Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

302 results about "Cupola furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cupola or cupola furnace is a melting device used in foundries that can be used to melt cast iron, Ni-resist iron and some bronzes. The cupola can be made almost any practical size. The size of a cupola is expressed in diameters and can range from 1.5 to 13 feet (0.5 to 4.0 m). The overall shape is cylindrical and the equipment is arranged vertically, usually supported by four legs. The overall look is similar to a large smokestack.

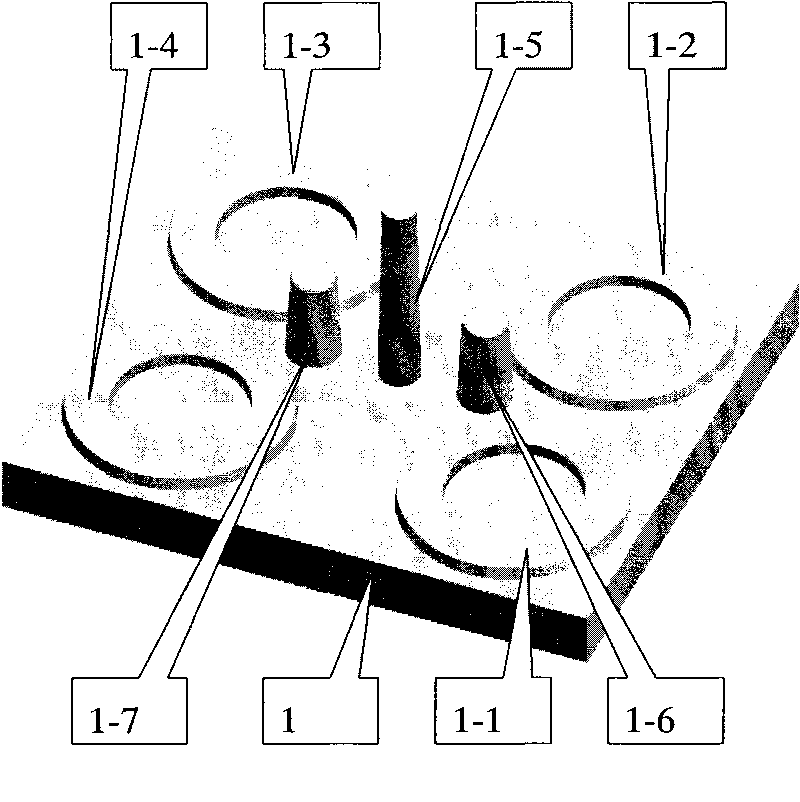

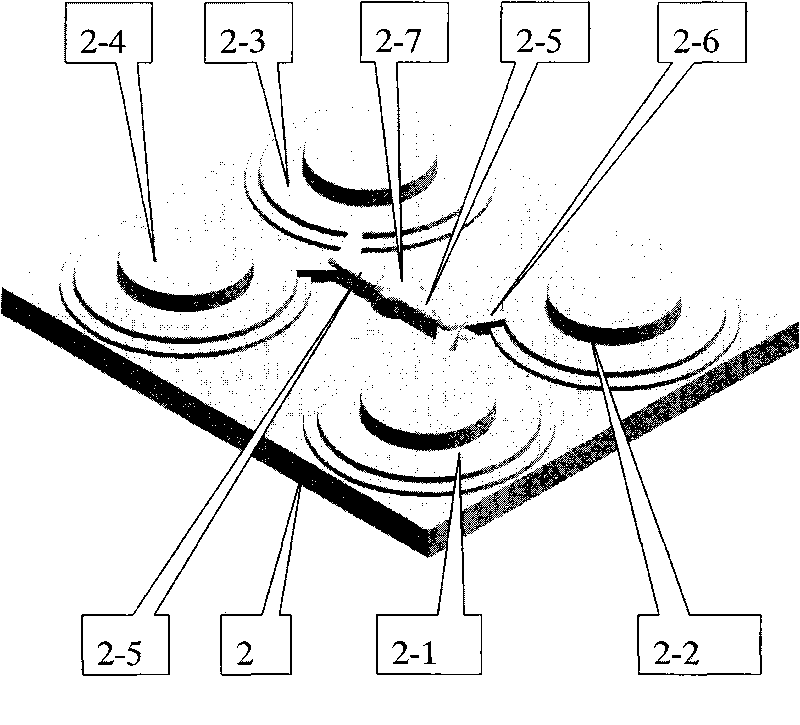

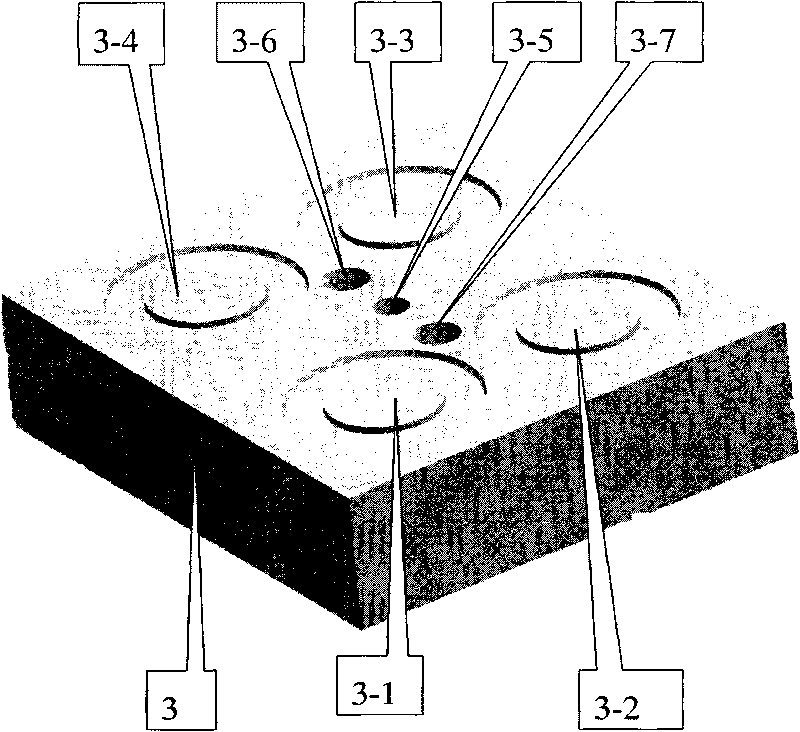

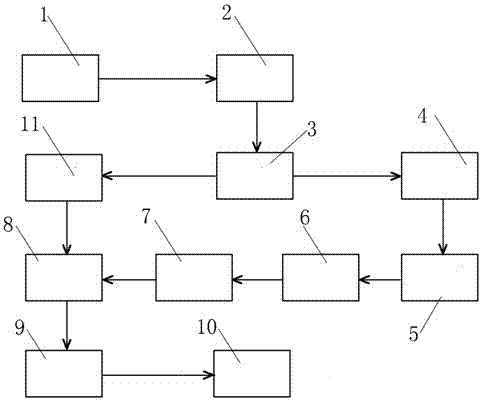

Process for casting thick and large nodular cast iron valve plate

The invention provides a process for casting a thick and large nodular cast iron valve plate. The process comprises the following steps of: (1) manufacturing a mould; (2) manufacturing a casting mould and a sand core; (3) drying and integrating; (4) smelting; (5) pouring; and (6) shaking out and cleaning. In the process, a large number of external chilling blocks and sand separation chilling blocks are used on upper and lower surfaces of a casting for chilling, appropriate placing positions and thickness are selected, and shrinkage cavity and shrinkage porosity of the casting are effectively avoided; meanwhile, a good graphite balling state is ensured by quickly chilling, a feeding head is avoided, the casting is easy to clean, 5 percent of molten iron using amount is saved, and production cost is reduced; a semi-closed casting system is adopted by a casting system, an ingate is uniformly distributed around the casting mould, and the casting mould is slightly scoured, and a good residue stopping effect is achieved; and under the action of chilling of chilling blocks, the thick and large nodular cast iron casting which is smelted by a cupola furnace is good in moulded surface, and meets production requirements, offscourings and sand are avoided, and process yield is improved by 5.9 percent.

Owner:TIJIN YIJI MACHINERY

Tundish covering agent for pure steel, and its making method

InactiveCN1461680AReduce energy consumptionReduce manufacturing costProcess efficiency improvementAdhesiveCupola furnace

A granular or spherical hollow covering agent of tundish for high-purity steel is prepared from the prefused grog chosen from hydrated lime, calcium carbonate, quartz sand, etc. the raw material including calcium carbonate, bauxite and quartz sand, and the adhesive through prefusing the powdered grog, mixing with raw material, grinding, stirring, adding additive and shaping. Its preparing process is also disclosed. Its advantages are no reaction on molten steel, and high quality of steel.

Owner:BAOSHAN IRON & STEEL CO LTD

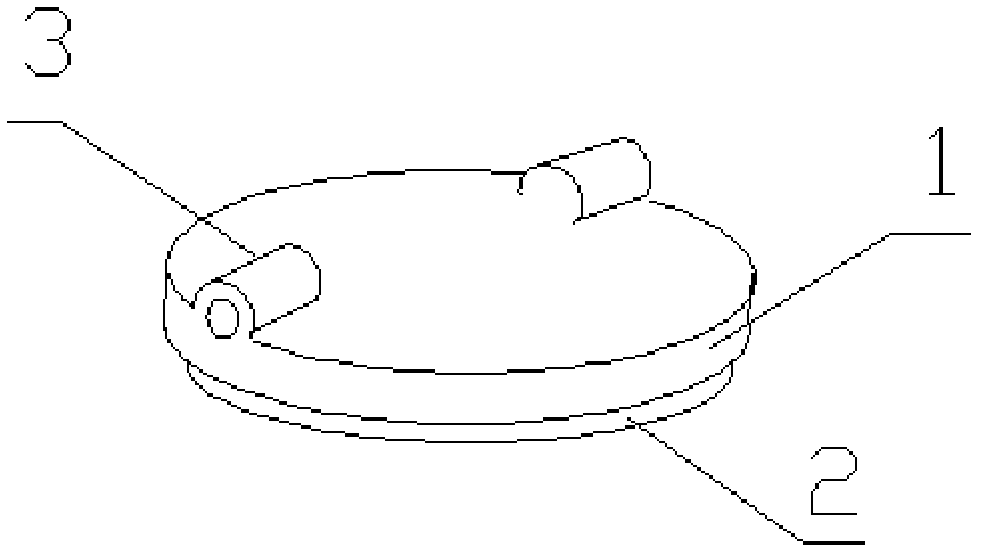

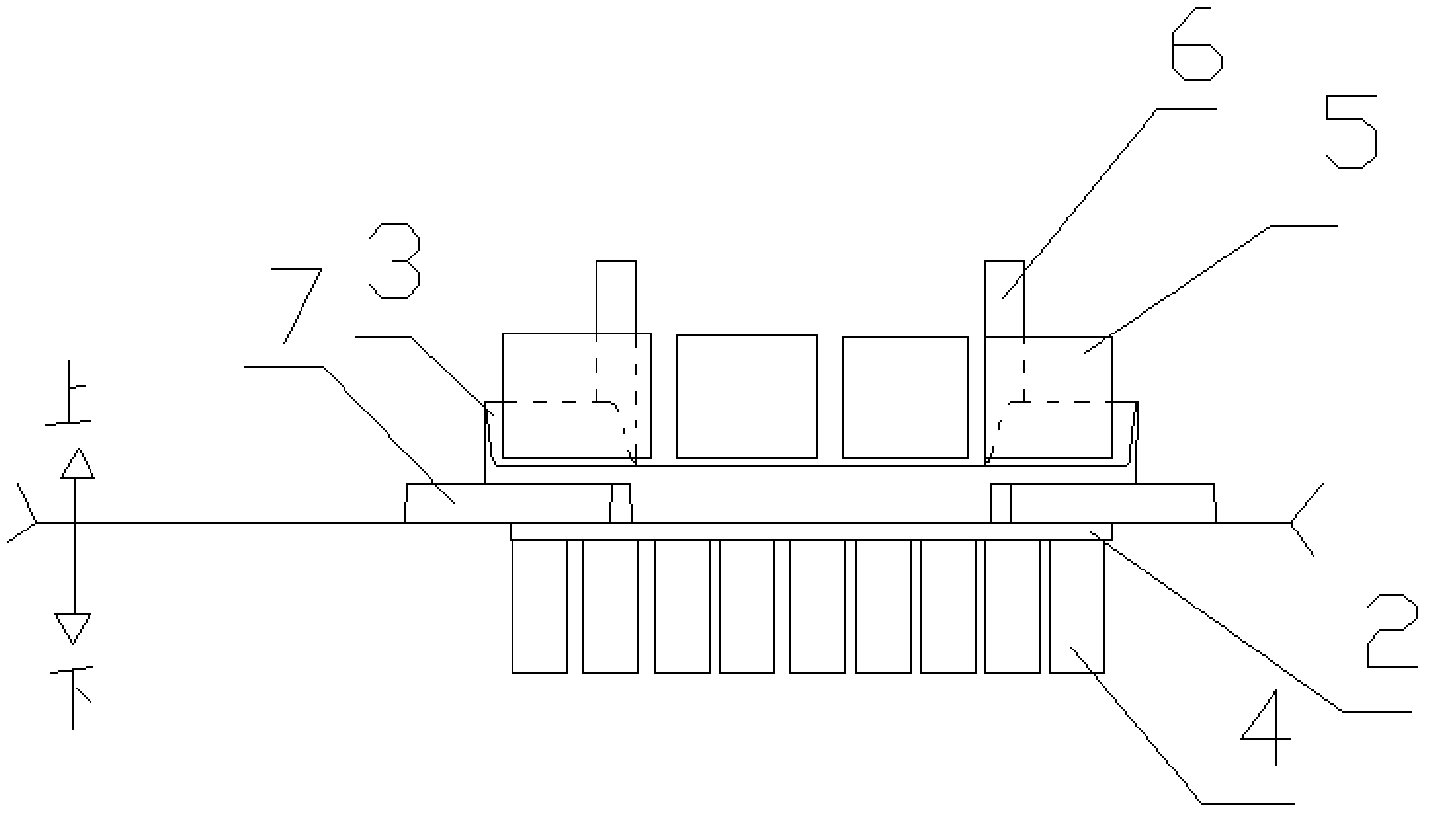

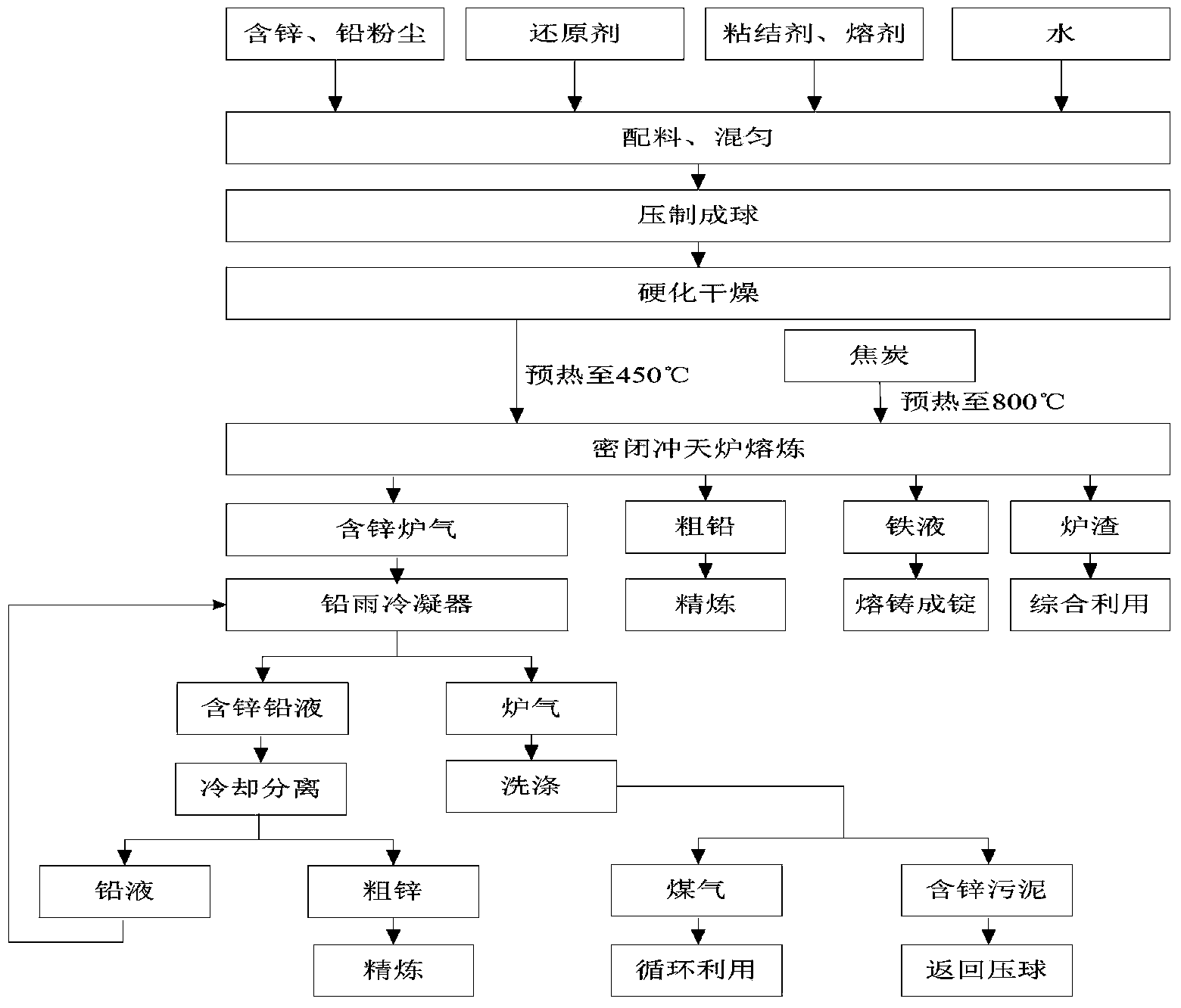

Method for processing dust containing zinc and lead in steel plant through closed cupola furnace

ActiveCN103468961AAdaptableIncrease production capacityProcess efficiency improvementSlagMixed materials

The invention discloses a method for processing the dust containing zinc and lead in a steel plant through a closed cupola furnace, and belongs to the field of steel production. The method is characterized in that the dust containing the zinc and the lead in the steel plant serves as the main raw material, certain quantities of a reducing agent, a binder, a fusing agent and water are added, and after fully mixing, the mixed materials are pressed by a ball pressing machine into balls; after being dried or maintained, the balls are conveyed into the closed cupola furnace to be smelted, and finally spelter, lead bullion and molten iron are obtained. The method has the advantages of being high in raw material adaptability, strong in production capability, high in processing efficiency and additional value of products and the like. The spelter, the lead bullion, the molten iron, gas, slag and the like can be directly obtained through the dust containing the zinc and the lead in the steel plant, the spelter and the lead bullion can be refined further, and the additional value of the products is improved. The molten iron is preprocessed and then is cast into ingots to be sold. After being processed, the slag can serve as building materials or cement or other production raw materials. The gas can serve as gas fuel to be used in the plant. The method is very obvious in economic benefits and environmental benefits.

Owner:UNIV OF SCI & TECH BEIJING

One-stage mineral wool technology high-effectly utilizing industrial furnace smelting slag heat

InactiveCN1418834AObvious fluctuationsSolve the problem of continuous temperature measurementGlass making apparatusQuality levelManganese

The one-step method for producing mineral wool by using industrial furnace molten slag sensible heat includes the following steps: according to the requirement for chemical composition of mineral wool adding proper auxiliary raw material, at the same time, in homogenizing furnace making concurrent heating and regulating its chemical composition temp. and viscosity to make them reach to the requirements of mineral wool molten body, making molten body acidity coefficient be up to 1.1-1.8 (acidity coefficient=SiO2+Al2O3 / CaO+MgO), and the molten body temp. is 1300-1340 deg.C, homogenizing its chemical components, feeding the thermally-refined molten body into high-speed centrifuge and feeding it into fibre-forming procedure of mineral wool so as to obtain the invented product.

Owner:杨铧

Production method of inorganic fiber by using red mud and fly ash

The invention discloses a production method of inorganic fiber by using red mud and fly ash, mainly comprising the following steps: using the red mud and the fly ash as the raw materials, mixing the raw materials with the one or more of quick lime and industrial solid slag at certain ratio, adding the water, and drying naturally or stream-curing to form the block materials, mixing the raw materials with the coke at certain ratio in a cupola furnace, performing the high temperature melting to obtain inorganic fiber melt, and enabling the melt to flow into a four-roller centrifuge, throwing the melt at extremely high speed through the high-speed rotation of the four-roller centrifuge to form the inorganic fiber with the diameter of 3 to 7 mu m and the length of 7 to 20 cm, and discharging the iron slag from an iron notch at the side bottom of the cupola furnace to recover the iron. The method of the invention transforms the wastes and the harms into treasures, and reduces environmental pollution of the red mud, the fly ash and the industrial solid slag with high calcium content. The method of the invention makes the full use of the resources such as Al2O3, SiO2, Na2O, CaO and Fe2O3 in the red mud, the fly ash and the industrial solid slag with high calcium content, recycles the waste materials, saves the coke and has low production cost.

Owner:HENAN ENERGY AND CHEMICAL INDUSTRY

Control method for producing low temperature spheroidal graphite cast iron

The invention discloses a control method for producing low temperature spheroidal graphite cast iron, and relates to spherical graphite-containing cast iron alloy. The control method comprises the following steps of: weighing 3.4 to 3.9 mass percent of C, 1.8 to 2.5 mass percent of Si, 0.1 to 0.4 mass percent of Mn, 0.035 to 0.07 mass percent of residual Mg and the balance of Fe, smelting and desulfurizing in a cupola furnace, transferring to a medium-frequency induction furnace for continuous smelting, adding a spheroidizing agent and an inoculators for spheroidization and inoculation, and casting to obtain a spheroidal graphite cast iron casting for a wind turbine. In the method, by controlling the components of the spheroidal graphite cast iron and improving a spheroidization and inoculation process, the number, size, morphology and distribution of graphite nodules are controlled; the cupola furnace and the medium-frequency induction furnace are adopted for double smelting; and the produced spheroidal graphite cast iron casting meets the impact toughness requirement and strength requirement at low temperature of wind turbine castings, and overcomes the defect that deformation or stress concentration easily occurs when the spheroidal graphite cast iron casting is subjected to heat treatment in an annealing mode, and defect of high cost in the prior art.

Owner:HEBEI UNIV OF TECH

Mangan-alloy production

A manganese alloy preparing process for metallurgical steelmaking and mechanical casting. It is prepared by manganese ore adding electronating agent, exothermal agent and catalyst, breaking and grinding into particle powder material, proportional mixing and adding binder to prepare composite manganese alloy palletizing; smelting composite manganese alloy into liquefied slag containing manganese by vertical furnace or cupola, converting into arc furnace, inducing furnace with electroslag furnace, preparing different slag system under arc furnace electrode or inducing coil and electroslag furnace electrode heat, reducing combined manganese in liquefied slag containing manganese into intermetallic combined manganese alloy. Its advantages include no pollution, low consumption and high efficient.

Owner:长沙东鑫环保材料有限责任公司

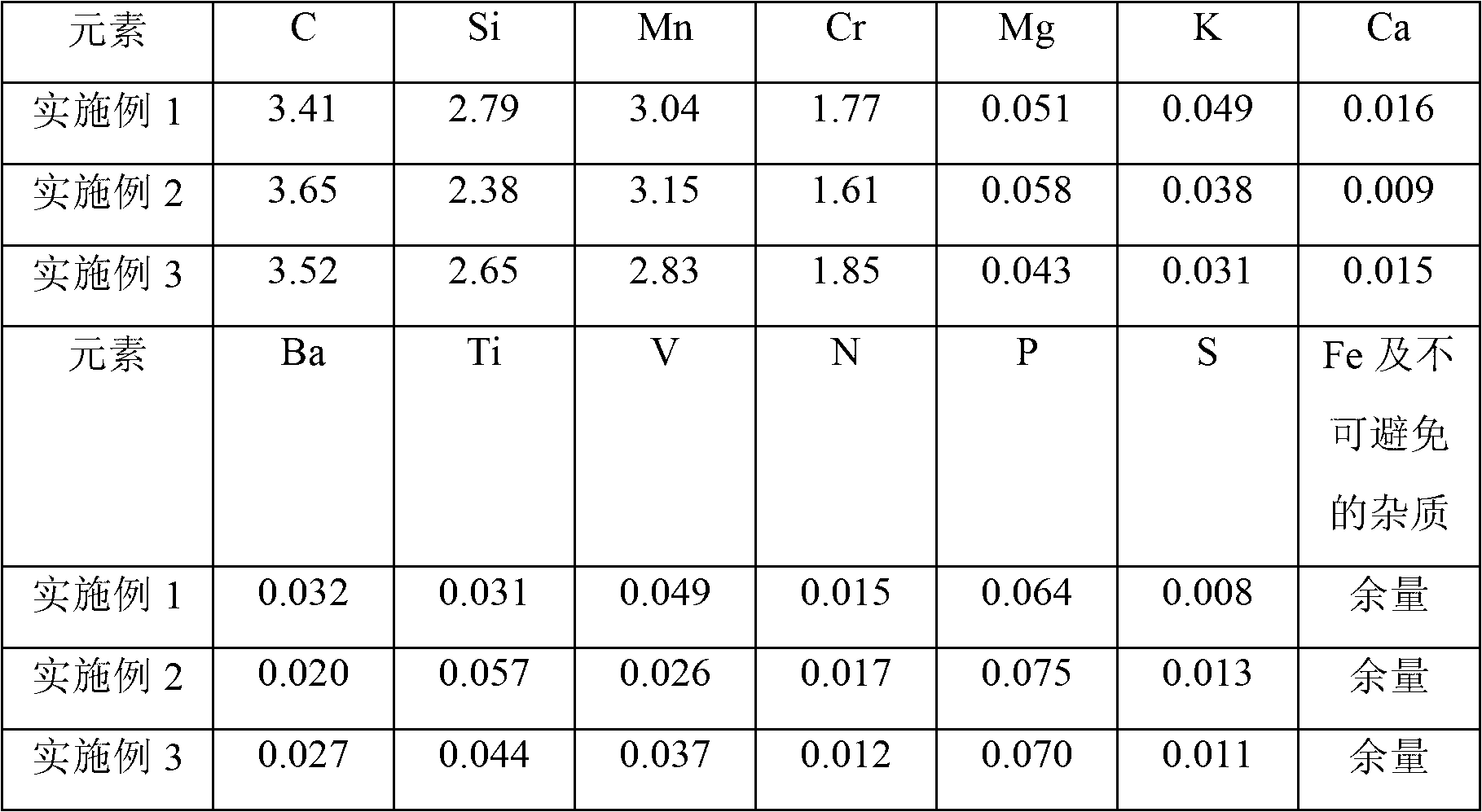

Carbide-containing ductile iron and its making method

The invention discloses a carbide-containing ductile iron and its making method. The carbide-containing ductile iron comprises the following components, by mass, 3.40-3.65% of C, 2.35-2.80% of Si, 2.80-3.15% of Mn, 1.60-1.85% of Cr, 0.04-0.06% of Mg, 0.03-0.05% of K, 0.008-0.016% of Ca, 0.018-0.035% of Ba, 0.03-0.06% of Ti, 0.025-0.050% of V, 0.012-0.018% of N, 0.10% or less of P, 0.02% or less of S, and the balance Fe and inevitable impurities. The carbide-containing ductile iron can be obtained through melting in an electric furnace or a cupola furnace, cast forming and isothermal quenching, and has the advantages of excellent performances, low cost, application popularization, and good effects.

Owner:BEIJING UNIV OF TECH

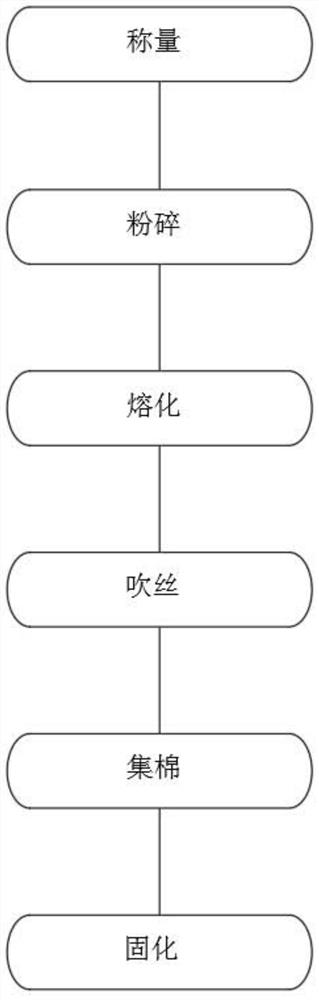

Manufacturing method of novel rock wool material

The invention discloses a manufacturing method of a novel rock wool material. The manufacturing method comprises the following steps: blending the following materials in parts by weight: 70-80 parts of basalt, 5-8 parts of limestone, 8-10 parts of slag, 20-30 parts of coke and 3-5 parts of auxiliary materials into a mixed raw material, placing into a cupola furnace, and fusing into magma at temperature lower than 900 DEG C; then forming a fiber, collecting wool, and paving the wool; then pressing on a three-dimensional wool presser, and solidifying and modifying to form the novel rock wool material. The rock wool material manufactured through the method disclosed by the invention has the advantages of uniformity in distribution, good hydrophobic effect and good mechanical property.

Owner:GUANGDE SKD ROCKWOOL MFG

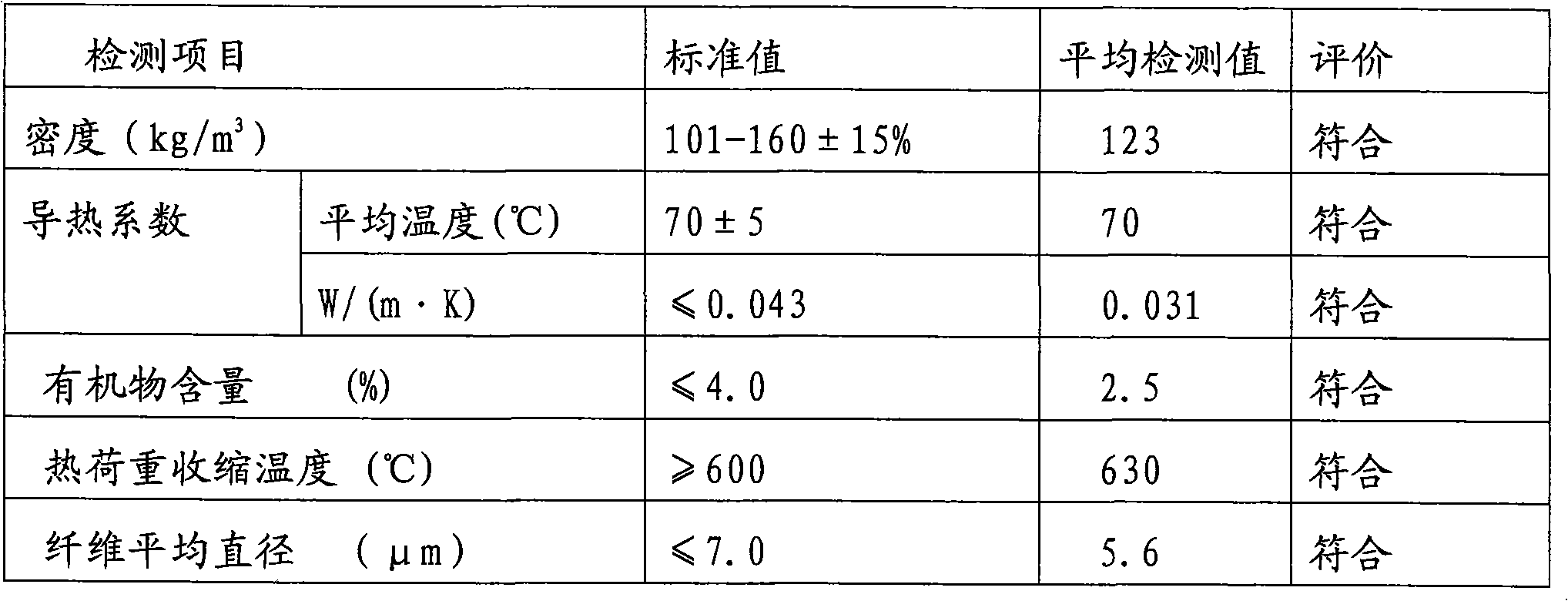

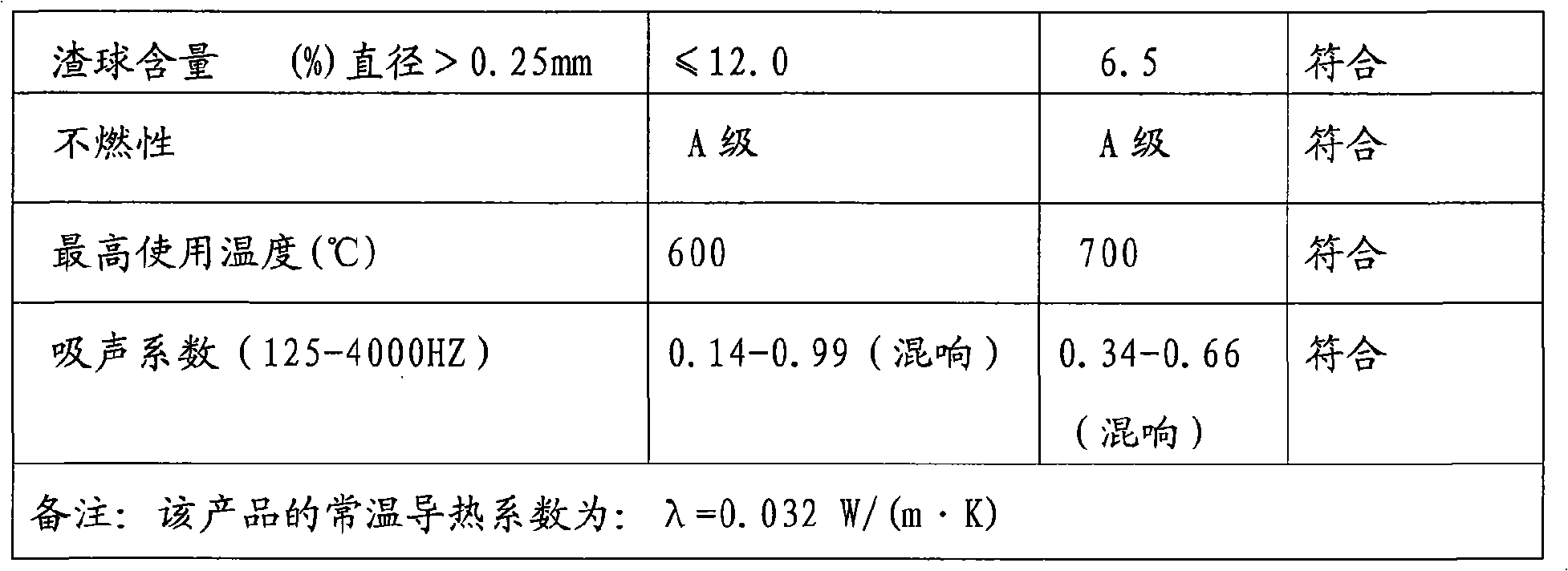

Method for preparing thermal insulation material with low heat conductivity coefficient

The invention discloses a method for preparing a thermal insulation material with a low heat conductivity coefficient, and belongs to the field of thermal insulation material manufacturing. The method comprises the steps that firstly, raw materials are processed, 600-680 kg per batch of basalt, 90-110 kg per batch of granite, 45-55 kg per batch of white rock, 140-150 kg per batch of coal gangue, 150-180 kg per batch of slag and 250-275 kg per batch of coke are mixed, crushed and preheated to the temperature ranging from 450 DEG C to 550 DEG C, the 28-34 m<3> per batch of liquid oxygen is added when the raw materials are fused and burned, and the temperature of a cupola furnace is kept at the temperature ranging from 890 DEG C to 970 DEG C; secondly, fibration is carried out on the materials; thirdly, rock wool is collected; fourthly, overlapping is carried out; fifthly, solidifying is carried out; sixthly, cutting and packaging are carried out. The the rock wool machined through the method is low in heat preservation heat conductivity coefficient, good in heat preservation effect, low in manufacturing cost and excellent in various properties.

Owner:MAANSHAN HONGDA INSULATION MATERIAL

Method for preparing nodular cast iron

InactiveCN103757172AImprove absorption rateImprove roundnessProcess efficiency improvementNuclear powerAdditive ingredient

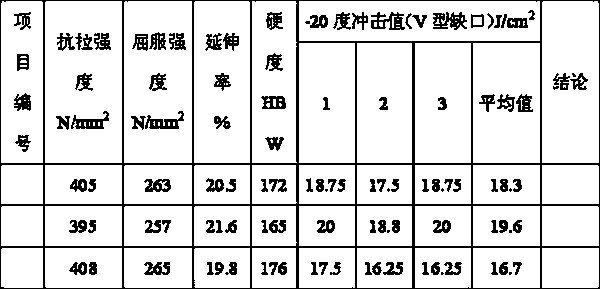

The invention discloses a method for preparing nodular cast iron. According to the invention, a cupola melting technology and an appropriate nodulizing process technology are adopted, inoculation is conducted for many times, and the box is opened in appropriate time, and therefore, that the high-quality low-temperature high-toughness nodular cast iron, of which the low-temperature comprehensive performance conforms to the QT400-18AL(-20 DEG C) standard is obtained is ensured. The nodular cast iron contains the following ingredients by weight percent: 3.3-3.6 percent of C, 1.8-2.2 percent of Si, less than 0.20 percent of Mn, 0.040 percent of P and Lt, 0.020 percent of S and Lt, 0.030-0.040 percent of Re and 0.040-0.055 percent of Mg. The nodular cast iron can meet the quality demands of low-temperature high-performance castings of wind power, nuclear power, high-speed rails and the like with higher quality requirements.

Owner:CHTC HEAVY IND

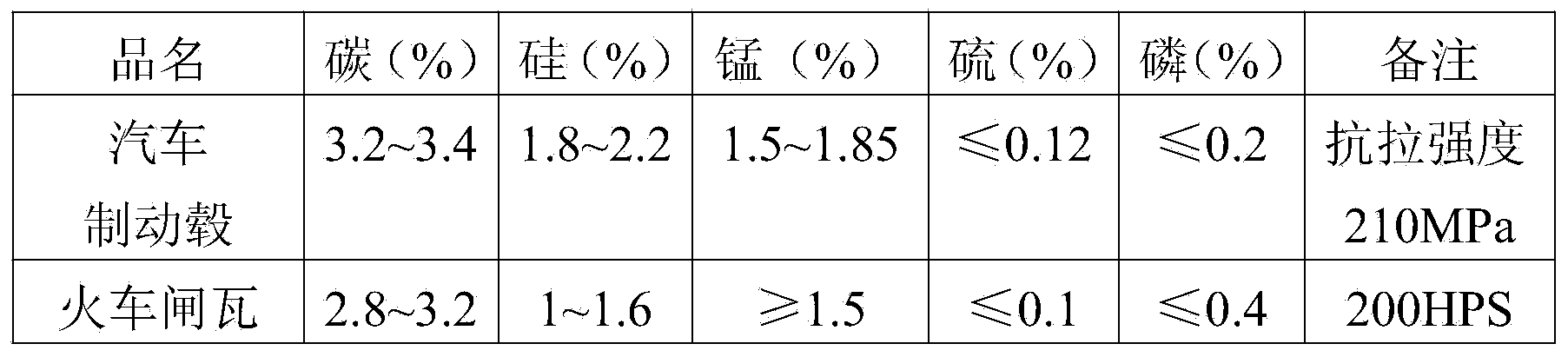

As-cast gray cast iron braking material with low alloy content and high thermal fatigue strength

The invention relates to the field of casting and discloses an as-cast gray cast iron braking material with low alloy content and high thermal fatigue strength. The as-cast gray cast iron braking material with low alloy content and high thermal fatigue strength comprises the following chemical components in percentage by weight: 3.5-3.7% of C, 1.6-2.0% of Si, 0.7-1.0% of Mn, 0.15-0.3% of Cu, 0.2-0.3% of Cr, 0.015-0.02% of Sb, 0.018-0.02% of Sn, not more than 0.08% of P, not more than 0.07% of S and the balance of Fe. A production method comprises the steps of: putting cast iron Q10 or Q12, waste steel, foundry returns and ferromanganese iron No. 60 in proportion as required into a cupola furnace for smelting, adding Cr and Sb alloy in certain proportion in a tapping water tank, adding silicon iron No. 75 and Sn and Cu alloy into a foundry ladle, performing primary inoculation and alloying on smelted molten iron, adding a composite inoculant into a casting ladle, performing secondary ladle-to-ladle inoculation, and pouring into a prefabricated sand mould for molding and cooling to obtain a product as required. Due to adoption of the technical scheme, materials are improved, the performance of a brake drum is enhanced and the production cost is reduced.

Owner:湖北三环铸造股份有限公司

Mn-Fe alloy production process

The present invention discloses production process of ferromanganese alloy for smelting steel and casting machine. The production process includes the following steps: crushing and grinding manganese ore with manganese content higher than 20 wt%, reductant, heat generating agent and catalyst separately, and mixing in certain proportion while adding adhesive to prepare manganese ore pellet; melting in a cupola into molten manganese-slag material; and smelting the molten manganese-slag material while adding conducting slag, iron ore and waste steel in an induction furnace heated with induction coil and conducting electrodes to obtain ferromanganese alloy as one kind of intermetallic compound. The production process has low power consumption, less environmental pollution and high production efficiency.

Owner:湖南华菱涟源钢铁有限公司

Automobile rear-bridge spiral conic gear of manganese-copper alloy autenite-bainite nodular iron and its preparing method

InactiveCN1936368AGuaranteed hardenabilityGuaranteed nodularityPortable liftingFurnace typesRoughcastCupola furnace

This invention relates to a MnCu alloy ADI car rear axle screw bevel gear and its preparation method, which takes ordinary pig iron as the raw material of said gear, applies a duplex method of cupola and electric cooker, takes rear earth, Mg and silicon iron alloy as the nodulizer to be processed then to slag and eliminate slag, gestates and casts the gear roughcast in two times, then finishes it after mechanical process, isothermal quenching and temper, in which, the composed weight percentage of said gear is: C 3.4-3.8%, Si 2.4-2.9%, Mn 0.4-1.0%, Cu 0.5-1.2%, P less than 0.06%, S less than 0.02% and the rest is iron.

Owner:WUHAN UNIV OF TECH +1

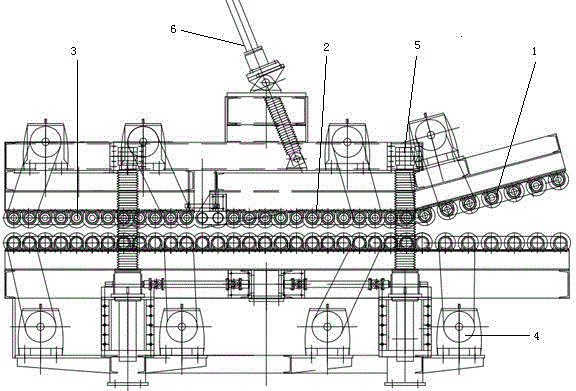

One-box four-type casting process of brake disk

ActiveCN101704069AQuick changeImprove interchangeabilityFoundry mouldsFoundry coresProduction lineHigh rate

The invention discloses a one-box four-type casting process of a brake disk. The process comprises the following technological steps: a sand processing procedure adopts a chassis rotary type rotor sand mixing machine, sand mixing is carried out according to a sand mixture ratio, the sand mixing efficiency is 120 tons / hour, and the sand mixing time is 3-5 minutes; a moulding procedure adopts a static-pressure production line with double-host wiring for moulding and a special mould of a one-box four-type brake disk, the production efficiency is 180 boxes / hour, and the moulding pressure intensity is 8-10MPa; a smelting procedure adopts a cupola and an electric furnace for double smelting, the pouring temperature is 1450-1490 DEG C, and 0.3% of degeneracy-resisting silicon-barium nucleating agent is added before the furnace; a pouring procedure adopts an automatic pouring truck for pouring, and the pouring time is 8-15 seconds; and a desanding and shot blasting procedure adopts a vibration type desanding machine for desanding, and then a stepping type suspended connection shot cleaning chamber is used for cleaning the brake disk. The production process has the characteristics of high rate of finished products, high technological casting yield, high mechanization degree, short production period, high production efficiency, small energy consumption and the like.

Owner:YANTAI WINHERE AUTO PART MFG

Dot graphite cast iron and its production method

A dot-graphite cast iron contanis C (2.2-3.6 wt.%), Si (1.0-1.8), Mn (0.4-1.2) and Fe (rest). It is prepared through smelting iron in copola furnace while controlling the contents of C, Si and Mn, adding modifier (SiFe, RE-SiFe, SiCa, Or AlBiSb alloy) to casting lalde, laying aside for 3-5 min, skimming, and casting at 1350 deg.C. The performance of its casting is higher than that of nodular graphite cast iron.

Owner:肖治平 +1

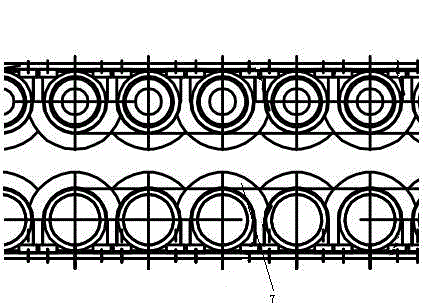

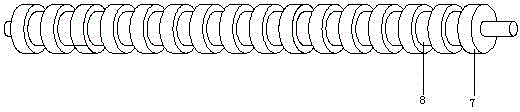

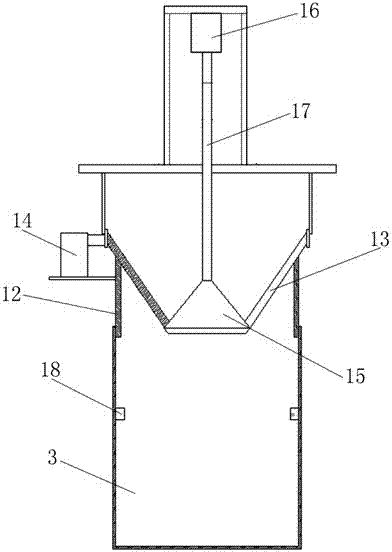

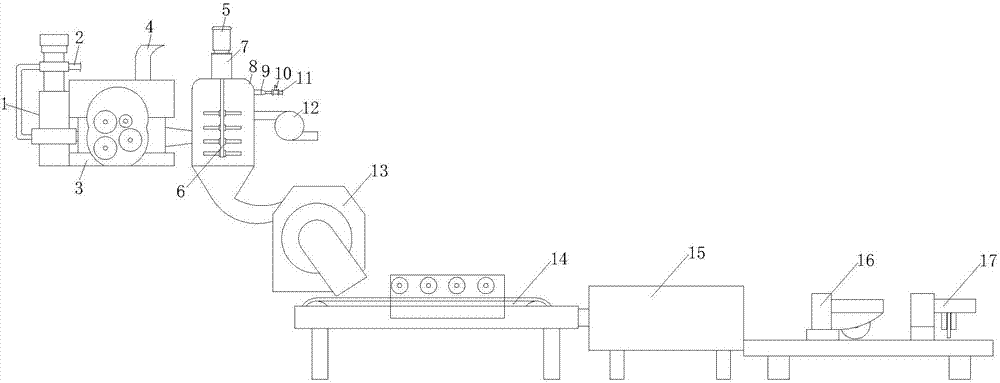

High-yield rock wool production line

ActiveCN103776260AUniform melting rateAutomatic adjustment of feed rateGlass making apparatusVertical furnacesProduction lineFiber

The invention relates to one technical field, in particular to a high-yield rock wool production line. The high-yield rock wool production line comprises an automatic weighing and feeding system, a fiber manufacturing system, a cotton collecting machine, a bob cotton distributing machine, a pleating machine, a curing stove, a cutting device, a packaging device and an exhaust gas and waste processing system. The high-yield rock wool production line is characterized in that the fiber manufacturing system comprises a cupola furnace and a fiber forming machine, the upper portion of the cupola furnace is provided with a material even distributing device, a material level controller is arranged inside a cupola furnace body, and the material level controller and an electric push rod are respectively connected with a controller through lines; the internal diameter of the cupola furnace body ranges from 1800 mm to 1900 mm, a water cooling device is arranged along the outer side of the cupola furnace body, a water cooling device is arranged in the air inlet of the cupola furnace, and the discharge port of the cupola furnace is connected with the feed port of the fiber forming machine through a movable chute. The high-yield rock wool production line has the advantages of being high in yield, even in fiber and cotton silk discharging, and stable in fiber forming quality.

Owner:TAISHI ROCK WOOL

Austenic cast iron with low Al and Ni content and medium Mn content and its production process

The present invention features that into austenic cast iron with low Al and Ni content and medium Mn content, 75 ferro-silicon alloy and / or Al is added to obtain metallographic structure comprising type-A graphite, austenic base and homogeneously distributed granular carbide of quantity not less than 1.5 %. The technological process includes melting charging material first in electric furnace or cupola furnace with tapping temperature over 1400 deg.c, adding 75 ferro-silicon alloy in iron ladle, and subsequent adding 75 ferro-silicon alloy and / or Al wire. The austenic cast iron of the present invention has the chemical composition of: C3.0-4.0 wt%, Si 2.0-3.0 wt%, Mn 8.0-10.0 wt%, Ni 1.0-4.0 wt%, Cu less than 3.0 wt% and Al not more than 0.3 wt%. It is suitable for use in electric equipment parts, engine piston ring and cylinder sleeve with operating temperature lower than 500 deg.c.

Owner:DONGHUA UNIV

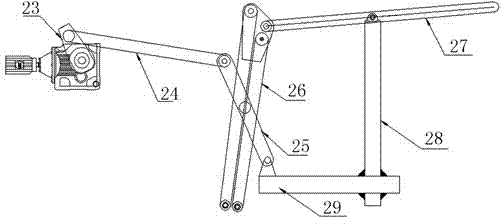

Process for producing vermicular cast iron by cupola-line frequency furnace duplex melting

The invention discloses a process for producing vermicular cast iron by cupola-line frequency furnace duplex melting, which comprises the following steps of melting base molten iron in a cupola, regulating molten iron ingredients in a line frequency furnace, heating, refining, vermicularizing, inoculating, processing, and the like. The process adopts a novel cupola composition method, optimizes the processing conditions, does not require desulphurization processing during the process of melting the base molten iron in the cupola and can produce the vermicular cast iron stably. The process can be used for producing various grades of vermicular cast iron, is especially suitable for the reconstruction that a traditional casting department of producing gray cast iron is converted into a department of producing the vermicular cast iron and has the advantages of less investment, simple operation and stable product quality.

Owner:GUANGXI YUCHAI MASCH CO LTD

Hollow-core rock wool and preparation method and applications thereof

InactiveCN101538122AFiber lengthIncrease elasticityGlass making apparatusJet aeroplaneChemical industry

The invention discloses a hollow-core rock wool and a preparation method and applications thereof, belonging to the field of temperature-preservation and heat-insulation materials. The hollow-core rock wool consists of the following materials by weight percentage: 60-70% of basalt, 20-30% of dolomite, 2-6% of diabase, and 4-8% of fluorite. After being mixed evenly, the materials are put into a cupola and melted at high temperature of 900-1000 DEG C, and then the hollow-core rock wool is obtained. The rock wool has long fiber, good temperature-preservation and heat-insulation properties, fireproofing capability, good elasticity, strong tensile force and good hand-feel, thus being head and shoulders above the slag cotton. All properties are in full compliance with standards of nation, national defense, industry, aerospace, navigation, construction, petroleum, chemical industry, and agriculture. The hollow-core rock wool can be used for the industries such as electric power, chemical industry, petroleum, construction, metallurgy, textile, shipping, automobile, train, airplane, heating pipe and the like, and is the temperature-preservation and heat-insulation material of industrial equipment such as pipeline storage tanks, boiler flues, heat exchangers, large airports, gyms, large-scale cold storage and the like, and civil building engineering.

Owner:鞠加会

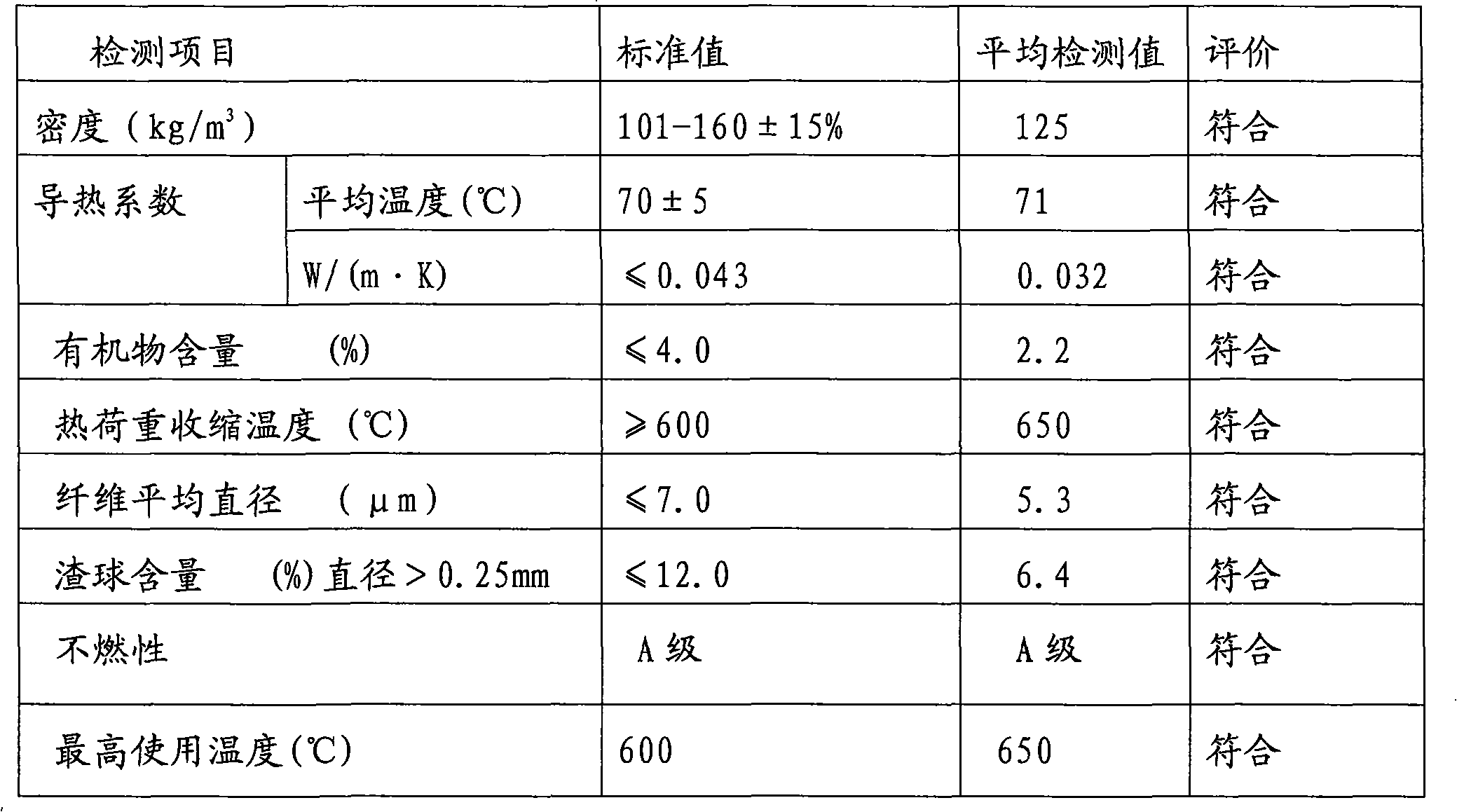

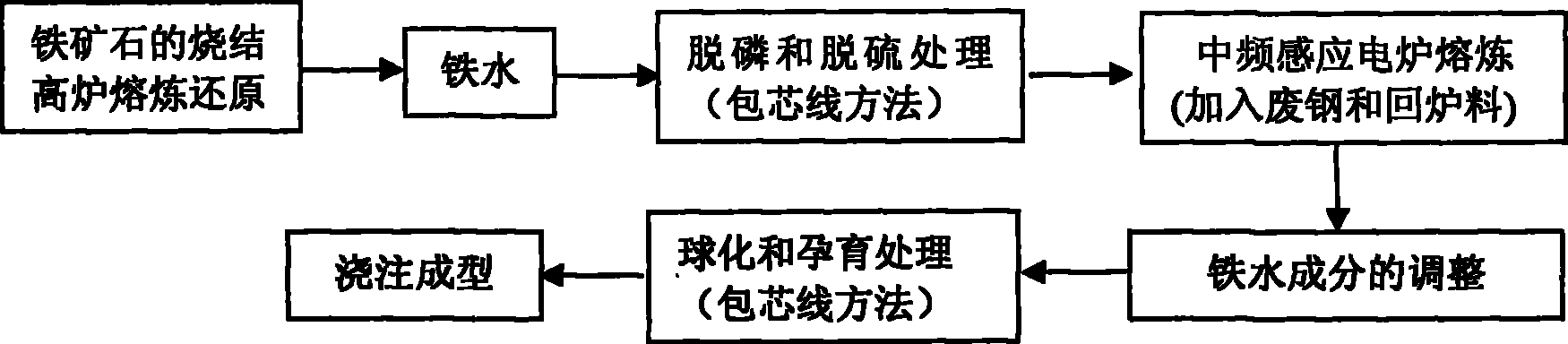

Short process production technique for preparing casting of wind power generation equipment

InactiveCN101787403AImprove melting efficiencySave coolingBlast furnace detailsElectric furnaceYarnCupola furnace

The invention discloses a short process production technique for preparing a casting of wind power generation equipment, relates to the manufacturing of cast iron alloy and is a short process production technique for preparing a thick and large section casting of the wind power generation equipment; the short process production technique includes that: molten iron obtained through the sintering of iron ore and the reduction of blast furnace smelting receives dephosphorization and desulfurization treatment and is injected into a medium-frequency induction furnace for smelting continuously with steel scrap and scrap returns, meanwhile the composition of the molten iron is regulated, and then spheroidization and inoculation are carried out to obtain the thick and large section casting for the wind power generation equipment after the final step of cast molding. The invention adopts the short process technique and accordingly improves the production efficiency; a cupola furnace is replaced by the medium-frequency induction furnace to accurately control the impurities and temperature of the molten iron and also have the effects of environmental protection and energy-saving and consumption reduction; core-spun yarns are adopted for the processes of dephosphorization, desulfurization, spheroidization and inoculation so that the treatments are quick and efficient, the number of graphite balls is effectively increased, and the thick and large section casting of high quality for the wind power generation equipment is obtained.

Owner:HEBEI UNIV OF TECH

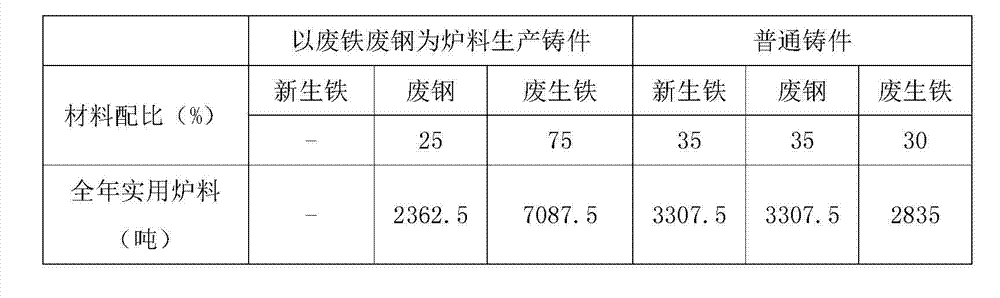

Method for producing high-strength cast iron by using waste iron and steel

InactiveCN102888484AGood castabilityImprove purityProcess efficiency improvementPorosityFine structure

The invention discloses a method for producing high-strength cast iron by using waste iron and steel. The method comprises the following steps of: weighing 68 to 72 weight percent of waste iron, 28 to 32 weight percent of waste steel and 1.4 to 1.6 weight percent of manganese iron; smelting metallic furnace charges, namely the waste iron and the waste steel at a high level by using two rows of cupolas, wherein the base coke blowing strength is about 100m<3> / m<2>.min, and the tapping temperature is controlled to be more than and equal to 1,450 DEG C, coke with low ash content and porosity and 85 percent of fixed carbon is adopted, so that the molten iron is always in a high temperature state and fully recarburized; and performing inoculation treatment on the molten iron, and when the molten iron is discharged, adding spare silicon iron into an iron charging groove. The cast iron is high in strength and has a fine structure, and the graphite content is low; and the casting performance and machining performance of the cast iron are high, the manufacturing cost is low, and harmful hereditary does not exist.

Owner:安徽金泰精密机床配件股份有限公司

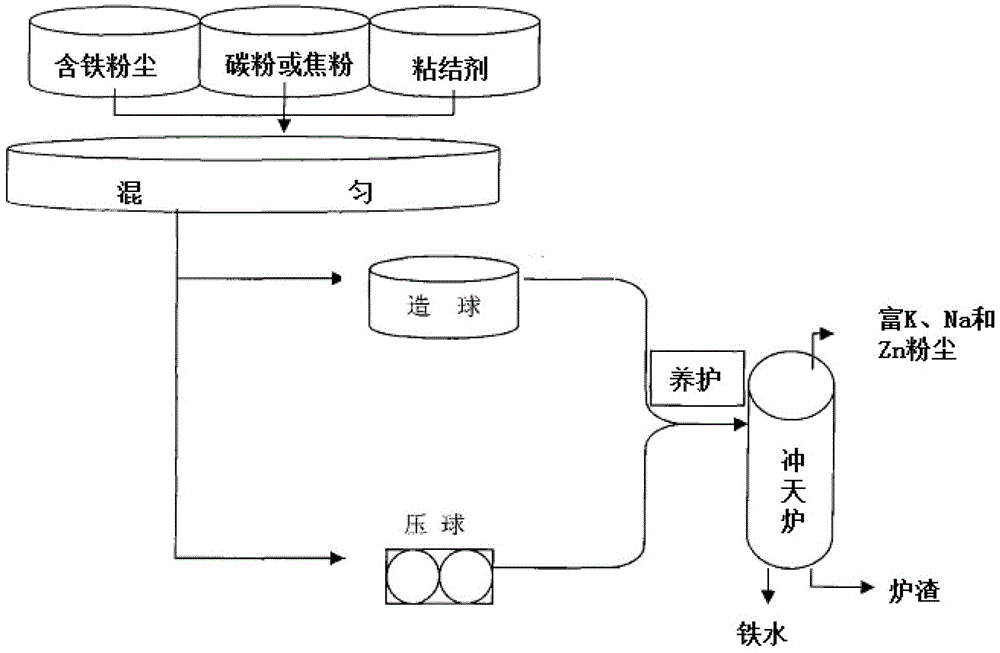

Method for treating iron-containing dust of iron and steel plant by using cupola furnace

The invention discloses a method for treating iron-containing dust in an iron and steel plant by using a cupola furnace, belonging to the technical field of iron making. The method is characterized by comprising the following steps of: blending, uniformly mixing, briquetting and maintaining raw materials including dust in the iron and steel plant, a carbonaceous reducing agent, a bonder and an additive, and then putting the raw materials into the cupola furnace for iron making, wherein the carbon content of carbon-containing pellets prepared by briquetting raw materials of various iron-containing dust in the iron and steel plant is about 10%, the compressive strength of the maintained pellets is greater than 1000N per each pellet, and the pellets are distributed into the cupola furnace for iron making through a material distribution system; and preheating blast through a hot blast furnace, preheating the wind temperature from a normal temperature to about 500-1200 DEG C, and enriching oxygen by 1-5% in the blast to achieve the aims of improving the smelting strength, increasing the output and reducing the coke ratio. By adopting the method, the dust of the iron and steel plant can be recycled to achieve the aims of saving energy, reducing emission and reducing environmental pollution, so that the method has good economic and social benefits.

Owner:UNIV OF SCI & TECH BEIJING

Nodular cast iron for rear axle housing of lorry and production method of nodular cast iron

The invention discloses nodular cast iron for a rear axle housing of a lorry. The nodular cast iron comprises, by weight percentage, 3.40-3.49% of C, 2.35-2.55% of Si, 0.50-0.60% of Mn, not more than 0.025% of S, not more than 0.055% of P, 0.03-0.04% of rear earth, 0.04-0.06% of Mg, and the balance of Fe. A production method the nodular cast iron includes: modeling with furan resin sand, using double connection of a cupola furnace and an electric furnace for smelting, adopting low spheroidizing temperature, paying attention to spheroidizing adding sequence, performing secondary drossing after spheroidizing, performing metal-stream inoculation during pouring, and controlling pouring time to pour the required nodular cast iron. The prepared nodular cast iron is excellent in mechanical performance, compact in matrix structure, low in cost, high in performance, competitive in market, and optimal for the rear axle housing, and adding of electrolytic copper is not needed.

Owner:HENAN GUANGRUI AUTO PARTS

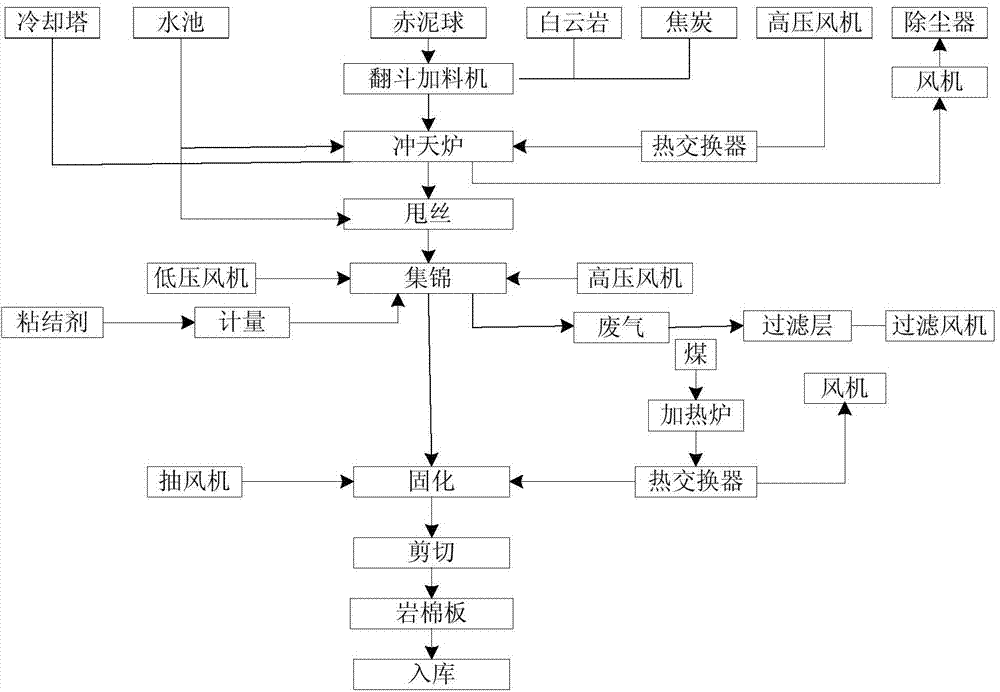

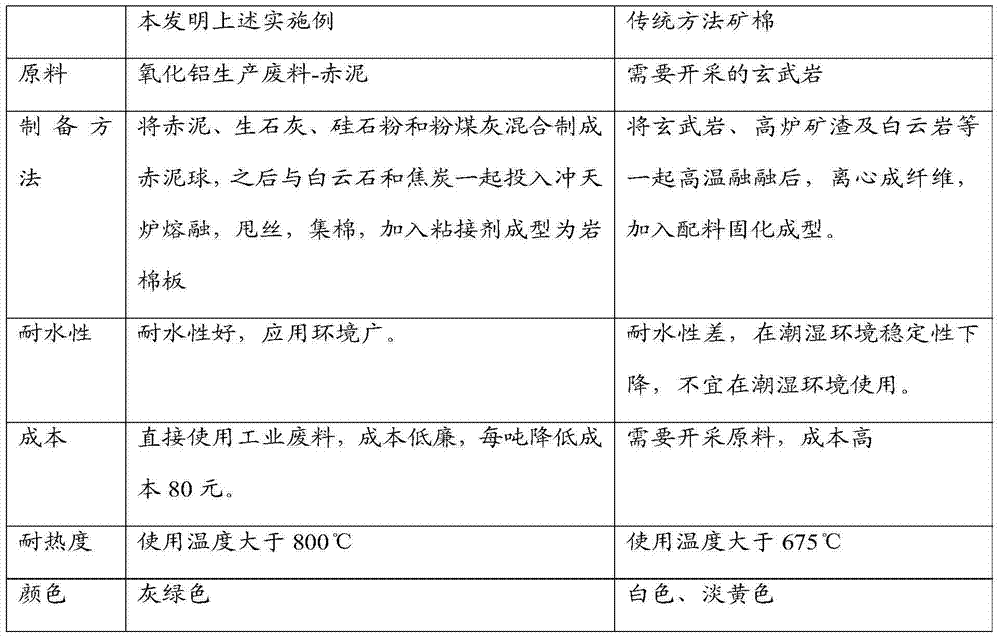

Rock wool and method for producing rock wool by utilization of high-alkali red mud

The invention belongs to the field of rock wool processing and specifically relates to rock wool and a method for producing rock wool by the utilization of high-alkali red mud. The method for producing rock wool by the utilization of high-alkali red mud comprises the following steps: (1) fully mixing red mud, quicklime, ground silica and fly ash, uniformly stirring and pressing by a ball press machine to obtain red mud balls; and (2) airing the pressed red mud balls and uniformly mixing the pressed red mud balls with blocky dolomite and coke, adding the mixture into a cupola furnace and fusing, carrying out fiber forming by the use of a centrifuge, applying a binder to produce flocculent mineral wool, and carrying out post-treatment to prepare the rock wool product. According to the rock wool and the method for producing rock wool by the utilization of high-alkali red mud, refuse reclamation can be realized, the environment is protected, production cost of rock wool can be reduced, and the prepared rock wool has good water resistance.

Owner:山东安格尔环保科技有限公司

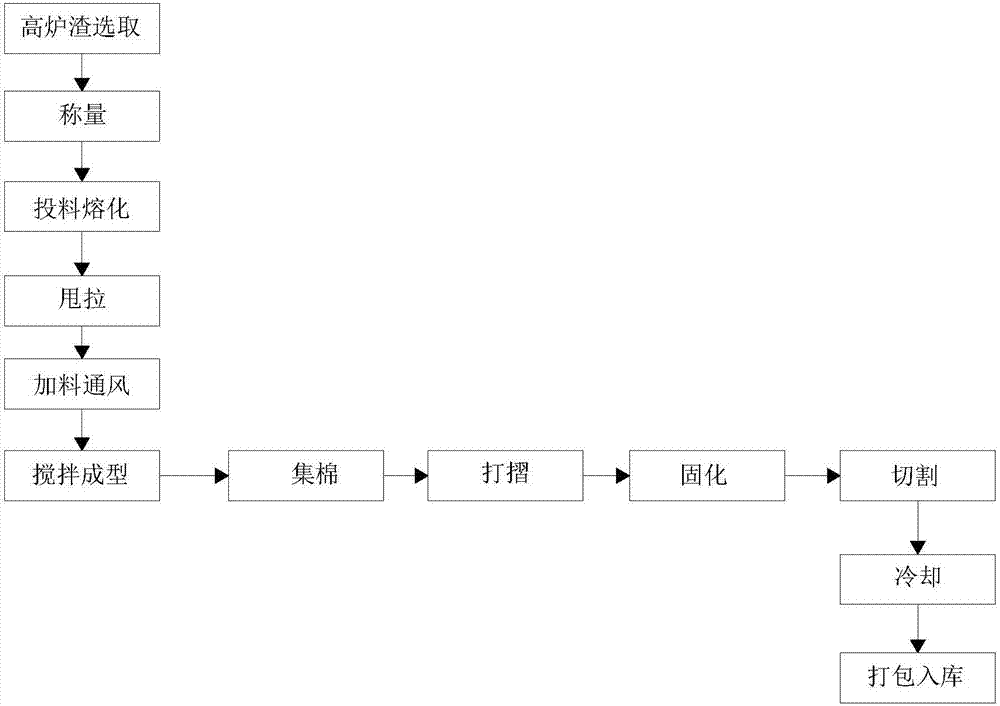

Technology and device for producing rock wool from molten blast furnace slag

PendingCN106863827AImprove product qualityImprove insulation effectGlass making apparatusFlat articlesSlagAdhesive

The invention discloses a technology and device for producing rock wool from molten blast furnace slag. The device comprises a cupola furnace. The cupola furnace is fixedly installed on a four-roller centrifugation machine for centrifuging molten blast furnace slag. A fold beating machine for flattening folds and rolling rock wool is installed below an outlet of a wool collection machine, one side of the fold beating machine is provided with a curing furnace used for curing so as to improve stress, one side of the curing furnace is provided with a first cutting device and a second cutting device which are used for slicing rock wool, and throwing and pulling, stirring forming, wool collection, fold beating, curing, cutting and other processes are carried out. According to the technology and device for producing rock wool from molten blast furnace slag, the cupola furnace and the four-roller centrifugation machine are combined into a whole, installation investment of equipment is reduced, the production cost is reduced, the weighed blast furnace slag value and the input adhesive, dustproof oil, water repellent and resin values are put in proportion, stirring forming, wool collection, fold beating, curing, cutting and other processes are carried out, the good production quality of rock wool is ensured, and the heat insulation effect is improved.

Owner:马鞍山市北益环保科技有限责任公司

High-strength inoculated casting and manufacturing method thereof

The invention discloses a high-strength inoculated casting and a manufacturing method thereof. The manufacturing method mainly comprises the following steps: (1) selection and proportioning of raw materials; (2) ball milling and stirring; (3) casting; (4) static primary curing, vapor recovery and waste heat reutilization; (5) demolding and cutting; and (6) autoclaved curing. According to the invention, a cupola furnace can be utilized to smelting high-strength cast iron, wherein the tapping temperature of molten iron is defined to 1470-1570, and the effect is good; the proportions of scrap steel and scrap machine iron are enhanced in the raw materials; a C-Si inoculator technique can be utilized to obtain an HT250 pig iron casting under the condition that CE is less than 2.7%; and the method has the advantages of reasonable raw material proportioning and low cost, solves the technical problems of high deformation tendency and insufficient hardness in the casting, recycles the resources, and is beneficial to environmental protection. The high-strength inoculated casting has the advantages of high strength, excellent elastic modulus and excellent wear resistance, and is a good material for reducing the casting deformation.

Owner:南京德惠新材料科技有限公司

Rock wool and method for producing and manufacturing rock wool

InactiveCN111847891ASimilar melting rateImprove melting efficiencyGlass furnace apparatusNon-woven fabricsFiberSlag

The invention discloses rock wool. The rock wool is prepared from the following raw materials in parts by weight: 390 parts of basalt, 60 parts of slag, 70 parts of dolomite, 0.7 part of a water repellent and auxiliary materials. According to the rock wool and the method for producing and manufacturing the rock wool in the invention, the basalt, the dolomite and the slag in the raw materials are crushed to particle size ranges of 80-120 mm, 40-60 mm and 60-100 mm, respectively, so the melting speeds of the basalt, the dolomite and the slag in a cupola furnace are guaranteed to be similar, andthe melting efficiency of the basalt, the dolomite and the slag and mixing effect after melting are improved to the maximum extent; and molten liquid passes through an adjustable launder to form a stable stream, the stable stream is conveyed to a wire roller centrifugal machine for thread throwing to prepare fibers, and the quality of the made fibers is improved.

Owner:湖南恒盛新材料有限公司

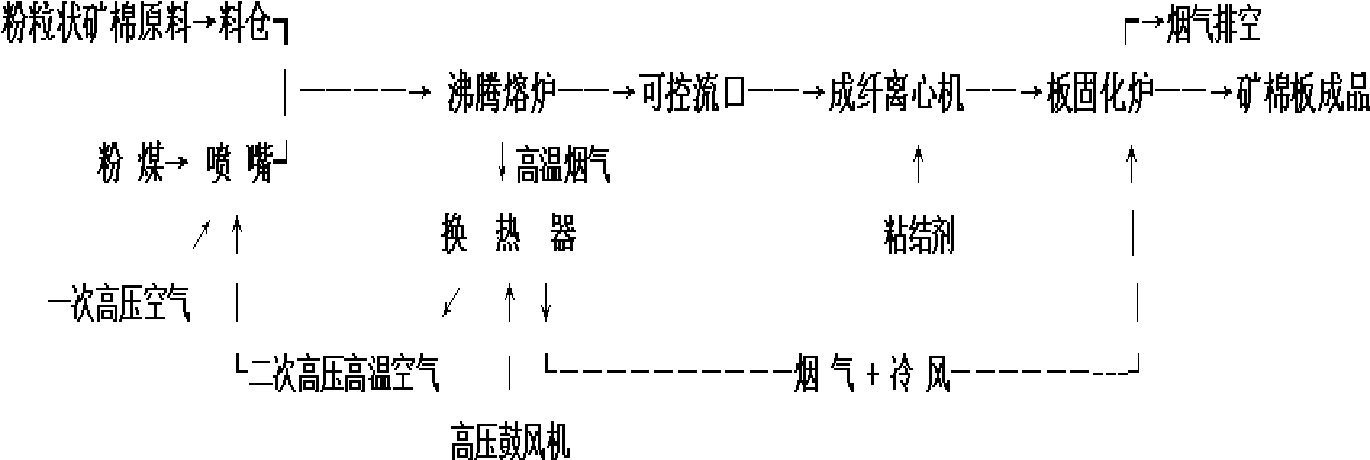

A mineral wool boiling melting method of directly using grainy waste slag and coal

The invention discloses a mineral wool boiling melting method of directly using grainy waste slag and coal, which pertains to the field of mineral wool production technology. The method includes: taking using grainy waste slag, etc., as mineral wool raw materials, continuously quantitatively adding into the melting bath of a boiling smelter, and using high-pressure and high-temperature air to spray the fuel (coal) into the melting body below the boiling smelter bath surface; providing raw materials, auxiliary materials for the melting bath of the boiling smelter so that the melting bath intensely boils to speed up melting and homogenization of mineral wool raw materials; mineral wool melt body controlling the flow quantity of the flow strand according to the fiber-forming mount requirement of fiber-forming machine, and then guiding the flow strand to the material roller of the fiber-forming machine, to performing the normal mineral wool fiber-forming process. The inventive melting has higher thermal efficiency, which can reach more than 40%, 10 to 15 percentages higher than the ordinary mineral wool cupola. And the invention can significantly reduce the mineral wool melting of the energy consumption.

Owner:洛阳了不起信息科技有限公司

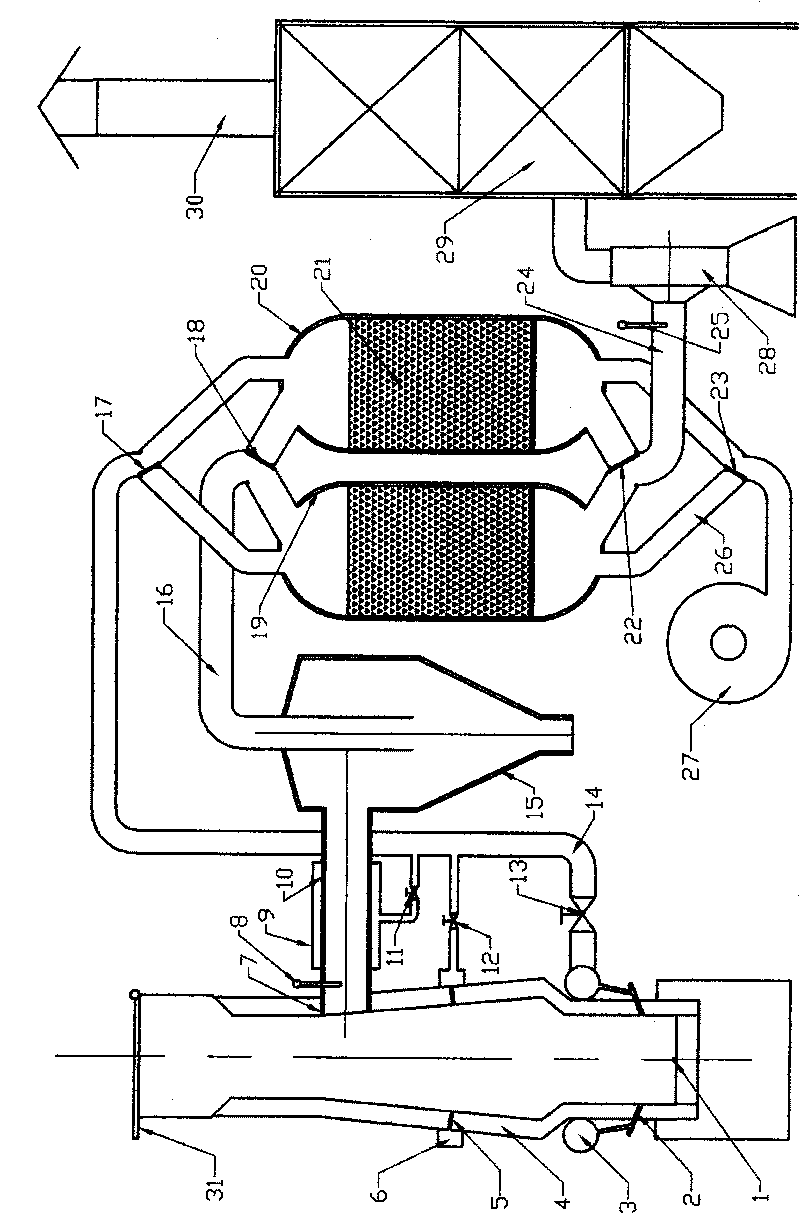

Heat accumulating type external heat blast cupola furnace

InactiveCN101726175AHigh thermal efficiencyStable combustionVertical furnacesEngineeringCupola furnace

The invention discloses a heat accumulating type external heat blast cupola furnace. The lower part of a furnace body is provided with a main air bellow; the middle part of the furnace body is provided with a primary combustion-supporting air bellow; the upper part of the primary combustion-supporting air bellow is provided with a furnace gas leading-out pipe; the furnace gas leading-out pipe is provided with a thermocouple and a secondary combustion-supporting air bellow; the other end of the furnace gas leading-out pipe is connected with a cyclone dust extractor; an air outlet of the cyclone dust extractor is connected with two heat accumulated type heat exchangers through smoke outlet pipes; the other ends of the heat exchangers are connected with a blast blower and a draught fan through pipelines provided with reversal valves; high-temperature hot blast output by the heat accumulated type heat exchangers is sent into the main air bellow, the primary combustion-supporting air bellow and the secondary combustion-supporting air bellow; an inlet smoke pipe of the draught fan is provided with a thermocouple; and an outlet of the draught fan is connected with a secondary dust collector. The heat accumulating type external heat blast cupola furnace does not use a combustion-supporting fuel to ignite furnace gas, the temperature of the hot blast reaches 600 to 900 DEG C, and the heat efficiency is over 60 percent which is far higher than that (25 to 35 percent) of the cupola furnace in general use at present.

Owner:赵文鹤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com