Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Good slag blocking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for casting thick and large nodular cast iron valve plate

The invention provides a process for casting a thick and large nodular cast iron valve plate. The process comprises the following steps of: (1) manufacturing a mould; (2) manufacturing a casting mould and a sand core; (3) drying and integrating; (4) smelting; (5) pouring; and (6) shaking out and cleaning. In the process, a large number of external chilling blocks and sand separation chilling blocks are used on upper and lower surfaces of a casting for chilling, appropriate placing positions and thickness are selected, and shrinkage cavity and shrinkage porosity of the casting are effectively avoided; meanwhile, a good graphite balling state is ensured by quickly chilling, a feeding head is avoided, the casting is easy to clean, 5 percent of molten iron using amount is saved, and production cost is reduced; a semi-closed casting system is adopted by a casting system, an ingate is uniformly distributed around the casting mould, and the casting mould is slightly scoured, and a good residue stopping effect is achieved; and under the action of chilling of chilling blocks, the thick and large nodular cast iron casting which is smelted by a cupola furnace is good in moulded surface, and meets production requirements, offscourings and sand are avoided, and process yield is improved by 5.9 percent.

Owner:TIJIN YIJI MACHINERY

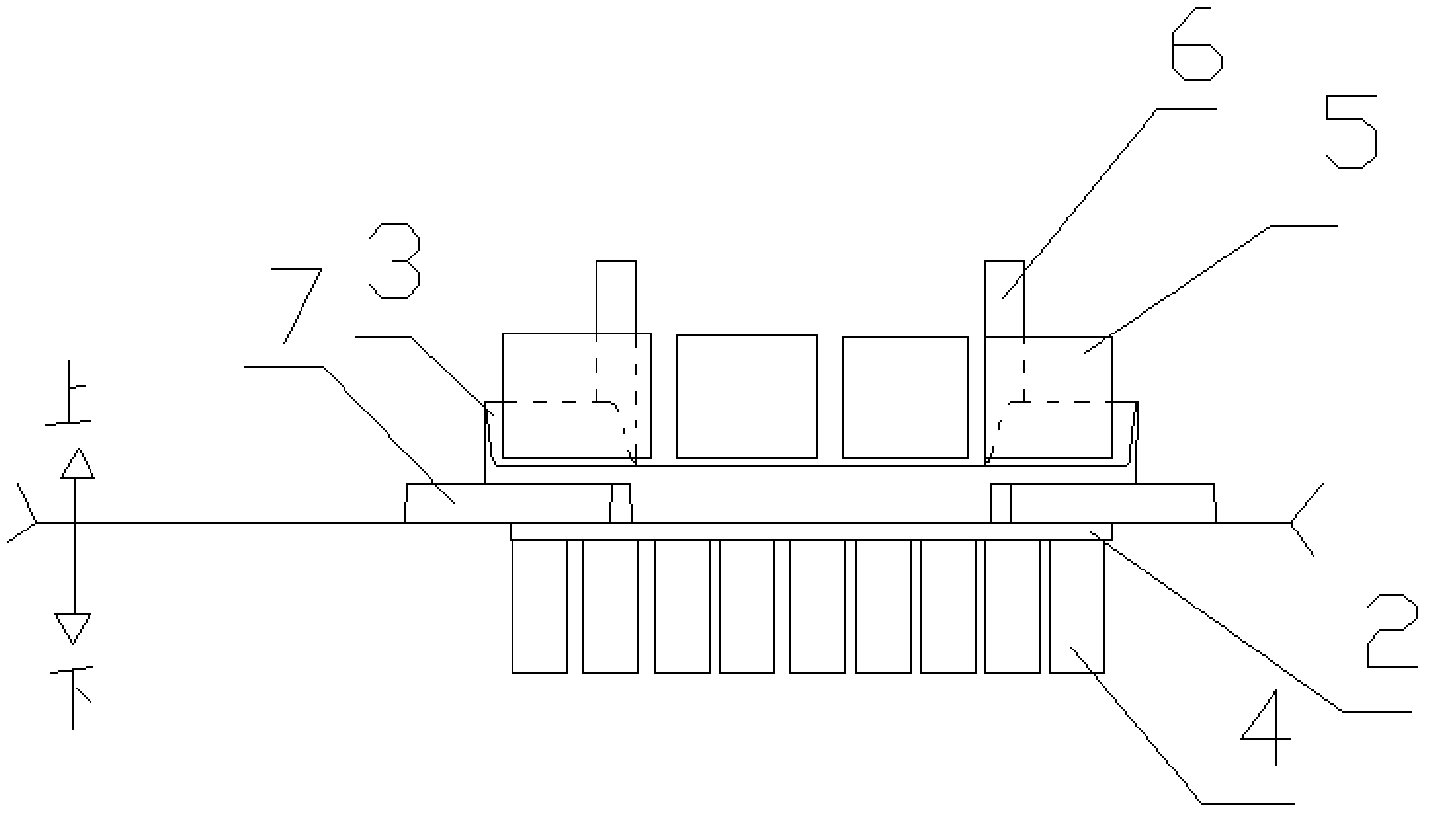

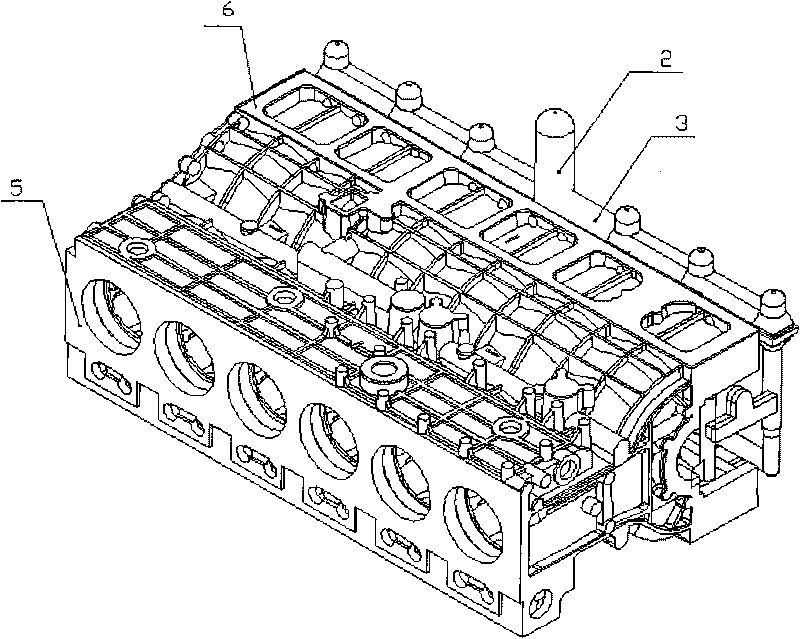

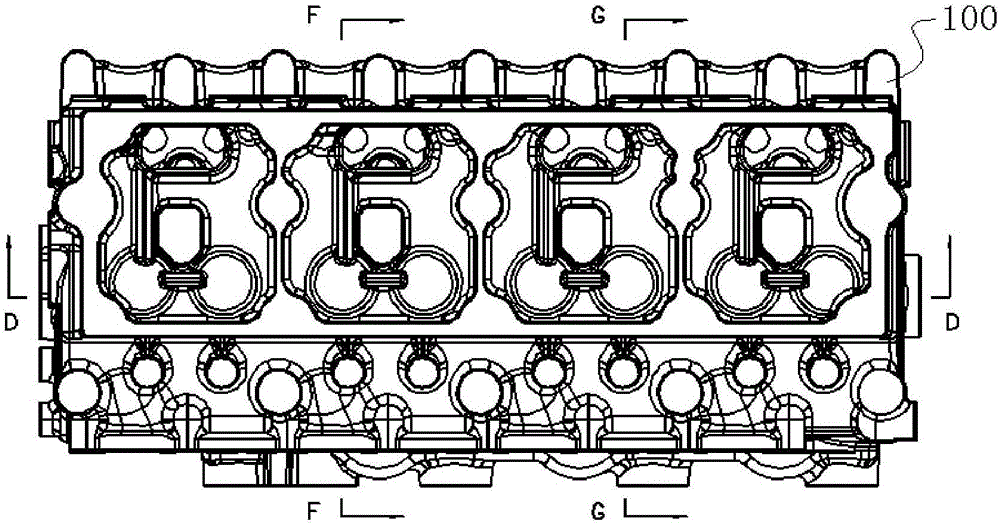

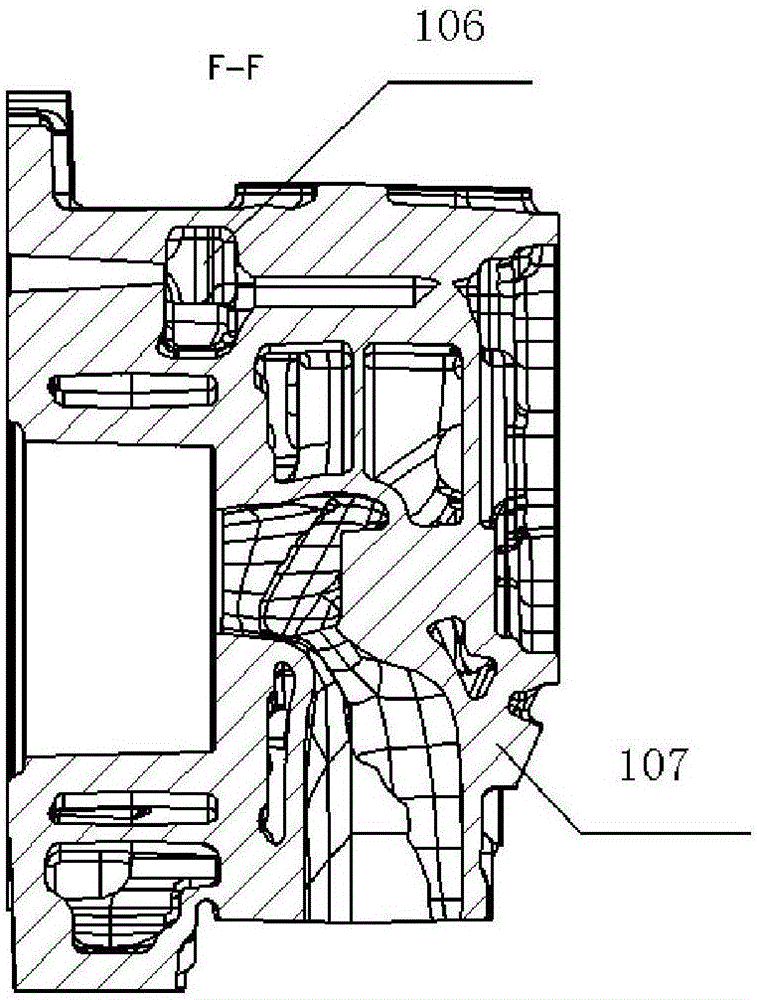

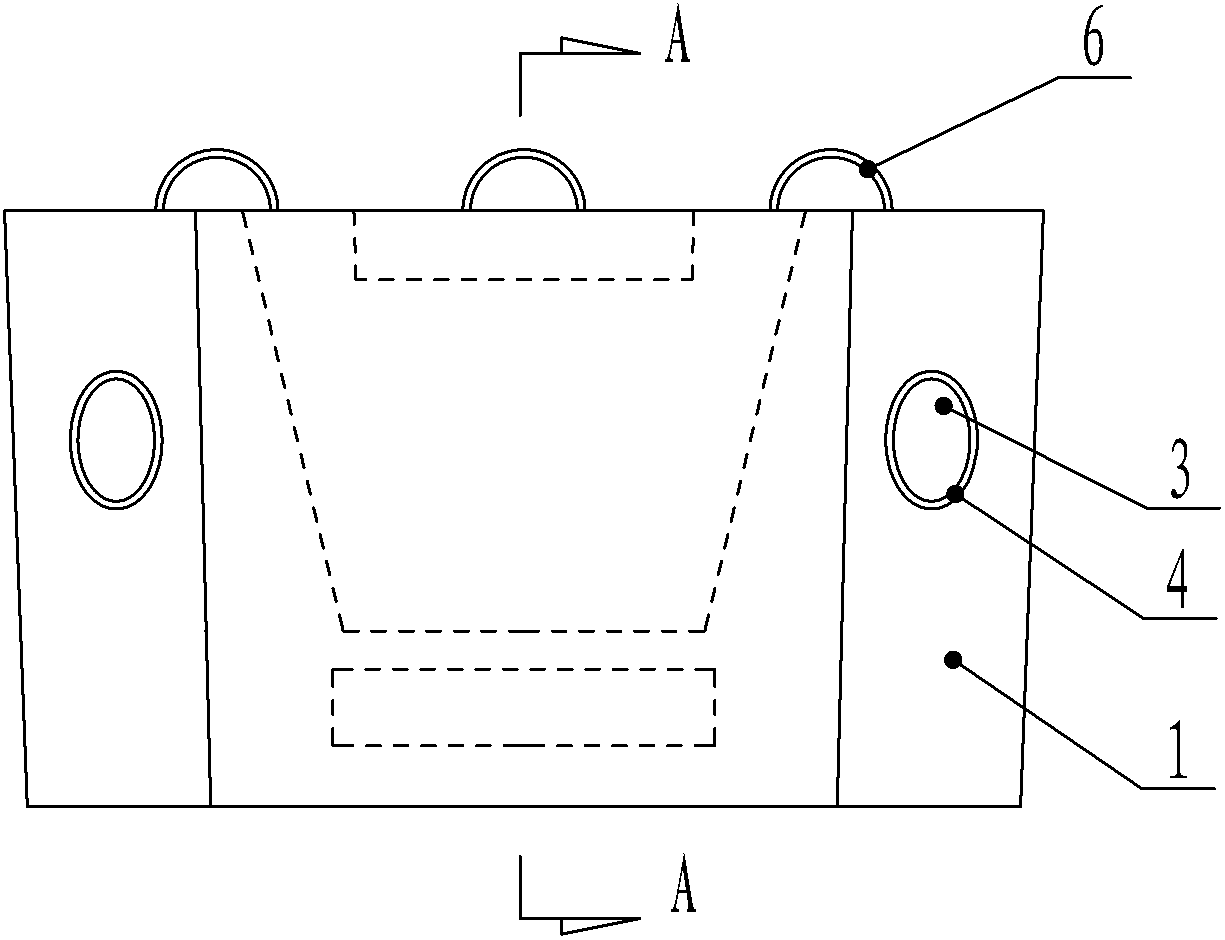

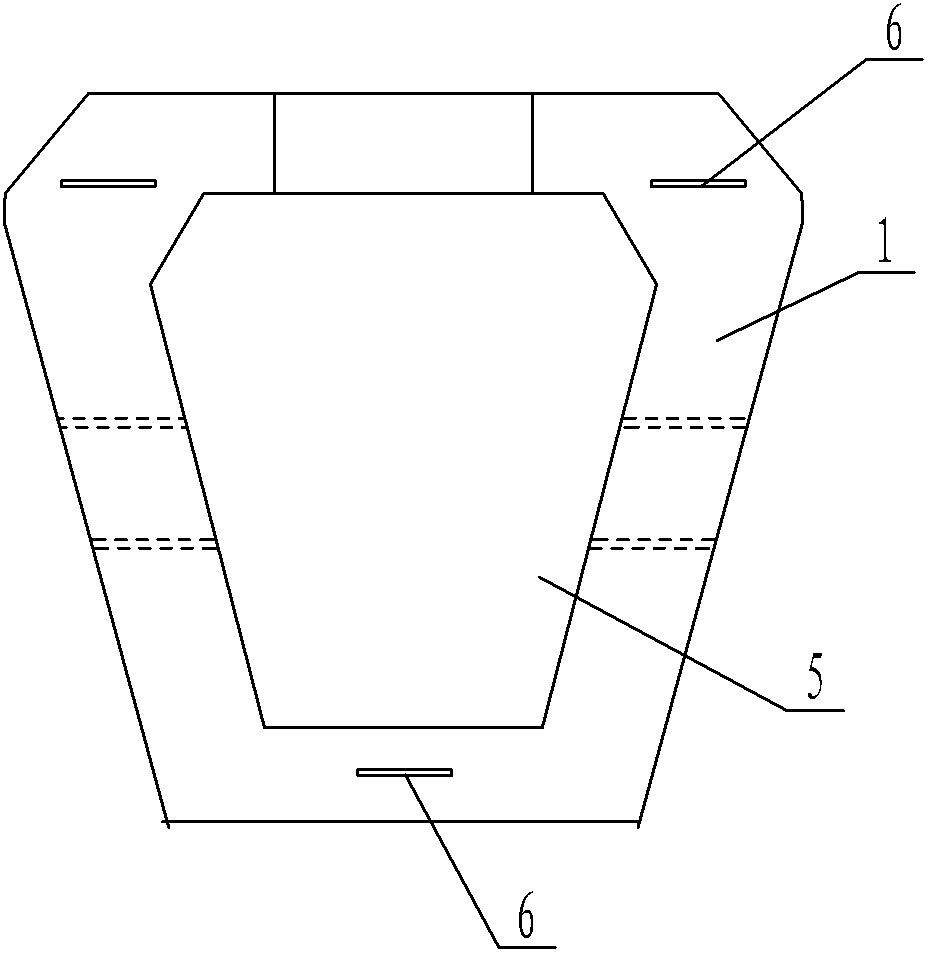

Casting method of large-scale high pressure resisting multi-cylinder-block cast

ActiveCN102699282AControl temperature distributionUniform temperature distributionFoundry mouldsFoundry coresSlagHigh pressure

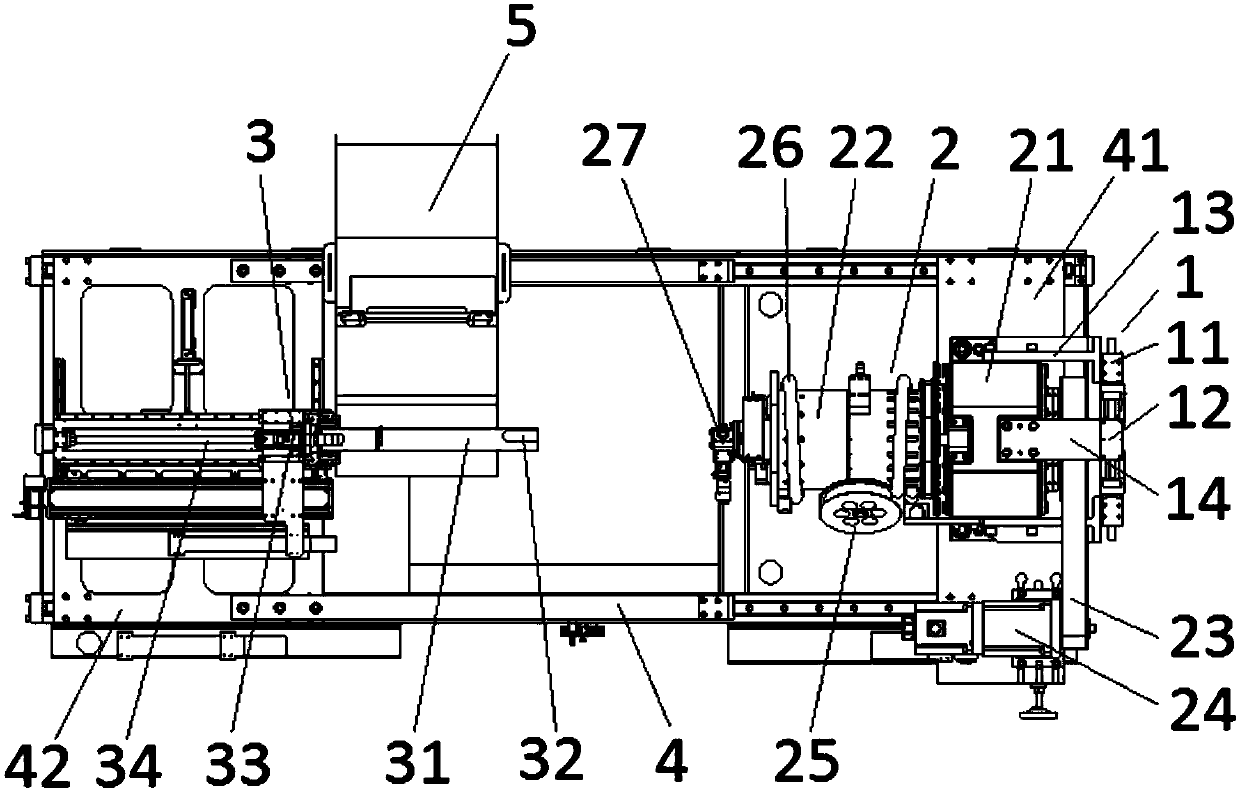

The invention relates to a casting method of large-scale high pressure resisting multi-cylinder-block cast. The method includes the following steps: (1) mold making, (2) sand mold making, and (3) casting molding: during the sand mold making of the step (2), a sprue is designed into a first sprue (1) and a second sprue (3), a cross gate is designed into a first cross gate (2) and a second cross gate (4), and an ingate (5) is designed into a plurality of parallel pouring gates. Cross section area of all pouring gates is set as the following relation: the cross section area of the first sprue (1) is larger than that of the first cross gate (2), the cross section area of the first cross gate (2) is smaller than that of the second sprue (3), the cross section area of the second sprue (3) is larger than that of the second cross gate (4), and the cross section area of the second cross gate (4) is smaller than that of the ingate (5). The casting method overcomes the defects that shrinkage cavities, shrinkage porosities, slag inclusion and the like do not exist in the cast and can meet quality requirements that cylinder holes can be used as cylinder inner walls after the cylinder holes are machined.

Owner:RIYUE HEAVY IND

Cylinder block casting device and method

InactiveCN101733363ALiquid surface activePrevent floatingFoundry mouldsFoundry coresSlagCasting mold

The invention discloses a cylinder block casting device and a method, wherein the device comprises a cylinder block casting mold and a cylinder block casting; the cylinder block casting consists of a pouring gate, a sorue, a cross gate, an ingate and a cavity; and the cylinder block casting is horizontally arranged on the cylinder block casting mold when the cylinder top surface of the cylinder block faces downwards and the machine leg surface of the cylinder block faces upwards. The method comprises the following steps: by using the above cylinder block casting device, the casting liquid is injected into the cylinder block casting device from the pouring gate of the cylinder casting, flows through the sorue, the cross gate and the ingate in sequence and flows in the cavity of the cylinder block casting to complete the casting of the cylinder block. The device and the method in the invention can overcome the defects of poor effects of exhaust and slag dam, low casting yield, easily-damaged bland, uneven wall thickness and the like so as to realize the purposes of good effects of exhaust and slag dam, high casting yield, difficult damaged blank, even wall thickness and high product quality.

Owner:GUANGXI YUCHAI MASCH CO LTD

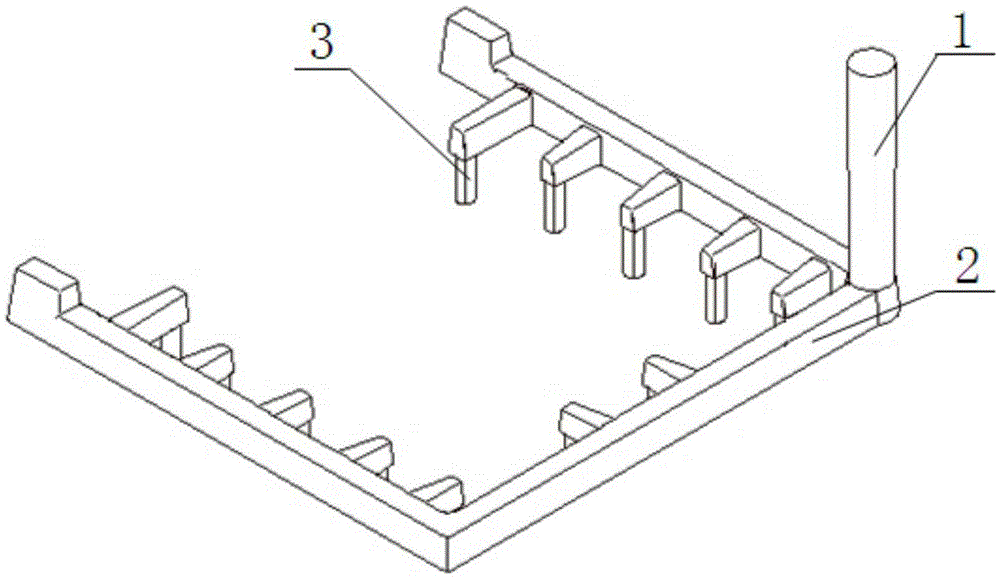

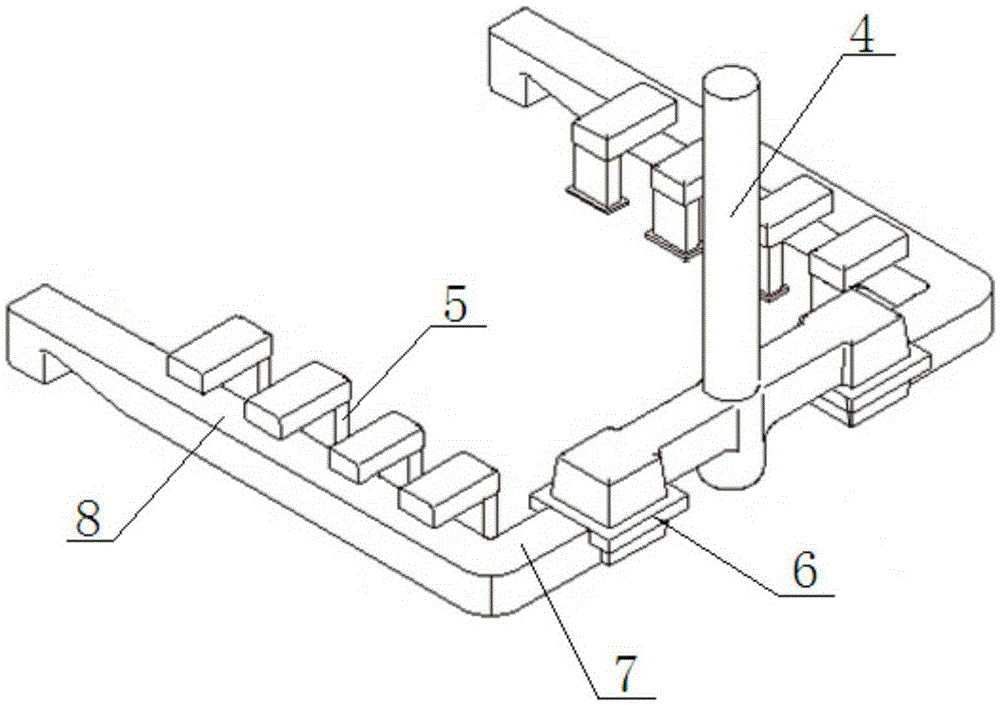

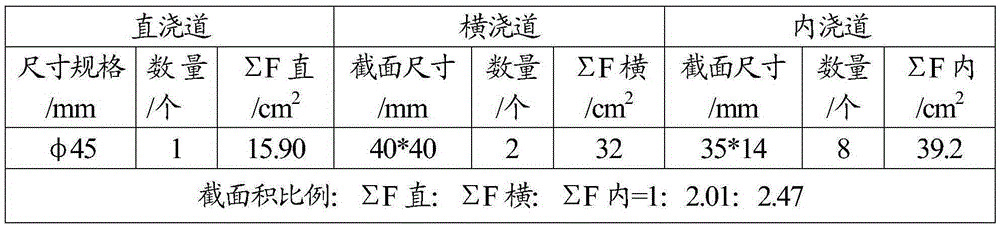

Open type top shower gating system for air cylinder cover

InactiveCN105328127AReduce inflow velocityPrevent splashFoundry mouldsFoundry coresSlagGreek letter sigma

The invention discloses an open type top shower gating system for an air cylinder cover. The system comprises a sprue, at least one cross gate and at least one ingate, wherein one end of the cross gate communicates with the sprue while the other end of the cross gate communicates with the ingate; the sectional area ratio of the sprue to the cross gate to the ingate is that sigma F (sprue): sigma F (cross gate): sigma F (ingate)=1: (1.5-2.5): (2-3); a filter screen is arranged in the cross gate. With the adoption of the system, a produced casting is stable in quality, the rejection rate caused by cold shut, sand inclusion, slag inclusion and other defects can be greatly decreased, and moreover, the production cost can be decreased.

Owner:四川共享铸造有限公司

Process for manufacturing saloon car clutch pressure plate casting

The invention provides an optimized process for manufacturing a saloon car clutch pressure plate casting on a vertical modeling production line. The process comprises the following steps of mulling sand, modeling, melting burden, inoculating iron, pouring, cooling, opening case and clearing casting, wherein in the modeling step, two and more raw castings are horizontally and asymmetrically arranged; a pouring iron liquid enters into a straight pouring channel through a pouring cup and an upper cross channel; and the straight pouring channel enters into a lower cross channel by passing through the middle of a casting cavity and then asymmetrically enters into the cavity from the lower side of the cavity. The pressure plate casting produced by using the process of the invention has a single-cast coupon tensile strength equal to or more than 250 MPa, a casting body tensile strength equal to or more than 200 MPa and the casting body hardness from 170 to 241HBS. The product metallographic structure mainly uses the A type graphite; the length of the graphite is 4 to 6 level; the matrix contains more than 95% of small pearlites and less ferrites; and all the parts of the casting have no casting flaw and meet the technical requirements of the saloon car clutch pressure plate casting.

Owner:上海华新合金有限公司

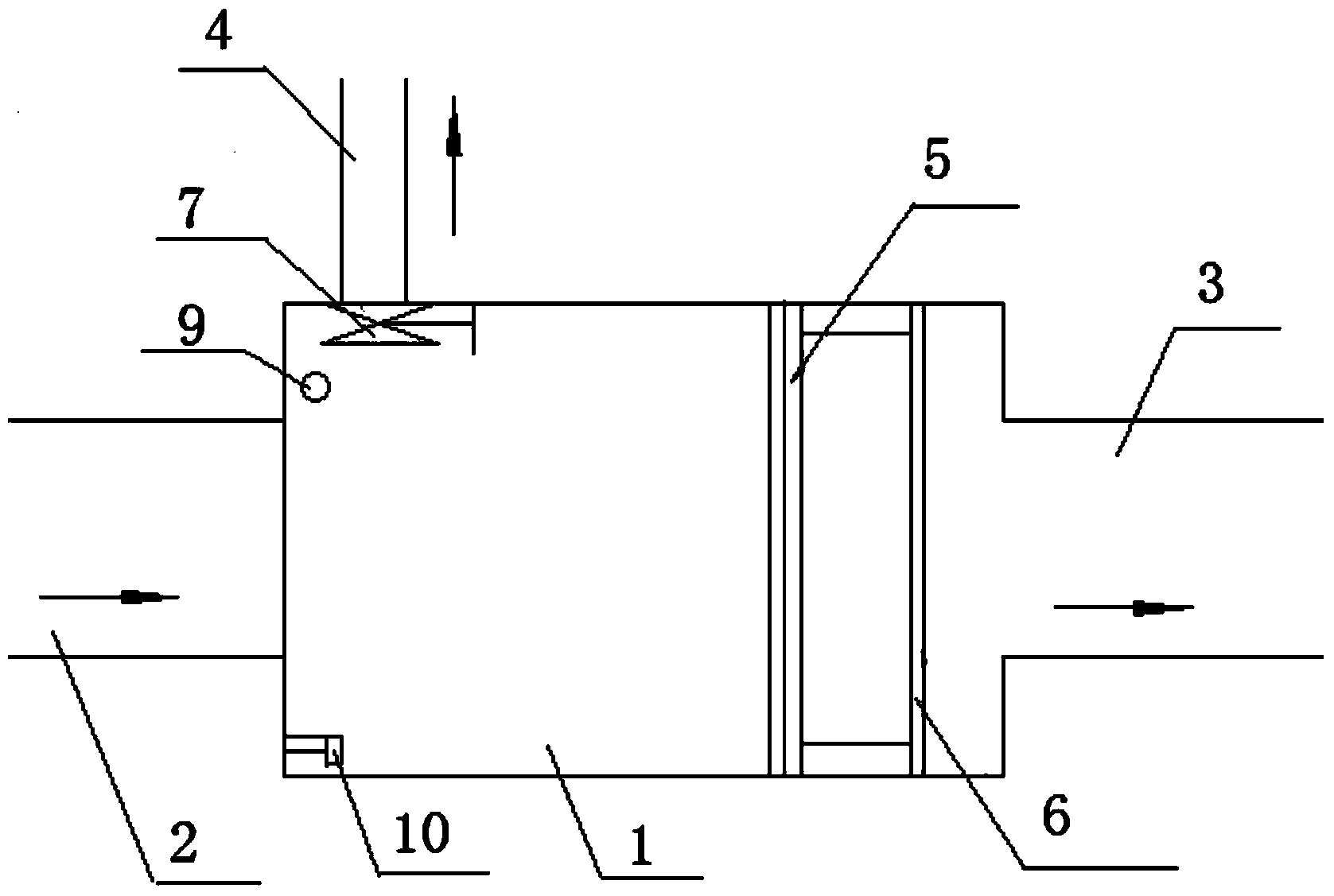

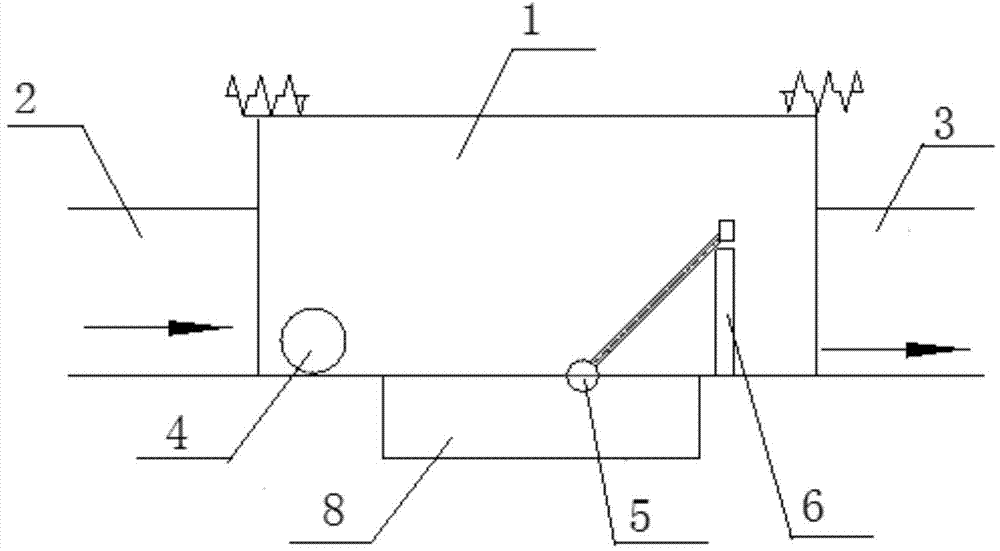

Combined system pipe network intercepting well system and control method thereof

ActiveCN103850327ARealize precise shut-offAccurate shut-offFatty/oily/floating substances removal devicesSewerage structuresSlagSewage

The invention discloses a combined system pipe network intercepting well system and a control method thereof. The system comprises a well body and a control unit, wherein an early rain overflow weir, a slag stop pontoon and a multi-stage adjustable overflow plate are arranged on a flow channel of the well body from left to right in sequence; a sewage intercepting pipe is arranged on the bottom part of the side wall of the well body between a rain and sewage combined water inlet pipe and the early rain overflow weir; an early rain intercepting pipe is arranged on the bottom part of the side wall of the well body between the early rain overflow weir and the multi-stage adjustable overflow plate; an electric intercepting check valve is arranged on each of the sewage intercepting pipe and the early rain intercepting pipe; a liquid sensor is arranged in the well body on the left side of the early rain overflow weir; a rainfall sensor is arranged out of the well body. According to the control method, the early rain range is exactly defined from the perspective of early rainwater runoff volume; the control unit controls the opening and the closing of the electric intercepting check valves on the sewage intercepting pipe and the early rain intercepting pipe by utilizing a liquid level signal and a rainfall signal, so that precise intercepting of early rain is effectively realized in a combined system pipe network intercepting well.

Owner:WUHAN SHENGYU DRAINING SYST

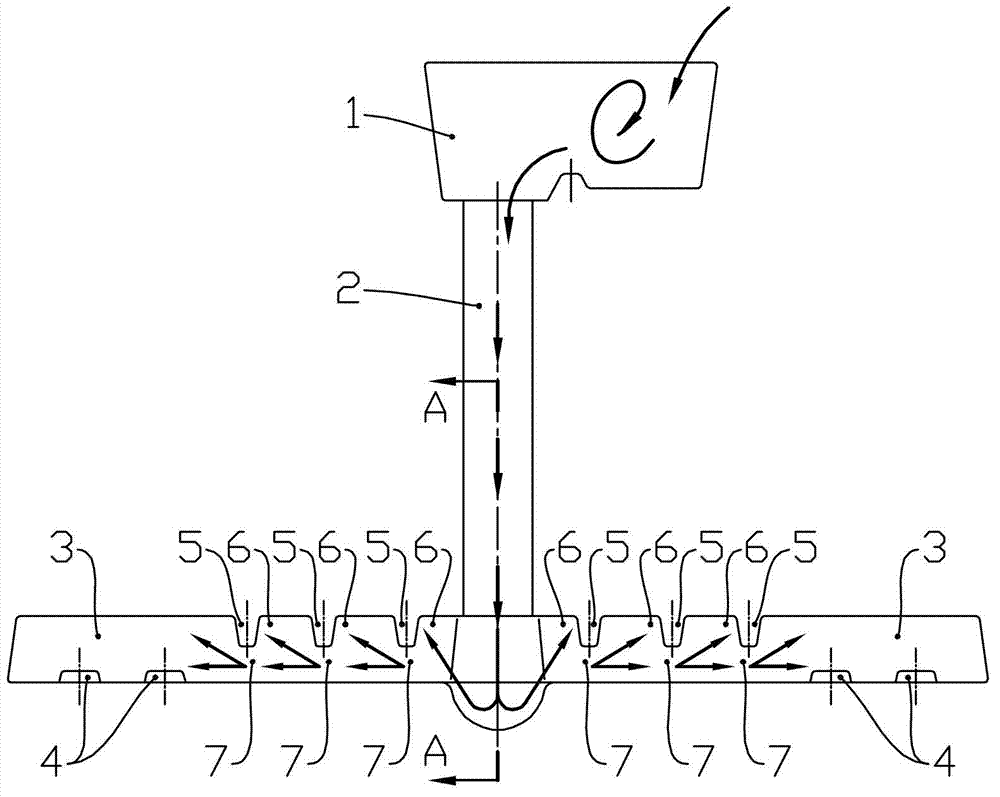

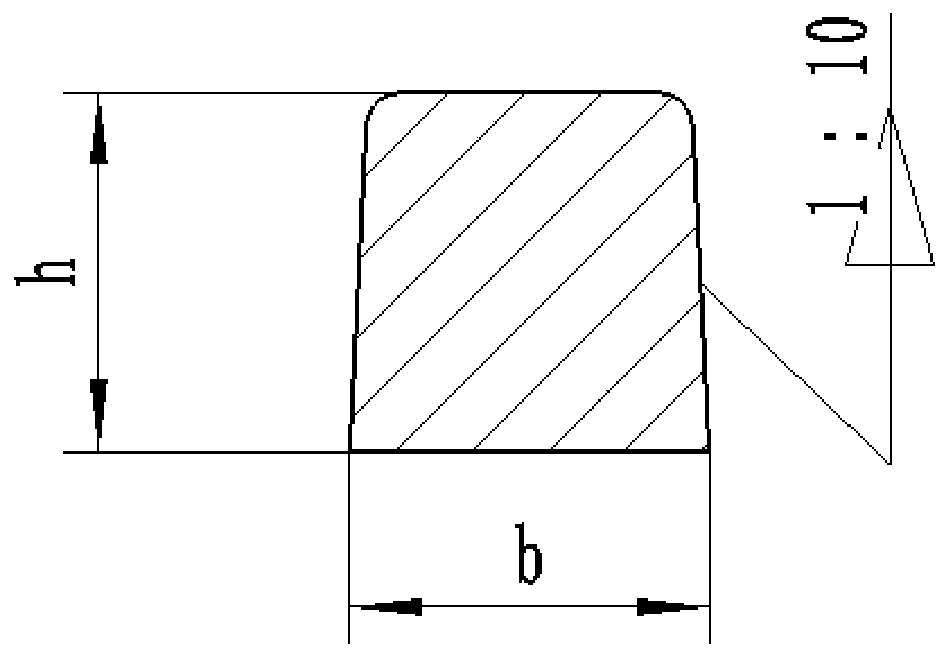

Casting method of tabular spheroidal iron piece and casting system thereof

InactiveCN101301681AReasonable structureSimple structureMolten metal conveying equipmentsCompensation effectSlag

The invention discloses a pouring method and a pouring system used for a plate-shaped ball iron casting. The method adopts a sand casting technique; the pouring system comprises a sprue cup, a sprue, a horizontal runner and a plurality of plate-shaped castings; the method adopts a type that the large plane of the plate-shaped casting is vertically arranged in parallel; the horizontal runner and the plate-shaped casting form a narrow seam edge gate so as to lead the molten steel to flow in along the wall and be stably filled from bottom to top during the pouring process. When the method and the pouring system of the invention are adopted, the molten steel is filled along the wall during the pouring process and the metal is sequentially solidified from bottom to top, thus ensuring the uniformity and consistency of the metallographic structure of the plate-shaped ball iron casting; furthermore, by the narrow seam edge gate, the pouring time is prolonged, the shrinkage compensation effect is provided during the pouring process, furthermore, the slag retaining effect is good and the defects such as slag inclusion, sand inclusion, etc. are avoided; the plate-shaped ball iron casting pouring system of the invention has reasonable and simple structure, saves the metal and has high process yield; furthermore, the pouring system is convenient to be removed; the casting adopts serial pouring, thus having small land occupying and high production efficiency.

Owner:鑫工艺(上海)材料科技有限公司

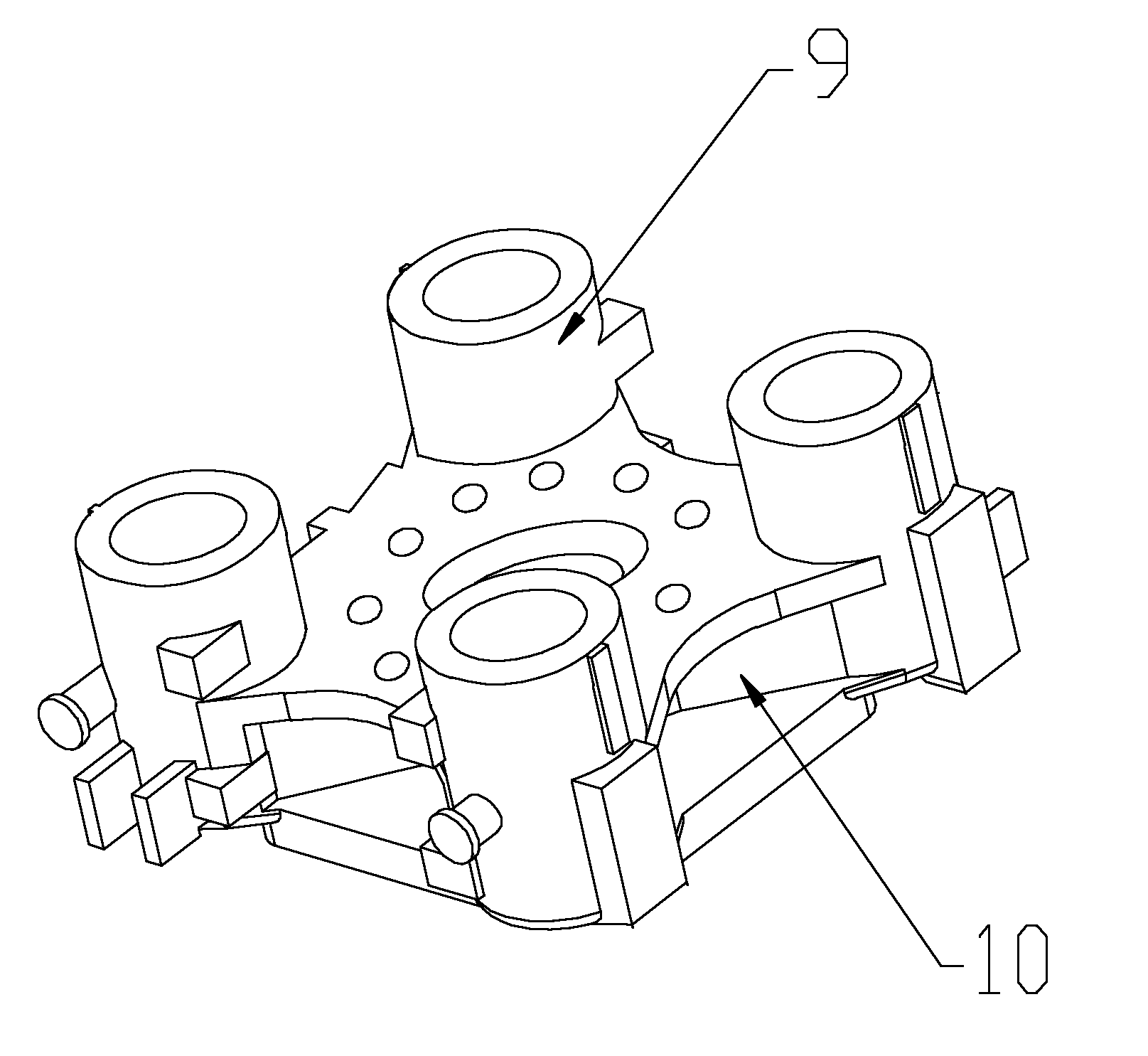

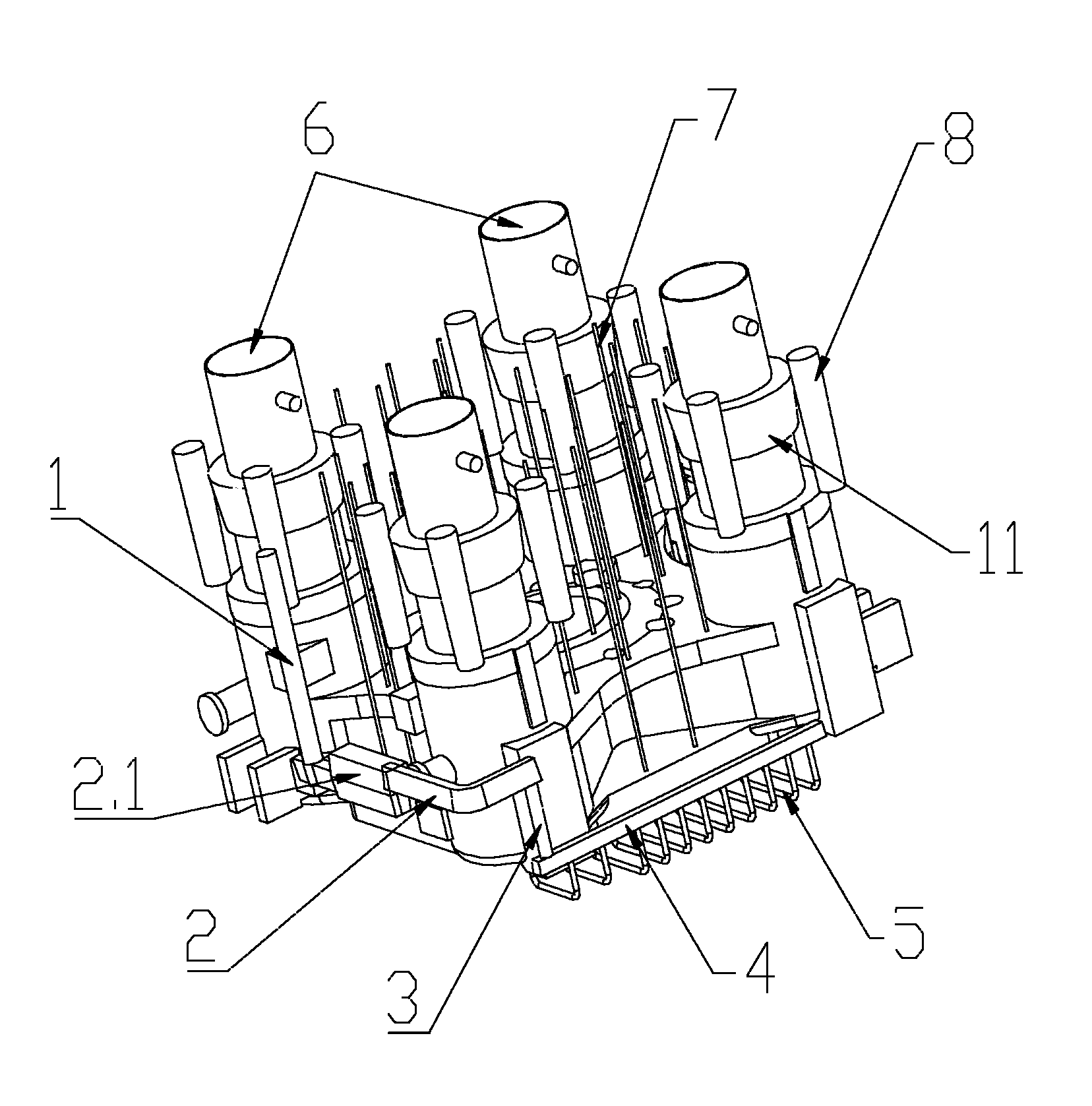

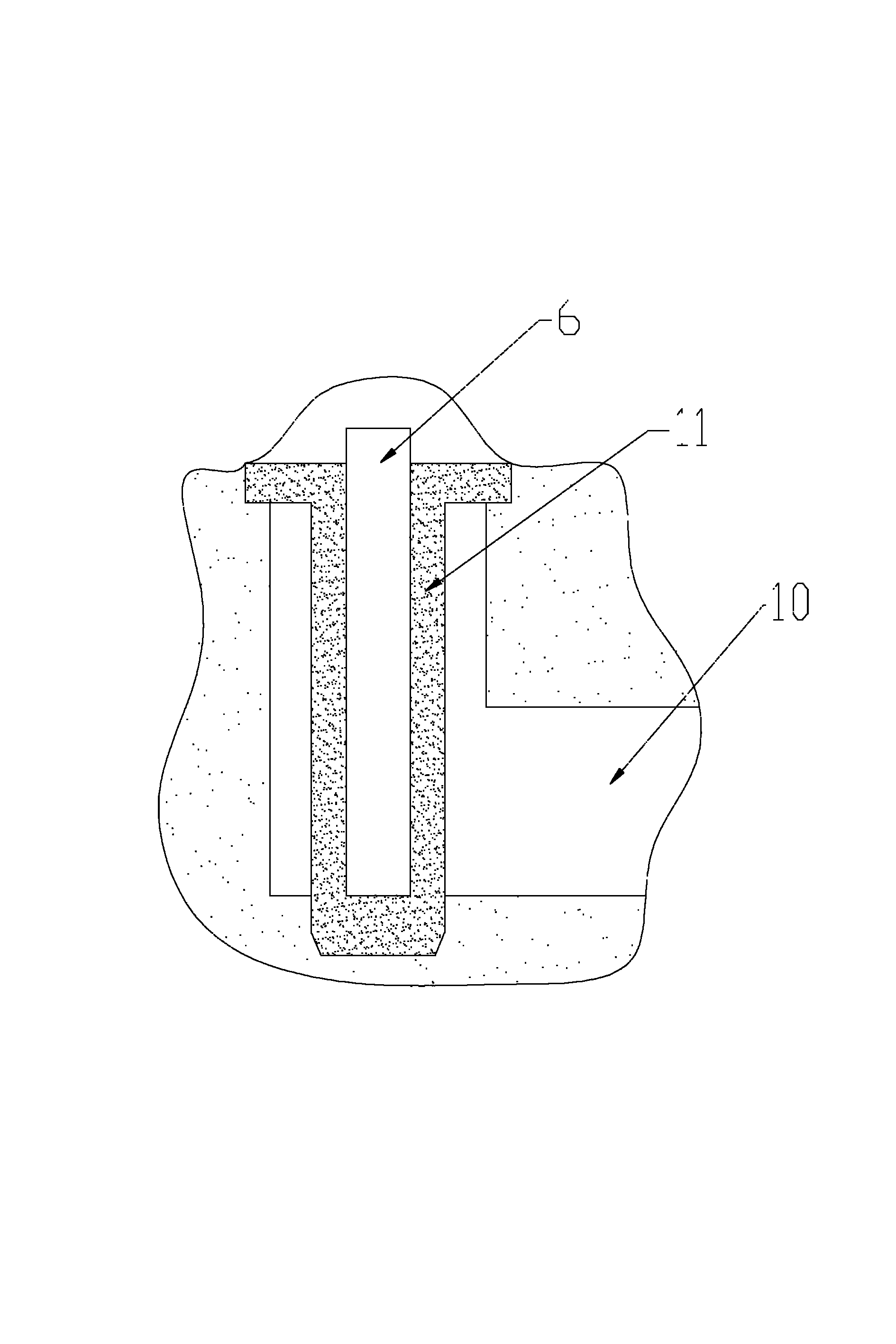

Composite casting system of crank shaft box

InactiveCN102873278AEasy to manufactureImprove production efficiencyFoundry mouldsFoundry coresSlagCrankshaft

The invention discloses a composite casting system of a crank shaft box. The composite casting system comprises a base plate core, a jacket core, a main core, an end face core, an outer cast core and a pouring system. The base plate core, the jacket core, the main core and the pouring system are sequentially overlapped from the bottom layer to the high layer to form a crank shaft box sand mould structure. The pouring system comprises two rows of pouring openings evenly arranged and gates located outside the two rows of pouring openings. The two rows of pouring openings are communicated with a pouring opening cup through a flow division pouring gate and a pouring gate cup. The gates comprise hole-shaped gates located at four corners and strip gates located between the hole-shaped gates and outside the two rows of pouring gates. The composite casting system adopts a rain type pouring system in the middle of a cast piece to conduct liquid feeding pouring from a plurality of positions of a shaft seat and reduces impact of pouring to casts, floating impurities cannot be easily adhered to the cast wall or the cast core, and the pouring system is good in slag blocking effect. The main core is arranged on the upper portion of a sand mould and on the shaft seat, and the two strip gates and the four hole-shaped gates are utilized to discharge air completely. The composite casting system does not require core drying and is stable in cast piece pouring.

Owner:SICHUAN XIANGYE MASCH CASTING CO LTD

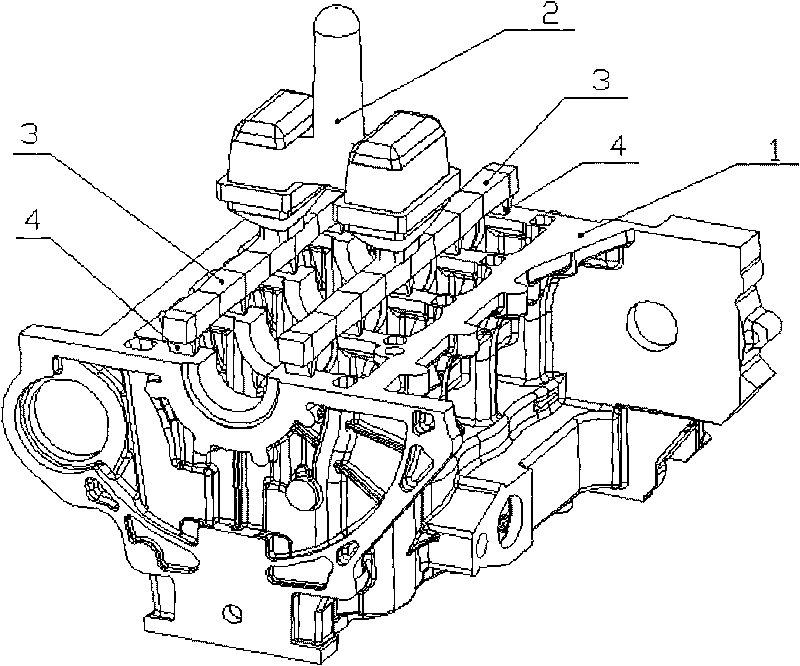

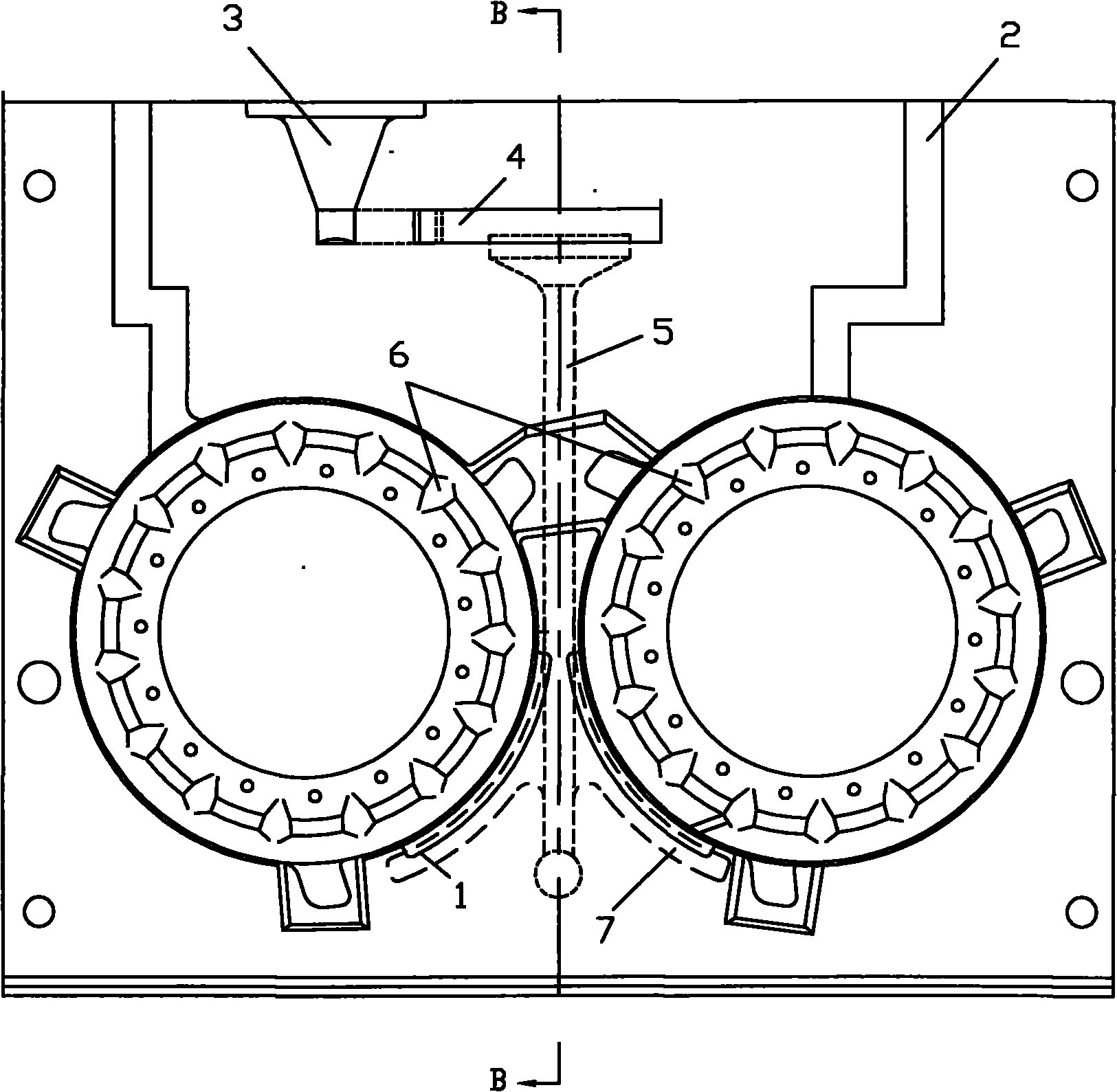

Pouring device for casting integrated composite air cylinder cover

ActiveCN106180572AUniform wall thicknessStable and even fillingFoundry mouldsFoundry coresSlagPulp and paper industry

The invention discloses a pouring device for casting an integrated composite air cylinder cover. The integrated composite air cylinder cover comprises air inlet ducts, air exhaust ducts, oil atomizer mounting holes, cylinder cover upper water jackets, cylinder cover lower water jackets, air cylinder holes, cylinder hole water jackets and cam tappet holes. The pouring device is used for casting the integrated composite air cylinder cover. The pouring device comprises a straight sprue runner, a main cross sprue runner, two branch cross sprue runners and a plurality of L-shaped inner sprue runners; the straight sprue runner is arranged vertically; a sprue cup is arranged at the upper end of the straight sprue runner; filter screens are arranged at the two ends of the main cross sprue runner; the bottom end of the straight sprue runner communicates with the main cross sprue runner; the two branch cross sprue runners are arranged in parallel; slag collection bags are arranged at the other ends of the two branch cross sprue runners respectively; the L-shaped inner sprue runners are uniformly arranged on the inner sides of the two branch cross sprue runners; an outlet end of each L-shaped inner sprue runner is in a gradually-reducing shape; and the L-shaped inner sprue runners are used for guiding molten metal into casting moulds. The pouring device can successfully cast the integrated composite air cylinder cover high in part complexity.

Owner:GUANGXI YUCHAI MASCH CO LTD

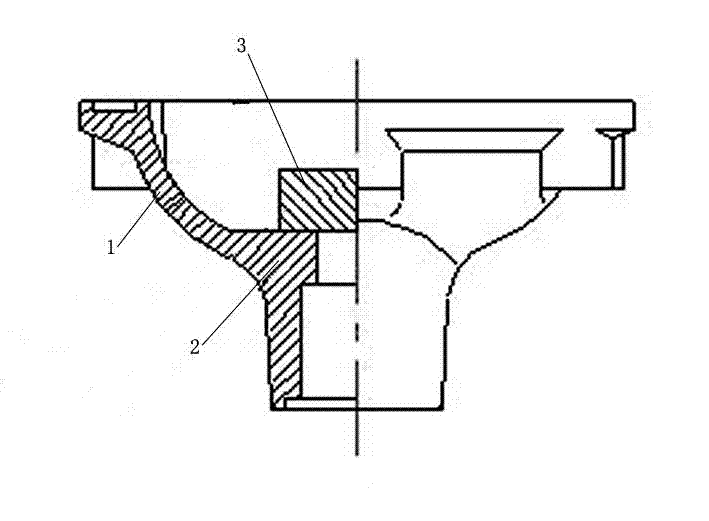

Novel composite current stabilizer and manufacturing method of the novel composite current stabilizer

ActiveCN102601329AHigh erosion resistance and thermal shock stabilityIncrease the number of pouring furnacesTundishChromium

The invention relates to the field of a current stabilizer for a continuous casting tundish, in particular to a novel composite current stabilizer and a manufacturing method of the novel composite current stabilizer. The novel composite current stabilizer comprises a bowl-shaped body with a sinking central part. The novel composite current stabilizer is characterized in that the bottom of the bowl-shaped body is internally provided with an impact plate; the thickness of the impact plate is 90-200mm; the side wall of the bowl-shaped body is provided with round flow guiding holes; each round flow guiding hole is internally embedded with a sleeve brick; and the inner diameter of the sleeve brick is 140-160mm and the wall thickness is 8-15mm. The number of the flow guiding holes is 2-6 and the flow guiding holes are distributed symmetrically. The impact plate and the sleeve bricks are made from an alumina magnesia carbon material; and the bowl-shaped body is made from alumina magnesia chromium castable. Compared with the prior art, the novel composite current stabilizer has the beneficial effects as follows: 1) the novel composite current stabilizer can bear the high-temperature flushing of high-temperature molten steel (1550-1650 DEG C) and has high erosion resistance and thermal shock resistance, and the service life can achieve 20-48 hours; and 2) the impact resistance and the erosion resistance of the current stabilizer are enhanced by the impact plate and the sleeve bricks which are embedded internally and the pass percent of continuous casting billets is further improved.

Owner:鞍山市星火特种耐火材料有限公司

Separate system pipe network catch basin system and control method thereof

ActiveCN103850331ARealize precise shut-offAccurate shut-offFatty/oily/floating substances removal devicesSewerage structuresTraffic capacityControl signal

The invention discloses a separate system pipe network catch basin system and a control method thereof. The system comprises a basin body and a control unit, wherein a first rain closure pipe, a dreg buoy and a multilevel adjustable overflow board are arranged on the lateral wall of the basin body from left to right; the first rain closure pipe is arranged at the bottom of the lateral wall of the basin body, and is provided with an electric closure check valve; the dreg buoy and the multilevel adjustable overflow board are arranged on a runner of the basin body; a liquid level sensor and a water quality sensor are arranged inside the basin body at the left side of the multilevel adjustable overflow board; a signal output end of the liquid level sensor and a signal output end of the water quality sensor are respectively connected with a control signal input end of the control unit; a control signal output end of the control unit is respectively connected with the electric closure check valve and the multilevel adjustable overflow board. According to the control method provided by the invention, a first rain range is practically defined by a runoff volume angle of the first rain; the control unit uses liquid level signals and rain quality signals inside the catch basin to control a valve on the first rain closure pipe to open and close, so that the first rain can be effectively and accurately closured in the separate system pipe network catch basin system.

Owner:安徽中科圣禹环境有限公司

Gearbox rear shell casting method

InactiveCN110449556AReduce casting defectsImprove mechanical propertiesFoundry mouldsFoundry coresShrinkage rateMechanical property

The invention discloses a gearbox rear shell casting method. The method includes the steps that modeling material selection is conducted; parting face selection is conducted; casting position determining is conducted; one box is adopted for containing one part; the casting shrinkage rate is set; the pattern draft is set; a sand core is designed, wherein a positioning core head is arranged on the sand core, resin self-hardening sand is adopted for manufacturing the sand, and an exhaust channel is formed in the sand core; a casting manner is selected, wherein a sealed intermediate injection typecasting system is adopted, a semispherical sprue base is arranged, and a funnel-shaped sprue cup provided with a foam type ceramic filter net is arranged; a chilling block is arranged; the sizes of inner frames of an upper box and a lower box are the same; smelting is conducted; casting forming is conducted; and heat treatment is conducted. By means of the gearbox rear shell casting method, sequential solidification is achieved at the defect position of a casting, a compact structure is formed, in addition, grains at the position are refined, and the mechanical performance of the casting canbe improved; and during casting, large impurities can be intercepted on the outer surface of a filter, micro impurities are adsorbed on the wall face of a channel, a metal liquid flowing manner is changed into a laminar flow manner from a turbulent flow manner, and the probability that filtered metal is further oxidized is lowered.

Owner:GUIZHOU UNIV

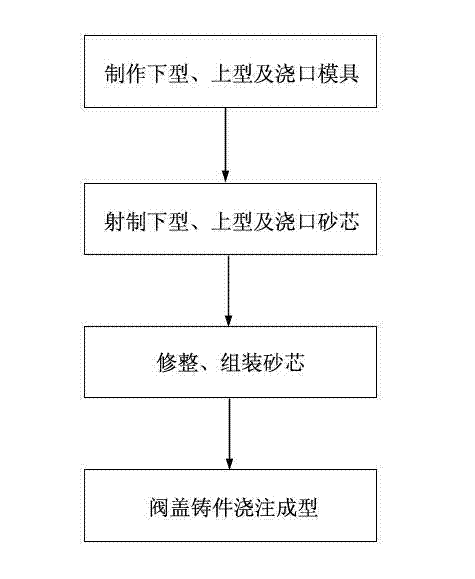

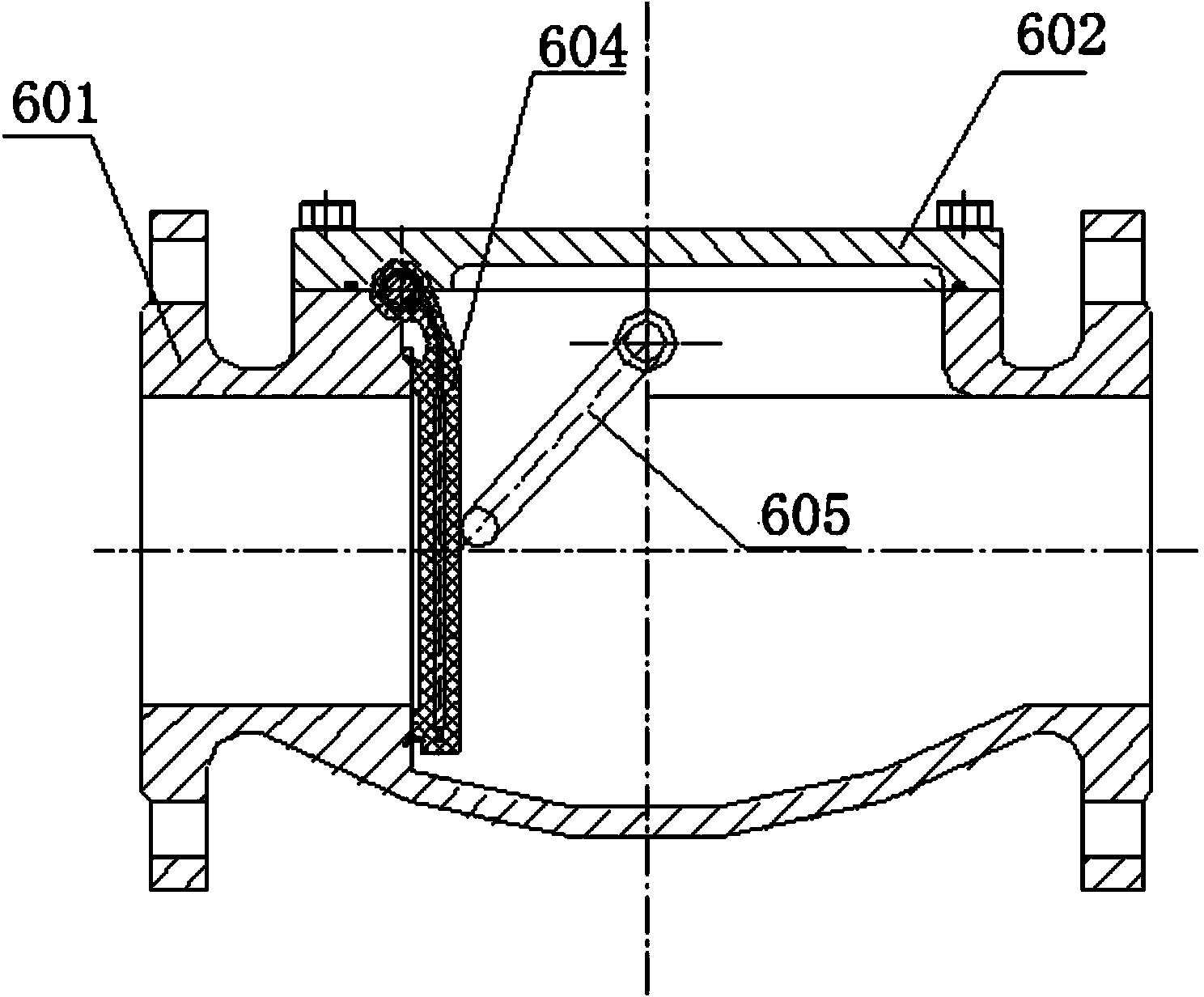

Casting method of valve cover casting

ActiveCN103084546AHigh surface hardnessHigh hardnessFoundry mouldsFoundry coresDuctile ironShrinkage porosity

The invention discloses a casting method of a valve cover casting. The method concretely comprises the following steps: 1, designing a technology and dies according to a proportional solidification technology, and making a lower type die, an upper type die and a cast die; 2, shooting on corresponding hot core box shooters to make a lower type sand core, an upper type sand core and a cast sand core; and 3, trimming and assembling the above sand cores, tightly clamping the assembled sand cores with a clamp, and carrying out cast molding to obtain the valve core casting. The valve cover casting has a high coated die sand mold surface hardness, can fully perform the graphitization expansion in nodular cast iron to carry out self-feeding, and adopts hot side casting of a cast gate, and the cast gate which is short, thin and wide can fully perform its self-adaptive adjustment effect; the shrinkage porosity and shrinkage cavity defects are thoroughly eliminated, the cast gate which is thin has a good slag baffling effect, defects comprising slag blowholes and the like are basically eliminated, and the casting yield is above 95%; and cold iron is thoroughly removed, the operation is simple, and the production efficiency is improved to a great extent.

Owner:WUHU JINMAO FLUID TECH CO LTD

Casting process for heavy-section workbench

InactiveCN102416437AReduce manufacturing costShorten the production cycleFoundry mouldsFoundry coresAlloyHardness

The invention relates to a casting process, in particular to a casting process for a heavy-section workbench. The casting process is characterized by comprising the following steps of: manufacturing a mold; molding; making a core; assembling the mold; casting: casting a downsprue sectional area, a cross gate sectional area and an in-gate sectional area in the ratio 1: (1.8-2.2):(0.7-0.9) by adopting a fully-enclosed casting system; and performing shakeout cleaning. In the casting process, a method for placing direct-cooled iron chill is adopted under the condition of not increasing the alloy adding amount, and a fully-enclosed casting system is adopted, so that the problems of hardness, shrinkage porosity and surface quality of a table-board can be solved, and the yield of castings can be increased simultaneously without increasing the cost.

Owner:NINGXIA KOCEL GRP CO LTD +1

Combined system pipe network intercepting well system and control method thereof

The invention provides a combined system pipe network intercepting well system and a control method thereof. The system comprises a well body and a control unit, wherein a well body runner is provided with a first rain overflow weir. a slag blocking float bowl and a multi-level adjustable overflow plate, wherein the bottom of a side wall between a water inlet pipe and the first rain overflow weir is provided with a sewage intercepting pipe; a first rain intercepting pipe is arranged between the first rain overflow weir and the multi-level adjustable overflow plate; the sewage intercepting pipe is provided with a first electric stop-check valve; the first rain intercepting tube is provided with a second electric stop-check valve; the left side of the first rain overflow weir is provided with a liquid level sensor and a water quality sensor; the signal output ends of the liquid level sensor and the water quality sensor are respectively connected with the control signal input end of a control unit; the control unit is respectively connected with the first electric stop-check valve, the second electric stop-check valve and the multi-level adjustable overflow plate. According to the control method, first rain is practically defined from the aspect of first rain runoff volume; liquid level and water quality signals are used for controlling the opening and closing of valves on the sewage intercepting pipe and the first rain intercepting pipe, so that accurate first rain intercepting is realized.

Owner:安徽中科圣禹环境有限公司

Waterpower auto-control separate system pipe network catch pit

The invention discloses a waterpower auto-control separate system pipe network catch pit. The waterpower auto-control separate system pipe network catch basin comprises a pit body, wherein a rainwater inlet pipe is arranged on the left end of the pit body, and a drain pipe communicated with natural water body is arranged on the right end of the pit body; an early stage rain intercepting pipe, a slag stop float bowl and a multi-level adjustable overflow plate are sequentially arranged on the side wall of the pit body from left to right; the early stage rain intercepting pipe is arranged at the bottom of the side wall of the pit body, and a float bowl intercepting check valve is arranged on the early stage rain intercepting pipe; the slag stop float bowl and the multi-level adjustable overflow plate are arranged on a runner of the pit body. According to the waterpower auto-control separate system pipe network catch pit, the float bowl intercepting check valve is arranged at the orifice of the early stage rain intercepting pipe, the intercepting for early stage rainwater is realized, the rainwater backflow of the early stage rainwater in the rainwater pipeline is also prevented, the float bowl intercepting check valve is simple in structure and convenient to operate; the slag stop float bowl avoids the blocking phenomenon; the height of the multi-level adjustable overflow plate can be adjusted in large range, and the adjustment of the drainage water level is realized; the effective separation of early rainwater is realized, and the early stage rainwater is intercepted and stored in a rainwater storage pond to the greatest extent, and is then delivered to a sewage treatment plant.

Owner:WUHAN SHENGYU DRAINING SYST

Sliding brick for converter sliding plate quick change slag-stopping tapping device

The invention discloses a sliding brick for converter sliding plate quick change slag-stopping tapping device. The sliding brick comprises a steel flowing hole fixed nozzle brick penetrating through the brick body, a connecting nozzle brick, a fixed sliding brick, a quick change sliding brick, a slidable sliding brick and a slidable nozzle brick. Steel flowing holes of the fixed nozzle brick, the connecting nozzle brick, the fixed sliding brick, the slidable sliding brick and the slidable nozzle brick are completely overlapped. The quick change sliding brick is arranged at one side of the fixed sliding brick. The sliding brick has the following characteristics: the connecting nozzle brick is in an oval shape, and is provided with a plate pressing slot on an upper end surface and a lower end surface; the fixed sliding brick, the quick change sliding brick and the slidable sliding brick are all in oval convex step shape; and the sliding nozzle brick is in a straight barrel lower convex step inversion shape. The sliding brick for converter sliding plate quick change slag-stopping tapping device of the invention has advantages of simple structure, long service life, suitability for converter sliding plate quick change slag-stopping tapping device, improvement on the slag-stopping effect and convenience for replacement.

Owner:马鞍山市雨山冶金新材料有限公司

Pouring system with gate runner

The invention discloses a pouring system with a gate runner and belongs to the fields of pouring systems. The existing pouring system adopts a dross filter so that a cost of dross filtration is high and a casting produces doped grid wires easily. The pouring system with a gate runner comprises an outer pouring gate, a sprue, the gate runner and ingates. The pouring system with the gate runner is characterized in that the top of the gate runner is provided with gates; front sides of the gates form slag retention spaces; and lower sides of the gates form a runner of which the cross area is reduced. The pouring system with the gate runner has the advantages that the gates can be directly made on a runner wood mold and be formed with a casting mold in molding sand feeding so that a dross filter purchase cost is reduced and economic benefits are obvious; a molding sand feeding process is more convenient than dross filter arrangement so that popularization and utilization are promoted; and good slag blocking effects are obtained only through control of gate height and a distance between at least two gates, wherein the control of gate height and a distance between at least two gates is carried out by a process designer according to demands.

Owner:ZHEJIANG JIALI WIND POWER TECH

Method for filling gap between bricks and lining of tapping hole of converter

ActiveCN102168161AExtended service lifeLess prone to puncture accidentsManufacturing convertersSteelmakingBrick

The invention discloses a method for filling a gap between bricks and a lining of a tapping hole of a converter, and belongs to the field of converter steelmaking. The method comprises the following steps of: (1) preparing slurry, wherein the slurry comprises more than or equal to 88 percent of MgO, more than or equal to 2 percent of CaO, and less than or equal to 4 percent of SiO2; (2) testing the performance of the slurry, wherein under the condition that the temperature is 110 DEG C and the time is 24h, the heating linear change of the slurry is -1.5 to 0 percent, the density is more than or equal to 2.45g / cm<3>, and the withstand voltage is more than or equal to 8MPa; (3) putting the slurry into a blowing tank in advance, controlling the pressure of an air source, mixing the slurry and water on line according to the proportion of (1:1)-(1:1.5), and directly filling the gap between the bricks and the lining of the tapping hole of the converter by spraying the slurry by a spraying pipe; (4) regulating the pressure, controlling the jet velocity of the spraying pipe, quickly filling the gap between the bricks and the lining of the tapping hole of the converter by utilizing the characteristic of high liquid fluidity of the slurry, and controlling an inner hole of the tapping hole to form a small and round inverted horn shape; and (5) sintering for 12 to 14 minutes after the gap between the bricks and the lining of the tapping hole of the converter is filled by using the slurry. The method can improve the service life of tapping holes and reduce labor intensity.

Owner:MAANSHAN IRON & STEEL CO LTD

Laser cutting machine for thin-walled pipe cutting of on-line pipe making pipe

PendingCN107738035AAvoid deformationPrevent inner wall damageWelding/cutting auxillary devicesAuxillary welding devicesWire cuttingLaser cutting

The invention relates to a laser cutting machine for thin-walled pipe cutting of an on-line pipe making pipe. The laser cutting machine for the thin-walled pipe cutting of the on-line pipe making pipecomprises a main body rack; a first movable platform is arranged at the front end of the main body rack; a second movable platform is arranged at the rear end of the main body rack; a rotary laser cutting device is arranged on the first movable platform; a pipe clamping component is arranged at the front end of the rotary laser cutting device; and the second movable platform is provided with a residue blocking component and a discharge component. The laser cutting machine for the thin-walled pipe cutting of the on-line pipe making pipe can be linked with pipe making equipment to carry out on-line cutting on a pipe and can machine a thin-walled pipe; the pipe is not prone to deformation when being clamped; an optical fiber / electrical line pipe is prevented from pulling and winding; and theresidue blocking component is adopted, so that damage to the inner wall of the pipe in the cutting process is avoided, the residue blocking effect is good, and the damage is little during pipe machining.

Owner:SUZHOU TIANHONG LASER

Casting system for lost-foam-casting cam shaft

The invention belongs to the technical field of lost-foam-casting, and relates to a casting system for a lost-foam-casting cam shaft. The casting system comprises a pouring cup, a sprue, a sprue base, a cross gate, a riser neck and a riser, wherein the bottom of the pouring cup is equipped with a filter device; the pouring cup is arranged on the top of the sprue and communicates with the sprue; the sprue base is arranged on the bottom of the sprue, and one end of the sprue base communicates with the sprue, and the other end of the sprue base communicates with the cross gate; one end, which is away from the sprue base and is inserted into a cam shaft mould cavity, of the cross gate is an in-gate; the in-gate communicates with the cam shaft mould cavity for guiding metal liquid to the cam shaft mould cavity; the in-gate is arranged at the riser neck with the biggest diameter cross area of the cam shaft; the riser is connected to the top end of the cam shaft; the riser is spherical; and a ratio of the area of the in-gate to the area of the cross gate to the area of the sprue is Sigma in-gate to Sigma S cross gate to Sigma S sprue being 1 to (1.2-1.3) to (1.4-1.9). The casting system solves the problem that slag blocking ability of the casting system during lost-foam-casting of a spheroidal graphite cast iron cam shaft.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Oxygen top blown rotary converter air curtain slag retaining steel outlet

The invention relates to a steel-tapping hole with curtain skimming of Linz-Donawitz, which is formed by channels of liquid steel and high pressure draught. The channel of liquid steel is divided into three parts: upper part, middle part and lower part. The upper part is entry channel of round cross-section, the middle part is air cavity channel of ellipse cross-section, and the lower part is outlet channel of round cross-section. The channel of high pressure draught is connected with the air cavity channel of steel-tapping hole. The brachydiagonal direction of ellipse structure of the air cavity channel points to the runner direction of high pressure draught. Diameters of outlet channel become smaller gradually. The favorable result of this invention is as follows: An air cavity of high pressure draught is formed in the steel-tapping hole for skimming, which guarantees liquid steel to drain away extremely and advances the tapping rate of furnaces. Long-range control can be realized with convenient operation and sensitive action.

Owner:UNIV OF JINAN

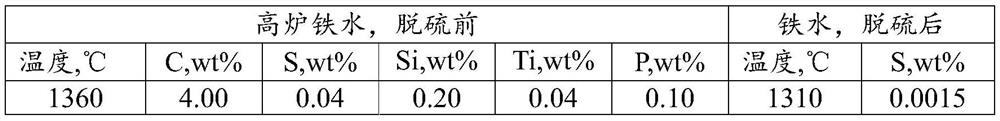

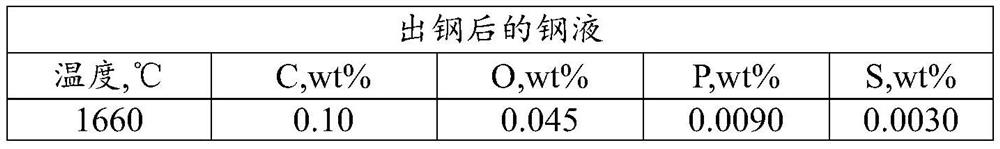

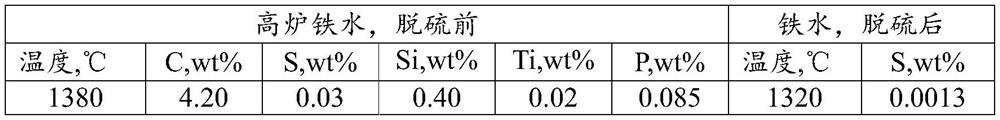

High-cleanliness spring steel and production method thereof

ActiveCN113061799ASmall sizeImprove purityManufacturing convertersProcess efficiency improvementSlagMolten steel

The invention discloses high-cleanliness spring steel and a production method thereof. The production method comprises the following steps: pretreatment: desulfurizing molten iron until the content of S in the molten iron is less than or equal to 0.0015%; mixing the molten iron and waste steel into molten steel, carrying out desiliconization, dephosphorization and oxygen blowing decarburization, obtaining the molten steel with the temperature of 111011110 DEG C, the C content of 0.1010.15%, the O content of smaller than or equal to 0.045%, the P content of smaller than or equal to 0.011% and the S content of 0.00110.008%, carrying out slag stopping tapping, carrying out deoxidation alloying, and the flow of argon blowing at the bottom of a steel ladle during tapping and the flow of argon blowing at the bottom of the steel ladle after tapping are 80011000 NL / min and 1001200 NL / min respectively; refining the molten steel to adjust chemical components and inclusions, and the flow rates of the argon blowing at the bottom of the steel ladle are respectively 1001500 NL / min, 2001100 NL / min and 501100 NL / min in other time when slag charge adding and alloying treatment are carried out and the temperature is increased by electrifying; then carrying out vacuum refining and vacuum breaking soft stirring in sequence, and the flow of the argon blowing at the bottom of the steel ladle is 20150 NL / min and 501100 NL / min; and casting into a steel billet. In the high-cleanliness spring steel prepared through the production method, the density of inclusions with the size larger than 5 micrometers is smaller than or equal to 0.5pcs / mm < 2 >, the length-width product of the maximum inclusions is smaller than or equal to 900 micrometers < 2 >, and the high-cleanliness spring steel has high cleanliness.

Owner:ZHANGJIAGANG RONGSHENG SPECIAL STEEL CO LTD +2

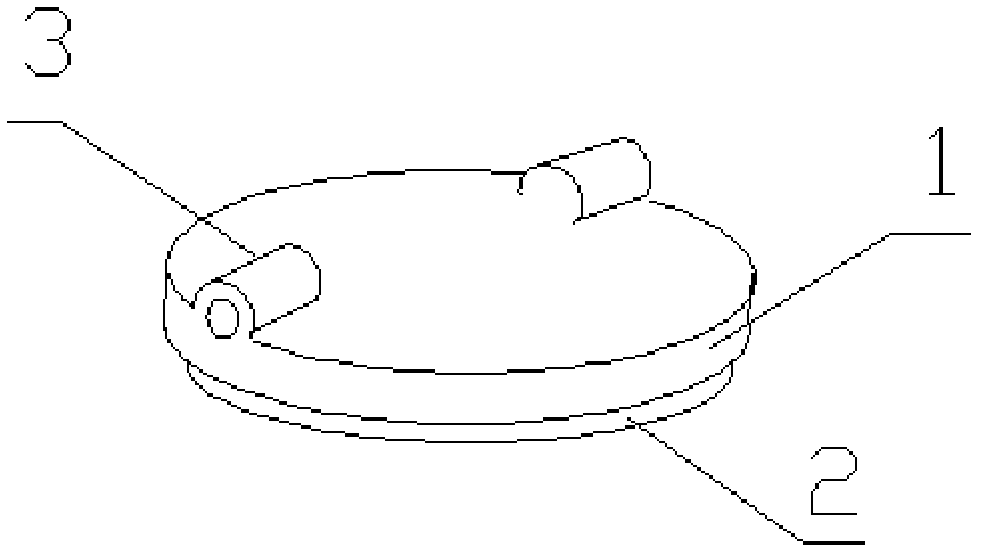

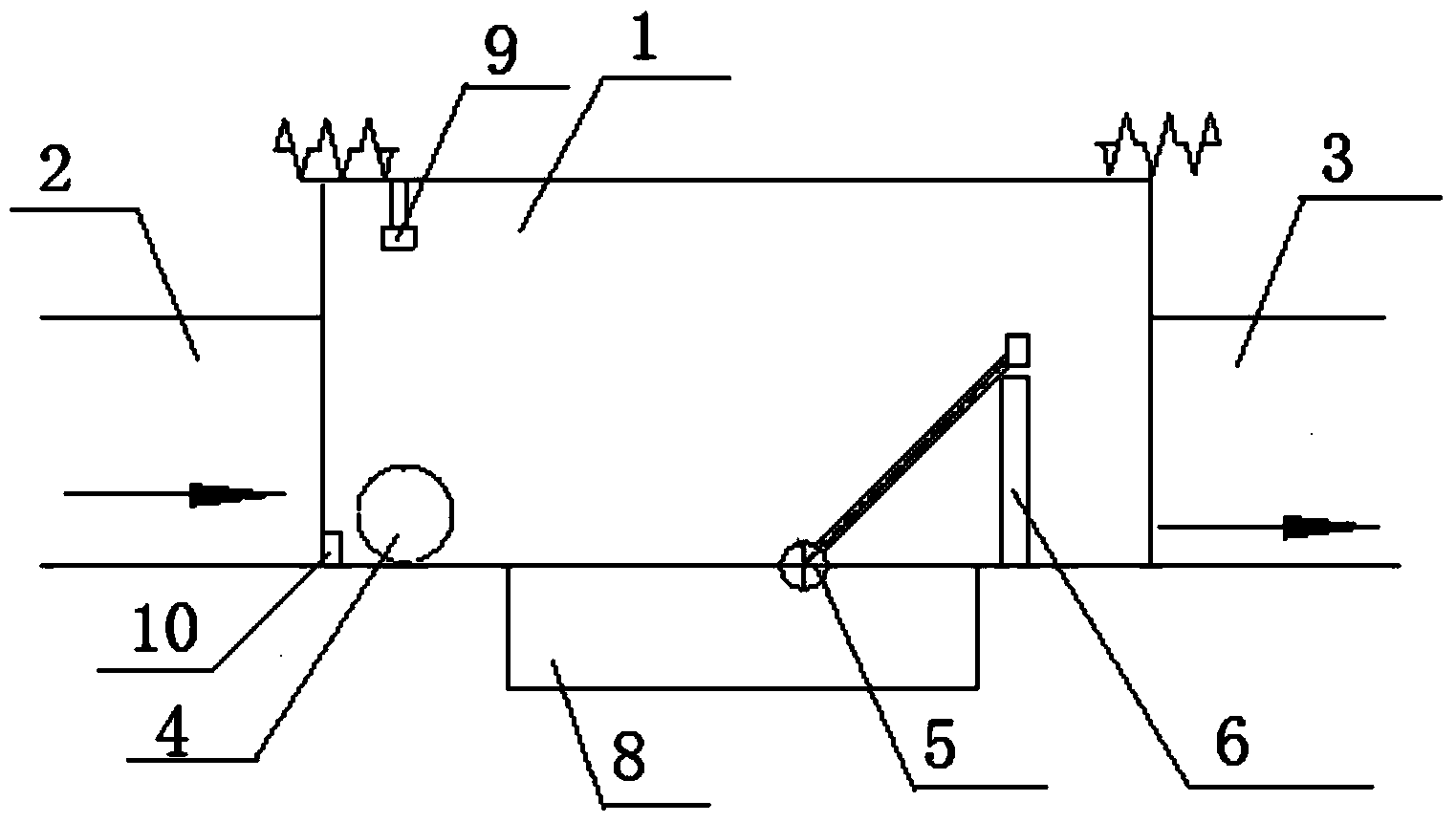

Residue-holding float bowl structure for drainage system

ActiveCN103850335AImprove slag blocking effectSimple structureFatty/oily/floating substances removal devicesAutomatic controlEngineering

The invention discloses a residue-holding float bowl structure for a drainage system. The structure comprises a tank body, wherein a cylindrical float bowl is arranged in the tank body and is in a hollow shape, two end planes of the tank body are sealed, and the float bowl is flatly placed to be vertical to a water current direction and the length of the float bowl stretches across the two side walls of the tank body, and rotary arms are fixedly connected on the two end planes of the float bowl and are respectively hinged onto the side walls of the tank body. When the float bowl structure is adopted to hold residues, a part of the hollow float bowl is immersed below the water surface, and the other part of the hollow float bowl floats above the water surface, and floating objects are blocked through the float bowl when the water flows through the float barrel, and the water discharges from the bottom of the float bowl, so that the structure solves the problem that a filter screen can be easily blocked in the prior art, and the residue-holding equipment are not needed to wash and maintain; furthermore, the size range of the floating residues held up by the floater structure is larger, the floating residues are held up more thoroughly, so that the residue-holding effect can be improved; in addition, the residue-holding can be automatically controlled through hydraulic power, and the float bowl structure is simple in structure, convenient to install, good in technology, and safe and reliable to use.

Owner:WUHAN SHENGYU DRAINING SYST

Hydraulic self control flow converging pipe network flow cut-off control well

ActiveCN103850328BSimple structureEasy to operateFatty/oily/floating substances removal devicesSewerage structuresSlagSewage

The invention discloses a hydraulic self control flow converging pipe network flow cut-off control well, which comprises a well body, wherein a rain and sewage flow converging water inlet pipe is arranged at the left end of the well body, the right end of the well body is provided with a water outlet pipe, a primary rain overflow weir, a slag blocking floating tube and a multi-stage adjustable overflow plate are sequentially arranged on the flow passage of the well body from the left side to the right side, a sewage flow cut-off pipe is arranged at the bottom of the side wall of the well body between the rain and sewage flow converging water inlet pipe and the primary rain overflow weir, a floating tube flow cut-off check valve is arranged on the sewage flow cut-off pipe, a primary rain flow cut-off pipe is arranged at the bottom of the side wall of the well body arranged between the primary rain flow overflow weir and the multi-stage adjustable overflow plate, and a flow cut-off check valve is arranged on the primary rain flow cut-off pipe. The floating tube flow cut-off check valve is arranged at an inlet of the sewage flow cut-off pipe, in addition, the flow cut-off check valve is arranged at the inlet of the primary rain flow cut-off pipe so that the flow rate of the flow cut-off sewage and the primary rain can be controlled, and in addition, the reverse flow of the sewage and the primary rain can be prevented; the slag blocking floating tube is used for blocking slag, so the blocking phenomenon is avoided, the adjustable height of the discharge water level can be realized through the multi-stage adjustable overflow plate, further, the effective separation of the primary rain is realized, and the primary rain can be conveyed to sewage treatment plants to the maximum after the flow cut-off operation.

Owner:WUHAN SHENGYU DRAINING SYST

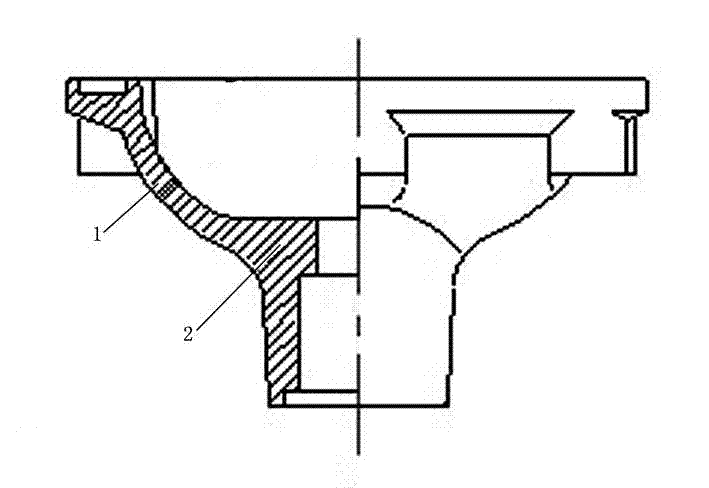

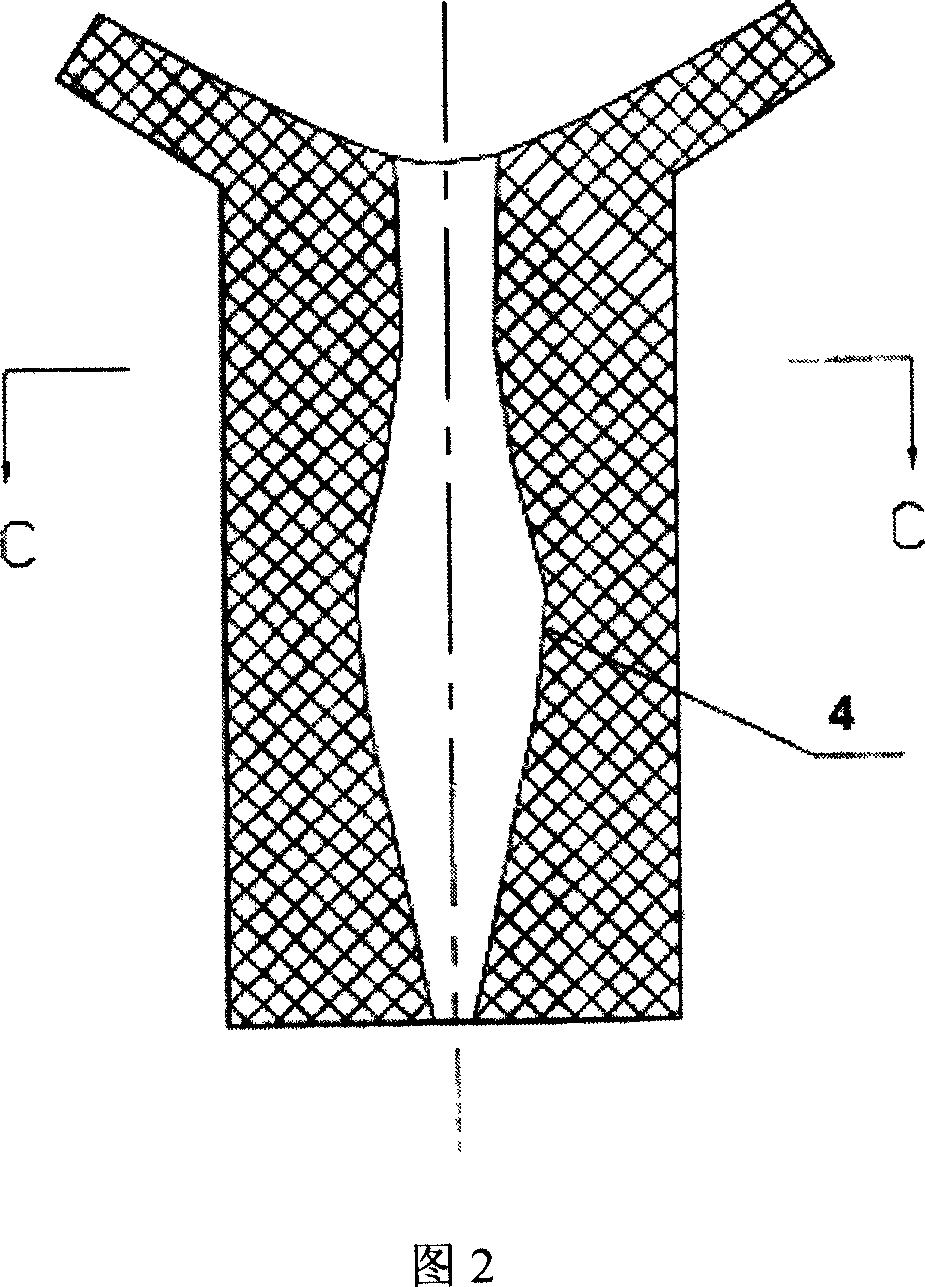

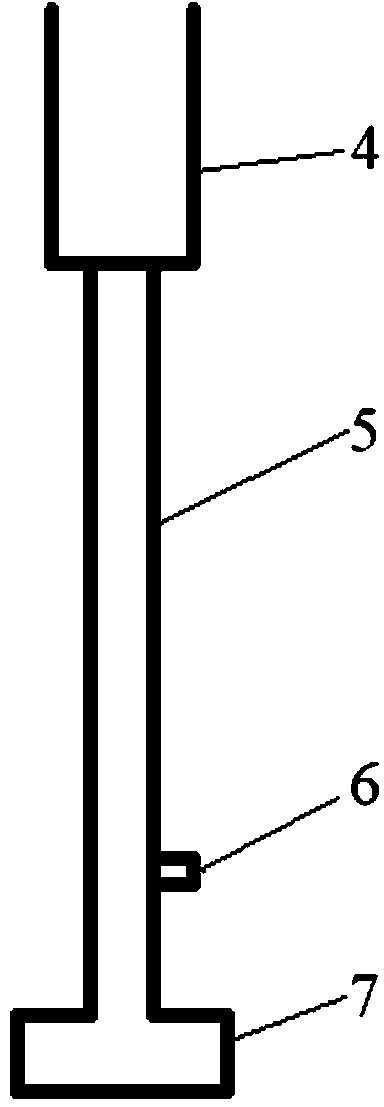

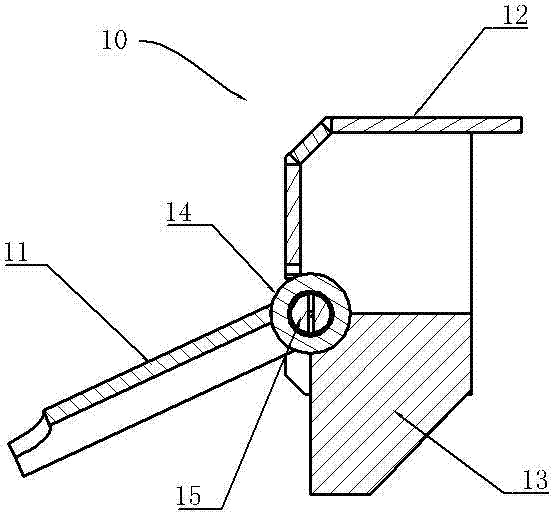

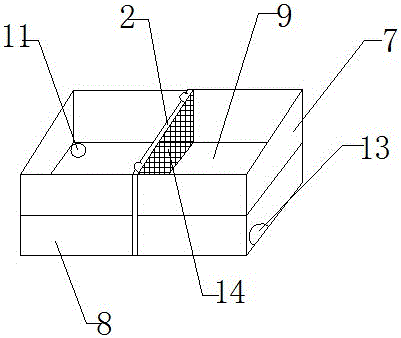

Method for operating converter slag blocking device

The invention discloses a converter slag blocking device. The converter slag blocking device comprises a slag blocking cone (2) and a pushing rod (5). The large end, close to the taper of the slag blocking cone, of the slag blocking cone (2) is provided with two grooves (8) which are symmetric about the axis of a slag blocking cone body and are parallel to each other. The invention further discloses a method for operating the converter slag blocking device. According to the technical scheme, the converter slag blocking device is simple in structure, convenient to manufacture, low in cost, free of maintenance cost and position influence, good in slag blocking effect and suitable for being used for slag blocking of any converter.

Owner:WUHU XINXING DUCTILE IRON PIPES

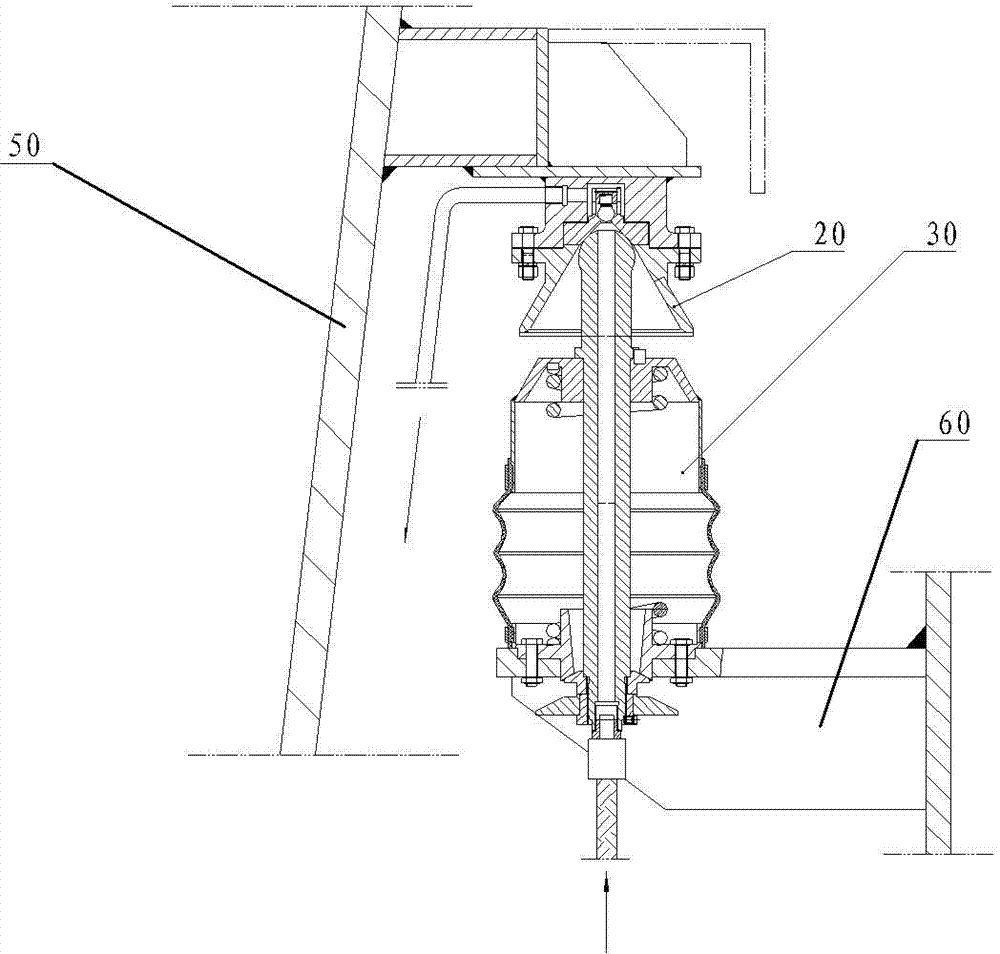

Slag-blocking structure for automatic argon-blowing joint device

ActiveCN104762442AEffective protectionAvoid dust accumulationCasting cleaning apparatusSlagEngineering

The invention provides a slag-blocking structure for an automatic argon-blowing joint device. The structure can overcome the problem of proneness to accumulation of slag and ash of a male joint terminal in conventional automatic argon-blowing joint devices, can effectively block high-temperature steel slag from splashing onto a spring of the male joint terminal and ensures service life of the spring. According to the invention, the slag-blocking structure comprises a female joint terminal and the male joint terminal of the automatic argon-blowing joint device, wherein the female joint terminal is arranged on the tank wall of a liquid steel tank, and the male joint terminal is arranged on a support of transloading equipment. The slag-blocking structure is characterized in that the slag-blocking structure further comprises a slag-blocking device installed on the support of the transloading equipment, and the slag-blocking device comprises a rotatable slag-blocking plate; when the female joint terminal and the male joint terminal of the automatic argon-blowing joint device are disconnected, the slag-blocking plate located right above the male joint terminal blocks high-temperature steel slag; and when the female joint terminal and the male joint terminal of the automatic argon-blowing joint device need to be connected, the slag-blocking plate can downward rotate so as to allow the joint body of the male joint terminal to be exposed and engaged with the joint body of the female joint terminal.

Owner:WUXI JULI HEAVY IND OFF

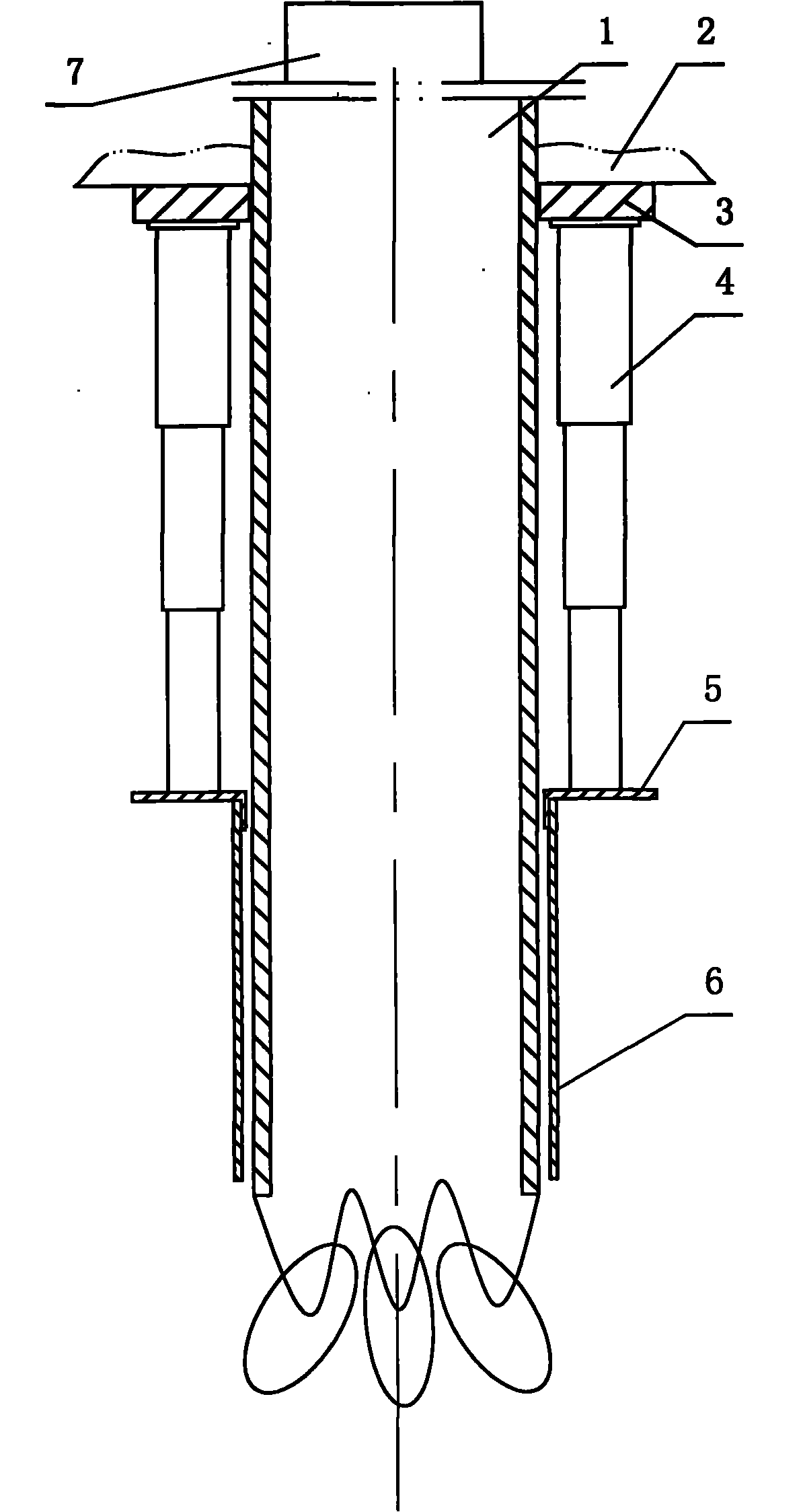

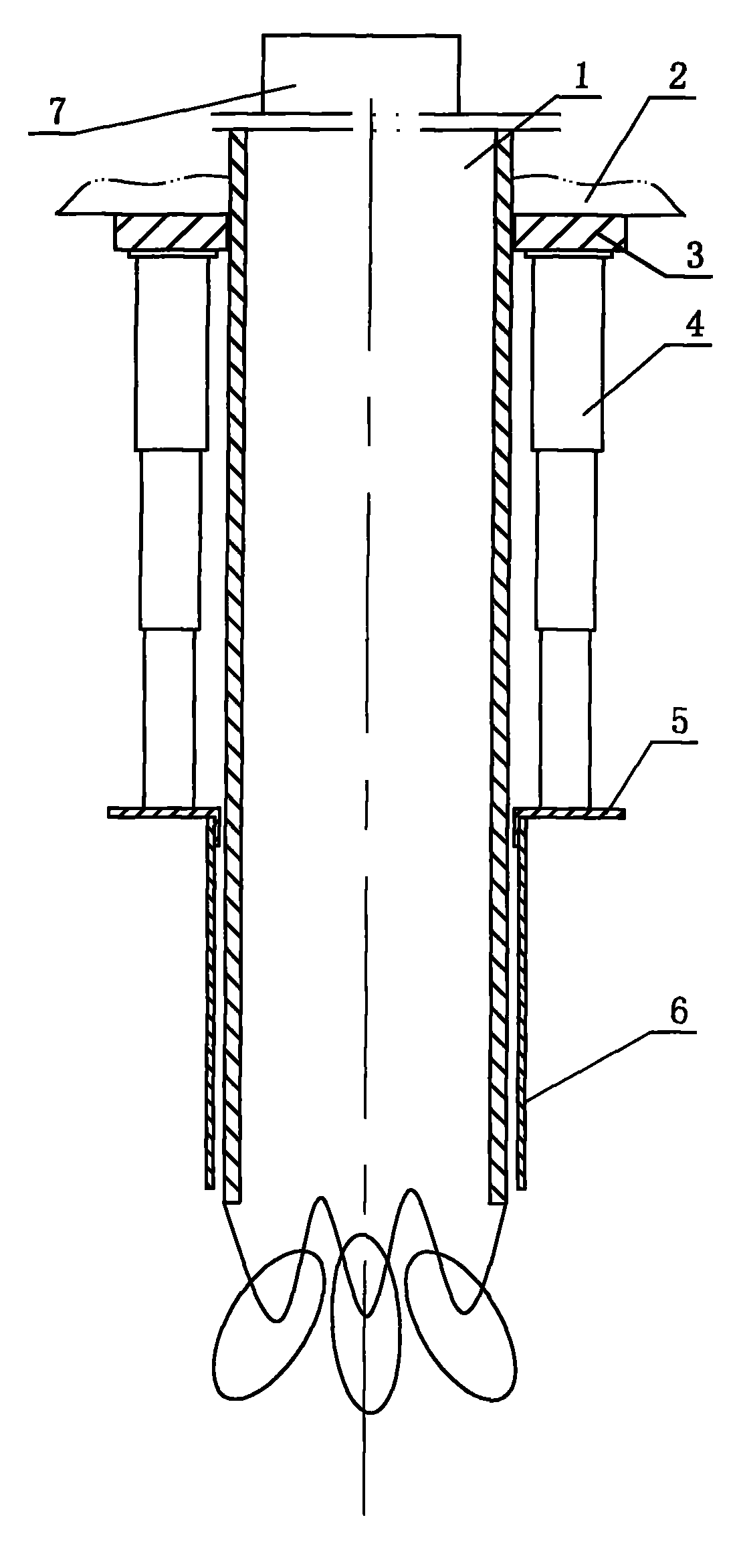

Large marine copper propeller casting pouring system

The invention discloses a large marine copper propeller casting pouring system. The large marine copper propeller casting pouring system comprises pouring system units which are connected in sequence as follows: a running gate, a labyrinth adapter trap, a side gate, a collected slag filtering unit, an annular track and inner gates; the running gate is connected above one flow inlet end of the labyrinth adapter trap; the labyrinth adapter trap is internally provided with a plurality of right-angled loops; the side gate is connected between the labyrinth adapter trap and the annular track; the collected slag filtering unit is arranged at a position of the side gate, close to the annular track, and a double-layer filter net is arranged inside the collected slag filtering unit; opposite to the position of an inlet, the annular runner is isolated by a vertical partition, two slag traps which are not communicated and are communicated with channels at two sides are arranged on the ends of the partition, and the slag traps are protruded towards the outer side of the annular track; and a downward concave platform is arranged on the inner side of the annular area of the annular track, and the upper annular plane of the concave platform is connected with the plurality of inner gates arranged vertically. The large marine copper propeller casting pouring system is a simple and high-efficiency pouring system, and the slag blocking capability of the pouring system can be greatly improved.

Owner:ZHENJIANG TONGZHOU PROPELLER

Slag blocking system for steel smelting

InactiveCN105855531AGuaranteed cleanlinessExtended Flow TrajectoryCasting cleaning apparatusSlagMolten steel

The invention provides a slag-retaining system for iron and steel smelting, which includes a machine body and a main body of a filter screen, a frame is arranged around the main body of the filter screen, a handle is provided on the frame, an upper filter layer and a lower filter layer of the machine body, and the upper filter layer and the lower filter layer are composed of The interlayers are separated from each other, the upper left corner of the interlayer is provided with a lower drain hole, the middle of the body is provided with a filter screen fixed slideway, the upper right corner of the body is provided with a material inlet, the lower right corner of the body is provided with a discharge port, and the mesh of the upper filter net The shape of the hole is square. Compared with the prior art, the present invention has the following benefits: the reasonable design of the size and shape of the mesh hole of the present invention can completely block the debris distributed in molten steel, and the main body of the filter screen can be removed from the Take it out from the body, clean or replace it, and keep the main body of the filter screen clean. The inner surface and outer surface of the body are each attached with a layer of fireproof and heat-resistant coating, which can increase the service life of the invention. The invention has simple structure, simple operation and convenient cleaning.

Owner:CHONGQING YUXI STEEL GRP CO LTD

Drilling machine tool special for opencast mining rotary drill rig and using method thereof

ActiveCN102086766AEven by forceAvoid uneven forceOpen-pit miningDrilling machines and methodsOpen-pit miningSlag

The invention relates to the technical field of mine mechanical equipment, in particular to a drilling machine tool special for an opencast mining rotary drill rig and a using method thereof. The special machine tool comprises a drill rod, a fixing seat, a rotary drill rig air compressor, a pneumatic control device and a slag blocking barrel, wherein the fixing seat is provided with a base, a group of pneumatic jacks and a gland; the base is a circular flat-plate base; the group of pneumatic jacks consists of 3 to 5 pneumatic jacks; and the central hole of the base is matched with the outer diameter of the drill rod. The using method comprises the following steps of: drilling a preset hole; sleeving the drill rod into the base, the pneumatic jacks, the gland and the slag blocking barrel in turn; running the drill rod and the pneumatic jacks synchronously; after the slag blocking barrel fully enters the hole, pulling the drill rod out; and inserting another slag blocking barrel until arequired drilling depth is achieved. The invention has the advantages that: the drilling machine tool has a simple structure and high hole forming rate and is convenient to operate; and depth controlis accurate.

Owner:ANSTEEL GRP MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com