Process for casting thick and large nodular cast iron valve plate

A casting process, the technology of ductile iron, which is applied in the field of casting process of thick ductile iron valve plate, can solve the problems of not being able to meet the production requirements, the difficulty of cleaning the feeding riser, and the low yield rate of the process, so as to save the amount of molten iron and prevent Shrinkage cavity and porosity, easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Take the casting of a thick ductile iron valve plate with an outline size diameter of Φ1500mm, a casting thickness of 180mm, and a thickness of 80mm at both ends of the convex position as an example.

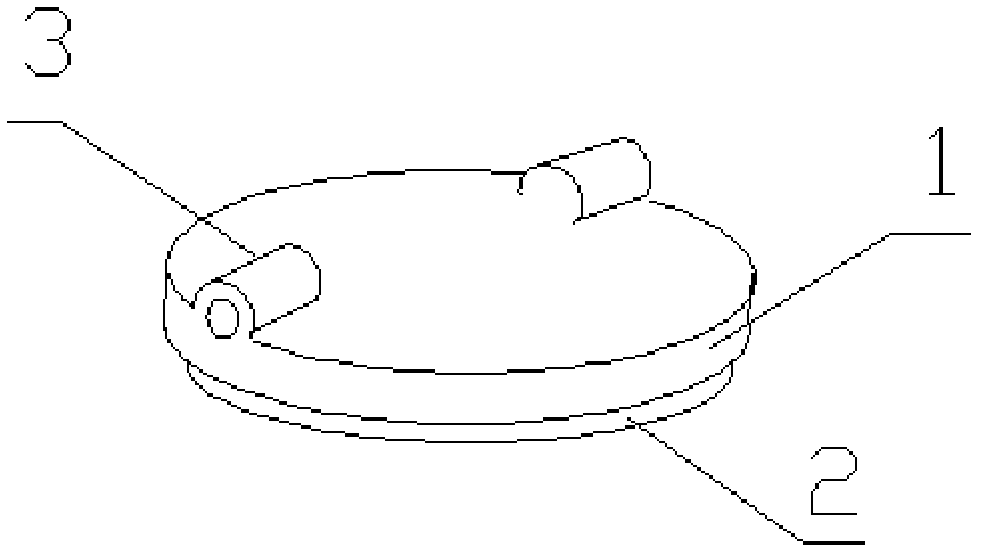

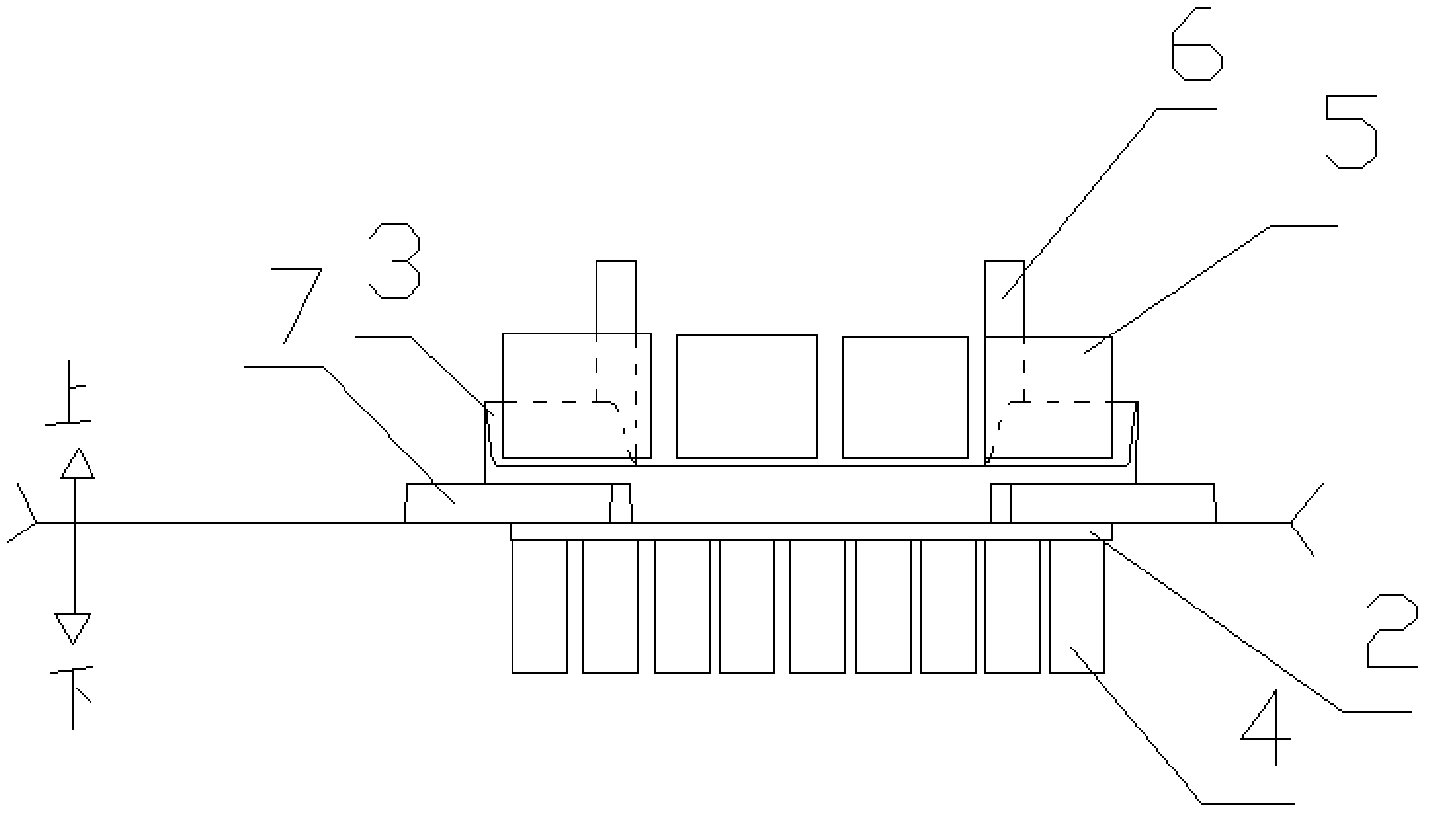

[0047] Such as figure 1 As shown, the valve plate is disc-shaped, the upper end surface of the disc 1 is provided with a flat-bottomed boss 2, and the edge of the lower end surface of the disc 1 is symmetrically provided with semi-annular lugs 3; the semi-annular lugs 3 have holes, away from The other end of the semi-annular lug 3 on the edge of the disc 1 is closed.

[0048] The casting process of the valve plate is as follows:

[0049] (1) Manufacture pattern: make pattern with red pine wood;

[0050] The parting surface is set at the junction of the disc 1 and the bottom boss 2 of the valve plate;

[0051](2) Modeling and core making: put the pattern in the sand box, set up the pouring system, fill the sand box with furan resin self-setting sand to make a mold by us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com