One-box four-type casting process of brake disk

A casting process and brake disc technology, which is applied in the field of automobile brake system production, can solve the problems that the artificial casting process cannot meet the needs of the factory, the pouring system has poor slag resistance ability, and cannot meet modern production, so as to reduce air pollution, Good for slag blocking and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: its processing step is:

[0065] (1) Sand treatment process: The sand mixing ratio used is 3 parts of new sand, 91 parts of old sand, 1 part of bentonite, 4 parts of coal powder, 0.8 part of water, and the sand mixing time is 3.5 minutes.

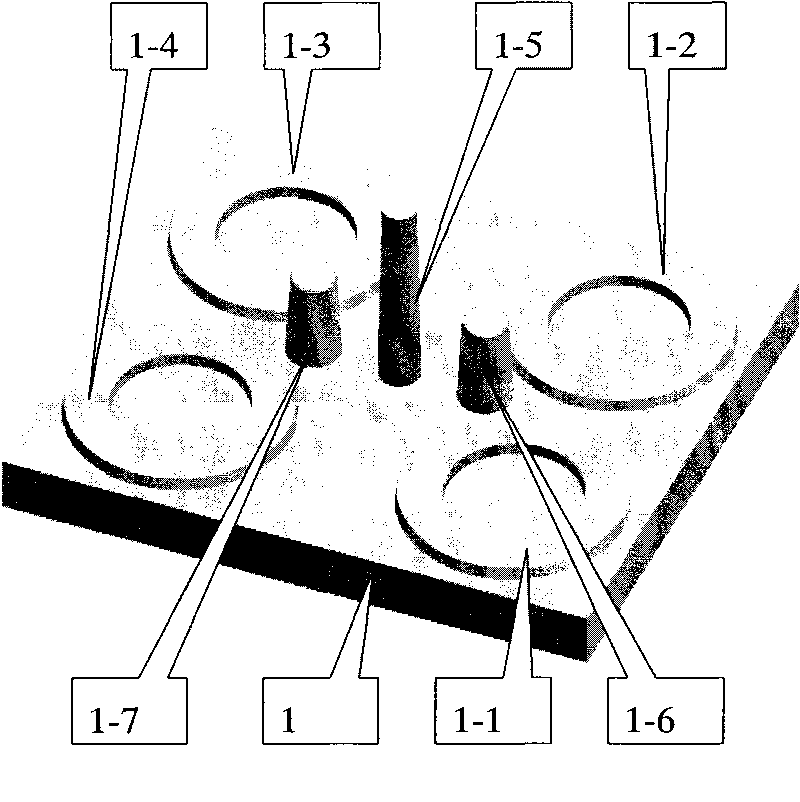

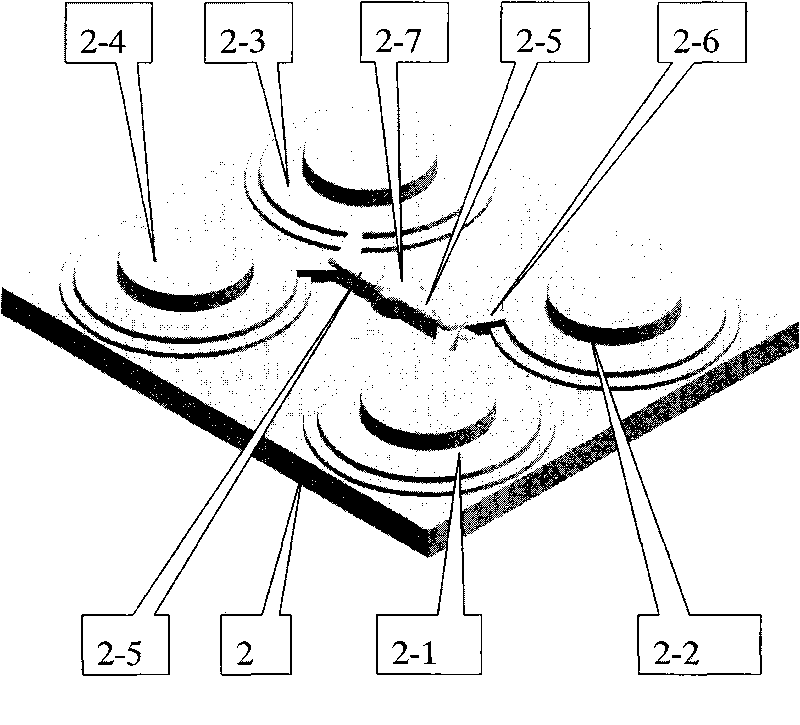

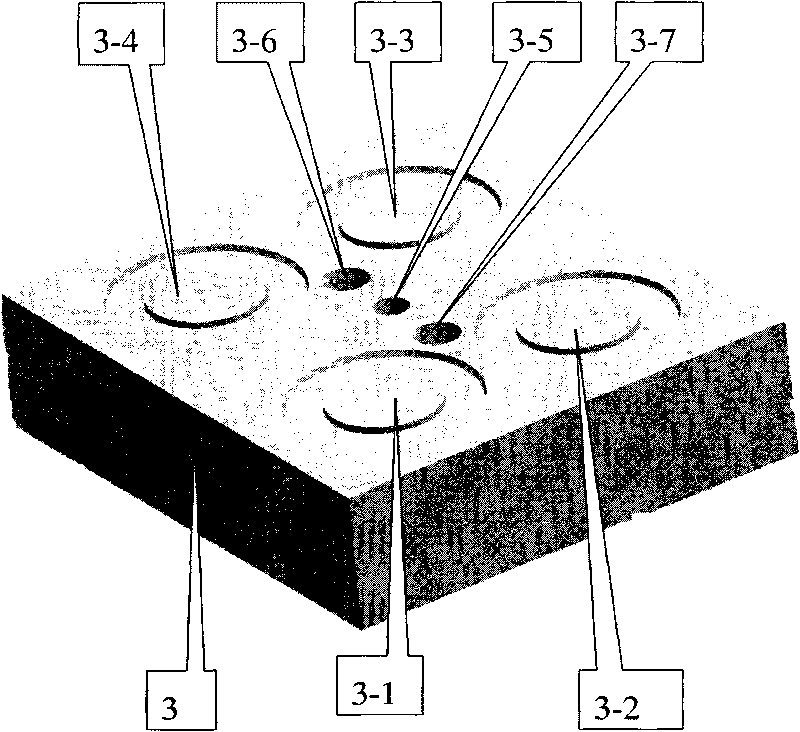

[0066] (2) Molding process: Turn on the automatic static pressure molding line, use a box of four-type special molds for brake discs, and adjust the pressure of the molding machine to 8Mpa for molding.

[0067] (3) Smelting process: open the double smelting of the cupola furnace and the electric furnace, so that the temperature of the molten iron reaches 1550°C and is released from the furnace.

[0068] (4) Pouring process: start the automatic pouring vehicle for pouring, the pouring temperature is 1490°C, and the pouring time is 15 seconds.

[0069] (5) Desanding and shot blasting process: After pouring, it is automatically transferred to the cooling line, from the cooling line to the vibrating desanding machine for d...

Embodiment 2

[0070] Embodiment 2: its processing step is:

[0071] (1) Sand treatment process: The sand mixing ratio used is 4 parts of new sand, 90 parts of old sand, 2 parts of bentonite, 3 parts of coal powder, 0.9 part of water, and the sand mixing time is 4 minutes.

[0072] (2) Molding process: Turn on the automatic static pressure molding line, use a box of four-type special molds for brake discs, and adjust the pressure of the molding machine to 9Mpa for molding.

[0073] (3) Smelting process: open the double smelting of the cupola furnace and the electric furnace, so that the temperature of the molten iron reaches 1550°C and is released from the furnace.

[0074] (4) Pouring process: open the automatic pouring vehicle for pouring, the pouring temperature is 1470°C, and the pouring time is 12 seconds.

[0075] (5) Desanding and shot blasting process: After pouring, it is automatically transferred to the cooling line, from the cooling line to the vibrating desanding machine for des...

Embodiment 3

[0076] Embodiment 3: its processing step is:

[0077] (1) Sand treatment process: The sand mixing ratio used is 5 parts of new sand, 89 parts of old sand, 3 parts of bentonite, 2 parts of coal powder, and 1 part of water, and the sand mixing time is 5 minutes.

[0078] (2) Molding process: Turn on the automatic static pressure molding line, use a box of four-type special molds for brake discs, and adjust the pressure of the molding machine to 9Mpa for molding.

[0079] (3) Smelting process: open the double smelting of the cupola furnace and the electric furnace, so that the temperature of the molten iron reaches 1550°C and is released from the furnace.

[0080] (4) Pouring process: start the automatic pouring vehicle for pouring, the pouring temperature is 1450°C, and the pouring time is 8 seconds.

[0081] (5) Desanding and shot blasting process: After pouring, it is automatically transferred to the cooling line, from the cooling line to the vibrating desanding machine for d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com