Laser cutting machine for thin-walled pipe cutting of on-line pipe making pipe

A technology for laser cutting machines and thin-walled tubes, applied in laser welding equipment, welding/cutting auxiliary equipment, applications, etc., can solve the problems of increased laser cutting processing, low concentricity, and pull-off, so as to prevent inner wall damage, Good slag blocking effect, not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

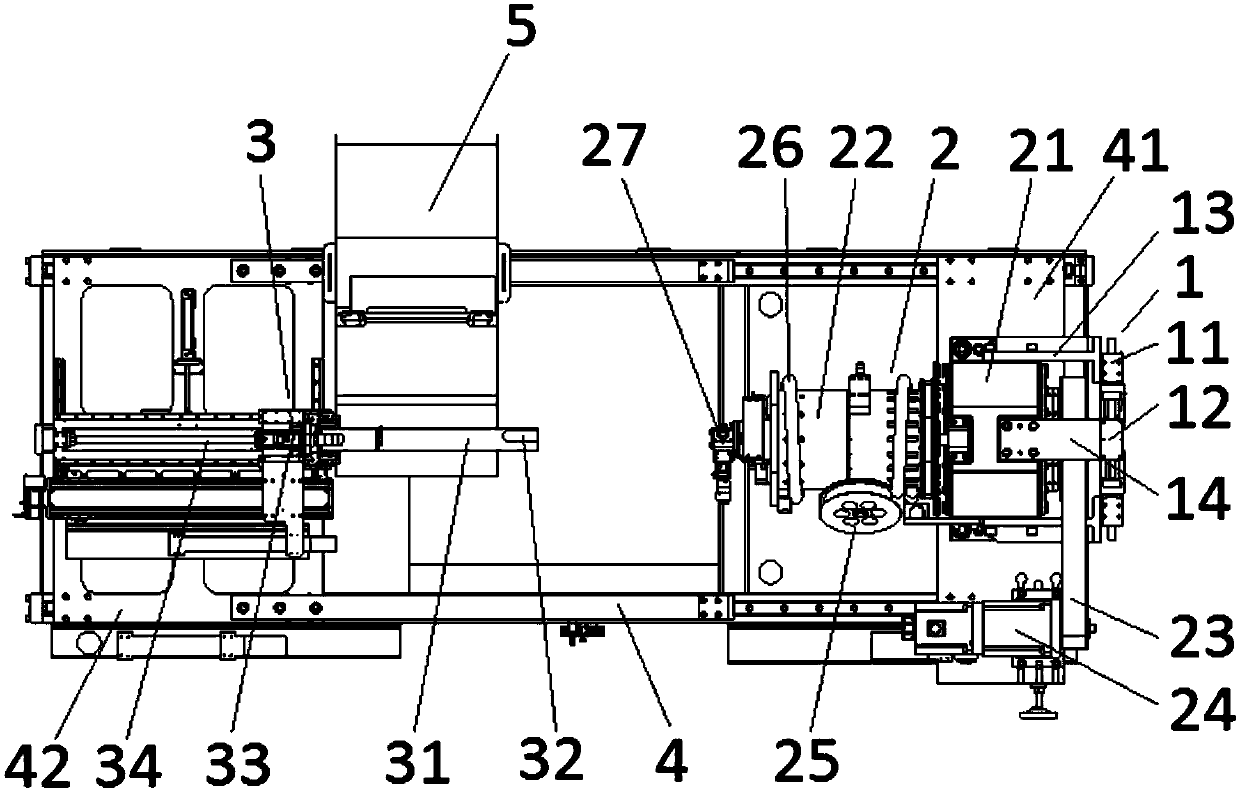

[0017] like Figure 1 to Figure 3 As shown, the present embodiment provides a laser cutting machine for cutting thin-walled tubes of an online tube machine, which includes a main body frame 4; the front end of the main body frame 4 is provided with a first mobile platform 41, and the rear end A second mobile platform 42 is provided at the end; the first mobile platform 41 is provided with a rotary laser cutting device 2; the front end of the rotary cutting device 2 is provided with a pipe clamping assembly 1; the second mobile platform 42 is provided with The slag blocking assembly 3 and the blanking assembly 5; wherein, the rotary laser cutting device 2 includes a main shaft 22; a fixed shell 21 is provided outside the right end of the main shaft 22; the right end of the main shaft 22 protrudes from the fixed shell 21 and is provided with Transmission part; the transmission part is connected with the main shaft rotating motor 24 through the belt 23; the left end of the main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com