Method and device for increasing water feed temperature at medium loads and low loads of steam turbine set

A technology for steam turbine unit and feed water temperature, which is applied in steam engine installations, mechanical equipment, machines/engines, etc., can solve the problems of small investment, large changes in feed water and steam extraction systems, etc., so as to reduce coal consumption, reduce denitration costs, and meet environmental protection requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

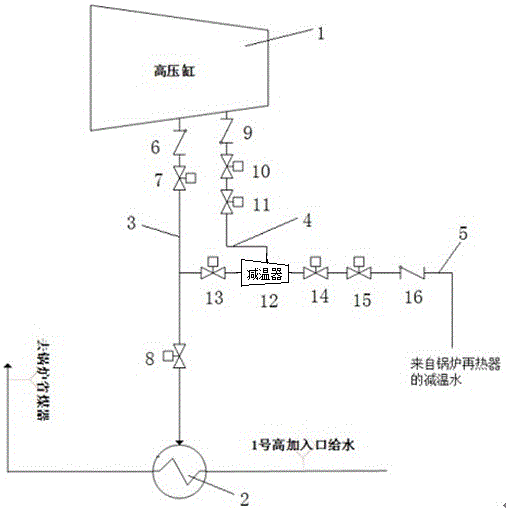

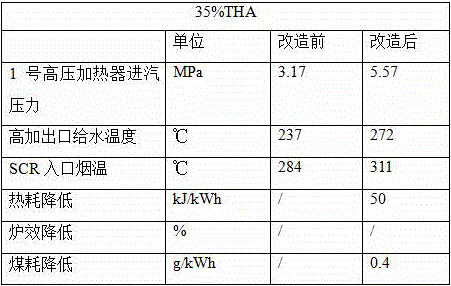

[0020] see figure 1 , a device for increasing the low-load feedwater temperature of a steam turbine unit. It is used on the No. 1 high-pressure heater 2 that maintains the water temperature of the feedwater through a section of steam extraction pipe 3 connected to high-pressure cylinder 1. The section of steam extraction pipe 3 is sequentially installed with a Pumping backstop door 6, one pumping electric door 7 and No. 1 high-pressure heater steam inlet electric main door 8, the device includes zero pumping pipeline 4 and zero pumping backstop door 9 installed on the zero pumping pipeline 4 in sequence, Zero-extraction electric door 10, zero-extraction adjustment door 11, desuperheater 12 and zero-extraction electric main door 13, said high-pressure cylinder 1 is provided with a zero-extraction steam extraction point, and the extraction pressure of said zero-extraction steam extraction point is higher than that of the connected Describe the steam extraction pressure of one se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com