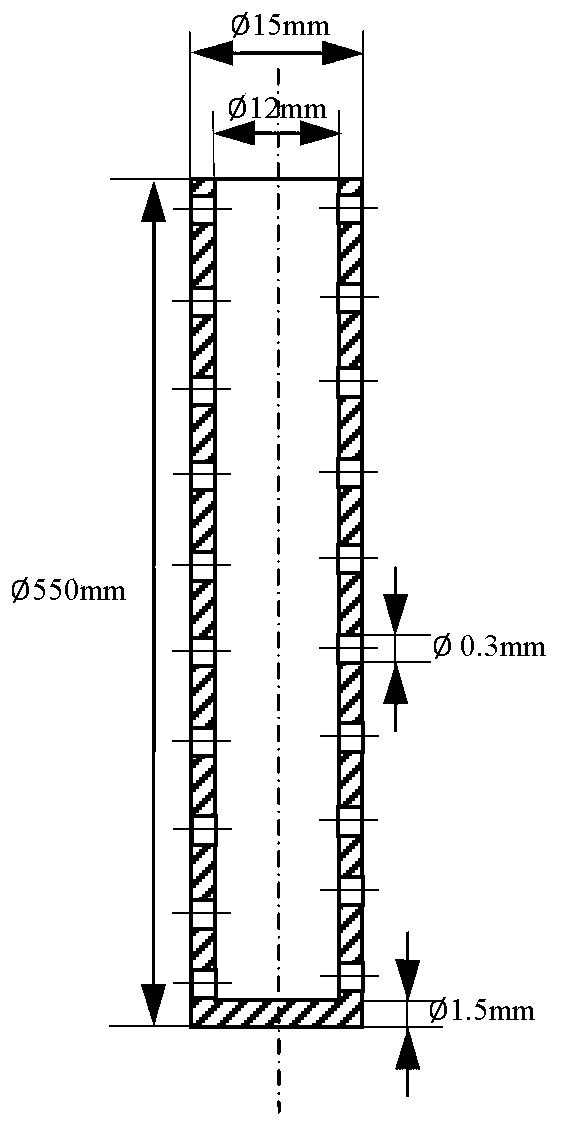

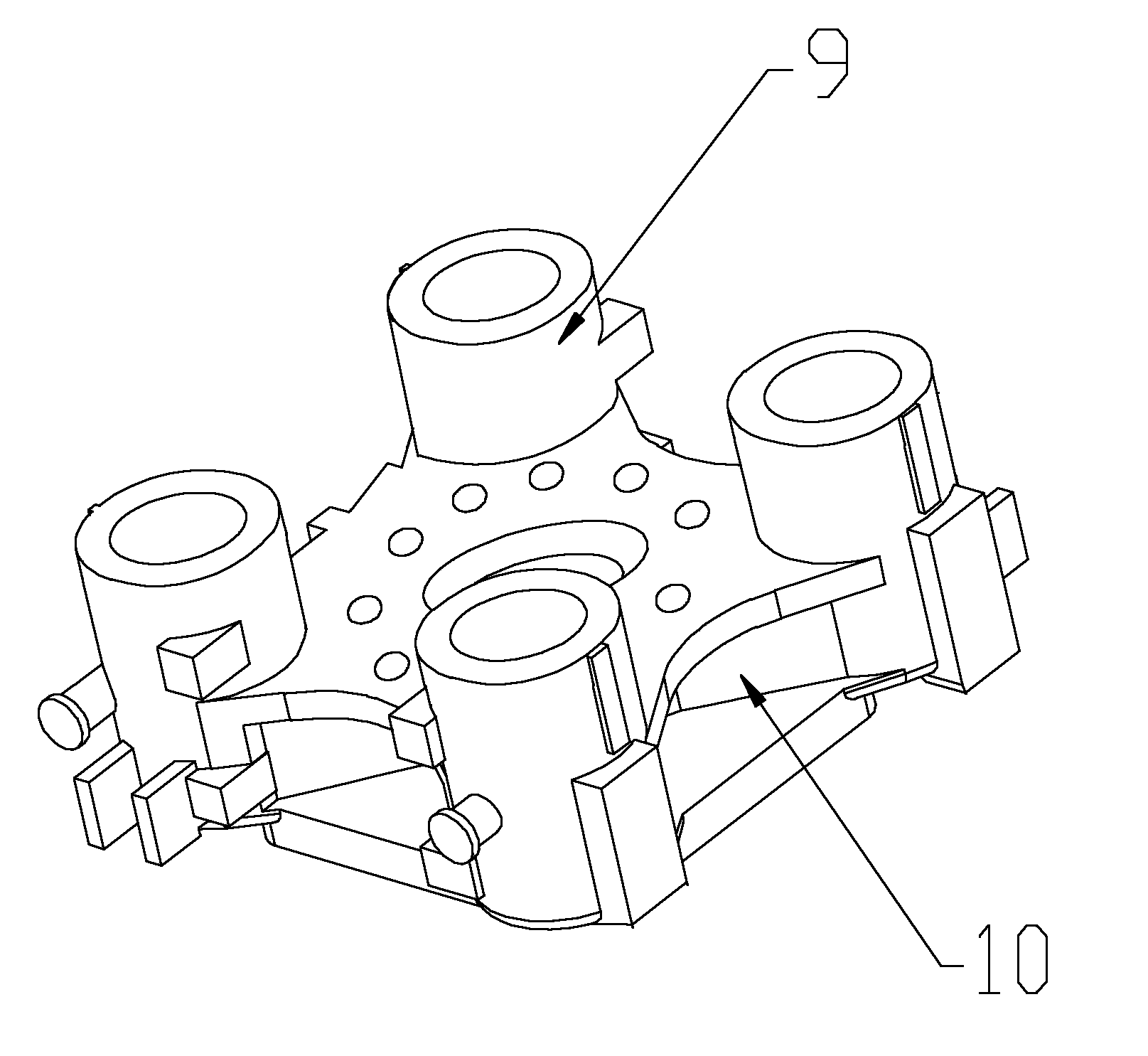

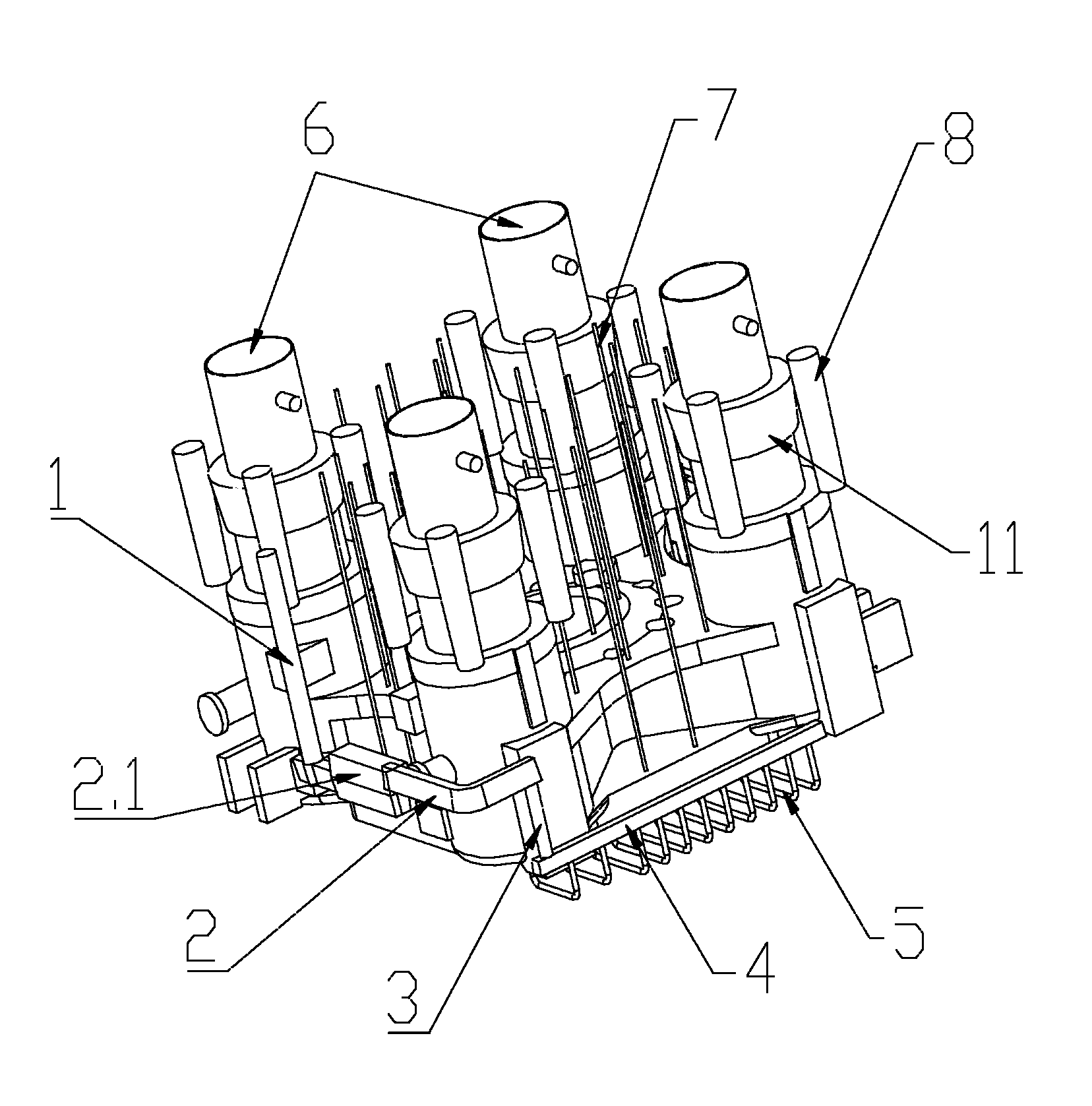

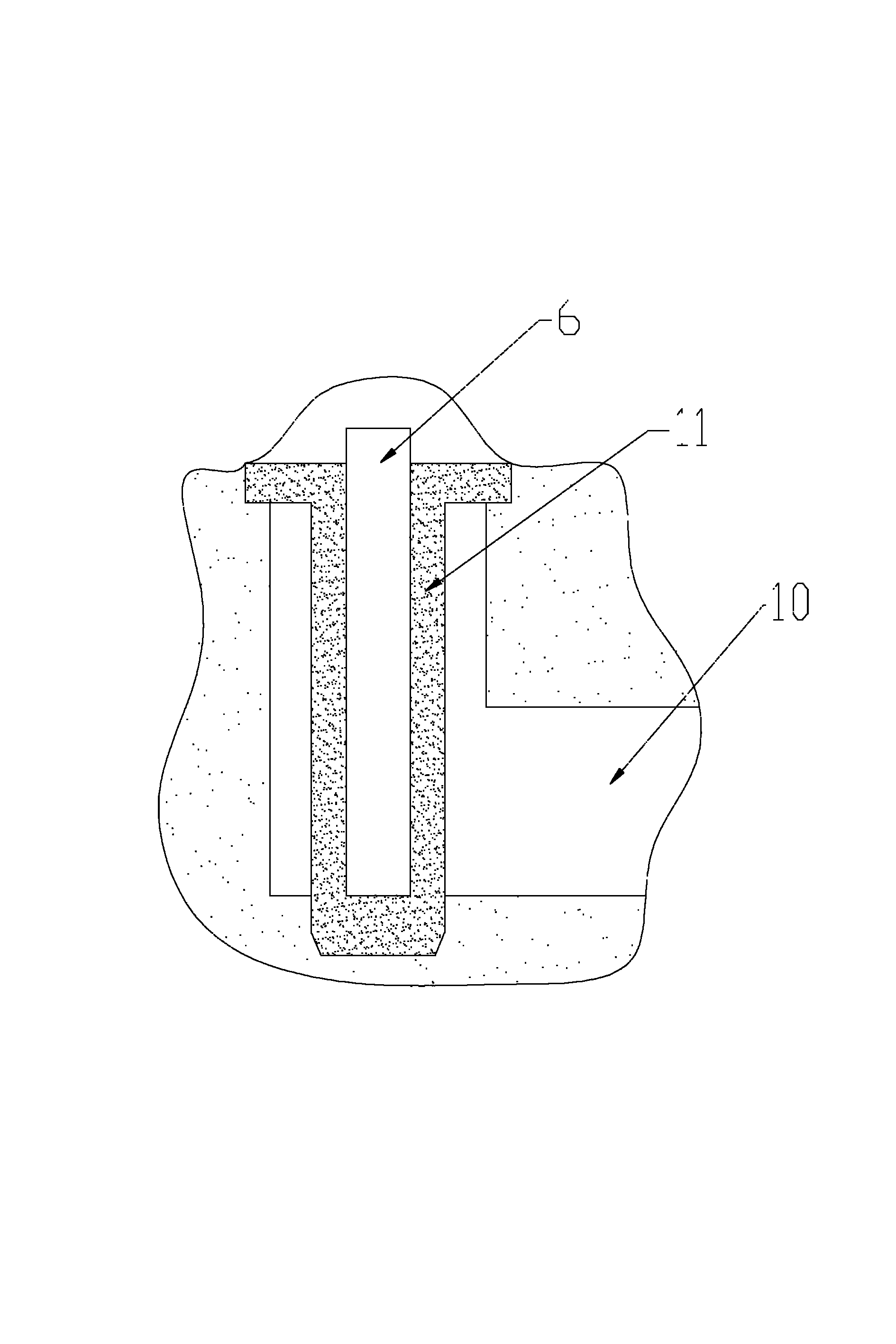

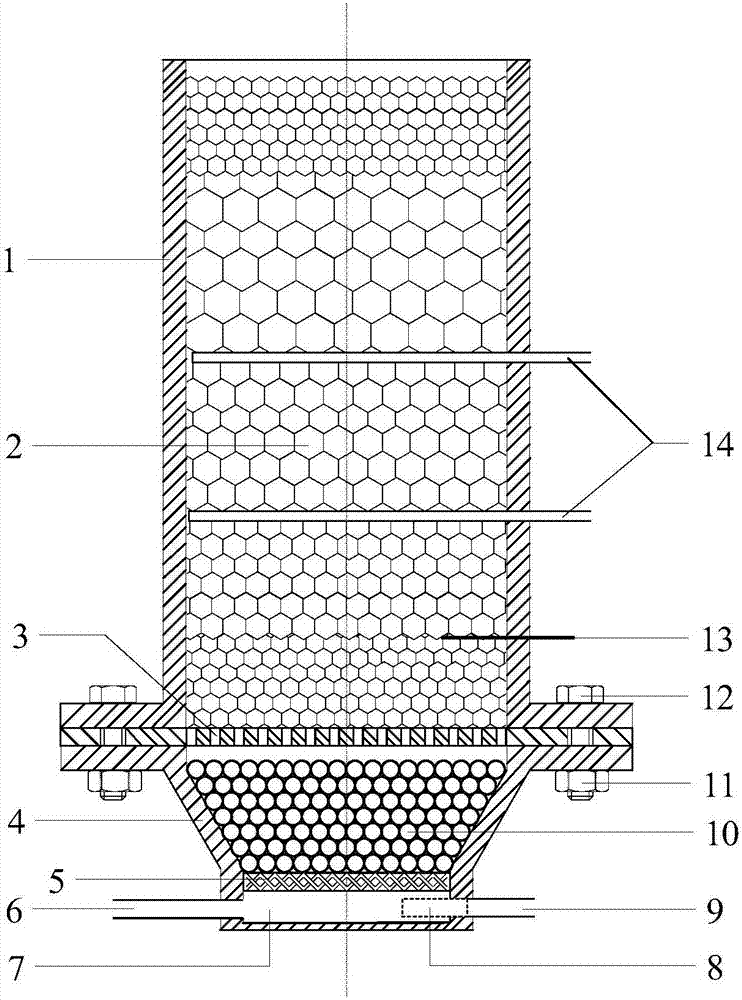

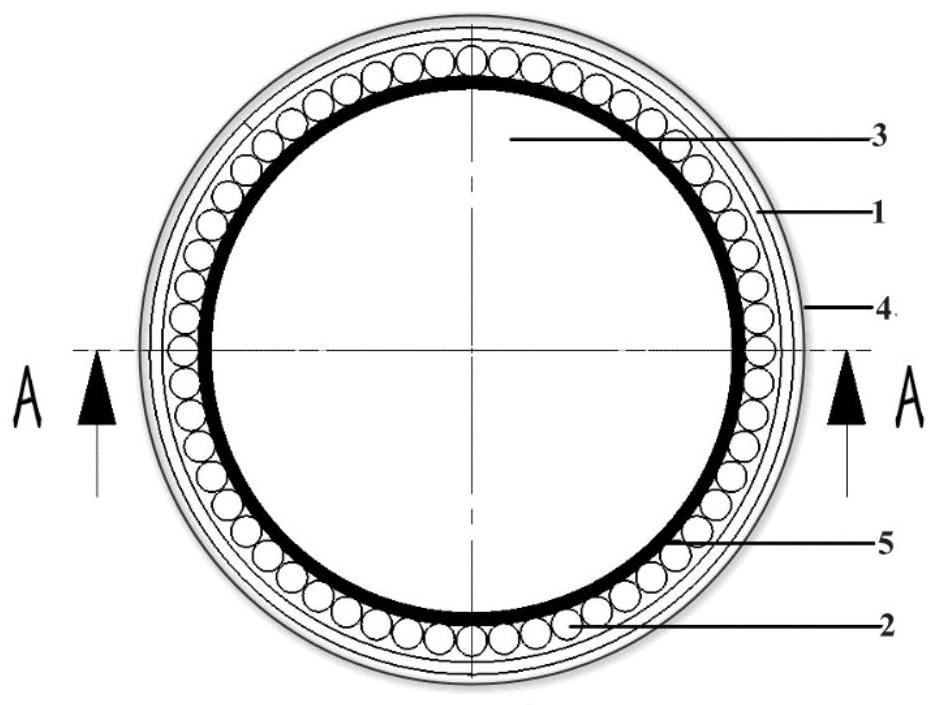

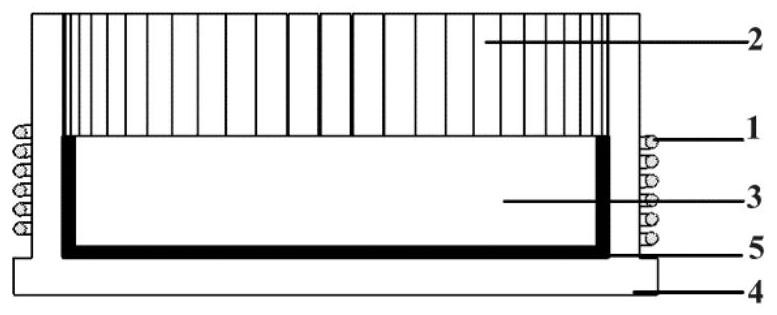

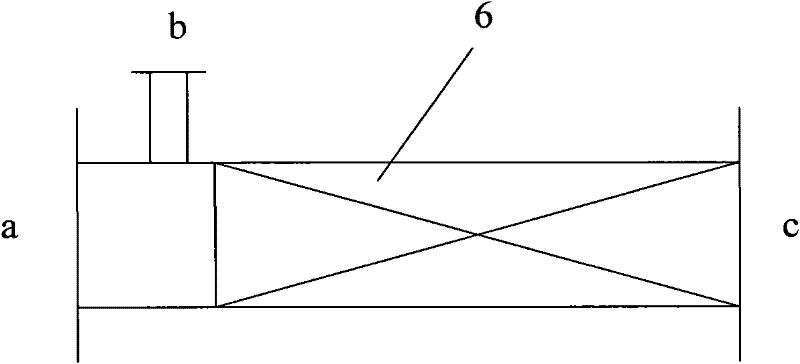

The invention relates to a casting method of large-scale high pressure resisting multi-cylinder-block cast. The method includes the following steps: (1) mold making, (2) sand mold making, and (3) casting molding: during the sand mold making of the step (2), a sprue is designed into a first sprue (1) and a second sprue (3), a cross gate is designed into a first cross gate (2) and a second cross gate (4), and an ingate (5) is designed into a plurality of parallel pouring gates. Cross section area of all pouring gates is set as the following relation: the cross section area of the first sprue (1) is larger than that of the first cross gate (2), the cross section area of the first cross gate (2) is smaller than that of the second sprue (3), the cross section area of the second sprue (3) is larger than that of the second cross gate (4), and the cross section area of the second cross gate (4) is smaller than that of the ingate (5). The casting method overcomes the defects that shrinkage cavities, shrinkage porosities, slag inclusion and the like do not exist in the cast and can meet quality requirements that cylinder holes can be used as cylinder inner walls after the cylinder holes are machined.

Owner:RIYUE HEAVY IND

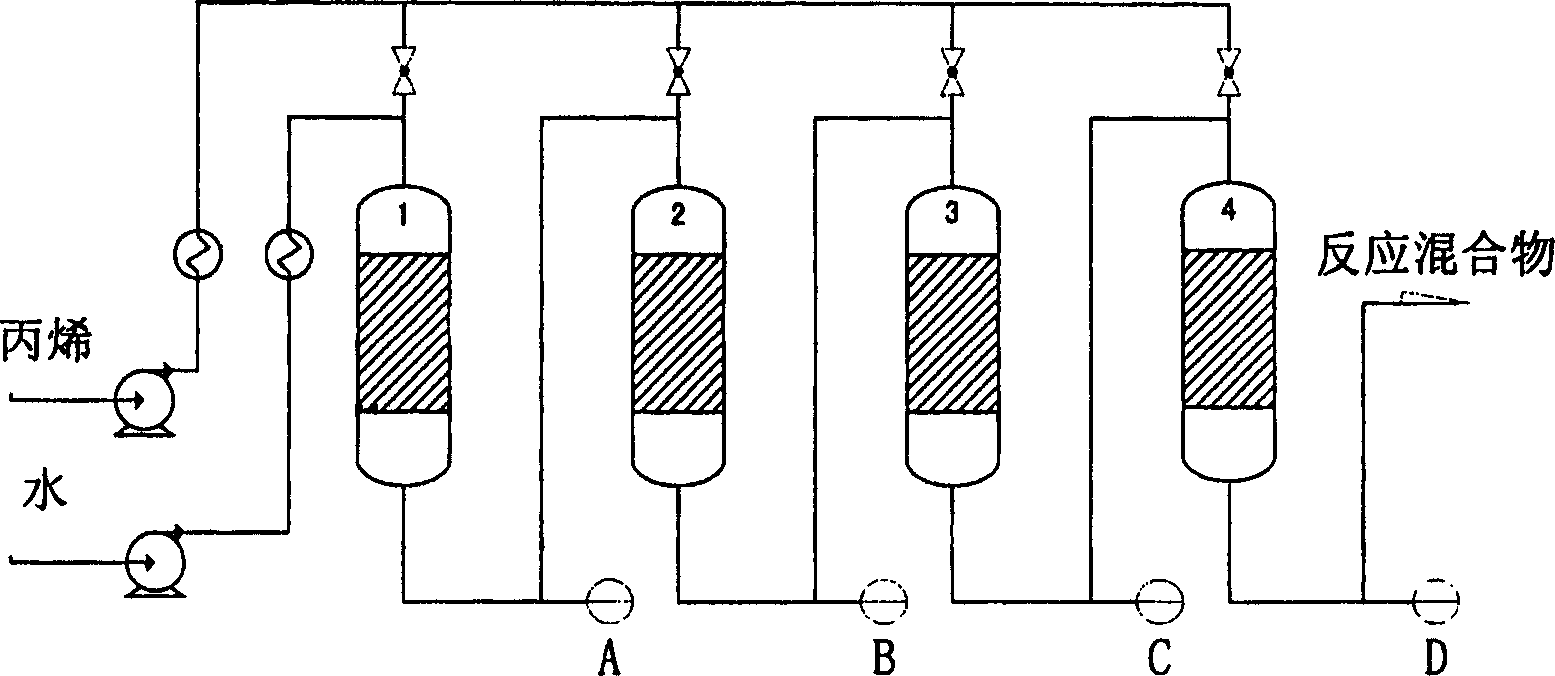

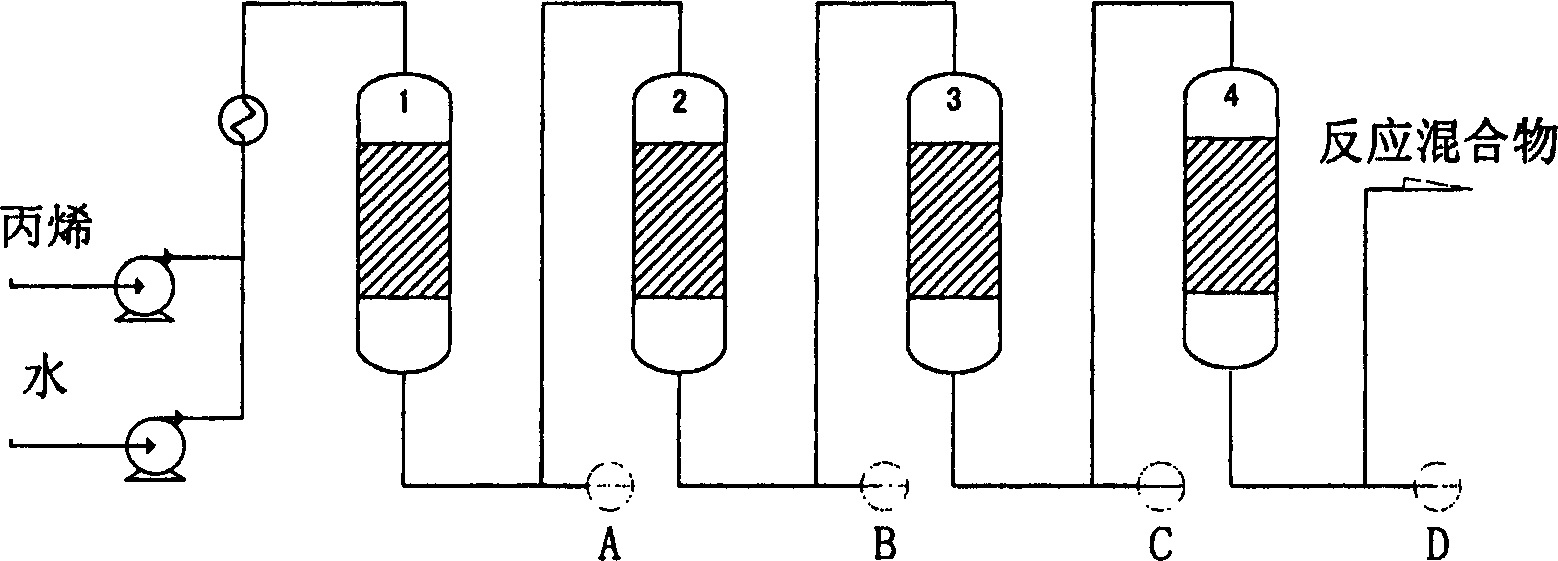

Process for producing lower alcohol by direct hydration of low carbon olefin

ActiveCN1670006AExtended service lifeStable differential pressurePreparation by hydroxy group additionCarbon numberHydration reaction

The invention discloses a method for producing lower alcohol by lower carbon number hydrocarbons direct hydration, which comprises: in the action of solid catalysts (such as cationic catalysts, molecular sieve catalysts or phosphate bergmeal), catalyze hydration synthesizing the lower alcohol by lower carbon number hydrocarbons with 2-5 carbon atoms using segmented feeding with mole ratio between combined feed water to lower carbon number hydrocarbons as 0.1-30 in the temperature of 80-200 Deg. C and in the pressure of 2.0-20.0 MPa. The production is alcohol and a compound of alcohol and ether with 2-5 carbon atoms correspondingly, and separating the alcohol of production flow to get the final production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

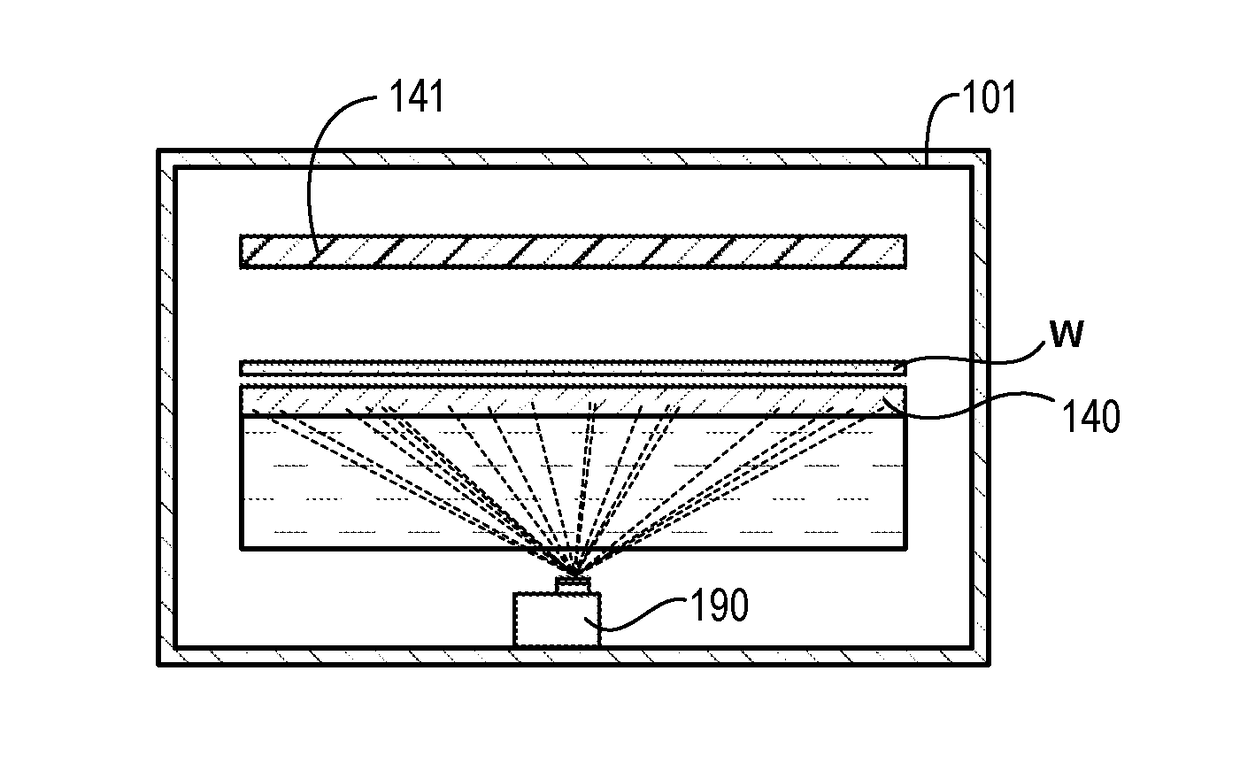

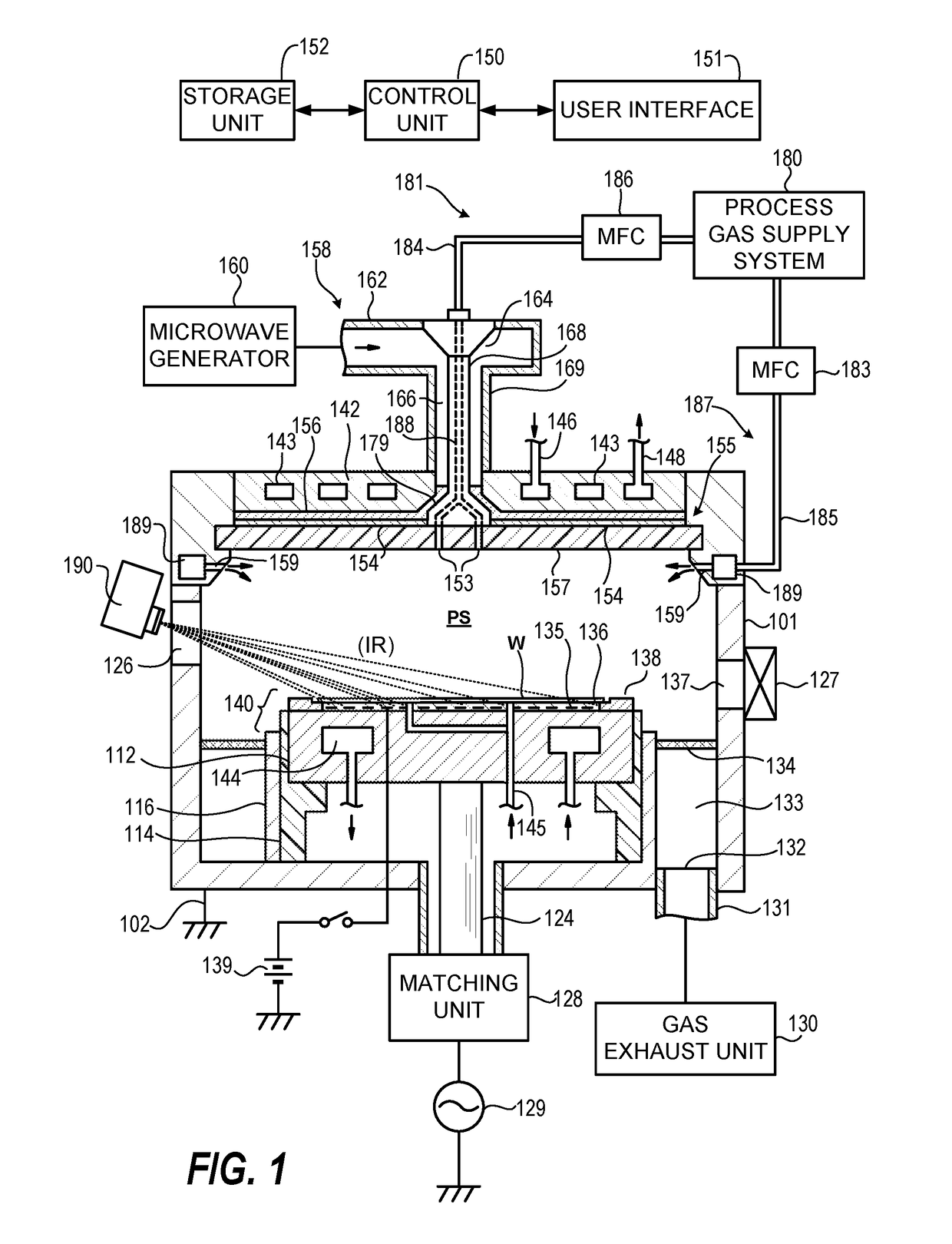

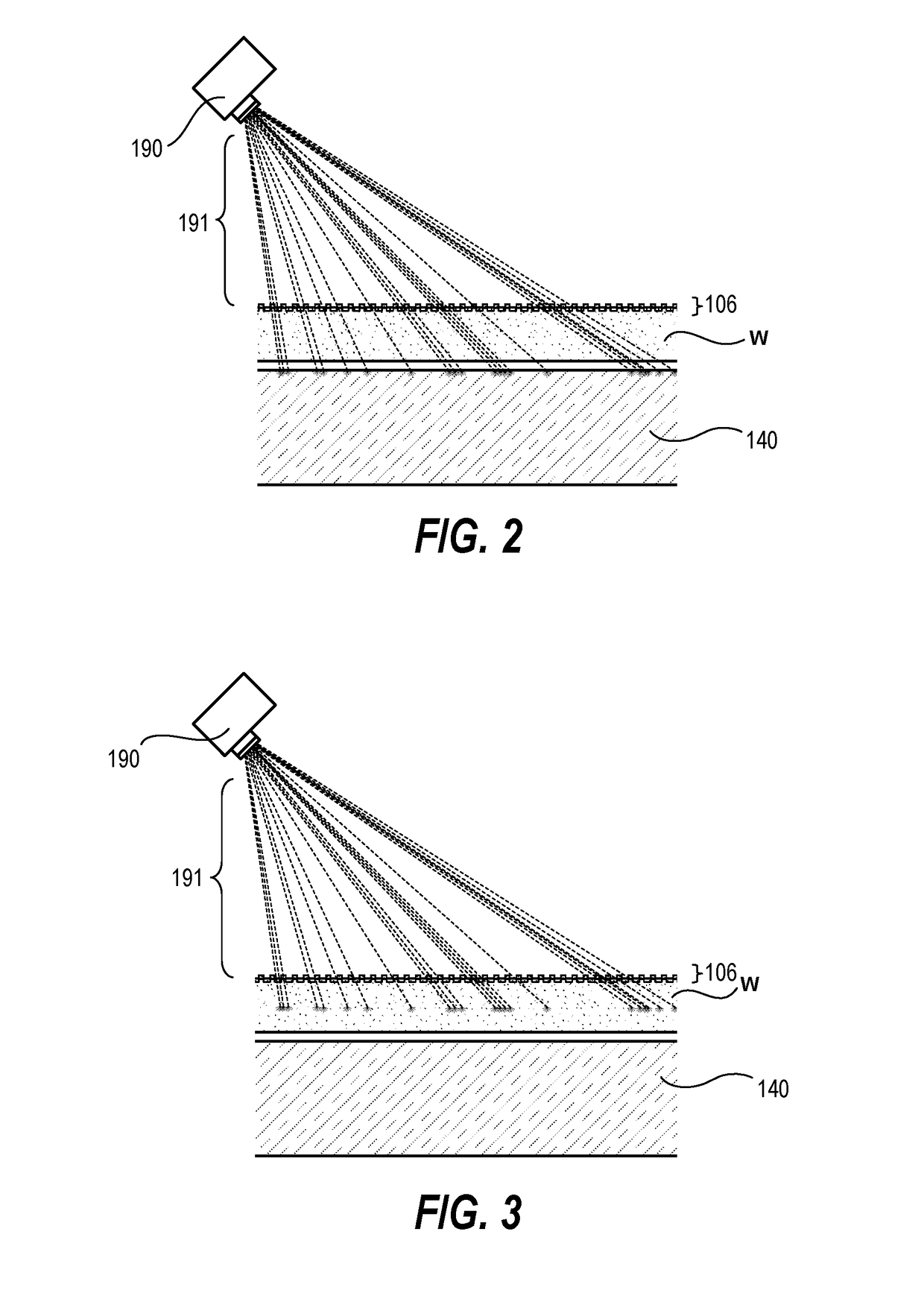

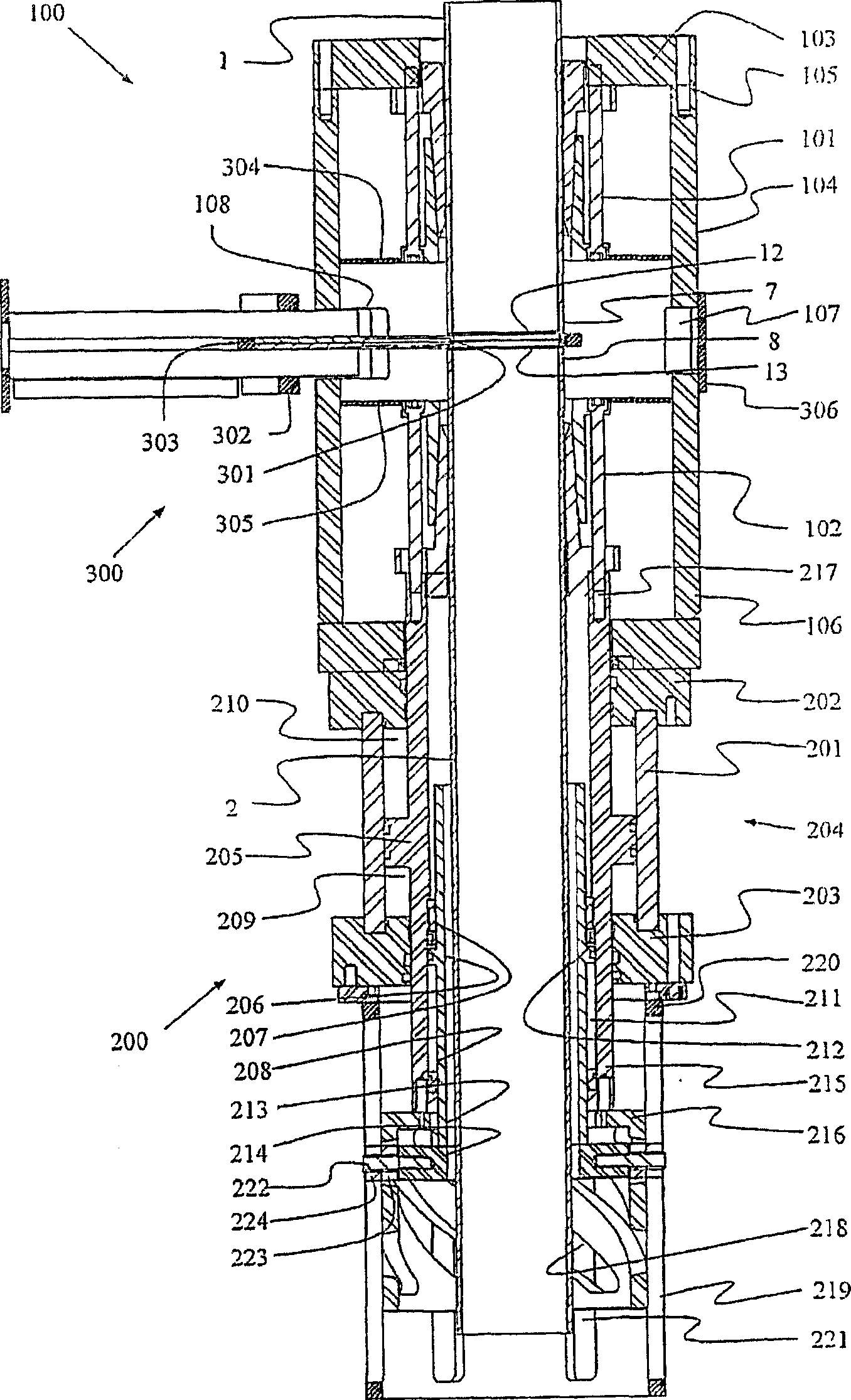

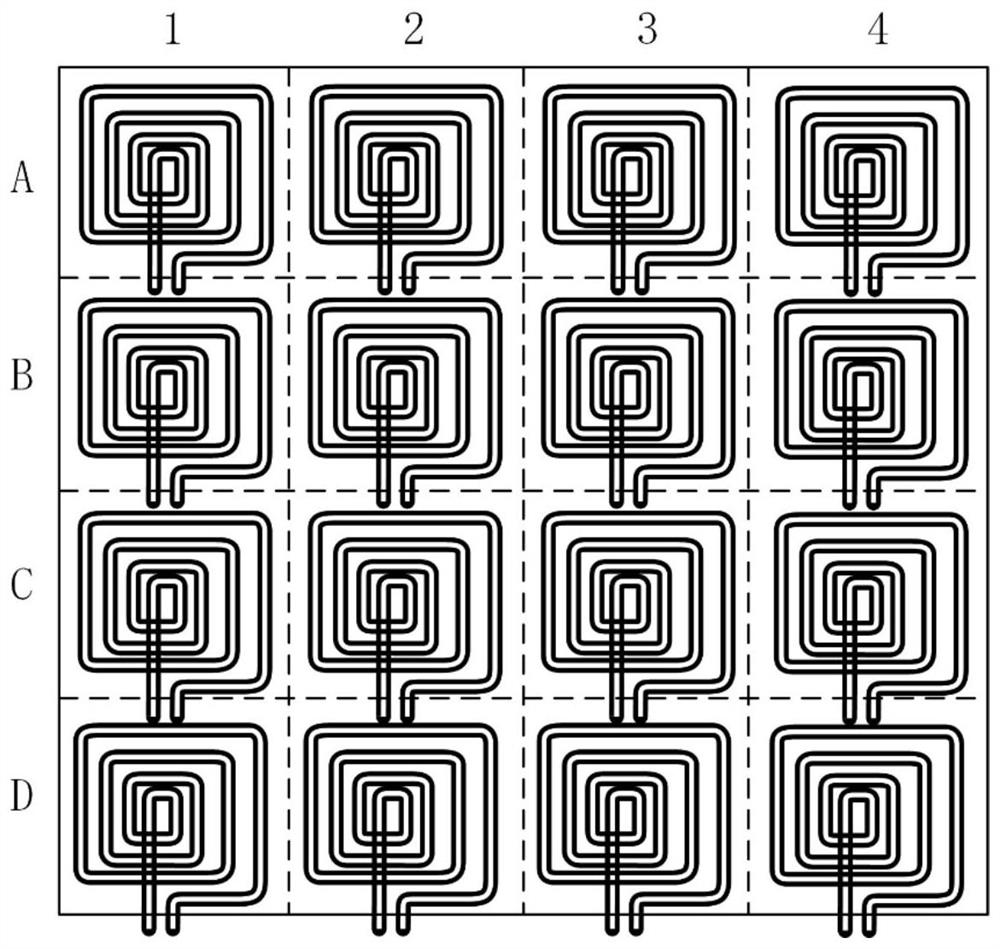

System and Method for Temperature Control in Plasma Processing System

ActiveUS20170278761A1Accurately control temperature distributionHigh precision machiningSemiconductor/solid-state device testing/measurementElectric discharge tubesTemperature controlControl system

Techniques herein include systems and methods for fine control of temperature distribution across a substrate. Such techniques can be used to provide uniform spatial temperature distribution, or a biased spatial temperature distribution to improve plasma processing of substrates and / or correct characteristics of a given substrate. Embodiments include a plasma processing system with temperature control. Temperature control systems herein include a primary heating mechanism to heat a substrate, and a secondary heating mechanism that precisely modifies spatial temperature distribution across a substrate being processed. At least one heating mechanism includes a digital projection system configured to project a pattern of electromagnetic radiation onto or into a substrate, or through the substrate and onto a substrate support assembly. The digital projection system is configured to spatially and dynamically adjust the pattern of electromagnetic radiation and selectively augment heating of the substrate by each projected point location.

Owner:TOKYO ELECTRON LTD

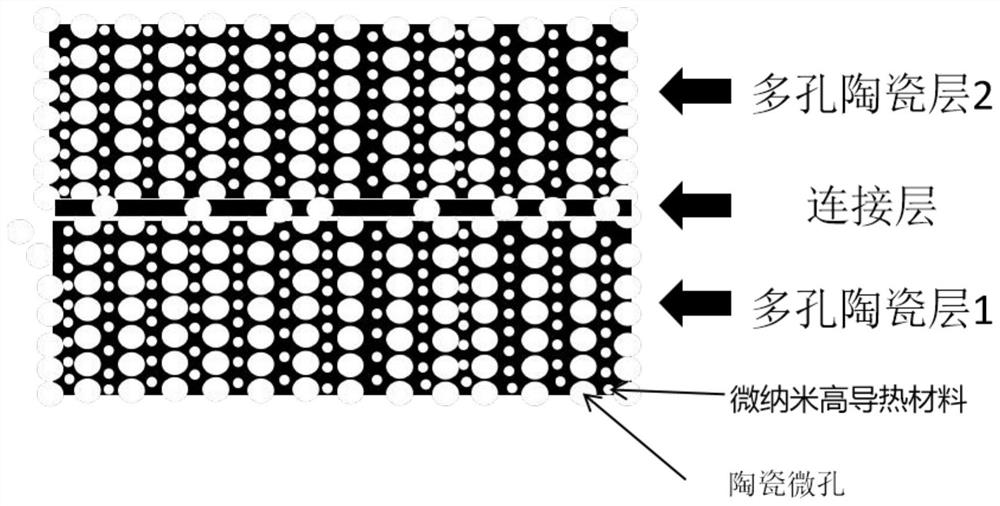

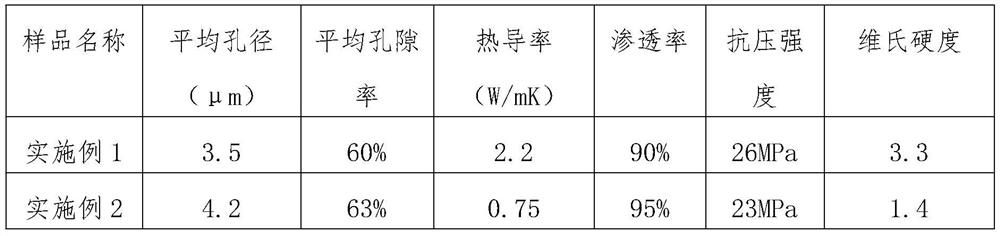

Multi-layer porous ceramic material and preparation method thereof

The invention provides a multi-layer porous ceramic material and a preparation method thereof, and particularly relates to the field of atomizers. The material is composed of multiple layers of porousceramics with different porosities and different thermal conductivities, and all the layers form an integrated composite material through an inorganic connecting layer formed by sintering. The ceramic material is formed by overlapping a plurality of layers of porous ceramics, and an inorganic connecting layer is formed in the sintering process, so that the prepared multi-layer ceramic forms a whole, and the cracking and deformation of the porous ceramic material are avoided. The composite material is ensured to form a unified whole, and the use performance of the material is improved.

Owner:深圳市天士力神通本草技术开发有限公司

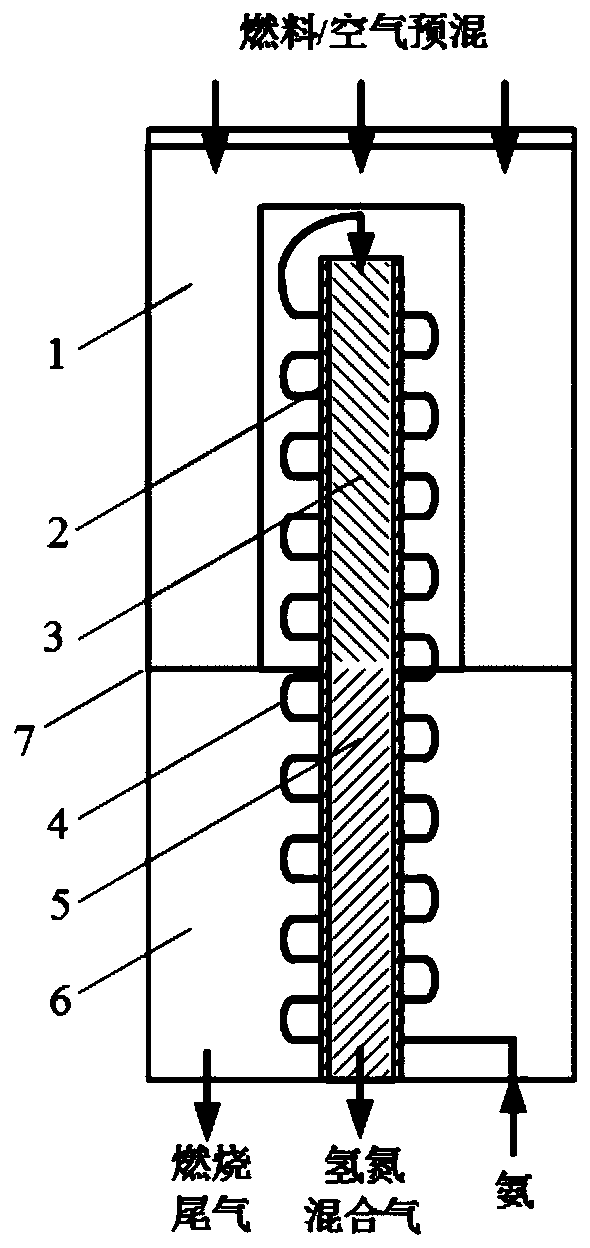

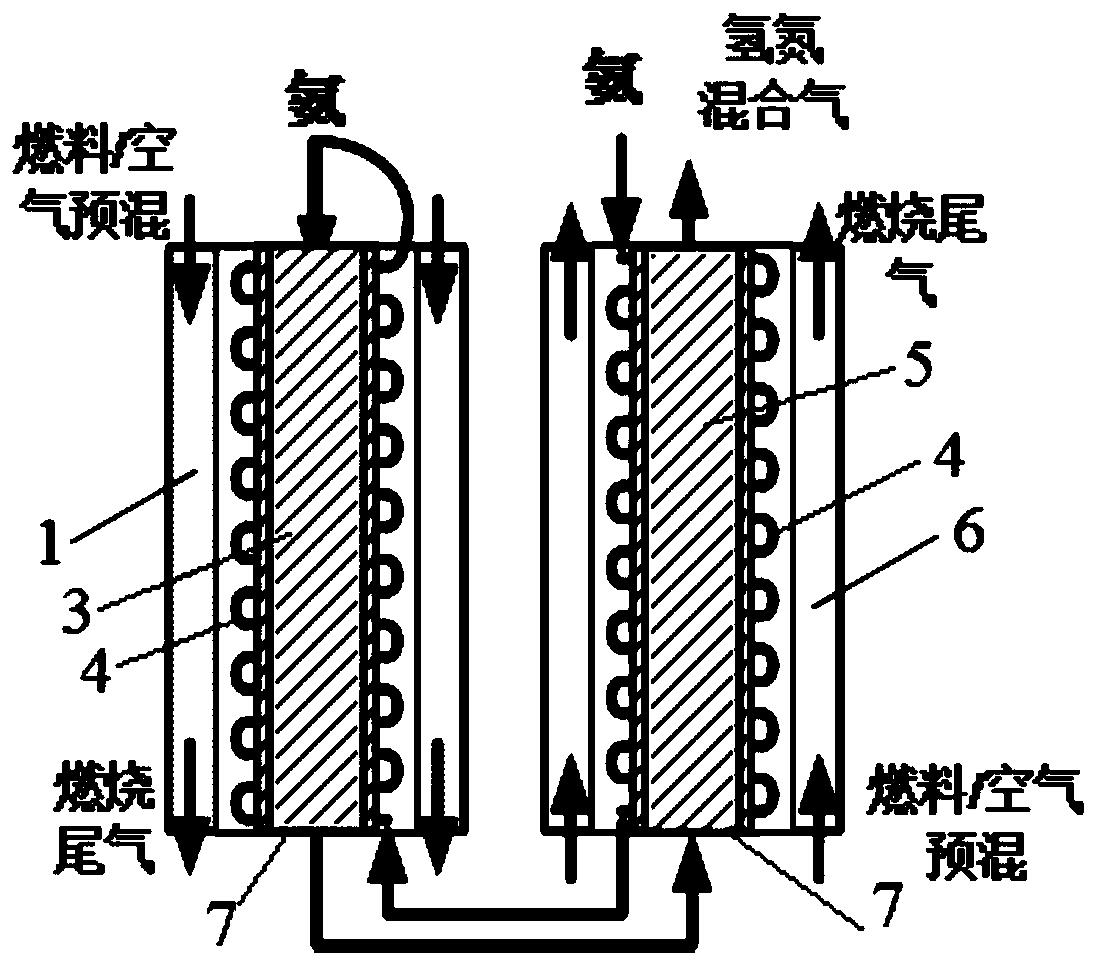

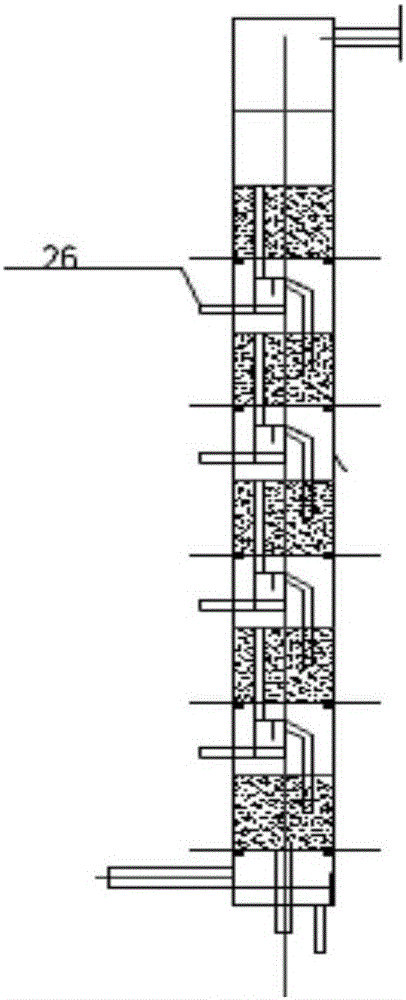

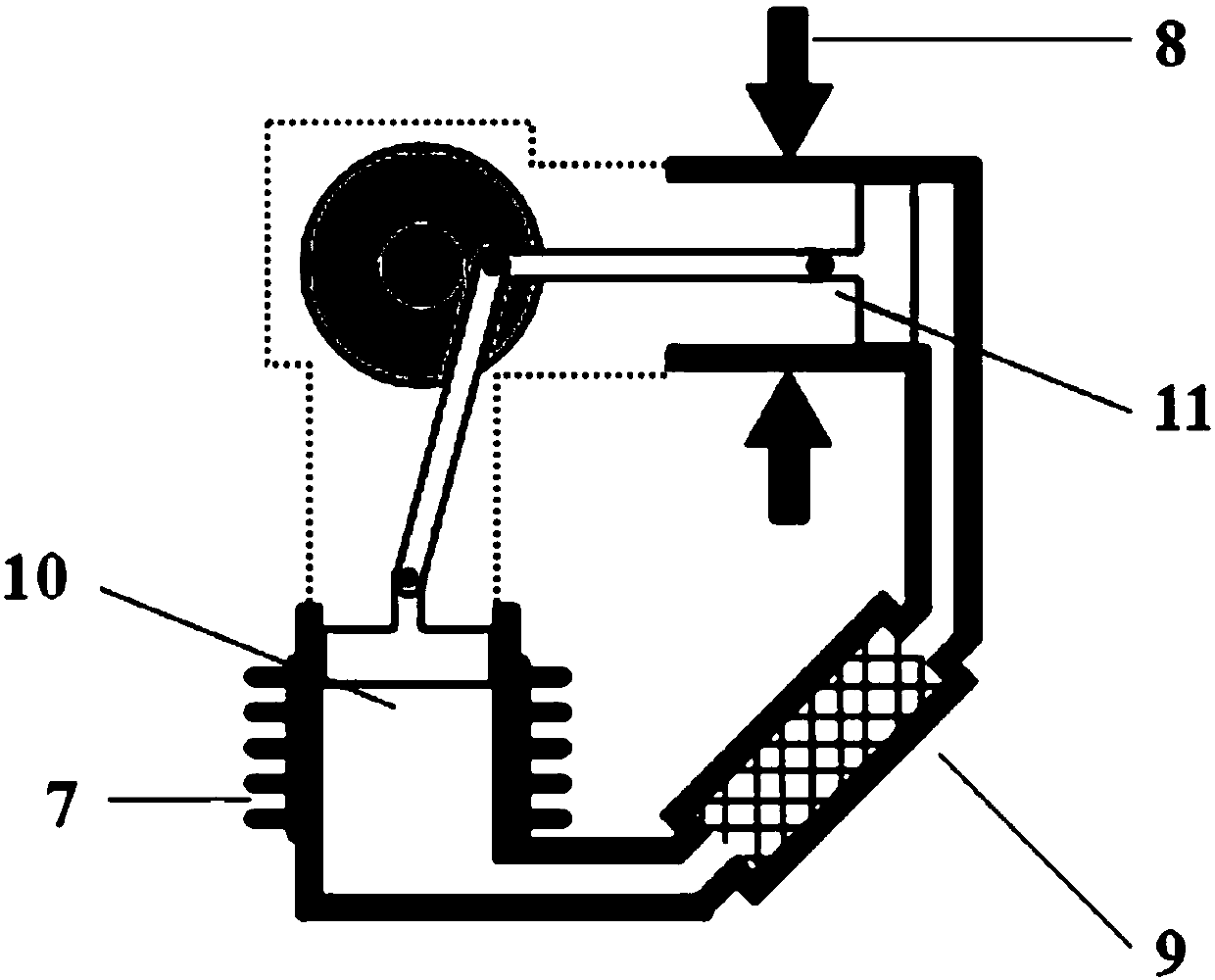

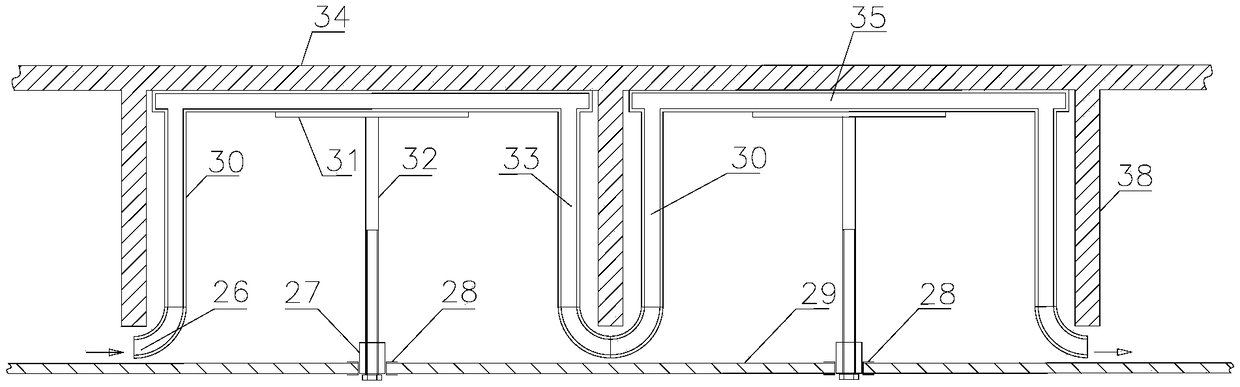

Ammonia decomposition device, ammonia decomposition system and hydrogen production method

ActiveCN110203882ADecompose thoroughlyImprove decomposition efficiencyGas treatmentHydrogen separation using solid contactDecompositionNitrogen

The invention belongs to the technical field of hydrogen production, and concretely relates to an ammonia decomposition device, an ammonia decomposition system and a hydrogen production method. The ammonia decomposition device comprises a shell, a heating zone, a heat exchange zone, a reaction section and a heat exchange coil. The heat exchange coil is spirally wound around the outer wall of the reaction section to sufficiently heat ammonia gas, so the heating efficiency of ammonia gas is increased; a first reaction section and a second reaction section which are sequentially communicated arearranged in the reaction section to ensure that the ammonia gas is decomposed after entering the first reaction section in order to generate a nitrogen and hydrogen mixture, so the decomposition efficiency of the ammonia gas is increased; and the second reaction section can perform secondary decomposition on the residual ammonia gas in the nitrogen and hydrogen mixture produced in the first reaction section, so the residual amount of ammonia gas in the nitrogen and hydrogen mixture in the second reaction section is reduced, thereby the ammonia gas is decomposed more thoroughly. The device makes the conversion rate of ammonia gas reach 99.9% or more and the residual amount of ammonia gas in the nitrogen and hydrogen mixture less than 1000 ppm.

Owner:福大紫金氢能科技股份有限公司

Method for preparing nickel-based high-temperature alloy

InactiveCN103981373AMelting parameters are easy to controlShorten smelting timeIncreasing energy efficiencyVacuum induction meltingCrucible

The invention relates to a method for preparing nickel-based high-temperature alloy, belonging to the field of alloy preparation. The method for preparing the nickel-based high-temperature alloy is an electron-beam melting process and comprises the steps of placing metal raw materials, which play a role in alloying, in a feeding device of an electron-beam melting furnace; placing other metal raw materials in a water-cooled copper crucible of the electron-beam melting furnace. The alloy raw materials are placed in the water-cooled copper crucible and are melted by using an electron-beam melting technology; different from the conventional vacuum induction melting, a metal melt is in contact with water-cooled copper directly, so that other impurities can not be introduced during electron-beam melting.

Owner:DALIAN UNIV OF TECH

Method for preparing cobalt-based high-temperature alloy

The invention relates to a method for preparing cobalt-based high-temperature alloy, belonging to the field of alloy preparation. The method for preparing the cobalt-based high-temperature alloy is an electron-beam melting process and comprises the steps of placing metal raw materials, which play a role in alloying, in a feeding device of an electron-beam melting furnace; placing other metal raw materials in a water-cooled copper crucible of the electron-beam melting furnace. The alloy raw materials are placed in the water-cooled copper crucible and are melted by using an electron-beam melting technology; different from the conventional vacuum induction melting, a metal melt is in contact with water-cooled copper directly, so that other impurities can not be introduced during electron-beam melting.

Owner:DALIAN UNIV OF TECH

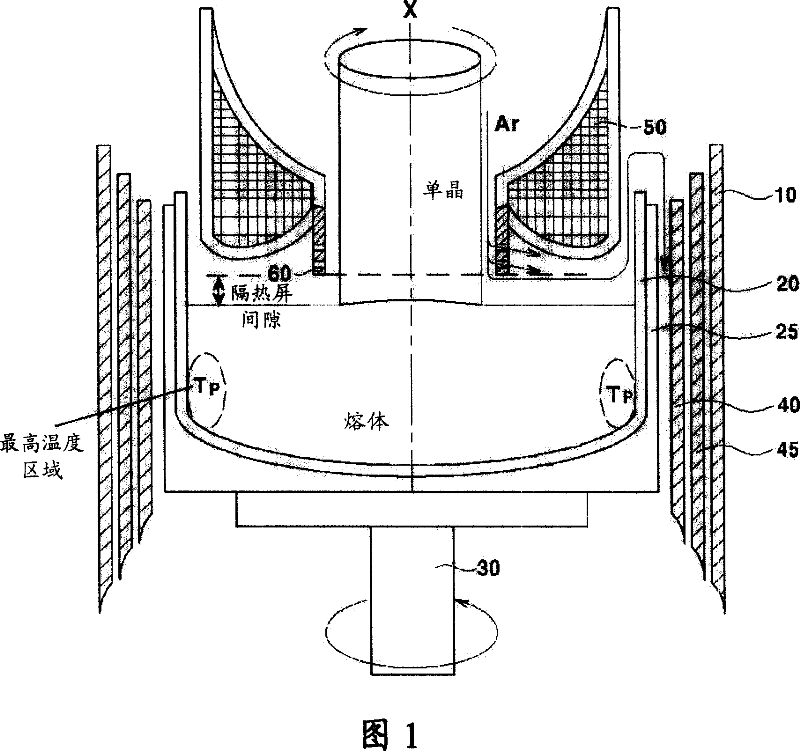

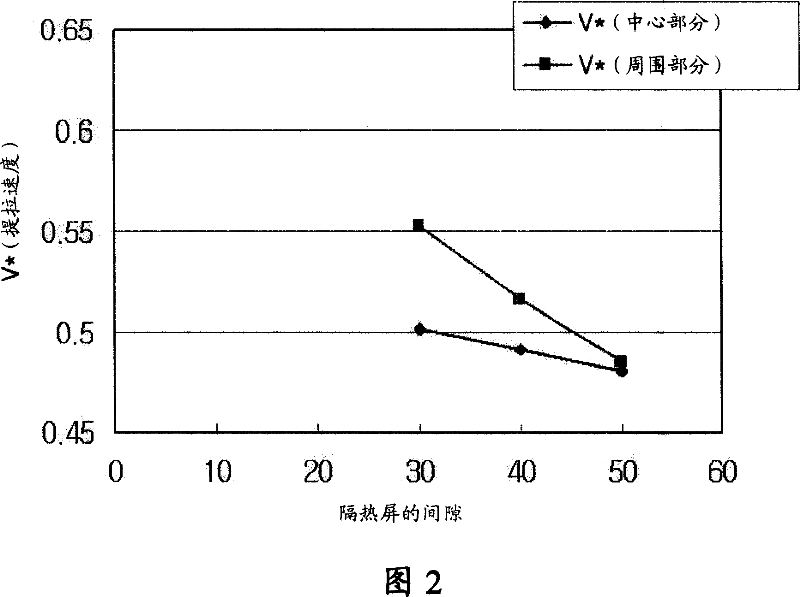

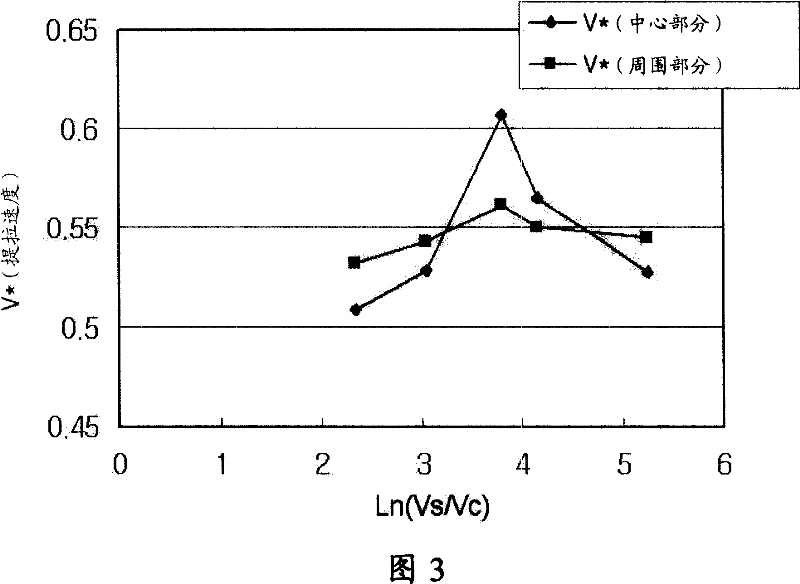

Method for producing high quality silicon single crystal and silicon single crystal wafer made by using the same

InactiveCN101037794AControl temperature distributionSolving inefficienciesPolycrystalline material growthSemiconductor/solid-state device manufacturingCzochralski methodIngot

In a method for producing a high quality silicon single crystal by the Czochralski method, a lower portion of a solid-liquid interface of a single crystal growth is divided into a central part and a circumferential part, and the temperature gradient of the central part and the temperature gradient of the circumferential part are separately controlled. When a silicon melt located at a lower portion of a solid-liquid interface of a single crystal growth is divided into a central part melt and a circumferential part melt, the method controls the temperature gradient of the central part melt by directly controlling the temperature distribution of a melt and indirectly controls the temperature gradient of the circumferential part melt by controlling the temperature gradient of the single crystal, thereby effectively controlling the overall temperature distribution of the melt, thus producing a high quality single crystal ingot free of defects with a high growth velocity.

Owner:斯尔瑞恩公司

Method for manufacturing dimethyl ether with solid acid catalysis methanol dehydration reaction

ActiveCN101108790AControl temperature distributionMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsLiquid stateSolid acid

A method that the solid acid catalyzes the methanol to dehydrate and react to produce the dimethyl ether is provided. Under the condition that the solid acid catalyst exists, the liquid state materials are adopted as the chill materials to control the catalyst bed temperature distribution. The reaction conditions are that the reaction pressure is 0.2MPa to 4.0 MPa, the reaction temperature is 120 DEG C. to 400 DEG C. and the feeding air speed is 0.5 to 20.0. The solid acid catalysts are the cation exchange resin, the ZSM-5 molecular sieve, the ZSM-35 molecular sieve, the MCM-22 molecular sieve, Gamma-alumina or the mixture of the above. The invention can make the bed temperature rapidly lower in the range set by the process via filling the cold-shocking materials. Because the catalyst bed temperature is distributed evenly, the invention greatly reduces the occurrence of the side-effects and the carbon deposit on the catalysts and prolongs the service life of the catalysts.

Owner:YANCHANG ZHONGKE (DALIAN) ENERGY TECH CO LTD

Non-uniform type porous medium combustor processing organic waste gas

PendingCN107023842ALower ignition pointLower emission levelsIncinerator apparatusCombustion chamberCombustor

The invention discloses a non-uniform type porous medium combustor processing organic waste gas. The non-uniform type porous medium combustor processing the organic waste gas is sequentially provided with a premixing chamber, a mixing chamber, a gas uniform distributor and a combustion chamber from bottom to top. An organic waste gas pipeline, an air pipeline and an oxygen pipeline are arranged in the pre-mixing chamber. The combustion chamber is filled with a porous medium of a non-uniform type honeycomb structure. The non-uniform type honeycomb structure comprises a lower layer, a middle layer and an upper layer. The middle layer is a combustion area. The pore diameter of the lower layer and the pore diameter of the upper layer are smaller that of the middle layer. From bottom to top, the pore diameter and the porosity of the middle layer are gradually increased. The intersection portion of the lower layer and the middle layer is provided with a heating wire igniter. The non-uniform type porous medium combustor processing the organic waste gas solves the problems that in the prior art, in the organic waste gas combustion processing process, combustion is not stable, the combustion temperature is high, and secondary pollutants such as nitric oxides are prone to generation.

Owner:SHANDONG UNIV

Shear assisted solid state weld and method of forming

InactiveCN1816412AControl temperature distributionPipeline systemsHigh frequency current welding apparatusEngineeringHot working

A shear-assisted solid state welding method for joining of metal parts, involves a first step of heating opposing surfaces in a non-passivating environment to a temperature in the hot working temperature range of the metal. A second step involves bringing the opposing surfaces into contact while still in the hot working temperature range, and applying compressive stress sufficient to substantially prevent sliding in response to shear displacement, causing plastic flow in the hot layers. A third step involves imposing relative shear displacement of the metal work pieces without disengaging the opposing surfaces. The shear displacement induces plastic shear strain within the hot layers to progressively induce bonding.

Owner:NOETIC TECH INC

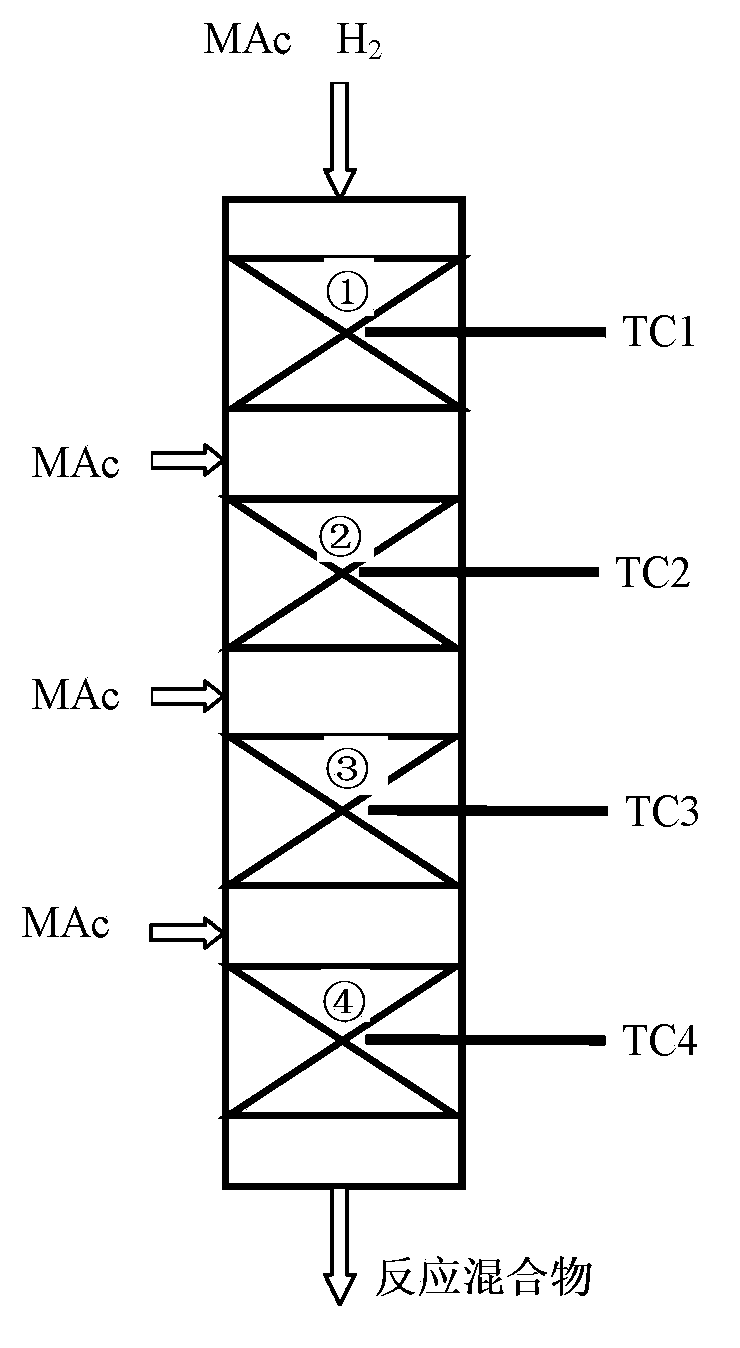

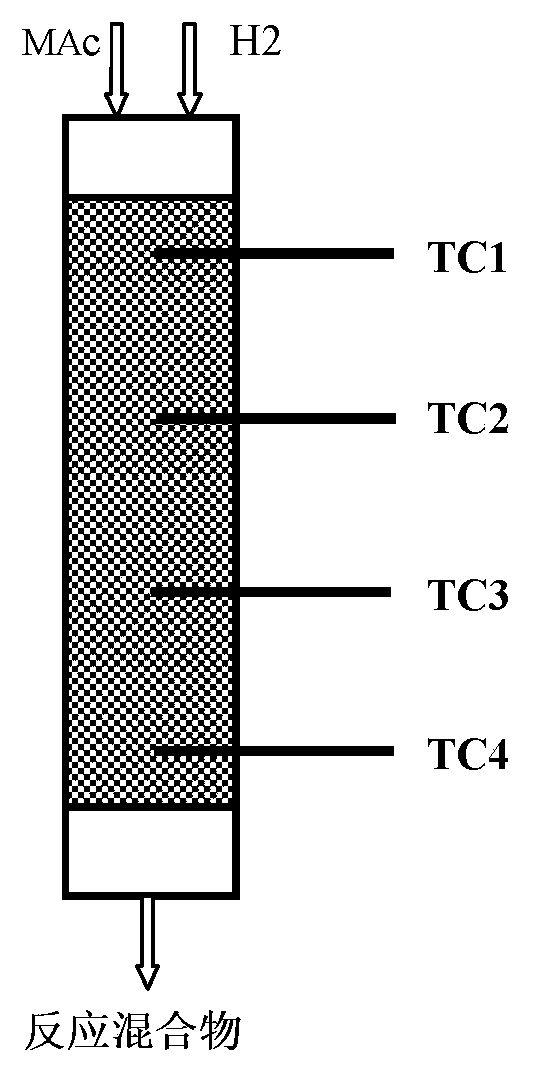

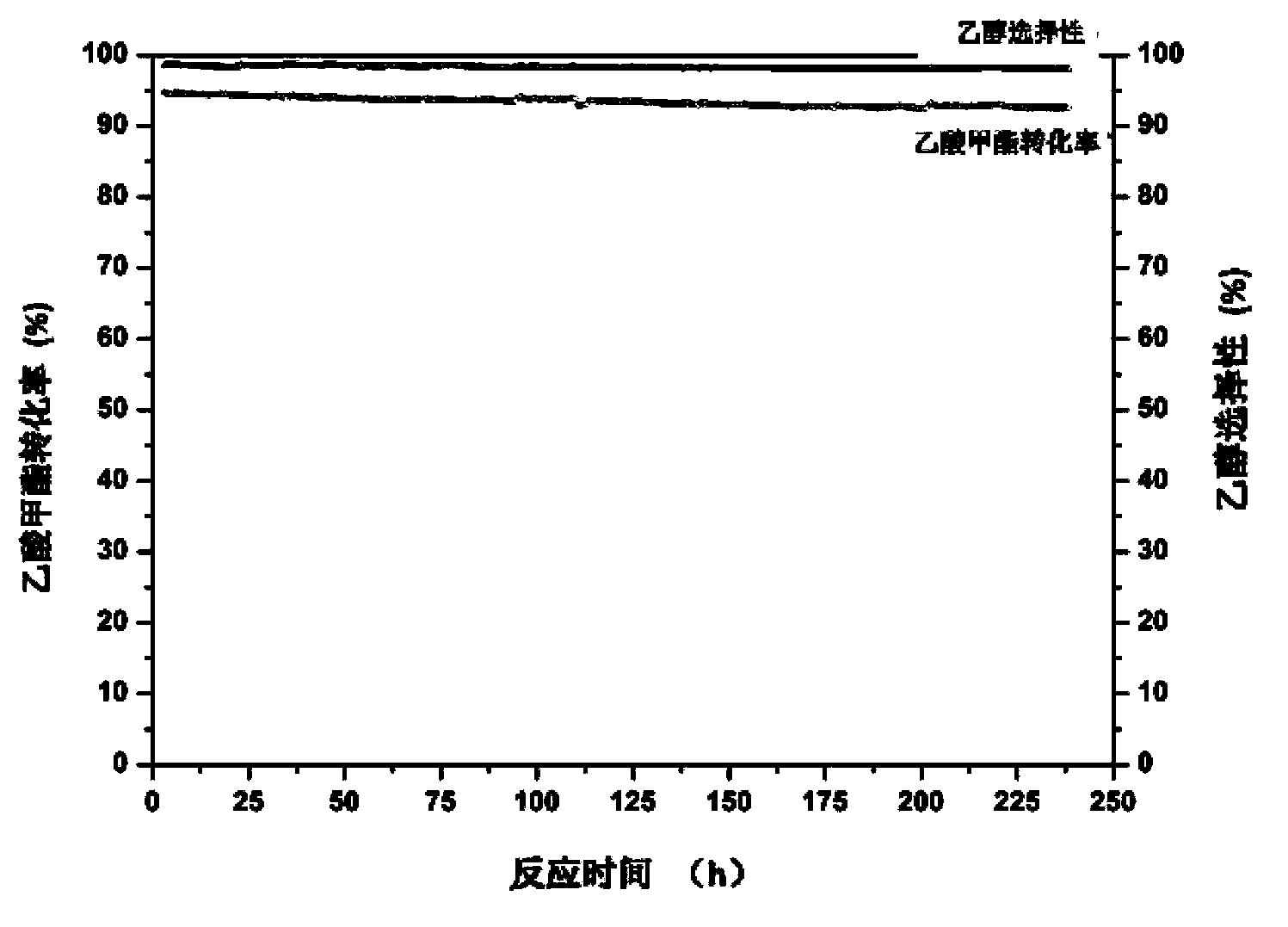

Method for preparing ethanol through low carbon ester hydrogenation

ActiveCN103896733AImprove conversion rateExtend your lifeOrganic compound preparationHeterogenous catalyst chemical elementsHydrogenation reactionReaction temperature

The present invention provides a method for preparing ethanol through low carbon ester hydrogenation. The method comprises that: a raw material gas containing a low carbon ester and hydrogen gas is subjected to a hydrogenation reaction through a reactor filled with a copper base catalyst at a reaction temperature of 200-320 DEG C under a reaction pressure of 0.5-20.0 Mpa at a volume space velocity of 1000-40000 h<-1> to prepare the ethanol, wherein the copper base catalyst adopts segmented loading, the low carbon ester in the raw material adopts segmented feeding, and a molar ratio of the low carbon ester to the hydrogen gas in the raw material gas is 1 / 2-1 / 100. According to the present invention, the raw material low carbon ester enters the segmentedly-loaded catalyst bed layer in a segmented manner so as to effectively control or adjust the temperature distribution of the catalyst bed layer, and avoid occurrence of warm spots, such that the side effects are reduced, the selectivity of the target product is increased, and the service life of the catalyst is substantially prolonged.

Owner:YANCHANG ZHONGKE (DALIAN) ENERGY TECH CO LTD

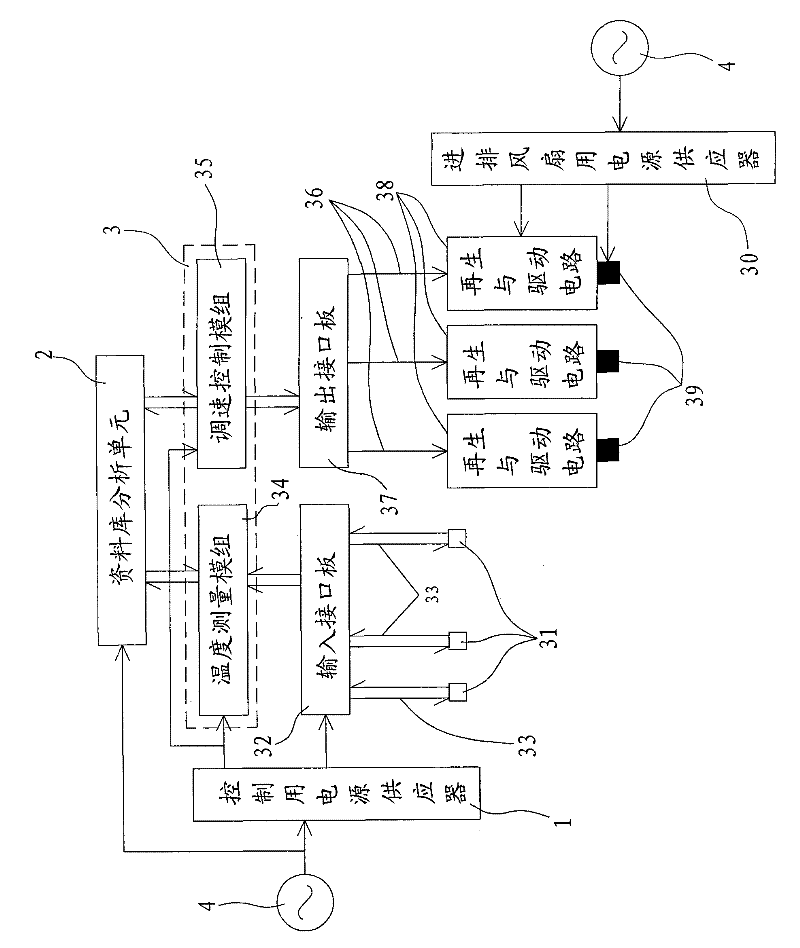

Indoor space temperature distribution measurement and automatic air inlet and exhaust control method and device

InactiveCN102444604ALow costReduce power consumptionPump controlNon-positive displacement fluid enginesTemperature measurementEngineering

The invention discloses an indoor space temperature distribution measurement and automatic air inlet and exhaust control method and device. More than one temperature sensor is arranged in an indoor space; a temperature to frequency conversion technology is adopted for converting each detected temperature value into periodic signals of different frequencies, so that a high signal to noise ratio can be obtained under long-distance transmission; a digital frequency detection technology is adopted for a temperature measuring module, so that the temperature value of a certain configuration point can be obtained once the frequency of a receiving signal is detected; and a digital direct-current variable-frequency technology is adopted for a speed-regulating control module, so that the rotating speed and direction of each adjustable-speed inlet and exhaust fan can be adjusted segmentally. Due to the adoption of the method and the device, the air temperature can be distributed at a specific target, and economic and stable effects are achieved.

Owner:KUN SHAN UNIVERSITY

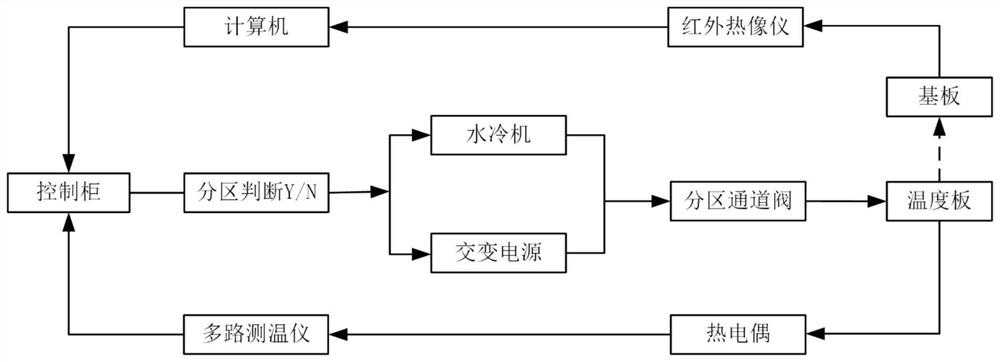

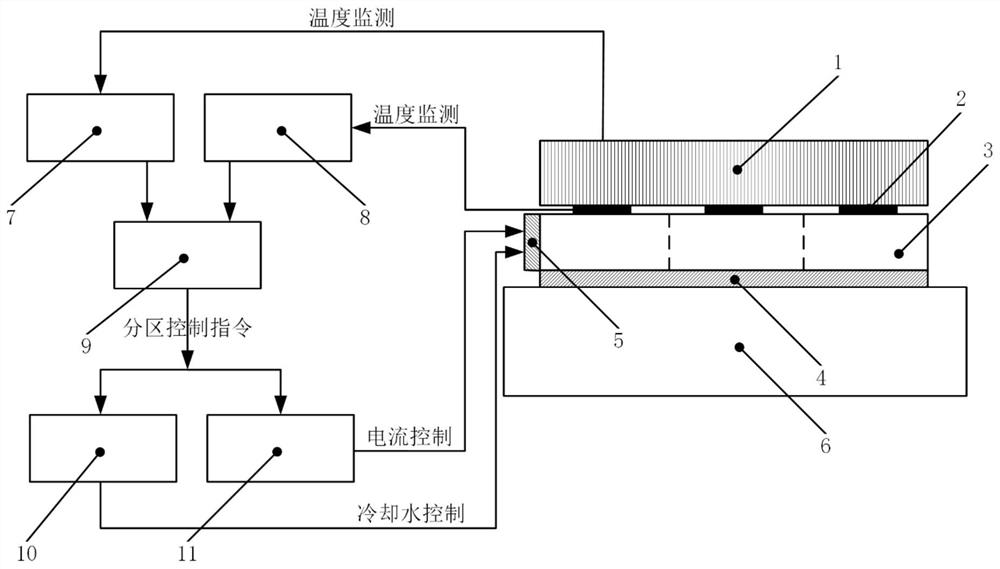

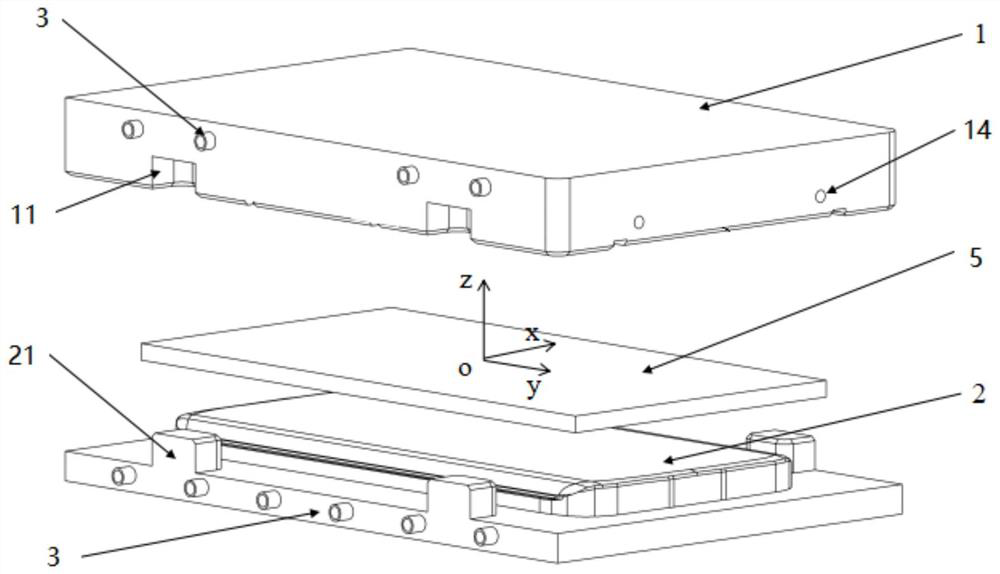

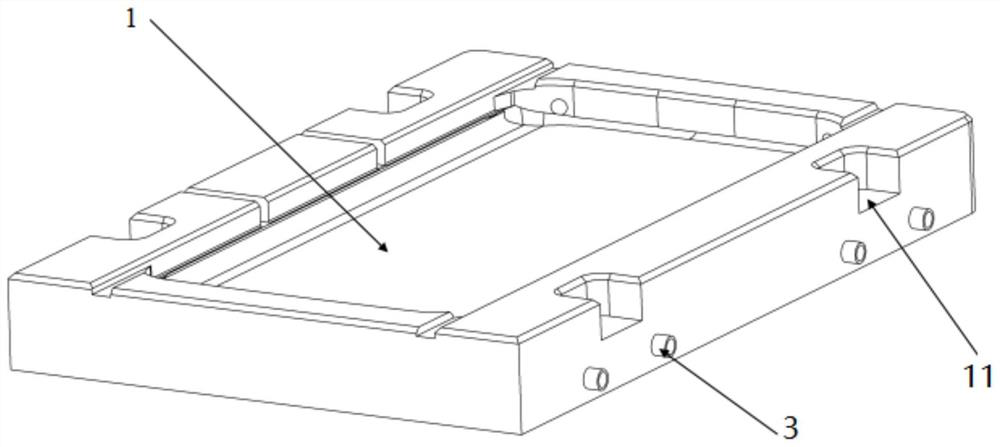

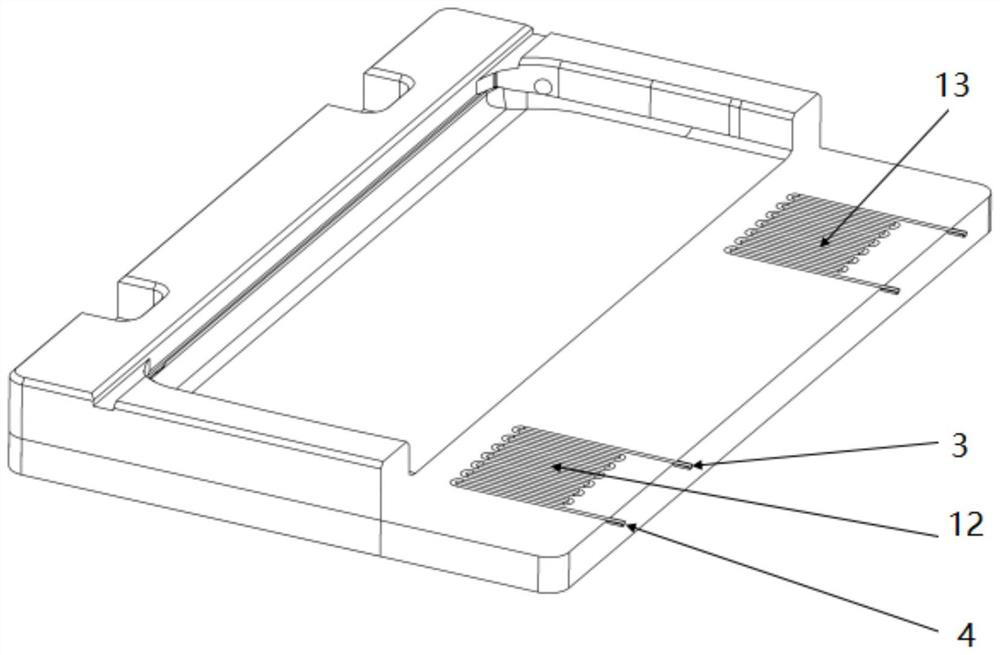

Temperature control device and control method of substrate for additive manufacturing

PendingCN113778154AControl temperature distributionControl stressTemperatue controlElectromagnetic heatingAlternate current

The invention belongs to the related technical field of additive manufacturing, and discloses a temperature control device and method of a substrate for additive manufacturing. The device comprises a temperature control board, a temperature detection system and a temperature control system. The temperature control board is arranged below the substrate and comprises a plurality of subareas, and each subarea is internally provided with a hollow metal spiral coil. The temperature monitoring system comprises an infrared thermal imager, a thermocouple and multiple channels of thermodetectors. The temperature control system comprises a control cabinet, a water cooling machine, an alternating current power supply and a subarea channel valve. The control cabinet performs electromagnetic heating or cooling water cooling on the substrate subareas based on a heat transfer rule and a temperature monitoring result. According to the invention, timely and accurate temperature regulation and control of different areas of the substrate for additive manufacturing can be achieved, so that temperature distribution of the substrate is regulated and controlled, stress and deformation of the substrate are controlled, and cracking and large deformation of the substrate in the additive manufacturing process are prevented.

Owner:HUAZHONG UNIV OF SCI & TECH

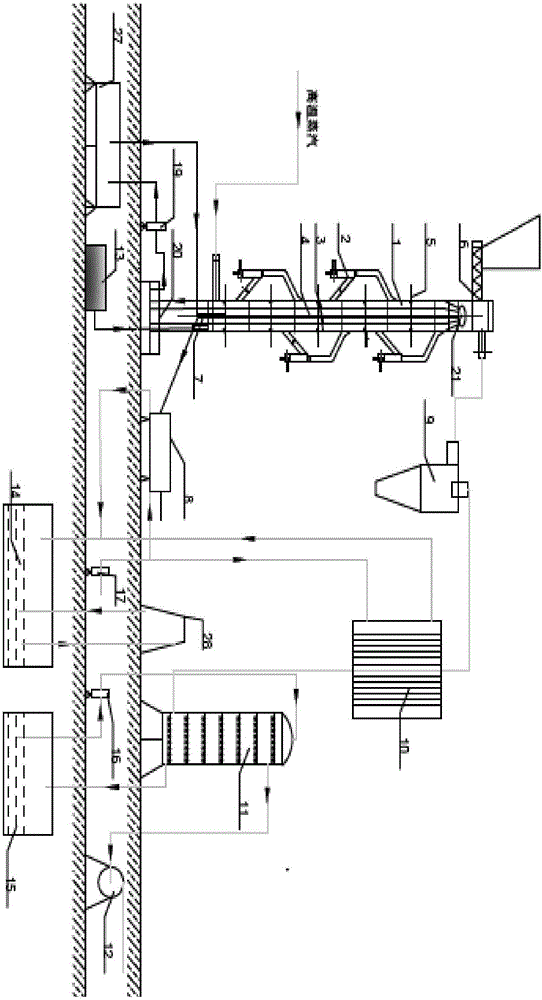

Multilayer fluidized bed parsing device for conducting pneumatic material return through row tube type heat exchange and coupling of molten salt

PendingCN105709710AHigh heat transfer efficiencyIncrease floor area ratioGas treatmentOther chemical processesSlagHeat transfer efficiency

The invention discloses a multilayer fluidized bed parsing device for conducting pneumatic material return through row tube type heat exchange and coupling of molten salt. The multilayer fluidized bed parsing device comprises a screw feeder (6), a multilayer fluidized bed (1), a slag cooler (8), a separator, a heat exchanger (10), a heat supply device, a water vapor generating unit and a spraying unit. The multilayer fluidized bed parsing device has the advantages of being high in heat transfer efficiency, high in plot ratio, even in heat exchange, controllable in stay time and the like and has an obvious advantage on the aspect of small granular activated coke compared with a traditional technology.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

A kind of method for preparing methyl acetate by carbonylation of dimethyl ether

ActiveCN103896769BExtend your lifeControl temperature distributionPreparation by carbon monoxide or formate reactionHydrogenReaction temperature

Provided is a method for preparing methyl acetate by dimethyl ether carbonylation, comprising passing a feed gas including dimethyl ether, carbon monoxide and optional hydrogen through a reactor filled with a mordenite and / or ferrierite molecular sieve based catalyst and reacting at a reaction temperature of 190-320°C, a reaction pressure of 0.5-20.0 MPa and a gas space velocity of 500-5000 h-1 so as to prepare methyl acetate, wherein the molar ratio of dimethyl ether to carbon monoxide is DME / CO=1 / 1-1 / 15, the molar ratio of hydrogen to carbon monoxide is H2 / CO=0-10 / 1, and the feed gas is distributed into each catalyst bed layer in a segmental feeding manner. A feed gas including dimethyl ether and carbon monoxide is uniformly distributed into each catalyst bed layer via a gas distributor, in a segmental feeding manner, which can remarkably improve the conversion rate of dimethyl ether, effectively control or adjust the temperature distribution of a catalyst bed layer, avoid the appearance of a hot spot, and prolong the service life of a catalyst.

Owner:YANCHANG ZHONGKE (DALIAN) ENERGY TECH CO LTD

A kind of method for preparing methyl acetate

ActiveCN103896768BExtend your lifeControl temperature distributionMolecular sieve catalystsCatalyst activation/preparationMolecular sieveHydrogen

Provided in the present invention is a process for preparing methyl acetate through carbonylation of dimethyl ether, comprising: passing a feed gas containing dimethyl ether, carbon monoxide, and optional hydrogen gas through a reactor loaded with a mordenite molecular sieve catalyst, and preparing methyl acetate by reacting same at a reaction temperature of 19 to 320°C, a reaction pressure of 0.5 to 20.0 Mpa, and a gas volume space velocity of 500 to 5000 h-1; wherein the mordenite molecular sieve catalyst is a hydrogen-type mordenite molecular sieve catalyst with an adsorbed organic amine, the molar ratio of the dimethyl ether to carbon monoxide in the feed gas is DME / CO = 1 / 1 to 1 / 15, the molar ratio of the hydrogen gas to carbon monoxide is H2 / CO = 0 to 10 / 1, and the dimethyl ether in the feed gas is charged into the reactor by means of feeding in stages. The present invention is characterized in that: through treatment by organic amine adsorption, the temperature distribution of catalyst bed can be effectively controlled so as to avoid the occurrence of hot points, and thereby side reactions are reduced, the selectivity of target product is improved, and the lifetime of the catalyst is greatly extended.

Owner:YANCHANG ZHONGKE (DALIAN) ENERGY TECH CO LTD

Method for controlling quality of water turbine guide vane casting through double-loop conductive crystallizer electroslag remelting

PendingCN114350970AUniform temperature distributionGood solidification quality and surface qualityCasting safety devicesFoundry mouldsSlagDual loop

The invention discloses a method for controlling the quality of a water turbine guide vane casting through electroslag remelting of a double-loop conductive crystallizer. The method comprises the specific steps that (1) slag materials are baked; 2) determining the slag quantity and the filling ratio of the upper crystallizer and the lower crystallizer; a bottom pad and a lower crystallizer are placed, and an arcing material is bound to an electrode end; (3) switching on a power supply, starting to add slag, and arcing to melt slag; (4) after all the slag materials are melted down, the remelting current and voltage are adjusted and set, and electroslag remelting in the lower crystallizer is carried out; (5) after the electroslag in the lower crystallizer is remelted, an upper conductive crystallizer is installed, electrodes are replaced, the remelting current and voltage are adjusted and set again, and electroslag remelting is conducted through a double loop of a power source, a consumable electrode, slag charge, a metal molten pool, a casting, a bottom water tank, a power source and a double loop of the power source, the consumable electrode, the slag charge, the upper conductive crystallizer and the power source; and (6) in the later stage of remelting, after feeding operation of the electroslag remelting point is stopped, power is cut off, and a remelted water turbine guide vane casting is obtained through cooling. By adopting the method, the water turbine guide vane casting with good surface and internal quality can be obtained.

Owner:SHENYANG RES INST OF FOUNDRY

Glass hot bending mold and glass hot bending method

PendingCN114212979AUniform temperature distributionEliminate temperature gradientsGlass reforming apparatusGlass productionComposite materialTemperature control

The invention belongs to the technical field of glass processing molds, and particularly relates to a glass hot bending mold and a glass hot bending method. The glass hot bending mold comprises a mold body, and the mold body comprises an upper mold and a lower mold; the upper mold and the lower mold are closed to form a sealing cavity; the upper mold and the lower mold respectively comprise a plurality of groups of mutually independent temperature control assemblies; the temperature control assembly comprises an air supply device and a micro-channel arranged in the upper mold or the lower mold; and the gas supply device is connected with the micro-channel and is used for supplying gas for adjusting the temperature into the micro-channel. The glass hot bending mold provided by the invention can eliminate the temperature gradient of the glass blank due to non-uniform heat transfer of the mold in the hot bending process.

Owner:GUANGDONG HUST IND TECH RES INST

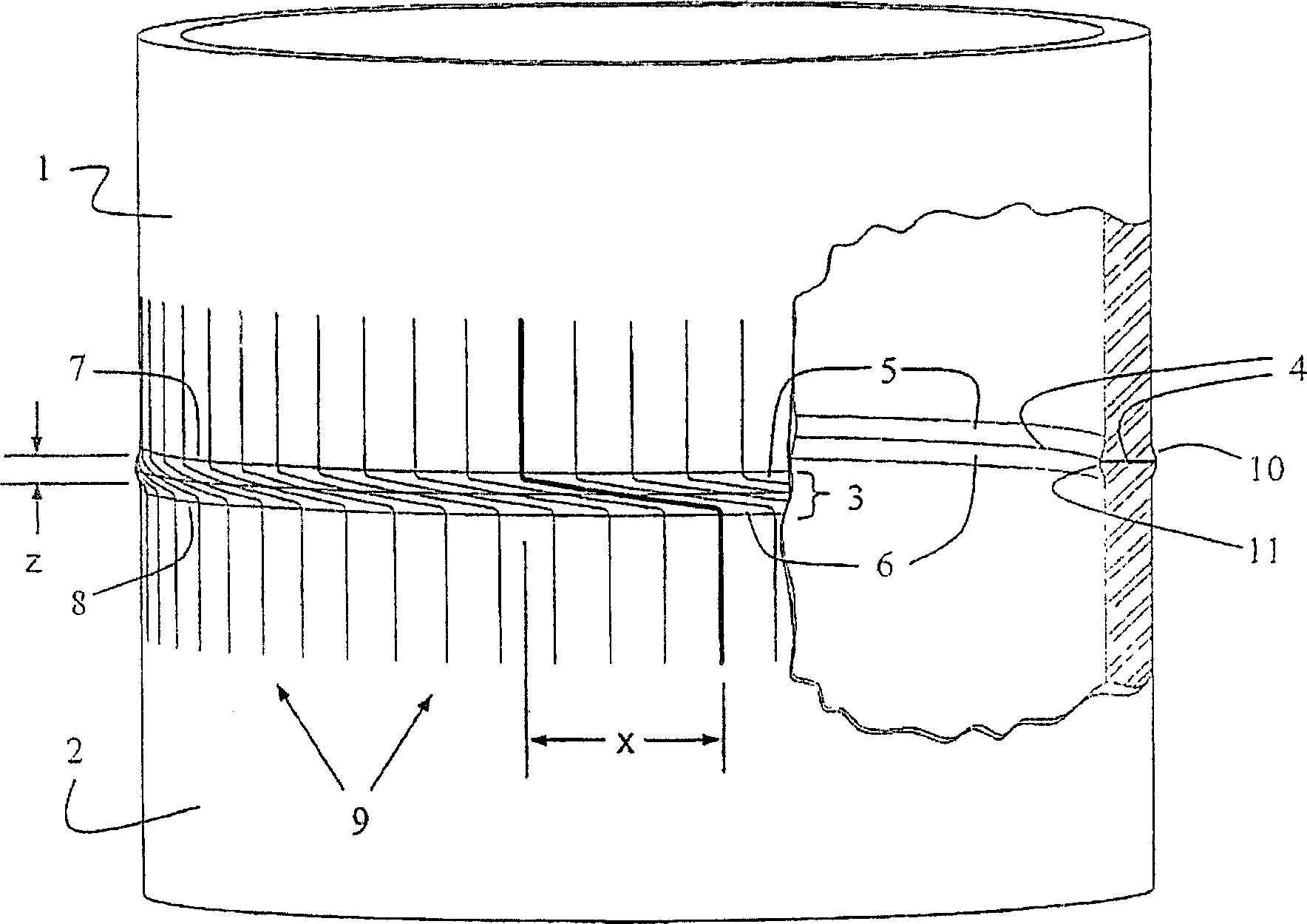

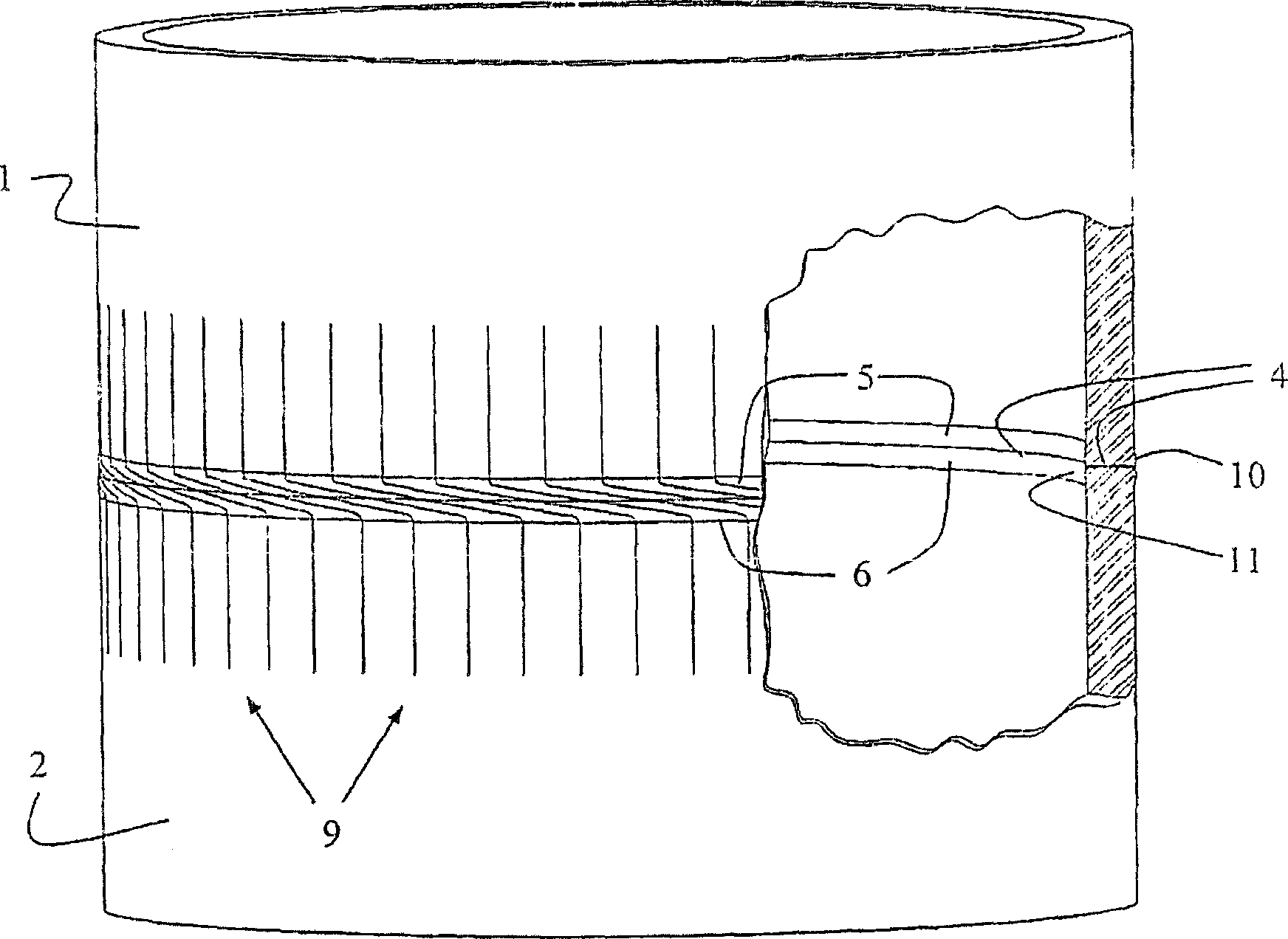

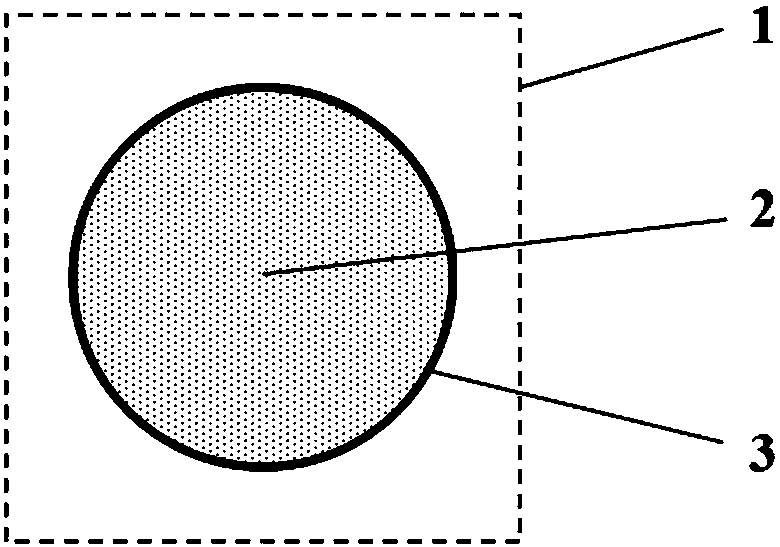

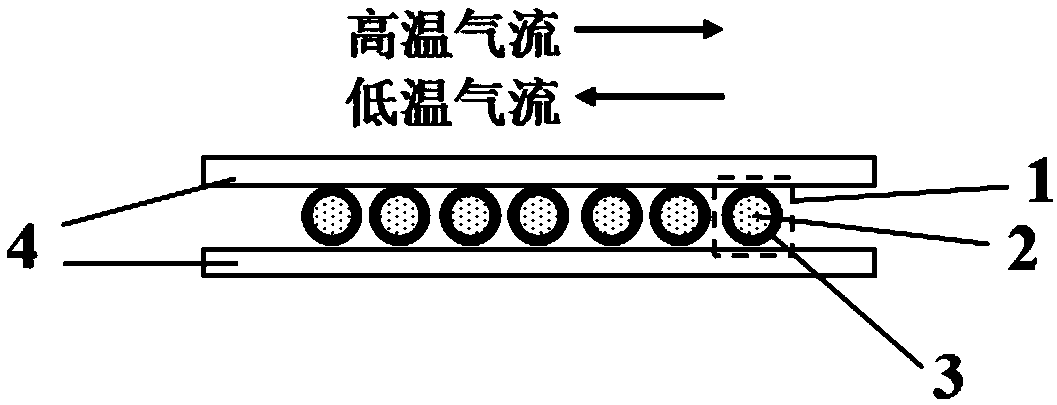

Heat regenerator based on phase change materials and stirling cycle system

PendingCN110273779AHigh specific heat capacityImprove work performanceHot gas positive displacement engine plantsDead volumeProduct gas

The invention discloses a heat regenerator based on phase change materials. The heat regenerator comprises a shell and a packing portion filling in a chamber formed by the shell, one end of the chamber is a hot end for allowing a high-temperature gas working medium to flow therein, the other end of the chamber is a cold end for allowing a low-temperature gas working medium to flow therein, the high-temperature gas working medium and the low-temperature gas working medium alternately flow through the chamber of the heat regenerator through the hot end and the cold end of the chamber correspondingly, wherein the packing portion comprises a plurality of phase change components composed of the phase change materials with different melting points, and the phase change components at least comprise the first melting point phase change component and the second melting point phase change component, and the first melting point phase change component close to the hot end has a higher melting point relative to the second melting point phase change component close to the cold end. According to the provided heat regenerator using the phase change materials as the packing, the heat storage density of the heat regenerator can be improved, the heat regeneration amount can be increased, the size of the heat regenerator also can be reduced, the dead volume of a system can be reduced, and then the efficiency of the whole machine can be improved.

Owner:ZHEJIANG UNIV

Casting method of large-scale high pressure resisting multi-cylinder-block cast

ActiveCN102699282BControl temperature distributionUniform temperature distributionFoundry mouldsFoundry coresSlagHigh pressure

The invention relates to a casting method of large-scale high pressure resisting multi-cylinder-block cast. The method includes the following steps: (1) mold making, (2) sand mold making, and (3) casting molding: during the sand mold making of the step (2), a sprue is designed into a first sprue (1) and a second sprue (3), a cross gate is designed into a first cross gate (2) and a second cross gate (4), and an ingate (5) is designed into a plurality of parallel pouring gates. Cross section area of all pouring gates is set as the following relation: the cross section area of the first sprue (1) is larger than that of the first cross gate (2), the cross section area of the first cross gate (2) is smaller than that of the second sprue (3), the cross section area of the second sprue (3) is larger than that of the second cross gate (4), and the cross section area of the second cross gate (4) is smaller than that of the ingate (5). The casting method overcomes the defects that shrinkage cavities, shrinkage porosities, slag inclusion and the like do not exist in the cast and can meet quality requirements that cylinder holes can be used as cylinder inner walls after the cylinder holes are machined.

Owner:RIYUE HEAVY IND

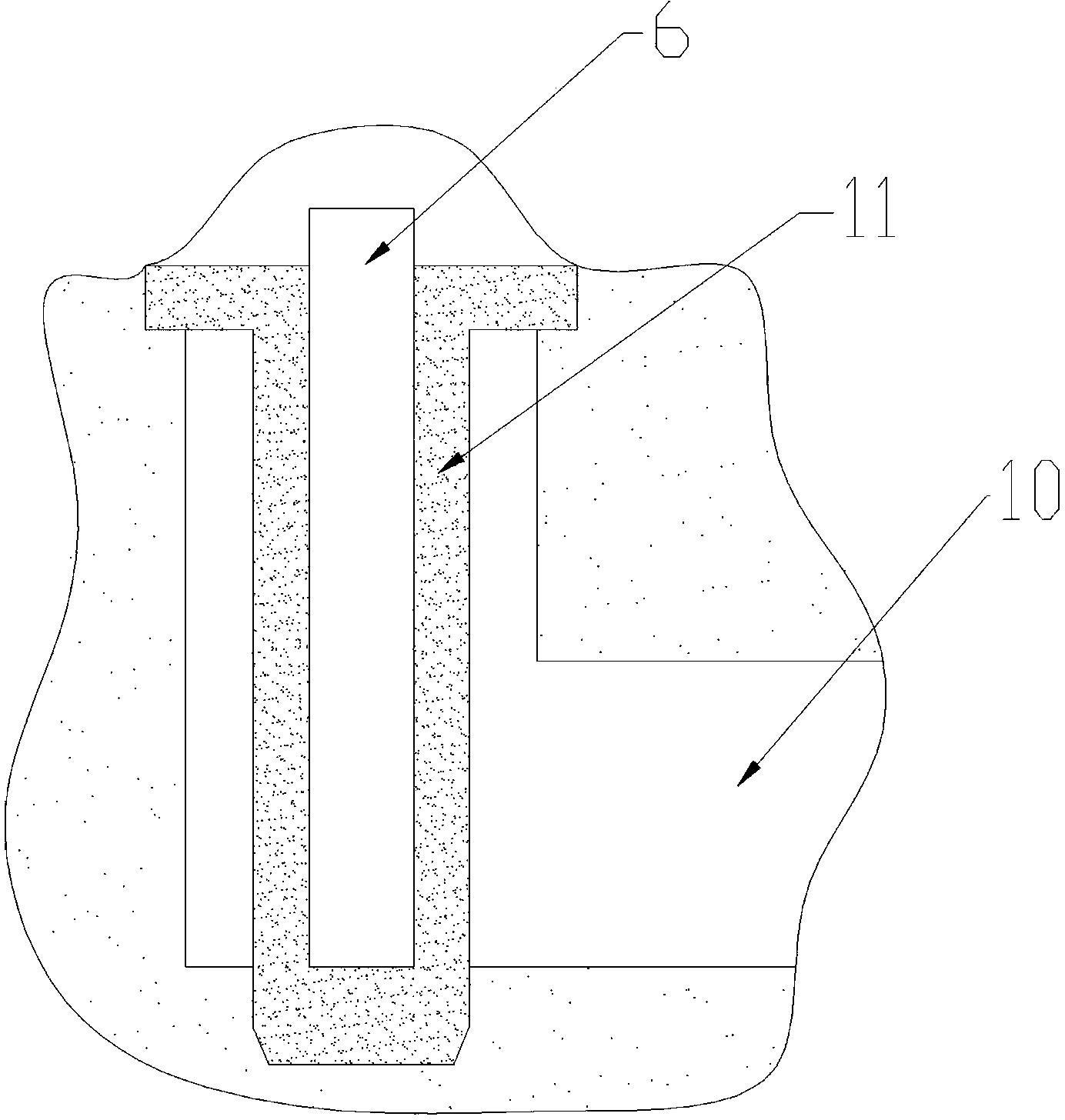

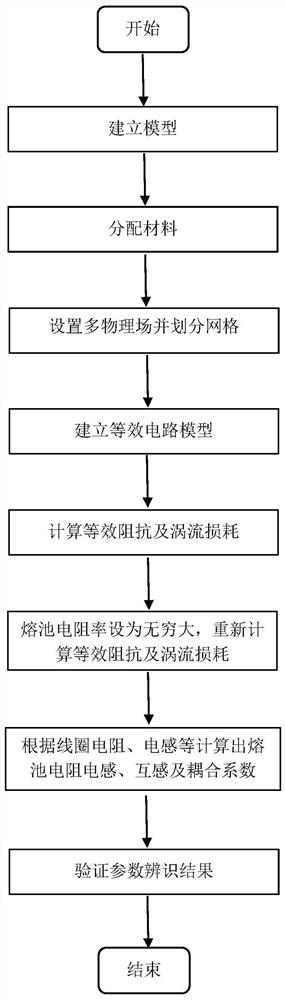

Equivalent circuit parameter identification method of induction heating model

PendingCN113255191AControl temperature distributionAccurate growth controlDesign optimisation/simulationSpecial data processing applicationsComputational modelHemt circuits

The invention belongs to the technical field of structural design of induction heating models, and relates to an equivalent circuit parameter identification method of an induction heating model. Comprising the steps of establishing a two-dimensional symmetric finite element simulation model, distributing materials, setting multiple physical fields and dividing grids, establishing an equivalent circuit model, calculating eddy current energy and analyzing the eddy current energy, replacing the materials, calculating resistance, inductance, mutual inductance and coupling coefficients of the model and verifying a parameter identification result. According to the invention, the working process of electromagnetic induction heating is simulated by adopting finite element calculation software COMSOL, so that the resistance and inductance characteristics of each part are analyzed, and the method has the following advantages that the two-dimensional symmetric model of the water-cooled crucible is established on the basis of considering main parts and peripheral parts, so that the error between a simulation result and actual work is reduced; by calculating system circuit parameters in a simulation state, data guidance is provided for coil turn number design, reactive compensation and application of power supply power in a melting process in actual production of an enterprise; and the experiment cost is saved.

Owner:DALIAN UNIV OF TECH

Process for producing resorcinol by continuously hydrolyzing m-phenylenediamine

ActiveCN101735019BSolve the problem of decomposition and deteriorationImprove mass transfer efficiencyOrganic chemistryOrganic compound preparationSulfateRetention time

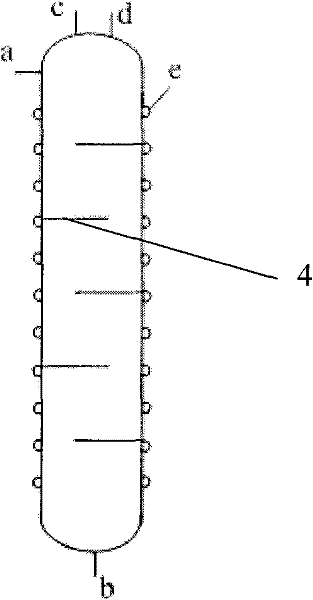

The invention discloses a process for producing resorcinol by continuously hydrolyzing m-phenylenediamine. The devices adopted by the process include a pipe mixer, a heat exchanger and a tower reactor, wherein baffle plates are distributed in the tower reactor from top down and the external wall of the tower reactor is provided with a heating pipe coil. The process comprises the following steps: 1, continuously preparing a hydrolysis raw material by using the pipe mixer to form homogeneous aqueous solution of m-phenylenediamine sulfate; 2, preheating the aqueous solution of m-phenylenediaminesulfate to 225 to 245 DEG C by the heat exchanger, continuously filling the aqueous solution of m-phenylenediamine sulfate to the tower reactor from the top part of the tower reactor, keeping the reaction and retention time of the reaction material in the tower reactor between 120 and 240 minutes, and performing continuous hydrolysis reaction; and 3, performing post-processing step of the hydrolysis reaction solution obtained by the hydrolysis reaction to obtain the resorcinol. The process has the characteristics of high equipment efficiency, short production period, high product yield, stable product quality and simple and convenient process control.

Owner:ZHEJIANG HONGSHENG CHEM IND +2

Production method of high alpha phase silicon nitride powder

ActiveCN112408992BControl temperature distributionPromote formationPhysical chemistryHeating furnace

The production method of high α-phase silicon nitride powder includes the following steps: A: grinding and pulverizing silicon powder to a D90 of 6 μm; B: loading the ground silicon powder into a sagger, and the thickness of the charging is within 15-30mm time; C: stack multiple saggars filled with silicon powder up and down into a stack, and the total thickness of silicon powder in each saggar in the stacked stack is less than or equal to 300mm; D: stack multiple stacks of silicon powder Put the saggars into the vacuum heating furnace, the total weight of the silicon powder in the multiple stacks of saggars filled with silicon powder is 70-100kg, and the multiple stacks of saggars filled with silicon powder are in an array form; Pumped to below 100Pa; F: filled with nitrogen to 60kPa; G: heating reaction. By adopting the method for large-scale production of silicon nitride, a high content of α phase can be obtained.

Owner:安阳亨利高科实业有限公司

A controllable electrolytic aluminum tank heat dissipation window waste heat recovery device

InactiveCN106949746BImprove working environmentImprove work efficiencyPhotography auxillary processesCharge composition/stateElectrolysisEngineering

Owner:QINGDAO UNIV

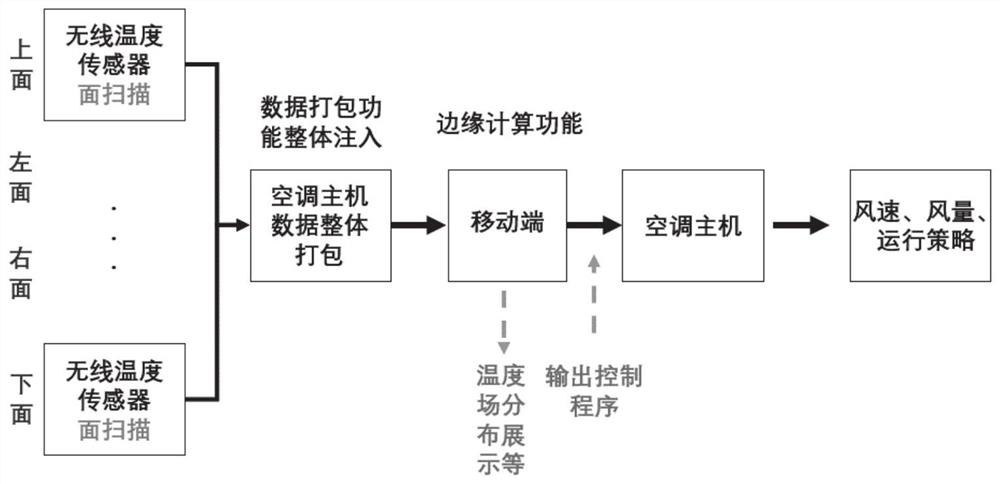

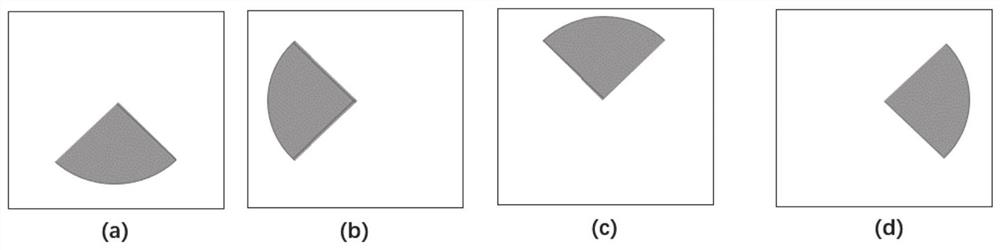

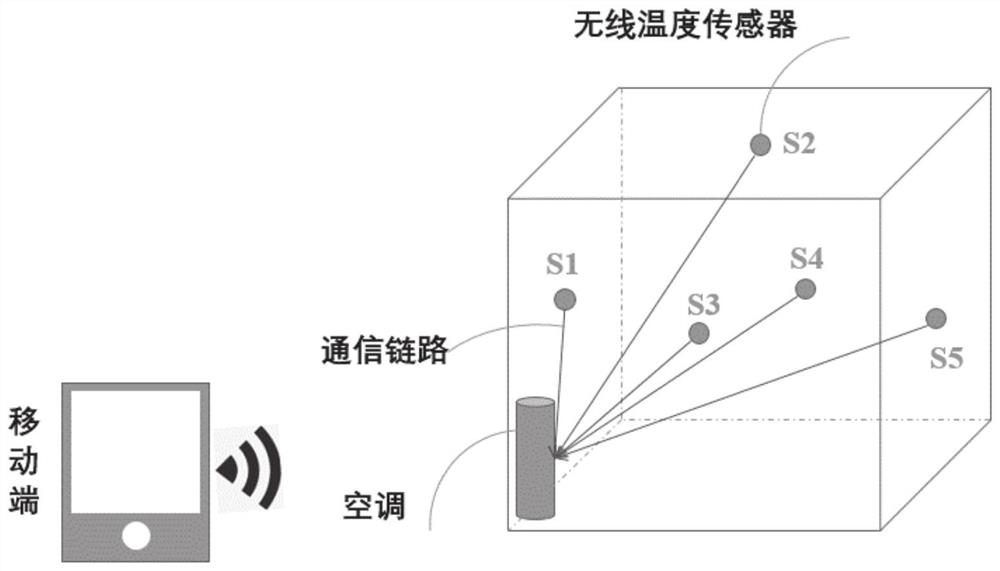

Intelligent temperature control system and method for air conditioner based on computing power of mobile client

PendingCN113883685ARealize processingReal-time sensing of temperatureMechanical apparatusSpace heating and ventilation safety systemsTemperature controlMobile end

The invention discloses an intelligent temperature control system and method for an air conditioner based on the computing power of a mobile client. The intelligent temperature control system for the air conditioner based on the computing power of the mobile client comprises a temperature sensor, an air conditioner host and a mobile terminal, wherein the temperature sensor is used for carrying out the surface scanning of the top surface and the side surface of a room, and obtaining the temperature information of the corresponding surface; the air conditioner host is used for storing the temperature information acquired by the temperature sensor and sending the temperature information to the mobile terminal; and the mobile terminal is used for constructing a 3D temperature field distribution diagram of the room according to the temperature information of each surface in the room, performing temperature assignment on each position point in the room according to the 3D temperature field distribution diagram, determining the position point with the highest temperature in the room according to the temperature of each position point in the room, and determining an air conditioner control strategy according to the temperature of the position point with the highest temperature, and sending the control strategy to the air conditioner host, so that temperature regulation and control are conducted on the position point with the highest temperature according to the air conditioner control strategy. Accurate regulation and control of temperature distribution in the room are realized.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO SHOUGUANG POWER SUPPLY CO +1

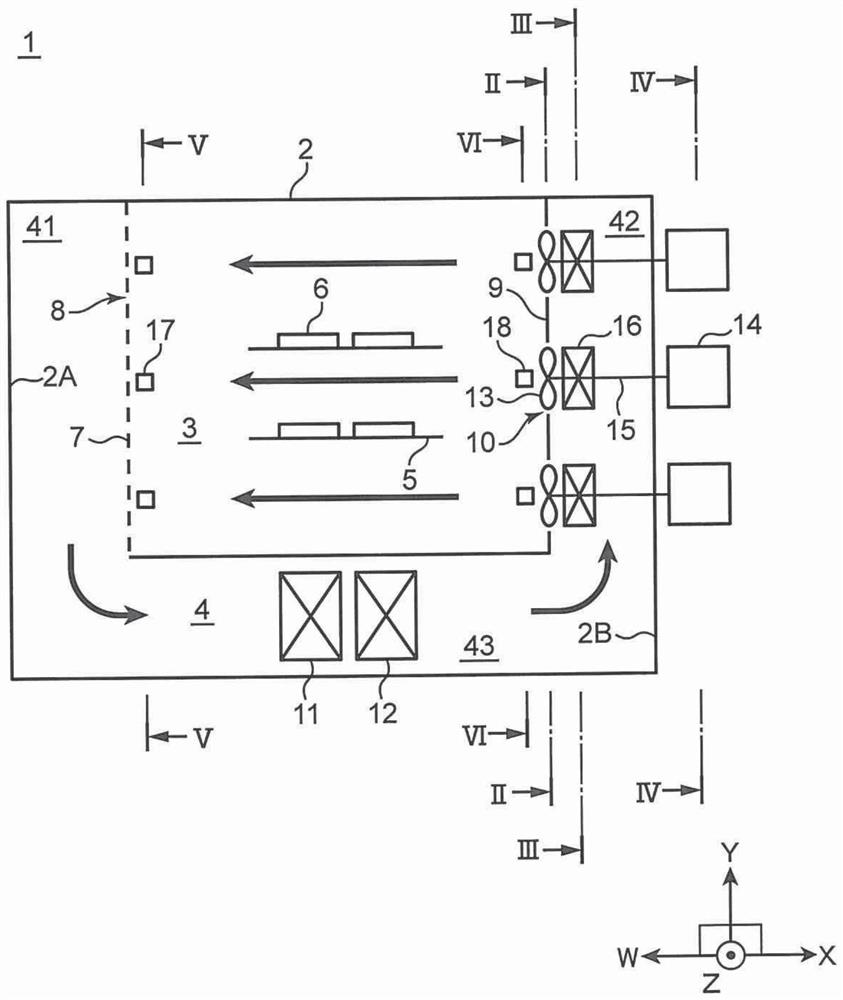

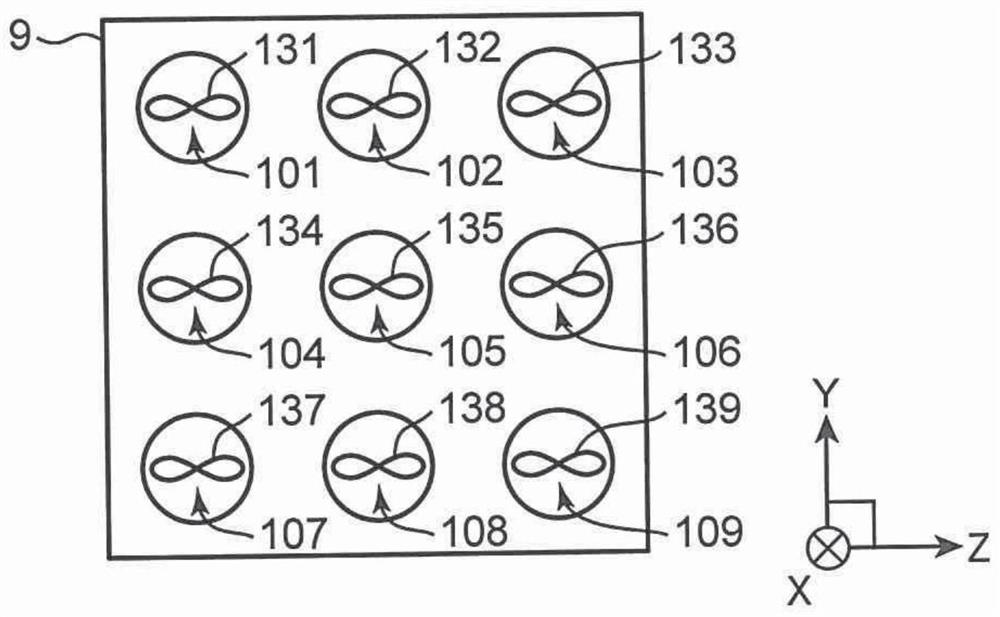

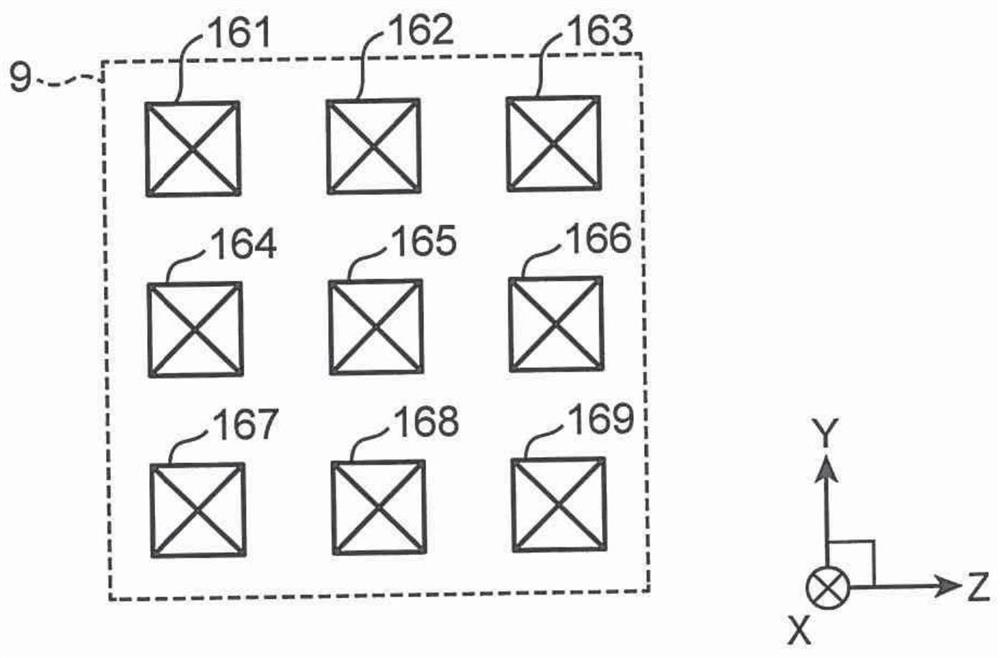

Environment forming device

ActiveCN113311888AControl temperature distributionWeather/light/corrosion resistanceTemperatue controlInterior spaceEngineering

An environmental test device (1) is provided with a test chamber (3) in which an object to be tested is accommodated; an air conditioning chamber (4) which is communicated with the test chamber; a cooler (11) and a main heater (12) for generating air-conditioned air by adjusting the temperature of air flowing into the air-conditioned chamber from the first wall surface (7) side of the test chamber; blowing fans (13) which are arranged side by side in a plurality of directions on the second wall surface (9) side of the test chamber facing the first wall surface (7), and which blow air-conditioned air from the air-conditioned chamber to the test chamber in the direction from the second wall surface (9) to the first wall surface (7); and a control unit (30) that individually controls the rotational speed of each of the plurality of blower fans (13). Therefore, the temperature distribution of the internal space of the test chamber (3) can be finely controlled.

Owner:ESPEC CORP

A Circulating Fluidized Bed/Bubbling Fluidized Bed Coupled Pressurized Oxygen-enriched Combustion Device

ActiveCN109297015BReduce volumeLow investment costFluidized bed combustionIndirect carbon-dioxide mitigationFurnace temperatureHearth

The invention discloses a circulating fluidized bed / bubbling fluidized bed coupled pressurized oxygen-enriched combustion device. The circulating fluidized bed / bubbling fluidized bed coupled pressurized oxygen-enriched combustion device comprises a circulating fluidized bed / bubbling fluidized bed coupled hearth, an air chamber, an air distribution plate, a cyclone separator, a return feeder, an external heat exchanger, a buried pipe heating face and a screen type heating face; the hearth adopts graded air supply and graded coal supply, the buried pipe heating face is arranged in the dense-phase zone, a lean-phase zone outlet is connected to the cyclone separator, the cyclone separator is used for separating solid materials in smoke gas in the hearth outlet, and the materials enter the return feeder and the external heat exchanger. The device is suitable for combustion of solid fuel under pressurizing and high inlet oxygen concentration, and advantages of a bubbling fluidized bed and acirculating fluidized bed can be achieved. The buried pipe heating face with the high capacity utilization rate is arranged on the bubbling and fluidizing area of the lower portion of the hearth, thelimited arrangement of the heating face can be effectively solved, and through graded coal supply, graded air supply and graded return feeding, the furnace temperature and in-furnace temperature distribution can be effectively controlled.

Owner:SOUTHEAST UNIV

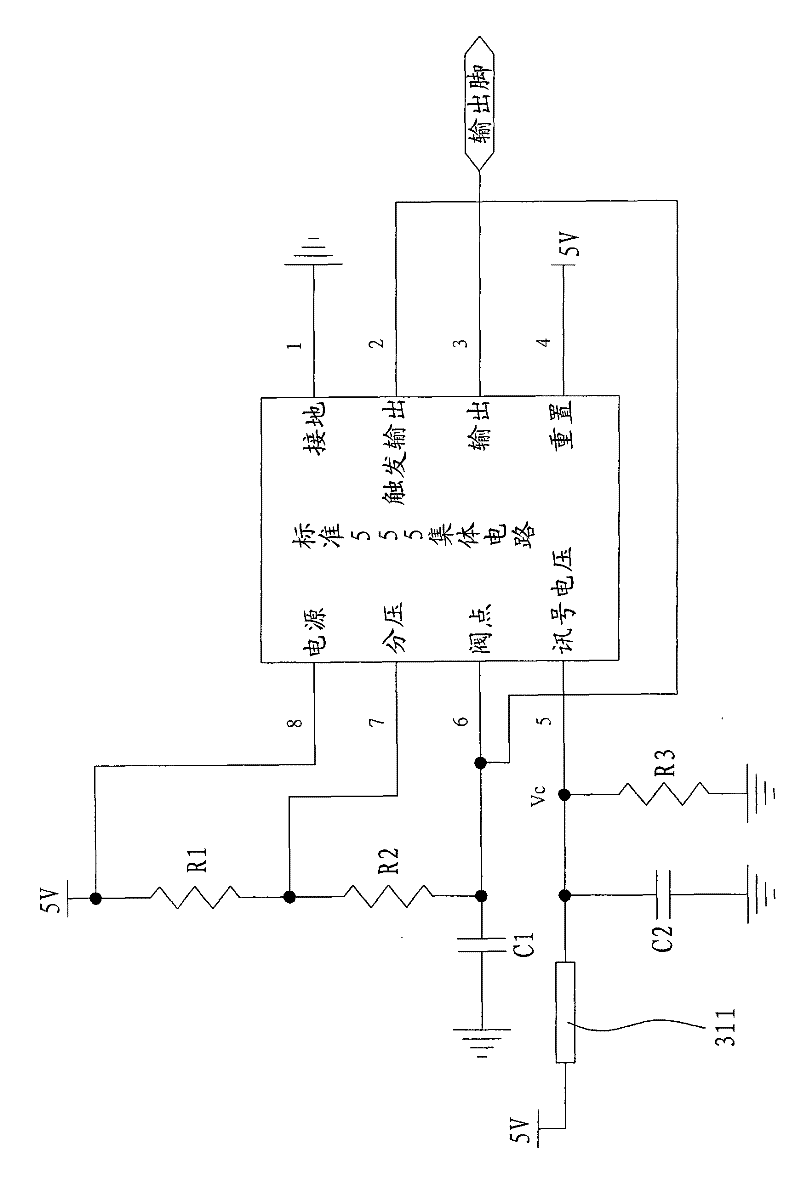

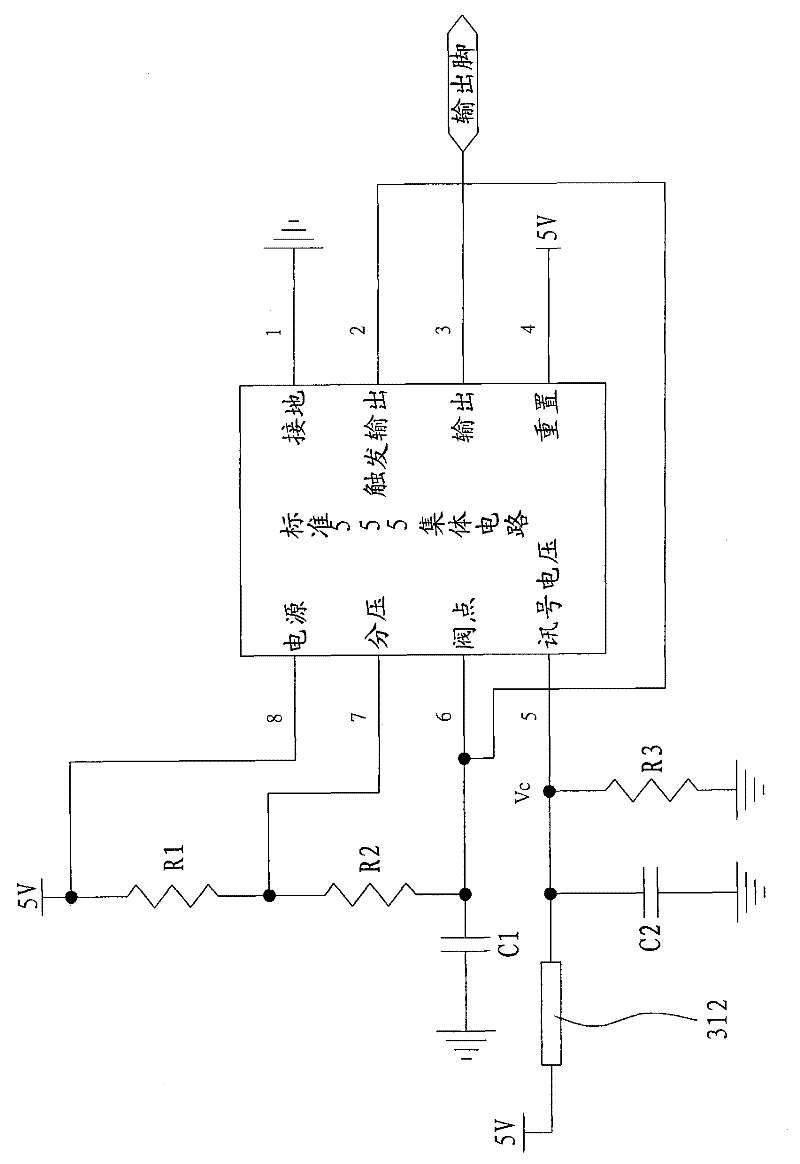

An air conditioner power supply control system based on multi-point temperature sensing

ActiveCN106247551BControl temperature distributionControl the temperature distributionMechanical apparatusSpace heating and ventilation safety systemsRemote controlPower control system

The invention provides an air conditioner power supply control system based on multipoint temperature sensing. The air conditioner power supply control system comprises refrigeration control units arranged in different space positions; the refrigeration control units include temperature sensors, control relays, refrigeration exhaust ports, control chips and communication modules; the control relays are used for controlling the power supply on and off of the refrigeration exhaust ports; the communication modules are connected with a remote control terminal; all the temperature sensors obtain the temperature data and send to the control chips; and all the control chips send the temperature data to the remote control terminal. The air conditioner power supply control system based on multipoint temperature sensing can control the temperature distribution in whole space through multipoint temperature detection, and guarantees the lowest refrigeration consumption.

Owner:HEFEI TONGYONG POWER EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com