Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Increase smoke temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

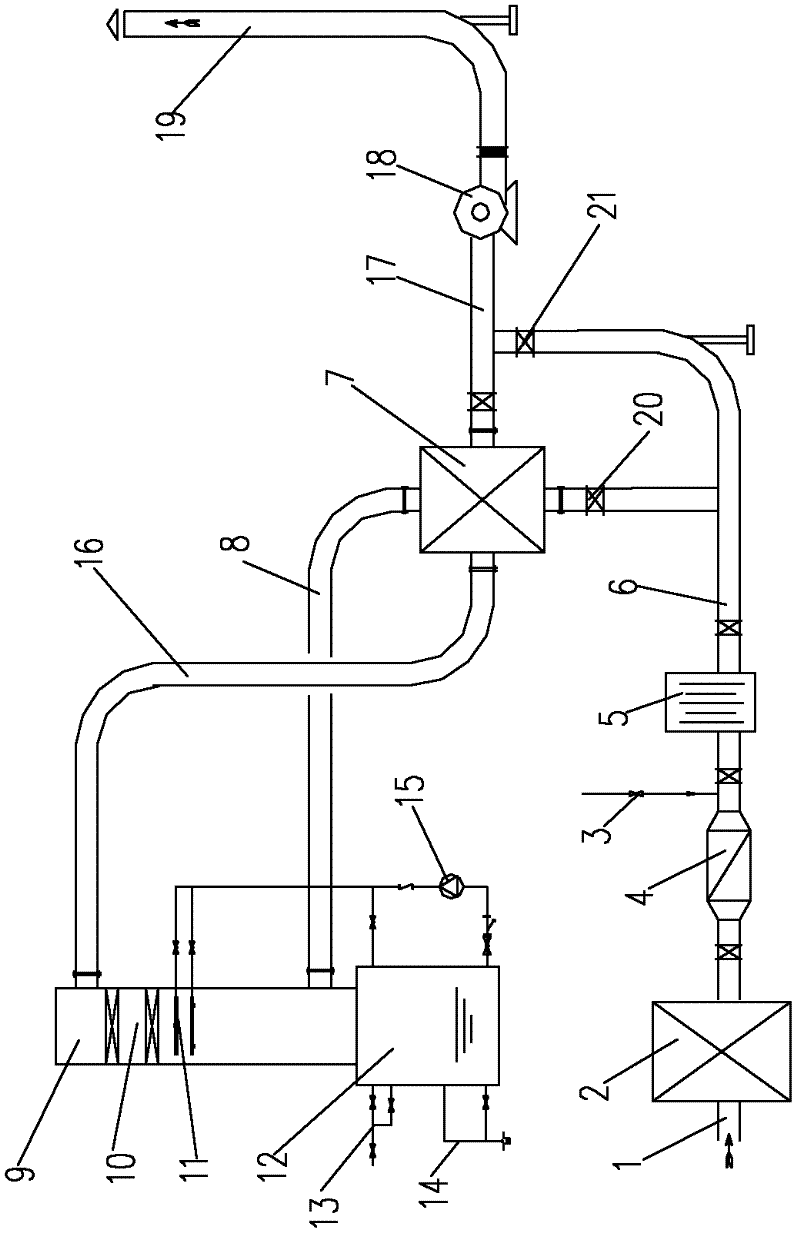

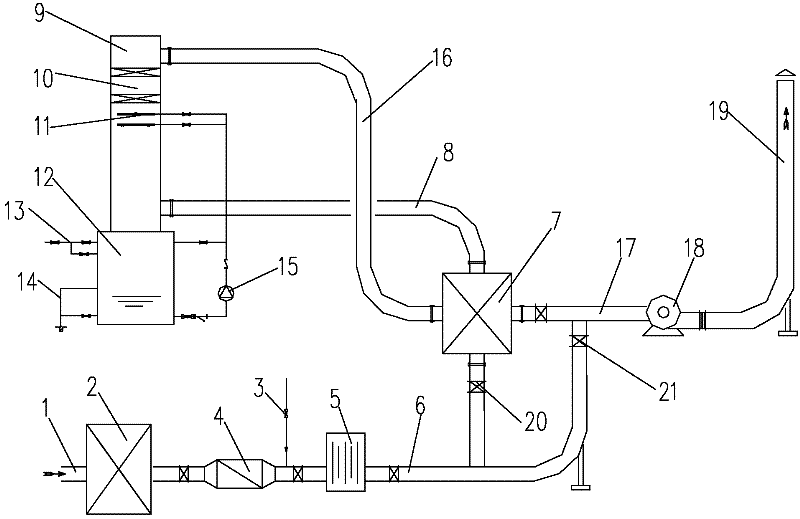

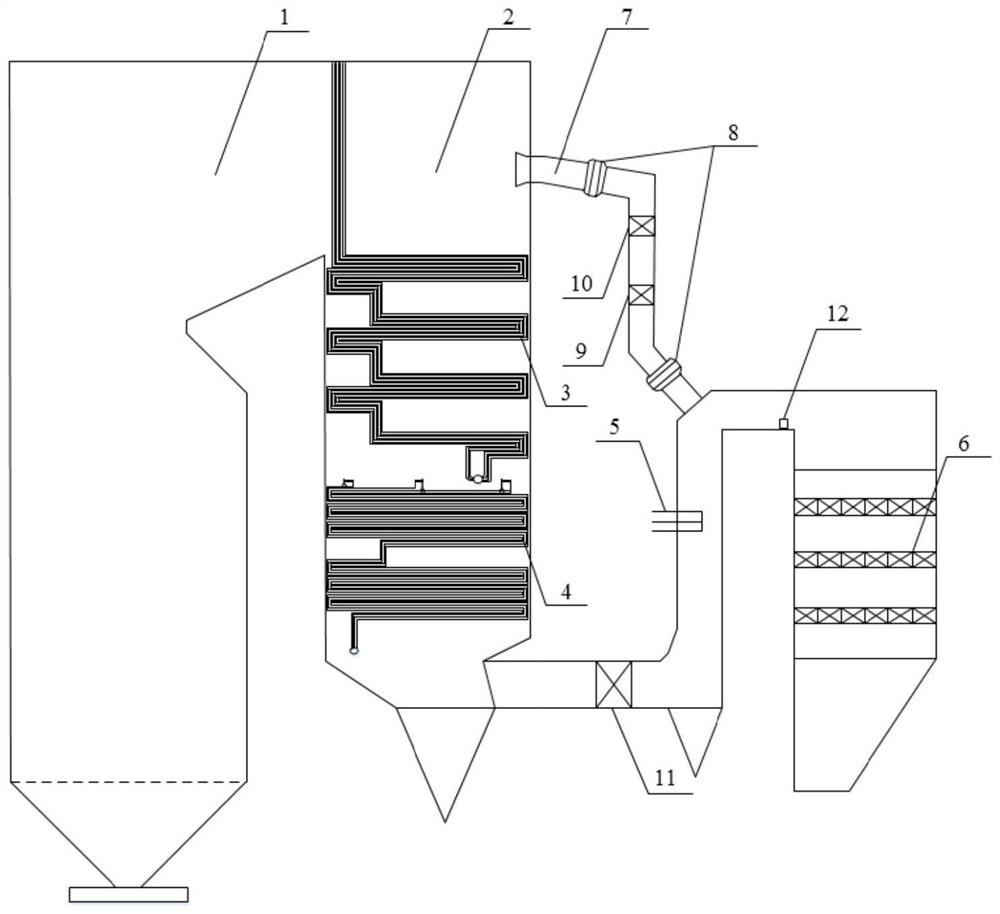

A flue gas purification system

ActiveCN102294171ARemove completelyHigh removal rateLighting and heating apparatusDispersed particle separationDecompositionEngineering

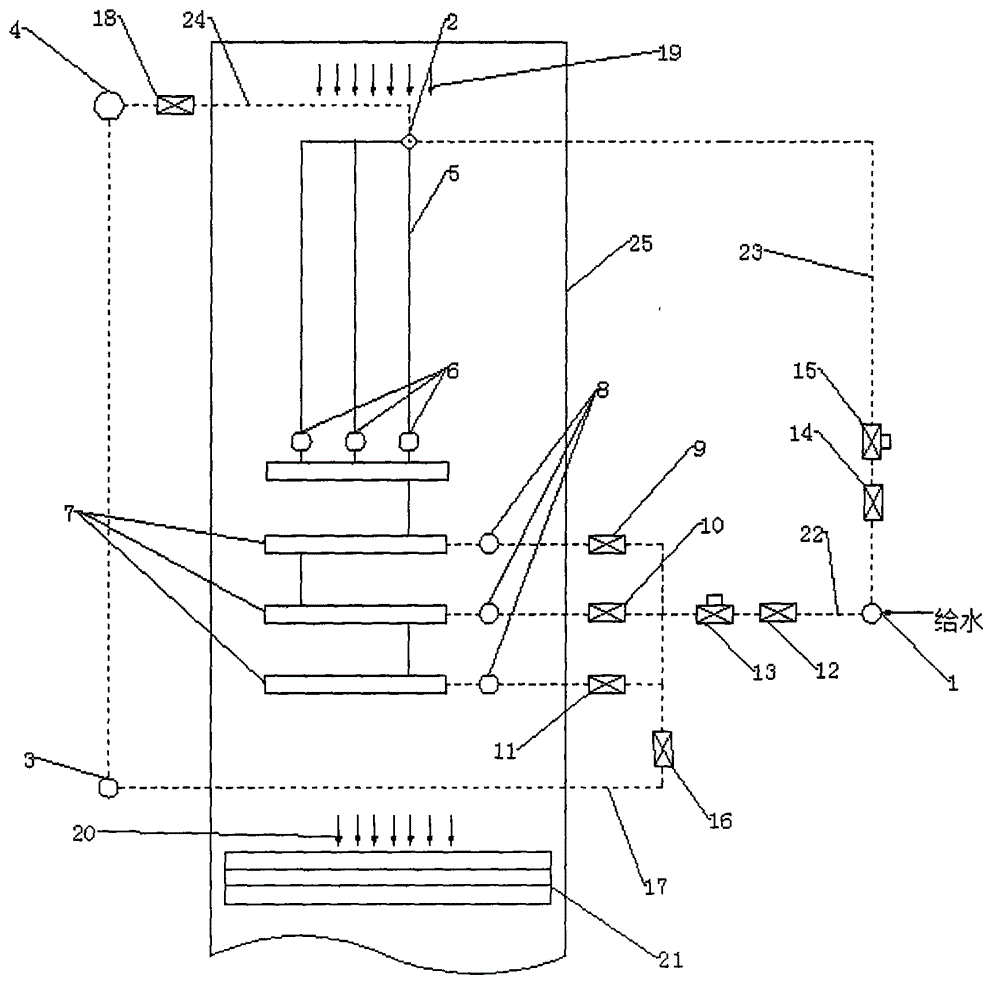

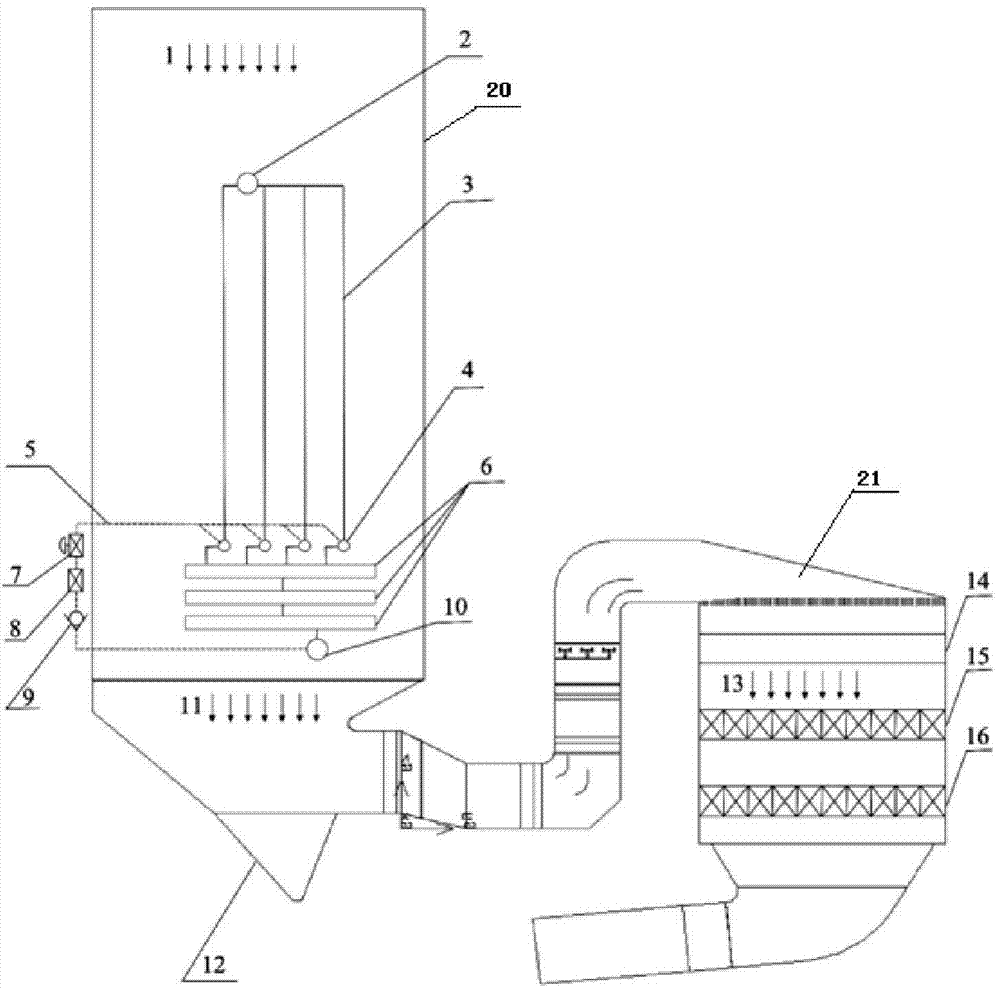

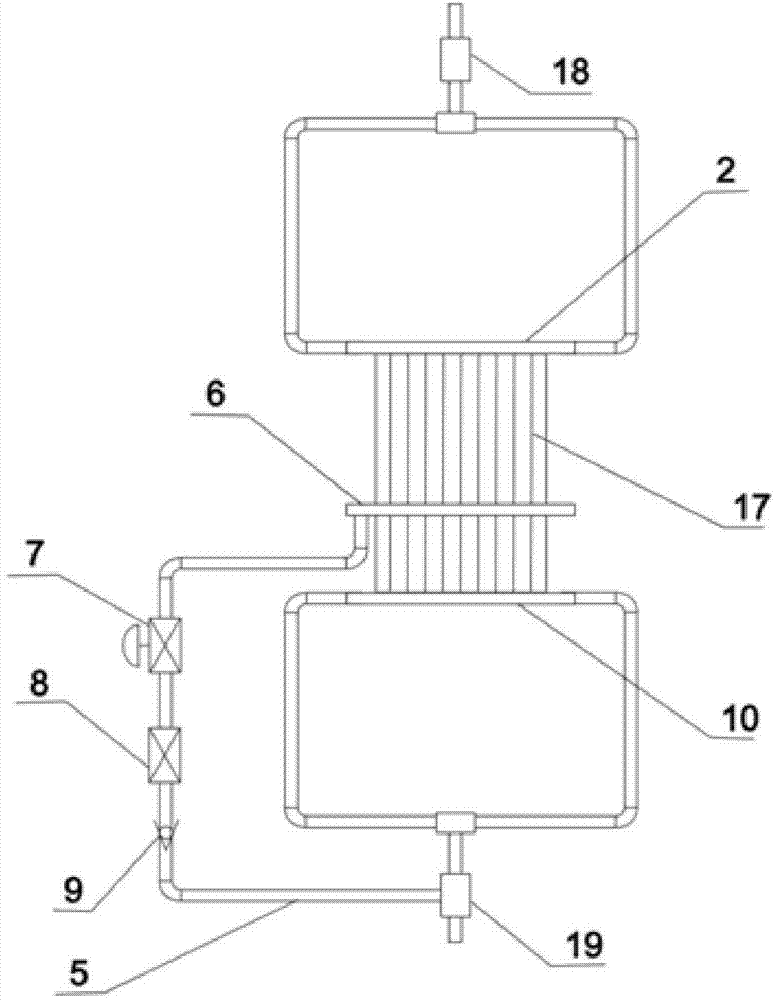

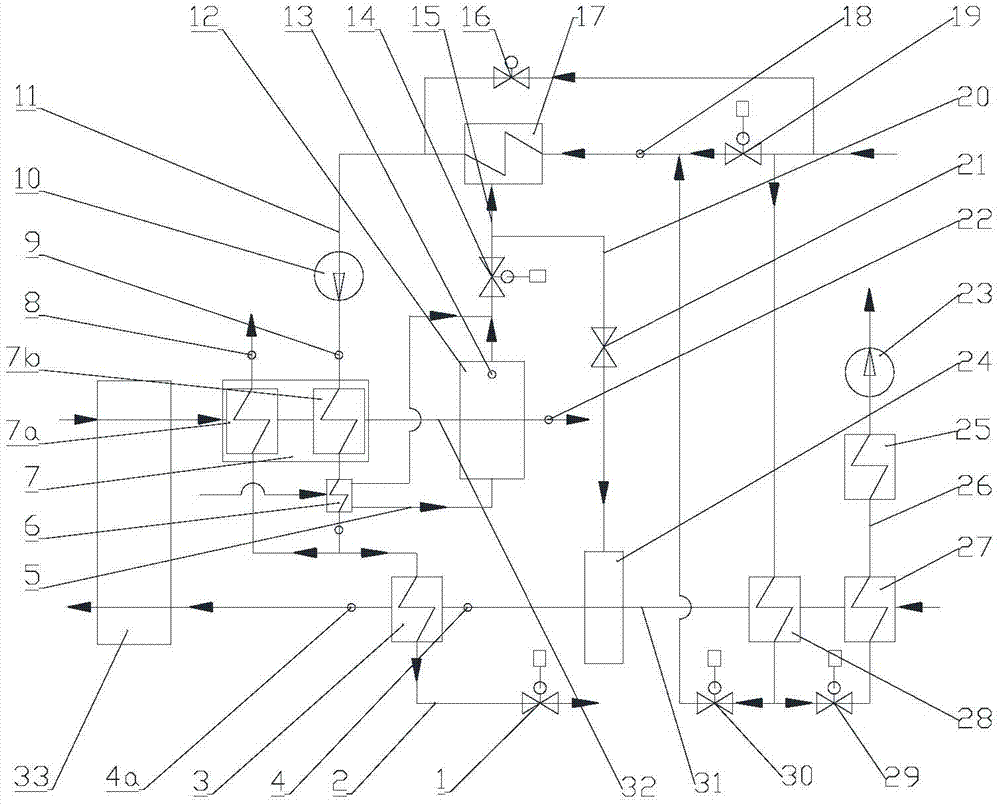

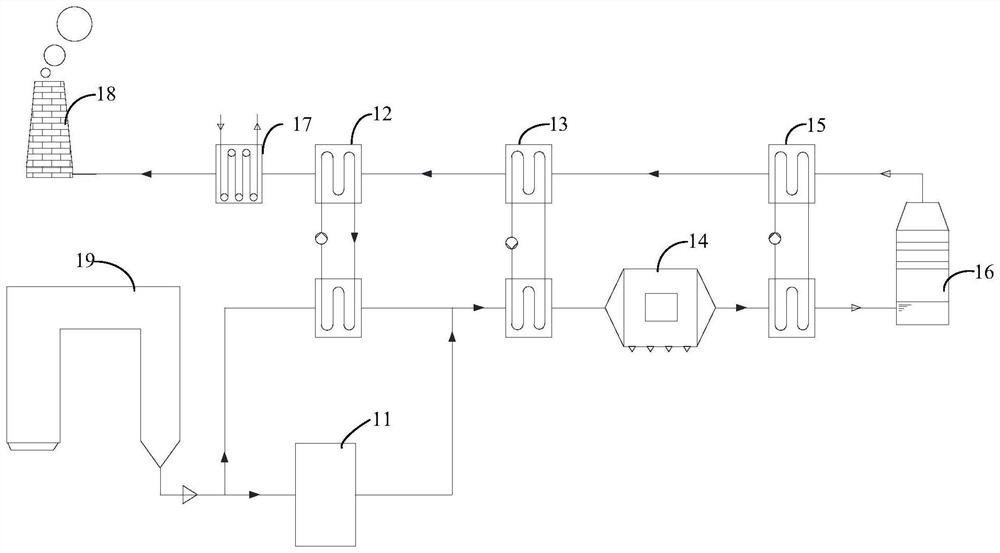

A flue gas purifying system comprises a deduster arranged on a flue gas inlet, and induced draught fan and a smoke evacuation chimney. An ammonia spraying apparatus for denitration, a catalytic converter for depriving dioxin and nitrogen oxide, and a reaction tower for depickling and eliminating white smoke are successively arranged between the deduster and the induced draught fan and are communicated by the gas flue. The reaction tower is a washing tower comprising a water tank arranged on the tower bottom, a secondary low temperature flue arranged on the tower body, a secondary high temperature flue for flue gas discharge arranged on an upper part of the tower body. The upper part of the internal tower is provided with at least a set of spray apparatuses, which are equipped with filling materials for heat absorption and Water flue gas obstruction on an upper part thereof; the water tank and the spraying apparatus connect with a circulating pump arranged on the pipe; and the water tank is also equipped with a water supplement apparatus and a pollution discharge apparatus. Besides, a flue gas heater can be arranged on a deduster outlet, and a smoke-smoke heat exchanger can be arranged between the catalytic converter and the reaction tower. The system of the invention can solve problems in a flue gas purifying system, such as large amount of fly ash, dioxin decomposition, large demand of ammonia water and visual pollution.

Owner:光大环保能源(苏州)有限公司 +1

Desulfurization-denitrification-dedusting integrated device of coke oven

InactiveCN108187489ANo dischargeReduce corrosionGas treatmentDispersed particle filtrationFlue gasProcess engineering

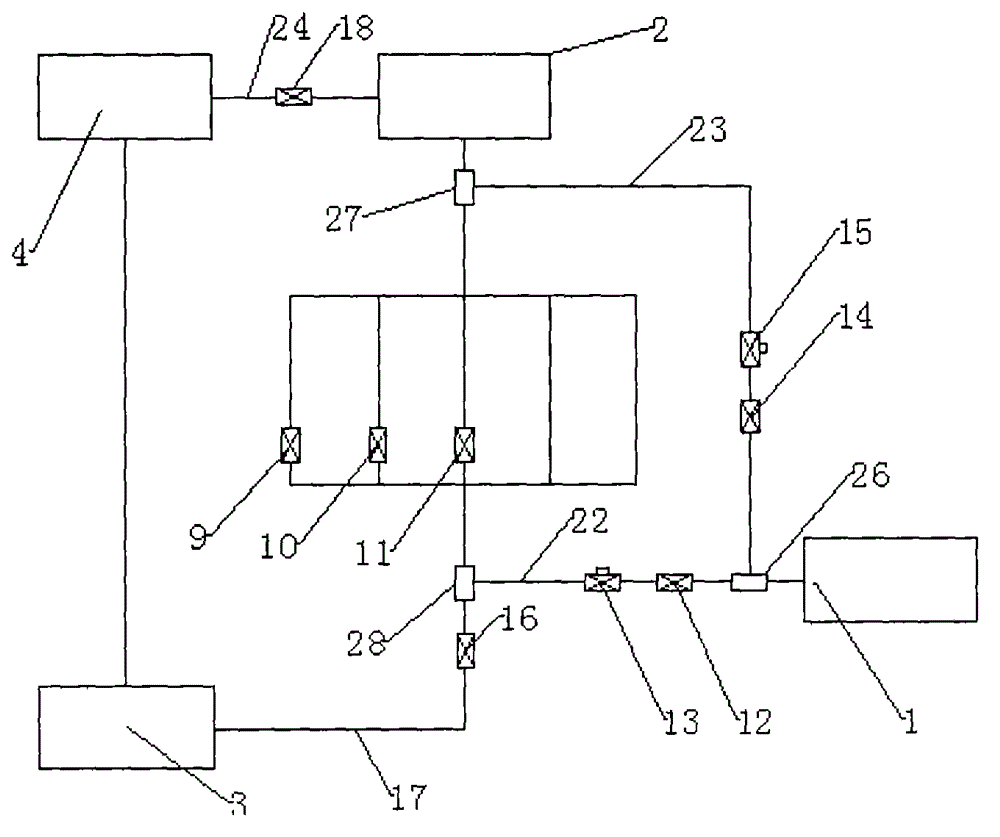

The invention discloses a desulfurization-denitrification-dedusting integrated device of a coke oven, and relates to the technical field of the flue gas treatment. The desulfurization-denitrification-dedusting integrated device of the coke oven comprises a flue gas system, a desulfurization system, a dedusting system and a denitrification system which are successively connected. The outlet of thedenitrification system is connected with a chimney through a draught fan. The desulfurization-denitrification-dedusting integrated device of the coke oven further comprises a flue gas reheating systemand a flue gas heating device. The outlet of the flue gas heating device is connected with the denitrification system, and the inlet of the flue gas heating device is connected with the outlet of theflue gas reheating system and the outlet of the dedusting system. The inlet of the flue gas reheating system is connected with the outlet of the draught fan. The desulfurization-denitrification-dedusting integrated device of the coke oven is suitable for the flue gas treatment of the coke oven, and has the advantages of small pollution, complete purification, low cost, long service life and the like.

Owner:杭州致蓝环保科技有限公司

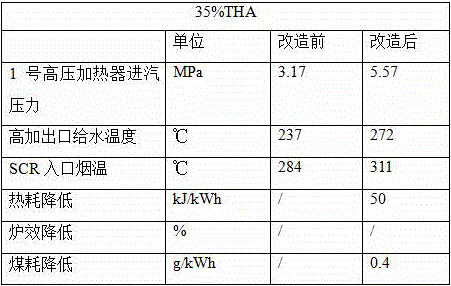

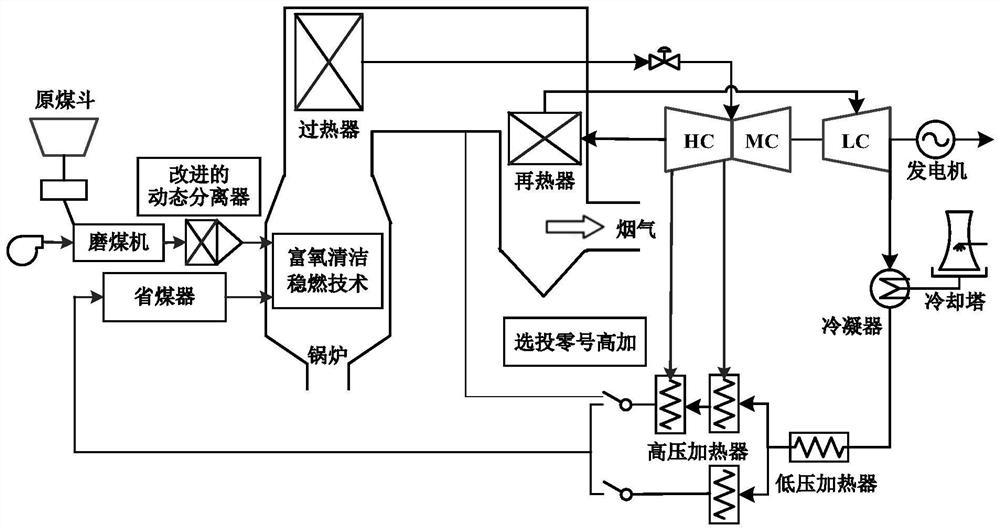

Full-load denitrification system for boiler deep peak load regulation and operation method thereof

PendingCN111649349AIncrease smoke temperatureReduce heat absorptionGas treatmentEmission preventionThermodynamicsFlue gas

The invention discloses a full-load denitrification system for boiler deep peak load regulation and an operation method thereof. The system has a structure that a main flue is sequentially provided with a tail flue shaft steering chamber, a heater and an economizer along the flow direction of flue gas; the inlet of a bypass flue is communicated with the tail flue shaft steering chamber, and the outlet of the bypass flue is set on the flue at the entrance of an SCR reactor; the economizer is connected with a water supply pipe; a No.0 high pressure heater, a No.1 high pressure heater, a No.2 high pressure heater, a No.3 high pressure heater, a water supply pump and a deaerator are provided in sequence on the water supply pipe along the opposite direction of water supply; the No.0 high pressure heater is connected with a No.0 high pressure pump-out pipe, and the No.0 high pressure pump-out pipe is provided with a No.0 high pressure pump-out pipe regulating valve. The system provided by the invention can realize the full-load denitrification of a unit and the regulation of the operating flue gas temperature by controlling the flue gas flow rate of the flue gas bypass and coupling and putting the No.0 high pressure heater into operation.

Owner:STATE GRID SHAANXI ELECTRIC POWER RES INST +2

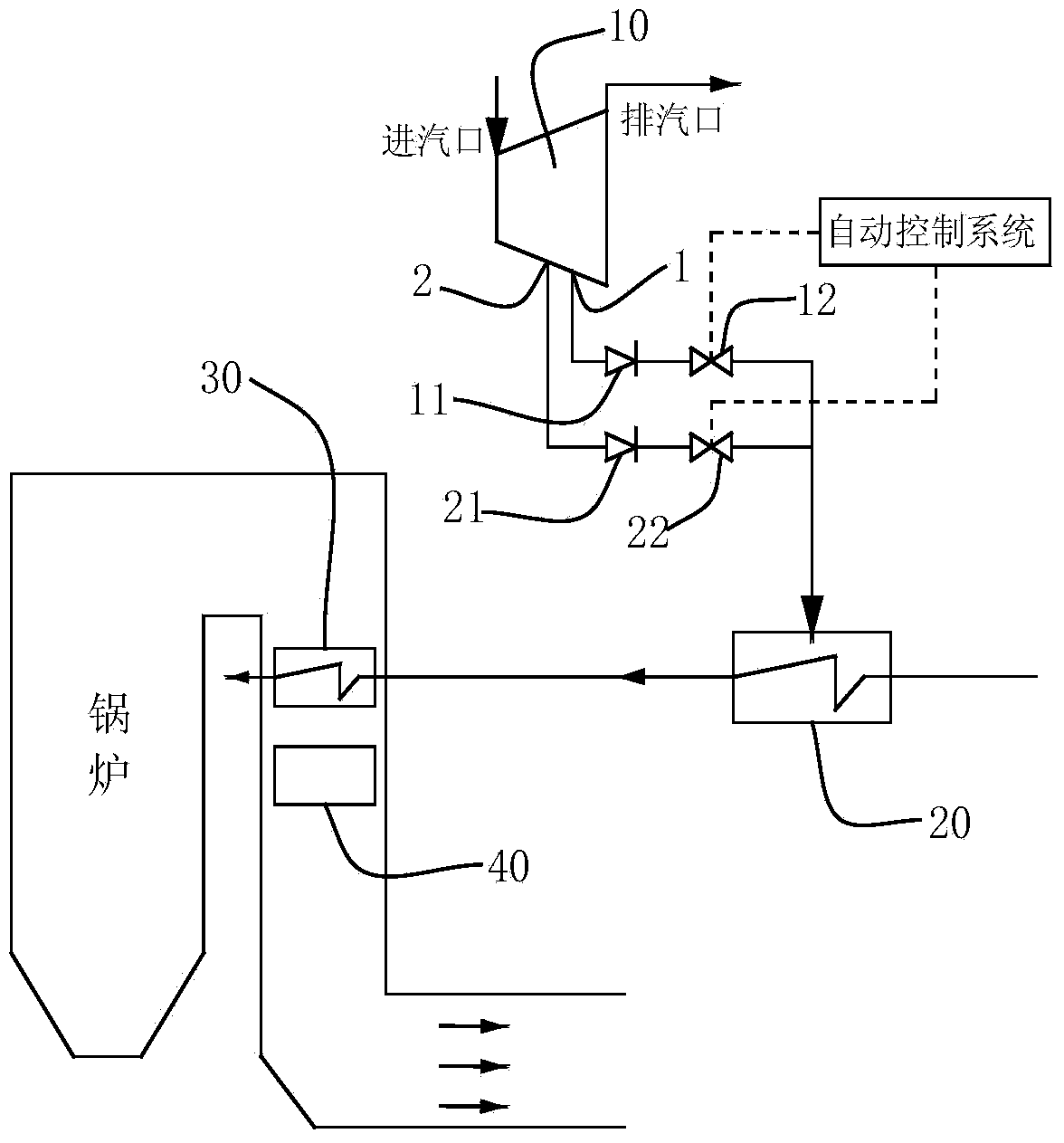

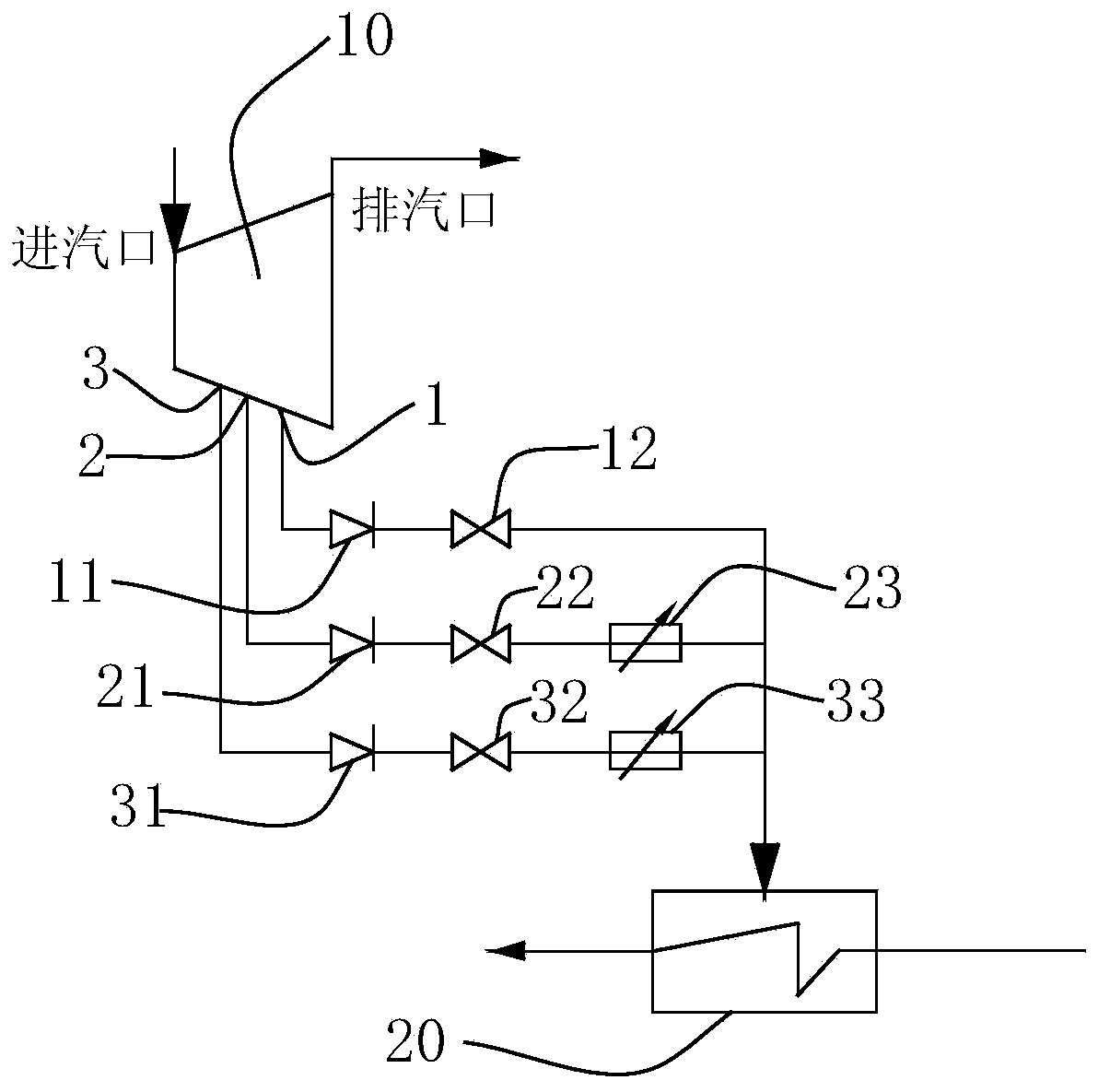

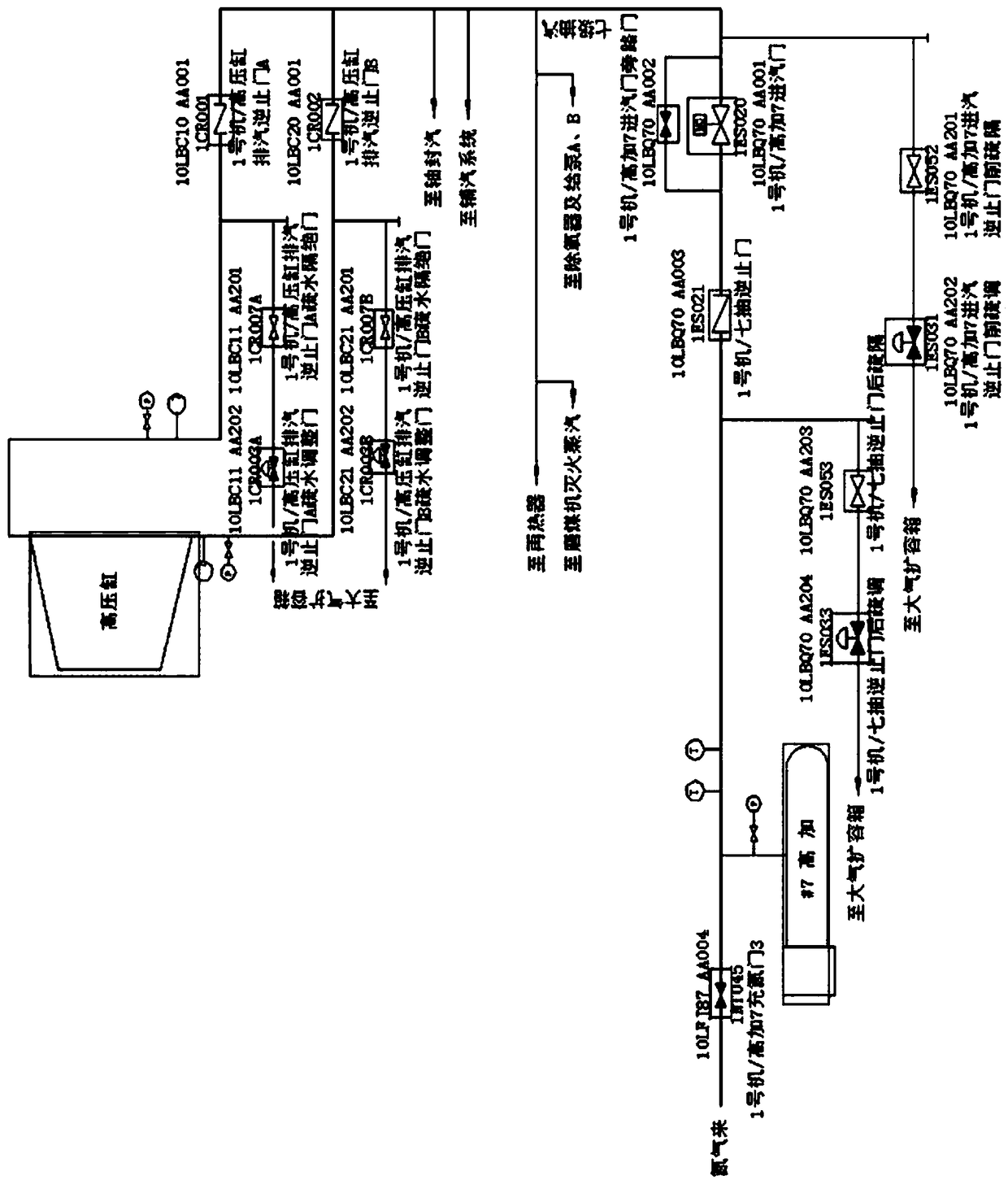

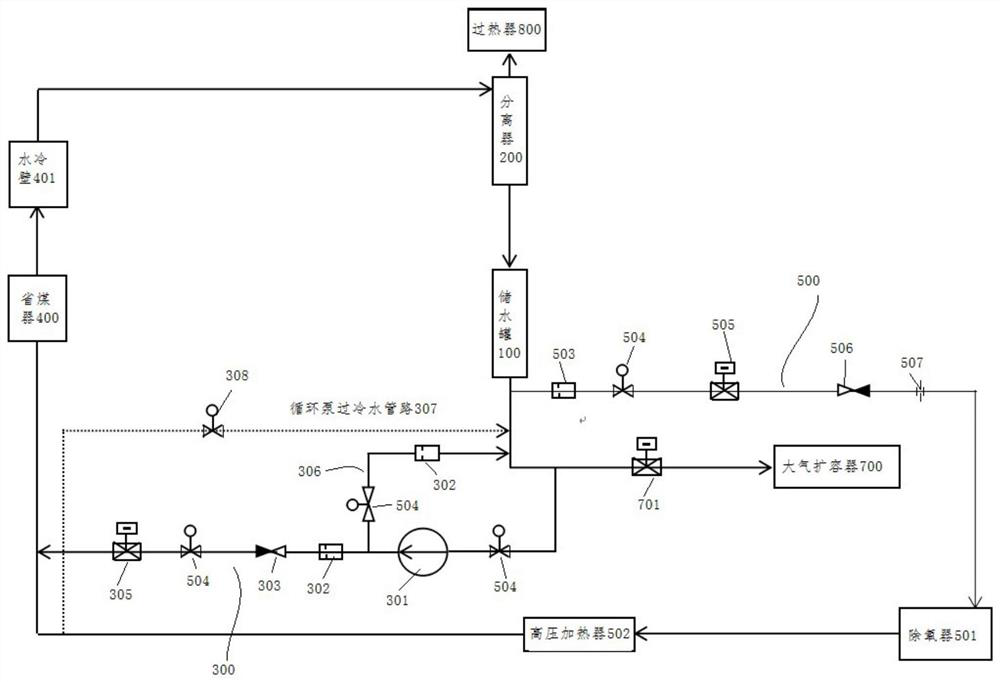

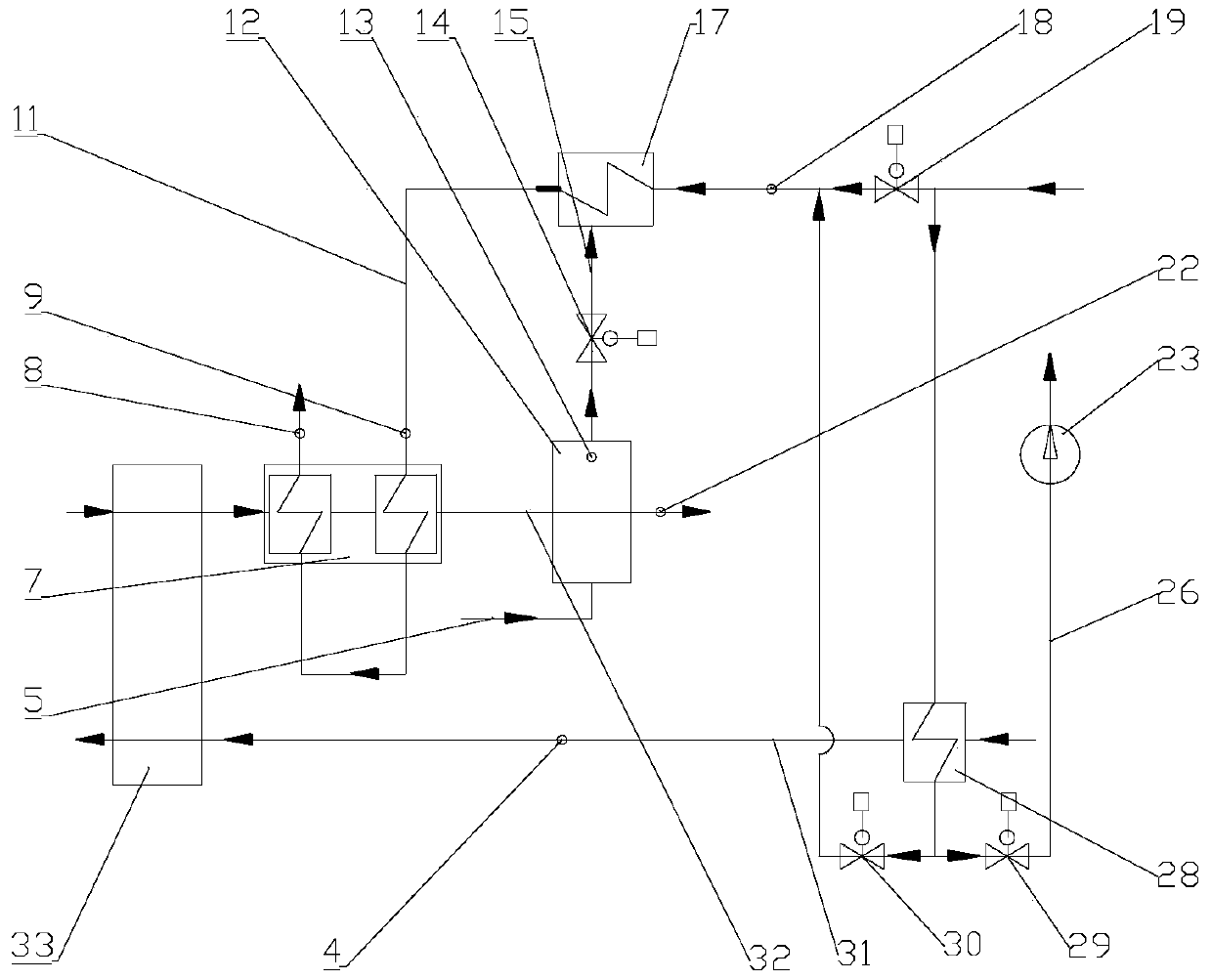

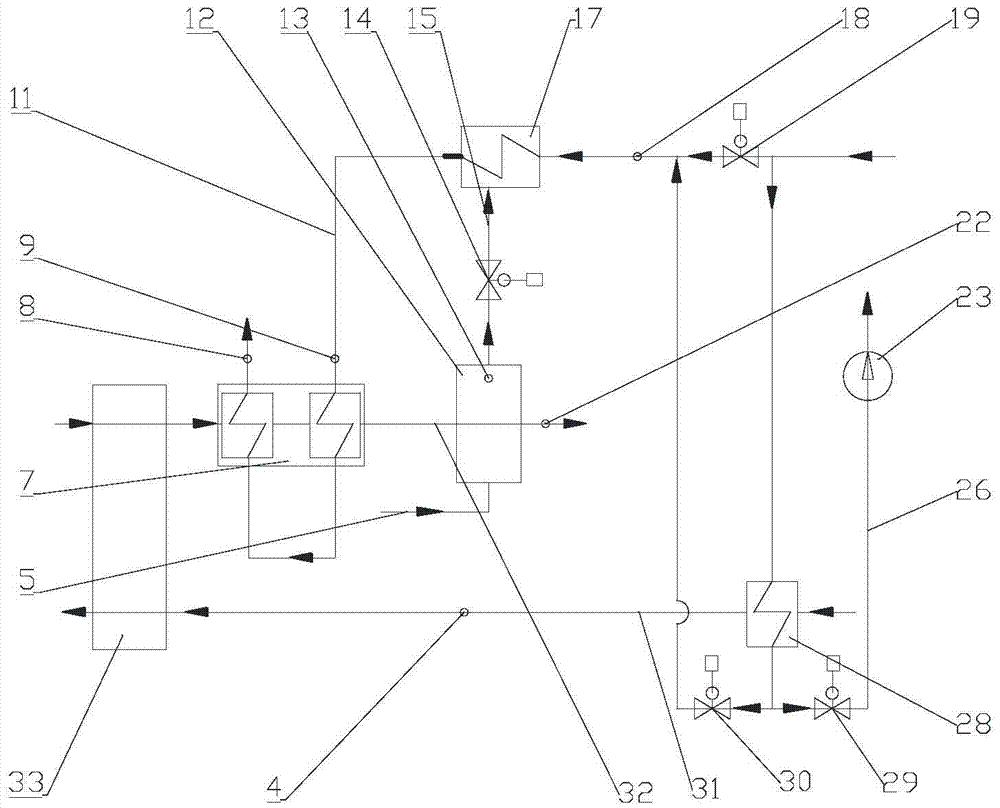

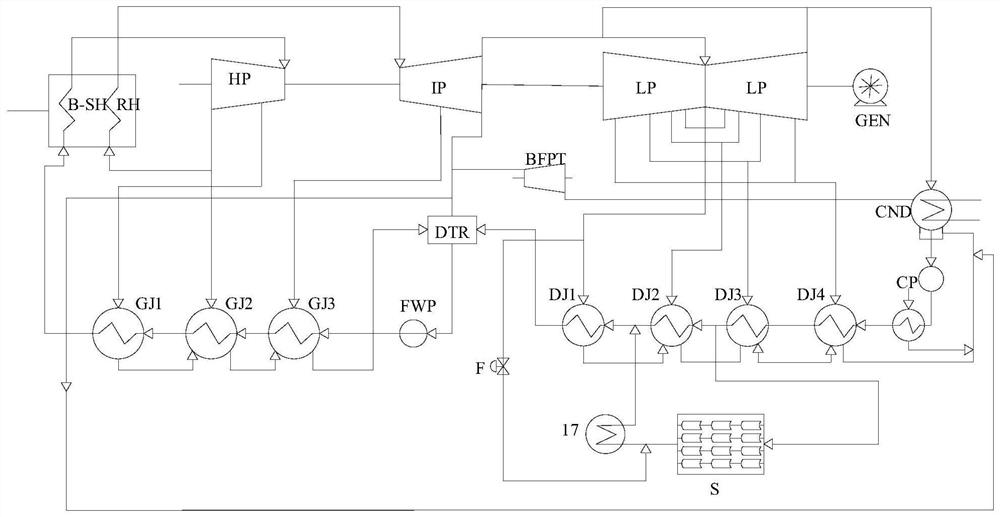

Regenerative system of turbogenerator unit and operation method thereof

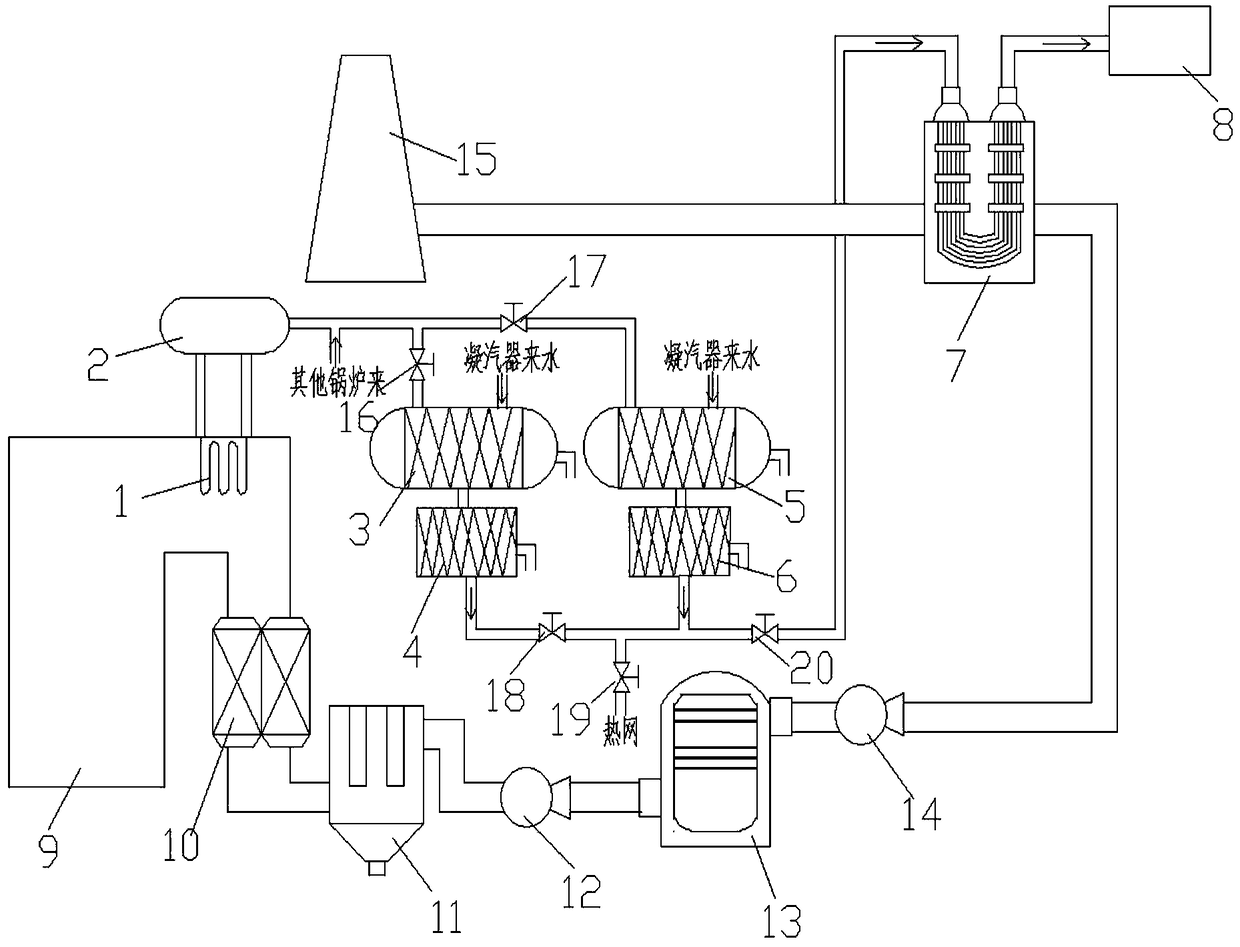

ActiveCN103644005ASolve environmental problems that cannot be put into operationIncrease feed water temperatureSteam useFeed-water heatersEngineeringHigh pressure

The invention discloses a regenerative system of a turbogenerator unit and an operation method thereof. The system comprises a high-pressure cylinder and a high-pressure heater, wherein an steam exhaust port and a plurality of high-pressure steam extraction ports whose steam extraction pressure is increased sequentially are formed in the high-pressure cylinder, the high-pressure steam extraction ports are connected with the same high-pressure heater through high-pressure steam extraction pipelines, and an extraction check valve and an isolated valve are arranged on each high-pressure steam extraction pipeline. When the turbogenerator unit operates at a rated load, a first high-pressure steam extraction port with the lowest steam extraction pressure supplies steam for the high-pressure heater, and the steam extraction pressure at the time is set to be P0; when the turbogenerator unit operates in a state lower than the rated load, a high-pressure steam extraction port with steam extraction pressure less than or equal to P0 or closer to P0 is selected to supply steam for the high-pressure heater, and the isolated valves on other high-pressure steam extraction pipelines are switched off. According to the regenerative system of the turbogenerator unit and the operation method thereof, a denitration system can operate normally when the unit operates at a low load, the boiler feeding temperature is increased, and the thermodynamic cycle efficiency of the unit is improved accordingly.

Owner:王振宇

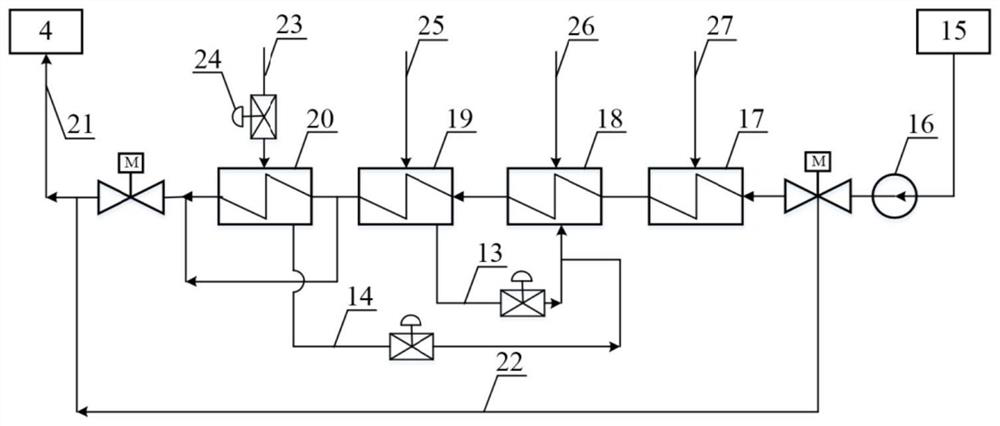

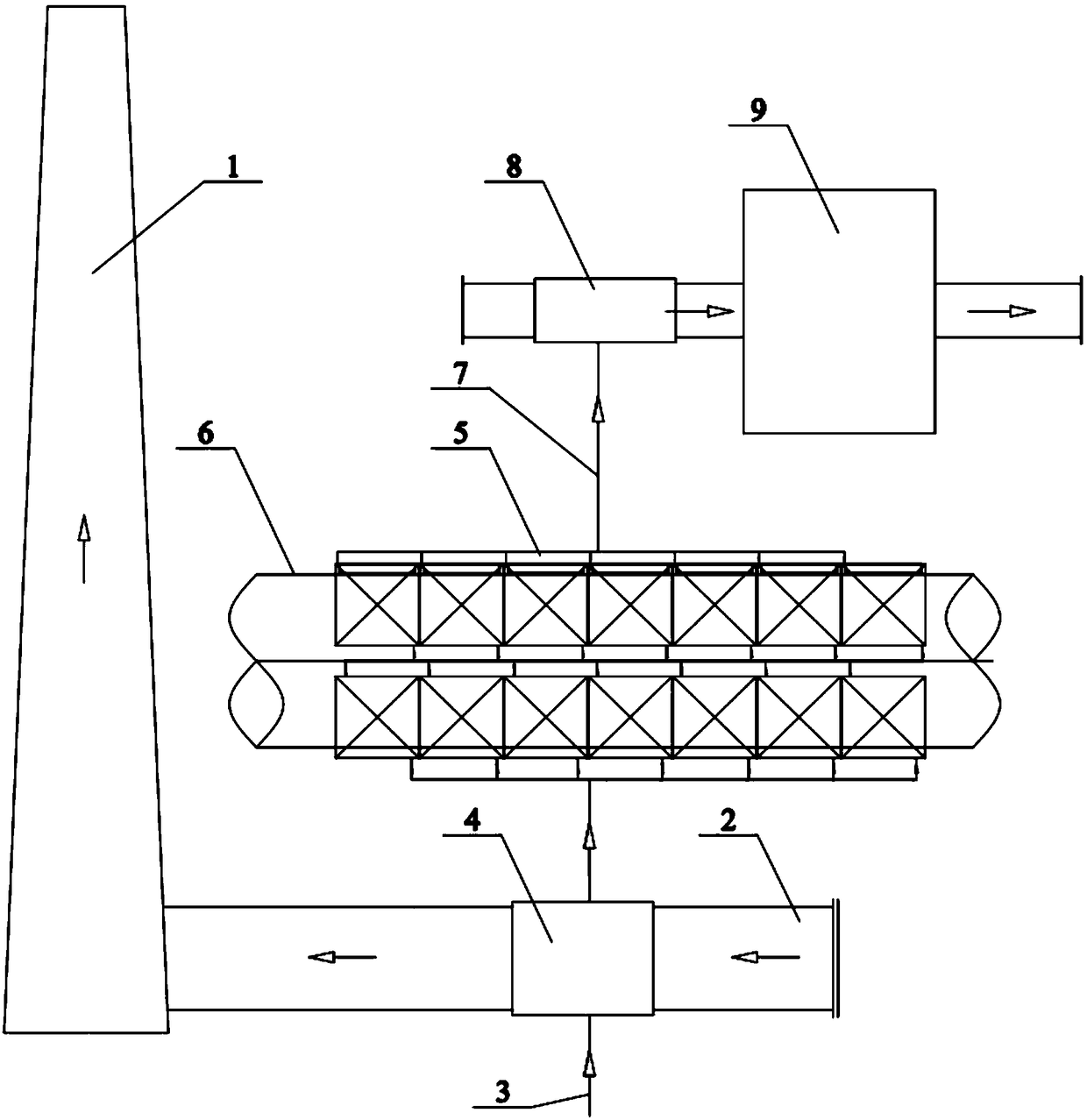

Combined air supply heating depth waste heat recycling system of low-low-temperature economizer of coal-fired unit

The invention relates to the field of smoke exhaust waste heat utilization of a boiler, and particularly discloses a combined air supply heating depth waste heat recycling system of a low-low-temperature economizer of a coal-fired unit. The waste heat recycling system is characterized in that a low-low-temperature economizer high-temperature segment is arranged in a front flue of an electrostatic precipitator, and a low-low-temperature economizer low-temperature segment is arranged at the position from an induced draft fan outlet to a desulfurizing tower inlet flue; the low-low-temperature economizer high-temperature segment is connected with a condensate pipeline of a condenser, and the low-low-temperature economizer low-temperature segment is in parallel connection with a primary air heater and a secondary air heater through low-low-temperature economizer low-temperature segment water outlet pipelines; and the water outlet pipeline of the primary air heater and the water outlet pipeline of the secondary air heater are communicated with a low-low-temperature economizer low-temperature segment water returning pipeline of the low-low-temperature economizer low-temperature segment. The temperature of the smoke of the desulfurizing tower inlet is reduced to about 50 DEG C, coal saving benefits are obtained, meanwhile, the water consumption of a desulfurizing tower is reduced, and the whole running benefits of a power plant is greatly improved.

Owner:SHANDONG HONGAO POWER TECHNOLOGY CO LTD

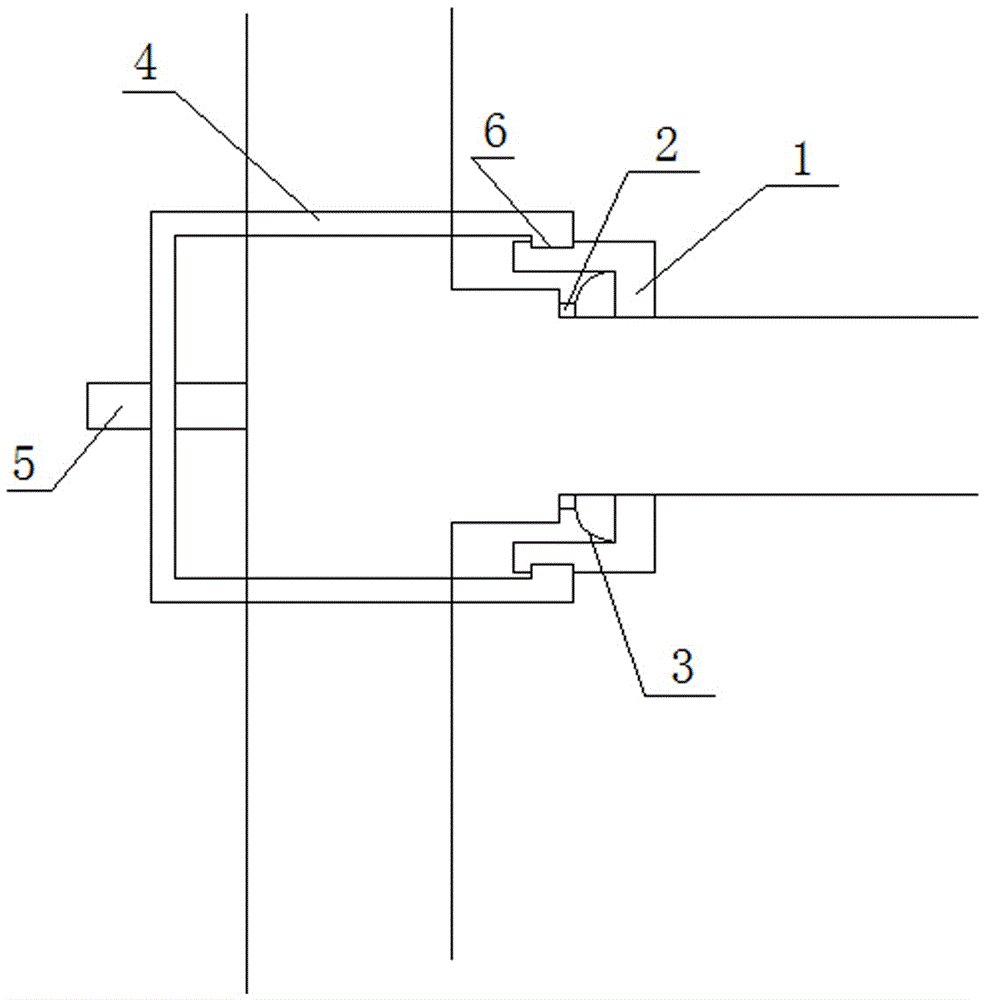

System unit and method for increasing temperature of SCR reactor

InactiveCN106765035AIncrease smoke temperatureSteam superheatersFeed-water heatersFlue gasProcess engineering

The invention provides a system unit for increasing the temperature of an SCR reactor. The system unit comprises a boiler reversing chamber and a coal economizer, and is characterized in that at the boiler reversing chamber, two bypass pipelines are connected to an inlet flue of the SCR reactor at the outlet of the coal economizer. According to the system, by utilizing pressure difference formed between different heated surfaces of a boiler in operation, about 510 to 550 DEG C of medium-temperature flue gas is sucked from the boiler reversing chamber, is divided and sent to the two bypass pipelines, and is connected to and enters the inlet flue of the SCR reactor at the outlet of the coal economizer. The amount of the sucked flue gas is not more than 10% of the total amount of the flue gas under the load, and the suction amount is relatively moderate, so boiler water supply and main reheated steam temperature are barely affected.

Owner:华电电力科学研究院有限公司东北分公司

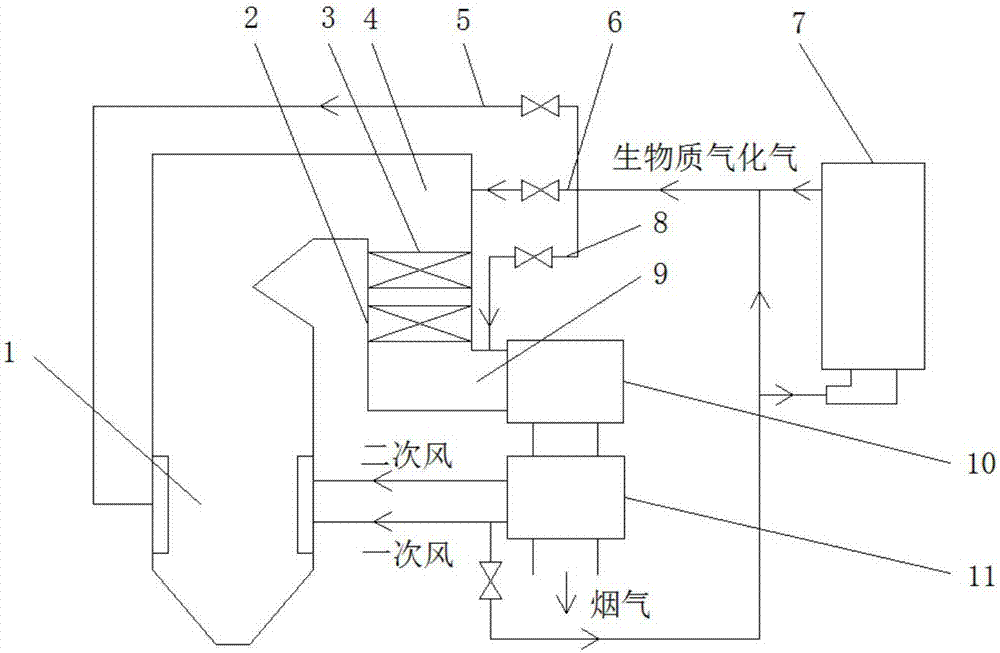

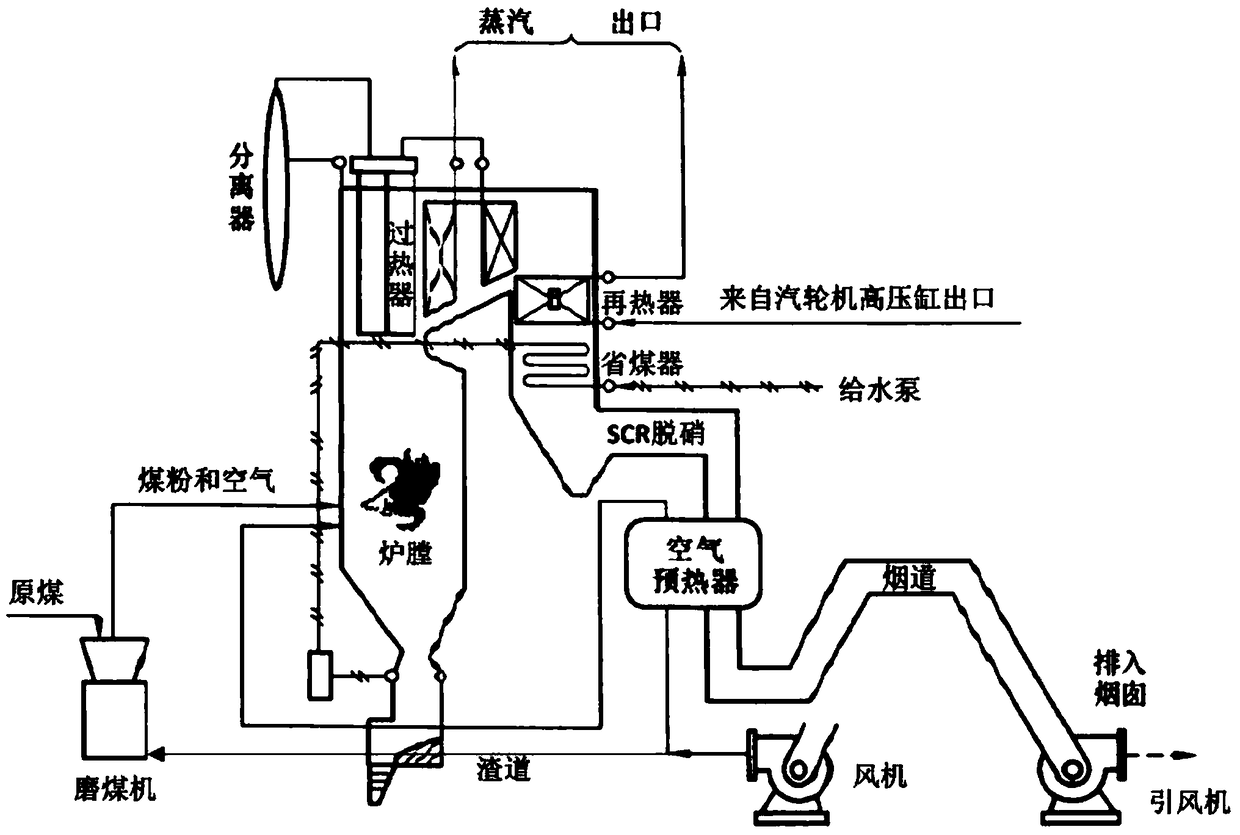

Power station boiler system and method for increasing tail fume temperature of power station boiler by integrating supplemental combustion for biomass gasification

InactiveCN107255269AIncrease smoke temperatureSafe and stable operationGas treatmentDispersed particle separationPower stationCombustion

The invention discloses a power station boiler system and a method for increasing the tail fume temperature of a power station boiler by integrating supplemental combustion for biomass gasification. According to the method, one or more fixed bed biomass gasifiers are additionally arranged, the gasifiers maintain the rated loads to continuously and stably operate, and hot primary air of the boiler is used as a gasification agent to promote the gasification efficiency of the gasifiers and increase the heat value of gasified gas; when the boiler operates with the low load, the biomass gasified gas is delivered into a flue behind a coal economizer or a steering fume chamber in front of the coal economizer, and the fume temperature at an outlet of the coal economizer is increased through supplemental combustion of the biomass gasified gas, so that a selective catalytic reduction fume denitration system operates safely and stably; supplemental-combustion gas is reduced correspondingly along with increasing of the loads, and the reduced gasification gas for supplemental combustion is delivered into the upper portion of a hearth so as to be combusted, and when the boiler operates with the full load, all the biomass gasified gas is delivered into the upper portion of the hearth so as to be combusted; and supplemental-combustion temperature increasing of the tail fume of the power station boiler is finally achieved through biomass resources, and meanwhile, the biomass resources can be further efficiently used for power generation.

Owner:GUODIAN SCI & TECH RES INST

Superheated steam temperature adjusting system and method suitable for SCR low-load operation

InactiveCN105889899ALow retrofit costLow running costSuperheating controlFeed-water heatersLow loadEngineering

The invention discloses a superheated steam temperature adjusting system and method suitable for SCR low-load operation. The system comprises a bypass system arranged between a low-temperature superheater outlet header and a first stage spray type desuperheater, a feed water heater arranged in front of an economizer inlet header, various pipes and valves, and the various pipes and the valves are connected with the steam temperature adjusting system. The steam flow of a low-temperature superheater is adjusted by adjusting the opening degrees of valves of the bypass system, so that part of superheated steam is used for heating economizer inlet fed water, the economizer inlet water temperature is increased, the heat exchange amount of an economizer system is reduced so as to control the fume temperature at an economizer outlet, and the fume temperature which does not reach the SCR operation condition originally at low load can meet the temperature requirement of SCR operation. The problem that a power plant SCR denitration system cannot be operated at low load is solved, and it is guaranteed that emission of nitric oxides in the full-load operation of a power plant meets the requirements.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

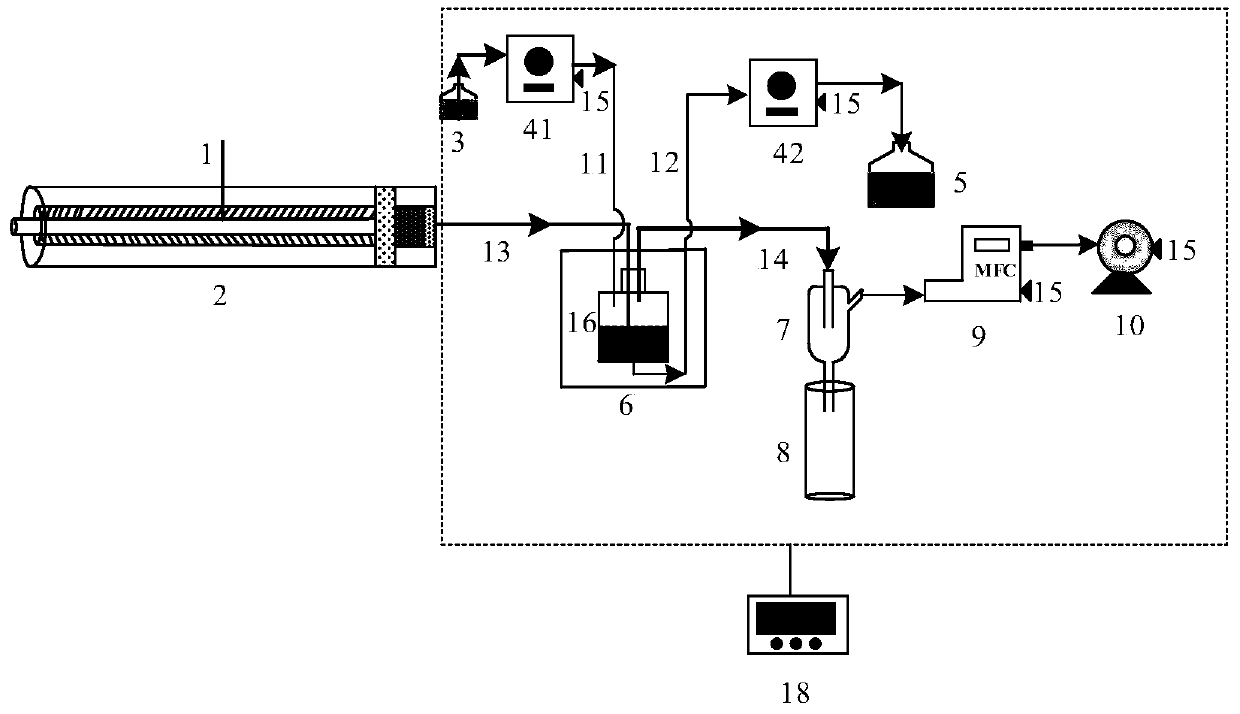

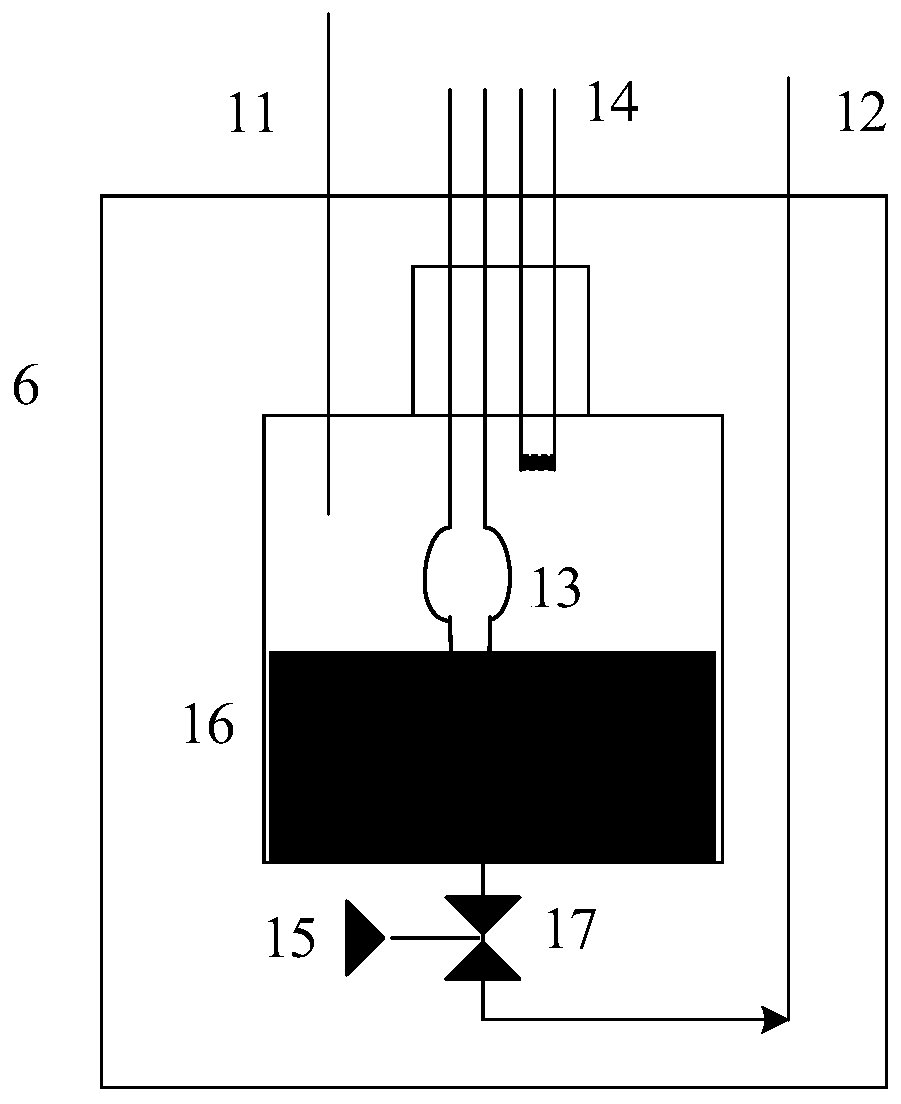

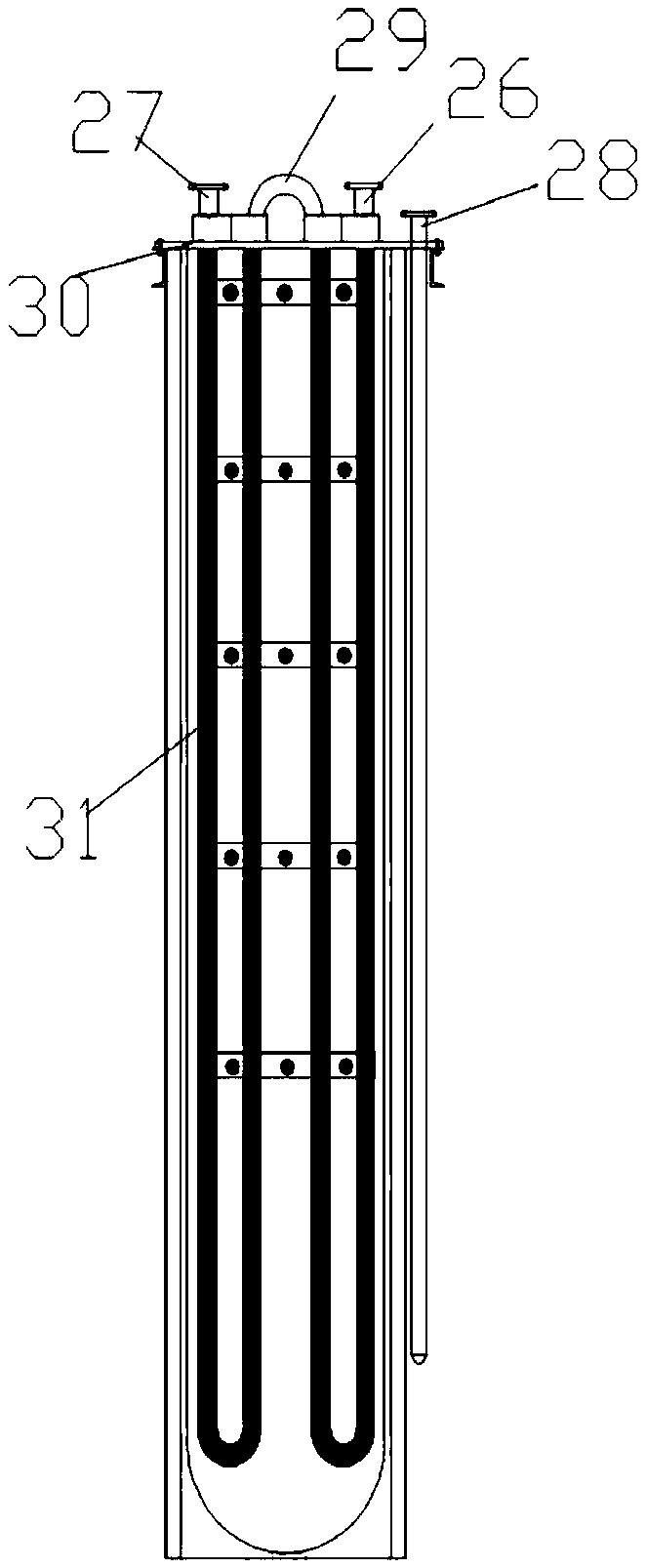

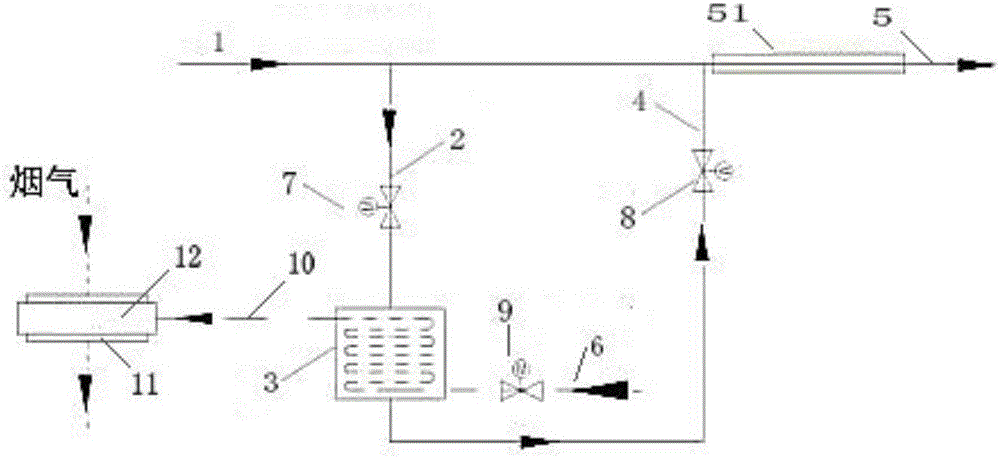

On-line sampling device and method for sulfur trioxide

PendingCN110426251AAdequate mass transferSmall and portableWithdrawing sample devicesPeristaltic pumpVapor–liquid separator

The invention provides an on-line sampling device and method for sulfur trioxide to reduce the human operation error of sampling personnel and improve the sampling accuracy. The device comprises a low-temperature absorber, an isopropanol sampling liquid extraction system and an air extraction system; the air extraction system comprises a gas-liquid separator, a gas mass flow meter and an air pump,wherein the gas mass flow meter and the air pump are successively connected to a gas outlet of the gas-liquid separator; the low-temperature absorber comprises an isopropanol absorption liquid bottle, a flue gas input pipe and a flue gas output pipe; the isopropanol absorption liquid bottle is filled with isopropanol absorption liquid and placed in an environment of -2 to 2 DEG C; the input end of the flue gas input pipe is connected with a heating gun, and the output end is inserted into the absorption liquid; the output end of the flue gas output pipe is higher than a set absorption liquidlevel, and the output end is connected with a gas inlet of the gas-liquid separator; the isopropanol sampling liquid extraction system includes an isopropanol sampling liquid output pipe, a suction peristaltic pump and a sampling collector which are successively connected to the bottom of the isopropanol absorption liquid bottle.

Owner:HUANENG POWER INT INC +1

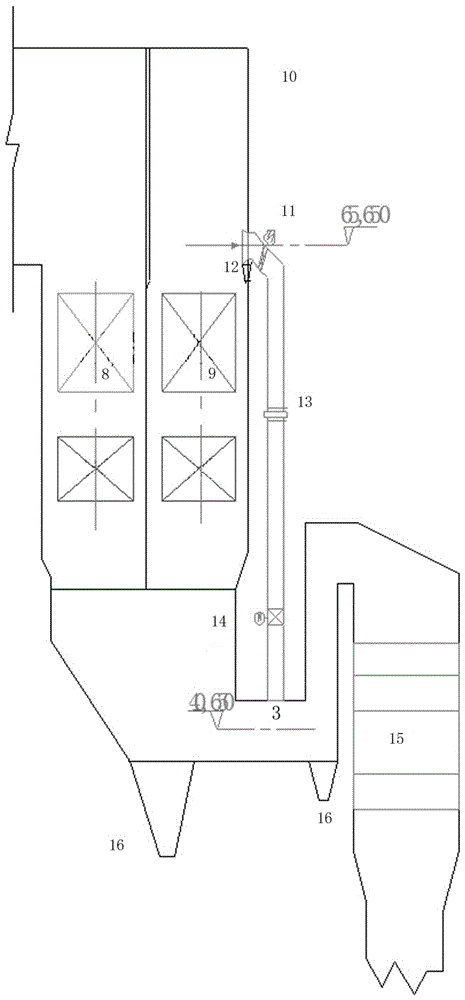

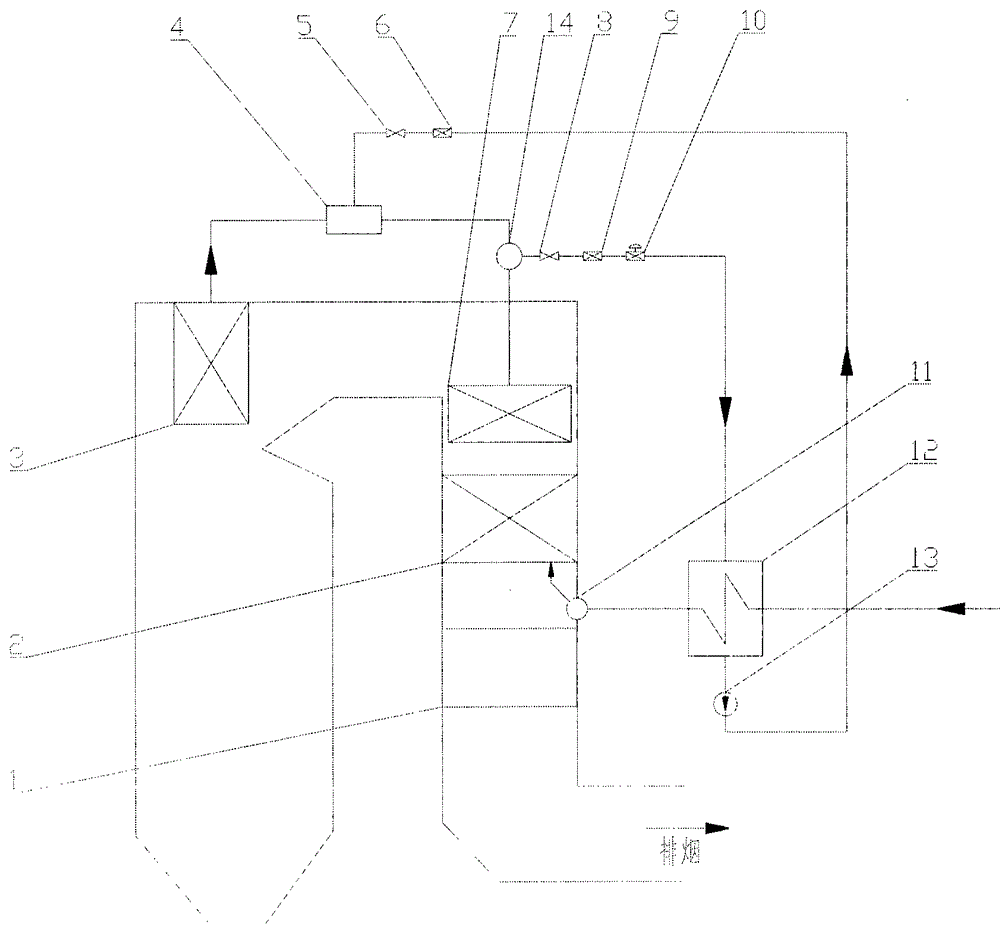

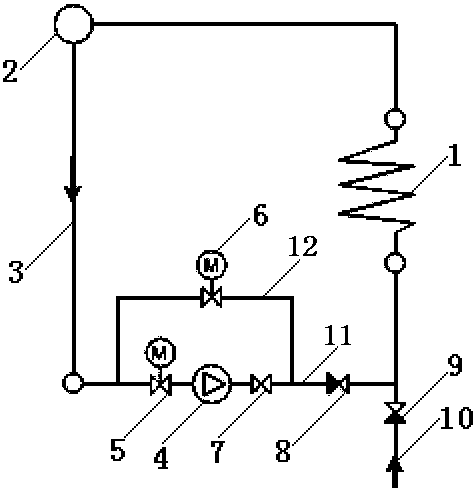

Economizer hot water recirculation system applicable for subcritical steam drum boiler generator set, and working method thereof

PendingCN108844058AIncrease working fluid temperatureIncrease smoke temperatureWater feed controlStart stopLow load

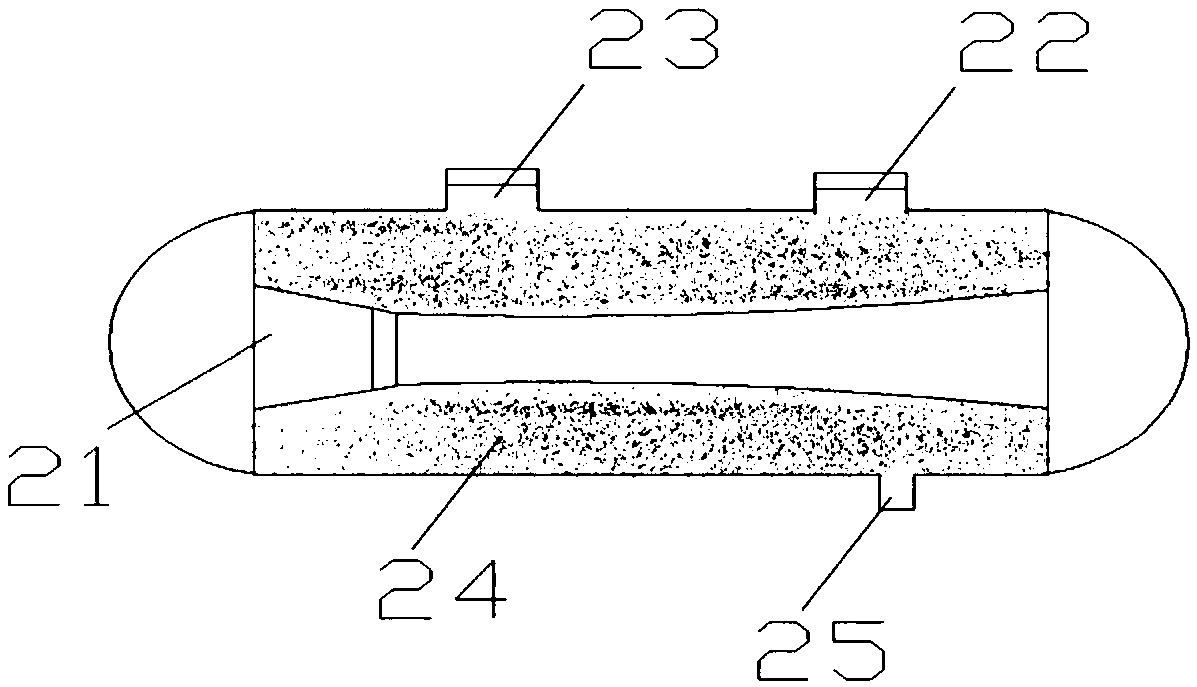

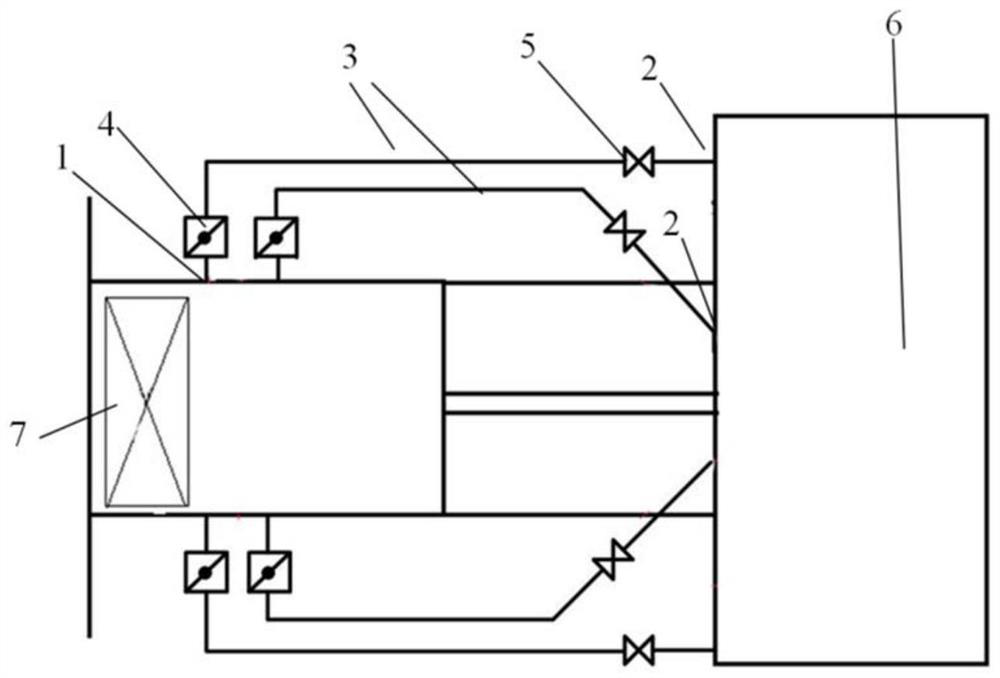

The invention relates to an economizer hot water recirculation system applicable for a subcritical steam drum boiler generator set, and a working method thereof. The hot water recirculation system comprises an economizer, a steam drum, a drop pipe and a water supply pipe, and a water outlet of the economizer, the steam drum and the drop pipe communicate with each other in sequence; the water supply pipe communicates with an inlet of the economizer; the hot water recirculation system further comprises a No.1 electric regulating valve, a No.2 electric regulating valve, a manual shutoff valve, aNo.1 check valve, a No.2 check valve, a circulating pump, a recirculation pipe and a bypass; the recirculation pipe communicates with a lower collection box of the drop pipe, and further communicateswith an inlet collection box of the economizer at the time; the recirculation pipe is provided with the circulating pump of which the both sides are provided with the No.1 electric regulating valve and the manual shutoff valve; the circulating pump is provided with the bypass which is provided with the No.2 electric regulating valve; and the recirculation pipe is provided with the No.1 check valve, and the water supply pipe is provided with the No.2 check valve. The hot water recirculation system can be used for preventing the economizer from being dry-burnt in the start-stop process, and improving the outlet smoke temperature of the economizer under the low load condition, so that the wide load denitrification is achieved.

Owner:HANGZHOU HUADIAN ENERGY ENG +1

Large pulverized coal boiler ultralow-load coal economizer switching bypass system

The invention provides a large pulverized coal boiler ultralow-load coal economizer switching bypass system. The system mainly solves the problem of low-temperature corrosion risk of a cold end and atail flue of an air preheater. The system is characterized in that firstly, a bypass pipeline valve is opened, then a water supply pipe valve and a downcomer valve are closed, a hydrophobic valve is opened, residual boiler feedwater in a coal economizer is introduced into a boiler hydrophobic system to be recycled through a coal economizer drain pipe, the boiler feedwater enters the downcomer through a bypass pipeline, and the boiler feedwater does not absorb the flue gas heat through the coal economizer, so that the temperature of the flue gas at an outlet of the coal economizer can be increased by 60-80 DEG C. According to the system, the connecting mode is relatively simple and convenient, only certain pipeline equipment needs to be additionally arranged, the equipment investment is saved, the usability of a SCR of a ultralow-load denitration device is enhanced, the lowest load of the boiler can meet the lowest commissioning flue gas temperature condition of the SCR of the denitration device at 15% BMCR.

Owner:HARBIN BOILER

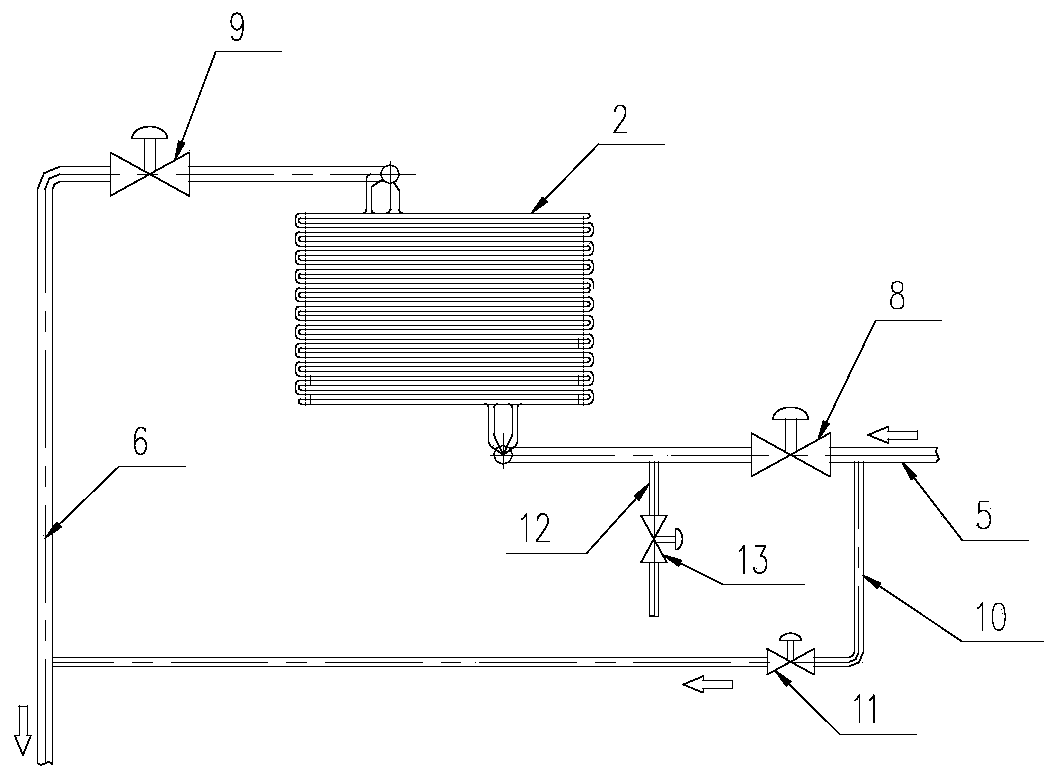

Waste incineration waste heat boiler system with flue gas reheating function

PendingCN111207373APrevent high temperature corrosionShorten the lengthSuperheating controlBoiler water tubesThermodynamicsFlue gas

The invention relates to a waste incineration waste heat boiler system with a flue gas reheating function. The waste incineration waste heat boiler system is characterized in that the waste incineration waste heat boiler system comprises a first flue to an N flue sequentially arranged in the flue gas flowing direction, the Nflue is a horizontal flue defined by superheaters in a surroundingmode, and a water-cooled evaporation screen, the first-level second superheater, the third-level superheater, a second-level reheater, the second-level second superheater, the second-level first superheater and the first-level first superheater are sequentially arranged in the horizontal flue; and the N flue communicates with a tail front flue, the tail front flue is connected with a tail rear flue in series, the tail front flue and the tail rear flue are composed of surrounding plates, and a first-level reheater and an economizer are arranged in the tail front flue and the tail rear fluecorrespondingly. The fume temperature in the area where a first-level reheater is located is low, and the first-level reheater is arranged in the tail flue composed of the surrounding plates, so thatcompared with the scheme that all convection heating surfaces are arranged in the horizontal flue, the floor space can be saved.

Owner:SHANGHAI BOILER WORKS

Economizer increasing fume temperature at SCR inlet by changing areas and flowing modes

ActiveCN105889895AIncrease smoke temperatureRaise the inlet smoke temperatureFeed-water heatersEngineeringRunning time

The invention discloses an economizer increasing the fume temperature at an SCR inlet by changing areas and flowing modes. A bypass is arranged on a water supply pipe connected with an economizer inlet header and is divided into two branch pipes, the first branch pipe is connected with economizer coiler headers, and the second branch pipe is directly connected with an economizer outlet header. Stop valves and flow regulating valves are sequentially arranged in the two branch pipes in the flowing direction of fluid correspondingly. The heating areas of economizer sets are regulated by regulating the valves of the first branch pipe, so that the heat exchange amount of an economizer system is reduced so as to control the fume temperature at an economizer outlet; and the flowing modes of fume and water are changed by regulating the valves of the second branch pipe, the low-load working condition which does not reach the SCR operation condition originally can meet the temperature requirement of SCR operation, and the continuous operation time of a power plant SCR denitration system is effectively prolonged. The activity of an SCR catalyst is improved due to increase of the fume temperature in the SCR system under the low-load working condition, so that the denitration capacity of the SCR system is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Boiler continuous blowdown wastewater waste heat utilization system and method

ActiveCN108800095ASimple structureEasy to installFeed water supplySteam boilersAir preheaterGas heater

The invention discloses a boiler continuous blowdown wastewater waste heat utilization system. The boiler continuous blowdown wastewater waste heat utilization system comprises a steam pocket, a boiler, an air preheater, a dry type dust collector, a first induced draft fan, a wet desulphurization tower, a second induced draft fan, a gas-gas heater, a desalting water tank and a chimney. A continuous blowdown wastewater waste heat recovery device and a filter cleaning device are arranged between the steam pocket and the gas-gas heater. An inlet of the continuous blowdown wastewater waste heat recovery device is connected with a water outlet of the steam pocket. An outlet of the continuous blowdown wastewater waste heat recovery device is connected with an inlet of the filter cleaning device.An outlet of the filter cleaning device is connected with a water inlet of the gas-gas heater. A water outlet of the gas-gas heater is connected with an inlet of the desalting water tank. The invention further discloses a method for utilizing boiler continuous blowdown wastewater waste heat through the system. The boiler continuous blowdown wastewater waste heat utilization system is simple in structure and achieves the effects that boiler continuous blowdown wastewater waste heat is recovered and used for eliminating gas fume white smoke and recovering water resources.

Owner:浙江巨化热电有限公司

Serpentine pipe bundle and heat exchange cover waste heat recovery device

InactiveCN109059562AEmission reductionIncrease temperatureIncreasing energy efficiencyWaste heat treatmentEngineeringSuperheater

The invention provides a serpentine pipe bundle and a heat exchange cover waste heat recovery device, and belongs to the field of cement kiln waste heat power generation. According to the serpentine pipe bundle and the heat exchange cover waste heat recovery device provided by the invention, hot water heat exchangers are arranged in flues, leading to a chimney, of a kiln head waste heat boiler anda kiln tail waste heat boiler. Cold water is introduced into the hot water heat exchangers from a cold water pipe, the cold water exchanges heat with flue gas in the hot water heat exchangers, the cold water is changed into hot water after heat exchange; the hot water is secondarily heated through a heat exchange cover installed on the barrel body of a cement kiln, thus water temperature is increased again; the hot water heated twice is conveyed to a hot air curtain through a hot water pipe, heat exchange between outdoor air and the hot water is completed in the hot air curtain; the heated air is led into a grate cooler, and output high-temperature flue gas is conveyed to the waste heat boilers. According to the serpentine pipe bundle and the heat exchange cover waste heat recovery device, not only the influence caused by weather on power generation can be avoided, but also temperature of the flue gas at an inlet of a superheater at the normal condition can be improved, generating capacity of boilers at the kiln head and the kiln tail are increased, emission of the hot flue gas to the air is also reduced, and environmental protection is facilitated.

Owner:孙海霞

Control method of using denitration device in thermal power generating unit starting stage before synchronization

InactiveCN108613165AIncrease temperatureRaise the inlet smoke temperatureGas treatmentDispersed particle separationEnvironmental resistanceNitrogen oxides

The invention provides a control method of using a denitration device in a thermal power generating unit starting stage before synchronization. The coal feeding amount during normal operation of the thermal power generating unit is limited to be a first coal feeding amount, the coal feeding amount of the thermal power generating unit in the starting stage is a second coal feeding amount, the second coal feeding amount is larger than the first coal feeding amount, so that flue gas temperature of a boiler outlet is improved. The method is simple and easy to implement, economical, environment-friendly, safe, and reliable; and on the premises that any new equipment is not added and system improvement is not needed, only the operation of the unit is adjusted, the temperature of the flue gas atan inlet of SCR can be effectively improved, the emission amount of the flue gas nitrogen oxide of a boiler is reduced, and the method is green and environment-friendly.

Owner:HUANENG POWER INT INC

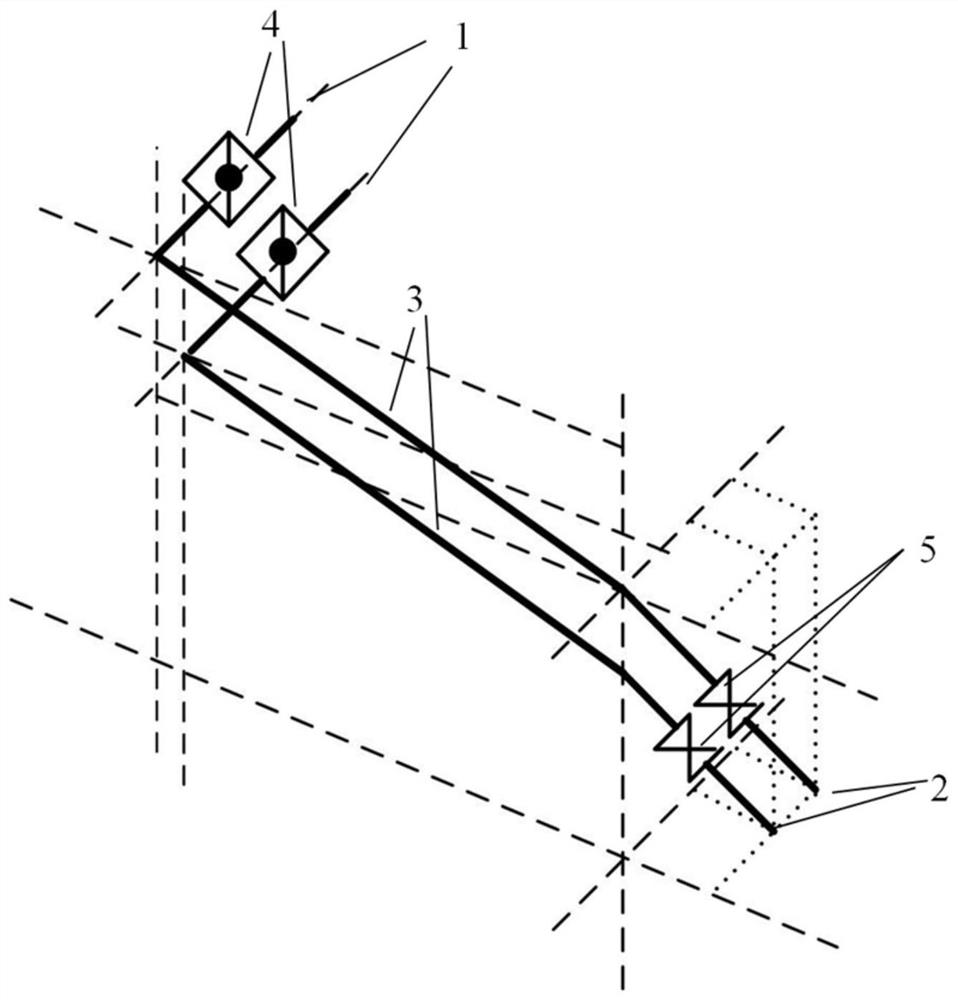

Unpowered multi-channel flue gas heating device and method

PendingCN112361369AEasy to get stuckAddressing Leaky DefectsLighting and heating apparatusThermodynamicsCombustion

The invention provides an unpowered multi-channel flue gas heating device and method. The unpowered multi-channel flue gas heating device comprises a flue gas extraction port and an insertion port, wherein the flue gas extraction port is formed in a side enclosure wall on a horizontal flue and is formed in the position at the downstream of a high-temperature superheater, the insertion port is formed in the front end of a horizontal flue of a SCR reactor; and the flue gas extraction port is connected to the insertion port through a connecting pipe. According to the unpowered multi-channel fluegas heating device and method, the device can to be put into use at any time by adjusting a valve according to load requirements, the valve is closed under high load, leakage is avoided in the closingprocess, jamming is avoided in the opening process, after the device is put into use, the SCR inlet flue gas temperature can be increased by 50 DEG C, and the hot primary air temperature can be increased by 30 DEG C. and remarkable effects of meeting the requirements of deep peak regulation of a large thermal power generating unit and the drying capacity of a coal pulverizing system at medium andlow load stages and improving the boiler combustion efficiency can be achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

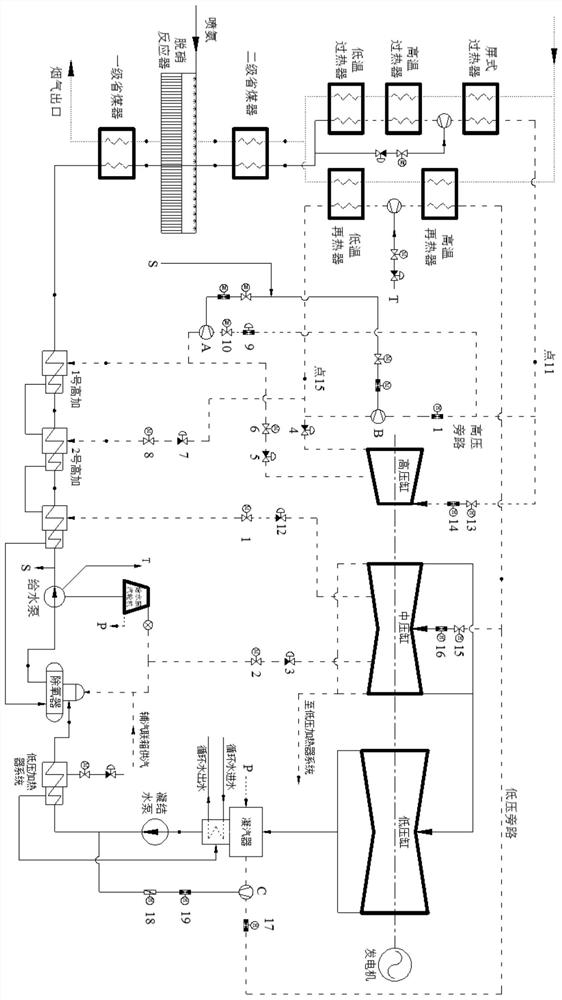

Coal economizer water temperature adjusting system for denitration input in unit starting process

ActiveCN112303604AEffective regulationReduce startup timeLiquid degasificationSteam generation using pressureSuperheaterNitrogen oxides

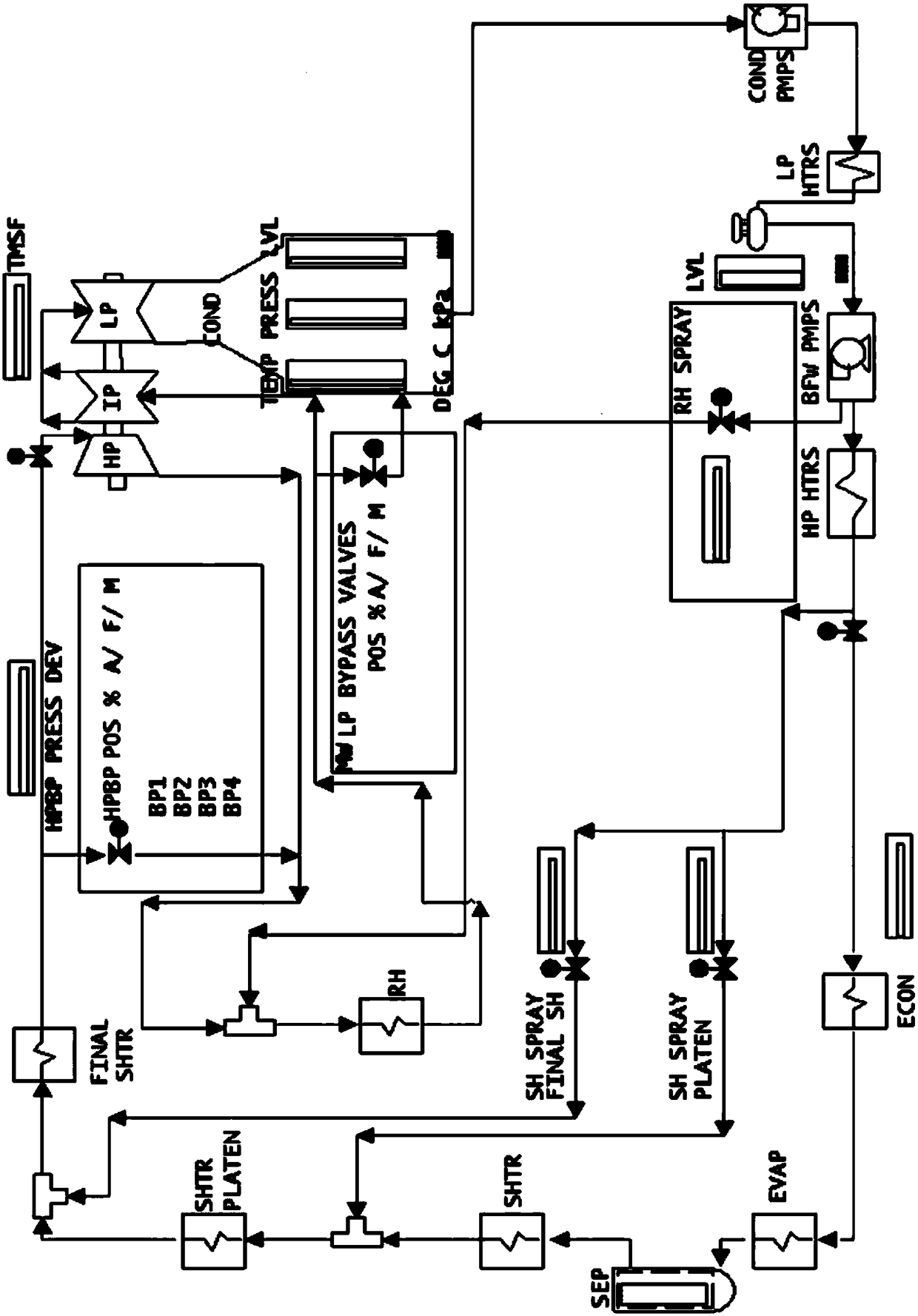

The invention discloses a coal economizer water temperature adjusting system for denitration input in the unit starting process. The system comprises a platen superheater, a high-pressure main steam valve, a high-pressure regulating valve, a high-pressure cylinder, a high-pressure bypass, a low-temperature reheater, a regulating valve, a second electric valve, a first high-pressure heater, a high-pressure cylinder steam exhaust check valve, a low-temperature reheater, a second-section steam extraction check valve, a first electric valve, a second high-pressure heater, a first-section steam extraction check valve, a first-section steam extraction electric valve, a high-temperature reheater, a medium-pressure main steam valve, a medium-pressure cylinder, a low-pressure bypass, a condenser, athree-section steam extraction check valve, a three-section steam extraction electric valve, a third high-pressure heater, a four-section steam extraction check valve, a four-section steam extractionelectric valve, an auxiliary steam header, a secondary economizer and a denitration reactor. The system can reduce nitrogen oxide emission in the starting stage.

Owner:XIAN THERMAL POWER RES INST CO LTD

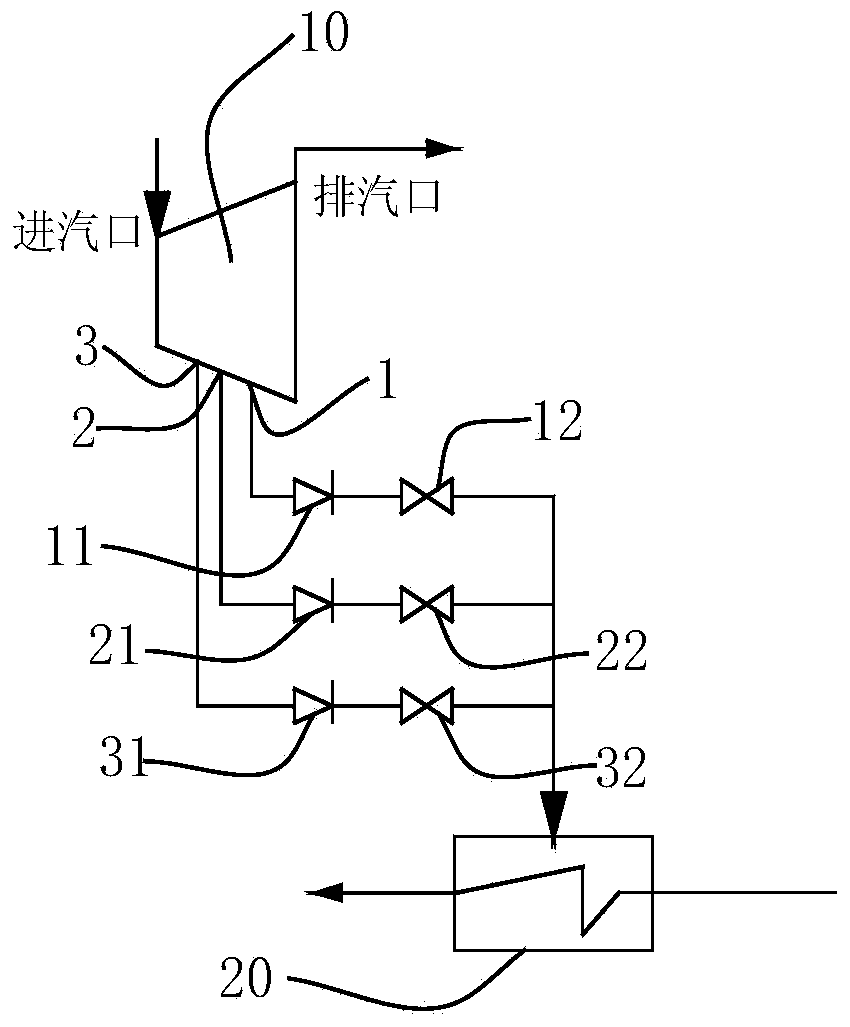

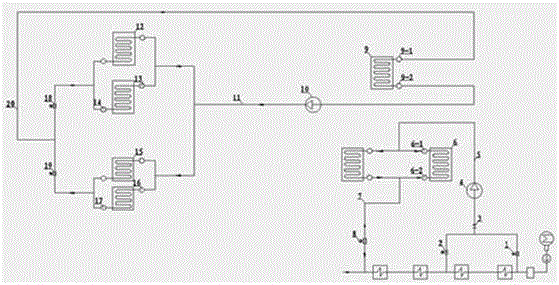

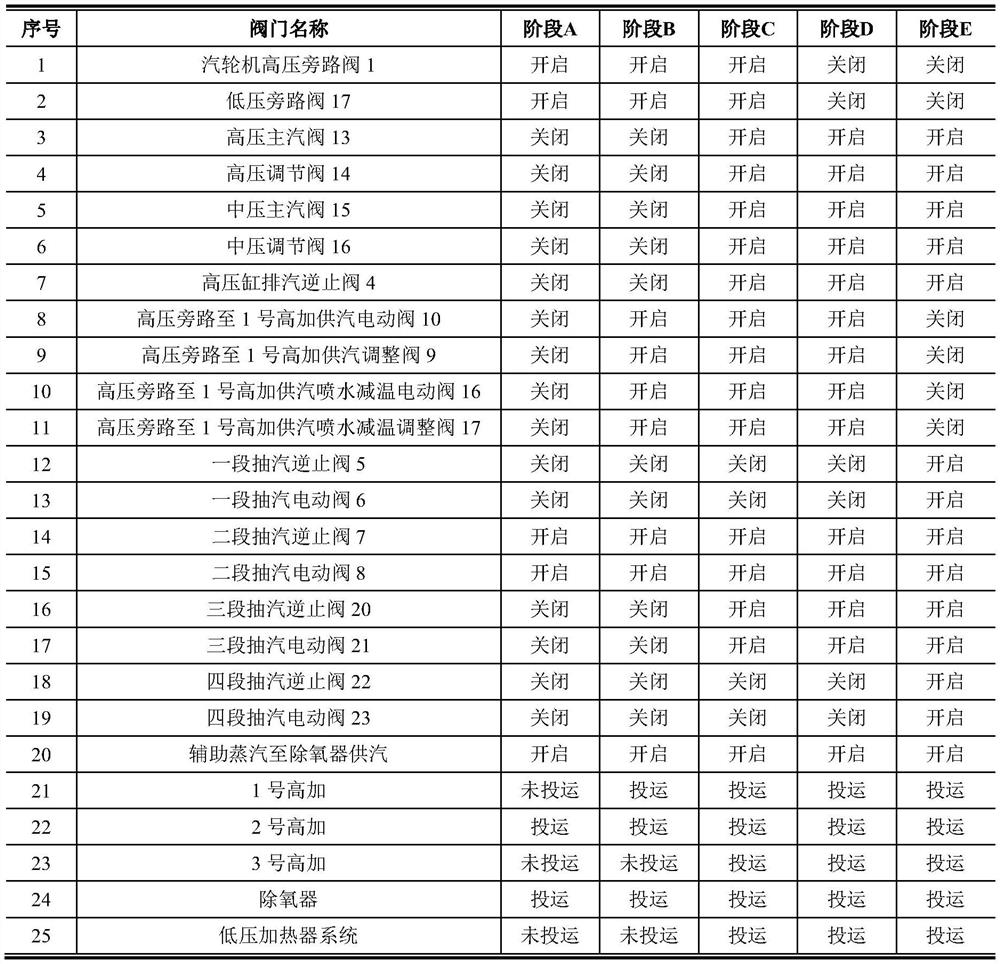

Coal economizer water temperature adjusting system under full-load denitration working condition

The invention discloses a coal economizer water temperature adjusting system under the full-load denitration working condition. The coal economizer water temperature adjusting system comprises a turbine high pressure cylinder, a first high pressure heater, a coal economizer, a boiler and a steam increasing machine, wherein the first-section steam extracting pipeline of the turbine high pressure cylinder is connected with the steam side of the first high pressure heater; the high pressure steam inlet of the steam increasing machine is connected with the high temperature steam pipeline of the boiler; the low pressure steam inlet of the steam increasing machine is connected with the first-section steam extracting pipeline of the turbine high pressure cylinder; the mixed steam outlet of the steam increasing machine is connected with the steam side of the first high pressure heater; and boiler feedwater passes through the first high pressure heater and enters the coal economizer after beingheated and warmed by steam. The coal economizer water temperature adjusting system is small in transforming workload and low in cost; and under high load or low load of a unit, an SCR denitration device effectively runs.

Owner:UNI RISING BEIJING TECH CO LTD

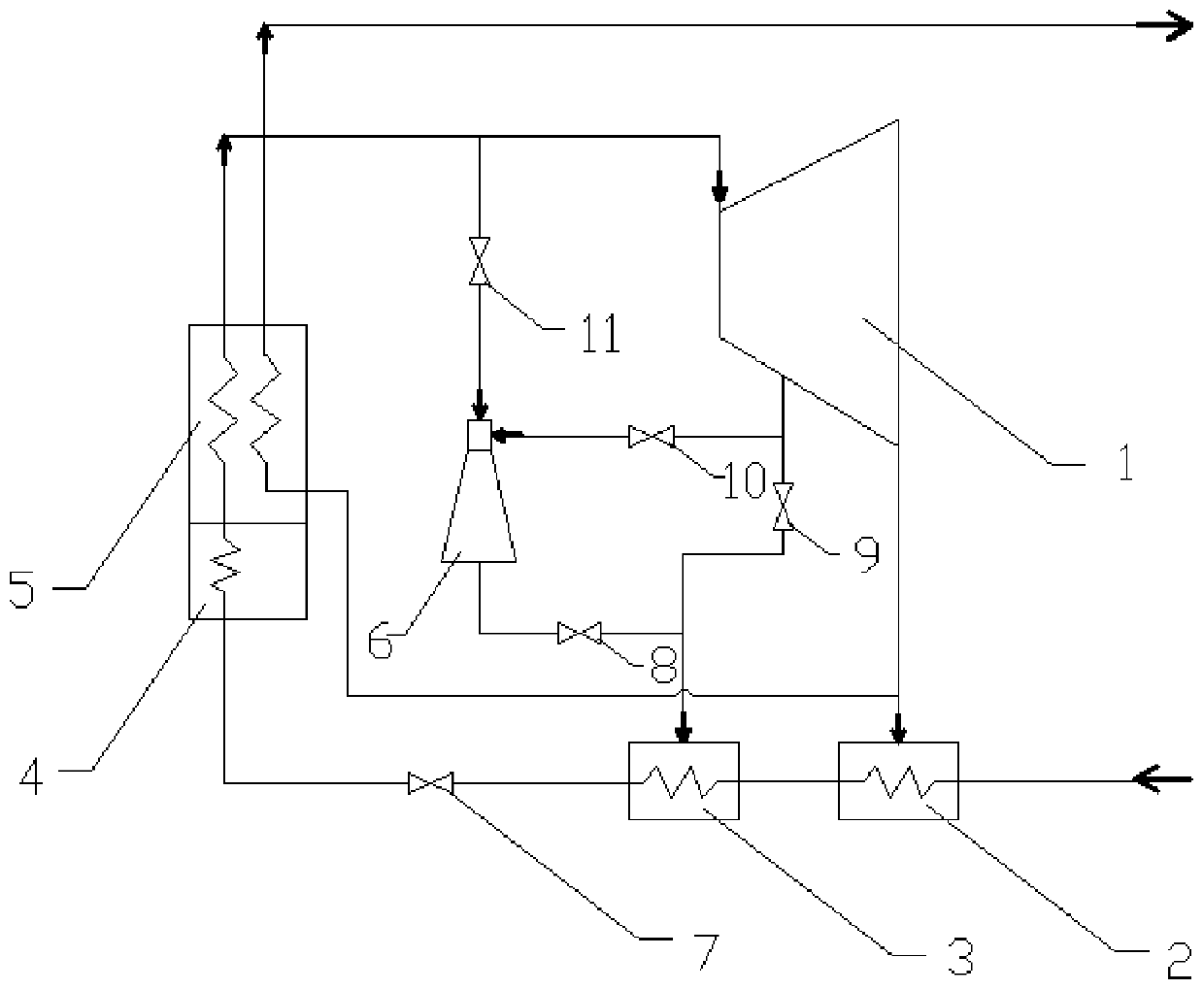

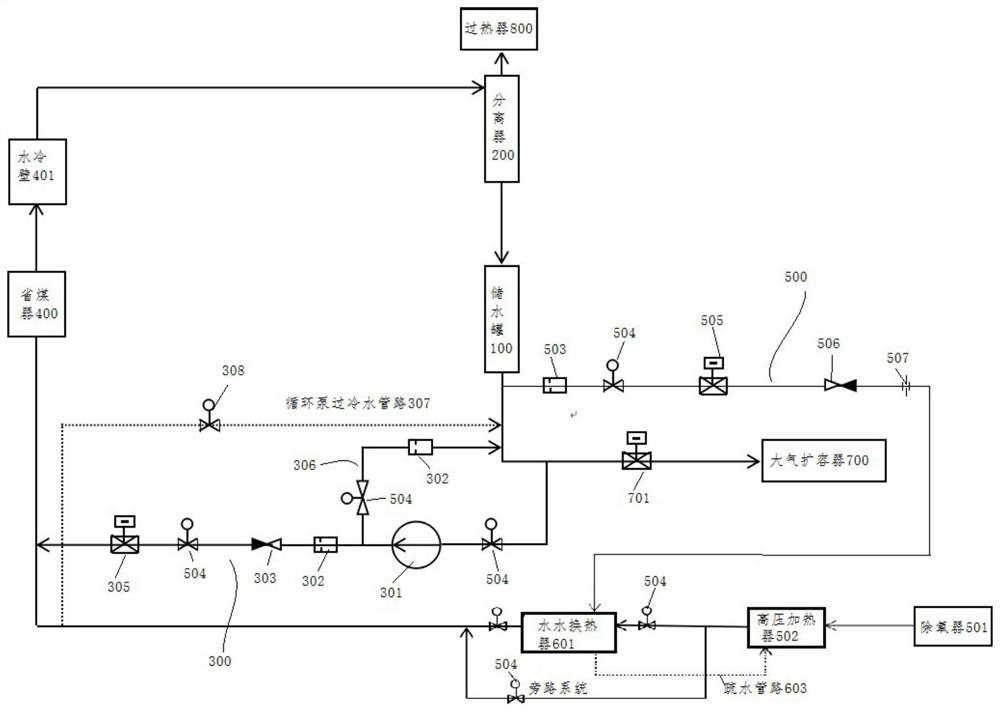

Dry and wet state undisturbed switching system suitable for supercritical unit in deep peak regulation state and control method

ActiveCN113864849ASafe and stable operationReduce startup timeLighting and heating apparatusSpace heating and ventilation detailsWater storage tankCirculator pump

The invention provides a dry and wet state undisturbed switching system suitable for a supercritical unit in a deep peak regulation state and a control method. The dry and wet state undisturbed switching system comprises a water storage tank; an outlet is connected with a T-connector; an inlet is communicated with the outlet of a separator; a hot water circulation system is communicated with the outlet of the water storage tank and is configured to circulate saturated water in the water storage tank to an inlet of an economizer by adopting a hot water circulation pump; then the saturated water flows through a water cooling wall to reach the separator to realize working medium recirculation; a water level fine adjustment system for the water storage tank comprises a deaerator and a high-pressure heater which are communicated with the outlet of the water storage tank, and is used for leading saturated water of the water storage tank into the deaerator; and the saturated water is heated by the high-pressure heater, circulated to the economizer and the water cooling wall and then reaches the separator. According to the switching system, flexible conversion of a dry state and a wet state of the unit and long-period flexible peak regulation of 20%-100% load of the supercritical unit can be achieved; safe and stable operation of the unit is guaranteed; starting time and working medium and heat emission are reduced in the starting stage of the unit; and effective heat recovery is achieved.

Owner:欧博源科技(北京)有限公司

Waste heat recovery system of phase change heat exchanger in thermal power generation enterprise

InactiveCN111288480AEmission reductionGood energy recoveryEmission preventionIndirect heat exchangersAir preheaterBoiler (power generation)

The invention belongs to the technical field of waste heat recovery of thermal power generation, and particularly relates to a waste heat recovery system of a phase change heat exchanger in a thermalpower generation enterprise. The waste heat recovery system comprises an air preheater, a dust remover, an induced draft fan, a desulfurization tower and a fan heater, the air preheater, the dust remover, the induced draft fan and the desulfurization tower sequentially communicate through pipelines, an air outlet of the fan heater communicates with an air inlet of the air preheater, and an air outlet of the air preheater is connected with a flue gas cooler through a pipeline, an air outlet of the flue gas cooler communicates with an air inlet of the dust remover, and an air outlet of the desulfurization tower is provided with a flue gas reheater. According to the waste heat recovery system, pollution emission can be effectively reduced, a heat exchanger after desulfurization can be added on a heat supply secondary water return side or a condensation water side, a good energy recovery effect can be achieved, waste heat can be further utilized to heat only cold air of a boiler, smoke temperature of an air preheater outlet is improved, and the utilization efficiency of thermal power generation energy is greatly improved.

Owner:天津博帆科技发展有限公司

Economizer improving SCR commissioning rate under low load working condition

The invention discloses an economizer improving the SCR commissioning rate under the low load working condition. A water supply pipeline of an inlet of the economizer is provided with a by-pass. A by-pass pipeline is connected with a middle header of the economizer. The by-pass is sequentially provided with a one-way valve, a throttling valve and a flow adjusting valve in the medium flowing direction. According to the economizer, the opening degree of a by-pass valve is adjusted under the low load condition so as to reduce medium flow between an inlet header and the middle header of the economizer in a boiler, the heat output of the smoke side of the economizer can be reduced, the smoke temperature of an outlet of the economizer rises, and the commissioning rate of a power plant SCR under the low load condition can be effectively improved; the catalyst activity of the SCR is promoted due to rising of the temperature of an SCR system, the SCR system obtains the higher denitration capacity, and therefore a power plant can meet the environmental protection index requirement better over a much longer time period.

Owner:SOUTHEAST UNIV

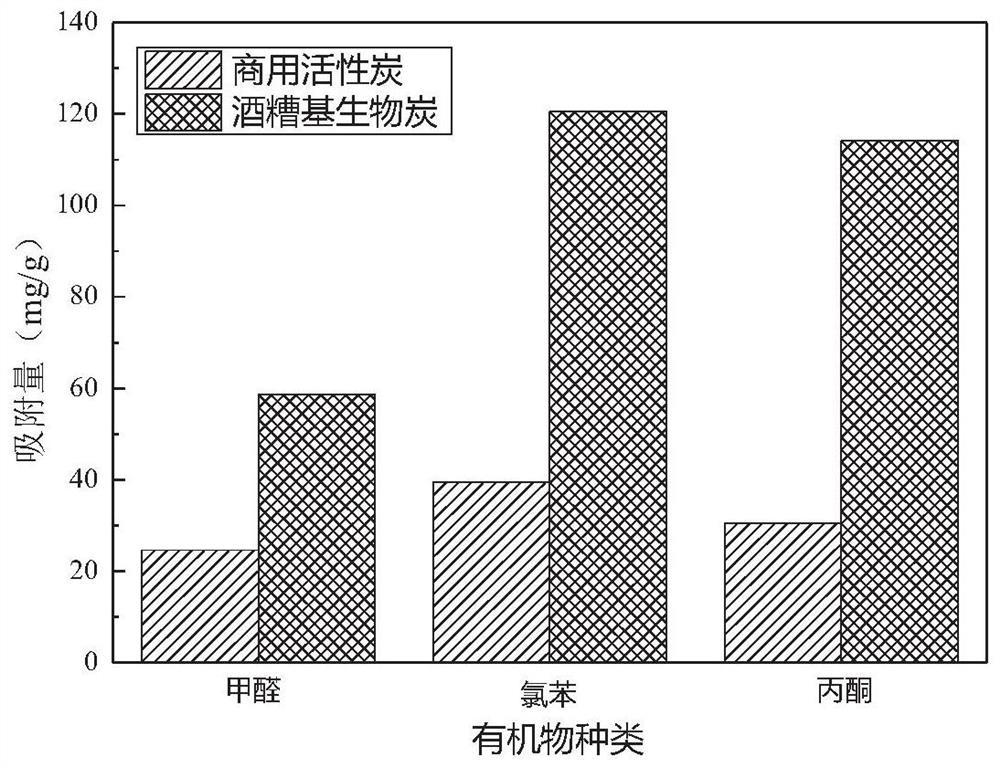

Distiller's grains-based biochar for adsorbing multi-component organic pollutants and preparation method thereof

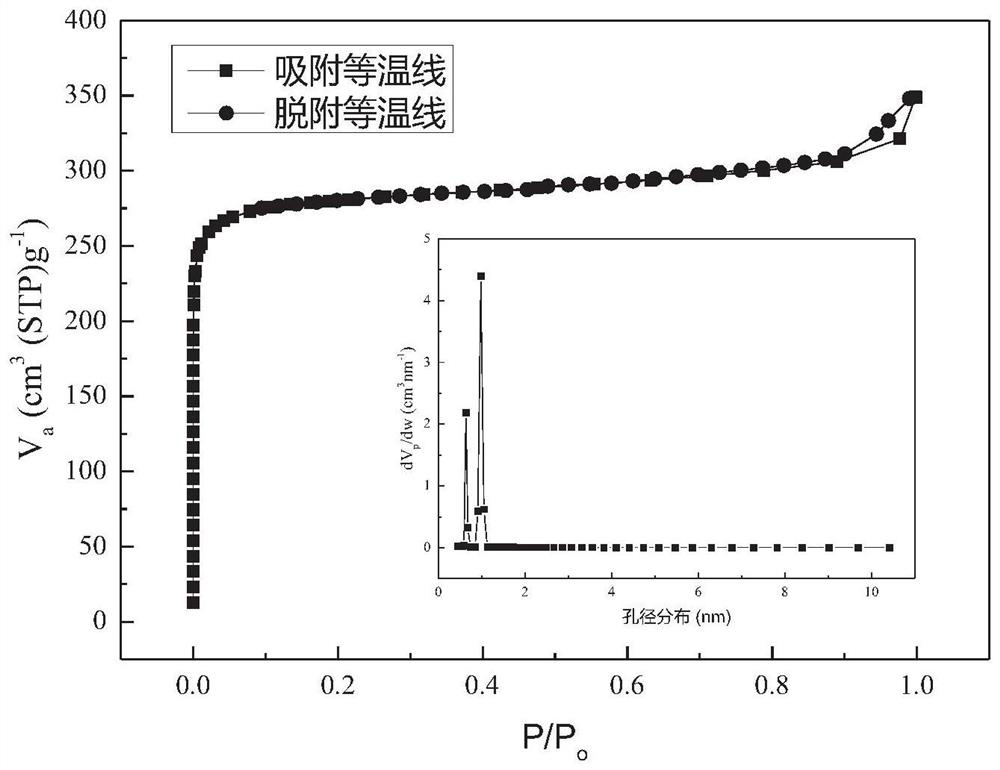

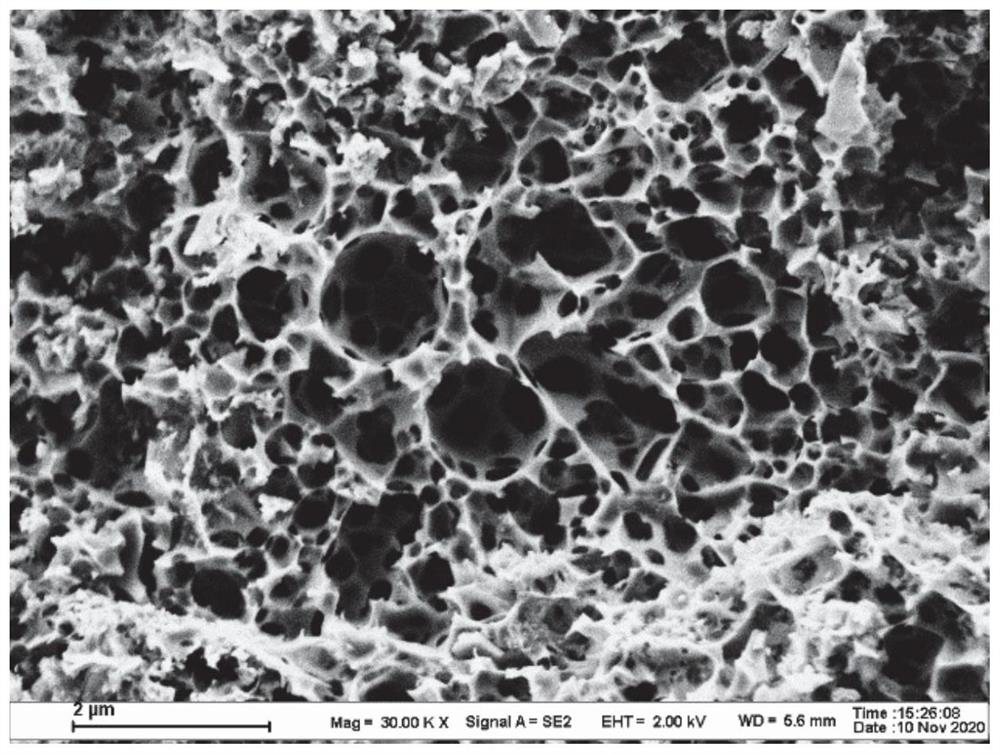

ActiveCN113231013BReduce dosageRaw materials are cheap and easy to getOther chemical processesDispersed particle separationAlkaline earth metalWastewater

The invention relates to a distiller's grains-based biochar for adsorbing multi-component organic pollutants and a preparation method thereof. Waste industrial distiller's grains and desulfurization wastewater from coal-fired power plants are used as raw materials, and the waste industrial distiller's grains are pretreated to obtain dry distiller's grains with distiller's grain raw material of a certain mesh number; mixing the distiller's grain raw material with an alkaline activator, and obtaining a preliminary activated distiller's grain-based biochar after high-temperature activation, cooling, and pickling; Distiller's grains-based biochar whose surface is modified by alkali metal ions, alkaline earth metal ions, transition metal ions, and acid radical ions in the desulfurization wastewater by immersing, filtering, and drying in power plant desulfurization wastewater; the distiller's grains-based biochar obtained in the above steps are inert Calcined under gas atmosphere and cooled to room temperature to obtain the final distiller's grains-based biochar with high-efficiency adsorption function. The preparation method is simple, the dosage of the activator is small, the activation temperature is low, and the industrial production is easy.

Owner:SOUTHEAST UNIV

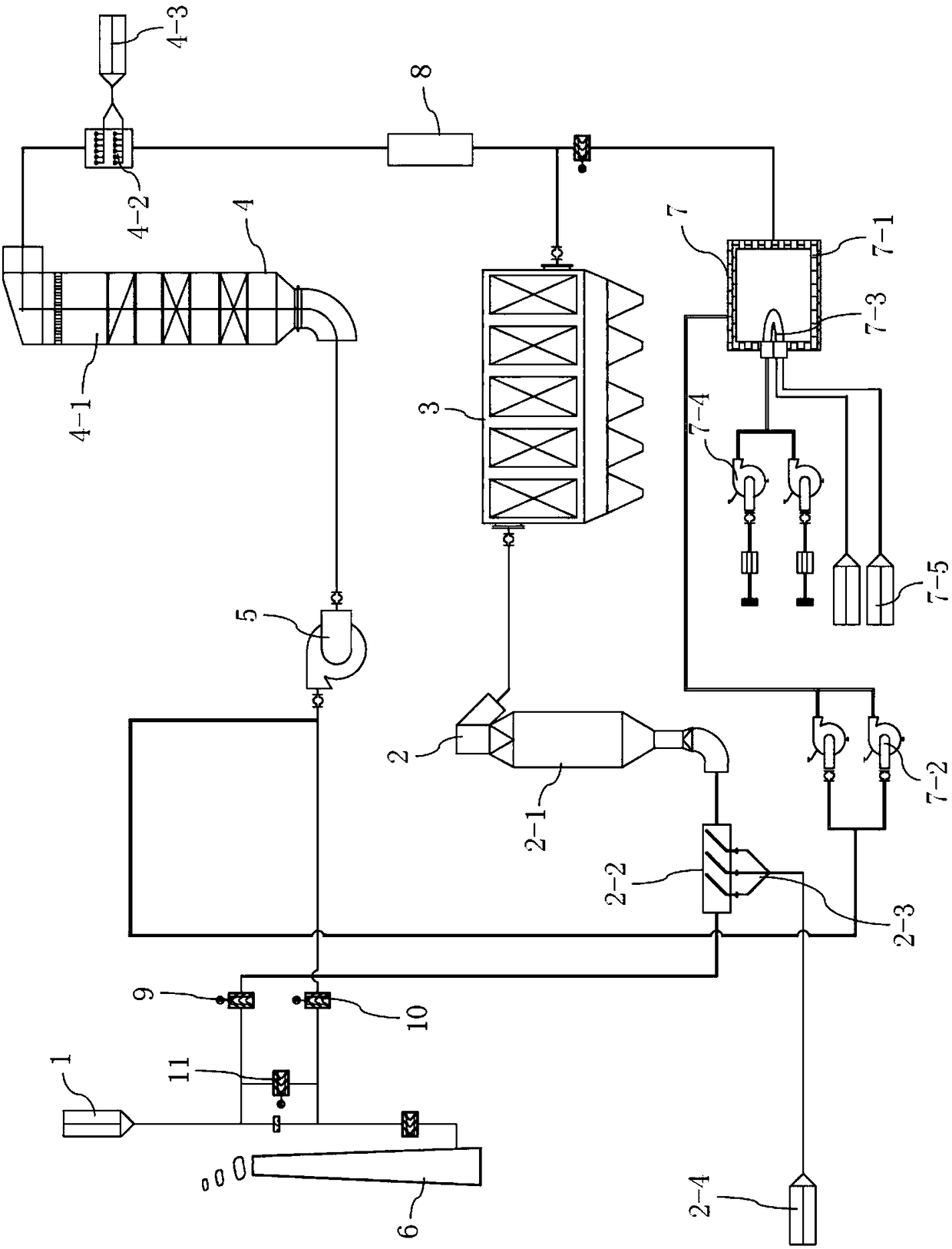

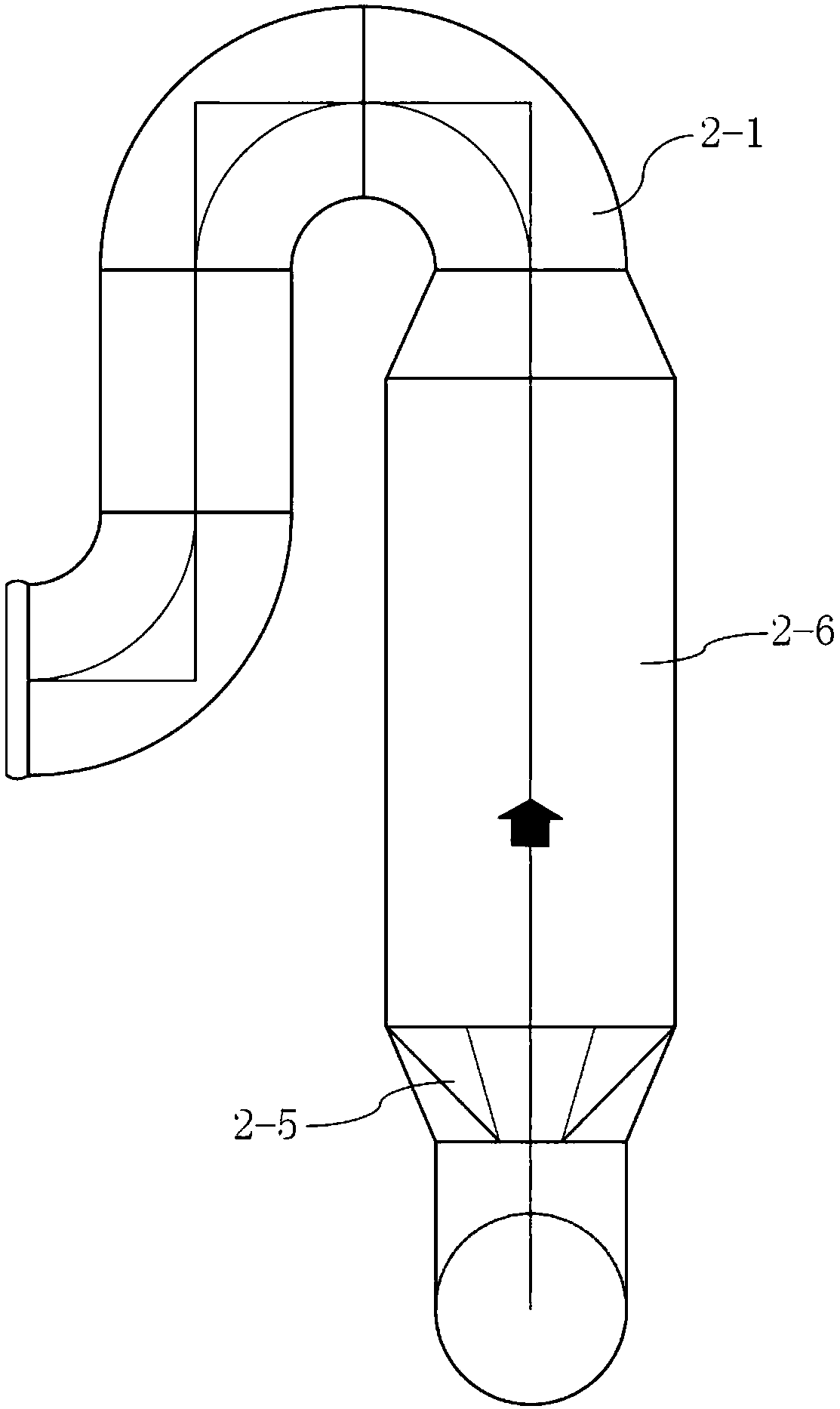

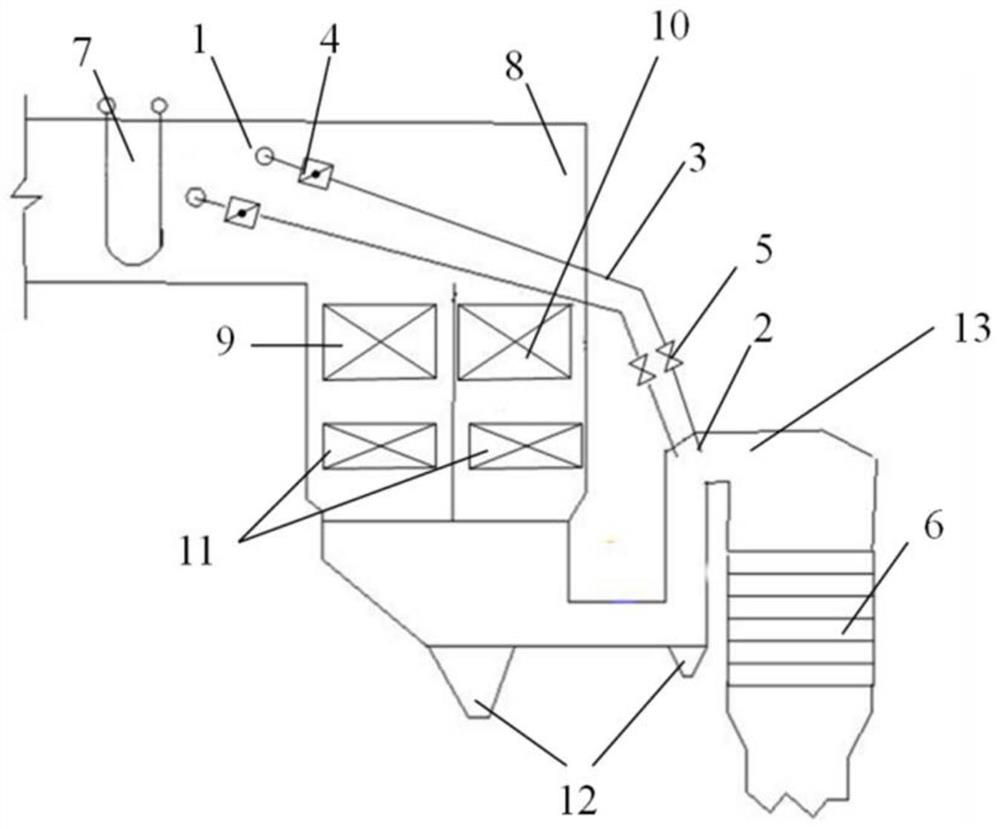

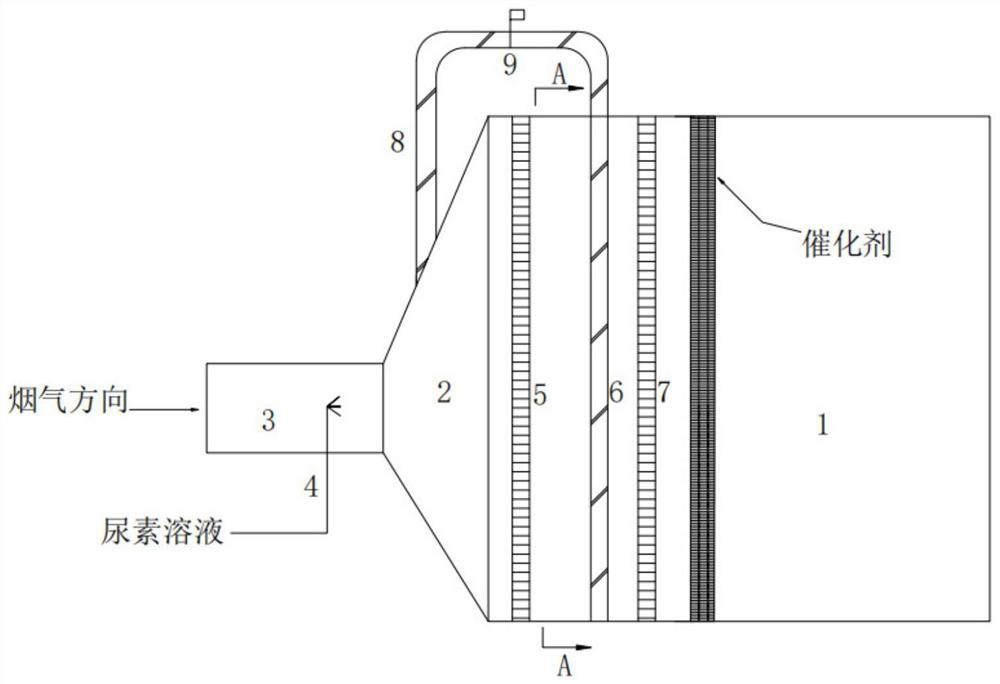

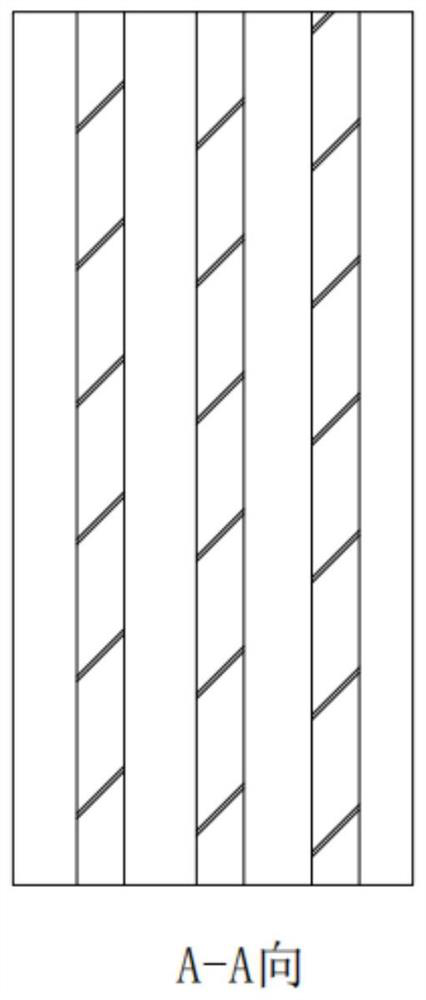

Wide-load gas turbine waste heat boiler denitration system

PendingCN114288851AIncrease smoke temperatureReduce yellow smoke phenomenonDispersed particle separationPtru catalystFlue gas

The invention discloses a wide-load gas turbine waste heat boiler denitration system which is characterized in that a transition flue is communicated with an inlet of a waste heat boiler body through a flared flue, and a first-layer heat exchanger unit, a waste heat boiler inner bypass flue section, a second-layer heat exchanger unit and a catalyst layer are sequentially arranged in the waste heat boiler body in the flue gas flowing direction, a bypass flue section in each waste heat boiler is communicated with an outlet of a diffusion section bypass flue section, an inlet of the diffusion section bypass flue section is communicated with a flared flue, a bypass flue baffle door is arranged on the diffusion section bypass flue section, and a urea solution spray gun is inserted into a transition flue. By means of the system, the smoke temperature of the gas turbine during low-load operation can be effectively increased, and the phenomenon that a chimney emits yellow smoke is reduced.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD

Temperature regulating system and method for increasing inlet flue gas temperature of SCR denitrification device

ActiveCN106540540ASimple structureEasy to transformDispersed particle separationNitrogen oxidesLow load

The invention belongs to the technical field of coal-fired boiler environment protection and particularly relates to a temperature regulating system and a method for increasing the inlet flue gas temperature of an SCR denitrification device. The temperature regulating system is simple in structure, easy to transform, easy to operate during operation and high in reliability. The method includes: when a boiler operates at low load, a heat exchanger outlet electric valve is completely opened, and the openness of a heat exchanger inlet valve is slowly regulated according to the previous flue gas temperature measuring point reading of the SCR denitrification device. The temperature regulating system is applied to the technical field of coal-fired boiler environment protection, SCR inlet flue gas temperature can be effectively increased, the discharge amount of nitrogen oxide of boiler flue gas can be lowered, and environment protection is achieved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

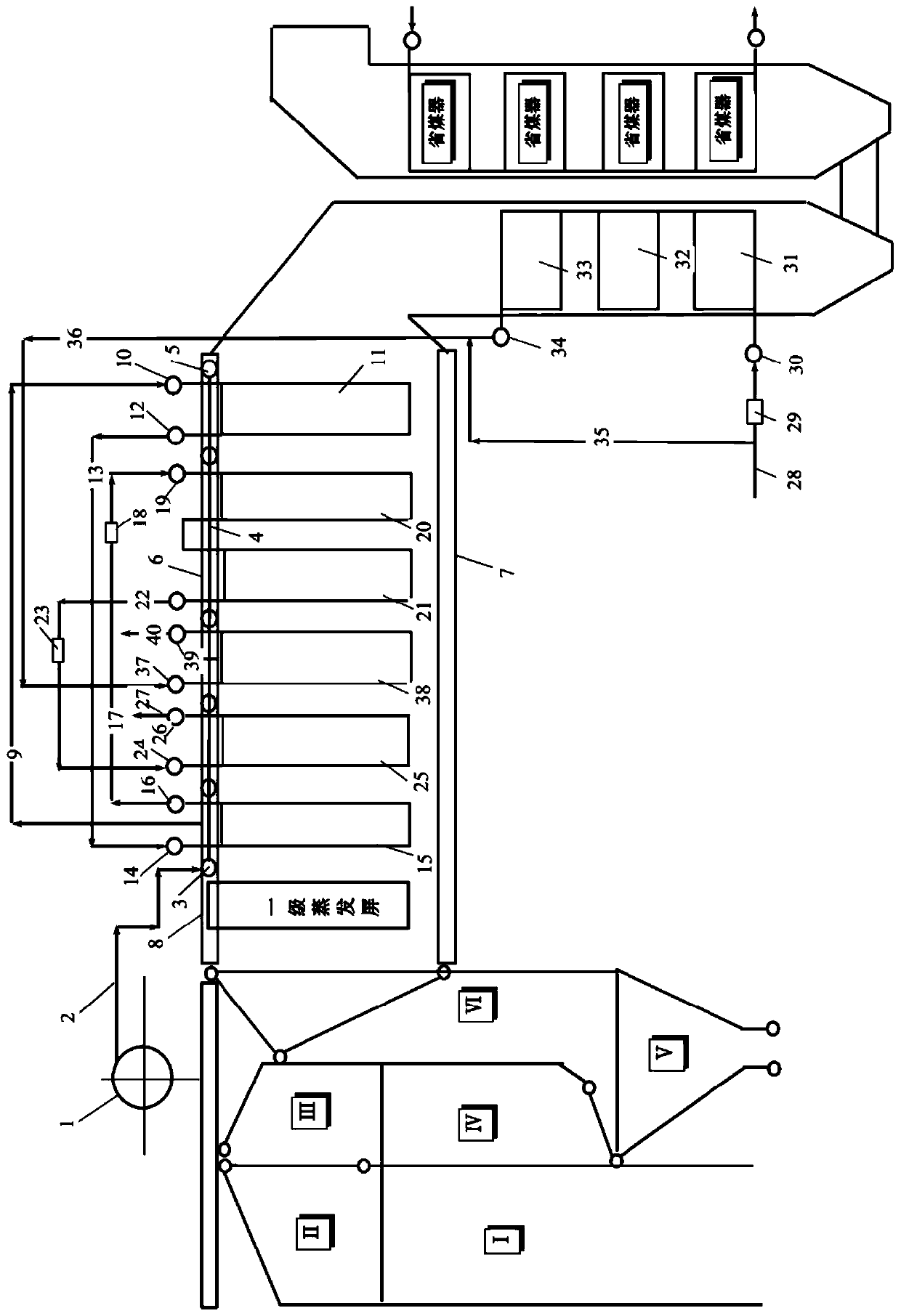

Air preheating system and air preheating method for comprehensive waste heat utilization with separate control phase change

ActiveCN106969373BImprove the benefits of waste heat recovery and utilizationAvoid corrosionCombustion processIndirect carbon-dioxide mitigationAir preheaterFlue gas

The invention discloses a respective-control phase change comprehensive waste heat utilization air preheating system and method. The system comprises an air preheater (33), an air preheater front air way (31), an air preheater rear flue (32), a condensate water main pipe (11), a steam main pipe (15), an air heater (28), a flue gas phase change cooler (12), a flue gas water cooler (7), a phase change water heater (17), a condensate water regulating valve (30), a steam flow regulating valve (14) and a liquid flow pipe (5). By means of the respective-control phase change comprehensive waste heat utilization air preheating system and method, a respective-control phase change heat exchange manner is adopted in a final-stage flue gas waste heat recovery heat exchanger, the final-stage flue gas waste heat recovery heat exchanger is combined with a condensate water air heater and a high-temperature flue gas cooler, and waste heat recovery benefits are improved.

Owner:SHANXI SANHESHENG IND TECH

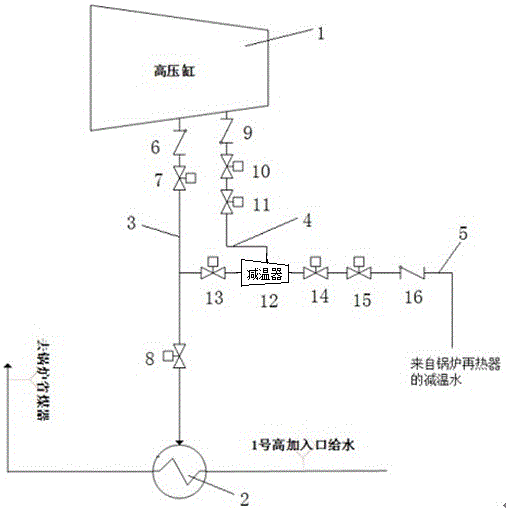

Method and device for increasing water feed temperature at medium loads and low loads of steam turbine set

InactiveCN106050337AIncrease feed water temperatureIncrease smoke temperatureSteam engine plantsLow loadEconomic benefits

The invention discloses a method and device for increasing the water feed temperature at medium loads and low loads of a steam turbine set. A new zero-extraction steam extraction heat regeneration module is additionally installed in front of a steam extraction point, is guided out from the new steam extraction point and is connected to an original steam extraction pipe section, when the unit load is lowered to a certain degree (about 35%-40%), the SCR entrance smoke temperature is lower than 310 DEG C and denitration commissioning is difficult, the steam extraction operation is switched into the newly-arranged steam extraction operation, the water feed temperature at an outlet of a first high-pressure heater can be increased through the new steam extraction module, the circulation heat efficiency can be improved, further the coal consumption can be reduced, the denitration inlet smoke temperature at the low loads is increased, a denitration system can be operated at high efficiency at full-load sections, the environmental requirement is met, the denitration cost is lowered, and the economic benefit and the environmental protection benefit are remarkable.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

Respective-control phase change comprehensive waste heat utilization air preheating system and method

ActiveCN106969373AImprove the benefits of waste heat recovery and utilizationAvoid corrosionCombustion processIndirect carbon-dioxide mitigationFlueProcess engineering

The invention discloses a respective-control phase change comprehensive waste heat utilization air preheating system and method. The system comprises an air preheater (33), an air preheater front air way (31), an air preheater rear flue (32), a condensate water main pipe (11), a steam main pipe (15), an air heater (28), a flue gas phase change cooler (12), a flue gas water cooler (7), a phase change water heater (17), a condensate water regulating valve (30), a steam flow regulating valve (14) and a liquid flow pipe (5). By means of the respective-control phase change comprehensive waste heat utilization air preheating system and method, a respective-control phase change heat exchange manner is adopted in a final-stage flue gas waste heat recovery heat exchanger, the final-stage flue gas waste heat recovery heat exchanger is combined with a condensate water air heater and a high-temperature flue gas cooler, and waste heat recovery benefits are improved.

Owner:SHANXI SANHESHENG IND TECH

Flue gas dehumidification system

PendingCN111911947AEnhanced Diffusion Dilution CapabilitiesLower exhaust gas temperatureLighting and heating apparatusArtificial lifeAir preheaterFlue gas

The converged flue gas sequentially passes through the rotary flue gas heat exchanger, the dust remover, the low-temperature water medium type flue gas heat exchanger and the desulfurizing tower to obtain desulfurized flue gas; and the desulfurized flue gas sequentially passes through the low-temperature water medium type flue gas heat exchanger, the rotary type flue gas heat exchanger, the high-temperature water medium type flue gas heat exchanger and the composite type flue gas heater to be conveyed to an external chimney. According to the flue gas dehumidification system, full gradient utilization of flue gas waste heat can be achieved, the efficiency can be improved, and the flue gas dehumidification effect of a unit can be improved. The invention belongs to the technical field of environmental protection, and discloses a flue gas dehumidification system. The flue gas dehumidification system comprises an air preheater, a high-temperature water medium type flue gas heat exchanger, arotary flue gas heat exchanger, a dust remover, a low-temperature water medium type flue gas heat exchanger, a desulfurizing tower and a composite flue gas heater; boiler flue gas comprises main fluegas and bypass flue gas, and the main flue gas passes through the air preheater and then is converged with the bypass flue gas passing through the high-temperature water medium type flue gas heat exchanger to obtain converged flue gas;.

Owner:HANDAN COLLEGE

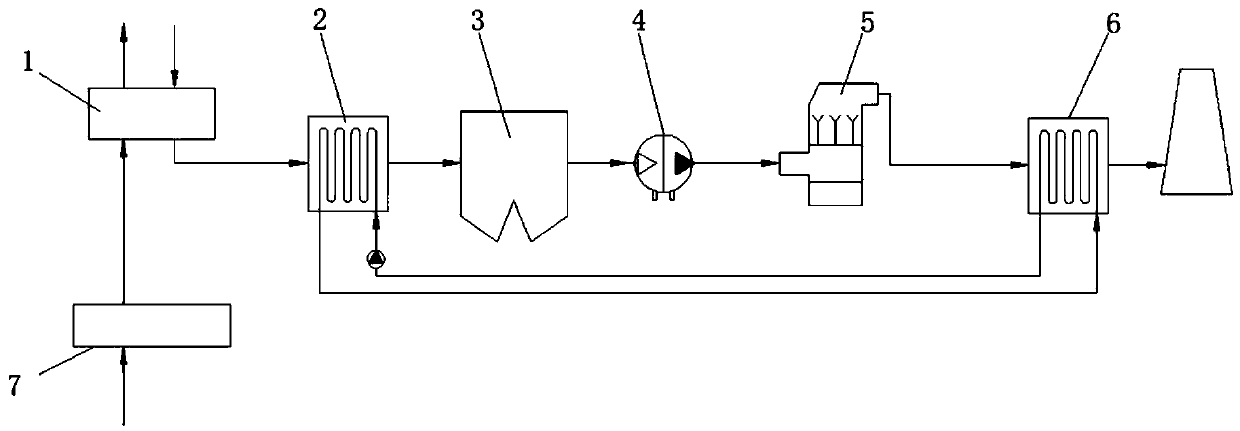

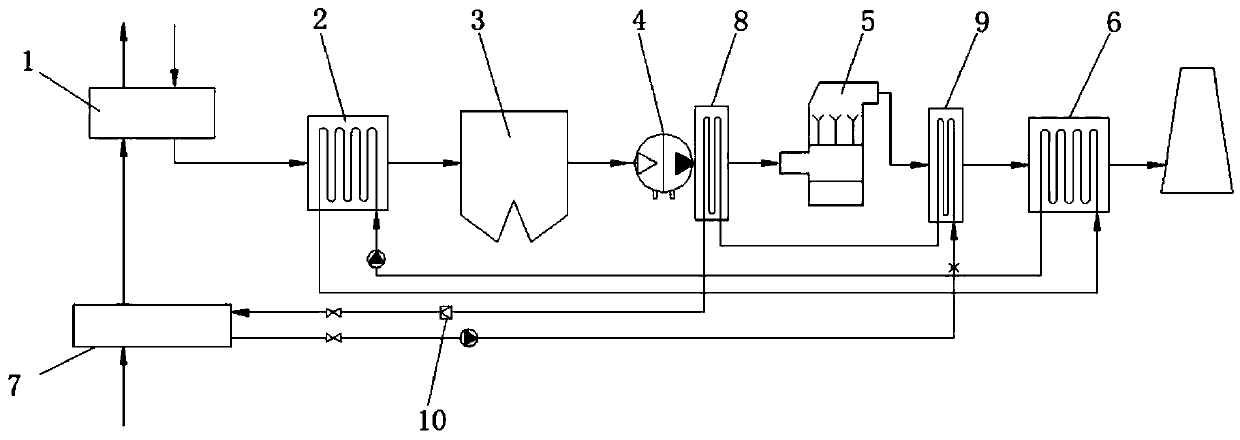

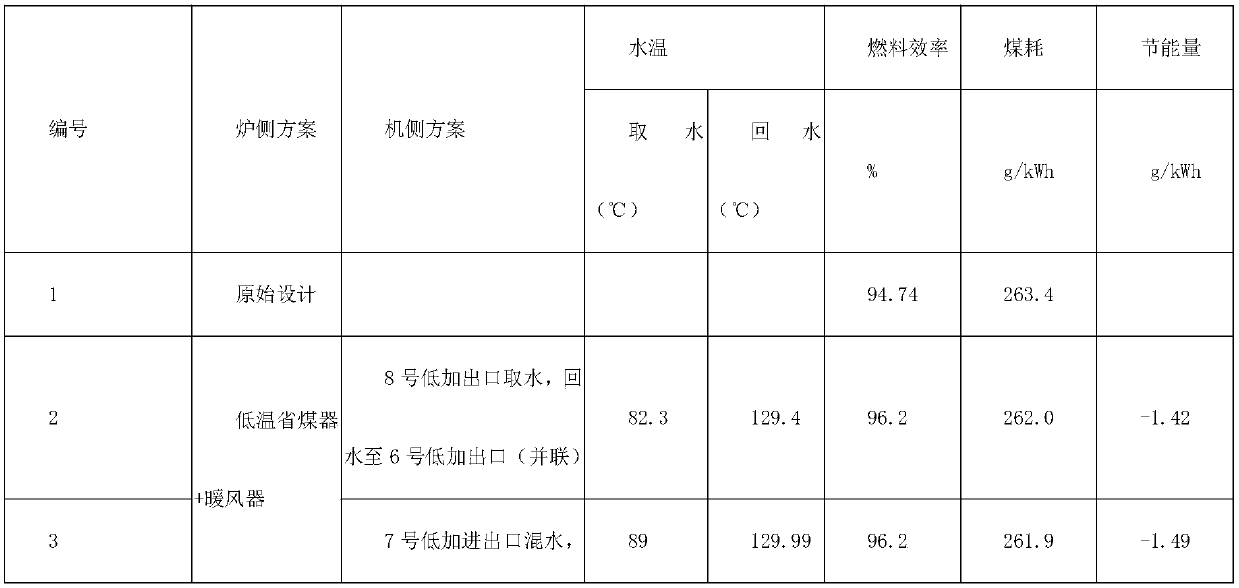

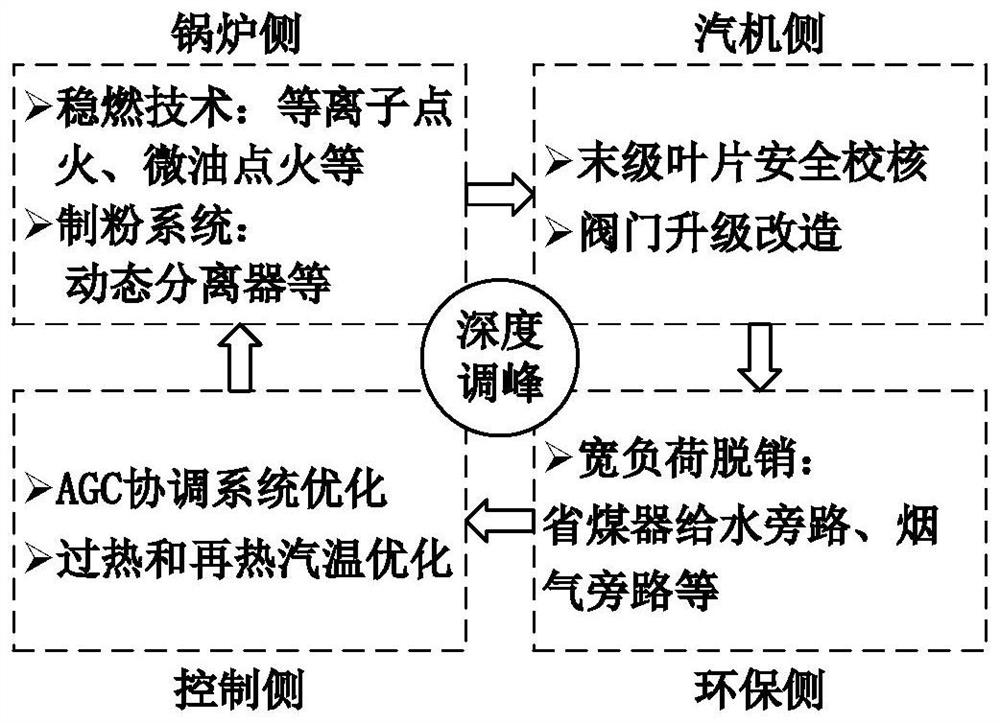

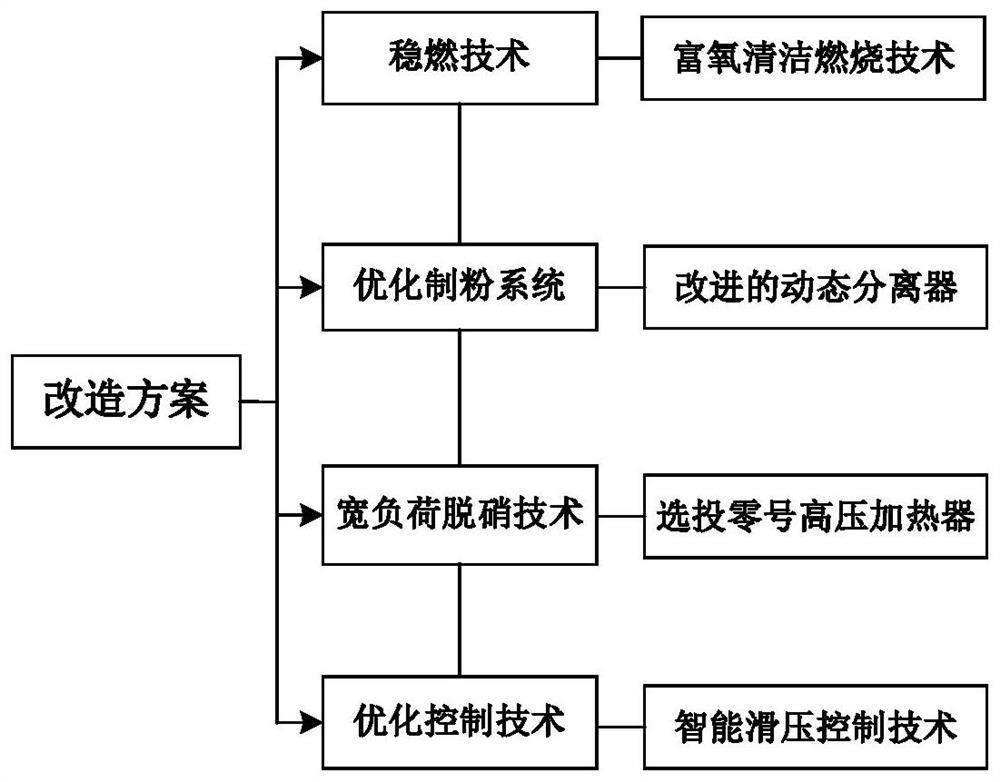

Flexiblity-oriented deep peak regulation transformation scheme for straight condensing unit

InactiveCN113310045AIncrease flexibilitySolve the problem of low-load operation adaptabilitySteam/vapor condensersPulverulent fuel combustion burnersThermodynamicsEngineering

The invention discloses a flexibility-oriented deep peak regulation transformation scheme for a straight condensing unit. The flexibility-oriented deep peak regulation transformation scheme for the straight condensing unit comprises the steps of S1, designing a transformation scheme from four aspects of a stable combustion technology, coal pulverizing system optimization, a wide-load denitration technology and a control optimization technology by analyzing characteristics and a transformation target of the straight condensing unit; S2, applying an oxygen-enriched clean stable combustion technology to realize low-load operation stable combustion and low NOx emission; S3, applying an improved dynamic separator to a coal pulverizing system to improve the combustion quality; S4, putting a zero high-pressure heater into the low-load operation state to increase the smoke temperature of an inlet of a denitration system and then to realize low-load denitration; and S5, dynamically adjusting the change rate of a sliding pressure given value through an intelligent sliding pressure control technology to optimize control. According to the flexibility-oriented deep peak regulation transformation scheme for the straight condensing unit, a good reference is provided for flexible transformation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com