Method for preparing nodular cast iron

A technology of ductile iron and molten iron, which is applied in the field of preparation of ductile iron, can solve the problems of low temperature impact toughness and high scrap rate, and achieve the effects of improving roundness, absorption rate and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of ductile iron of the present invention is realized through the following steps:

[0028] a. Selection of raw materials: coke: fixed carbon content ≥ 85%, sulfur content < 0.50%, water content < 3%; new iron: carbon content 4.2-4.3%, silicon content: 0.9-1.1%, phosphorus content < 0.040% , sulfur content: <0.020%; steel scrap: low manganese high-quality carbon steel scrap: carbon ≤0.5%, manganese <0.3%;

[0029] b. Adopt cupola oxygen-enriched air supply process to increase the temperature of molten iron: the bottom coke height of cupola is 1800-2000mm, and the batch material is 500kg; among them, new iron is 380-420kg, scrap steel is 80-120kg, coke is 55-60kg; >1450°C;

[0030] c. Spheroidization inoculation treatment: Spheroidization treatment is carried out by using the cover bag method, and the nodulizer rare earth magnesium alloy FeSiMg8Re3 is added into the preheated spheroidization treatment bag, and the amount of nodulizer added is 1.5~ ...

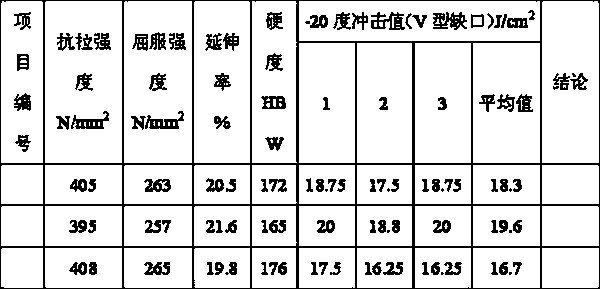

Embodiment 1

[0039] a. Selection of raw materials:

[0040] Shanxi high-quality foundry coke: fixed carbon content ≥ 85%, sulfur content < 0.50%, water content < 3%

[0041] Shanxi high-quality Q10 pig iron: carbon content 4.2~4.3%, silicon content: 0.9~1.1%, phosphorus content <0.040%, sulfur content: <0.020%; low-manganese high-quality carbon scrap steel: carbon ≤0.5%, manganese <0.3%,

[0042] b. Smelting treatment process: the bottom coke height of the cupola furnace is 1800~2000mm, and the furnace material is smelted with Q10 pig iron and scrap steel with 500kg layer coke according to the following ratio, including 420kg of newborn iron, 80kg of scrap steel, and 50kg of coke; the chemistry of molten iron after smelting The ingredients are shown in Table 1; the furnace temperature is above 1450°C;

[0043]c. Spheroidization treatment: spheroidization is carried out by using the capping spheroidization method, and the rare earth magnesium alloy FeSiMg8Re3 is used in an amount of 1.5~1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com