Method for treating iron-containing dust of iron and steel plant by using cupola furnace

A technology for iron and steel plants and cupola furnaces is applied in the field of iron-containing dust in iron and steel plants in cupola furnaces, so as to avoid the sintering process, increase the unit time, and improve the reduction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

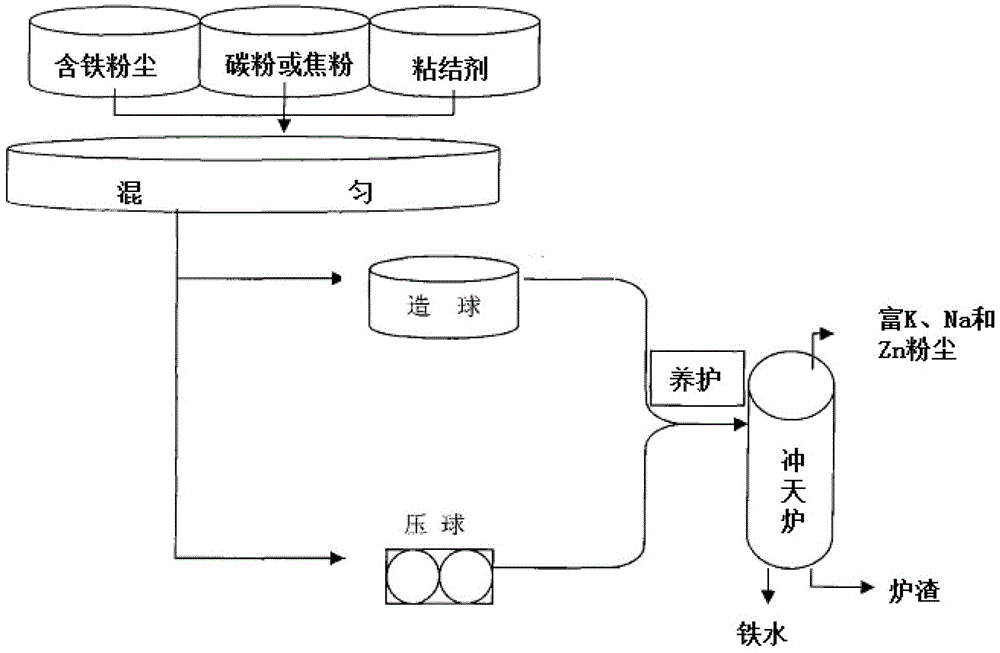

Image

Examples

Embodiment 1

[0028] Dust from the sintering process, blast furnace process and steelmaking process of the iron and steel plant (the composition is shown in Table 1), coal powder, cement clinker and sodium carboxymethyl cellulose in a ratio of 100:15~20:6~12:0.5~ 2. Mix, moisten, and make cold-solidified carbon-containing pellets. After natural curing for 7 to 10 days, they are distributed into the cupola through the distribution system for smelting to produce molten iron (see Table 2 for its composition).

[0029]

[0030] name TF C K Na Zn Pb R 2 Blast furnace bag ash 15~30 10~30 0.20~5 0.1~1 0.5~5 0.1~1 -- Sintered head ash 15~30 -- 10~30 0.1~2 0.5~5 1~20 2~3 Blast furnace gravity ash 15~30 10~30 0.1~1 0.1~1 0.5~2 0.1~1 -- Electric Furnace Dust 50~60 0.5~2 -- -- 0.5~10 0.1~1 2~3

[0031] name C Si S P content 4.0~4.3 0.4~1.2 0.03~0.08 0.08~0.12

Embodiment 2

[0033] Take cupola using 100% dust carbonaceous pellets as an example, assuming that the dust carbonaceous pellets have a carbon content of 10%, an iron content of 45%, and 3% oxygen in the blast, preheat the blast Temperature up to 1000°C. Through theoretical calculation, the economic and technical indicators of the smelting process for carbon-containing pellets in cupola-treated dust can be obtained, as shown below.

[0034] Coke ratio: 400~600kg / tHM

[0035] Coal for dusty carbon-containing pellets: 200~300kg / tHM

[0036] Furnace top gas volume: 2000~2300Nm 3 / tHM

[0037] Furnace top gas composition: CO:20~35%, CO 2 :10~25%, N 2 :40~50%, H 2 :2~5%

[0038] Theoretical combustion temperature: 2200~2400℃

[0039] Oxygen consumption: 60Nm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com