Slag blocking system for steel smelting

A technology for iron and steel smelting and filter screen, applied in the field of iron and steel smelting, can solve the problems such as the inability to effectively improve the flow trajectory of molten steel, the uneven flow of molten steel in the tundish, and the inability to reasonably distribute the flow direction of molten steel, so as to achieve a good slag blocking effect and improve the flow trajectory. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

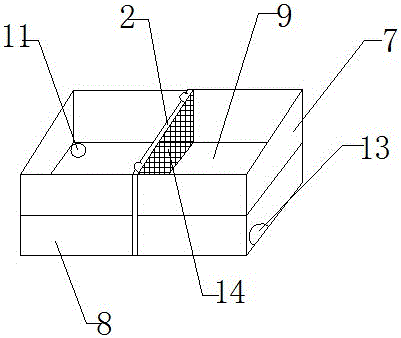

[0017] The specific embodiment: when in use, molten steel is input from the feed port, enters the upper filter layer 7, passes through the upper layer filter screen 3 of the filter screen main body 2, carries out slag blocking, then flows into the lower filter layer 8 from the lower leakage hole 11, passes through The lower layer filter screen 4 is used for the second slag blocking, and finally the molten steel that has been slag blocking is discharged from the discharge port 13. The filter screen main body 2 can be installed and fixed on the middle position of the body from the filter screen fixing slideway, and the present invention The reasonable design of the size and shape of the mesh hole 14 of the upper filter 3 and the lower filter 4 can completely remove the slag distributed in the molten steel, and the slag is blocked twice in the molten steel, so that the slag can be removed more thoroughly , improve the molten steel flow track at the same time, so that the slag bloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com