High-yield rock wool production line

A production line and high-yield technology, applied in lighting and heating equipment, furnace types, glass manufacturing equipment, etc., can solve the problems of unstable fiber quality, large gap between rock wool finished products, and low output, and achieve a high degree of automation and melting The effect of uniform rate and stable melt flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

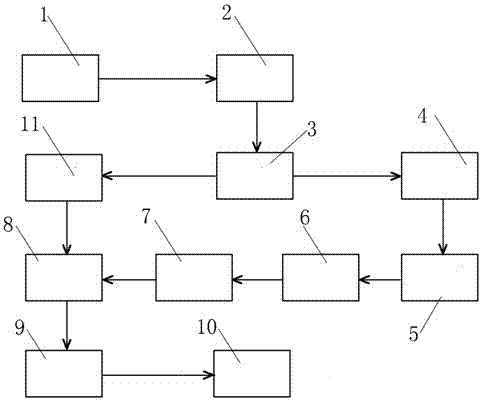

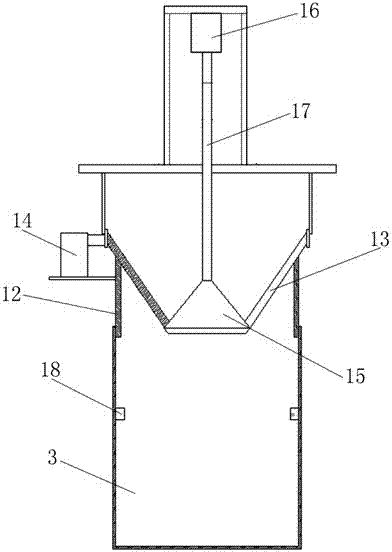

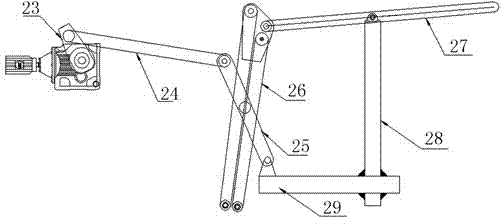

[0010] The present invention will be further described now in conjunction with accompanying drawing, figure 1 It is an embodiment of the present invention, including automatic weighing and feeding system 1, fiber making system, cotton collector 5, pendulum cloth cotton machine 6, folding machine 7, curing furnace 8, cutting equipment 9, packaging equipment 10 And exhaust gas waste treatment system 11, described fiber system comprises cupola 3 and fiber forming machine 4, and the top of cupola 3 is provided with uniform distribution device 2, and this uniform distribution device 2 comprises support 12, rotary funnel 13, motor 14 , blocking block 15 and electric push rod 16, support 12 is cylindrical, is arranged on the top of cupola 3 body of heater and is fixedly connected with body of heater, and rotating funnel 13 is a conical tube, and its lower end stretches into support 12 inside, and its The upper part is movably connected with the bracket 12 through a thrust bearing, te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com