Welding rod for high current welding stainless steel pressure vessels

A technology for pressure vessels and stainless steel, which is applied in the field of high-current welding electrodes for stainless steel pressure vessels, which can solve problems such as cracks and cracks, and achieve uniform melting speed, small spatter, and good arc stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

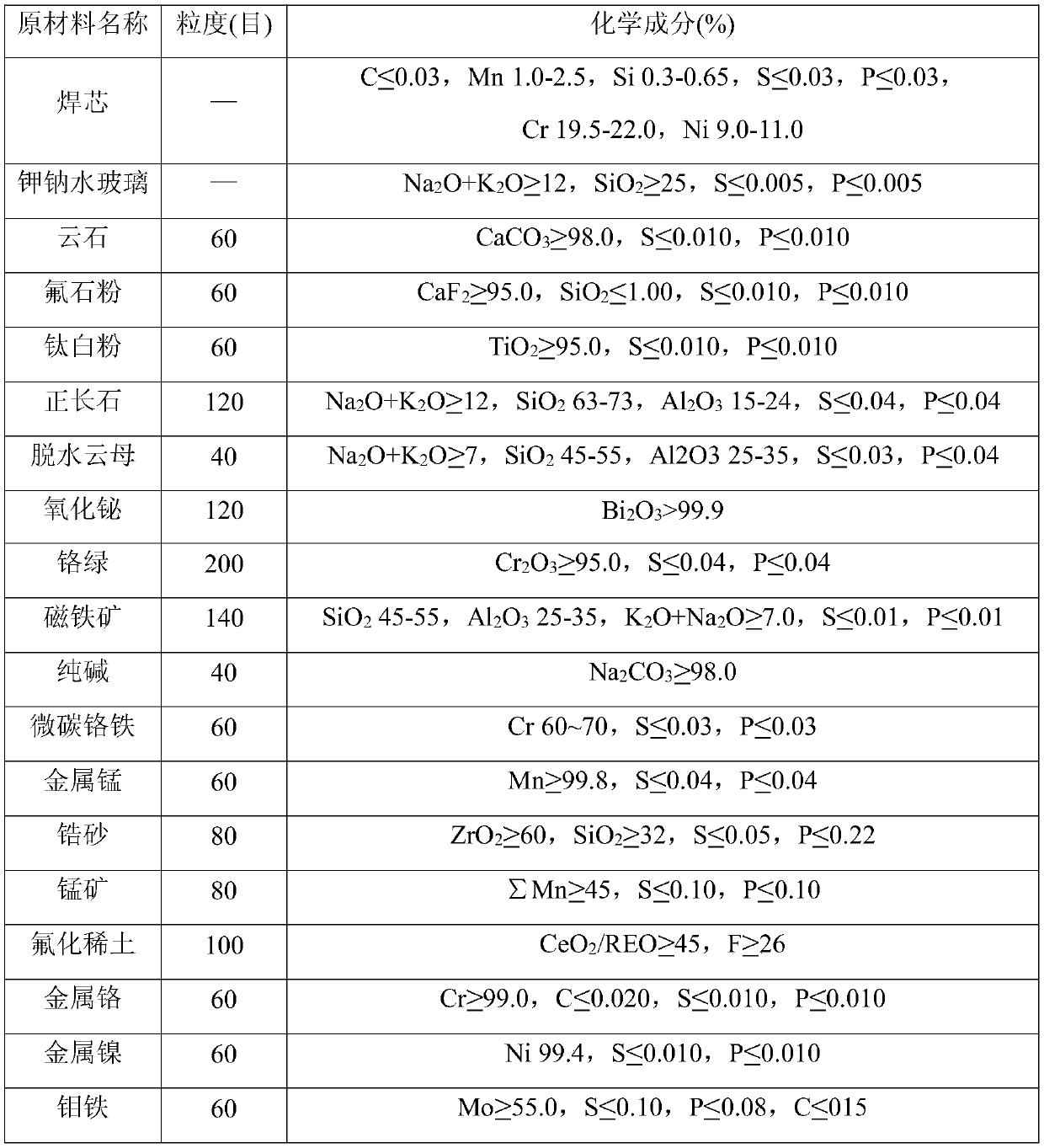

[0035] The composition of the coating is: 36% titanium dioxide, 19% orthoclase, 13% fluorspar powder, 8% marble, 0.2% bismuth oxide, 1.5% arc stabilizer, 7% deoxidizer , 5% slagging agent and 10.3% alloying agent. Wherein, the arc stabilizing agent comprises 77% of dehydrated mica and 23% of soda ash, accounting for 77% of the total weight of the arc stabilizing agent. The deoxidizer comprises 42% of micro-carbon ferrochrome, 50% of metal manganese and 8% of rare earth fluoride, accounting for the total weight of the deoxidizer. The slagging agent comprises 20% of zircon sand, 40% of magnetite and 40% of manganese ore which account for the total weight of the slagging agent. The alloy agent comprises 9.7% of metal nickel, 58% of metal chromium, 29% of chromium oxide green and 3.3% of molybdenum iron, accounting for the total weight of the alloy agent.

[0036] According to the above ratio, mix and stir the components of the coating evenly, add potassium sodium water glass wi...

Embodiment 2

[0038] The composition of the coating is: 33% titanium dioxide, 16% orthoclase, 14% fluorspar powder, 9% marble, 0.3% bismuth oxide, 2% arc stabilizer, 8.5% deoxidizer , 6% slagging agent and 11.2% alloying agent. Wherein, the arc stabilizing agent comprises 75% of dehydrated mica and 25% of soda ash, accounting for the total weight of the arc stabilizing agent. The deoxidizer comprises 47% of micro-carbon ferrochrome, 47% of metal manganese and 6% of rare earth fluoride, accounting for the total weight of the deoxidizer. The slagging agent comprises 16% of zircon sand, 33% of magnetite and 51% of manganese ore, accounting for the total weight of the slagging agent. The alloying agent comprises 9% of metallic nickel, 62.5% of metallic chromium, 26% of chromium oxide green and 2.5% of molybdenum iron, accounting for the total weight of the alloying agent.

[0039] Mix and stir the components of the coating according to the above ratio, add potassium sodium water glass with a ...

Embodiment 3

[0041] The composition of the coating is: 32% titanium dioxide, 17% orthoclase, 14% fluorspar powder, 8% marble, 0.3% bismuth oxide, 2% arc stabilizer, 8% deoxidizer , 7% slagging agent and 11.7% alloying agent. Wherein, the arc stabilizing agent comprises 75% of dehydrated mica and 25% of soda ash, accounting for the total weight of the arc stabilizing agent. The deoxidizer comprises 37.5% of micro-carbon ferrochromium, 56.25% of metal manganese and 6.25% of rare earth fluoride, accounting for the total weight of the deoxidizer. The slagging agent comprises 14% of zircon sand, 28% of magnetite and 58% of manganese ore accounting for the total weight of the slagging agent. The alloy agent comprises 8.5% of metal nickel, 70% of metal chromium, 21% of chromium oxide green and 0.5% of molybdenum iron, accounting for the total weight of the alloy agent.

[0042] Mix and stir the components of the coating according to the above ratio, add potassium sodium water glass with a total...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com