Multifunctional pipe tool inner wall cleaning device and cleaning method thereof

The utility model relates to a cleaning device and a multi-functional technology, which is applied to the field of multi-functional pipe inner wall cleaning devices, and can solve the problems of single cleaning method, low operation efficiency and high energy consumption, and achieve the effects of convenient use, simple structure and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

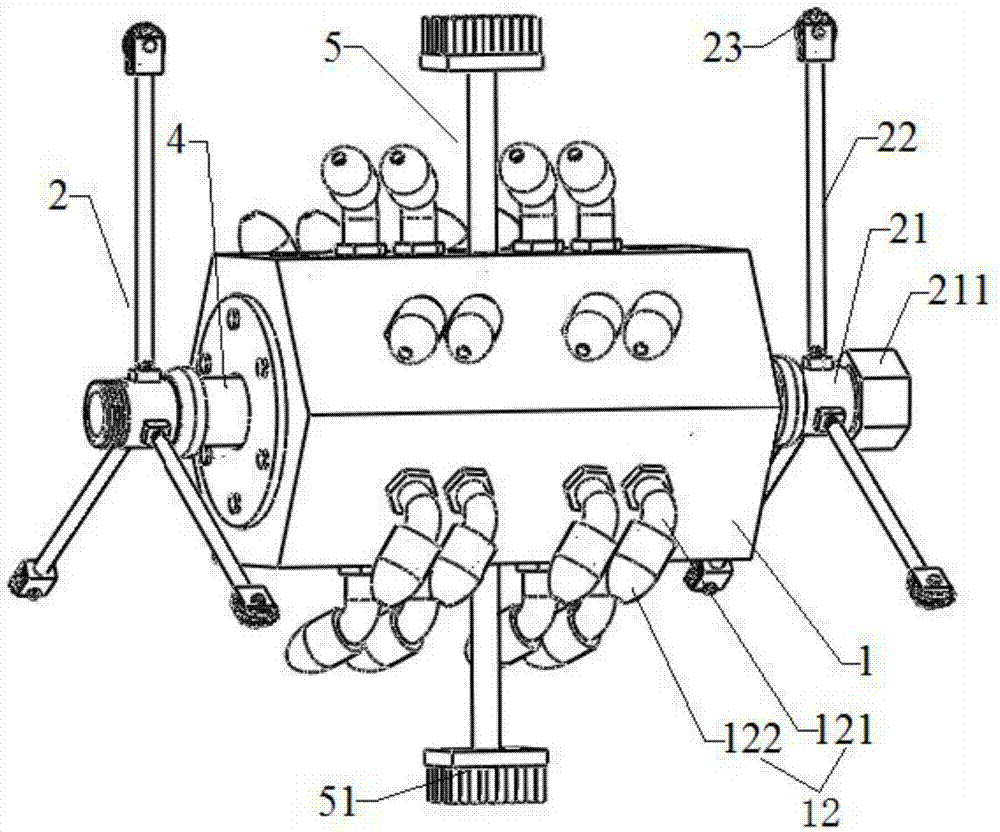

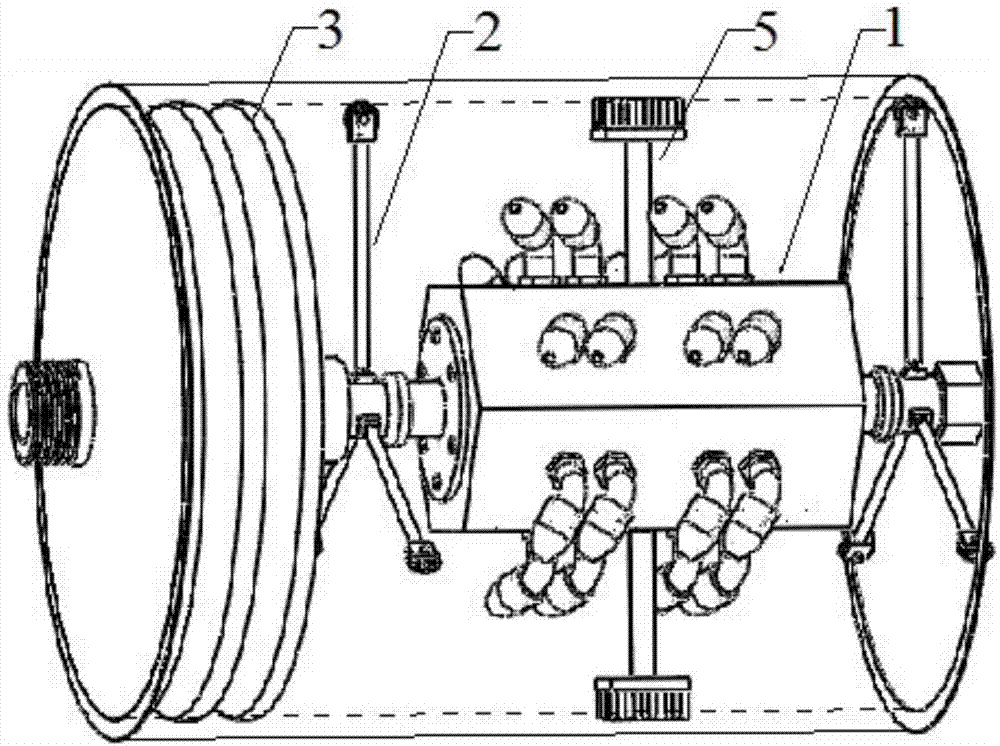

[0084] Example: such as Figures 1 to 6 As shown, the multifunctional pipe inner wall cleaning device of this embodiment includes a coaxially arranged spray cylinder 1, two traveling mechanisms 2, a pipe pig 3 and a central shaft 4;

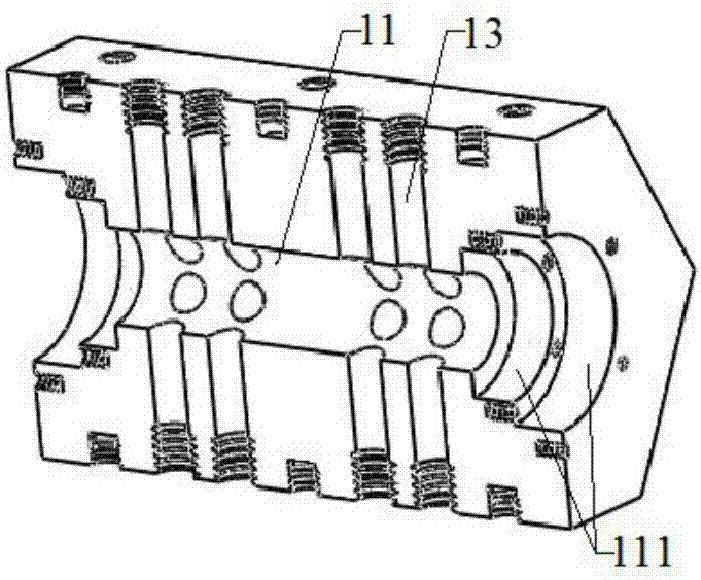

[0085] The above-mentioned spray tube 1 is a columnar structure arranged horizontally, and a cavity 11 is coaxially arranged inside it;

[0086] The above-mentioned central shaft 4 is hollow inside and has openings at both ends; the above-mentioned central shaft 4 passes through the above-mentioned cavity 11, and runs through the two ends of the above-mentioned spray tube 1, and the above-mentioned central shaft 4 passes through a plurality of slots 41 provided on the outer wall and the above-mentioned cavity. 11 connected, the above-mentioned spray tube 1 can rotate relative to the above-mentioned central axis 4;

[0087] A plurality of spray head assemblies 12 evenly distributed on the circumference are detachably installed on the outer circum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com