Method suitable for controlling concentration of hydrogen sulfide tail gas in low-temperature methanol washing process

A technology of low-temperature methanol washing and tail gas concentration, which is applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as the adverse effects of sulfur recovery operations, and achieve the effects of meeting environmental protection requirements, easy control, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

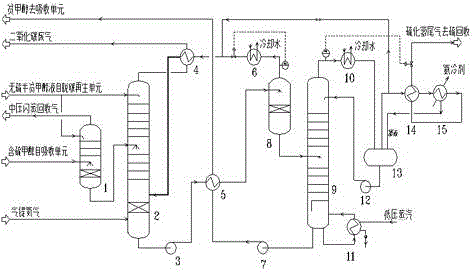

Image

Examples

Embodiment 1

[0028] In this example 1, the sulfur-containing rich liquid 84m from the low-temperature methanol washing absorption unit 3 / h, temperature: -23°C, pressure: 3.52MPa, the specific composition is:

[0029] composition H 2 CO CO 2 CH 4 N 2 h 2 S COS CH 3 Oh ∑ wt% 0.01 0.20 24.46 19ppm 0.01 0.37 0.03 74.92 100.0

[0030] (1) Medium pressure flash evaporation

[0031] The sulfur-containing methanol-rich liquid from the low-temperature methanol washing gas purification and absorption unit, which has dissolved sulfide and carbon dioxide, first enters the medium-pressure flash tower 1 from the middle for decompression flash evaporation, the purpose of which is to remove the dissolved combustible gas in the solution through flash evaporation CH 4 , CO, H 2 Wait for the desorption to be recovered. The flash pressure is controlled in the range of 1.2MPa (Pa means absolute pressure), during which part of the H 2 S, CO 2 is also flas...

Embodiment 2

[0043] In this embodiment 2, the sulfur-containing rich liquid 182m from the low-temperature methanol washing absorption unit 3 / h, temperature: -20°C, pressure: 3.28MPa, the specific composition is:

[0044] composition H 2 CO CO 2 CH 4 N 2 h 2 S COS CH 3 Oh ∑ wt% 98ppm 0.20 20.9 155ppm 109ppm 0.70 0.12 78.08 100.0

[0045] In this embodiment, the process steps are the same as those in Embodiment 1. According to the change of raw material sulfur-rich liquid conditions, in order to meet the technological requirements of the sulfur recovery unit, some operating parameters will change as follows:

[0046] The flash pressure of medium pressure flash tower 1 is 0.75MPa;

[0047] The pressure in the reabsorption tower 2 is 0.19MPa;

[0048] The pressure of low-pressure nitrogen used for gas stripping is 0.4MPa;

[0049] The total sulfur (H 2 S+COS) content is 15.9% (v);

[0050] The temperature of the methanol-rich liquid en...

Embodiment 3

[0057] In this embodiment 3, 120m of sulfur-containing rich liquid from the low-temperature methanol wash absorption unit 3 / h, temperature: -27°C, pressure: 2.54MPa, the specific composition is:

[0058] composition H 2 CO CO 2 CH 4 N 2 h 2 S COS CH 3 Oh C 2 h 6 C 3 h 8 ∑ wt% 91ppm 0.1 20.5 0.1 72ppm 0.8 280ppm 78.0 557ppm 0.4 100.0

[0059] In this embodiment, the process steps are the same as in Embodiment 1. According to the change of raw material sulfur-rich liquid conditions, in order to meet the technological requirements of the sulfur recovery unit, some operating parameters will change as follows:

[0060] The flash pressure of medium pressure flash tower 1 is 0.6MPa;

[0061] The pressure in the reabsorption tower 2 is 0.15MPa;

[0062] The total sulfur (H 2 S+COS) content is 10.2% (v);

[0063] The temperature of the methanol-rich liquid entering the heat flash tank 8 is 77.5°C;

[0064] The flas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com