Oxygen top blown rotary converter air curtain slag retaining steel outlet

A technology of oxygen top blowing and tapping, which is applied in the manufacture of converters and other directions, can solve the problems of consuming slag blocking materials and complicated equipment, and achieve the effects of avoiding consumption, convenient operation and improving tapping rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically described below in conjunction with the accompanying drawings and specific embodiments.

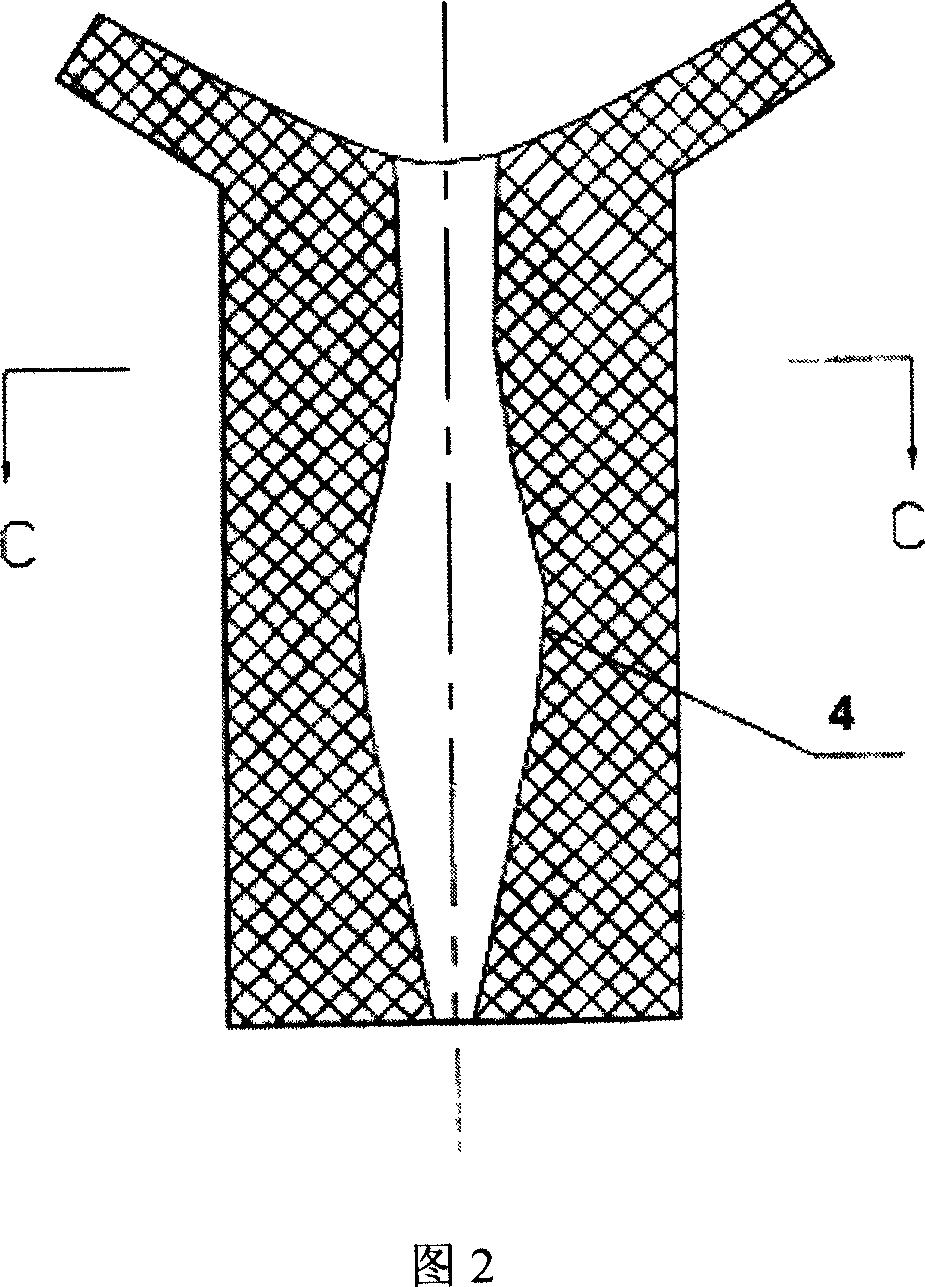

[0017] The structure of the gas curtain slag-retaining taphole of the oxygen top-blown converter of the present invention is shown in Fig. 1-Fig. 4 .

[0018] Fig. 1 is the schematic diagram of the main view sectional structure of the present invention, molten steel enters the taphole from the taphole inlet 1, passes through the taphole inlet passage 2, the taphole air chamber passage 4, the taphole outlet passage 5, and passes through the taphole Outlet 6 is discharged and flows into the ladle. The high-pressure gas enters the molten steel flow channel of the tapping hole from the high-pressure air flow channel 3. The flow direction of the high-pressure gas forms an angle of 45 degrees with the tapping hole channel. After the high-pressure gas enters the air cavity, a high-pressure air cavity is formed to prevent steel slag dirty. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com