Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99results about How to "Low particle size requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

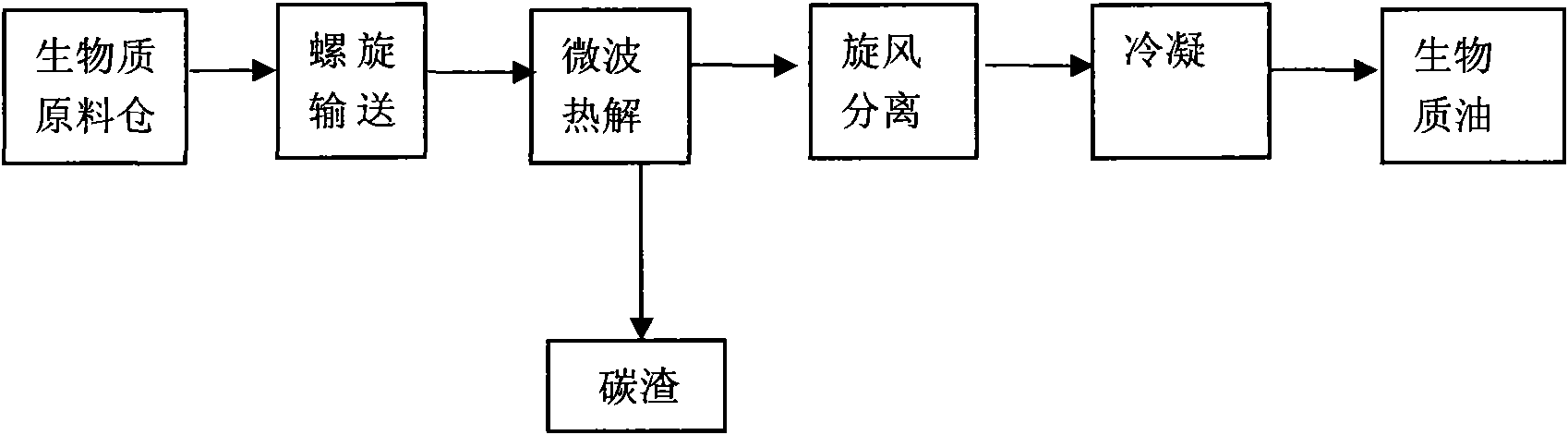

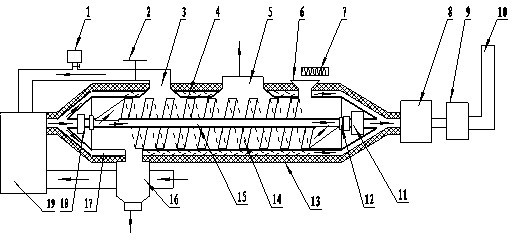

Method for preparing biomass oil in microwave thermal decomposition way

InactiveCN101560404AImprove microwave absorption performanceFast heatingLiquid hydrocarbon mixture productionMicrowave pyrolysisScrew conveyor

The invention discloses a method for preparing biomass oil in a microwave thermal decomposition way, which comprises the following steps: biomass enters a screw conveyer from a storage hopper, the feeding speed of the screw conveyer is 30-60 kilogram / h; the biomass enters a microwave pyrolysis reactor through the screw conveyor, the temperature of the biomass after absorbing microwave rapidly rises to 450-550 DEG C to reach the best temperature 475-500 DEG C of the biomass producing the oil; the biomass is thermally decomposed in the microwave pyrolysis reactor to produce high-temperature organic steam, the organic steam is sent to a cyclone separating device for gas and solid separation to remove carbon grains and sand; the organic steam is discharged through the cyclone separating device, the biomass is sent to a condenser for quenching, a condensable part of the biomass is changed into the biomass oil, and the biomass oil is dropped into an oil tank, thereby the biomass oil is prepared. The invention accords with the best process requirement of the biomass oil extraction without thermal conduction and has low cost, controllable and precise thermal decomposition temperature and no thermal inertia.

Owner:上海鸿泽企业发展有限公司

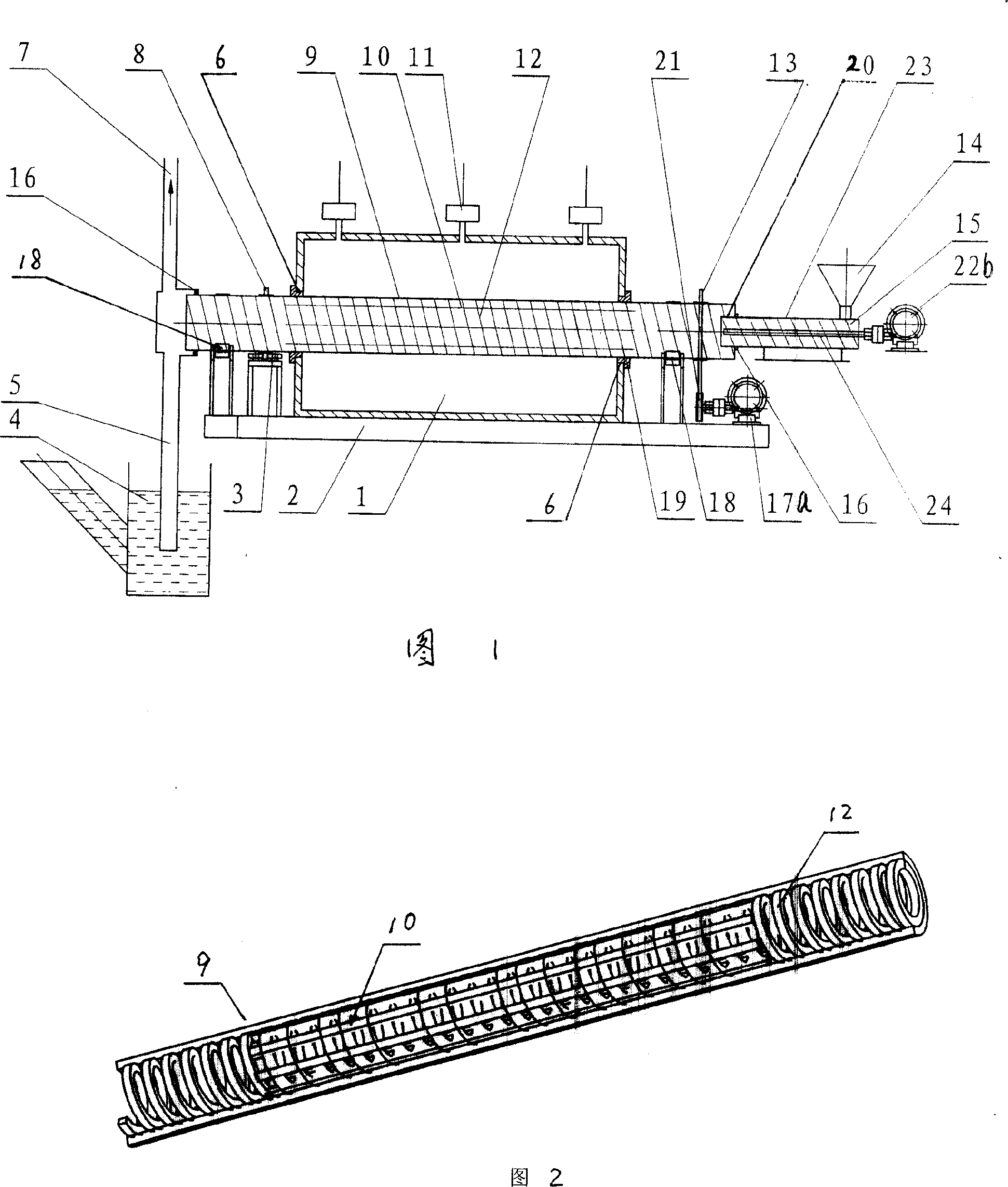

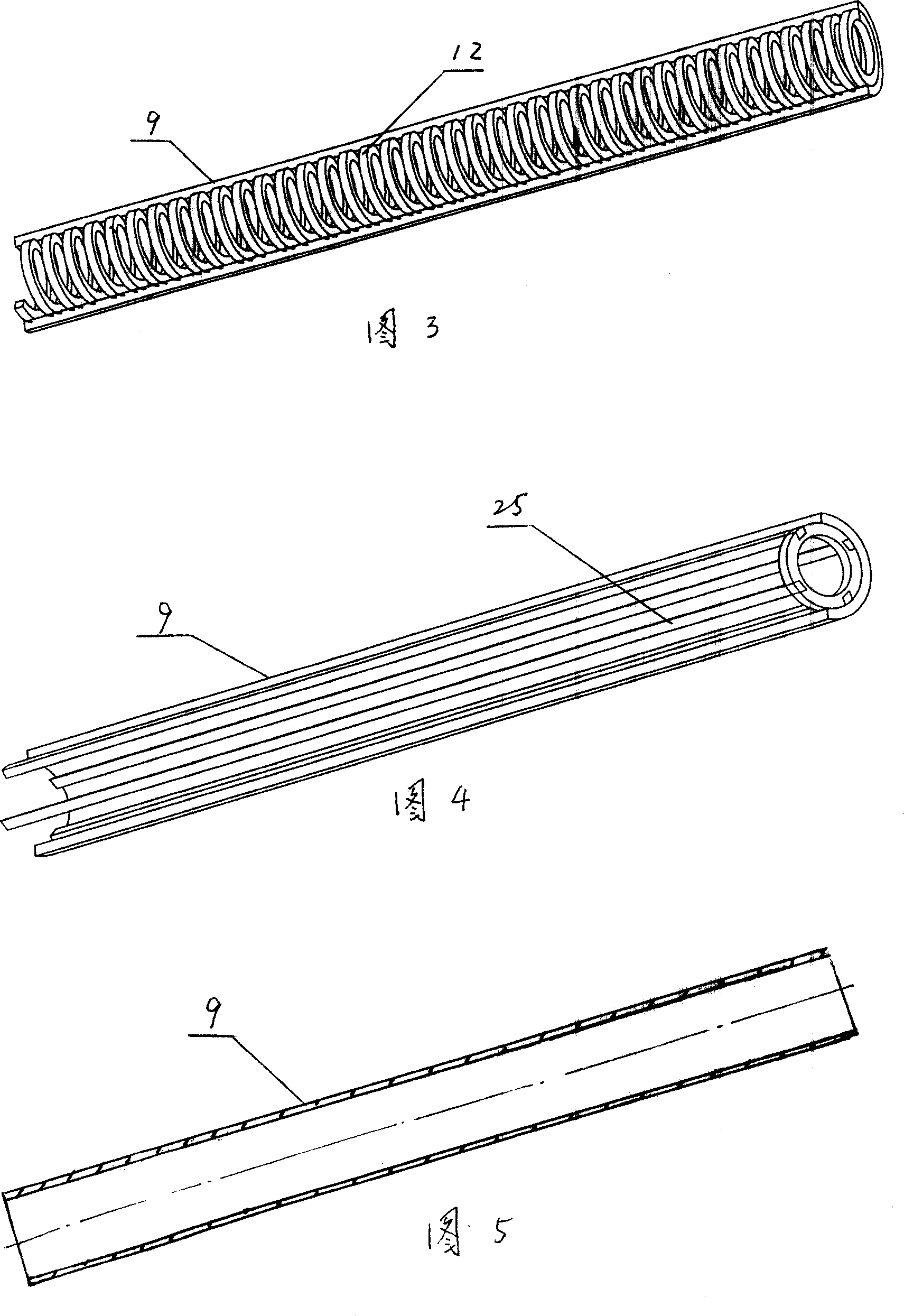

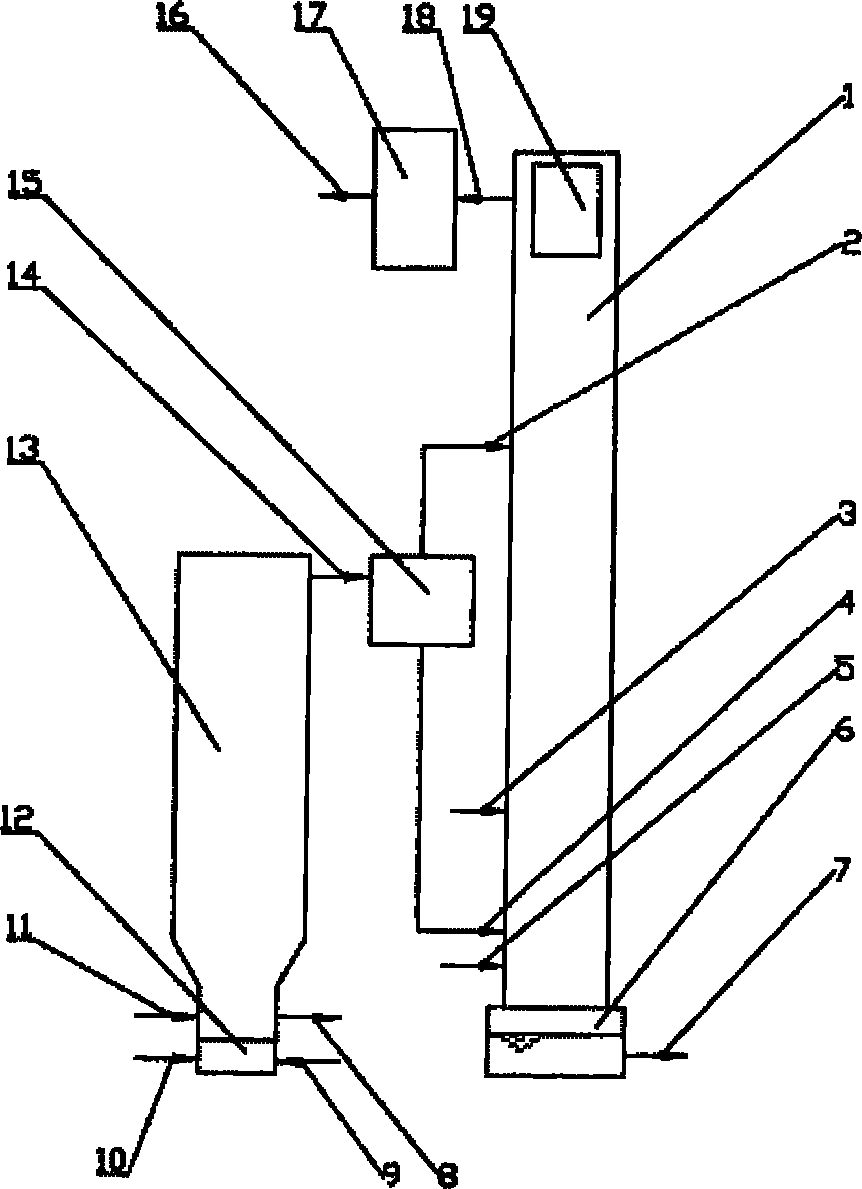

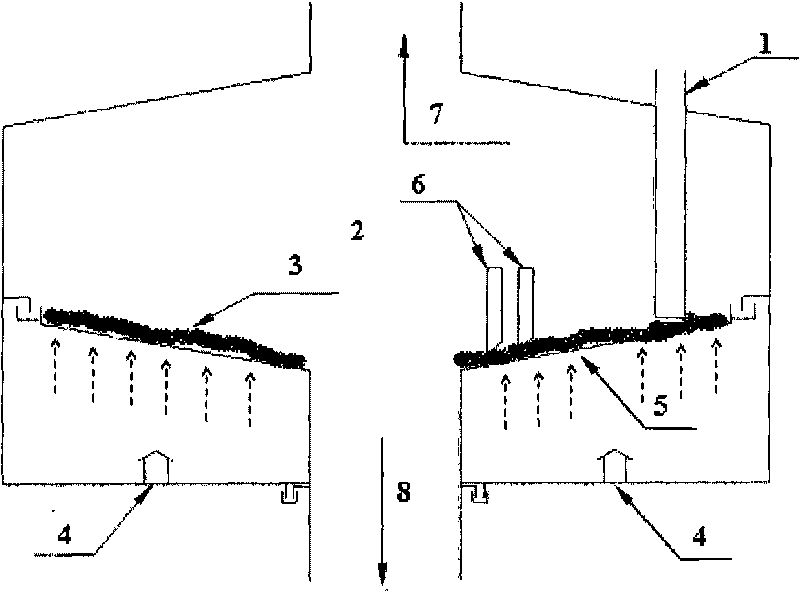

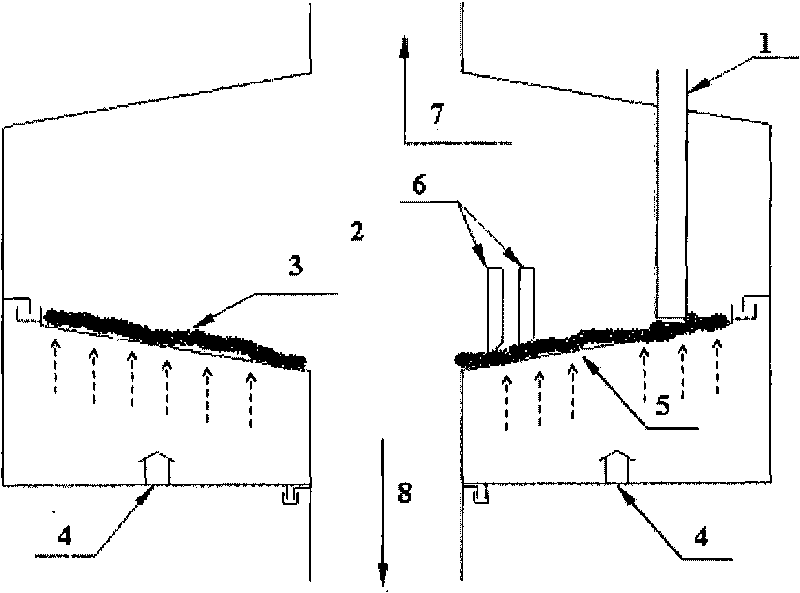

Microwave drum dry distiller and its application in dry distilling and pyrolyzing oil shale

InactiveCN101020828AFast heatingRapid responseSpecial form destructive distillationMicrowave ovenSlag

The present invention relates to carbon material pyrolyzing and dry distilling technology, and is especially one kind of microwave drum dry distiller and its application in dry distilling and pyrolyzing oil shale. The microwave drum dry distiller includes one microwave oven, and one inner screw drum on supporting rolls. The inner screw drum set on the microwave oven has material inlet, slag discharging barrel, gas exhausting pipe, and discharging port connected to the spiral conveyer. Granular oil shale entering to the microwave oven spirally through the inner screw drum absorbs microwave for dry distilling and pyrolysis so as to produce shale oil, fuel gas and semi-coke. The present invention has simple structure, convenient operation, fast dry distilling, high energy utilizing rate, environment friendship and other advantages.

Owner:NORTHEAST DIANLI UNIVERSITY +1

Method for pellet formation using steel-making slurry

InactiveCN1594607ARaw material balling performance improvementReduce the requirement of raw material particle sizePellet FormationWater content

The invention relates to a pelletizing method using sludge of steel production and belongs to pelletizing technology in metallurgy field. The method comprises: adjusting sludge concentration to 10-40%, adding 3-10% (weight percentage) sludge in mixture of iron ore powder and bentonite, continuously spraying it in palletizing disk, The advantage of the method : material sphericity is improved greatly. Bentonite usage can reduce greatly in mixture, which promote the pelletizing quality. Pelletizing disk don't take on sandification. Aqueous sludge can minimize the extra water. The enterprise has electric furnace, open-hearth furnace, revolving furnace and pelletizing line can use the method.

Owner:攀钢集团成都钢铁有限责任公司

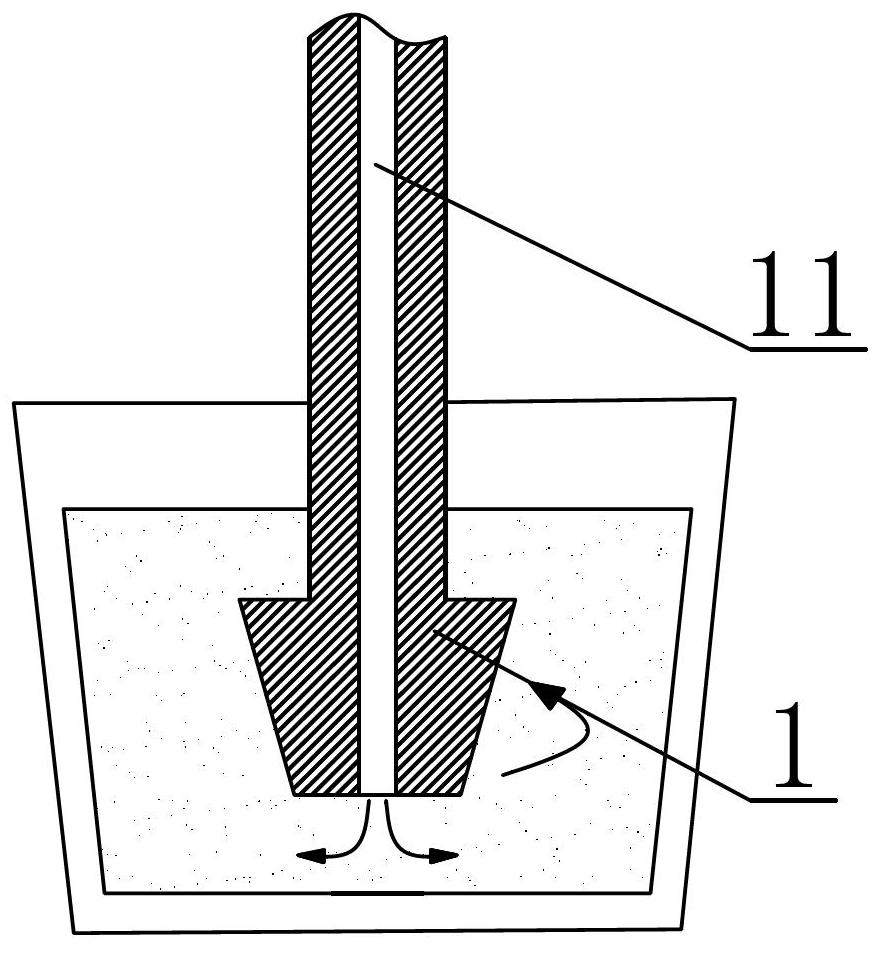

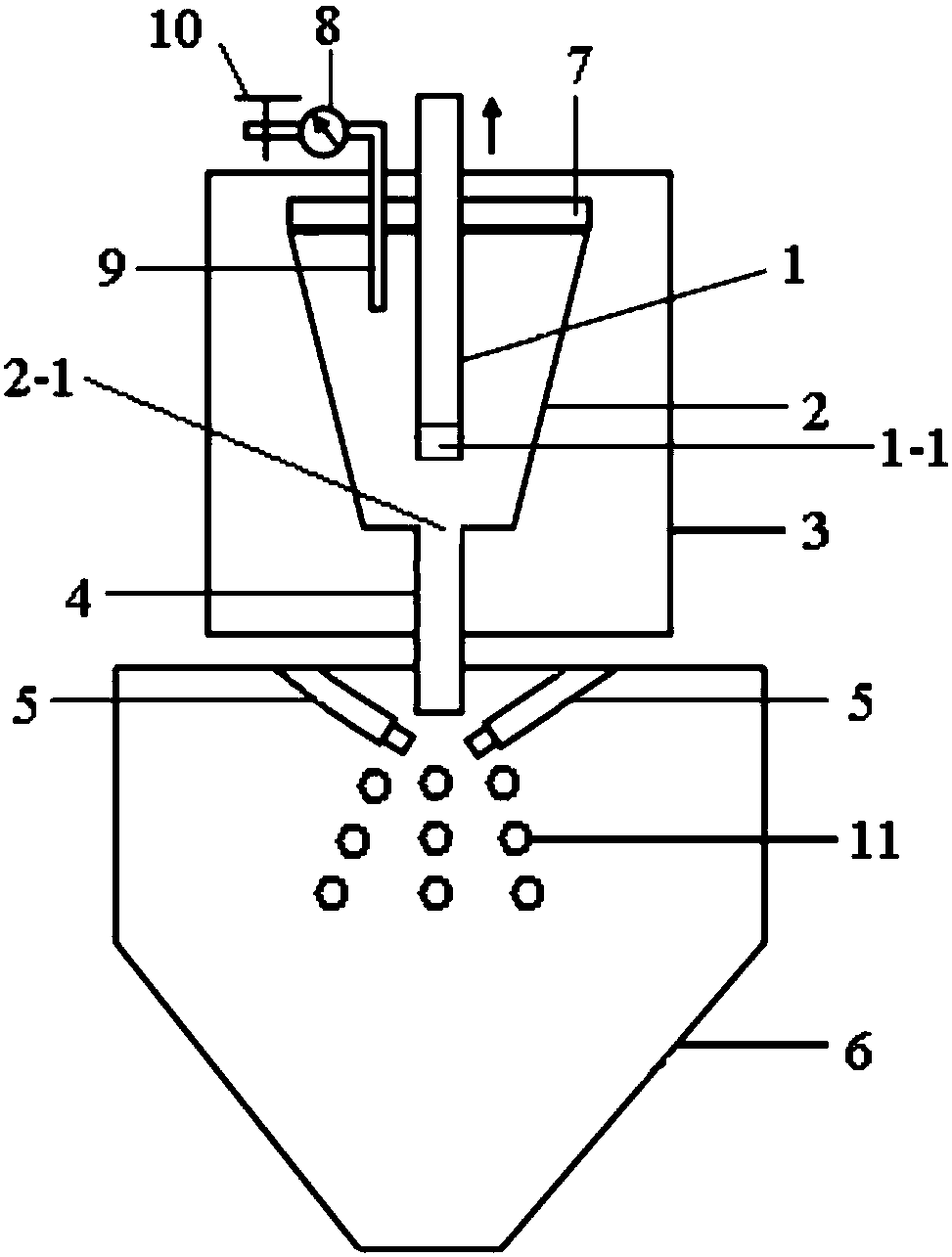

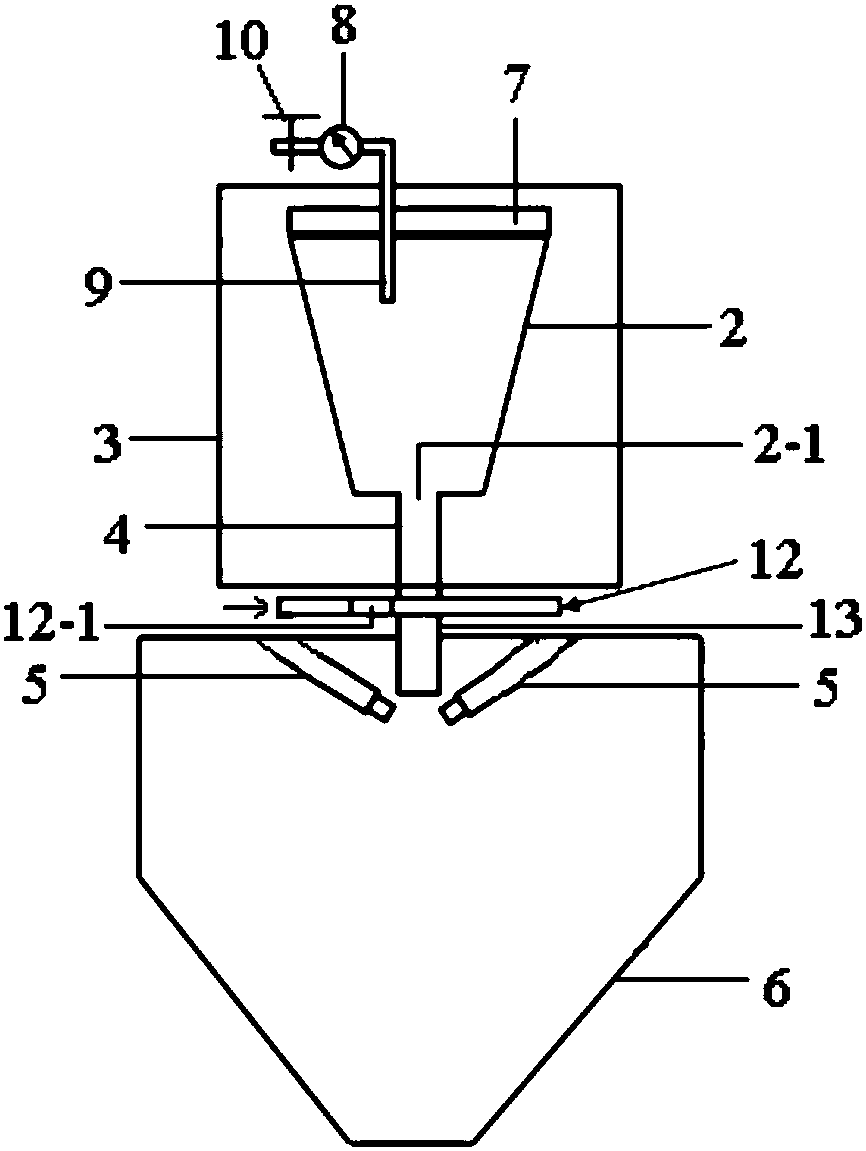

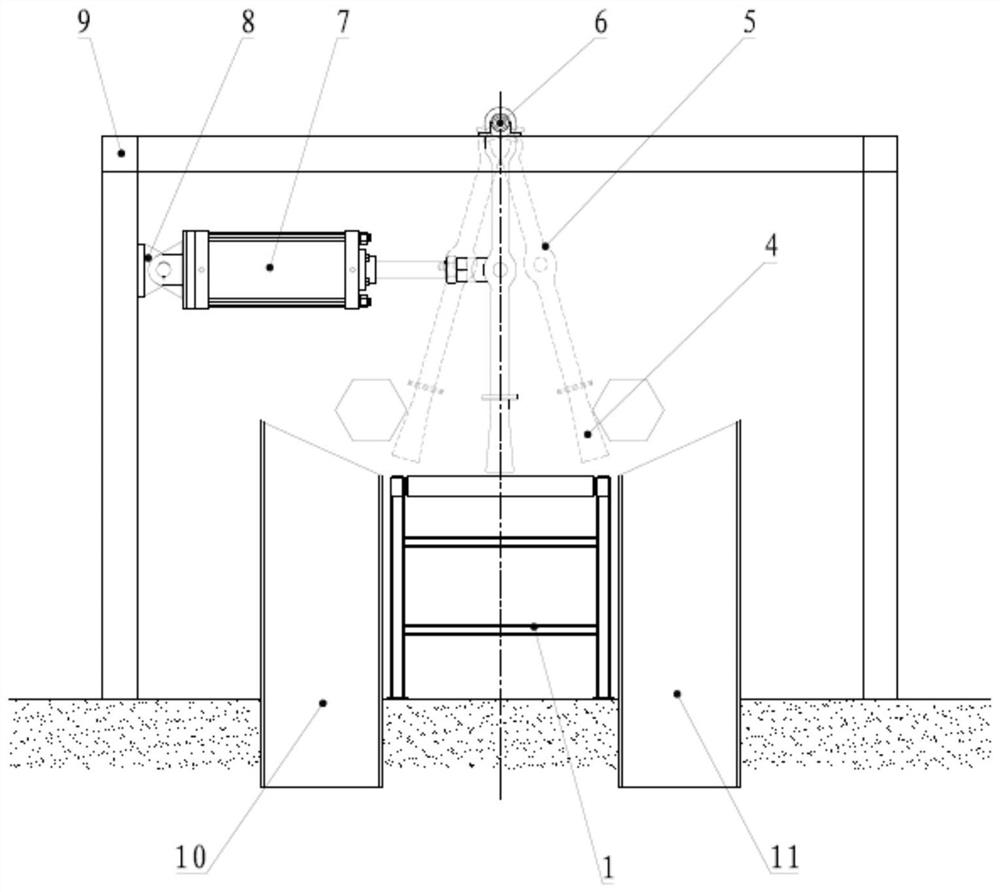

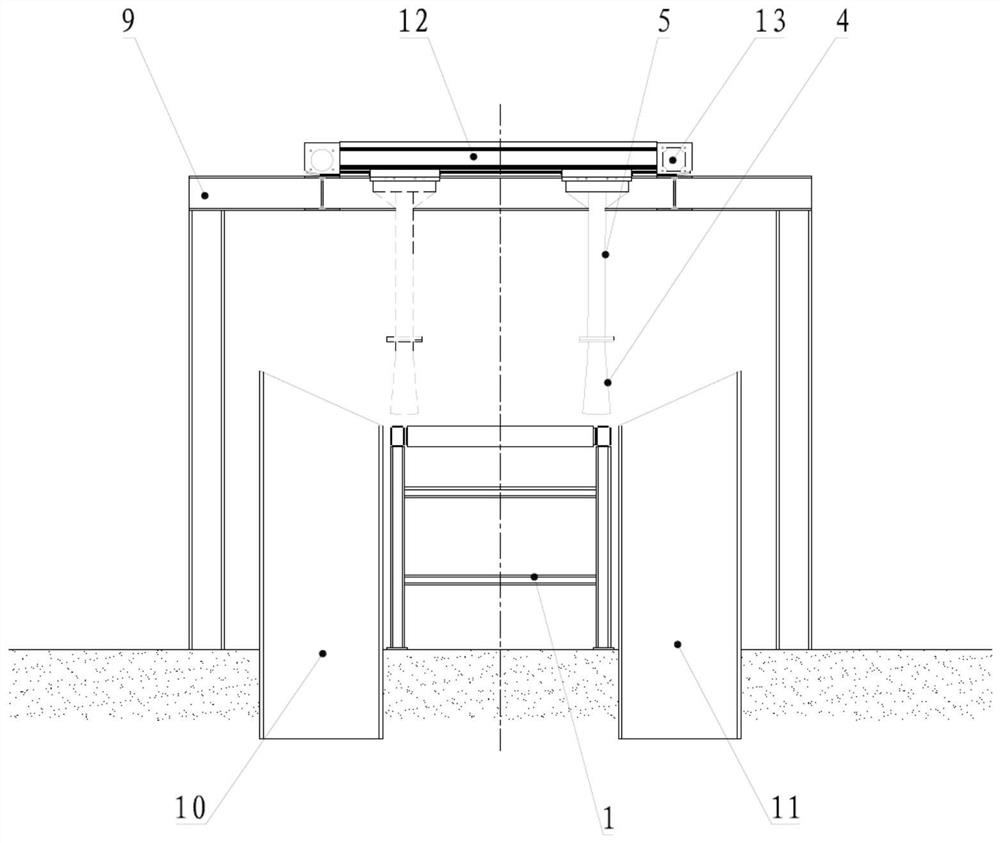

KR (knotted reactor) powder spraying, stirring and desulfurizing device and method

InactiveCN102676741AThe desulfurization cycle is shortenedReduced desulfurization working timeGranularityEngineering

The invention relates to a KR (knotted reactor) powder spraying, stirring and desulfurizing device. The KR powder spraying, stirring and desulfurizing device comprises a stirring head and a driving device for controlling the stirring head to act, wherein the driving device comprises a connecting rod linked with the stirring head, a lifting device for driving the connecting rod to move up and down and a stirring motor for driving the connecting rod to rotate. The KR powder spraying, stirring and desulfurizing device is characterized by further comprising a feeding system and a high-pressure gas source, wherein a through hole for introducing high-pressure inert gas and desulfurizing agents is formed on the stirring head, and an inlet of the through hole is communicated with a desulfurizing agent outlet and a high-pressure gas source outlet of the feeding system. The invention further relates to a method for desulfurizing molten iron by using the KR powder spraying, stirring and desulfurizing device. By using the device, efficient, fast and precise desulfurization can be realized, and the effects of reducing the requirements for granularity of desulfurizing agents, reducing the temperature drop and reducing the loss of the stirring head can be achieved.

Owner:ZENITH STEEL GROUP CORP

A method for direct reduction of industrial waste slag in rotary hearth furnace

InactiveCN102277461ALow mechanical strength requirementIncrease flexibilityProcess efficiency improvementHearthProcess conditions

The invention relates to a direct reduction method for treating industrial waste slag in a rotary hearth furnace, belonging to a new direct reduction ironmaking process in the metallurgical industry. The main process is: ingredients - mixing - pellets - drying - preheating - reduction - metallized pellets. Metallized pellets with a metallization rate of over 80% can be obtained after reduction in a rotary hearth furnace. The present invention comprehensively recycles and utilizes valuable elements in iron-containing industrial waste residues, economically obtains reducing agent resources, and solves the problem of low falling strength of cold solidified carbon-containing pellets prepared in the process of comprehensive recycling of industrial waste residues It has the advantages of high metallization rate, simple operation, easy control of process conditions, less equipment investment, low production cost, easy to meet raw material conditions, etc., and the overall process is more energy-saving than the furnace smelting process. It is also more environmentally friendly, and more importantly, the method can comprehensively recycle industrial waste, reduce its pollution to the environment, and save energy and protect the environment.

Owner:UNIV OF SCI & TECH BEIJING

Coal gasification method

InactiveCN102373089ALow investment costLow running costGranular/pulverulent flues gasificationFluidized bedOxygen

The invention provides a fluidized bed-entrained flow bed gas gasification method. The method comprises the following steps: 1) carrying out reaction on raw material coal and a mixture of air and steam or a mixture of oxygen and steam to obtain gas containing incompletely reacted coal and ash; 2) separating the gas obtained from the step 1) to obtain condensed fine coal air-flow and light fine coal air-flow, and carrying out reaction on the condensed fine coal air-flow with air or oxygen to obtain gas containing coal and ash; 3) carrying out reaction on the gas obtained from the step 2) and steam to obtain gas containing coal and ash; 4) carrying out reaction on the gas obtained from the step 3), the light fine coal air-flow separated from the step 2) and a mixture of steam and carbon dioxide to obtain final gas containing coal and ash. The method lowers investment and operating cost of a traditional pulverizing system by an entrained flow bed gasification method and has a substantially increased gasification temperature than a traditional fluidized bed gasification method, so as to reduce equipment cost and increase gasification efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

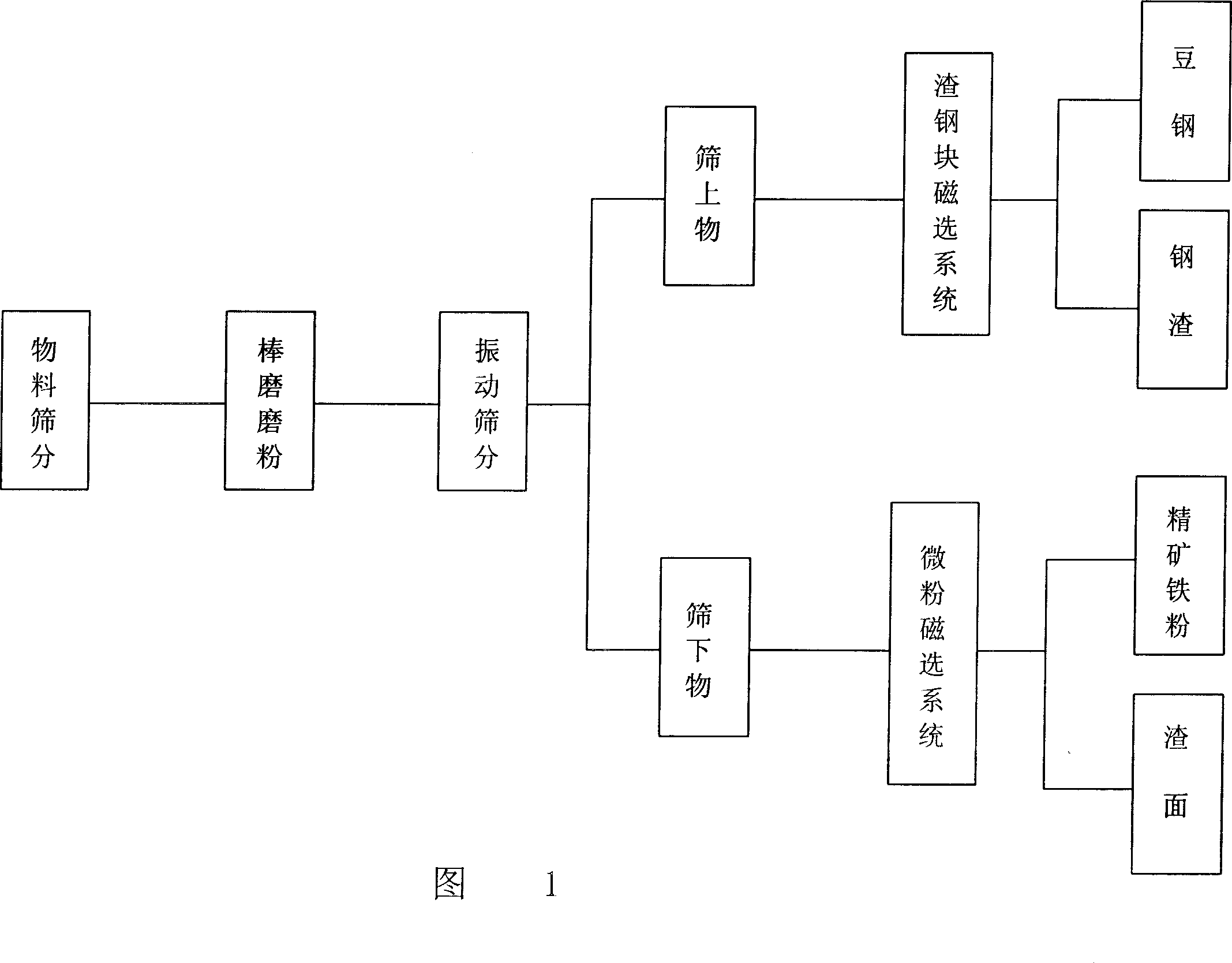

Process for treating slag steel

The invention discloses a rod milling-magnetic cobbing disposing technology of steel-smelting slag in the metallurgical resource synthetic utility technological domain, which comprises the following steps: sieving materials; milling powder; vibrating to screen; magnetting; separating refined ore powder and slag; magnetting the screen material; separating soy steel and steel block slag.

Owner:ANYANG IRON & STEEL GRP

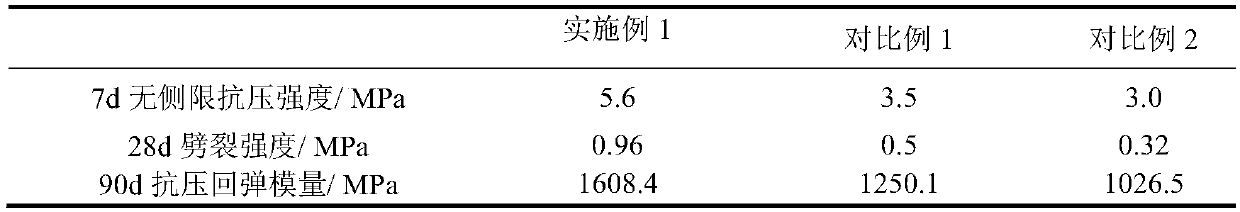

Granule curing agent and high-strength low-shrinkage cracking-resistance road surface base layer material prepared using same

ActiveCN109626892AReduce the plasticity indexLow water absorptionCement productionFiberCrack resistance

The invention discloses a granule curing agent and a high-strength low-shrinkage cracking-resistance road surface base layer material prepared using the same. The curing agent is a powder reagent which is prepared by taking low Ca micro-expansive cement, an alkaline catalyst, waste steel slags, high Ca powder coal ash, an expanding agent, an internal curing agent and composite fibers. The curing agent aims at solving the difficult problem of insufficient stable soil material mechanical performance and durability when curing soil exceeds a normal particular dimension; the high-strength low-shrinkage cracking-resistance road surface base layer material prepared using the granule curing agent has the advantages of excellent mechanical performance, stable water resistance and cracking resistance, durability and excellent energy-saving environmental-friendly characteristics, the cost of an engineering project can be effectively reduced, the material can be generally applied to the fields ofroad base layers, soft base treatment, ecological slope protection, dam anti-seepage walls, filling materials, building foundation treatment and the like, and the material has wide application prospects.

Owner:WUHAN MUNICIPAL CONSTR GROUP

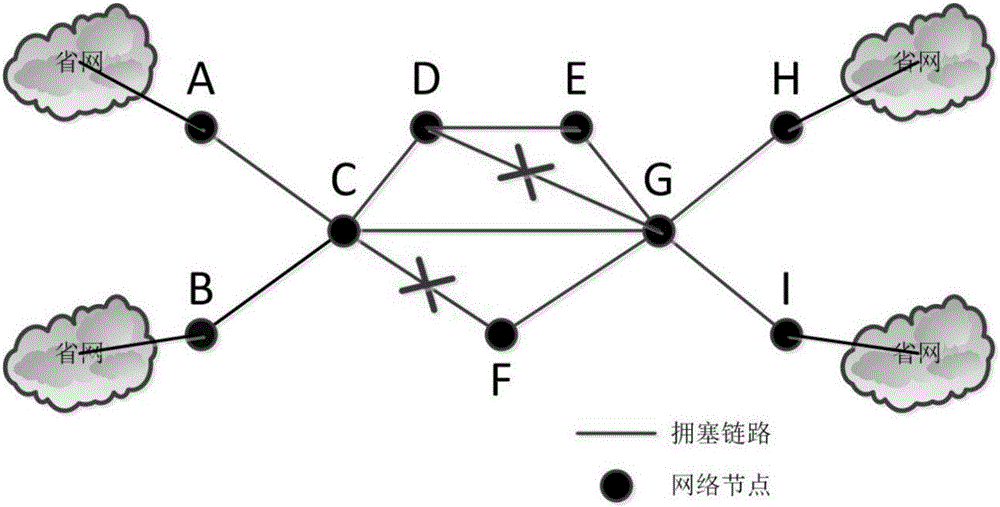

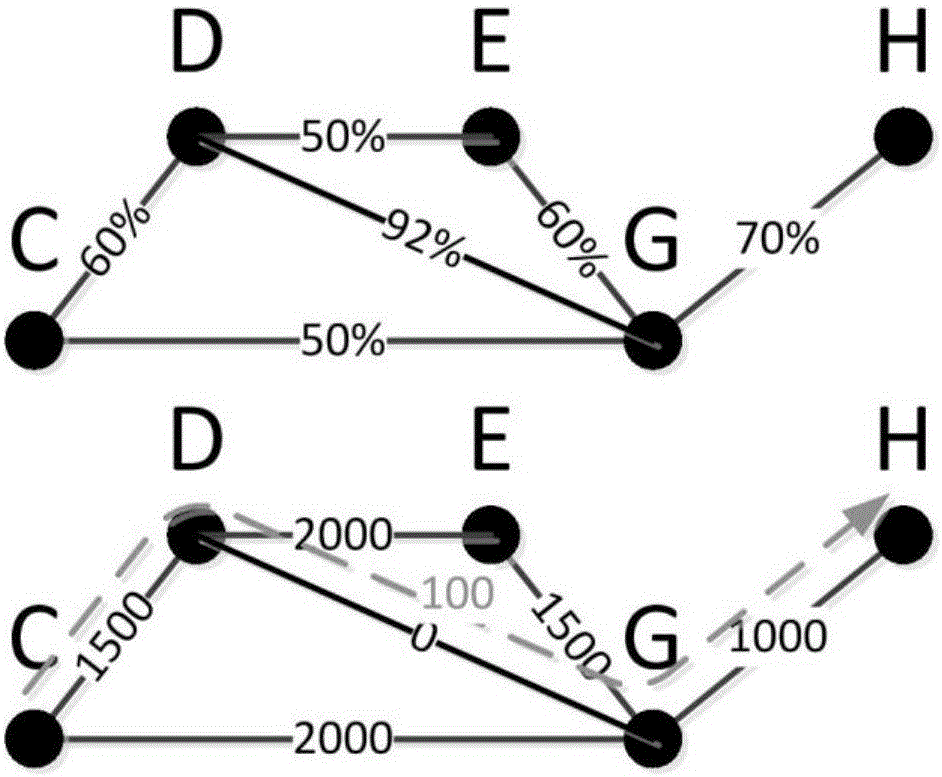

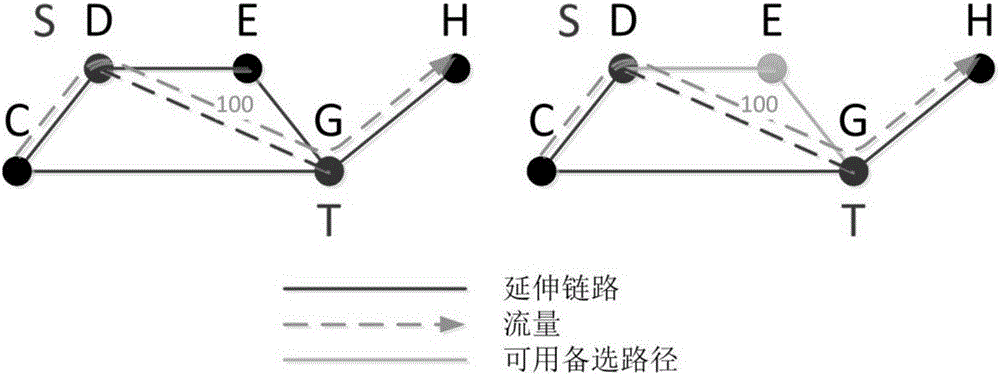

Backbone network traffic scheduling method for eliminating link congestion

InactiveCN106059941AEliminate congestion problemsEasy to handleData switching networksCongestion windowDistributed computing

The present invention discloses a backbone network traffic scheduling method for eliminating link congestion. A congestion part of an original route is transferred to an alternative path of the congestion part, thereby bypassing a congestion link. Specifically, for a certain congestion link, due to overlarge, some traffics on the congestion link fails to find a proper candidate path, an algorithm temporarily skips the traffic and processes next traffic; and when the algorithm traverses all traffics on the congestion link and migrates all traffics that can be migrated, the algorithm may split all residual convergence flows on the link if the link is still in a congestion state, a large convergence flow is split into several small convergence flows, at most a maximum quantity of small convergence flows, so that a probability that the traffic finds the candidate path is increased, and the congestion link is adjusted.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for rapidly and directly dipping nickel sulfide concentrate under action of ultrasonic wave

InactiveCN101717857AEnhanced mass transferReduced drag filmProcess efficiency improvementPotassium nitrateUltrasound - action

The invention discloses a method for rapidly and directly dipping nickel sulfide concentrate under the action of ultrasonic wave, belonging to the field of heavy non-ferrous metal hydrometallurgy. The method comprises the following steps of: crushing nickel ore (or directly using commercially-sold ore fines) and ensuring that the granularity of over 90 percent of ore is 0.15-0.08 mm; evenly mixing the nickel ore and water and placing the mixture into a stainless steel reactor, wherein the weight ratio of the water to the nickel ore is 5-30:1; adding an oxidant which can be sodium nitrate or potassium nitrate, wherein the weight ratio of concentrated sulfuric acid to the nickel ore is 0.5-1.1:1; finally keeping the ultrasonic frequency at 20.02kHz and the power at 50-150W under the action of ultrasonic wave; and directly dipping at normal pressure and normal temperature for 40-60 min. The invention has the characteristics of operation at normal pressure, high reaction speed, high leaching rate up to 97-99 percent for only 40-60 min and relative safety and low cost by taking solid nitrate as the oxidant.

Owner:JIANGSU UNIV

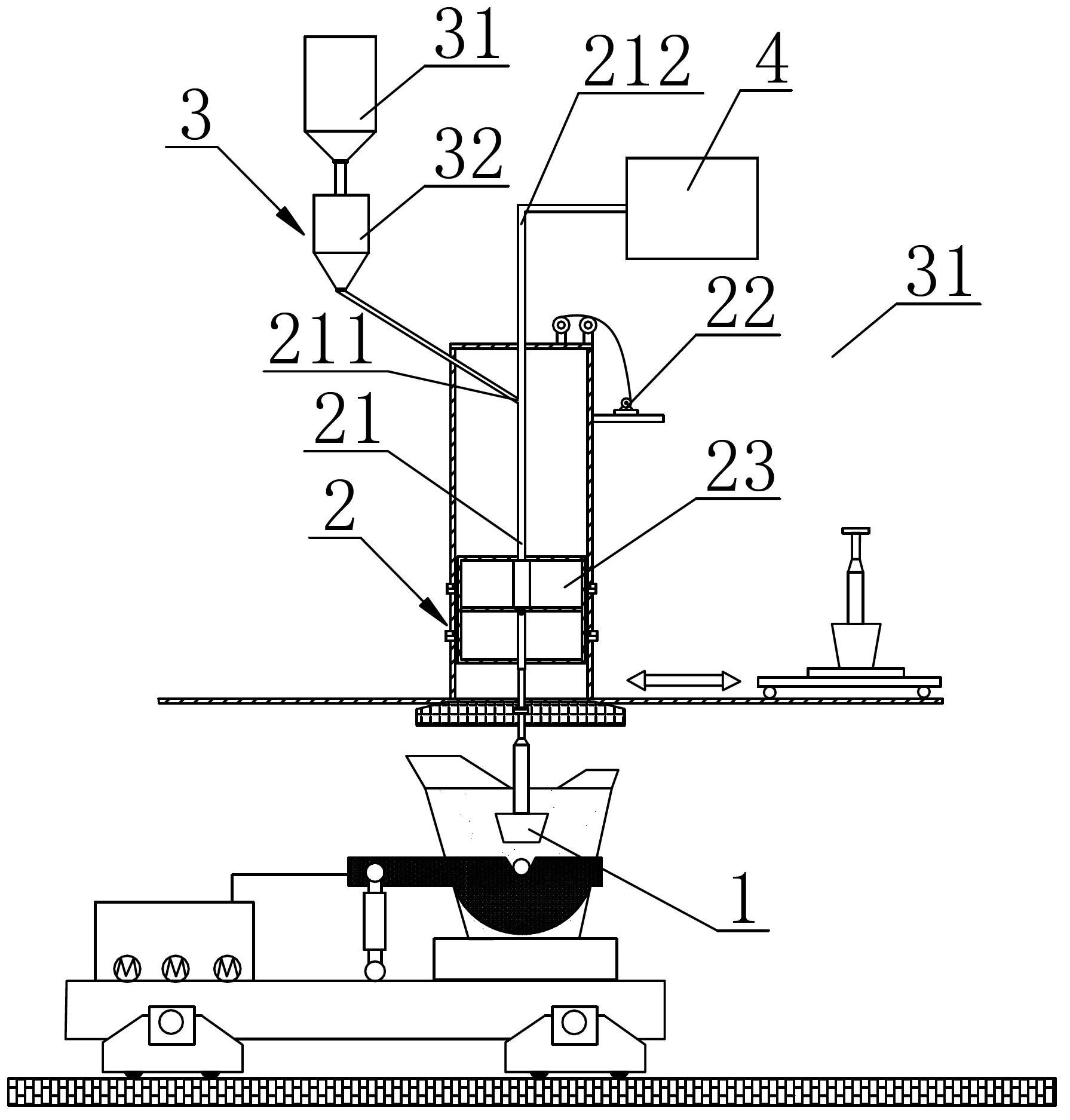

Process for upgrading low-rank coal in an internally heating way with heated gas carrier

InactiveCN101701158ALower energy consumption ratioImprove thermal efficiencyDirect heating destructive distillationSolid fuelsFlue gasProduct gas

The invention discloses a process for upgrading low-rank coal in an internally heating way with the heated gas carrier, comprising the following steps: (1) the crushed and screened raw coal is added to a rotating furnace grate arranged at the bottom of a reactor through a raw coal feeding elephant trunk; (2) hypoxic heated gas enters the reactor from a heating gas inlet arranged below the reactor to directly contact the raw coal sample and transfer heat to the raw coal sample through a hole chiseled on the rotating furnace grate, and the hypoxic heated gas and the raw coal sample are dried and subjected to the pyrolysis reaction; and (3) after a certain time of reaction, with the rotation of the rotating furnace grate, the processed raw coal sample is fixed on a plow-type mechanical stirrer which is arranged above the rotating furnace grate and is pushed to a discharge opening, and the tail gases of the heated gas are discharged out of a gas exhausting opening. The invention uses the hypoxic cyclic flue gas as the heat source to distill the low-rank coal and ensures that the hypoxic cyclic flue gas directly exchanges heat with the solid low-rank coal, thereby having high thermal efficiency and low energy consumption ratio. In addition, the invention has low requirement for the size of the granules of the processed low-rank coal and wide application range and can effectively reduce the content of the dust in the tail gases to be good for the transportation of the final product.

Owner:HUNAN HUAYIN ENERGY TECH

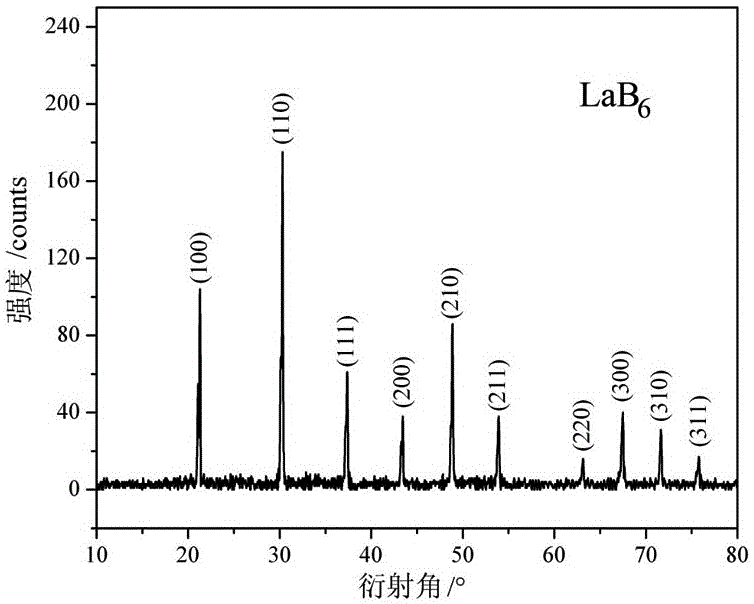

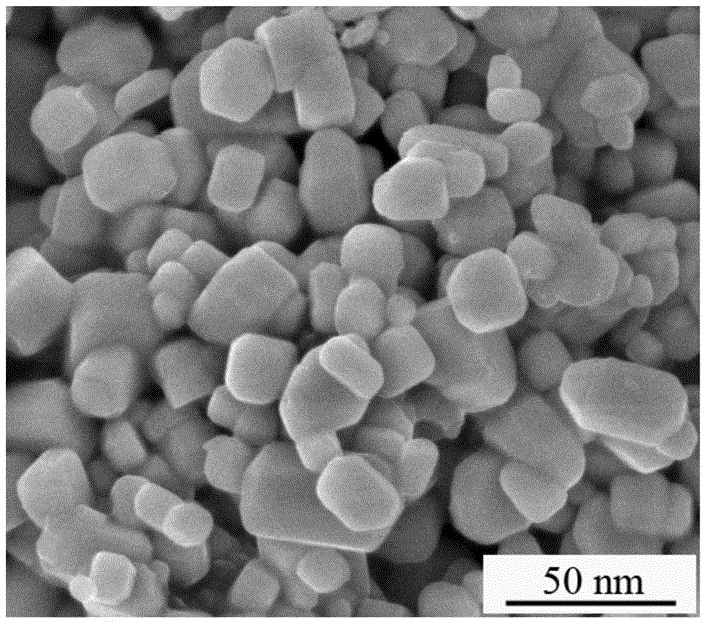

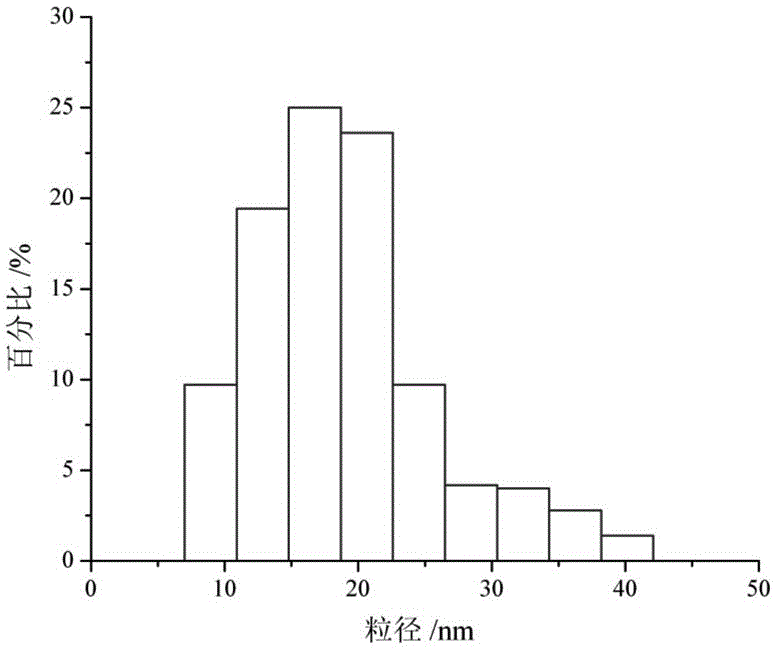

Preparation method of lanthanum hexaboride nanometer powder and application of lanthanum hexaboride nanometer powder

ActiveCN106395843AHigh purityFine and uniform particle sizeMetal boridesNanotechnologyLanthanumLiquid phase

The invention discloses a preparation method of lanthanum hexaboride nanometer powder and an application of the lanthanum hexaboride nanometer powder. The preparation method includes: mixing a lanthanum source and a boron source with fused salt prior to heating to a molten state to enable the lanthanum source and the boron source to perform liquid phase reaction in the fused salt and allow the lanthanum source to be reduced to lanthanum hexaboride by the boron source, and obtaining an initial product after cooling; washing and filtering the initial product to remove the fused salt, and obtaining the lanthanum hexaboride nanometer powder after drying. The preparation method has the advantages that the prepared lanthanum hexaboride nanometer powder is controllable in particle size, uniform in particle size, agglomeration free, high in purity, wide in source of raw materials, low in reaction temperature, simple and controllable in process, free from specific requirements on equipment, low in cost and the like, the lanthanum hexaboride nanometer powder prepared with the method can be used for preparing lanthanum hexaboride blocks or coated cathode electron emitter materials, and high application value is achieved.

Owner:NAT UNIV OF DEFENSE TECH

Method for synthesizing organic bentonite by ultrasonic wave combined with microwave

InactiveCN101182002ASimple processEliminate filter washSilicon compoundsCation-exchange capacityIon exchange

The invention discloses a method used for synthesizing organic bentonite by ultrasonic wave associating with microwave. Granular or powder bentonite is mixed to be pasty with surfactant solution, wherein, the quantity of the surfactant is 0.2 to 2.5 times cation exchange capacity of the bentonite; then the surfactant and the bentonite go through ion exchanging by the microwave conditioning after ultrasonic oscillation treatment of the ultrasonic wave and the organic bentonite is obtained. The invention has simple processing and saves original processes such as filtering, rinsing, etc., and does not produce waste water as well as reduces energy consumption; the invention has small amount of water attending reaction, little energy waste caused by water absorption and low total energy consumption and does not need stirring in process; the ultrasonic wave speeds up the reaction and the synthesizing time is short; the ultrasonic wave simultaneously exerts grinding effect and the requirement for original soil particles of the bentonite is low; the microwave conditioning effect improves product quality and absorption performance and has good effect of removing organic pollutants.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Iron increase and phosphorous reduction method for oolitic high phosphorus hematite

InactiveCN101440416AIncrease profitTo achieve the purpose of increasing iron and reducing phosphorusMagnetic separationPhosphoric acidIron increased

The invention discloses an iron-increasing phosphorous-reducing method for oolitic high-phosphorus hematite. The method comprises the following steps: (1) phosphorus-containing oolitic hematite is crushed till the particle size is not more than 0.25 millimeter, and then is added to a roaster; (2) a reduction chamber of the roaster is supplied with reduction gas, and crushed material is reduced for 10 to 60 minutes at a temperature between 700 and 1,450 DEG C in the roaster; (3) reduced mineral is isolated from oxygen, cooled to not higher than 100 DEG C and then magnetically separated; obtained coarse iron powder per ton is added with 1 to 1.5 kilograms of sodium silicate; the obtained coarse iron powder is ball-milled till the particle size is not more than 0.055 millimeter; obtained fine iron powder is immersed in acid solution with the concentration between 0.5 and 18 percent at normal temperature for 30 to 300 minutes; and the proportion of the acid solution to the fine iron powder is not less than 1:1; and (4) the fine iron powder is poured into a hydroextractor so as to reduce phosphoric acid. The method has the advantages of simple process, low requirement on the quality of raw material and the particle size of ore, no consumption of electric energy and high-quality coke, low energy consumption, high phosphorous reducing rate and high metal yield.

Owner:周玉平

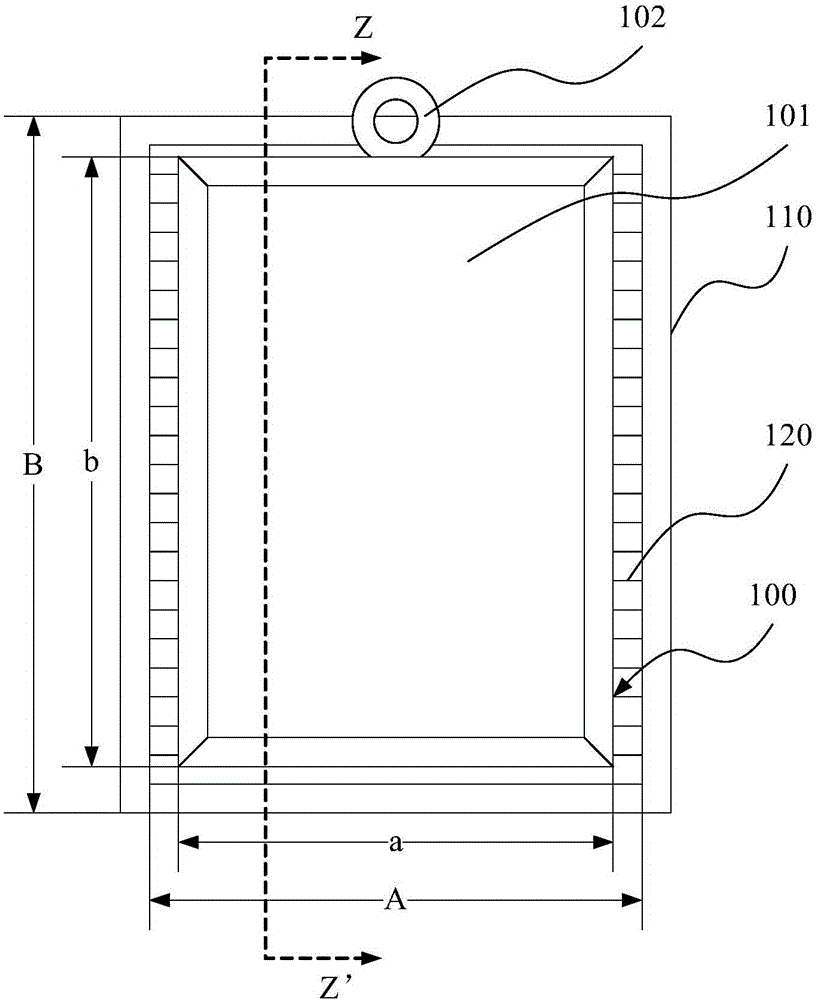

Liquid refrigerating chip for semiconductor laser and preparation method thereof

ActiveCN101635432AEasy maintenanceEasy to makeLaser detailsSemiconductor lasersSemiconductor laser theoryHigh heat

The invention relates to a liquid refrigerating chip for a semiconductor laser and a preparation method thereof. The liquid refrigerating chip comprises a refrigerating chip body, wherein, the refrigerating chip body is in a polygonal flaky shape; a fixed through-hole is vertically opened at the middle part of the refrigerating chip body; a liquid inlet through-hole and a liquid outlet through-hole are arranged on two sides of the fixed through-hole respectively; a radiating fin is arranged in the liquid inlet through-hole; and a chip mounting area is arranged at one end of the refrigerating chip body, which is adjacent to the liquid inlet through-hole. The liquid refrigerating chip has the advantages of not only simple fabrication, low fabrication cost and simple use and maintenance, but also high heat-dissipation capability, high reliability and low requirements for sealing.

Owner:FOCUSLIGHT TECH

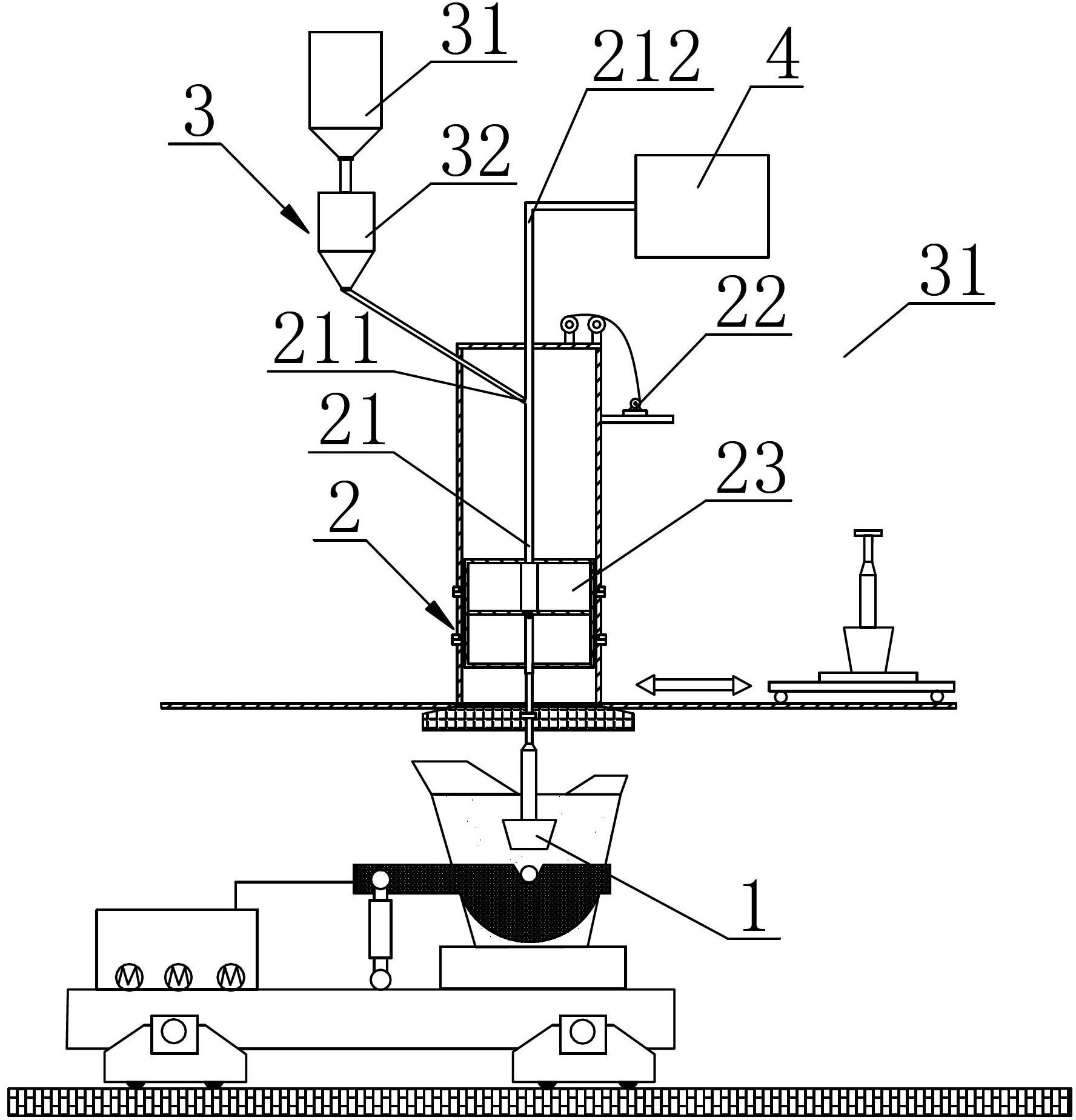

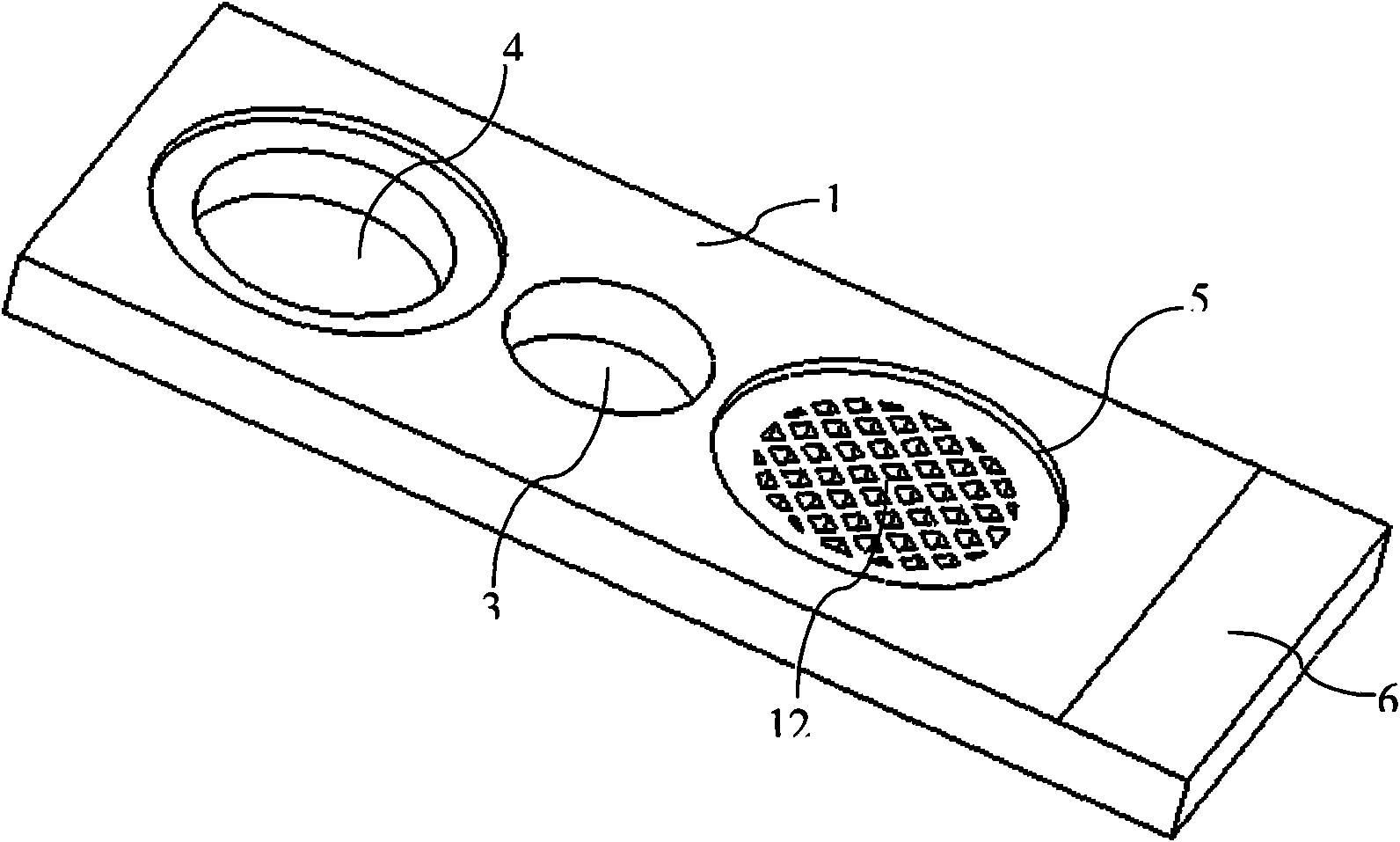

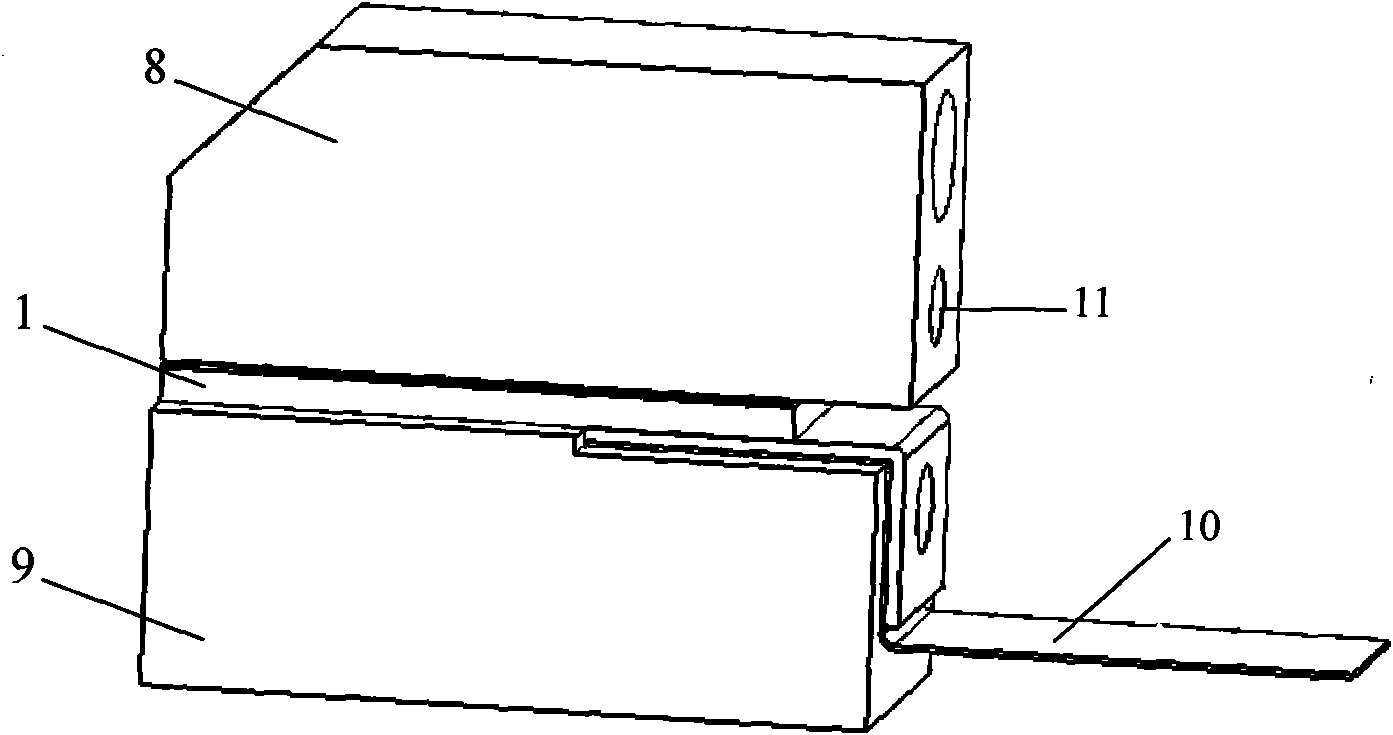

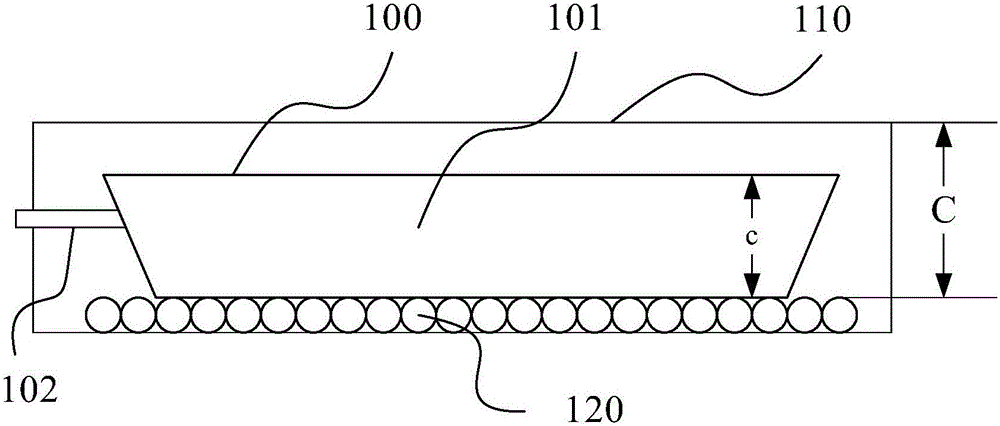

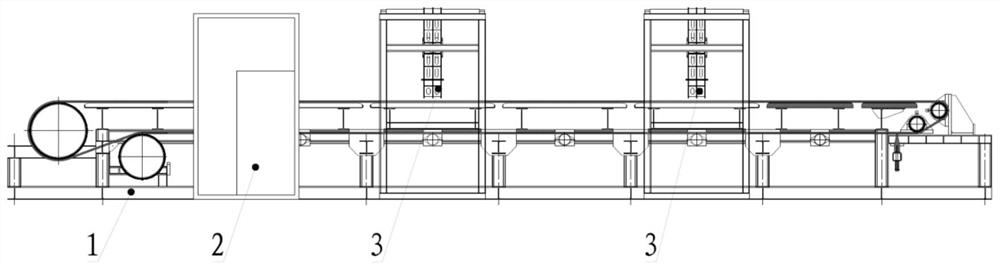

Large spiral low-order lignite quality improving system

InactiveCN102627991ADoes not affect movementLow particle size requirementSolid fuelsCombustion chamberPlate heat exchanger

A large spiral low-order lignite quality improving system comprises a spiral heat exchanger, a combustion chamber, a lignite feeding device, a quenching box and a dedusting device. The spiral heat exchanger is horizontally placed and composed of an outer sleeve, a rotating shaft and a motor, wherein the rotating shaft and the motor are sleeved in the outer sleeve, and the rotating shaft is in transmission connection with the motor. A spiral blade is axially arranged along the rotating shaft, the wall of the outer sleeve, the rotating shaft and the spiral blade are all of hollow structures, tow ends of the spiral blade are communicated with a hollow cavity of the rotating shaft, the inlet end of a hollow cavity of the wall of the outer sleeve and the inlet end of the hollow cavity of the rotating shaft are communicated with the combustion chamber, and the outlet end of the hollow cavity of the wall of the outer sleeve and the outlet end of the hollow cavity of the rotating shaft are communicated with the dedusting device. The lignite feeding device is arranged on the upper portion of the spiral heat exchanger and close to the side of the dedusting device, and the quenching box is arranged on the lower portion of the spiral heat exchanger and close to the side of the combustion chamber. The large spiral low-order lignite quality improving system requires no pre-drying process, is strong in adaptability of coal types and particularly suitable for improving quality of sticky lignite, only needs to pre-break raw coal, is safe in operation, simple in structure and high in heat exchange efficiency, can perform large-scale continuous production easily and can obtain semi-coke, tar and coal gas with high quality.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for preparing hard alloy mixture by attritor milling process

The invention relates to a method for preparing a hard alloy mixture, in particular to a method for preparing a hard alloy mixture by an attritor milling process. |By adopting attritor milling and adding a certain amount of dispersing agent, adhesive and the like, a superfine hard alloy mixture is obtained. The method for preparing the hard alloy mixture by the attritor milling process has the characteristics of high milling efficiency, low energy consumption, suitability for mass production and the like, and can be widely applied to preparation of the superfine hard alloy mixture.

Owner:浙江东钨实业有限公司

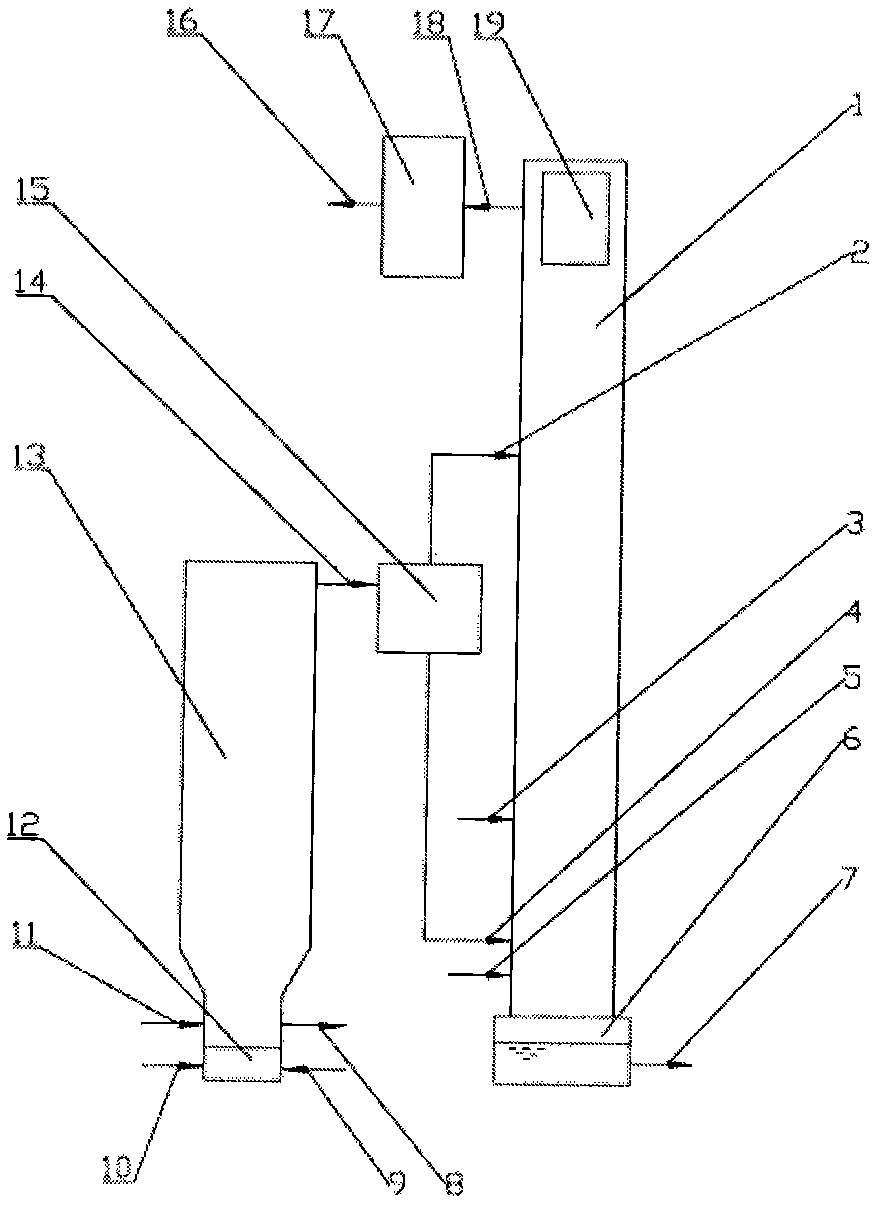

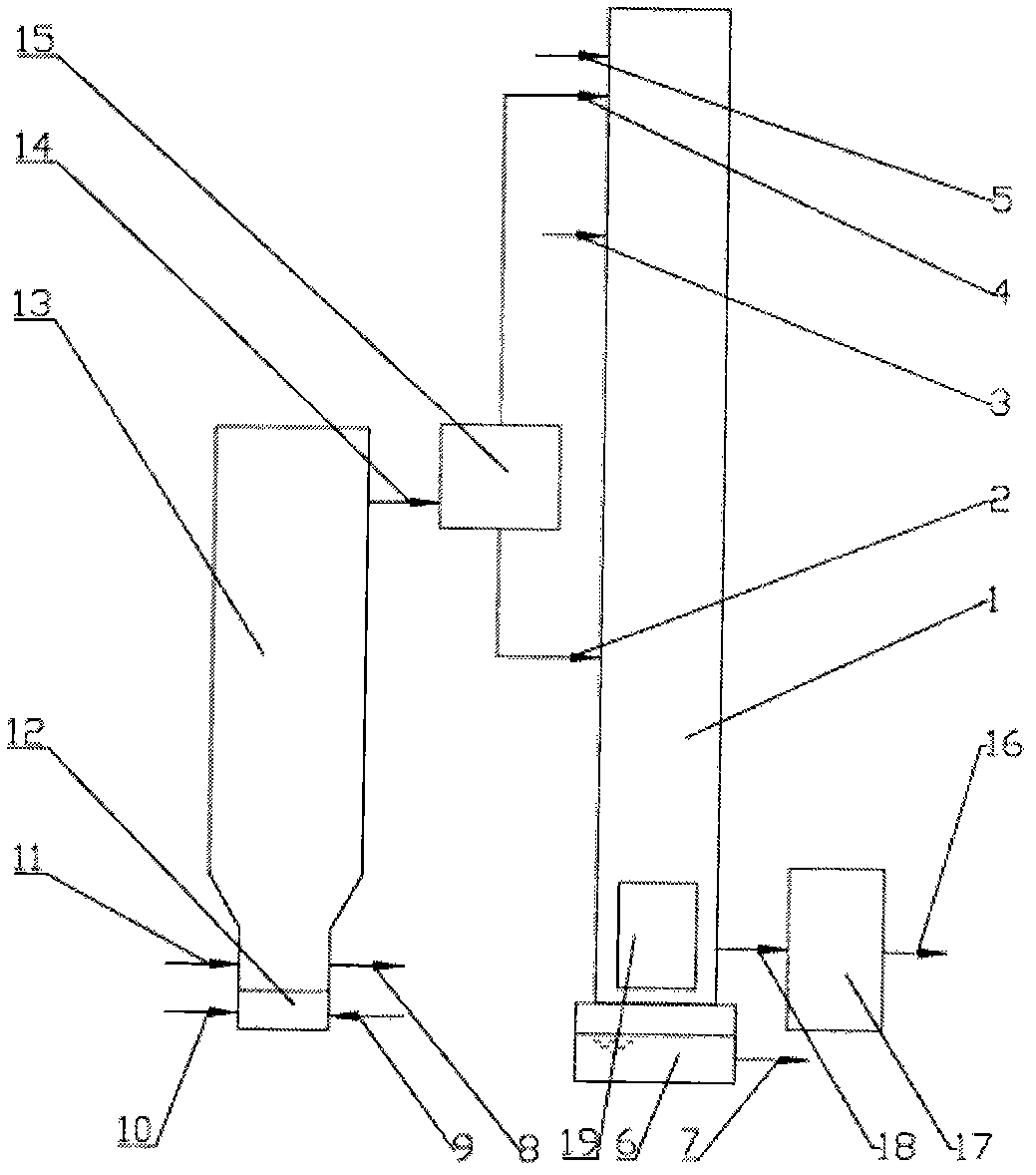

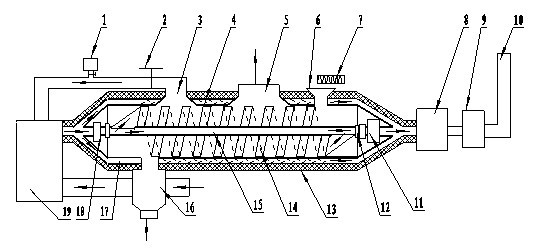

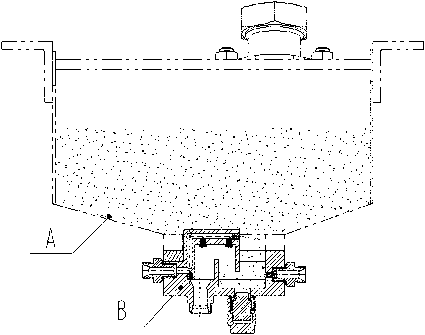

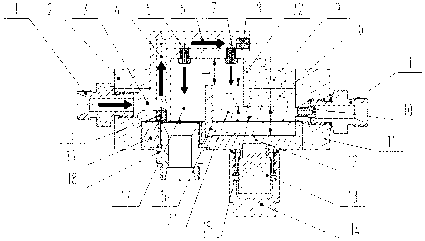

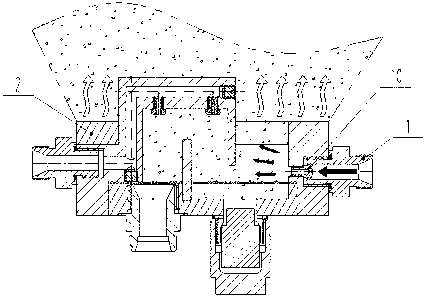

Bio-oil preparation technology

InactiveCN103666516AImprove microwave absorption performanceLow particle size requirementBiofuelsLiquid hydrocarbon mixture productionGas solidMicrowave pyrolysis

The invention belongs to the technical field of fuel oil, particularly relates to a bio-oil preparation technology. The bio-oil preparation technology is characterized in that the technology comprises the following steps: smashing biomass materials; drying; feeding smashed biomass materials to a screw conveyer; feeding the materials into a microwave pyrolysis reactor to be pyrolyzed; performing primary cooling on pyrolyzed products; performing gas-solid separation on high-temperature organic steam produced through pyrolysis in the microwave pyrolysis reactor to remove carbon granules and sand therein; performing secondary cooling and collecting bio-oil; performing third-time cooling and collecting oil with low-boiling point; collecting non-condensed gas for recycling. According to the invention, bio-oil is prepared by adopting the technology, and the biomass materials and carbon residues have good performance on absorbing microwave, so that the microwave heating speed is fast, outside and inside heating can be realized at the same time, and heat conduction is not needed, so that the preparation technology meets the requirements for bio-oil extraction of an optimal process; the requirement of the particle size of raw materials is lowered, so that the cost of pre-treatment is reduced; the pyrolysis temperature can be precisely controlled, and the thermal-inertia is avoided.

Owner:山东易能生物能源有限公司

Method for extracting potassium chloride from carbonate type salt lake

The invention relates to a method for extracting potassium chloride from a carbonate type salt lake. The method comprises the following steps: based on brine pan potassium mixed ore as a raw material, adding water to the raw material, fully stirring so that the raw material is completely dissolved and then heating to 60-90 DEG C; carrying out solid-liquid separation at the temperature of 60-90 DEG C so as to obtain tailings and a mother liquid; and finally, cooling the mother liquid to 0.0-15 DEG C and then carrying out solid-liquid separation so as to obtain the mother liquid which can be circularly used and a KCl product. According to the invention, KCl is prepared by using a hot melting method, process is simple, production time is short, and the obtained KCl product has high purity.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

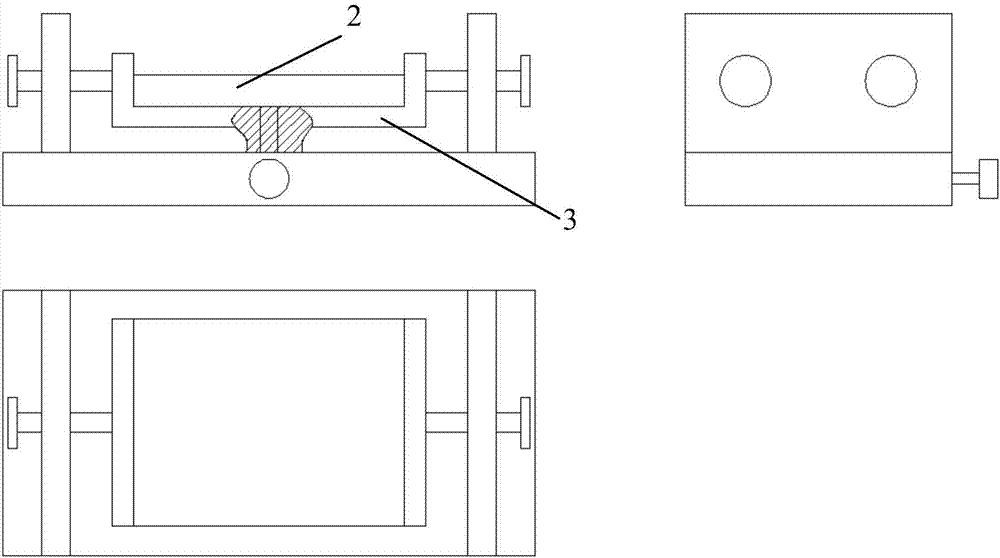

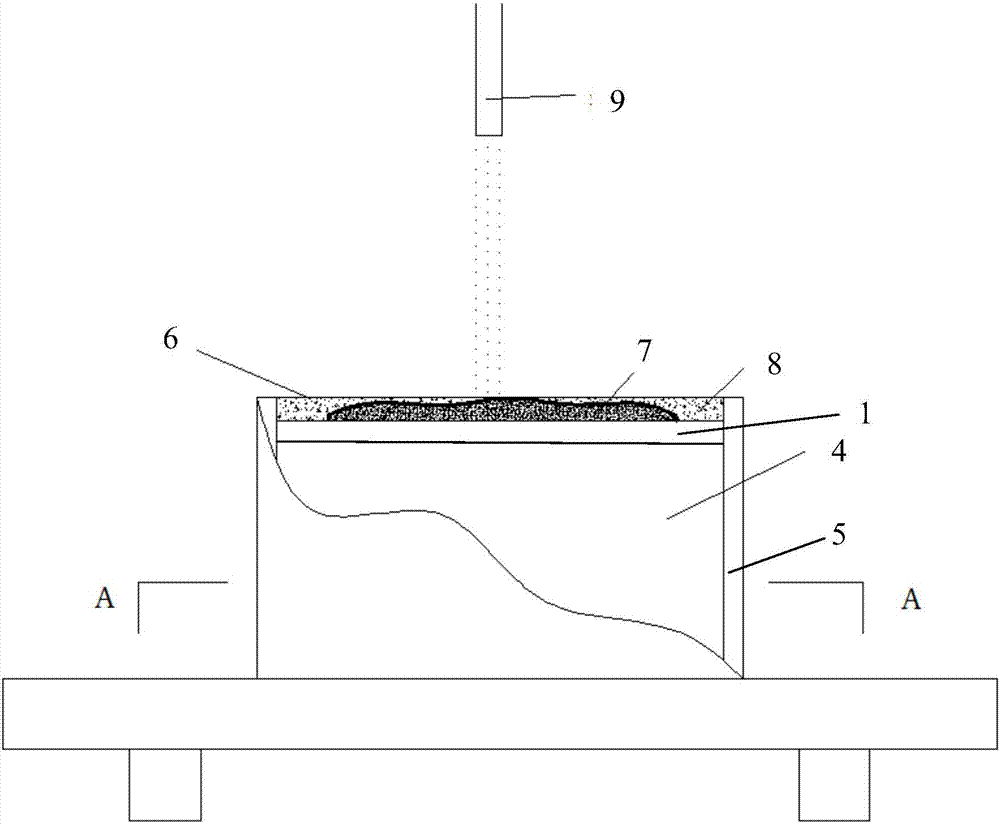

Method for preparing composite coating by using preset piece method to conduct laser multi-layer cladding

The invention belongs to the technical field of laser cladding high performance coatings and particularly relates to a method for preparing a composite coating by using a preset piece method to conduct laser multi-layer cladding. The method for preparing the composite coating by using the preset piece method to conduct laser multi-layer cladding comprises the following steps that A, the surface of a base material is preprocesses, corrosion oil dirt and dust on the surface of a workpiece are cleaned, and drying is conducted; B, powder processing is conducted, specifically, the powder to be prepared to be preset pieces is placed in a vacuum drying box, dried at the temperature of 80 DEG C for 24 h and laid flatly in a fixture groove flat plate provided with a T300 sloping grain carbon fiber cloth in a laid mode, and adhesion agent solutions are sprinkled uniformly to form a uniform water layer; C, the preset pieces preprocessed in the step B is placed in the vacuum drying box together with the groove flat plate, and vacuum heating and hardening is conducted at the temperature of 75-90 DEG C for 4 h; and D, laser cladding is conducted, specifically, the preset pieces prepared in the step C are placed in a base material set position, and multi-layer cladding is conducted under the protective atmosphere to enable the preset pieces to be combined with the base material to form a cladding layer with a certain thickness.

Owner:EAST CHINA JIAOTONG UNIVERSITY

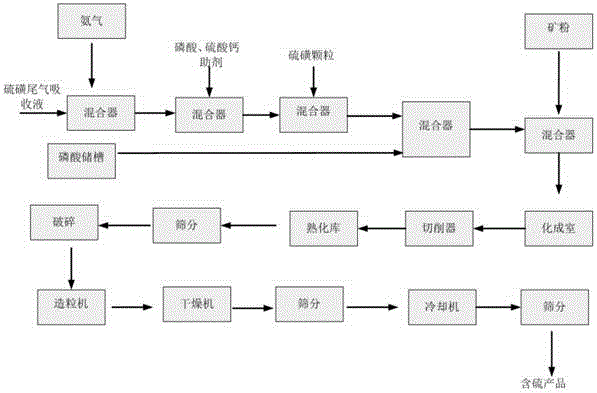

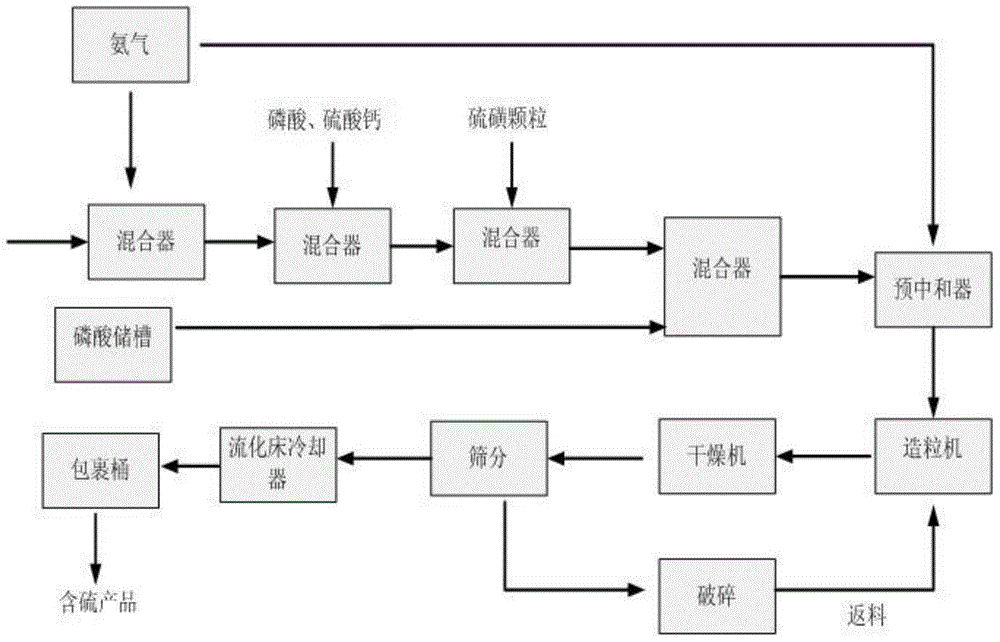

Preparation method for sulfur-containing phosphate fertilizer

The invention discloses a preparation method for a sulfur-containing phosphate fertilizer. The method includes: firstly adding additives into an absorption liquid of sulfuric acid tail gas, endowing the absorption liquid with dispersibility to sulfur granules, performing mixing, then adding the mixture into phosphoric acid, using an existing phosphate fertilizer production device, and carrying out reaction, granulation and drying, thus obtaining the product. The method provided by uses sulfuric acid plant tail gas absorption liquid cyclically, utilizes existing ammonium phosphate, triple superphosphate plant and other traditional phosphate fertilizer devices to prepare the fertilizer containing over two nutrient elements of nitrogen, phosphorus, potassium and sulfur, and provides a low cost product upgrading method for traditional device.

Owner:YUNNAN YUNTIANHUA

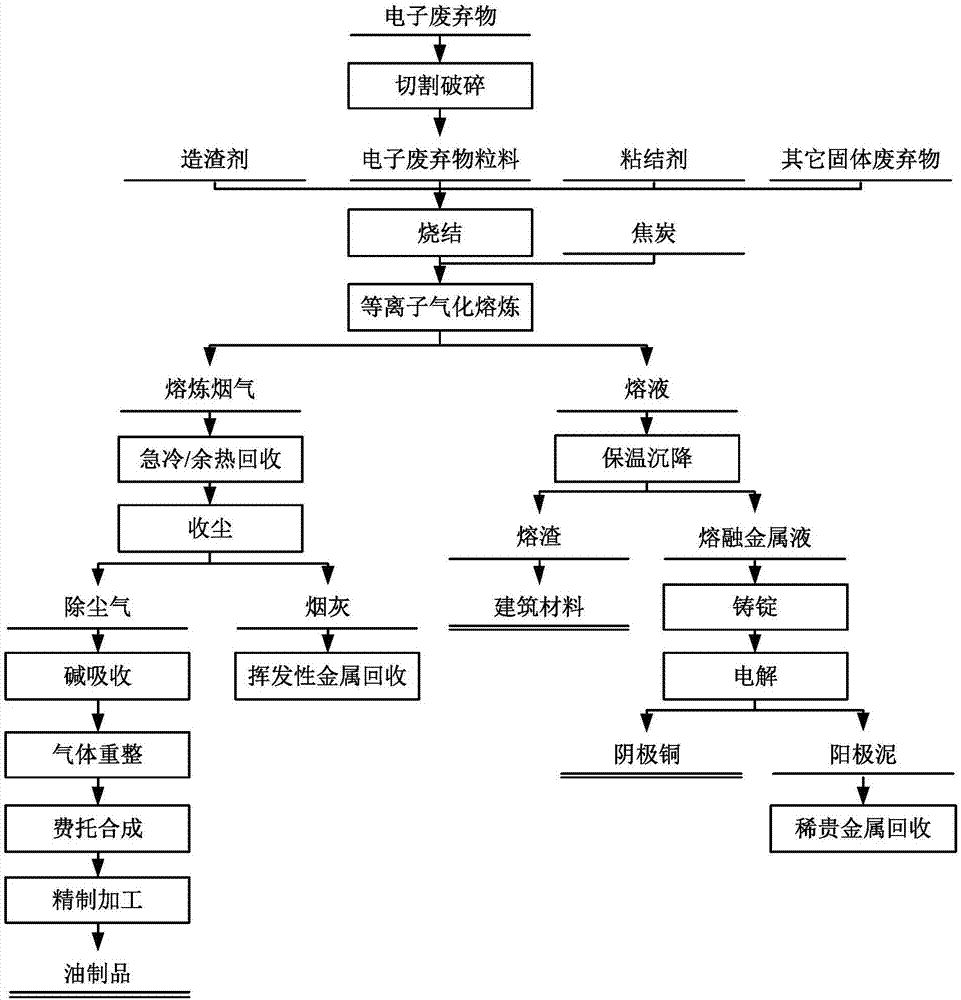

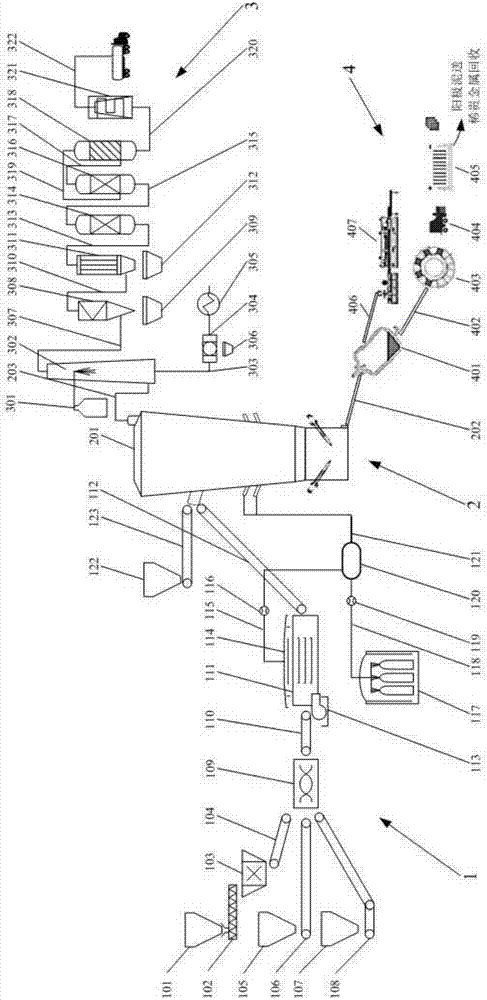

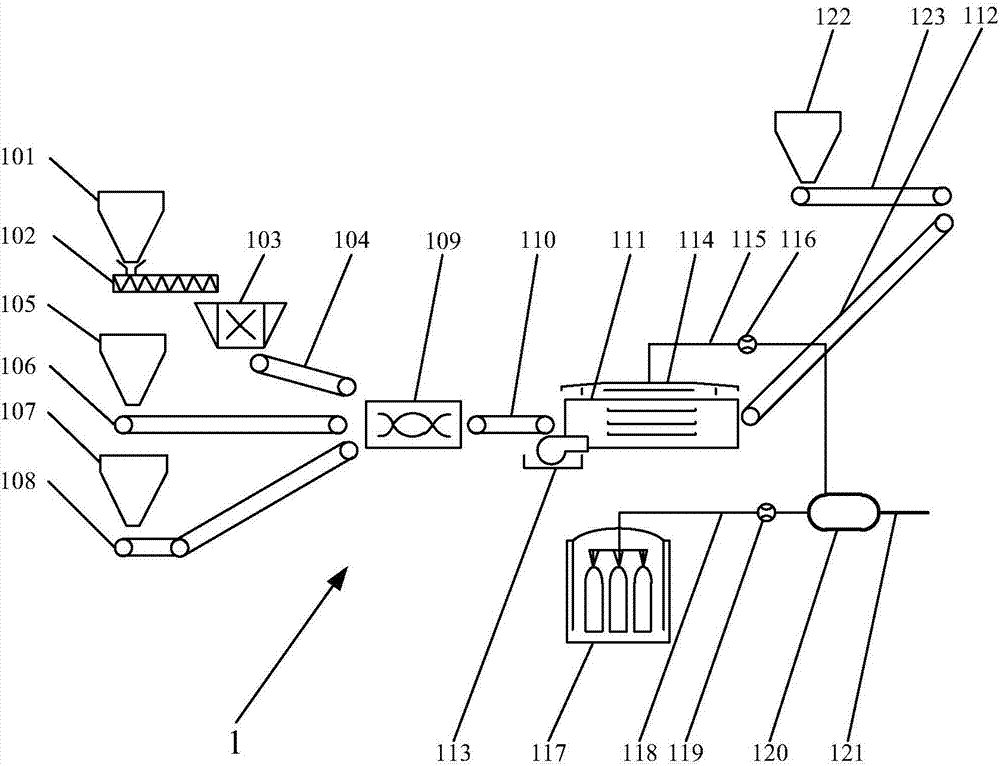

Comprehensive resourceful treatment system and method of electronic wastes

PendingCN107470327ALow particle size requirementReduce pollutionWaste processingSolid waste disposalElectronic wasteOrganic matter

The invention discloses a comprehensive resourceful treatment system and a method of electronic wastes. The treatment method comprises the steps of: 1) particle sintering; 2) plasma gasification smelting; 3) smelting smoke oiling; and 4) valuable metal recovery. Such procedures as sintering gas harmlessness, smelting smoke afterheat recovery and harmlessness, tail gas recycling and metal comprehensive recovery are arranged in shorter process flow to realize full harmlessness, reduction and resourceful utilization of the electronic wastes; and the method can be popularized and applied to similar resourceful recovery field of solid wastes mixed by organic matters and metal materials.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

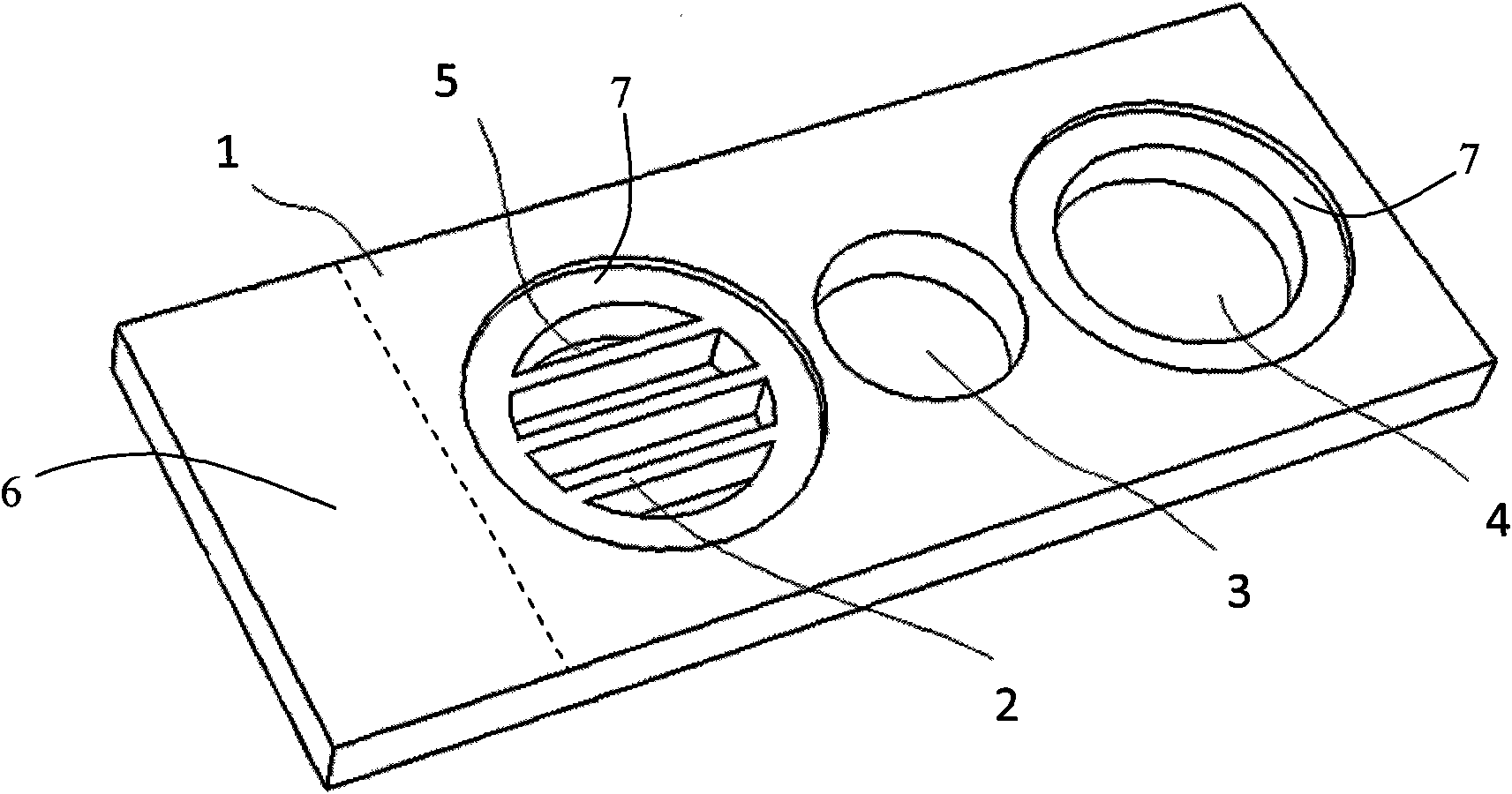

Sand sprayer for locomotives and application method thereof

ActiveCN103318192AGuaranteed Granularity RequirementsLow particle size requirementLocomotivesHigh pressureCavity wall

A sand sprayer for locomotives is installed below a sandbox and comprises a sand spray body provided with a cavity and a high-pressure air flue which communicates with the cavity. A vertical separator plate divides the cavity from the bottom into a sand inlet cavity and a sand outlet cavity, wherein the upper parts of both the sand inlet cavity and the sand outlet cavity communicate with each other. The sand inlet cavity is divided by a suspended cavity wall of the sand inlet cavity from the upper part into a sand inlet chamber and a sand lift chamber, wherein bottoms of both the sand inlet chamber and the sand lift chamber communicate with each other. The sand inlet chamber communicates with a sandbox outlet. The top of the sand lift chamber is provided with a sand lift tuyere which communicates with the high-pressure air flue. The sand lift tuyere blows sand, which flows into the sand inlet chamber from the sandbox and enters the sand lift chamber through the bottom of the sand inlet chamber, into the sand outlet cavity. The top of the sand outlet cavity is provided with a sand outlet tuyere which communicates with the high-pressure air flue and is used for blowing sand out of a sand outlet at the bottom of the sand outlet cavity. The invention also provides an application method of the sand sprayer. The sand sprayer provided by the invention is applicable to be used under the condition of nonuniform particle size of sand grains and is not easy to obstruct. By the use of the sand sprayer, sand flow is smooth, idle running of locomotives can be inhibited timely, and normal operation of locomotives is guaranteed.

Owner:湖南联诚电气科技有限公司

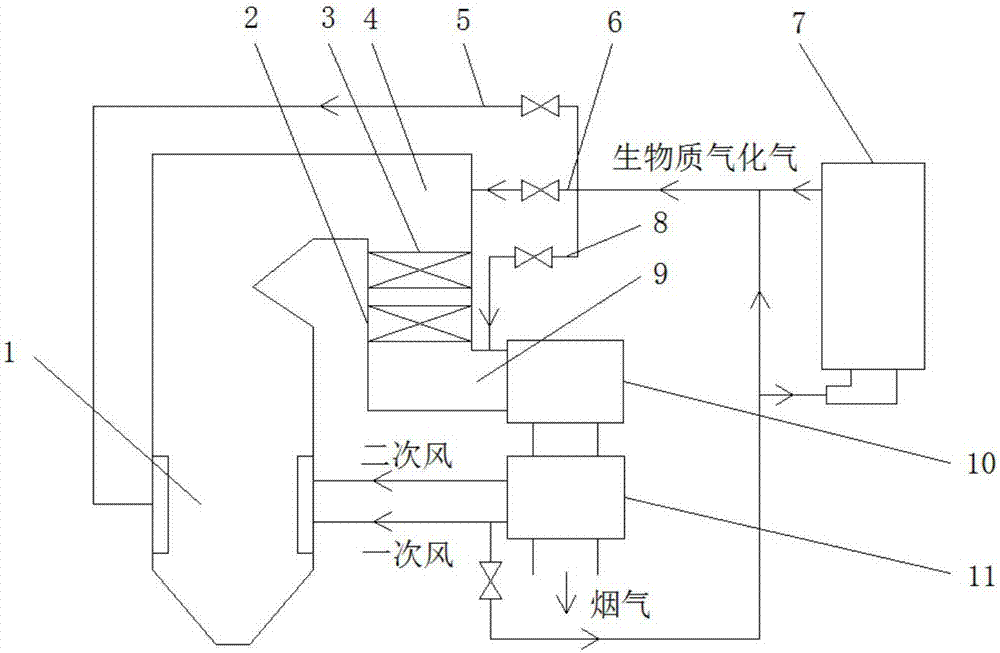

Power station boiler system and method for increasing tail fume temperature of power station boiler by integrating supplemental combustion for biomass gasification

InactiveCN107255269AIncrease smoke temperatureSafe and stable operationGas treatmentDispersed particle separationPower stationCombustion

The invention discloses a power station boiler system and a method for increasing the tail fume temperature of a power station boiler by integrating supplemental combustion for biomass gasification. According to the method, one or more fixed bed biomass gasifiers are additionally arranged, the gasifiers maintain the rated loads to continuously and stably operate, and hot primary air of the boiler is used as a gasification agent to promote the gasification efficiency of the gasifiers and increase the heat value of gasified gas; when the boiler operates with the low load, the biomass gasified gas is delivered into a flue behind a coal economizer or a steering fume chamber in front of the coal economizer, and the fume temperature at an outlet of the coal economizer is increased through supplemental combustion of the biomass gasified gas, so that a selective catalytic reduction fume denitration system operates safely and stably; supplemental-combustion gas is reduced correspondingly along with increasing of the loads, and the reduced gasification gas for supplemental combustion is delivered into the upper portion of a hearth so as to be combusted, and when the boiler operates with the full load, all the biomass gasified gas is delivered into the upper portion of the hearth so as to be combusted; and supplemental-combustion temperature increasing of the tail fume of the power station boiler is finally achieved through biomass resources, and meanwhile, the biomass resources can be further efficiently used for power generation.

Owner:GUODIAN SCI & TECH RES INST

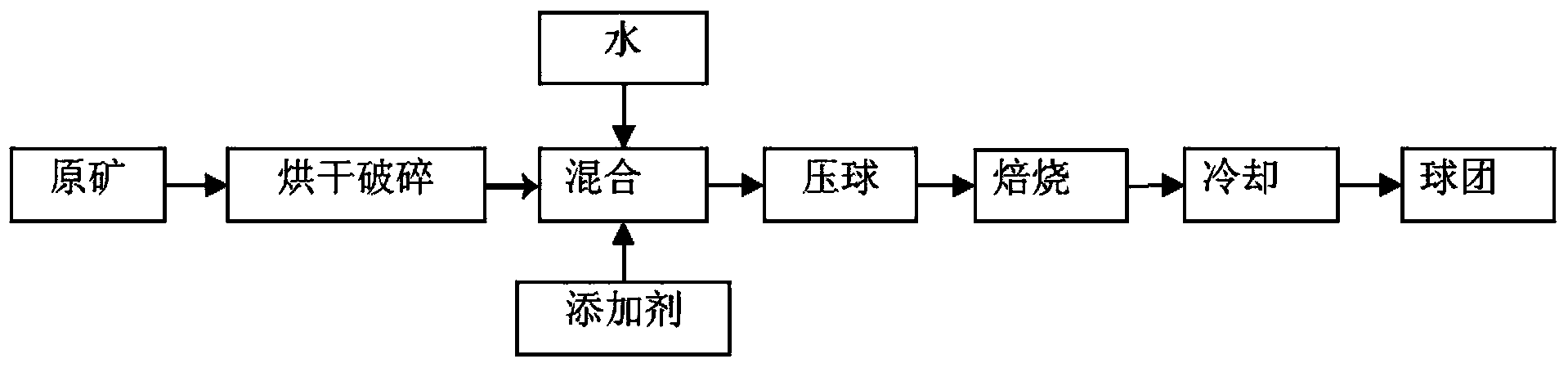

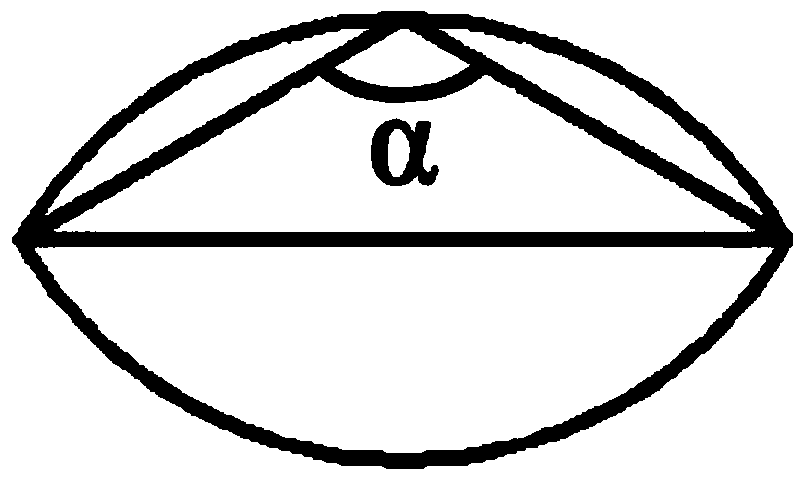

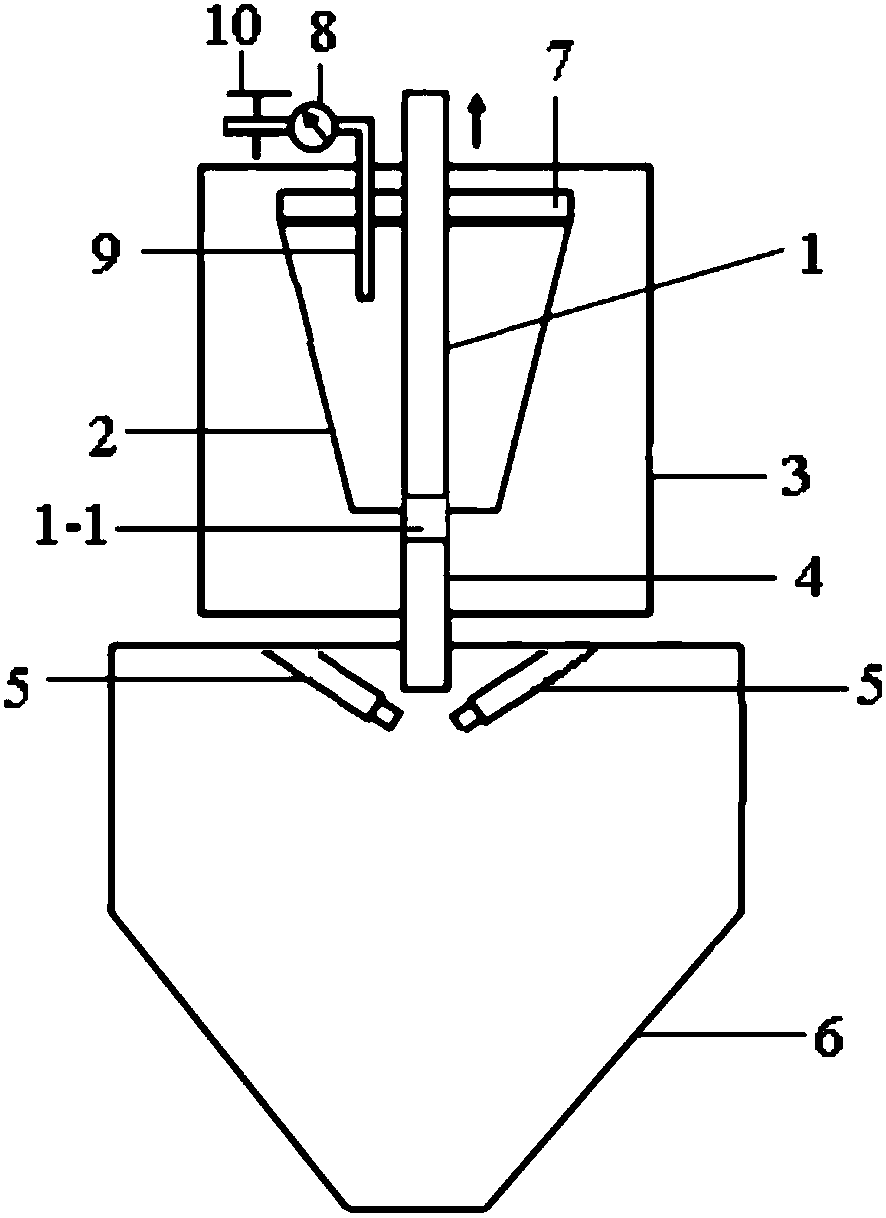

Process for briquetting oxidation pellets from laterite nickel ore

The present invention provides a process for briquetting production of oxidation pellets from low-grade laterite nickel ore. The process comprises: drying and crushing laterite nickel ore to obtain laterite nickel ore powder with a particle size of less than 3 mm; adding water and an additive to the laterite nickel ore powder, uniformly mixing to obtain a mixing material, and briquetting the mixing material into green pellets; and carrying out oxidation baking on the green pellets, and cooling to obtain the oxidation pellets. With the technical scheme, the low-grade laterite nickel ore can be utilized, and the briquetting process can be adopted to produce the oxidation pellets meeting the shaft furnace production indexes, such that the complete drying and pre-baking process produced by application of the pelletizing technology can be reduced, the heat energy consumption can be reduced, the oxidation pellets have high nickel content, and the added value is substantially increased.

Owner:SHENWU TECH GRP CO LTD

Method for preparing alumina-based nano eutectic composite micro powder by high-temperature melt aerosol method

ActiveCN108516808AImprove performanceNo need to worry about uniformityComposite ceramicHigh pressure

The invention relates to a method for preparing alumina-based nano eutectic composite micro powder by a high-temperature melt aerosol method, and relates to a preparation method of alumina-based nanoeutectic composite ceramic powder, which aims to solve the problems of complex process and low efficiency of the preparation of the nano eutectic powder in the prior art. The preparation method comprises the following steps of: heating Al2O3 and diluent composite powder to be melted, preserving heat for a period of time, gas-atomizing the system by using a gas atomization method, crushing the meltinto superfine liquid drops by using high-pressure inert gas by. Under the action of surface tension, the superfine liquid drops deposit in the atomization tower and form spherical superfine power material. The spherical nano eutectic powder material with high purity is prepared through the separation and collection of the spherical superfine power material by using a filter. The process is simple, and the alumina-based nano eutectic powder is prepared by directly adopting a high-temperature melting method combined with a gas mist quenching method, wherein the nano eutectic crystal grains have small crystal grain spacing, excellent powder performance, are micron-grade spherical particles, has good forming property and does not need granulation, so that the process cost is low.

Owner:HARBIN JEHOT ADVANCED MATERIALS CO LTD

Combined ore-dressing method for recovering superfine cassiterite from oxidized tin tailings

The invention provides a combined ore-dressing method for recovering superfine cassiterite from oxidized tin tailings. The method comprises the following steps: adding 10-1500g flocculating agent and / or coagulant into one ton of tin-containing tailings, and uniformly mixing, thereby acquiring an ore pulp material; stirring for 0.5-5 minutes till forming a coagulated tin mineral; and then performing conventional gravity concentration, separation and enrichment, thereby acquiring a tin middling product and tailings, wherein the grade of the tin middling product can reach 2-3.5% and the recovery rate can reach 40-65%. The ore-dressing method for recovering superfine tin is simple, the process is simple and short, and the cost of drugs is low. By using the method, the purpose of recovering tin from the superfine grain / slurry tin tailings, with low cost, no environmental pollution and high efficiency, can be achieved. The method can be easily industrialized.

Owner:KUNMING UNIV OF SCI & TECH

Material feeding tank and material feeding system of electron beam smelting furnace, and smelting method

The invention relates to a material feeding tank and a material feeding system of an electron beam smelting furnace, and a smelting method. The material feeding tank comprises: a tank for placing a substance, wherein the material of the tank is the same as the substance; and a connection ring positioned at one edge of the tank, wherein the connection ring is used for connecting to a transmission device so as to install the tank into a material feeding box. According to the present invention, the tank and the connection ring form the material feeding tank, such that the bulk material feeding can be performed on the electron beam smelting furnace by using the material feeding box; the use of the bulk material vibration and feeding system in the prior art is eliminated; the material feeding speed is reduced, the collision of the material during the falling process is avoided, and the material scattering is avoided, such that the waste of the material is avoided, and the material smelting yield is improved; and the bulk material feeding is performed on the electron beam smelting furnace by using the material feeding tank, such that the material feeding speed is reduced, the material temperature increasing is retarded, the gas release is retarded, the splashing of the molten metal liquid is reduced, the waste of the material is reduced, and the yield is increased.

Owner:宁波创润新材料有限公司

Method for recovering iron from zinc hydrometallurgy rotary kiln slag

InactiveCN107149979AAchieve regenerationThe process steps are simpleMagnetic separationProcess efficiency improvementSlagHydrometallurgy

The invention relates to a method for recovering iron from zinc hydrometallurgy rotary kiln slag. The method comprises the steps of: primary ore grinding, weak magnetic rough separation, weak magnetic scavenging, secondary ore grinding and weak magnetic selection. The method is simple in process steps, can extract iron concentrates with the grade of higher than 58% from the rotary kiln slag, changes wastes into valuable materials, and realizes the resource regeneration.

Owner:汉源县伟业环保科技有限公司

Shifting rod type sorting system and sorting method

InactiveCN113305035AImprove sorting efficiencyImprove efficiencySortingDust controlStructural engineering

The invention provides a shifting rod type sorting system and a sorting method. The shifting rod type sorting system comprises a conveyor (1), a recognition system (2) and an execution system (3); materials advance on the conveyor (1); the recognition system (2) recognizes the materials, and coal and gangue are recognized and distinguished; and the gangue is pulled out through the execution system (3). According to the shifting rod type sorting system and the sorting method, the sorting efficiency is high, the sorting particle size range is wide, a sorting system structure is simple, the sorting system cost is low, the sorting system structure is compact, the occupied area is small, flying dust generated in the sorting process is little, and generally, a totally-closed protective cover, an air suction pipeline system, dust removal equipment and the like do not need to be additionally arranged.

Owner:BIRTLEY TIANJIN IND EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com