Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

296 results about "Energy parameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for efficient frame erasure concealment in linear predictive based speech codecs

ActiveUS20050154584A1Improve concealmentPromote recoveryError preventionTransmission systemsStability parameterFrequency spectrum

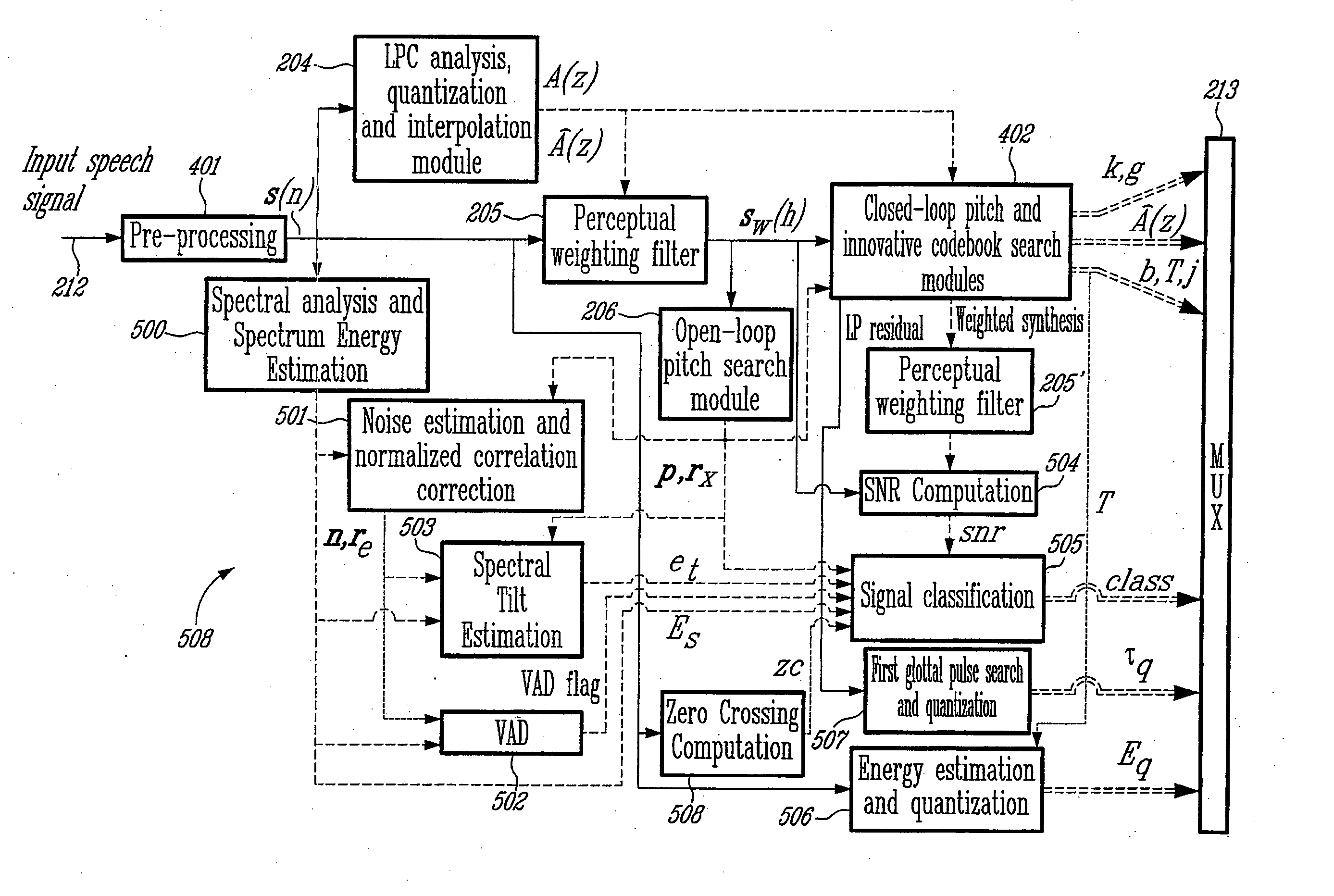

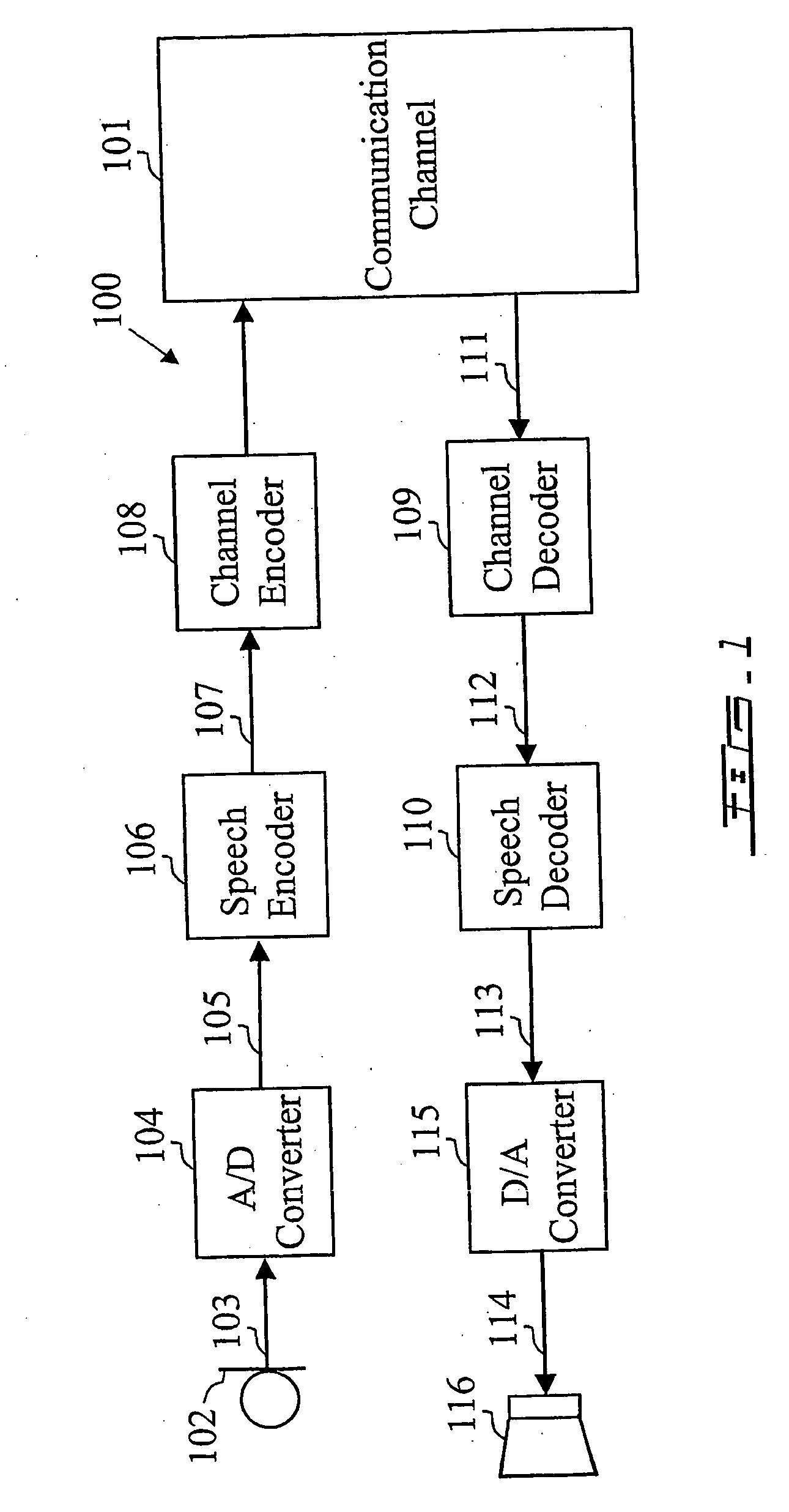

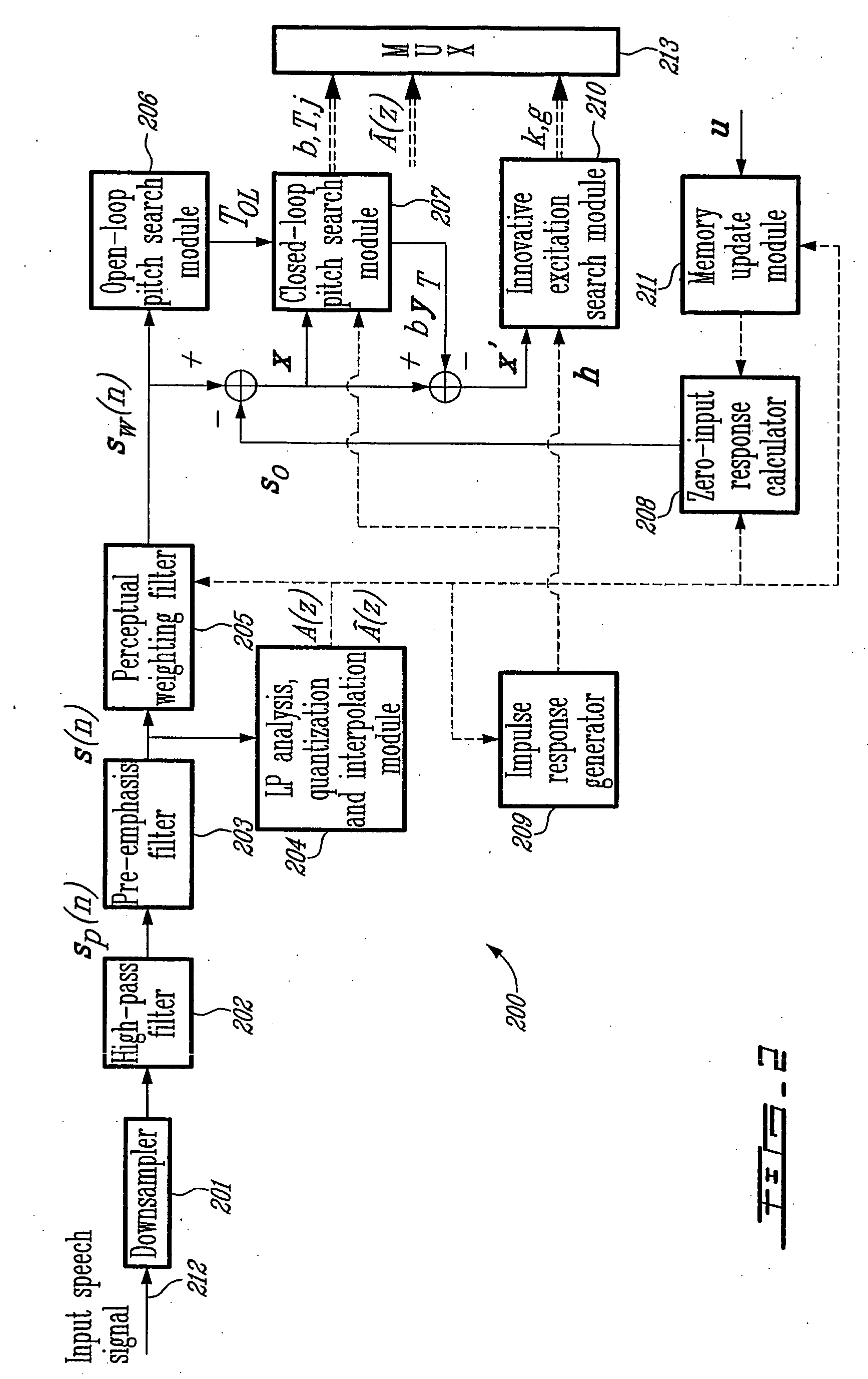

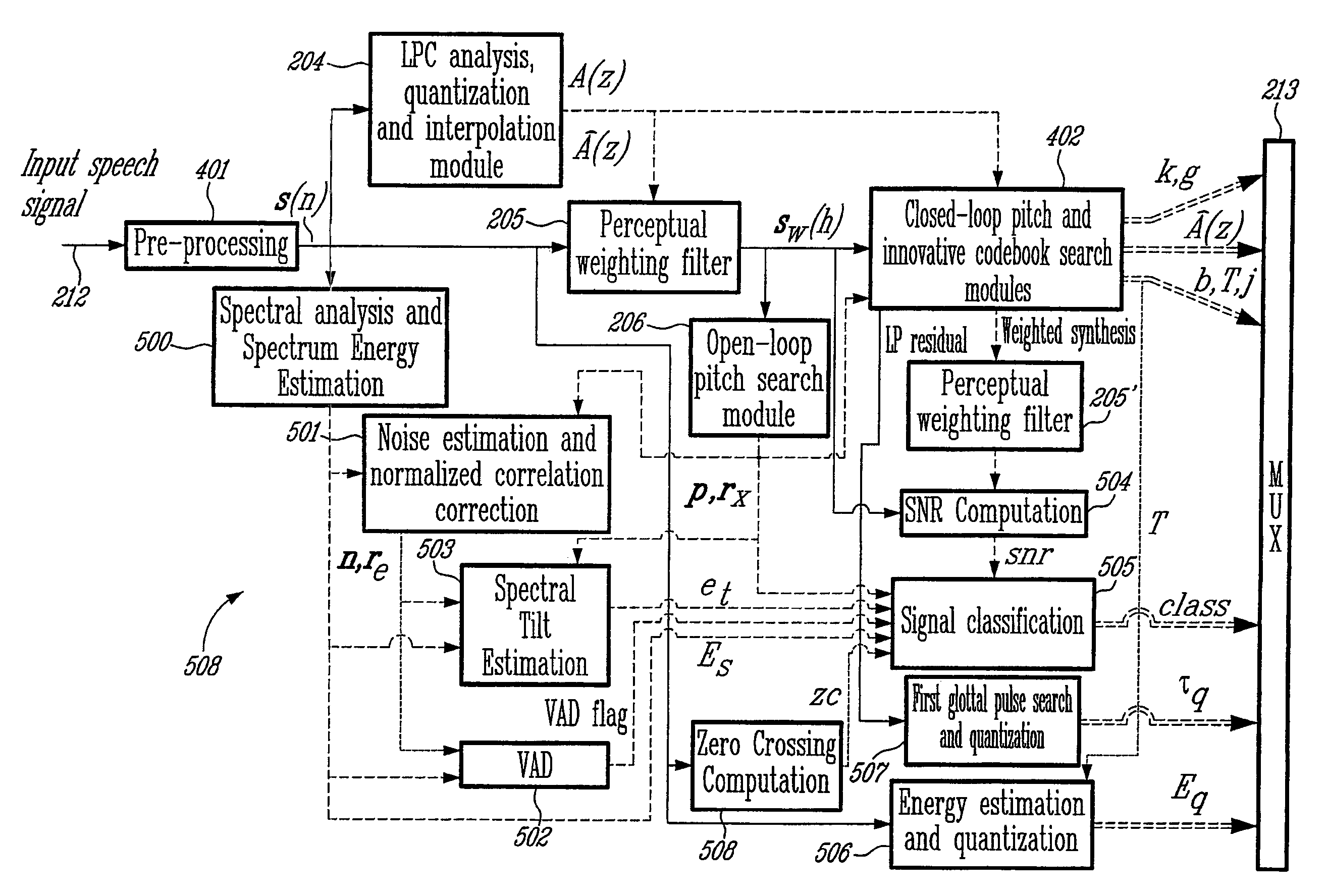

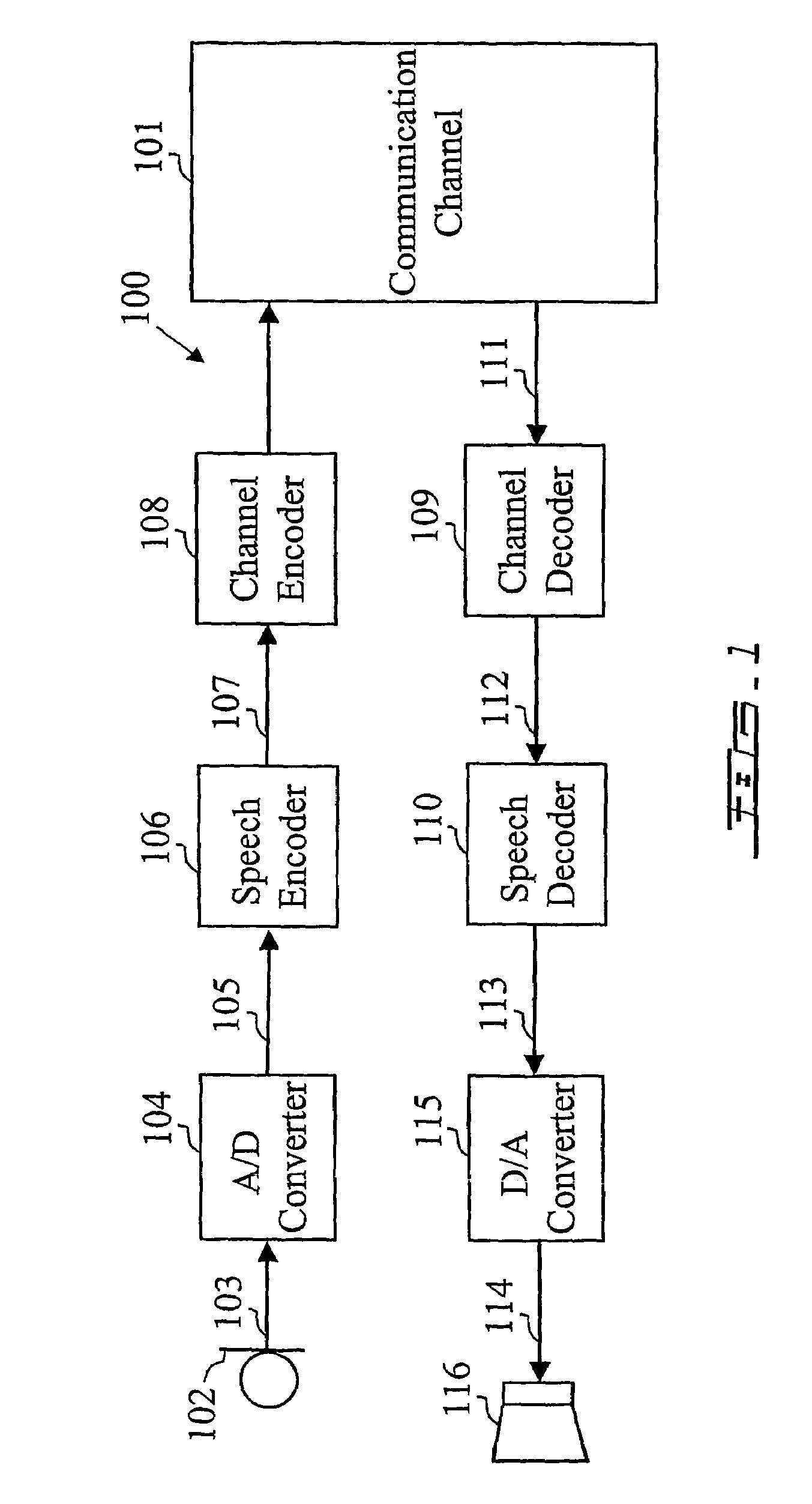

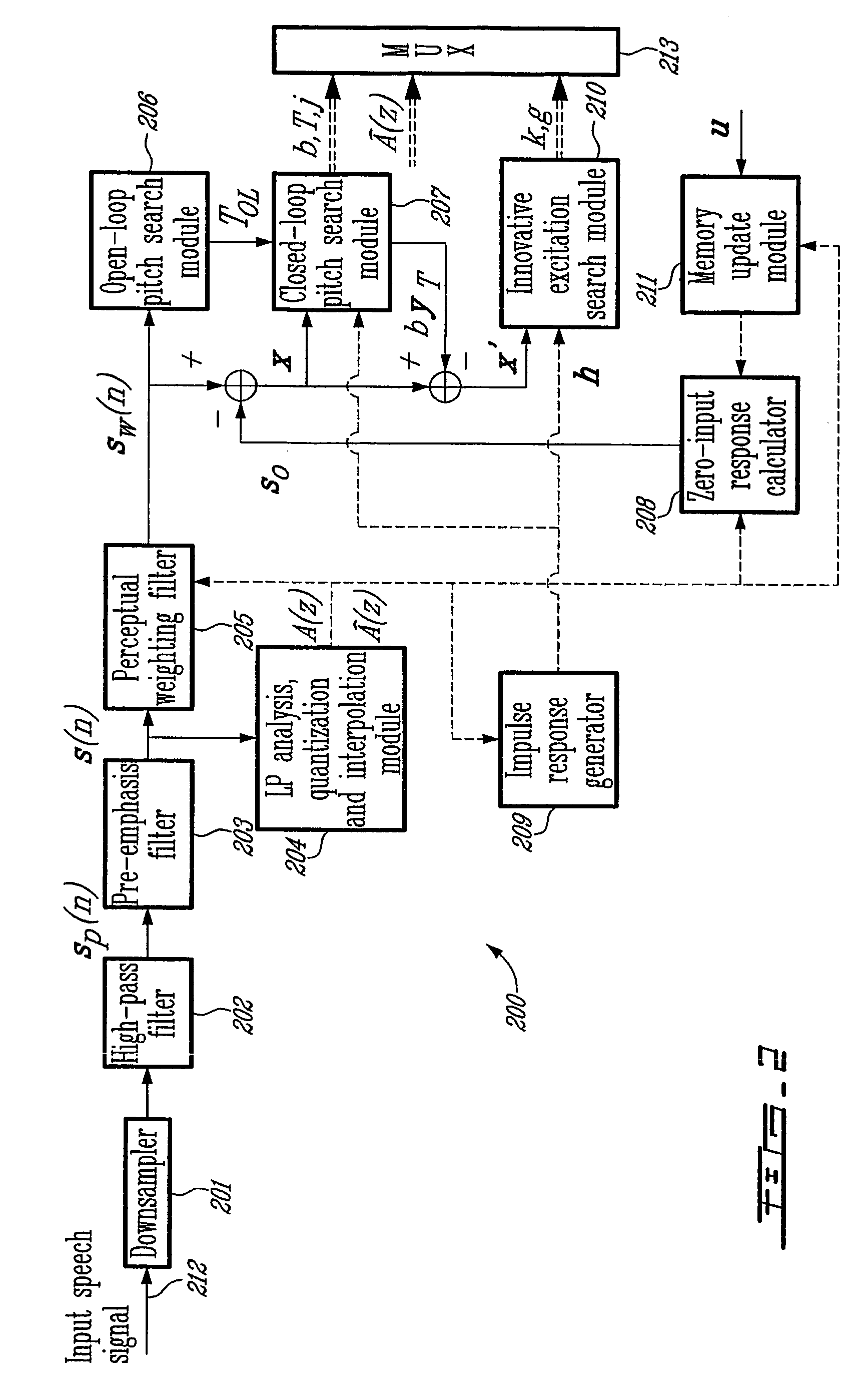

The present invention relates to a method and device for improving concealment of frame erasure caused by frames of an encoded sound signal erased during transmission from an encoder (106) to a decoder (110), and for accelerating recovery of the decoder after non erased frames of the encoded sound signal have been received. For that purpose, concealment / recovery parameters are determined in the encoder or decoder. When determined in the encoder (106), the concealment / recovery parameters are transmitted to the decoder (110). In the decoder, erasure frame concealment and decoder recovery is conducted in response to the concealment / recovery parameters. The concealment / recovery parameters may be selected from the group consisting of: a signal classification parameter, an energy information parameter and a phase information parameter. The determination of the concealment / recovery parameters comprises classifying the successive frames of the encoded sound signal as unvoiced, unvoiced transition, voiced transition, voiced, or onset, and this classification is determined on the basis of at least a part of the following parameters: a normalized correlation parameter, a spectral tilt parameter, a signal-to-noise ratio parameter, a pitch stability parameter, a relative frame energy parameter, and a zero crossing parameter.

Owner:VOICEAGE EVS LLC

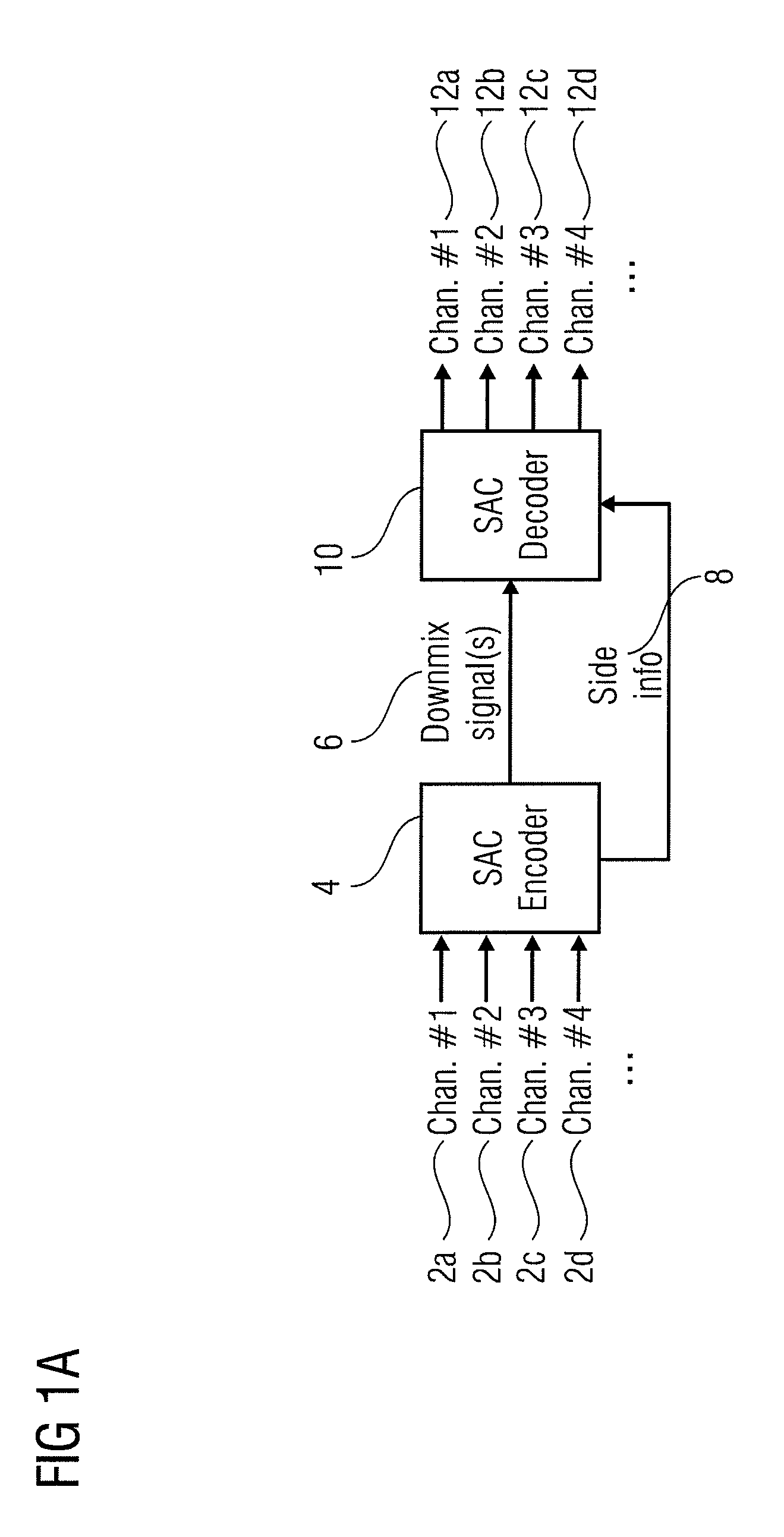

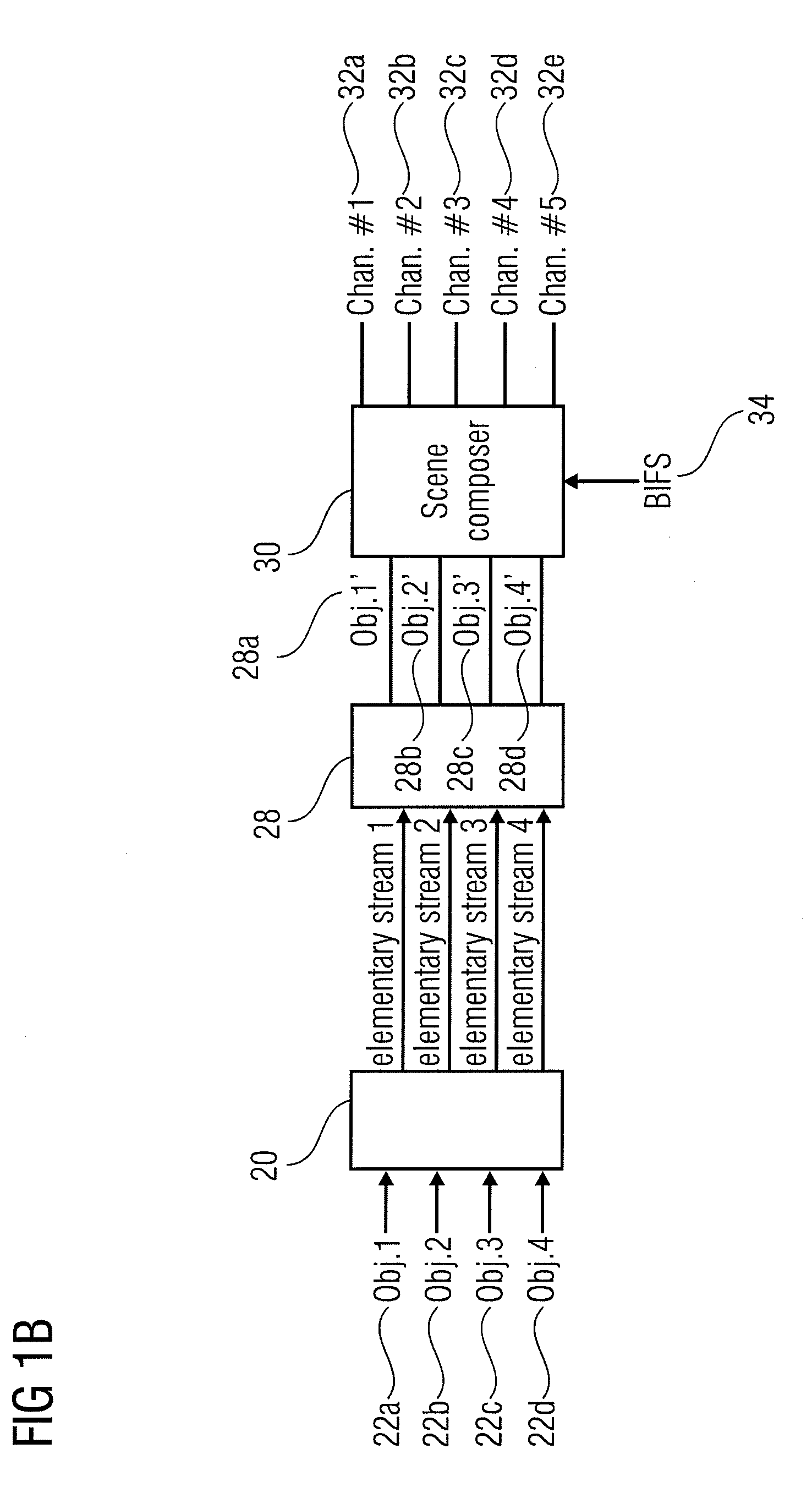

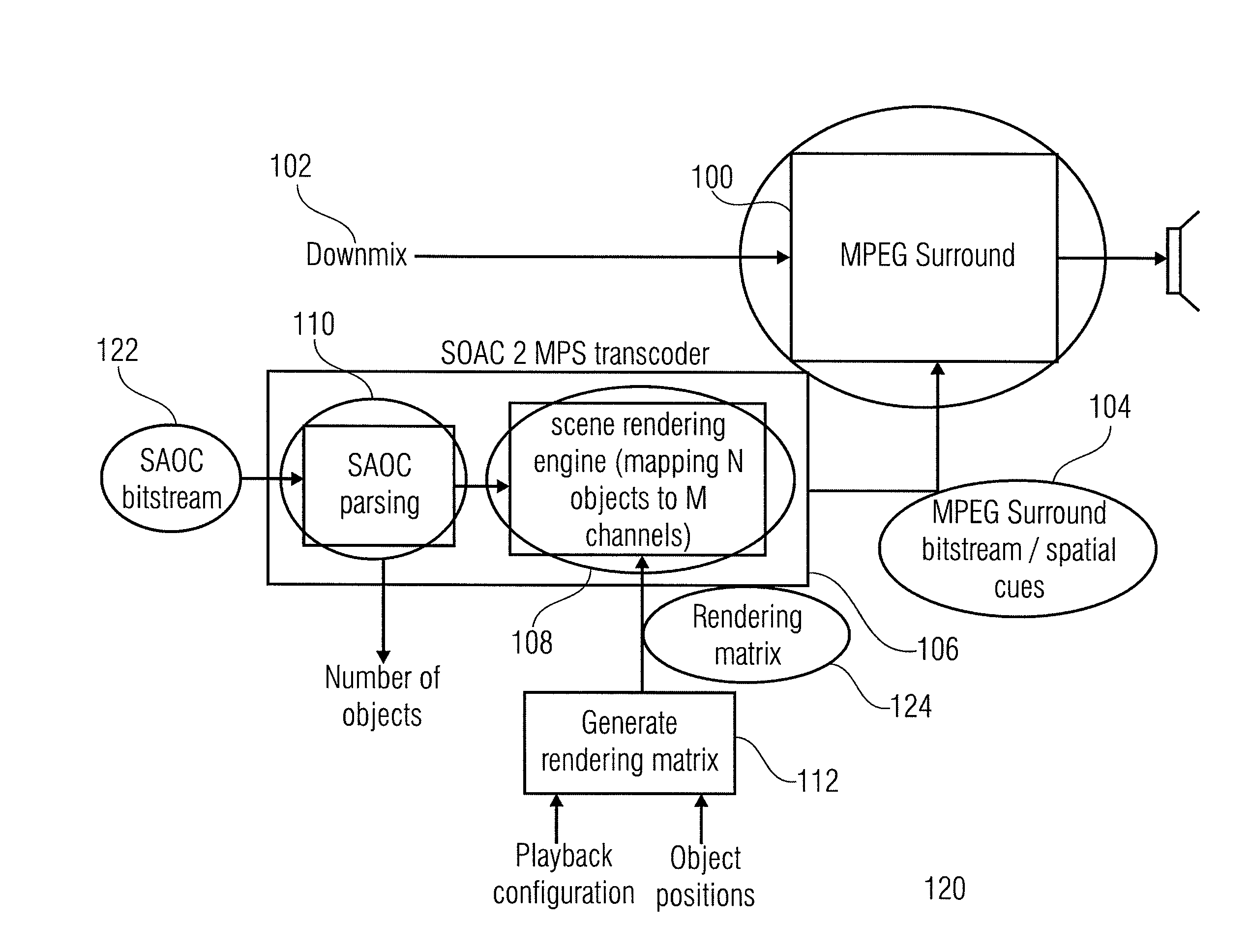

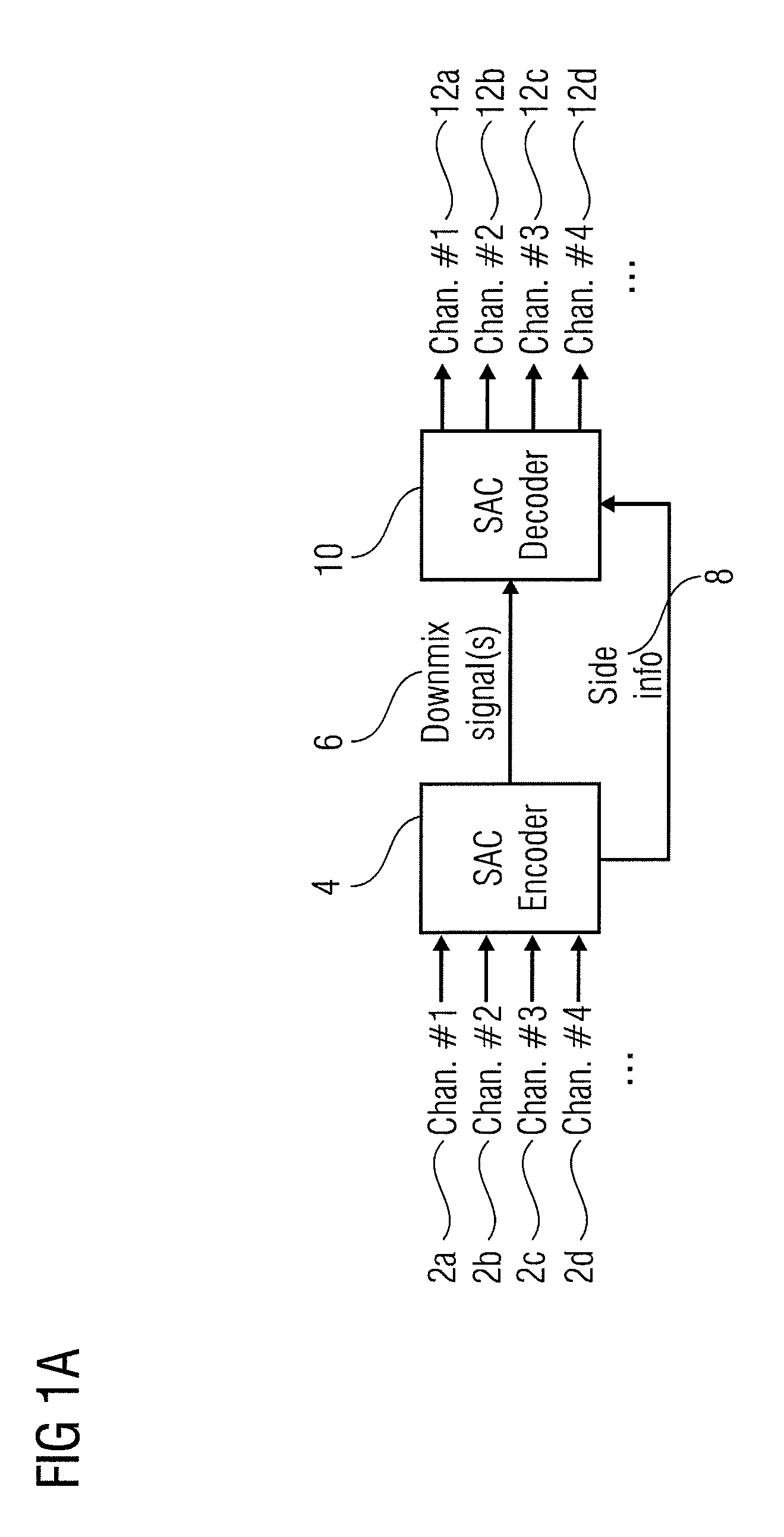

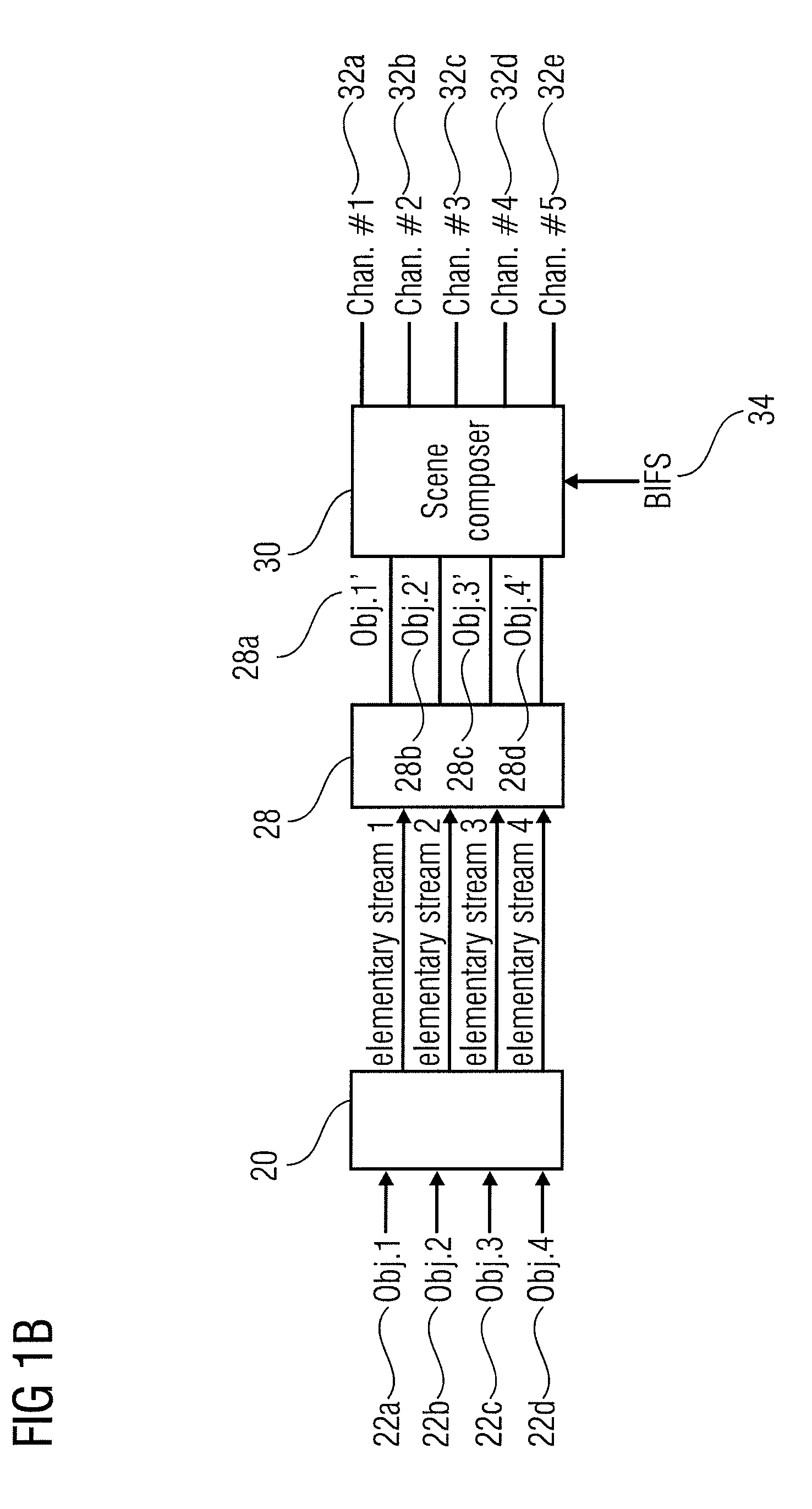

Apparatus and Method for Multi-Channel Parameter Transformation

ActiveUS20110013790A1Reduce complexityReduce system complexitySpeech analysisTwo-channel systemsChannel parameterLoudspeaker

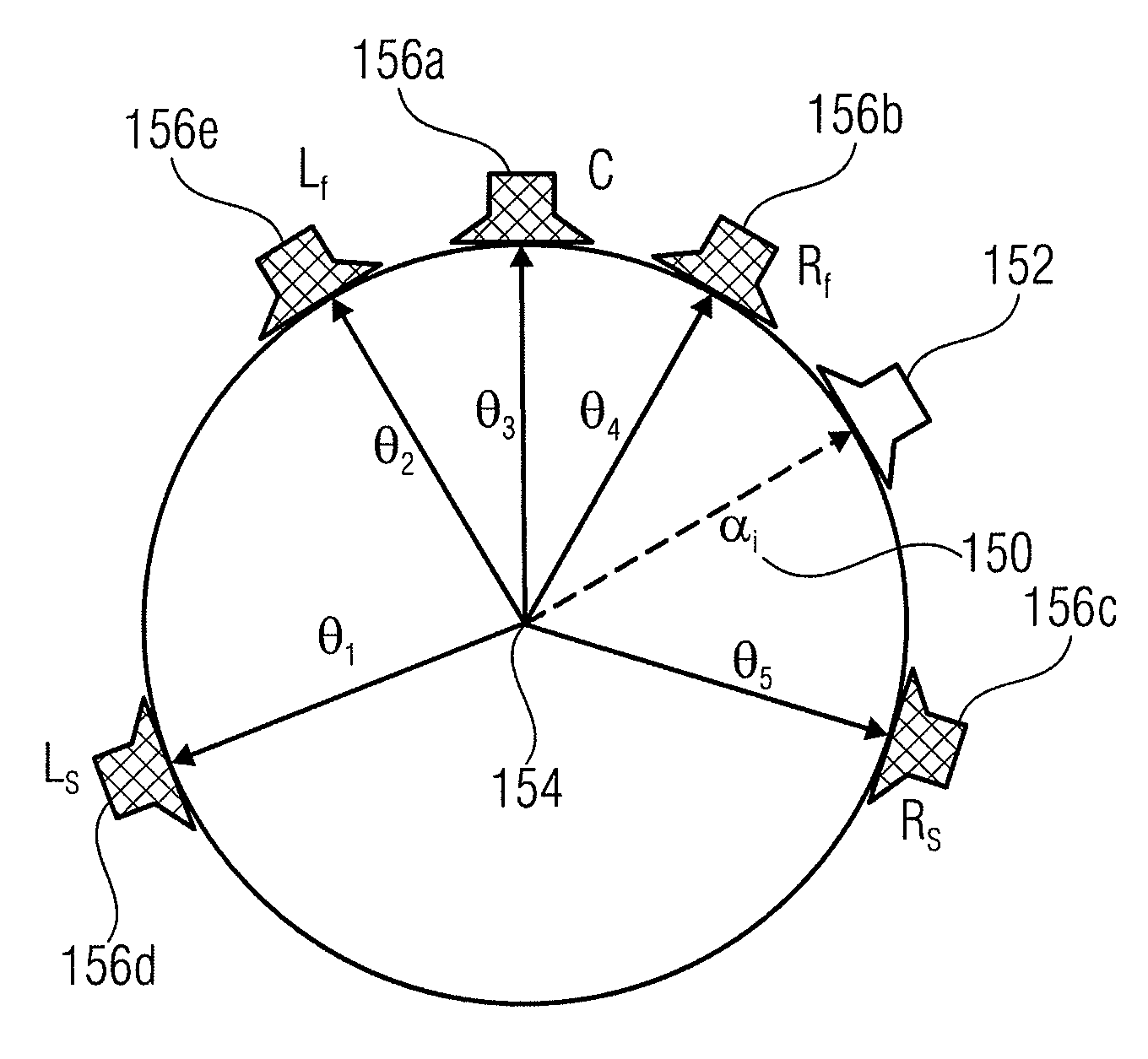

A parameter transformer generates level parameters, indicating an energy relation between a first and a second audio channel of a multi-channel audio signal associated to a multi-channel loudspeaker configuration. The level parameter are generated based on object parameters for a plurality of audio objects associated to a down-mix channel, which is generated using object audio signals associated to the audio objects. The object parameters have an energy parameter indicating an energy of the object audio signal. To derive the coherence and the level parameters, a parameter generator is used, which combines the energy parameter and object rendering parameters, which depend on a desired rendering configuration.

Owner:DOLBY INT AB +2

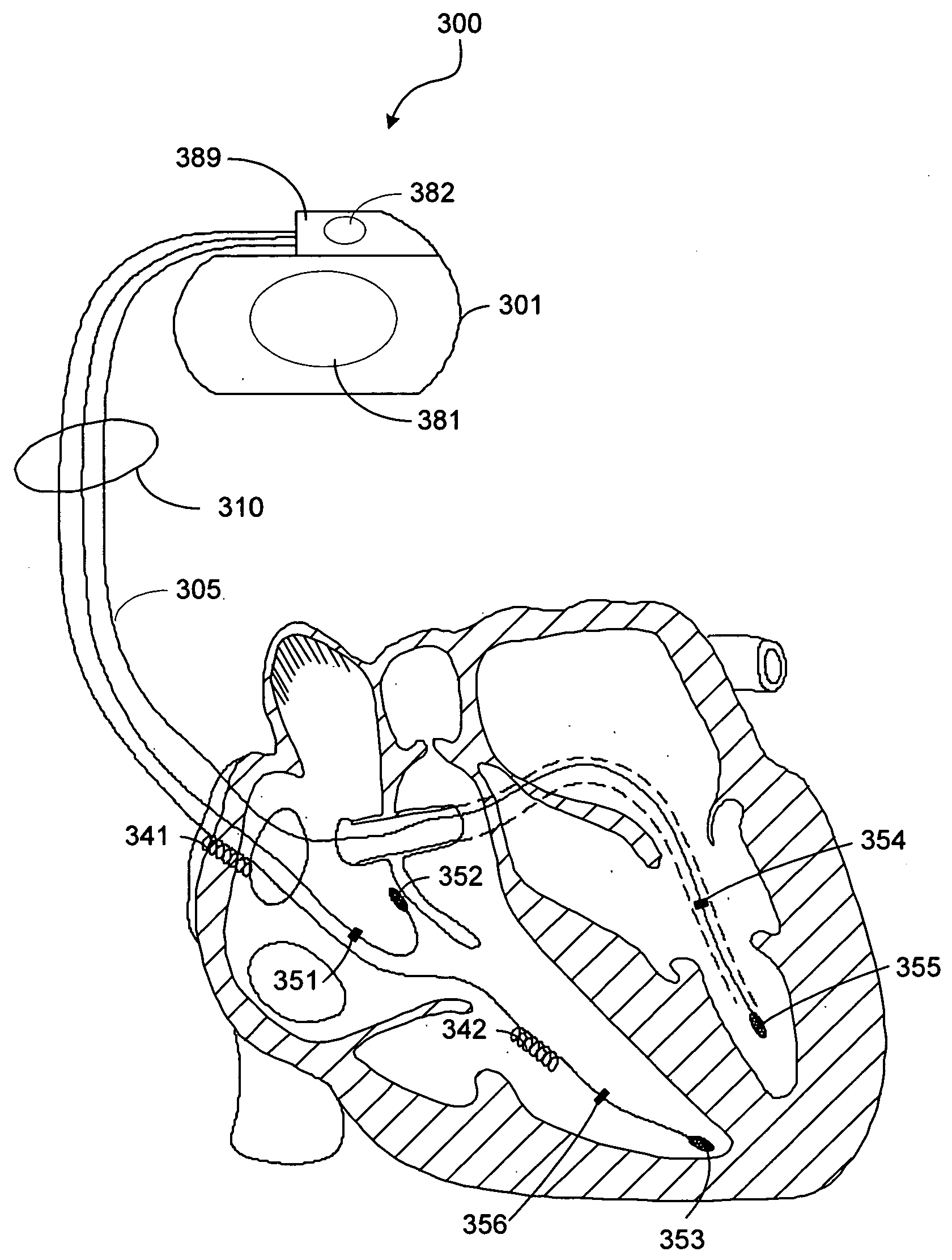

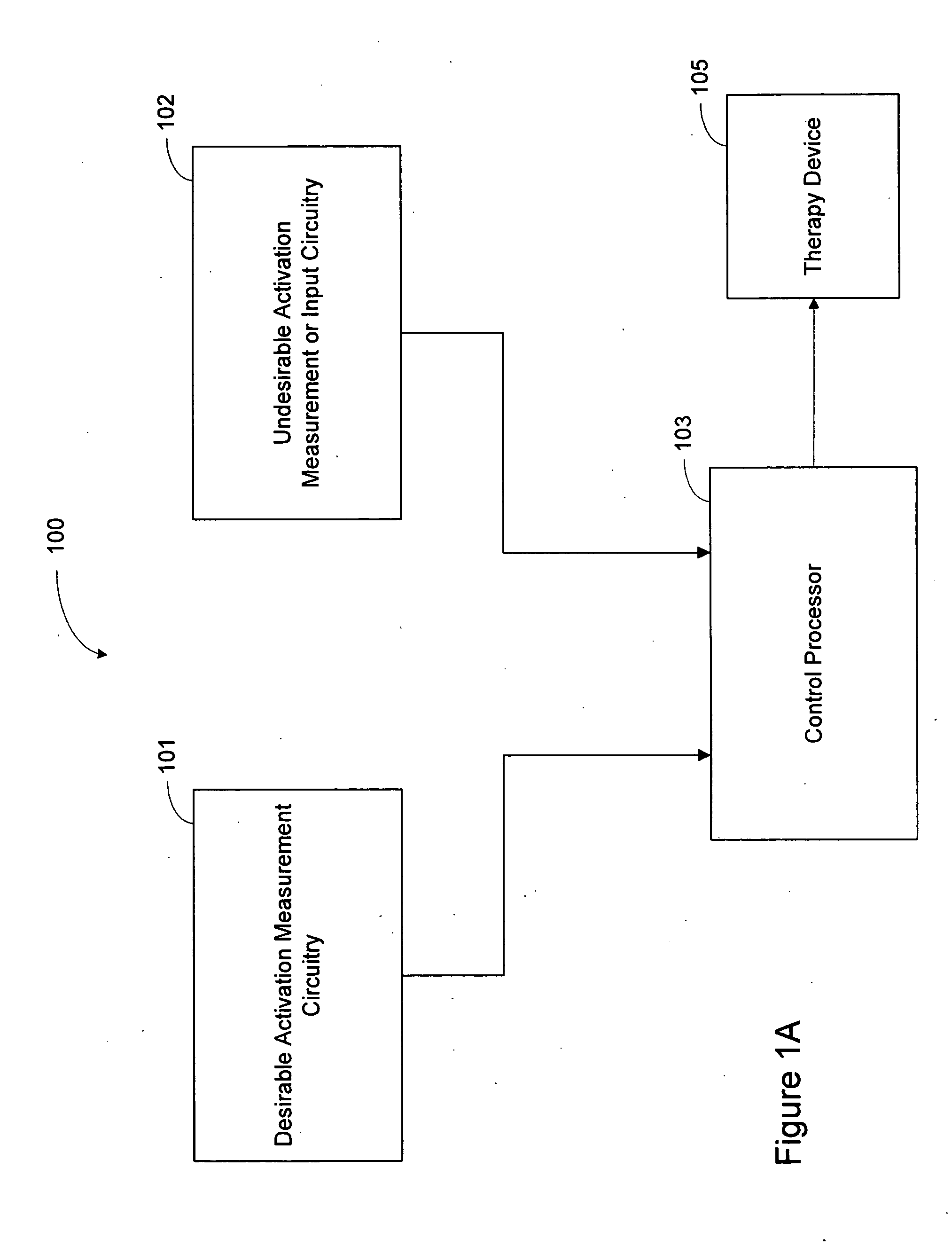

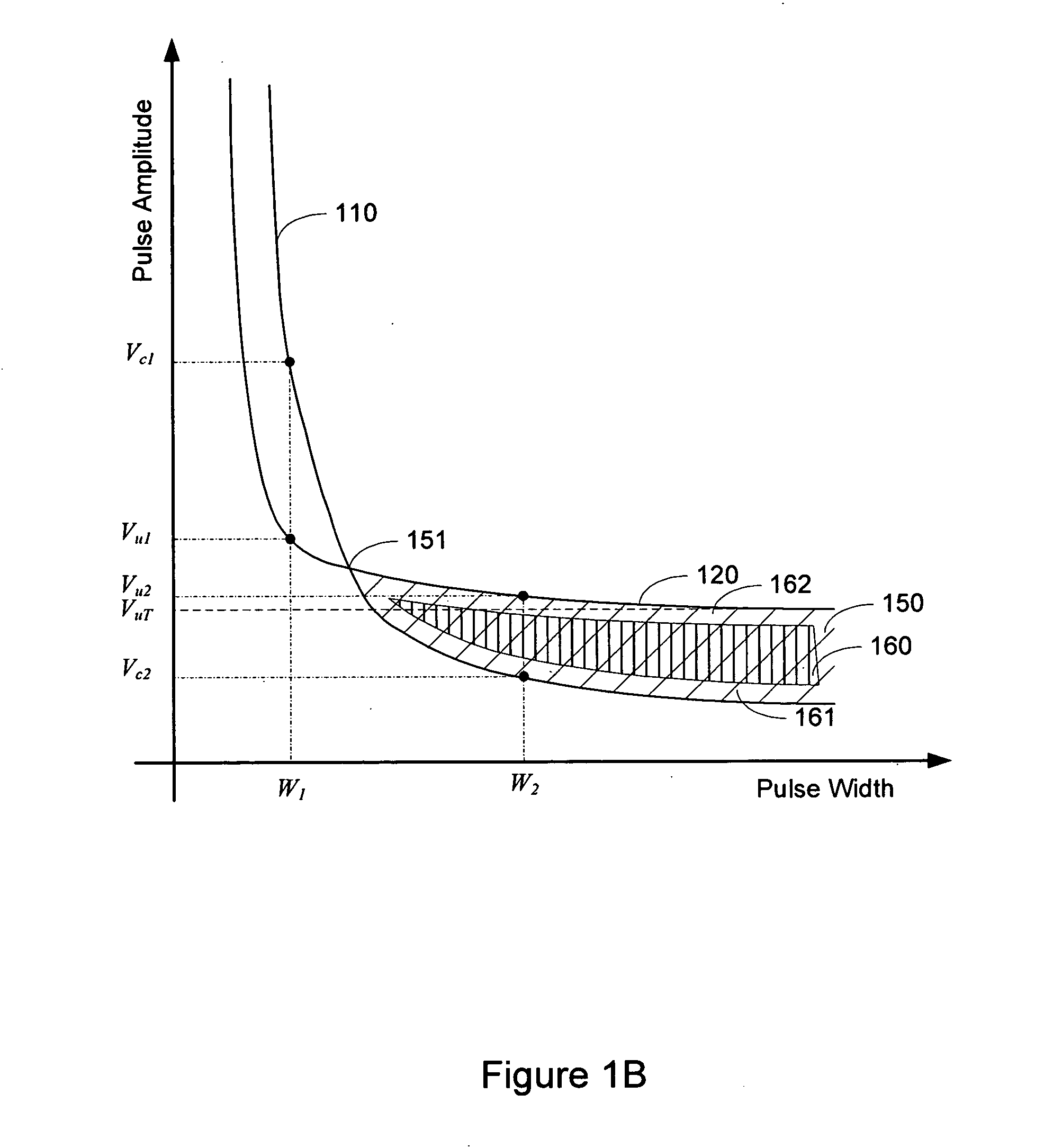

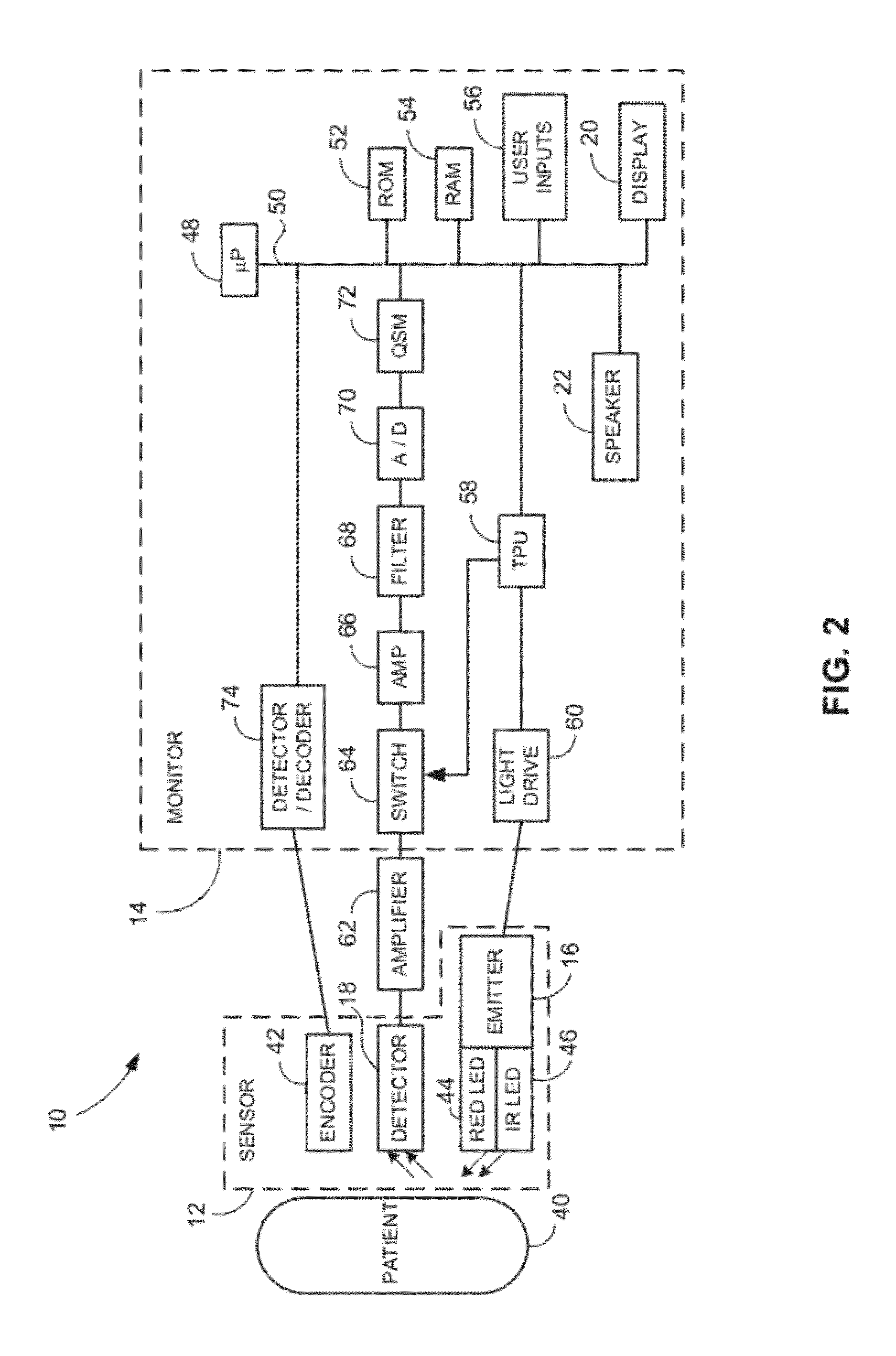

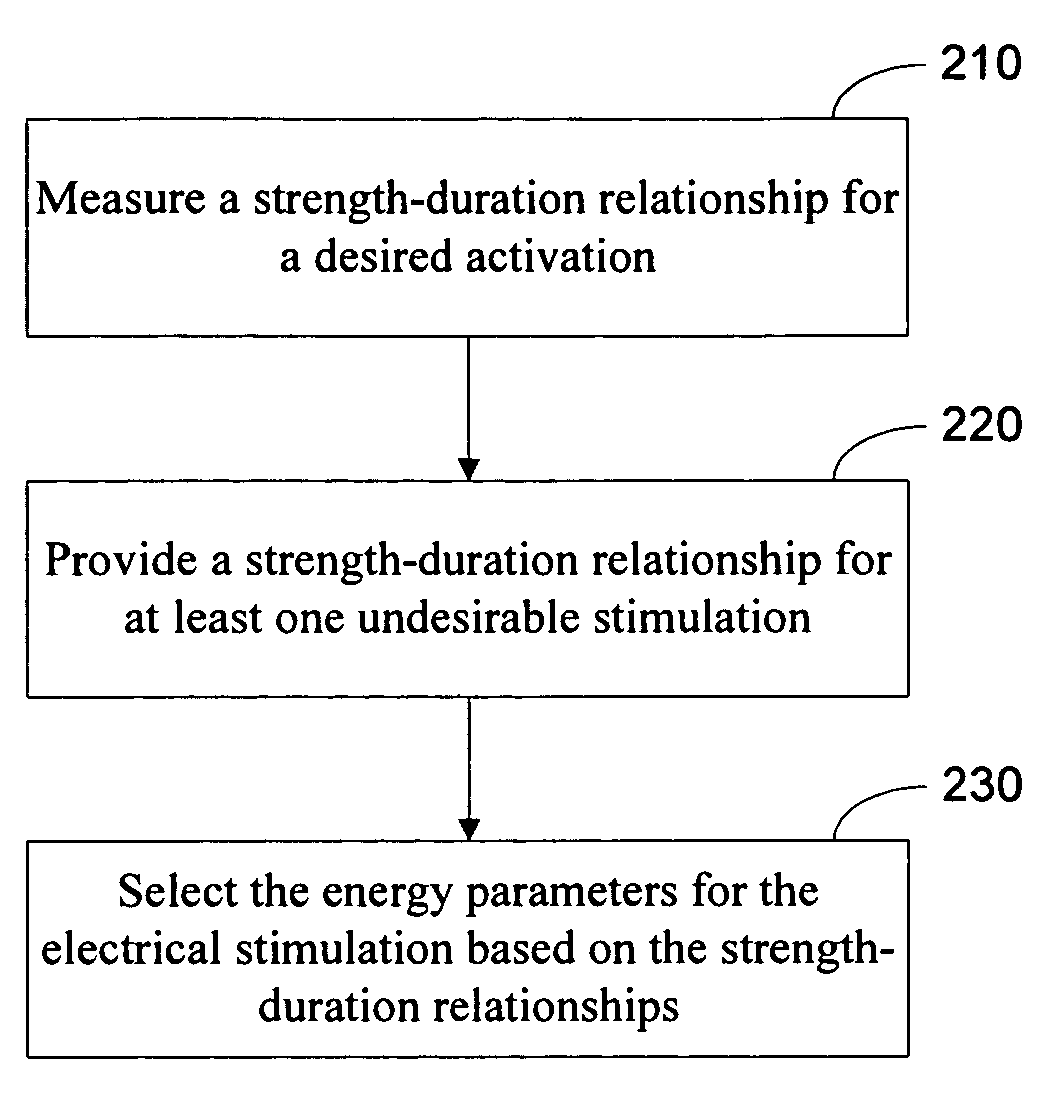

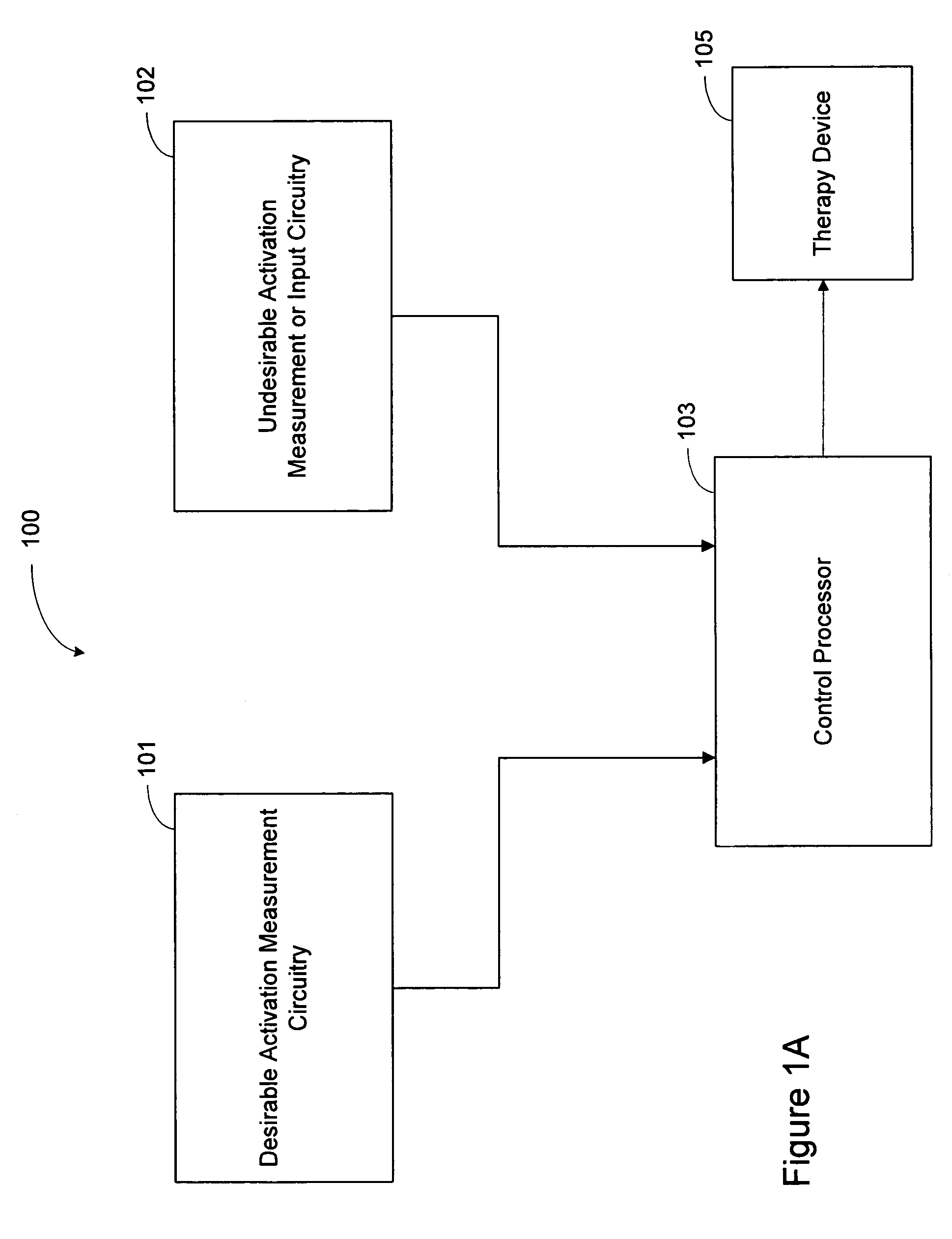

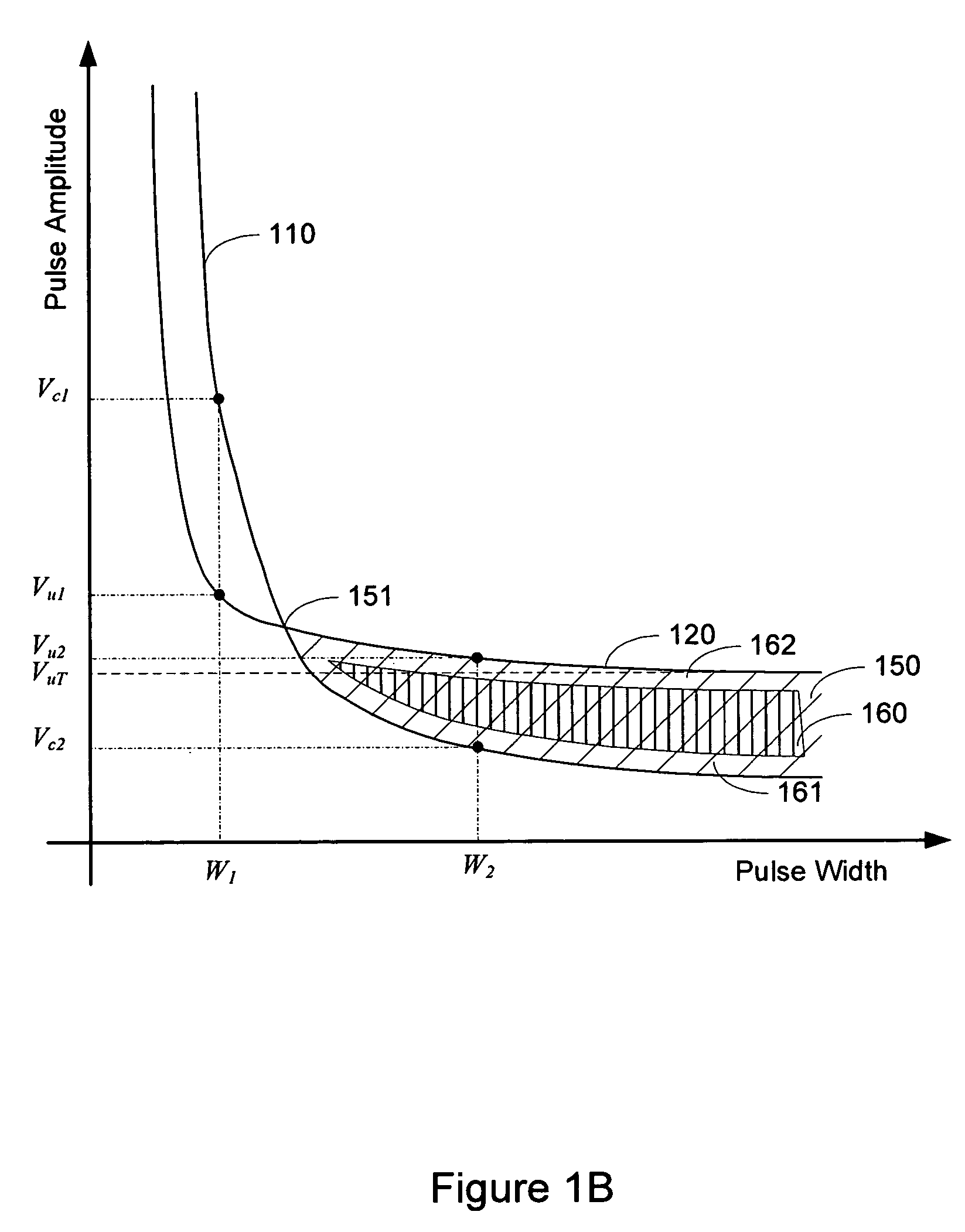

Therapeutic electrical stimulation that avoids undesirable activation

Approaches for determining energy parameters for electrical stimulation pulses that produce a desired activation and avoid an undesirable activation are described. A strength-duration relationship for at least one desired activation produced by therapeutic electrical stimulation is measured. A strength-duration relationship for at least one undesirable activation produced by the therapeutic electrical stimulation is provided. A medical device selects, based on the desired and undesirable strength-duration relationships, one or more energy parameters for the therapeutic electrical stimulation that produce the desired activation and avoid the undesirable activation.

Owner:CARDIAC PACEMAKERS INC

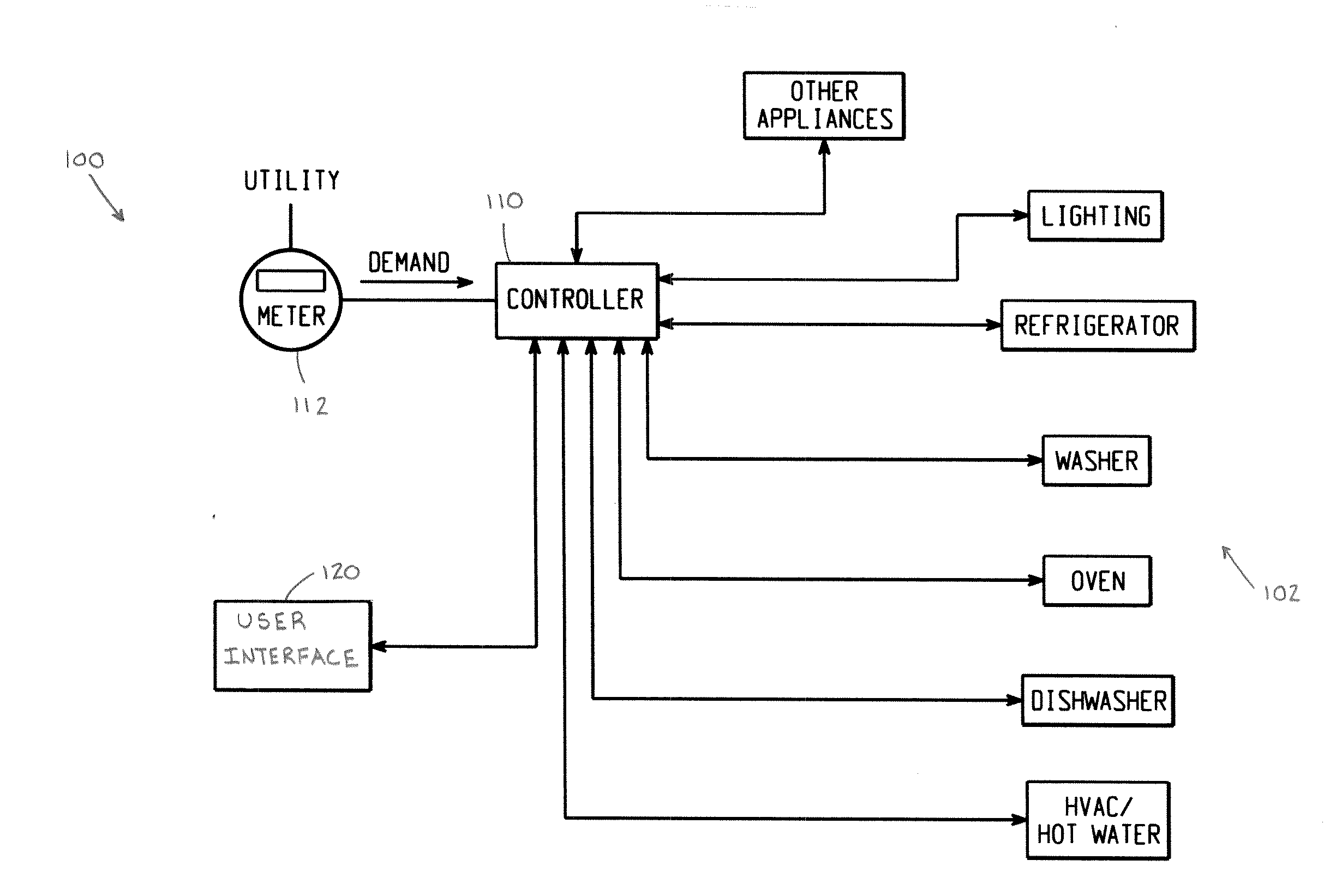

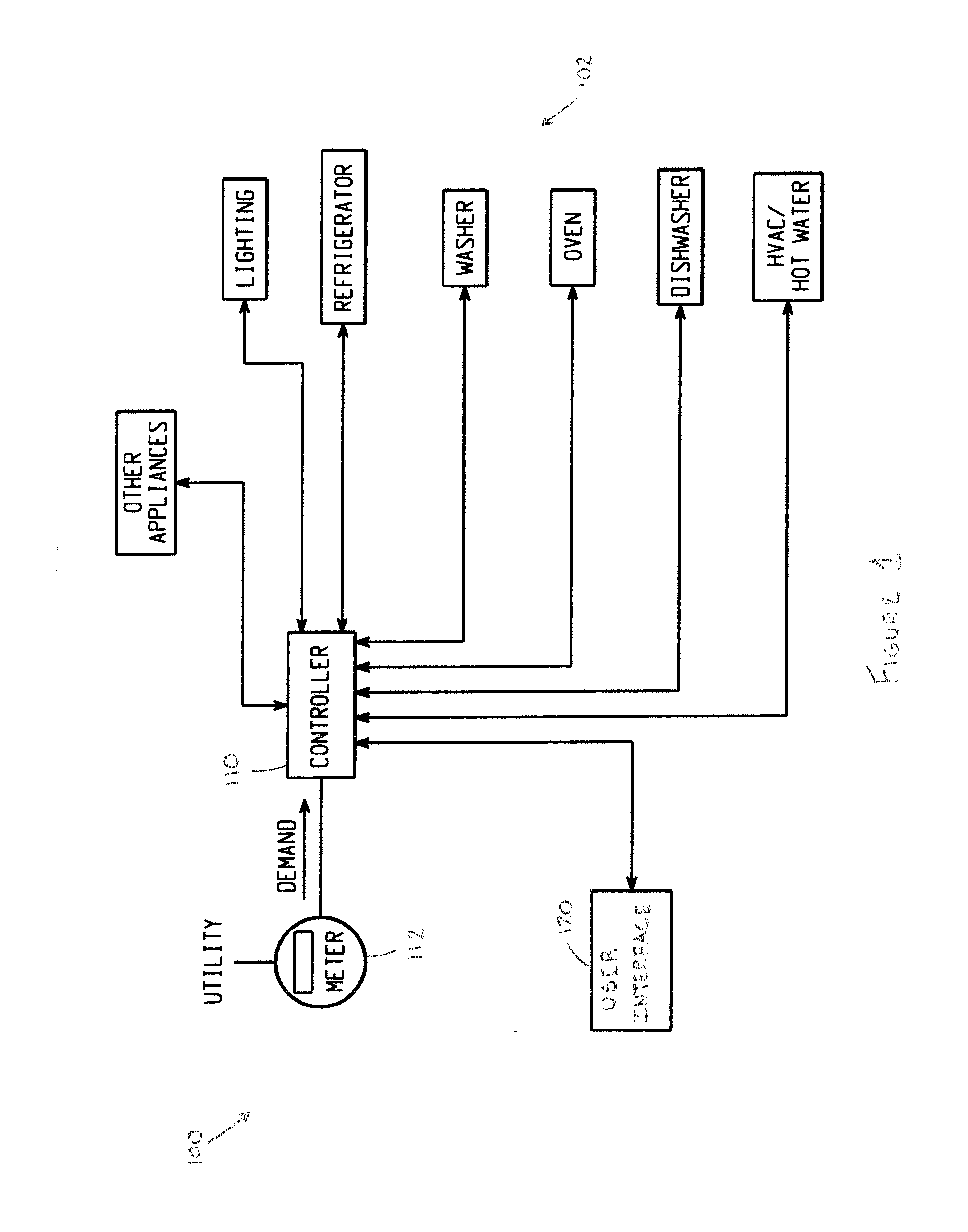

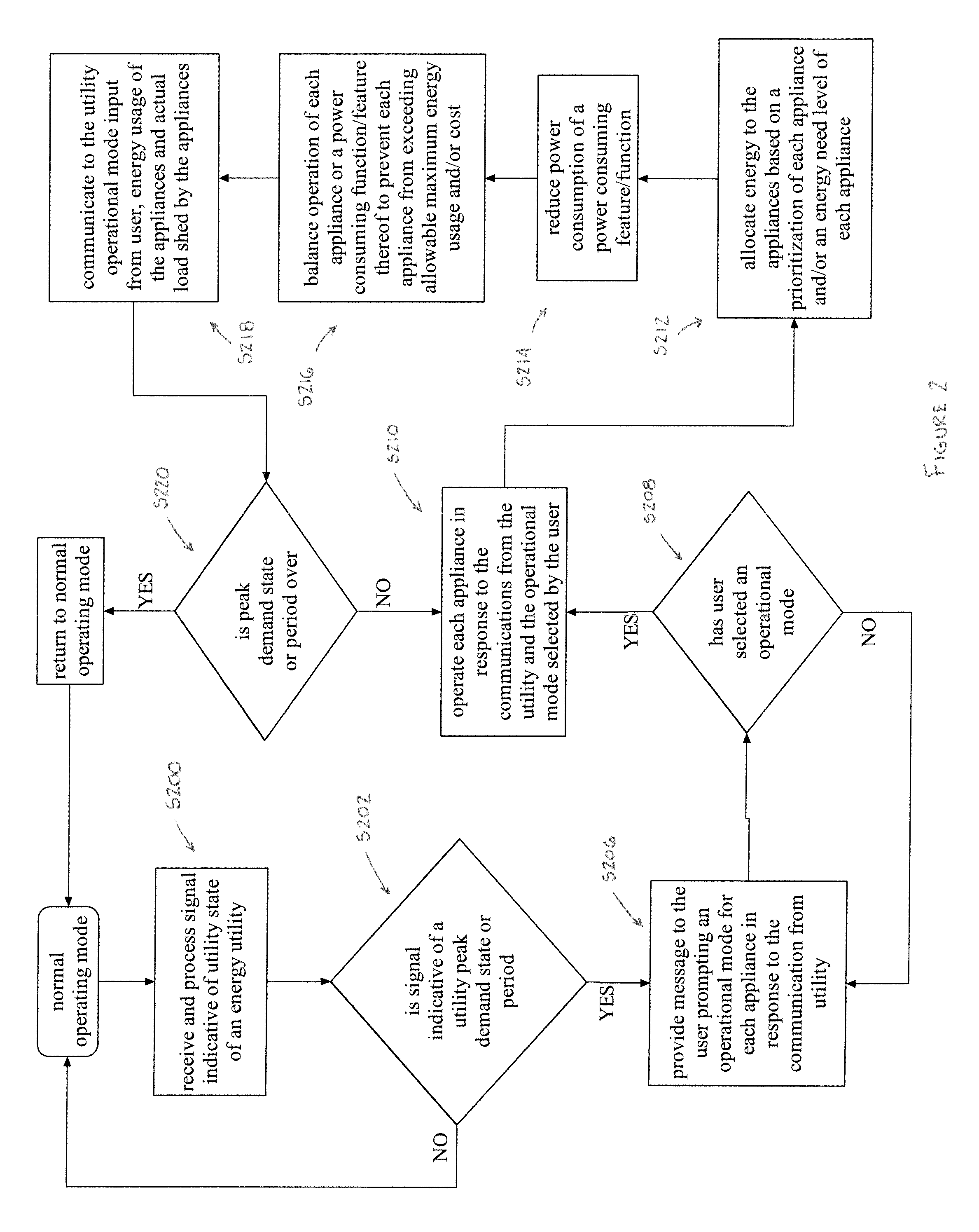

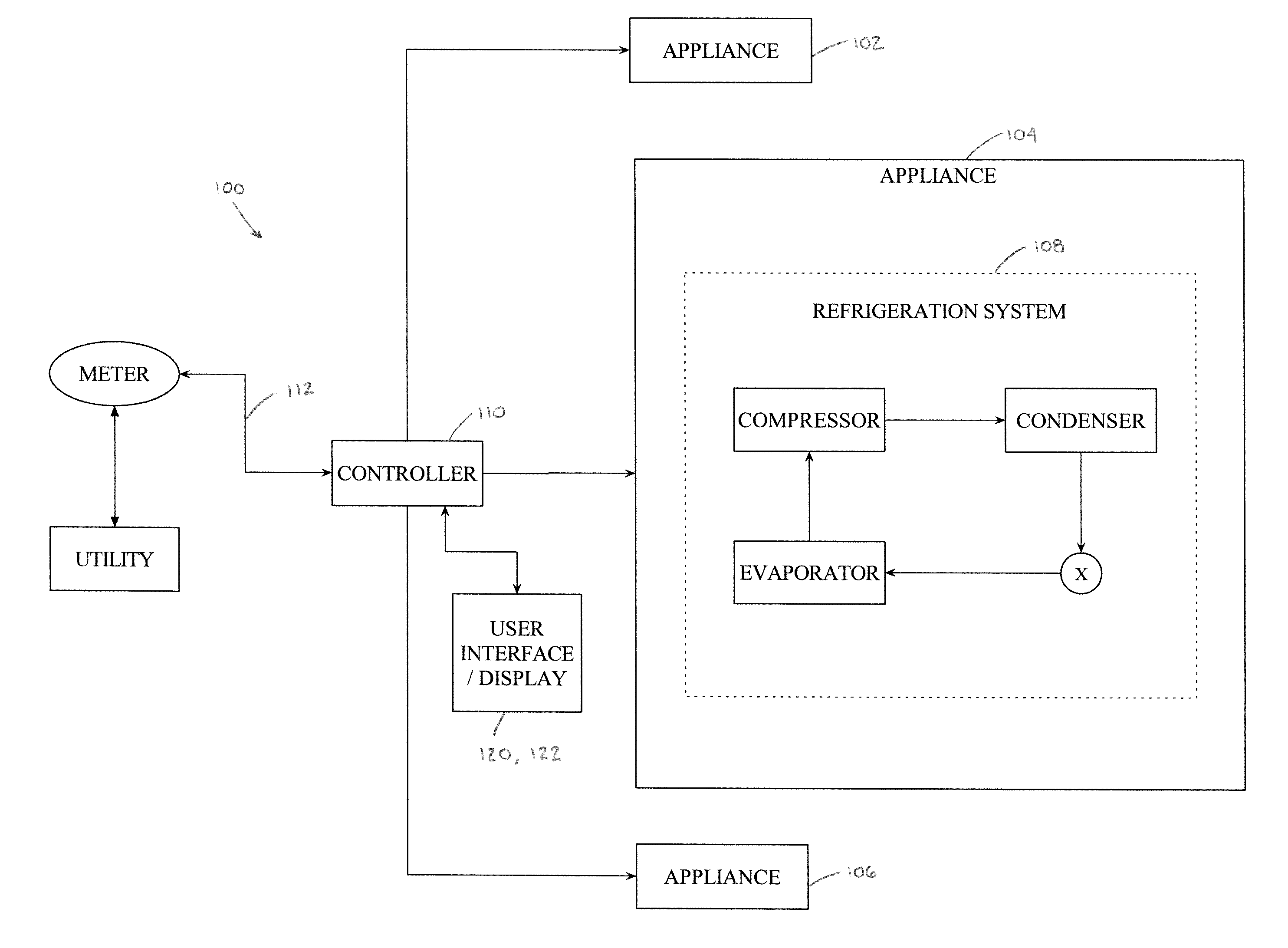

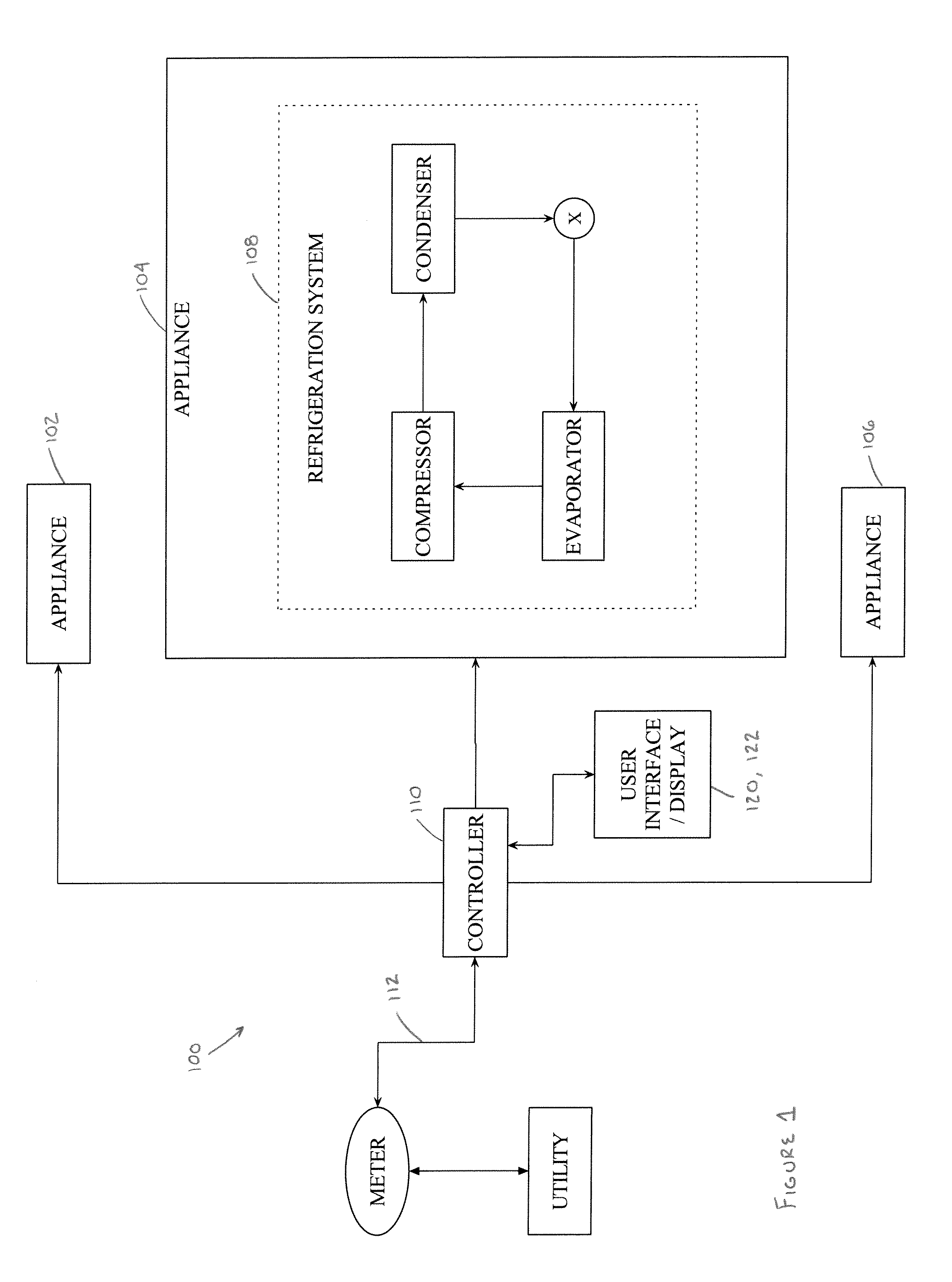

Household energy management system and method for one or more appliances

A household energy management system and method for one or more appliances includes a controller for managing power consumption within a household. The controller is configured to receive and process a signal indicative of one or more energy parameters of an associated energy utility. The controller includes a user interface for receiving energy management input for at least one appliance of the one of more appliances from a user. The controller at least one of controls and operates the at least one appliance in one of a plurality of operating modes, including at least a normal operating mode and an energy savings mode, in response to the input received by the user via the user interface in conjunction with the received signal.

Owner:GENERAL ELECTRIC CO

Method and device for efficient frame erasure concealment in linear predictive based speech codecs

ActiveUS7693710B2Improve concealmentPromote recoveryError preventionTransmission systemsStability parameterFrequency spectrum

The present invention relates to a method and device for improving concealment of frame erasure caused by frames of an encoded sound signal erased during transmission from an encoder (106) to a decoder (110), and for accelerating recovery of the decoder after non erased frames of the encoded sound signal have been received. For that purpose, concealment / recovery parameters are determined in the encoder or decoder. When determined in the encoder (106), the concealment / recovery parameters are transmitted to the decoder (110). In the decoder, erasure frame concealment and decoder recovery is conducted in response to the concealment / recovery parameters. The concealment / recovery parameters may be selected from the group consisting of: a signal classification parameter, an energy information parameter and a phase information parameter. The determination of the concealment / recovery parameters comprises classifying the successive frames of the encoded sound signal as unvoiced, unvoiced transition, voiced transition, voiced, or onset, and this classification is determined on the basis of at least a part of the following parameters: a normalized correlation parameter, a spectral tilt parameter, a signal-to-noise ratio parameter, a pitch stability parameter, a relative frame energy parameter, and a zero crossing parameter.

Owner:VOICEAGE EVS LLC

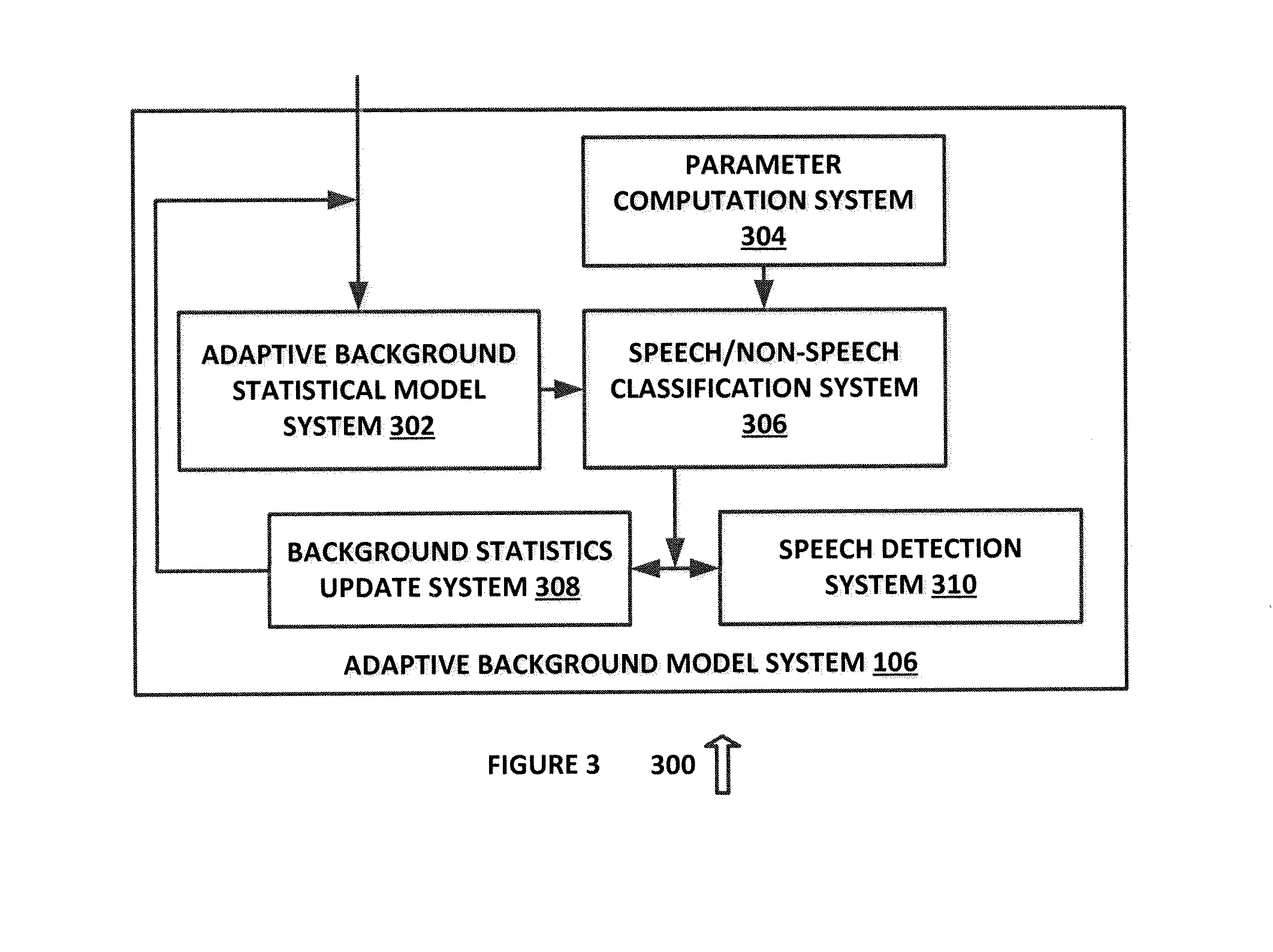

Robust speech boundary detection system and method

A system for audio processing comprising an initial background statistical model system configured to generate an initial background statistical model using a predetermined sample size of audio data. A parameter computation system configured to generate parametric data for the audio data including cepstral and energy parameters. A background statistics computation system configured to generate preliminary background statistics for determining whether speech has been detected. A first speech detection system configured to determine whether speech was present in the initial sample of audio data. An adaptive background statistical model system configured to provide an adaptive background statistical model for use in continuous processing of audio data for speech detection. A parameter computation system configured to calculate cepstral parameters, energy parameters and other suitable parameters for speech detection. A speech / non-speech classification system configured to classify individual frames as speech frames or non-speech frames, based on the computed parameters and the adaptive background statistical model data. A background statistics update system configured to update the background statistical model based on detected speech and non-speech frames. A second speech detection system configured to perform speech detection processing and to generate a suitable indicator for use in processing audio data that is determined to include speech signals.

Owner:SYNAPTICS INC

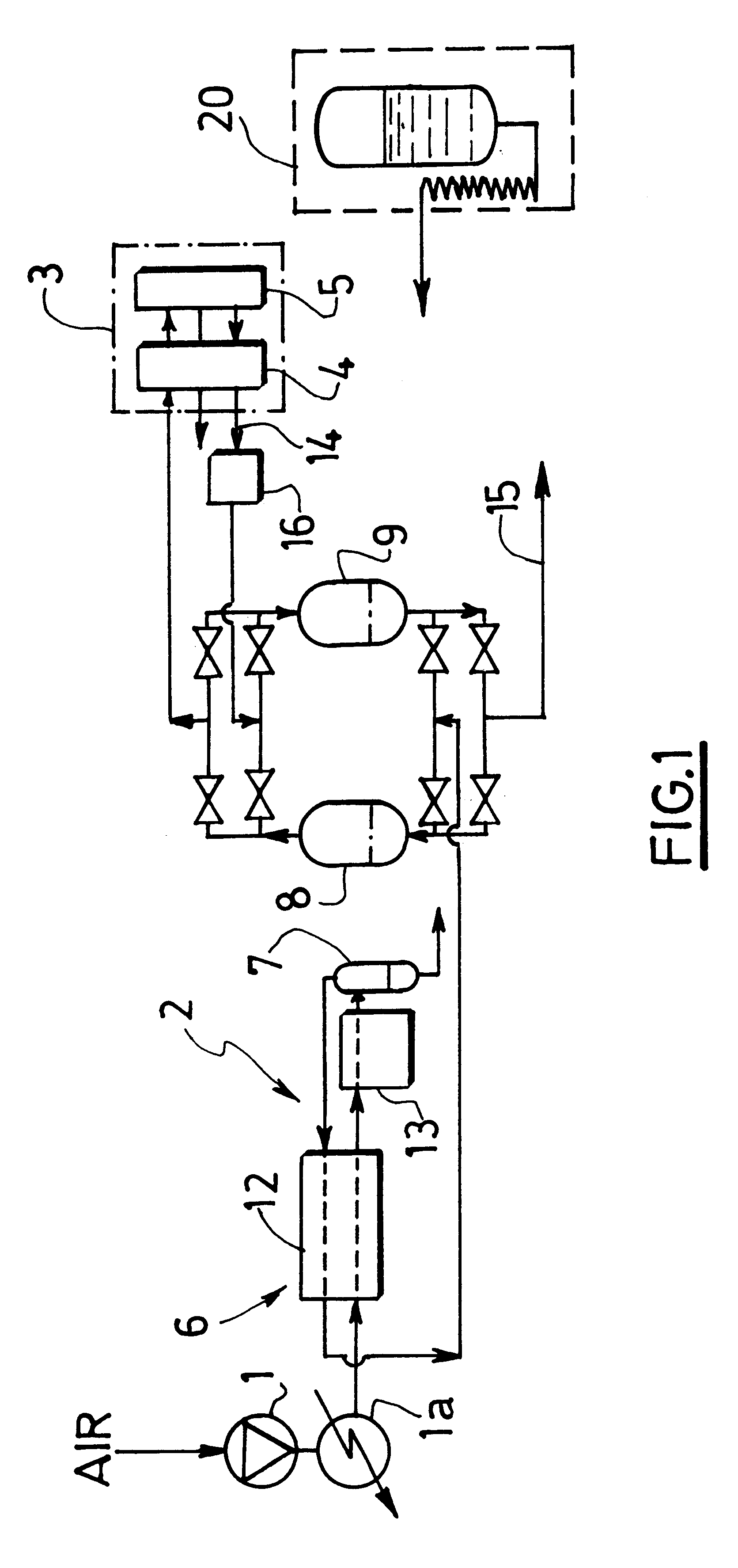

Management of an air purification system with thermal regeneration

InactiveUS6402809B1Reduce amountReduce the amount requiredSolidificationGas treatmentDistillationEngineering

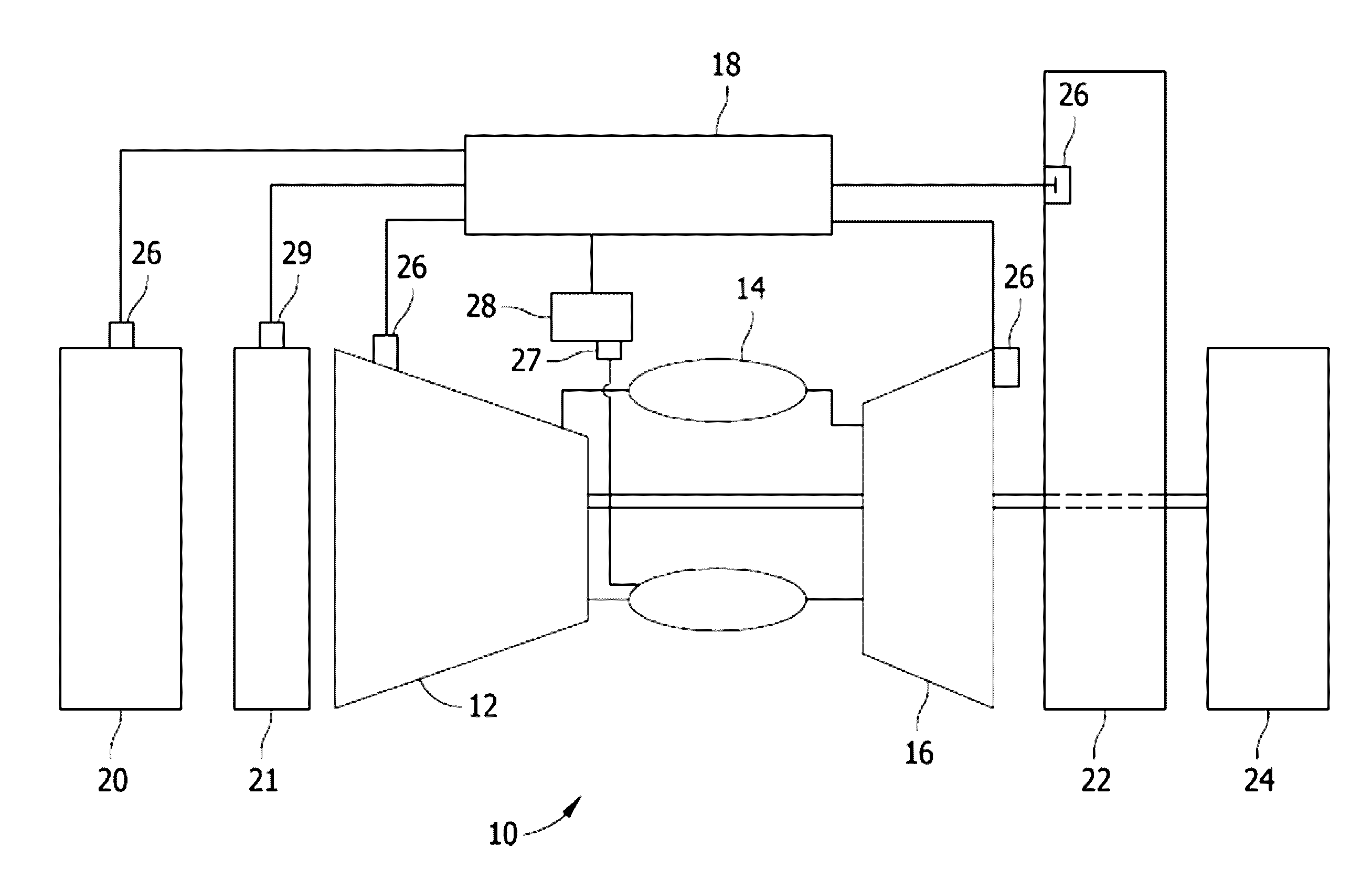

A process and a system for purifying gas, such as air, before cryogenic distillation, in which at least one energy parameter, chosen from the flow rate of the regeneration gas entering and / or leaving at least one adsorber, the duration of the regeneration step and the regeneration temperature of the regeneration gas entering at least one adsorber, is controlled, modified and / or regulated depending on at least one operating condition chosen from the pressure of the gas to be purified entering and / or leaving at least one adsorber, the flow rate of the gas to be purified entering and / or leaving at least one adsorber, the temperature (Ta) of the gas to be purified entering at least one adsorber and the content of impurities contained in the gas to be purified entering at least one adsorber and depending on the thermal profile of the heat front output by at least one adsorber at the end of regeneration.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

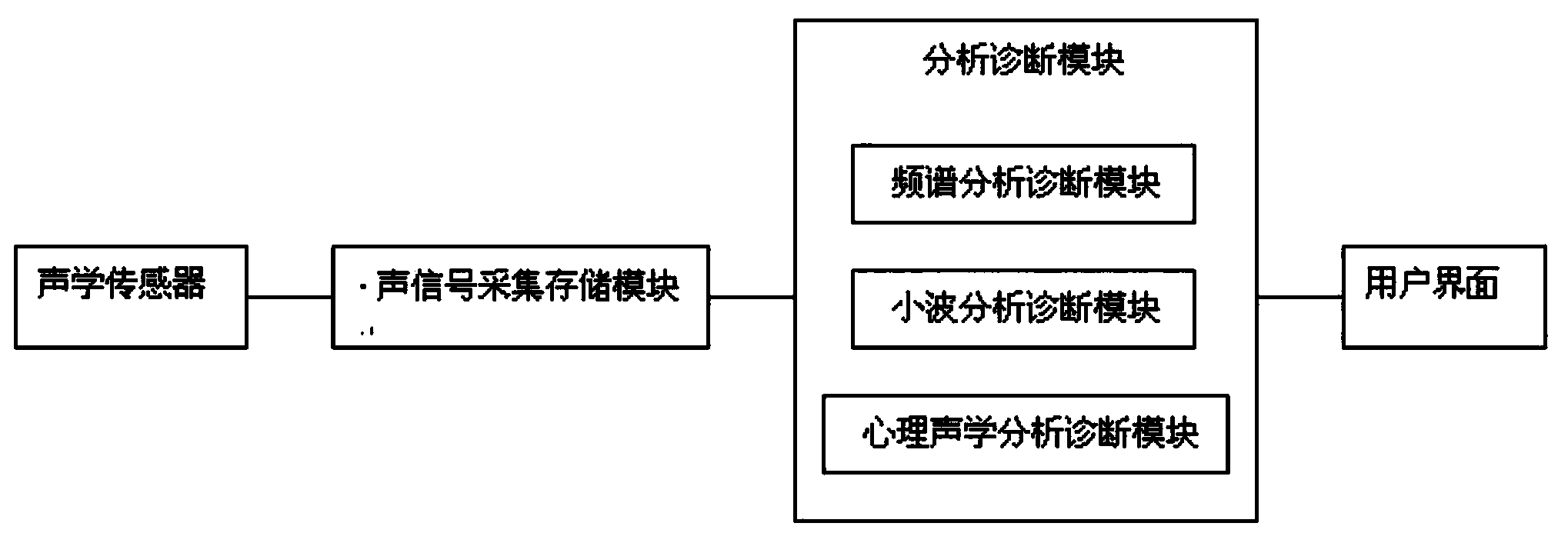

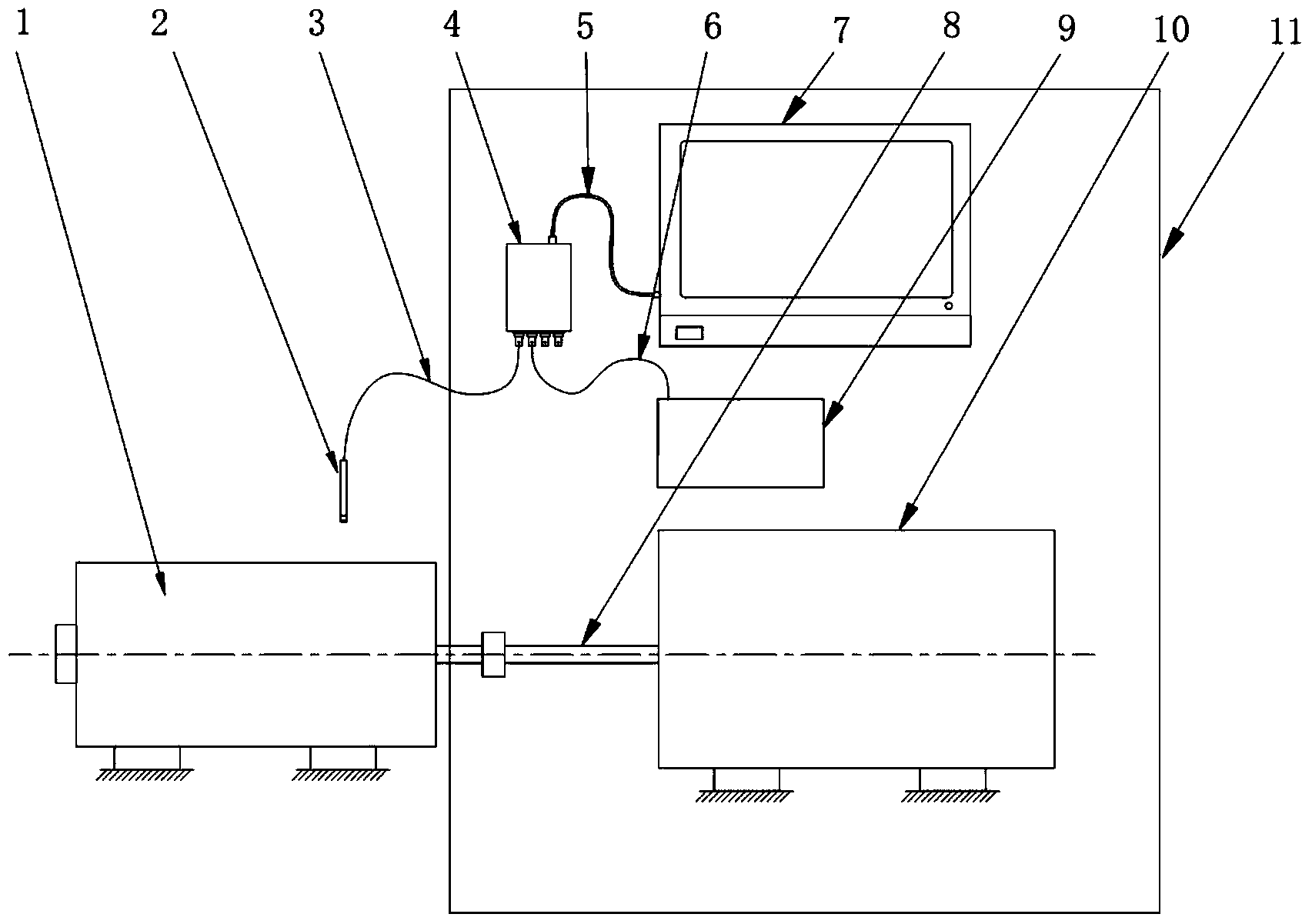

Abnormal engine sound fault on-line diagnostic system and diagnostic method

InactiveCN103558029AAbnormal sound fault coverage is wideRapid diagnosisSubsonic/sonic/ultrasonic wave measurementEngine testingProduction lineFrequency spectrum

The invention provides an abnormal engine sound fault on-line diagnostic system and diagnostic method. The diagnostic system comprises a sound signal sensor, a sound signal collecting and storing module and an analysis and diagnosis module. The analysis and diagnosis module comprises a spectral analysis and diagnosis module, a wavelet analysis and diagnosis module and a psychological acoustics analysis and diagnosis module, wherein the spectral analysis and diagnosis module is used for obtaining frequency spectrum parameters through the spectral analysis, the wavelet analysis and diagnosis module is used for obtaining energy parameters through the wavelet analysis, and the psychological acoustics analysis and diagnosis module is used for obtaining psychological acoustics parameters through the psychological acoustics analysis. The spectral analysis and diagnosis module, the wavelet analysis and diagnosis module and the psychological acoustics analysis and diagnosis module are used for extracting the frequency spectrum parameters, the energy parameters and the psychological acoustics parameters respectively to show abnormal sound fault characteristics. The abnormal engine sound fault on-line diagnostic system replaces manual work to carry out on-line diagnostic working on the abnormal engine sound fault, the diagnostic accuracy and consistency are high, the abnormal sound fault diagnosis requirements for real-time performance, fastness and accuracy of an engine production line can be met, and the working efficiency of an engine detection line is improved.

Owner:CHONGQING CONSTR ELECTROMECHANICAL CO LTD

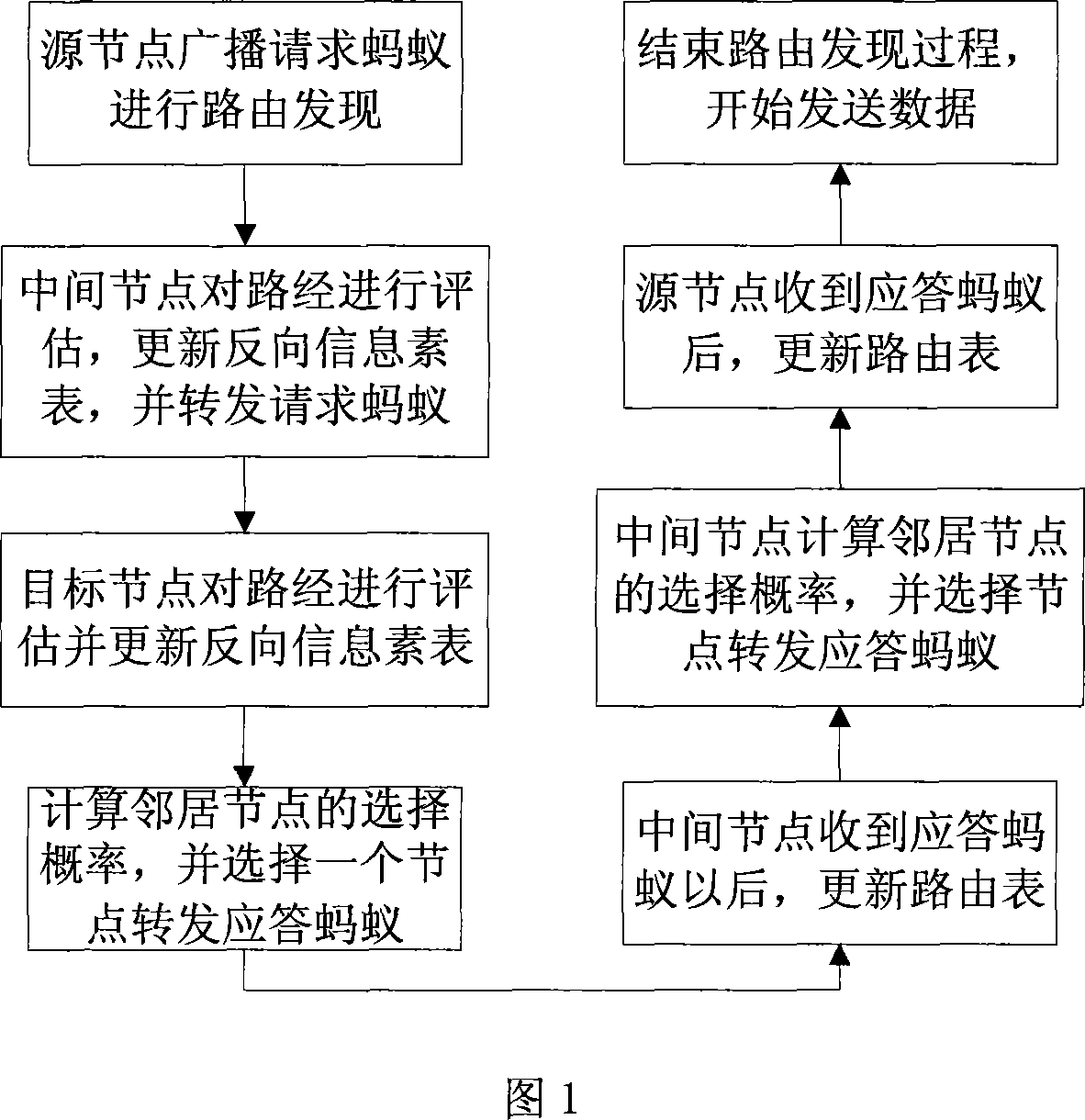

Ant algorithm based wireless self-organized network energy-saving routing method on demand

InactiveCN101083616ASimple structureImprove QoSEnergy efficient ICTData switching networksMethod selectionEnergy consumption

The invention relates to wireless self organized network energy saving needed route method based on ant colony optimization. The route building includes the following steps: broadcasting state information of asking ant to search network and store in each node reverse information pheromone list; responding the anti while receiving the request and selecting one neighbor node as the next step reverse source node; building the route from the source node to destination node. The route maintenance is that energy parameter is inducted; and new route finding process will be forced to do to avoid node from dying untimely while node energy consumption is overmuch.

Owner:SHANGHAI JIAO TONG UNIV

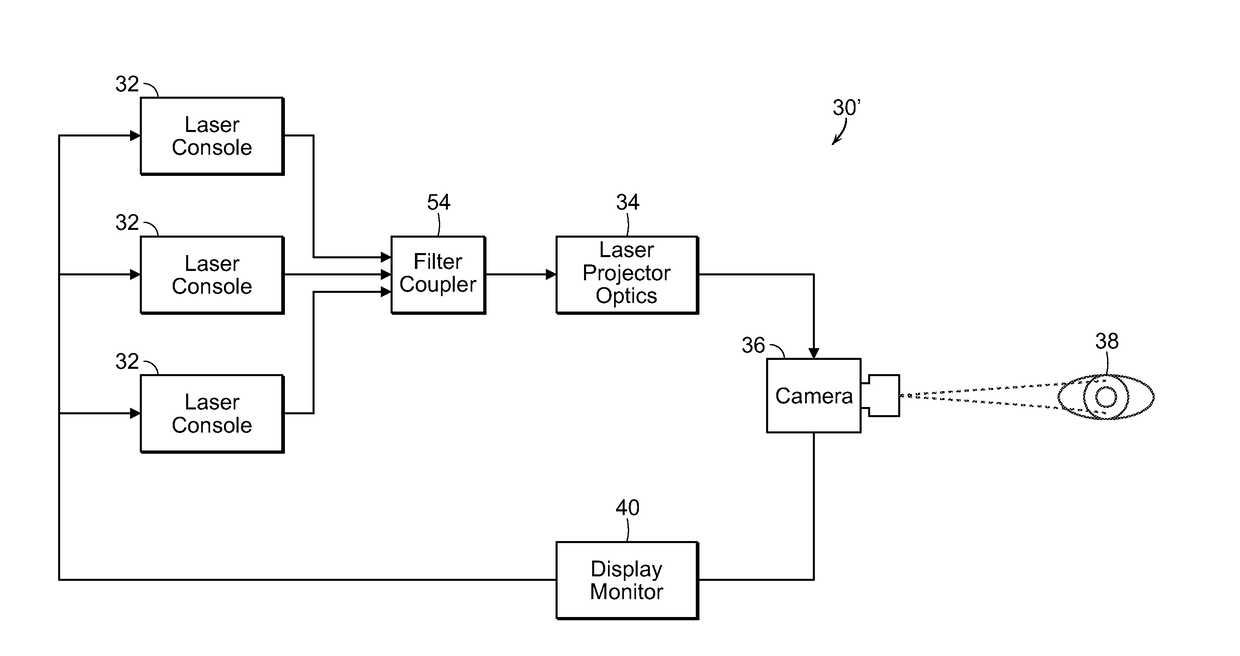

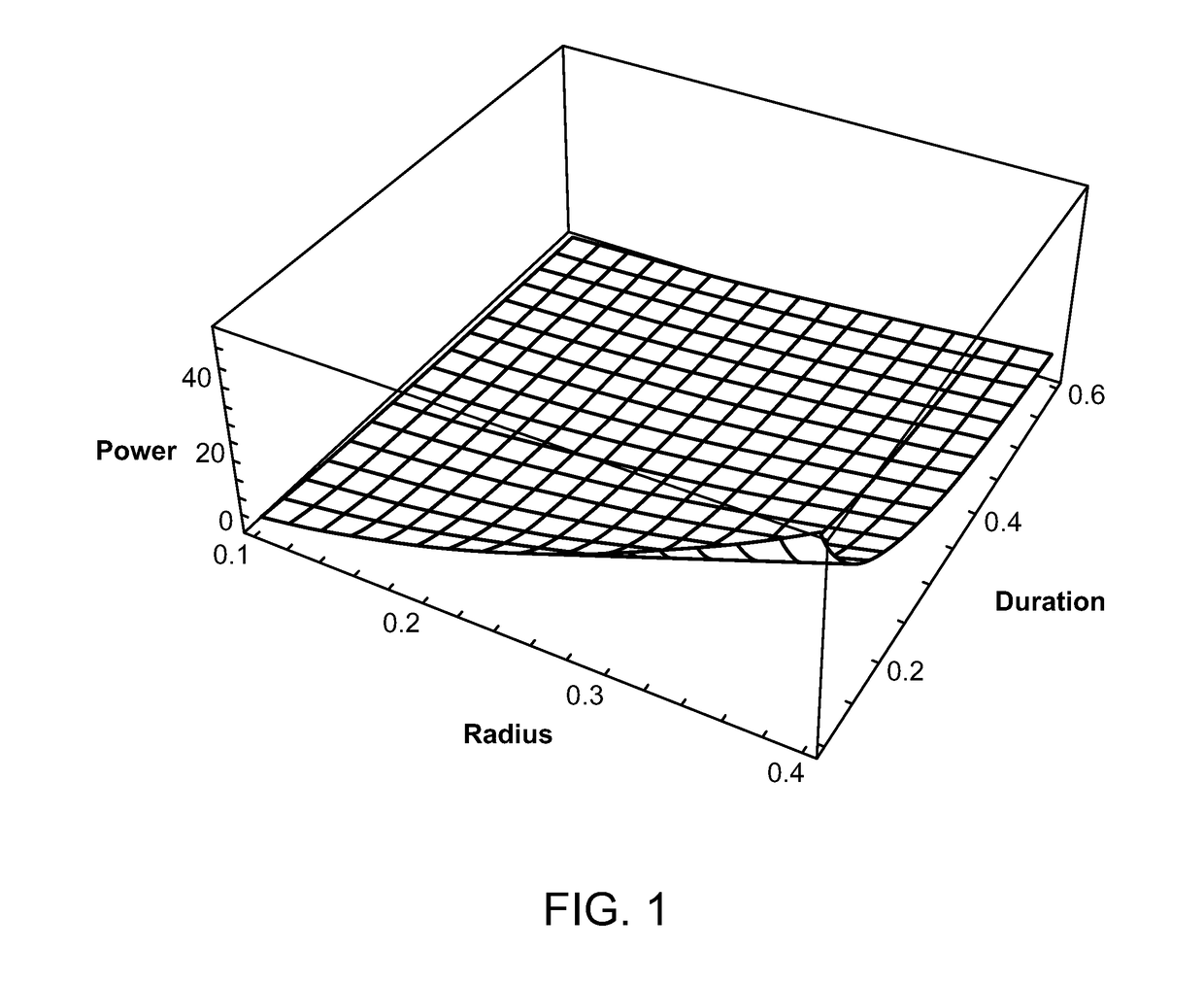

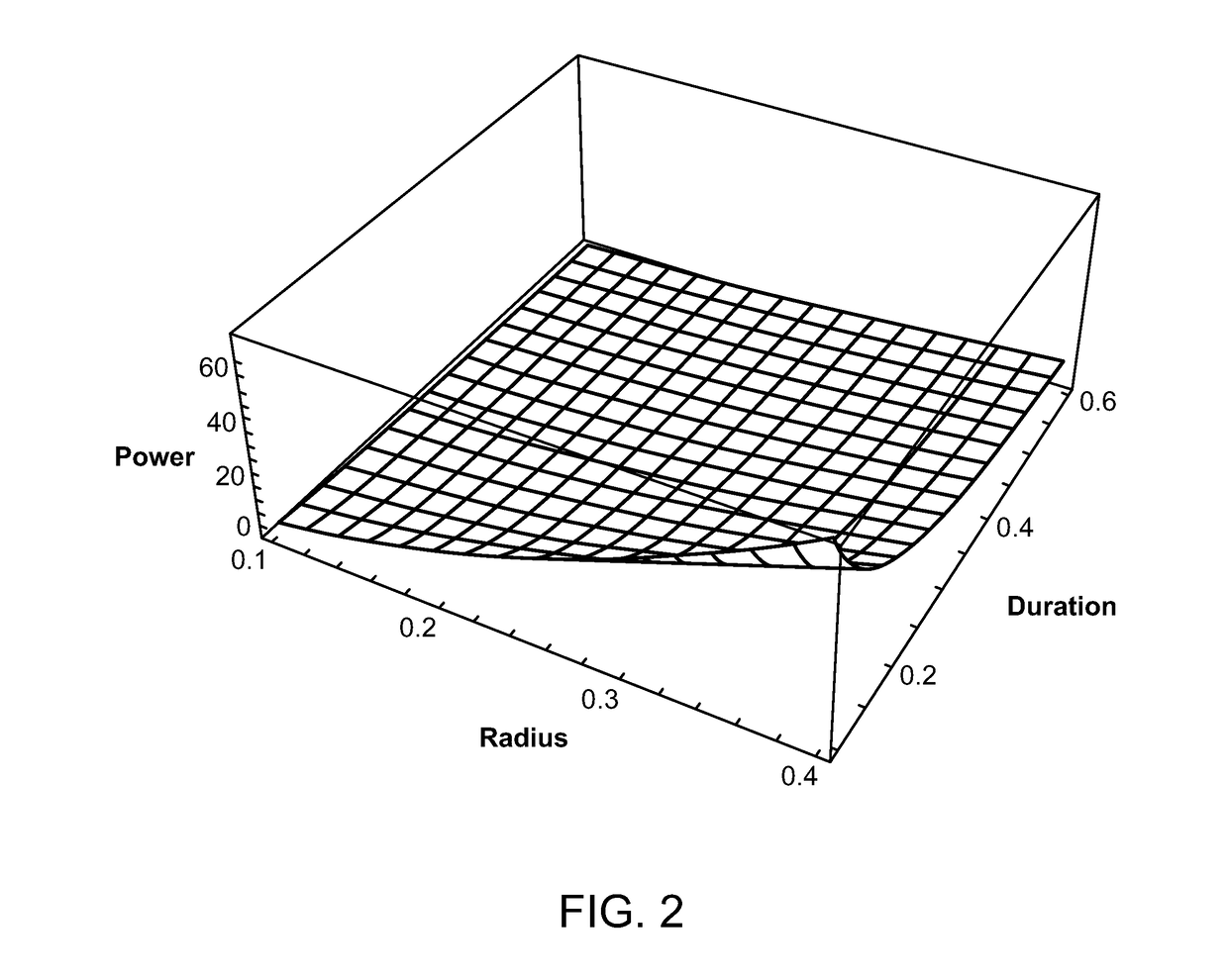

Process for providing protective therapy for biological tissues or fluids

ActiveUS20170232269A1Facilitate protein repairIncrease temperatureUltrasound therapyLaser surgeryMedicineTreatment targets

A process that provides protective therapy for biological tissues or fluids includes applying a pulsed energy source to a target tissue or a target fluid having a chronic progressive disease or a risk of having a chronic progressive disease to therapeutically or prophylactically treat the target tissue or target fluid. The pulsed energy source has energy parameters selected so as to raise the target tissue or bodily target fluid temperature up to a predetermined temperature for a short period of time to achieve a therapeutic or prophylactic effect, while the average temperature rise of the target tissue or target fluid over a longer period of time is maintained at or below a predetermined level so as not to permanently damage the target tissue or target fluid.

Owner:OJAI RETINAL TECH

Apparatus and method for multi-channel parameter transformation

ActiveUS8687829B2Reduce system complexityReduce complexityGain controlSpeech analysisChannel parameterLoudspeaker

A parameter transformer generates level parameters, indicating an energy relation between a first and a second audio channel of a multi-channel audio signal associated to a multi-channel loudspeaker configuration. The level parameter are generated based on object parameters for a plurality of audio objects associated to a down-mix channel, which is generated using object audio signals associated to the audio objects. The object parameters have an energy parameter indicating an energy of the object audio signal. To derive the coherence and the level parameters, a parameter generator is used, which combines the energy parameter and object rendering parameters, which depend on a desired rendering configuration.

Owner:DOLBY INT AB +2

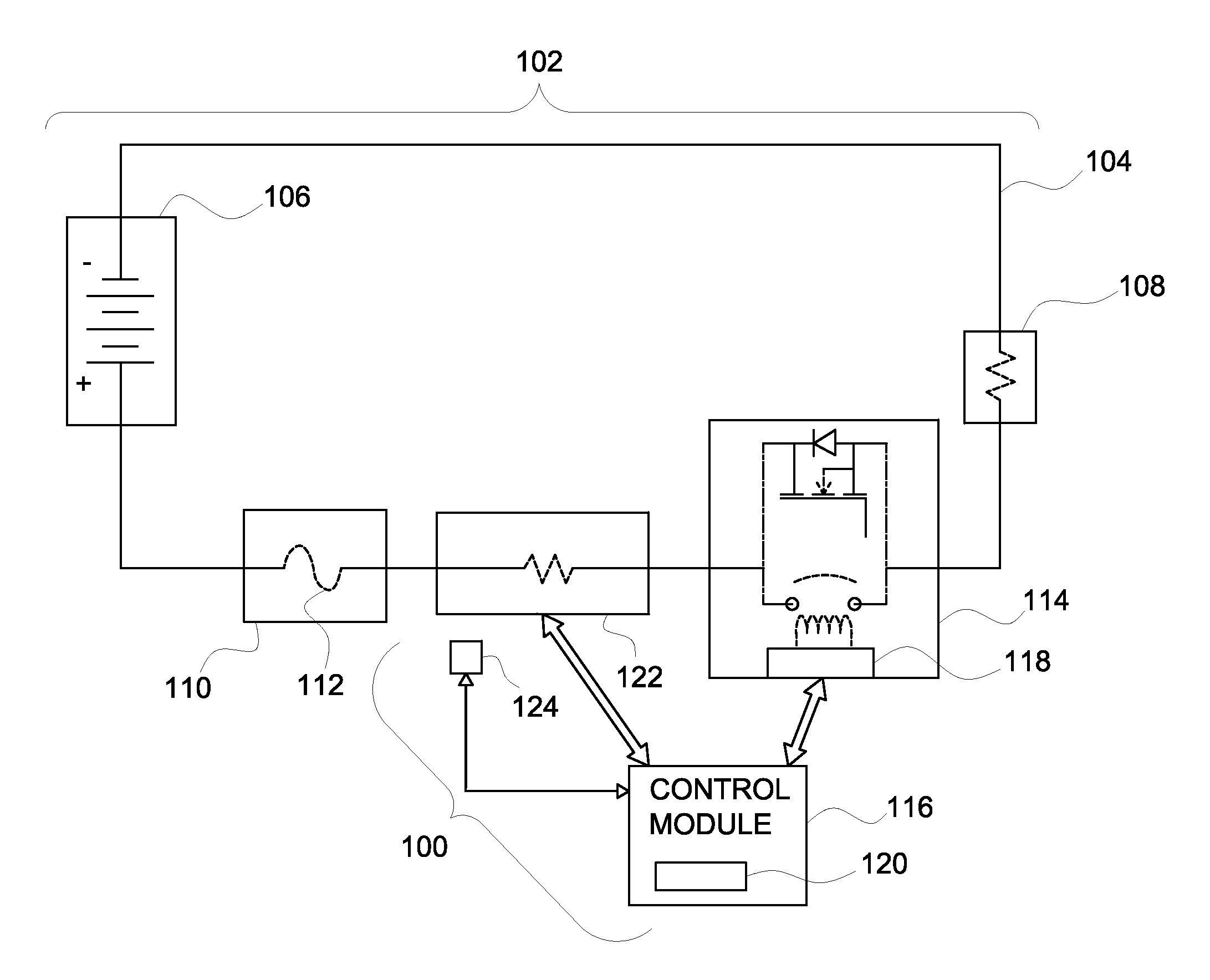

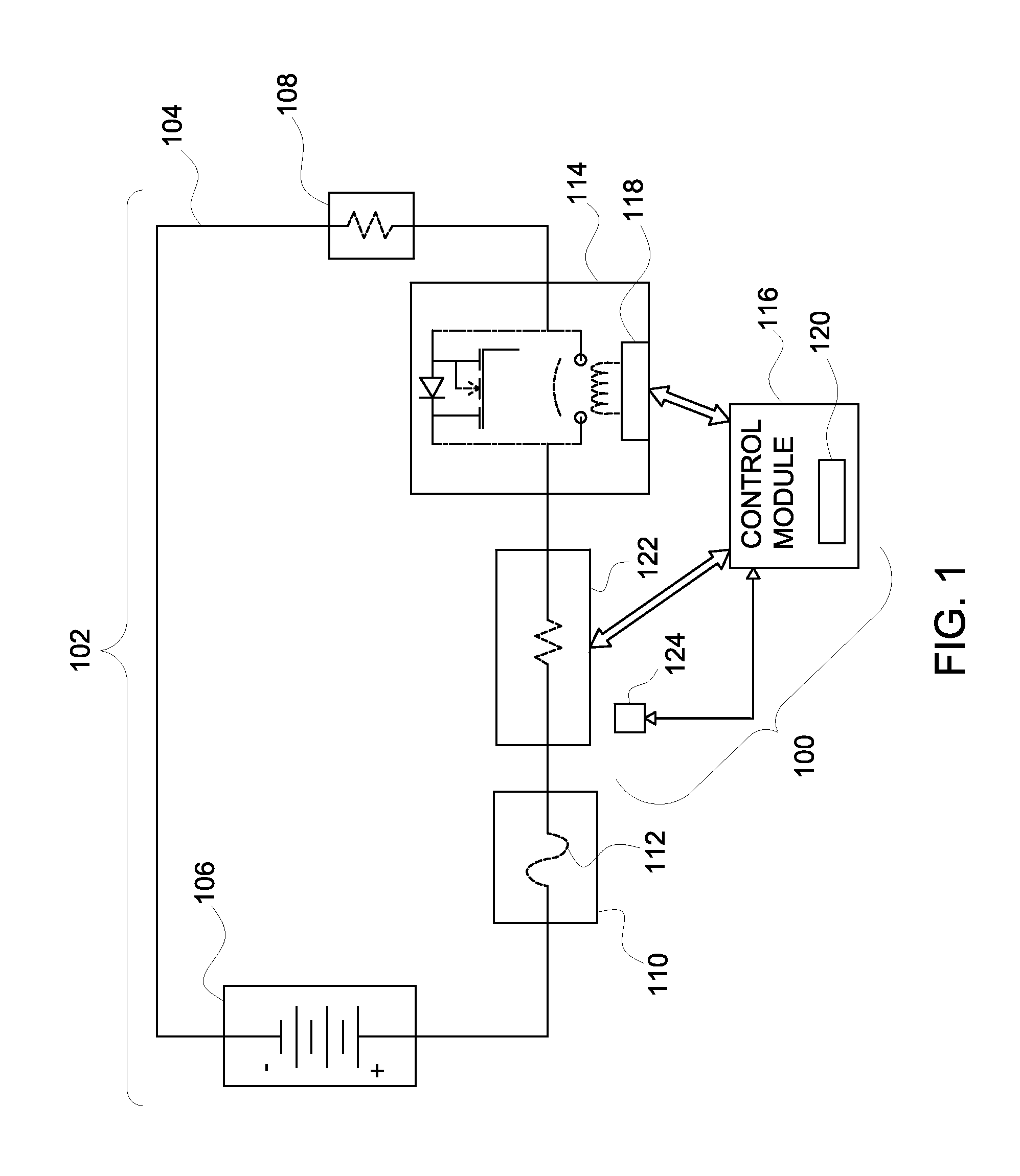

Electric circuit protection system and method for protecting an electric circuit

ActiveUS8587912B2Arrangements responsive to excess currentEmergency protective arrangements for limiting excess voltage/currentEnergy basedEngineering

An electric circuit protection system includes a control module and a circuit sensor communicatively coupled with the control module. The control module is communicatively coupled with a switch that is joined with a circuit having a power source and a fuse. The control module is configured to monitor a degradation factor related to an energy threshold value of the fuse and direct the switch to open the circuit to prevent the power source from supplying current through the fuse. The circuit sensor is configured to measure an energy parameter of the current supplied by the power source through the circuit or that is demanded by a load from the power source. The control module is configured to direct the switch to open the circuit based on the energy threshold value and the energy parameter.

Owner:GENERAL ELECTRIC CO

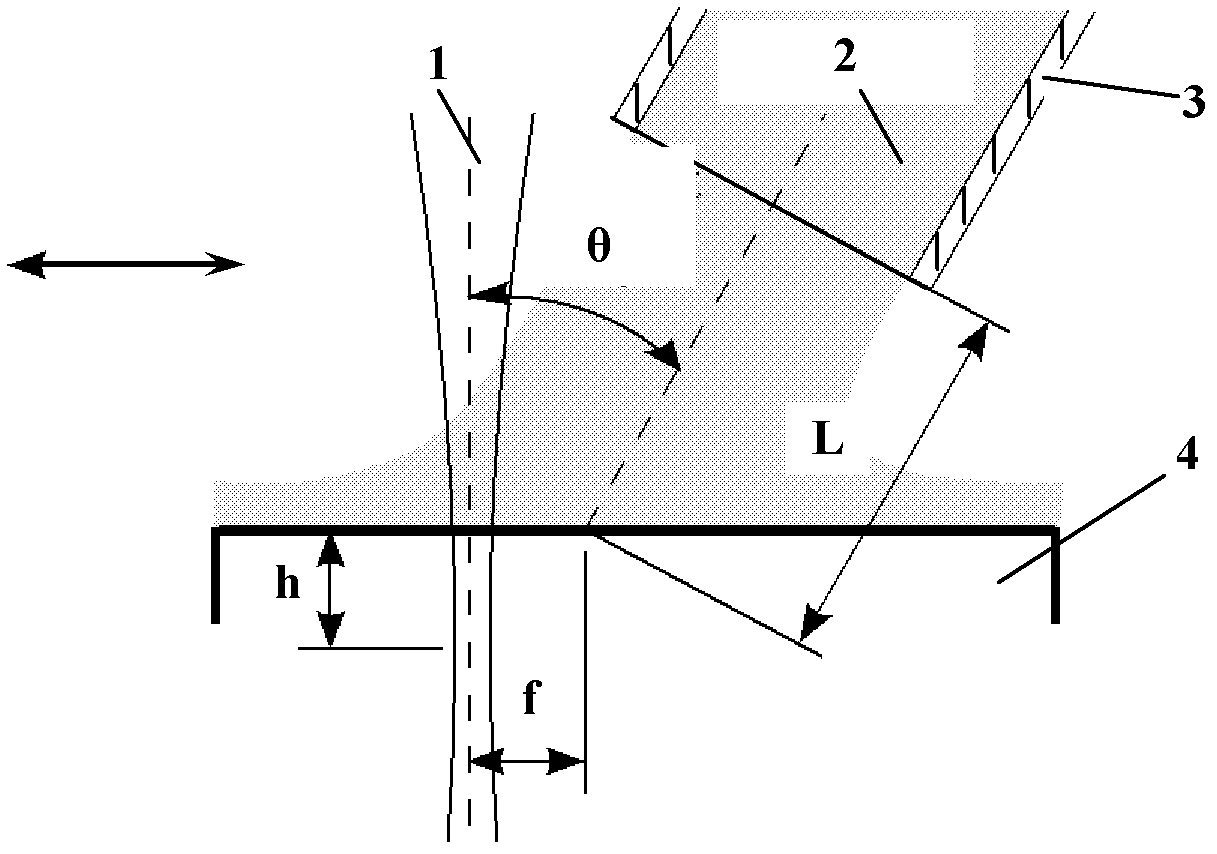

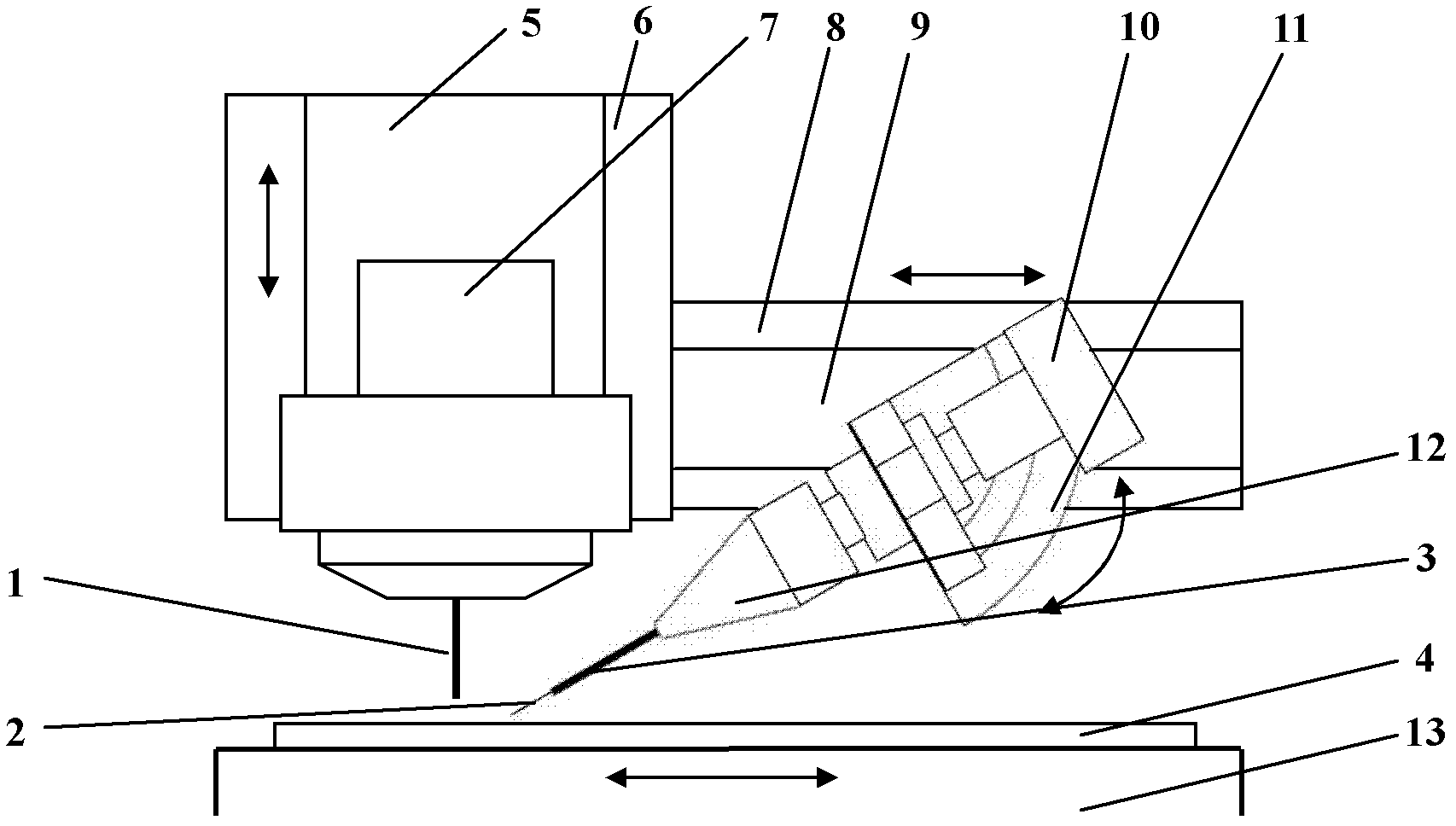

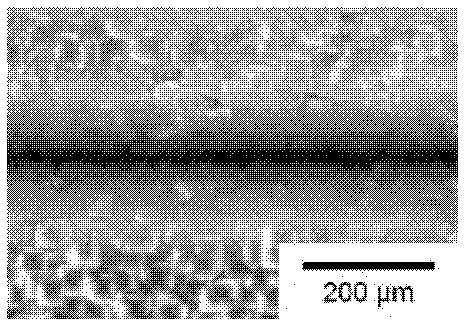

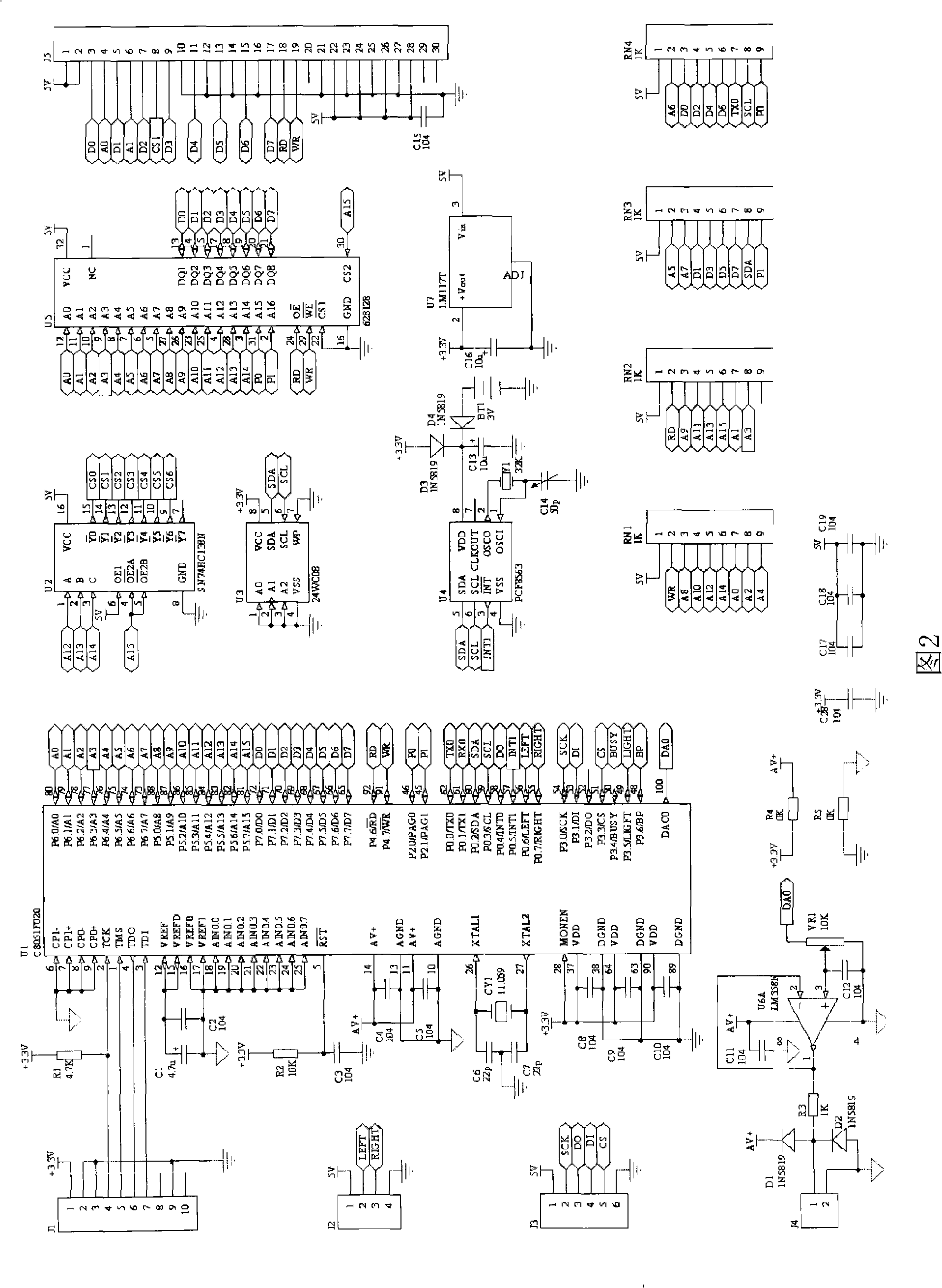

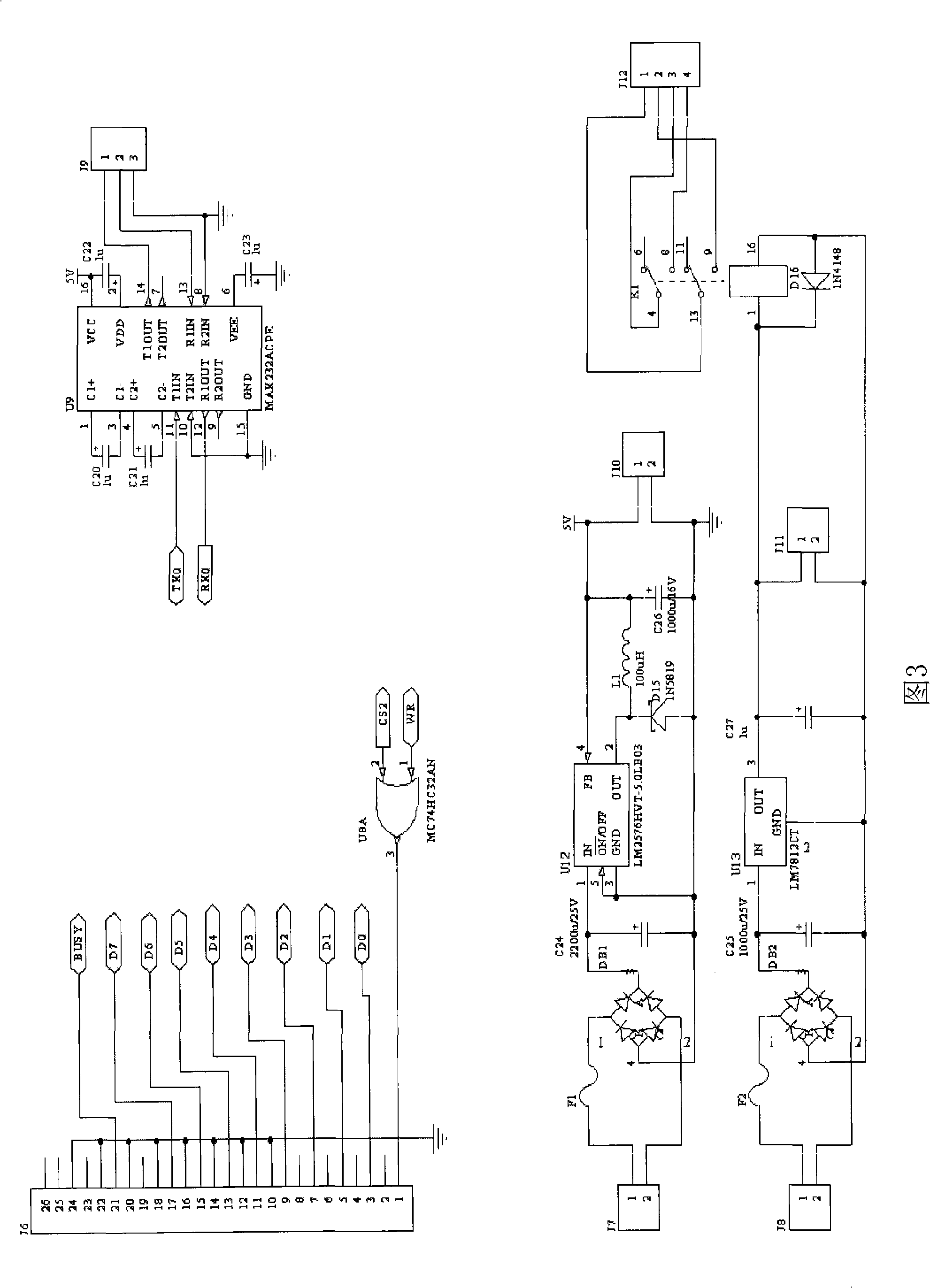

Laser-water jet composite micromachining process and device

InactiveCN102528280ALittle thermal impactReduce energy inputLaser beam welding apparatusEngineeringSlide plate

The invention relates to a laser micromachining process and in particular relates to a laser-water jet composite micromachining process and device. The composite micromachining process comprises the following steps of: positioning water jet at the back of a laser beam, leaning the water jet, and simultaneously acting the water jet on the surface of a material, wherein the parameter of a water jet offset distance is as follows: the water jet offset distance, namely the range of the distance between a laser beam action point and post-positioned water jet erosion point, is 0.4-0.8mm; the focal plane position (fpp) parameter of the laser beam is minus 0.6mm-0mm; the energy parameter of laser pulse is 0.3mJ-0.6mJ; the overlap coefficient of mobile laser pulse is 99.3%-99.9%; and the pressure of water jet is 5MPa-20Mpa, and the erosion angle of the water jet is 30-60 degrees. The device provided by the invention is composed of a base body consisting of a horizontal guide rail and a vertical guide rail, a horizontal slide plate, a vertical slide plate, a rotary adjusting support, a water jet unit and a laser cutting unit. According to the invention, the laser heating and softening temperature is far less than the melting or gasifying temperature, the heat influence on a material machining zone is reduced, and high-efficiency, stable and near-nondestructive precise machining is realized.

Owner:SHANDONG UNIV

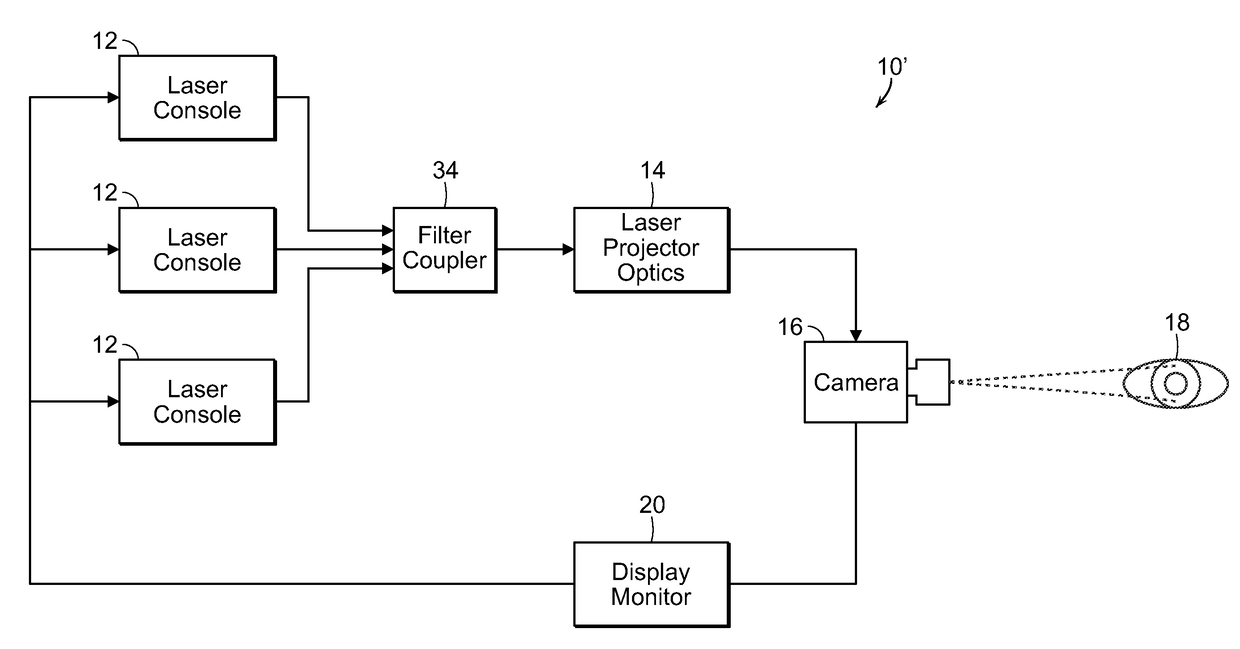

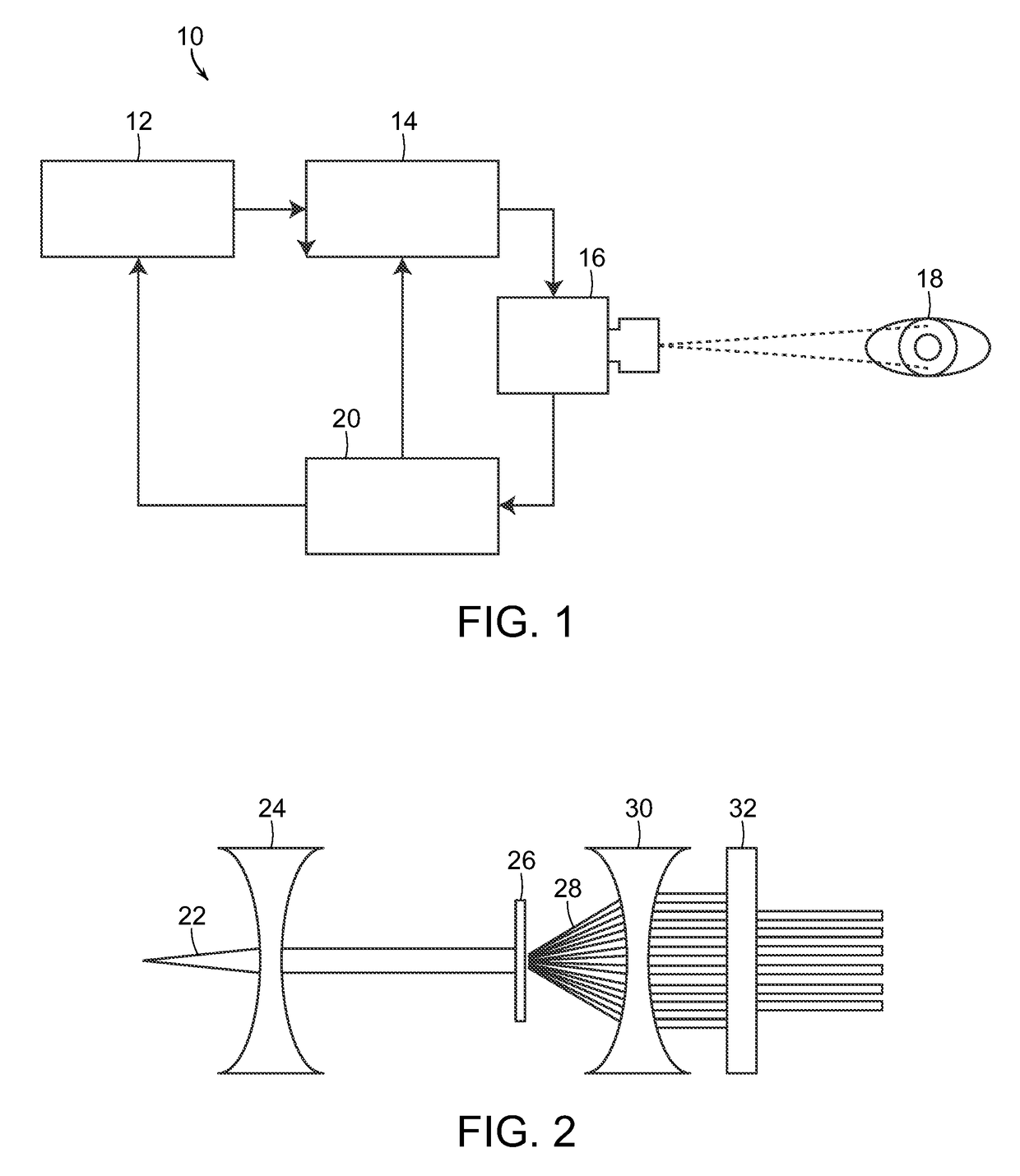

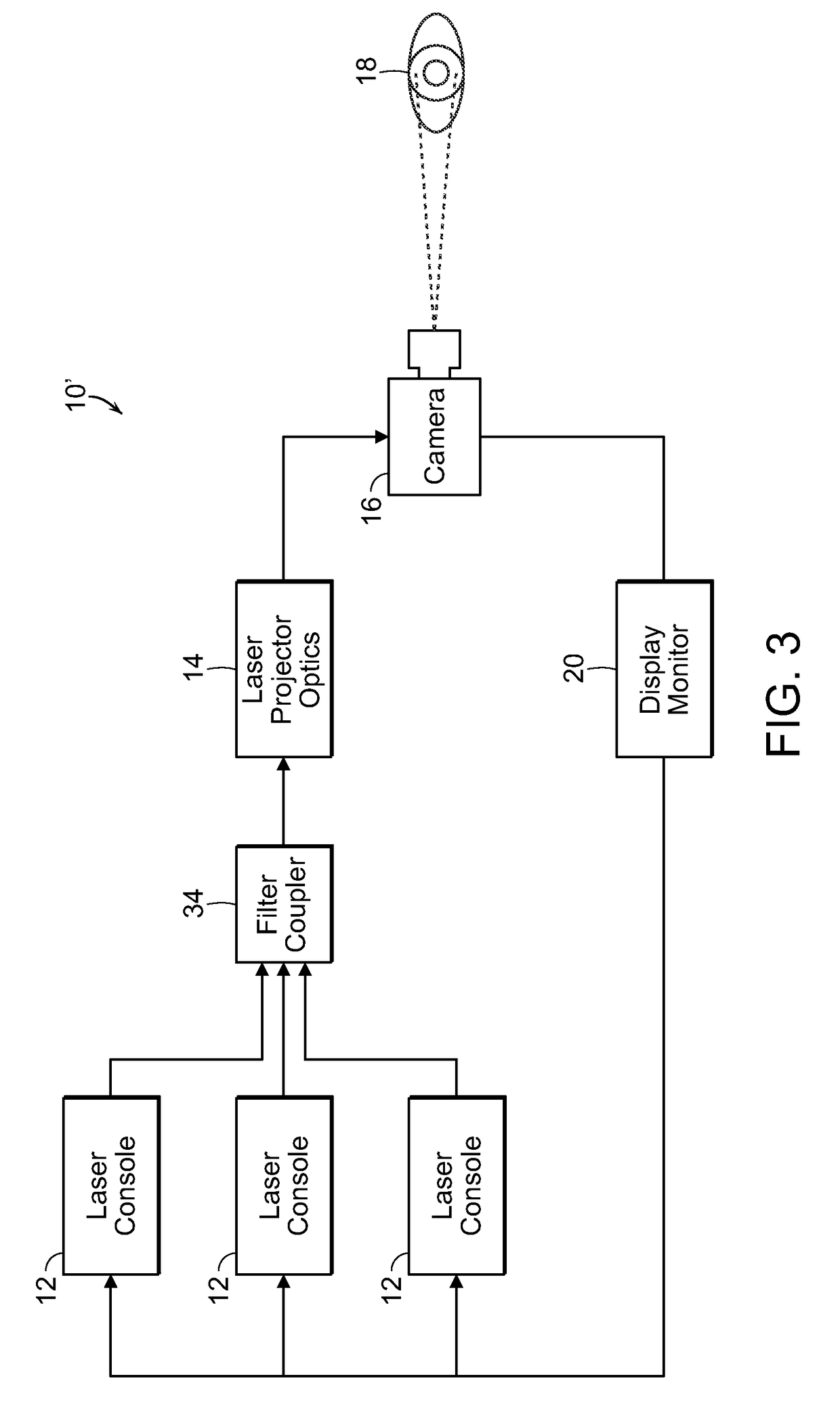

System and process for treatment of myopia

ActiveUS20170319383A1Preventing and treating myopiaIncrease temperatureUltrasound therapyLaser surgeryCelsius DegreePulse energy

A process for preventing or treating myopia includes applying a pulsed energy, such as a pulsed laser beam, to tissue of an eye having myopia or a risk of having myopia. The source of pulsed energy has energy parameters including wavelength or frequency, duty cycle and pulse train duration, which are selected so as to raise an eye tissue temperature up to eleven degrees Celsius to achieve therapeutic or prophylactic effect, such as stimulating heat shock protein activation in the eye tissue. The average temperature rise of the eye tissue over several minutes is maintained at or below a predetermined level so as not to permanently damage the eye tissue.

Owner:OJAI RETINAL TECH

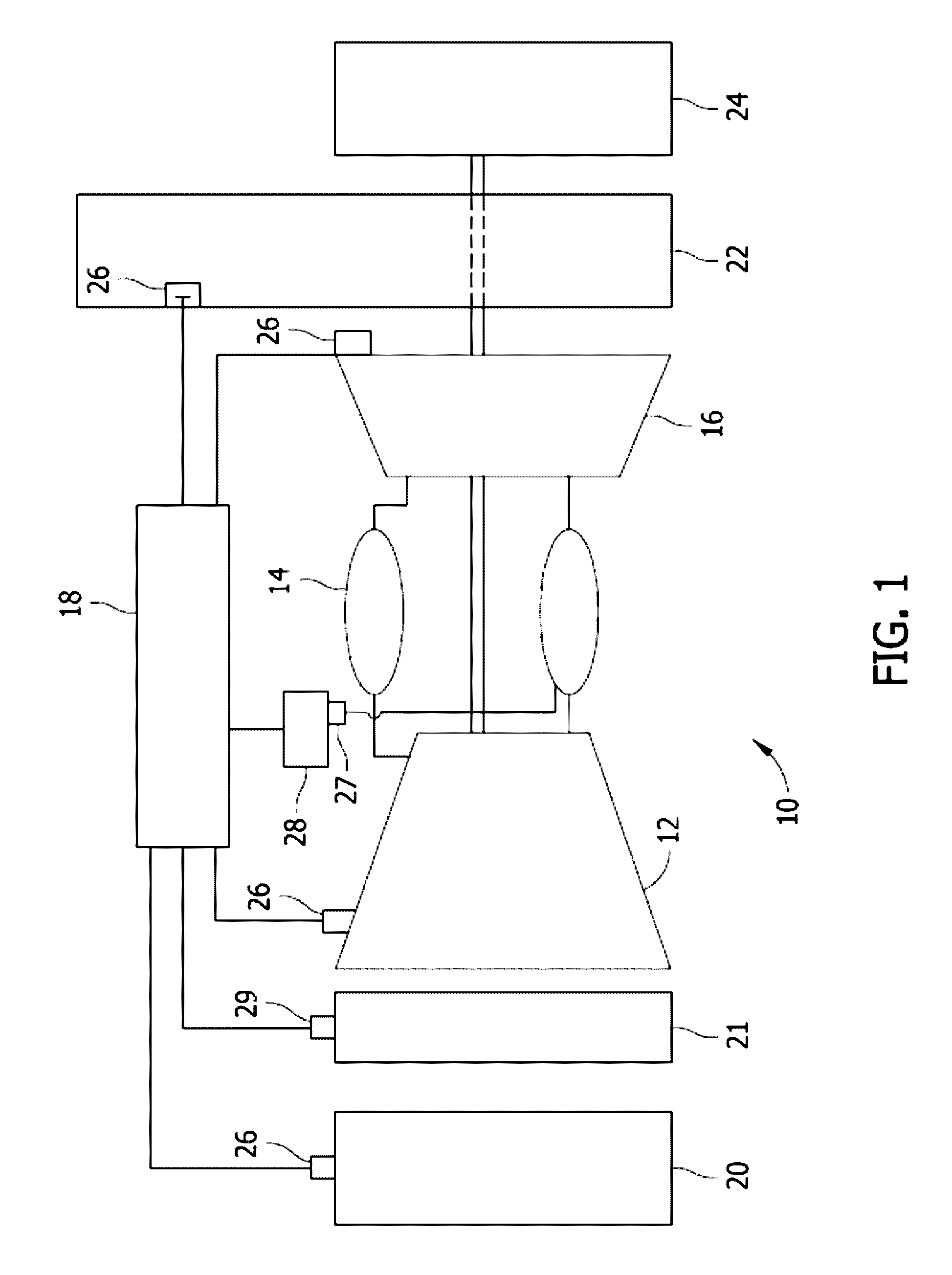

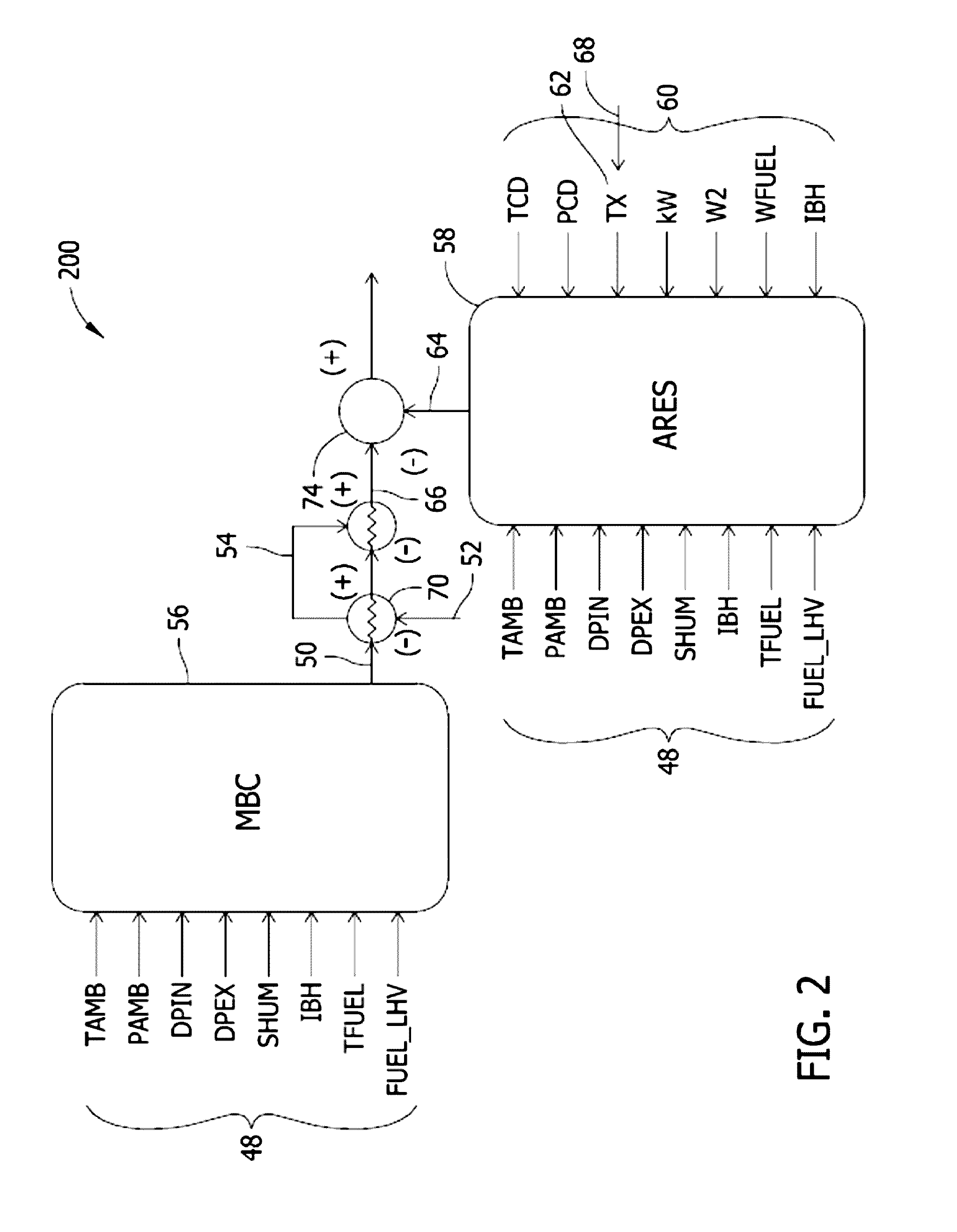

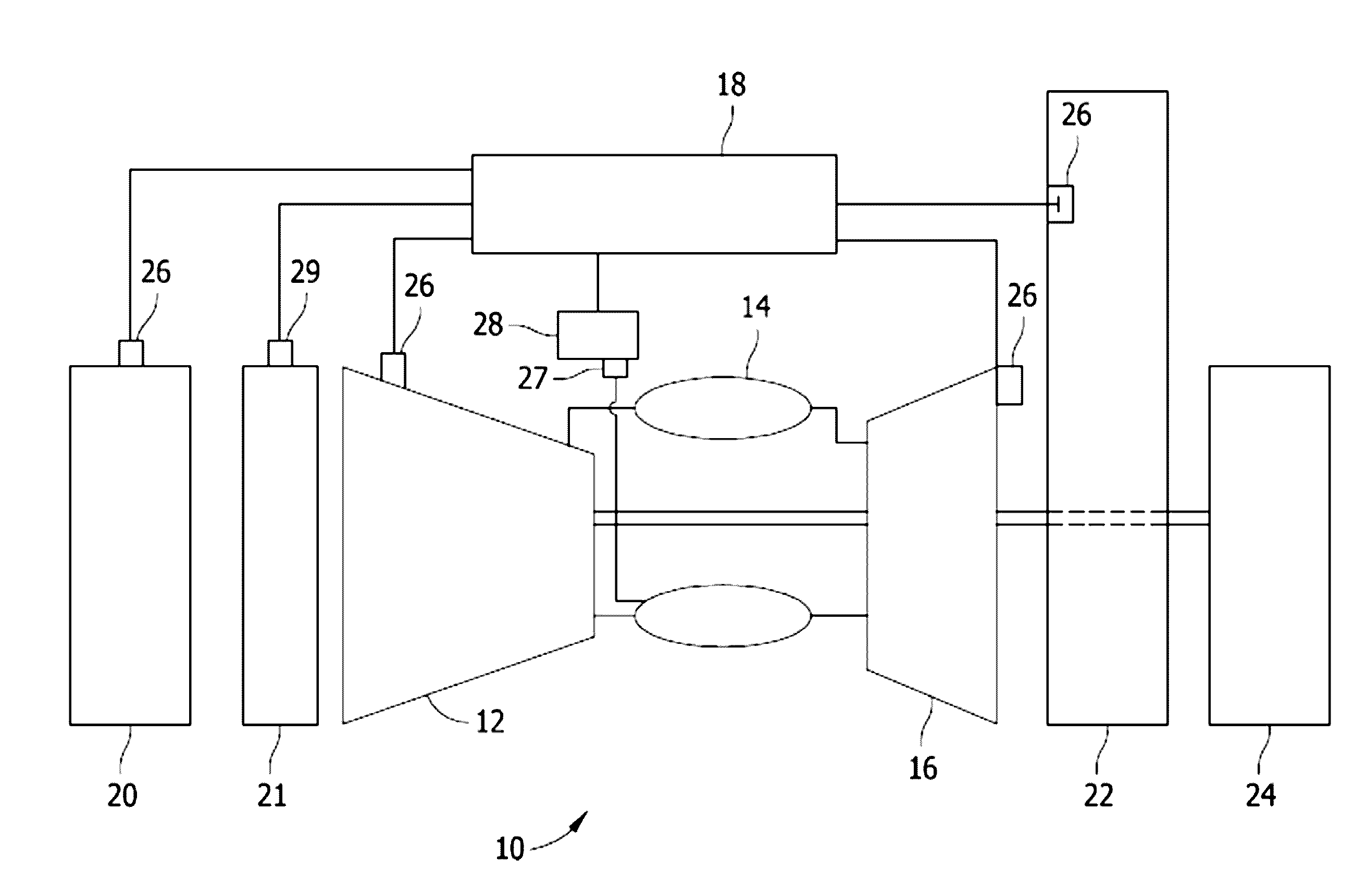

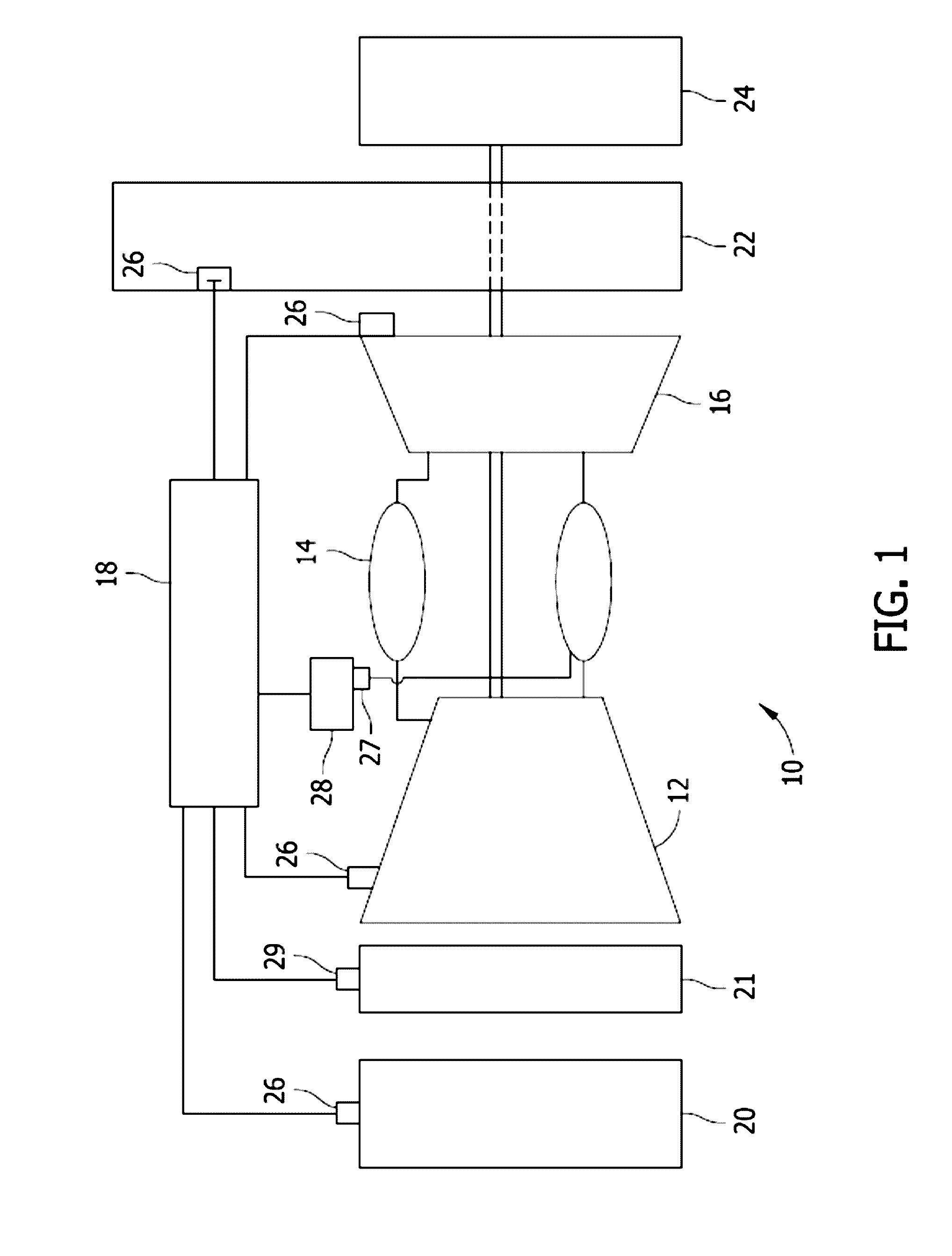

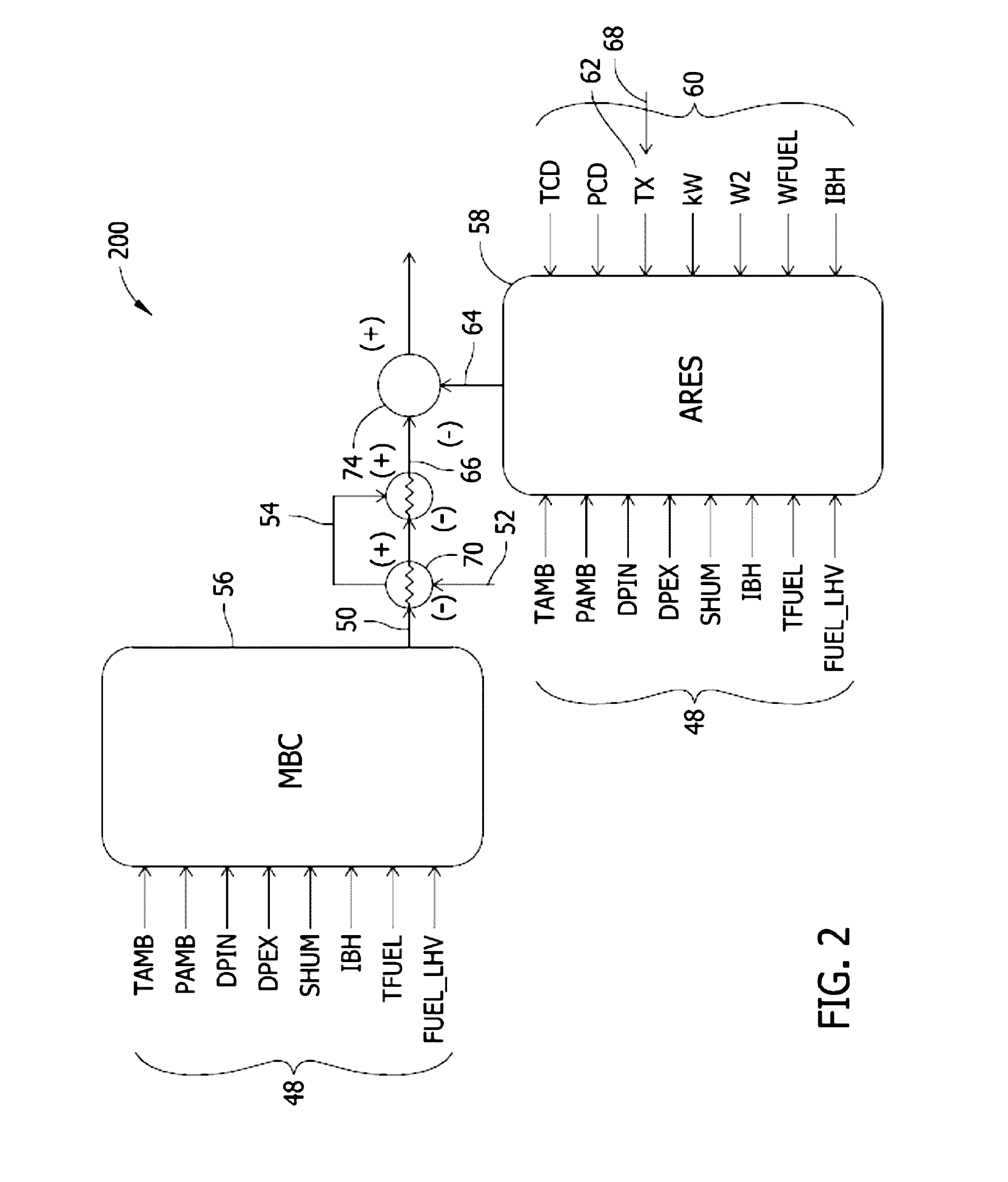

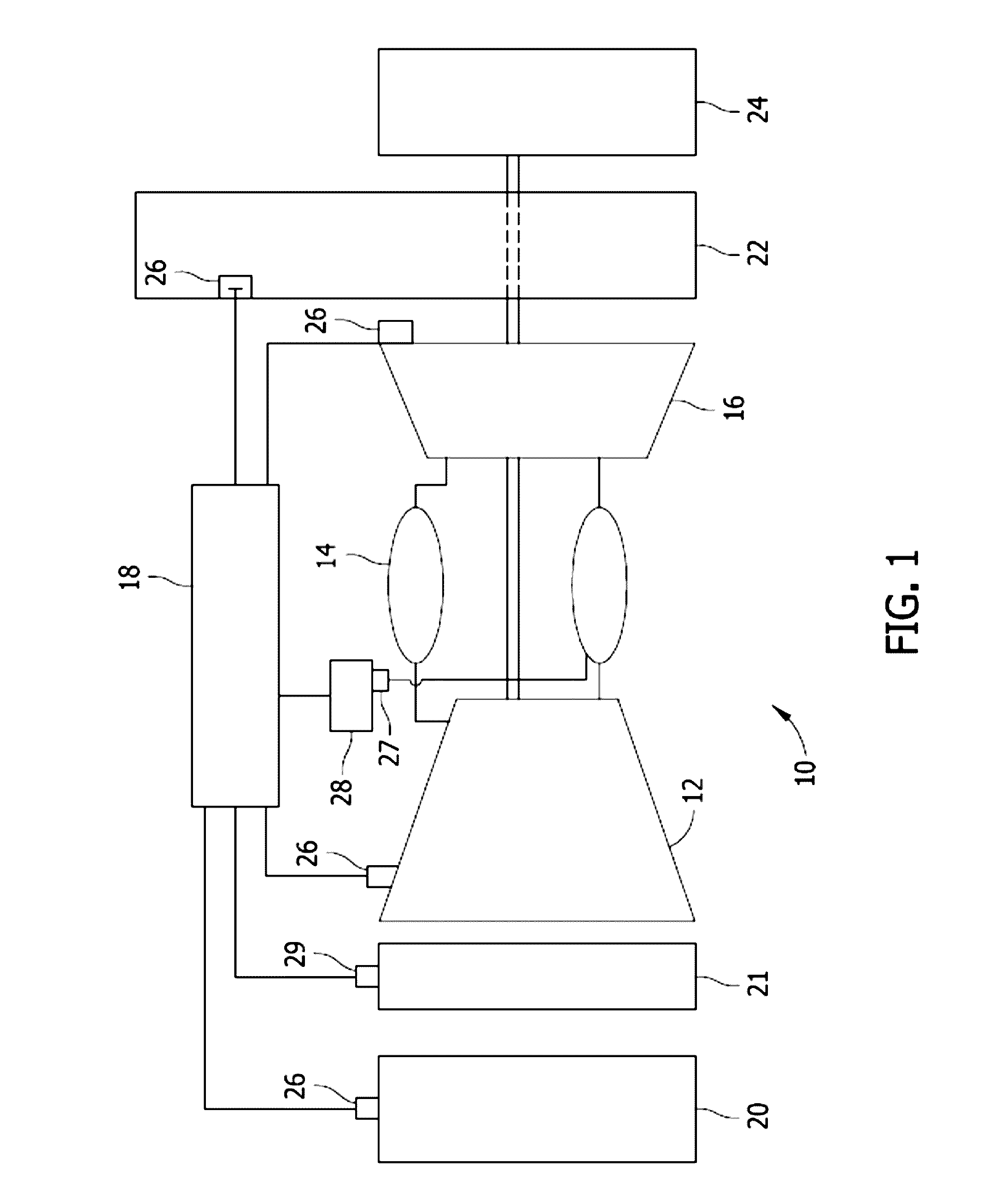

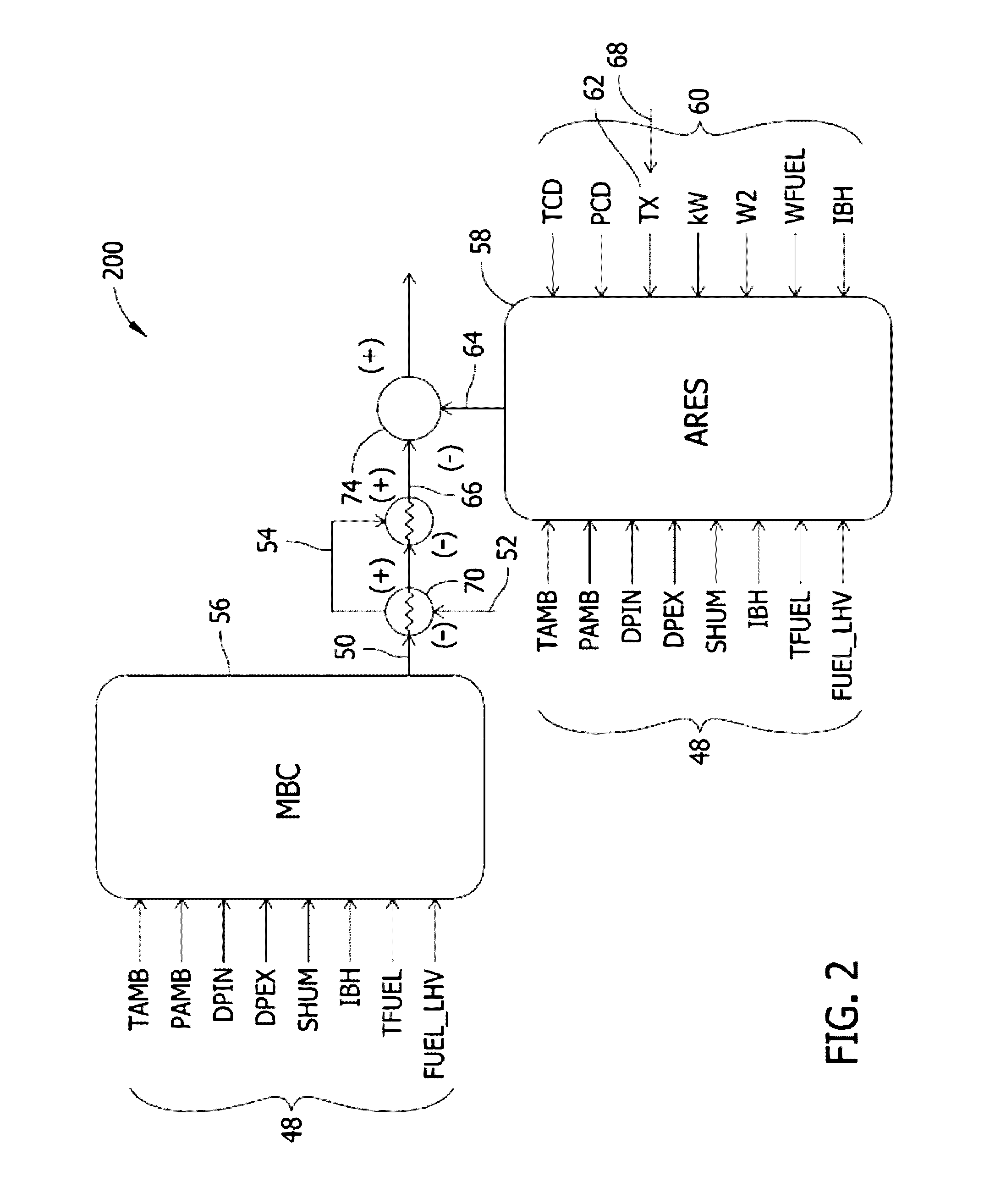

Application of probabilistic control in gas turbine tuning for power output-exhaust energy parameters, related control systems, computer program products and methods

ActiveUS20160305333A1Reduce variationEngine fuctionsGas turbine plantsControl systemProcess engineering

Various embodiments include a system having: at least one computing device configured to tune a set of gas turbines (GTs) by performing actions including: commanding each GT in the set of GTs to a base load level, based upon a measured ambient condition for each GT; commanding each GT in the set of GTs to adjust a respective power output to match a nominal power output value, and subsequently measuring an actual exhaust energy value for each GT; and adjusting an operating condition of each GT in the set of GTs based upon a difference between the respective measured actual exhaust energy value and a nominal exhaust energy value at the ambient condition.

Owner:GENERAL ELECTRIC CO

Application of probabilistic control in gas turbine tuning for fuel flow-exhaust energy parameters, related control systems, computer program products and methods

ActiveUS20160305344A1Reduce variationEngine fuctionsTurbine/propulsion fuel controlControl systemEngineering

Various embodiments include a system having: at least one computing device configured to tune a set of gas turbines (GTs) by performing actions including: commanding each GT in the set of GTs to a base load level, based upon a measured ambient condition for each GT; commanding each GT in the set of GTs to adjust a respective fuel flow value to match a nominal fuel flow value, and subsequently measuring an actual exhaust energy value for each GT; and adjusting an operating condition of each GT in the set of GTs based upon a difference between the respective measured actual exhaust energy value and a nominal exhaust energy value at the ambient condition.

Owner:GENERAL ELECTRIC CO

Systems And Methods For Detecting And Monitoring Arrhythmias Using the PPG

Owner:NELLCOR PURITAN BENNETT IRELAND

3dsMax-based nuclear facility model radiation field dosage simulation method

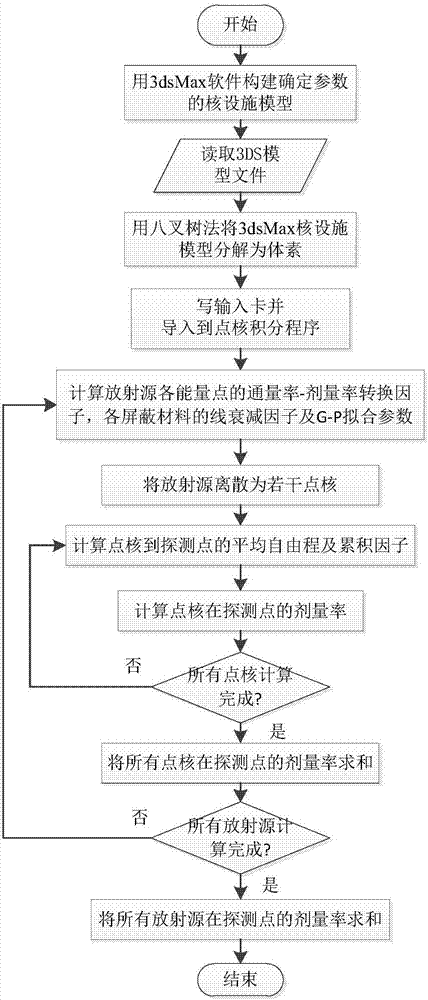

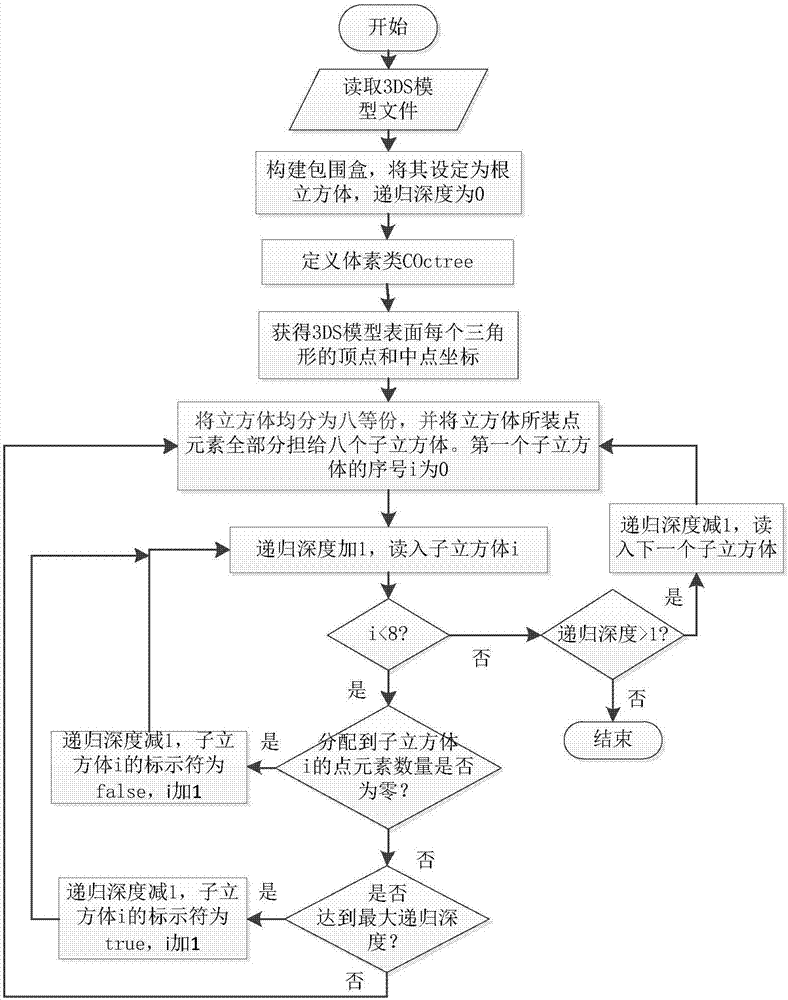

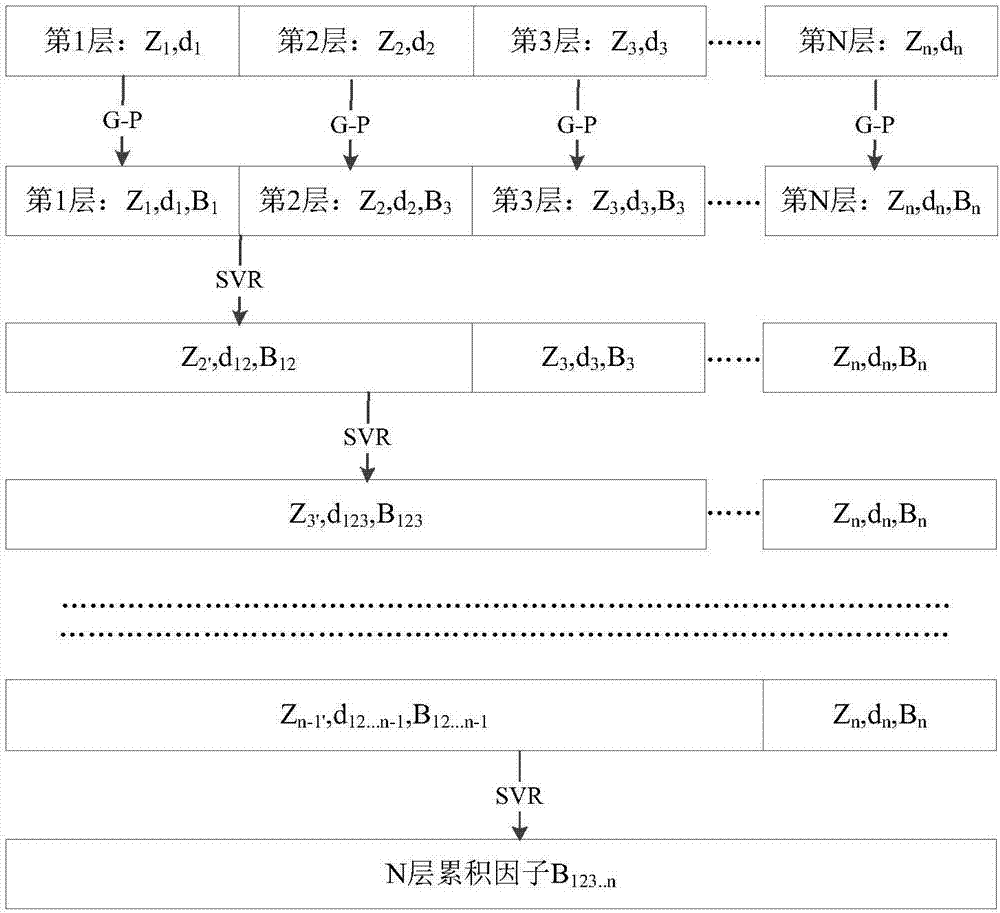

ActiveCN107194103AQuick assignmentRealize radiation field dose calculationDesign optimisation/simulationSpecial data processing applicationsVoxelDecay factor

The invention provides a 3dsMax-based nuclear facility model radiation field dosage simulation method. The method comprises the following steps of: constructing a model by 3dsMax software according to determined nuclear facility parameters, and storing a file in a 3DS format; importing a 3DS nuclear facility model file and obtaining model parameters; decomposing the 3dsMax nuclear facility model into voxels by using an octree method; writing determined voxel parameters and material information into an input card; importing the input card into a point nuclear integration program; calculating an accumulation factor; calculating a mean free path, in a radiation field, of a gamma ray; establishing a flux rate-dosage rate conversion factor, quality decay factors of chemical elements and materials and a single-layer accumulation factor database by utilizing an SQLite database engine; carrying out combined operation on a box by using a Boolean connective operator, and constructing a complicated radiation field geometric structure; and calculating a three-dimensional radiation field dosage by using a point nuclear integration method. The method provided by the invention is capable of realizing radiation field dosage calculation of complicated 3dsMax nuclear facility models with sizes, materials and energy parameters.

Owner:HARBIN ENG UNIV

Application of probabilistic control in gas turbine tuning for emissions-exhaust energy parameters, related control systems, computer program products and methods

ActiveUS20160305335A1Reduce variationEngine fuctionsGas turbine plantsControl systemProcess engineering

Various embodiments include a system having: at least one computing device configured to tune a set of gas turbines (GTs) by performing actions including: commanding each GT in the set of GTs to a base load level, based upon a measured ambient condition for each GT; commanding each GT in the set of GTs to adjust a respective emissions value to match a nominal emissions value, and subsequently measuring an actual exhaust energy value for each GT; and adjusting an operating condition of each GT in the set of GTs based upon a difference between the respective measured actual exhaust energy value and a nominal exhaust energy value at the ambient condition.

Owner:GENERAL ELECTRIC CO

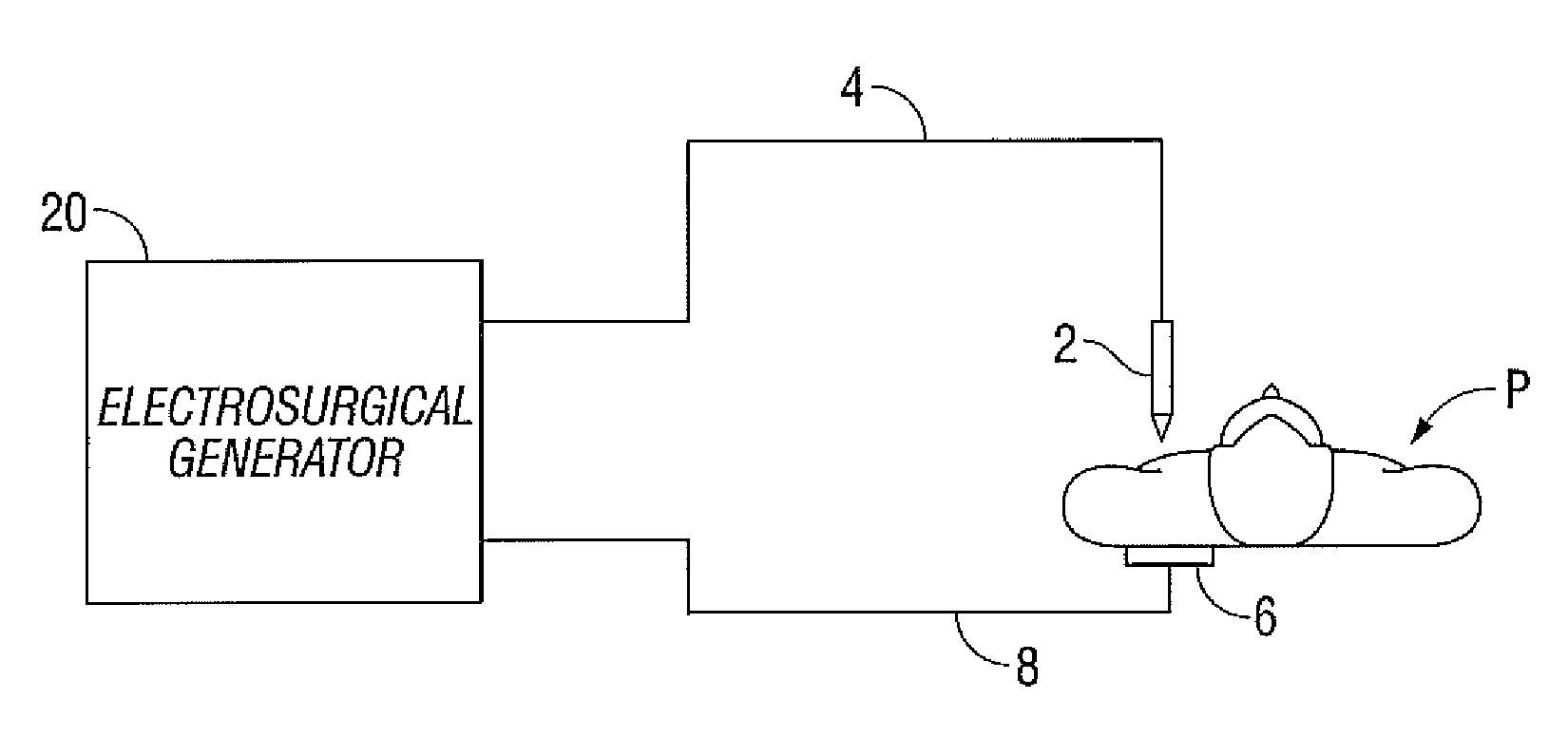

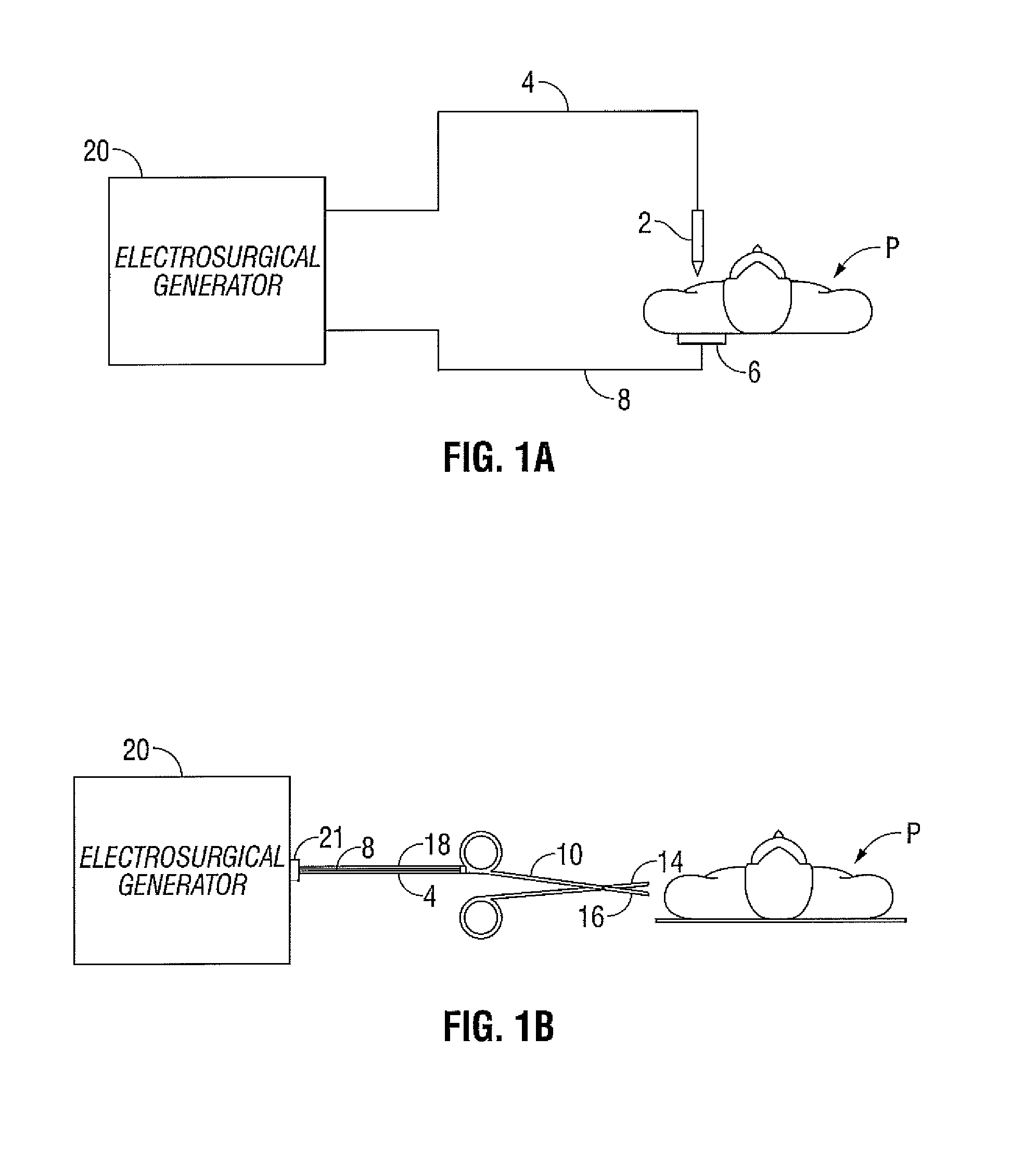

System and Method for Process Monitoring and Intelligent Shut-Off

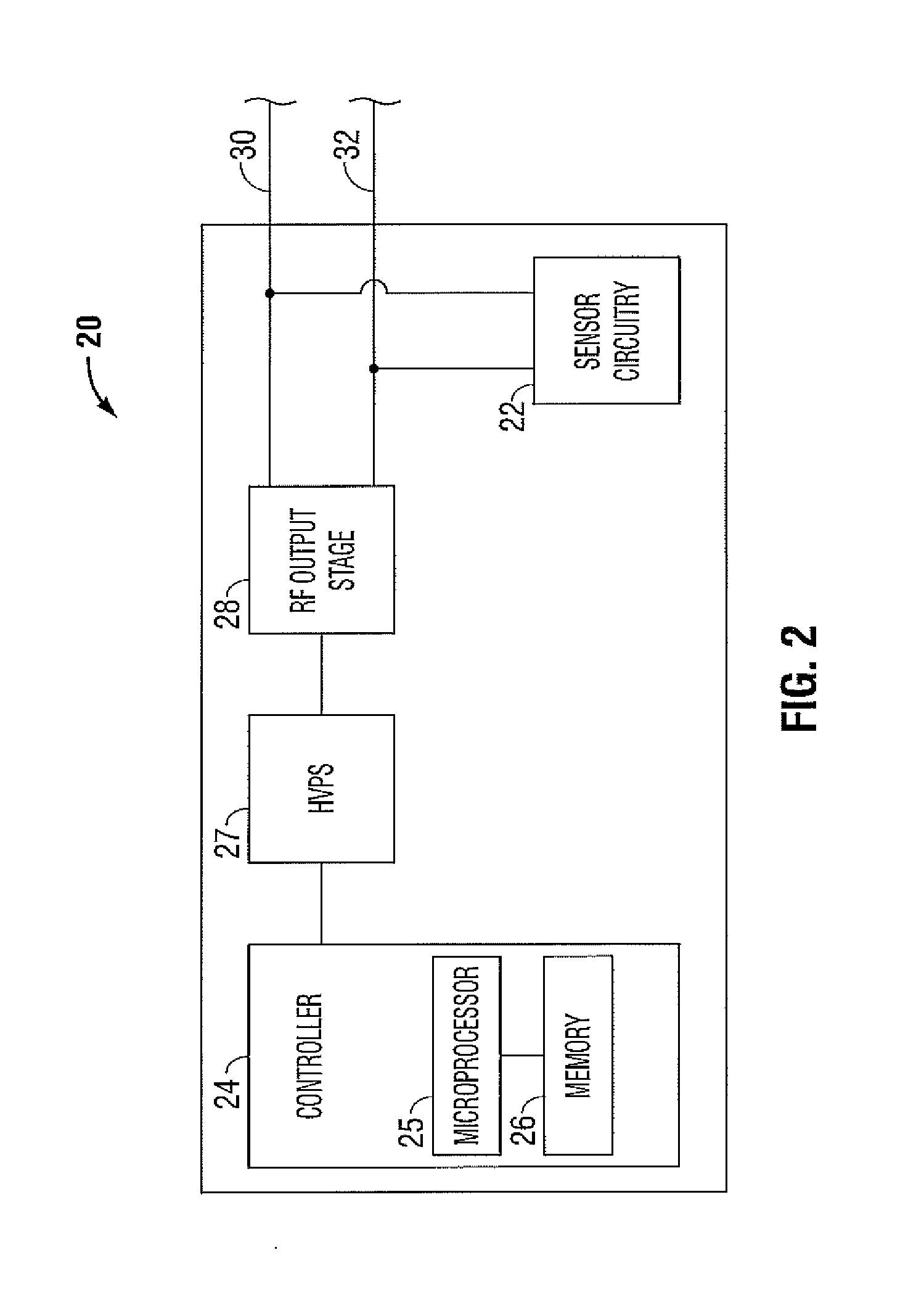

ActiveUS20120265194A1Surgical instruments for heatingSurgical instruments using microwavesEngineeringBiomedical engineering

An electrosurgical generator for supplying electrosurgical energy to tissue is disclosed. The generator includes sensor circuitry configured to measure at least one tissue or energy parameter and a controller configured to generate a plot of the at least one tissue or energy parameter including a plurality of tissue parameter values, wherein the controller is further configured to normalize the plot of the at least one tissue or energy parameter with respect to treatment volume.

Owner:TYCO HEALTHCARE GRP LP

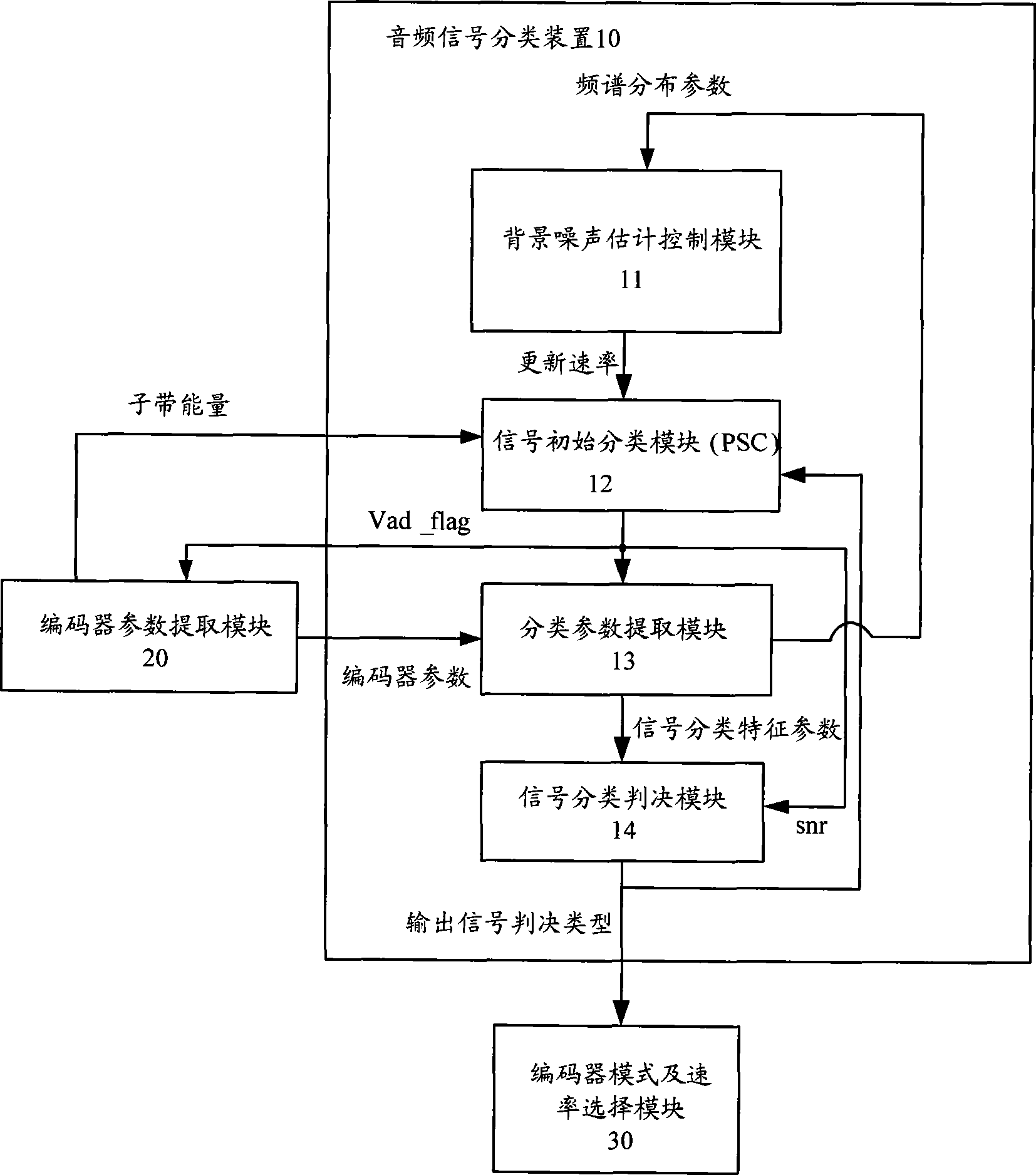

Audio signal classification apparatus and method used in wideband audio encoder and decoder

InactiveCN101393741AImprove accuracyImprove efficiencySpeech analysisFrequency spectrumClassification methods

The invention discloses an audio signal sorting device in a broadband audio codec, wherein a background noise estimating and controlling module is used for receiving the spectral distribution parameter of a sorting parameter extracting module and sending the update rate to a signal initial sorting module; the signal initial sorting module is used for carrying out the initial sorting of the audio input signal according to the sub-band energy parameter and the update rate, and sending the initial sorting results to a sorted parameter extracting module and a signal sorting determining module; the sorted parameter extracting module is used for extracting and sorting the input signals, sending the sorting characteristic parameter of the acquired signal to the signal sorting determining module and feeding the acquired spectral distribution parameter back to the background noise estimating and controlling module at the same time; and the signal sorting determining module is used for setting the final sorting mark for the sorting characteristics parameter according the initial sorting results, wherein the final sorting mark is used for defining the determining sort of the output signal. The invention further discloses an audio signal sorting method in the broadband audio codec.

Owner:ZTE CORP

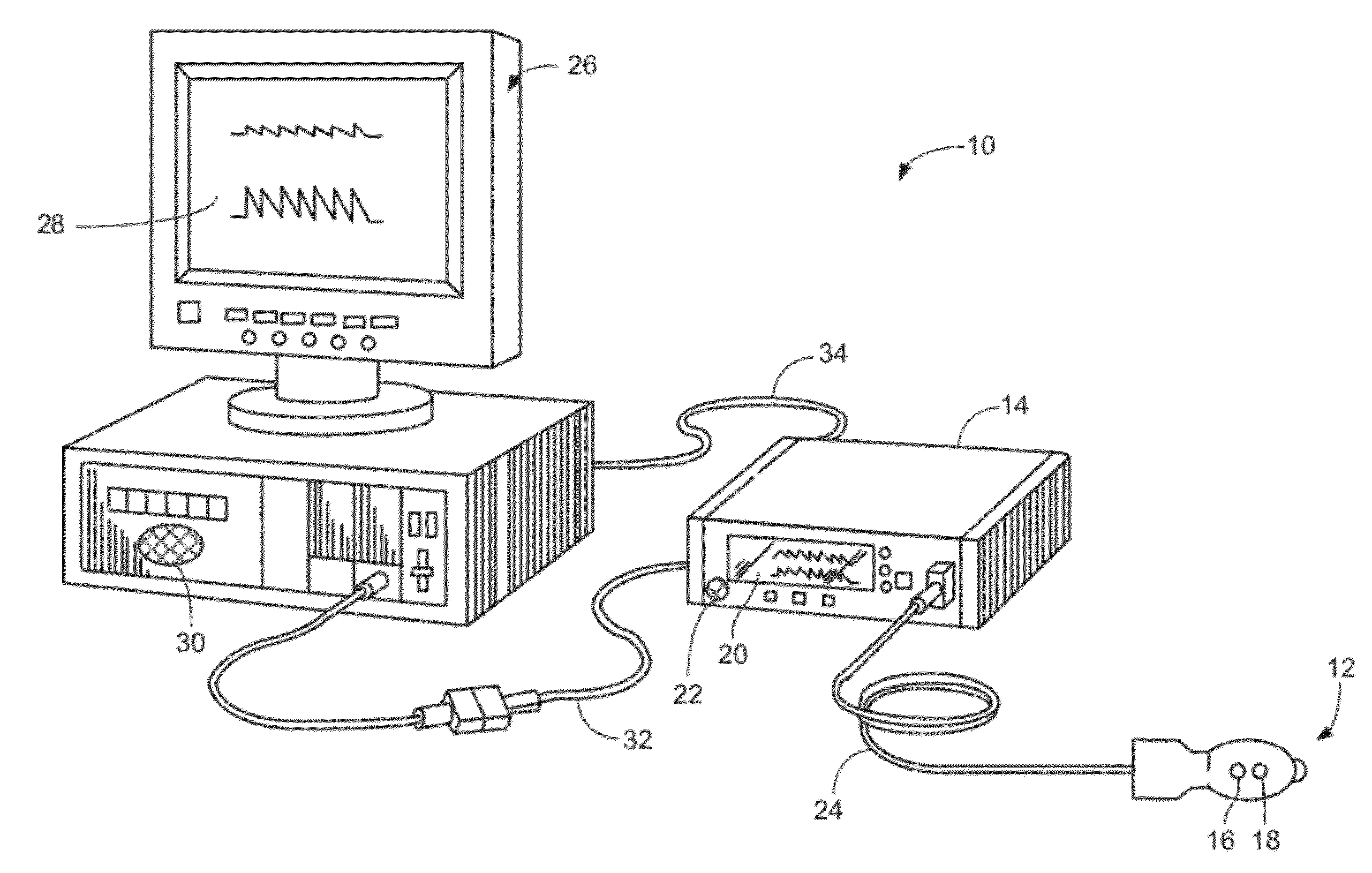

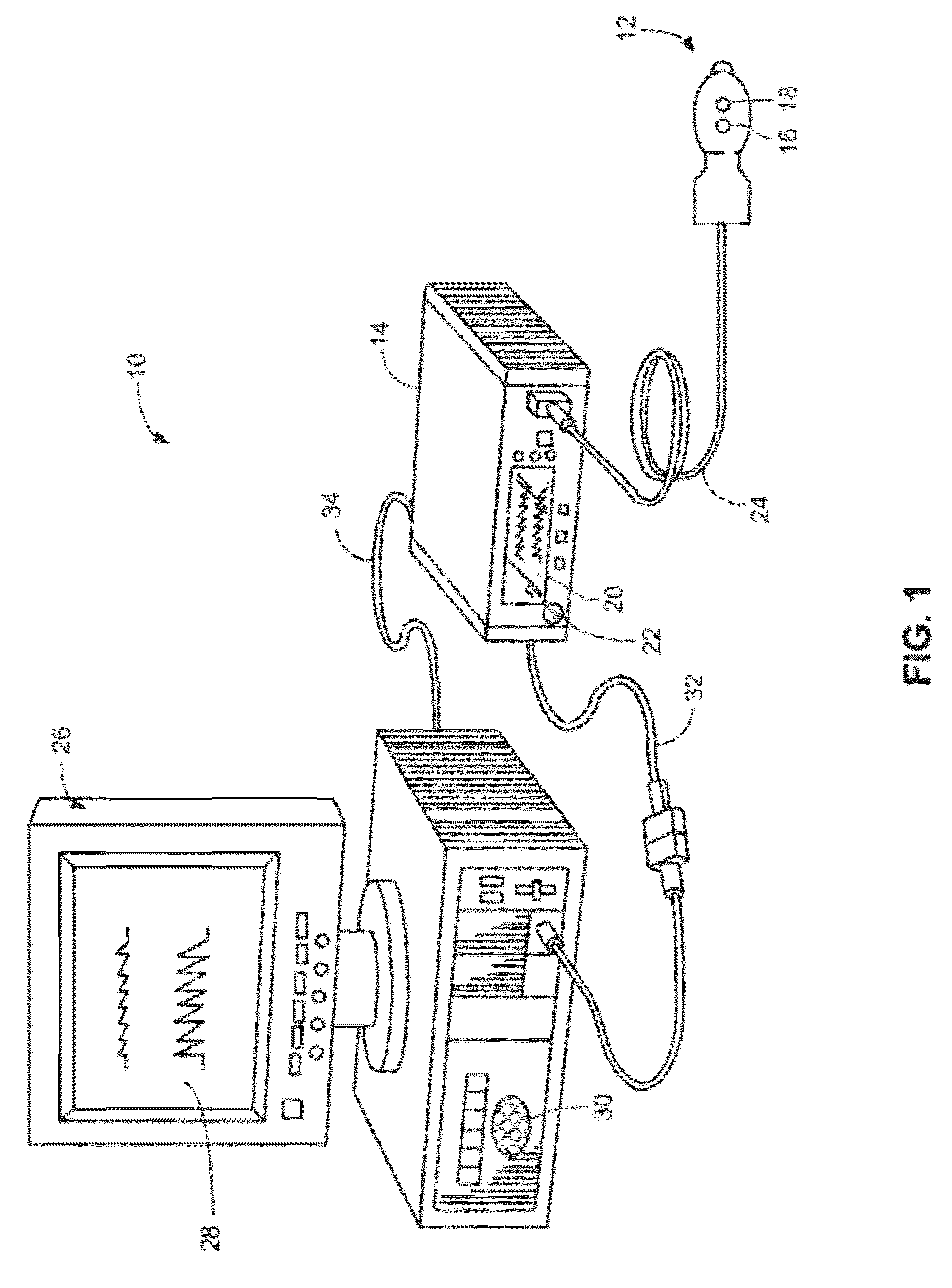

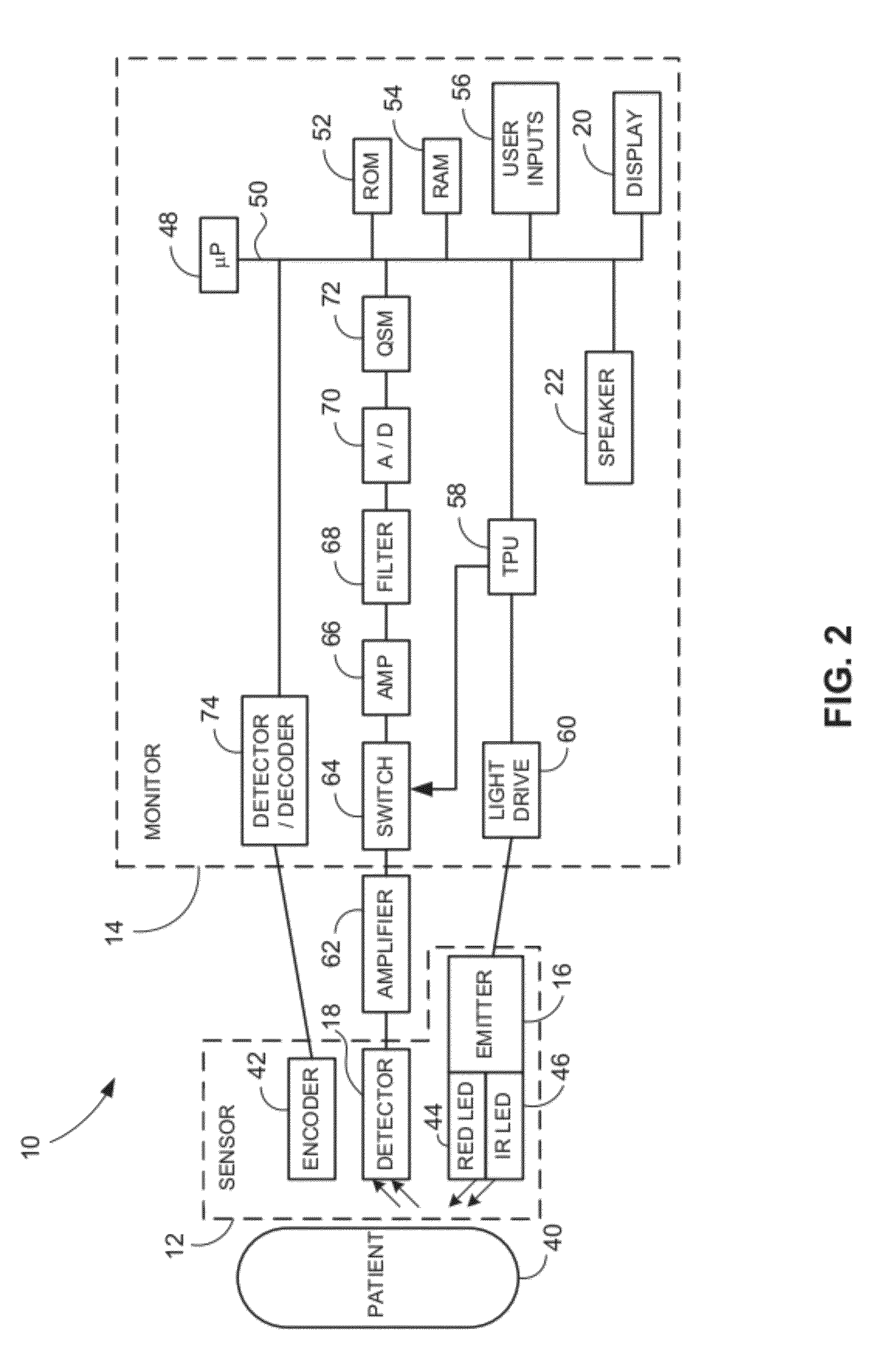

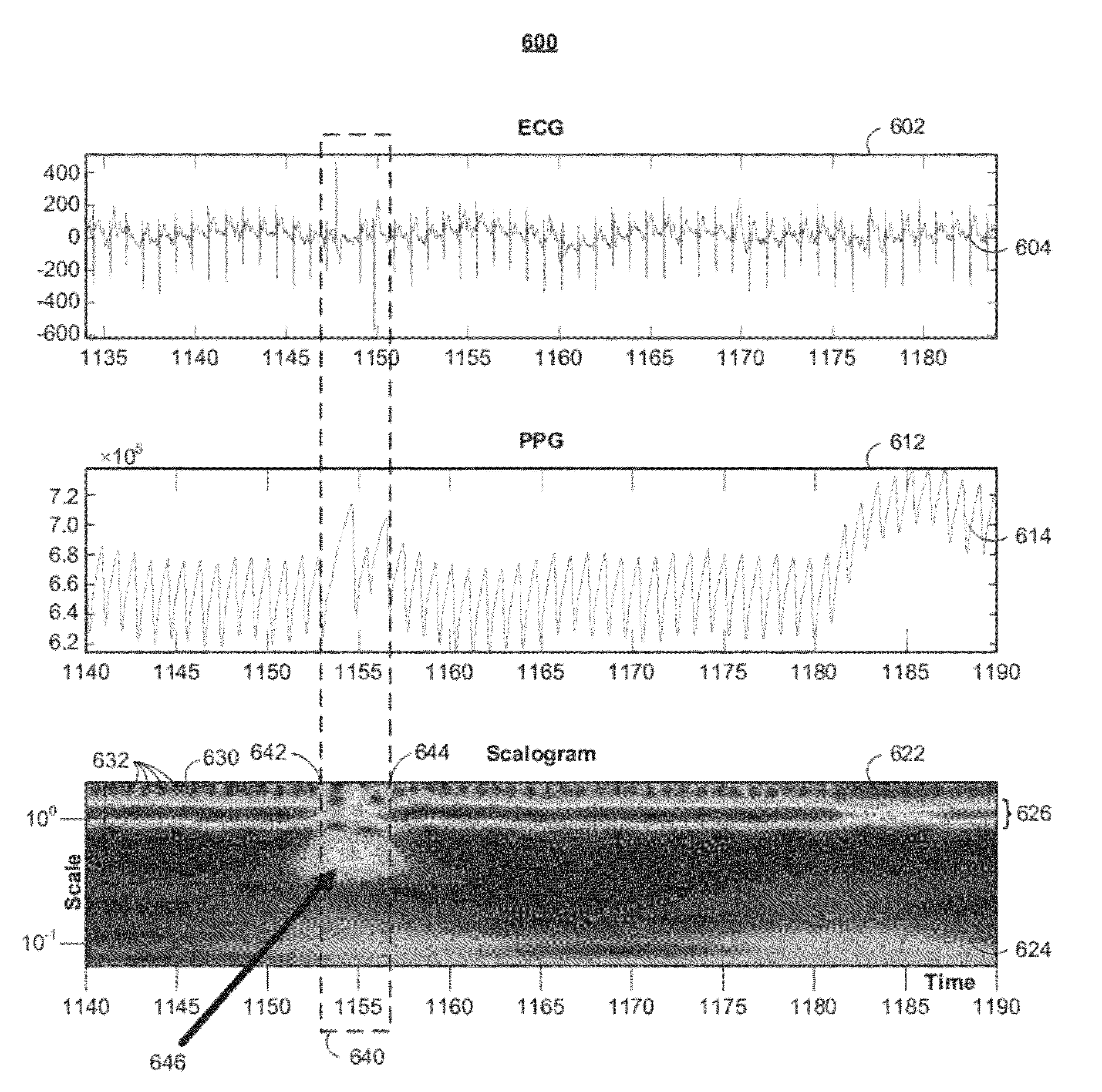

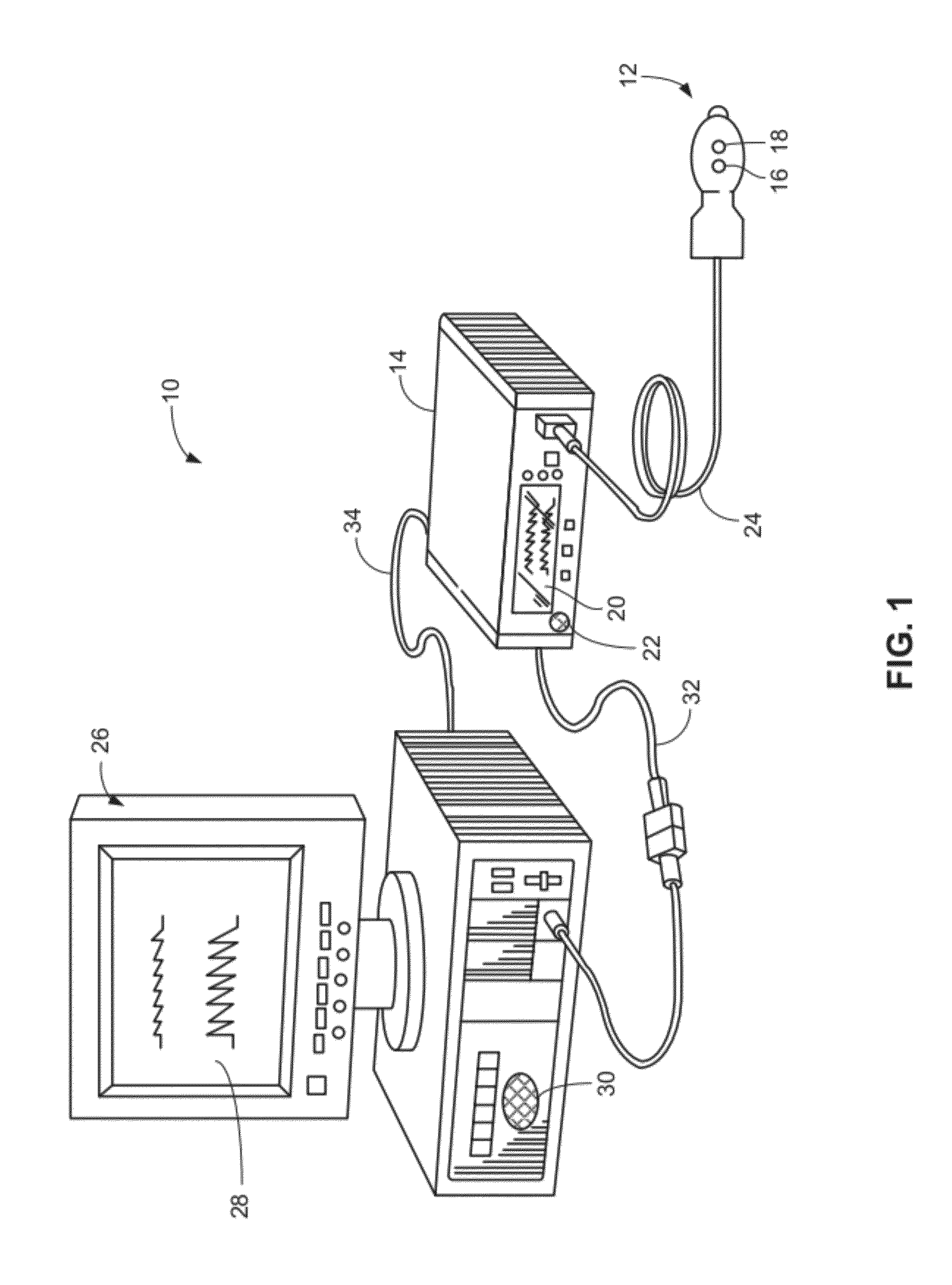

Systems and methods for detecting and monitoring arrhythmias using the PPG

Systems and methods for detecting and monitoring arrhythmias from a signal are provided. A signal processing system may transform a signal using a wavelet transformation and analyze changes in features of the transformed signal to detect pulse rhythm abnormalities. For example, the system may detect pulse rhythm abnormalities by analyzing energy parameters, morphology changes, and pattern changes in the scalogram of a PPG signal. Further, the system may detect pulse rhythm abnormalities by analyzing both the PPG signal and its corresponding scalogram. Physiological information, such as cardiac arrhythmia, may be derived based on the detected pulse rhythm abnormality.

Owner:NELLCOR PURITAN BENNETT IRELAND

Therapeutic electrical stimulation that avoids undesirable activation

Energy parameters for electrical stimulation pulses that produce a desired activation, and avoid an undesirable activation, are determined. A strength-duration relationship for at least one desired activation produced by therapeutic electrical stimulation is measured. A strength-duration relationship for at least one undesirable activation produced by the therapeutic electrical stimulation is provided. A medical device selects, based on the desired and undesirable strength-duration relationships, one or more energy parameters for the therapeutic electrical stimulation that produce the desired activation and avoid the undesirable activation.

Owner:CARDIAC PACEMAKERS INC

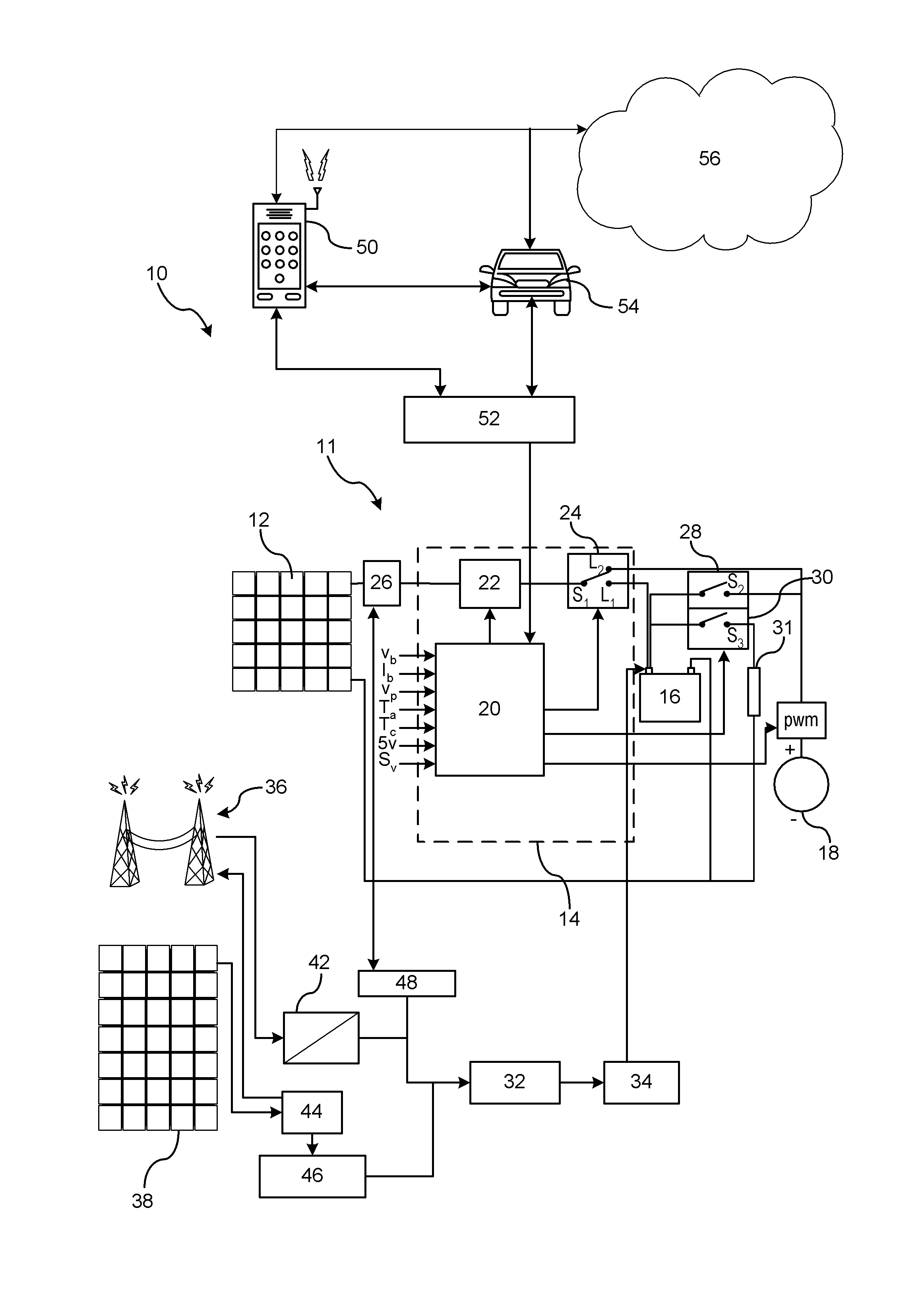

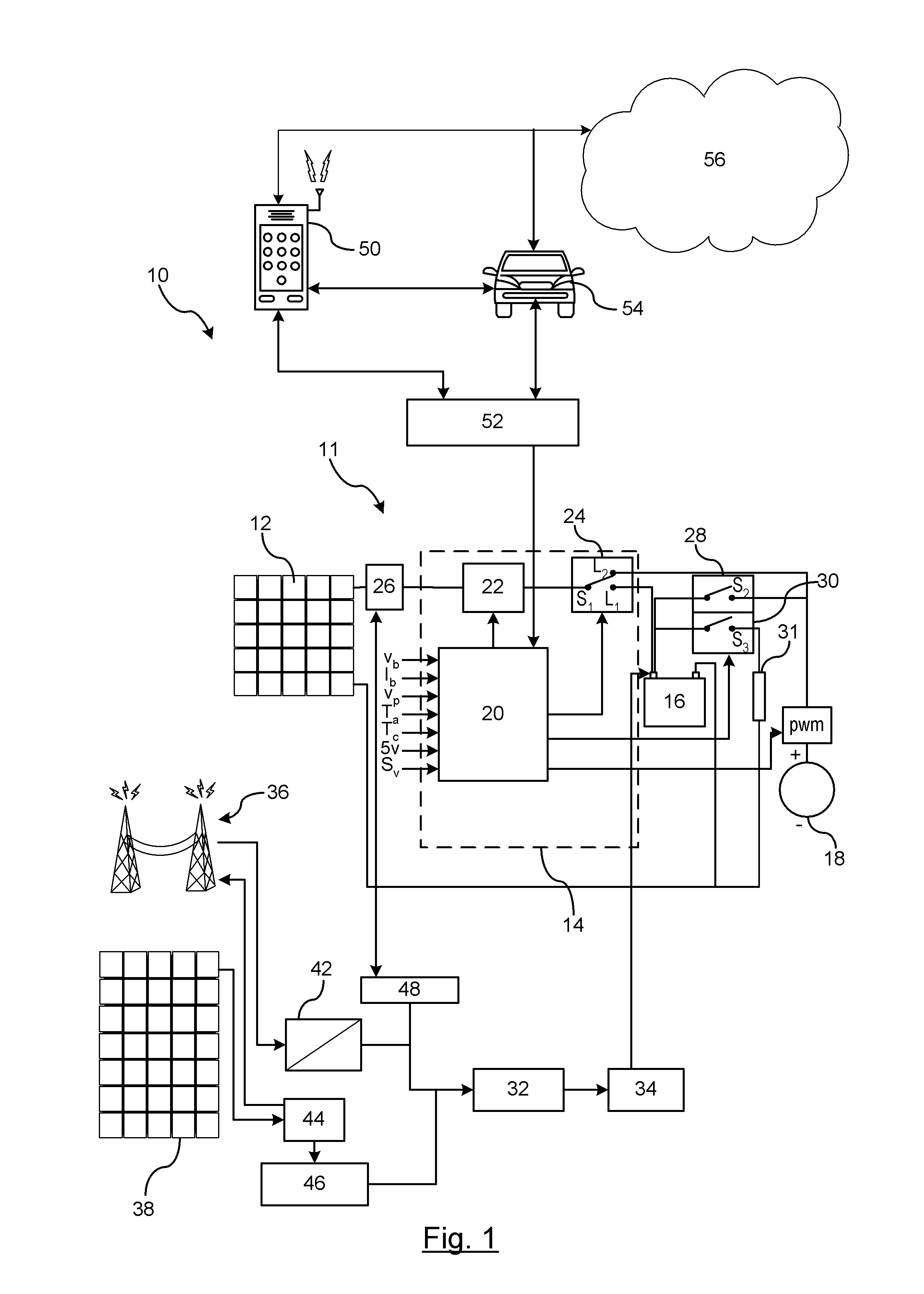

Personalized charging management for a vehicle

ActiveUS20130110330A1Convenience needsHybrid vehiclesBatteries circuit arrangementsPersonalizationElectric vehicle

A configurable energy management system for recharging an electric vehicle. An in-vehicle renewable energy source generates electrical energy for recharging an in-vehicle energy storage device. The at least one off-vehicle renewable energy source provides electrical energy to the vehicle for recharging the in-vehicle energy storage device. A vehicle communication module transmits and receives data. An integration module integrates in-vehicle energy parameter data, in-vehicle renewable energy parameter data, off-vehicle renewable energy parameter data, user parameter data, and web-based data. A user interface device communicates user parameter data to the integration module. The user parameter data includes a prioritization of preferential parameters in re-charging the in-vehicle energy storage device. The integration module identifies an optimal energy source for re-charging the vehicle based on the in-vehicle energy parameter data, in-vehicle renewable energy parameter data, off-vehicle renewable energy parameter data, user parameter data, and the web-based data.

Owner:GM GLOBAL TECH OPERATIONS LLC

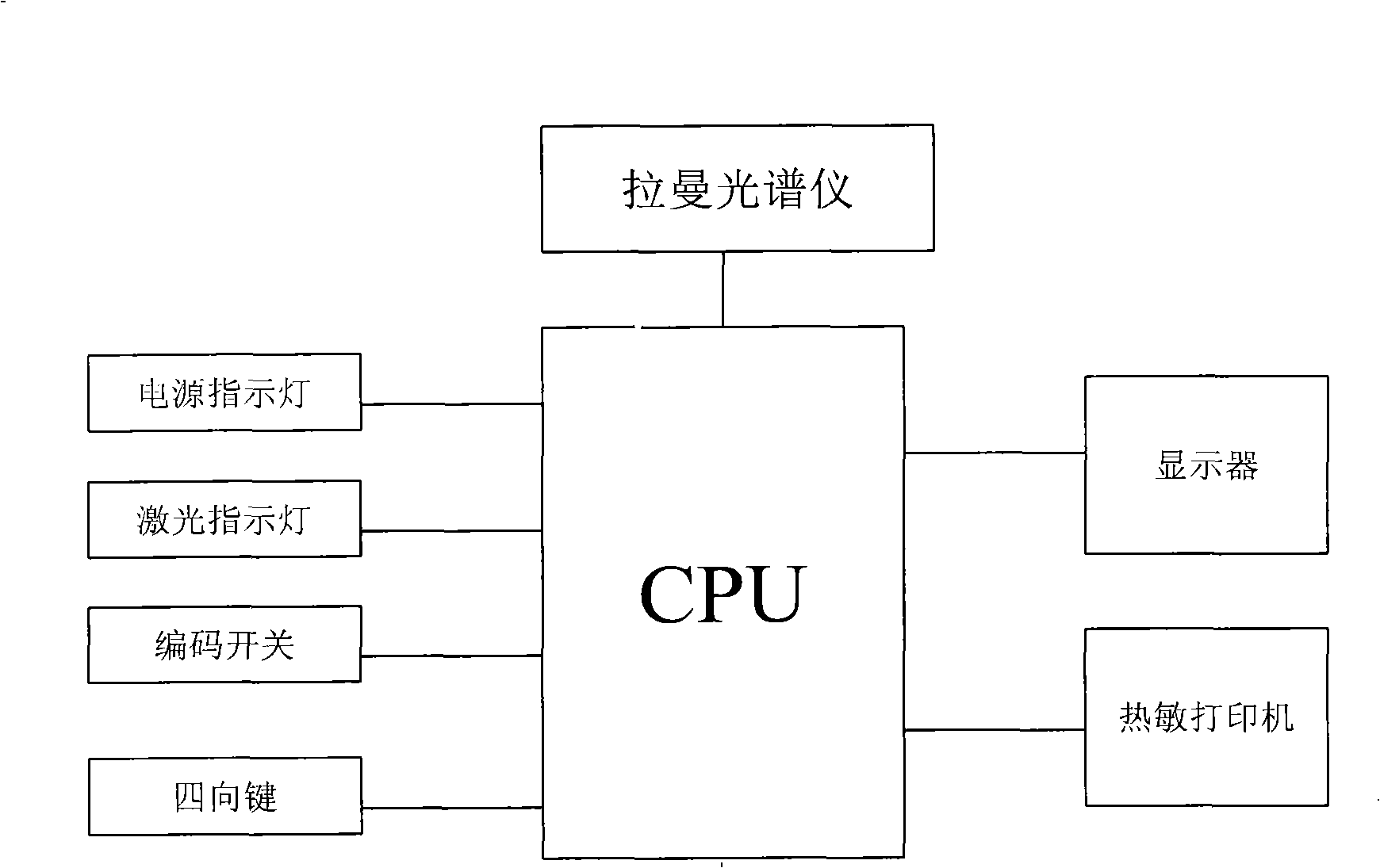

Portable Raman optical spectrum olive oil discrimination data processing system

InactiveCN101303305AConvenient mobile detectionSolve the detection speed is slowRaman scatteringSpecial data processing applicationsContinuous scanningMicrocontroller

The invention provides a portable Raman spectrum data processing system for olive oil real and false identification, comprising a Raman spectrometer, a housing, an analyzer panel, and a calculation and control device for the micro-controller. Wherein a near-infrared laser with a emission wavelength of 785nm is selected as the laser source the Raman spectrometer the laser energy parameter is selected between 100-200mw, time division parameter is selected between 5-20s. An optimum Raman peak strength is calculated from the two parameters mentioned, 5 spectrum scans are continuously carried out, and an average Raman spectrum of the 5 scanning is finally obtained, which ranges from 250-2300cm[-1]. The test sample is scanned with a resolution between 4-10cm[-1]. The calculation and control device for the micro-controller is used for obtaining Raman spectrum with flat baseline, with spectrum drawn by using corresponding strength of spectrum between 1265cm[-1] to 1441cm[-1] as horizontal axis, using corresponding strength of spectrum between 1657cm[-1] to 1441cm[-1] as vertical axis, and marking points of the sample therein.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

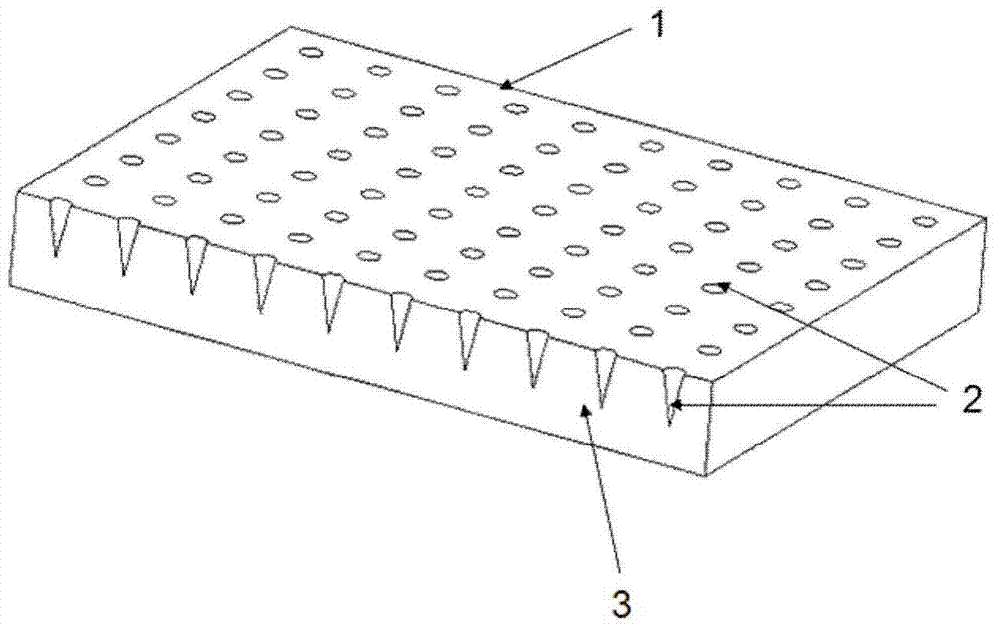

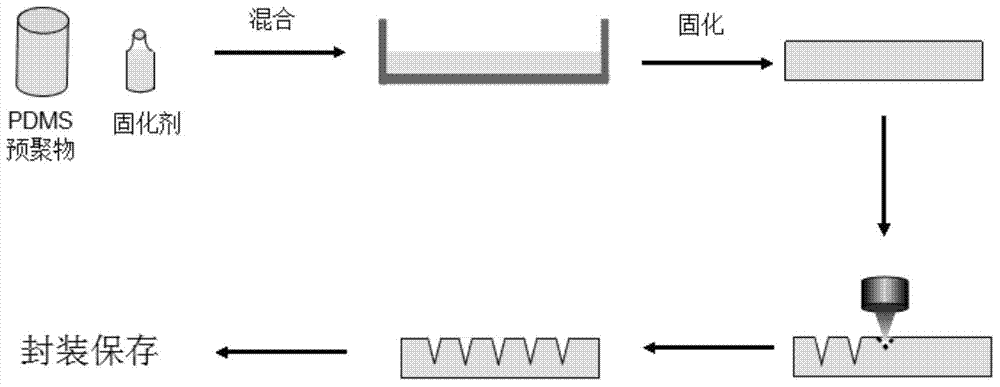

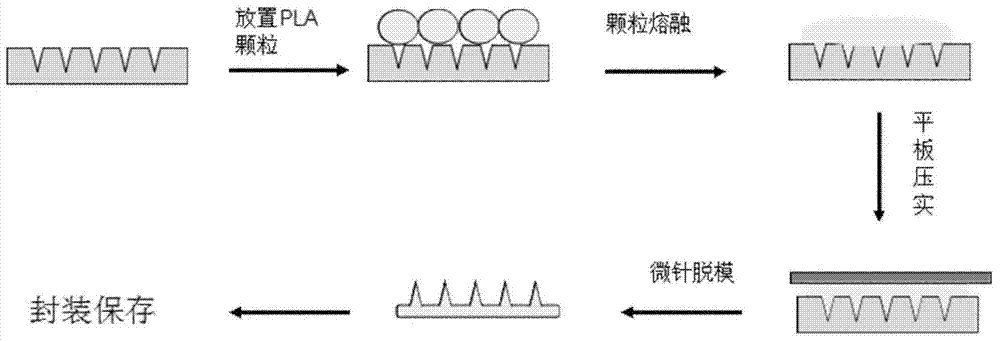

Microneedle template and preparation method thereof

InactiveCN104844814AGood micropore uniformityImprove uniformityMicroneedlesMedical devicesDimethyl siloxaneLaser beams

The invention belongs to the technical field of dosing equipment and specifically relates to a microneedle template and a preparation method thereof. The microneedle template is prepared from a polydimethylsiloxane film; a micropore array is formed in the surface of the polydimethylsiloxane film; and the polydimethylsiloxane film is prepared by mixing a polydimethylsiloxane film prepolymer and a curing agent. Compared with the prior art, the microneedle template is excellent in micropore uniformity; the template is firm and durable, and applicable to preparing microneedle products of a plurality of types by use of a melt or solution pouring method; and as being proven, the prepared microneedles can be applied to transdermal drug delivery or skin preprocessing. In addition, the preparation method only comprises directly perforating the surface of the polydimethylsiloxane only by use of a laser beam; the preparation material is simple, the method is simple and easy to implement, the preparation efficiency is high and the production automation can be realized; and besides, the shape and size of the micropores can be controlled by adjusting the laser energy parameter according to production requirements, and the microneedle templates of different structure parameters can be designed.

Owner:BEIJING UNIV OF CHEM TECH

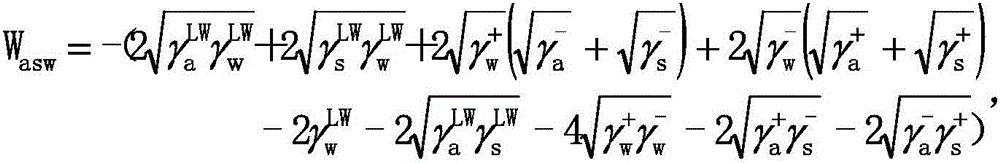

Asphalt-aggregate interface adhesion property testing method

InactiveCN105806747AEasy to operateClimate change adaptationSurface/boundary effectAsphaltMaterials science

The invention discloses an asphalt-aggregate interface adhesion property testing method. The method comprises the following steps: A, selecting three testing liquids which are not dissolved in asphalt and have known surface energy; B, heating the asphalt or a warm mixing agent till a flowing state is achieved, respectively casting on a plate, cooling to form a smooth plane, and grinding aggregate into a smooth plane of which two sides are parallel to each other; C, respectively dripping the three liquids on the smooth plane formed by the asphalt, the warm mixing agent or the aggregate in the step B, and respectively measuring contact angles of three testing liquids on the surface of the asphalt, the aggregate or the warm mixing agent; D, calculating the surface energy of the asphalt, the aggregate or the warm mixing agent; E, respectively constructing adhesion models in different systems, and calculating adhesion work of the adhesion models; and F, establishing energy parameters, and evaluating the influence of an additive to the adhesion property of asphalt-aggregate in an implementation sequence of steps A, B, C-F or B, A, C-F. By adopting the asphalt-aggregate interface adhesion property testing method, the influence of the additive to the adhesion property of the system can be evaluated.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

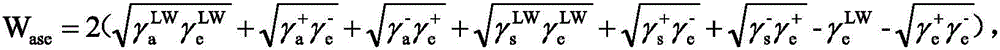

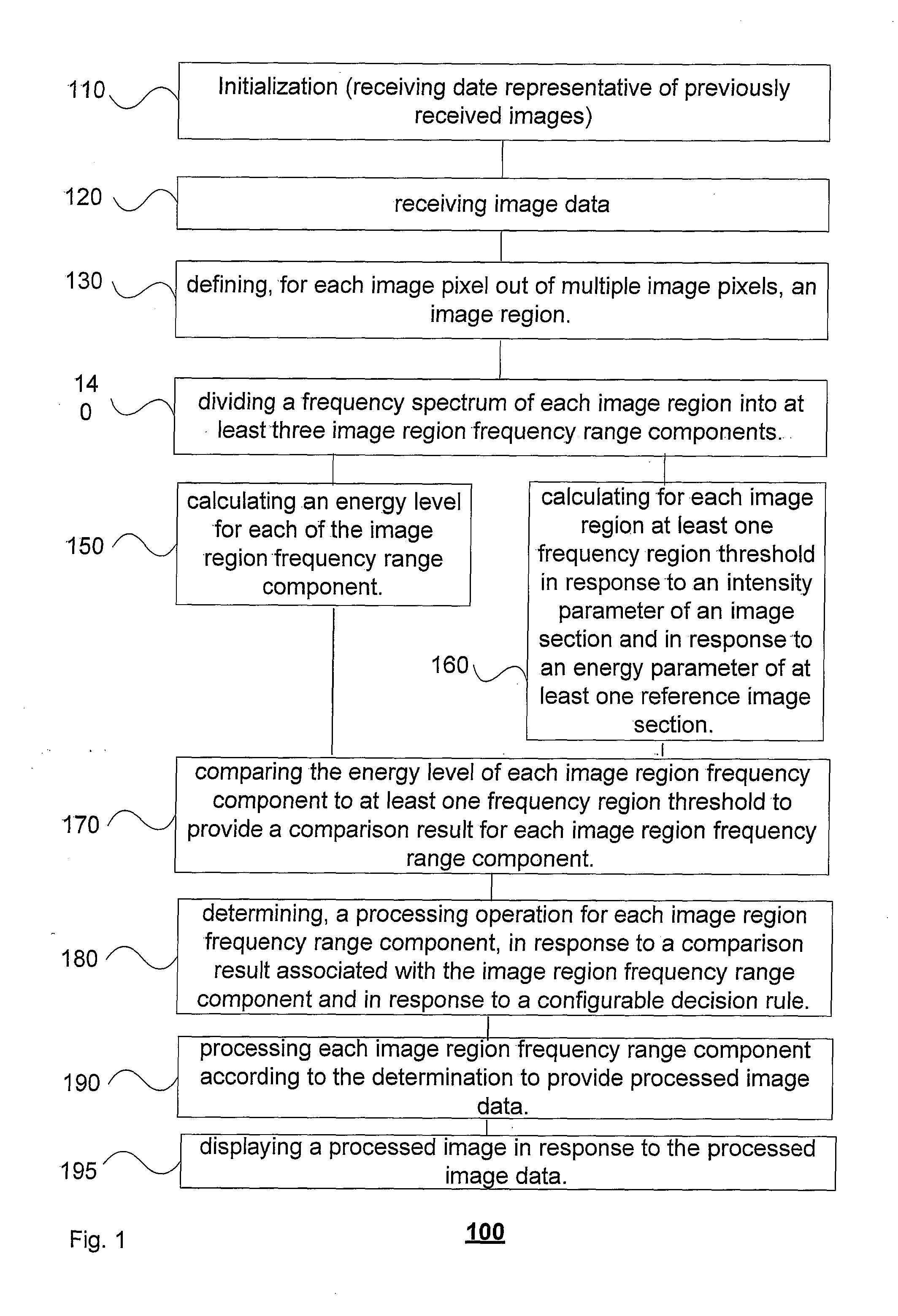

Method and system arranged for filtering an image

A method and a system, the system includes: a memory unit, an image region definer, a spectral analyzer, a determination module, and an image processor. The spectral analyzer is arranged to divide a frequency spectrum of each image region into at least three image region frequency range components (IRFRCs); and calculate an energy level for each IRFRC. The comparator configured to compare the energy level of each IRFRC to at least one frequency region threshold to provide a comparison result for each IRFRC; wherein each frequency region threshold is calculated based on an intensity parameter of an image section and based on an energy parameter of at least one reference image section; a determination module arranged to determine a processing operation for each IRFRC, based on a comparison result associated with the IRFRC and based on a configurable decision rule.

Owner:NXP USA INC

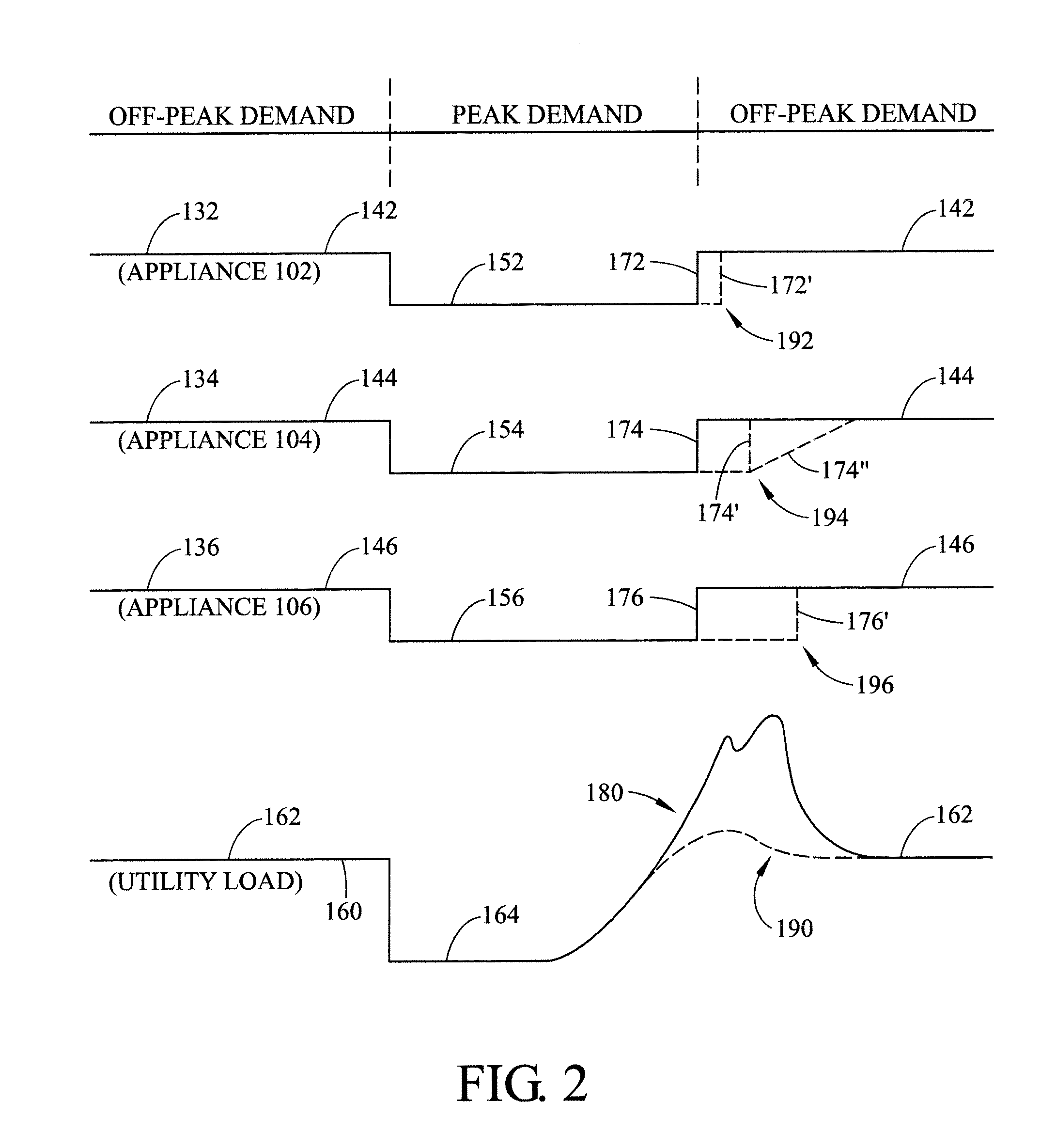

Appliance demand response randomization after demand response event

ActiveUS20110148199A1Avoid energyDc network circuit arrangementsPower network operation systems integrationNuclear engineeringPeak value

An energy management system and method for one or more appliances includes a controller for managing power consumption within a household. The controller is configured to receive and process a signal indicative of one or more energy parameters of an associated energy supplying utility, including at least a peak demand period or an off-peak demand period. The controller is configured to at least one of communicate to, control and operate one or more appliances in one of a plurality of operating modes, including at least a normal operating mode and an energy savings mode in response to the received signal. The one or more appliances operate in the normal operating mode during the off-peak demand period and operate in the energy savings mode during the peak demand period. The controller is configured to control the return of the one or more appliances to the normal operating mode after the peak demand period is over to prevent an energy surge for the associated energy supplying utility.

Owner:HAIER US APPLIANCE SOLUTIONS INC

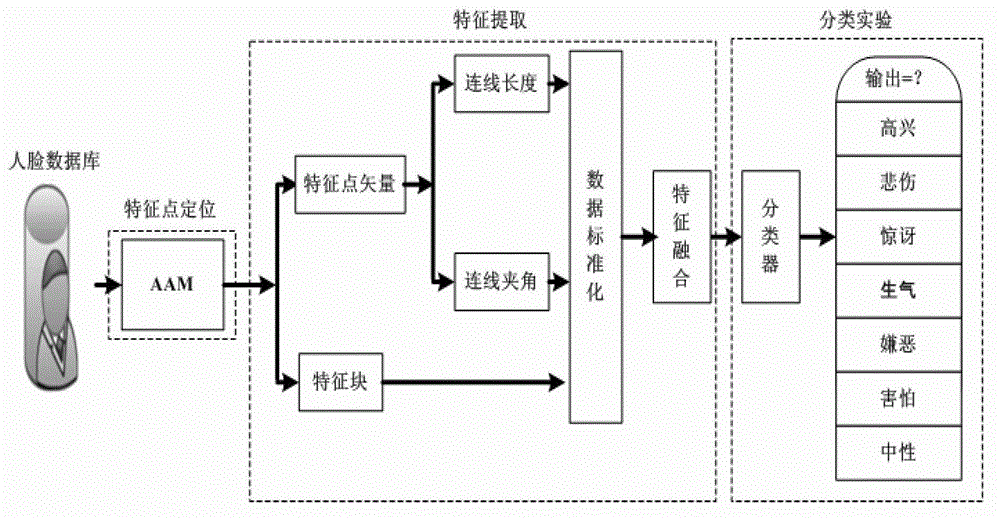

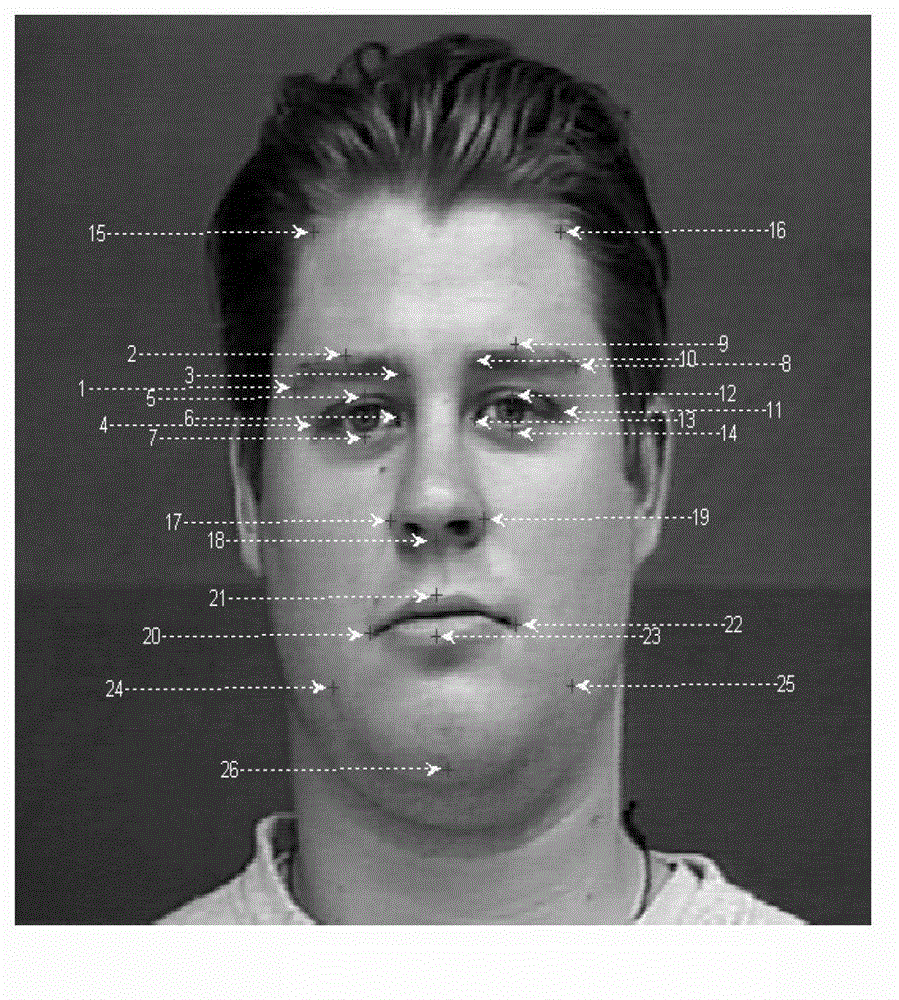

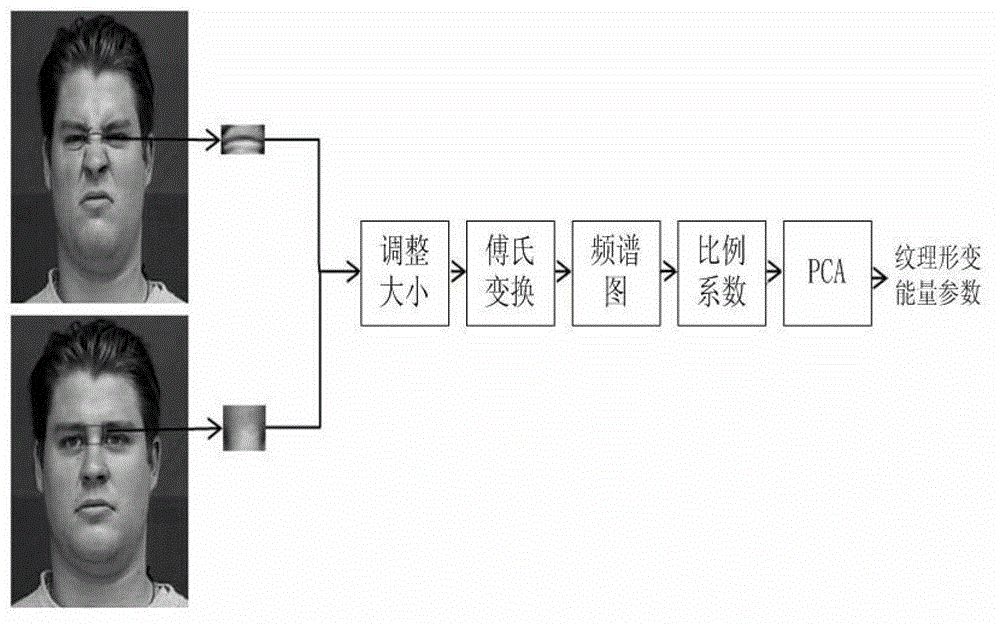

Facial expression recognition method based on feature point vectors and texture deformation energy parameter

InactiveCN102945361ASolve the impact of facial expression recognitionCharacter and pattern recognitionNerve networkPrincipal component analysis

The invention provides a facial expression recognition method based on feature point vectors and a texture deformation energy parameter. The method comprises the following steps: 1, respectively carrying out feature point positioning on neutral expressions and extreme expressions at a beginning end of a facial expression sequence by an AAM (Automatic Acoustic Management) tool of an OPENCV (Open Source Computer Vision Library); 2, forming feature point vectors with the selected 26 feature points to suit facial expression recognition, dividing the feature point vectors into a Euclidean distance d (representing a size) between the feature points and an included angle alpha (representing a direction) of connecting lines, calculating a distance coefficient ratio kd of the feature points according to d and alpha, and subtracting a redundant part kl to obtain kd - final (k alpha-final can be obtained in the same way); 3, establishing a feature block according to the feature points, calculating a texture deformation energy coefficient matrix, and finally obtaining the texture deformation energy parameter ks - final by PCA (Principal Component Analysis); and 4, inputting final features, namely using k final = kd - final + k alpha - final + ks - final as the training data of an RBF (Radial Basis Function) nerve network, and finally realizing facial expression recognition.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com