Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

179 results about "Bullion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bullion is gold, silver, or other precious metals in the form of bars, ingots, or specialized coins that is said to maintain its worth better than conventional currencies and is therefore kept as a form of emergency currency by both governments and private citizens alike. Typically, bullion is used for trade on a global market where government backed currencies may not be sufficent. The word "bullion" comes from the French word bouillon, which meant "boiling", and was the term for the activity of a melting house which creates the ingots or bars from the raw material. The value of bullion is typically determined by the value of its precious metals content, which is defined by its purity and mass. To assess the purity of gold bullion, the centuries-old technique of fire assay is still employed, together with modern spectroscopic instrumentation, to accurately determine its quality to ensure that the true worth of the bullion is paid out; maintaining its security as an investment.

Method and device for smelting jamesonite by bottom-blowing pool

The invention relates to a method and a device for smelting jamesonite by a bottom-blowing pool. The method comprises the following steps of: performing pool smelting, oxidation and desulfurization on the jamesonite by using a bottom-blowing oxidation furnace to produce antimony-containing high-lead slag, a lead-antimony alloy and flue gases suitable for acid preparation; reducing the antimony-containing high-lead slag and blowing the lead-antimony alloy by using a bottom-blowing smelting furnace to produce antimony oxides and lead bullion capable of being used for electrolysis; and reducing the antimony oxides by using a bottom-blowing reduction furnace to produce needle antimony. In the smelting method of the invention, the three bottom-blowing furnaces and an electrically-heated settler are adopted to treat the jamesonite to produce the lead bullion, the needle antimony and the slag; therefore, compared with the prior art, the method has the advantages of short flow, good lead-antimony separation effect, fewer intermediate products, less revert, high resource utilization rate and production continuity; and the bottom-blowing oxidation furnace can realize spontaneous heating balance by sulfide combustion with low energy consumption and high recovery rate and can greatly reduce the cost.

Owner:JIYUAN YUGUANG NONFERROUS METALLURGY DESIGN & RES INST CO LTD

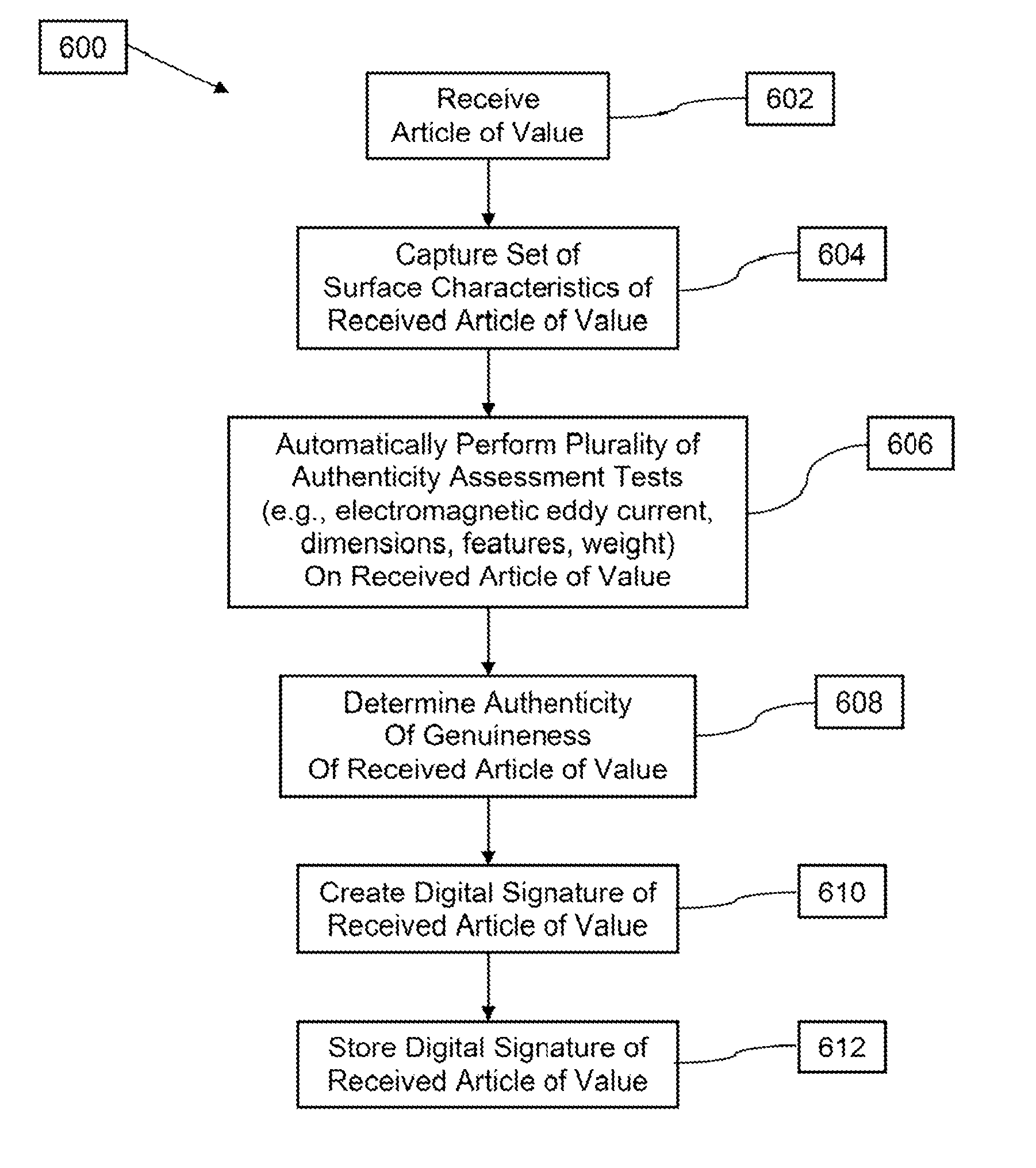

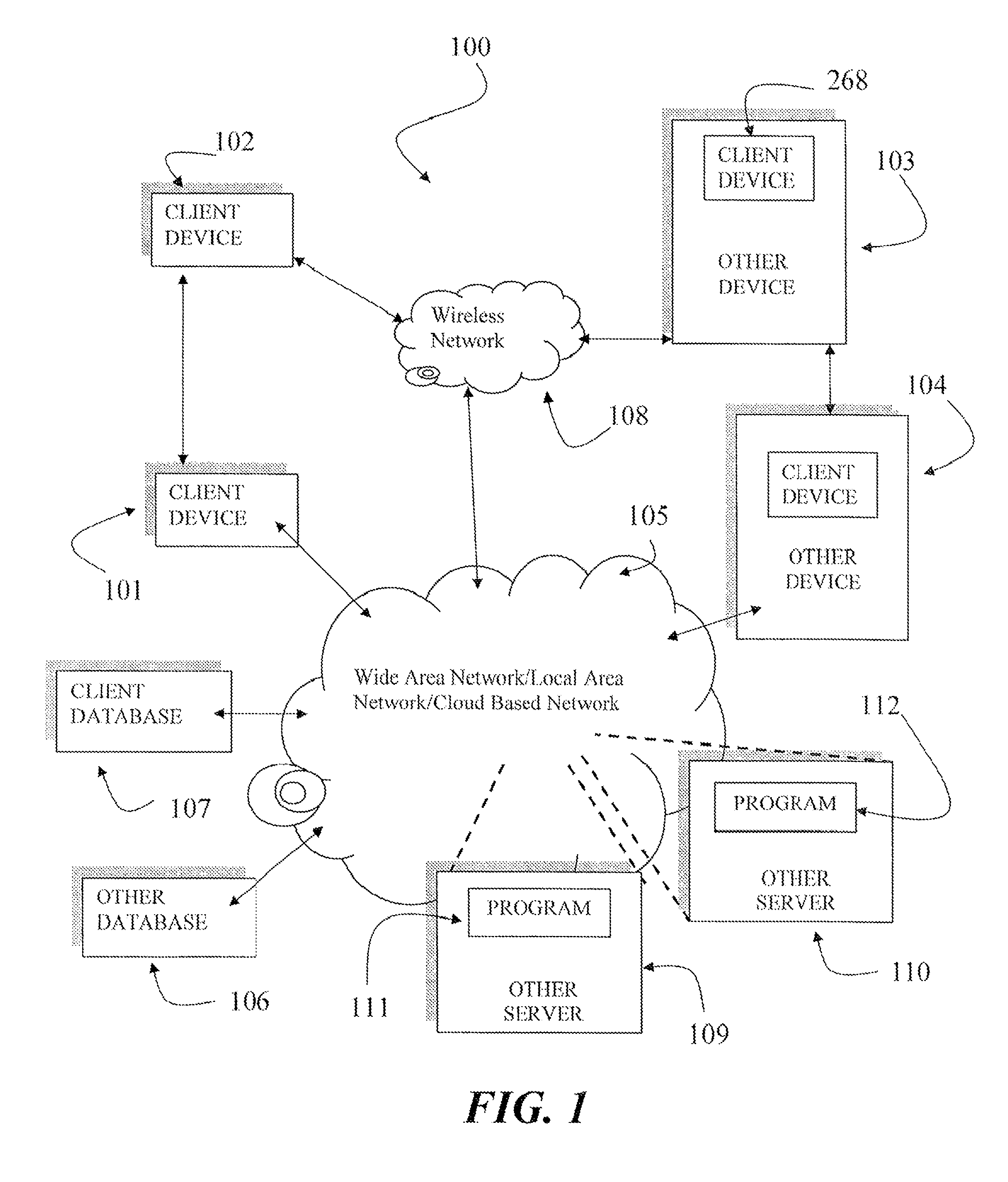

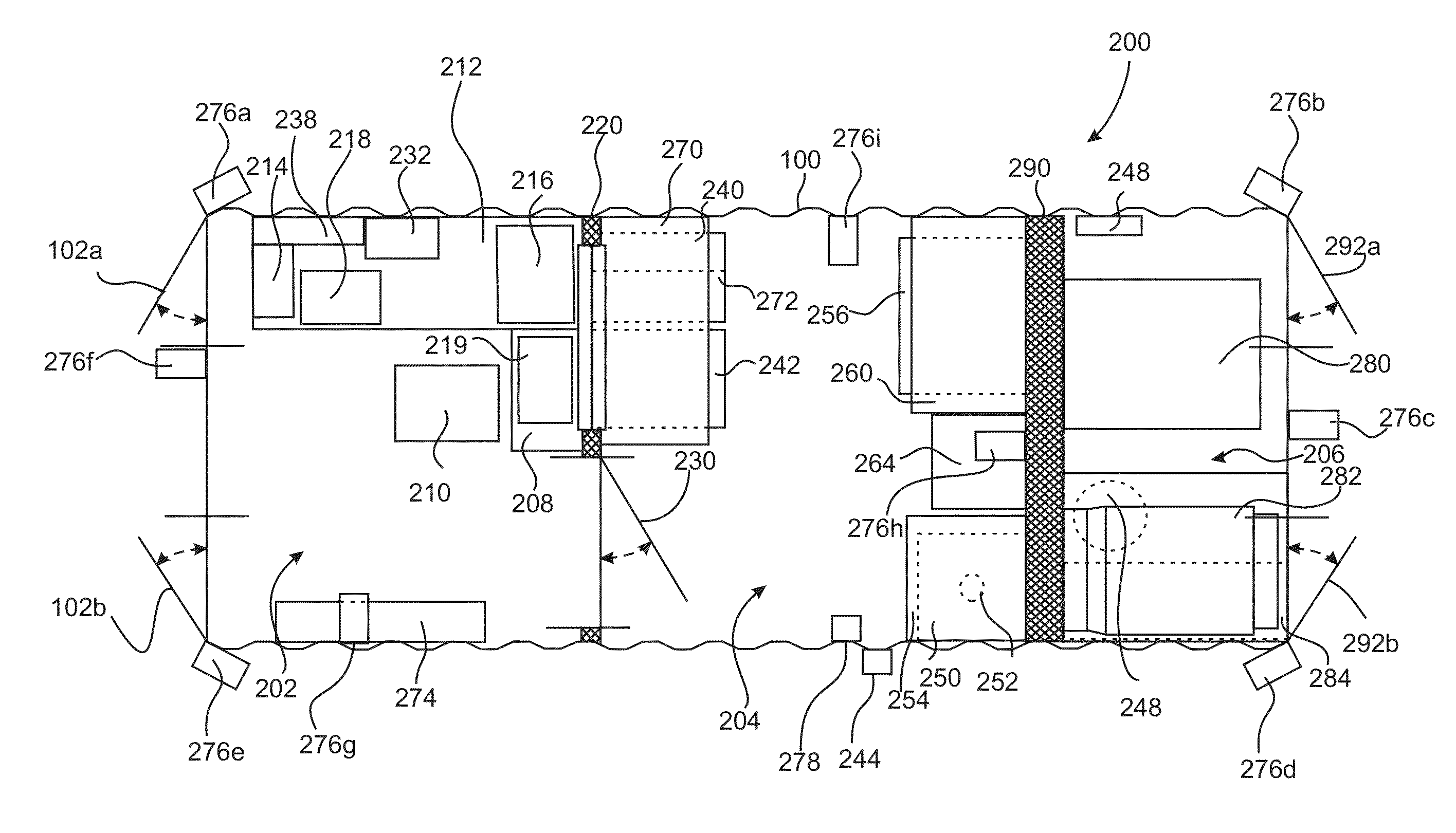

Methods, systems and apparatus for automated authentication

The present disclosure is directed to an automated precious metal bullion authentication apparatus and system that, without human intervention, develops and disseminates information to enable a user to distinguish between genuine and non-genuine precious metals bullion items. The systems and devices may work together with third-party hardware or software and, with Internet access, may be utilized 24 / 7, 365 days a year. The system or device enables a user to receive directly at a point of sale, or anywhere in public or private, information regarding whether an item is genuine or not. Information regarding genuineness of an item may be provided to the user before, during, or after a monetary or non-monetary exchange or transaction between individuals or entities. The system or device identifies and authenticates precious metal bullion items automatically through a multiplicity of procedures and renders a conclusion based on data from acquired digital images and other physical measurements.

Owner:SECURITY PACIFIC CAPITAL CORP

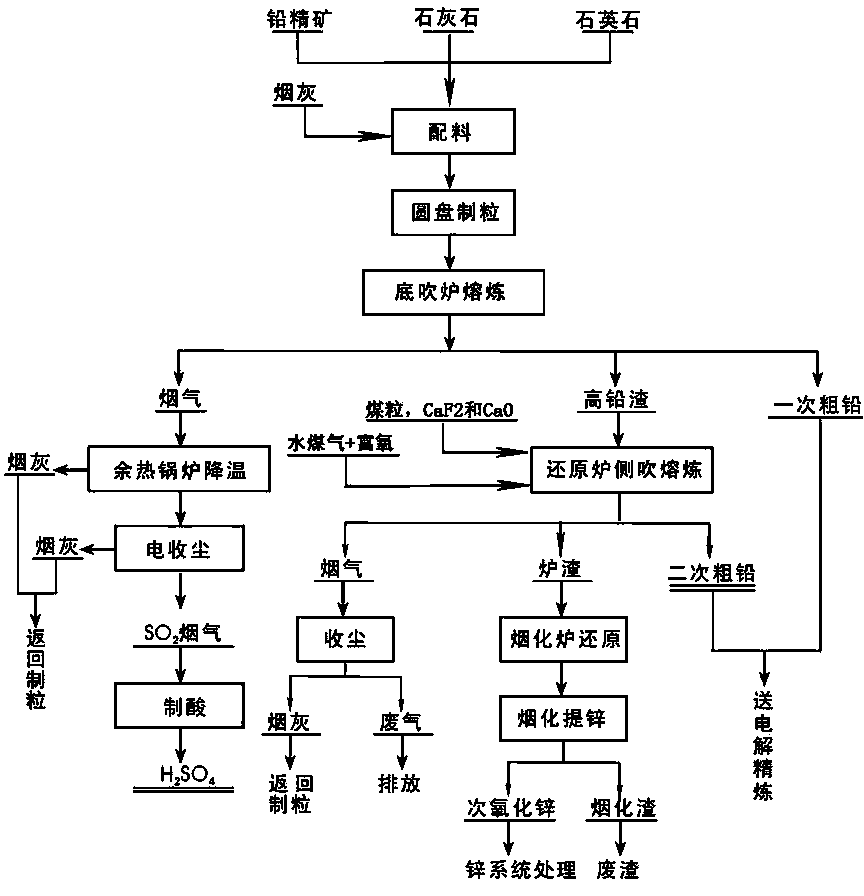

Oxygen bottom-blowing smelting and liquid-state high-lead slag side-blowing direct reduction process

InactiveCN102634674AEasy to separateShort and easy smelting processProcess efficiency improvementSlagOxygen

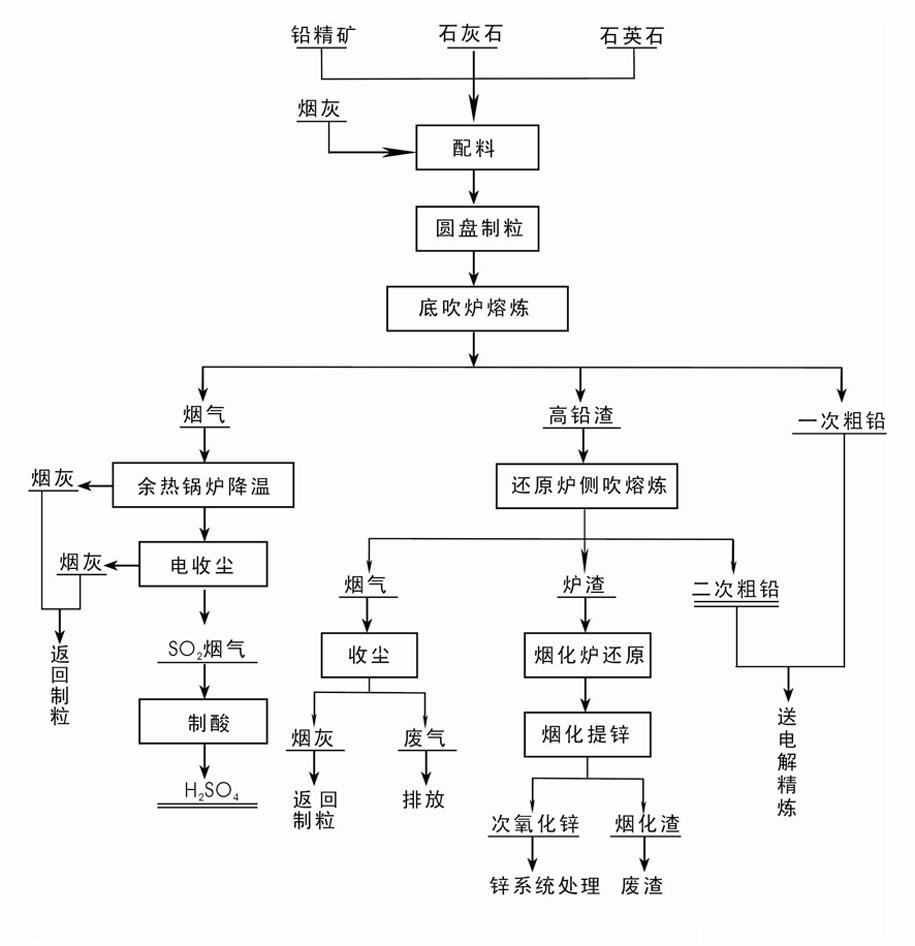

The invention relates to an oxygen bottom-blowing smelting and liquid-state high-lead slag side-blowing direct reduction process, belonging to the technical field of metallurgy. The process mainly comprises the steps of: directly injecting liquid-state high-lead slag melt subjected to oxidization smelting by a bottom oxygen blowing smelting furnace into a reduction furnace, and directly reducing liquid-state high-lead slag into secondary lead bullion through side blowing in the reduction furnace by adopting crushed coal as fuel; and after high-sulfur smoke produced by the bottom oxygen blowing smelting furnace is subjected to waste heat recovery by a first waste heat boiler and dust collection by an electric dust collector, and delivering the high-sulfur smoke to a sulfuric acid workshop for acid making. According to the process disclosed by the invention, a blast furnace, a slag casting machine and corresponding auxiliary facilities are omitted, the advantages of little investment and high automation level are achieved, and the industrial production of low pollution and low-carbon and economy is realized.

Owner:HUNAN HUAXIN RAREANDPRECIOUS METALS TECH CO LTD

Apparatus, system and method for a precious coin exchange platform and for valuation and trade of precious coins

An apparatus, system and method for buying and selling interests in at least one coin pool. The apparatus, system and method includes an assessment of at least one coin for inclusion in the at least one coin pool, wherein the at least one coin constitutes legal tender in at least one country, principally precious metals selected from the group of gold, silver, platinum, palladium, and rhodium, an international mintage of less than 10,000, a national mintage limit of at least one of no more than a predetermined threshold mintage and a production limit in a certain timeframe, a non-business strike, a non-bullion, and a proof. The present invention may additionally include a valuing of the at least one coin for a buy in accordance with at least one of a currency exchange value, an award, and a projected value increase, a purchasing of the at least one coin and placing the at least one coin into the at least one pool in accordance with the assessing and the valuing, and an offering of the interests in the coin pool in accordance with said purchasing.

Owner:BAKER DAVID N

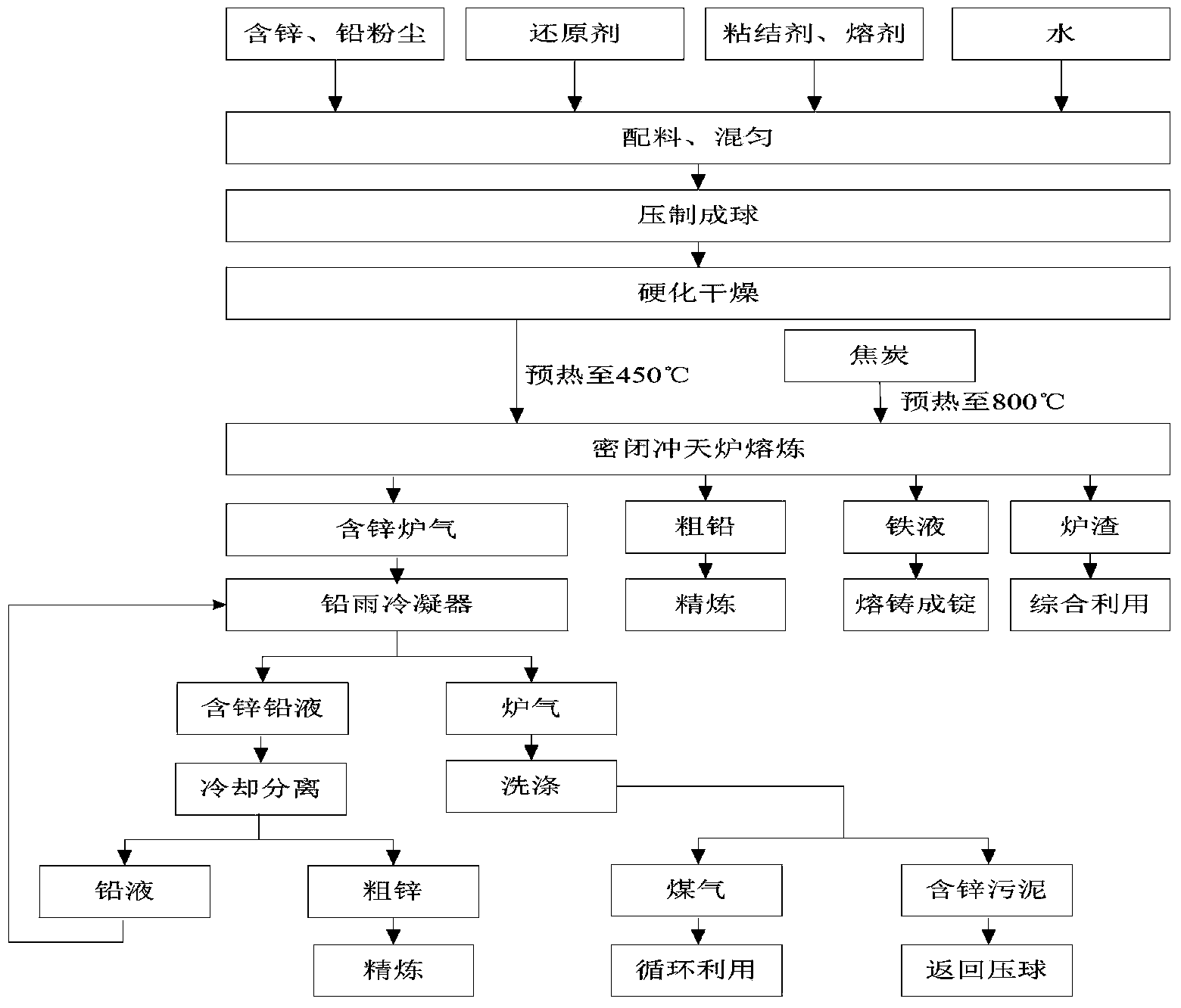

Method for processing dust containing zinc and lead in steel plant through closed cupola furnace

ActiveCN103468961AAdaptableIncrease production capacityProcess efficiency improvementSlagMixed materials

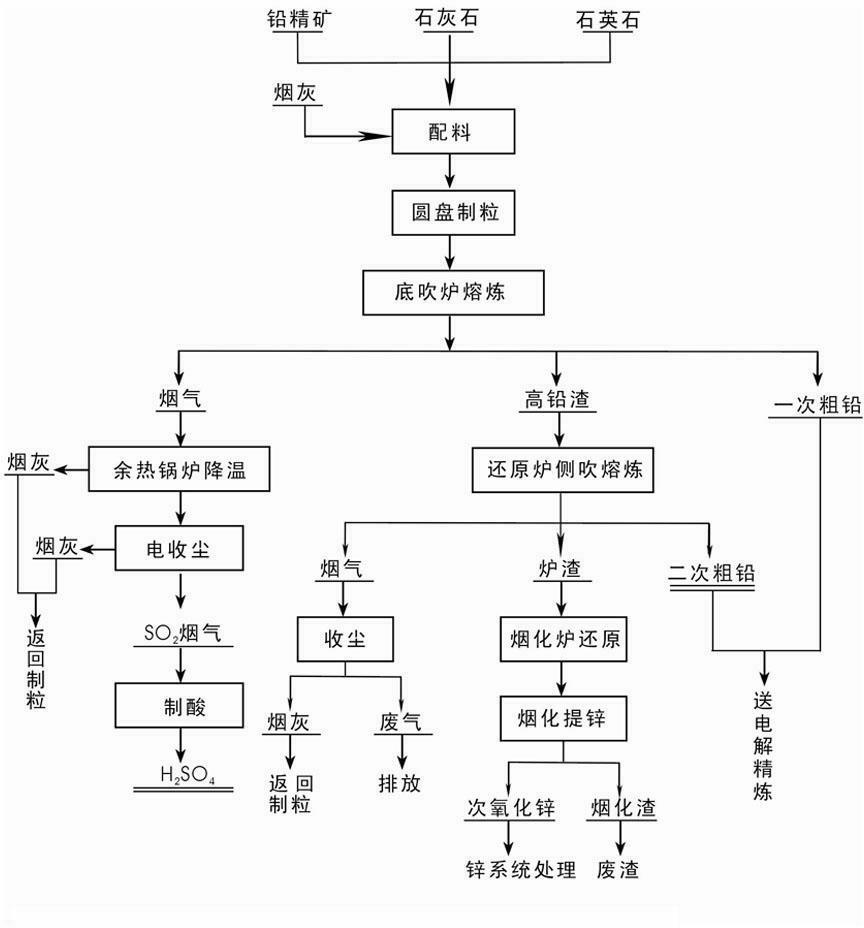

The invention discloses a method for processing the dust containing zinc and lead in a steel plant through a closed cupola furnace, and belongs to the field of steel production. The method is characterized in that the dust containing the zinc and the lead in the steel plant serves as the main raw material, certain quantities of a reducing agent, a binder, a fusing agent and water are added, and after fully mixing, the mixed materials are pressed by a ball pressing machine into balls; after being dried or maintained, the balls are conveyed into the closed cupola furnace to be smelted, and finally spelter, lead bullion and molten iron are obtained. The method has the advantages of being high in raw material adaptability, strong in production capability, high in processing efficiency and additional value of products and the like. The spelter, the lead bullion, the molten iron, gas, slag and the like can be directly obtained through the dust containing the zinc and the lead in the steel plant, the spelter and the lead bullion can be refined further, and the additional value of the products is improved. The molten iron is preprocessed and then is cast into ingots to be sold. After being processed, the slag can serve as building materials or cement or other production raw materials. The gas can serve as gas fuel to be used in the plant. The method is very obvious in economic benefits and environmental benefits.

Owner:UNIV OF SCI & TECH BEIJING

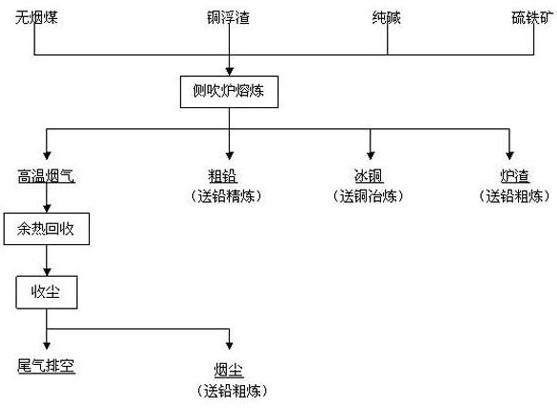

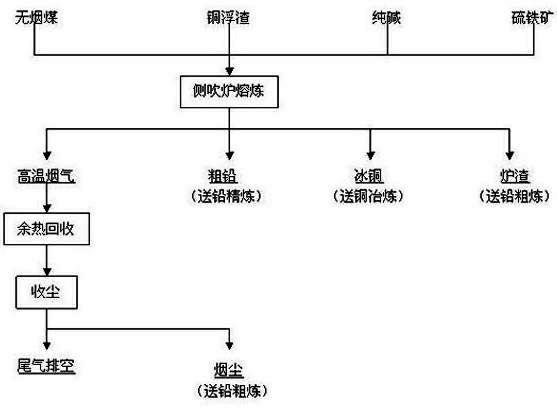

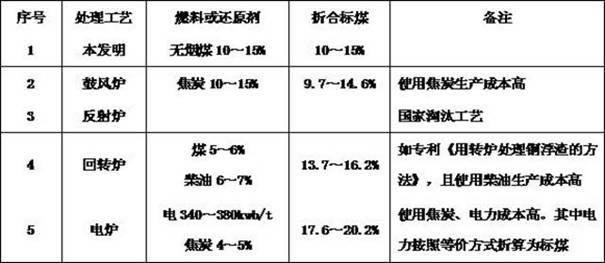

Method for producing lead bullion by means of copper dross side-blown smelting

The invention belongs to the technical field of metallurgy, and relates to a method for producing lead bullion by means of copper dross side-blown smelting. The method comprises the following steps of: 1) burdening copper dross, sodium carbonate and pyrite according to the proportion of 100:(8-10):(6-8), evenly feeding for 1-2 hours, wherein the feeding temperature is 600-800 DEG C, and evenly blowing anthracite by high-pressure wind; 2) smelting for 1-2 hours at the temperature of 600-800 DEG C after feeding, rising the temperature to 1100-1200 DEG C and smelting for 2-3 hours, and smelting the metallic lead and the chemical combination-state lead in the copper dross into the lead bullion; and 3) stopping blowing the anthracite, separating for 0.5-1 hour in a cleaning way, discharging the lead bullion and the copper matte in a siphon way, opening a slag hole to discharge the slag, and carrying out waste heat recovery and dust collection on the high-temperature smoke to be discharged to the air after the high-temperature smoke reaches the standard. The method takes the anthracite as the fuel or the reducing agent, and the other methods use the coke, the diesel oil or the electric energy, so that the method is more economical and suitable for large-scale production.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Reduction sulfur-fixing bath smelting method and device of low-sulfur lead-containing secondary material and iron-rich heavy metal solid waste

InactiveCN102965510AEliminate pollutionClean and efficient recyclingProcess efficiency improvementMelting tankSlag

The invention discloses a reduction sulfur-fixing bath smelting method and device of a low-sulfur lead-containing secondary material and iron-rich heavy metal solid waste. The reduction sulfur-fixing bath smelting method comprises the steps of: with iron-rich heavy metal solid waste as a sulphur-fixing agent and smokeless conny as a reducing agent, firstly, fully uniformly mixing raw materials such as the low-sulfur lead-containing secondary material with the sulphur-fixing agent and a solvent, drying and pelleting, then continuously adding a mixed pelleted material and the reducing coal (fuel) into an oxygen side-blowing bath smelting furnace for reduction sulphur-fixing smelting, further producing lead bullion, iron sulphur and sulphur-containing slag in one step under the condition that no sulfur dioxide is generated. According to the method, sulphur in the raw materials is fixed in the sulphur-containing slag and iron sulphur, so that low-concentration sulfur dioxide pollution is thoroughly eliminated, valuable elements such as iron, gold, silver, tin, antimony and bismuth in the sulphur-fixing agent are recycled with high efficiency at low cost, and continuous cleaning smelting of the low-sulfur lead-containing secondary material and continuous harmless treatment of the iron-rich heavy metal solid waste are realized. The reduction sulphur-fixing bath smelting method has the advantages of changing harmful substances into beneficial substances, recycling waste materials, and being simple in process, environmental-friendly, and low in cost, and has important significance for continuous clean smelting of the low-sulfur lead-containing secondary material and the treatment and recycling of the heavy metal solid waste.

Owner:CENT SOUTH UNIV

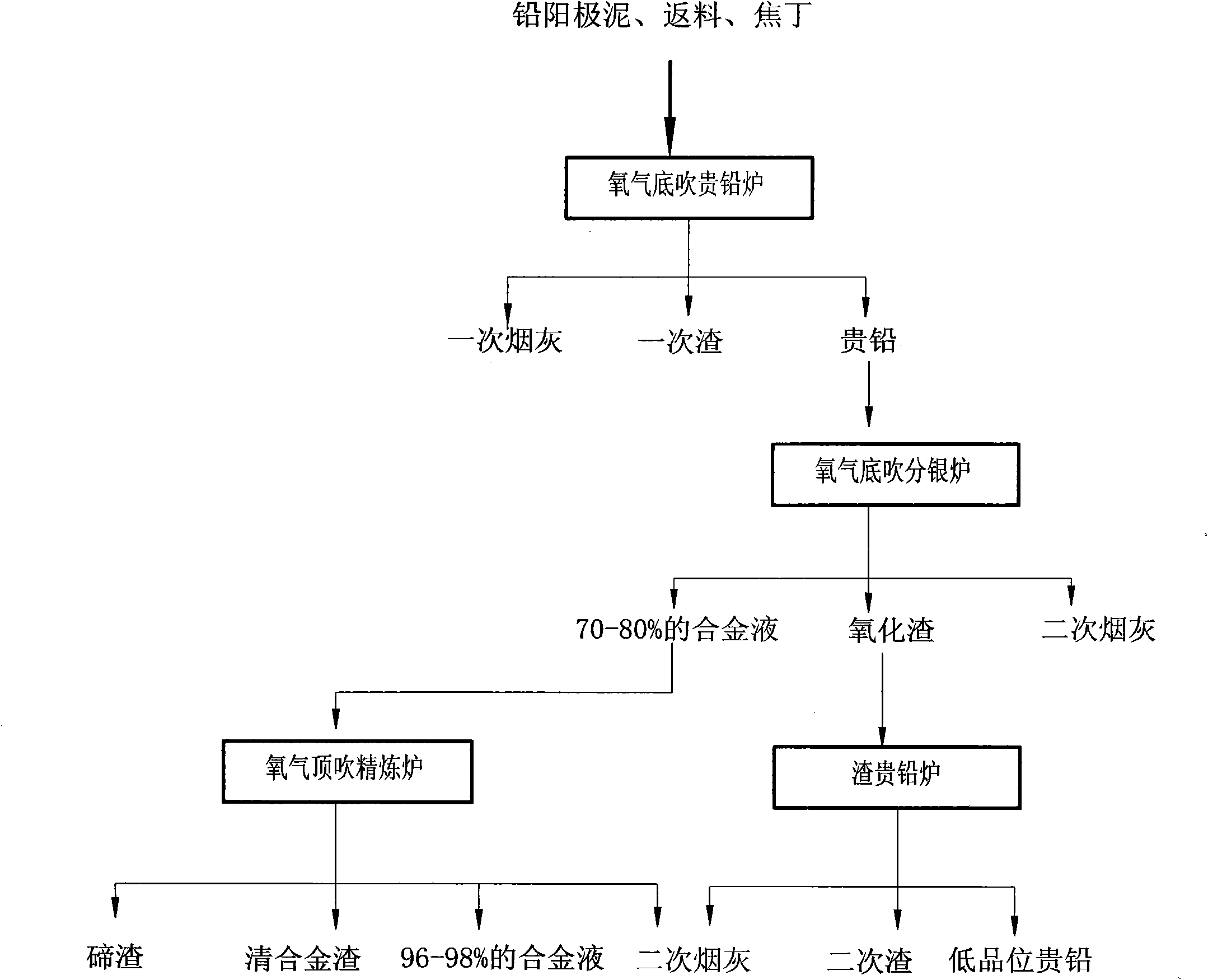

Method and device for continuously treating lead anode slime

ActiveCN101892388AEnables continuous processingShort processing cycleProcess efficiency improvementMelting tankSmelting process

The invention relates to a method and device for continuously treating lead anode slime by bath smelting. The method comprises the following steps: proportionally adding lead anode slime, recycled materials and nut coke as charging materials into an oxygen bottom blowing bullion lead furnace for smelting to generate bullion lead of which the bullion grade is 25-50%, primary slag and primary soot; adding the bullion lead into an oxygen bottom blowing silver-smelting furnace to react to generate oxidizing slag, secondary soot and alloy liquid of which the bullion grade reaches 70-80%; introducing the alloy liquid into an oxygen top blowing refining furnace to react to generate tellurium slag, clear alloy slag, secondary soot and alloy liquid of which the bullion grade reaches 96-98%; and discharging the oxidizing slag, then enabling the oxidizing slag to enter a slag bullion lead furnace, and adding the nut coke to react to generate low-grade bullion lead, secondary slag and secondary soot, wherein the low-grade bullion lead is returned for proportioning. The invention realizes the continuous treatment of the anode slime, strengthens the smelting process, improves the direct recovery rate of the bullion, lowers the production cost, reduces the environmental pollution, and shortens the treatment period of the anode slime.

Owner:JIYUAN YUGUANG NONFERROUS METALLURGY DESIGN & RES INST CO LTD

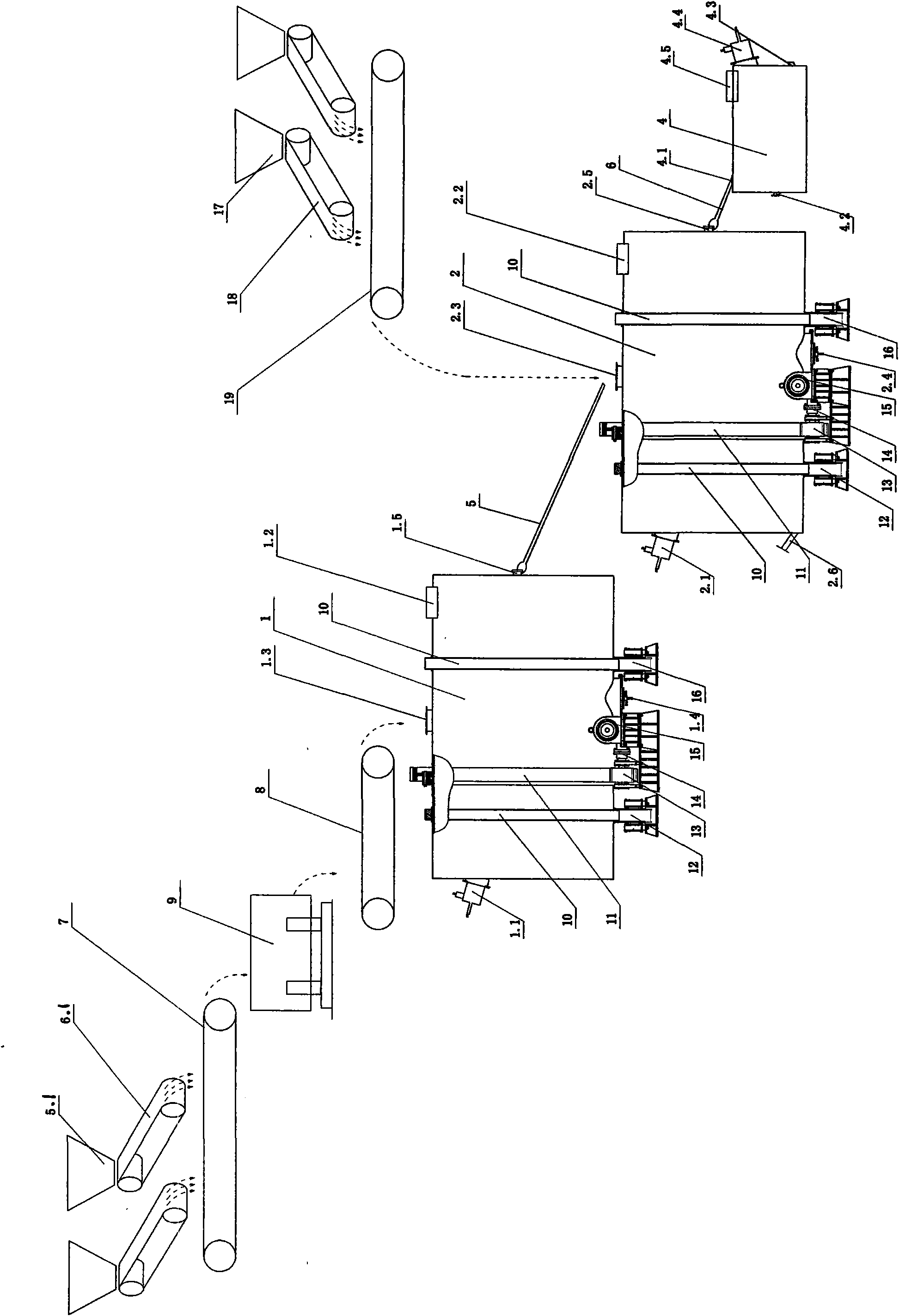

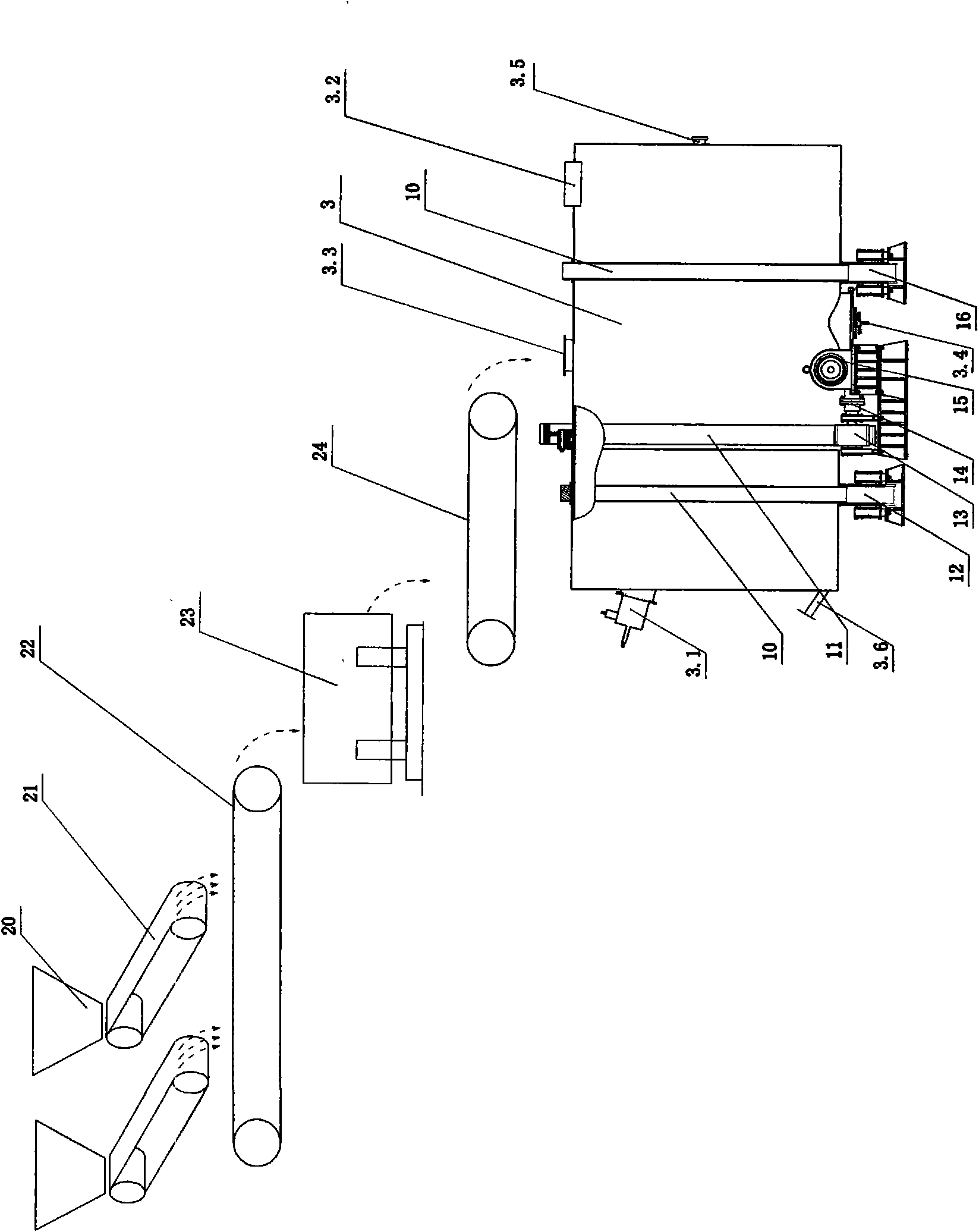

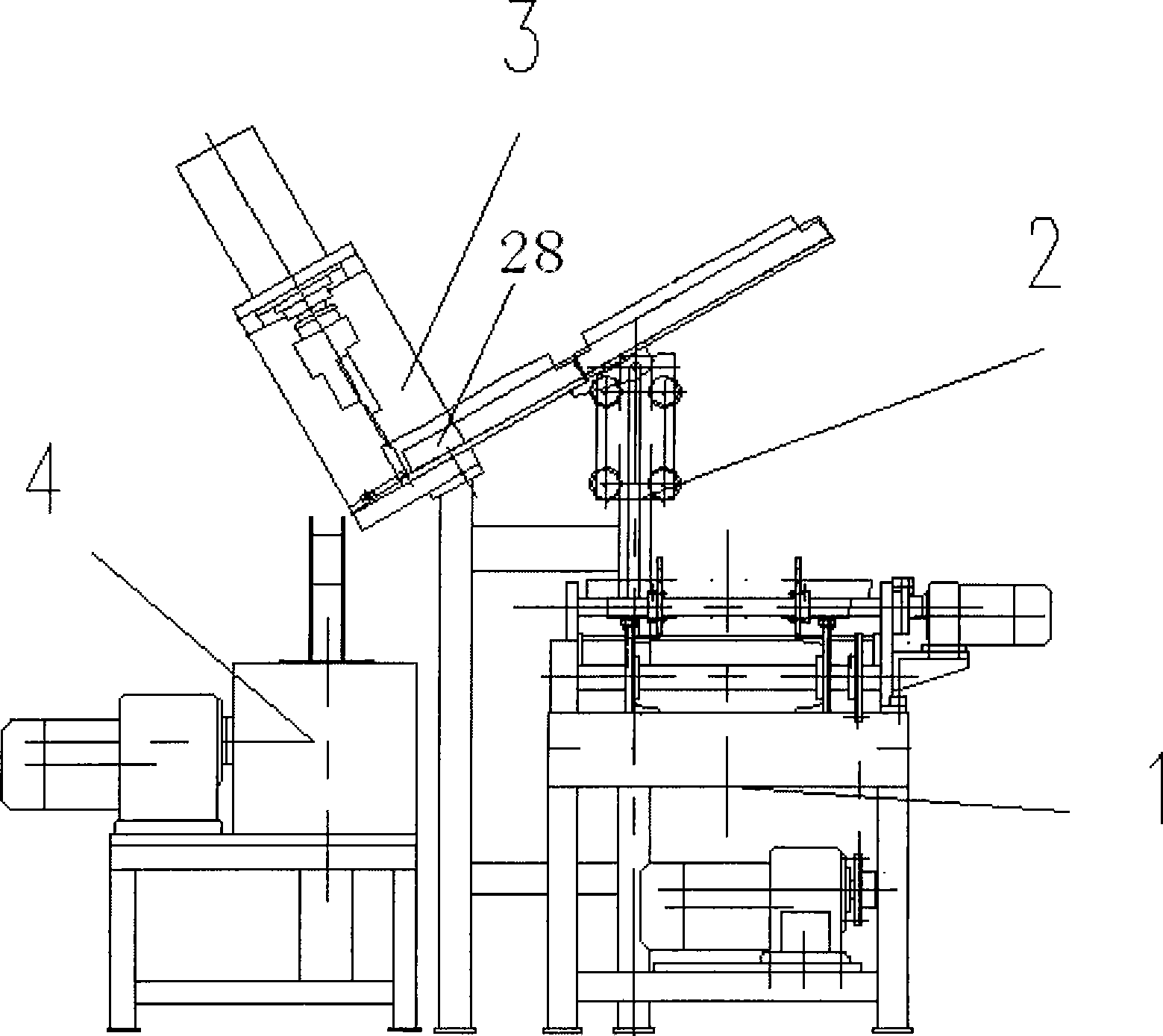

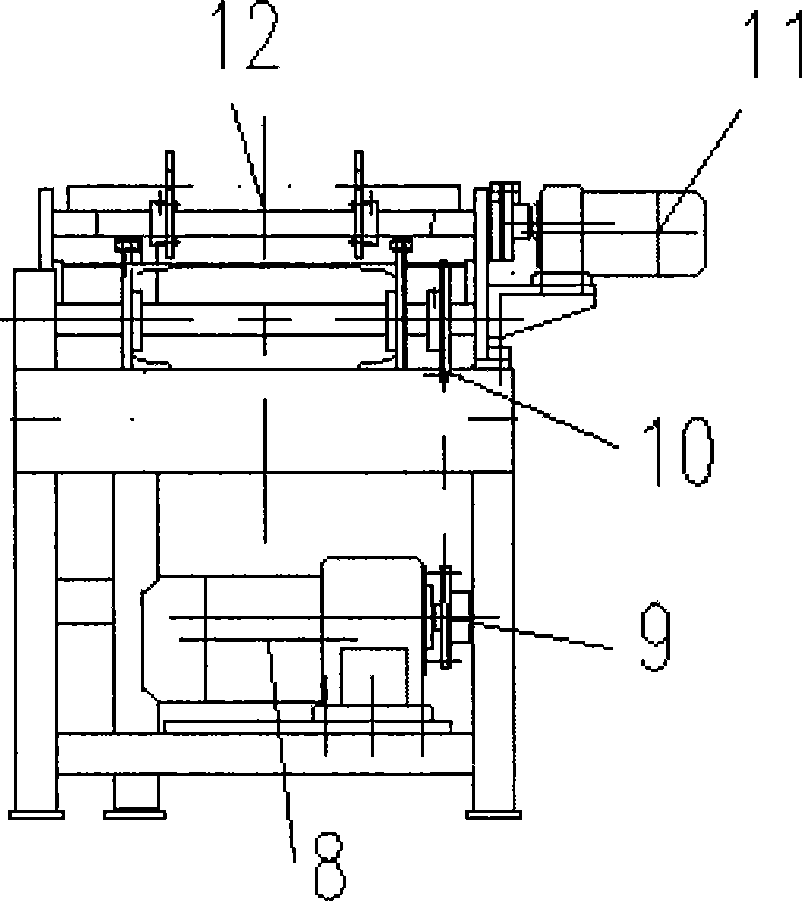

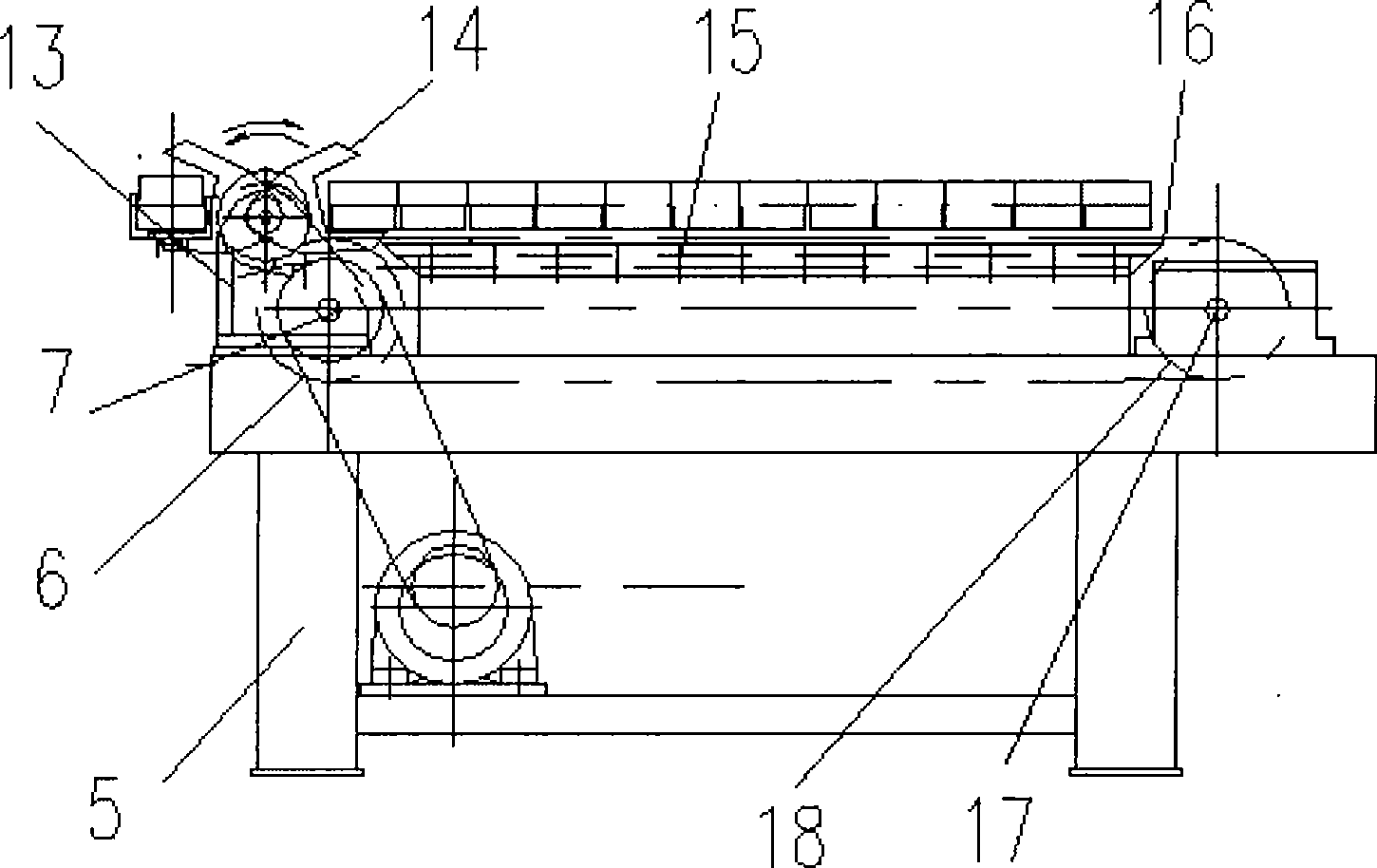

Lead bullion granulation automation line production process and apparatus

The invention belongs to a device through which a particle pipeline of soft metal is automatically divided in the cold state, in particular to a manufacturing method and device for lead ingot granulation automation line. The invention adopts the manufacturing method that lead ingot is transmitted to a lead ingot cake-cutting mechanism to cut lead ingot into cakes through a feeding mechanism, then the lead cakes are transmitted to a granulating machine to form particles, and the entire manufacturing process is automatically controlled. The invention relates to a manufacturing method and device for lead ingot granulation automation line, and an automatic lead ingot granulating manufacturing device mainly comprises a feeding mechanism, a lead ingot cake-cutting mechanism (3) and a granulating machine (4), wherein, a feed groove (22) of the feeding mechanism is butted with a lower anvil groove (28) of the lead ingot cake-cutting mechanism (3), and the lower anvil groove (28) of the lead ingot cake-cutting mechanism (3) is butted with a feed inlet of the granulating machine (4) so as to realize the full-automatic process that the lead ingot is transmitted into the lower anvil groove (28) of the lead ingot cake-cutting mechanism (3) through the feeding mechanism, the lead ingot is cut into lead cakes and transmitted into the feed inlet of the granulating machine (4) through the lead ingot cake-cutting mechanism (3), and the lead cakes are cut into granular lead through the granulating machine (4).

Owner:CECEP ENVIRONMENTAL PROTECTION EQUIP CO LTD

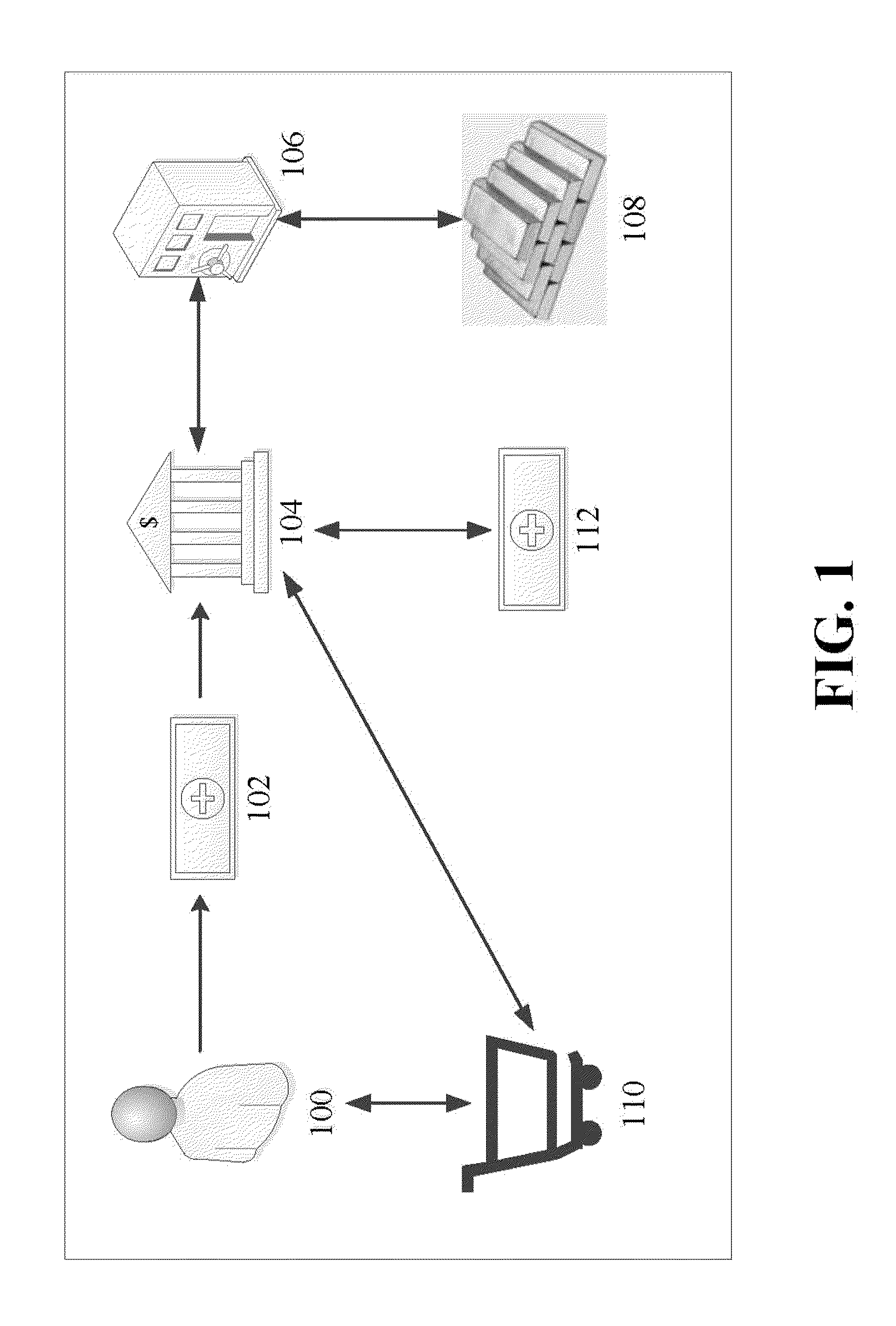

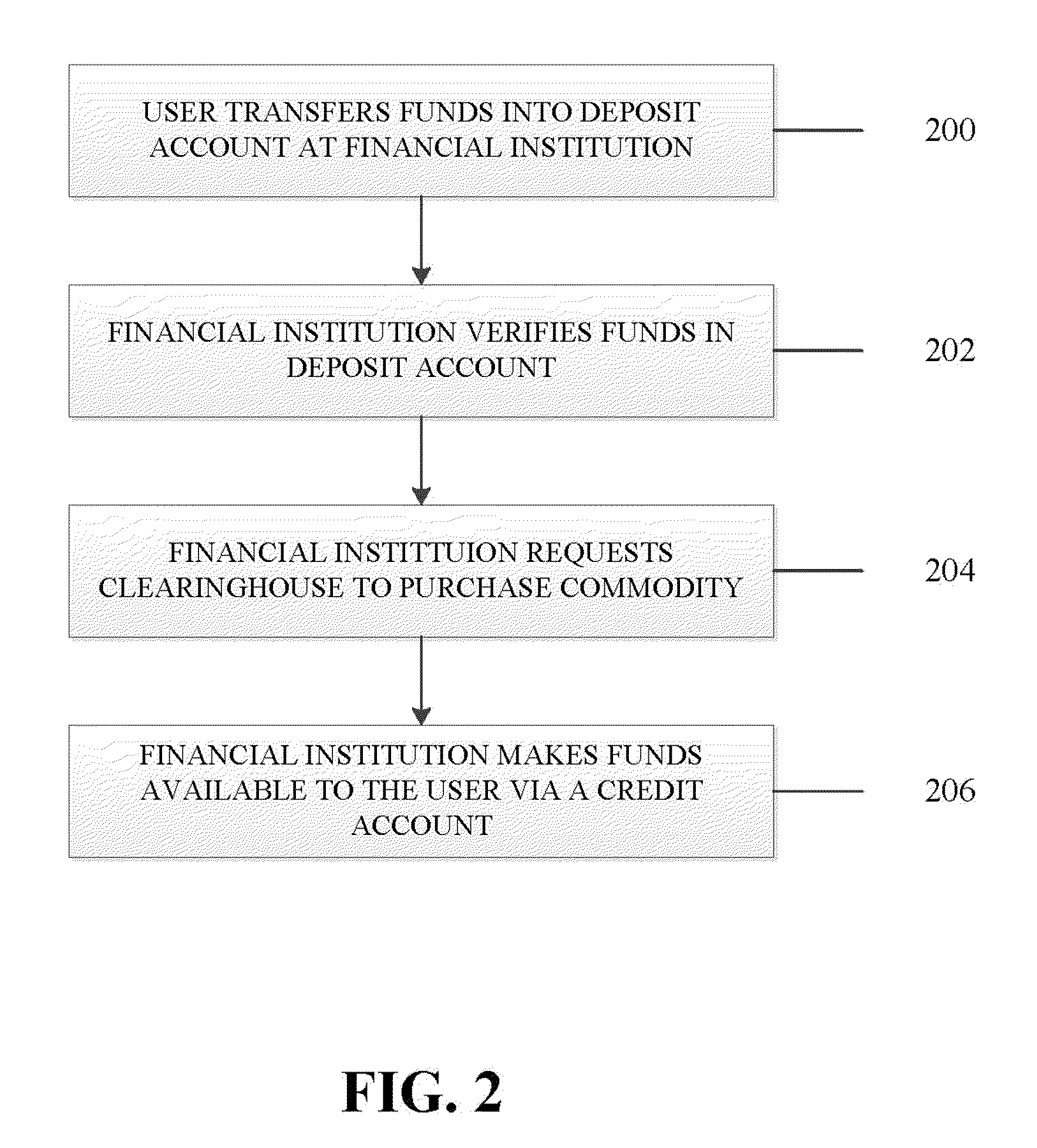

System and method for providing a pre-paid commodity-based credit account

This invention relates to a system and method that provides a pre-paid credit account, where the value of the account is based on the market price of an underlying commodity instrument. More specifically, this invention relates to a system and method for managing cash assets in the form of gold bullion that is maintained by a financial institution on behalf of an account holder, thereby allowing the account holder to utilize the purchasing power of the gold bullion assets in a convenient fashion.

Owner:BAYAA AHMAD +1

Method of extracting valuable element from waste water and waste slag

ActiveCN101078056ASimple configurationAdaptablePhotography auxillary processesSolid waste managementBrickSlag

A method to extract charge elements with drain water and waster slag, It contains the following technology steps: a To acidulate; the cyanide tailings and blended with acid drain water. b To add protection alkali; To enter the agitated tank before floatation, and add protection alkali to neutralize and precipitate the ion of impurity. C To recover by flotation; the beneficiated ore will be produced out after a rude choice, two scavengings, and a choice. d To floatate the smelting end product of beneficiated ore; to produce out end product: vitriol, copper, bullion bar, sycee, and iron ore concentrate, the remained tailings will be sell to produce brick, the arrangement of the technology equipment is simple, and the operation is stable and easy to control, It' s adaptability to the cyanide tailings produced by different technology is very high, It not only eliminates the pollution to environment caused by the pile-up of tailings, but also further accelerates the reclaim of the useful element, and at the same time, it saves a part of cost spend in dealing with the drain water.

Owner:SHANDONG HUMON SMELTING

Method for recovering gold and lead by smelting refractory gold ore and lead-containing waste residue raw materials through oxygen enrichment molten pool

ActiveCN104263965AAchieve recyclingSimple processPhotography auxillary processesProcess efficiency improvementElectrolysisSlag

The invention discloses a method for recovering gold and lead by smelting refractory gold ore and lead-containing waste residue raw materials through an oxygen enrichment molten pool. The method comprises the following steps: uniformly mixing the refractory gold ore, lead-containing materials and a fusing agent, pelleting and drying, so as to obtain granular materials; performing oxidizing smelting on the obtained granular materials through an oxygen bottom blowing furnace to obtain sulphur dioxide smoke gas, lead bullion and high lead skim, and performing reduction smelting on the high lead skim in a reduction furnace to obtain slag and lead bullion; and performing electrolytic refining on the lead bullion to obtain refined lead and gold-bearing anode slime, wherein the gold recovering rate is larger than 99%, the lead recovering rate is larger than 95%, sulphur is removed in the form of the sulphur dioxide smoke gas, and the removing rate reaches 95% above. The slag is used as high-silicon mixed ingredients for cement or construction, after the sulphur dioxide smoke gas is subjected to dust removal to recycle valuable metals, the sulphur dioxide smoke gas is used for preparing acid, resources are sufficiently and comprehensively recycled, and the environmental protection and economy are achieved. The method is simple in operation and low in cost, and the method can be applied to large-scale industrial production.

Owner:湖南锐异资环科技有限公司

Method for smelting arsenic-containing gold concentrate

InactiveCN101078057AGood processing effectHigh recovery rateSulfur compoundsProcess efficiency improvementCooling towerArsenic oxide

A kind of smelting method of aurin mine containing arsenic, it contains the following technology steps: primary burning, second-class burning, The burning residue after burning will be added into the pickling ark with the soot separated to be pickled. The filtrate will be used to extract copper, the filter cake will be separated and cyanide residue and golden mud can be gained, and the golden mud will be smelted to extract gold bullion. The character of it is that the smoke gas, which has been catch dust by primary burning and second-class burning, will be drew arsenic in according to hop-pocket drying method. The process is as following, the smoke gas containing arsenic will enter the spray cooling tower and be quench by spraying water, the arsenic oxide will become solid and be separated out from gaseous crystal, the smoke gas will take arsenic oxide solid into bag arsenic catcher, and the arsenic oxide solid will be collected into ash bucket after being filtrated by hop-pocket, and then will be packed and finished product can be gained. The smoke gas after arsenic catching will enter the acid making system, and produce vitriol by cleanse workshop section, translation workshop section and dried absorbing workshop section, the finished vitriol product will be gained, and the off-gas will be exhaled into air. The technology of it is simple and feasible, and it is easy to operate, the coefficient of recovery and arsenic catching rate are both high, the investment of it is low, and the running cost of it is low.

Owner:SHANDONG HUMON SMELTING

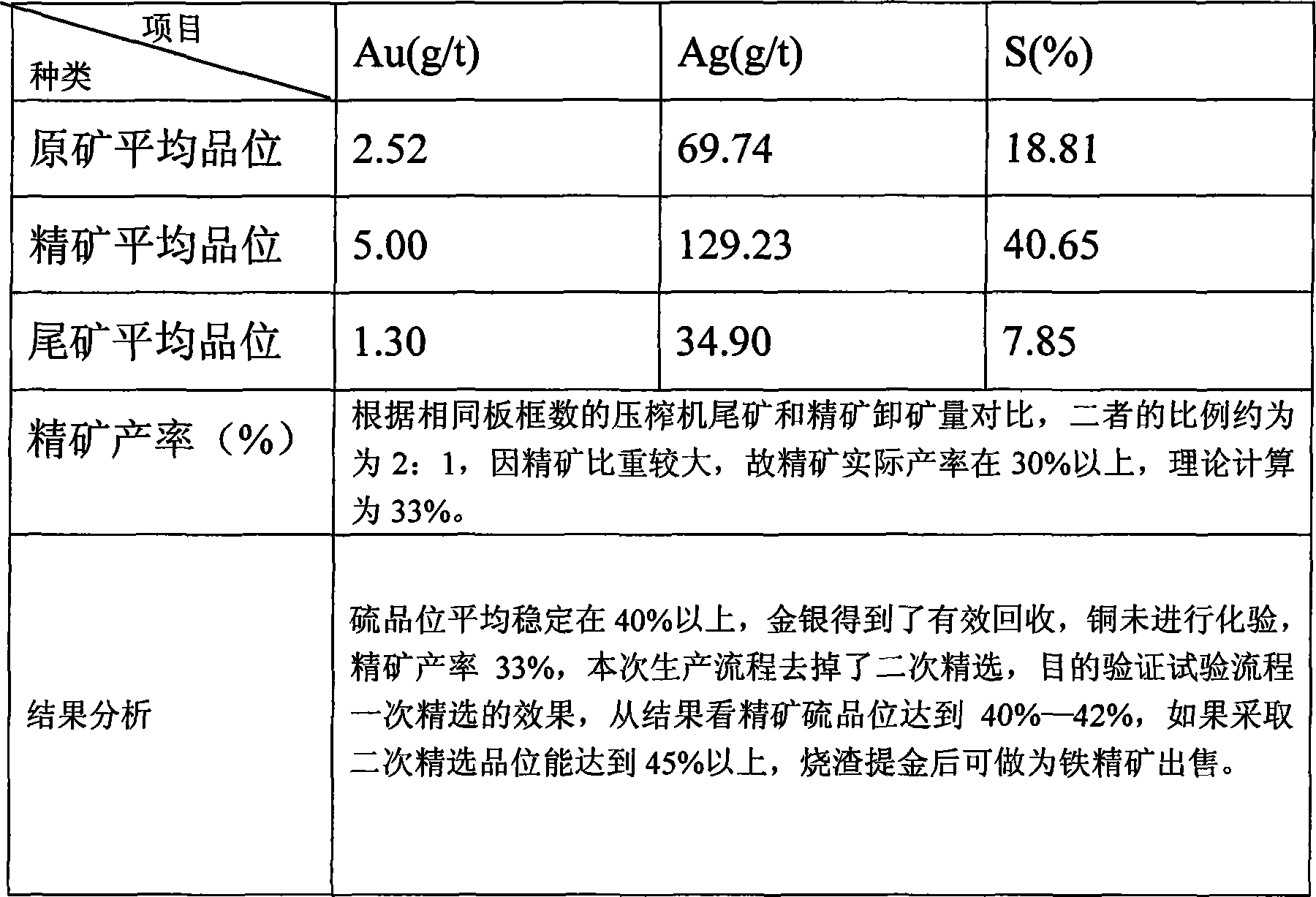

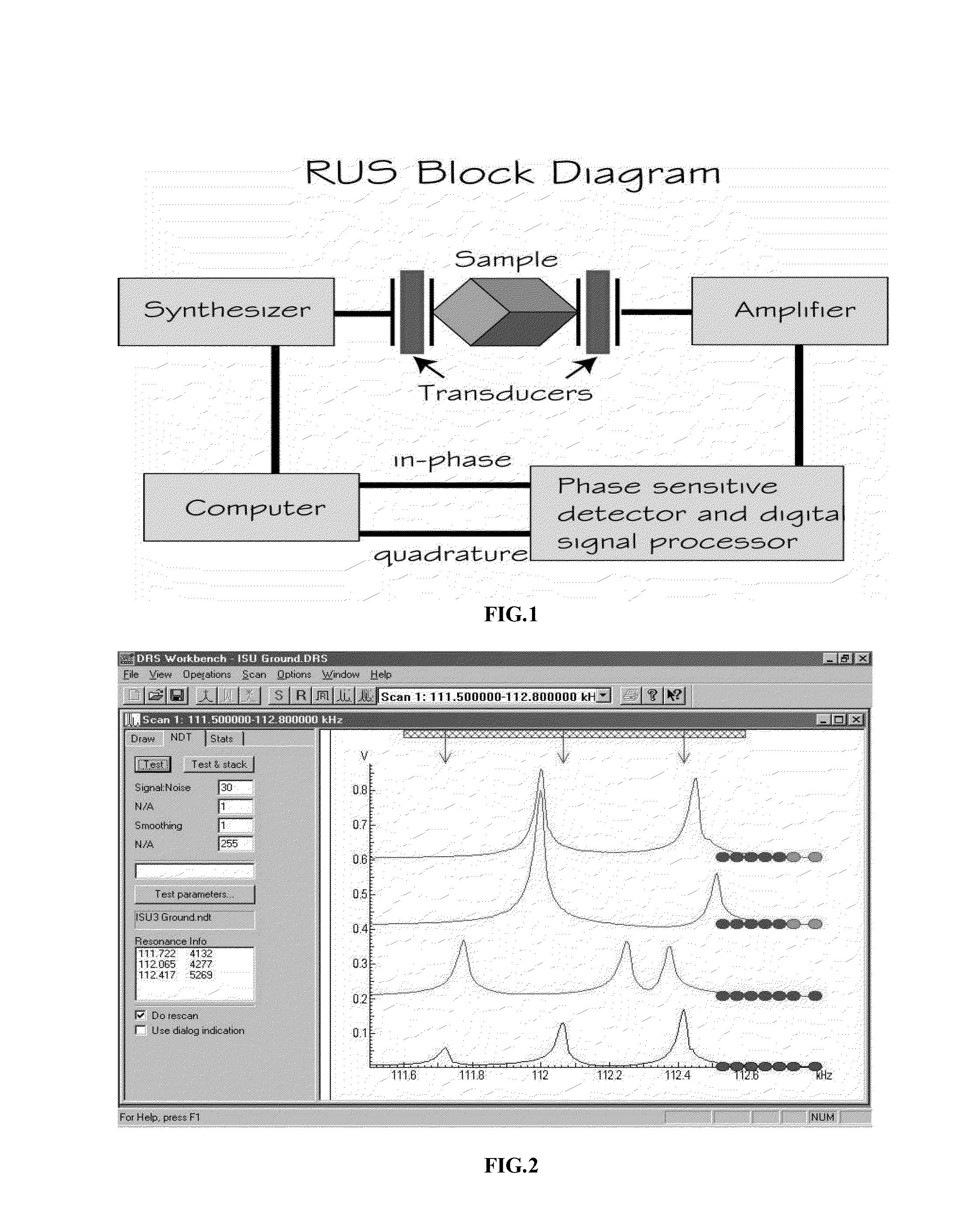

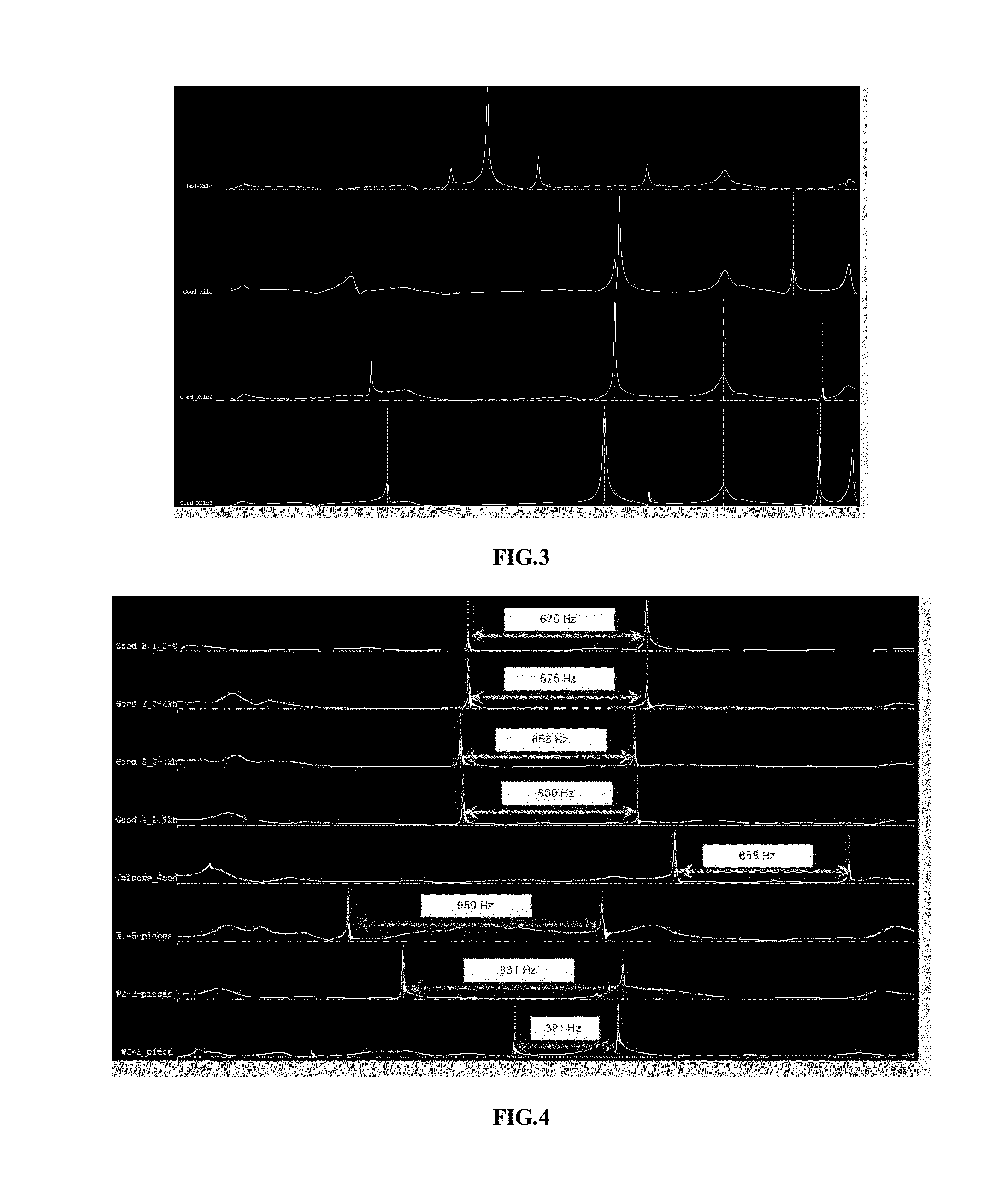

Method for detecting the purity of gold bullion

ActiveUS20140298911A1Easy to processEasy to displayVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveBullion

The density of gold and tungsten are almost identical, allowing for substitution by unscrupulous entities. The detection of the replacement is difficult to detect by common nondestructive testing methods, and repositories have resorted to drilling, cutting and melting samples of gold bars to certify their integrity. Resonant ultrasound spectroscopy allows a digital fingerprint to be produced, which has been shown to be effective in the detection of tampering. These spectra are representative of the dimensions, density and elastic constants of any solid object. Since the dimensions and density are essentially identical for pure and adulterated gold samples, only the elastic constant variance changes the spectral fingerprint. The method described in this application provides a reliable and accurate process to certify the integrity of gold samples.

Owner:RHODES GEORGE WYATT +1

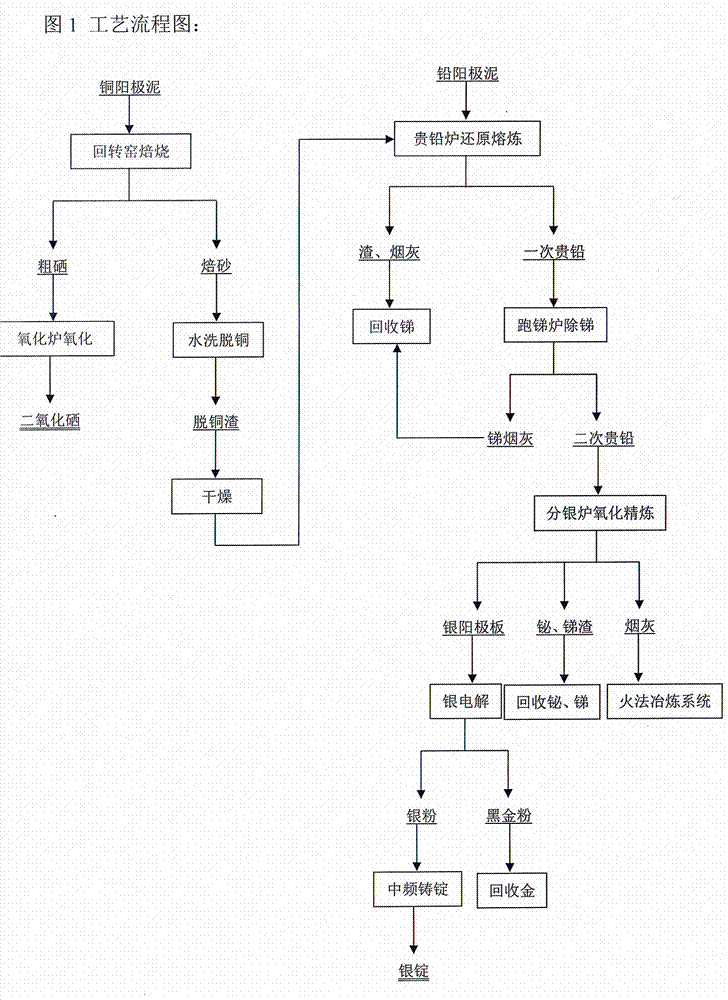

Mixed treatment technology of copper and lead anode slime

InactiveCN107574300ASolve the problem of large amount of waste waterAchieve recyclingSelenium/tellurium compundsElectrolysisSoot

The invention provides a mixed treatment technology of copper and lead anode slime. The mixed treatment technology comprises the technical steps that crude selenium and calcine are obtained after copper anode slime is subjected to sulfatizing roasting, a selenium dioxide product is obtained after crude selenium is subjected to oxidation, calcine is rinsed, and copper is removed; decoppering slagsare mixed with lead anode slime after being dried, a mixture of the decopper slags and lead anode slime is subjected to reduction smelting through a bullion lead furnace, soot, slags and primary bullion lead are obtained, and antimony is recycled from soot and the slags; primary bullion lead enters an antimony removing furnace, antimony is removed, antimony soot and secondary bullion lead are obtained, antimony is recycled from antimony soot, and secondary bullion lead is subjected to oxidation refining through a silver-smelting furnace; bismuth slags, tellurium slags, soot and a silver anodeplate are obtained through oxidation refining of the silver-smelting furnace, bismuth is recycled from the bismuth slags, tellurium is recycled from the tellurium slags, soot returns to a pyrometallurgy system to be treated, and the silver anode plate is subjected to silver electrolysis; and silver powder and black gold dust are generated through silver electrolysis, gold is recycled from black gold dust, silver powder is molten, and silver ingots are generated through pouring. According to the technology, mixed treatment of copper and lead anode slime and comprehensive recovery of various valuable metals like gold, silver, copper, lead, selenium, antimony, bismuth, tellurium are mainly achieved, and the problem that the quantity of wastewater generated in a traditional copper anode slimetreatment technology is effectively solved.

Owner:SHANDONG HUMON SMELTING

Exquisite gold bar ornament sand pointing technique

The invention discloses a pointing sand process of bullion jewelry, comprising pouring wax-drawing powder-roasting mold-reversing mold-holding mold-grinding-blowing sand-pointing sand-milling-shaping. The process combines with two technique of engraving and nailing sand. The product is subjected to nailing sand (pointing sand) using the surface density (fineness) of the diamond needle, therefore the contrast effect of the product is enhanced with more nicety and higher efficiency and the surface gloss of the product is very light and beautiful.

Owner:深圳明丰珠宝首饰有限公司

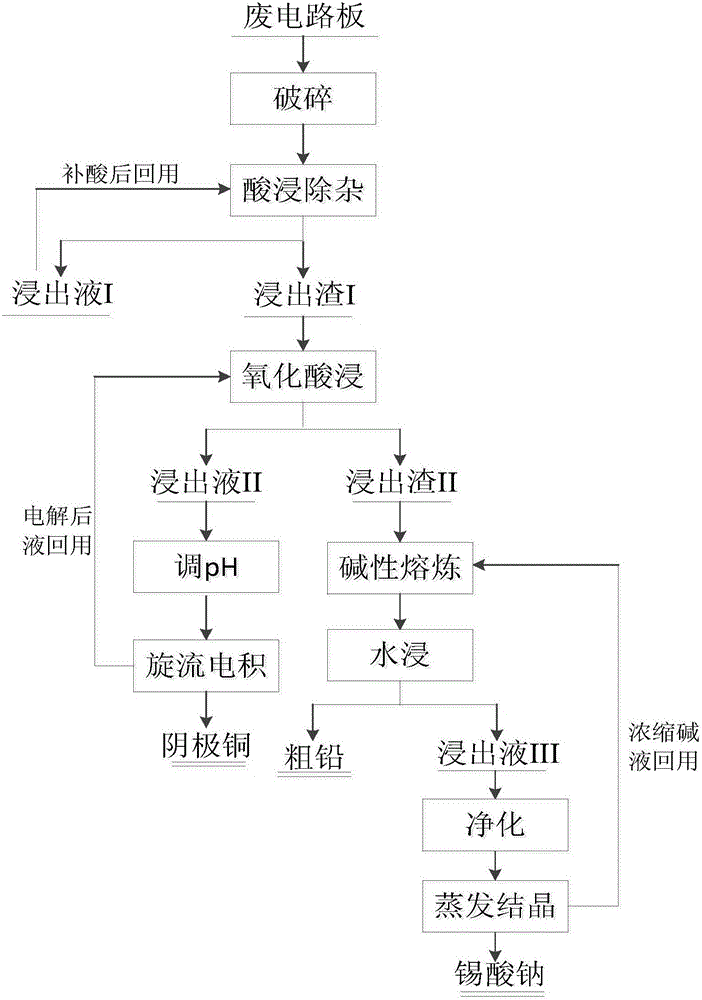

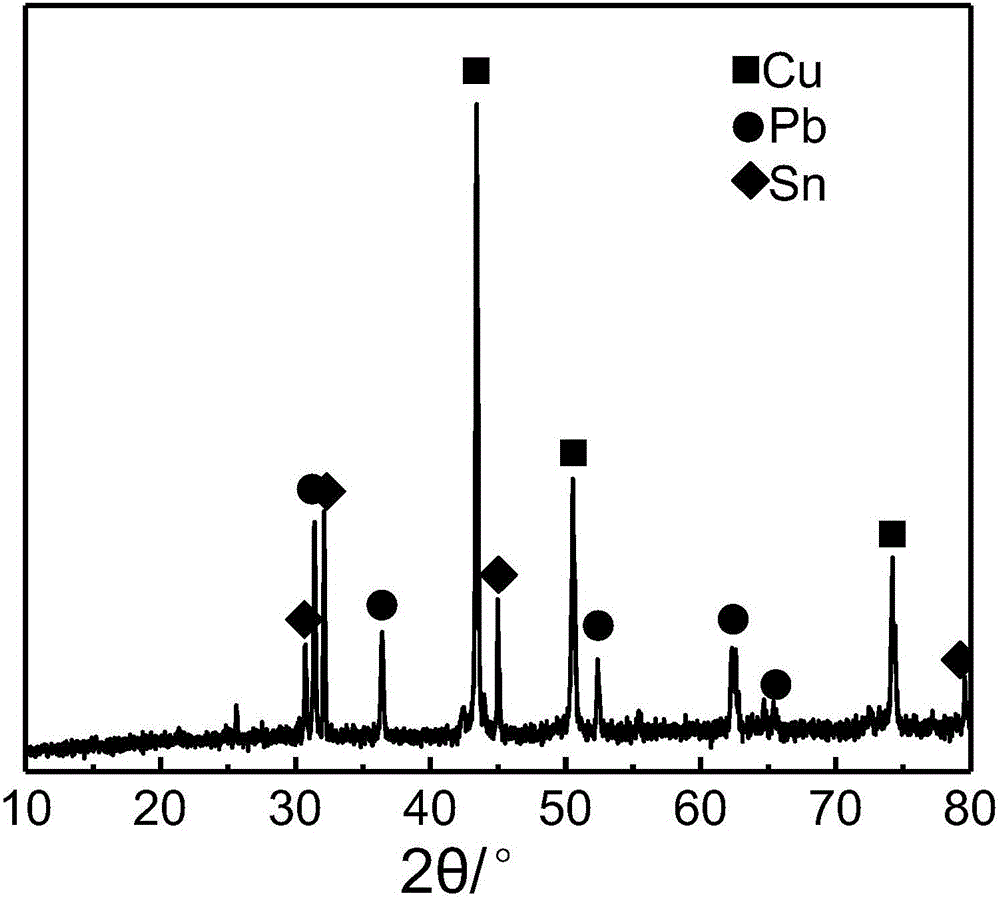

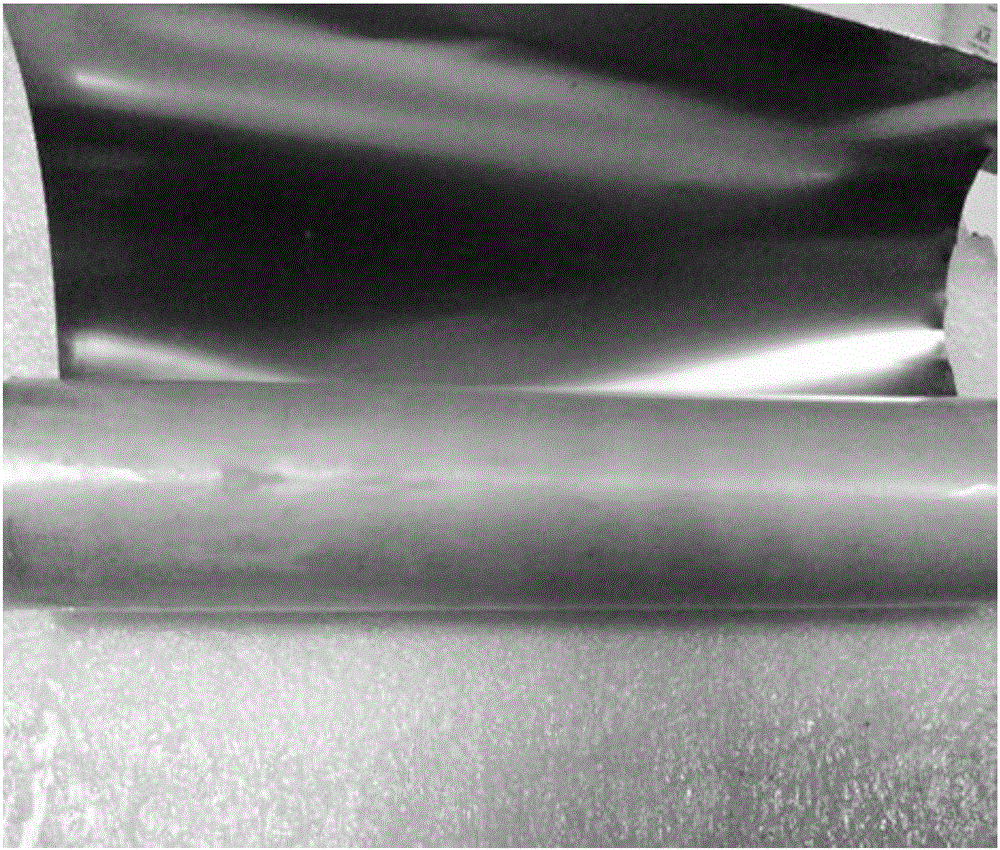

Method for recycling valuable metal in waste circuit board

The invention discloses a method for recycling valuable metal in a waste circuit board. The method includes the following steps that the waste circuit board is subject to smashing and reselection to prepare multi-metal powder; a dilute acid solution is added into the multi-metal powder, agitation leaching is carried out, filtering is carried out, and leaching slag I and leaching liquid I are obtained; an acid solution is added into the leaching slag I according to the liquid-solid mass ratio of the acid solution to the leaching slag I being 10-40:1, then an oxidizing agent is added, agitation leaching is carried out, filtering is carried out after leaching is finished, and leaching slag II and leaching liquid II are obtained; the leaching liquid II is subject to cyclone electrodeposition to obtain cathode copper and an after-electrolysis solution; alkali and a reducing agent are added into the leaching slag II, smelting is carried out under the condition that the temperature ranges from 400 DEG C to 600 DEG C, water leaching is carried out, filtering is carried out, and lead bullion containing precious metal and leaching liquid III are obtained; and the leaching liquid III is purified and is subject to evaporation and concentration to obtain a concentrated alkali solution and sodium stannate crystals. According to the method for recycling the valuable metal in the waste circuit board, the procedure is short, the efficiency is high, the cost is low, cleanness is achieved, and pollution is avoided.

Owner:广西自贸区西江资源循环科技产业股份有限公司

Method of producing aluminium titanium alloy using aluminium electrolytic tank

The invention relates to a method to produce aluminum titanium alloy by using aluminum electro-bath. The feature is that the raw material is alumina and titanium dioxide, and the purity of alumina should over 98%, as well as titanium dioxide; selecting cryolite molten salt aluminum electro-bath; adding alumina and titanium dioxide into the electro-bath to liquating into the cryolite melt, and the consistency of alumina is 2-5%, the titanium dioxide is below 1%. Under the effect of DC, the metallic aluminum and metallic titanium would be separated out on the cathode of the electro-bath. The equal aluminum titanium alloy would be formed under the whisking of magnetic field force of electro-bath. Aluminum absorbing package would absorb the alloy out and cast into aluminum titanium alloy bullion. The advantage of the invention is low energy consumption, low cost, high content of titanium in the alloy that could reach 2.5% and the actual recycle ratio of titanium could reach 98%.

Owner:包头铝业有限公司

Liquid-state high-lead slag side-blowing water-gas reduction process

ActiveCN103361491AEasy to separateSignificant synergistic effectProcess efficiency improvementLiquid stateSlag

The invention relates to a liquid-state high-lead slag side-blowing water-gas reduction process, and belongs to the technical field of metallurgy. The process mainly comprises the steps of: directly injecting liquid-state high-lead slag melt subjected to oxidization smelting by a bottom blowing furnace into a reduction furnace, and directly reducing liquid-state high-lead slag into secondary lead bullion through side blowing in the reduction furnace by adopting combination of water gas and oxygen-enriched air. The reduction process is simple in technology, low in production cost and good in reduction controllability, and helps to realize low-pollution low-carbon-economy industrialized production.

Owner:HUNAN HUAXIN RAREANDPRECIOUS METALS TECH CO LTD

Method for separating copper from lead through vacuum distillation of copper scum

The invention provides a method for separating copper from lead through vacuum distillation of copper scum. The method comprises the following steps of: holding the copper scum in a vacuum environment; performing distillation separation under the conditions of pressure intensity of 5-200 Pa and temperature of 900-1,300 DEG C for 30-180 minutes; getting Pb and PbS in the copper scum in a gas phase under distillation and condensing to obtain lead bullion; and remaining Cu2S and Cu in the copper scum in distillation residue copper matte, thereby realizing separation of copper and lead in the copper scum. The method has the advantages of less types and number of added auxiliary materials, simple process, short flow, complete separation of copper and lead, low energy consumption, low environmental pollution and capabilities of flexibly adjusting production scale and easily realizing industrial production.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of cyanide-free gold plating reagent sodium gold sulfite

ActiveCN105568269ASimple processProcess safetyGold compoundsLiquid/solution decomposition chemical coatingDissolutionIon

The invention relates to a preparation method of a gold salt for gold plating, particularly a preparation method of a cyanide-free gold plating reagent sodium gold sulfite, belonging to the technical field of chemistry. The preparation method comprises the following steps: gold rolling, gold bullion cleaning, gold dissolution, nitre removal, solonization, solonization, cleaning, complexing reaction, and crystallization by concentration. The method has the advantages of simple technique and high safety, can not generate dangerous intermediates in the process, can effectively lower chlorine ions, and can be used for producing the odorless green environment-friendly product.

Owner:烟台招金励福贵金属股份有限公司

Methods, systems and apparatus for automated authentication

The present disclosure is directed to an automated precious metal bullion authentication apparatus and system that, without human intervention, develops and disseminates information to enable a user to distinguish between genuine and non-genuine precious metals bullion items. The systems and devices may work together with third-party hardware or software and, with Internet access, may be utilized 24 / 7, 365 days a year. The system or device enables a user to receive directly at a point of sale, or anywhere in public or private, information regarding whether an item is genuine or not. Information regarding genuineness of an item may be provided to the user before, during, or after a monetary or non-monetary exchange or transaction between individuals or entities. The system or device identifies and authenticates precious metal bullion items automatically through a multiplicity of procedures and renders a conclusion based on data from acquired digital images and other physical measurements.

Owner:SECURITY PACIFIC CAPITAL CORP

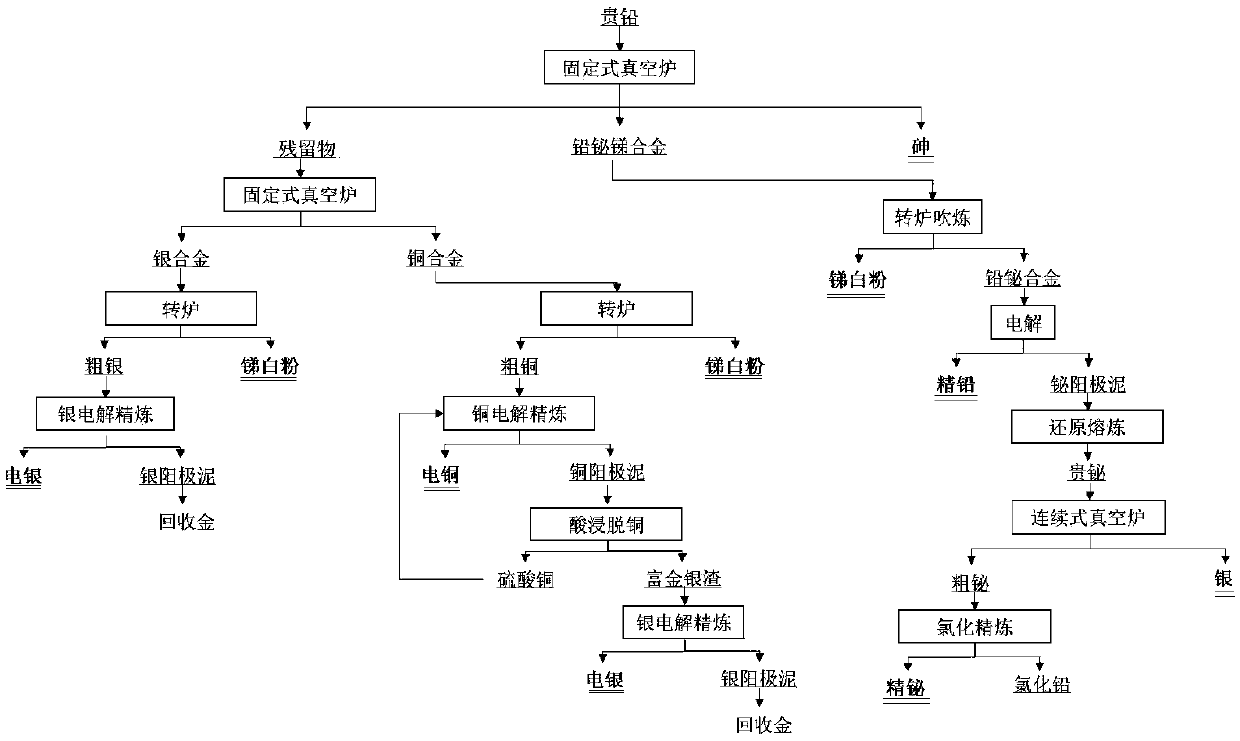

Bullion lead comprehensive treatment method

ActiveCN110172578AAchieve enrichmentImprove direct yieldAntimony oxides/hydroxides/oxyacidsLead halidesElectrolysisAntimony trioxide

The invention belongs to the technical field of solid waste recycling and reusing and particularly relates to a bullion lead comprehensive treatment method. Through the bullion lead comprehensive treatment method provided by the invention, open-circuit of arsenic, lead, bismuth and antimony and high-efficiency enrichment of precious metals gold and silver are realized through twice vacuum distillation, and elementary arsenic, a lead-bismuth-antimony alloy, a silver alloy and a copper alloy can be obtained respectively; the lead-bismuth-antimony alloy, the silver alloy and the copper alloy aretreated through oxidizing refining, electrolytic refining and chlorination refining to obtain refined lead, refined bismuth, antimony trioxide and electrolytic silver and electrolytic silver, and goldenrichment is realized; the bullion lead comprehensive treatment method has the advantages of being high in metal direct yield, low in energy consumption, short in flow, simple in equipment and the like in the whole treatment process; and moreover, vacuum distillation belongs to the physical process; the alloys can be separated through the saturated vapor pressure difference of the metals withoutgeneration of waste water, waste gas and waste residues, and industrialization, automation and continuity of bullion lead treatment can be achieved easily.

Owner:KUNMING UNIV OF SCI & TECH +1

Transportable, self-contained assay facility and method of using same to procure and assay precious metals

InactiveUS20130118948A1Efficient transportAccurate measurementMaterial analysis using wave/particle radiationContainer/bottle contructionAssayBullion

A transportable, self-contained assay facility built in a modified standard shipping container that is completely equipped to melt and assay precious metals, particularly gold and silver. An induction furnace melts the metal that is then poured into an ingot. The ingot is weighed and analyzed using an XRF alloy analyzer and the percentage of gold and / or other metals recorded. The value of the gold at current market prices is calculated and the assay and the value of the ingot is printed and given to the seller. The seller may opt to receive the ingot and pay the assayer an assay fee. Alternately, the seller may ask to be paid in cash, by bullion, wire transfer, or by an open hedge. A transfer or hedge is initiated and confirmed from the assay facility. The ingots may be securely stored in a safe within the assay facility.

Owner:AOW HLDG

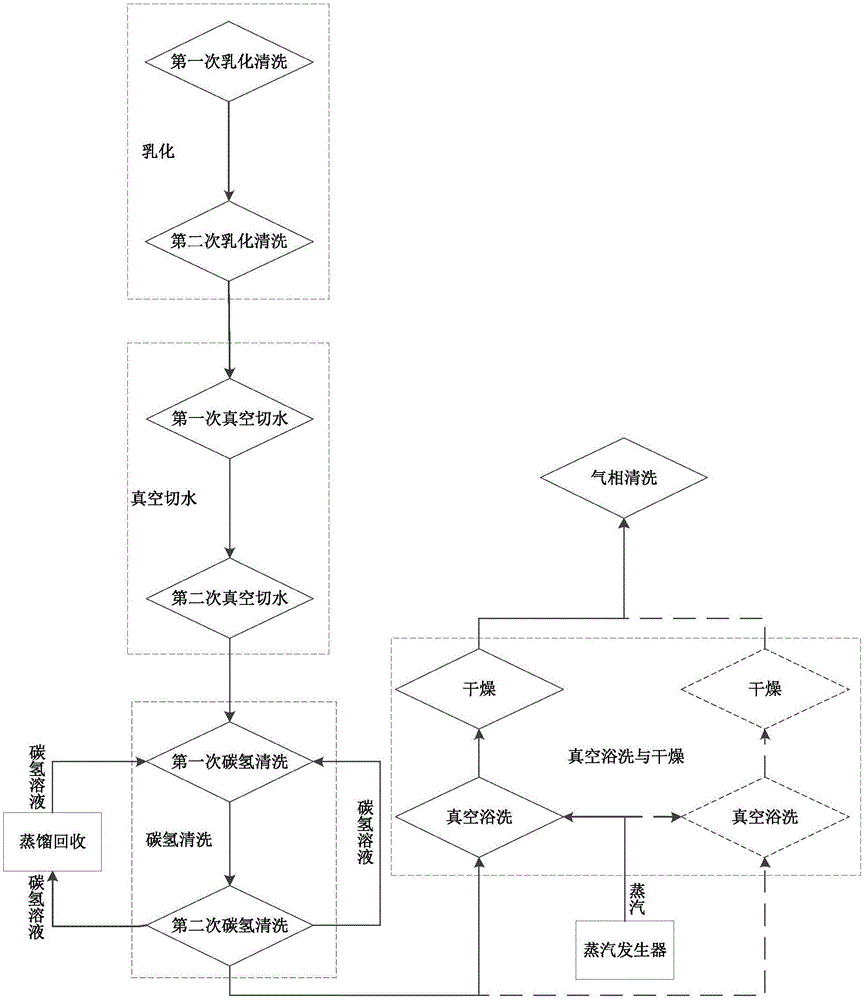

High-precision washing process for raw part of gold coin or silver coin

The invention discloses a high-precision washing process for a raw part of a gold coin or a silver coin and relates to the field of surface clearing of work pieces. The high-precision washing process comprises the following sequentially-set steps: emulsification, vacuum water shearing, hydrocarbon washing, vacuum bath-washing and gas-phase washing; therefore high-precision washing of the raw part of the gold coin or silver coin can be realized by means of control on vacuum degree, temperature of a detergent, ultrasonic wave frequency and washing time in each step. The high-precision washing process disclosed by the invention is complete in pollutant treatment, high in yield, high in automation degree in each step and capable of satisfying the environment protection requirements by adopting an environment-friendly detergent in each step.

Owner:SHENZHEN XINCHENGNUO ENVIRONMENTAL PROTECTION IND CO LTD

Method for production of bullion lead by two-section smelting processing on lead anode slime

ActiveCN103820643AImprove volatile removal rateEasy to recycleProcess efficiency improvementBullionAnthracite

The invention relates to a method for production of bullion lead by two-section smelting processing on lead anode slime, and belongs to a noble metal pyrometallurgical technology. The method improves the traditional technology that bullion lead is produced by processing the lead anode slime in a pyrometallurgical-process reducing smelting way. In comparison with an existing traditional technology for production of bullion lead by lead anode slime, the method has the advantages as follows: in the same converter, the technology includes two processes of low-temperature oxidation and high-temperature retailoring, the auxiliary material adding and charging method is changed into that after the lead anode slime is subjected to complete oxidation and converting, a reducing agent and a fluxing agent are further added for retailoring. Therefore, the method greatly reduces the adding amounts of anthracite coal as the reducing agent and soda ash as the fluxing agent, and lowers fuel consumption, the efficiency of arsenic and antimony removal is high, high-grade bullion lead is obtained, and the production capacity of the original converter is increased by 50%.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Method for efficiently recycling valuable metal in copper dross

ActiveCN104846207ALow recovery rateEasy to leach and separateProcess efficiency improvementElectrolysisIndium

The invention discloses a method for efficiently recycling valuable metal in copper dross, comprising the following steps: crushing the copper dross, levigating, classifying, atomizing for pulverization, adding a sulfuric acid solution and an oxidizing agent for acid leaching, and performing residue and fluid separation on slurry to obtain lixivium and leaching residues; adding an extracting agent into the lixivium to extract indium, extracting germanium from the extract after indium is extracted, and producing cathode copper by adopting a conventional electrowinning method from the extract after the germanium is extracted; mixing the leaching residues with lead concentrate, adding into an oxygen-enriched top blown converter or bottom blown converter for reduction smelting so as to produce lead bullion, further performing electrolysis refining on the lead bullion, recycling lead, and further trapping gold, silver, bismuth, stibium, platinum and palladium in anode mud for recycling treatment. The method has the advantages of being high in metal recycling rate, low in production cost, good in economic benefits, high in raw material adaptability, clean, environment-friendly and the like.

Owner:KUNMING METALLURGY INST

Method for recycling lead bullion from lead copper matte

ActiveCN106011497ALow particle size requirementLow melting pointProcess efficiency improvementBullionZinc smelting

The invention discloses a method for recycling lead bullion from lead copper matte. The method comprises the following steps that firstly, after being crushed, the lead copper matte is mixed with sodium carbonate and coke, and a mixture is obtained; secondly, the mixture obtained in the first step is arranged in a smelting furnace to be heated, the mixture is melted into molten mass, then, insulating stirring is conducted, and a stirring tool adopted during insulating stirring is an iron stirring tool; and thirdly, after insulating stirring is over, standing insulating is conducted, the molten mass is layered, the upper layer is enriched copper matte, the lower layer is the lead bullion, and then the lead bullion and the enriched copper matte are independently discharged and collected. The method for recycling the lead bullion from the lead copper matte is short in technology process, the valuable metal recycling rate is high, the lead bullion recycling rate is higher than 90%, the content of lead in the obtained lead bullion is higher than 97%, copper and zinc in the lead copper matte can be enriched, and high-grade raw materials capable of being directly used for copper and zinc smelting are obtained.

Owner:ZHUZHOU SMELTER GRP

Method for electrolyzing high-content low-grade lead bullion

InactiveCN103290429ARich in metal gradesLarge range of controlPhotography auxillary processesProcess efficiency improvementElectrolysisSlag

The invention relates to a method for electrolyzing high-content low-grade lead bullion. The method comprises the following steps of melting the high-content low-grade lead bullion containing copper, antimony and bismuth into a pot to be stirred for removing the copper, thoroughly removing the copper-containing floating slag, adding alkali to remove arsenic and tin, pumping the lead liquid into an anode plate casting machine to be cast into an anode plate, reasonably matching the use amount of the combined additives to electrolyze the anode plate and the electrolyte according to the chemical components of the anode plate and the chemical components of the electrolyte, extracting cathode lead, washing the cathode lead with water to remove the electrolyte on the surface of the lead and thus obtaining the precipitated lead, casting the refined precipitated lead to obtain lead pig with the quality reaching the No.1 national standard, gathering the antimony, bismuth, copper, gold and silver onto the anode plate to form anode paste, and further comprehensively recovering the antimony, bismuth, copper, gold and silver in balance. By adopting the method, the lead bullion with high contents of copper, antimony and bismuth can be electrolyzed into the qualified precipitated lead in one step, so that the secondary electrolysis cost can be reduced, and the enriched metal grade in the anode paste can be improved.

Owner:湖南省桂阳银星有色冶炼有限公司

Lead melting copper removal refining process for industrial frequency coreless-type electric induction furnace

ActiveCN103540762ANo emissionsMeet the technical requirements of the processPhotography auxillary processesProcess efficiency improvementElectrolysisLead sheet

The invention relates to a lead melting copper removal refining process for an industrial frequency coreless-type electric induction furnace. The process comprises the following steps: heating and melting a lead bullion raw material through the industrial frequency coreless-type electric induction furnace, pressing slag, and performing quick cooling to liquate copper from lead bullion; injecting the lead bullion obtained after copper removal into an anode casting unit to cast an anode plate, putting a lead anode plate into an electrolytic tank, applying direct current, and liquating anode lead on a cathode after the anode lead forms lead ions and enters an electrolyte; melting the liquated lead through the industrial frequency coreless-type electric induction furnace, sequentially performing oxidation refining and alkaline refining, dredging the slag, and then injecting a lead solution into a pouring unit to obtain an electrolytic lead ingot and oxidized slag; pumping the lead solution after slag dredging into a cathode sheet unit to enable a lead-solution-adhered roller to rotate so as to obtain a cathode lead sheet. The lead melting copper removal refining process for the industrial frequency coreless-type electric induction furnace is respectively applied to the working procedures such as lead melting copper removal, liquated lead refining ingot casting and cathode sheet manufacturing with electric energy, which is conveniently and easily obtained, through the industrial frequency coreless-type electric induction furnace, and has the advantages of reasonable process, low equipment investment, low energy consumption, great economic benefit, good environment-friendly effect and the like.

Owner:SHAANXI ZINC IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com