Hollow-core rock wool and preparation method and applications thereof

A technology of rock wool and hollow core, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low heat preservation, short rock wool fibers, poor tensile force, etc., and achieve the effect of cool hand feeling, strong toughness and good tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

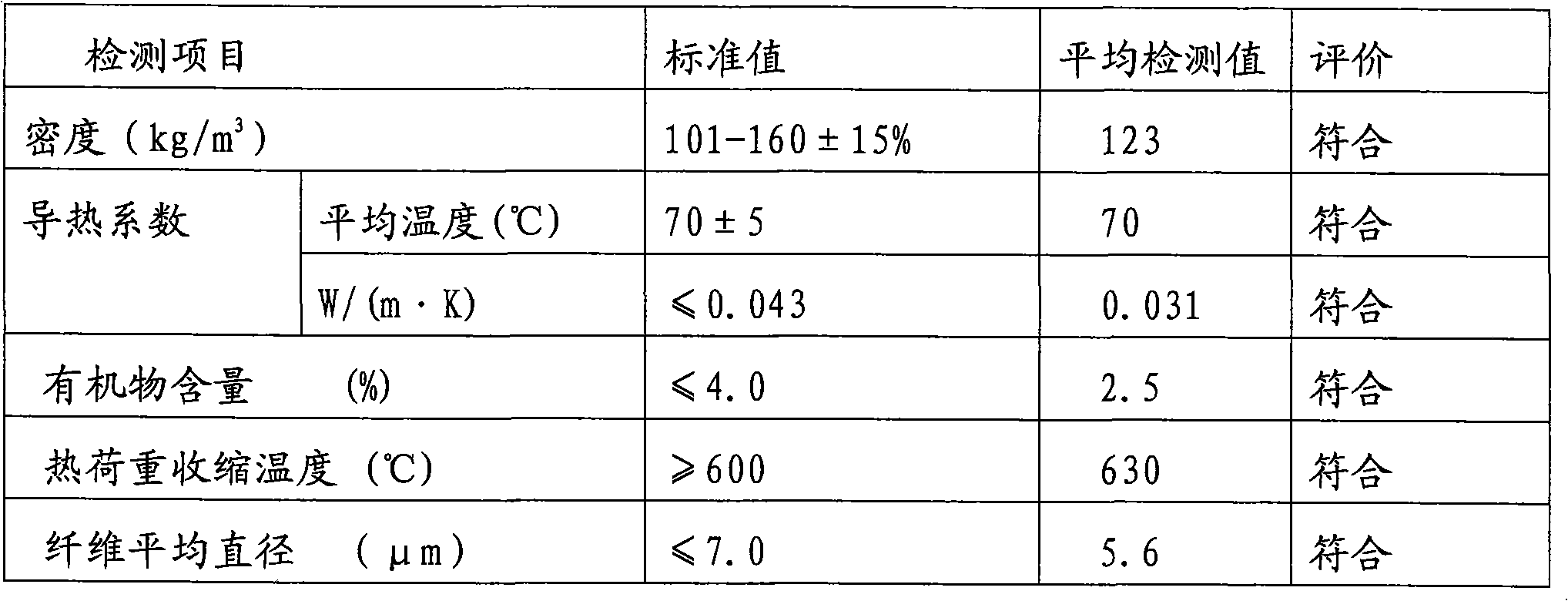

Embodiment 1

[0025] Take each raw material according to the following weight ratio: basalt 60kg, dolomite 30kg, diabase 6kg, fluorite 4kg;

[0026] Mix the above raw materials evenly and put them into the cupola (purchased from Longhua Complete Equipment Factory of Langfang Longhua Energy Saving Materials Co., Ltd., specification: annual output of 3,000 tons), melt at a high temperature of 900-1000°C, and guide the melt into The rollers of the four-roller high-speed centrifuge (purchased from Nanjing Fiberglass Research Institute, specification: annual output 2000-3000 tons) are formed into fibers. During the fiberization process, the melt is subjected to cooling water in the rollers and a high-pressure fan in contact with the rollers. (Purchased from Harbin High Pressure Fan Factory; specification: 919-2900 rpm, wind pressure: 5008-5697m 3 / n) The resulting cold air is cooled and blown into cotton.

[0027] Wherein, in the preparation process, each specific process parameter preferably a...

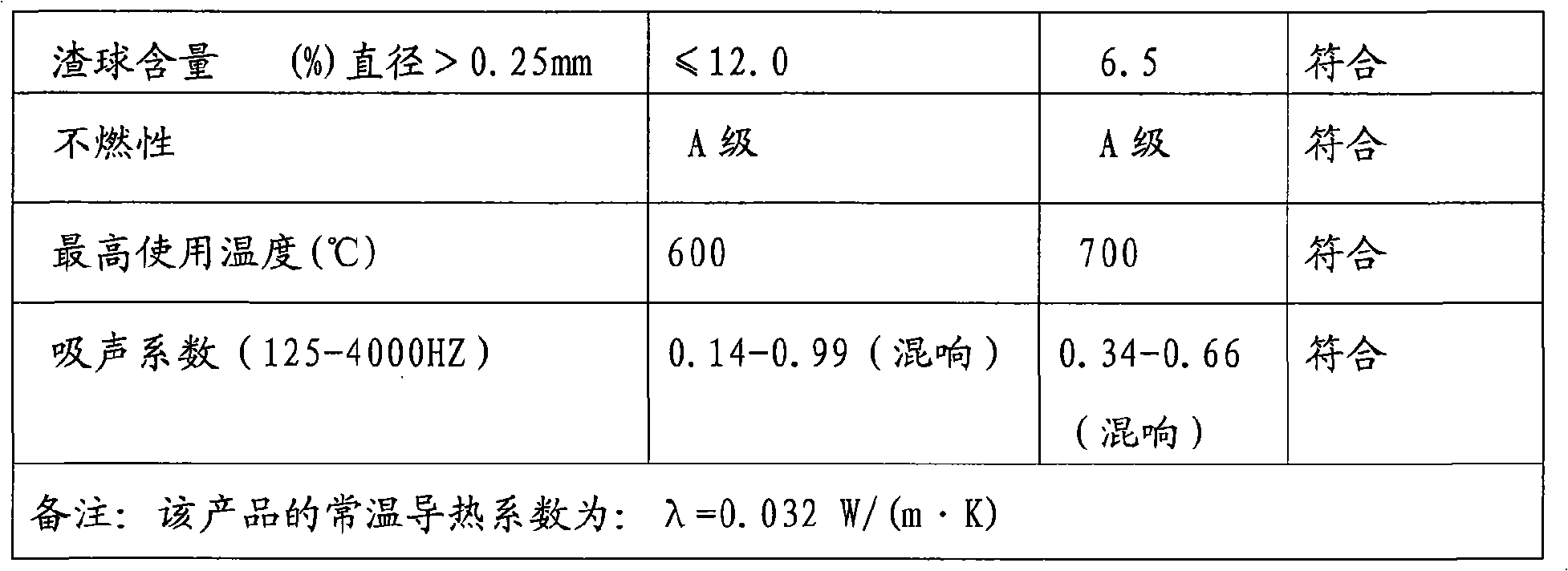

Embodiment 2

[0036] Take each raw material according to the following weight ratio: basalt 70kg, dolomite 20kg, diabase 2kg, fluorite 8kg;

[0037] Mix the above raw materials evenly and put them into the cupola (purchased from Longhua Complete Equipment Factory of Langfang Longhua Energy Saving Materials Co., Ltd., specification: annual output of 3,000 tons), melt at a high temperature of 900-1000°C, and guide the melt into The rollers of the four-roller high-speed centrifuge (purchased from Nanjing Fiberglass Research Institute, specification: annual output 2000-3000 tons) are formed into fibers. During the fiberization process, the melt is subjected to cooling water in the rollers and a high-pressure fan in contact with the rollers. (Purchased from Harbin High Pressure Fan Factory; specification: 919-2900 rpm, wind pressure: 5008-5697m 3 / n) The resulting cold air is cooled and blown into cotton.

[0038] Wherein, in the preparation process, each specific process parameter preferably a...

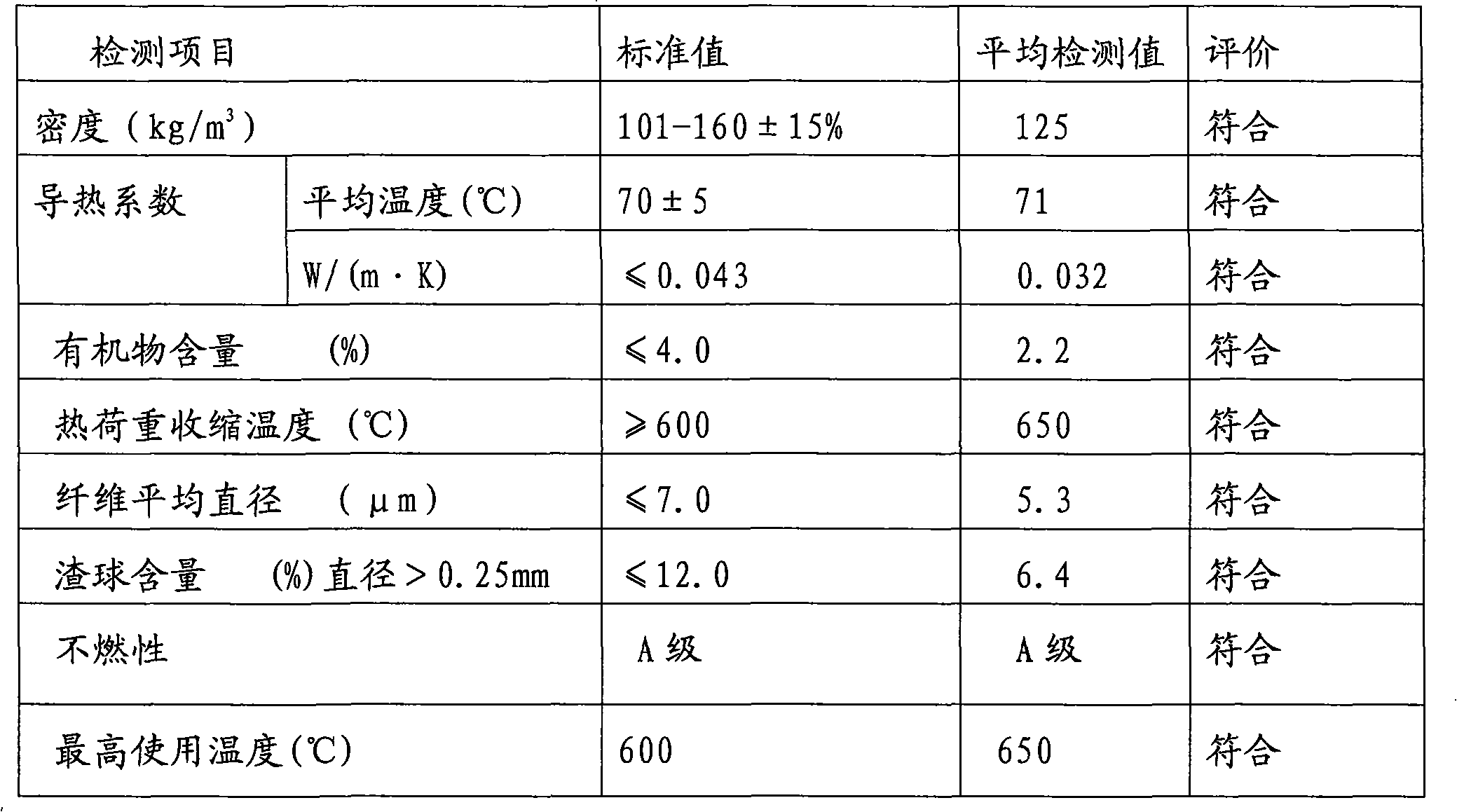

Embodiment 3

[0047] Take each raw material according to the following weight ratio: Heilongjiang Muling mesobasalt 65kg, dolomite 25kg, diabase 4kg, fluorite 6kg;

[0048] Mix the above raw materials evenly and put them into the cupola (purchased from Longhua Complete Equipment Factory of Langfang Longhua Energy Saving Materials Co., Ltd., specification: annual output of 3,000 tons), melt at a high temperature of 900-1000°C, and guide the melt into The rollers of the four-roller high-speed centrifuge (purchased from Nanjing Fiberglass Research Institute, specification: annual output 2000-3000 tons) are formed into fibers. During the fiberization process, the melt is subjected to cooling water in the rollers and a high-pressure fan in contact with the rollers. (Purchased from Harbin High Pressure Fan Factory; specification: 919-2900 rpm, wind pressure: 5008-5697m 3 / n) The resulting cold air is cooled and blown into cotton.

[0049] Wherein, in the preparation process, each specific proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com