Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

129results about How to "Lower ignition point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

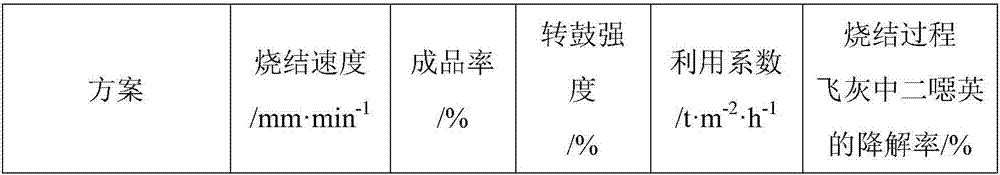

Dioxin control method for iron ore sintering garbage fly ash coprocessing process

ActiveCN107159678ARealize normal sinteringEffectively fixedTransportation and packagingSolid waste disposalSludgeLitter

The invention discloses a dioxin control method for the iron ore sintering garbage fly ash coprocessing process. According to the method, garbage fly ash, lime milk, flammable solid fuel and sludge are subject to mixed granulation and drying, and small balls containing garbage fly ash are obtained; iron core sintering raw materials are granulated and then are mixed with the small balls of the garbage fly ash, and after distribution, ignition and sintering are carried out. According to the method, on the premise that the iron ore sintering is not affected, efficient decomposing of dioxin contained in the fly ash can be achieved, dioxin secondarily formed in the garbage fly ash sintering process is prevented, according to the method, the decomposing rate of the garbage fly ash dioxin reaches 90% or above, meanwhile, effective solidifying of the garbage fly ash can be ensured, and in the sintering process, the aim of cleaning the garbage fly ash is achieved.

Owner:CENT SOUTH UNIV +1

Coal-saving devulcanized coke cleaning clean synergistic agent and preparation technique thereof

InactiveCN101348743ALower ignition pointImprove oxidation effectSolid fuelsStrontium carbonateFerrosilicon

The invention relates to a process for preparing a clean synergist for saving coal, desulfurization and cleaning coke. Active calcium oxide and magnesium hydrate are mixed and added with sodium carbonate, ferrosilicon powders, manganese dioxide, strontium carbonate and barium hydroxide in turn and finally added with active carbon and evenly mixed to prepare the clean synergist which comprises the following compositions in percentage by weight: 20 to 30 percent of the active calcium oxide, 9 to 12 percent of the magnesium hydrate, 12 to 20 percent of the sodium carbonate, 8 to 10 percent of active carbon, 12 to 15 percent of the ferrosilicon powders, 8 to 12 percent of the manganese dioxide, 3 to 5 percent of the strontium carbonate and 5 to 7 percent of the barium hydroxide. on the premise of unchanging the prior coal burning process and equipment of various boilers and the prior smoke exhaust process and equipment, the clean synergist of the process is only needed to add according to the physicochemical index of coal used by customers, thereby achieving the functions of saving the coal, the desulfurization and cleaning the coke.

Owner:陈宏谋 +1

Boiler coal combustion-improving desulfurizing agent composition and preparation method thereof

ActiveCN103194294AGood synergyHigh selectivitySolid fuelsFuel additivesActivated attapulgiteSodium acetate

The invention provides a boiler coal combustion-improving desulfurizing agent composition. The composition comprises the following components in parts by weight: 3-9 parts of sodium carbonate, 1-2 parts of sodium acetate, 3-9 parts of calcium carbonate, 4-9 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 3-10 parts of ferric oxide, 8-22 parts of potassium permanganate, 8-22 parts of potassium chlorate, 15-40 parts of activated attapulgite clay, 7-13 parts of manganese oxide, 4-8 parts of copper oxide, 4-8 parts of alumina, 3-8 parts of copper carbonate, 3-10 parts of zinc oxide, 3-10 parts of zinc nitrate, 4-11 parts of sodium dichromate, 0.5-1.5 parts of barium molybdate, 0.5-1.5 parts of vanadium pentoxide, 0.2-0.5 part of cerium oxide and 1-3 parts of dispersing agent JFC. The composition is an additive suitable for coal-fired boilers in the petroleum, chemical, power, thermoelectricity and metallurgy industries, can absorb and solidify sulfur dioxide generated in the combustion process, adsorbs dust and other harmful substances in quantity and simultaneously removes smoke dust scales and jelly adhering to the inner walls of combustors, thus inhibiting the concentration of flue gas emission.

Owner:GANSU HEIMA PETROCHEM ENG

Coal-saving desulfurization additive for power plant boiler

InactiveCN101230302ATo achieve the purpose of sulfur fixation and desulfurizationLower ignition pointFuel additivesSilicon dioxideAmmonium nitrate

The invention discloses a power plant boiler used coal-saving desulfurating additive, which is prepared by mixing calcium oxide, silicon dioxide, calcium ammonium nitrate, sodium nitrate, potassium permanganate, ammonium nitrate, iron oxide, alumina, activated carbon and borax by curtain weight percentages; and then using a pulverizing mill to pulverize the mixture into power, the granularity of which is 80-100 MU; putting the power into a stirrer and stirring the power; packing the power into finished product after the power is tested to be qualified. The invention has obvious sulfur capturing and desulfurizing effects, can save energy and support combustion, can lower the blackness of the exhausted smoke, can clear ashes and remove coke, and need not change the existing combustion process and equipment. The invention is in particular applicable for the coals with high ash content, high sulfur content and low volatile constituent content. The invention can reduce equipment leakage accident caused by poor quality of coal, can ensure the safe operation of the boiler effectively, can ensure the safe operation of electric generating set, therefore being worthy to be spread by all thermal power plants.

Owner:SHAANXI E LEELY POWER DEV

High water absorption resin water suction gel fire extinguisher and its application

InactiveCN100444912CImprove water retentionImprove fire extinguishing effectFire extinguisherFiberOrganic solvent

Owner:ZHEJIANG UNIV

Multifunctional additive for pulverized coal injected into blast furnace and multifunctional additive addition method

InactiveCN103266190ALower ignition pointReduced responseSolid fuelsBlast furnace detailsReaction rateUltimate tensile strength

The invention provides a multifunctional additive for pulverized coal injected into a blast furnace and a multifunctional additive addition method and belongs to the field of blast furnace iron making. The multifunctional additive is a powdery compound mixture, the particle size of the multifunctional additive is required to be larger than 100 meshes, and the proportion of the multifunctional additive with the particle size of above 200 meshes is required to account for above 80%. The multifunctional additive has the characteristics of being capable of obviously improving the combustion characteristic of the pulverized coal, reducing the ignition point, increasing the precipitation yield of volatiles, the combustion speed and the combustion heat, passivating the reaction activity of coke, reinforcing the supporting effect of a skeleton and inhibiting the low-temperature reduction degradation of iron-containing furnace burden. After 1%-6% of multifunctional additive is added to the pulverized coal injected into the blast furnace, the ignition point of the injected pulverized coal can be obviously reduced by 14 DEG C, the yield of the volatiles is increased by 23.38%, the combustion ratio of the pulverized coal is increased by 11.9%, the average reaction rate of the pulverized coal is increased by 8.7%, the low-temperature reduction degradation index (RDI) of sinters at 500 DEG C is increased by 23.10%, the coke reactivity (CRI) of the pulverized coal is reduced by 11.23%, and the post-reaction strength (CSR) of the pulverized coal is increased by 10.57%.

Owner:UNIV OF SCI & TECH BEIJING

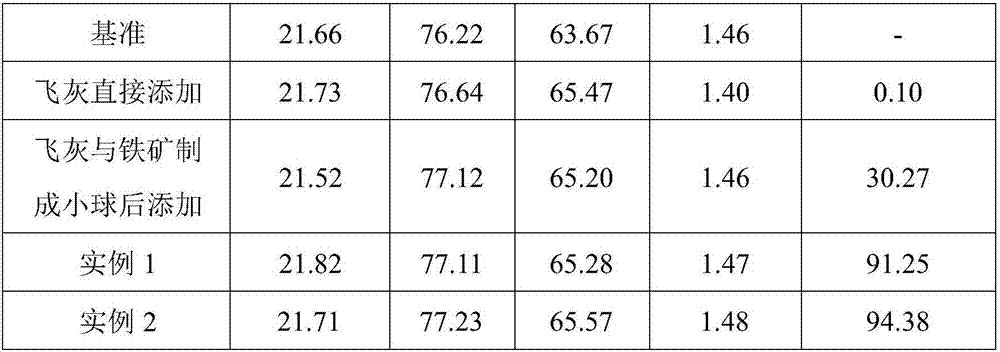

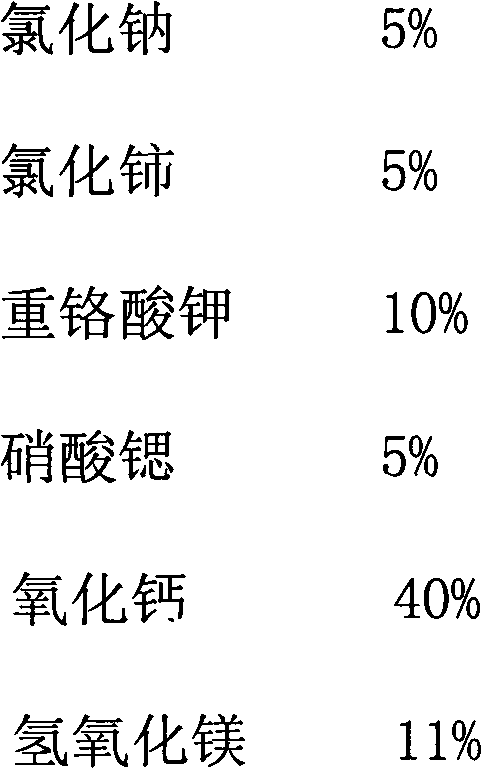

Multifunctional rare earth sulfur-fixing denitration energy-conservation additive

The invention discloses a multifunctional rare earth sulfur-fixing denitration energy-conservation additive, which solves the problems that the conventional sulfur-fixing agent has relatively low sulfur-fixing rate and does not have the function of reducing NOx emission. The additive is characterized by consisting of the following raw materials in percentage by mass: 8 to 10 percent of rare earth compound, 12 to 15 percent of inorganic salt, 51 to 65 percent of alkaline earth metal compound, 5 to 8 percent of aluminum compound, 5 to 8 percent of zinc compound and 5 to 8 percent of silicon compound. The additive is prepared by the following steps of: grinding the raw materials into fine particles with the particle size of 100 to 300 meshes; proportioning the particles according to the mass percentage at normal temperature; uniformly stirring and mixing; preparing powder from the mixture; and compounding. The additive has the advantages of capability of being popularized in a large area, high sulfur-fixing rate and denitration function and is suitable for coal-smoke type heavily-polluted production links.

Owner:阳泉鑫环高新技术有限责任公司

Non-uniform combustion catalyst and uses thereof

InactiveCN101116821ALower ignition pointEfficient use ofMetal/metal-oxides/metal-hydroxide catalystsPlatinum oxidePalladium oxide

The present invention discloses a non-uniformly distributed combustion catalyst and the application thereof. The present invention belongs to the catalyst field, and in particular relates to the catalytic combustion catalyst product. The technical problem solved by the present invention is to provide the catalyst product with non-uniformly distributed active components and the preparation method. Another objective of the present invention is to apply the catalyst with non-uniformly distributed active components to the catalytic combustion reaction of methanol, methane and natural gas. The active components of the catalyst consist of one species or a plurality of species in palladium oxide, rhodium oxide, platinum oxide, cobalt oxide, nickel oxide and chromium oxide, and the active components are non-uniformly distributed in the catalyst in an eggshell-shape, of which the content occupies the 0.01-5 percent of the catalyst weight; the weight of an alumina carries occupies 95-99.99 percent. The present invention can decrease the combustion point of fuel, and can make the active component of precious metals utilized with high efficiency.

Owner:HANERGY TECH

Combustion improver and fuel made of same as well as fuel production method and application

InactiveCN103173260ALow costNo damageSolid fuelsLump/pulverulent fuel preparationSodium acetateInorganic compound

The invention provides a combustion improver and a fuel made of the combustion improver as well as a fuel production method and application. The catalysis combustion improver is prepared by the following steps of: by taking humic acid sodium, potassium nitrate, lemon acid, sodium acetate, sodium dodecyl benzene sulfonic and the like as raw materials, dispersing the catalyst raw materials such as the potassium nitrate in dispersate, grinding to below 120 meshes, then adding the dispersate to blended coal for uniform mixing, and adding to the blended coal again, wherein the dispersate accounts for 5-10% of the blended coal. The catalysis combustion improver can be used for solving the technical problem that a conventional catalysis combustion improver is high in cost, is severely corrosive to equipment and possibly generates poisonous organic matters to influence environments. The combustion improver provided by the invention is a chloride-free organic and inorganic compound combustion improver, is low in cost and has no secondary pollution and damage to combustion equipment.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

Metallurgical molded coal manufactured by raw materials containing humic acid

The invention relates to an industrial composite binding agent molded coal, in particular to a metallurgical molded coal manufactured by raw materials containing humic acid. The molded coal directly takes weathered coal and brown coal as the raw materials which are mixed with coal dust; after being processed by special treatment, the mixture is pressed by a ball press to be molded. The manufactured molded coal has the drying cold strength of 980N / piece, the hot strength of 450N / piece, the thermal stability (more than 6mm) of 93.4%, the drop strength (more than 13mm) of 97.6%, low ignition point and the burning rate of more than 92%. The metallurgical molded coal is suitable for bituminous coal and anthracite which have high ash fusion point, low sulphur content and the fixed carbon content of more than 70%, thus being applicable to a metallurgical furnace.

Owner:SHANXI LUAN MINING GRP

Micro-carbon casting powder for high-carbon steel in square and rectangular billets and preparation method thereof

ActiveCN110976797ASolve the problem of carbon increaseImprove insulation effectProcess efficiency improvementSteelmakingLithium carbonate

The invention discloses micro-carbon casting powder for high-carbon steel in square and rectangular billets and a preparation method of the micro-carbon casting powder, and belongs to the technical field of steelmaking metallurgical auxiliary materials. The invention discloses micro-carbon casting powder for the high-carbon steel in the square and rectangular billets is prepared from following rawmaterials in cluding, 40-65 parts of a special pre-melting material, 0-30 parts of wollastonite, 3-8 parts of quartz, 1-5 parts of bentonite, 0-3 parts of magnesia, 2-7 parts of albite, 2-6 parts offluorite, 1-4 parts of sodium carbonate, 1-4 parts of sodium fluoride, 1-3 parts of lithium carbonate, 2-6 parts of sodium nitrate, 0-1.5 parts of medium-carbon graphite, 0-1.5 parts of high-carbon amorphous graphite, 1-2.5 parts of superfine color black and 1.8-3.8 parts of a binding agent. The casting powder is low in carbon content, high in pre-melting ratio, not prone to generating a slag ring, capable of generating heat automatically and capable of being applied to the high carbon steel in special steel in the square and rectangular billets, capable of avoiding local recarburization of the high carbon steel in the special steel, meanwhile, low in fluorine content and capable of avoiding erosion to nozzle slag lines.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

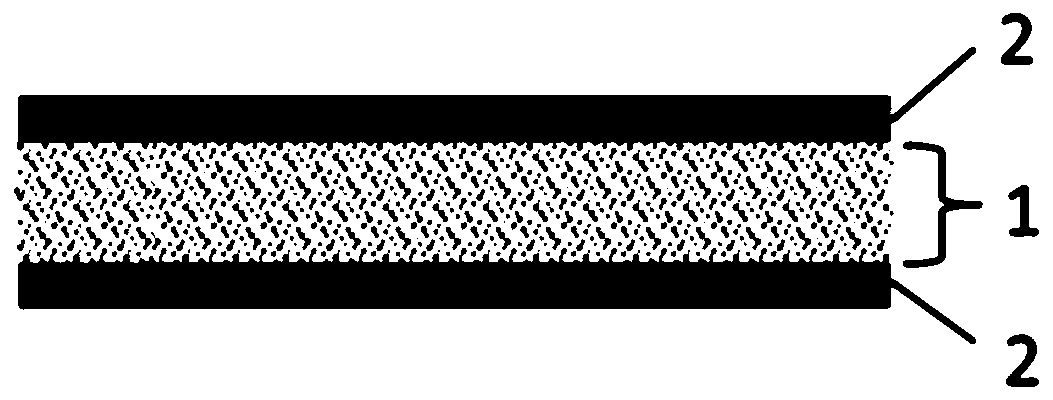

Current collector and preparation method and application thereof

ActiveCN111048788AReduce weightLower ignition pointElectrode carriers/collectorsFire rescueThermodynamicsElectrical battery

The invention provides a current collector and a preparation method and application thereof. The current collector comprises a functional film layer and metal layers arranged on the upper surface andthe lower surface of the functional film layer, wherein the functional film layer comprises a flame retardant. According to the current collector and the preparation method thereof, the flame retardant is added into the functional film layer so that the ignition point can be effectively reduced, the flame retardant can be released into electrolyte from the current collector at high temperature toachieve an active fire extinguishing effect, and the safety performance of the battery is remarkably improved; the functional film layer can also bear the metal layers on the upper surface and the lower surface, the weight of the current collector is reduced and the energy density of the battery is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

Boiler decoking agent

The invention relates to a decoking agent capable of reducing and removing coke blocks and deposited ash which are positioned in a coal burning boiler and an industrial boiler. The decoking agent comprises the following components in percentage by weight: 3%-10% of potassium nitrate, 1%-5% of magnesium nitrate, 0.5%-2% of cupric nitrate, 5%-20% of ammonium sulfate, 0%-2% of picric acid and 0%-2% of borax. According to the decoking agent, an copper ion is a combustion-supporting catalyst, and can reduce the ignition point of deposited carbon and promote the sufficient combustion of coal powder; borax can crisp the coke blocks, promote the combustion of carbon contained in the coke blocks and realize the falling of the coke blocks; the nitrate is an oxidizing agent, can release oxygen for combustion support under the condition of high temperature and can clean coke and the deposited ash by synergically generating explosion effect with picric acid. The decoking agent disclosed by the invention has the advantages of low cost and easiness for obtaining of raw materials, simple preparation process and convenience for use without causing any corrosion or generating any secondary pollution on the boilers.

Owner:聂冰晶 +1

Un-equipartition combustion catalyst and method for preparing the same

InactiveCN101116815ALower ignition pointEfficient use ofMetal/metal-oxides/metal-hydroxide catalystsHigh heatMethanol

The present invention discloses a catalyst for the catalytic combustion of methanol, hydrogen, methane and natural gas. The present invention consists of a metal oxide active component occupying 0.01-5 percent of the catalyst weight and an alumina carrier occupying 99.99-95 percent of the catalyst weight. The preparation method of the catalyst is that: active alumina is firstly placed in alkaline precipitant for presaturation treatment, baked in a short time under high temperature, impregnated in the salt solution containing metal ions, dried and roasted to obtain the catalyst product. The evaluation result of using the catalyst shows that: the combustion point of gas is reduced; the conversion of gas is increased.

Owner:HANERGY TECH

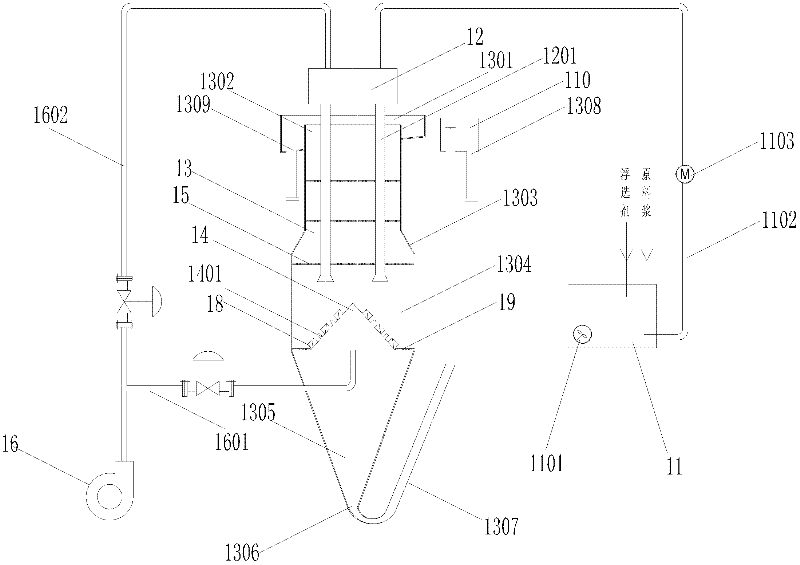

Method simultaneously for moisture removal and solid fuel preparation from sludge and products

ActiveCN108358421AChange fuel propertiesLower ignition pointSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningBound waterSludge

The invention provides a method simultaneously for moisture removal and solid fuel preparation from sludge. The method comprises the following steps: step S01: subjecting wet sludge to pretreatment under heating so as to obtain heat conditioned sludge; step S02: cooling the heat conditioned sludge so as to obtain cold sludge, adding a carburetting conditioning agent into the cold sludge, and carrying out uniform mixing so as to obtain carburetted conditioned sludge; step S03: subjecting the carburetted conditioned sludge to dehydration treatment; and step S04: subjecting the dehydrated carburetted conditioned sludge to heat drying so as to obtain a solid sludge fuel. Through combined application of a heat conditioning process and a conditioned sludge sensible heat direct utilization systemin pretreatment of the sludge, the method provided by the invention avoids the problem of excessively high energy consumption, and integrates advantages like improvement of sulfur-fixing, chlorine-fixing, nitrogen-fixing and phosphorus-fixing abilities of modified heat-conditioned sludge and reduction of the content of bound water in a reasonable energy consumption range.

Owner:HUAZHONG UNIV OF SCI & TECH

Continuous-casting mold flux for decreasing sticking steel breakouts and preparation method thereof

The invention discloses a continuous-casting mold flux for decreasing sticking steel breakouts and a preparation method thereof. The continuous-casting mold flux for decreasing the sticking steel breakouts comprises the following chemical components of, by weight, 32.5-35.5 percent of SiO2, 29.5-31.5 percent of CaO, 1.5-3.0 percent of MgO, 2.2- 3.0 percent of Al2O3, 0.5-1.5 percent of Fe2O3, 11.0-13.0 percent of Na2O, 10.0-12.0 percent of F-, 3.0-4.0 percent of C solid and the balance unavoidable impurity, wherein the binary basicity is 0.87 to 0.93; a melting point is 1050 to 1070 DEG C; and the viscosity below 1300 DEG C is 0.115Pa*S to 0.135Pa*S. In the practical application of the mold flux, a flame in a crystallizer is uniform; the spreadability is better; caking and agglomerating phenomena do not exist; a melt cinder is stable; the lubrication is sufficient; and the rate of the sticking steel breakouts can be decreased to below 5 percent from original 10 to 20 percent.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

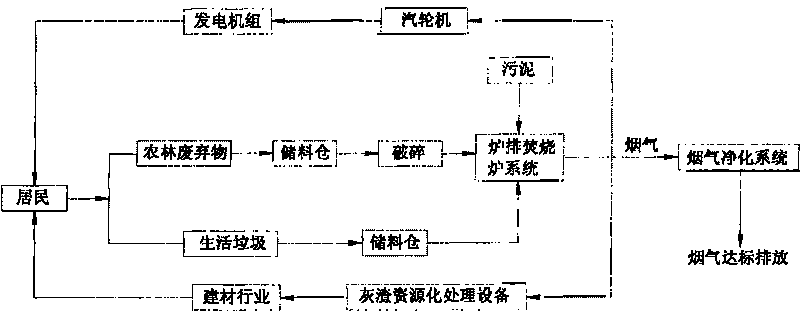

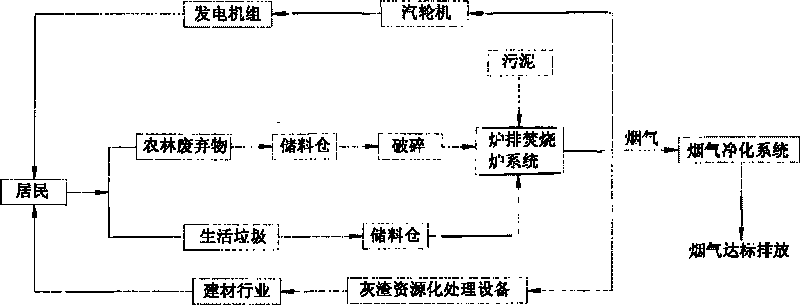

Method for mixed burning of agriculture and forestry waste, sludge and household garbage by using grate furnace

The invention relates to the technical field of energy environmental engineering and provides a method for mixed burning of agriculture and forestry waste, sludge and household garbage by using a grate furnace. The method comprises burning the agriculture and forestry waste, sludge and household garbage in a grate garbage burning furnace, igniting by using agriculture and forestry waste, and adding household garbage and sludge in the furnace to realize mixed burning when the temperature of the furnace rises to 850 DEG C, wherein the mass percent of the agriculture and forestry in the mixed fuel is within 40 percent, the mass percent of sludge in the mixed fuel is within 30 percent, the burning temperature of the grate burning furnace is controlled at 850 to 1000 DEG C, and the smoke gas generated by burning stayed in the furnace is controlled above two seconds. The invention is low in the cost, improves the burning efficiency of the garbage burning furnace, solves the problem of pollution caused by the sludge, ensures that the agriculture and forestry waste can be recycled, reduces discharge of pollutants, particularly heavy metal and dioxin and reduces the consumption of fossil energy.

Owner:SOUTHEAST UNIV

Process for preparing granular biomass fuel by using pig manure and prepared product

InactiveCN102492514AGood deodorizing effectNo pollution in the processBiofuelsSolid fuelsDry weightIgnition point

The invention discloses a process for preparing granular biomass fuel by using pig manure and a prepared product. The process disclosed by the invention comprises the following steps of: (1) mixing raw materials such as the pig manure, biomass powder crumb and high charcoal ash in proportion; and according to the proportion, the final product comprises 60-90% of pig manure, 10-30% of biomass powder crumb and 1-30% of high charcoal ash by dry weight; (2) dehydrating the mixed raw material obtained in the step (1); and (3) pelletizing the raw material dehydrated in the step (2). According to the invention, the biomass powder crumb and the high charcoal ash are added into the pig manure, thus peculiar smell of manure is removed and ignition point of the obtained fuel is reduced.

Owner:FUJIAN LONGYAN LONGNENG FRYASH COMPREHENSIVE UTILIZATION

Chromium-based boiler slag-removing ash-removal coal-saving composition and preparation method thereof

ActiveCN104910996AHigh active specific surface areaHigh hydrogen contentSolid fuelsFuel additivesPetroleumElectric power

The present invention relates to an additive product suitable for coal-fired boilers of electric power, thermal power, petroleum, chemical and metallurgical industries, and particularly relates to a chromium-based boiler slag-removing ash-removal coal-saving composition, and the chromium-based boiler slag-removing ash-removal coal-saving composition consists of the following components in parts by weight: 50 to 65 parts of chromium oxide, 8 to 15 parts of copper oxide, 5 to 9 parts of cerium oxide, 5 to 9 parts of barium molybdate, 7 to 14 parts of cobaltous oxide, 12 to 17 parts of potassium permanganate, 10 to 16 parts of manganese carbonate, 12 to 17 parts of barium carbonate, 8 to 15 parts of titanium dioxide, zinc oxide, 15 to 20 parts of zinc oxide, 6 to 10 parts of potassium chlorate, 6 to 10 parts of potassium perchlorate, 20 to 28 parts of sodium carbonate, 25 to 35 parts of active attapulgite carclazyte and 0.1 to 0.3 part of alkyl glycerol ether sulfonate. The chromium-based boiler slag-removing ash-removal coal-saving composition is an environmentally-friendly product which is efficient in combustion helping, and high in coal saving ratio, can reduce pollution, improve combustion efficiency, and extend the boiler service life, and is convenient to use and stable in performance, and when in use, only the chromium-based boiler slag-removing ash-removal coal-saving composition is added into a fuel to participate in the combustion without equipment transformation.

Owner:GANSU HEIMA PETROCHEM ENG

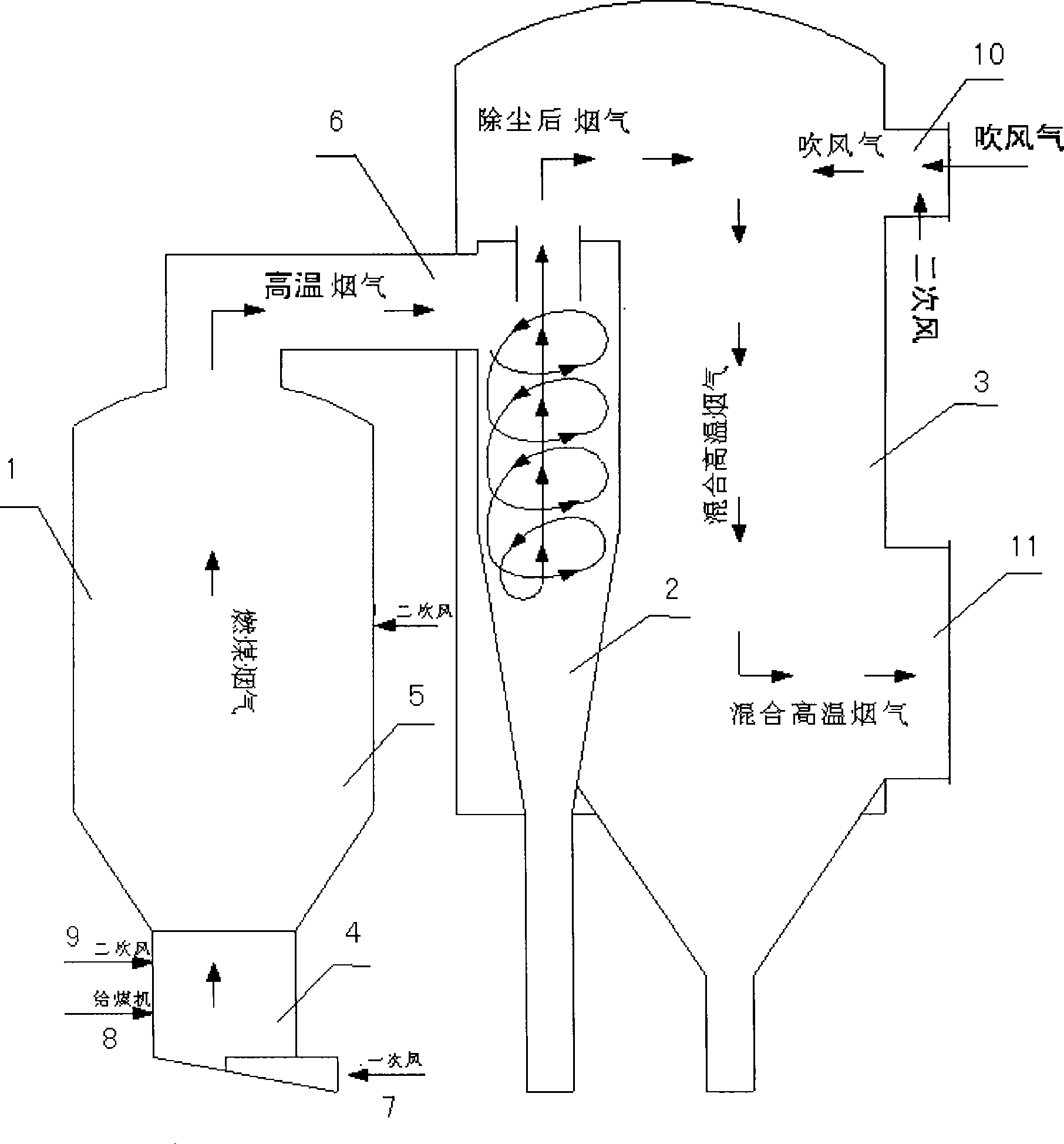

Process and device for reclaiming blown gas made from coal and by oxygen-enriched combustion

InactiveCN101545636ALower ignition pointRaise conditions for fireIndirect carbon-dioxide mitigationIncinerator apparatusAir preheaterFlue gas

The invention relates to a process and a device for reclaiming blown gas made from coal and by oxygen-enriched combustion. The flow of the reclaiming process comprises that: gas making furnace residue and coal ash are sent to the lower part of a fluidized bed furnace through a screw-type coal feeder and subjected to heat exchange through an air preheater, primary air fluidization at the temperature of approximately 120 DEG C and partial combustion reaction; uncombusted portions are continuously combusted in secondary air and generate high-temperature flue gas at the temperature of between 950 and 1,000 DEG C which enters a cyclone dust collector in a blown gas combustion furnace; flue gas subjected to dust collection by the cyclone dust collector is drained into the blown gas combustion furnace from the top of the cyclone dust collector; the blown gas is completely combusted under the action of the secondary air; flue gas reaches the temperature of between 950 and 1,050 DEG C, is drained out from the blown gas combustion furnace and enters a boiler system; and finally flue gas at the temperature of between 130 and 150 DEG C is emptied by chimneys. The device of the reclaiming process comprises the fluidized bed furnace, the blown gas combustion furnace and the cyclone dust collector, wherein a furnace chamber of the fluidized bed furnace is communicated with the cyclone dust collector in the blown gas combustion furnace through a flue; the lower part of the fluidized bed furnace is provided with a primary air and fuel inlet, and the lower part and the middle part of the fluidized bed furnace are provided with a secondary air inlet respectively; the inside of the blown air combustion furnace is provided with the cyclone dust collector; and the upper part of the blown air combustion furnace is provided with a blown gas inlet and the lower part of the blown air combustion furnace is provided with a flue gas outlet pipe.

Owner:杭州东安科技有限公司

Process for preparing activated carbon livestock excrement fuel

InactiveCN102533380AGood deodorizing effectNo pollution in the processBiofuelsSolid fuelsActivated carbonFeces

The invention discloses a process for preparing activated carbon livestock excrement fuel, which comprises the following steps of: (1) mixing and stirring raw materials, wherein on a dry weight basis, the raw materials comprise 60 percent-80 percent of livestock excrement, 10 percent-30 percent of biomass silt-sized grain, and 1 percent-30 percent of activated carbon; (2) dehydrating the raw materials stirred by the step (1); and (3) granulating the raw materials dehydrated by the step (2). The process for preparing the activated carbon livestock excrement fuel has the advantages that: the process is simple, and activated carbon used as a deodorizer can be prepared through flotating or carbonizing pulverized fuel ash.

Owner:FUJIAN LONGYAN LONGNENG FRYASH COMPREHENSIVE UTILIZATION

Carbon nanometer combustion improver and preparation method and preparation device thereof

InactiveCN102304408AIncrease surface temperatureHigh thermal efficiencySolid fuelsPolyvinyl alcoholStearate

The invention relates to an energy-saving and pollution-relieving liquid coal nano combustion improver and a preparation method and a preparation device thereof, and belongs to the field of combusting coal combustion improving additives. The energy-saving and pollution-relieving liquid coal nano combustion improver comprises the following components in percentage by mass: 15 to 23 percent of emulsifier which consists of polyoxyethylenated castor oil and sorbitan tristearate, 18 to 27 percent of penetrating agent which consists of sodium butylnaphthalene sulfonate and sodium diethylhexyl sulfosuccinate, 12 to 20 percent of castor oil serving as an oxidant, 20 to 47 percent of activator which consists of polyvinyl alcohol and beta-methyl acrylic acid and 8 to 10 percent of nano material which consists of TiO2, ZnO, MgO and Fe2O3. When the energy-saving and pollution-relieving liquid coal nano combustion improver is used, a special coal combustion improver spray atomizing system is used to uniformly spray the improver onto coal according to a ratio of 0.04 to 0.06 percent. The coal nano combustion improver prepared by the invention has the advantages of stable performance, convenience for use, as well as capability of improving the combustion efficiency of coal, reasonably improving combustion environment, capturing sulfur, removing nitrates, saving energy and reducing emission.

Owner:临沂盛荣热电有限公司

Resource utilization method of biomass waste

The invention relates to a resource utilization method of biomass waste residues. The method comprises the following steps: biomass waste residues such as bark, wood sawdust, papermaking sludge and waste plastics are mixed with raw coal, the mixture is sent into a circulation fluidized bed coal firing boiler for burning, wherein the weight content of biomass to raw coal dry basis is no more than 30%; wood sawdust with the particle size which is no more than 15mm is directly mixed with raw coal to be sent into the circulation fluidized bed boiler for burning; bark or waste plastics are grinded to particles or plate-shaped particles, the obtained particles are sent into the circulation fluidized bed boiler through an independent conveyer to be mixed with raw coal; and the dewatered papermaking sludge of which water content is less than 80%, is mixed with raw coal and then the mixture is sent into the circulation fluidized bed boiler for burning.

Owner:YONGZHOU XIANGJIANG PAPER CO LTD

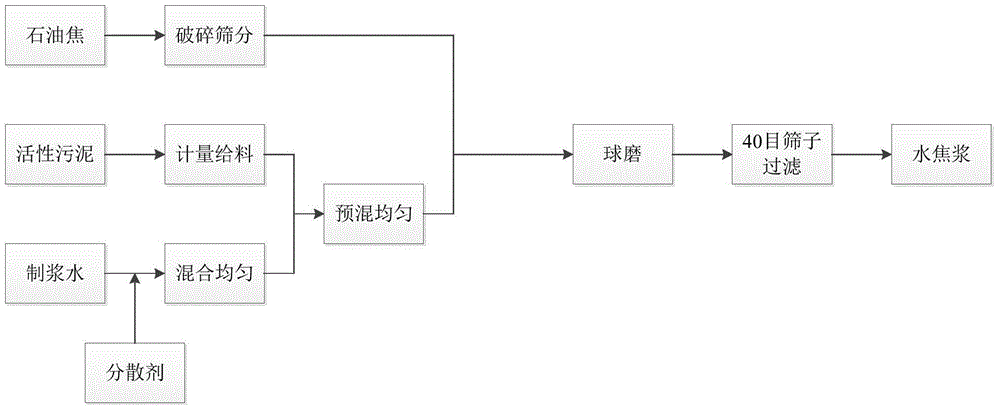

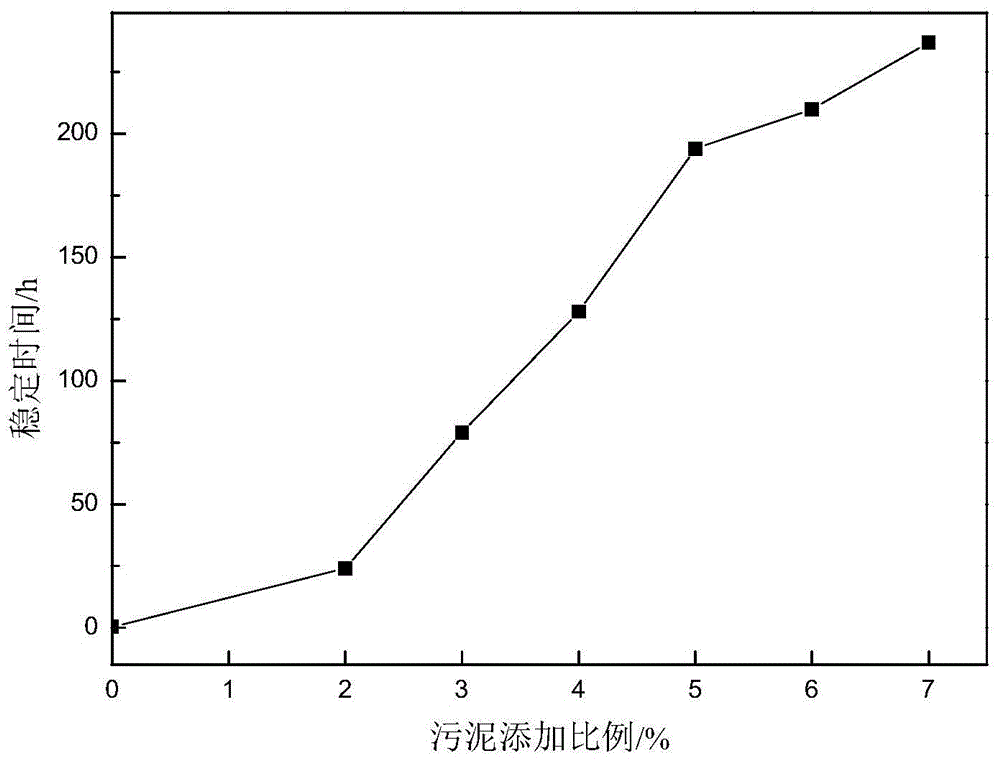

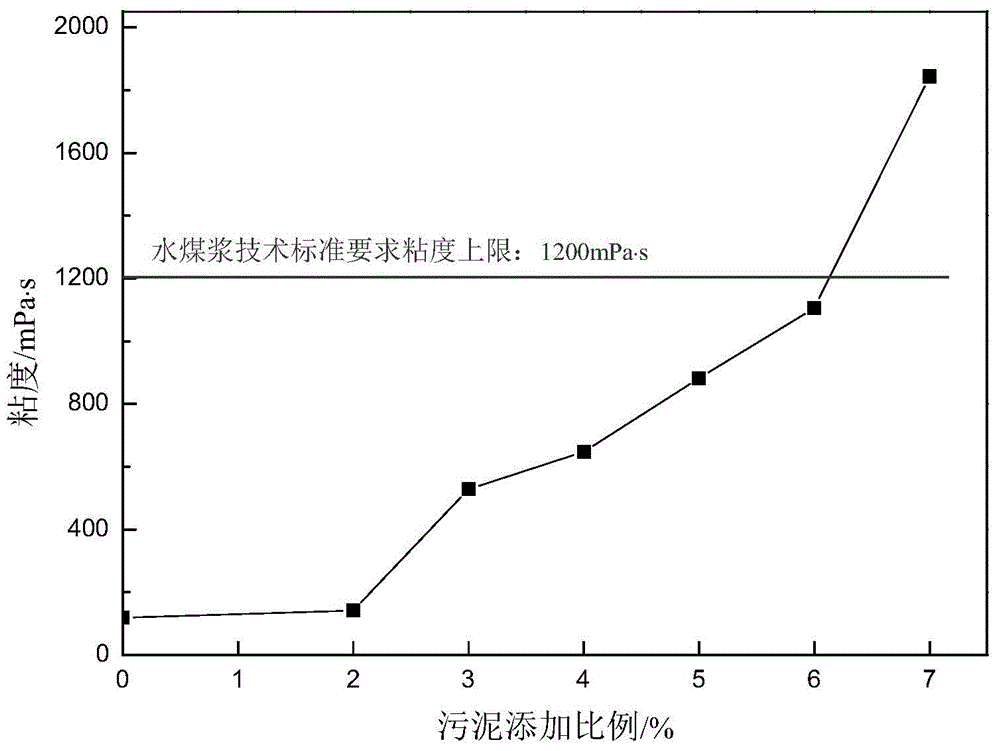

Method for improving stability of water-coke slurry

The invention relates to a method for improving stability of water-coke slurry. The water-coke slurry is prepared from the raw materials, including petroleum coke, activated sludge, water and a dispersing agent. The method comprises the steps of (1) sieving petroleum coke through a sieve, and remaining petroleum coke of which the particle size is less than 0.8mm; (2) dissolving the dispersing agent into water, and uniformly agitating for later use; (3) integrally uniformly mixing the dispersing agent solution obtained in step (2) and activated sludge, pouring into a ball mill tank together with the petroleum coke processed in step (1), wherein the quantity ratio of large balls to small balls in the ball mill tank is 30: 150; a ball mill rotates at the speed of 230 to 380r / min; the ball milling costs 30 to 50 minutes; (4) filtering the slurry obtained by ball milling through a sieve with 40 meshes so as to remove impurities and large particles and obtain water-coke slurry. According to the method, the activated sludge is doped into the water-coke slurry to greatly improve the stability of the water-coke slurry, so that the problem of poor stability of the water-coke slurry can be completely solved; meanwhile, a new treatment way is provided to the activated sludge of a melting plant, and the sludge treatment cost of the melting plant can be reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

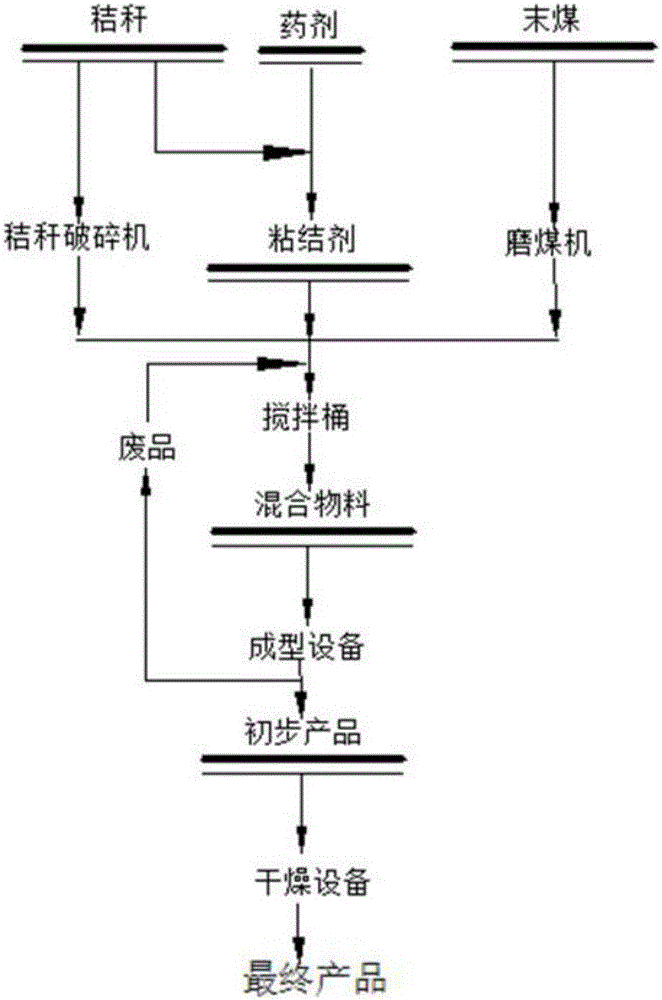

High-efficiency energy-saving solid mixed fuel moulding technology

InactiveCN105695030AWell mixedImprove the extrusion effectBiofuelsSolid fuelsAutomatic controlMass ratio

The invention relates to a high-efficiency energy-saving solid mixed fuel moulding technology applicable to being used in the field of mixed fuel. The high-efficiency energy-saving solid mixed fuel moulding technology comprises the following steps: firstly naturally drying biomass until moisture content is 20%, then crushing and screening by utilizing a scissor-type crushing machine for selecting a part with the granularity of 2-7mm, crushing slack coal until the granularity is 2-3mm by adopting a two-stage crushing and grinding technology, conveying the crushed biomass and slack coal in a mass ratio of 25-30% into a stirring barrel by virtue of a pneumatic conveying pipeline provided with an automatic control device respectively, adding a composite binder in a mass ratio of 10%, uniformly mixing the components in the stirring barrel, then conveying mixture to moulding equipment by utilizing a conveyor belt, adjusting the shape and size according to practical requirements, moulding, screening qualified moulded products, and conveying the qualified moulded products to a packaging opening to be packaged. The whole technology is high-efficiency, energy-saving and high in automation degree. The produced fuel has good combustion activity, low pollutant discharge, high strength and strong applicability.

Owner:CHINA UNIV OF MINING & TECH

Sulfur-fixation, denitration and coke-cleaning additive for coal-fired boiler

InactiveCN107739642AImprove breathabilityAccelerated destructionSolid fuelsEmission standardRare earth

The invention discloses a coal-fired boiler sulfur-fixing, denitrification and coke-clearing additive, which is composed of the following raw materials in parts by weight: 8-20 parts of nano-titanium dioxide; 20-50 parts of natural marble; 1-6 parts of rare earth components; 20-20 parts of nitrate 30 parts; 3-10 parts of plant ash; 5-10 parts of activated carbon; each raw material in said parts by weight is stirred evenly and added to coal powder for further mixing. The invention can effectively reduce coal consumption, reduce sulfur dioxide emission rate and nitrogen oxide emission, and has coke cleaning effect, realize effective sulfur fixation, denitrification and coke cleaning, stable performance, high coal saving rate, high emission reduction rate, simple use and convenient application Advantages, what is more characteristic is that it overcomes the defects of traditional pulverized coal boilers relying on external exhaust pipes to implement flue gas desulfurization and denitrification equipment with large investment and poor results. The invention is combined with the traditional flue gas wet desulfurization and denitrification process, can effectively reduce the desulfurization and denitrification cost of enterprises, and fully complies with the national air pollution emission standards.

Owner:李旺

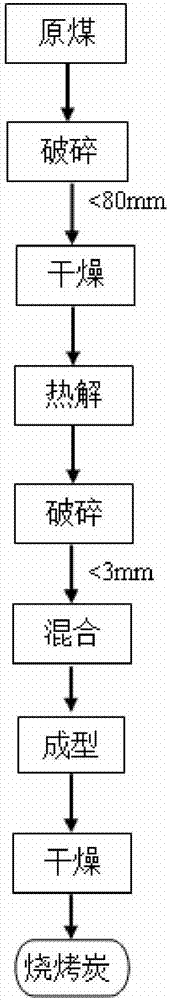

Preparation method of clean lignite-based semicoke barbeque charcoal

InactiveCN107083250ALower ignition pointReduce manufacturing costSolid fuelsSpecial form destructive distillationSulfurCrusher

The invention discloses a preparation method of clean lignite-based semicoke barbeque charcoal, and belongs to the technical field of barbeque charcoal preparation by lignite-based semicoke. The barbeque charcoal is prepared from the lignite-based semicoke, binder and water. Lignite is crushed below 80 mm by crushing, the crushed lignite is subjected to drying in a drying machine and a pyrolitic reaction in a pyrolizing furnace in sequence, the solid lignite semicoke is produced, and after being crushed below 3 mm by a crusher, the lignite semicoke is sent for subsequent blending and stirring; solid semicoke powder, the binder, sulfur fixing agent and the like are subjected to stirring and blending treatment through a blender, and a blended material and the water are sent into an edge mill for grinding and secondary blending for formed mixture preparation; the mixture is conveyed to a forming machine through a conveyor, and barbeque charcoal products in different shapes are prepared through the forming machine; the wet formed barbeque charcoal is conveyed to a mesh-belt dryer for drying treatment. According to the method, the lignite semicoke is adopted as a raw material, so that the ignition point and the production cost of the barbeque charcoal are effectively lowered, which are beneficial to use and popularization of the barbeque charcoal.

Owner:霍林郭勒市嘉华能源技术开发有限公司

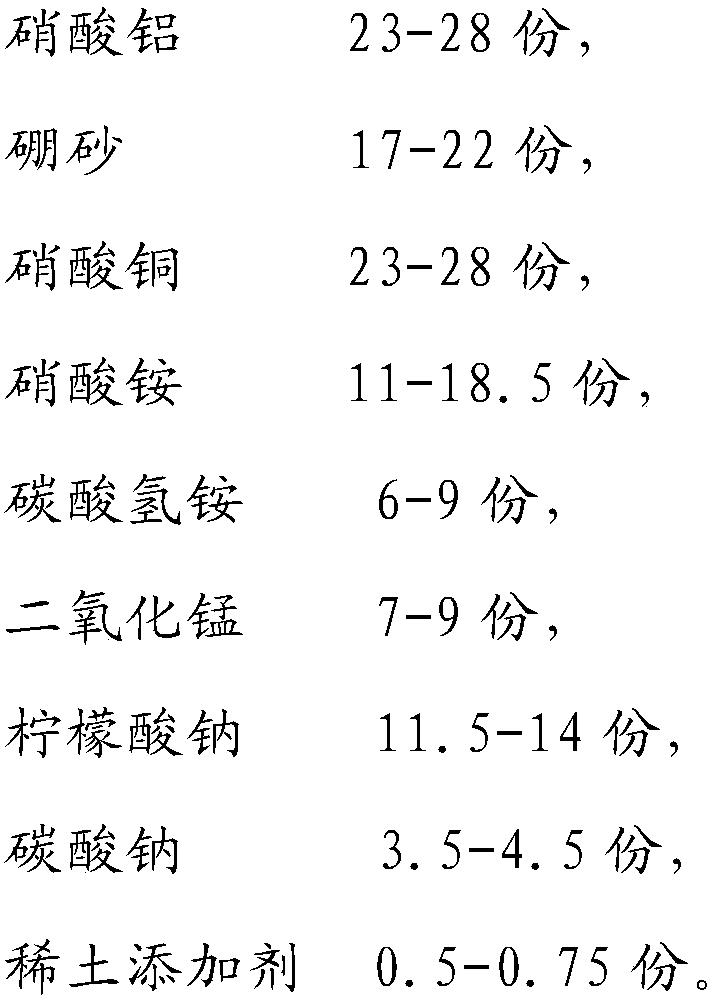

Boiler decoking agent

InactiveCN109679704APromote combustionLower ignition pointSolid fuelsFuel additivesCopper nitrateRare earth

The invention relates to a boiler decoking agent. The boiler decoking agent is prepared from components in parts by weight as follows: 20-30 parts of aluminium nitrate, 15-25 parts of borax, 20-30 parts of copper nitrate, 10-20 parts of ammonium nitrate, 5-10 parts of ammonium bicarbonate, 6-10 parts of manganese dioxide, 10-15 parts of sodium citrate, 3-5 parts of sodium carbonate and 0.15-1 partof a rare earth additive. The boiler decoking agent has the following beneficial effects: pulverized coal combustion is promoted, and coking is reduced. Copper ions generated in the decoking agent can be subjected to a reaction with coal ash, so that ignition point of carbon deposit can be reduced, and pulverized coal combustion can be promoted; meanwhile, it is unexpectedly found that the reaction process is faster in presence of manganese dioxide, and the decoking effect is better under the synergy of manganese dioxide and copper nitrate. Under synergy of sodium citrate and the other components, exhaust gas can be removed and sulfur dioxide can be absorbed in advance in a hearth when sodium citrate is burnt with coal, besides, an absorption process is enhanced by a buffer action of sodium citrate, waste gas containing 500 ppm-5% of sulfur dioxide can be treated, the desulfurization degree is as high as 80%-90%, and the problem of secondary pollution is solved.

Owner:汪保安

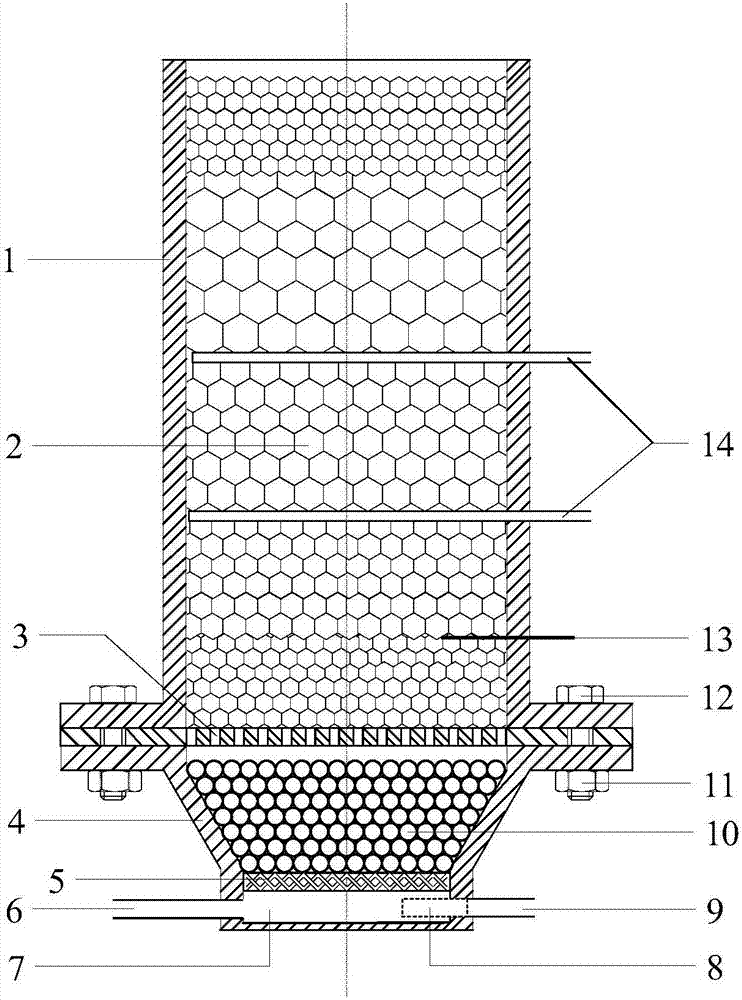

Non-uniform type porous medium combustor processing organic waste gas

PendingCN107023842ALower ignition pointLower emission levelsIncinerator apparatusCombustion chamberCombustor

The invention discloses a non-uniform type porous medium combustor processing organic waste gas. The non-uniform type porous medium combustor processing the organic waste gas is sequentially provided with a premixing chamber, a mixing chamber, a gas uniform distributor and a combustion chamber from bottom to top. An organic waste gas pipeline, an air pipeline and an oxygen pipeline are arranged in the pre-mixing chamber. The combustion chamber is filled with a porous medium of a non-uniform type honeycomb structure. The non-uniform type honeycomb structure comprises a lower layer, a middle layer and an upper layer. The middle layer is a combustion area. The pore diameter of the lower layer and the pore diameter of the upper layer are smaller that of the middle layer. From bottom to top, the pore diameter and the porosity of the middle layer are gradually increased. The intersection portion of the lower layer and the middle layer is provided with a heating wire igniter. The non-uniform type porous medium combustor processing the organic waste gas solves the problems that in the prior art, in the organic waste gas combustion processing process, combustion is not stable, the combustion temperature is high, and secondary pollutants such as nitric oxides are prone to generation.

Owner:SHANDONG UNIV

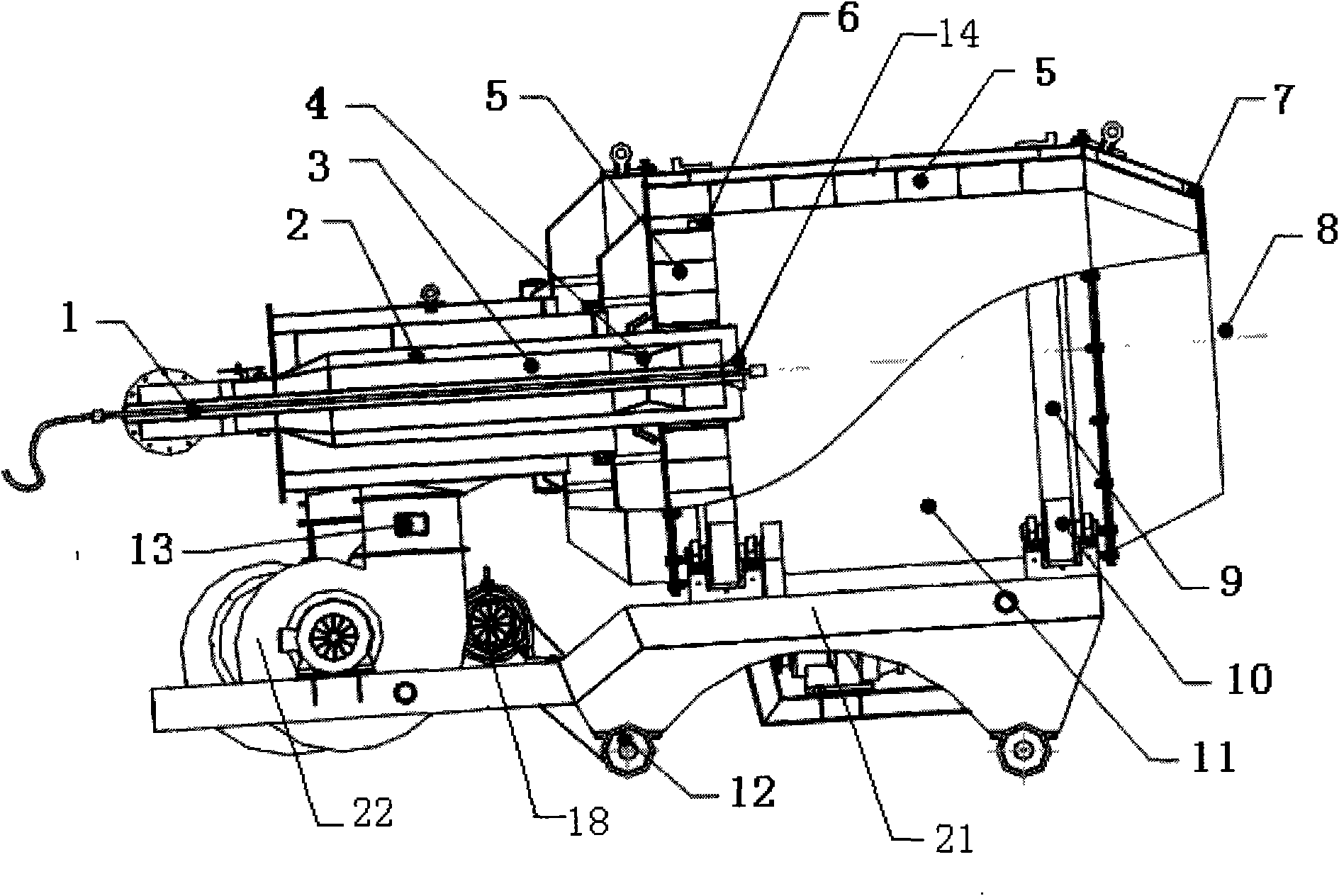

Multifunction coal dust combustor

InactiveCN101650027AFully stable combustionEasy to burnPulverulent fuel combustion burnersAutomatic controlCombustion chamber

The invention discloses a multifunction coal dust combustor of the technical field of road construction and maintenance machinery, comprising a traveling chassis, a combustion furnace, an air and coaldust regulating mechanism, a drive mechanism, a blower, an automatic ignition device and an electric control system, wherein the air and coal dust regulating mechanism consists of an electromotion air valve, a pipeline, a flap valve and a Venturi pipe; an air outlet is connected with the combustion furnace; the pipeline comprises an automatic ignition device channel, a dense coal dust channel, athin coal dust channel, a secondary air channel and a third air channel which are arranged in sequence from inside to outside; the outlet end of the dense coal dust channel is connected with the Venturi pipe; the outlet of the Venturi pipe is provided with a bluff body; and the flap valve is arranged on the inlet ends of the dense coal dust channel and the thin coal dust channel. The multifunctioncoal dust combustor has high degree of automation, sufficient combustion and high efficiency, thereby lowering demands on coal quality, and long service life and can realize the functions of automatic rotation of a combustion chamber, automatic travel of the whole combustor, automatic ignition, air oil automatic regulation and temperature automatic control.

Owner:HENAN ROADY ROAD MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com