Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

781 results about "Heat regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Separation of carbon dioxide (CO2) from gas mixtures

ActiveUS7618606B2Good repeatabilityMaterial nanotechnologyCombustible gas catalytic treatmentCo2 removalSorbent

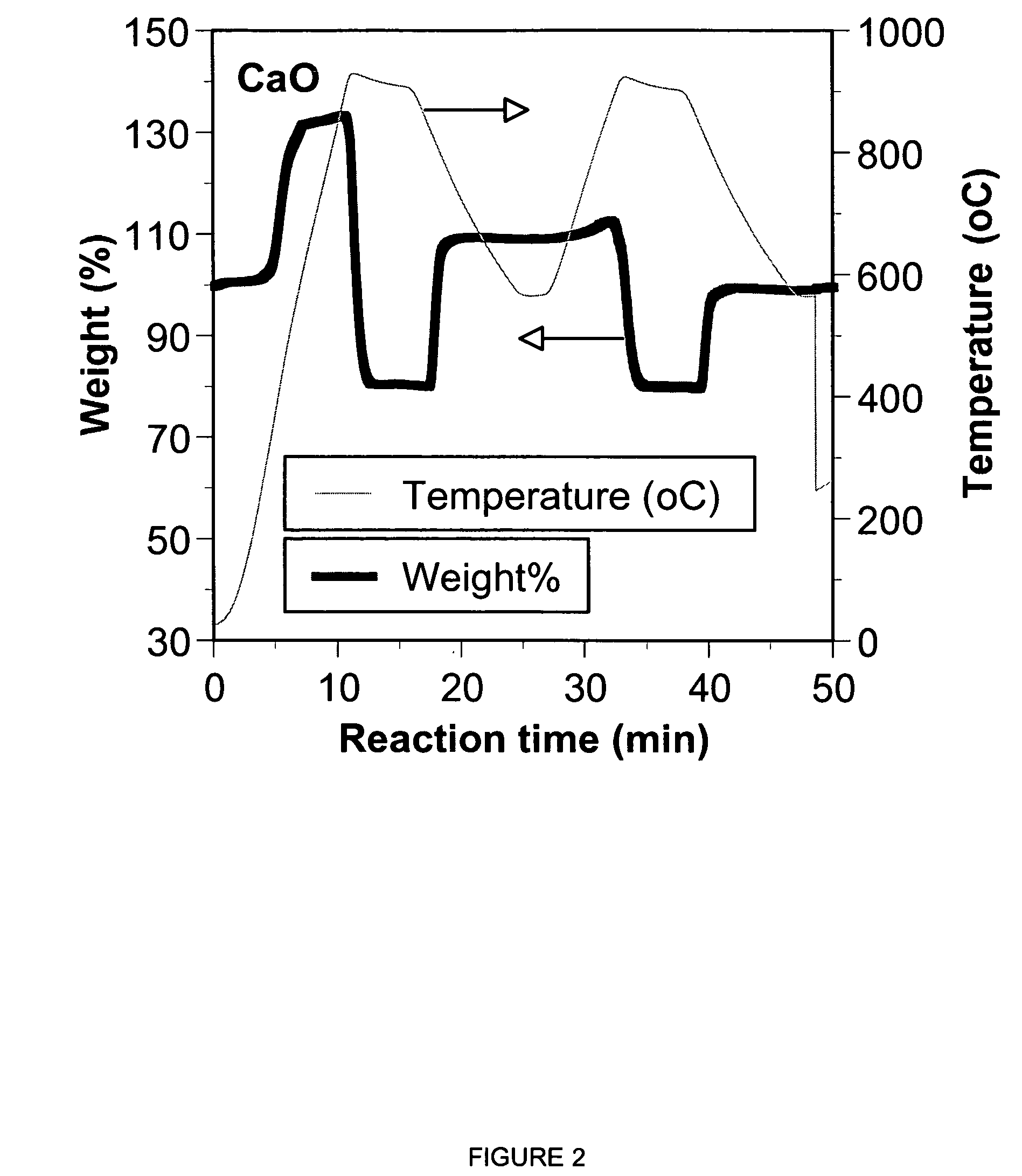

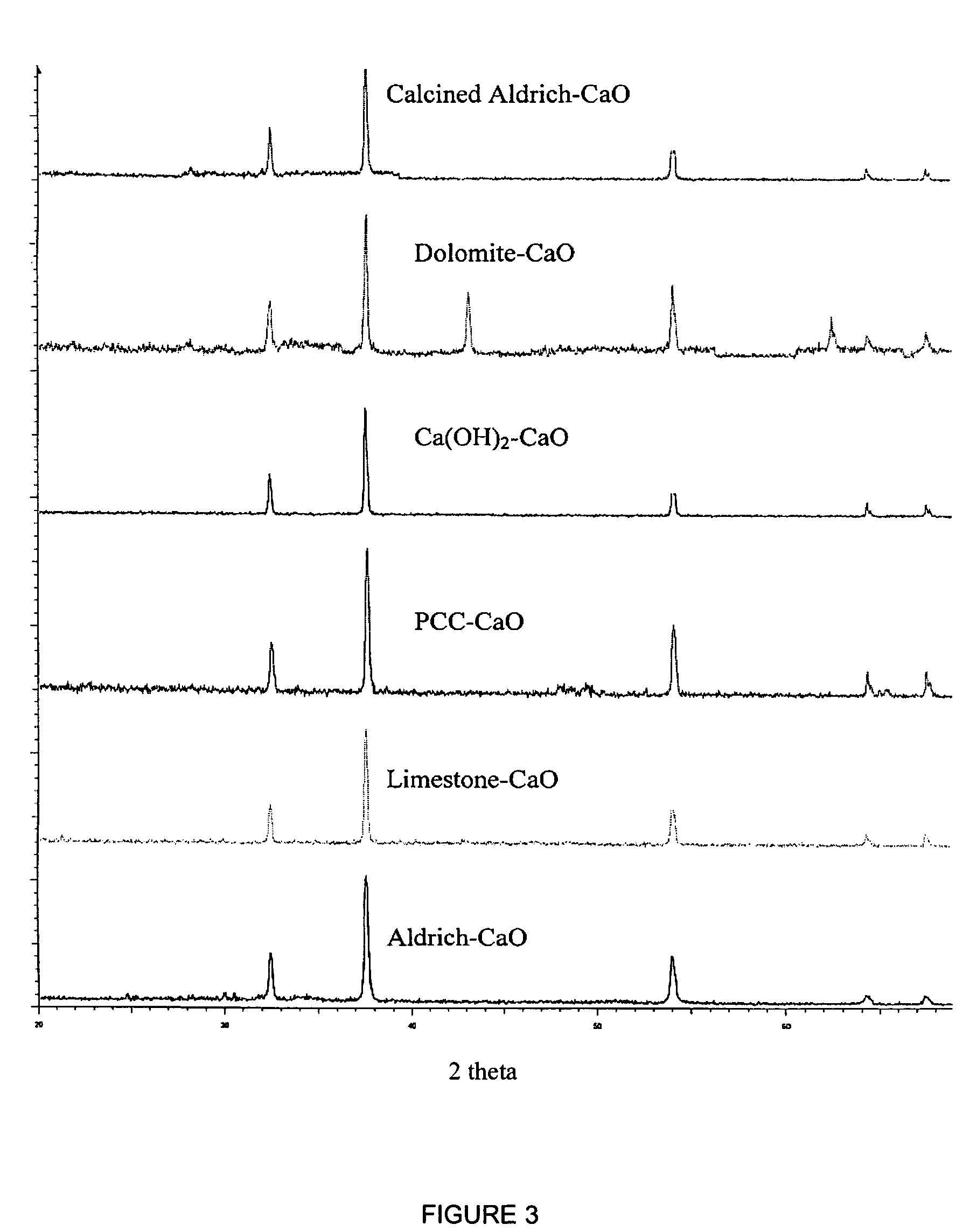

A reaction-based process has been developed for the selective removal of carbon dioxide from a multicomponent gas mixture. The proposed process effects the separation of CO2 from a mixture of gases by its reaction with metal oxides. The Calcium based Reaction Separation for CO2 process consists of contacting a CO2 laden gas with calcium oxide in a reactor such that CaO captures the CO2 by the formation of calcium carbonate. Once “spent”, CaCO3 is regenerated by its calcination leading to the formation of fresh CaO sorbent. The “regenerated” CaO is then recycled for the further capture of more CO2. This process also identifies the application of a mesoporous CaCO3 structure, that attains >90% conversion over multiple carbonation and calcination cycles. Lastly, thermal regeneration (calcination) under vacuum provided a better sorbent structure that maintained reproducible reactivity levels over multiple cycles.

Owner:THE OHIO STATES UNIV

Management of an air purification system with thermal regeneration

InactiveUS6402809B1Reduce amountReduce the amount requiredSolidificationGas treatmentDistillationEngineering

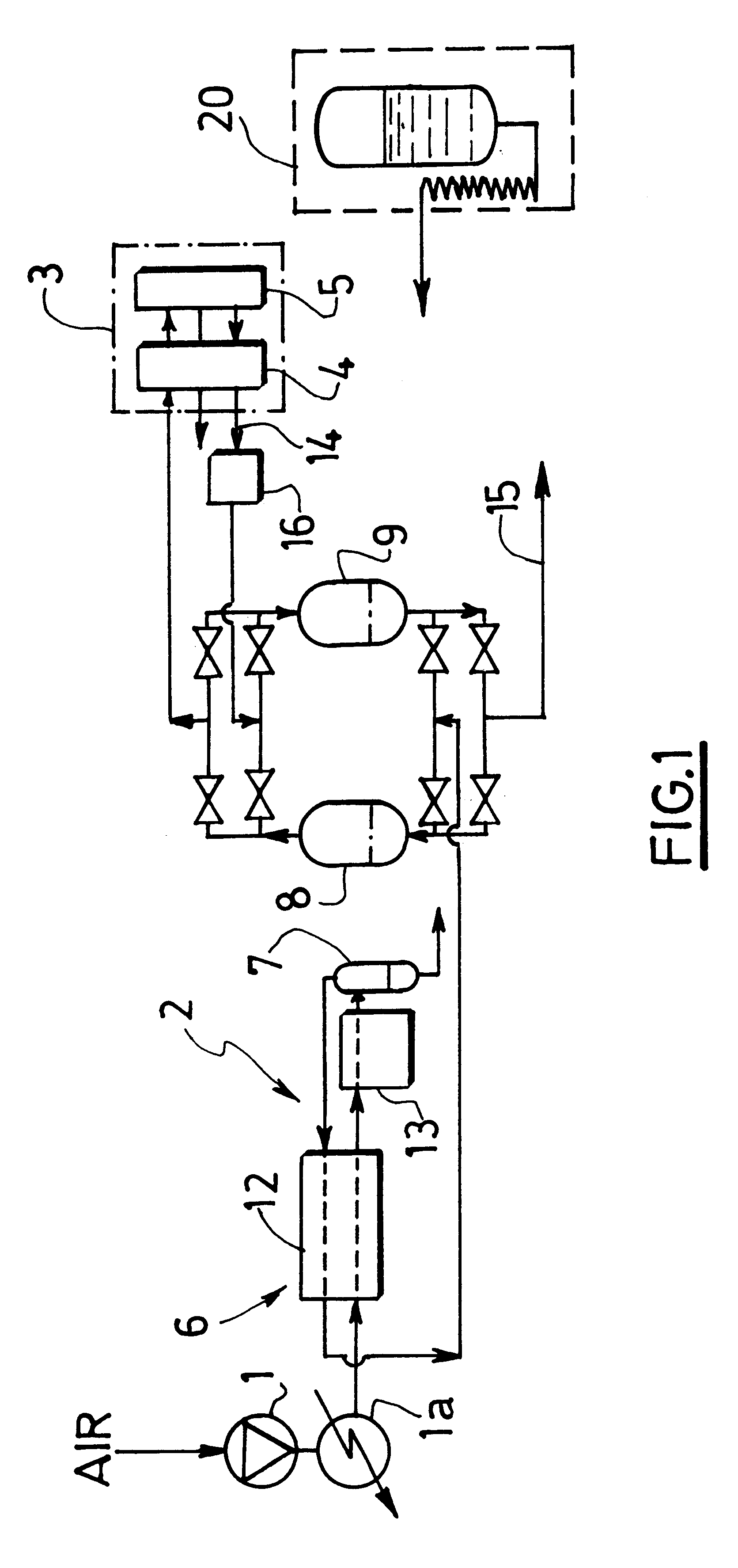

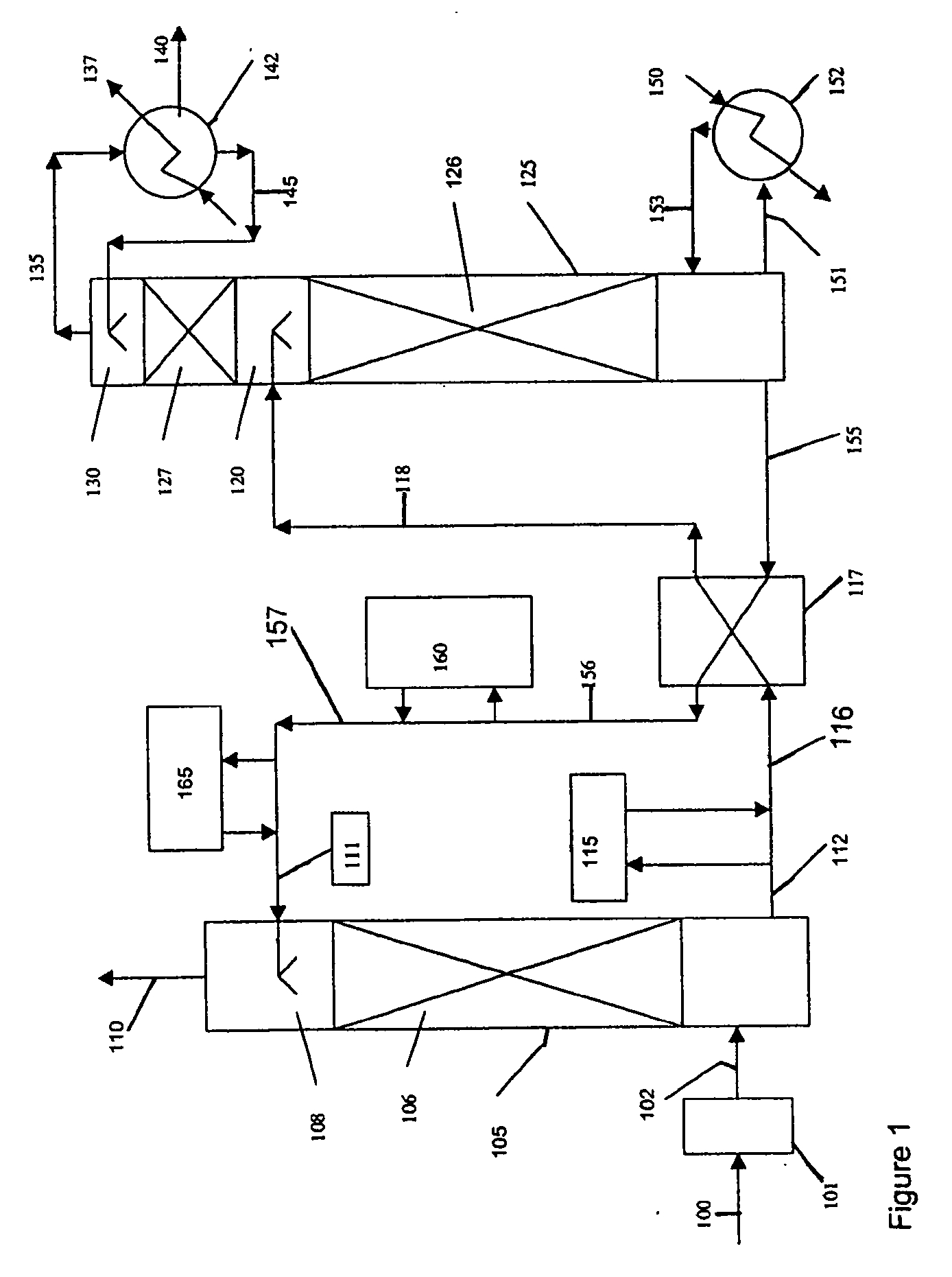

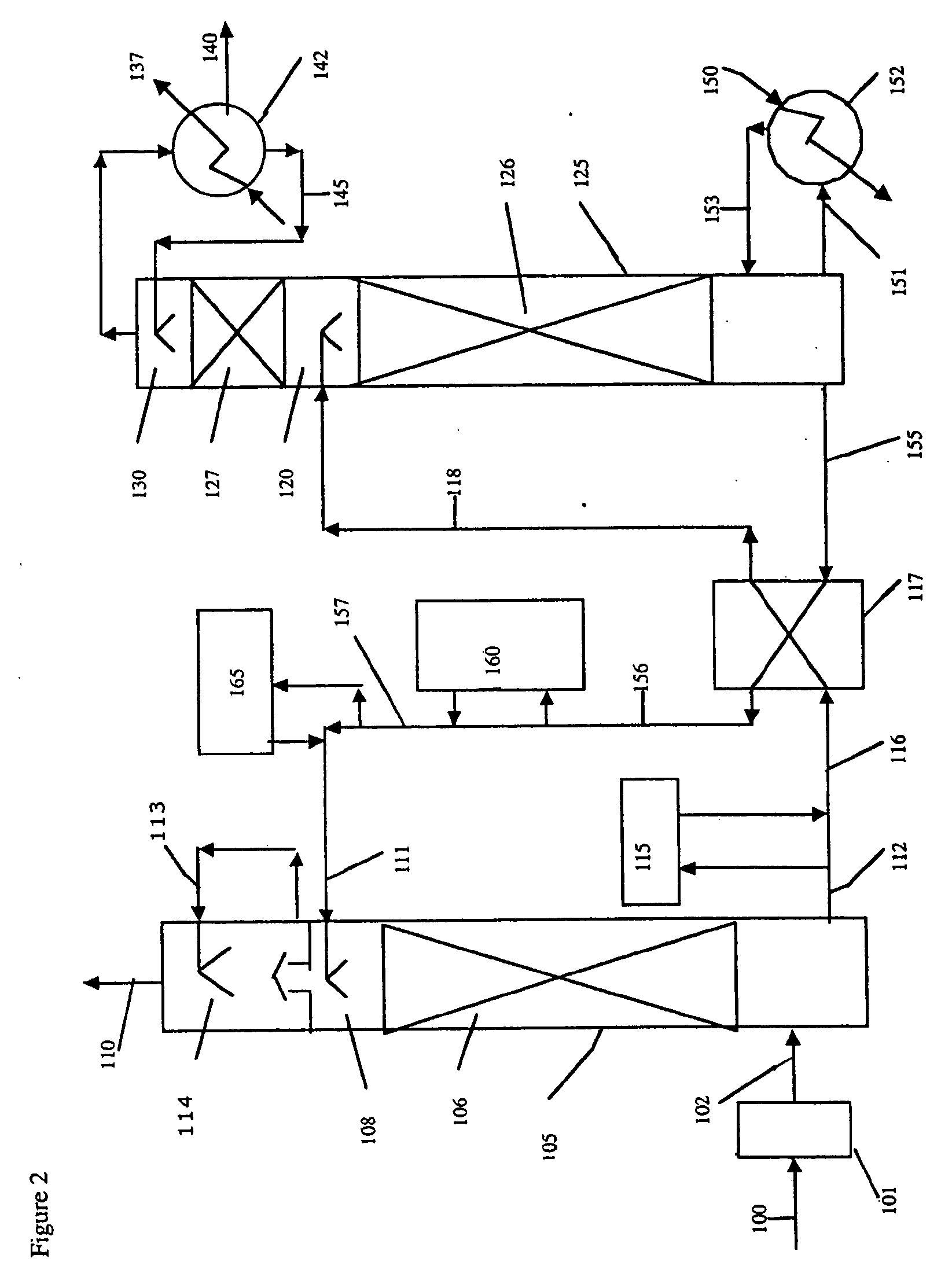

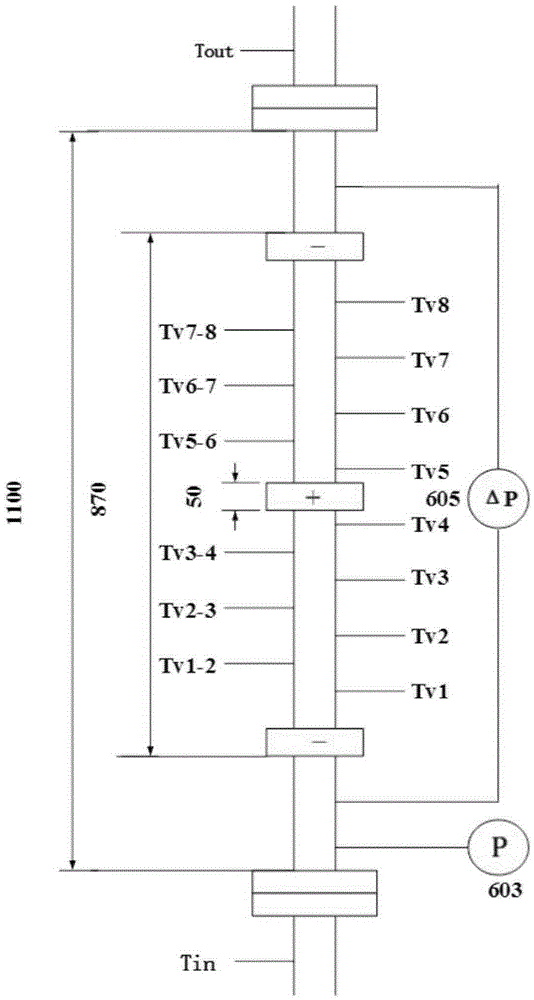

A process and a system for purifying gas, such as air, before cryogenic distillation, in which at least one energy parameter, chosen from the flow rate of the regeneration gas entering and / or leaving at least one adsorber, the duration of the regeneration step and the regeneration temperature of the regeneration gas entering at least one adsorber, is controlled, modified and / or regulated depending on at least one operating condition chosen from the pressure of the gas to be purified entering and / or leaving at least one adsorber, the flow rate of the gas to be purified entering and / or leaving at least one adsorber, the temperature (Ta) of the gas to be purified entering at least one adsorber and the content of impurities contained in the gas to be purified entering at least one adsorber and depending on the thermal profile of the heat front output by at least one adsorber at the end of regeneration.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

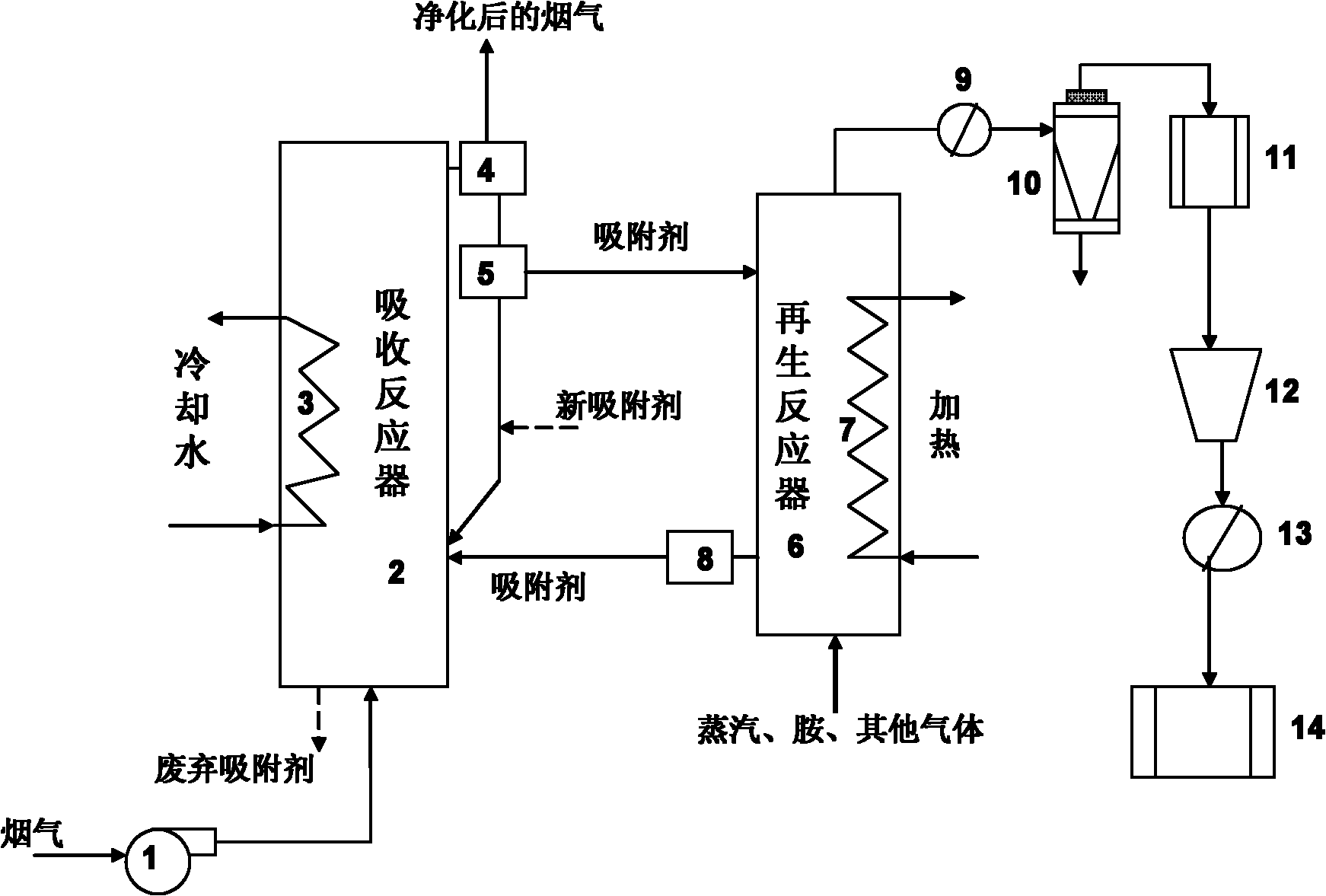

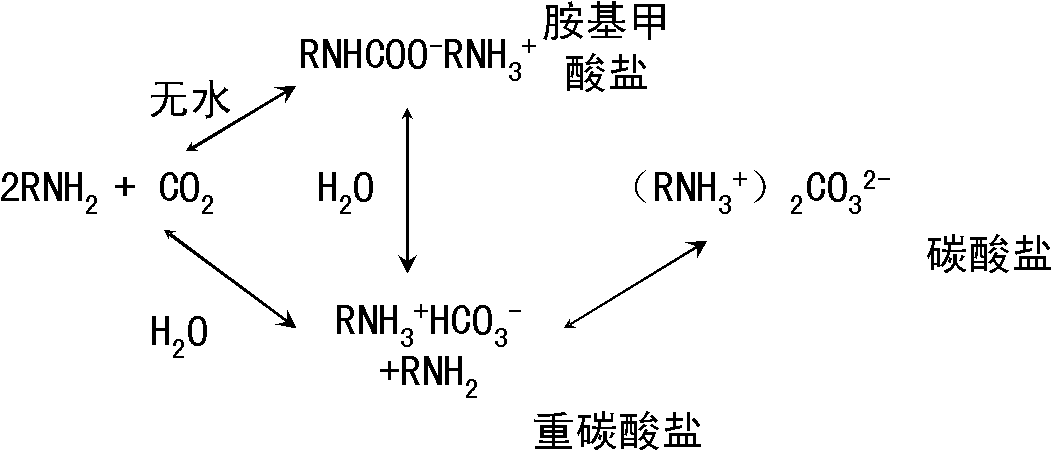

Process and equipment for removing CO2 in flue gas by utilizing amine solid adsorbent

InactiveCN102198360AHigh specific surface areaHigh porosityProductsMethane captureChemistryProduct gas

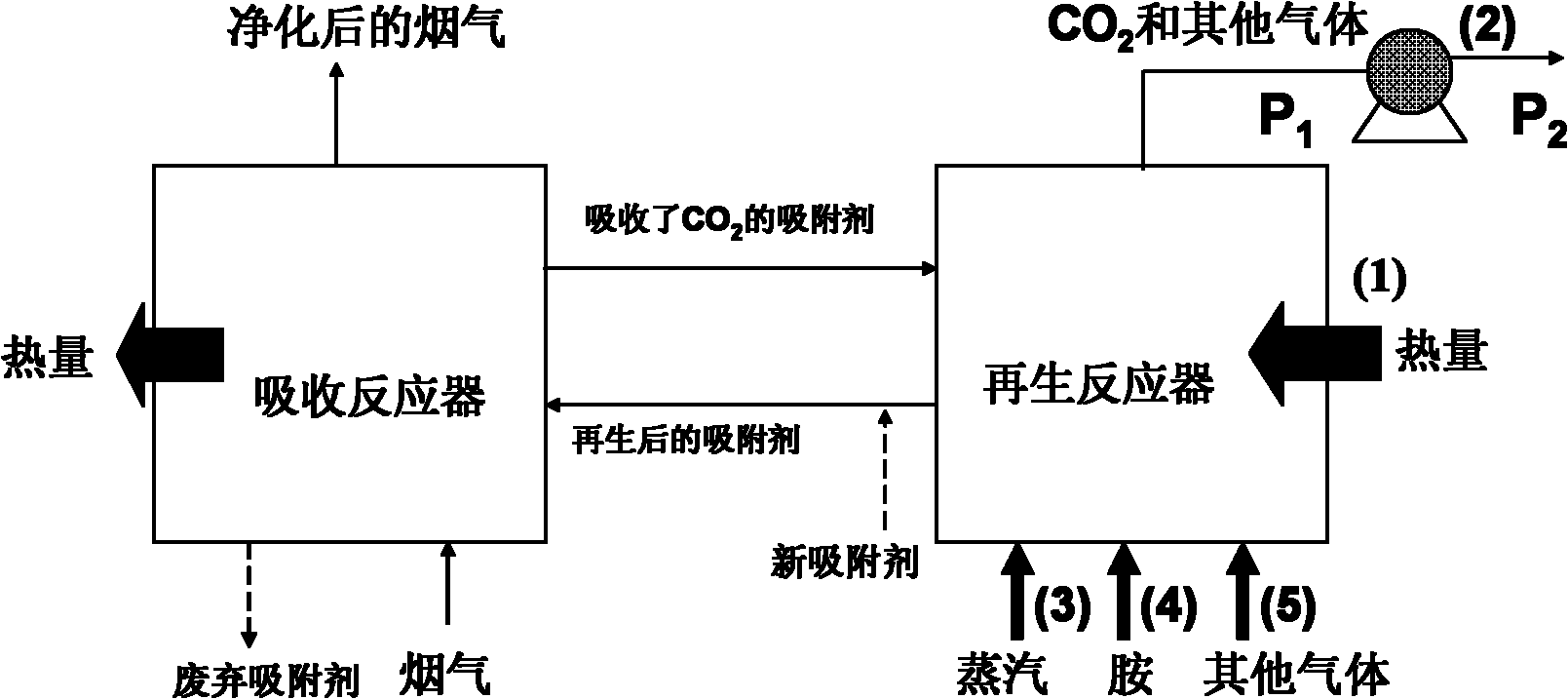

The invention belongs to the technical field of separation of CO2 in flue gas discharged during s combustion process, and in particular relates to a process and equipment for removing CO2 in flue gas by utilizing an amine solid adsorbent. In the process, the CO2 gas in the flue gas is fully contacted with the amine solid adsorbent so that CO2 gas molecules are rapidly diffused into pores of the solid adsorbent to react with amine liquids in the pores and then the CO2 is rapidly adsorbed by the adsorbent, and meanwhile the amine solid adsorbent adsorbed with the CO2 is regenerated by utilizing one or more regeneration methods such as thermal regeneration, vacuum regeneration, steam regeneration, amine steam regeneration and gas introduction regeneration. The adopted main equipment consists of a CO2 absorption reactor using the amine solid adsorbent, a regeneration reactor, a gas-solid separator, a gas-liquid separator and the like. The process and equipment provided by the invention have the advantages of simple and compact overall design, low investment and operating cost, stable and reliable operating performance and capability of efficiently separating the CO2 in the flue gas with low cost.

Owner:TSINGHUA UNIV

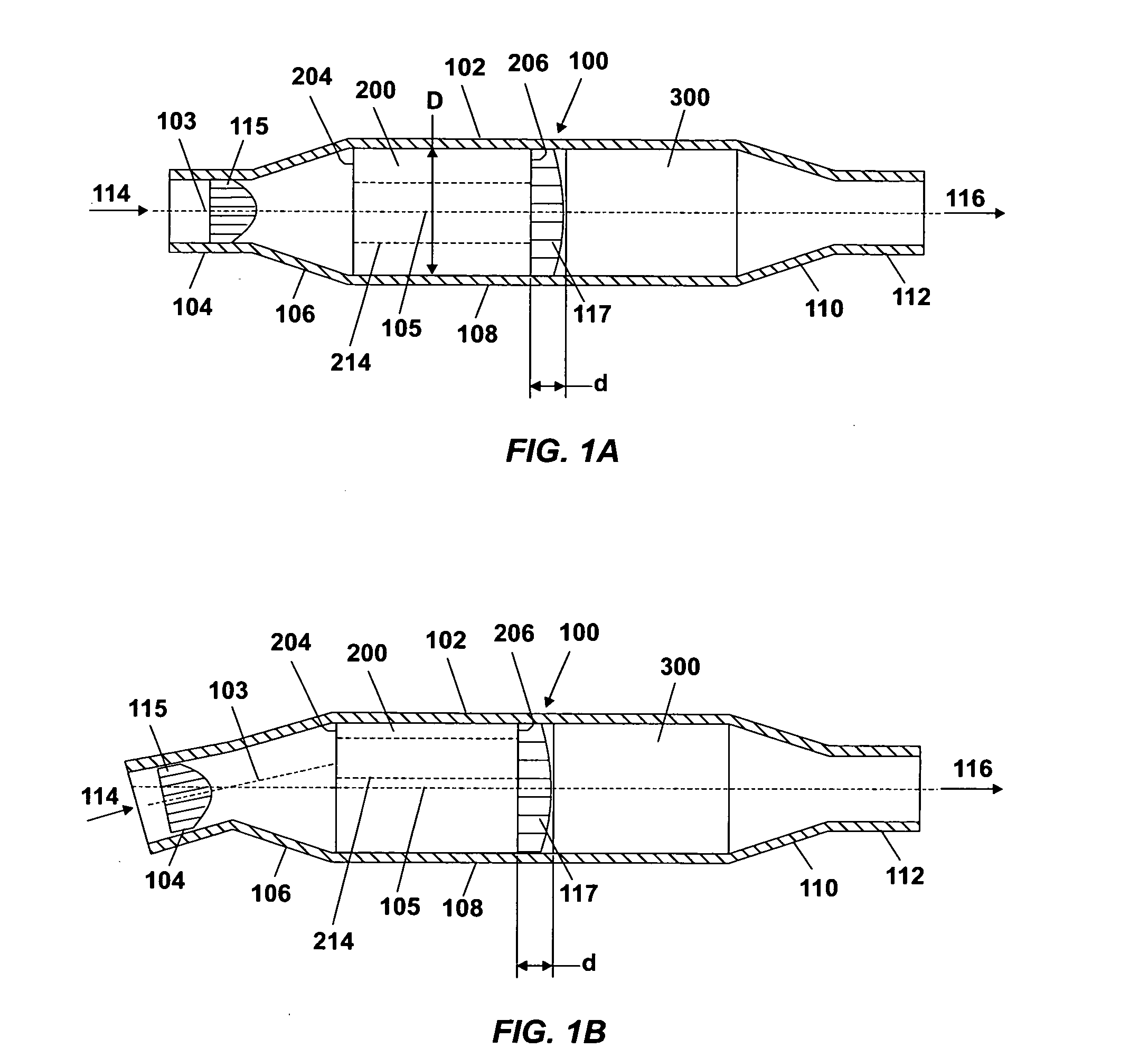

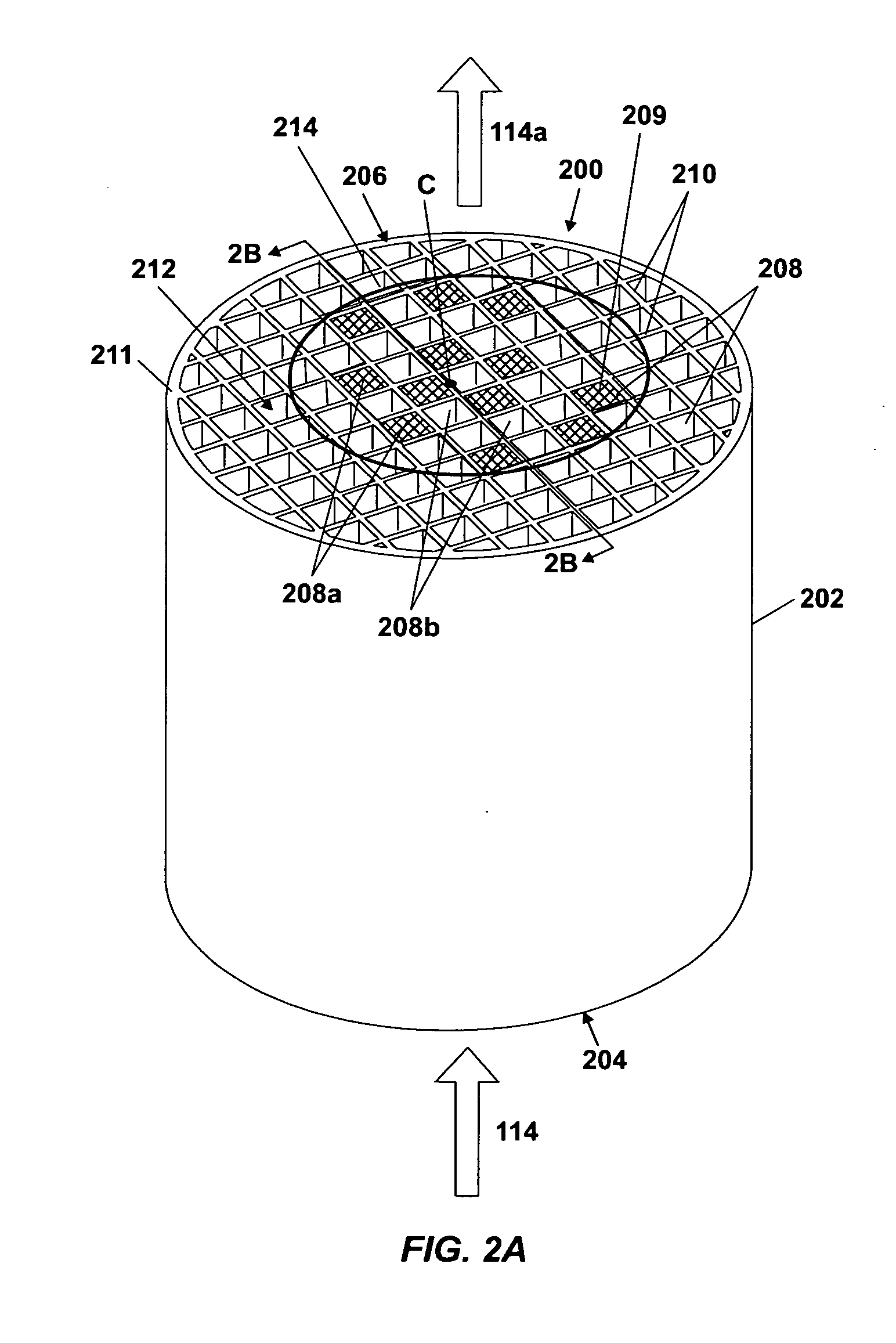

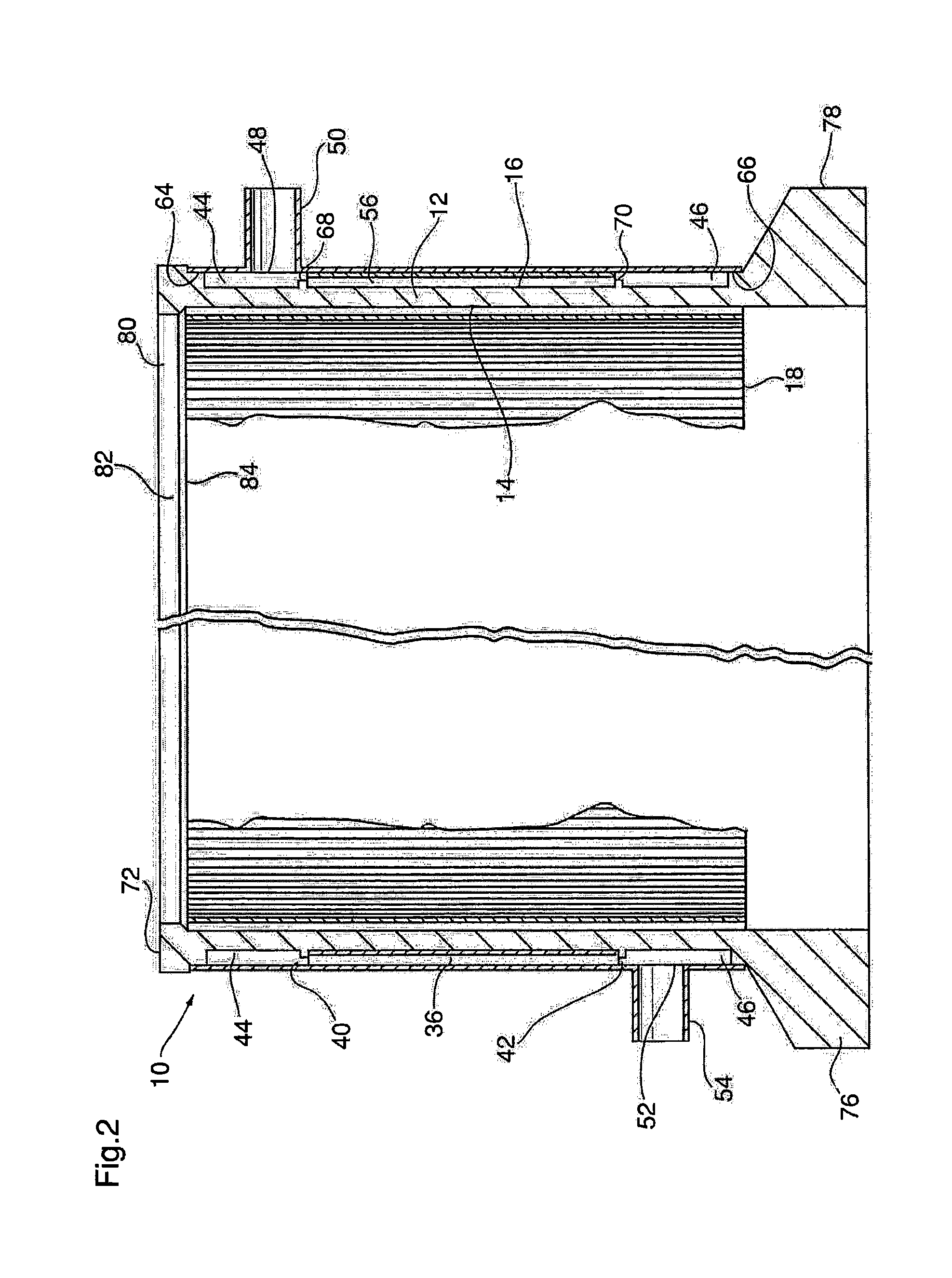

Flow-through honeycomb substrate and exhaust after treatment system and method

InactiveUS20080110341A1Weakening rangeReduce the temperatureCombination devicesAuxillary pretreatmentParticulatesAfter treatment

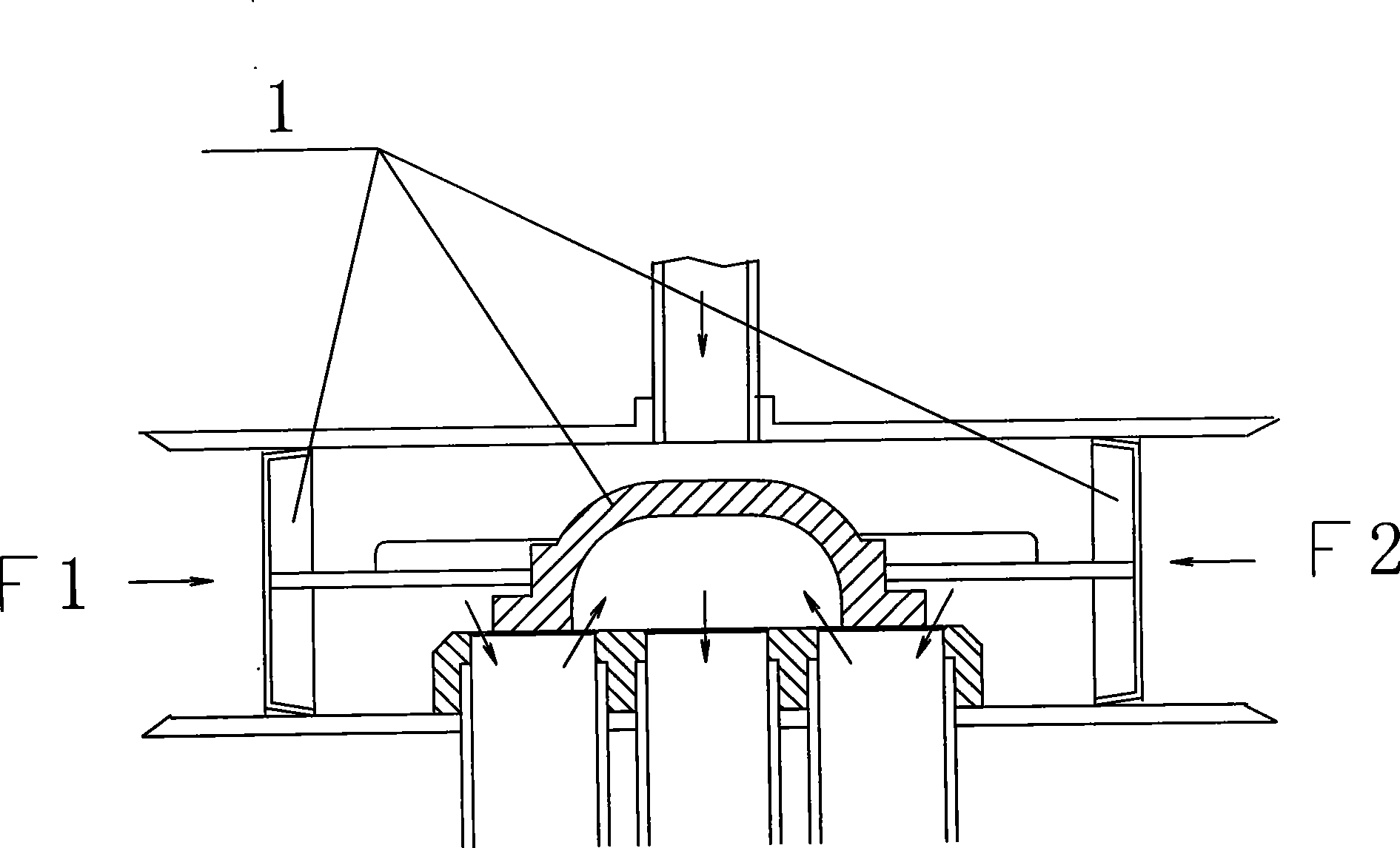

A system and method including a radially non-uniformly plugged flow-through honeycomb substrate positioned upstream of a wall-flow particulate filter for controlled thermal regeneration of the wall-flow particulate filter. The flow-through honeycomb substrate has an inlet face and an outlet face and a plurality of longitudinal walls extending between the inlet face and the outlet face. The longitudinal walls define a plurality of parallel channels extending between the inlet face and the outlet face. The honeycomb substrate has a flow-through region including a first portion of the parallel channels and a flow-control region including a second portion of the parallel channels. The first portion of the parallel channels includes unplugged channels and the second portion of the parallel channels includes plugged channels. The flow-control region adjusts flow distribution through the substrate such that flow having a first flow distribution received at the inlet face emerges at the outlet face with a second flow distribution, different than the first flow distribution.

Owner:CORNING INC

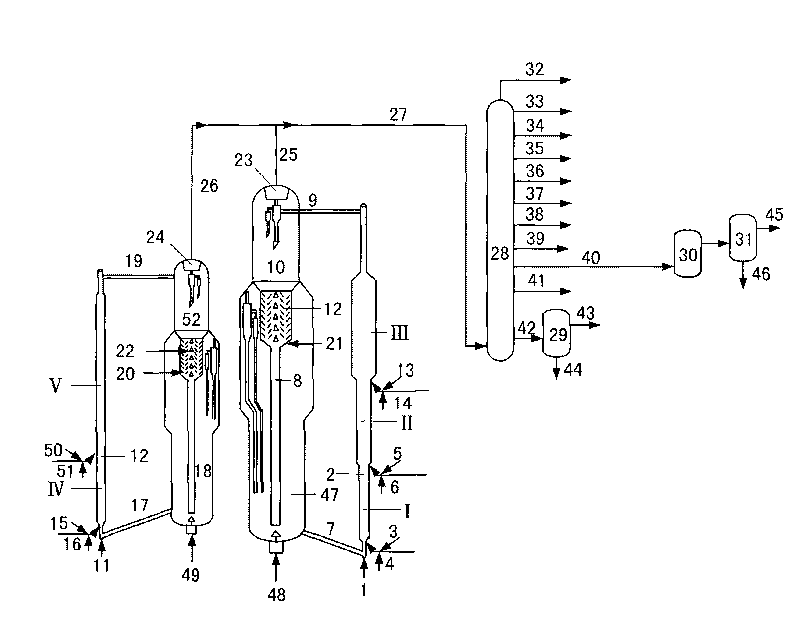

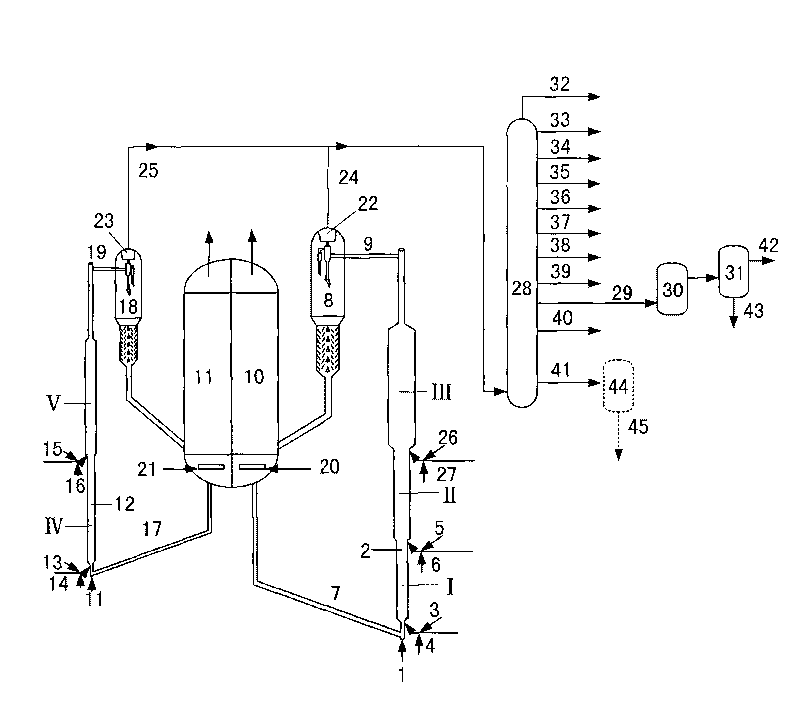

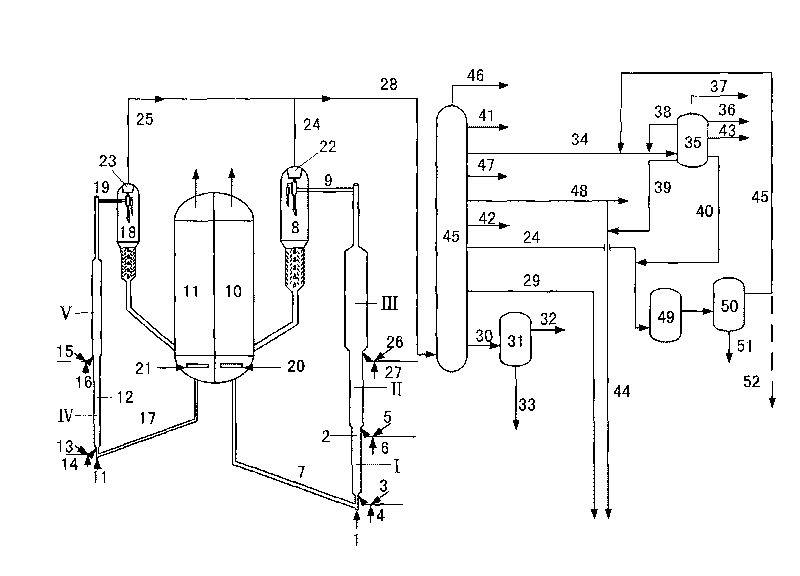

Catalytic conversion method for preparing lower olefins and aromatics

The invention relates to a catalytic conversion method for preparing lower olefins and aromatics. Raw oil with different cracking performances enters different reaction zones of a first riser reactor to contact with a catalytic cracking catalyst for cracking reaction to separate a spent catalyst from reaction oil gas, wherein the spent catalyst after stripping enters a first regenerator and returns to a first riser after scorching regeneration, the reaction oil gas is separated to obtain a product containing lower olefins, gasoline, distillates with distillation range of 180-250 DEG C and catalytic wax oil, wherein the gasoline is extracted by light aromatics to obtain light aromatics and gasoline raffinate; the raw materials are cracked to be sent into a second riser reactor to contract with a hot regenerated catalyst for catalytic conversion; and the spent catalyst is burned and regenerated in a second regenerator and then returns to a second riser reactor. The method uses heavy rawmaterials to furthest produce the lower olefins, such as propylene, ethylene, and the like, particularly the propylene, the production rate can exceed 40 wt%, and at the same time the method can coproduce the aromatics, such as toluene, xylene, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and apparatus for NOx and Hg removal

InactiveUS20060021506A1Prevent buildupReduce probabilityNitrogen compoundsUsing liquid separation agentCyclic processMercury vapour

A cyclic process for the removal of NOx from a NOx containing feed gas, and optionally removal mercury vapour and / or sulfur dioxide is provided. A process is also provided by which an iron chelate absorbent may be thermally regenerated.

Owner:CANSOLV TECH INC

Control method for four-way valve

ActiveCN101504236AReduce the number of commutationsReduce startup timeFluid circulation arrangementCompression machines with reversible cycleHeat regenerationIndoor air

The invention discloses low-reversing reliability and frequency method for controlling a four-way valve, which comprises control processes under the following use conditions: during heat generation, time A is determined according to an ambient temperature and an unloading electromagnetic valve is turned off at the same time, then the cold air-resistance operation of an indoor fan and an inverter compressor are started, a pilot valve of a four-way wave is turned on to act when the inverter compressor operates for 180+A seconds, and the four-way valve realizes inversion and an outdoor fan operates at the same time; for machine stop during heat generation, the inverter compressor and the outdoor fan are turned off first, then the unloading electromagnetic valve is turned on to allow an exhaust pipe and an intake pipe to be communicated continuously for time B, and finally the pilot valve of the four-way valve is controlled to be turned off to reset and the indoor fan is turned off at the same time, wherein the time B is between 5 and 15 seconds; and during heat regeneration, the unloading electromagnetic valve is turned off first and the pilot valve of the four-way valve is controlled to be turned on to act at the same time, then the inverter compressor is started, and the indoor fan starts cold air-resistance operation and the outdoor fan starts operation when the inverter compressor operates for 180 seconds.

Owner:安徽奥克斯智能电气有限公司

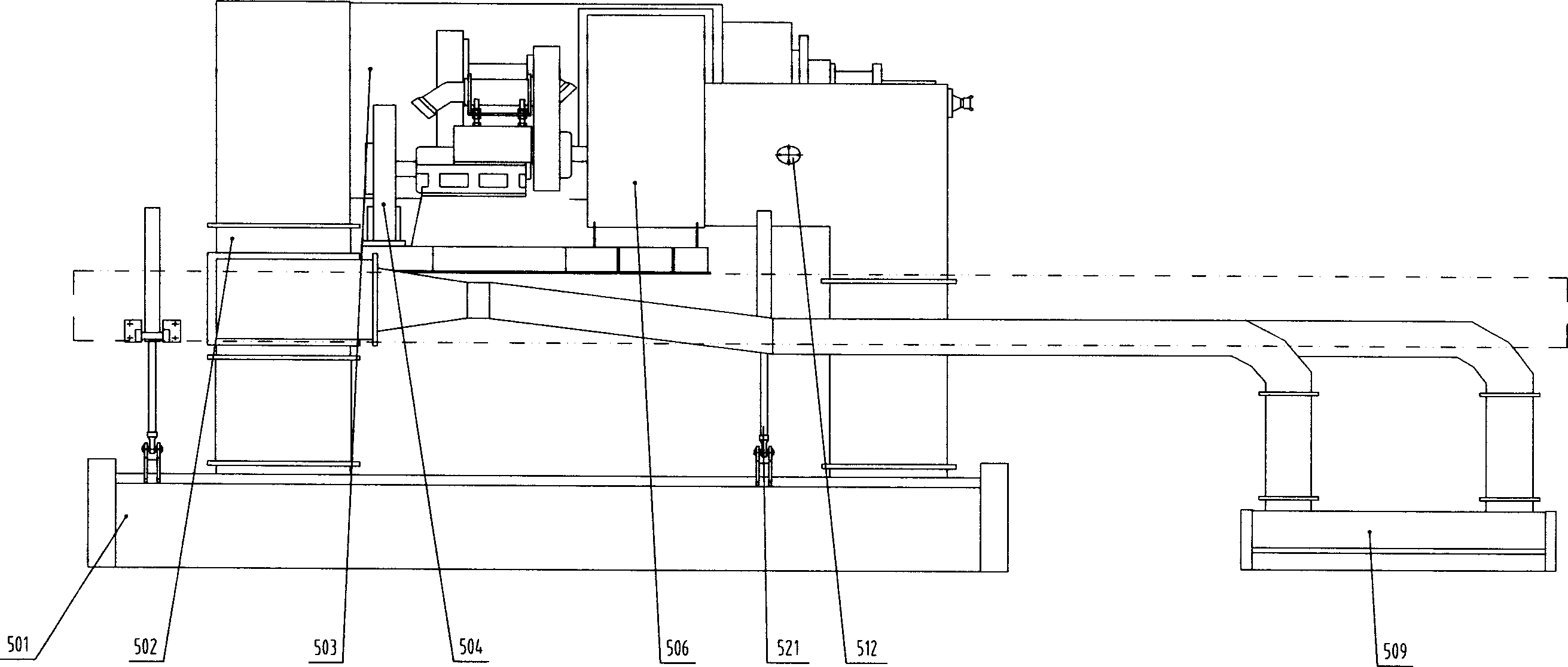

Supercritical Freon heat exchange experiment system and experiment method thereof

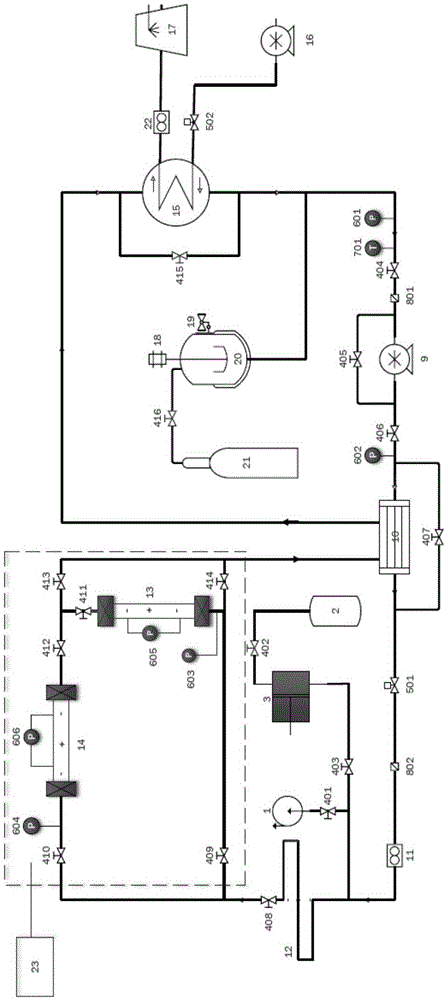

ActiveCN105301047AVersatileSimple and reliable structureMaterial heat developmentEngineeringHigh pressure

The invention discloses a supercritical Freon heat exchange experiment system and an experiment method thereof. The system comprises a vacuum and Freon injection module consisting of a vacuum pump, a coolant tank, a coolant recycling and injection machine, a valve and a pipeline connected to a main loop, a circulating module consisting of a shield pump and a closed type loop pipeline, a heat return module consisting of a heat regenerator and a bypass pipeline, a preheating module consisting of a snake-shaped preheating section and a direct current power supply, an experiment module consisting of an experiment section and a relevant valve, and a pressure adjustment module consisting of a high-pressure nitrogen bottle, a pressure stabilizer, a safety valve and a pressure reduction valve, wherein Freon flows into the experiment section after being subjected to heat regeneration and preheated from the outlet of the shield pump, and then finally returns to the inlet of the shield pump after being cooled by a condenser, thus forming a closed circulation. The invention further provides an experiment method of the system. The system can bear a higher-temperature working condition and a higher-pressure working condition, ensure that the Freon can run cyclically under a supercritical state, and also easily, conveniently and quickly adjust system parameters.

Owner:XI AN JIAOTONG UNIV

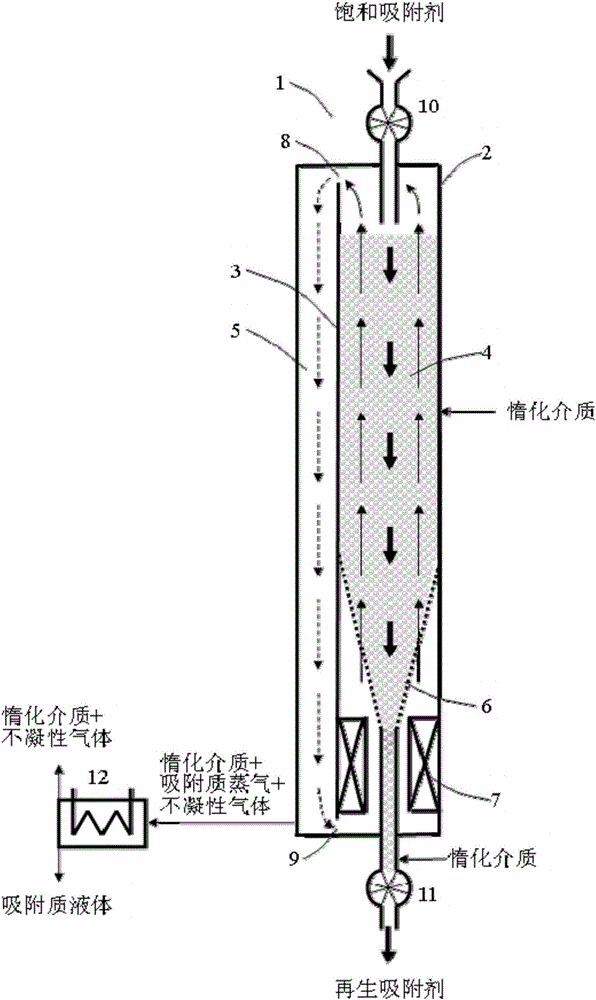

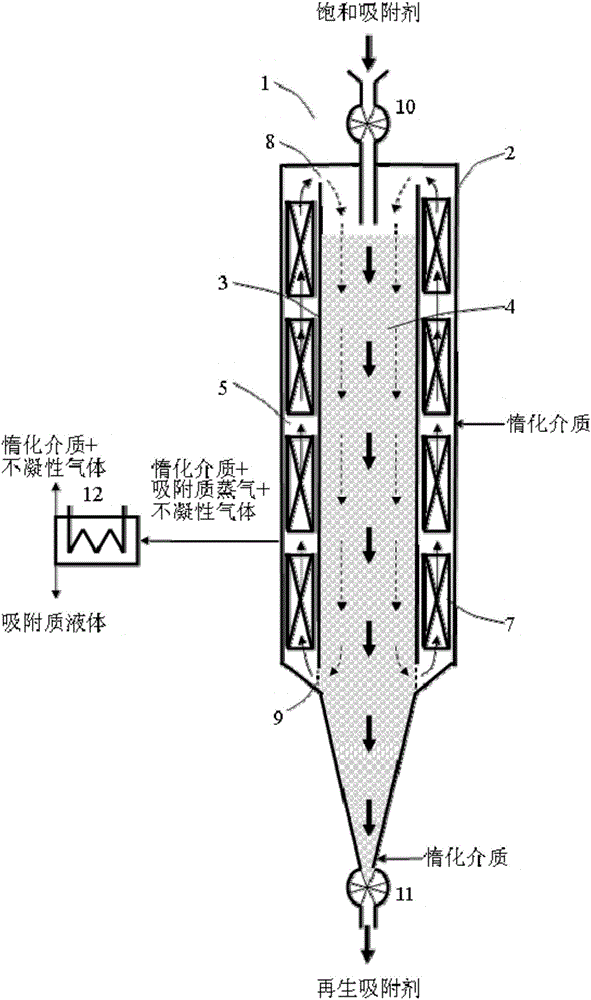

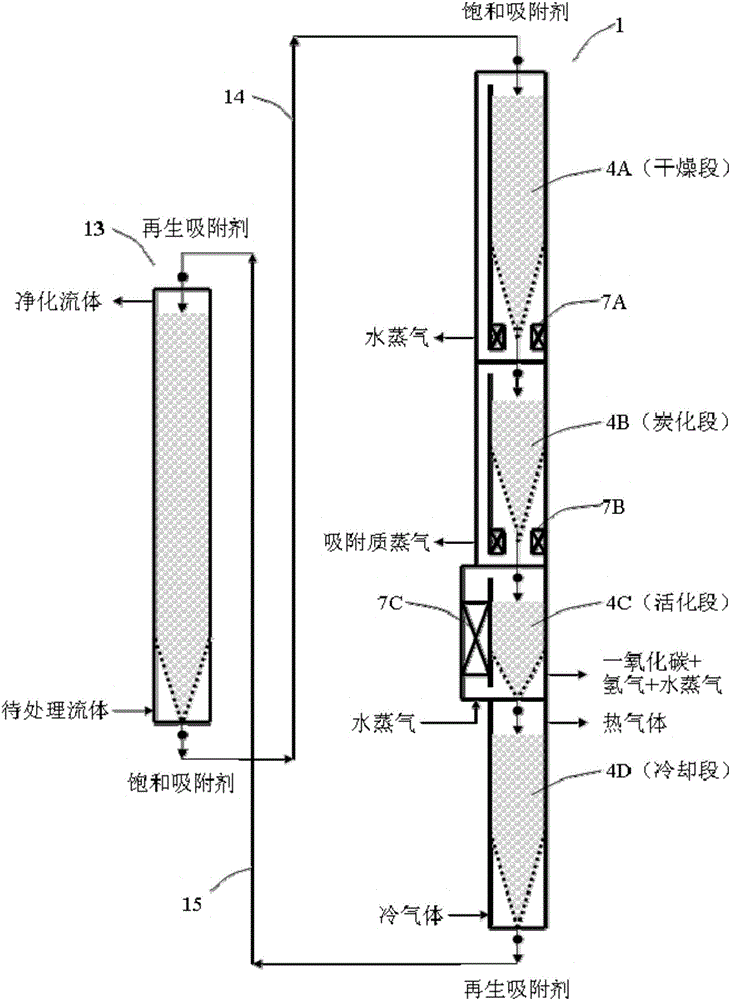

A solid adsorbent regenerating device and an adsorption device applying the regenerating device

InactiveCN106563428AReduce consumptionReduce heat lossGas treatmentSpecific water treatment objectivesSorbentNatural convection

A solid adsorbent regenerating device and an adsorption device applying the regenerating device are disclosed. The regenerating device includes a regenerating heater and an absorbent bed. The regenerating device is configured in a manner that heating by the regenerating heater allows gas in the regenerating device to circularly flow between the regenerating heater and the adsorbent bed, and heat provided by the regenerating heater is transferred through the circular airflow to the adsorbent bed so that an adsorbent is heated and regenerated. According to one embodiment, the inside of a furnace body of the regenerating device is divided into two parts, top ends of the two parts are communicated with each other, bottoms of the two parts are communicated with each other, and the regenerating heater is in one of the two parts. The adsorption device applying the regenerating device is also disclosed. Circular heating in a natural convection manner is utilized to regenerate the solid adsorbent. The regenerating device and the adsorption device have advantages of low consumption of inert gas, no or extremely low waste emission, a high heat efficiency, simple equipment, a low cost, and the like.

Owner:GUANGDONG UNIV OF TECH

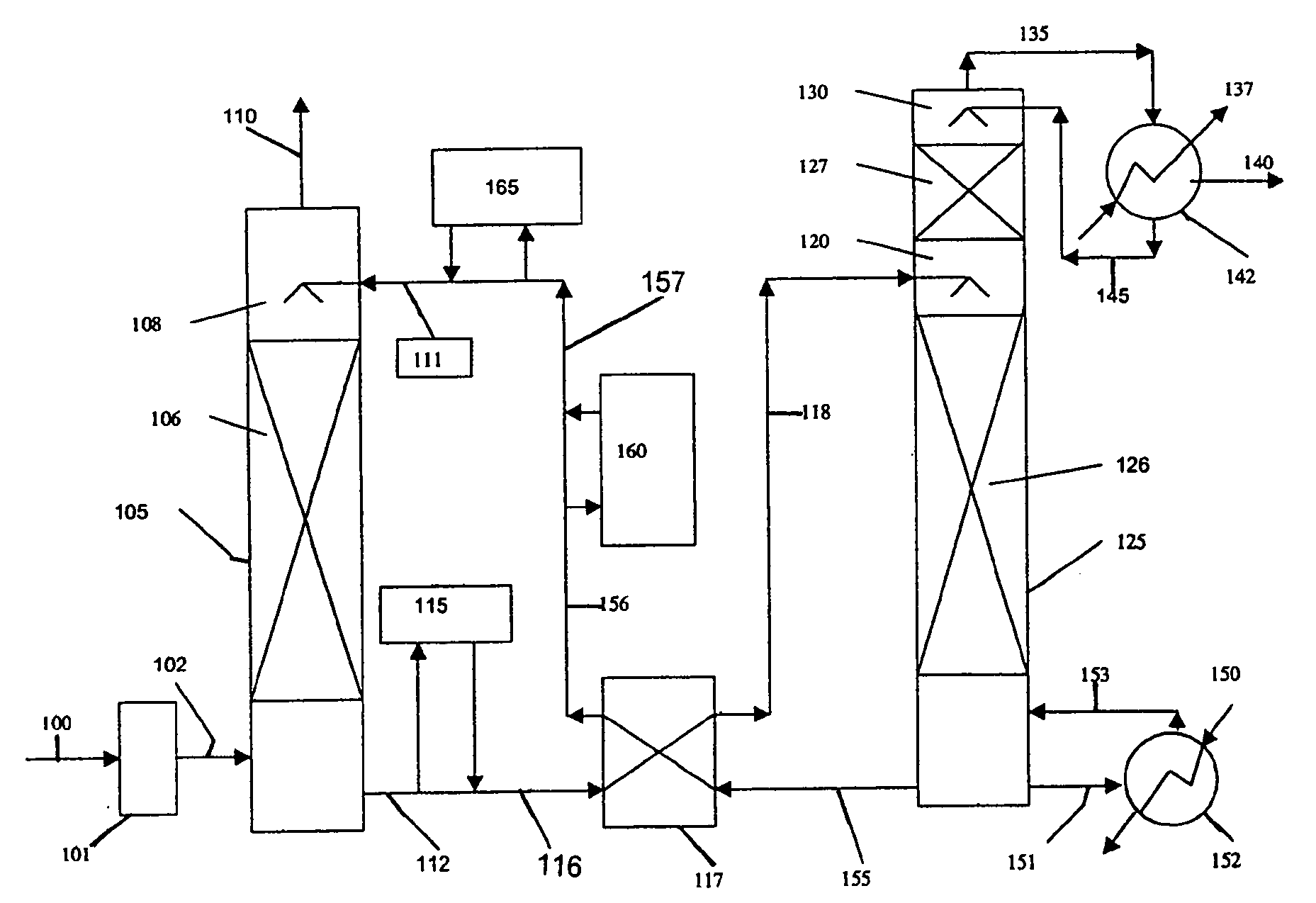

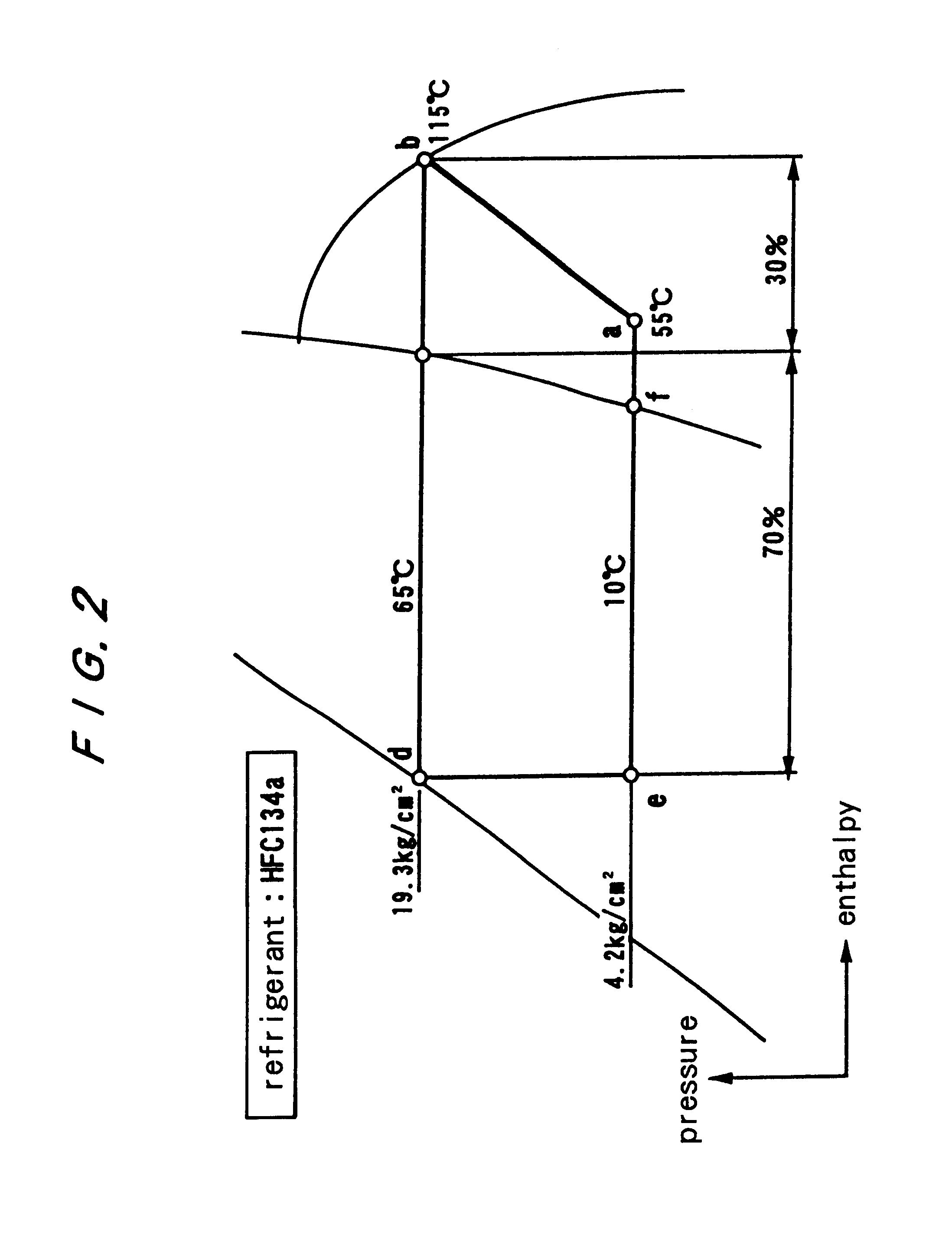

Air Conditioning system and method for operating the same

InactiveUS6199389B1Improve dehumidification effectIncrease sensible heatAir treatment detailsHeat recovery systemsDesiccantEngineering

This invention provides an energy saving air conditioning system having an improved dehumidifying ability by raising the temperature or enthalpy of a compressed superheated vapor of a refrigerant for the heat pump, thereby to increase the proportion of the sensible heat in the heat discharged in a high-temperature heat source of the heat pump, and then increased enthalpy is used to heat regeneration air to improve the dehumidifying capability of the desiccant. The system includes a desiccant 103 for dehumidifying process air, a heat pump 200 having a compressor 260 for supplying heat to regeneration air for regenerating the desiccant, by utilizing process air as a low temperature source 240 and regeneration air as a high temperature source 220, and the system is operated so as to heat the refrigerant flowing into the compressor in the heat pump with regeneration air after it has regenerated the desiccant, so that the temperature of the compressed refrigerant flowing into the compressor will be increased, and then the gained heat is transferred to the regeneration air to increase its temperature before regenerating the desiccant.

Owner:EBARA CORP

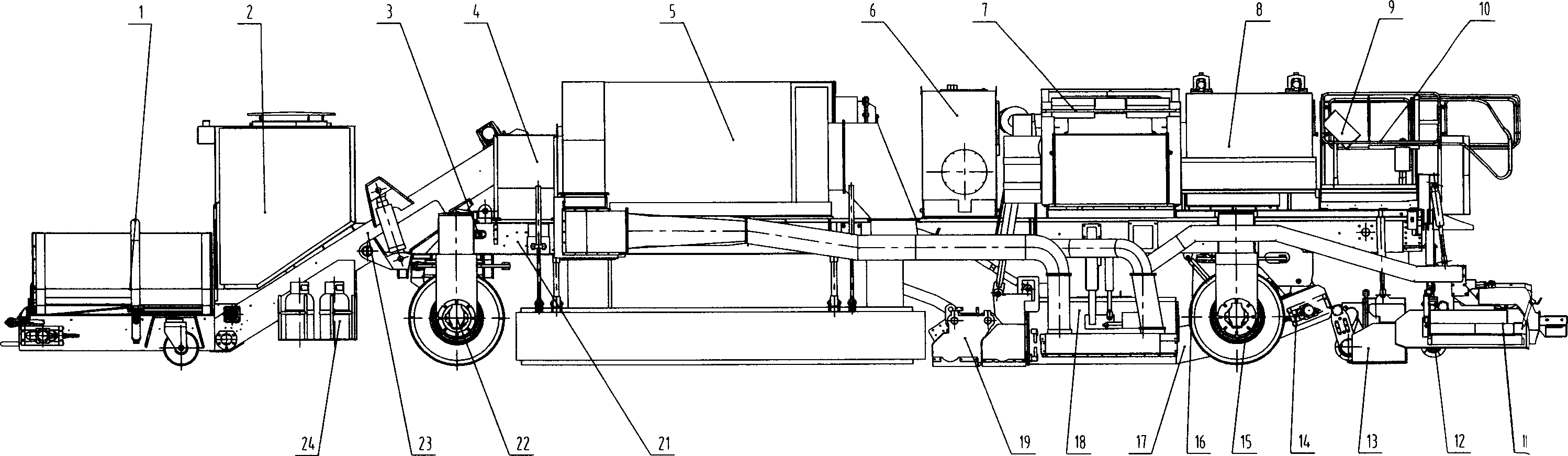

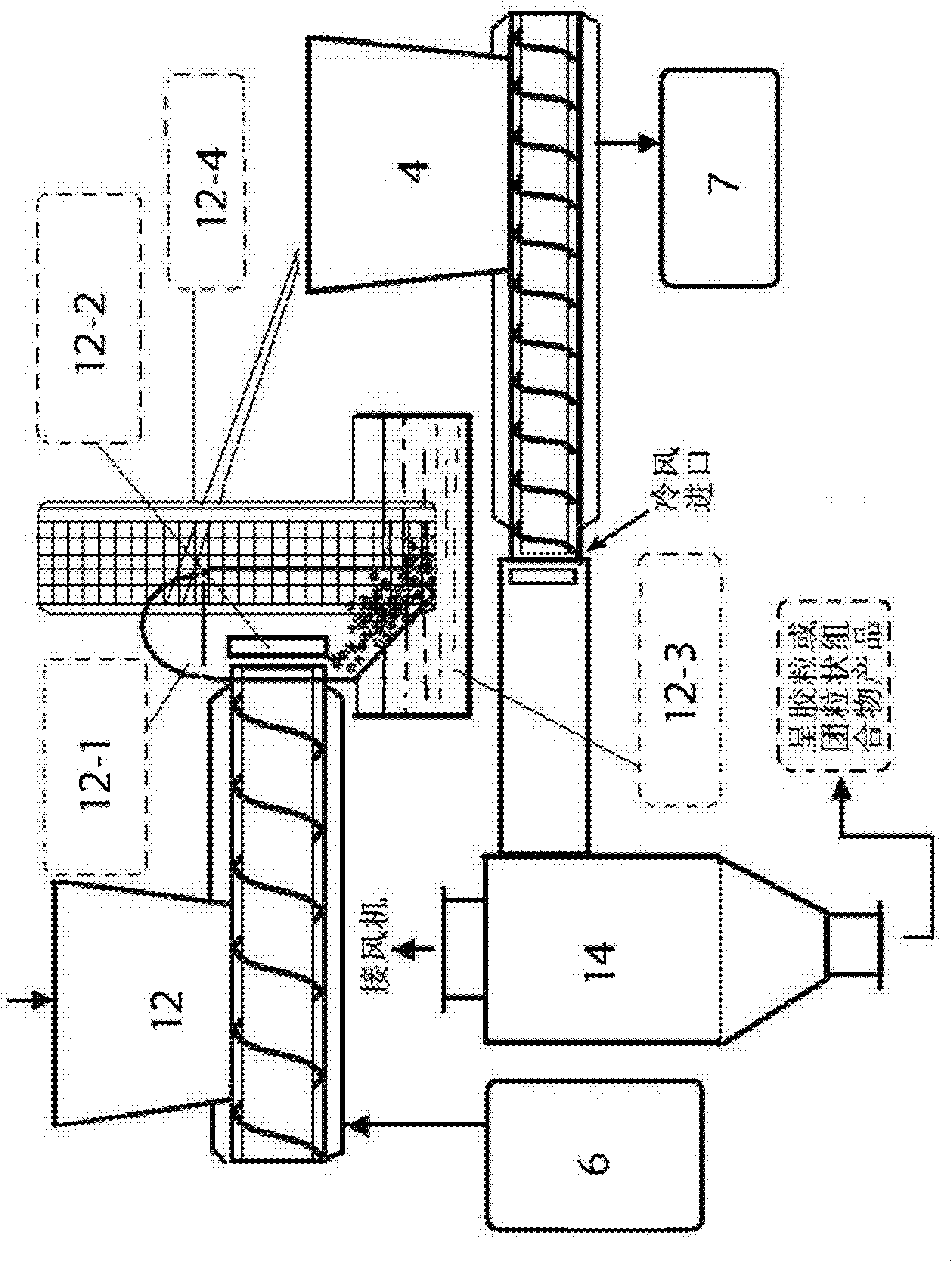

In-place heat regeneration asphalt pavement remixer

InactiveCN1908309AImprove mobilityPromote environmental protectionRoads maintainenceAir cycleSprayer

The invention relates to an earth heat regenerate pitch road mixer, which comprises: a frame, a material hopper, a sprayer, a transfer hopper, a hot air cycle heater, a regenerator, a laying device, a front bridge, a back bridge, a cabin, a control system and a power system, wherein the material hopper, sprayer, transfer hopper, hot air cycle heater and regenerator are fixed on the frame; the material hopper via the new pitch front transfer device is connected to the transfer hopper; the laying device comprises a regenerated pitch mixing laying device and new pitch mixing laying device; the outlet of continuous feeding device is connected to the inlet of regenerated pitch mixing laying device; the transfer hopper via the new pitch horizontal transfer device is connected to the inlet of new pitch mixing laying device. The invention has simple operation and high automatic degree.

Owner:ZOOMLION HEAVY IND CO LTD

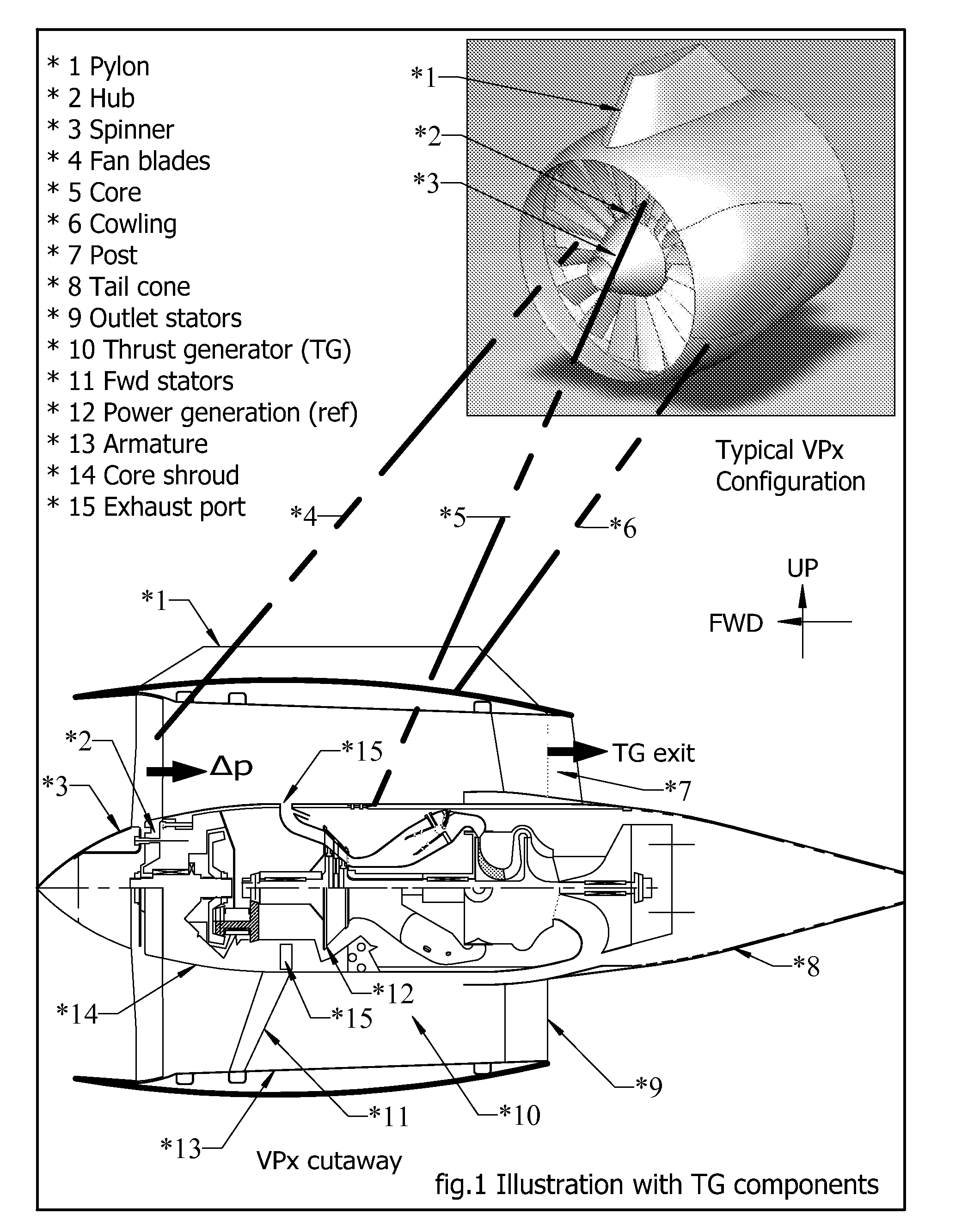

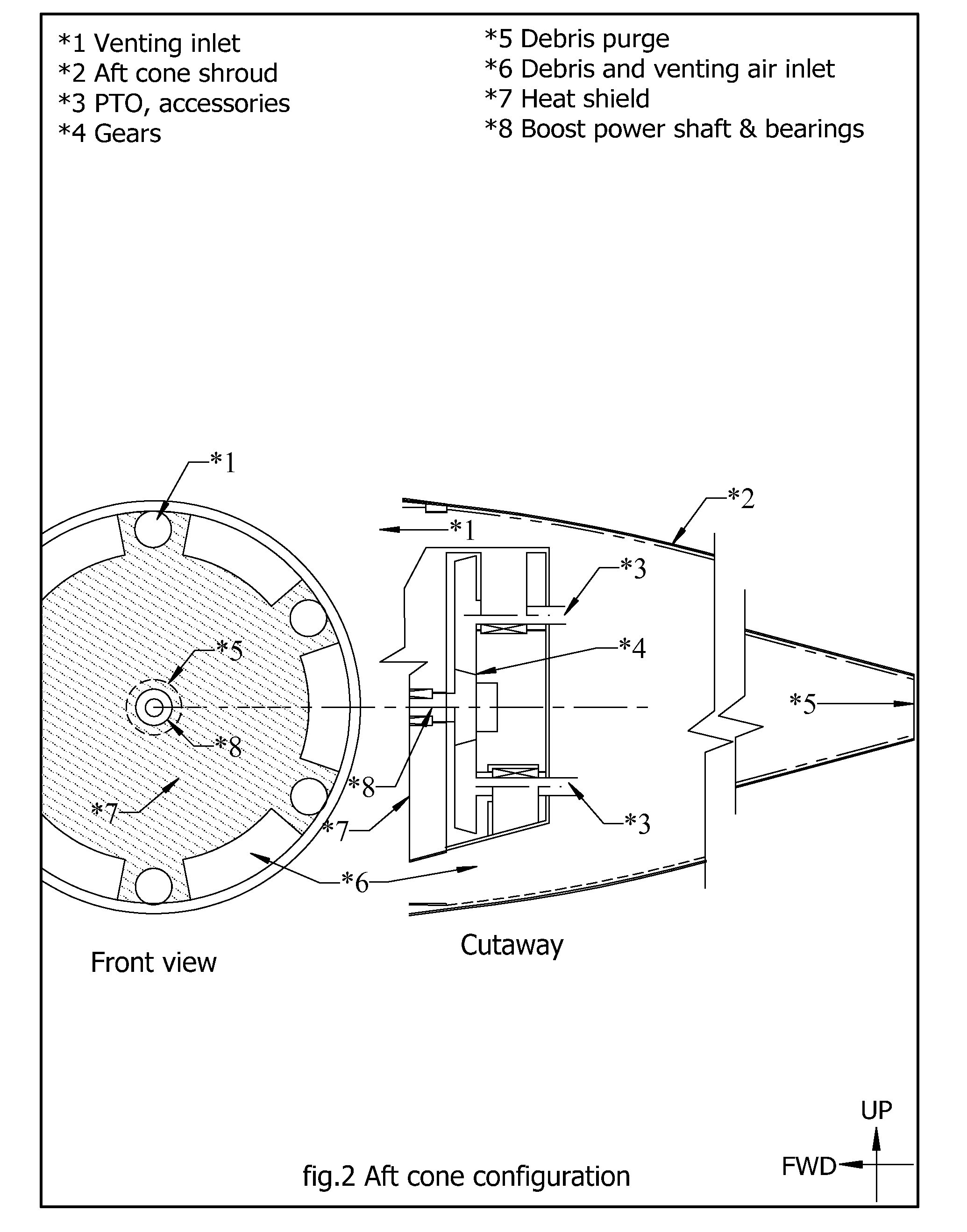

Heat regeneration for a turbofan, a Velarus Propulsion

InactiveUS20100180568A1Extend your lifeEasy to manufactureContinuous combustion chamberGas turbine plantsCombustion chamberFan blade

The invention adds details and alternate design supplementing the concept established with my patent application Ser. No. 12 / 013,431, Aircraft Propulsion System (APS). The APS ultimate fuel economy objectives requires long term design development, and this invention compromises some fuel economy for the expediency of short term implementation of a heat regeneration for turbofans via the re-arrangement of existing components and a few unique items readily designed. While this Velarus Propulsion (VPx) attains only 42% fuel economy, it retains the original APS fundamental architecture implementing heat regeneration for a turbofan engine, as well as the additional benefits of noise and emission abatement. This invention consists of the three APS technologies as follows:a) A novel arrangement of the power generation core features the turbine exhaust entering directly into the thrust chamber, thus providing heat regeneration with an appropriate configuration of the thrust chamber.b) The design of a modified combustor introduces the concept of a supersonic nozzle driving the turbines which allows for greater combustor's chamber temperature while injecting the gases at temperatures acceptable to current turbine blade metallurgy. This feature increases the engine thermal efficiency.c) The hub design allows for two options, a simpler fixed fanblade design or an advanced controllable pitch fan blade, increasing the mission and performance flexibility of a given turbofan size.In addition, this invention adds functionality to the aft cone, such as debris purge, accessories installation, and thrust reversers free from hot gases.

Owner:SACHS HUMBERTO W

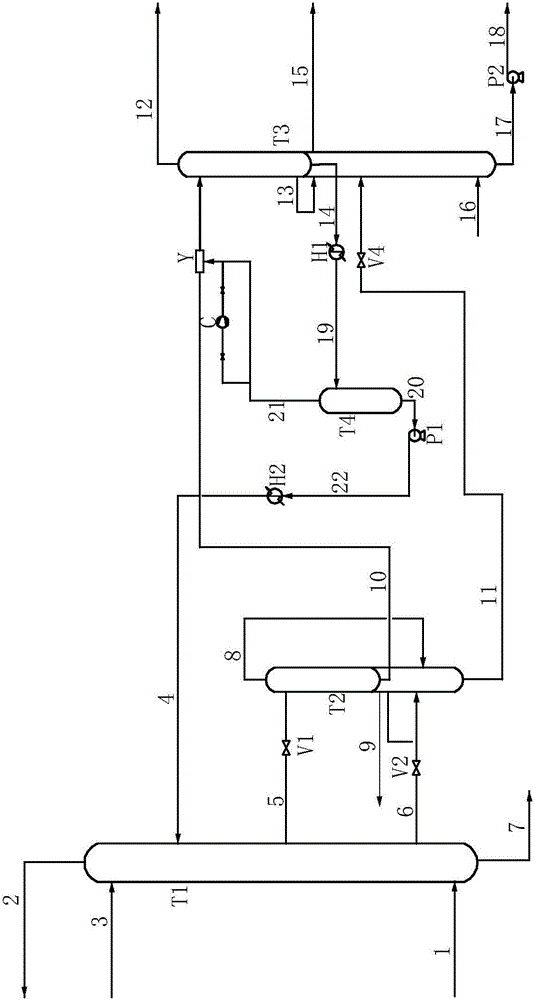

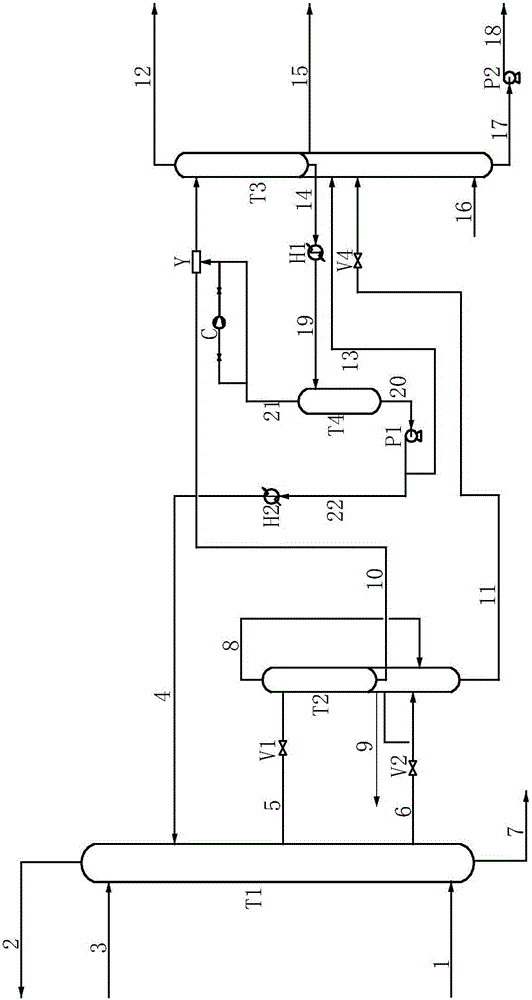

Natural gas absorbent regeneration and energy conservation technology and device

InactiveCN103071475AAvoid wastingReduce dosageGaseous fuelsCombustible gas purificationCompressed natural gasNatural gas dehydration

The invention relates to a natural gas absorbent regeneration and energy conservation technology and a natural gas absorbent regeneration and energy conservation device. The technology and the device can overcome the defects that the energy consumption is great and the heating time is long when the absorbent is regenerated. The technical scheme is as follows: a process of two towers is adopted, one tower is used for dehydration of natural gas and the other one is used for regeneration of natural gas. The two towers are switched for dehydration and regeneration of natural gas. During dehydration of natural gas, compressed natural gas first enters into the dehydration tower A to be dehydrated and obtain dried natural gas after being separated by a front filter separator, then the natural gas enters into a gas storage tank after being separated by a back filter separator; during heating and regeneration of absorbent, after flow reduction and depressurization, the regenerated natural gas is first heated in a heat exchanger and a heater and enters into the dehydration tower B to regenerate the absorbent, then, the natural gas enters into the heat exchanger to be cooled, and finally the natural gas enters into a recovery tank after being separated by a condensation separator; and during cold blowing and regeneration of the absorbent, after flow reduction and depressurization, the regenerated natural gas enters into the dehydration tower B to cold blow and reduce the temperature of the absorbent. According to the technology, complementary utilization of energy is achieved, energy consumption in absorbent regeneration is reduced, and energy-saving operation of the device is realized.

Owner:SOUTHWEST PETROLEUM UNIV

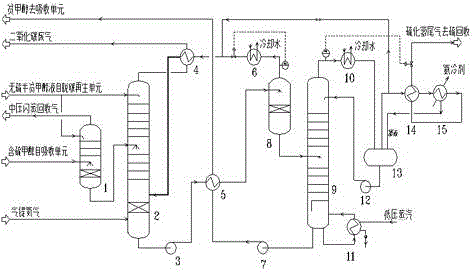

Method suitable for controlling concentration of hydrogen sulfide tail gas in low-temperature methanol washing process

ActiveCN104437004AEasy to operateEasy to controlDispersed particle separationFlash distillationPressure reductionFlash evaporation

The invention discloses a method suitable for controlling the concentration of hydrogen sulfide tail gas in a low-temperature methanol washing process. The method comprises the steps that a sulfur-bearing methanol rich solution dissolved with sulfide and carbon dioxide is subjected to flash evaporation via a medium-pressure flash evaporation tower; fuel gas such as CH4, CO and H2 dissolved in the solution is desorbed and recovered; the methanol solution after the flash evaporation is subjected to pressure reduction and gas stripping to allow a carbon dioxide component to be desorbed from the solution; sulfide is still dissolved in the methanol solution via secondary washing and absorption of the solution to achieve sulfide enrichment; the sulfur-bearing methanol rich solution is heated and then subjected to the flash evaporation; flash evaporation gas returns to a secondary absorption tower to strengthen the sulfide enrichment; the obtained sulfur-bearing methanol solution enters a heat regeneration tower to allow sulfide and residual CO2 to be fully desorbed by the action of steam stripping of methanol steam; and non-condensable gas, namely the acid sulfide tail gas is obtained by further condensation and cooling via a tail gas heat exchanger and a hydrogen sulfide tail gas chiller. The method has the advantages that the method is energy-saving and consumption-reducing, and can adapt to different sulfur recovery technology requirements.

Owner:SEDIN ENG

Industrialized heat regeneration asphalt mixture and preparation method thereof

The invention discloses a factory hot recycled asphalt mixture, which comprises the following components in weight percentage: 44-92% of new aggregate, 1-3% of mineral powder, 5-50% of old asphalt mixture and 1.7-3.0% new asphalt binder, wherein the weight ratio of fine material with a particle size of 0-15mm to coarse material with a particle size of 15-25mm in the old asphalt mixture is 0.5-2:1. The invention also discloses its preparation method. The industrial heat-regenerated asphalt mixture of the present invention can save a large amount of asphalt and gravel materials without regenerating agent, save engineering investment, turn waste into treasure, and save energy; In terms of water damage performance, it is not inferior to the fresh asphalt mixture; in addition, the preparation method of the invention can effectively reduce the smoke phenomenon caused by the old material when heated, reduce the pollution to the environment, and has a good environmental protection effect.

Owner:SHANGHAI HIGHWAY BRIDGE (GRP) CO LTD +1

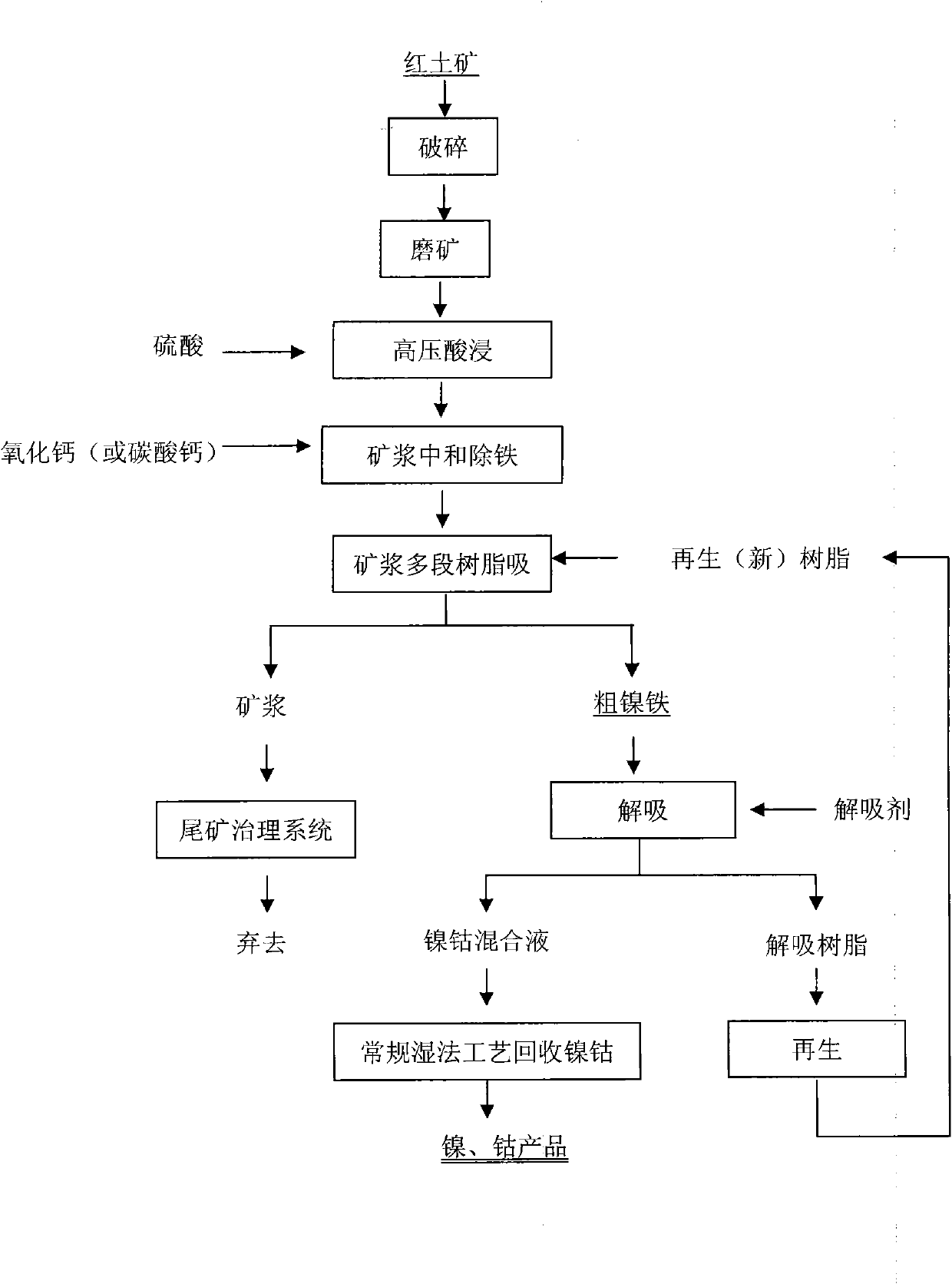

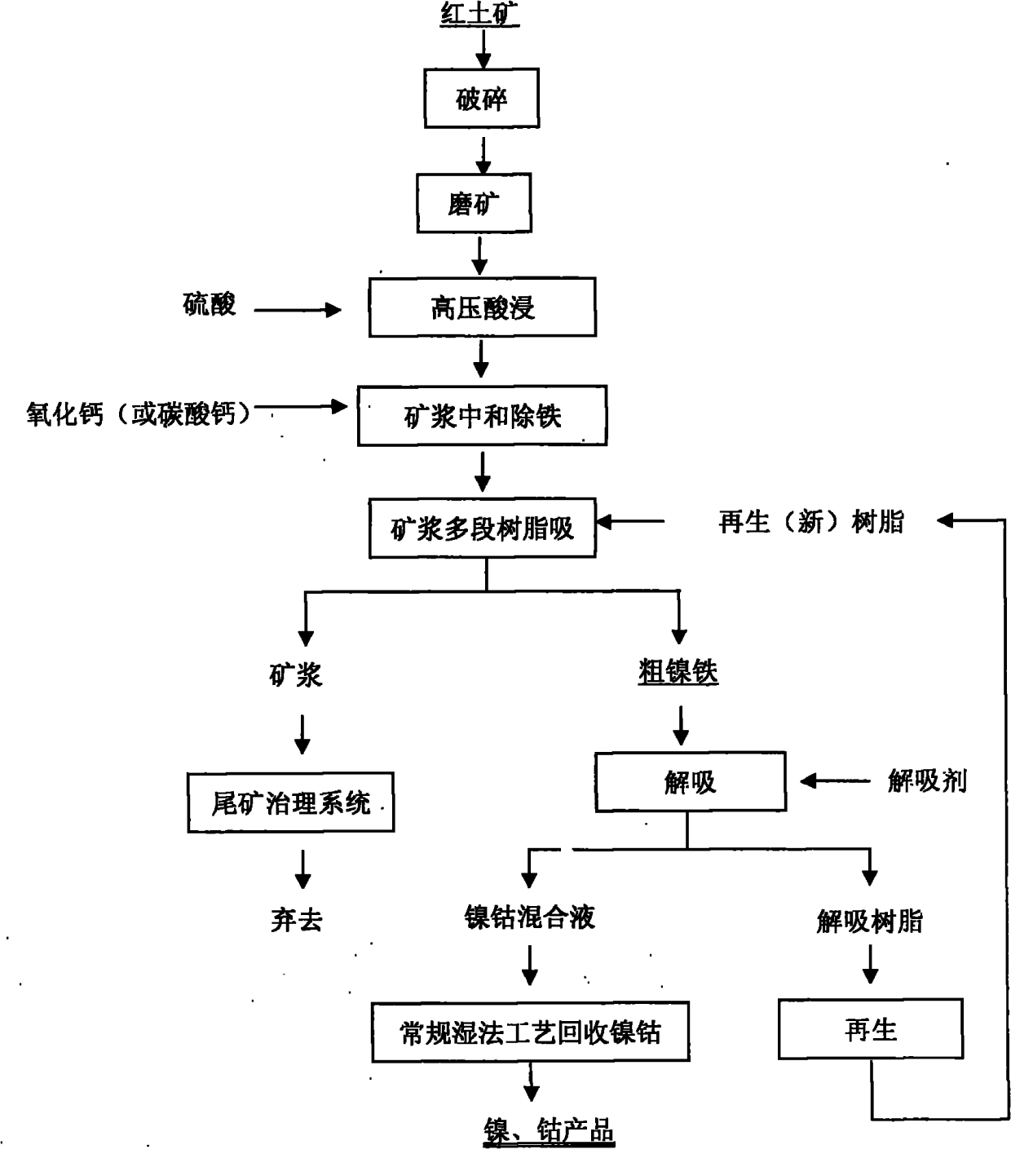

Process for extracting nickel-cobalt from laterite by using resin-in-pulp adsorption technology

ActiveCN101974685AReduce governance costsReduce the burden of separationProcess efficiency improvementDesorptionLaterite

The invention relates to a process for extracting nickel-cobalt from laterite by using resin-in-pulp adsorption technology. The process comprises the following steps of: milling the laterite, and adding sulfuric acid into the milled laterite to perform high-pressure leaching; pouring the ore pulp after the leaching into a reaction kettle for neutral impurity removal; directly pouring the ore pulpafter the impurity removal into an adsorption tank to perform resin adsorption; adopting multilevel counter current absorption to perform desorption on the loaded resin so as to obtain pure nickel and cobalt mixed solution; and performing extraction separation to obtain a nickel-cobalt product. The resin can be used repeatedly after regeneration, the damaged resin is less, the service life of theresin is long, the desorption of the loaded resin and the regeneration of a poor resin are performed at normal temperature and normal pressure and are simple and easy to operate without a pressure vessel and heat regeneration device, thereby saving energy resources and reducing equipment investment. The ore pulp after adsorption is uniformly neutralized to reduce the tailings treating cost. The process shortens the technological process, reduces the liquid-solid separation burden, and reduces a great number of washing and filtering process steps, thereby reducing the production energy consumption and reducing the production cost. The process is simple, and the recovery rate of nickel and cobalt is over 90 percent.

Owner:JILIN JIEN NICKEL IND +1

Active coke/charcoal flue gas desulphurization denitration and elemental sulfur-recovery technology and device

ActiveCN104001403AIncrease profitLow mechanical strength requirementDispersed particle separationSulfur preparation/purificationSulfurSorbent

The invention discloses an active coke / charcoal flue gas desulphurization denitration and elemental sulfur-recovery technology and device. The technology utilizes active coke / charcoal as an adsorbent and can realize synergetic removal of pollutants in flue gas in an adsorption tower, and the adsorbed active coke / charcoal are fed into a regeneration tower for heat regeneration; the regenerated active coke / charcoal is screened by a screening machine, the active coke / charcoal having large granule sizes is returned to the adsorption tower and then are subjected re-adsorption, and the active coke / charcoal having granule sizes less than 1.5mm is fed into a gasification furnace for water gas synthesis; and the water gas and SO2 obtained by heat regeneration undergo a reaction in a reduction tower to produce elemental sulfur steam, the sulfur steam from the reduction tower is fed into a condenser and then is condensed into sulfur solids, and the non-condensable gas from the top of the condenser is fed into the adsorption tower. The technology and device realize synthesis of water gas from small-granule active coke / charcoal obtained by adsorption-regeneration, realize reduction and enrichment of SO2 thereby preparing elemental sulfur, improve an active coke / charcoal utilization rate and realize high-value recovery of a sulfur resource.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Warm mix regenerant for asphalt pavement and its preparation method and use method

InactiveCN102285774ALow degree of agingIncrease flexibilitySolid waste managementRoad surfaceToughening

The invention relates to an asphalt pavement warm-mix regeneration agent, a preparation method and a use method thereof. In the asphalt pavement regeneration technology, the heating temperature of the hot regeneration technology is high, and it is easy to age again when mixed with the old asphalt pavement material, and the old material parameter is small; the cold regeneration technology takes a long time to form the strength of the mixture and needs to add cement, which reduces the durability . The asphalt pavement warm-mix rejuvenator of the present invention has the following formula: 15-60 parts of long-chain alkanes and naphthenes, 10-15 parts of high-oil asphalt, 15-60 parts of furfural extraction oil, 5-10 parts of dispersant, plasticizer 1-5 parts, 5-10 parts of toughening agent and 1-5 parts of anti-aging agent are mixed and melted, mixed with milled asphalt mixture old material, new stone material and new asphalt at a temperature of 120-150 ° C. The present invention increases the parameters of old asphalt pavement materials to more than 50%, and controls the mixing temperature in the warm zone, which not only reduces mixing energy consumption and mechanical loss, but also effectively reduces the aging degree of asphalt pavement and improves the old asphalt pavement. The utilization rate of materials; the traffic can be opened faster.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

In-situ warm-mixing regenerant for bituminous pavement, preparation method and construction method of in-situ warm-mixing regenerant

ActiveCN103013144ALow costLow heating temperatureRoads maintainenceBuilding insulationsRoad surfaceMaterials science

The invention relates to an in-situ warm-mixing regenerant for a bituminous pavement, and a preparation method and a construction method of the in-situ warm-mixing regenerant. The strength of a cold-regenerating mixture is longer in formation time; a finish coat in a certain thickness is required to be paved additionally; the property of the regenerated mixture is poorer; a lower level cold mixing technology is used generally; and cement is required to be added generally, so that the durability of the level is reduced. The in-situ warm-mixing regenerant for the bituminous pavement comprises the following raw materials in parts by mass: 10-30 parts of naphthenic hydrocarbon, 20-40 parts of furfural extract oil, 30-50 parts of deionized water, 10-20 parts of microwave absorption agent, 5-10 parts of surfactant, 5-10 parts of dispersing agent and 1-5 parts of antiaging agent. According to the in-situ warm-mixing regenerant, the preparation method and the construction method, the mixing cost can be lowered; the construction efficiency is improved; a use ratio of old materials is increased; compared with in-situ heat regeneration, the ageing of a bituminous mixture is reduced; the service life of the pavement is prolonged; a cooling rate is reduced; the discharge amount of harmful gas and dust is decreased; new aggregates and new bitumen are not required to be added; and the material cost is lowered.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

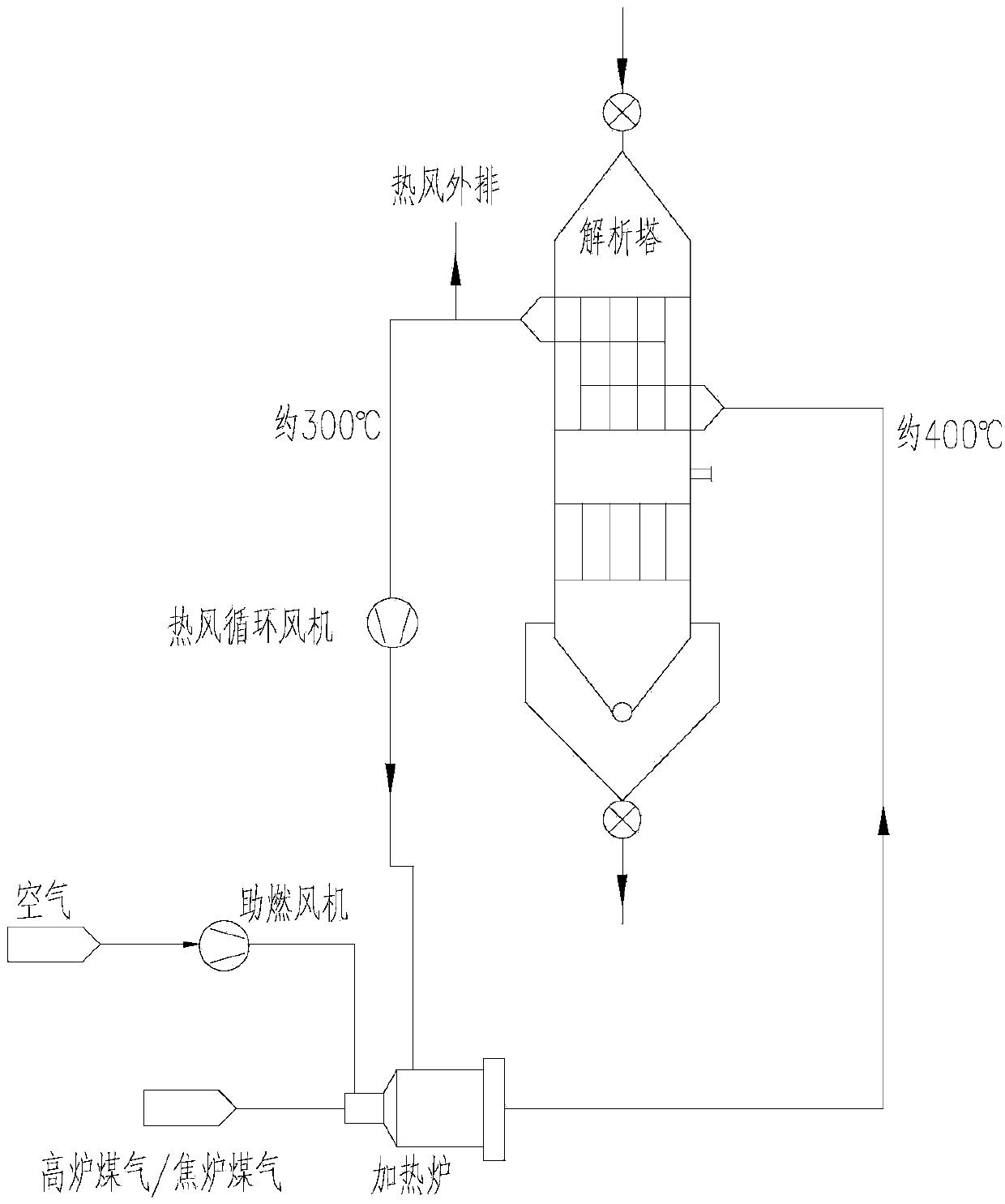

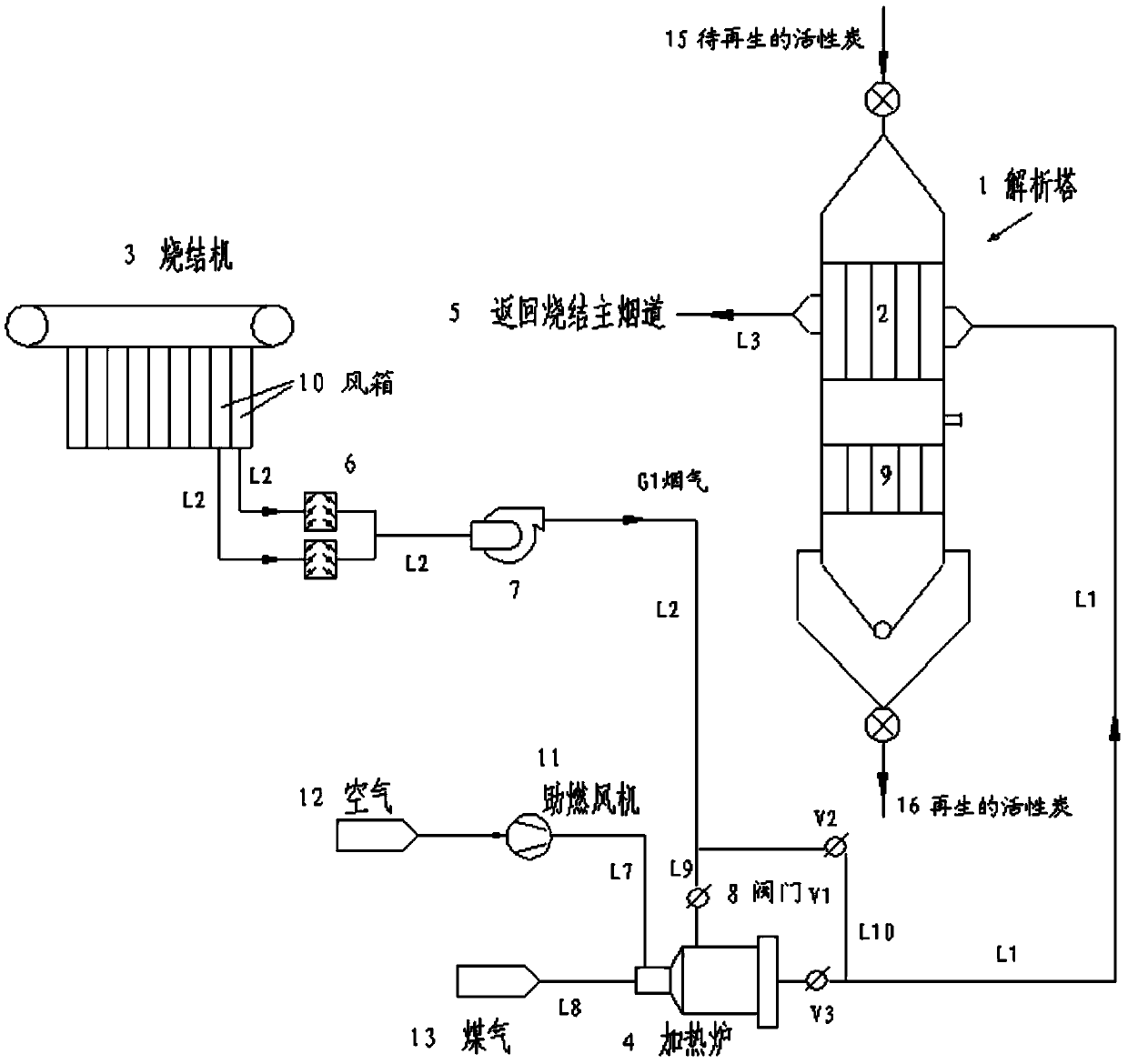

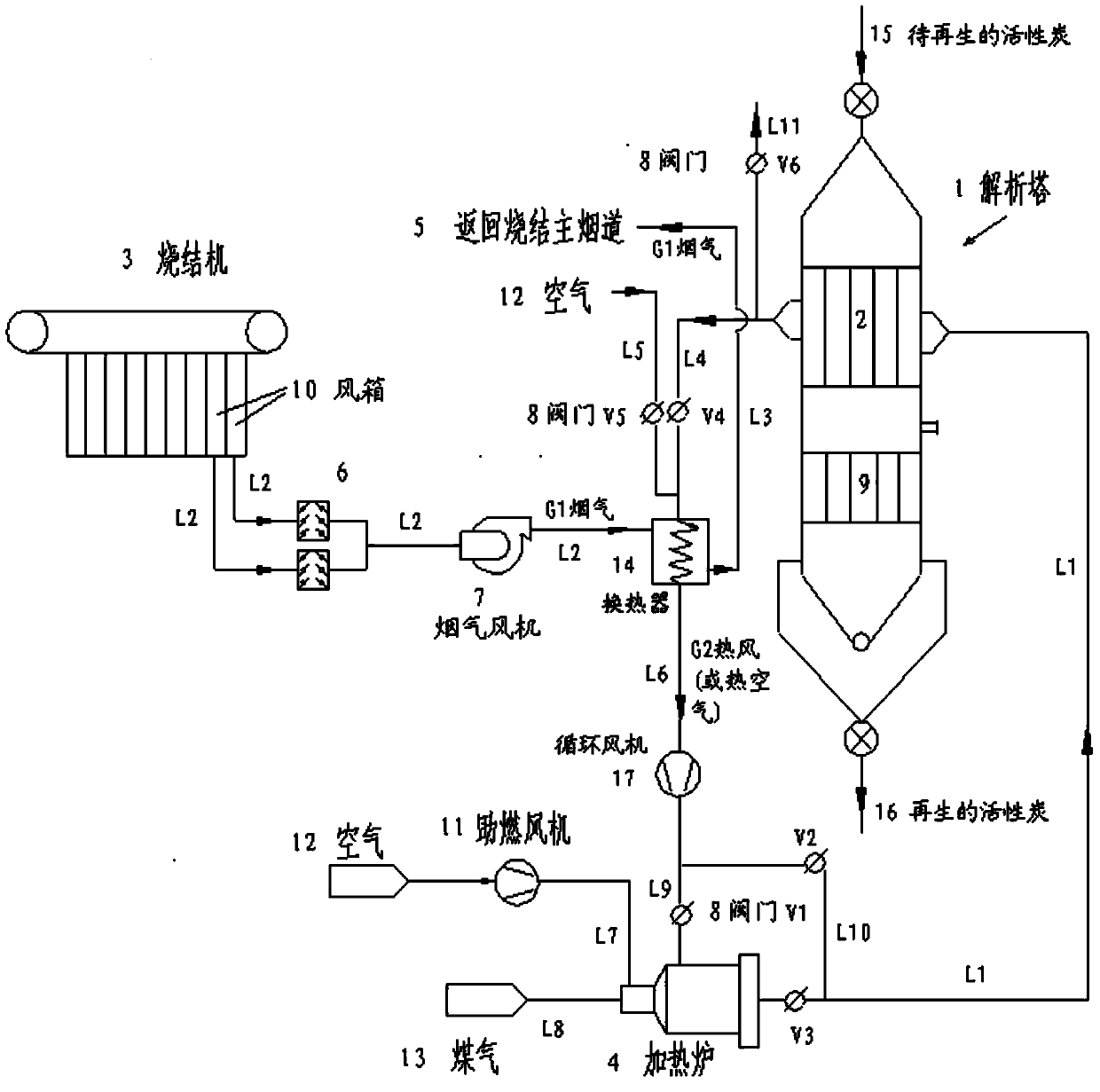

Thermal regeneration method and device of activated carbon

ActiveCN104190389AEasy to operateEasy to controlOther chemical processesCombustible gas purificationActivated carbonNitrogen oxides

The invention provides a thermal regeneration method of activated carbon. The method comprises the steps of (1) transferring activated carbon which adsorbs pollutants including sulfur oxide, nitrogen oxide and dioxin in an adsorption tower of a dry process desulphurization and denitration device into an activated carbon analysis tower from the bottom of the adsorption tower, wherein the desulphurization and denitration device comprises the activated carbon adsorption tower and the activated carbon analysis tower; and (2) carrying out heat exchange on the activated carbon and heating gas in the analysis tower to enable the activated carbon to be heated up to the activated carbon regeneration temperature T1 to enable the activated carbon to be analyzed and regenerated at the temperature T1, wherein the heating gas is high temperature flue gas G1 coming from one or two bellows at the tail of a sintering machine, or hot air G2 formed by indirect heat exchange between air with room temperature and the high temperature flue gas G1 coming from the one or two bellows at the tail of the sintering machine. The invention also provides a regeneration device of activated carbon.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD +1

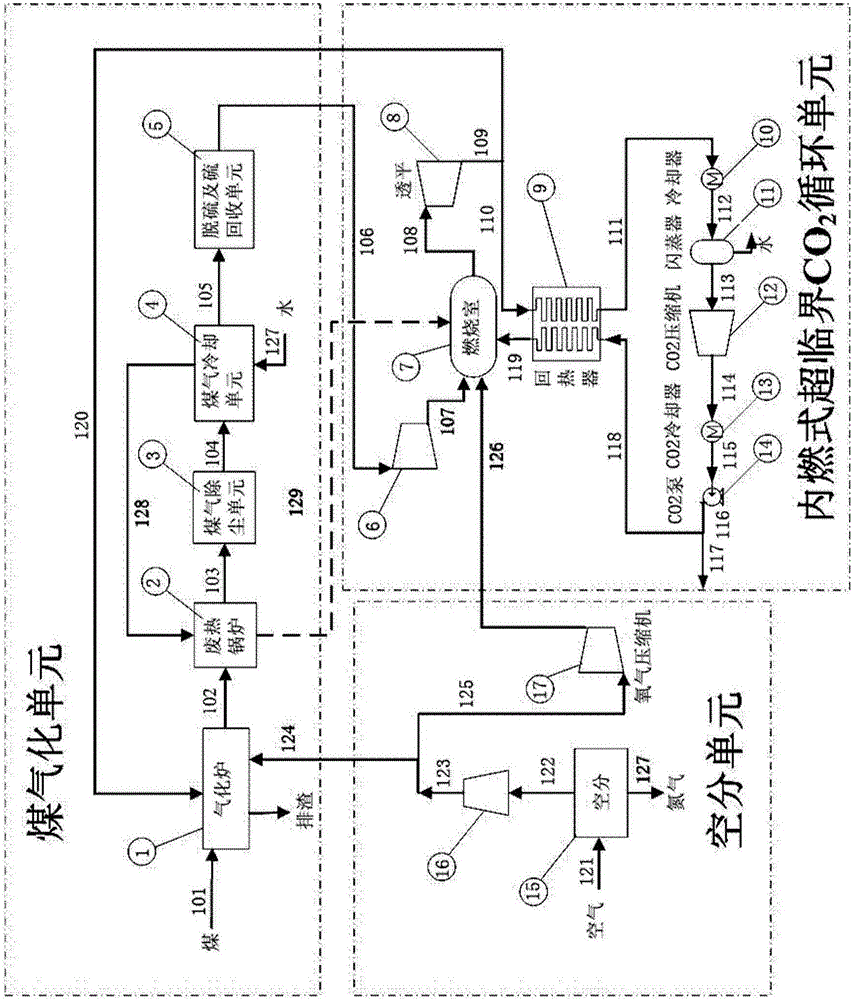

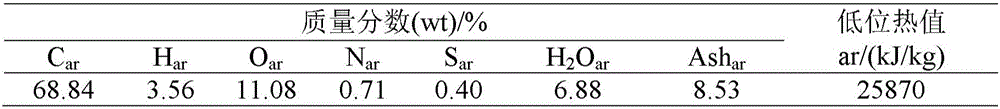

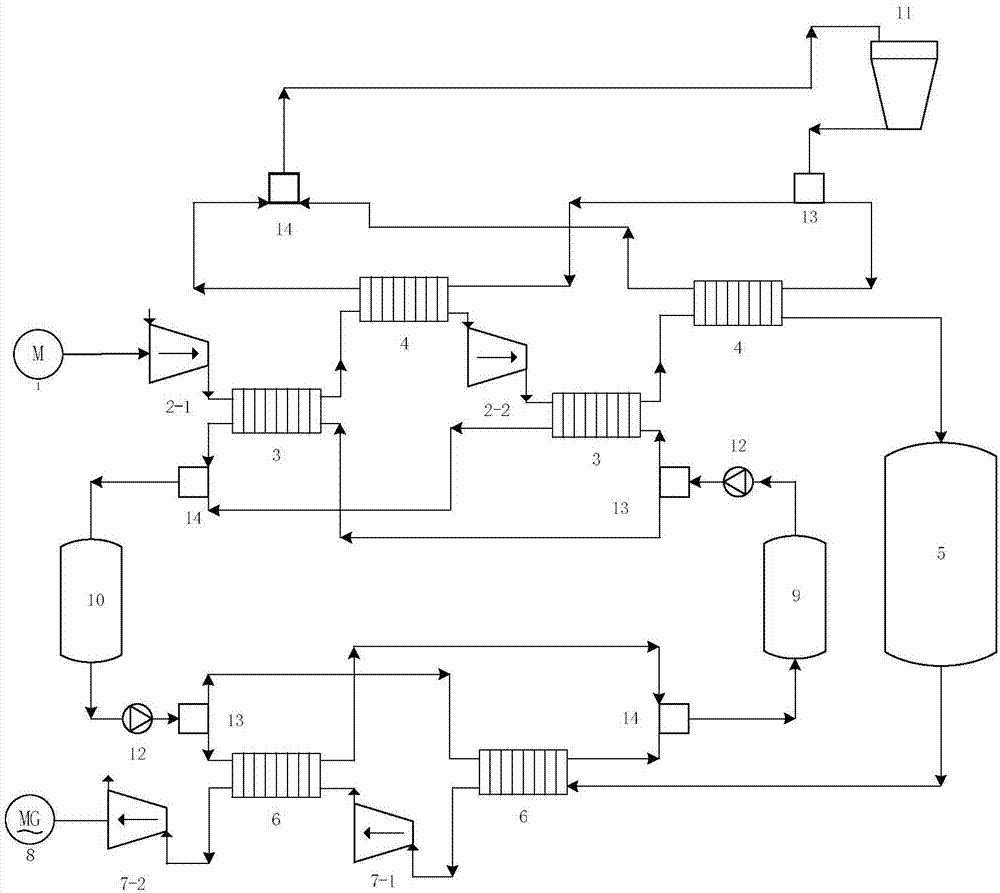

Gasification supercritical CO2 cycle power generation system

ActiveCN105820842AReduce oxygen consumptionReduce air separation power consumptionGas turbine plantsGasification processes detailsThermal energyCombustion chamber

A gasification supercritical CO2 cycle power generation system comprises a gasification unit, an air distribution unit and an internal combustion type supercritical CO2 circulation unit, wherein air is input into the air distribution unit, oxygen is generated and output in two paths, one path of oxygen is input into a gasification furnace, and the other path of oxygen is input into a combustion chamber of the internal combustion type supercritical CO2 circulation unit .The internal combustion type supercritical CO2 circulation unit further comprises a turbine for converting heat energy into mechanical energy and a heat regeneration unit used for heat exchanging, and a part of gas is extracted from the portion between turbine stages, or a turbine outlet or a cold side hot end outlet of the heat regeneration unit to serve as a gasification agent to be input into the gasification furnace in the gasification unit .While zero CO2 emission of the gasification supercritical CO2 cycle power generation system is achieved, high system efficiency is obtained, and the net efficiency is higher than that of an integrated gasification combined cycle power generation system based on pre-combustion trapping by 8-14%.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

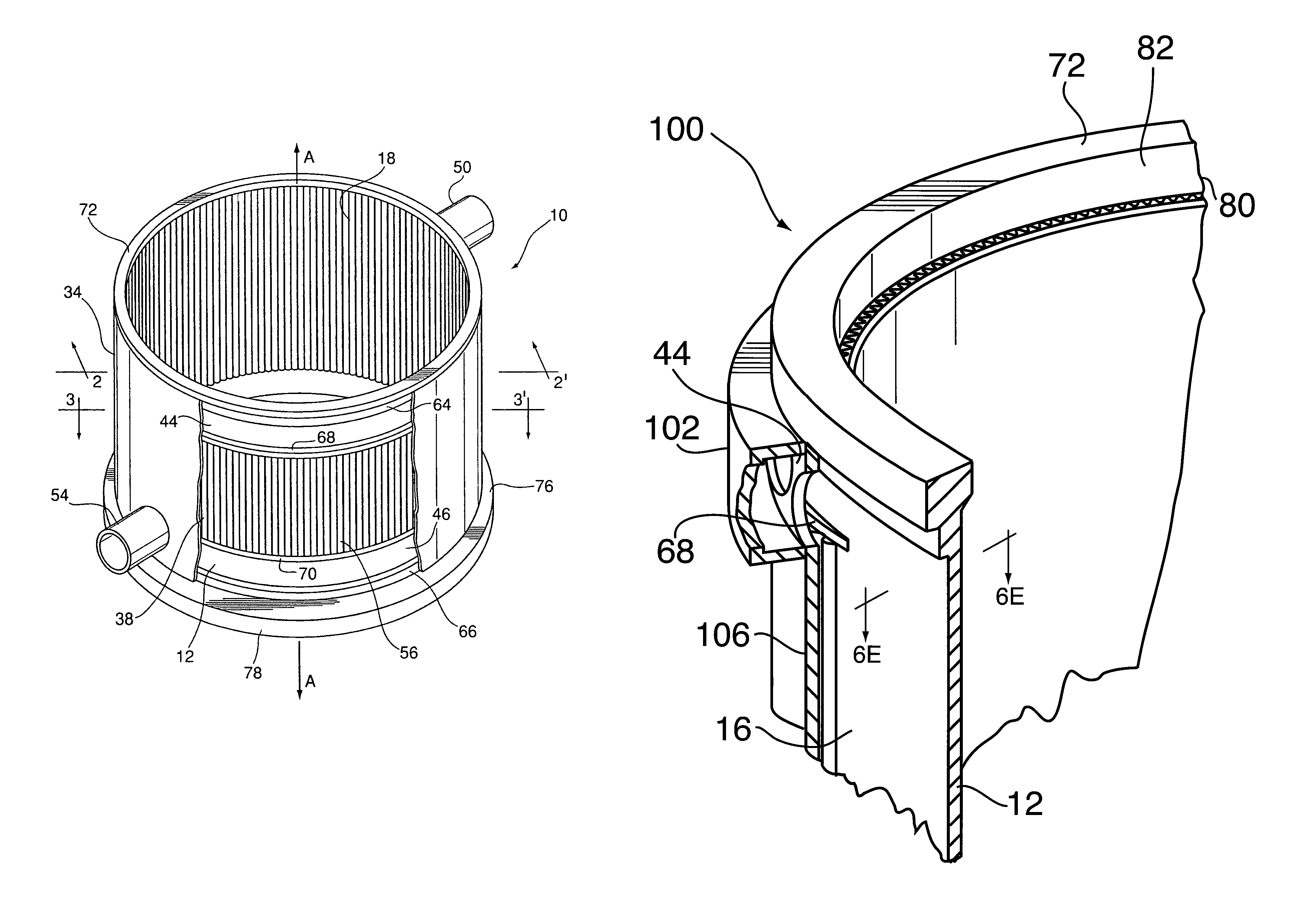

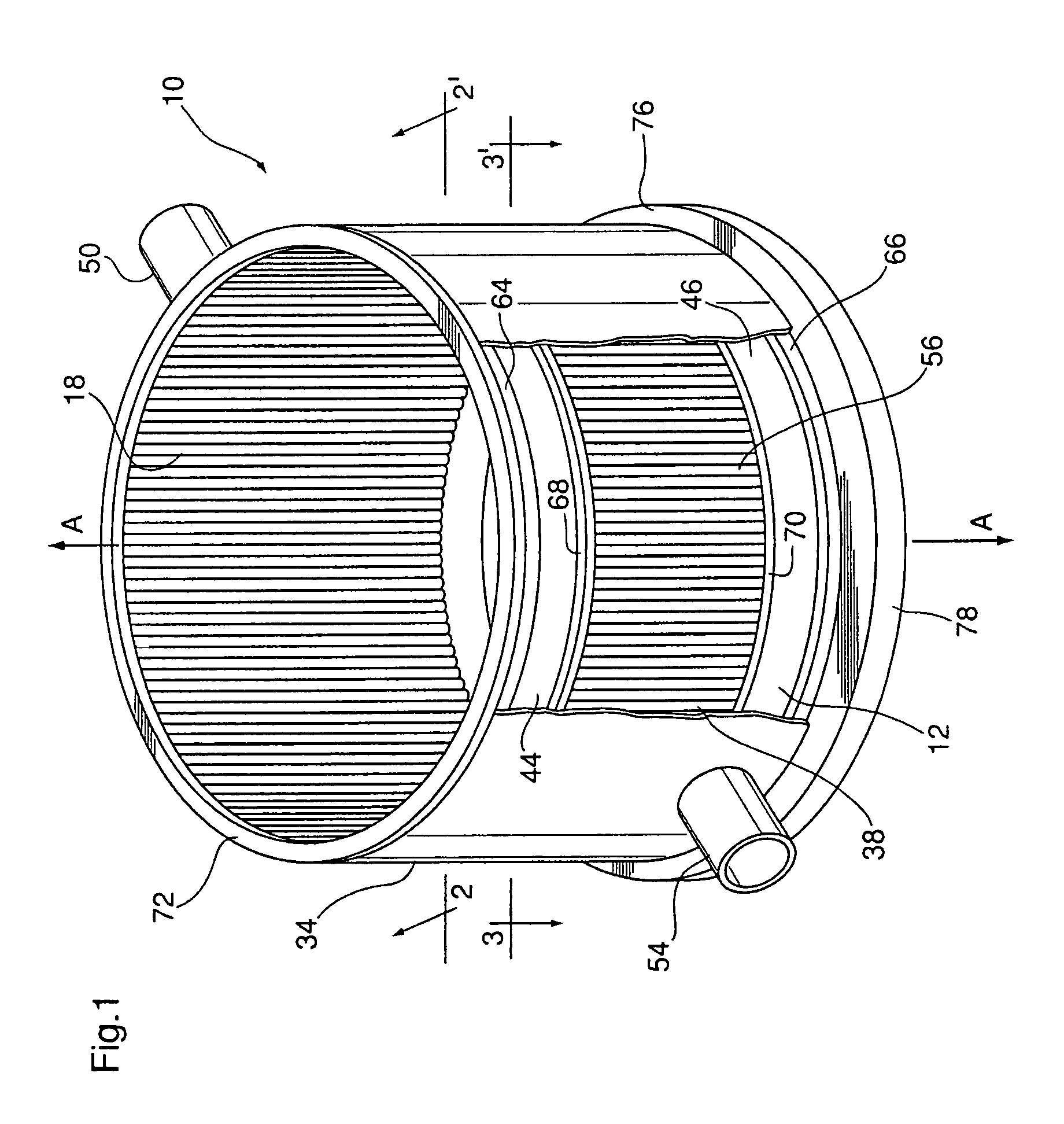

Finned cylindrical heat exchanger

InactiveUS8474515B2Stationary tubular conduit assembliesHeat transfer modificationWorking fluidCoolant flow

A cylindrical heat exchanger for use as a gas cooler in a thermal regenerative machine such as a Stirling engine includes an imperforate middle wall of sufficient strength and thickness to withstand the pressure exerted by the working fluid. The heat exchanger includes an inner corrugated wall located within an axial gas flow passage inside the middle wall, and an outer corrugated wall which defines an axial coolant flow passage along the outer surface of the middle wall. The coolant flow passage preferably contains a corrugated intermediate wall.

Owner:DANA CANADA CORP

Non-supplemental-combustion type compressed air energy storage system

ActiveCN107299891AEmission reductionImprove energy storage efficiencyPump installationsPositive-displacement liquid enginesThermal energy storageEngineering

The invention relates to the field of electric energy storage, in particular to a non-supplemental-combustion type compressed air energy storage system. The system comprises a high-temperature compressor unit, a gas storage device, a turbine generator unit and a heat regeneration system. The inlet of the gas storage device is connected with the high-temperature compressor unit to store high-pressure gas compressed by the high-temperature compressor unit; the outlet of the gas storage device is connected with the turbine generator unit and provides the compressed air for power generation of the turbine generator unit; the heat regeneration system comprises coolers, a high-temperature heat transfer medium storage device, a low-temperature heat transfer medium storage device and heat regeneration devices. By the adoption of the high-temperature compressor, compression heat temperature can be made to reach 250-360 DEG C; high-efficiency heat storage and heat regeneration are adopted, then the temperature of the compressed gas entering the turbine generator unit is increased, and therefore the efficiency of energy storage is improved.

Owner:TSINGHUA UNIV

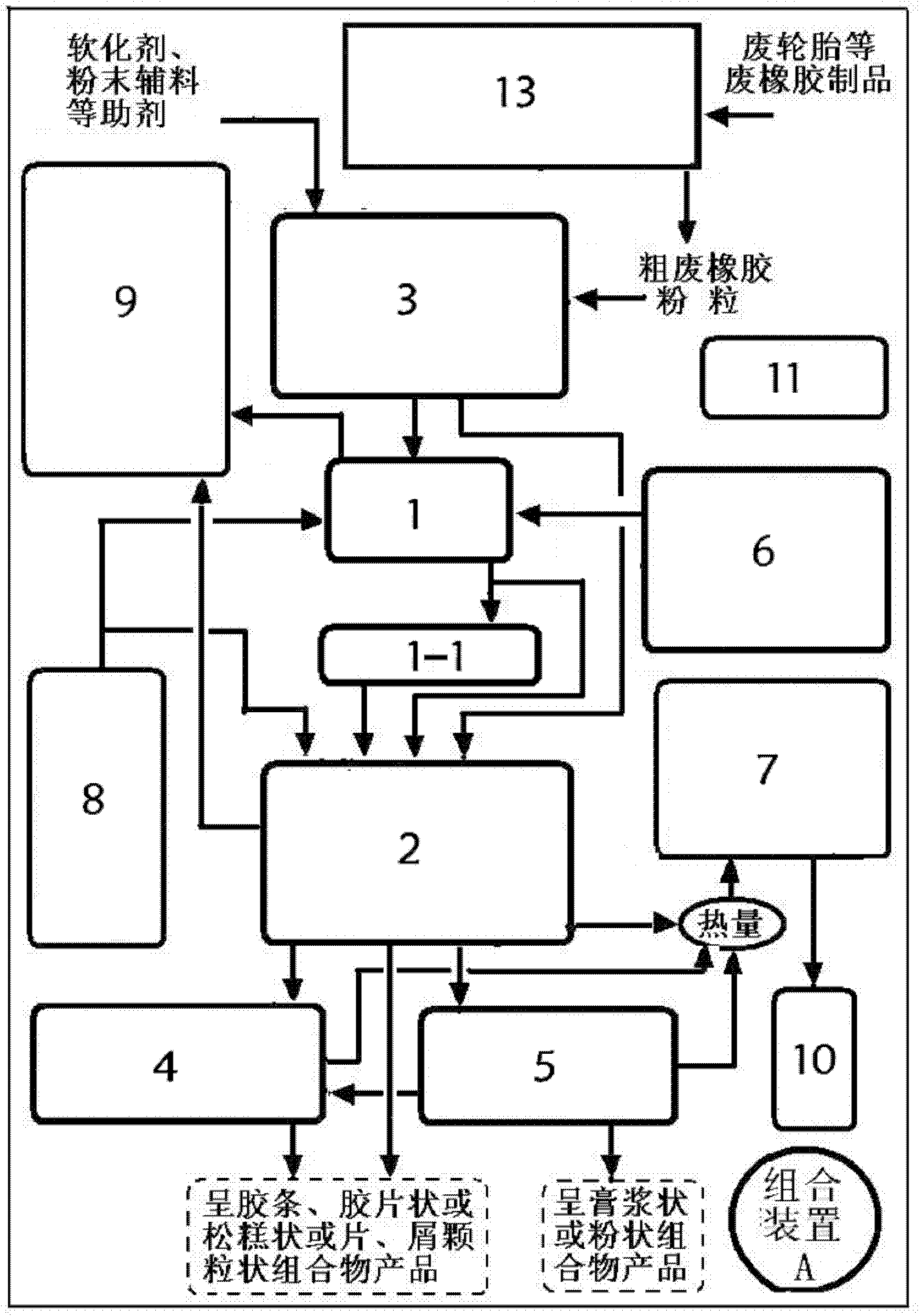

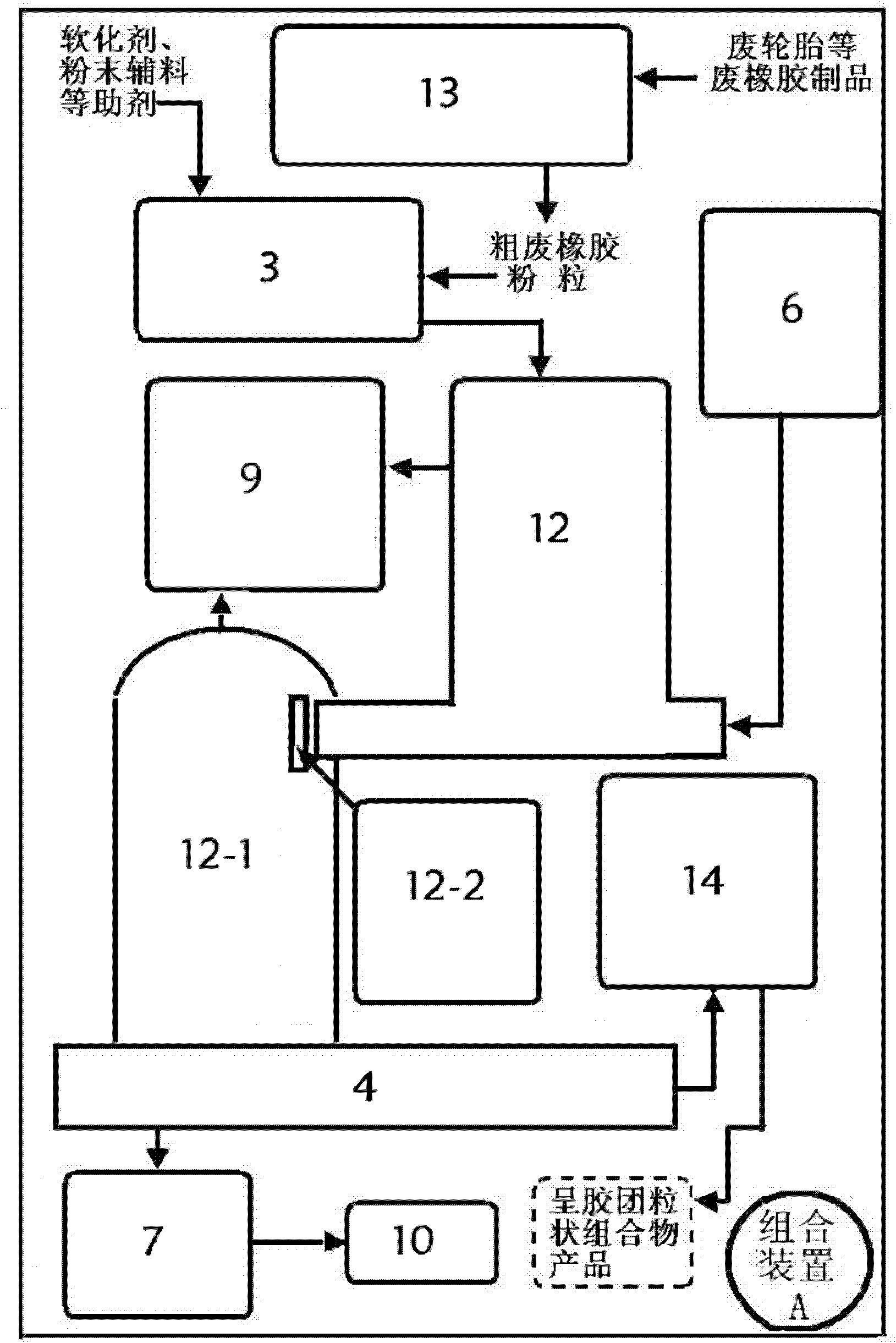

Heat regeneration method for waste rubber

InactiveCN102030934AMeet the environmental protection requirements of cleaner productionMeet environmental protection requirementsPlastic recyclingLiquid hydrocarbon mixture productionPolymer scienceWaste rubber

The invention provides a heat regeneration method for waste rubber. The method comprises the following steps of: feeding a waste rubber crude powder material / environmentally-friendly softening agent / powder auxiliary material in the weight ratio of 100 / 8-150 / 20-1,500 into a stirring heater, performing anoxybiotic heating, introducing into a stirring cooler and cooling to the temperature of less than 100 DEG C so as to obtain a product; or partially or completely extracting the powder auxiliary material in the fed materials for slow feeding, adding the extracted powder auxiliary material into the stirring heater before the materials which are put into the stirring heater at an early stage are discharged, or / and adding the extracted powder auxiliary material when a hot material is introduced into the stirring cooler, cooling the mixture to the temperature of less than 100 DEG C and discharging; or initially mixing the materials in a formula, guiding the mixture into a screw extruder, allowing the mixture to pass through a heating section and a mixing section, cooling the material to the temperature of less than 100 DEG C and discharging a product; or performing thermal cracking on all-known waste rubber through heat regeneration or establishing a multi-direction migration relation for a material or / and energy in the process of preparing carbon black from fuel oil and fuel gas.

Owner:陈汇宏 +1

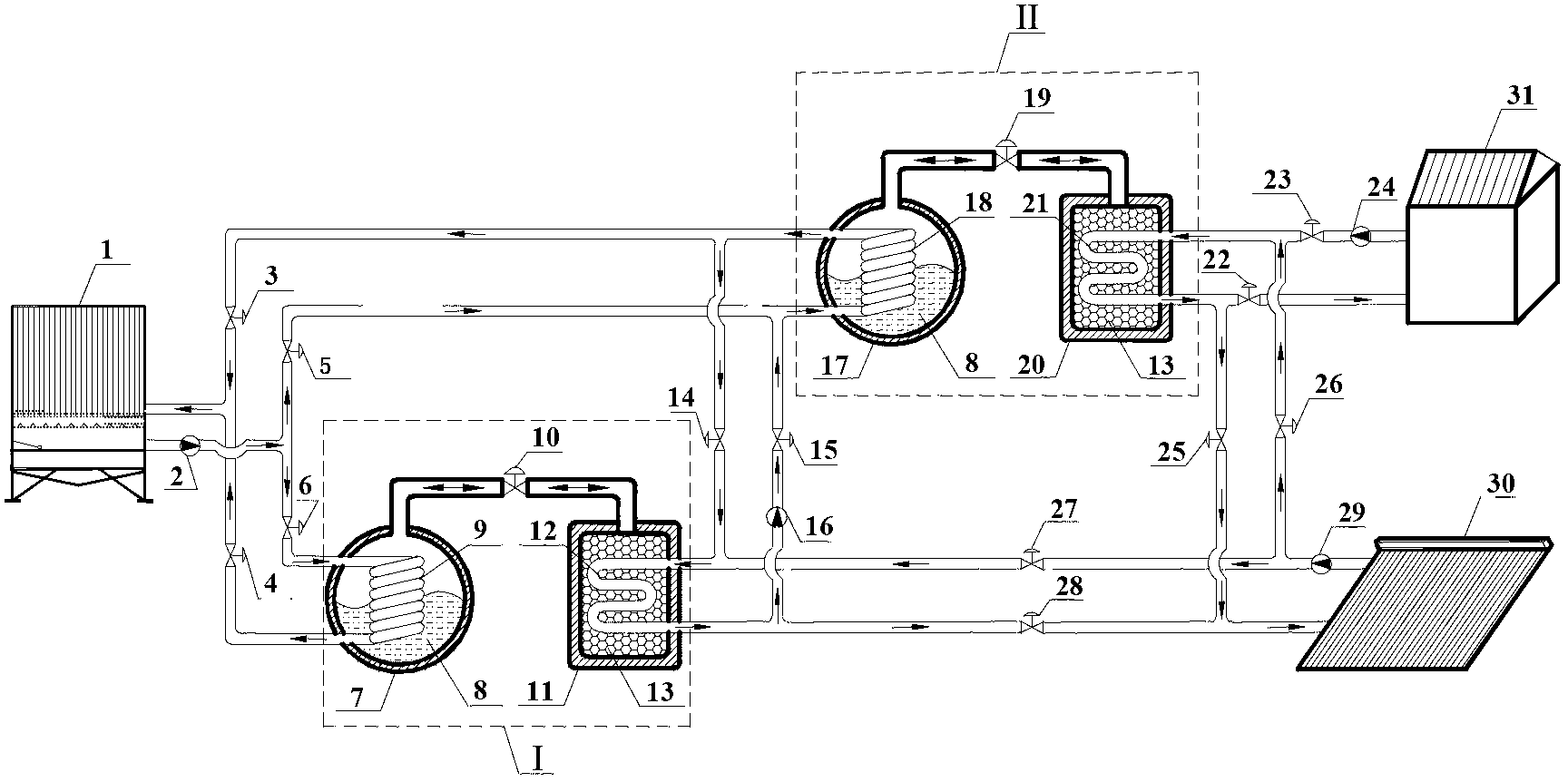

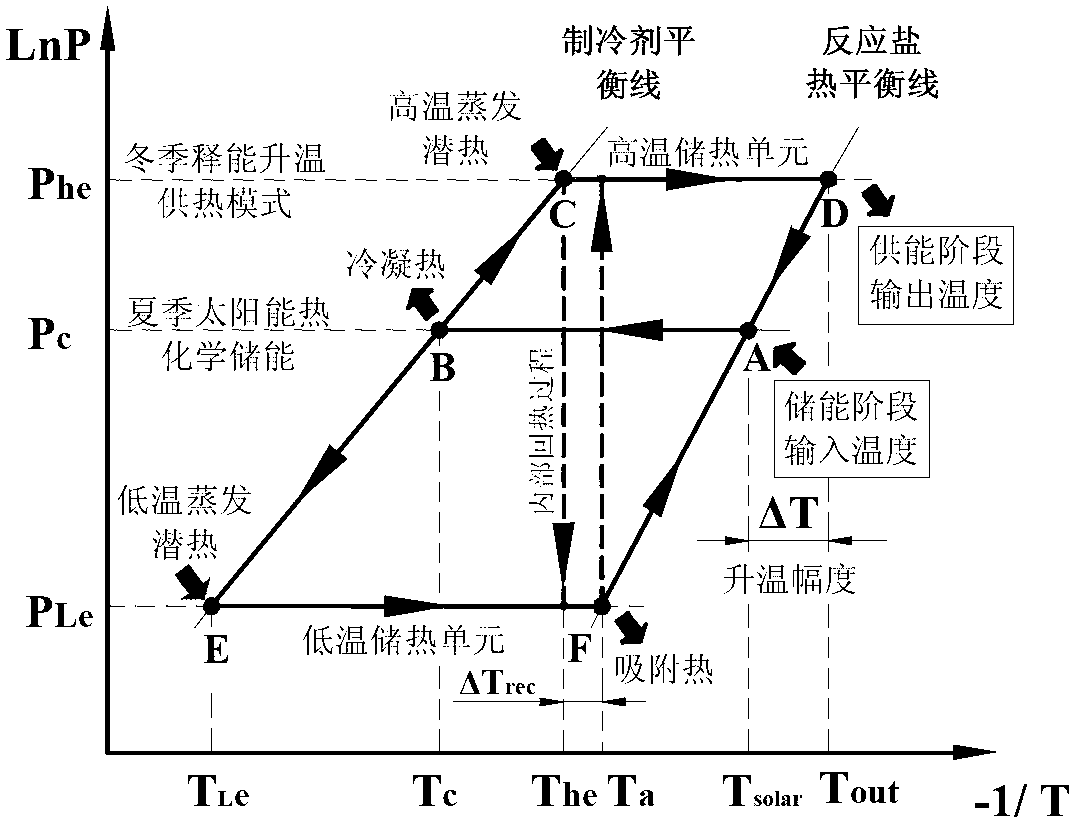

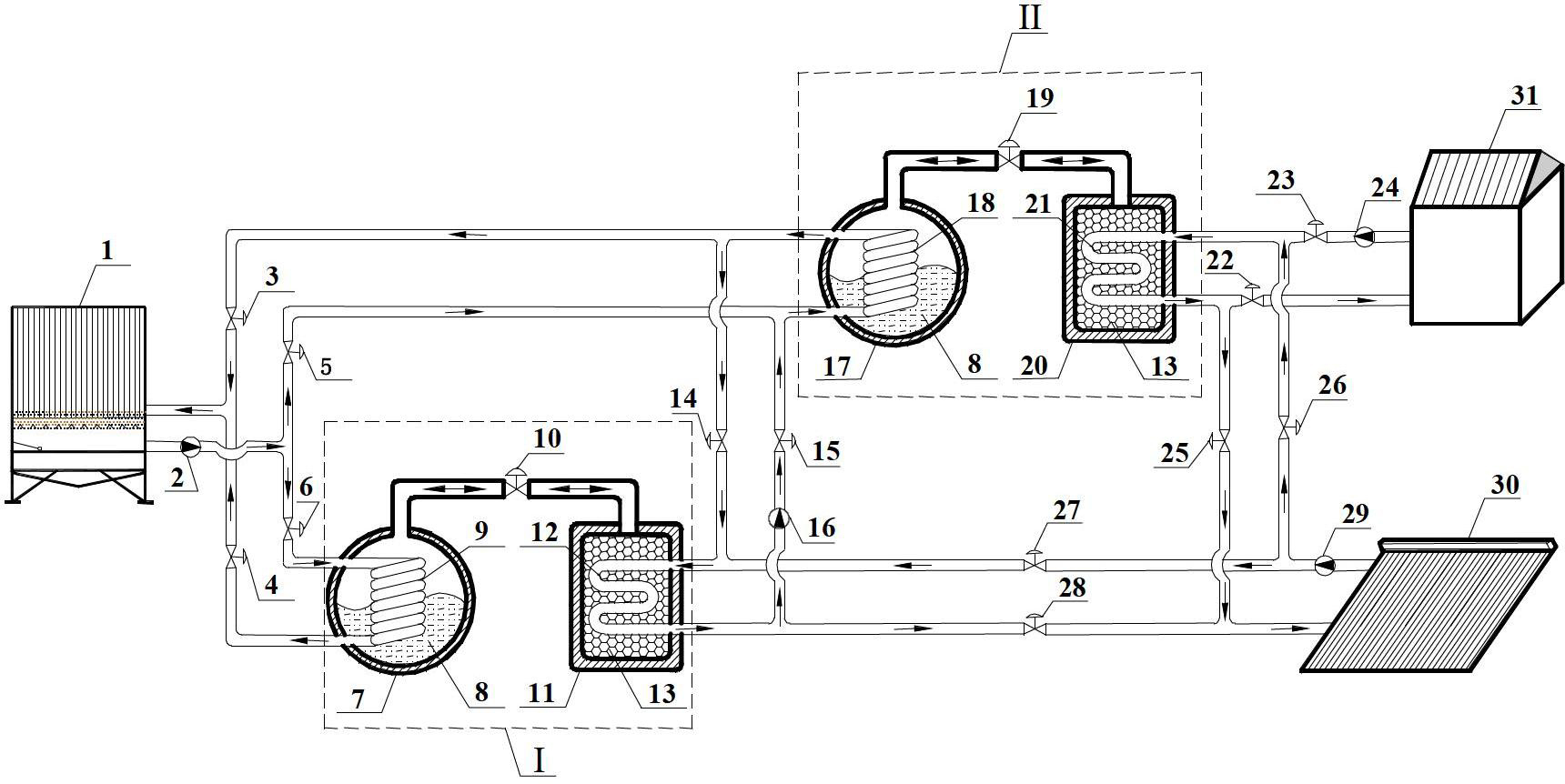

Solar thermochemical adsorption seasonal efficient energy storage device and method

ActiveCN102705997ASignificant advantagesSignificant positive effectExothermal chemical reaction heat productionSolar heat devicesThermal energyCooling tower

The invention relates to a solar thermochemical adsorption seasonal efficient energy storage device and method, and belongs to the technical field of solar thermal storage. When solar thermal energy is stored in summer, a solar thermal collector, a heating circulating pump, a heating switching valve and a solid-gas chemical reactor heat exchange coil are connected one another, a cooling tower, a cooling circulating pump, a cooling switching valve and a liquid accumulator heat exchange coil are connected one another, and solar efficient thermal storage is realized by converting solar thermal energy into chemical adsorption potential energy; and when solar thermal energy is released for supplying heat in winter, an internal reaction heat cascaded regeneration technology is carried out, a low-temperature reactor heat exchange coil, a heat regeneration circulating pump, a heat regeneration valve and a high-temperature liquid accumulator heat exchange coil are connected one another, a high-temperature reactor heat exchange coil, a heat supply circulating pump, a heat supply valve and a heat user are connected one another, and the warm-up heating to the outside through the stored solar heat is realized by converting chemical adsorption potential energy into thermal energy. Compared with the prior art, the device has the remarkable advantages that the energy storage density is high, the thermal loss is small during the seasonal energy storage period, the energy stored quality is enhanced, and the like.

Owner:SHANGHAI JIAO TONG UNIV

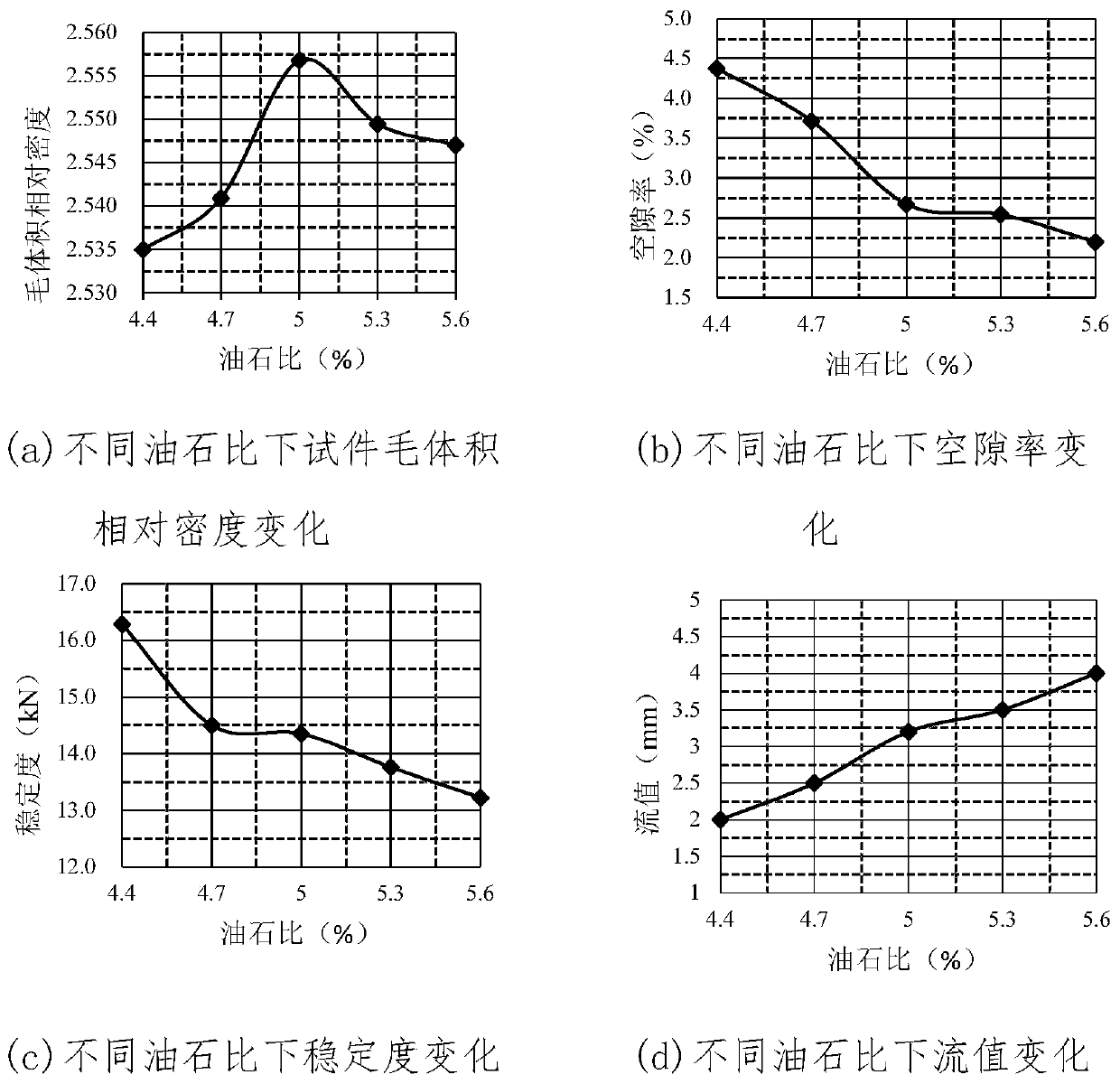

Mix proportion design method of plant-mixed hot recycled asphalt mixture

The invention discloses a mix proportion design method of a plant-mixed hot recycled asphalt mixture, relates to the technical field of road engineering, and belongs to the hot recycling technology ofasphalt materials. According to the method of the invention, the high-temperature and low-temperature comprehensive properties of a hot recycled asphalt mixture are fully considered; the asphalt mixture is composed of materials of a performance-decided thermal regeneration asphalt mixture, improper selection of an optimal asphalt-aggregate ratio caused by the inaccurate evaluation of the aging degree of recycled asphalt in RAP, inaccurate volume index test and the like is avoided; therefore, an RAP mixing amount and the performance of the recycled asphalt mixture are influenced, the optimal asphalt consumption OAC of the hot recycled asphalt mixture is determined through the performance, and the pavement performance of the hot recycled asphalt mixture is ensured.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

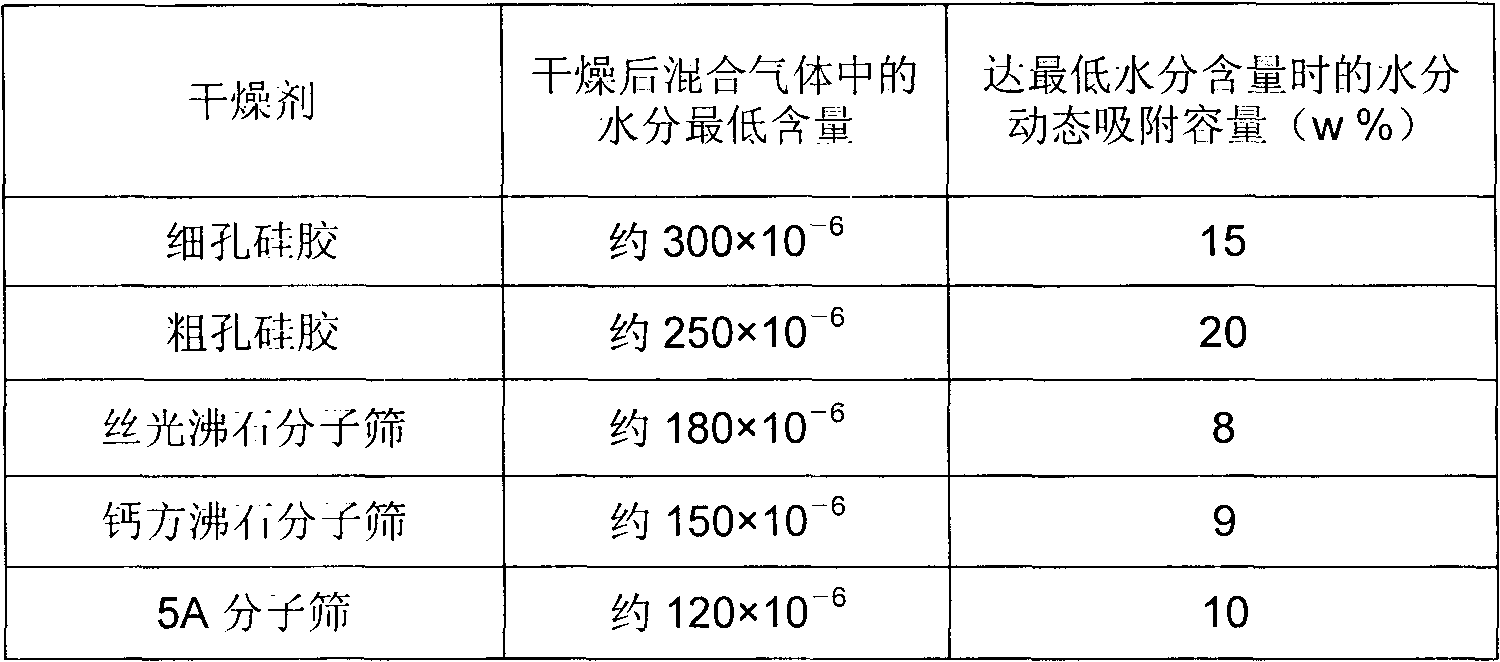

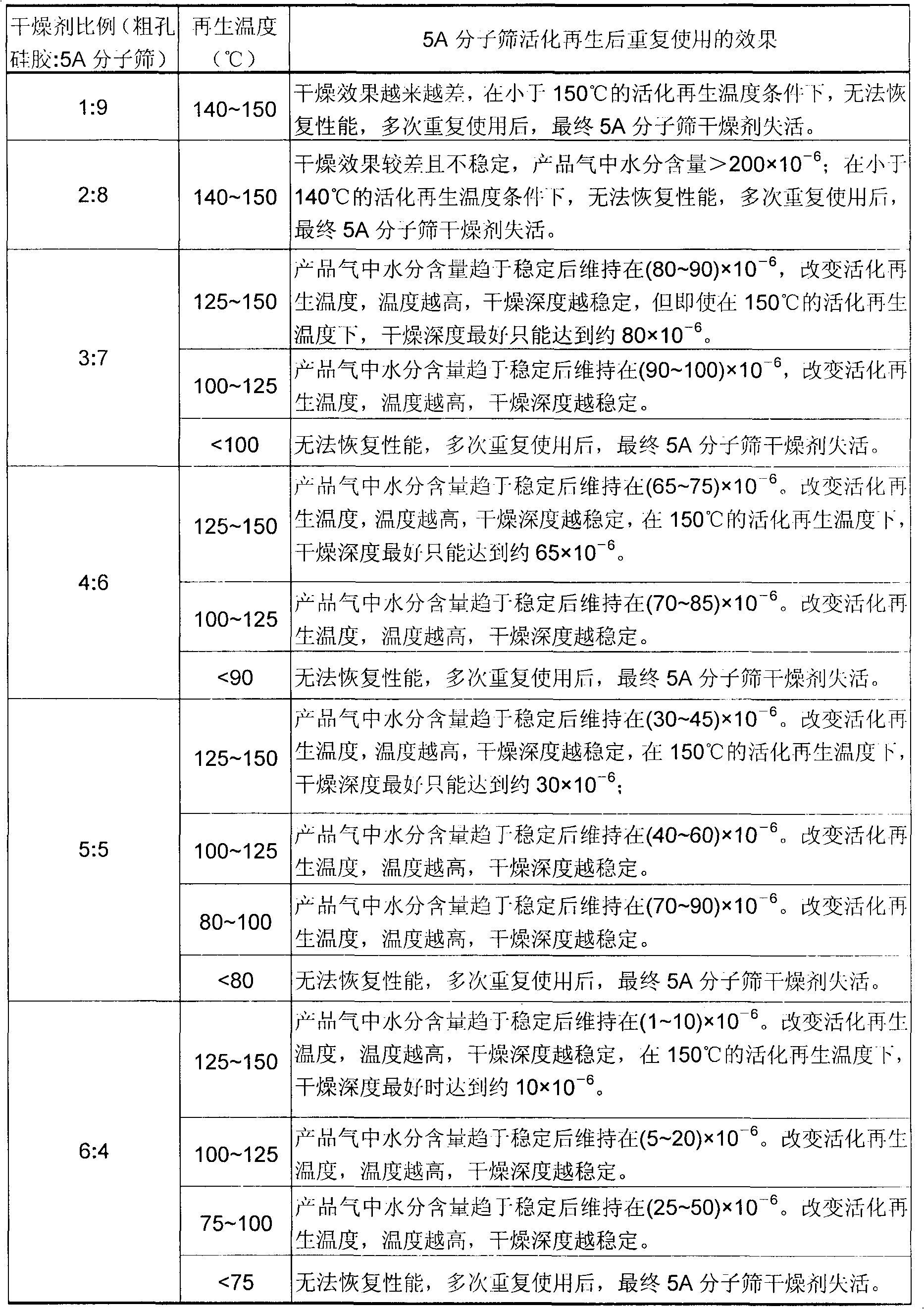

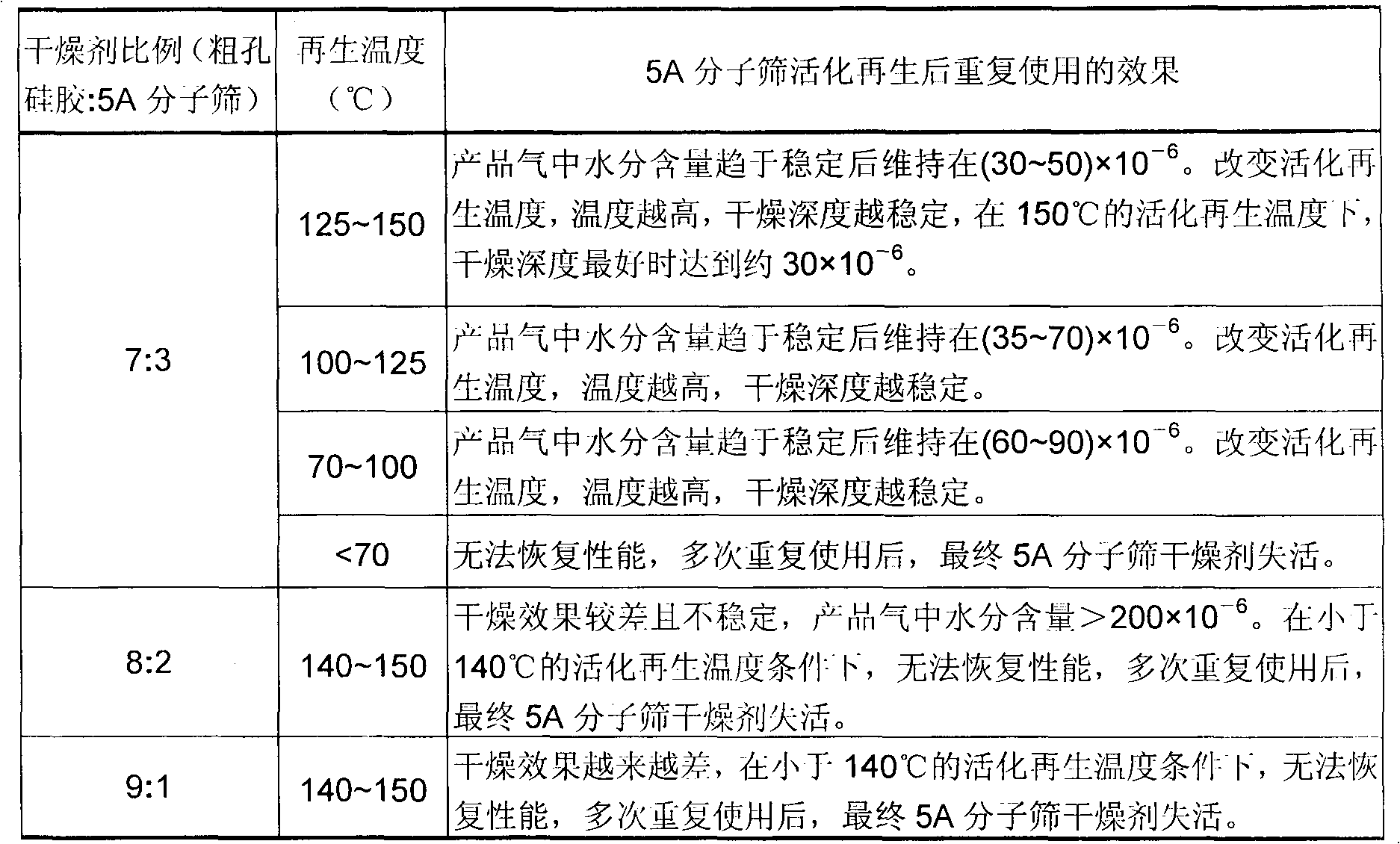

Method for removing moisture from chloroethylene or gas mixture with chloroethylene

ActiveCN101898068AReduce moisture contentReduce the content of other impuritiesDispersed particle separationHalogenated hydrocarbon preparationDesorptionSilica gel

The invention relates to a method for removing moisture from chloroethylene or gas mixture with chloroethylene. The method comprises the following steps: sending moisture-contained chloroethylene or gas mixture with chloroethylene from the entrance end into a dryer which is at least filled with macropore silica gel and 5A molecular sieve desiccant; performing adsorption drying under the gauge pressure of 0.30-0.70MPa; obtaining dry chloroethylene or gas mixture product with chloroethylene from the exit end of the dryer, at least heating desiccant in the dryer for desorption and cooling the desiccant to regenerate the desiccant, and performing the next adsorption drying operation repeatedly, wherein the average pore diameter of the silica-gel desiccant is 8.0-10.0nm, the specific surface area is 300-400m<2> / g, the pore volume is 0.8-1.0ml / g and the heat regeneration temperature of the desiccant is 70-150 DEG C. The total moisture content of the gas product dried by the method of the invention is up to (10-100)*10<-6>; and compared with the common drying methods and technologies such as solid caustic soda method, before and subsequent gravity dewatering method and coalescer dewatering and drying method, the method has the advantages of high dewatering accuracy, low operating cost, high recovery rate, more environmental friend and the like.

Owner:四川开元科技有限责任公司

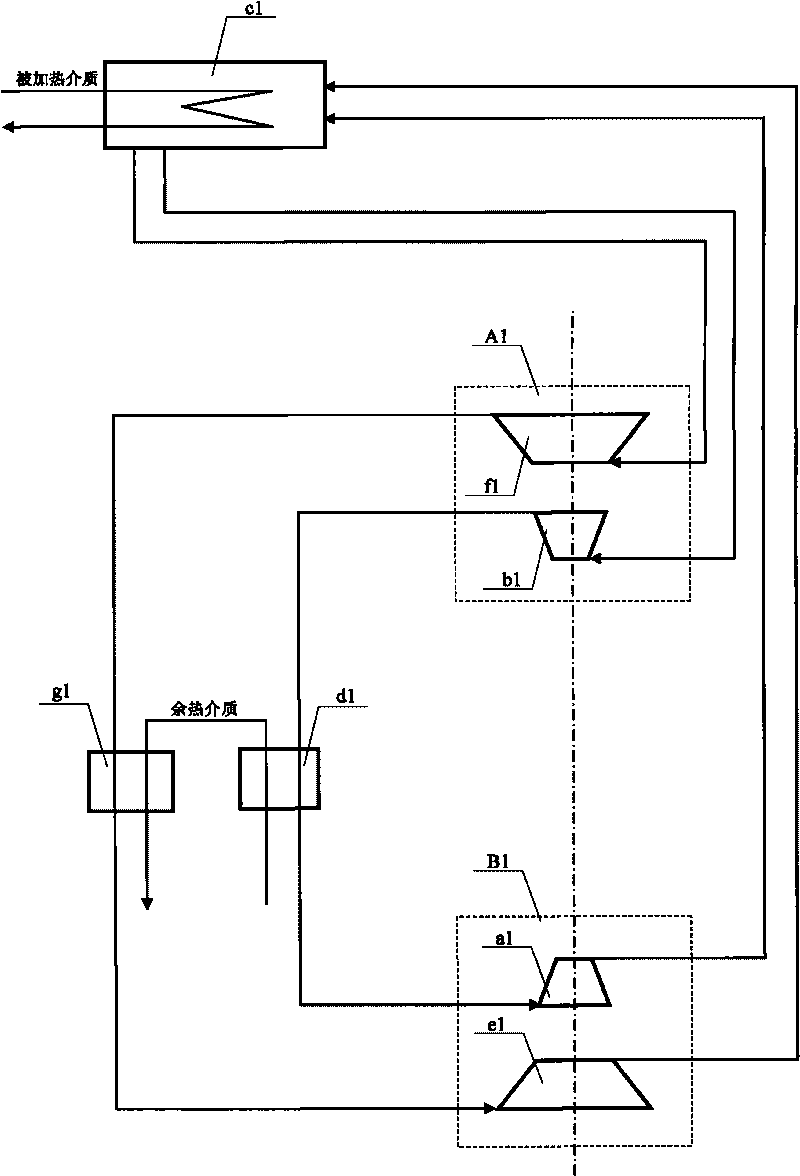

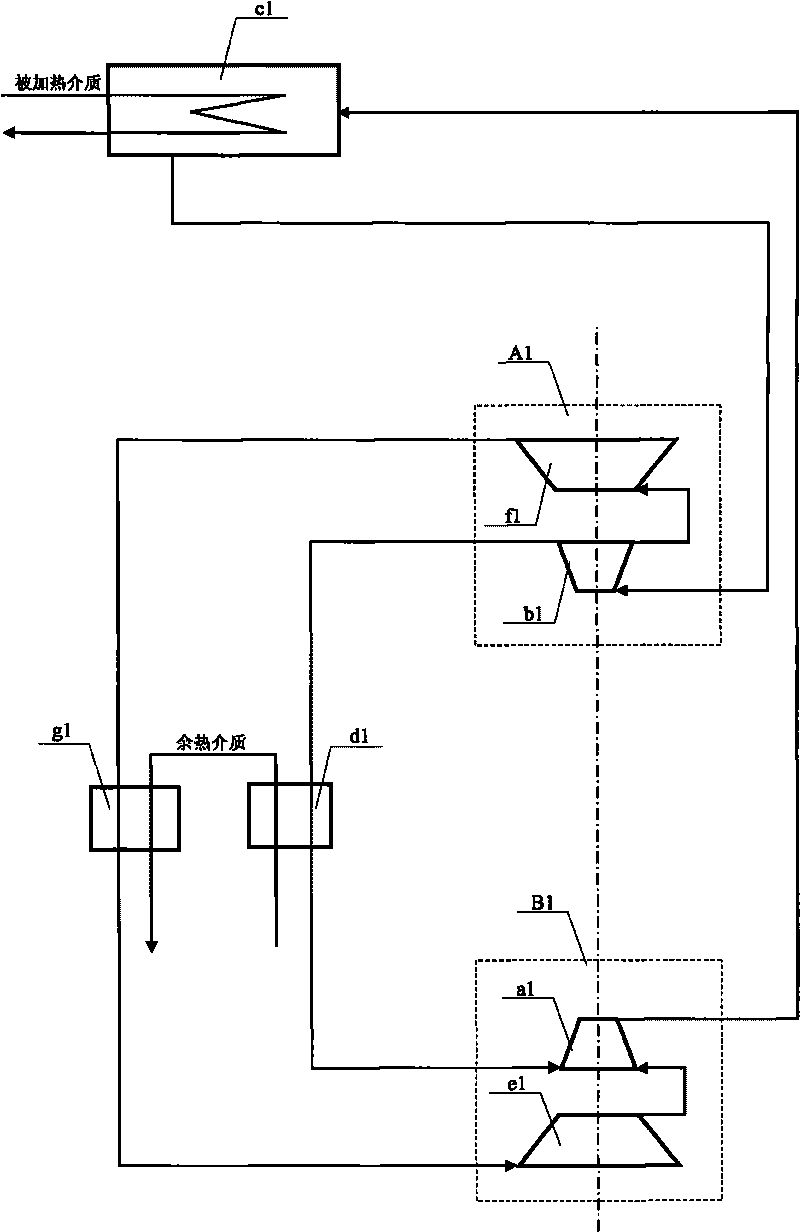

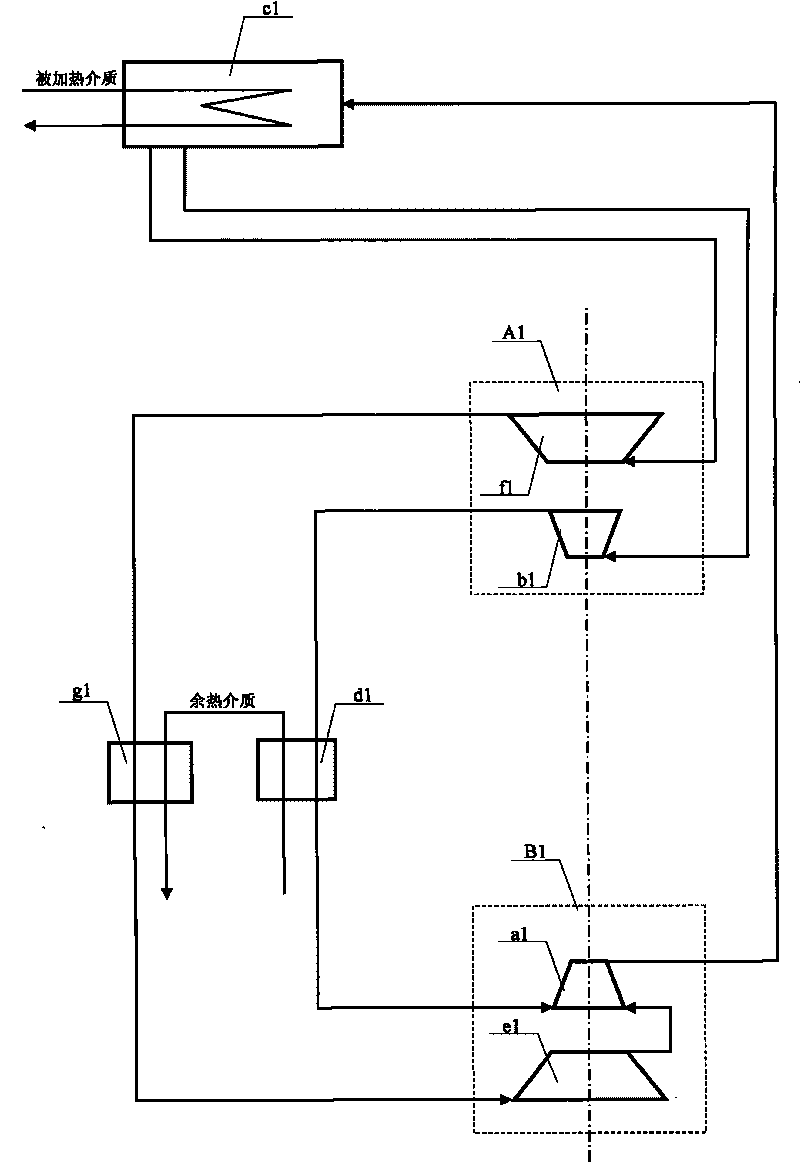

Sectionalized heat absorption, sectionalized compression and sectionalized expansion gas compression type heat pump

The invention relates to a sectionalized heat absorption, sectionalized compression, sectionalized expansion gas compression type heat pump, belonging to the field of heap pumps or refrigeration. Aiming at avoiding the defects of a machine seat with a single evaporator during large variation ranges of waste heat and medium temperature, the invention provides a gas compression type machine set which comprises more than two compressors, more than two expanders, more than two evaporators, a heater, and the like and realizes sectionalized heat absorption, sectionalized compression and sectionalized expansion, wherein a first compressor, a heat supply device, a first expander and a first heat exchanger form a first section of gas compression type heat pump structure which utilizes higher-temperature waste heat and a technological process; a second compressor, a second supply device, a second expander and a second heat exchanger form a second section of gas compression type heat pump structure which utilizes low-temperature waste heat and a technological process, by parity of reasoning; and a heat regeneration machine set can be formed by additionally providing a heat regenerator. The invention reduces the heat transfer temperature difference and increases the performance index; the heat pump used on the occasion with large ranges of waste heat and medium temperature can increase the utilization rate of the waste heat; and when used as a refrigerating machine within large temperature range of refrigerated media, the invention can reduce the power consumption.

Owner:李华玉

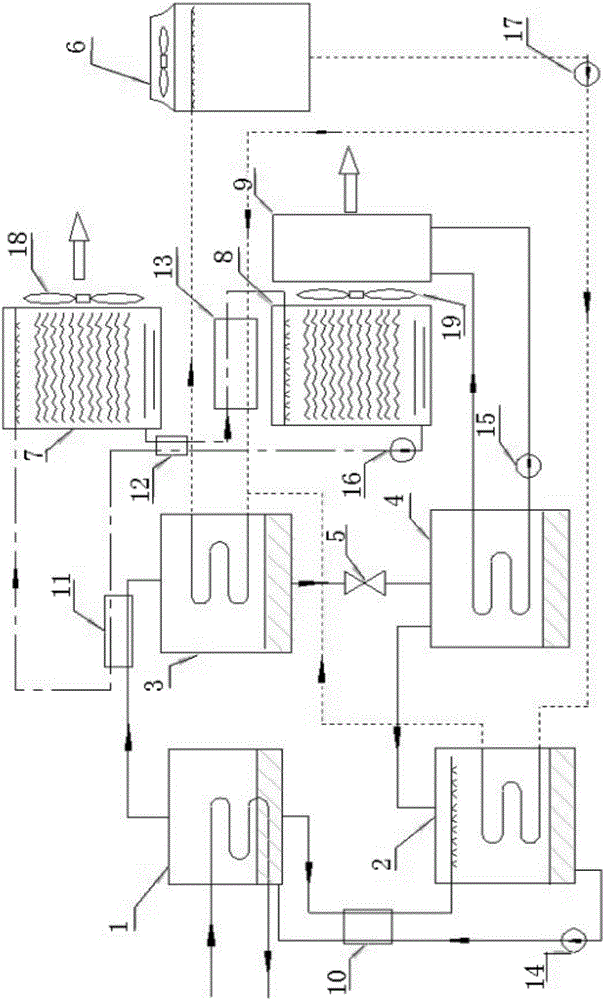

Dehumidification solution condensation heat regeneration low-temperature heat source absorption type coupling air conditioner device and regulation and control method

ActiveCN106091187AImprove performanceRaise the evaporation temperatureMechanical apparatusBoiler absorbersCooling towerBusiness efficiency

Owner:SOUTHEAST UNIV

Energy-saving gas washing process

ActiveCN105920978AReduce concentrationReduce energy consumptionDispersed particle separationSulfurGas phase

The invention relates to an energy-saving gas washing process, comprising the following steps: subjecting raw gas to countercurrent contact with methanol in an absorbing column, and washing out acidic gas from the raw gas; delivering obtained carbon-rich methanol to the upper portion of a medium-pressure flashing column, and delivering rich methanol to the lower segment of the medium-pressure flashing column; delivering via an ejector, liquid carbon-rich methanol in the medium-pressure flashing column to the upper part of a re-absorbing column, and delivering sulfur-rich methanol at the bottom of the medium-pressure flashing column to the lower part of the re-absorbing column for flashing; returning two parts of liquid flashed from the upper part of the re-absorbing column respectively to the re-absorbing column and a negative-pressure flashing column; using flashed liquid rich methanol as main washing methanol, delivering flashed gas to a suction ejector, and delivering flashed sulfur-rich methanol to a subsequent heat regeneration system.

Owner:SINOPEC NINGBO ENG +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com